Page 1

ENGLISH

User manual

© Copyright HT ITALIA 2009 Release IT 1.00 - 16/03/2009

Page 2

HT-5000

Indice:

1 SAFETY PRECAUTIONS AND PROCEDURES ..........................................................2

2 DESCRIZIONE GENERALE.........................................................................................3

3 PREPARATION FOR USE ...........................................................................................3

3.1 Initial ......................................................................................................................3

3.2 Supply voltage.......................................................................................................3

3.3 Calibration .............................................................................................................3

3.4 Storage..................................................................................................................3

4 OPERATING INSTRUCTIONS.....................................................................................4

4.1 Instrument description ...........................................................................................4

4.1.1 Description of the receiver RX5000 ............................................................................. 4

4.1.2 Display and control panel of RX5000........................................................................... 5

4.1.3 Description of transmitter TX5000................................................................................ 6

4.2 Connection and initial use of transmitter TX5000 ..................................................7

4.2.1 Transmitter signals and operation modes .................................................................... 7

4.2.2 Options for direct and inductive signal coupling........................................................... 8

4.2.2.1 Direct coupling on cables and pipes ................................................................................... 8

4.2.2.2 Coupling with special accessories .................................................................................... 10

4.2.2.3 Inductive signal coupling ................................................................................................... 11

4.2.2.4 Signal coupling in non-metallic pipes................................................................................ 13

4.2.3 Initial use of the transmitter TX5000 .......................................................................... 14

4.3 Use of receiver RX5000 ......................................................................................15

4.3.1 Modes of operation for the receiver RX5000 ............................................................. 15

4.3.1.1 Regulating the sensitivity level to match the reception signal strength............................. 16

4.3.1.2 Handling the receiver and locating the line ....................................................................... 17

4.3.1.3 Changing of the system settings ....................................................................................... 18

4.3.2 General site surveying ............................................................................................... 19

4.3.3 Determining the direction of a line.............................................................................. 20

4.3.4 Determining the depth of a line .................................................................................. 21

4.3.5 Functional test of the receiver .................................................................................... 24

5 MAINTENANCE .........................................................................................................26

5.1 Replacement floor cap of the receiver RX5000 ...................................................26

5.2 Replacement batteries of receiver RX5000 .........................................................26

5.3 Replacement batteries of transmitter TX5000 .....................................................27

5.4 Cleaning ..............................................................................................................27

5.5 End of life ............................................................................................................27

6 TECHNICAL SPECIFICATION...................................................................................28

6.1 Technical characteristics of receiver RX5000......................................................28

6.2 Technical characteristics of transmitter TX5000..................................................29

6.3 General specifications .........................................................................................29

6.4 Accessories .........................................................................................................29

6.4.1 Standard accessories................................................................................................. 29

6.4.2 Optional accessories.................................................................................................. 29

7 SERVICE....................................................................................................................30

7.1 Warranty conditions.............................................................................................30

7.2 Service ................................................................................................................30

EN - 1

Page 3

HT-5000

1 SAFETY PRECAUTIONS AND PROCEDURES

This instrument conforms with safety Standard IEC/EN61010-1 related to electronic

measuring instruments. For your own safety and to avoid damaging the instrument follow

the procedures described in this instruction manual and read carefully all notes preceded

by this symbol .

When taking measurements:

• It is important to observe the general electric regulations of the particular country in

which the device will be setup and used, as well as current national regulations for

accident prevention and current company internal regulations (work, operating and

safety regulations

• The use of original accessories ensures system safety and reliable operation. The use

of other parts is not permitted and shall result in termination of the warranty

• Connections to live cables should be made by qualified personnel

• Keep you insulated from the object under test

• Do not touch exposed metal parts such as test lead ends, sockets, fixing objects,

circuits etc

• Avoid doing that if you notice anomalous conditions such as breakages, deformations,

fractures, leakages of battery liquid, blind display etc

• HT-5000 can only locate lines which emit a signal. Therefore it is important to always

exercise extreme caution when digging, even if no lines have been found

• Refer always to the user manual. An improper use may damage the instrument or its

components

The following symbols are used on meter and in manual:

CAUTION - refer to the instruction manual - an improper use may damage the

instrument or its components

Double insulated meter

EN - 2

Page 4

HT-5000

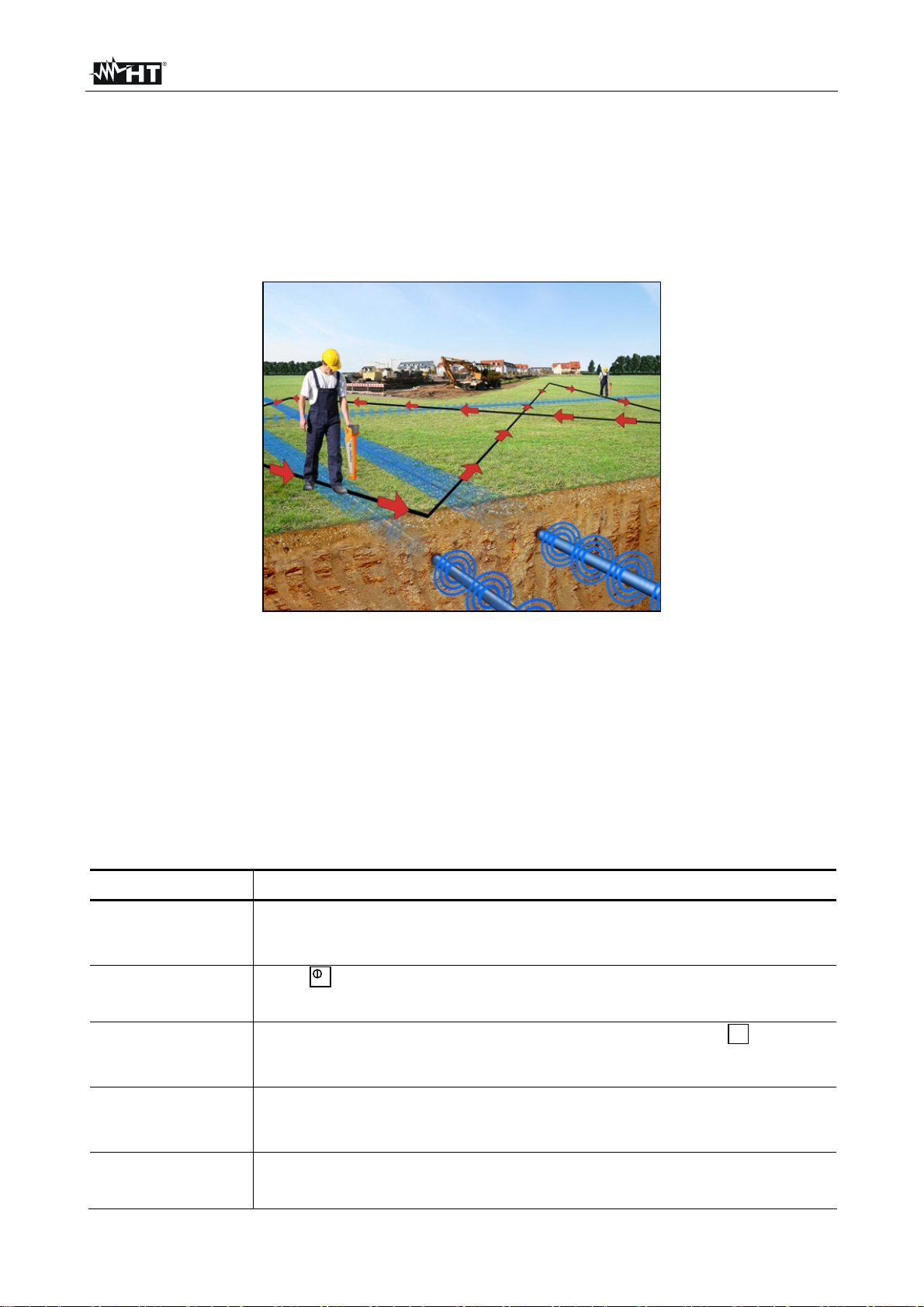

2 DESCRIZIONE GENERALE

The HT-5000 location system is designed for the uncomplicated and user-friendly

determination of the location, orientation and depth of metallic lines (e.g. cable and pipe

lines). It can be used to probe areas for unknown lines or for locating specific lines.

HT-5000 (composed by a TX5000 transmitter unit and RX5000 receiver unit) is

distinguished by the following features:

• Robust construction for use in poor weather and in harsh environments

• Simple, user-friendly operation concept with a minimum number of controls

• Reliable battery status indicator

The RX5000 receiver is distinguished by the following features:

• passive signal modes for locating lines without the TX5000 transmitter

• active signal modes for locating lines / probes when used together with a transmitter

• Automatic depth determination when used together with a transmitter

• Semi-automatic depth estimation in passive signal modes

• Sensitivity level can be adjusted automatically or manually

• Lighted display for use in dim environments

3 PREPARATION FOR USE

3.1 INITIAL

This instrument was checked both mechanically and electrically prior to shipment.

All possible cares and precautions were taken to let you receive the instrument in perfect

conditions. Notwithstanding we suggest you to check it rapidly (eventual damages may

have occurred during transport – if so please contact the local distributor from whom you

bought the item).

Make sure that all standard accessories mentioned in paragraph 6.4. are included.

Should you have to return back the instrument for any reason please follow the

instructions mentioned in chapter 7

3.2 SUPPLY VOLTAGE

The TX5000 unit is supplied by 6x1.5V alkaline batteries type IEC LR20 included as

standard accessories. The battery life is about 40 hours. The RX5000 unit is supplied by

10x1.5V alkaline batteries type IEC LR06 with battery life of about 40 hours

3.3 CALIBRATION

The instrument complies with the technical specifications contained in this manual and

such compliance is guaranteed for 12 months

3.4 STORAGE

After a period of storage in extreme environmental conditions exceeding the limits

mentioned in paragraphs 6.1 and 6.2 let the instrument resume normal operating

conditions before using it

EN - 3

Page 5

HT-5000

4 OPERATING INSTRUCTIONS

4.1 INSTRUMENT DESCRIPTION

4.1.1 Description of the receiver RX5000

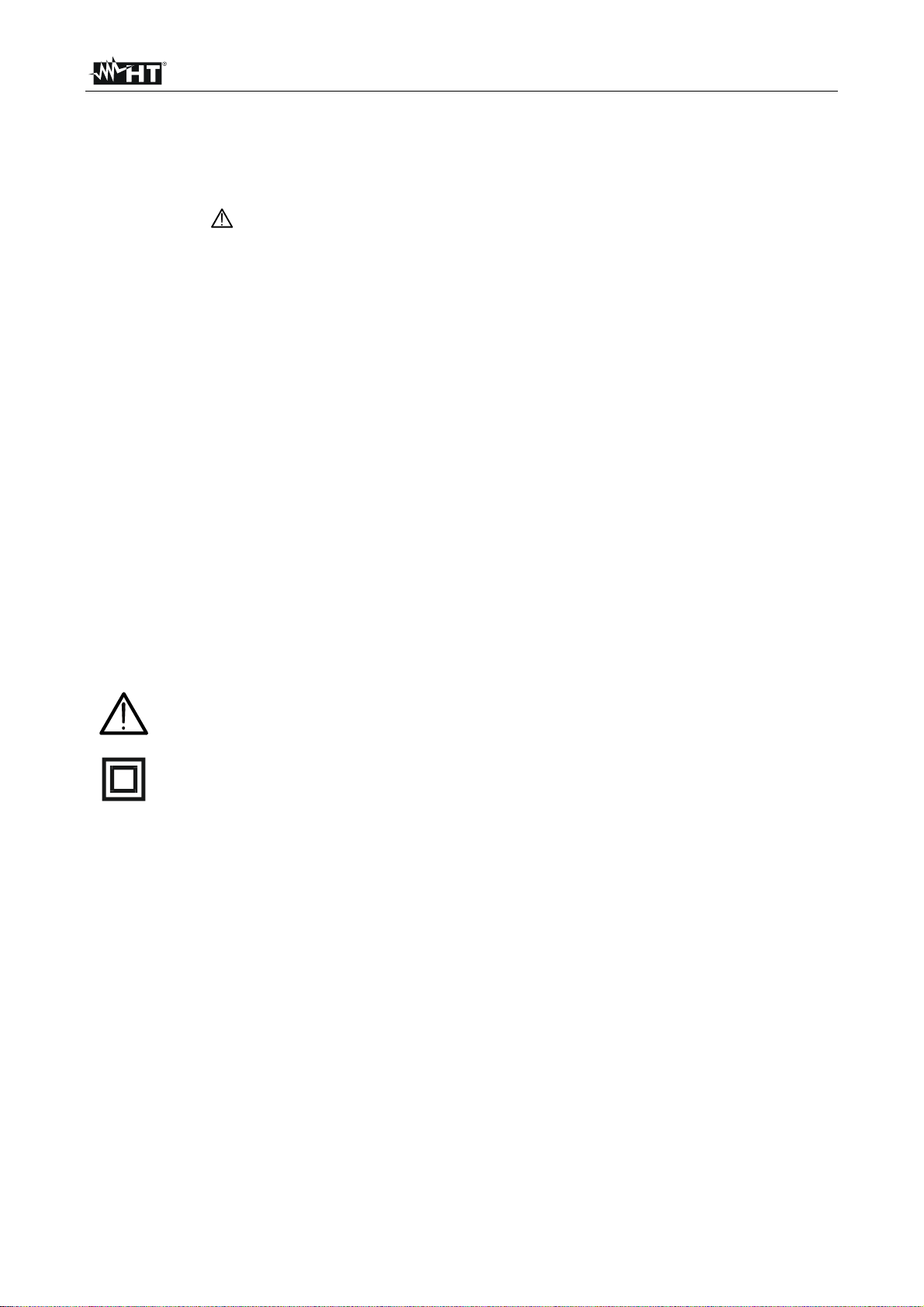

Fig. 1: Description of the receiver RX5000

Item Description

1

Control panel with display (see paragraph 4.1.2)

Speaker with volume control

The speaker plays back various acoustic signals (e.g. beeps

with modulating pitch relative to the signal strength)

2

Quieter Louder

When the receiver is switched on, the volume is set at a

standard level. The receiver will only start with the volume

at a different level if the volume has been manually

increased before switching off the receiver

3

Headphone jack

To connect headphones with a 3.5 mm plug connector

4 Battery compartment

5

Floor cap

This replaceable floor cap serves to protect the housing

EN - 4

Page 6

HT-5000

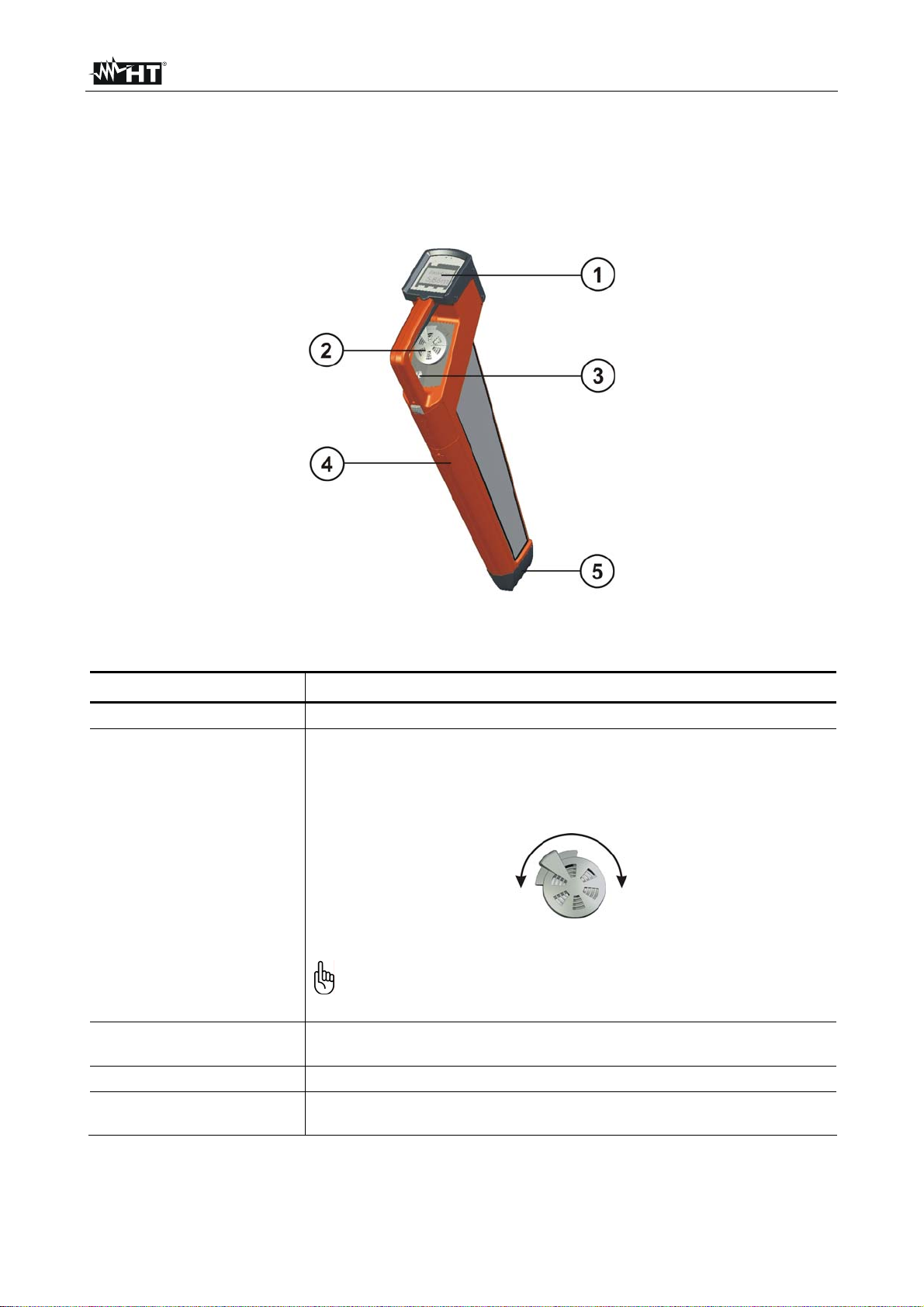

4.1.2 Display and control panel of RX5000

1

2

3

5

4

6

Fig. 2: Display and control panel of RX5000

Item Description

Light sensor

Light sensitive photo cells to automatically regulate the display

1

lighting

The display lighting can be manually activated for one

minute by briefly covering the light sensor

On/Off switch

By quickly pressing this button the receiver can be switched on

2

or off

The RX5000 will switch off automatically if no functions are

carried out within 7 minutes of being switched on

Display

3

Provides a visual indication of reception strength, line depth,

mode of operation, battery status and menu items

Function key 1

4

Depending on the status of the system, this button is used to:

• Manually decrease reception sensitivity

• Start measuring depth

Function key 2

5

Depending on the status of the system, this button is used to:

• Adjust reception sensitivity

• Start measuring depth

Function key 3

6

Depending on the status of the system, this button is used to:

• Select the mode of operation / receiving frequency

• Manually increase reception sensitivity

EN - 5

Page 7

HT-5000

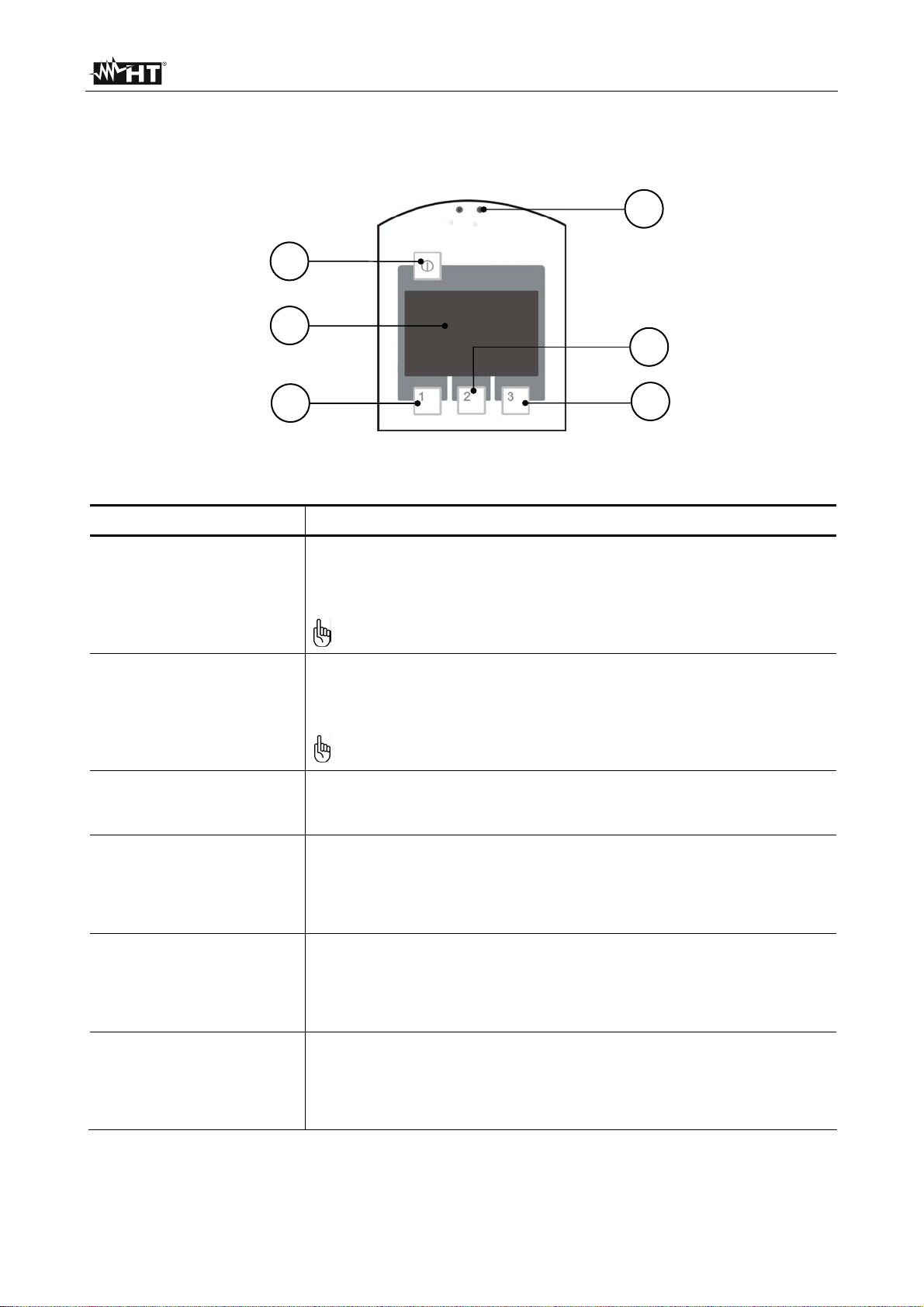

4.1.3 Description of transmitter TX5000

The TX5000 transmitter is distinguished by the following features:

• Inductive coupling of the signal using the integrated antenna or transmitter clamp

• Direct (galvanic) coupling of the signal using connected equipment (such as the

measurement cable and power socket adapter)

• Two-step adjustable transmission power (0.1W / 0.5W)

• Selectable signal output continuous or pulsed

Fig. 3: Front panel of transmitter TX5000

Item Description

Battery status indicator

1

When the battery status LED blinks in red, the batteries need

to be replaced

On/Off switch

By quickly pressing this button the TX5000 can be switched on

2

or off.

All appropriate LED’s blink when the transmitter is on,

depending on operating function

Signal type function key

3

This key is used to switch between continuous and pulsed

signal output

Jacks for connecting accessories

These jacks are used to create a direct galvanic connection

4

with the target line or to create a connection using a special

connection set (e.g. 100mm transmitter clamp or house

connection set)

Mode function key

5

This key is used to switch between inductive and direct signal

coupling (galvanically or via transmitter clamp)

Signal strength function key

6

This key is used to select one of two signal strength levels

(0.1W or 0.5W)

EN - 6

Page 8

HT-5000

4.2 CONNECTION AND INITIAL USE OF TRANSMITTER TX5000

4.2.1 Transmitter signals and operation modes

The type and strength of the output signal can be configured by the user as follows to

meet the specific requirements of either the line to be located or the site to be surveyed:

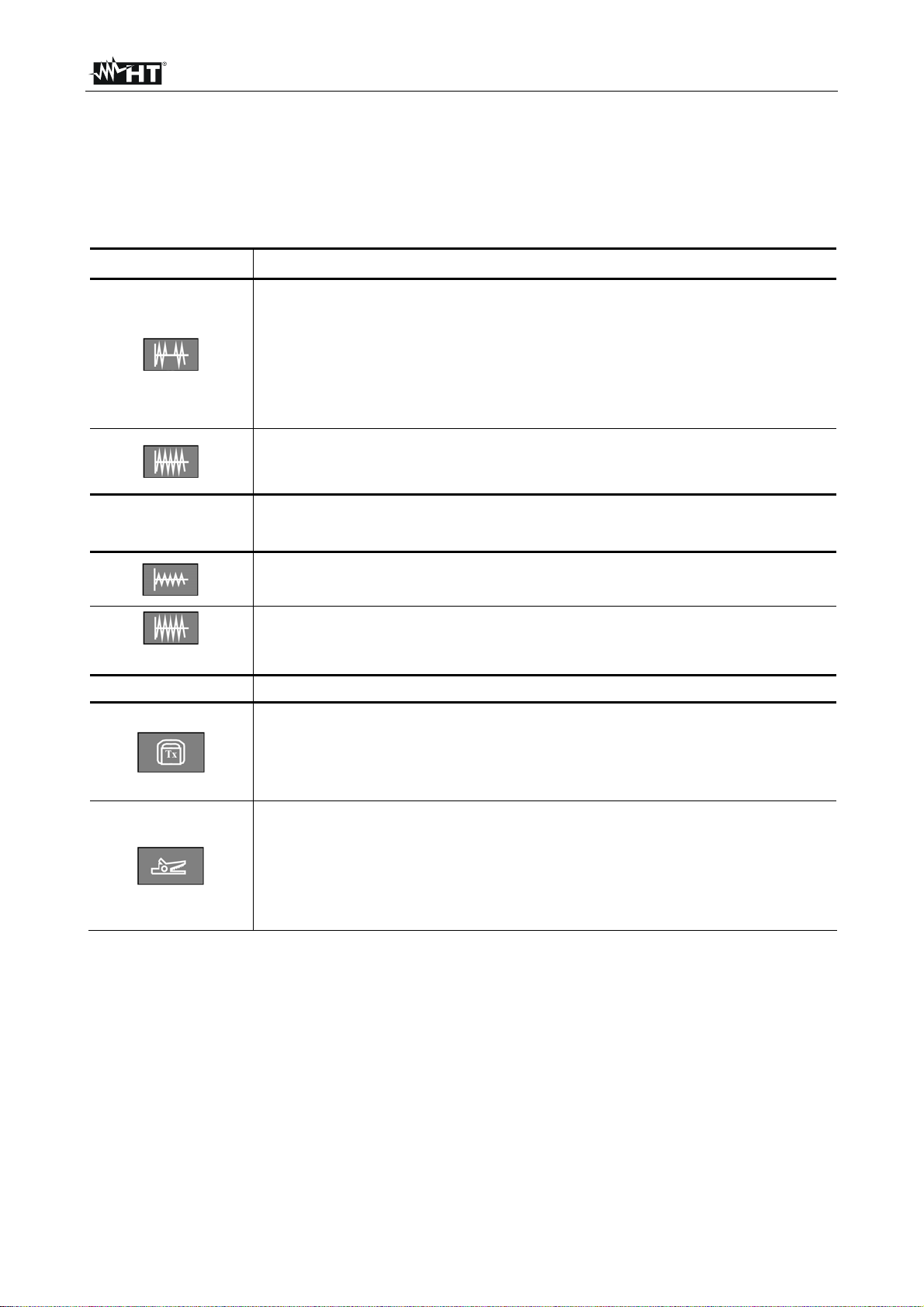

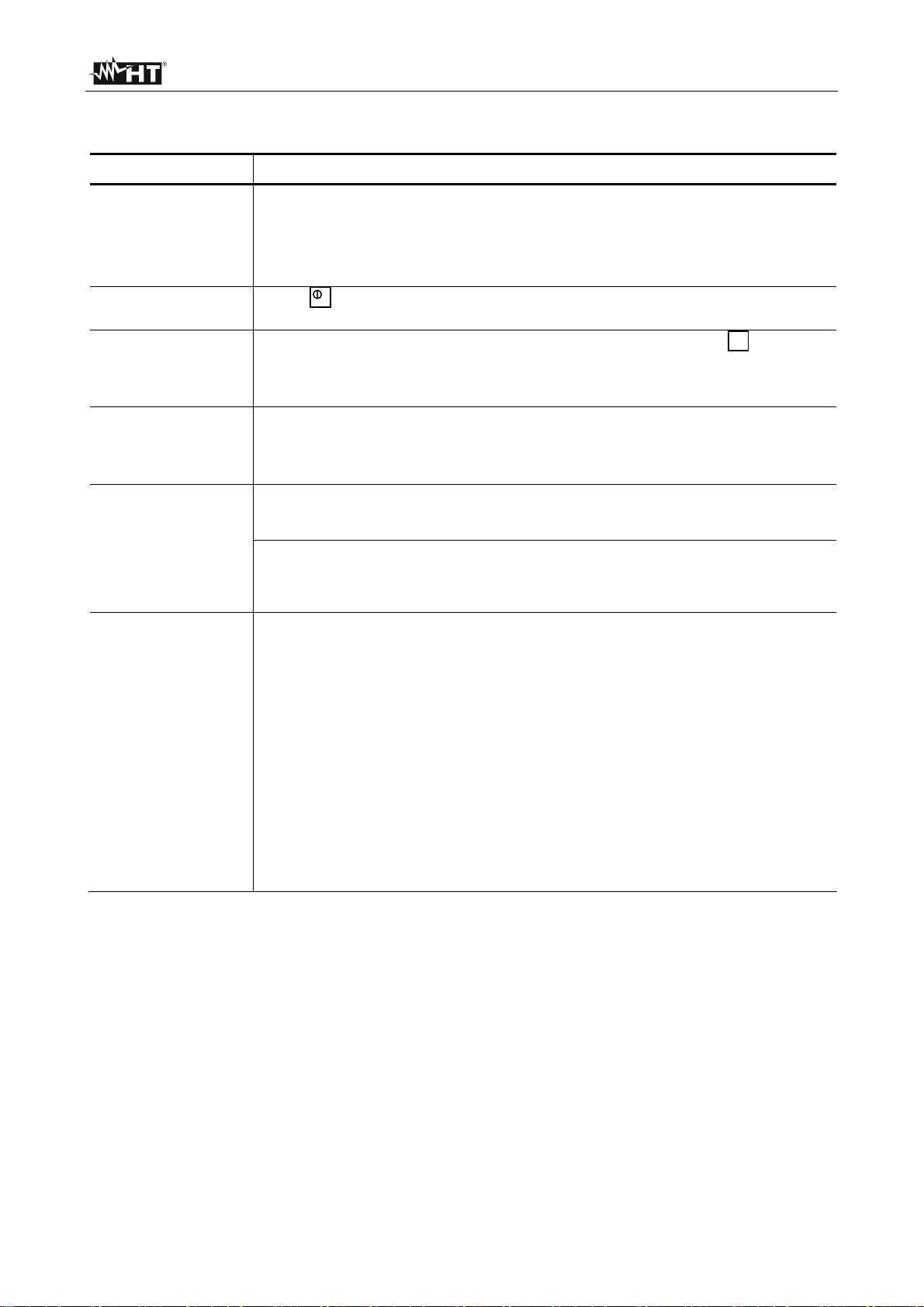

Symbol Signal type

Pulsed signal

As it is more easily distinguished from other signals, the pulsed signal

is helpful for locating when there is interference within the frequency

range of the transmitter. This also helps to conserve the batteries

Depth measurements cannot be made using a pulsating signal

Continuous signal

This signal type has to be activated before a taking a depth

measurement

Symbol Signal strength

Low output signal strength (0.1W)

Low signal strength conserves the batteries

High output signal strength (0.5W)

Symbol Operation modes

Inductive connection

In this mode of operation the transmitter's signal is emitted through

the integrated antenna and is thereby inductively coupled with any

metallic lines located within a certain radius

Direct connection

In this mode of operation the signal is directly coupled with a metallic

line via the measurement cable which is connected to the jacks on

the front panel of the transmitter. Transmitter clamps, alligator clips or

power socket adapters (for example) may be used to connect the

measurement cable to the lines

EN - 7

Page 9

HT-5000

4.2.2 Options for direct and inductive signal coupling

CAUTION

If the transmitter is connected to electrical service cables, it has to be

considered that the device is designed to achieve CAT II / CAT III 440 V and

CAT IV 300 V with Class 2 protection (double insulation) according to IEC / EN

61010-1. This means that the maximum voltage between the two terminals

must not exceed 440 V in measurement categories CAT II / CAT III and 300 V

in measurement category CAT IV

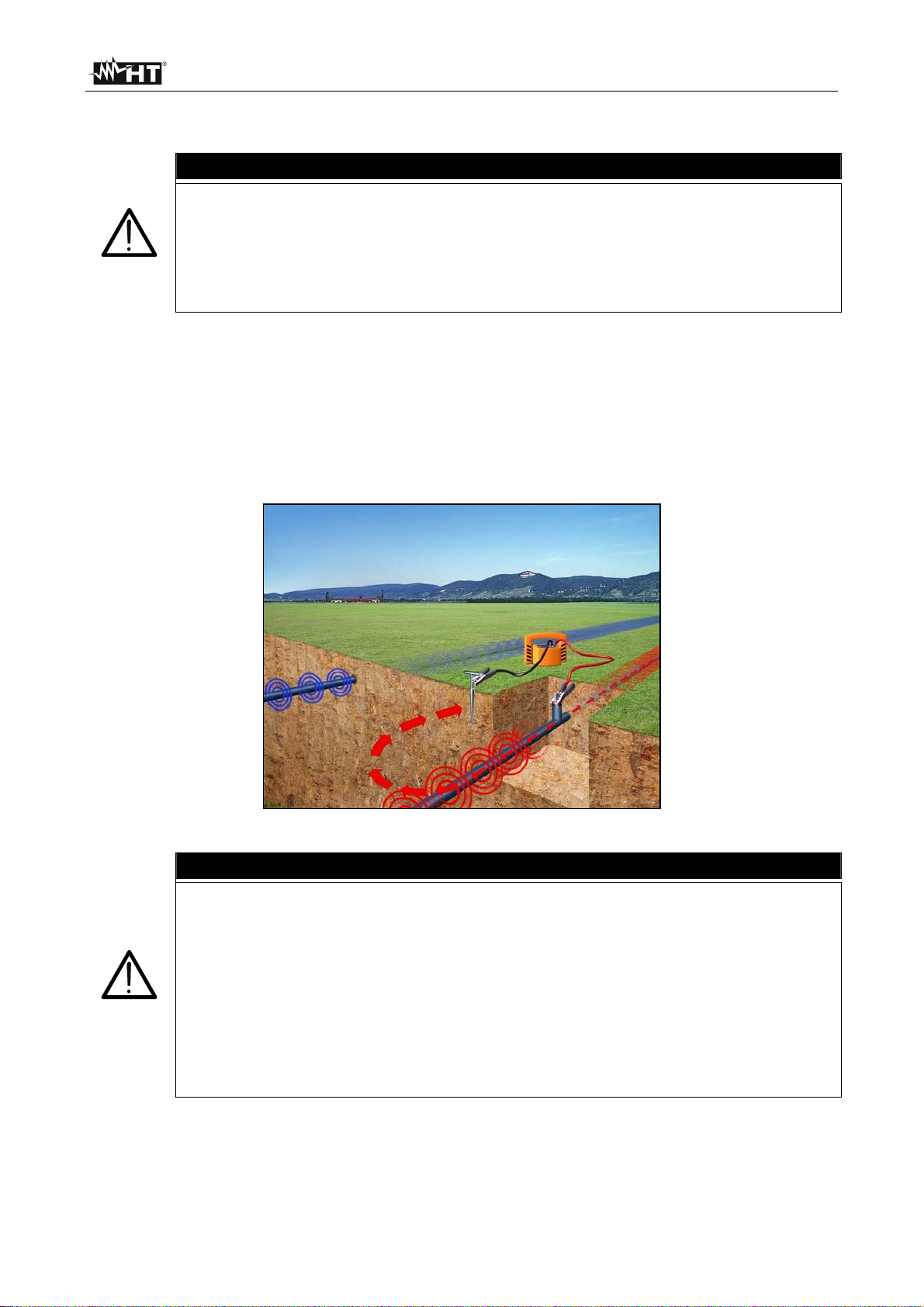

4.2.2.1 Direct coupling on cables and pipes

Direct galvanic coupling is practical for cables which are easily accessible and free of

current. The method of connection is dependent upon the position and nature of the lines

(e.g. insulation, cable conduit, accessibility of the cable ends).

Direct coupling presents a reliable option for selective cable location, as the signal can be

coupled onto a specific cable with virtually no loss.

The following illustration shows an example of direct coupling:

Fig. 4: Direct coupling on cables and pipes

CAUTION

If the lines being located are energised, the following five safety precautions

should be taken before connecting the transmitter:

1. Disconnect power supply

2. Secure against reconnection

3. Check for presence of current

4. Make earth connection and short circuit of parts

5. Cover or block access to adjacent components which are energized

If the system cannot be de-energized the use of the inductive coupling

clamp is possible to perform the location of objects

The following table explains various basic principles of direct galvanic coupling.

EN - 8

Page 10

HT-5000

Application Principle of coupling

Single-wire lines or pipes (with

or without insulation against

earthing)

The distance between the earth

spike and the ends of the

connected lines should be as great

as possible

There is a danger of the return

current flowing through the

earth into adjacent lines, which

could result in their path being

follow

Single-wire cable with metallic

screen and earthing insulation

Short circuit between internal

conductor and screen at the end of

the cable with earthing at the

beginning and end of the cable as

well

If the earth connections made

are unfavourable, the current

in the internal conductor and

the return current in the screen

will cancel each other out.

Under certain circumstances

this can prevent the cable from

being detected. Alternatively, a

connection without an earth

connection can also be made

Multiple-wire cable (internal

conductor connected or

disconnected) with metallic

screen and earthing insulation

verso terra

Same application as in example 1

Metallic conduit (with or without

insulation against earthing)

The earth spike and the conduit

should be spaced as far apart as

possible. Under certain

circumstances, optimum

positioning of the earth spike may

require several attempts

If a return wire is available

The spacing of the return wire

should correspond to at least

10 times the depth of the line being

located

Pair of wires (with or without

screen) with short circuit at the

end of the cable

Adjacent conductors

horizontal Ö

Minimum of the reception

signal

vertically Ö

Maximum of the reception

signal

EN - 9

Page 11

HT-5000

4.2.2.2 Coupling with special accessories

The signal from the transmitter can be directly coupled into plug sockets, antenna

connections coax and telephone jacks with the aid of a suitable adapter cable (Cod.

890008852). In doing so, it is not necessary to disconnect the lines.

Fig. 5: Couplng via adapter cable

The transmitter signal can be coupled onto easily accessible cables with the aid of a

100mm transmitter clamp (Cod. 820005314). In doing so, it is not necessary to disconnect

the cables

Fig. 6: Coupling via transmitter clamp

By ensuring that the transmitter clamp is completely closed around the cable, only a small

leakage field will be generated. This can significantly reduce the unwanted coupling of the

signal onto neighbouring lines.

Ideally the cables will be grounded at both ends, but even if they are not grounded at one

end, selecting high power transmitter output will assist easy location

EN - 10

Page 12

HT-5000

A

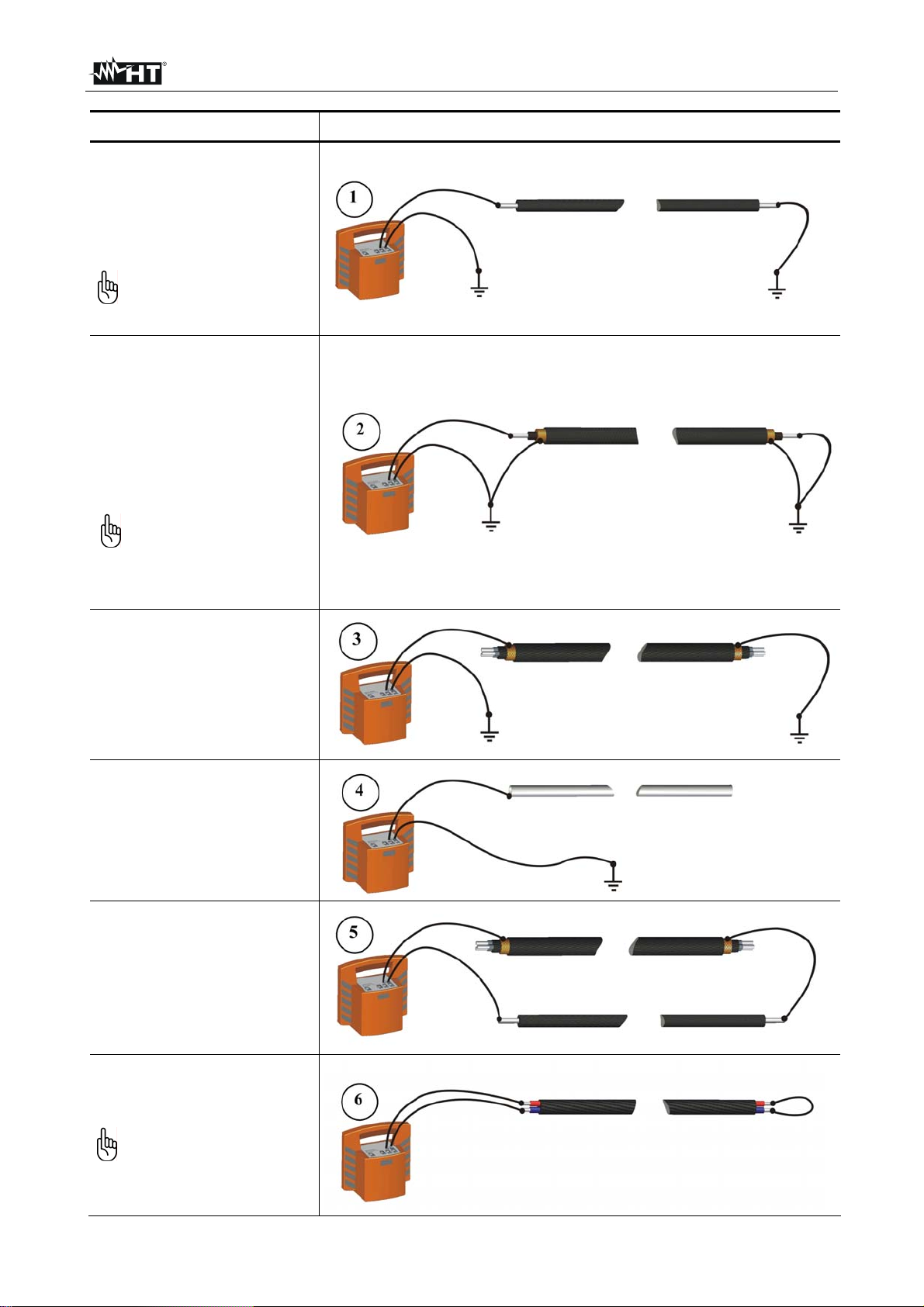

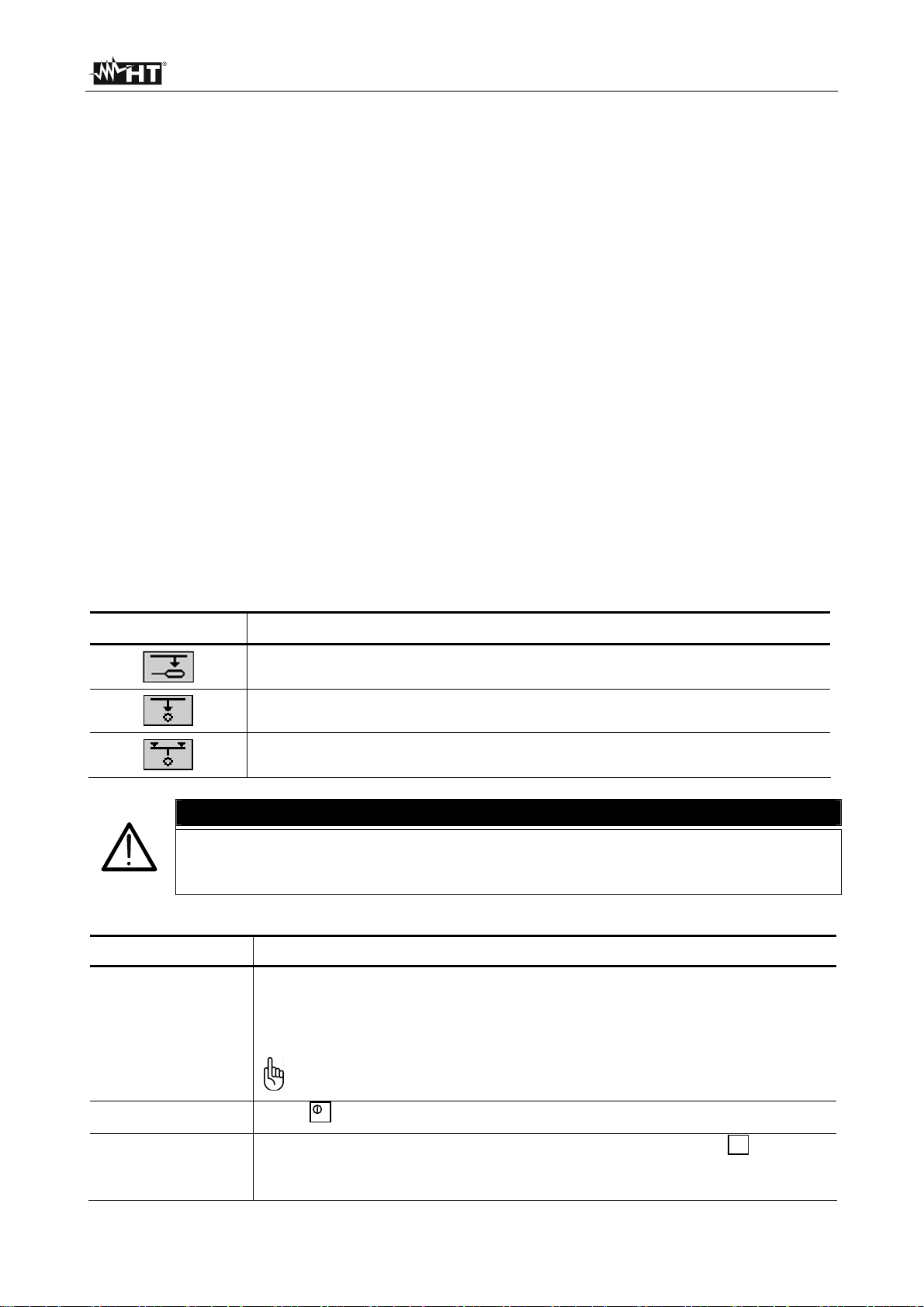

4.2.2.3 Inductive signal coupling

For lines which are not easily accessible, the signal from the transmitter has to be

inductively coupled via the integrated antenna. The inductive coupling of the signal is

highly recommended if unknown lines are to be located (e.g. at a construction site).

To determine the orientation of a specific line, the transmitter has to be positioned directly

above the presumed line as shown in Fig. 7. In doing so, the best signal coupling is

achieved when the handle of the transmitter housing is aligned with the presumed lay of

the line

Fig. 7:Inductive signal coupling

CAUTION

When locating lines using inductive signal coupling, the following guidelines

should be observed:

s the signal can be coupled onto other conductors when using inductive

•

coupling, direct coupling of the transmitter is always preferable when

locating lines selectively. Inductive signal coupling should only be opted for

in cases where the line being located is not easily accessible (see

paragraph 4.2.1 and 4.2.2)

• While taking measurements, make sure that a distance of at least 15m is

always maintained between the receiver and transmitter in order to prevent

the coupling of the transmitter's signal through the air

• When searching for unknown lines at a site, the position of the transmitter

has to be changed at least once by one metre and 90°

• It is also a good idea to position the transmitter at visible cable ends such as

at distribution boxes or light poles

EN - 11

Page 13

HT-5000

p

Under certain circumstances lines at lower depths can 'hide' deeper, adjacent lines, thus

making it more difficult to locate them.

In such cases, the transmission characteristics of the transmitter TX5000 can be fully

utilised and the lines which have already been located can be masked out (see Fig. 8)

Fig. 8: Masking-out lines

Line with weaker

inductive coupling

Line with good

inductive cou

ling

Follow the steps listed below in order to locate lines by masking-out adjacent lines

Step Action

Use the RX5000 and TX5000 to locate and pinpoint a buried line (see

1

paragraph 4.3.2)

With the RX5000 rested on the ground straight above the located

2

line, ask a colleague to place the TX5000 on its back (see Fig. 8)

nearby the line path (at least 15m away from the receiver)

Slide the TX5000 across the line until the signal strength bargraph is

lowest, indicating that the transmitter is directly above the line which,

thus, is masked-out

3

Note that adjacent lines may not be parallel with the first cable

route, so sweep the receiver around in a circle about 10m - 15m

radius from the transmitter, with the handle pointing towards the

transmitter. Any metallic lines within 2.5m of the transmitter will be

coupled with the transmitted signal

Pinpoint and determine the direction of any buried lines (see

4

paragraph 4.3.1.2)

EN - 12

Page 14

HT-5000

4.2.2.4 Signal coupling in non-metallic pipes

With the aid of the FlexSonde GOK50-R the transmitter's signal can be transmitted

through non-metallic pipes, as shown in the picture below:

Fig. 9: Signal coupling in non-metallic pipes

Alternatively, any other active probe (e.g. a camera probe) with adequate transmitting

frequency can be located using the receiver. For a detailed description, please refer to the

manual of the respective product.

When locating non-metallic pipes, the following guidelines should be observed:

• Contrary to the line location, a probe location has to be performed in perpendicular

position to the probe, i.e., the handle of the receiver has to be hold at right angle to the

probe

• Practice locating the probe or FlexSonde head before pushing it into the drain or duct.

• Strongest signal will be detected when the receiver is above and perpendicular to the

probe (as shown in Fig. 9)

The signal transmitted by the probe results in three signal maxima on the ground surface

level. Typically, there is a smaller maximum in front of the actual signal maximum and one

behind it.

For this reason, it should be always evaluated whether there are further signal maxima in

front of or behind the detected signal maximum. An accurate depth determination can only

be performed directly above the actual (highest) signal maximum.

If the receiver is operated in automatic sensitivity level adjustment mode, these lower

signal maxima are usually masked-out

EN - 13

Page 15

HT-5000

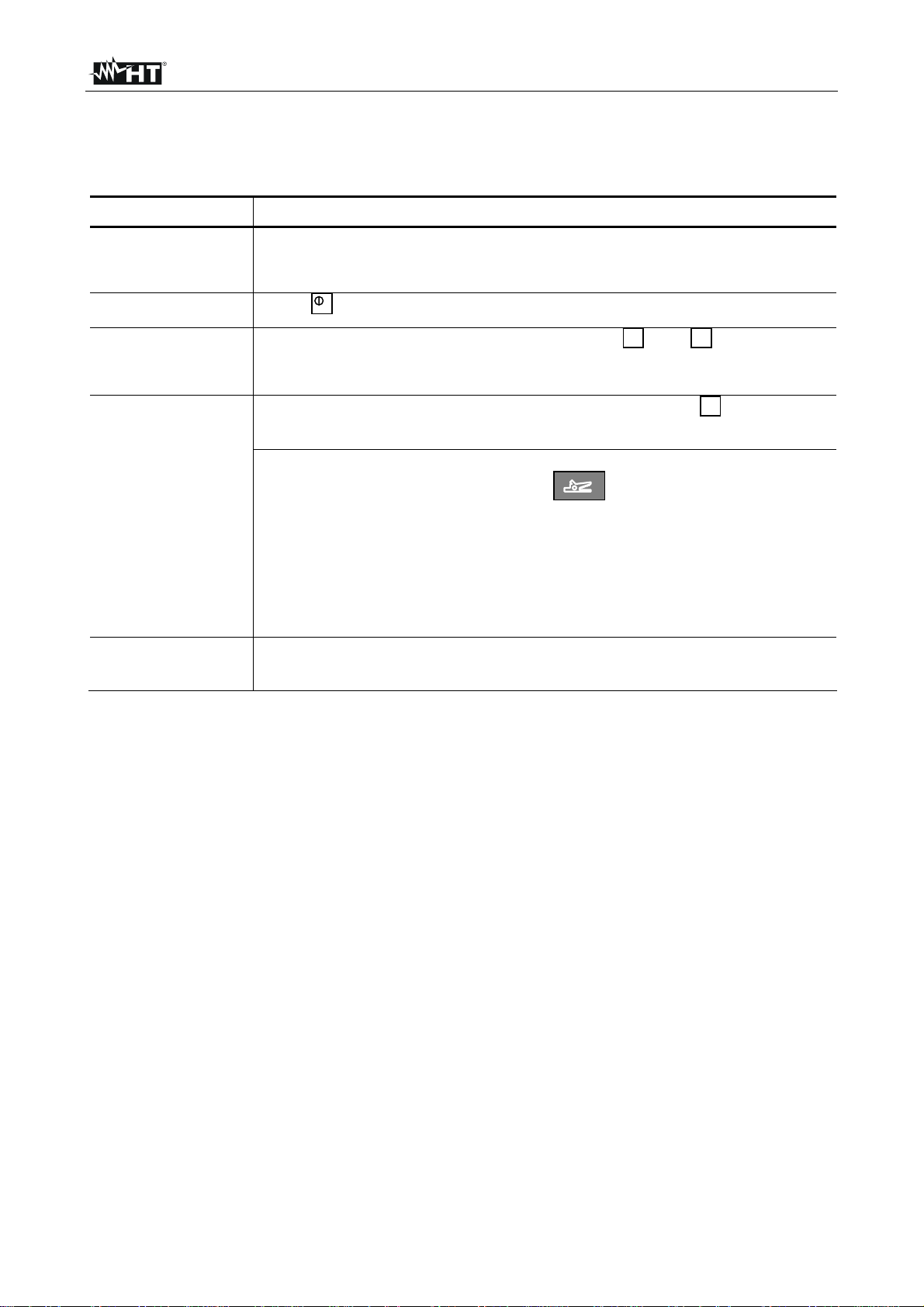

4.2.3 Initial use of the transmitter TX5000

Follow the steps listed below in order to prepare the transmitter to search for lines in

conjunction with the receiver:

Step Action

Connect the transmitter to the line to be located using the most

1

suitable method, or place the transmitter on the site to be searched

see paragraph 4.2.2

2

3

Press to switch on the transmitter

Select the desired output signal using the and function keys

M P

(see paragraph 4.1.3)

A green LED indicates that the respective setting is active

Select the desired mode of operation using the button (see

C

paragraph 4.1.3)

Result:

4

In Direct mode, an LED next to the

good the connection is to the connected line:

symbol indicates how

• Green blinking: good (low-resistance) connection

• Alternating red and green: sufficient connection

• Red blinking: poor/no (high-resistance) connection

As described in paragraph 4.3.1 use the RX5000 to locate metallic

5

conductors

EN - 14

Page 16

HT-5000

4.3 USE OF RECEIVER RX5000

4.3.1 Modes of operation for the receiver RX5000

If a TX5000 transmitter is not available, a site can also be probed by means of passive line

location.

The RX5000 receiver is capable of detecting radio signals in the frequency range between

15kHz to 23kHz as well as power signals in the frequency range between 50/60Hz.

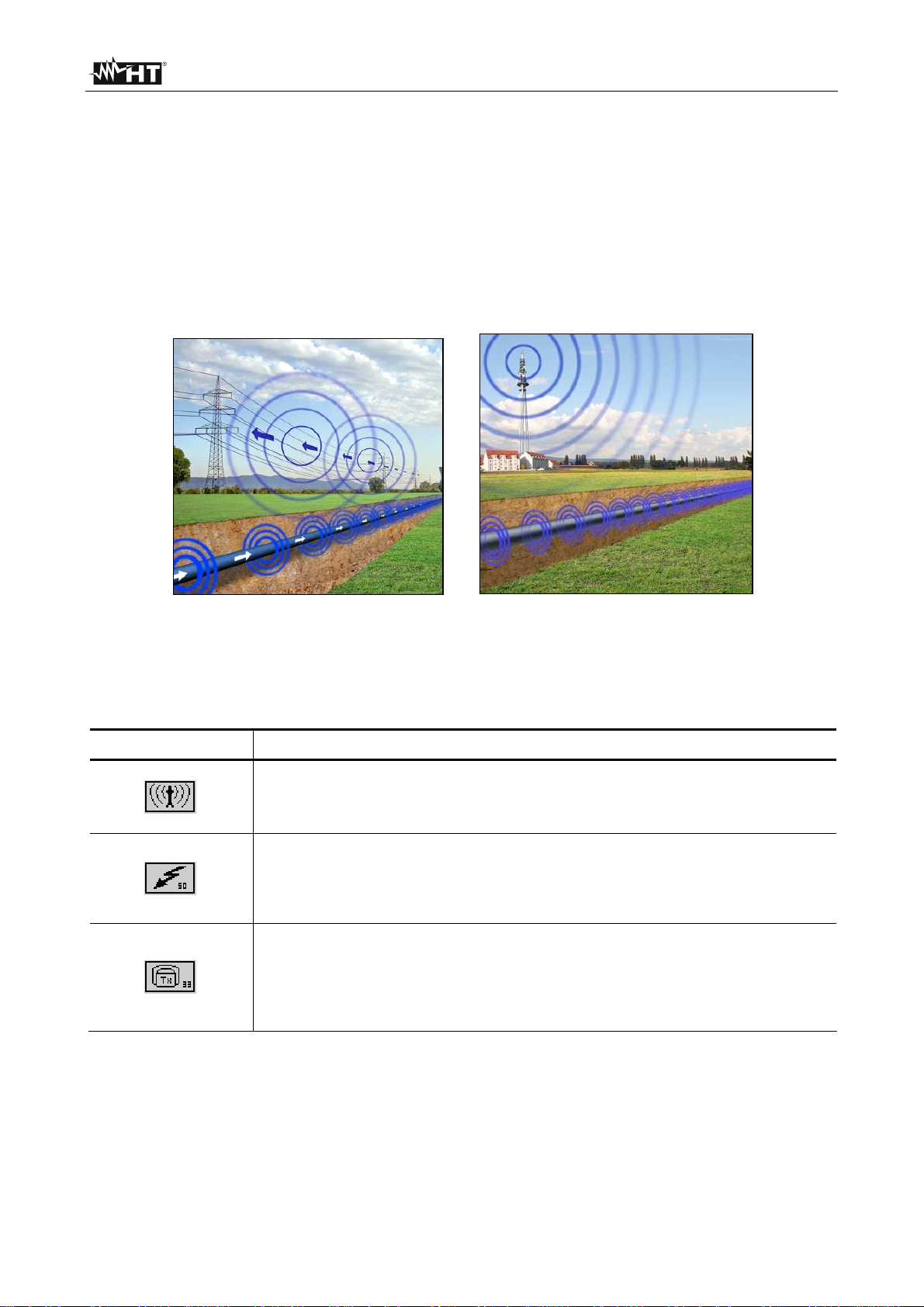

The following pictures illustrate how each of the signals couple onto conductors buried in

the ground:

Fig. 10: Use of receiver RX5000

The two options explained above for passive location together with the options of active

location with a transmitter or a probe transmitting a signal with an appropriate frequency

result in the following modes of operation:

Symbol Mode of operation

RADIO

For locating cables which are carrying VLF reradiated radio signals

POWER GRID

For locating mains power supply cables, through which current with a

grid frequency is flowing

TRANSMITTER

For locating cables or pipes, onto which the signal from an active

transmitter is coupled. The figure indicates the currently selected

frequency which has to correspond to the frequency of the transmitter

TX5000

EN - 15

Page 17

HT-5000

4.3.1.1 Regulating the sensitivity level to match the reception signal strength

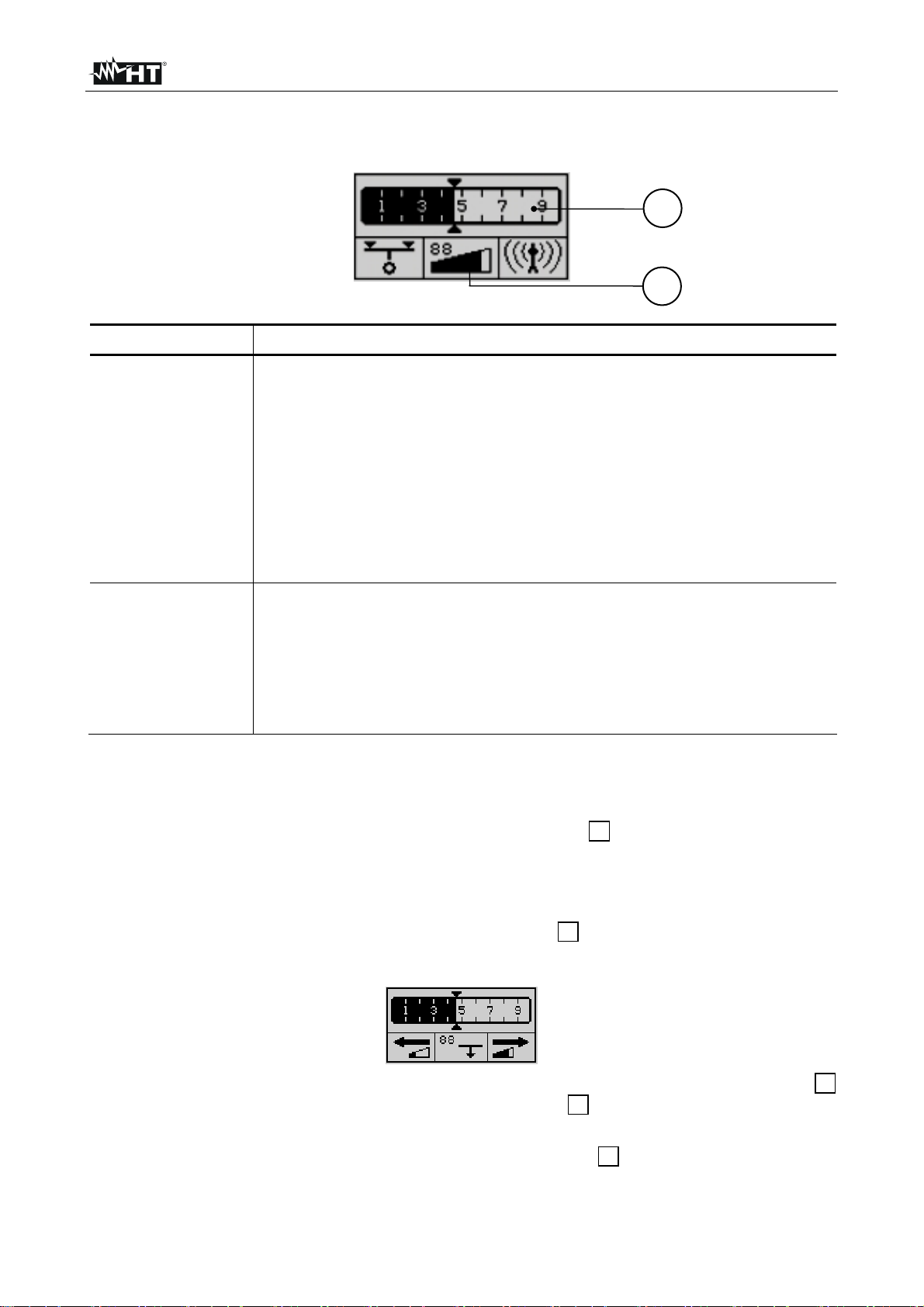

Reception signal strength and sensitivity are shown in the following segments of the

display:

1

2

Item Mode of operation

Reception signal display bargraph

The strength of the reception signal is represented by this bargraph

scale. These are relative values which are based on the sensitivity

level set in the receiver

The triangles (▲▼) above and below the scale are a visual marker

1

for maximum values. They move towards the right as long as the

signal strength increases and continue in this direction until it either

levels off or decreases. The maximum marker remains in this position

for 3 seconds and thus provides the user with a helpful visual aid for

determining the maximum signal strength

Sensitivity display (gain level in %)

The sensitivity level set in the receiver (which coincides with the total

spectrum which the receiver is capable of processing) is represented

2

by this scale. The higher the level of sensitivity is set, the more

capable the receiver is of detecting weaker signals.

The numeric display above the bars shows the utilisation factor as a

percent

Should the scale for reception signal strength bargraph provide virtually no indication, or

the display is completely utilised, either a manual or automatic adjustment of the sensitivity

level has to be made.

To start an automatic sensitivity level adjustment, the

¾

2

button has to be pressed

once. The sensitivity level of the receiver will be automatically adjusted so that the

strength of the signal currently being received will be optimally displayed (fill half of the

scale)

¾ To start a manual sensitivity level adjustment, the

2

button has to be pressed for

about 2 seconds. The following indicator will appear in the display:

¾ Now the sensitivity of the receiver can be decreased by one percent by pressing the

button, or increased by one percent by pressing the button. This process can be

accelerated by holding down the respective button

¾ To exit the manual sensitivity level adjustment menu, the

1

3

2

button has to be pressed

for two seconds. By pressing the button only short, the depth measurement process will

begin

EN - 16

Page 18

HT-5000

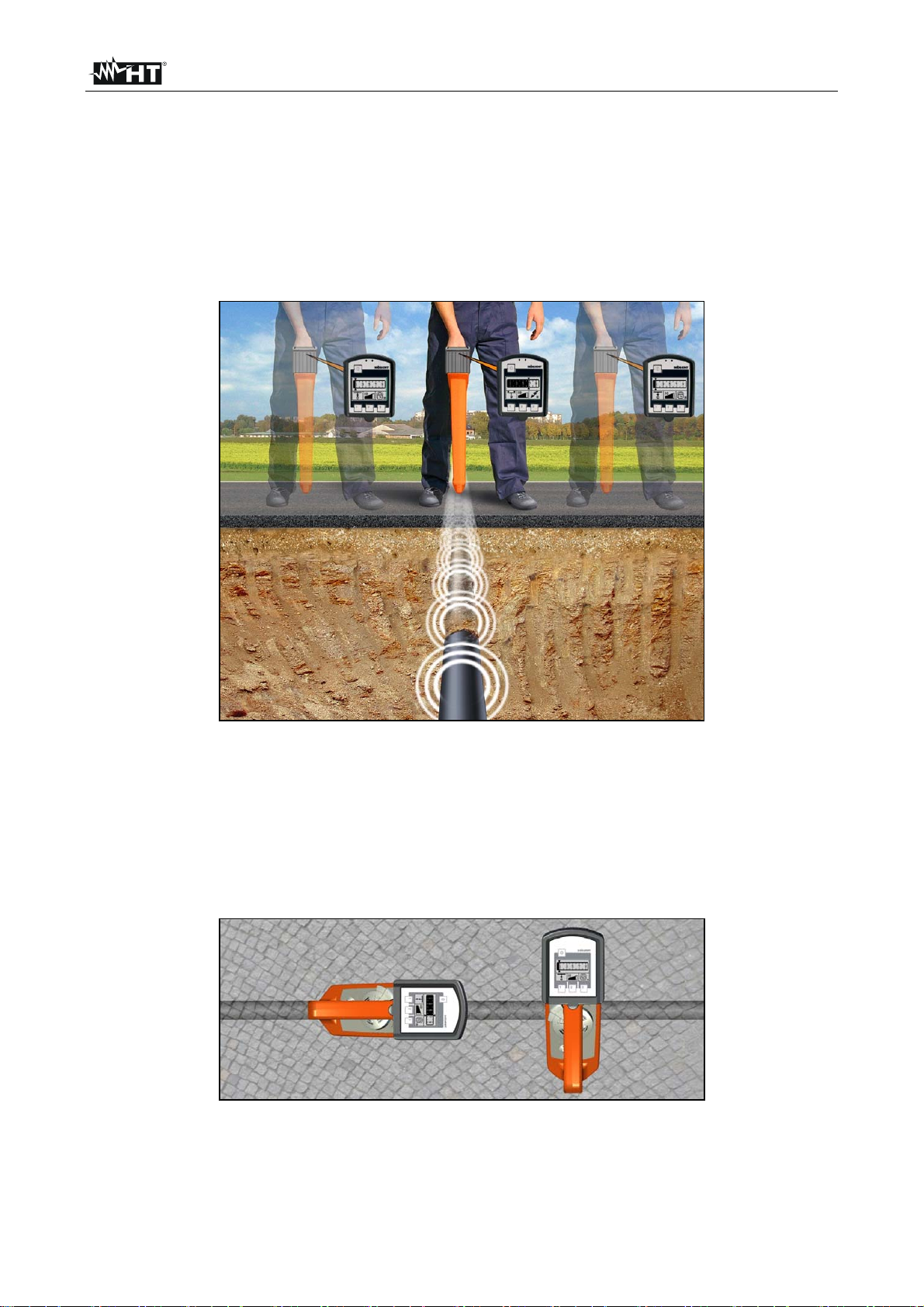

4.3.1.2 Handling the receiver and locating the line

In order to be able to determine the position and orientation of a metallic conductor, the

following rules should be internalised and applied when locating lines.

As shown in Fig. 11 the receiver should always be held in front of the body in an upright

position and as close to the ground as possible. When the transmitter is brought directly

over a metallic conductor, the maximum signal strength will be measured. If the receiver is

moved away from the conductor towards the side and is not rotated while doing so, the

signal will drop off proportionately

Fig. 11: Handling the receiver RX5000

The alignment of the receiver in relation to the orientation of the conductor (the antenna

being the starting point of alignment) has the following effects on the reception signal

strength:

• Receiver in line with the conductor Ö maximum signal strength

• Receiver perpendicular to the conductor Ö minimum signal strength

Fig. 12: Alignment of the receiver RX5000

EN - 17

Page 19

HT-5000

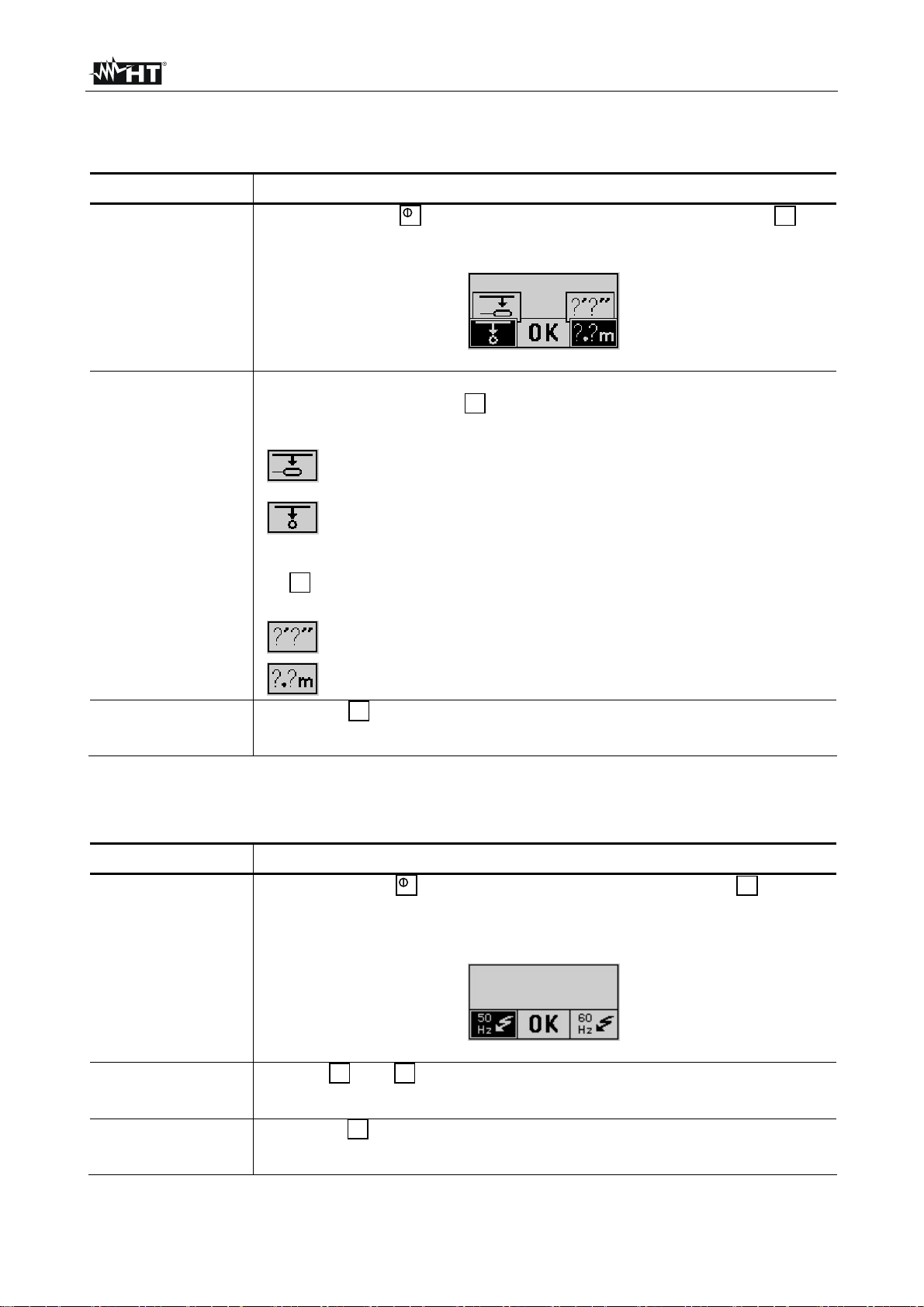

4.3.1.3 Changing of the system settings

Proceed as follows to change the settings:

Step Action

Briefly press the button while continuing to hold down the key

until an audible signal is heard. The following image is display:

1

Now one of the following depth measurement processes may be

selected by pressing the key:

Select this symbol if you want to determine the depth of a

probe which has been pushed into a non-metallic pipe

Select this symbol if you want to determine the depth of a

2

line, the signal of an active transmitter is coupled onto

Now a unit of length used by the system may be selected by pressing

3

the key:

1

1

Feet (ft)

Metre (m)

2

3

Press the key to save the settings. The changes will remain in

effect even after the receiver is switched off and back on again

Proceed as follows to change the receiving frequency of operation modes with more than

one possible frequency:

Step Action

Briefly press the key while continuing to hold down the key until

3

an audible signal is heard. The selectable frequencies are now visible

in the display:

1

3 1

2

3

Use the and keys to switch between 50 and 60Hz. The active

setting is marked with a black background

Press the key to save the settings. The changes will remain in

2

effect even after the receiver is switched off and back on again

EN - 18

Page 20

HT-5000

4.3.2 General site surveying

A general site probing urgently needs to be conducted and there is inaccurate or no

information available as to the location and orientation of metallic conductors on a site

planned for construction (e.g. excavation work).

When a site is to be searched for unknown conductors, a systematic approach should be

taken. The following picture illustrates how to proceed:

Fig. 13: General site surveying

Carry out a passive survey in POWER GRID and RADIO modes using a grid search

pattern to cover the site and locate conductors in all directions

If the site will be surveyed with the aid of the TX5000 transmitter used on induction, the

position of the transmitter should be changed by at least one metre and 90° after the first

sweep of the site and the site should be probed again in the same manner. The minimum

spacing of 15m between the transmitter and receiver must always be maintained

Follow the steps below when probing a site for unknown metallic conductors:

Step Action

If the site will be searched with the aid of the TX5000 transmitter, it

1

needs to be configured as described in paragraph 4.2.3 before

proceeding

Press to switch on the receiver RX5000

2

3

3

Select the desired mode of operation by pressing the key (see

paragraph 4.3.1). The symbol for the currently selected mode of

operation is shown in the lower right-hand corner of the display

Pace off the site as previously described and make a grid search of

4

the site (see Fig. 13). Adjust the sensitivity of the receiver as needed

if the signal level is too strong / weak (see paragraph 4.3.1.1)

When a conductor is located, pinpoint the strongest signal (see

5

paragraph 4.3.1.2) and mark the location

EN - 19

Page 21

HT-5000

4.3.3 Determining the direction of a line

Step Action

If the direction of the conductor will be determined with the aid of the

TX5000 transmitter, couple the transmitter's signal onto the metallic

1

conductor in such a way that there is as little signal loss as possible

(see paragraph 4.2.2 and paragraph 4.3.1)

2

3

Press to switch on the receiver

Select the desired mode of operation by pressing the key (see

3

paragraph 4.3.1). The symbol for the currently selected mode of

operation is shown in the lower right-hand corner of the display

Hold the receiver perpendicular to the position of a known metallic

4

conductor, e.g. above a location which was marked during the

probing of the site (see paragraph 4.3.2)

Rotate the receiver (through its own axis) over this location until the

maximum signal strength is indicated (see paragraph 4.3.1.2)

5

Result: The receiver is in line with the conductor when it is positioned

where the signal is strongest, which is prerequisite for determining

the direction of the line

To determine the path over an extended distance, proceed by

moving forward while maintaining the maximum signal strength. If the

signal becomes weaker, check that the conductor has not changed

direction or become deeper, move and/or rotate the receiver to the

left and right until the maximum signal strength is detected again.

6

The path of the metallic conductor should always be followed until it

exits the site being searched, and its path should be clearly marked

along the way with paint/chalk or marker flags

Adjust the sensitivity of the receiver as needed if the signal level is

too strong / weak. It is advisable to manually adjust the sensitivity

level (see paragraph 4.3.1.1)

EN - 20

Page 22

HT-5000

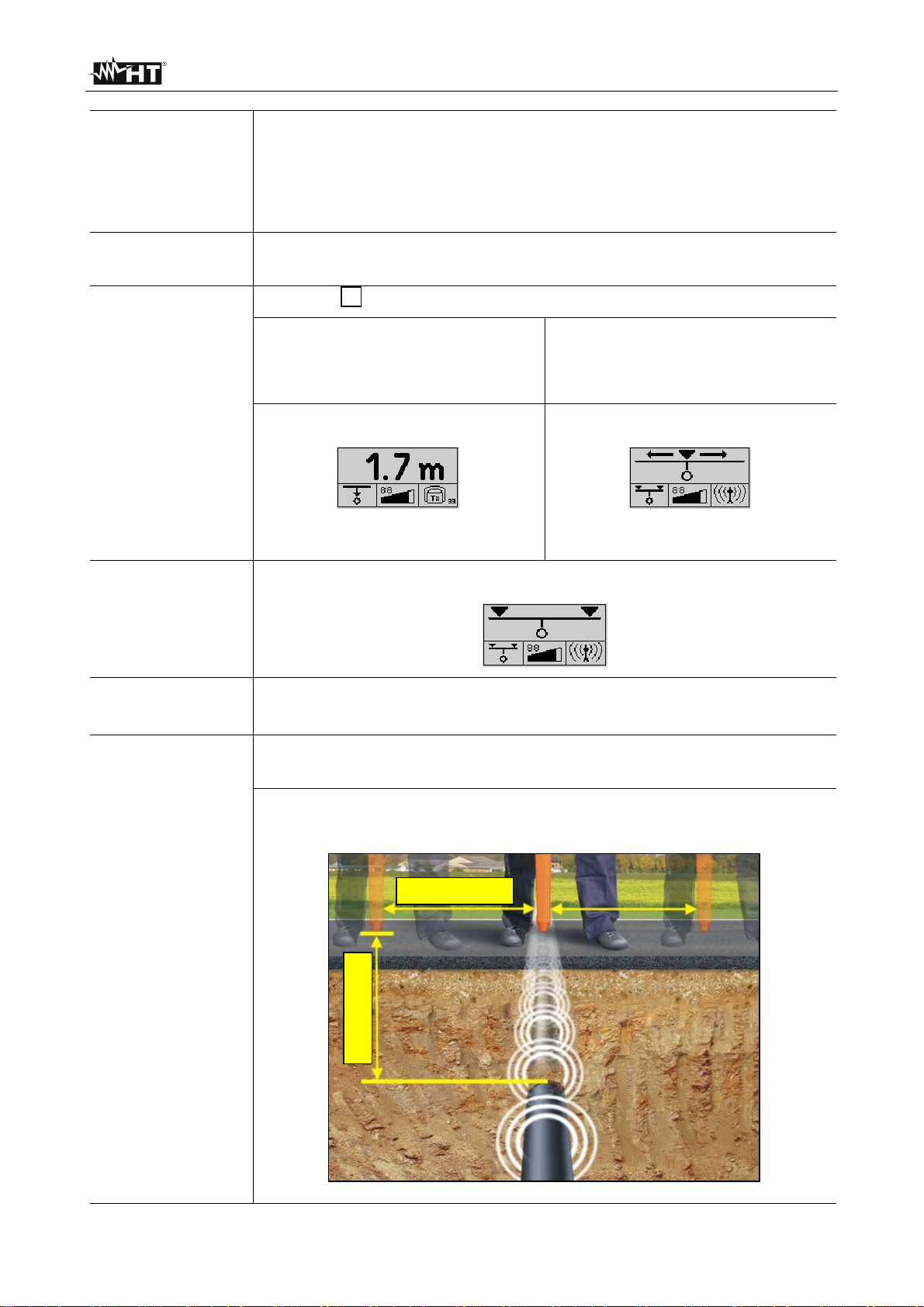

4.3.4 Determining the depth of a line

The RX5000 receiver has an automatic push key depth measurement feature. One

precondition is that a clear signal from the TX5000 transmitter is coupled onto the

conductor to be measured. For this procedure, the transmitter's signal has to be

continuous (not pulsed) (see paragraph 4.2.1).

In addition to this precondition, automatic depth measurement will only function when the

mode of operation of the receiver is set to TRANSMITTER. It will not function if set to

POWER GRID or RADIO

If these preconditions are not met, a rough estimate of the depth may be made using the

manual method

If the depth of a non-metallic pipe needs to be determined, the measurement has to be

made with aid of a probe, e.g. FlexSonde GOK50-R (see paragraph 4.2.2.4). In order to

accommodate the transmission characteristics of a probe, the RX5000 receiver has a

special depth measurement mode which has to be activated through the system settings

(see paragraph 4.3.1.3)

As a result, the way a depth measurement can be performed depends not only on the

active operation mode but also on how the depth measurement mode is set (Transmitter

or Probe). A symbol in the lower left of the display indicates which mode is currently

accessible

Symbol Description

For determining the depth of a probe which has been pushed into a

non-metallic pipe

For determining the depth of a line, the signal of an active transmitter

is coupled onto

For determining the depth of a line which carries radio signals or grid

frequency signals

ATTENZIONE

Even after the depth has been successfully determined, all excavation work

should be done with caution. This is particularly important if a rough estimate

Follow the steps below to determine the depth of a metallic conductor:

of the depth was made, as this can result in even greater deviations

Step Action

If the depth of the conductor will be determined with the aid of the

TX5000 transmitter, couple the transmitter's signal onto the metallic

conductor in such a way that there is as little signal loss as possible

1

(see paragraph 4.2.2 e paragraph 4.3.1)

Do not forget to set the transmitter to continuous signal, not a

pulsed signal when measuring depth

2

3

Press to switch on the receiver

Select the desired mode of operation by pressing the key (see

3

paragraph 4.3.1). The symbol for the currently selected mode of

operation is shown in the lower right-hand corner of the display

EN - 21

Page 23

HT-5000

With a steady grip, hold the receiver perpendicular to the position of a

known metallic conductor, e.g. above a location which was marked

4

during the site survey. The signal strength bargraph should show

zero (see paragraph 4.3.2). In doing so, the tip of the receiver should

touch the ground

Rotate the receiver (through its own axis) over this location until the

5

maximum signal strength is indicated (see paragraph 4.3.1.2)

Press the button to begin measuring the depth

1

6

7

8

For automatic depth measure

(while working in TRANSMITTER

or PROBE mode)…

…the depth value is displayed (

The other steps can be skipped

For making a rough estimate of

the depth (while working in

RADIO or POWER GRID

mode)....

…the herewith symbol is shown

continue from step 7

Move slowly to one side until the following symbol appears in the

display and an acoustic signal sounds:

Mark this spot, then move in the opposite direction to the other side of

the line until the symbol appears in the display again

Mark this spot as well, then measure the distance between the two

spots

Result: Half the distance between the two spots corresponds

approximately to the depth of the line

Distance

9

Depth

EN - 22

Page 24

HT-5000

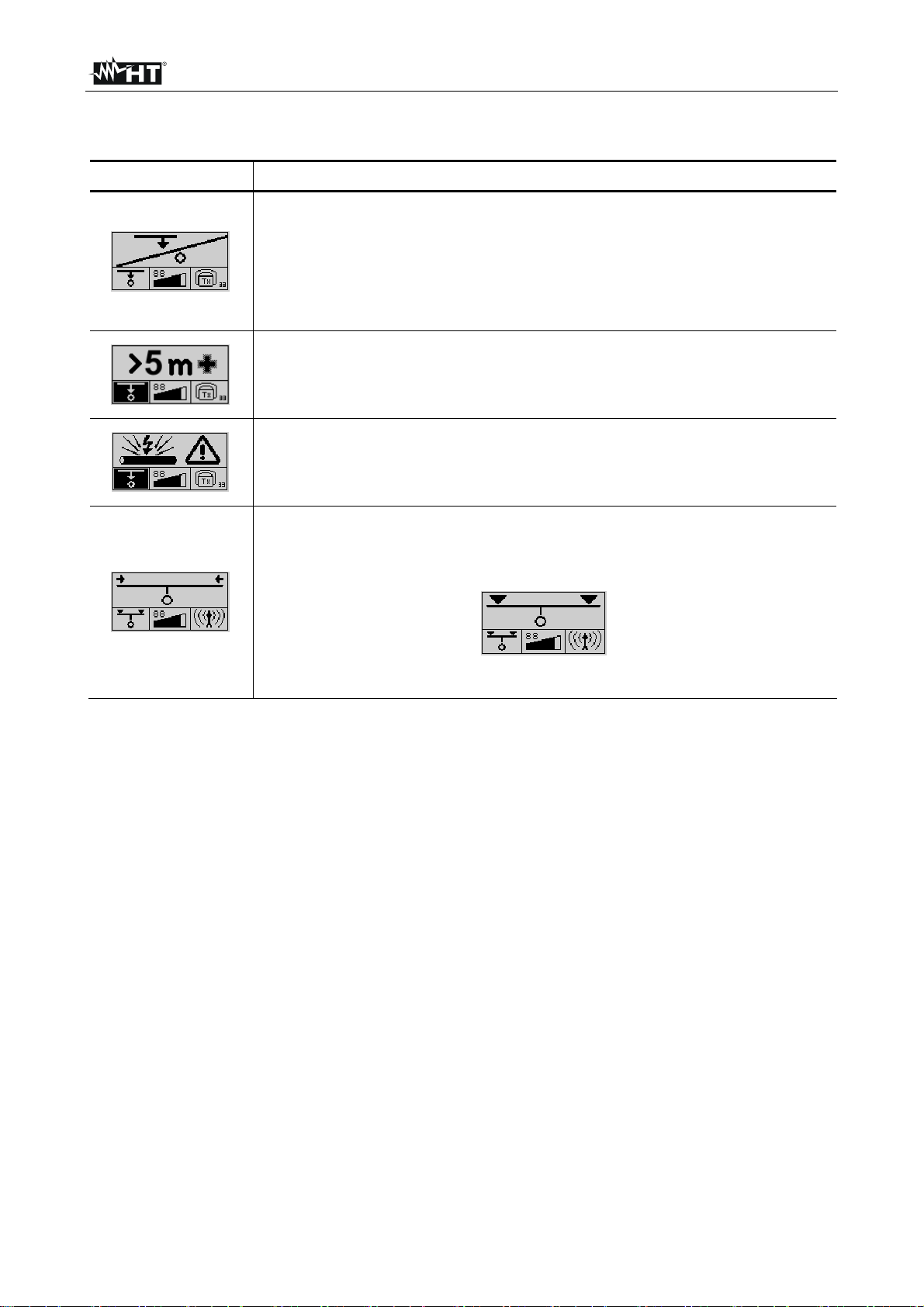

During the depth measuring process, the following symbols are used to notify the user

about certain characteristics and errors:

Symbol Meaning

For of one of the following reasons, the depth could not be

measured:

• The signal received was too weak or too irregular

• The receiver was not held steady enough during the measure

• The receiver was not positioned directly above the line at the

beginning of the process

The depth of the metallic conductor / probe exceeds the measuring

range (5m / 7m). Depth measurement cannot be performed

The depth of the metallic conductor amounts to less than 30 cm (1 ft).

Such conductors must be specially marked in order to prevent

damage during construction

The receiver was moved too far to the left or right while making a

rough estimate. Move in the opposite direction until the following

symbol appears

Proceed as described in step 8 on the previous page

EN - 23

Page 25

HT-5000

4.3.5 Functional test of the receiver

If problems or strange measuring results occur during a line location procedure, it may be

helpful to check the functionality of the receiver using the integrated self-test. This test may

provide information about possible malfunctions of the instrument. Preferably, the self-test

should be performed in an interference-free environment without live cables

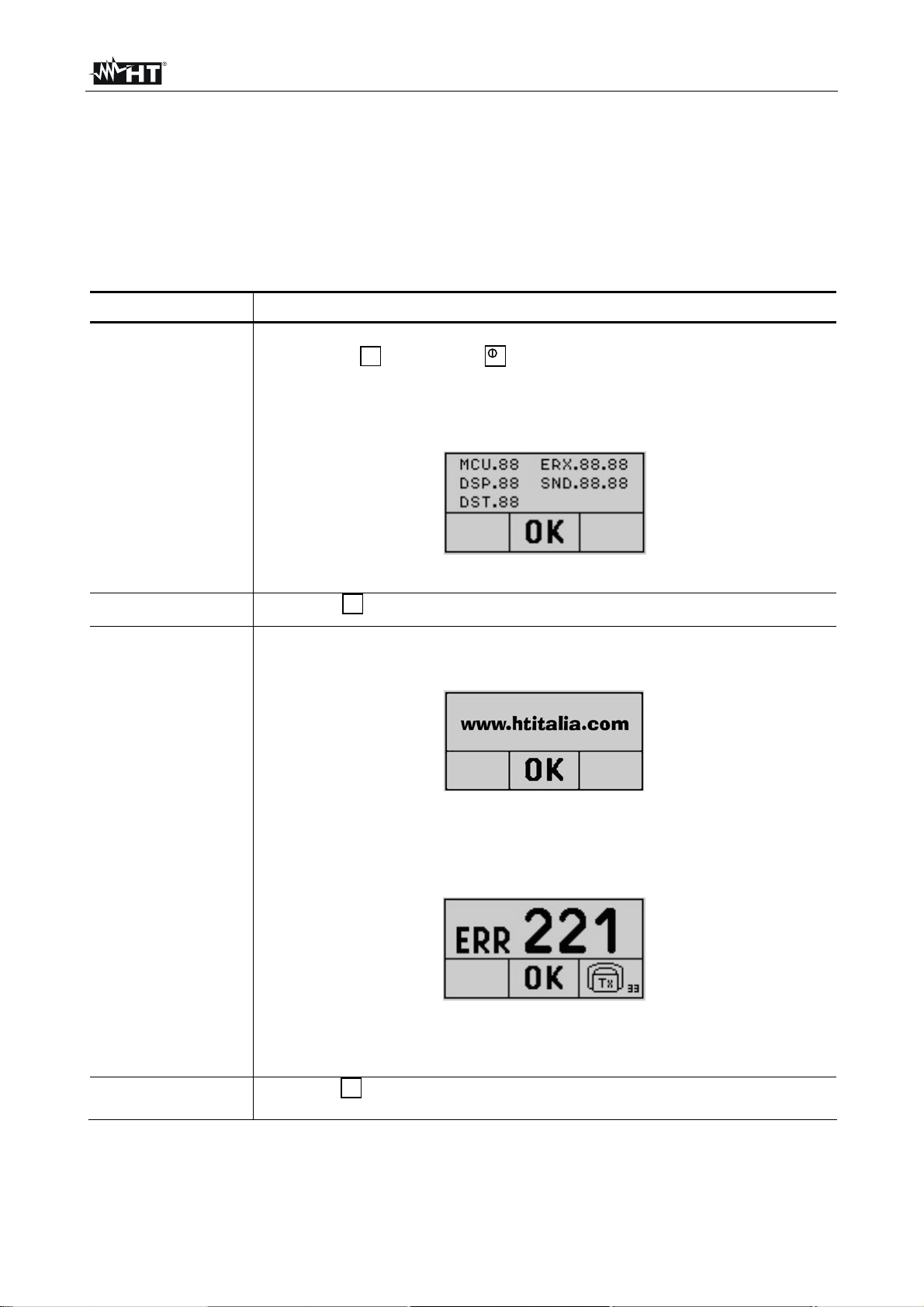

Proceed as follows to perform a self-test:

Step Action

1

2

Switch off the receiver RX5000. The test can be started by pressing

and holding followed by for at least 3 seconds

2

If the self-test is successfully accessed, the display should show the

software and hardware versions of the receiver components:

Press the function key to start the self-test

2

If the test is successfully passed without any problems, the display

shows the following information:

If a fault is recognized during the test, the self-test procedure is

3

terminated and the display indicates the respective error code (see

next page):

If this is the case, the error code should be forwarded to the service

department of HT ITALIA

2

4

Press the function key to exit the self-test

EN - 24

Page 26

HT-5000

Error code Description

000

201

Unimplemented frequency

Not enough battery power for the self-test procedure

Interferences too strong for the self-test procedure

210

In this case, the self-test should be repeated in an environment

with less interferences

220

230

240

250

Fault internal module L1. Contact service dept of HT ITALIA

Fault internal module L2. Contact service dept of HT ITALIA

Fault internal modules L1 and L2. Contact service dept of HT ITALIA

Generic fault. Contact service dept of HT ITALIA

EN - 25

Page 27

HT-5000

5 MAINTENANCE

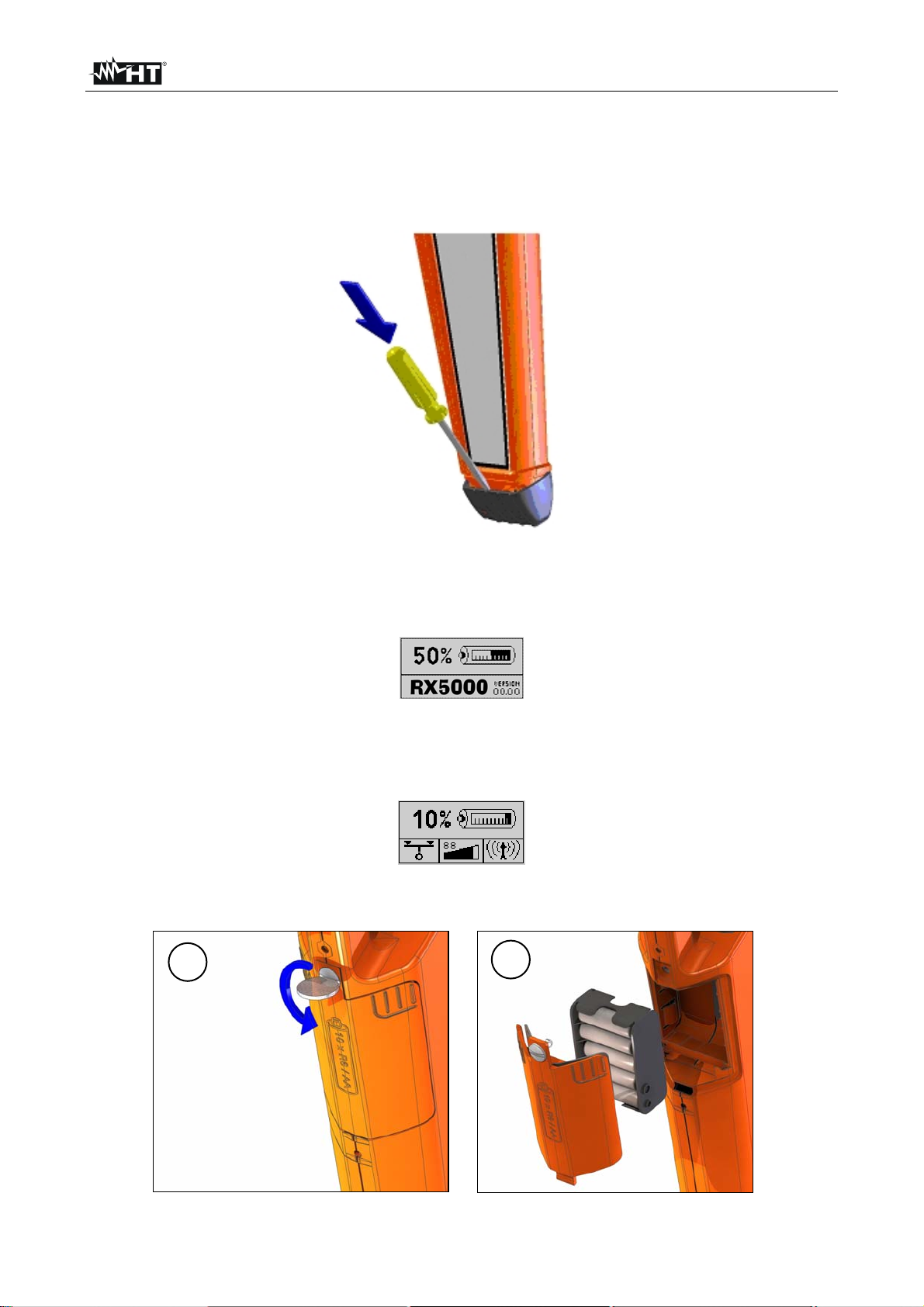

5.1 REPLACEMENT FLOOR CAP OF THE RECEIVER RX5000

The plastic floor cap, which prevents the tip of the receiver from being damaged, can be

easily replaced with the aid of a pointed object (e.g. screwdriver).

Fig. 14: Replacement of the floor cap

5.2 REPLACEMENT BATTERIES OF RECEIVER RX5000

The status of the receiver's batteries is checked upon start-up and indicated in the display:

The system regularly checks the battery strength as well. If battery capacity falls below 10

% of the threshold value, an audible warning signal is given and the current status of the

batteries is shown in the upper part of the display:

In order to replace the 10x1.5V batteries type AA, the battery housing must be removed

(e.g. using a coin) as described in the following illustrations

1

2

Fig. 15: Replacement internal batteries of RX5000

EN - 26

Page 28

HT-5000

5.3 REPLACEMENT BATTERIES OF TRANSMITTER TX5000

The batteries in the transmitter TX5000 have to be replaced as soon as the red LED

battery indicator starts to blink

Should this occur while the user is busy locating a line with the receiver, he/she will be

informed of the weak batteries via the reception signal:

Type of signal Normal signal Signal when batteries are weak

In order to change the 6x1.5 V batteries type LR20, both screws on the back of the

transmitter must be (e.g. with the aid of a coin) turned through ¼ turn (1) and the battery

tray must be pulled (2) (see Fig. 16). Please note that all the batteries are fitted in the

same direction

Fig. 16: Replacement batteries of TX5000

5.4 CLEANING

To clean the instrument use a soft dry cloth. Never use a wet cloth, solvents or water

5.5 END OF LIFE

CAUTION: this symbol indicates that equipment and its accessories shall be

subject to a separate collection and correct disposal

EN - 27

Page 29

HT-5000

6 TECHNICAL SPECIFICATION

6.1 TECHNICAL CHARACTERISTICS OF RECEIVER RX5000

Parameter Value

Frequency ranges

• Mode 1: Radio

• Mode 2: Power network

• Mode 3: Transmitter

Sensitivity

• Mode 1: Radio

• Mode 2: Power network

• Mode 3: Transmitter

Depth determination

• Depth range

• Resolution

• Accuracy (signal without disturb)

- Mode 1: Radio

- Mode 2: Power network

- Mode 3: Transmitter

15kHz ÷ 23kHz

50Hz / 60Hz

32.768kHz

Refer to a depth of 1m

> 20µA

> 7µA

> 5µA

…of a conductor …of a probe

0.3m÷5m (12in÷16ft)

0.1m

±20%rdg

±20%rdg

±5%rdg (up to 2m)

±20%rdg (2÷5m)

0.3m÷7m (12in÷23ft)

0.1m

±10%rdg (up to 2m)

±20%rdg (2÷7m)

Power supply

Battery life

Working temperature

• Operation

• Storage

Size (LxWxH)

10x1.5V batteries type IEC AA LR06

40 hours (for intermittent use with alkaline

batteries, 20 °C)

according to IEC/EN60068-1

-20 ÷ 55°C (-4 ÷ 131°F)

-30 ÷ 70°C (-22 ÷ 158°F)

660 x 252 x 99mm (26 x 10 x 4)”

Weight (included batteries) 2.5kg (5lb)

Mechanical protection

Dust and water protected

according to a IEC/EN60529

IP67 up to the lower edge of the battery

IP56 for all parts above this delineation

EN - 28

Page 30

HT-5000

6.2 TECHNICAL CHARACTERISTICS OF TRANSMITTER TX5000

Parameter Value

Transmitted power (switchable) 0.1W / 0.5W

Frequency

Power supply

Battery life

Working temperature

• Operation

• Storage

Category of measure

Size (LxWxH)

32.768kHz

6x1.5V batteries type IEC LR20

40 hours (for intermittent use with alkaline

batteries, 20 °C)

according to IEC/EN60068-1

-20 ÷ 55°C (-4 ÷ 131°F)

-30 ÷ 70°C (-22 ÷ 158°F)

CAT II / CAT III 440V, CAT IV 300V

260 x 255 x 140mm (10.2 x 10 x 5.5)”

Weight (included batteries) 1.7kg (3lb)

Mechanical protection

Dust and water protected

6.3 GENERAL SPECIFICATIONS

according to a IEC/EN60529

IP56

Parameter Value

Sinusoidal vibrations

Peak acceleration

Frequency

According to IEC / EN 60068–2–6

20m/s2

10Hz ÷150Hz

Free fall

Max. height (packaged)

Safety

Protection class

Insulation

Relative humidity

According to IEC/EN60068-2-32

80cm (weight up to10kg)

IEC/EN61010-1

III (according to IEC/EN61140)

Double insulation

max 93% at 30°C

6.4 ACCESSORIES

6.4.1 Standard accessories

• Transmitter TX5000 • 6x1.5V batteries IEC LR20

• Receiver RX5000 • 10x1.5V batteries IEC LR06

• 2 cables R/B banana + alligator clip, 2m • Carrying bag

• 1 cable black banana + alligator clip, 10m • User manual

• 1 earth metal probe

6.4.2 Optional accessories

• Flexi sonde set for locating non-metallic pipes – Cod GOK50-R

• Transmitter clamp, 100mm diameter for the inductive coupling – Cod. 820005314

• Set of cables (Shuko plug + cable with RJ11 + coax cable) – Cod. 890008852

EN - 29

Page 31

HT-5000

7 SERVICE

7.1 WARRANTY CONDITIONS

This instrument is guaranteed for one year against material or production defects, in

accordance with our general sales conditions. During the warranty period the manufacturer

reserves the right to decide either to repair or replace the product.

Should you need for any reason to return back the instrument for repair or replacement

take prior agreements with the local distributor from whom you bought it. Do not forget to

enclose a report describing the reasons for returning (detected fault). Use only original

packaging. Any damage occurred in transit due to non original packaging will be charged

anyhow to the customer.

The warranty doesn’t apply to:

• Accessories and batteries (not covered by warranty).

• Repairs made necessary by improper use (including adaptation to particular

applications not foreseen in the instructions manual) or improper combination with

incompatible accessories or equipment.

• Repairs made necessary by improper shipping material causing damages in transit.

• Repairs made necessary by previous attempts for repair carried out by non skilled or

unauthorized personnel.

• Instruments for whatever reason modified by the customer himself without explicit

authorization of our Technical Dept.

• Use not provided by the instrument's specifications or in the instruction manual.

The contents of this manual may not be reproduced in any form whatsoever without the

manufacturer’s authorization.

Our products are patented and our logotypes registered. We reserve the right to

modify specifications and prices in view of technological improvements or

developments which might be necessary.

7.2 SERVICE

Shouldn’t the instrument work properly, before contacting your distributor make sure that

batteries are correctly installed and working and replace them if necessary.

Should you need for any reason to return back the instrument for repair or replacement

take prior agreements with the local distributor from whom you bought it. Do not forget to

enclose a report describing the reasons for returning (detected fault). Use only original

packaging. Any damage occurred in transit due to non original packaging will be charged

anyhow to the customer.

The manufacturer will not be responsible for any damage to persons or things.

EN - 30

Loading...

Loading...