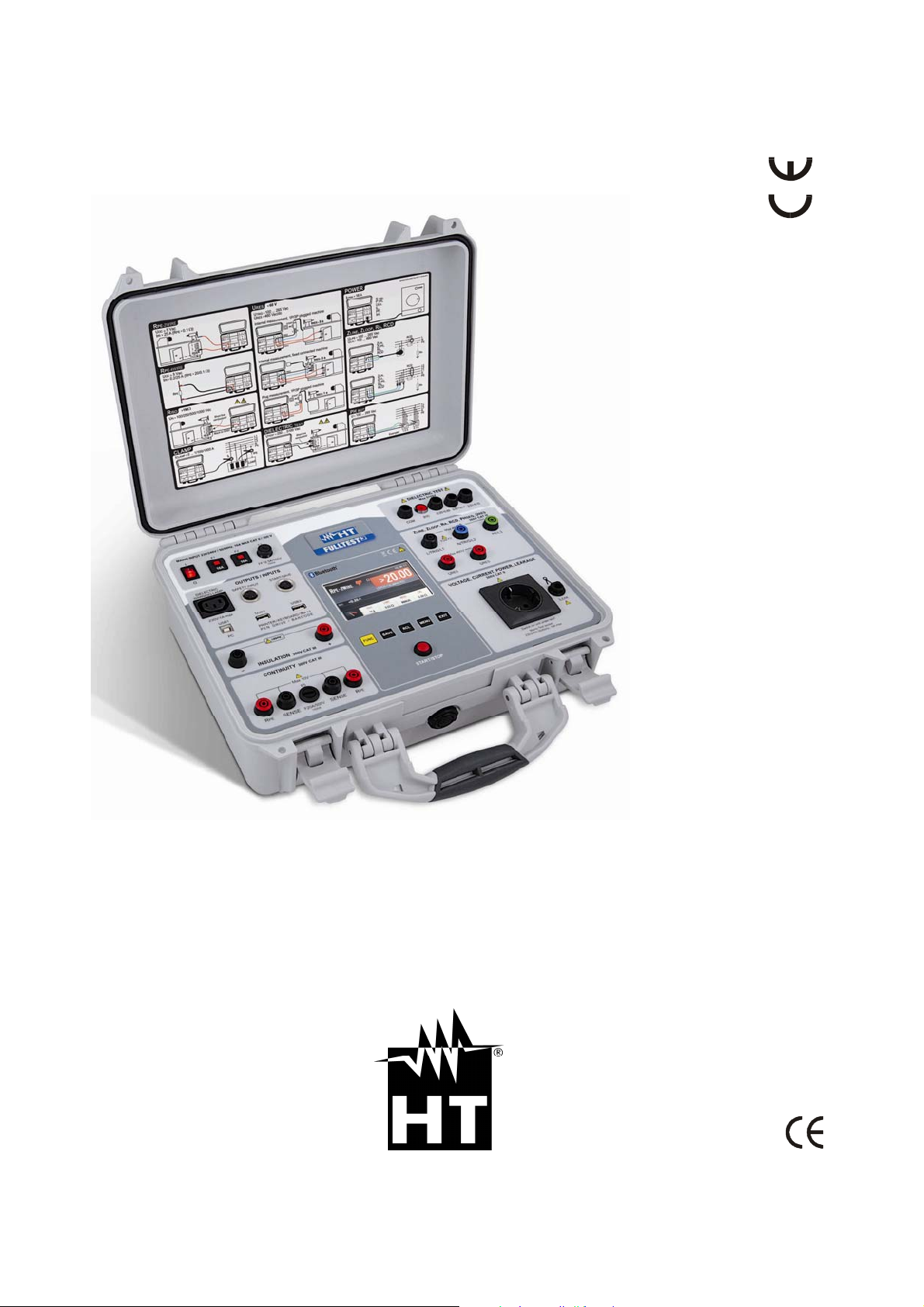

Page 1

3

FULLTEST

User’s manual

Copyright HT ITALIA 2014 Release EN 1.01 - 24/01/2014

Page 2

FULLTEST 3

Table of contents:

1. SAFETYPRECAUTIONSANDPROCEDURES.............................................................................................3

1.1. PRELIMINARYINSTRUCTIONS...................................................................................................... 4

1.2. DURINGUSE................................................................................................................................4

1.3. AFTERUSE...................................................................................................................................5

1.4. OVERVOLTAGECATEGORIES‐DEFINITIONS..................................................................................5

2. GENERALDESCRIPTION.........................................................................................................................6

2.1. WORKING....................................................................................................................................6

2.2. OPENINGTHEINSTRUMENT'SCOVER...........................................................................................8

3. PREPARATIONFORUSE........................................................................................................................9

3.1. PRELIMINARYCHECKS..................................................................................................................9

3.2. POWERSUPPLY...........................................................................................................................9

3.3. CALIBRATION...............................................................................................................................9

3.4. TRANSPORTANDSTORAGE..........................................................................................................9

4. OPERATINGINSTRUCTIONS................................................................................................................10

4.1. INSTRUMENT‐DESCRIPTION.....................................................................................................10

4.2. TURNINGONTHETESTER..........................................................................................................11

4.3. MEASUREMENTFUNCTIONSELECTION......................................................................................12

5. MEASUREMENTS................................................................................................................................13

5.1. CONTINUITY‐TWOWIREMETHOD(RPE‐2WIRE)........................................................................13

5.1.1. RPE‐2WIREDISPLAYEXPLANATION...............................................................................................13

5.1.2. CALIBRATIONOFTESTLEADS........................................................................................................14

5.1.3. LIMITVALUEADJUSTMENT...........................................................................................................15

5.1.4. RPE‐2WIREMEASUREMENT..........................................................................................................16

5.2. CONTINUITY‐FOURWIREMETHOD(RPE‐4WIRE).......................................................................18

5.2.1. RPE‐4WIREDISPLAYEXPLANATION...............................................................................................18

5.2.2. CALIBRATIONOFTESTLEADS........................................................................................................19

5.2.3. RPE‐4WIREMEASUREMENT..........................................................................................................20

5.3. INSULATIONRESISTANCE(M)..................................................................................................22

5.3.1. RISODISPLAYEXPLANATION.........................................................................................................22

5.3.2. RISOMEASUREMENT....................................................................................................................23

5.4. DIELECTRIC(DIELECTRIC)............................................................................................................25

5.4.1. WARNINGS....................................................................................................................................25

5.4.2. DIELECTRICDISPLAYEXPLANATION..............................................................................................26

5.4.3. DIELECTRICTEST............................................................................................................................27

5.5. RCD(RCD)..................................................................................................................................29

5.5.1. RCDDISPLAYEXPLANATION..........................................................................................................29

5.5.2. EXPLANATIONOFRCDTESTCURRENTS........................................................................................30

5.5.3. RCDMEASUREMENT.....................................................................................................................31

5.6. LOOPIMPEDANCE/SHORT‐CIRCUITCURRENT(LOOP)...............................................................33

5.6.1. LOOPDISPLAYEXPLANATION........................................................................................................33

5.6.2. LIMITVALUEEXPLANATION..........................................................................................................34

5.6.3. PROSPECTIVESHORT‐CIRCUITCURRENTCALCULATION...............................................................35

5.6.4. LOOPMEASUREMENT...................................................................................................................36

5.7. GLOBALEARTHRESISTANCE/CONTACTVOLTAGE(RA)..............................................................39

5.7.1. RALIMITVALUECALCULATION.....................................................................................................39

5.7.2. RADISPLAYEXPLANATION............................................................................................................39

5.7.3. RAMEASUREMENT.......................................................................................................................40

5.8. RESIDUALVOLTAGE(URES)........................................................................................................42

5.8.1. EXPLANATIONOFLINEARMODE..................................................................................................42

5.8.2. EXPLANATIONOFNONLINEAR MODE...........................................................................................43

5.8.3. URESDISPLAYEXPLANATION........................................................................................................44

5.8.4. TRIGGERCONDITIONS...................................................................................................................44

5.8.5. URESMEASUREMENT...................................................................................................................45

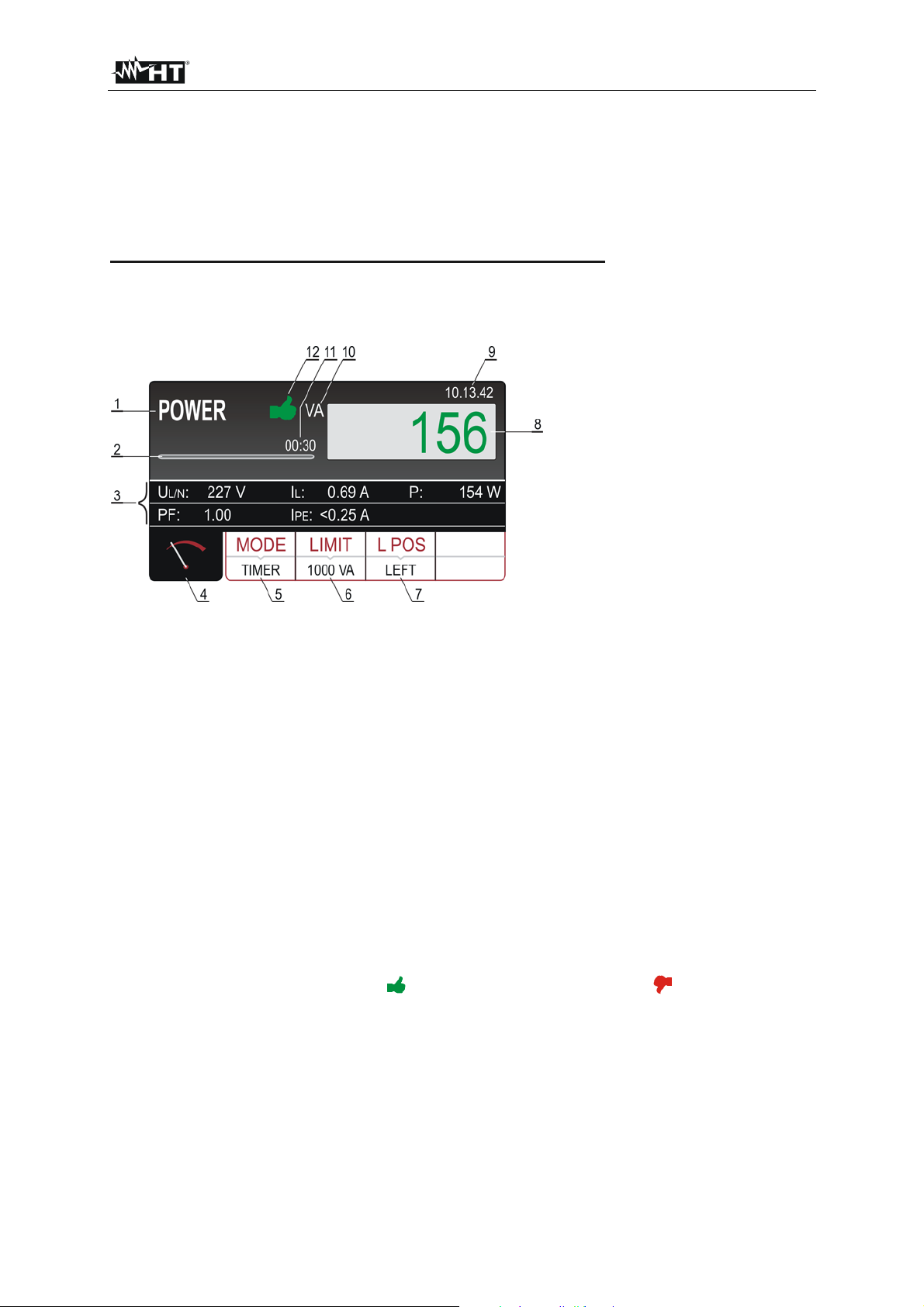

5.9. POWER(POWER).......................................................................................................................48

5.9.1. POWERDISPLAYEXPLANATION....................................................................................................48

5.9.2. POWERMEASUREMENT...............................................................................................................49

5.10. PHASESEQUENCE(PHASESEQ)...................................................................................................51

EN - 1

Page 3

FULLTEST 3

5.10.1. PHASESEQUENCEDISPLAYEXPLANATION...............................................................................51

5.10.2. PHASESEQUENCEMEASUREMENT..........................................................................................52

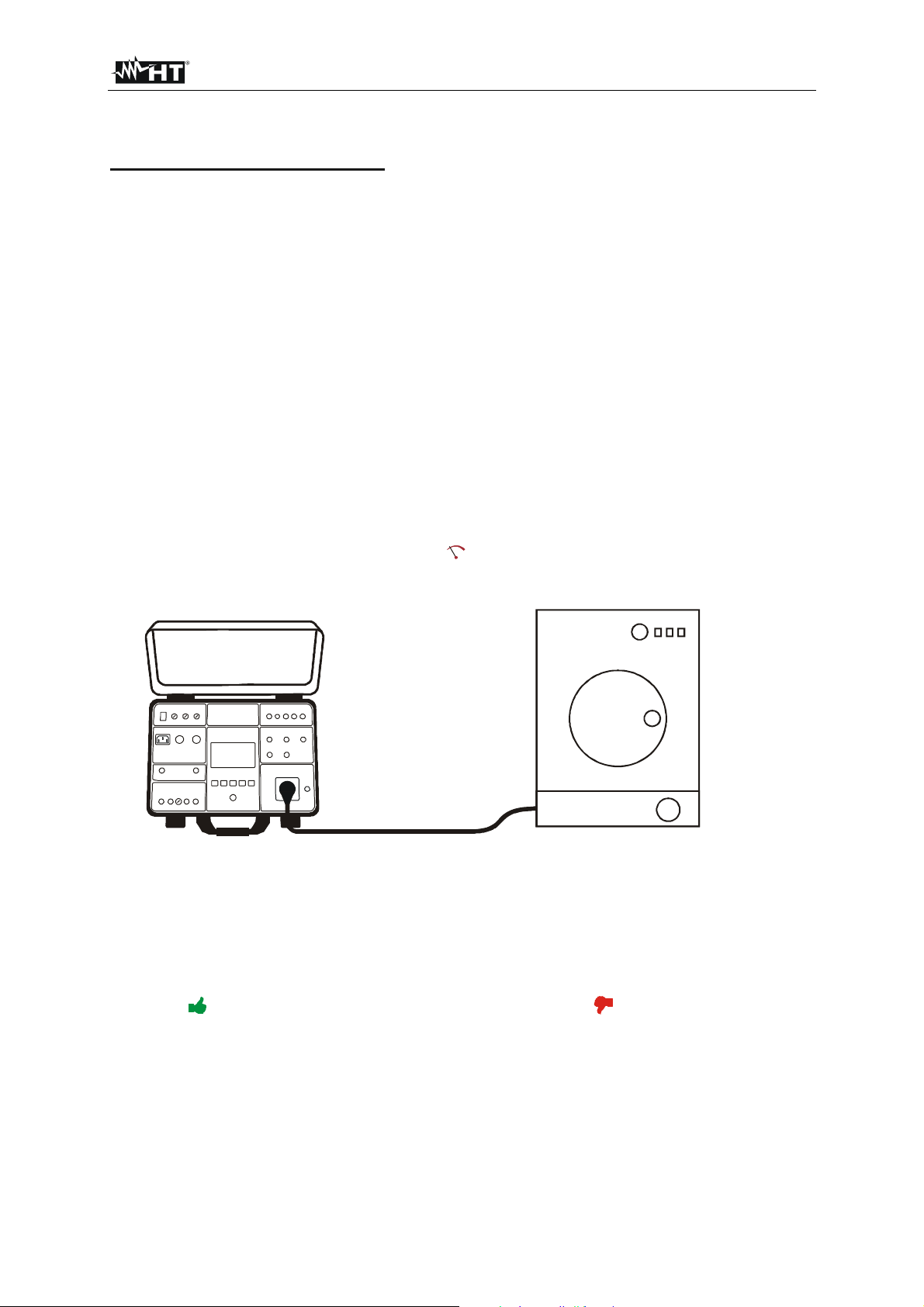

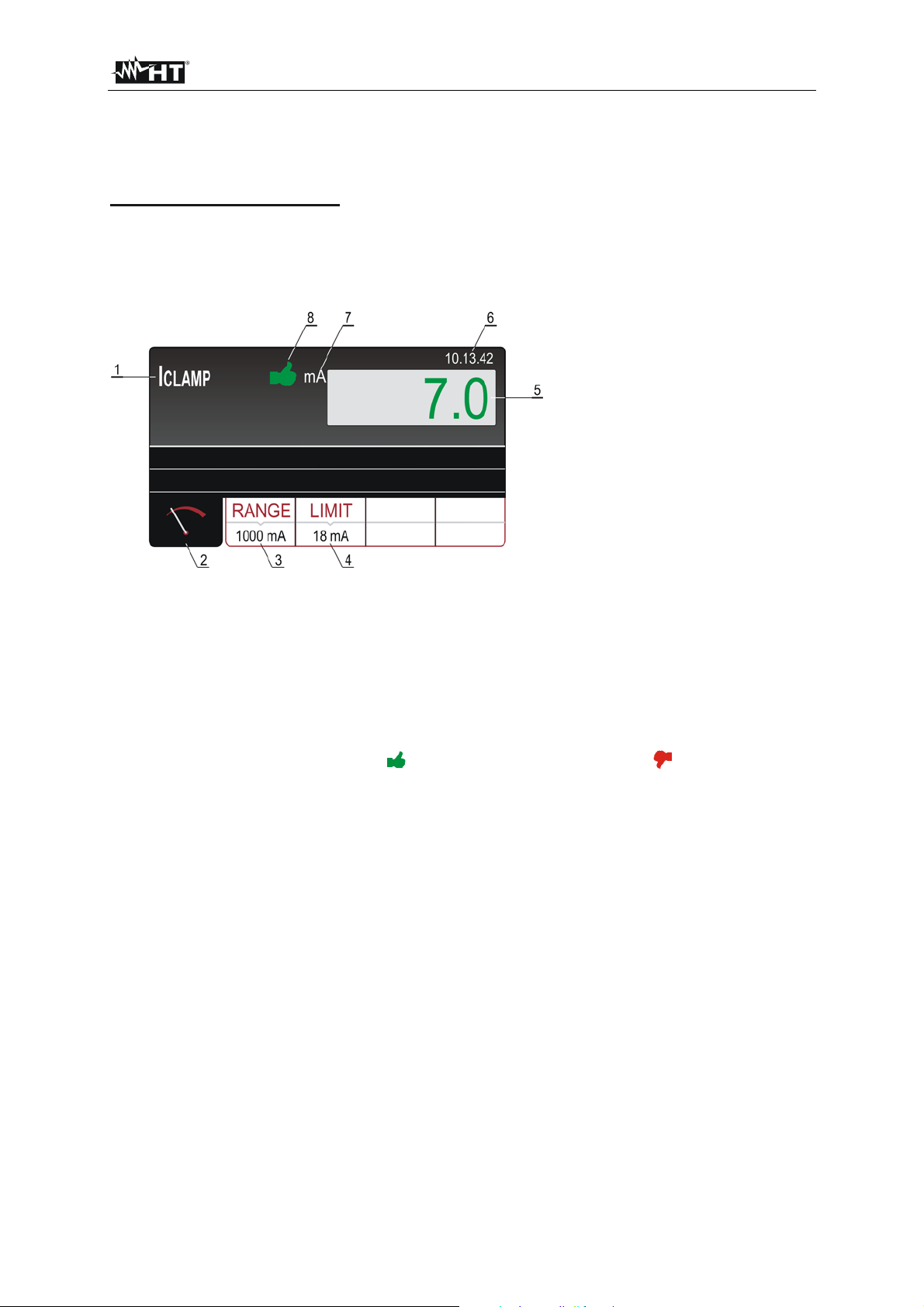

5.11. CURRENTMEASUREMENTUSINGCURRENTCLAMP(ICLAMP)....................................................53

5.11.1. ICLAMPDISPLAYEXPLANATION...............................................................................................53

5.11.2. ICLAMPMEASUREMENT..........................................................................................................54

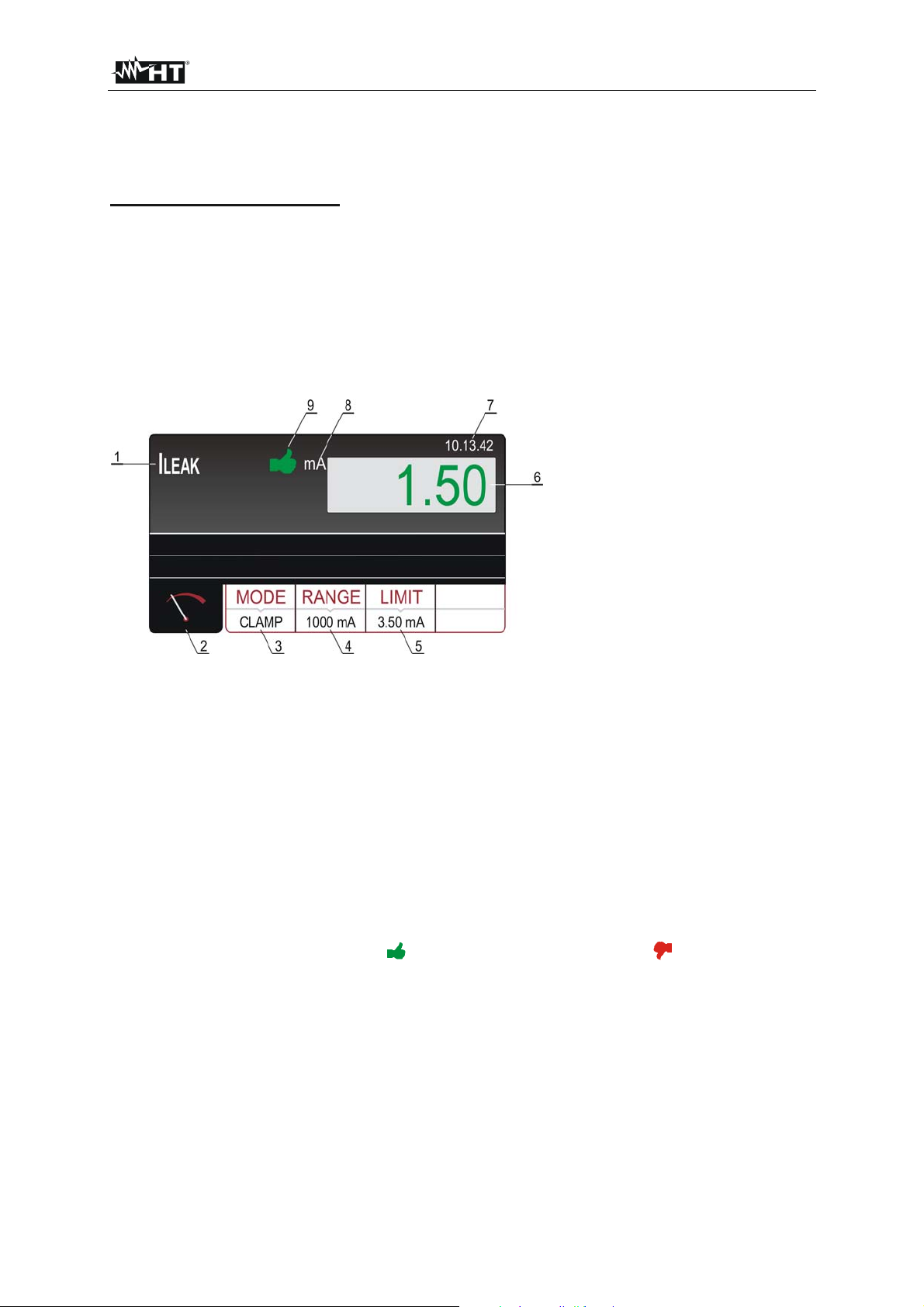

5.12. LEAKAGECURRENT(ILEAK)........................................................................................................55

5.12.1. LEAKAGEDISPLAYEXPLANATION.............................................................................................55

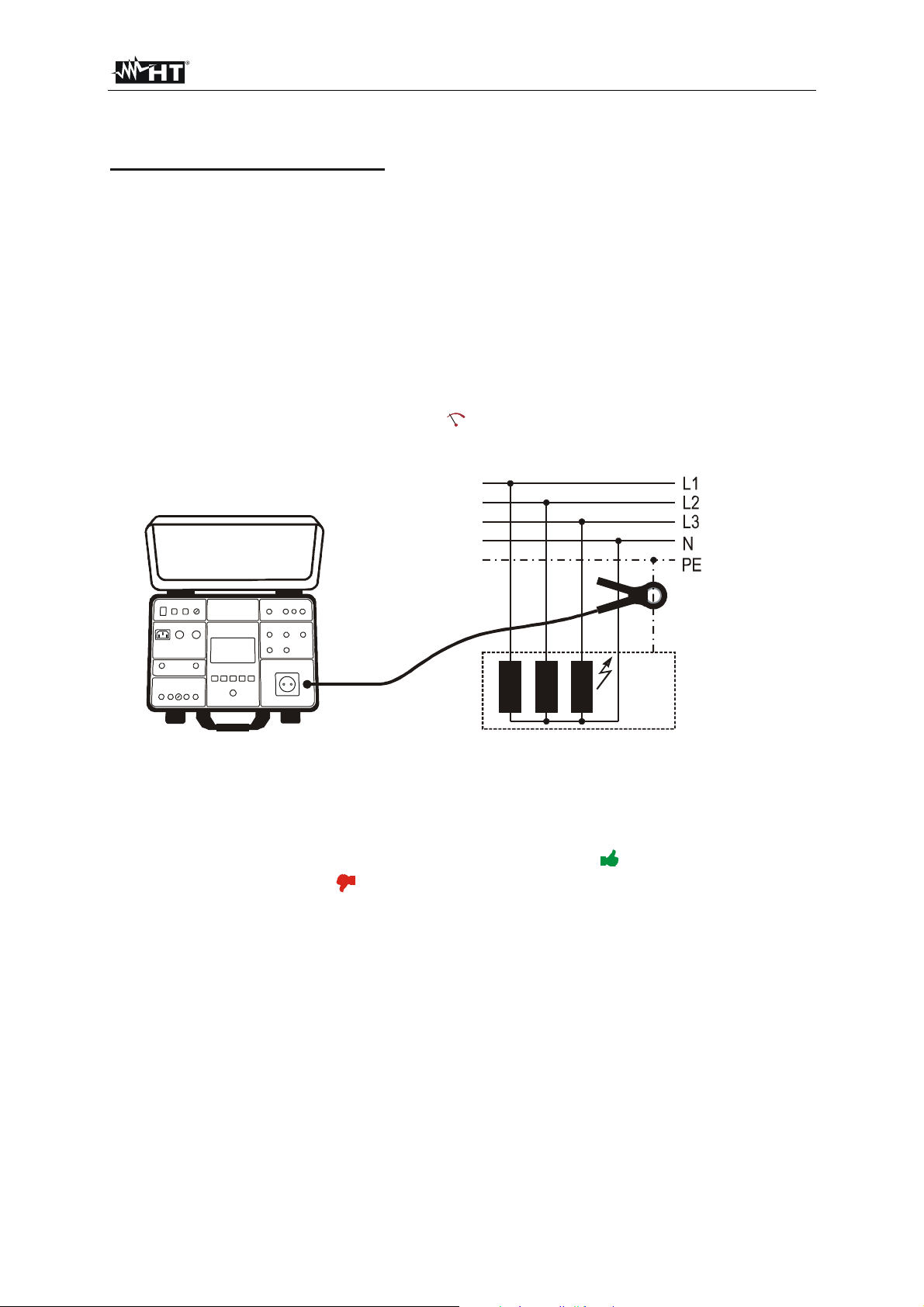

5.12.2. LEAKAGECURRENTMEASUREMENTUSINGCURRENTCLAMP................................................57

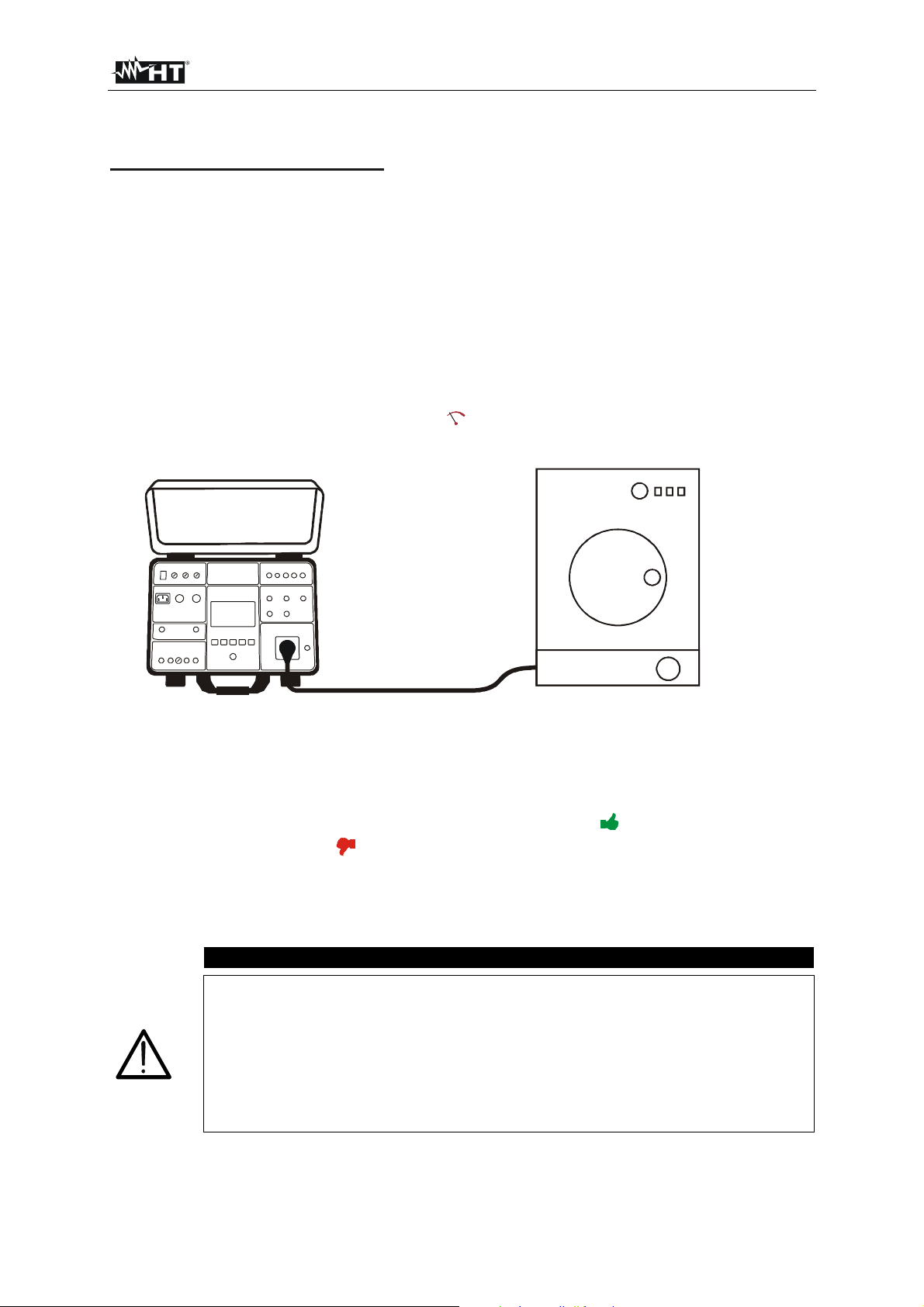

5.12.3. LEAKAGECURRENTMEASUREMENTONSCHUKOSOCKET......................................................58

6. MENUFUNCTIONS..............................................................................................................................60

6.1. MEMORYmenu.........................................................................................................................60

6.1.1. MEMORYINFOmenu....................................................................................................................60

6.1.2. CLEARmenu..................................................................................................................................61

6.1.3. USBmenu......................................................................................................................................61

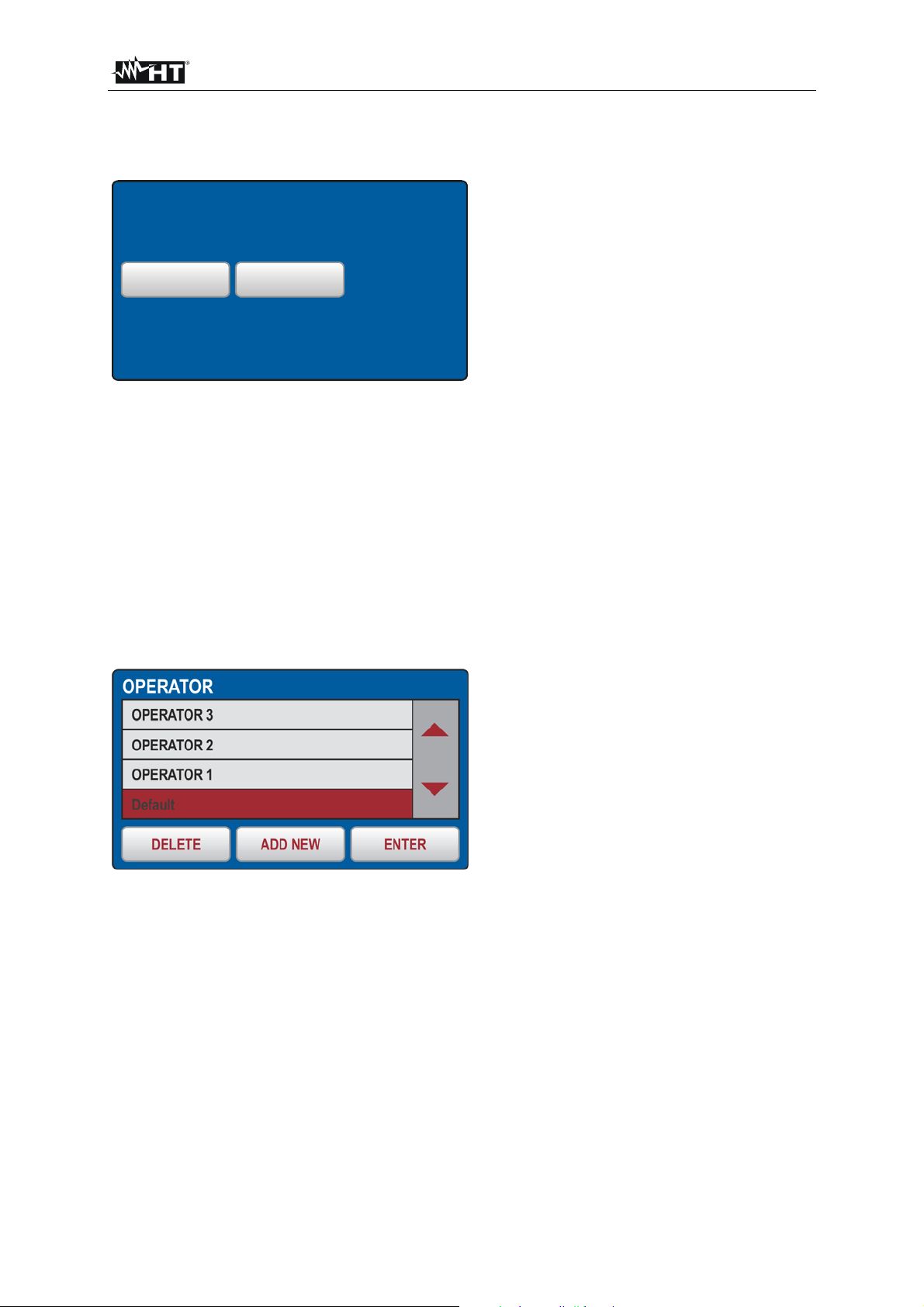

6.2. SELECTOPERATORmenu...........................................................................................................61

6.3. LANGUAGEmenu...................................................................................................................... 62

6.4. TESTERINFOmenu....................................................................................................................62

6.5. SETUPmenu..............................................................................................................................63

6.5.1. LEVELNAMESmenu......................................................................................................................63

6.5.2. LIMITCONTACTVOLTAGEmenu...................................................................................................64

6.5.3. DATE/TIMEmenu..........................................................................................................................64

6.5.4. RESETmenu...................................................................................................................................64

6.5.5. NOMINALVOLTAGEmenu............................................................................................................69

6.5.6. SAFETYmenu.................................................................................................................................69

6.6. SOUNDmenu.............................................................................................................................70

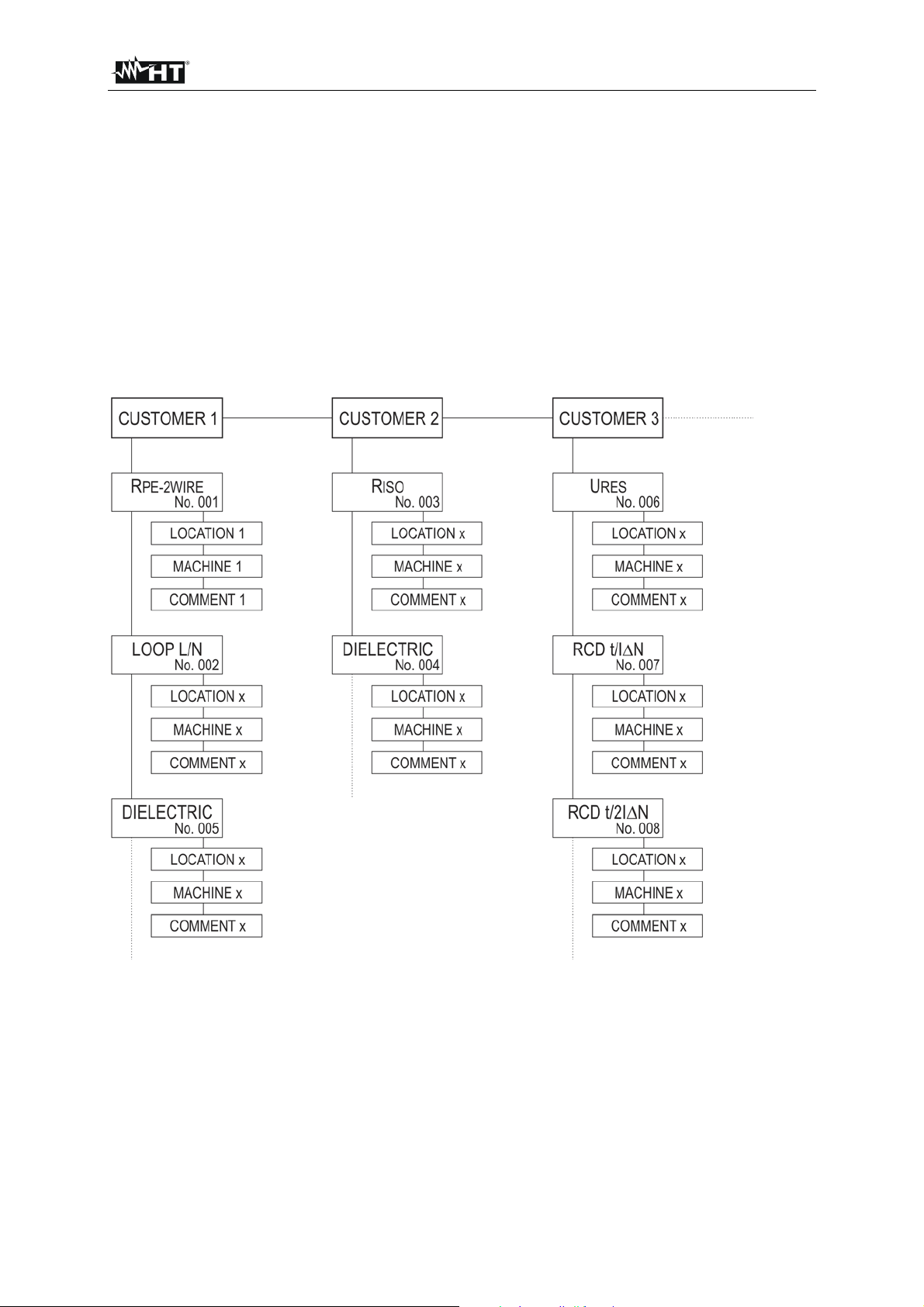

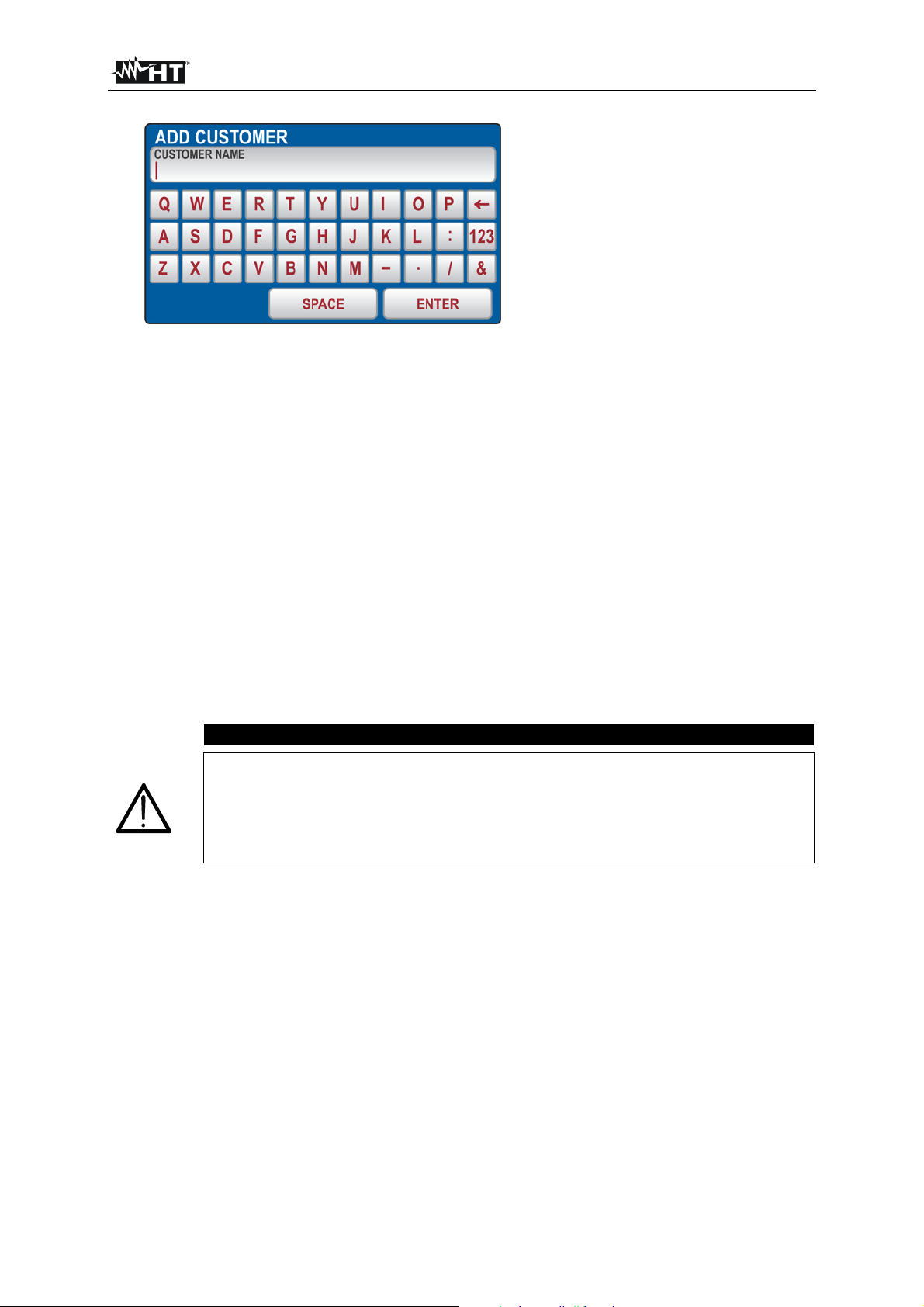

7. MEMORYFEATURES...........................................................................................................................71

7.1. MEMORYSTRUCTURE................................................................................................................71

8. MEMORIZINGEXAMPLE.....................................................................................................................72

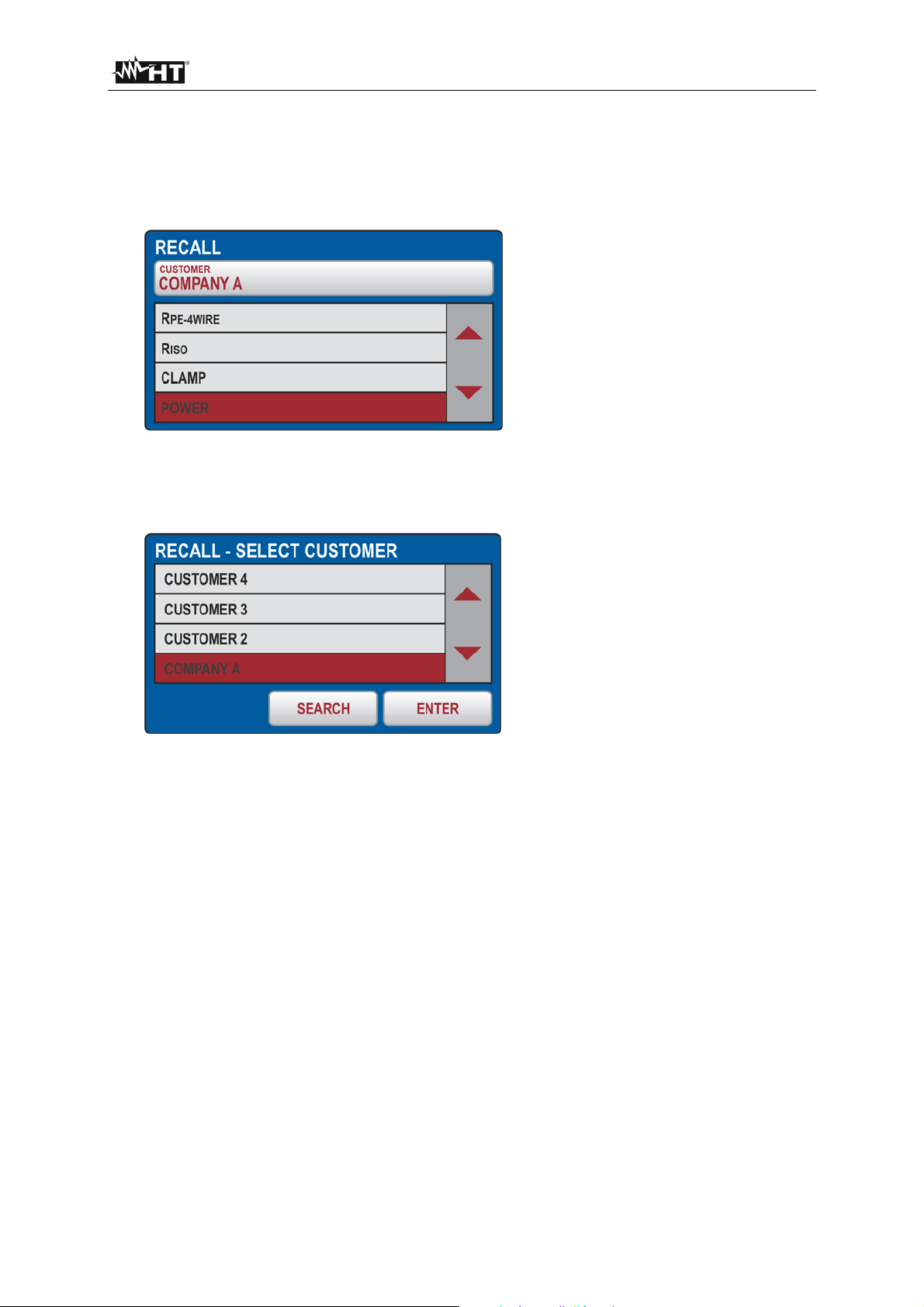

9. RECALLRESULTS.................................................................................................................................74

10. ENTRYOFDATABYUSINGANEXTERNALKEYBOARD..........................................................................76

11. ENTRYOFDATAUSINGABARCODEREADER....................................................................................... 76

12. FWUPDATEOFTHEFULLTEST3..........................................................................................................76

13. MAINTENANCE...................................................................................................................................76

13.1. CLEANING..................................................................................................................................76

13.2. FUSEREPLACEMENT..................................................................................................................76

14. TECHNICALSPECIFICATIONS................................................................................................................78

14.1. MEASUREMENTFUNCTIONS......................................................................................................78

14.2. GENERALSPECIFICATION...........................................................................................................89

14.3. ACCESSORIES.............................................................................................................................89

15. SERVICE..............................................................................................................................................90

15.1. WARRANTYCONDITIONS...........................................................................................................90

15.2. AFTER‐SALESERVICE..................................................................................................................90

EN - 2

Page 4

FULLTEST 3

1. SAFETY PRECAUTIONS AND PROCEDURES

CAUTION

For your own safety and to avoid damaging the instrument follow the procedures

described in this instruction manual and read carefully all notes marked with this symbol.

This instrument complies with safety Standards EN61557 and EN61010-1 related to electronic

measuring instruments. When taking measurements:

Avoid doing this in humid or wet places - make sure that humidity is within the limits indicated in

section “Environmental conditions”.

Avoid doing this in rooms where explosive gas, combustible gas, steam or excessive dust is

present.

Keep you insulated from and do not touch the object under test, any exposed metal part such as

test lead ends, sockets, fixing objects, circuits etc.

Avoid doing this if you notice anomalous conditions such as breakages, deformations, fractures,

blind display etc.

The following symbols are used in this instruction manual:

Warning of a potential danger, comply with instruction manual.

☞

Reference, please pay utmost attention.

UUT Unit under test

Caution, dangerous voltage. Danger of electrical shock.

Symbol for marking of electrical and electronic equipment (WEEE Directive).

Conformity symbol, the instrument complies with the valid directives. It complies with the

EMC Directive and the Low Voltage Directive.

EN - 3

Page 5

FULLTEST 3

1.1. PRELIMINARY INSTRUCTIONS

CAUTION

The instrument must be connected to a power socket with grounded PE terminal. If this

is not assured, the instrument will display PE DISCONNECTED, SWITCH OFF NOW

message and will perform no measurement.

The instruction manual contains information and references, necessary for safe operation and

maintenance of the instrument. Prior to using the instrument, the user is kindly requested to

thoroughly read the instruction manual and comply with it in all sections.

Failure to read the instruction manual or to comply with the warnings and references contained

herein can result in serious bodily injury or instrument damage.

In order to avoid electrical shock, the valid safety and national regulations regarding excessive

contact voltages must receive utmost attention when working with voltages exceeding 60 V DC or

50 V (25 V) RMS AC. The value in brackets is valid for limited ranges (as for example medicine).

The operator is recommended to respect the usual safety regulations aimed at protecting against

dangerous currents and protecting the instrument against improper use.

This instrument has been designed for use in environments of pollution degree 2.

It can be used for tests on electrical installations of overvoltage category III, 300V maximum

voltage to earth.

Do not effect measurements on circuit exceeding the specified voltage limits.

Only the original test leads supplied along with the instrument guarantee compliance with the

safety standards in force. They must be in good conditions and, if necessary, replaced with

identical ones.

Do not take measurements under environmental conditions exceeding the limits indicated in this

manual.

Before connecting the test probes to the installation make sure that the right function is selected.

The instrument may only be used in dry and clean environments. Dirt and humidity reduce

insulation resistance and may lead to electrical shocks, in particular for high voltages.

Never use the instrument in precipitation such as dew or rain. In case of condensation due to

temperature jumps, the instrument may not be used.

Start any test series by earth bond resistance measurement.

At earth bond resistance, insulation resistance and dielectric measurements unit under test must

be voltage-free. If necessary check the unit is voltage-free i.e. by using a voltage tester.

When modifying the instrument, the operational safety is no longer ensured.

1.2. DURING USE

CAUTION

An improper use may damage the instrument and/or its components or injure the

operator.

Only skilled technicians, who know the possible risks involved to the dangerous voltages use are

allowed to operate the instrument.

The instrument may only be connected to mains voltage as indicated on the type shield.

The instrument may only be used within the operating ranges as specified in the technical data

section.

Disconnect the test leads from the circuit under test before selecting any function.

Only touch test leads and test probes at handle surface provided. Never directly touch test probes.

Never touch any unused terminal when the instrument is connected to circuits.

EN - 4

Page 6

FULLTEST 3

Do not measure resistance in presence of external voltages; although the instrument is protected,

an excessive voltage may cause malfunctioning.

Do not open the instrument! Dangerous voltages inside!

Connecting one terminal to the test object and working with one probe or holding both probes in

one hand is prohibited.

Use safety probes with protection against contact or with two-hand operation only. Always hold

only one probe in one hand.

It is prohibited to touch the unit under test during the test. If need be, additional measures must be

taken (e.g. cover made of insulating mats) to protect the person performing the test against

inadvertent contact with the unit under test.

1.3. AFTER USE

Disconnect all test leads from the circuit under test and switch off the instrument.

1.4. OVERVOLTAGE CATEGORIES - DEFINITIONS

Standard EN61010-1 (Safety requirements for electrical equipment for measurement, control and

laboratory use, Part 1: General requirements) defines what a measurement category (usually called as

Overvoltage Category) is. At paragraph 6.7.4: Measuring circuits it says:

(OMISSIS)

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of the low-voltage

installation.

Examples are electricity meters and measurements on primary overcurrent protection devices

and ripple control units.

Measurement category III is for measurements performed in the building installation.

Examples are measurements on distribution boards, circuit breakers, wiring, including cables,

bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and equipment for

industrial use and some other equipment, for example, stationary motors with permanent

connection to fixed installation.

Measurement category II is for measurements performed on circuits directly connected to the

low voltage installation.

Examples are measurements on household appliances, portable tools and similar equipment.

Measurement category I is for measurements performed on circuits not directly connected to

MAINS.

Examples are measurements on circuits not derived from MAINS, and specially protected

(internal) MAINS-derived circuits. In the latter case, transient stresses are variable; for that

reason, the norm requires that the transient withstand capability of the equipment is made

known to the user.

EN - 5

Page 7

FULLTEST 3

2. GENERAL DESCRIPTION

Dear Customer, the instrument you have purchased, whether used according to the instructions given in

this manual, will grant you accurate and reliable measurements. Thanks to a development of newest

conception assuring overvoltage category III you will enjoy the highest safety.

The Machinery Tester FULLTEST 3 is a measurement instrument used for final inspection of electrical

equipment of machines, control cabinets, switchgears as well as other devices complying with

IEC/EN60204-1 and IEC/EN61439-1 standards.

2.1. WORKING

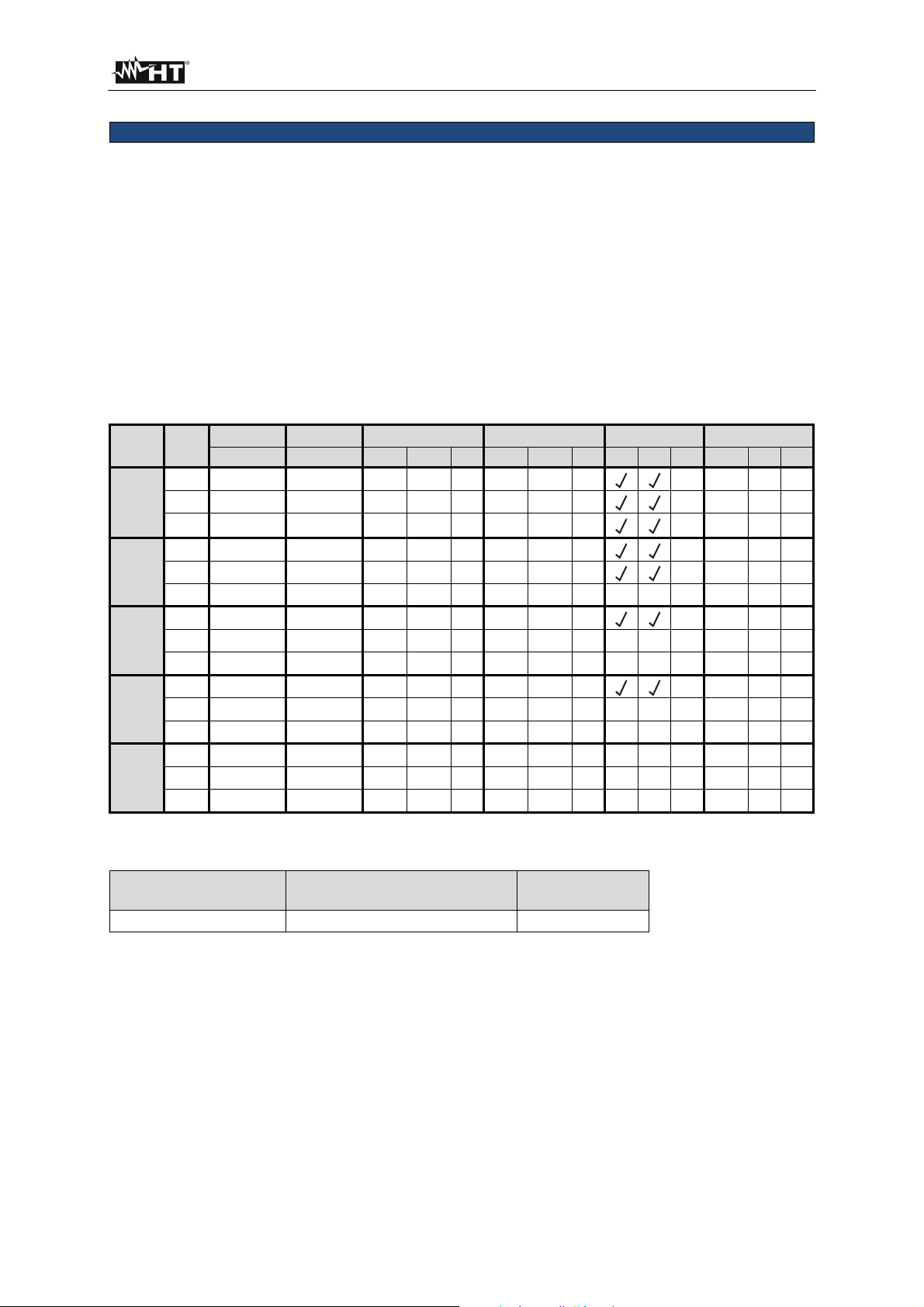

The instrument can carry out the following tests, further to the regulations listed below:

Continuity of protective conductor

- 2-wire or 4-wire measurement method.

- Compensation of test leads in case of 2-wire measurement.

- Open-circuit test voltage 6 V approx.

- Test current 200 mA and 25 A.

- Limit value adjustable, visual and acoustic warning in case of exceeded

value.

EN61557-4

EN61439-1-§10.5.2

EN60204-1-§18.2.2

EN60598-1

EN60335-1-§27.5

EN60335-1-§A.1

EN50106

EN60950

CEI 64-8/7-CEI64/13

Insulation resistance

- Test voltage 100 V, 250 V, 500 V and 1000 V DC.

- MAN (manual) mode.

- TIMER mode.

- AUTO mode.

- Limit value adjustable, visual and acoustic warning in case of exceeded

value.

Dielectric test

- Adjustable test voltage 250 V up to 5100 V AC.

- Trip out current adjustable 1 110 mA, visual and acoustic warning in

case of exceeded limit value.

- Display and trip out based on real or apparent current.

EN61557-2

CEI64-8

CEI23-51

CEI64-8/7-CEI64/13

EN61439-1-§11.9

EN60204-1

EN60598-1

EN61439-1-§9.1

EN60204-1-§18.4

EN60598-1

EN60335-1-§13.3

EN60335-1-§A.2

- MANUAL mode.

- RAMP mode (predefined automatic rising of test voltage).

- BURN mode.

- Protection against unauthorised use (safety measure).

- Red warning lamp connector (safety measure).

- Safety input connector (safety measure).

EN - 6

Page 8

FULLTEST 3

RCD test

- AC, A and B type.

- General, selective and delayed characteristic.

- Voltage range 100 ... 265 V.

- Limit contact voltage 25 or 50 V.

- IN = 10, 30, 100, 300, 500, 650 or 1000 mA.

- Trip out time at IN/2 (AC, A and B type).

- Trip out time at IN (AC, A and B type).

- Trip out time at 2IN (AC and A type).

- Trip out time at 5IN (AC and A type) or at 4IN (B type).

- Ramp test (AC, A and B type).

- AUTO test (AC, A and B type).

- Visual and acoustic warning in case of exceeded limit value.

Loop impedance measurement

- ZL/N, ZL/L and ZL/PE measurement.

- Voltage range 100 460 V.

- IPSC calculation.

- Limit value adjustable, visual and acoustic warning in case of exceeded

value.

Global earth resistance

- Selectable test current with regard to involved RCD.

- IN = 10, 30, 100, 300, 500, 650 or 1000 mA.

- Measurement with IN/2 (without tripping out RCD)

- Voltage range 100 265 V.

- Contact voltage UC measured during the measurement.

- Limit value (RA) fixed to 25 or 50 V/IN, visual and acoustic warning in

case of exceeded value.

Residual voltage

- Measurement on power plug (2-wire method).

- Measurement on internal components (4-wire method).

- Limit discharge time 1 s or 5 s.

- LINEAR or NONLINEAR mode.

- Visual and acoustic warning in case of exceeded limit value.

Power (on schuko socket)

- Apparent power P

APP.

- Real power P.

- Mains voltage U

L/N.

- Load current IL.

- Power factor PF.

- Leakage current IPE (differential method).

- Internal phase position exchange.

- Limit value (apparent power) adjustable, visual and acoustic warning in

case of exceeded value.

Phase sequence

- Mains voltages UL1/2, UL2/3, UL3/1 simultaneously displayed.

EN61557-6

EN60204-1-§18.2

EN61557-3

EN60204-1-§18.5

EN61557-7

EN - 7

Page 9

FULLTEST 3

Clamp current

- Measurement in combination with HT96U current clamp.

- Three ranges 1 A, 100 A and 1000 A.

- Limit value adjustable, visual and acoustic warning in case of exceeded

value.

Leakage current

- Measurement of IPE current on schuko socket (differential method).

- Measurement with current clamp type HT96U, three ranges 1 A, 100 A

and 1000 A.

- Limit value adjustable, visual and acoustic warning in case of exceeded

value.

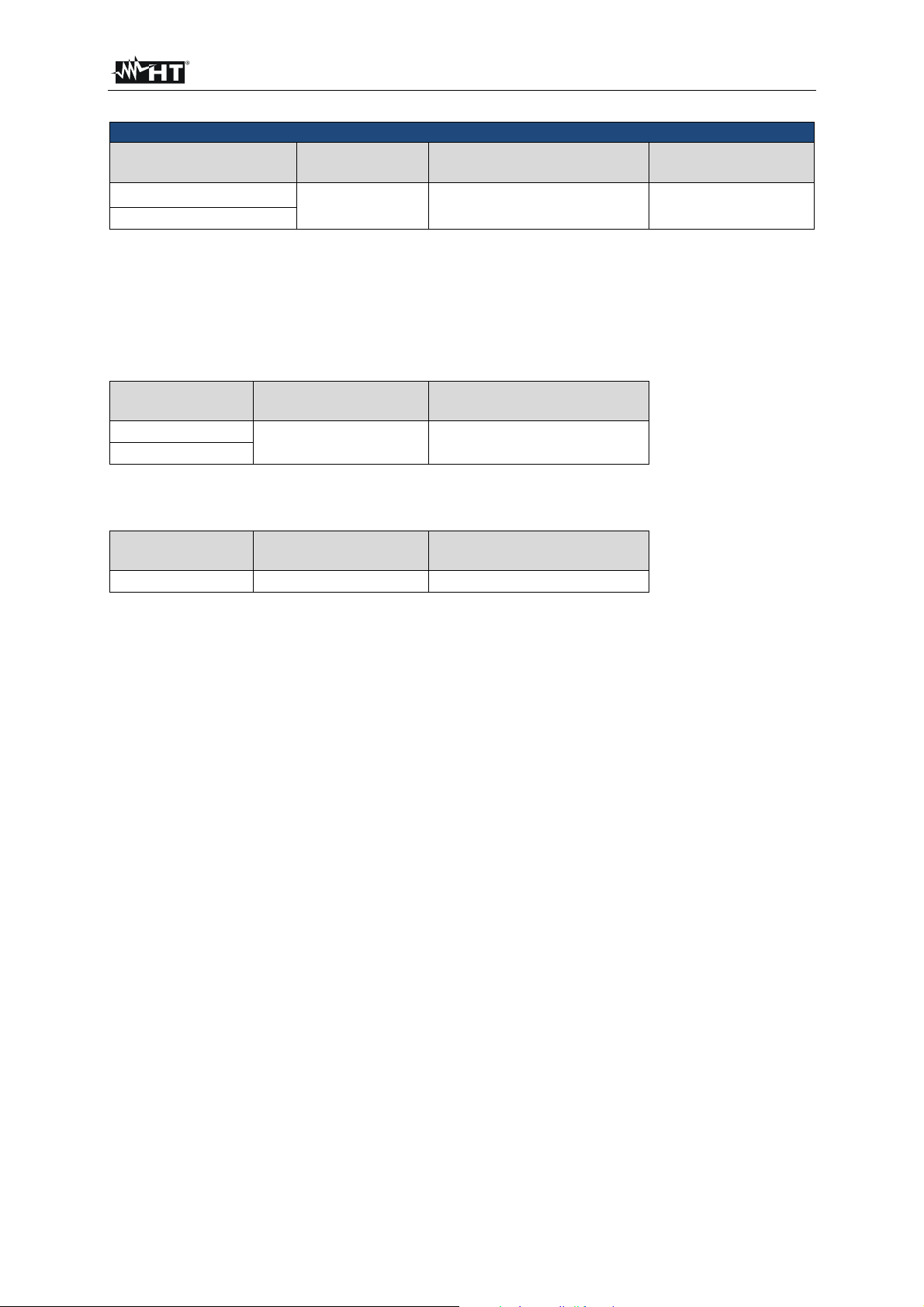

GENERAL advantages

- Portable Machinery & Panel Tester constructed according to the

IEC/EN60204-1 and IEC/EN61439-1 standards.

- Operation system WINDOWS EMBEDDED COMPACT 7 supports all

measurements and operations.

- Easy and clear operation by using the touch screen and intuitive hard

keys.

- TRMS measurements.

- Data memory for 999 measurement results, three levels (e.g.

CUSTOMER, LOCATION, MACHINE) plus additional COMMENT.

- Real time clock included.

- Integrated interface (USB 2.0) for transfer of measurement results to PC.

- Separate interface (USB 2.0) for connection of USB barcode reader, USB

keyboard, USB memory stick, printer or IMP57-impedance tester.

- Graphic colour touch screen 102×60 mm, 480×272 dots.

- Compact housing with external accessory bag.

- Quick connection diagrams and limit values under the instrument cover.

- Fuse protection in case of overload.

- PC Software TOP VIEW available.

- Complete test accessories included.

- Blue tooth communication.

- Remote START/STOP and SAVE function.

- *HELP screens available.

- *20 programmable AUTO test procedures.

* Special FW version.

2.2. OPENING THE INSTRUMENT'S COVER

The instrument is built in a robust plastic case that allows comfortable transport.

We recommend the user to follow the next opening instructions:

1

Place the unit on to a hard horizontal surface.

2

Press on the case cover with your hands, see the

mark 1.

Unlock the fixing hooks of the cover, see the mark 2.

Open the cover into vertical position.

Figure 1: Opening the instrument’s cover

EN - 8

Page 10

FULLTEST 3

3. PREPARATION FOR USE

3.1. PRELIMINARY CHECKS

This instrument was checked both mechanically and electrically prior to shipment. All possible cares and

precautions were taken to let you receive the instrument under perfect conditions. Notwithstanding we

suggest you to check it rapidly (possible damages may have occurred during transport – if so please

contact the local distributor from whom you purchased the item).

Make sure all standard accessories according to Packing List are included.

Should you have to return back the instrument for any reason please follow the instructions mentioned

in paragraph “TRANSPORT AND STORAGE”.

3.2. POWER SUPPLY

Earthed plugs must energize the instrument. To avoid any risk the instrument does not allow to effect

measurements when there is not such a connection (refer to paragraph “TURNING ON THE TESTER”

for details).

3.3. CALIBRATION

The instrument complies with the technical specifications contained in this manual and such a

compliance is guaranteed for 1 year. Annual recalibration is recommended.

3.4. TRANSPORT AND STORAGE

Please keep the original packaging for potential later transport, e.g. for calibration. Any transport

damage due to faulty packaging will be excluded from warranty claims.

Instruments must be stored in dry and closed areas. In case of an instrument being transported in

extreme temperatures, a recovery time of minimum 2 hours is required prior to instrument operation.

EN - 9

Page 11

FULLTEST 3

4. OPERATING INSTRUCTIONS

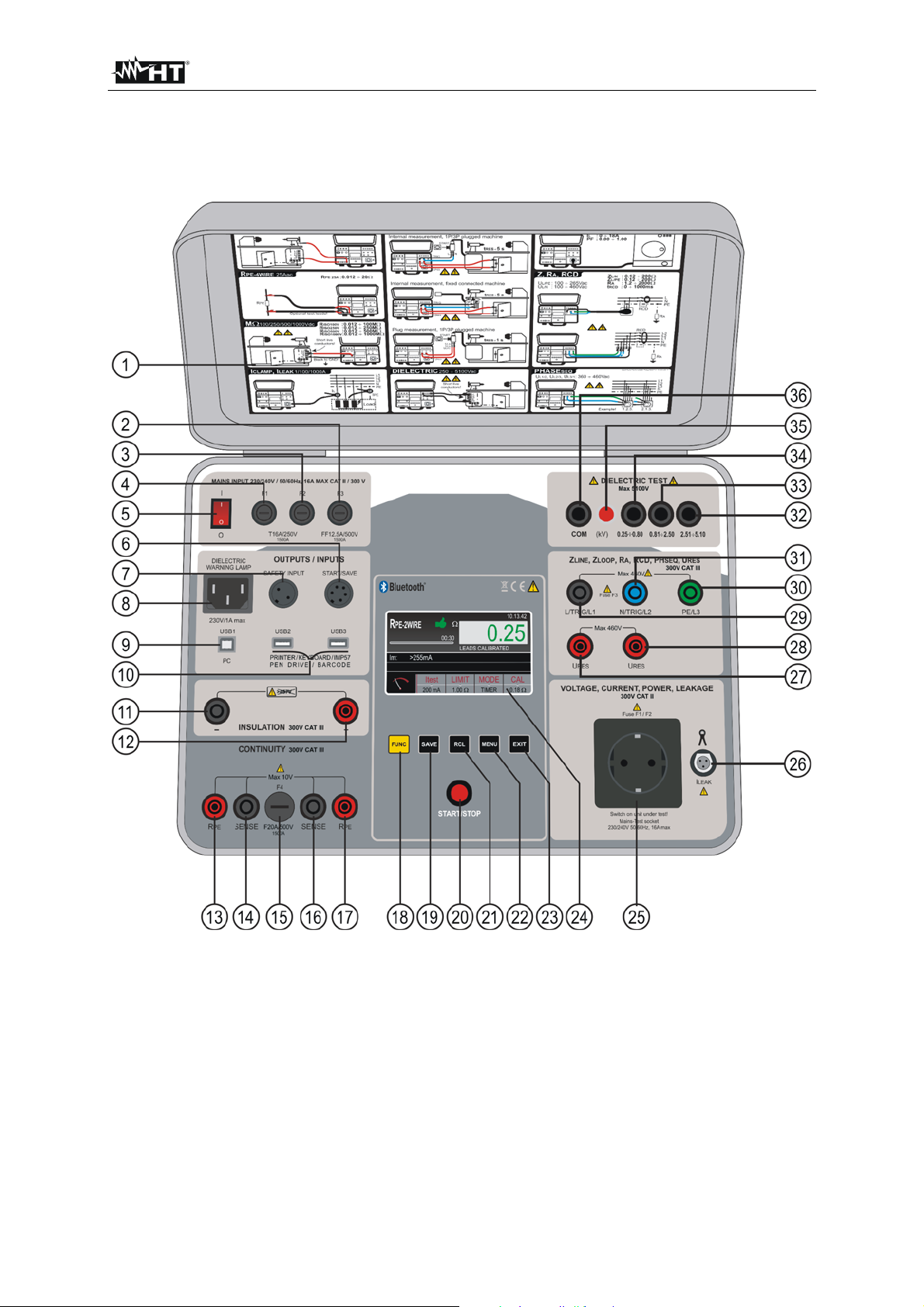

4.1. INSTRUMENT - DESCRIPTION

Figure 2: Instrument description

LEGEND

1 Quick instruction label under the cover.

2 Fuse F3, type T12.5A/500V 6.3×32 mm which protects internal circuitry in LOOP, RA and RCD

measurements.

3 General tester fuse F2, type T16A/250V 5×20 mm which protects internal circuitry in POWER, RPE

and DIELECTRIC measurements.

4 General tester fuse F1, type T16A/250V 5×20 mm which protects internal circuitry in POWER, RPE

and DIELECTRIC measurements.

5 ON/OFF mains switch (with red pilot lamp).

EN - 10

Page 12

FULLTEST 3

6 Connector for START/SAVE remote control adapter.

7 Connector SAFETY INPUT for connection of external safety switch (for example protection door). It

disables DIELECTRIC tests in case the switch is open.

8 IEC female connector for connection of red WARNING LAMP in DIELECTRIC test. The lamp is

active when the test is on (parallel operation to HV lamp on front panel, reference 35).

9 USB 1 connector for connection with PC.

10 USB 2 and USB 3 connectors for connection of USB stick, USB barcode reader, USB printer, USB

keyboard or IMP57 impedance meter.

11 Negative RISO terminal.

12 Positive RISO terminal.

13 RPE current generator terminal.

14 SENSE voltage terminal.

15 Fuse F4, type F20A/500V 6.3×32 mm which protects internal circuitry in RPE measurement.

16 SENSE voltage terminal.

17 RPE current generator terminal.

18 FUNC hard key to select appropriate measurement function.

19 SAVE hard key to save test result.

20 START/STOP button which starts or stops selected measurement.

21 RCL hard key to recall saved result.

22 MENU hard key to open MAIN MENU.

23 EXIT hard key to exit existing screen and return it one step back.

24 Colour LCD touch-screen display.

25 Mains test socket for POWER and LEAKAGE measurement.

26 CLAMP connector for HT96 current clamp.

27 URES measurement terminal.

28 URES measurement terminal.

29 L/TRIG/L1 terminal for LOOP, RA, RCD, PHASE SEQUENCE and URES measurements.

30 PE/L3 terminal for LOOP, RA, RCD and PHASE SEQUENCE measurements.

31 N/TRIG/L2 terminal for LOOP, RCD, PHASE SEQUENCE and URES measurements.

32 DIELECTRIC test terminal for test voltages 2.51 5.10 kV.

33 DIELECTRIC test terminal for test voltages 0.81 2.50 kV.

34 DIELECTRIC test terminal for test voltages 0.25 0.80 kV.

35 DIELECTRIC on lamp. It lights when DIELECTRIC test is running.

36 DIELECTRIC COM (common) test terminal.

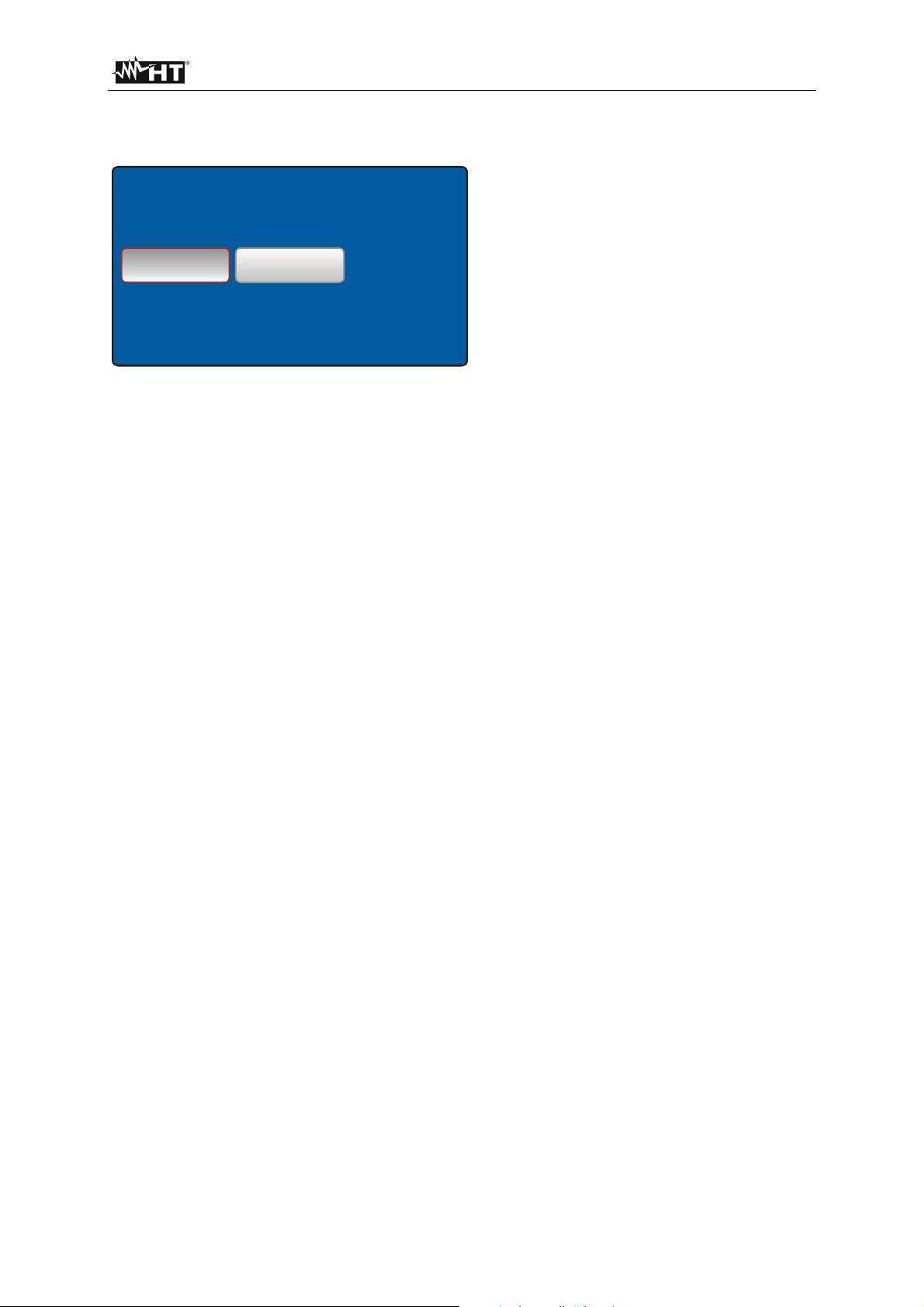

4.2. TURNING ON THE TESTER

After switching on mains switch (5) the tester will upload WINDOWS first (it will take 30 s approx.), then

last used measurement screen will appear. A beep-beep sound signal will be given as soon as the

tester is ready for measurements.

CAUTION

In case energizing socket is not earthed properly PE DISCONNECTED message

will appear and the tester will not perform any further operation. In this case

switch off the tester immediately and check the energizing socket!

EN - 11

Page 13

FULLTEST 3

4.3. MEASUREMENT FUNCTION SELECTION

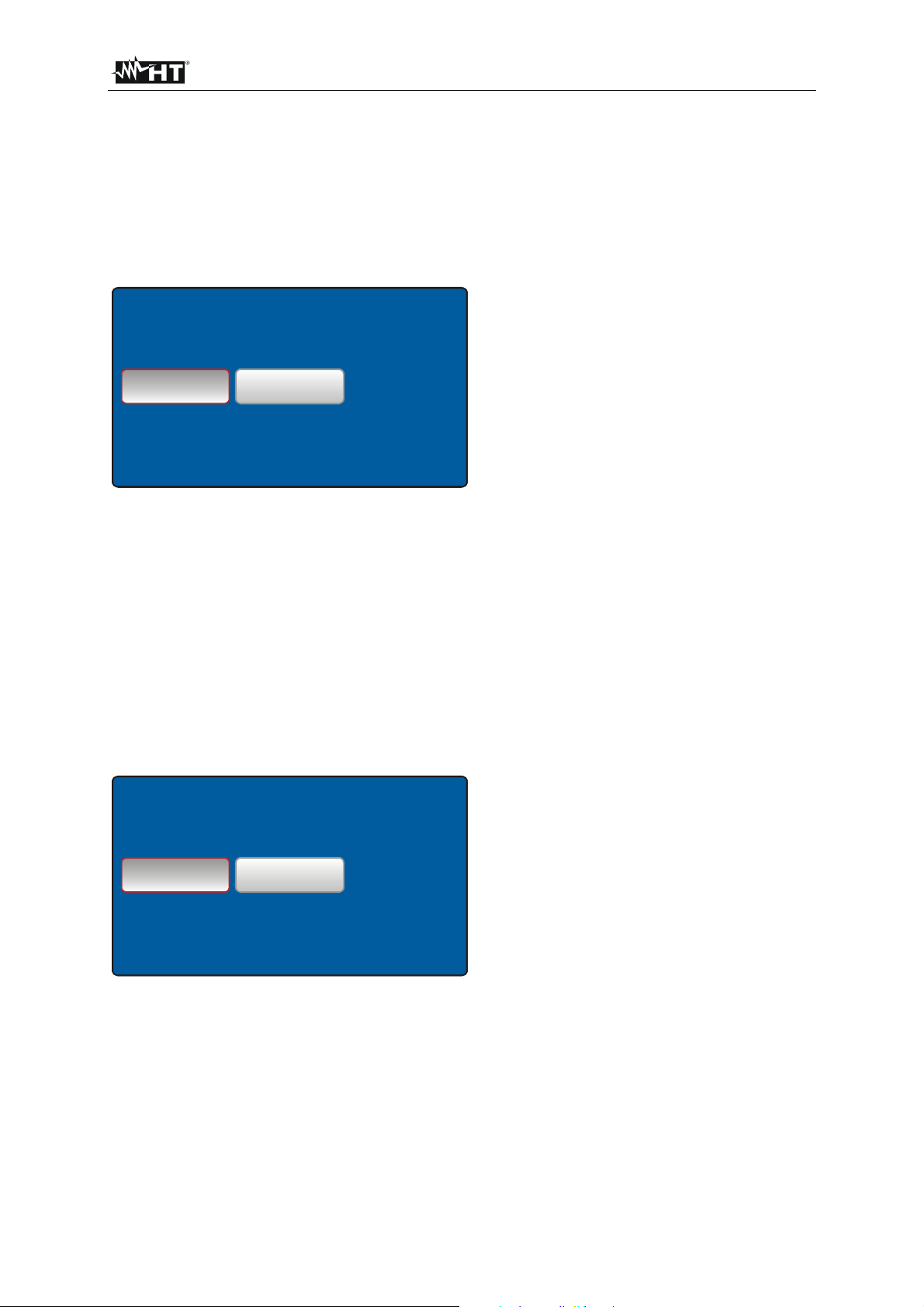

Press the FUNC hard key (yellow), the function selection screen will appear.

R

PE-2WIRE

R

PE-4WIRE

M

DIELECT

RCD

LOOP

R

A

U

RES

POWER

PHASE

I

CLAMP

I

LEAK

SEQ

Figure 3: Function selection screen

Select wished function by pressing appropriate touch-screen key, basic measurement screen of

selected function will appear, see an example of RPE-2WIRE basic measurement screen below. Other

functions use adapted screens, but follow the same system.

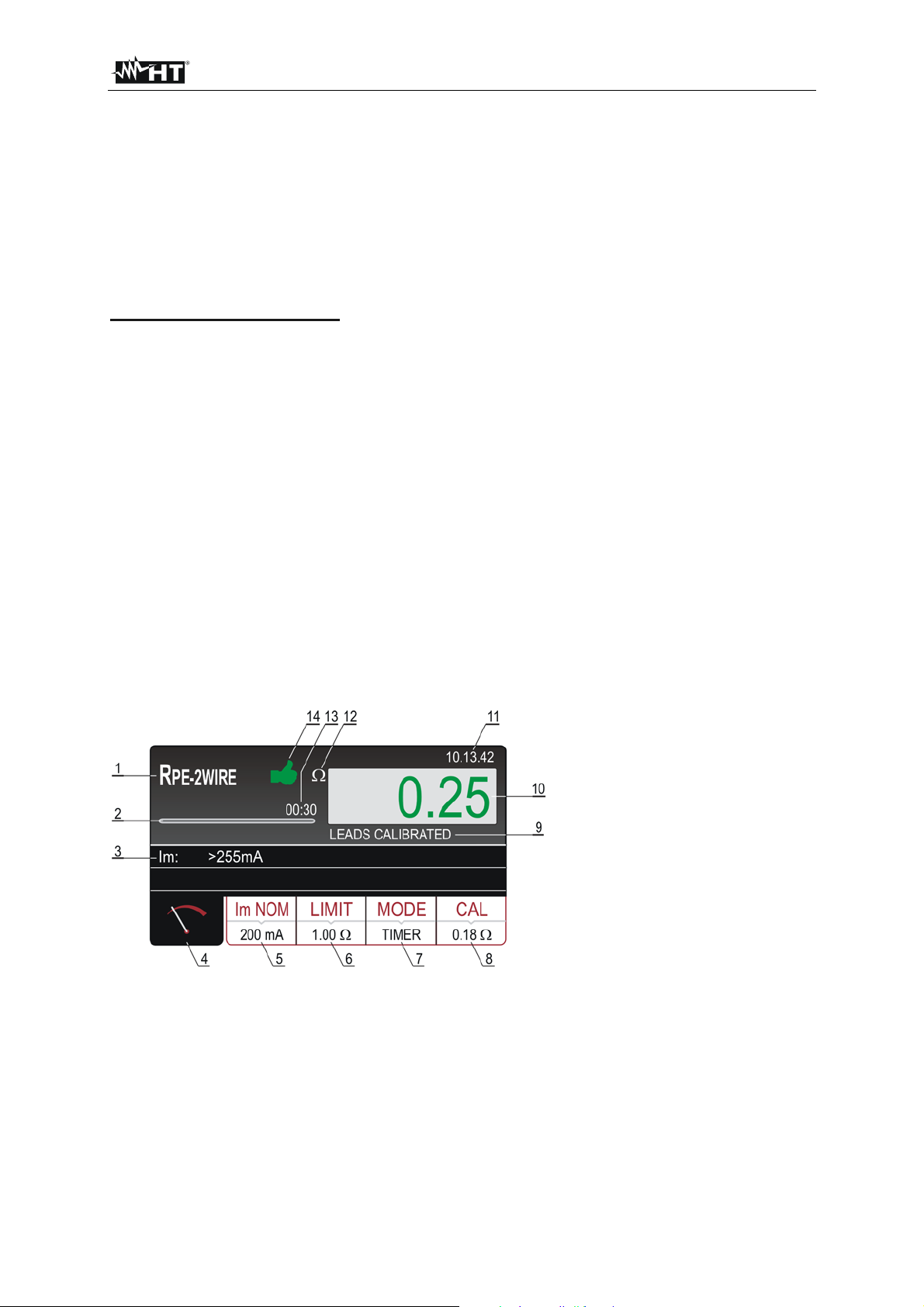

Figure 4: Basic measurement screen in RPE-2WIRE function

1 ..... Selected function.

2 ..... Progress bar, it follows measurement time during the measurement (in TIMER mode only).

3 ..... Two lines reserved for sub-results (no value in basic screen yet).

4 ..... Measurement screen touch-screen key.

5 ..... Measurement parameters touch-screen keys.

6 ..... Test lead calibration status (LEADS CALIBATED or LEADS NOT CALIBRATED).

7 ..... Measurement result field (result in green colour - OK, result in red colour - not OK, result in white

colour – not judged).

8 ..... Real time clock (hh.mm.ss).

9 ..... Unit of the measurement result.

10 ... Set measurement time (in TIMER mode only).

EN - 12

Page 14

FULLTEST 3

5. MEASUREMENTS

5.1. CONTINUITY - TWO WIRE METHOD (RPE-2WIRE)

Complying with EN 60204-1, continuity of protective bonding circuit between PE terminal and

relevant points of the protective conductor system must be checked by injecting a measurement

current of 0.2 A up to 10 A approx.

5.1.1. RPE-2WIRE DISPLAY EXPLANATION

Adjustable/selectable parameters:

Im NOM - nominal measurement current 200 mA or 25 A AC

LIMIT (meas. current 200 mA) - continuity limit value 0.01 19.99, 20.0 200.0

LIMIT (meas. current 25 A) - continuity limit mode STANDARD, 60204 SET Z or 60204 SET L

LIMIT (test current 25 A, STANDARD mode) -

continuity limit value 0.01 20.00

MODE - measurement mode MANUAL or TIMER

CAL (meas. current 200 mA) - calibration of test leads 0.00 5.00

CAL (meas. current 25 A) - calibration of test leads 0.000 1.999, 2.00 5.00

TIMER - measurement time 00:01 60:00 (1 s 60 min), resolution 1 s

LENGTH - wire length 0.1 999.9 m, resolution 0.1 m

SECTION - wire section 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm2

MATERIAL - wire material Cu (Cupper) or Al (Aluminium)

ZLINE - input line impedance 0.001 2.000 , resolution 0.001

PROTECTION - over-current protection device MCB B, MCB C, MCB D, MCB K, FUSE gG or

FUSE aM

In - nominal current of protection device Depends on selected protection device, see the

chapter 5.1.3. LIMIT VALUE ADJUSTMENT

Figure 5: Display with RPE-2WIRE test result

1 ..... Selected function.

2 ..... Progress bar, it follows measurement time during the measurement (in TIMER mode only).

3 ..... Sub-result - measurement current Im that was flowing through UUT during the measurement.

4 ..... Measurement screen touch-screen key.

5 ..... Im NOM touch-screen key to select nominal test current (200 mA or 25 A). Currently selected value

is displayed on the bottom of the key.

EN - 13

Page 15

FULLTEST 3

6 ..... LIMIT touch-screen key to select limit value (200 mA measurement) or limit mode (25 A

measurement). Currently selected value or CALC is displayed on the bottom of the key. CALC

message means the value is calculated.

7 ..... MODE touch-screen key to select operation mode (MANUAL or TIMER). Currently selected mode

is displayed on the bottom of the key. TIMER mode is available in 200 mA measurement and in 25

A measurement if STANDARD limit mode is selected.

8 ..... CAL touch-screen key to carry out calibration of test leads. Currently calibrated value is displayed

on the bottom of the key. In case of no calibration, the value 0.00 is displayed in red colour.

9 ..... Test lead calibration status (LEADS CALIBATED or LEADS NOT CALIBRATED).

10 ... Measurement value (in green colour - result OK, in red colour - result not OK).

11 ... Real time clock (hh.mm.ss).

12 ... Unit of measurement result ().

13 ... Set measurement time (in TIMER mode only).

14 ... Measurement result status (symbol in green colour - result OK, symbol in red colour - result

not OK or symbol in yellow colour – result OK, but measurement current too low).

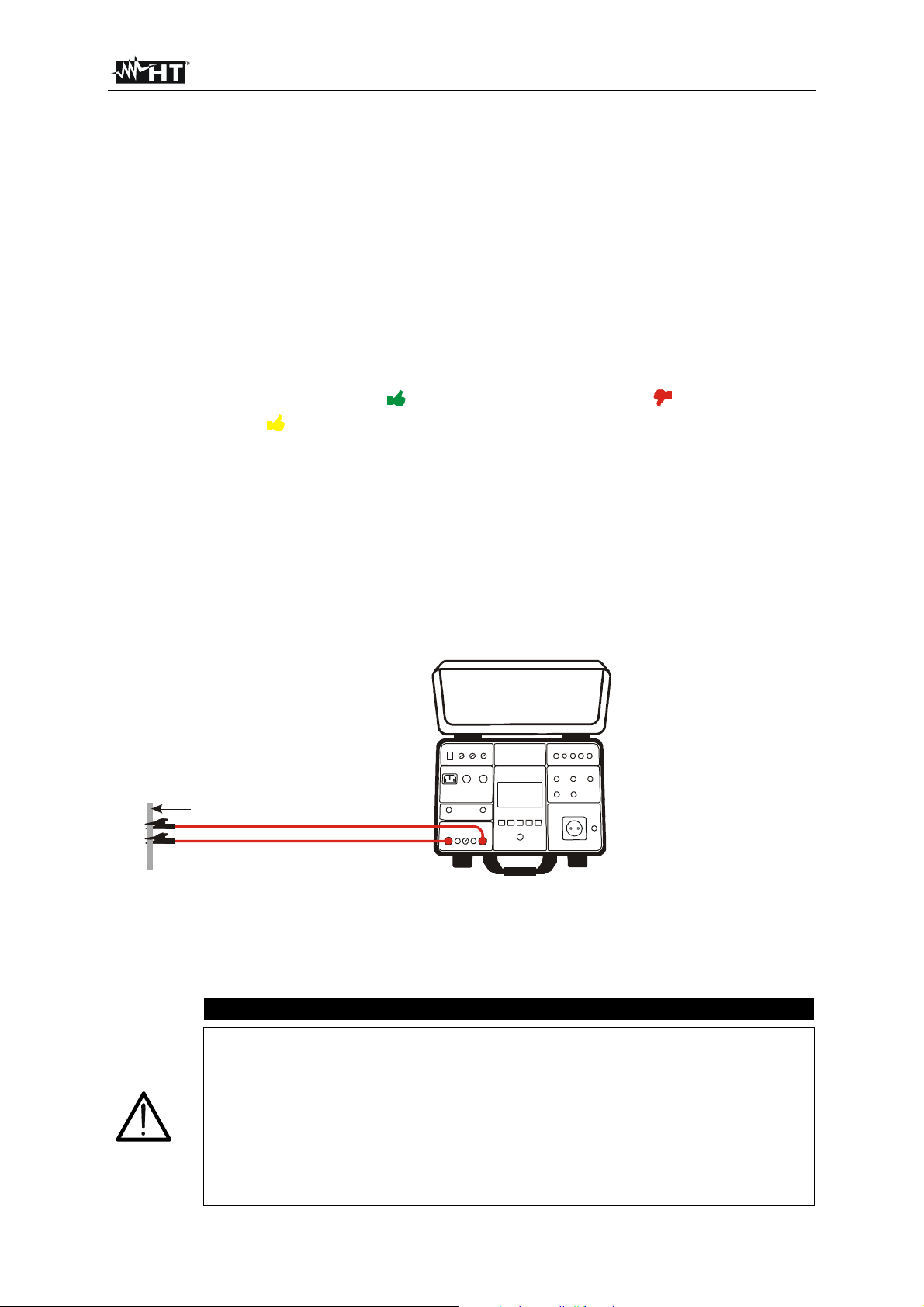

5.1.2. CALIBRATION OF TEST LEADS

In order test leads not to influence the test results, resistance of the leads must be calibrated (zeroed).

Follow the next steps to calibrate test lead’s resistance:

1) Select test current that will be used for later measurement (200 mA or 25 A) by pressing the

Im NOM touch-screen key (5) first.

2) Press the CAL touch-screen key (8), the message “SHORTCIRCUIT TEST LEADS AND PRESS

START TO CALIBRATE” will appear.

3) Connect test leads according to the figure below, make sure two crocodiles are connected as close

as possible to each other to a piece of unisolated wire.

Short unisolated wire

2

Red test leads 2,5 mm

Figure 6: Connection of test leads for calibration purpose

4) Press the START button. The measurement will be done and value without calibration will be

displayed for a moment, then the value will be set to zero (0.00). Test leads are thus calibrated,

measurements can follow.

CAUTION

The calibration must be done separately for each test current (200 mA and 25

A)!

The calibration must be repeated when test leads are changed (replaced,

shortened or extended)!

Max resistance that can be calibrated is 5 !

Existing calibration can be annulled if test leads are opened when calibration

is carried out!

Calibration is not needed in R

PE-4WIRE function!

EN - 14

Page 16

FULLTEST 3

The following specific information may be shown on the display during calibration:

Information displayed Description

SHORTCIRCUIT TEST LEADS

AND PRESS START KEY TO

CALIBRATE

OPEN TEST LEADS,

CALIBRATION ANNULED

Calibration has been started (CAL touch-screen key has

been pressed).

Shortcircuit test leads and press the START button!

Test leads are opened after pressing the START button.

Press YES key … existing calibration will be annulled!

Press NO key … existing calibration will stay untouched!

Connected resistance is higher than 5 and lower than

RPE > 5

CALIBRATION FAILED

measurement range, calibration can not be carried out.

Existing calibration will stay untouched.

Reduce external resistance and repeat the calibration!

5.1.3. LIMIT VALUE ADJUSTMENT

Test current 200 mA is selected:

Limit value can be selected within the range from 0.01 up to 99.99 in steps of 0.01 .

Test current 25 A is selected:

There are three possibilities to select the limit value.

- STANDARD selection.

Limit value can be selected within the range from 0.01 up to 20.00 in steps of 0.01 .

- EN60204 SET L selection.

Limit value is calculated on bases of wire length (L), wire section (SECTION) and wire material

(MATERIAL), where the parameters can be selected/adjusted within the following ranges:

- L (length) 0.1 up to 999.9 m in steps of 0.1 m

- SECTION (wire section) 1, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm

2

- MATERIAL (wire material) Cu (Copper) or Al (Aluminium)

- EN60204 SET Z selection.

Limit value is calculated on bases of entered line impedance (Z

LINE), type of protection (TYPE),

nominal current (IN) and wire section (SECTION), where the parameters can be selected within the

following ranges:

- Zline (line impedance) 0.001 up to 2.000 in steps of 0.001

- TYPE (type of protection) MCB B, MCB C, MCB D, MCB K, FUSE gG or FUSE aM

- In (nominal current) - 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB B)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB C)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25 or 32 A (MCB D, MCB K)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500, 630, 800, 1000 or 1250 A (FUSE gG)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500 or 630 A (FUSE aM)

- SECTION (wire section) 1, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm

2

EN - 15

Page 17

FULLTEST 3

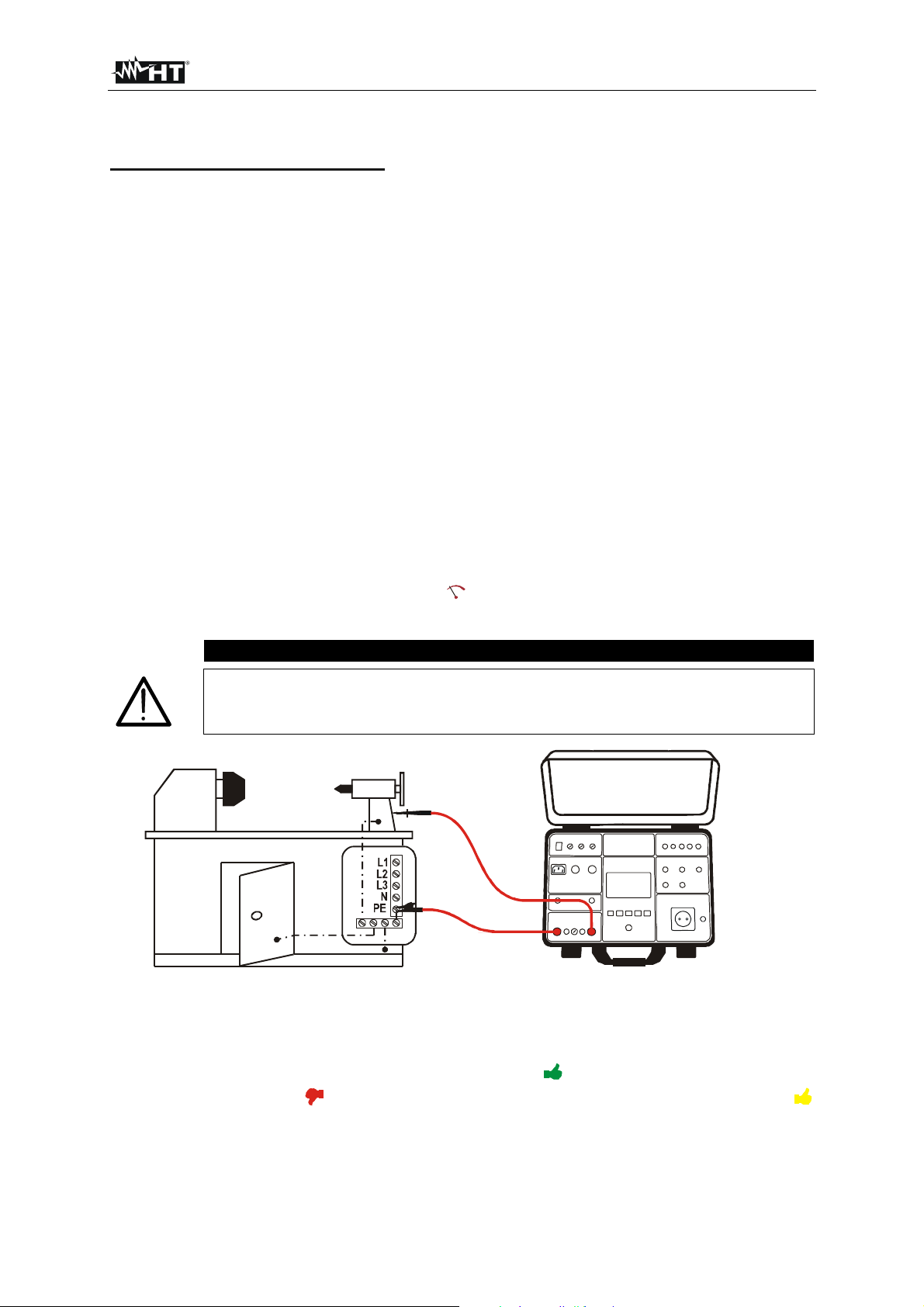

5.1.4. RPE-2WIRE MEASUREMENT

Measured quantities and display ranges:

Resistance RPE 0 200 (nominal test current 200 mA)

0 20 (nominal test current 25 A)

Measurement current Im 10 255 mA (nominal test current 200 mA)

0.2 30.0 A (nominal test current 25 A)

1) Select the RPE-2WIRE measurement by pressing the FUNC hard key first.

2) Check selected test current (200 mA or 25 A) and modify it if needed by pressing the Im

NOM (5)

touch-screen key first.

3) Check selected limit value and modify it if needed by pressing the LIMIT (6) touch-screen key first.

Four independent preset limit values are available in STANDARD limit mode selection for quicker

operations. Select the one closest to wished value and modify it by using the + and ― touch screen

keys if needed.

4) Check selected mode (MANUAL or TIMER) and modify it if needed by pressing the MODE (7)

touch-screen key first. In MANUAL mode the measurement will start after pressing the

START/STOP button and will stop after pressing the START/STOP button again. In TIMER mode

the measurement will start after pressing the START/STOP button and will stop after elapsing set

measurement time or after pressing the START/STOP button again.

5) Check the status of test lead calibration and carry out the calibration if needed, see the instructions

in chapter “CALIBRATION OF TEST LEADS” above.

6) Select measurement screen by pressing the

(4) touch-screen key and check all settings again.

7) Connect the test leads according to the figure below.

CAUTION

Before connecting test leads to UUT obligatory assure there is no external voltage

higher than 10 V between the test points where test leads will be connected to,

otherwise fuse F4 may blow!

Figure 7: Connection of test leads in RPE-2WIRE function

8) Carry out the measurement by pressing the START/STOP button. Test result will currently be

displayed in green (result lower than or equal to set limit value) or in red colour (result higher than

set limit value). Final result will be equipped with green

(result OK) or with red

symbol and with longer beep sound (result not OK) or with yellow

symbol and with beep-beep sound

symbol and with beep-beep sound (result OK, but measurement current was too low). See the

display outlook with test result on figure 5.

9) Save the test result by pressing the SAVE hard key twice, for further instructions see the

“MEMORIZING EXAMPLE” section.

EN - 16

Page 18

FULLTEST 3

CAUTION

Max external voltage between two RPE or between two SENSE test terminals

is 10 VAC, no DC external voltage is allowed! In case of higher external

voltage fuse F4 (T20A/500V, 6.3×32 mm) may blow!

Measurement time in MANUAL mode is limited to 60 min!

The following specific information can be shown on the display during measurement:

Information displayed Description

Measurement result is negative probably because of

shorter test leads than calibrated (negative value is higher

CHECK CALIBRATION

than 5 digits).

Calibrate test leads again!

External voltage higher than 3 V is applied between two

RPE or between two SENSE test terminals

(measurement is not running) or higher than 10 V

EXTERNAL VOLTAGE

(measurement is running).

External voltage higher than 5 30 V is applied between

any RPE or SENSE test terminal and GND.

Remove external voltage!

LIMIT OUT OF RANGE

FUSE F4!

Calculated limit value is < 1 (EN60204 SET Z limit mode)

Fuse F4 is blown.

Internal fuse may be blown!

ERROR 1!

The fuse is not customer replaceable, send the tester into

a service department.

EN - 17

Page 19

FULLTEST 3

5.2. CONTINUITY - FOUR WIRE METHOD (RPE-4WIRE)

Complying with EN 60204-1, continuity of protective bonding circuit between PE terminal and

relevant points of the protective conductor system must be checked by injecting a measurement

current of 0.2 A up to 10 A approx.

Limit values are the values which correspond to the length, cross section and material of measured

conductor.

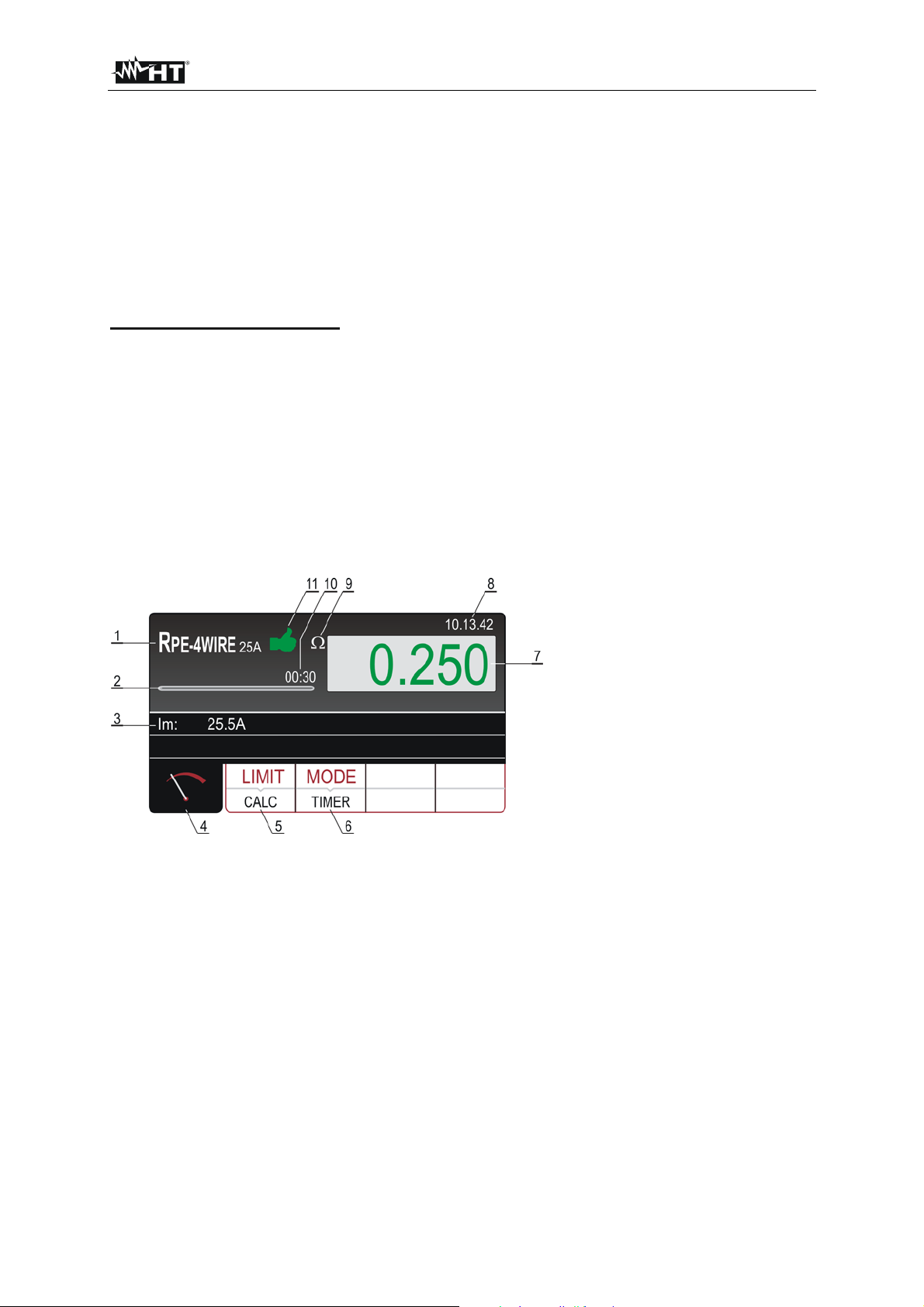

5.2.1. RPE-4WIRE DISPLAY EXPLANATION

Adjustable/selectable parameters:

LIMIT - continuity limit mode STANDARD, 60204 SET Z or 60204 SET L

MODE - measurement mode MANUAL or TIMER

TIMER – measurement time 00:01 60:00, resolution 1 s

LENGTH - wire length 0.1 999.9 m, resolution 0.1 m

SECTION - wire section 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm2

WIRE - wire material Cu (Cupper) or Al (Aluminium)

ZLINE - input line impedance 0.001 2.000 , resolution 0.001

PROTECTION - over-current protection device MCB B, MCB C, MCB D, MCB K, FUSE gG or

FUSE aM

In - nominal current of protection device Depends on selected protection device, see the

chapter 5.1.3. LIMIT VALUE ADJUSTMENT

Figure 8: Display with RPE-4WIRE test result

1 ..... Selected function.

2 ..... Progress bar, it follows measurement time during the measurement (in TIMER mode only).

3 ..... Measurement current flowing through UUT during the measurement.

4 ..... Measurement screen touch-screen key.

5 ..... LIMIT touch-screen key to select limit mode (STANDARD, 60204 SET Z or 60204 SET L).

Currently selected value (STANDARD mode) or CALC (60204 SET Z or 60204 SET L mode) is

displayed on the bottom of the key. CALC message means the value is calculated.

6 ..... MODE touch-screen key to select operation mode (MANUAL or TIMER). Currently selected mode

is displayed on the bottom of the key. TIMER mode is available only if STANDARD limit mode is

selected.

7 ..... Measurement value (in green colour - result lower than or equal to set limit value, in red colour -

result is higher than set limit value).

8 ..... Real time clock (hh.mm.ss).

9 ..... Unit of measurement result ().

EN - 18

Page 20

FULLTEST 3

10 ... Set measurement time (in TIMER mode only).

11 ... Measurement result status (symbol in green colour - result OK, symbol in red colour –

result not OK).

5.2.2. CALIBRATION OF TEST LEADS

The calibration is not needed because of 4-wire method.

EN - 19

Page 21

FULLTEST 3

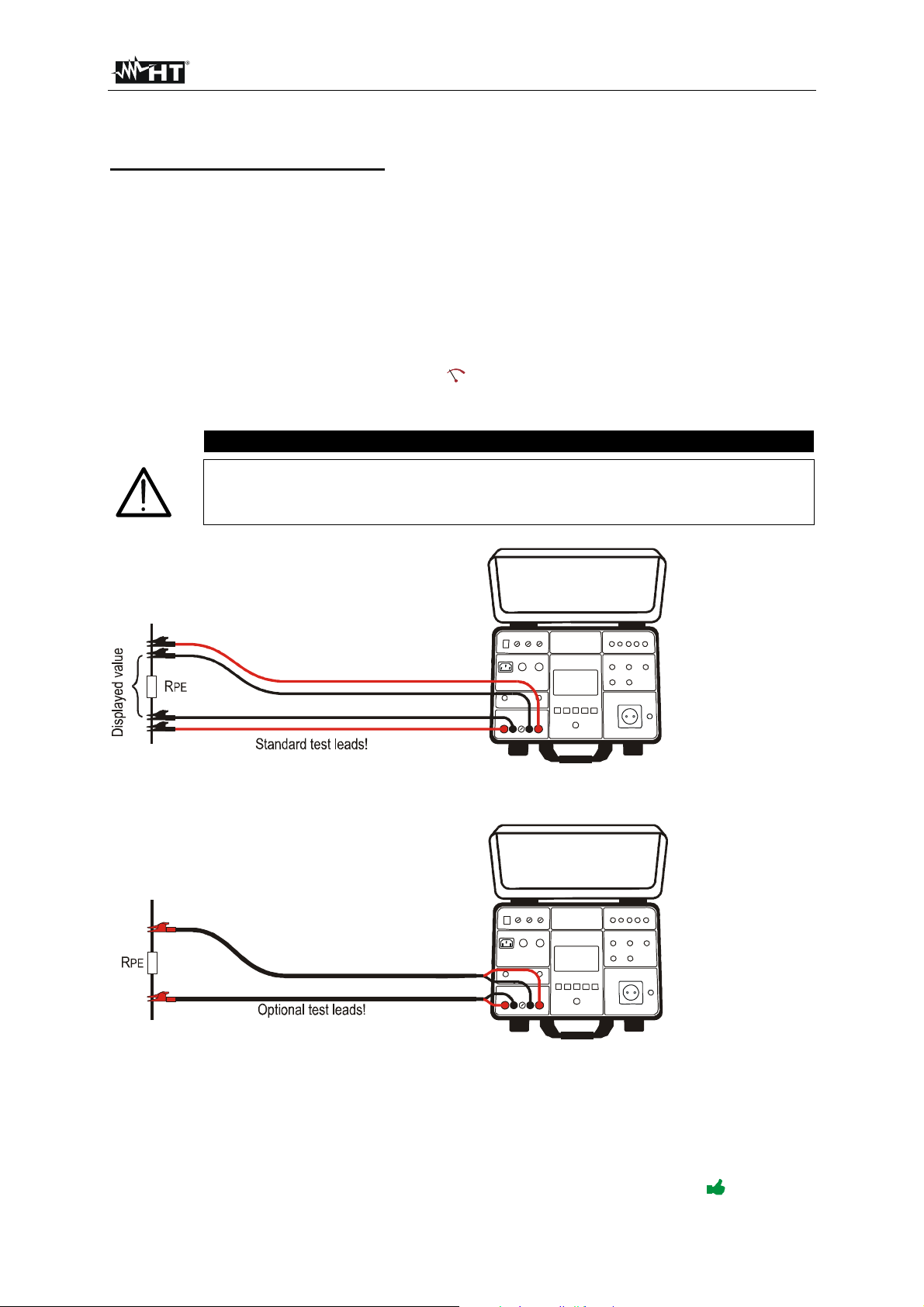

5.2.3. RPE-4WIRE MEASUREMENT

Measured quantities and display ranges:

Continuity RPE 0 20

Test current 0.2 30 A

1) Select the RPE-4WIRE function by pressing the FUNC hard key first.

2) Check selected limit value and modify it if needed by pressing the LIMIT (6) touch-screen key first.

Four independent preset limit values are available in STANDARD limit mode selection for quicker

operations. Select the one closest to wished value and modify it by using the + and ― touch screen

keys if needed.

3) Check selected mode and modify it if needed by pressing the MODE (7) touch-screen key first.

4) Select measurement screen by pressing the (4) touch-screen key and check all settings again.

5) Connect the test leads according to the figure below.

CAUTION

Before connecting test leads to UUT obligatory assure there is no external voltage

higher than 10 V between the test points where test leads will be connected to,

otherwise fuse F4 may blow!

Figure 9: Connection of standard test leads

Figure 10: Connection of optional Kelvin test leads

6) Carry out the measurement by pressing the START/STOP button. The measurement will start to

run and will be stopped after pressing the START/STOP button again (MANUAL mode) or after

elapsing set measurement time (TIMER mode).

Test result will currently be displayed in green (result lower than or equal to set limit value) or in red

colour (result is higher than set limit value). Final result will be equipped with green symbol and

EN - 20

Page 22

FULLTEST 3

with beep-beep sound (result OK) or with red symbol and with longer beep sound (result not

OK). See the display outlook with test result on Figure 8.

7) Save the test result by pressing the SAVE hard key twice, for further instructions see the

“MEMORIZING EXAMPLE” section.

CAUTION

Max external voltage between two RPE or between two SENSE test terminals

is 10 VAC, no DC external voltage is allowed! In case of higher external

voltage fuse F4 (T20A/500V, 6.3×32 mm) may blow!

If SENSE test leads are not connected, then measurement result will include

also the resistance of current test leads.

Measurement time in MANUAL mode is limited to 60 min!

The following specific information can be shown on the display during measurement:

Information displayed Description

External voltage higher than 3 VAC is applied between

two RPE or between two SENSE test terminals

(measurement is not running) or higher than 10 VAC

EXTERNAL VOLTAGE

(measurement is running).

External voltage higher than 5 30 V is applied between

any RPE or SENSE test terminal and GND.

Remove external voltage!

FUSE F4!

Fuse F4 is blown.

Internal fuse may be blown!

EROR1!

The fuse is not customer replaceable, send the tester into

a service department.

EN - 21

Page 23

FULLTEST 3

5.3. INSULATION RESISTANCE (M)

• According to EN 60204-1, the insulation resistance between shorted active conductors of power

circuit and the earth bonding system must be checked by applying a test voltage of 500 V DC. The

limit value is 1 M.

• Ensure that all switches on the unit under test are closed in order to test all it’s components. For

purpose of the measurement, all active conductors (L1, L2, L3 and N) must be shortcircuited.

5.3.1. RISO DISPLAY EXPLANATION

Adjustable/selectable parameters:

Utest - nominal test voltage 100, 250, 500 or 1000 V DC

MODE - operation mode MANUAL, TIMER or AUTO

LIMIT - insulation resistance limit 0.01 100.0 M

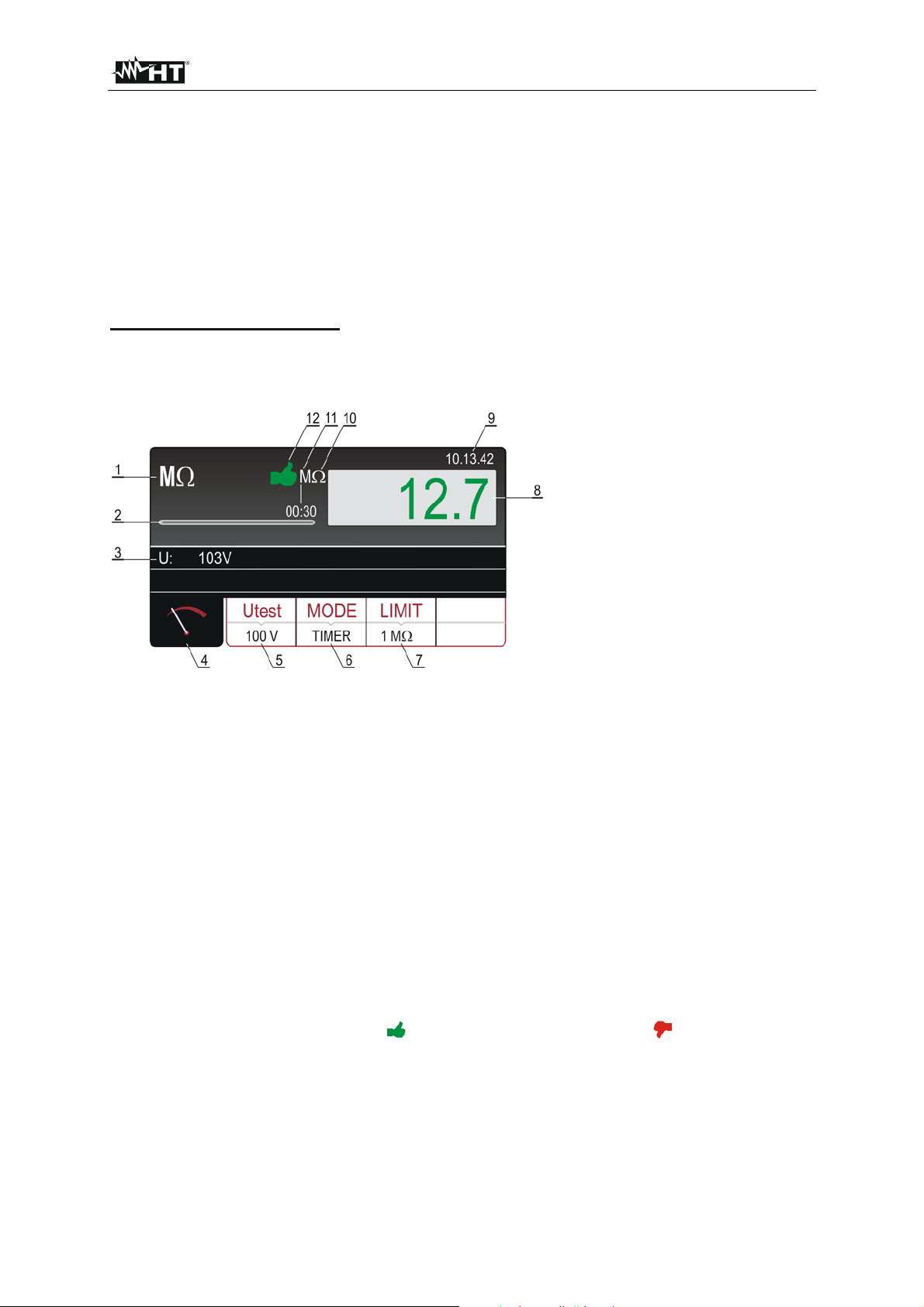

Figure 11: Display with RISO test result

1 ..... Selected function.

2 ..... Progress bar, it follows measurement time during the measurement (in TIMER mode only).

3 ..... Test voltage applied during the measurement.

4 ..... Measurement screen touch-screen key.

5 ..... Utest touch-screen key to select nominal test voltage (100, 250, 500 or 1000 V). Currently selected

value is displayed on the bottom of the key.

6 ..... MODE touch-screen key to select operation mode (MANUAL, TIMER or AUTO). Currently selected

mode is displayed on the bottom of the key.

7 ..... LIMIT touch-screen key to select limit insulation resistance. Currently selected value is displayed

on the bottom of the key.

8 ..... Measurement value (in green colour - result OK, in red colour - result not OK).

9 ..... Real time clock (hh.mm.ss).

10 ... Unit of the measurement result M).

11 ... Set measurement time (in TIMER mode only).

12 ... Measurement result status (symbol in green colour - result OK, symbol in red colour - result

not OK).

EN - 22

Page 24

FULLTEST 3

5.3.2. RISO MEASUREMENT

Measured quantities and display ranges:

Insulation resistance RINS 0 100 M (test voltage 100 V)

0 250 M (test voltage 250 V)

0 500 M (test voltage 500 V)

0 1000 M (test voltage 1000 V)

Test voltage Utest 0 1100 V

1) Select M function by pressing the FUNC hard key first.

2) Check selected test voltage (100, 250, 500 or 1000V) and modify it if needed by pressing the Utest

(5) touch-screen key first.

3) Check selected mode and modify it if needed by pressing the MODE (6) touch-screen key first.

MANUAL, TIMER or AUTO mode can be selected.

4) Check selected limit value and modify it if needed by pressing the LIMIT (7) touch-screen key first.

Four independent preset limit values are available for quicker operations. Select the one closest to

wished value and modify it by using the + and ― touch screen keys if needed.

5) Select measurement screen by pressing the (4) touch-screen key and check all settings again.

6) Connect the test leads according to the figure below.

Figure 12: Connection of test leads

7) Carry out the measurement by pressing the START/STOP button. The measurement will start to

run and will be stopped after pressing the START/STOP button again (MANUAL mode) or after

elapsing set measurement time (TIMER mode) or after reaching stabile result (AUTO mode).

Test result will currently be displayed in green colour (result higher than or equal to set limit value)

or in red colour (result lower than set limit value). Final result will be equipped with green

symbol and with beep-beep sound (result OK) or with red

symbol and with longer beep sound

(result not OK). See the display outlook with test result on Figure 11.

8) Save the test result by pressing the SAVE hard key twice, for further instructions see the

“MEMORIZING EXAMPLE” section.

EN - 23

Page 25

FULLTEST 3

CAUTION

Connect COM test lead to chassis if the UUT is grounded. In case of reversed

test leads measurement result may be affected by instrument’s internal

resistance of 10 M!

Due to the measurement of insulation resistance, capacitive UUT will be

charged with test voltage. The UUT will be discharged after finishing the

measurement via internal resistance of approx. 2 M. The UUT can retain

dangerous voltage in case of premature removal of test leads. Ensure that the

UUT is discharged through the measurement instrument (not through short

circuit)!

Measurement time in MANUAL mode is limited to 60 min!

The following specific information can be shown on the display during the measurement:

Information displayed Description

External voltage higher than 10 VAC approx. is applied

between positive and negative test terminals

(measurement is not running) or higher than 50 VAC

approx. (measurement is running).

EXTERNAL VOLTAGE

Negative external voltage higher than 10 VDC approx. is

applied between positive and negative test terminals

(measurement is running).

Remove external voltage!

External capacitor (or internal) that was charged during the

DISCHARGING!

measurement is discharging.

Wait until the message disappears! Do not disconnect test

leads until the message is present!

EN - 24

Page 26

FULLTEST 3

5.4. DIELECTRIC (DIELECTRIC)

According to EN 60204-1, electric equipment must withstand a voltage test between shorcircuited

active conductors of power circuit and the earth bonding system for approx. 1 s.

The test shall be carried out at twice the rated supply (or 1000 V whichever is greater) 50 Hz.

Components not rated for this test voltage may be disconnected before carrying out the test.

5.4.1. WARNINGS

WARNING, DANGER OF ELECTRICAL SHOCK

The Machine Tester FULLTEST 3 supplies high voltage of a dangerous power. According to EN 50191

the following precautionary measures must be taken prior to a test:

• Block access to danger area.

• Put up warning signs (Attention! High voltage, danger to life).

• Install warning lamps (red, green) to be easily visible.

• Install EMERGENCY-OFF switch into the mains installation outside the dangerous area.

• Electrical trained personnel may only do the tests under supervision of specialist staff and have to be

trained regularly.

• Use safety probes with protection against contact or with two-hand operation only. Always hold only

one probe in one hand.

• Connecting one test terminal to the UUT and working with one probe or holding both probes in one

hand is prohibited.

• It is prohibited to touch the unit under test during the test. If need be, additional measures must be

taken (e.g. cover made of insulating mats) to protect the person performing the test against

inadvertent contact with the test object.

Testing may commence only after all safety measures were taken.

Ensure that all switches on the UUT are closed in order to test all it’s components. For the purpose of

measurement all active conductors (L1, L2, L3 and N) must be shortcircuited.

EN - 25

Page 27

FULLTEST 3

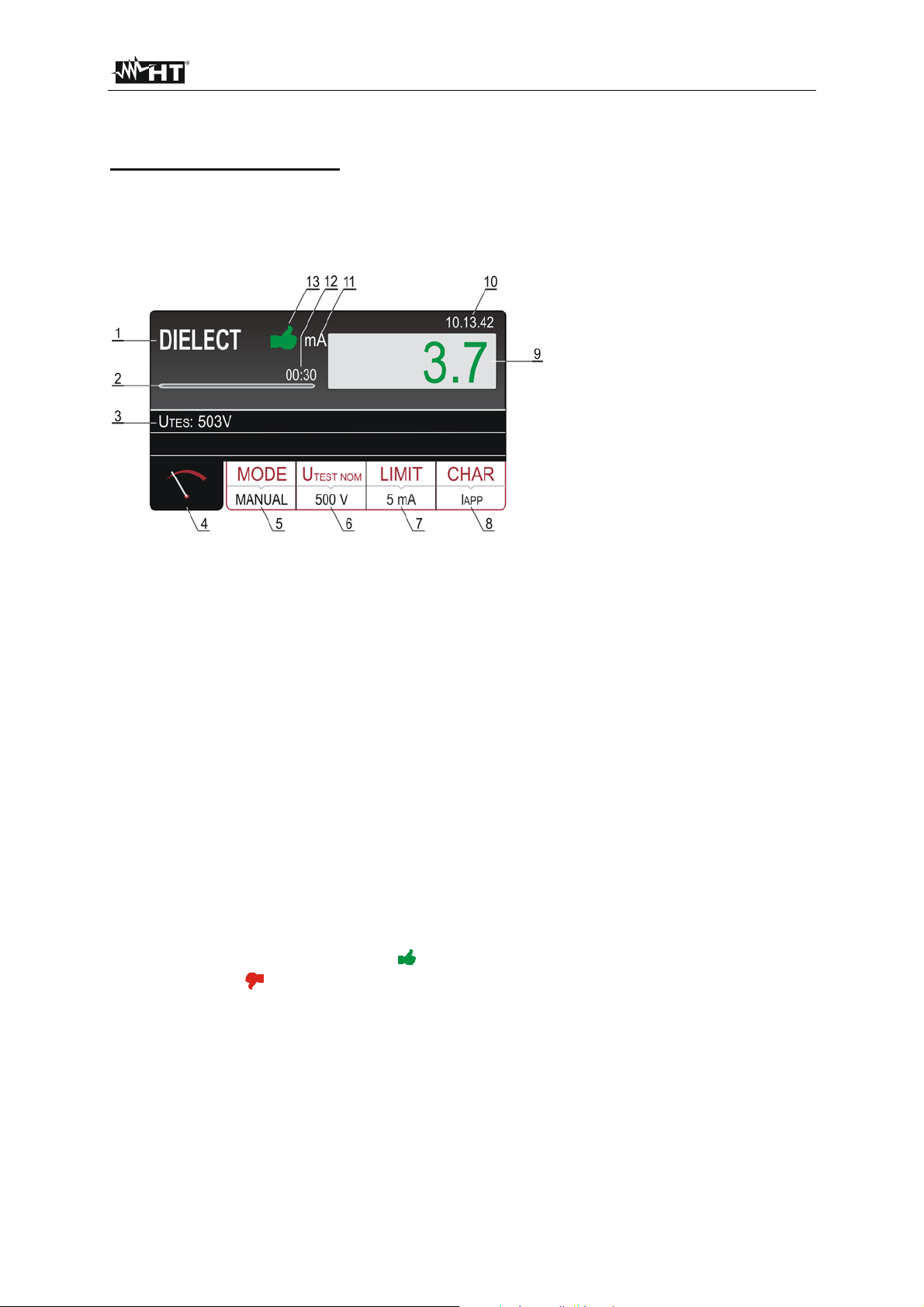

5.4.2. DIELECTRIC DISPLAY EXPLANATION

Adjustable/selectable parameters:

MODE - operation mode MANUAL, RAMP or BURN

UTEST NOM - nominal test voltage 250 5100 V AC

LIMIT - current limit 1 110 mA

CHAR - current character IAPP or IREAL

Figure 13: Display with DIELECTRIC test result

1 ..... Selected function.

2 ..... Progress bar, it follows test time during the measurement (in RAMP mode only).

3 ..... Test voltage applied during the measurement.

4 ..... Measurement screen touch-screen key.

5 ..... MODE touch-screen key to select operation mode (MANUAL, RAMP or BURN). Currently selected

mode is displayed on the bottom of the key.

6 ..... UTEST NOM touch-screen key to select nominal test voltage (250 up to 5100 V). Currently

selected value is displayed on the bottom of the key.

7 ..... LIMIT touch-screen key. Currently selected limit leakage current (trip out current) is displayed on

the bottom of the key.

8 ..... CHAR (character) touch-screen key to select the character of displayed leakage current (IAPP or

REAL). Currently selected character is displayed on the bottom of the key.

I

9 ..... Leakage current in green colour if the result is lower than or equal to set limit value. If break-

through occurred during the test then limit value will be displayed in red colour.

10 ... Real time clock (hh.mm.ss).

11 ... Unit of the test result (mA).

12 ... Set measurement time (in RAMP mode only).

13 ... Measurement result status (symbol

in green colour - result lower than or equal to set limit

value, symbol in red colour - break through occurred during the test or result higher than set

limit value).

EN - 26

Page 28

FULLTEST 3

5.4.3. DIELECTRIC TEST

Measured quantities and display ranges:

Apparent leakage current IAPP 0 200 mA

Real leakage current IREAL 0 200 mA

Test voltage 250 5.100 V

Explanation of measurement modes:

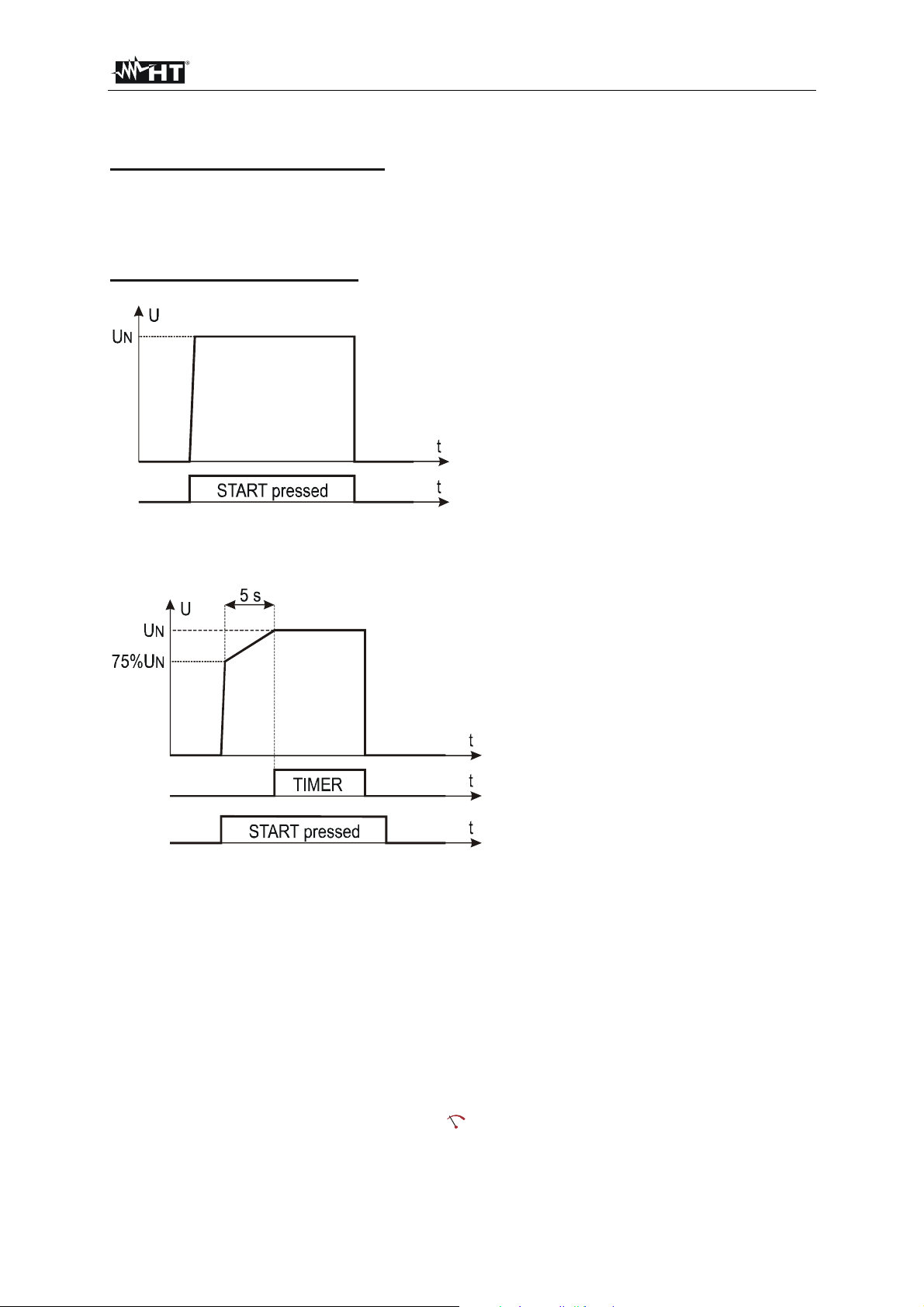

MANUAL or BURN mode:

Figure 14: Presence of test voltage with regard to pressed START button in MANUAL or BURN mode

RAMP mode:

Figure 15: Presence of test voltage with regard to pressed START button and set time in RAMP mode

1) Select DIELECTRIC measurement by pressing the FUNC hard key first.

2) Check selected mode and correct it if needed by pressing the MODE (5) touch-screen key first.

MANUAL, RAMP or BURN mode can be selected.

3) Check selected test voltage (250 up to 5100V) and correct it if needed by pressing the UTES NOM

(6) touch-screen key first.

4) Check selected limit current and correct it if needed by pressing the LIMIT (7) touch-screen key

first. Four independent preset limit currents are available for quicker operations. Select the one

closest to wished value and modify it by using the + and ― touch screen keys if needed.

5) Check selected character of displayed current (IAPP or IREAL) and correct it if needed by pressing

the CHAR (8) touch-screen key first.

6) Select measurement screen by pressing the (4) touch-screen key and check all settings again.

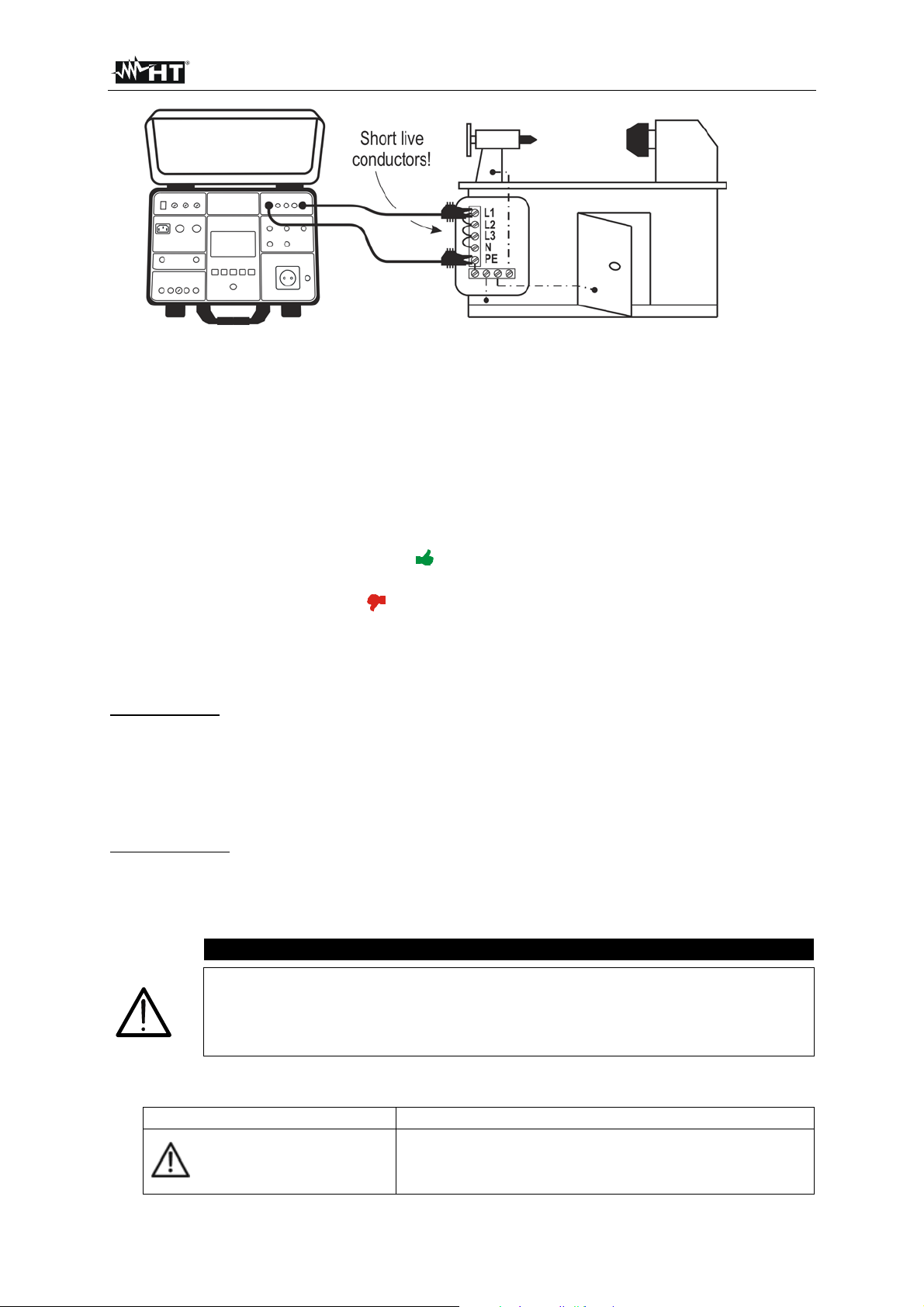

7) Connect the test leads according to the figure below.

EN - 27

Page 29

FULLTEST 3

Figure 16: Connection of test leads

8) Carry out the test by pressing the START/STOP button. Warning with explanation of how to

connect test leads with regard to selected test voltage will be displayed. Check the connection then

confirm it by pressing the YES touch-screen key, the message “READY” will appear and will stay

present for 10 seconds. START/STOP button is active while “READY” message is present. Press

and keep pressing the START/STOP button, test voltage will be applied to test terminals. The test

will be stopped after releasing the START/STOP button (MANUAL or BURN mode) or after

elapsing set test time (RAMP mode).

Test result will currently be displayed in green colour if it is lower than or equal to set limit value.

Final result will be equipped with green symbol and with beep-beep sound (result OK). If break

through occurred during the test then the test will be stopped and limit test current will be displayed

in red colour equipped with red symbol and with longer beep sound. See the display outlook

with test result on the figure 13.

9) Save test result by pressing the SAVE hard button twice, for further instructions see the

“MEMORIZING EXAMPLE” section.

SAFETY INPUT

In order to reach higher level of safety the SAFETY INPUT connector is installed. Safety switch of a

mechanical barrier can be connected there in order to disable DIELECTRIC function in case the safety

switch is opened. For this purpose select SAFETY INPUT enabled mode in the menu as follows:

MENU hard key SETUP touch-screen key SAFETY touch-screen key ENABLED touch-

screen key.

WARNING LAMP

According to EN 50191 the highest level of safety must be undertaken when working with high voltages

like used in DIELECTRIC test. For this purpose the FULLTEST 3 offers an output to drive the high

voltage warning lamp. Use only the lamps supplied by original supplier of the FULLTEST 3 tester.

CAUTION

Always connect COM terminal to GND if measured UUT is grounded,

otherwise possible capacitive leakage current may flow to ground which may

disturb the measurement!

Measurement time in MANUAL mode is limited to 60 min!

The following specific information can be shown on the display during measurement:

Information displayed Description

Internal fuse may be blown!

EROR1!

The fuse is not customer replaceable, send the tester into

a service department.

EN - 28

Page 30

FULLTEST 3

5.5. RCD (RCD)

5.5.1. RCD DISPLAY EXPLANATION

Adjustable/selectable parameters:

TYPE - type of RCD AC, A or B

CHARACTERISTIC - RCD characteristic GENERAL, SELECTIVE or DELAYED

IN - nominal differential current 10, 30, 100, 300, 500, 650 or 1000 mA

MEAS - type of measurement t/1/2IN, t/IN, t/2IN, t/5IN, I or AUTO

POL - test current polarity POS (positive) or NEG (negative)

DELAY – delay time in DELAY characteristic 0 700 ms

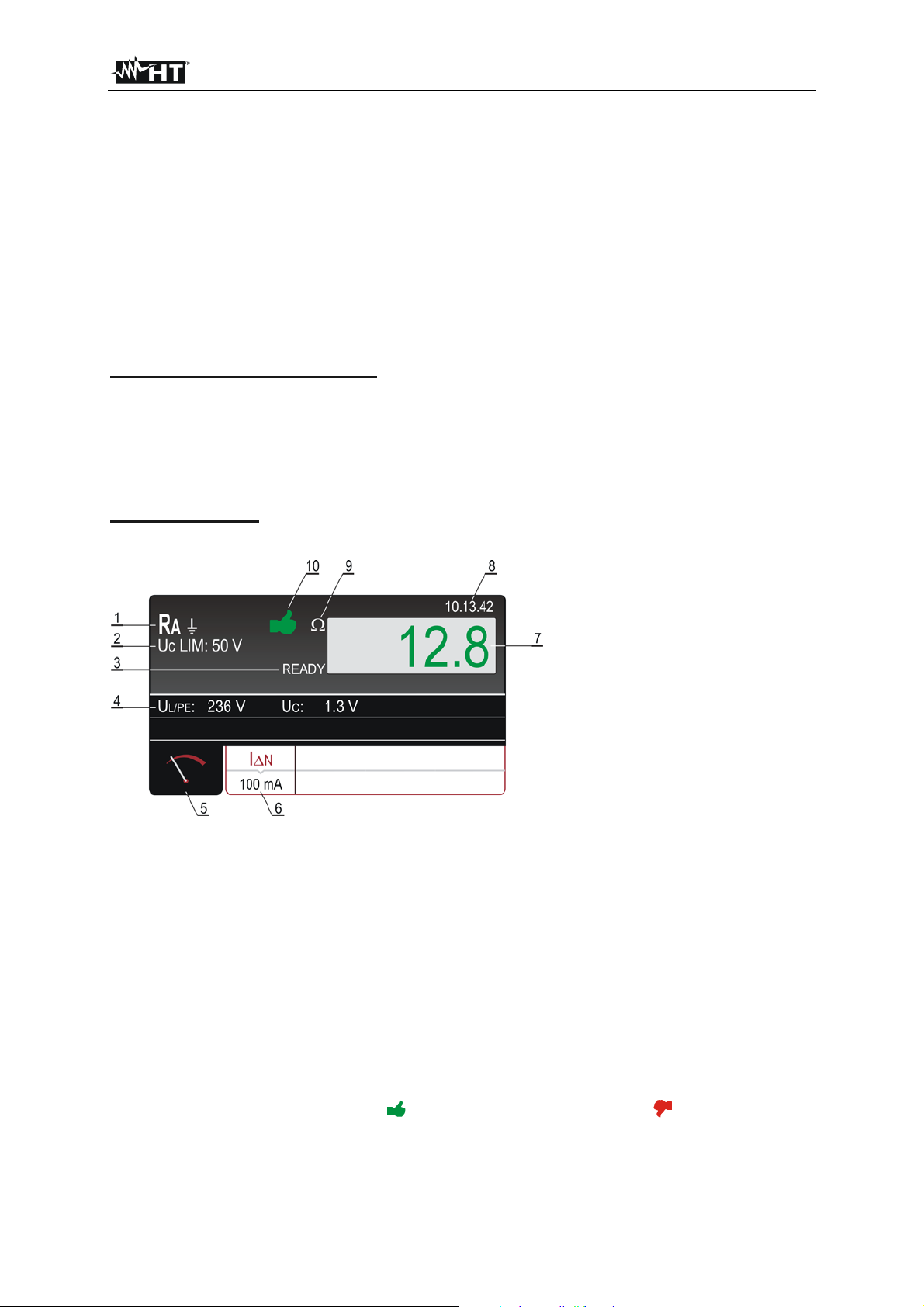

Figure 17: Display with RCD test result

1 ..... Selected function.

2 ..... Selected limit contact voltage (25 or 50 V). It can be selected in MENUSETUPCONTACT

VOL. menu.

3 ..... Sub-results - mains voltages UL/N and UL/PE at which the test was carried out.

4 ..... Measurement screen touch-screen key.

5 ..... TYPE touch-screen key to select the type of RCD (AC, A or B) and characteristic (GENERAL,

SELECTIVE or DELAYED). Currently selected type and characteristic are displayed on the bottom

of the key.

N touch-screen key to select nominal differential current of the RCD (10, 30, 100, 300, 500, 650

6 ..... I

or 1000 mA). Currently selected value is displayed on the bottom of the key.

7 ..... MEAS touch-screen key to select the measurement (t

/1/2IN, t/IN, t/2IN, t/5IN, I or AUTO).

Currently selected measurement is displayed on the bottom of the key.

8 ..... POL touch-screen key to select test current polarity (POS - positive or NEG - negative).

9 ..... Test result (in green colour - result OK, in red colour - result not OK).

10 ... Real time clock (hh.mm.ss).

11 ... Unit of the test result (ms).

12 ... Measurement result status (symbol in green colour - result OK, symbol in red colour - result

not OK).

EN - 29

Page 31

FULLTEST 3

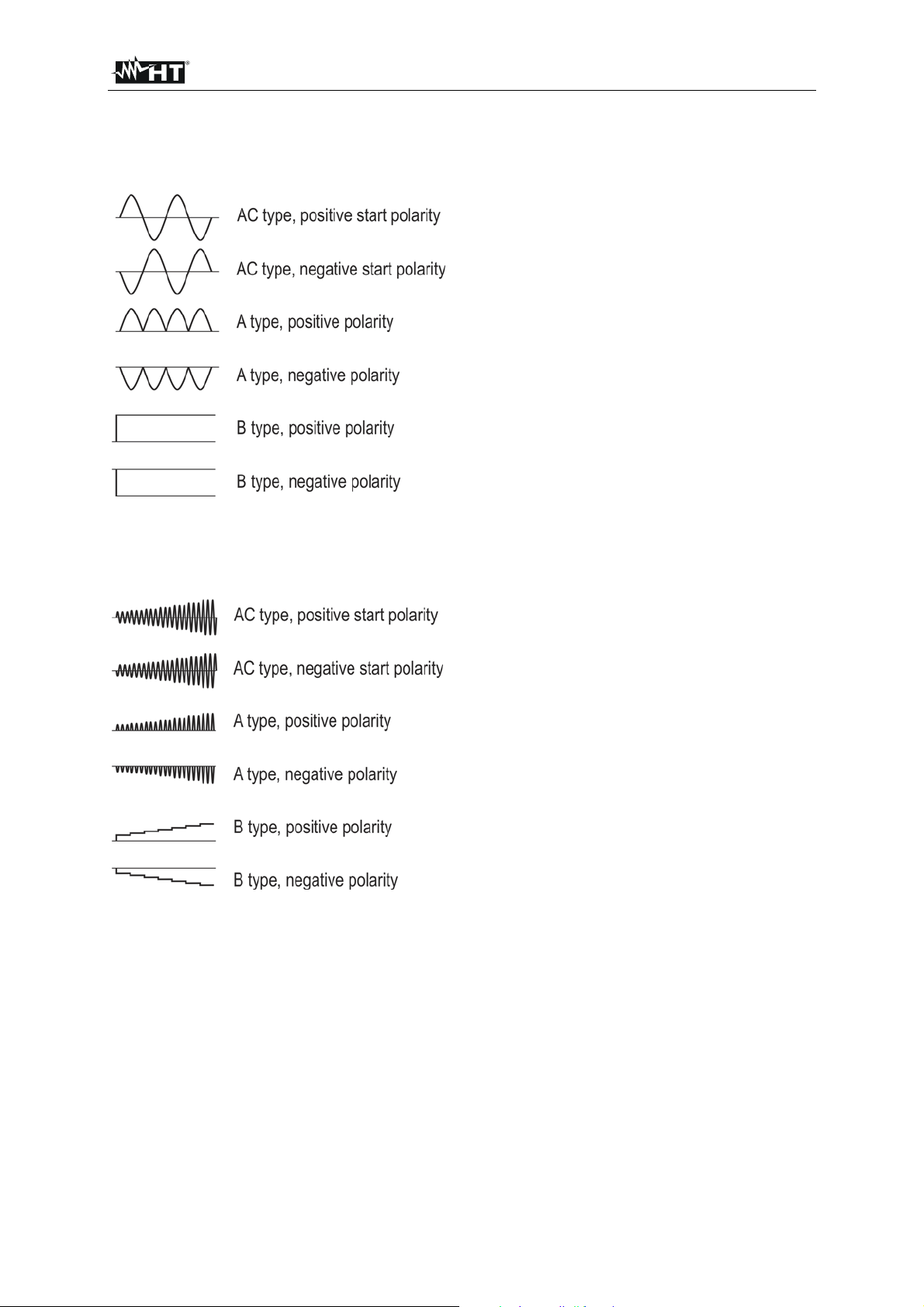

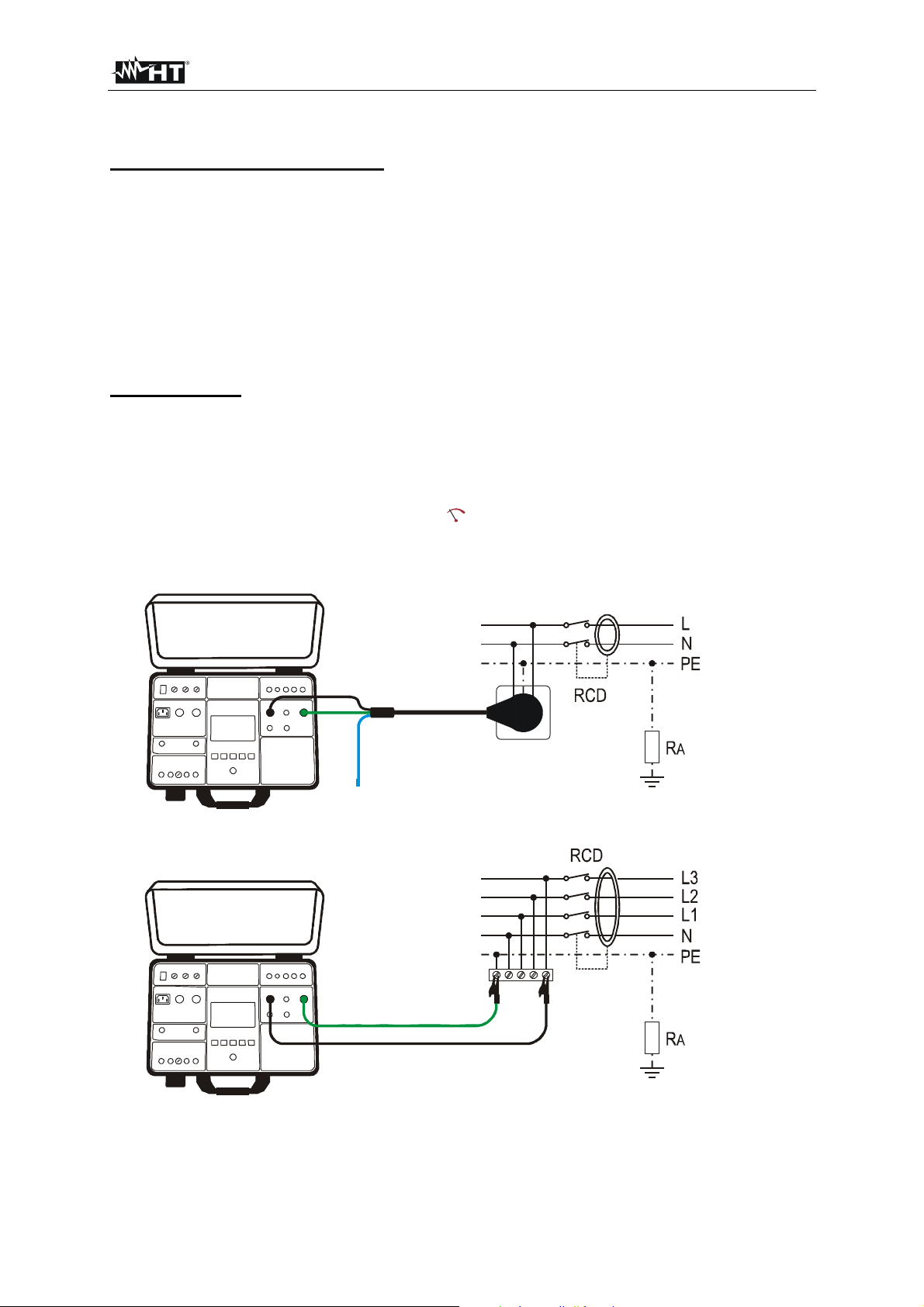

5.5.2. EXPLANATION OF RCD TEST CURRENTS

See the figures below for test current shapes with regard to selected RCD type and test current polarity.

Figure 18: Test current shapes with regard to selected RCD type and test current polarity in trip time

measurement

Figure 19: Test current shapes with regard to selected RCD type and test current polarity in RAMP test

EN - 30

Page 32

FULLTEST 3

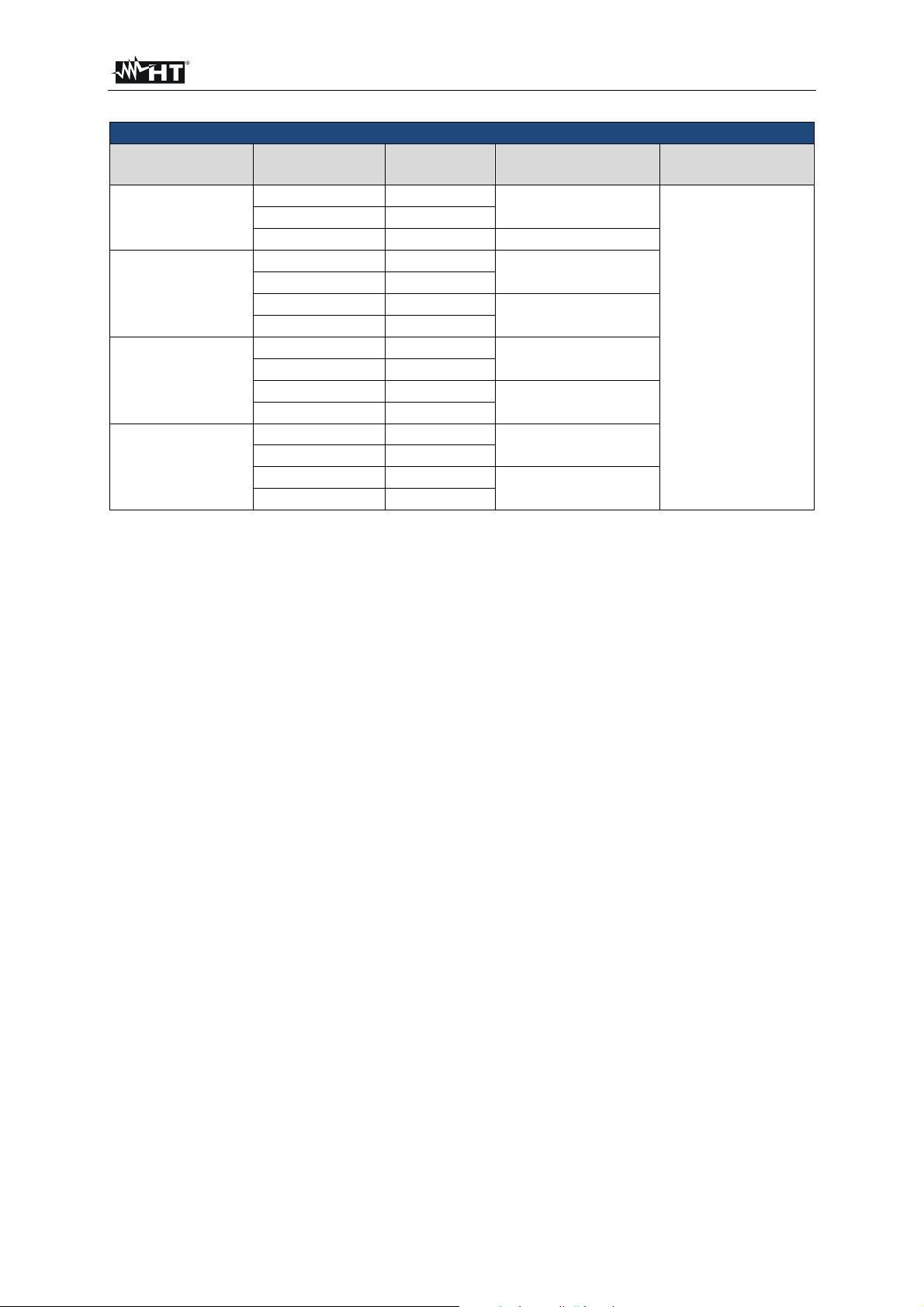

5.5.3. RCD MEASUREMENT

Measured quantities and display ranges:

Trip out time at IN/2 0 1000 ms (AC, A, B, general, selective, delayed)

Trip out time at IN 0 1000 ms (AC, A, B, general, selective, delayed)

Trip out time at 2IN 0 200 ms (AC, A, general), 0 250 ms (AC, A, selective)

Trip out time at 4IN 0 200 ms (B, general), 0 250 ms (B, selective)

Trip out time at 5IN 0 50 ms (AC, A, general), 0 150 ms (AC, A, selective)

AUTO test YES (general, selective)

Trip out current (Ramp test) 10 110% of IN in steps of 5% of IN (general)

Input requirements:

Mains voltage UL/N (READY condition) 100 265 V AC

Mains voltage U

L/PE (READY condition) 100 265 V AC

1) Select the RCD function by pressing the FUNC hard key first.

2) Check selected RCD type (AC, A or B) and selected characteristic (GENERAL, SELECTIVE or

DELAYED) and modify it if needed by pressing the TYPE (5) touch-screen key first. If DELAYED

characteristic is selected, the screen will turn to delay time adjustment mode automatically.

3) Select nominal differential current by pressing the IN touch-screen key first.

4) Select wished measurement by pressing the MEAS touch-screen key first (t/1/2IN, t/IN, t/2IN,

t/5IN, I or AUTO).

5) Check selected polarity and modify it if needed by pressing the POL (8) touch-screen key first.

6) Select measurement screen by pressing the (4) touch-screen key and check all settings again.

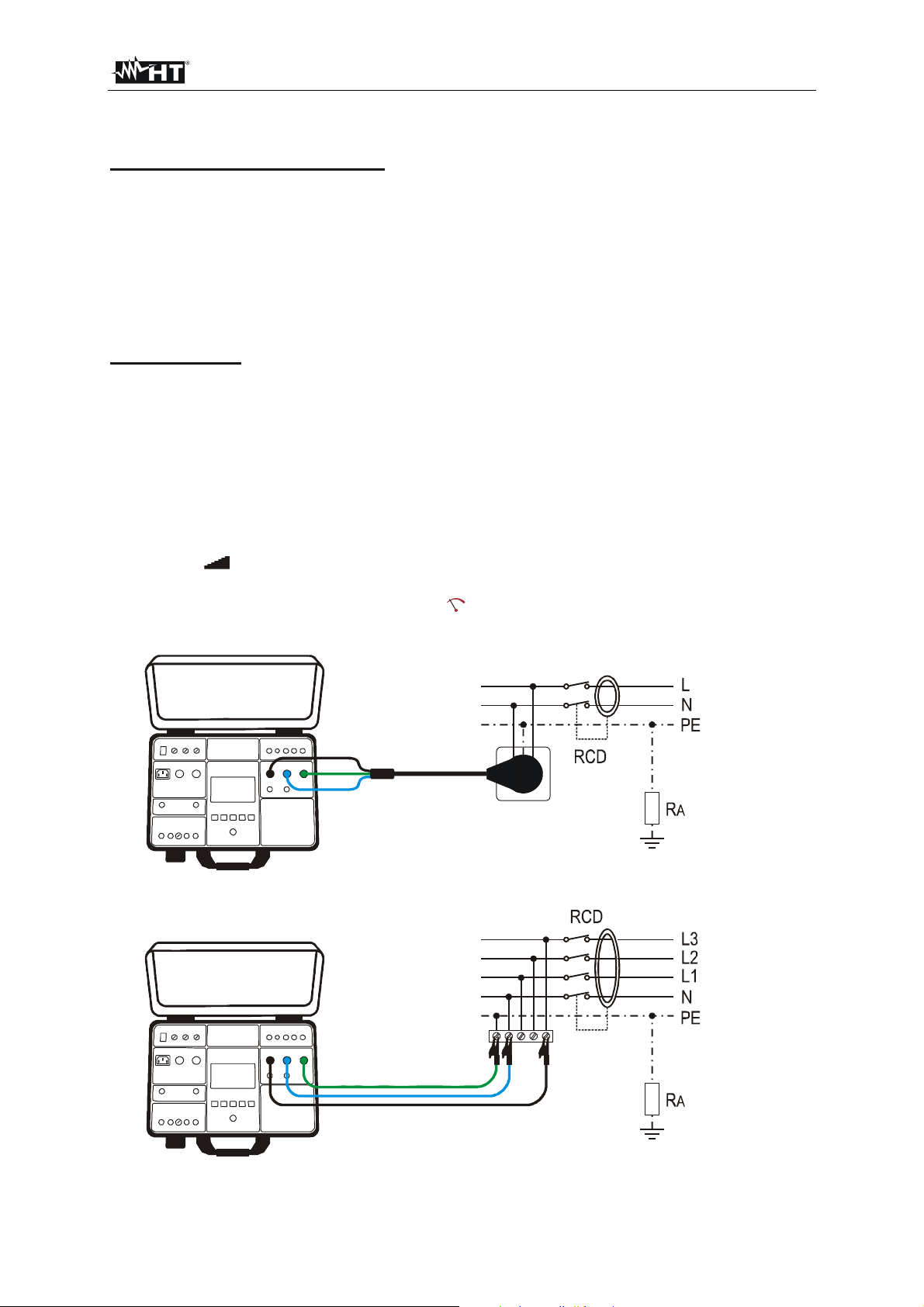

7) Connect the test leads according to one of the figures below.

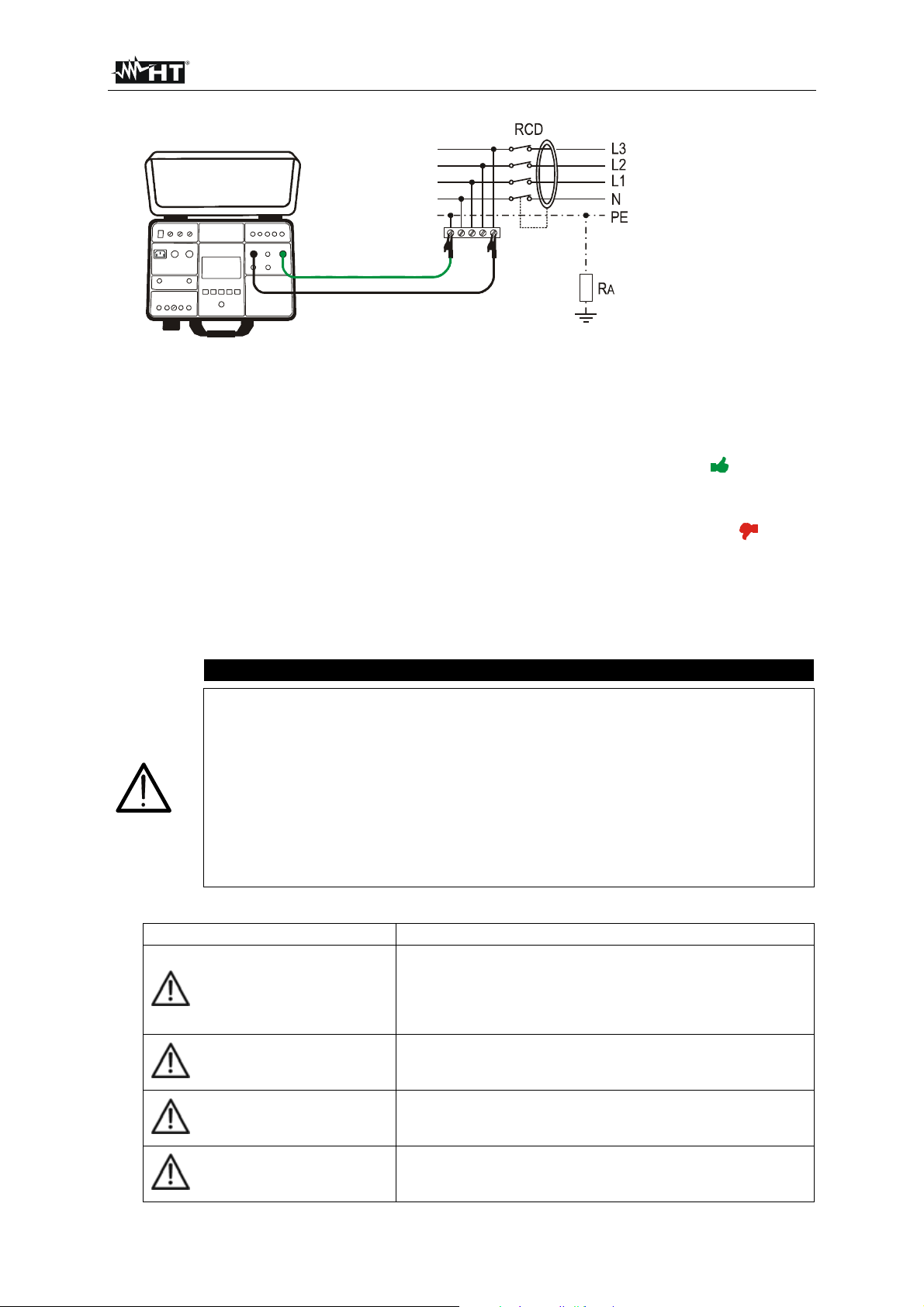

Figure 20: Connection of schuko test cable

Figure 21: Connection of test leads

EN - 31

Page 33

FULLTEST 3

READY message will appear as soon as the tester is properly connected to the installation and

mains voltage is present, see the “Input conditions” above.

8) Carry out the measurement by pressing the START button.

9) Test result will be displayed in green colour equipped with green symbol and with beep-beep

sound if it is within limit range, see the table of allowed trip out times below. If the result is out of

limit range, then it will be displayed in red colour equipped with red symbol and with longer

beep sound. See the display outlook with test result on the figure 17.

10) Save the test result by pressing the SAVE hard key twice, for further instructions see the

“MEMORIZING EXAMPLE” section.

11) Press the EXIT hard key to clear displayed result, actual input voltages UL/N and UL/PE will start to

be displayed again.

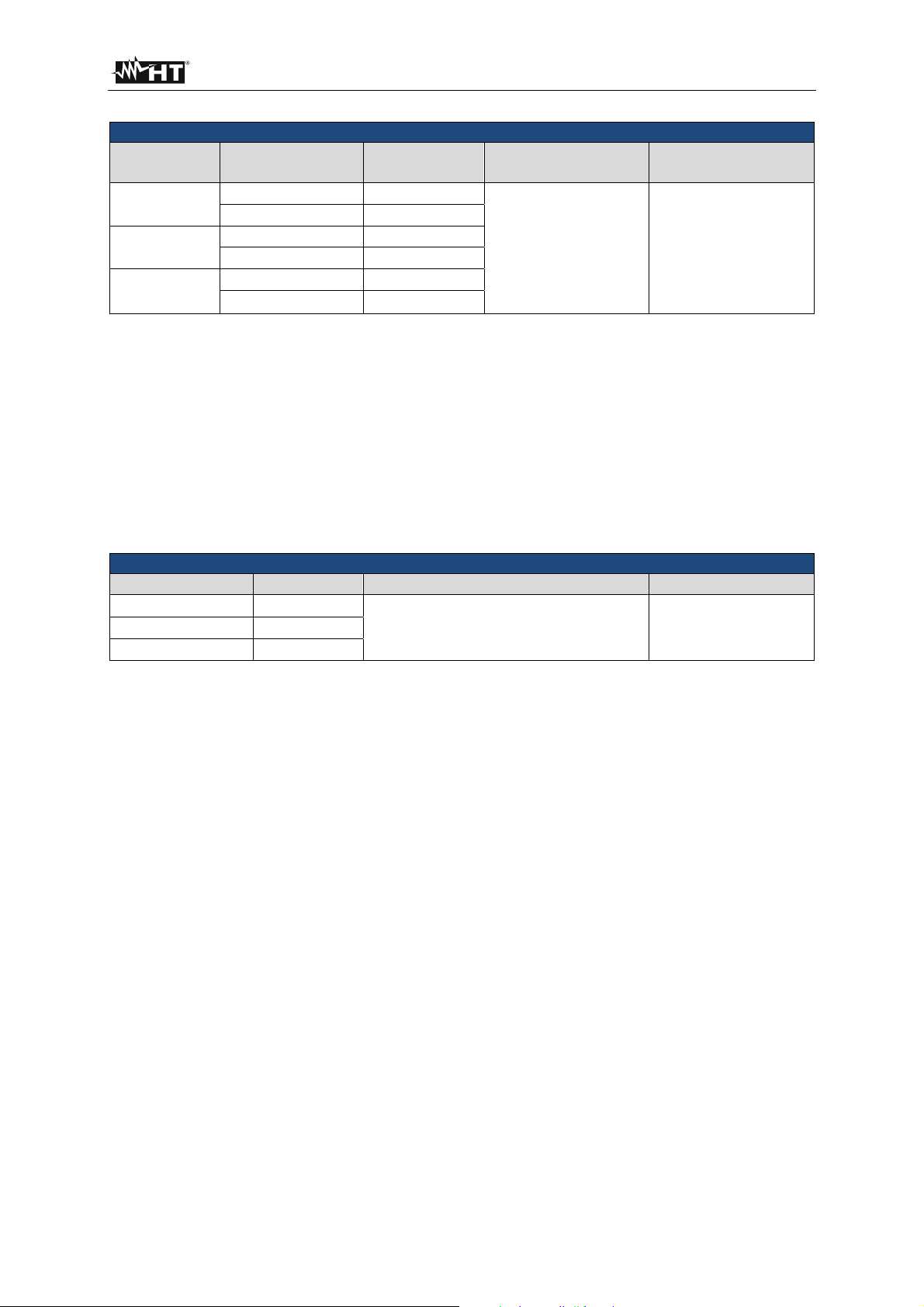

Allowed trip out times:

Characteristic / I IN/2 IN 2IN (4) 5IN

GENERAL >1000 ms

SELECTIVE >1000 ms

DELAYED >1000 ms

300 ms 150 ms 40 ms

130 500 ms 60 200 ms 50 150 ms

D (D + 300) ms

- -

D … Delay time which can be set to 0 700 ms

CAUTION

When selecting RCD type (TYPE), nominal differential current (IN) or

measurement (MEAS) it may happen that wished parameter will not be

available (displayed in watery colour). In this case the level of other parameter

or even other two parameters shall be reduced first.

In case both voltages UL/N and UL/PE within required range 100 265 V are

present at L/N/PE test terminals (also displayed) but there is no READY

message displayed, check if energizing socket is correctly earthed!

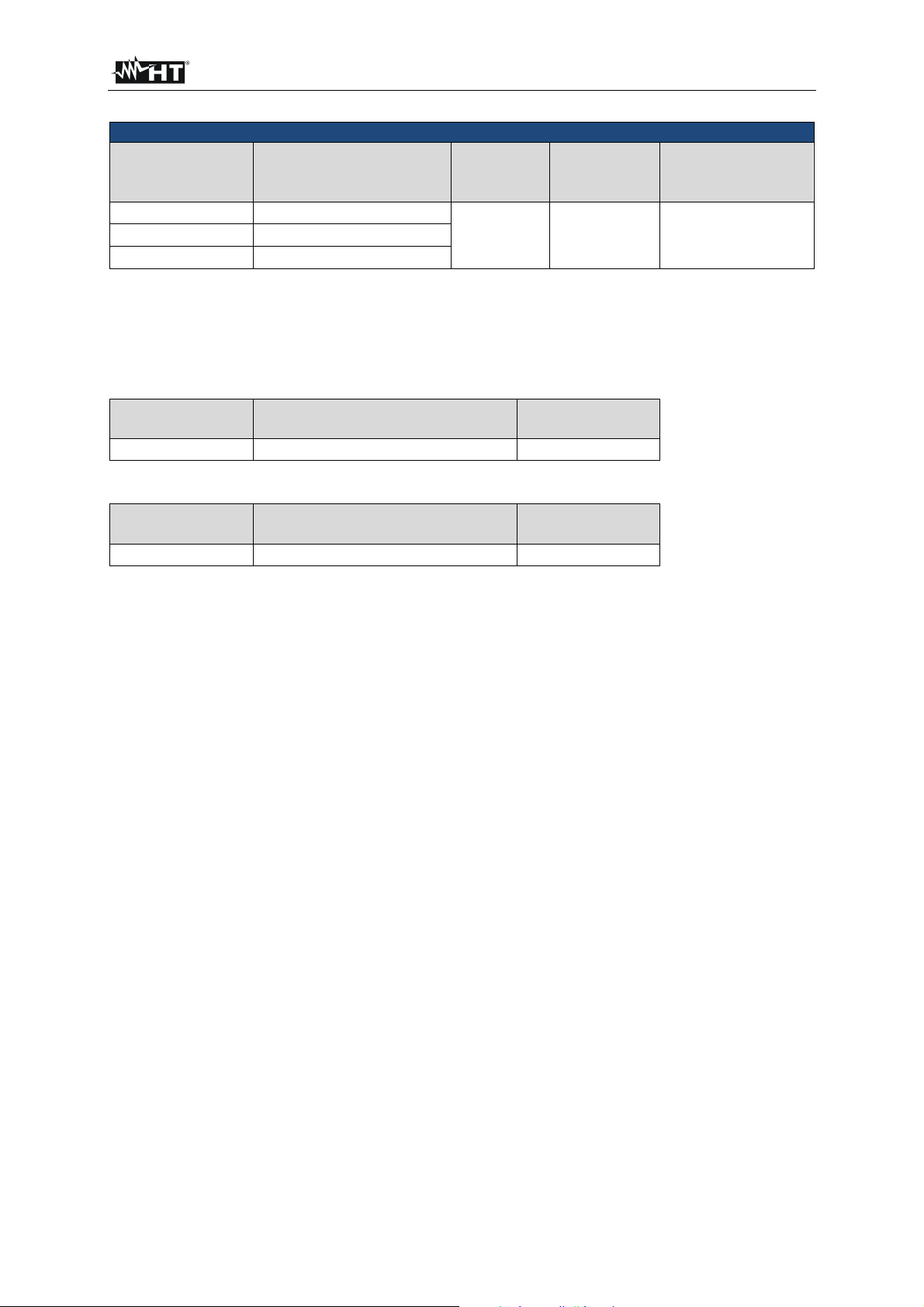

The following specific information can be shown on the display during the measurement:

Information displayed Description

L/N or UL/PE out of required range 100

VOLTAGE OUT OF RANGE

Input voltage U

265 V after pressing the START key.

Input voltage failed during the measurement (disconnection

MEASUREMENT FAILED!

FUSE F3!

of test leads, installation fuse tripped etc.)

Fuse F3 is blown.

Internal circuitry is overheated.

HOT!

Wait to cool it down!

EN - 32

Page 34

FULLTEST 3

5.6. LOOP IMPEDANCE / SHORT-CIRCUIT CURRENT (LOOP)

• According to EN 60204-1, the conditions for protection against electric shock in installations with

automatic disconnection of mains voltage are:

• Measurement or evaluation of fault loop impedance and testing the over-current protection device

involved in the fault loop.

• Limit values are shown in the Table 10 of EN 60204-1.

5.6.1. LOOP DISPLAY EXPLANATION

Adjustable/selectable parameters:

MODE - measurement mode LOOPL/N, LOOPL/L, LOOPL/PE, IMP57L/N, IMP57L/L or IMP57L/PE

LIMIT - limit value mode STD, kA, I2t, TRIP CURR. or Ut, see the explanation below

Ib – breaking capacity of protection 1, 1.5, 3, 4.5, 6, 10, 15, 16, 20 or 25 kA

PROTECTION - type of protection MCB B, MCB C, MCB D, MCB K, FUSE gG or FUSE aM

In - nominal current of protection See the values in chapter “LIMIT VALUE EXPLANATION” below

Tset - max allowed tripping time 0.1 s, 0.2 s, 0.4 s or 5 s

WIRE - wire material Cu (Copper) or Al (Aluminium)

COATING - wire coating PVC, BUTYL RUBBER or EPR/XLPE

SECTION - wire section 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm2

N - number of conductors 1 99

Figure 22: Display with LOOPL/N test result

1 ..... Selected function.

2 ..... Selected nominal voltage (230 or 240 V) needed for calculation of short-circuit current.

3 ..... READY message. It is displayed when present mains voltage UL/L, UL/N or UL/PE within required

range is present.

4 ..... Sub-results - mains voltage U

calculated prospective short-circuit current I

L/PE or UL/PE or UL/L at which the measurement has been done and

SC.

5 ..... Measurement screen touch-screen key.

6 ..... MODE touch-screen key to select measurement mode (LOOP L/N, LOOP L/L, LOOP L/PE, IMP57

L/N, IMP57 L/L or IMP57 L/PE). Currently selected mode is displayed on the bottom of the key.

7 ..... LIMIT touch-screen key to select limit mode (STD, kA, I2t, TRIP CURR. or Ut). Currently selected

mode is displayed on the bottom of the key.

8 ..... PROT. (protection) touch-screen key to select the type of protection (MCB B, MCB C, MCB D,

MCB K, FUSE gG or FUSE aM) and nominal current of selected protection. Currently selected type

is displayed on the bottom of the key.

EN - 33

Page 35

FULLTEST 3

9 ..... WIRE touch-screen key to select the material of measured wire (Cu or Al), coating (PVC, BUTYL

RUBBER or EPR/XLPE), section (1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50 or 70 mm

2

) and number of

conductors (1 99). Currently selected material is displayed on the bottom of the key.

10 ... Measurement result (in green colour - result OK, in red colour - result not OK).

11 ... Real time clock (hh.mm.ss).

12 ... Unit of the test result ().

13 ... Measurement result status (symbol in green colour - result OK, symbol in red colour - result

not OK).

5.6.2. LIMIT VALUE EXPLANATION

There are five possibilities to select the limit prospective short-circuit current ISC LIM, which is the bases

for final evaluation.

STD - no verification.

No limit is used in this case meaning test result is not evaluated and is therefore always considered as

neutral (displayed in white colour).

kA - verification if short-circuit current is lover than breaking capacity of involved over-current protection

device.

Measured ISC MAX must be lower or equal than entered breaking capacity Ib of involved over-current

protection device, where breaking capacity Ib can be selected among the following values:

- Ib (breaking capacity) 1, 1.5, 3, 4.5, 6, 10, 15, 16, 20 or 25 kA

I2t - verification if over-current protection device reacts before wires are overheated and thus damaged.

On bases of measured ISC MAX and entered over-current protection device (PROTECTION) and

nominal current of the over-current protection device (In) trip out time of the over-current protection

device (t) is calculated. See the evaluation equation in the table “PROSPECTIVE SHORT-CIRCUIT

CURRENT CALCULATION” below. Entered parameters can be selected among the following values:

- PROT (type of protection) MCB B, MCB C, MCB D, MCB K, FUSE gG or FUSE aM

- In (nominal current) - 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB B)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB C)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25 or 32 A (MCB D, MCB K)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500, 630, 800, 1000 or 1250 A (FUSE gG)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500 or 630 A (FUSE aM)

- MATERIAL (wire material) Cu (Cupper) or Al (Aluminium)

- COATING (wire coating) PVC, BUTYL RUBBER or EPR/XLPE

- SECTION (wire section) 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70 mm

2

- N (number of conductors) 1 99

TRIP CURRENT - verification if over-current protection device reacts within set time at measured shortcircuit current.

On bases of measured ISC MIN and entered over-current protection device (PROTECTION) and nominal

current of the over-current protection device (In) trip out time is calculated which must be lower than or

equal to entered Tset. Entered parameters can be selected among the following values:

- PROT (type of protection) MCB B, MCB C, MCB D, MCB K, FUSE gG or FUSE aM

- In (nominal current) - 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB B)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB C)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25 or 32 A (MCB D, MCB K)

EN - 34

Page 36

FULLTEST 3

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500, 630, 800, 1000 or 1250 A (FUSE gG)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500 or 630 A (FUSE aM)

- Tset (max trip time) 0.1, 0.2, 0.4 or 5 s

Ut - verification if short-circuit current is high enough over-current protection device to react within set

time.

On bases of entered over-current protection device (PROTECTION), nominal current of the over-current

protection device (In) and Tset required short-circuit current (Ia) is calculated. Measured ISC MIN must

be higher than or equal to calculated current Ia. Entered parameters can be selected among the

following values:

- PROT (type of protection) MCB B, MCB C, MCB D, MCB K, FUSE gG or FUSE aM

- In (nominal current) - 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB B)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25, 32, 40, 50 or 63 A (MCB C)

- 0.5, 1, 1.6, 2, 4, 6, 10, 13, 16, 20, 25 or 32 A (MCB D, MCB K)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500, 630, 800, 1000 or 1250 A (FUSE gG)

- 2, 4, 6, 8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80, 100, 125, 160,

200, 250, 315, 400, 500 or 630 A (FUSE aM)

- Tset (max trip time) 0.1, 0.2, 0.4, 5 or 10 s

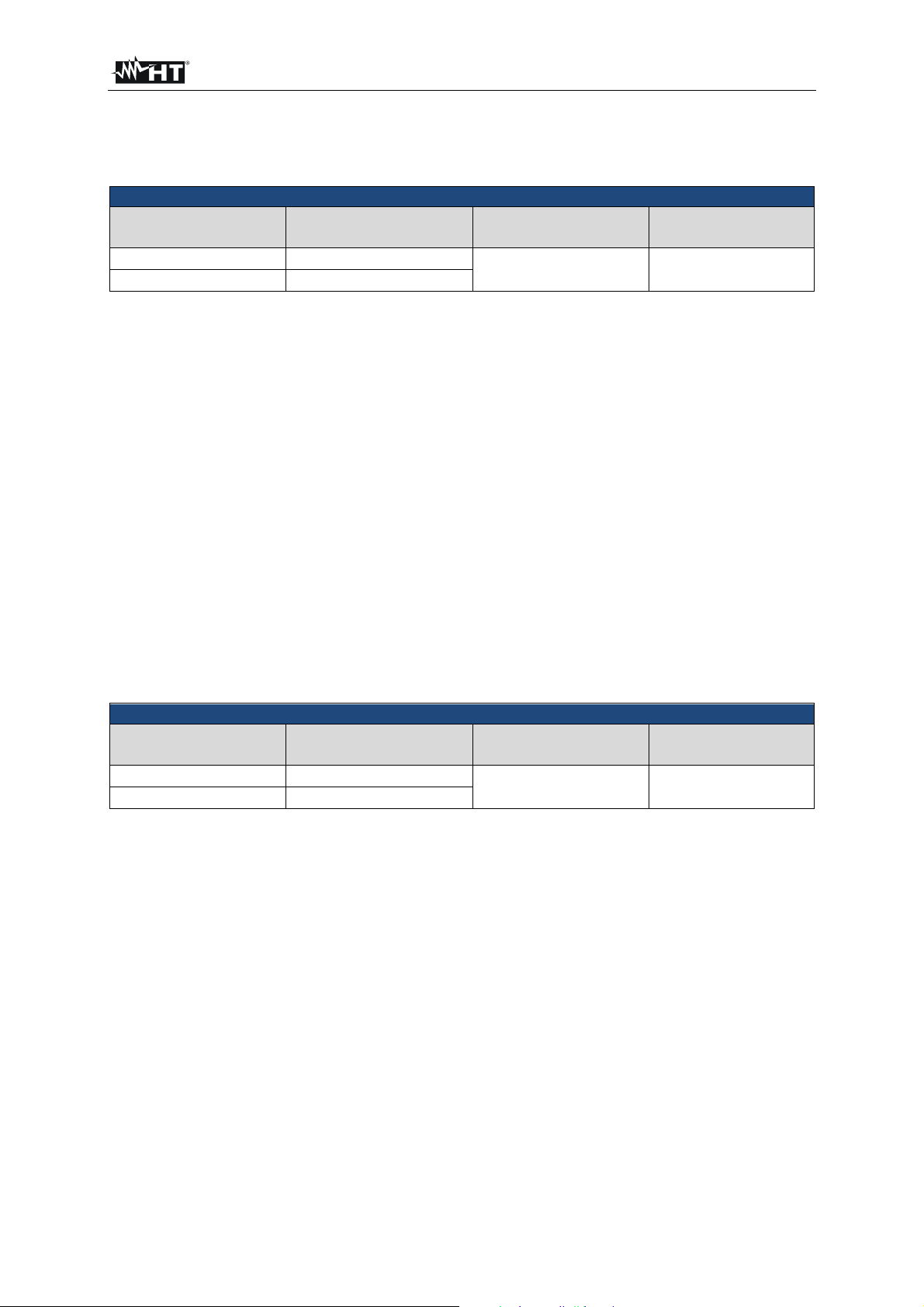

5.6.3. PROSPECTIVE SHORT-CIRCUIT CURRENT CALCULATION

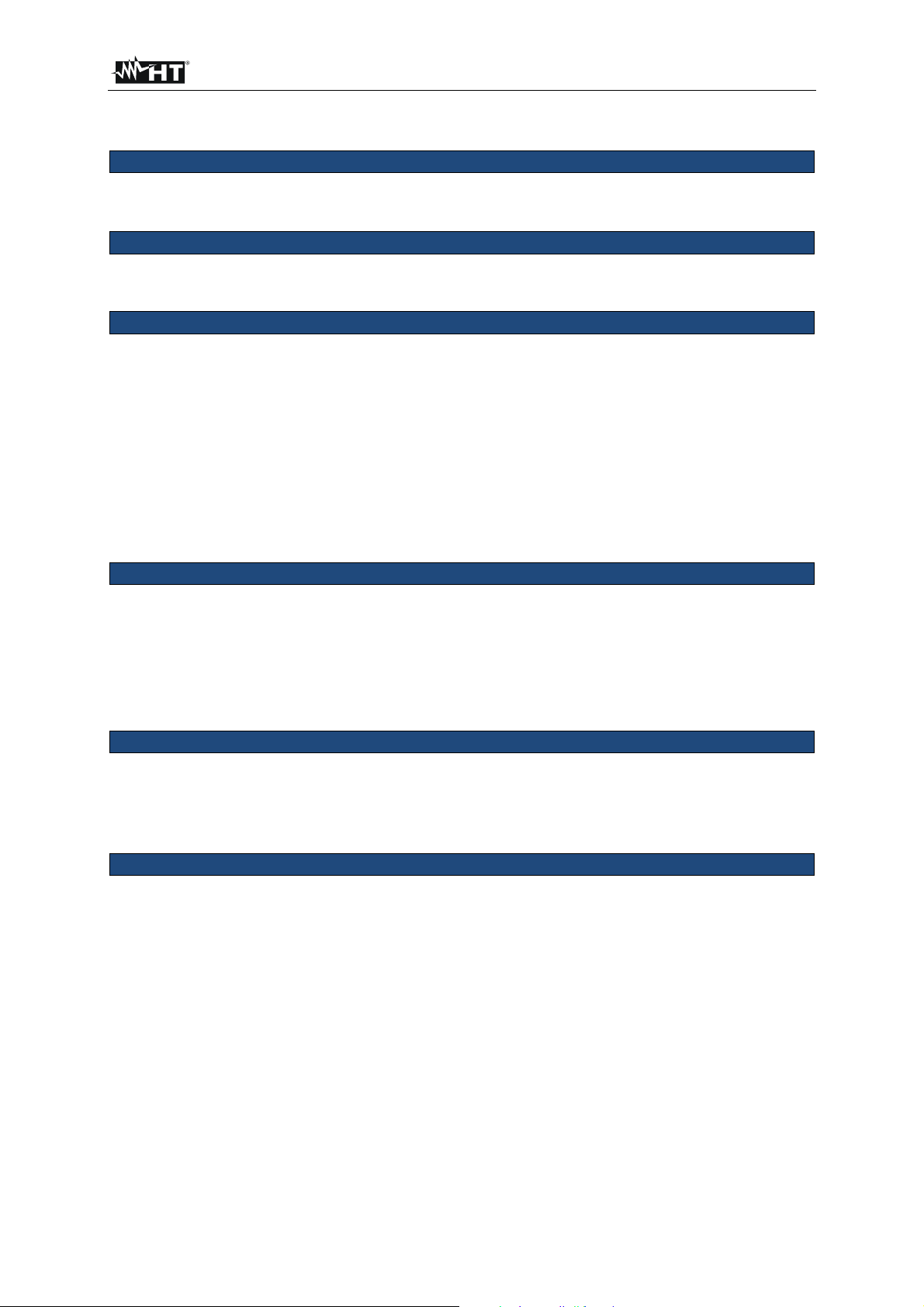

Evaluation table and short-circuit current calculation:

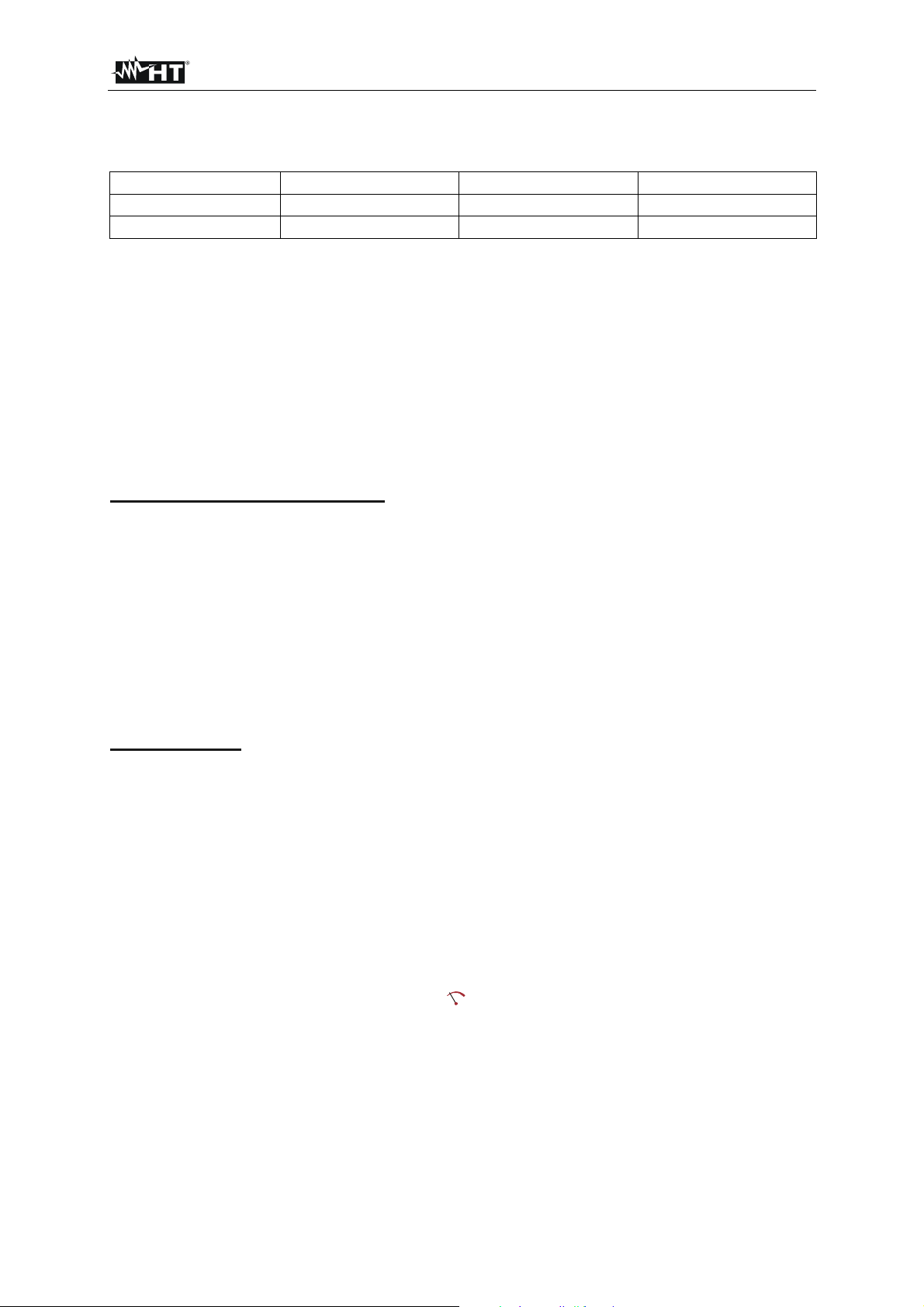

LIMIT mode TT – Evaluation condition TN – Evaluation condition

L/L STD No evaluation No evaluation

kA ISC L/L MAX 3PH < BC ISC L/L MAX 3PH < BC

I2t (ISC L/L MAX 3PH)2 × t < (K × N × S)2 (ISC L/L MAX 3PH)2 × t < (K × N × S)2

TRIP CURR. ISC L/L MIN 2PH Tmax, Tmax < Tlim ISC MIN 2PH Trip time T, T < Tlim

Ut

L/N STD No evaluation No evaluation

kA ISC L/L MAX 3PH < BC ISC L/L MAX 3PH < BC

I2t (ISC L/N MAX)2 × t < (K × N × S)2 (ISC L/N MAX)2 × t < (K × N × S)2

L/N

TRIP CURR.

Ut

STD

kA ISC MAX L/N < Breaking capacity

ISC MIN 2PH Trip time T, T < Tlim ISC MIN 2PH Trip time T, T < Tlim

No evaluation No evaluation

ISC MAX L/N < Breaking capacity IB

IB

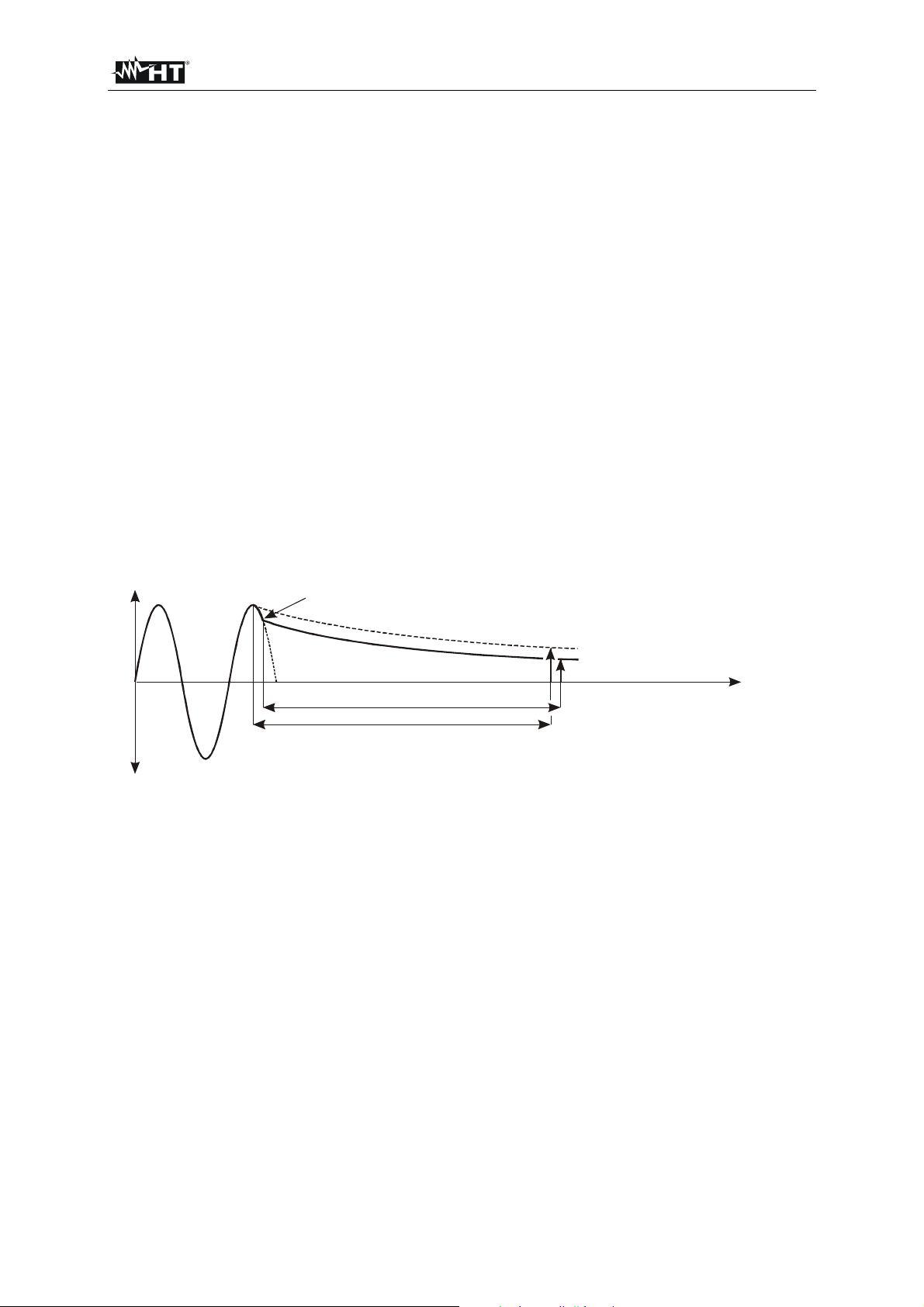

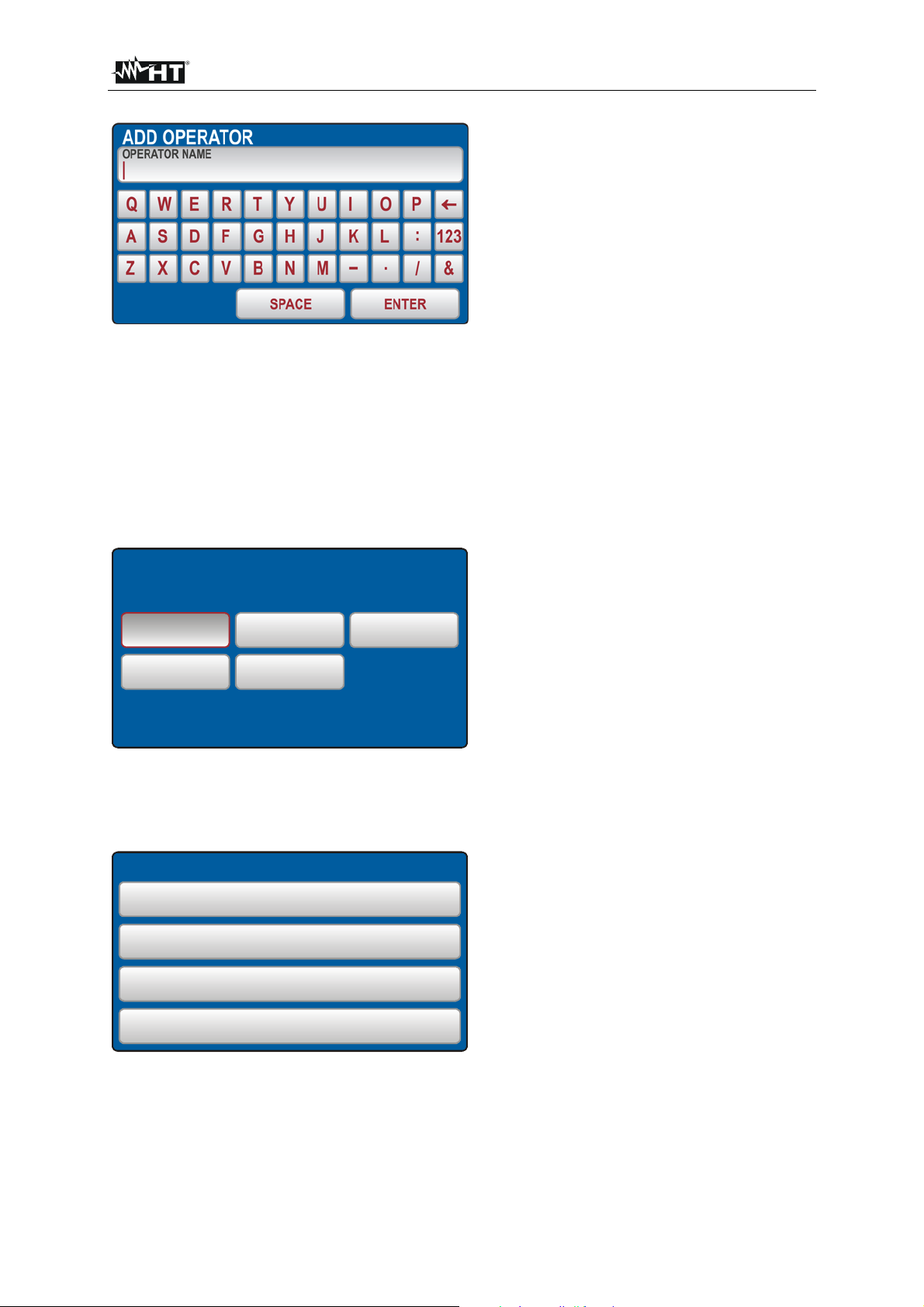

I2t (ISC MAX L/N)2 × T < (K × N × S)2 (ISC MAX L/N)2 × T < (K × N × S)2