Page 1

User manual

EQUITEST 5071

Copyright HT ITALIA 2013 Versione EN 1.00 - 15/01/2013

Page 2

Page 3

EQUITEST 5071

Table of contents

1. PRECAUTIONS AND SAFETY MEASURES .................................................................. 2

1.1. Preliminary instructions ......................................................................................................... 2

1.2. During use ............................................................................................................................. 3

1.3. After use ................................................................................................................................ 3

Definition of measurement (overvoltage) category ......................................................................... 3

2. GENERAL DESCRIPTION .............................................................................................. 4

3. PREPARATION FOR USE .............................................................................................. 4

3.1. Initial checks .......................................................................................................................... 4

3.2. Instrument power supply ....................................................................................................... 4

3.3. Calibration ............................................................................................................................. 4

3.4. Storage .................................................................................................................................. 4

4. INSTRUMENT DESCRIPTION ........................................................................................ 5

4.1. Front panel ............................................................................................................................ 5

4.2. Input and output leads ........................................................................................................... 5

4.3. Description of function keys .................................................................................................. 6

4.4. Display description ................................................................................................................ 6

4.5. Initial screen .......................................................................................................................... 6

4.6. Backlight ................................................................................................................................ 7

5. INITIAL SETTINGS ......................................................................................................... 7

5.1. Adjusting display contrast ...................................................................................................... 7

5.2. Adjusting date and time ......................................................................................................... 8

5.3. Language setting ................................................................................................................... 8

6. OPERATING INSTRUCTIONS ........................................................................................ 9

6.1. LOW: Continuity of protective conductors with 200mA....................................................... 9

6.1.1.Calibration of measuring cables .................................................................................................. 10

6.1.2.Measuring.................................................................................................................................... 11

6.1.2.1. Anomalous situations in "AUTO", "RT+", "RT-" mode........................................................................... 13

6.2. LOW10A: Continuity of protective conductors with 10A ................................................... 14

6.2.1.Measuring.................................................................................................................................... 14

6.2.2.Anomalous situations .................................................................................................................. 16

6.3. LOW10AE204: Continuity 10A in compliance with IEC/EN60204-1:2006 ........................ 17

6.3.1.Measuring.................................................................................................................................... 18

6.3.2.Anomalous situations .................................................................................................................. 20

6.4. LOOP/Ra

6.4.1.High-resolution impedance measurement (0.1 m) ................................................................... 22

6.4.2."P-N" mode: measurement procedure and results ..................................................................... 22

6.4.3."P-P" mode: measurement procedure and results...................................................................... 24

6.4.4."P-PE" mode: measurement procedure and results ................................................................... 25

6.4.5."RA" mode: measurement procedure and results ................................................................... 27

6.4.6." " mode: measurement procedure and results ....................................................................... 29

: Loop impedance, overall earth resistance and phase sequence .................. 21

6.4.6.1. Anomalous situations in "P-P", "P-N", "P-PE","RA", " " mode ...................................................... 30

7. OPERATIONS WITH THE MEMORY ............................................................................ 34

7.1. Storage of measurement results ......................................................................................... 34

7.2. Recalling and deleting data from the memory ..................................................................... 34

8. CONNECTING THE INSTRUMENT TO THE PC .......................................................... 35

9. MAINTENANCE ............................................................................................................ 36

9.1. General information ............................................................................................................. 36

9.2. Battery replacement ............................................................................................................ 36

9.3. Cleaning the instrument ...................................................................................................... 36

9.4. End of life ............................................................................................................................ 36

10. TECHNICAL SPECIFICATIONS ............................................................................. 37

10.1. Reference standards ........................................................................................................... 38

10.2. General characteristics ........................................................................................................ 38

10.3. Environmental conditions .................................................................................................... 38

10.4. Accessories ......................................................................................................................... 38

11. SERVICE ................................................................................................................ 39

11.1. Warranty conditions ............................................................................................................. 39

11.2. Service ................................................................................................................................ 39

EN - 1

Page 4

EQUITEST 5071

1. PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with Standards IEC/EN61557 and

IEC/EN 61010-1 relevant to electronic measuring instruments.

For your safety and in order to prevent damaging the instrument, please

carefully follow the procedures described in this manual and read all notes

preceded by the symbol with the utmost attention.

Before and after carrying out the measurements, carefully observe the following

instructions:

Do not carry out any voltage or current measurement in humid environments

Do not carry out any measurements in case gas, explosive materials or flammables are

present, or in dusty environments

Avoid contact with the circuit being measured if no measurements are being carried out

Avoid contact with exposed metal parts, unused measuring probes, circuits, etc.

Do not carry out any measurement in case you find anomalies in the instrument such

as deformation, substance leaks, absence of display on the screen, etc.

Pay special attention when measuring voltages higher than 25V in special

environments (such as construction sites, swimming pools, etc.) and 50V in normal

environments, since a risk of electrical shock exists.

Only use original accessories.

In this manual, and on the instrument, the following symbols are used:

CAUTION: observe the instructions given in this manual; improper use could

damage the instrument, its components and create dangerous situations for the

operator.

CAUTION

Presence of dangerous voltage ( 30V): electrical shock hazard

Double-insulated meter

AC voltage or current

Connection to earth

1.1. PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in environments of pollution degree 2.

The instrument may be used for measuring and verifying the safety of electrical

systems of overvoltage category CAT III 300V (to earth) or CAT II 350V (to earth).

We recommend following the normal safety rules devised to protect the user against

dangerous currents and the instrument against incorrect use.

Only the accessories provided together with the instrument will guarantee safety

standards. If necessary, replace them with identical models.

Do not test circuits exceeding the specified current and voltage limits. Do not perform

any test under environmental conditions exceeding the limits indicated in § 10.3.

Check that the batteries are correctly inserted.

Before connecting the test leads to the circuit to be tested, make sure that the switch is

correctly set.

EN - 2

Page 5

EQUITEST 5071

1.2. DURING USE

Please carefully read the following recommendations and instructions:

CAUTION

Failure to comply with the caution notes and/or instructions may damage

the instrument and/or its components or be a source of danger for the

operator.

Before activating the rotary switch, disconnect the test leads from the circuit under test.

When the instrument is connected to the circuit under test, never touch any terminal,

even if unused.

Avoid measuring resistance if external voltages are present. Even if the instrument is

protected, excessive voltage could cause damage.

1.3. AFTER USE

When measurements are complete, turn off the instrument by pressing and holding the

ON/OFF key for some seconds.

If the instrument is not to be used for a long time, remove the batteries and follow the

instructions given in § 9.2.

DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard “IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements” defines what measurement

category, commonly called overvoltage category, is. § 6.7.4: Measured circuits, reads:

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of the low-

voltage installation

Examples are electricity meters and measurements on primary overcurrent protection

devices and ripple control units.

Measurement category III is for measurements performed inside buildings.

Examples are measurements on distribution boards, circuit breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and

equipment for industrial use and some other equipment, for example, stationary motors

with permanent connection to fixed installation.

Measurement category II is for measurements performed on circuits directly

connected to the low-voltage installation

Examples are measurements on household appliances, portable tools and similar

equipment

Measurement category I is for measurements performed on circuits not directly

connected to MAINS.

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the standard requires that the transient withstand capability of

the equipment is made known to the user.

EN - 3

Page 6

EQUITEST 5071

2. GENERAL DESCRIPTION

Instrument EQUITEST 5071 carries out the following measurements:

LOW: Continuity test of protective conductors with test current of 200mA in

compliance with standard IEC/EN61557-4

LOW10A: Continuity test of protective conductors with test current of 10A in

compliance with standard IEC/EN60439-1

LOW10AE60204: Continuity test of protective conductors with test current of 10A in

compliance with standard IEC/EN60204-1:2006.

LOOP/Ra : measurement of line impedance and fault loop impedance with

calculation of the assumed short-circuit current, also with high

resolution (0.1m) with optional accessory IMP57 / measurement of

overall earth resistance without causing the differential protections’

tripping (function RA) / phase rotation.

3. PREPARATION FOR USE

3.1. INITIAL CHECKS

Before shipping, the instrument has been checked from an electric as well as mechanical

point of view. All possible precautions have been taken so that the instrument is delivered

undamaged.

However, we recommend rapidly checking it to detect any damage possibly suffered

during transport. In case anomalies are found, immediately contact the Dealer.

We also recommend checking that the packaging contains all components indicated in §

10.4. In case of discrepancy, please contact the Dealer. In case the instrument should be

returned, please follow the instructions given in § 11.

3.2. INSTRUMENT POWER SUPPLY

The instrument is supplied by six 1.5V alkaline batteries type LR6 AA AM3 MN 1500, not

included in the package. For battery installation, follow the instructions given in § 9.2.

The instrument AUTOMATICALLY turns OFF display backlight after

approximately 5 seconds.

In order to extend the battery life, in case battery voltage is too low, the

instrument deactivates display backlighting.

3.3. CALIBRATION

The instrument has the technical specifications described in this manual. Its performance

is guaranteed for 12 months from the date of purchase.

3.4. STORAGE

In order to guarantee precise measurement, after a long storage time under extreme

environmental conditions, wait for the instrument to come back to normal condition (see

§ 10.3)

CAUTION

EN - 4

Page 7

EQUITEST 5071

4. INSTRUMENT DESCRIPTION

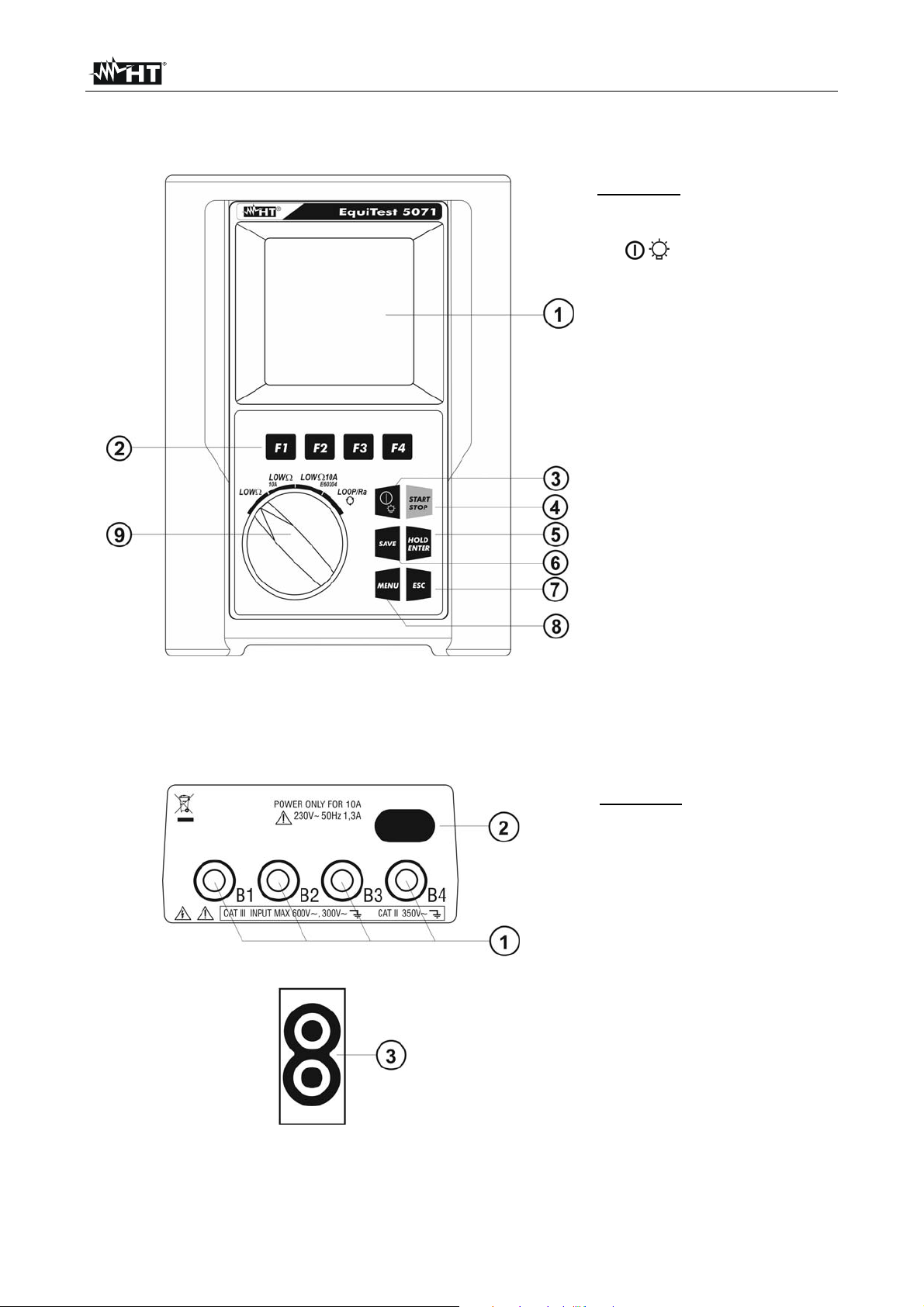

4.1. FRONT PANEL

CAPTION:

1. LCD display

2. F1, F2, F3, F4 keys

3. / key

4. START/STOP key

5. HOLD/ENTER key

6. SAVE key

7. ESC key

8. MENU key

9. Rotary selector switch

Fig. 1: Description of the instrument’s front panel

4.2. INPUT AND OUTPUT LEADS

CAPTION:

1. B1, B2, B3, B4 inputs

2. Input for external

230V/50Hz power supply

for functions LOW10A

and LOW10AE60204

3. Optical serial output for

PC connection

Fig. 2: Description of the instrument’s inputs and outputs

EN - 5

Page 8

EQUITEST 5071

4.3. DESCRIPTION OF FUNCTION KEYS

Key Description

Key to switch on/off the instrument. Press and hold the key for

/

some seconds to turn off the instrument. Shortly press this key

to activate display backlighting.

F1, F2, F3, F4

Keys for programming the internal parameters associated with

the functions of the instrument.

START/STOP Key for starting measuring. STOP function not enabled.

SAVE Key for saving measurement results.

HOLD/ENTER

ENTER key to confirm the parameters set within the general

menu of the instrument. HOLD function not enabled.

MENU Key to access the instrument’s general menu.

ESC Key to quit the selected mode shown on the display.

4.4. DISPLAY DESCRIPTION

The display is a graphic module with a resolution of 128 x 128 dots. The first line of the

display shows the instrument’s date and time. In the top right-hand corner of the display

there is the battery charge indicator.

LOW 30.11.12

----

R+ R-

---- ----

---mA ---mA

AUTO 0.11

FUNC CAL

For the sake of brevity, these symbols will be omitted in the following screenshots of this

manual.

4.5. INITIAL SCREEN

When turning on the instrument with the / key, the following screen appears for a few

seconds:

It contains (further to the name of the Manufacturer and to

HT5071

the instrument model):

The serial number (SN:) of the instrument.

HT

SN:12345678 V: 1.59

Baud Rate 57600

CALIBRATION DATE:

30.11.12

The firmware version (V:) in the instrument's memory.

The date of the last instrument calibration

(CALIBRATION DATE).

The serial transmission speed (Baud Rate).

Press ESC to exit this screen.

EN - 6

Page 9

EQUITEST 5071

4.6. BACKLIGHT

During instrument operation, a further short pressing of the / key turns on the display’s

backlighting. In order to save battery efficiency, backlighting automatically turns off after

approx. 5 seconds. A frequent use of backlighting reduces the batteries’ life.

5. INITIAL SETTINGS

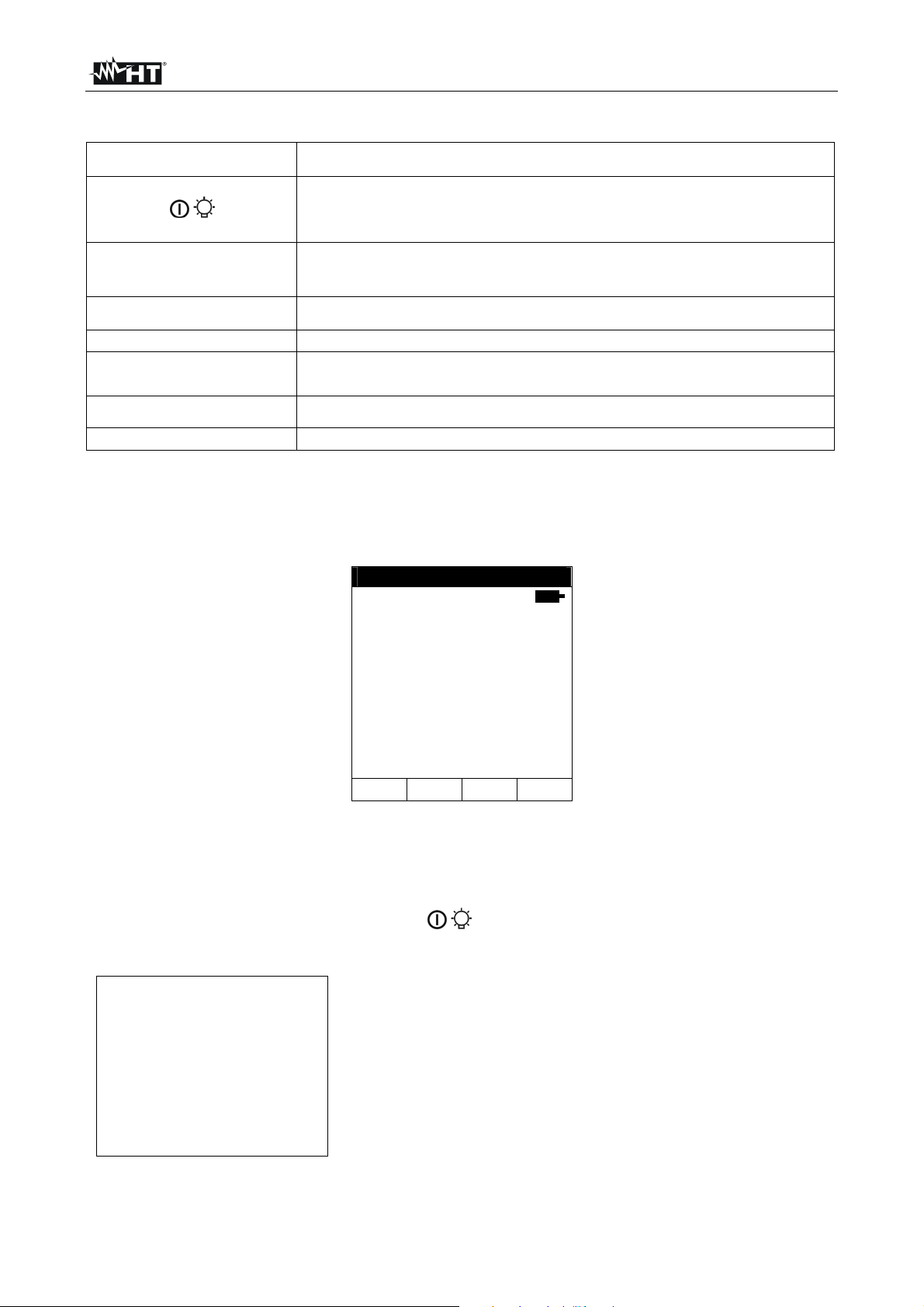

When pressing the MENU key, the display shows the following screen, which allows

accessing the General Menu:

GENERAL MENU

SAFETY TEST MEMORY

CONTRAST

DATE&TIME

LANGUAGE

The following items are available:

Safety Test Memory memory area for saving measuring results.

Contrast function to adjust display contrast.

Date&Time function to adjust system date/time.

Language function to select system language.

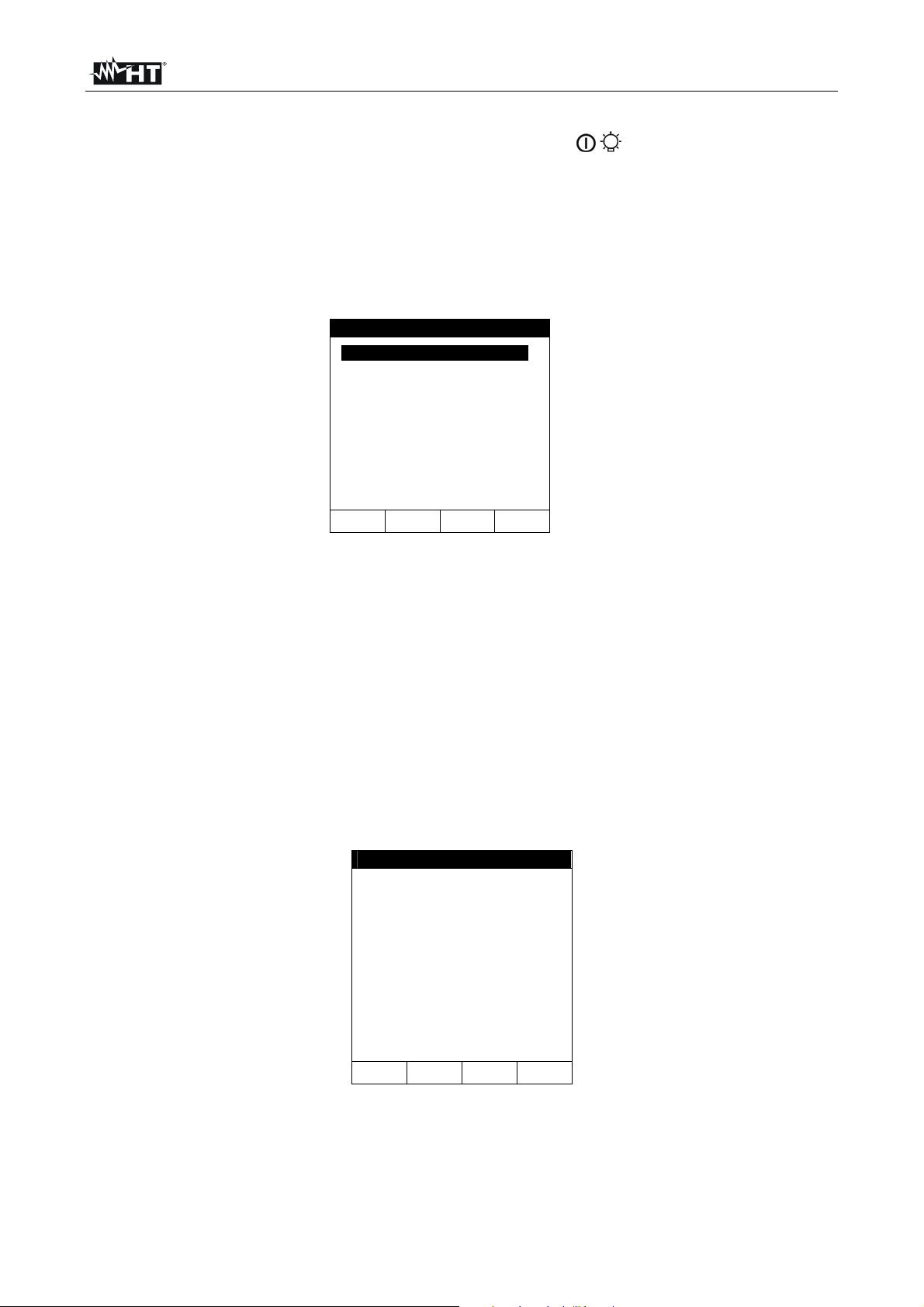

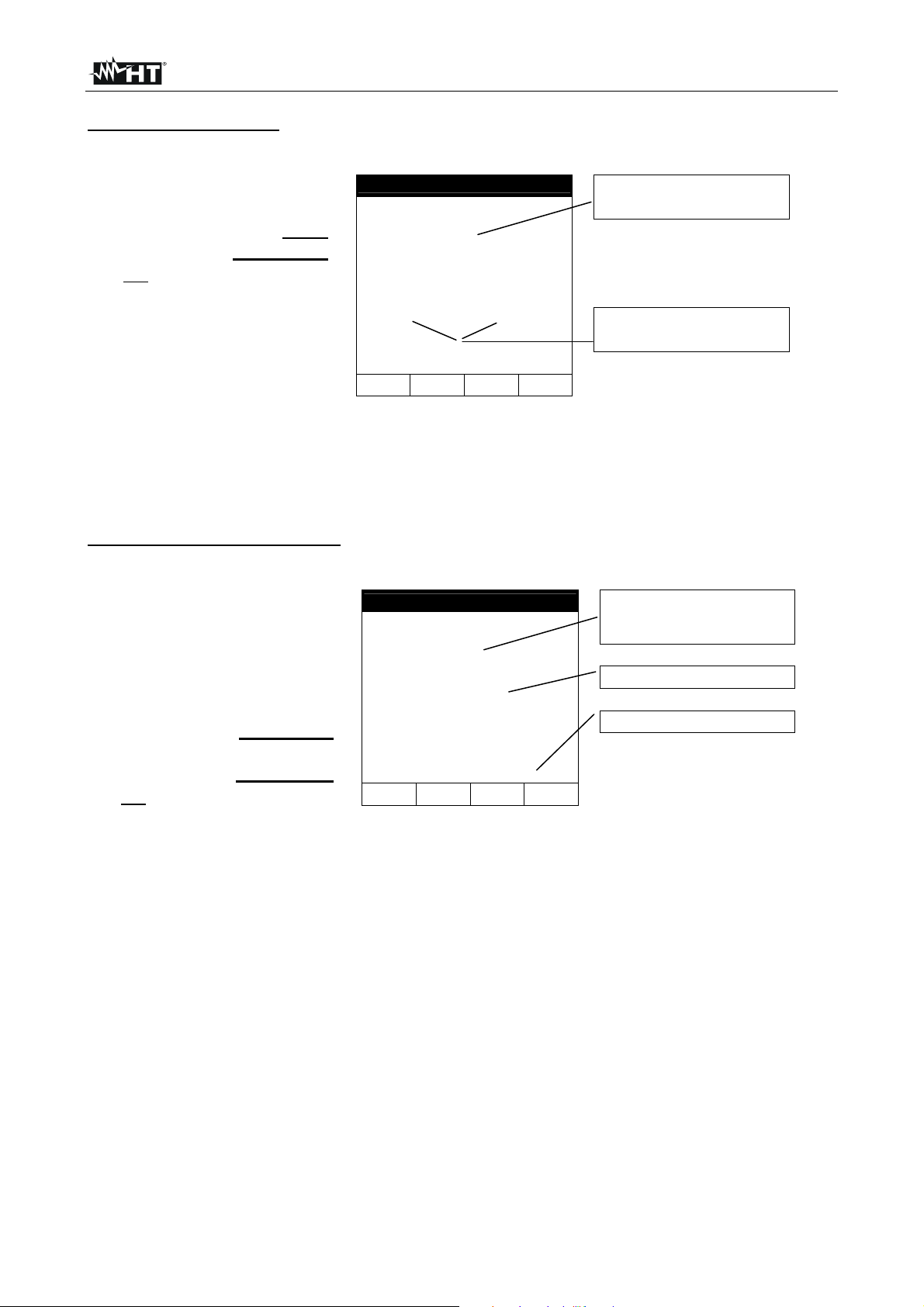

5.1. ADJUSTING DISPLAY CONTRAST

Proceed as follows:

1. Press the MENU key with the selector switch in any position to enter the General

Menu.

2. Use the F1 key to move the cursor to “CONTRAST”. Confirm with ENTER. The

following screen appears on the display:

CONTRAST

CONTRAST

35%

+ -

3. Use the F3 and F4 keys to set the desired percentage value.

4. Press the ENTER key to confirm. The settings made shall remain valid also after

switching off the instrument.

5. Press the ESC key to exit without saving.

EN - 7

Page 10

EQUITEST 5071

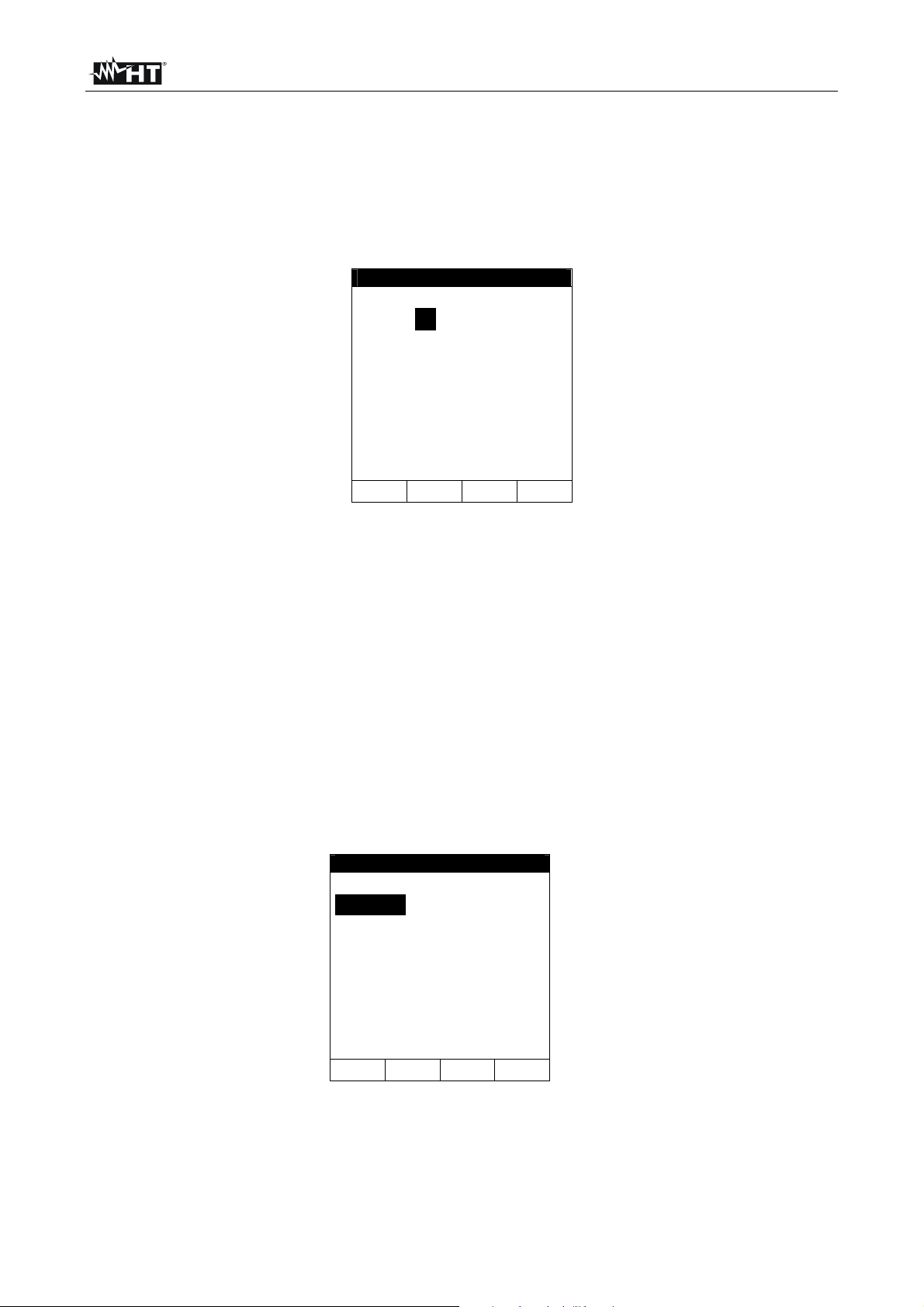

5.2. ADJUSTING DATE AND TIME

Proceed as follows:

1. Press the MENU key with the selector switch in any position to enter the General

Menu.

2. Use the F1 key to move the cursor to “DATE&TIME”. Confirm with ENTER. The

following screen appears on the display:

DATE&TIME

25 . 08 . 12

15 : 25 : 00

+ -

3. Use the F1 and F2 keys to alternately select the date and time fields. The selected field

appears with a black background. The date is expressed with format: “gg.mm.aa” while

time is expressed in format: “hh:mm:ss”

4. Use the F3 and F4 keys to increase or decrease the value of date/time.

5. Press the ENTER key to confirm. The settings made shall remain valid also after

switching off the instrument.

6. Press the ESC key to exit without saving.

5.3. LANGUAGE SETTING

Proceed as follows:

1. Press the MENU key with the selector switch in any position to enter the General

Menu.

2. Use the F1 key to move the cursor to “LANGUAGE”. Confirm with ENTER. The

following screen appears on the display:

LANGUAGE

ITALIAN

ENGLISH

SPANISH

GERMAN

FRENCH

3. Use the F1 and F2 keys to select the desired language among those available.

4. Press the ENTER key to confirm. The settings made shall remain valid also after

switching off the instrument.

5. Press the ESC key to exit without saving.

EN - 8

Page 11

EQUITEST 5071

6. OPERATING INSTRUCTIONS

6.1. LOW: CONTINUITY OF PROTECTIVE CONDUCTORS WITH 200mA

Measurement is carried out in compliance with standard IEC/EN61557-4.

Before carrying out the continuity test, make sure there is no voltage at the

ends of the conductor to be analyzed.

Turn the rotary switch to LOW.

With the F1 key it is possible to select one of the following measuring modes

(which cyclically appear when pressing the key):

“AUTO” mode (the instrument carries out two measurements with

inverted polarity and displays their average value). Recommended mode

for continuity test

“RT+” mode (measurement with positive polarity and with the possibility

of setting a duration time for testing). In this case, the operator may set a

sufficiently long measuring time to be able to move the protective

conductors while the instrument is carrying out the test, in order to find

out a possible bad connection.

“RT-” mode (measurement with negative polarity and with the possibility

of setting a duration time for testing). In this case, the operator may set a

sufficiently long measuring time to be able to move the protective

conductors while the instrument is carrying out the test, in order to find

out a possible bad connection.

With the F2 key it is possible to select the “CAL“ mode (compensation of the

resistance of the cables used for measuring).

CAUTION

CAUTION

Continuity test is carried out by applying a current higher than 200mA in

case resistance does not exceed 5 (including the measuring cables’

resistance saved as offset value in the instrument after carrying out the

calibration procedure). For higher resistance values, the instrument carries

out the test with a current lower than 200mA.

EN - 9

Page 12

EQUITEST 5071

A

6.1.1. Calibration of measuring cables

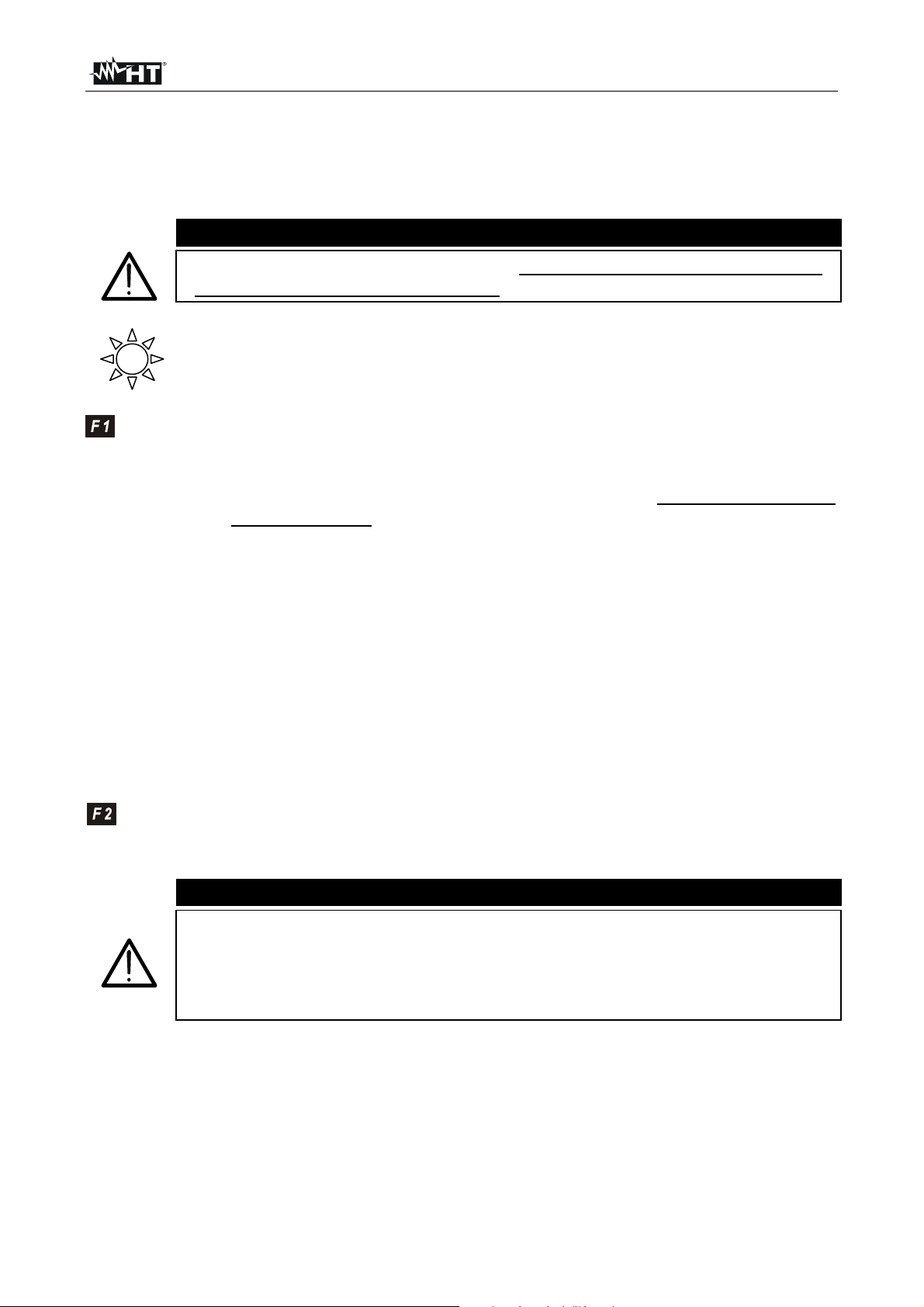

1. Insert the black cable and the blue cable into the relevant input terminals B1 and B4 of

the instrument.

Fig. 3: Terminal connection during calibration procedure

2. If, for the measurement to be carried out, the length of the cables provided should be

insufficient, extend the blue cable.

3. Insert two alligator clips into the cable terminals.

4. Short-circuit the measuring cables’ ends, taking care that the conductive parts of the

alligator clips have good contact (see Fig. 3)

5. Press the F2 key. The instrument calibrates.

CAUTION

Never disconnect the terminals from the measuring points when the

instrument shows the message "MEASURING…".

LOW 30.11.12

----

R+ R-

---- ----

---mA ---mA

UTO 0.11

FUNC CAL

This numerical

value indicates

that calibration has

been carried out

6. At measurement end, the instrument gives out a double sound, to indicate that

calibration has been correctly carried out. The value of calibration is updated and

displayed above the F2 key. This value shall remain saved also after the instrument

has been switched off.

CAUTION

The instrument calibrates the measuring cables only if their resistance is

lower than 5

Before carrying out any measurement, always make sure that calibration

is referred to the cables currently used. In a continuity test, if the purified

resistance value (i.e. the value of resistance minus the calibration offset

value) is negative, the symbol “CAL” flashes on the display.

7. To delete the calibration parameter it is necessary to carry out a calibration

procedure with a lead resistance higher than 5 (e.g. with open leads). When

carrying out a deletion, the symbol “- - -“ is shown on the display above the F2 key.

EN - 10

Page 13

EQUITEST 5071

6.1.2. Measuring

1. Select the desired mode using the F1 key.

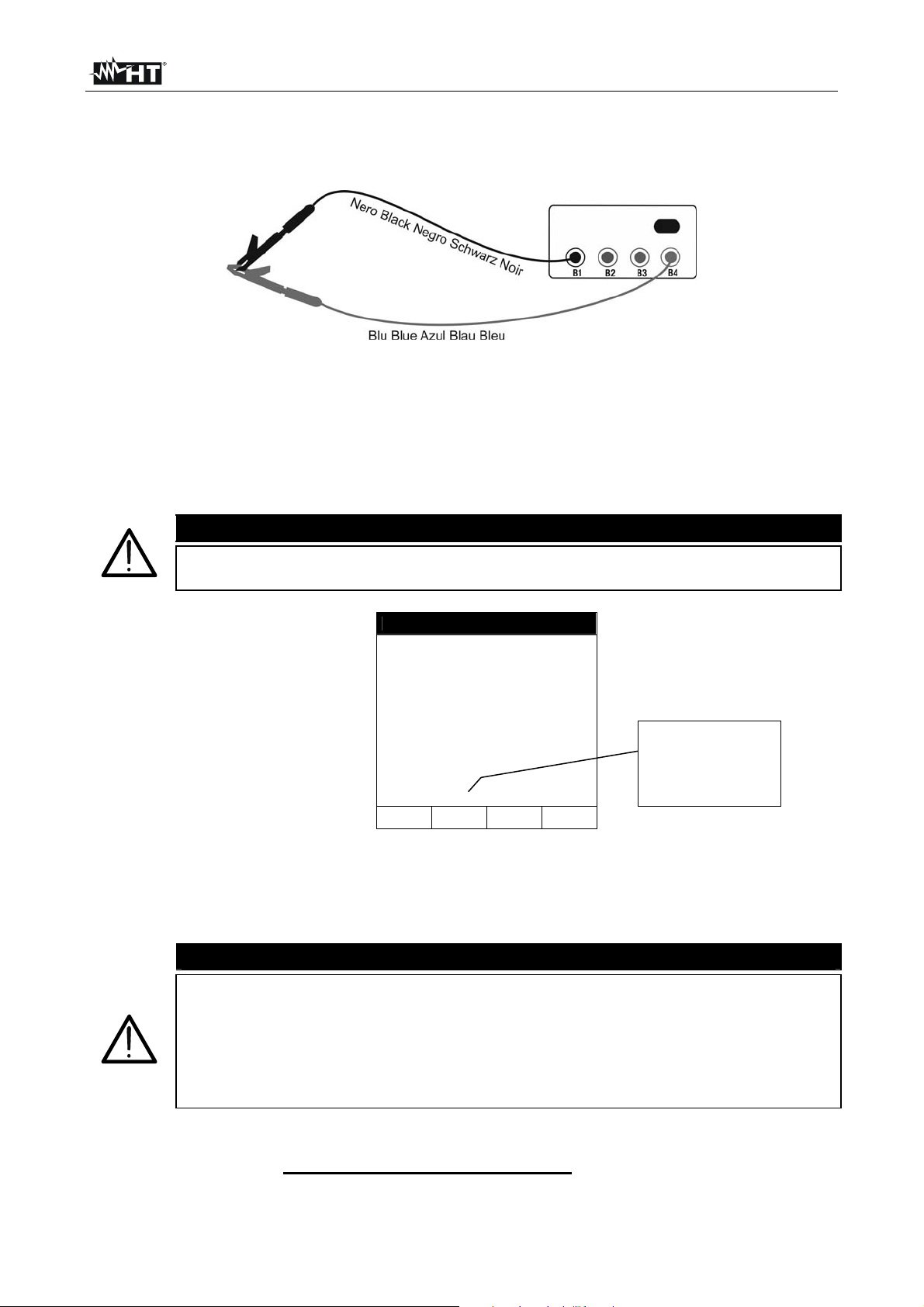

2. Insert the black cable and the blue cable into the relevant input terminals B1 and B4 of

the instrument:

Fig. 4: Instrument connection for LOW test

3. If, for the measurement to be carried out, the length of the cables provided should be

insufficient, extend the blue cable.

4. Insert two alligator clips into the cable terminals.

5. Short-circuit the measuring cables’ ends, taking care that the conductive parts of the

alligator clips have good contact. Press the START/STOP key. If the instrument

shows a resistance value different from 0,00 repeat the calibration operation (see

§ 6.1.1)

6. Connect the instrument terminals to the ends of the conductor whose continuity you

want to test (see Fig. 4)

7. If mode "RT+" or "RT-" is selected, use the F3, F4 keys to set the test time.

8. Press the START/STOP key. The instrument carries out the measurement. In "RT+" or

"RT-" mode, press the START/STOP key again to stop the test.

CAUTION

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

EN - 11

Page 14

EQUITEST 5071

A

A

T

"AUTO" mode results

t the end of the test, in

case the average value

of resistance Ravg

measured is lower than

5, the instrument gives

out a double sound to

signal the positive

result of the test. The

following screen

appears on the display:

LOW 30.11.12

1.05

R+ R-

1.07 1.03

219mA 219mA

AUTO 0.11

FUNC CAL

verage value of

resistance Ravg

Value of test current

The results can be saved by pressing the SAVE key twice (see § 7.1).

"RT+" or “RT-" mode results

During the test, an

audible beep sounds in

case the measured

resistance value exceeds

99.9.

If, at the end of the test,

the maximum RT+ or RT-

resistance value

measured is lower than

5, the instrument gives

out a double sound to

LOW 30.11.12

1.07

RT+ 0.11

FUNC CAL

219mA

IME: 10s

Maximum value of

resistance measured

during test

Test current

Duration of test

signal the positive

result of the test. The

following screen appears

on the display:

The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 12

Page 15

EQUITEST 5071

6.1.2.1. Anomalous situations in "AUTO", "RT+", "RT-" mode

If the instrument detects

a voltage higher than

approx. 15V at the input

terminals, the message

to the side appears on

the display.

If the instrument detects

that:

R

CALIBRATION

the message to the side

appears on the display.

> R

MEASURED

LOW 30.11.12

R+ R-

-.-- -.--

---mA ---mA

AUTO 0.11

FUNC CAL

LOW 30.11.12

R+ R-

0.00 0.00

219mA 219mA

AUTO 0.11

FUNC CAL

-.- -

VOLT IN INPUT

0.00

CAL > RES

The test cannot be

carried out because

voltage has been

detected at the

instrument’s inputs

CAUTION:

R

CALIBRATION

> R

MEASURED

In case a resistance

higher or equal to 5

but lower than 99,9 is

detected, at the end of

the test the instrument

gives out a long sound

and the following screen

appears on the display.

PREVIOUS RESULTS CANNOT BE SAVED.

LOW 30.11.12

5.17

R+ R-

5.17 5.17

209mA 209mA

AUTO 0.11

FUNC CAL

Resistance higher than 5

Test current

The results can be saved by pressing the SAVE key twice (see § 7.1).

In case a resistance

higher than 99,9 is

detected, at the end of

the test the instrument

gives out a long sound

and the following screen

appears on the display.

LOW 05.06.12

> 99.9

R+ R-

-.-- -.--

---mA ---mA

AUTO 0.11

FUNC CAL

Resistance with a value

higher than 99.9

CAUTION: Resistance

value out of range

The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 13

Page 16

EQUITEST 5071

6.2. LOW10A: CONTINUITY OF PROTECTIVE CONDUCTORS WITH 10A

Measurement is carried out in compliance with standards IEC/EN60439-1.

Measurement is carried out by voltammetric method with 4 wires. Therefore, the calculated

value is not influenced by the value of resistance of the measuring cables, so it is not

necessary to carry out any preventive calibration of the cables used for measuring (unlike

with function LOW).

CAUTION

Before carrying out the continuity test, make sure there is no voltage at the

ends of the conductor to be analyzed.

Measurement may be influenced by parallel impedance of additional

circuits or by transient currents. Make sure none of these parasite

elements is present before measuring and always keep test cables

outstretched in order to prevent “coil effects”.

CAUTION

The instrument performs the test with a current 10A only if resistance is

lower than approx. 0.45.

6.2.1. Measuring

1. Turn the rotary switch to LOW10A. The following screen appears on the display:

LOW 10A 30.11.12

-----

RLIM: 0.100

----A

2. Use the F3 and F4 keys to set the maximum limit threshold RLIM for measurement in

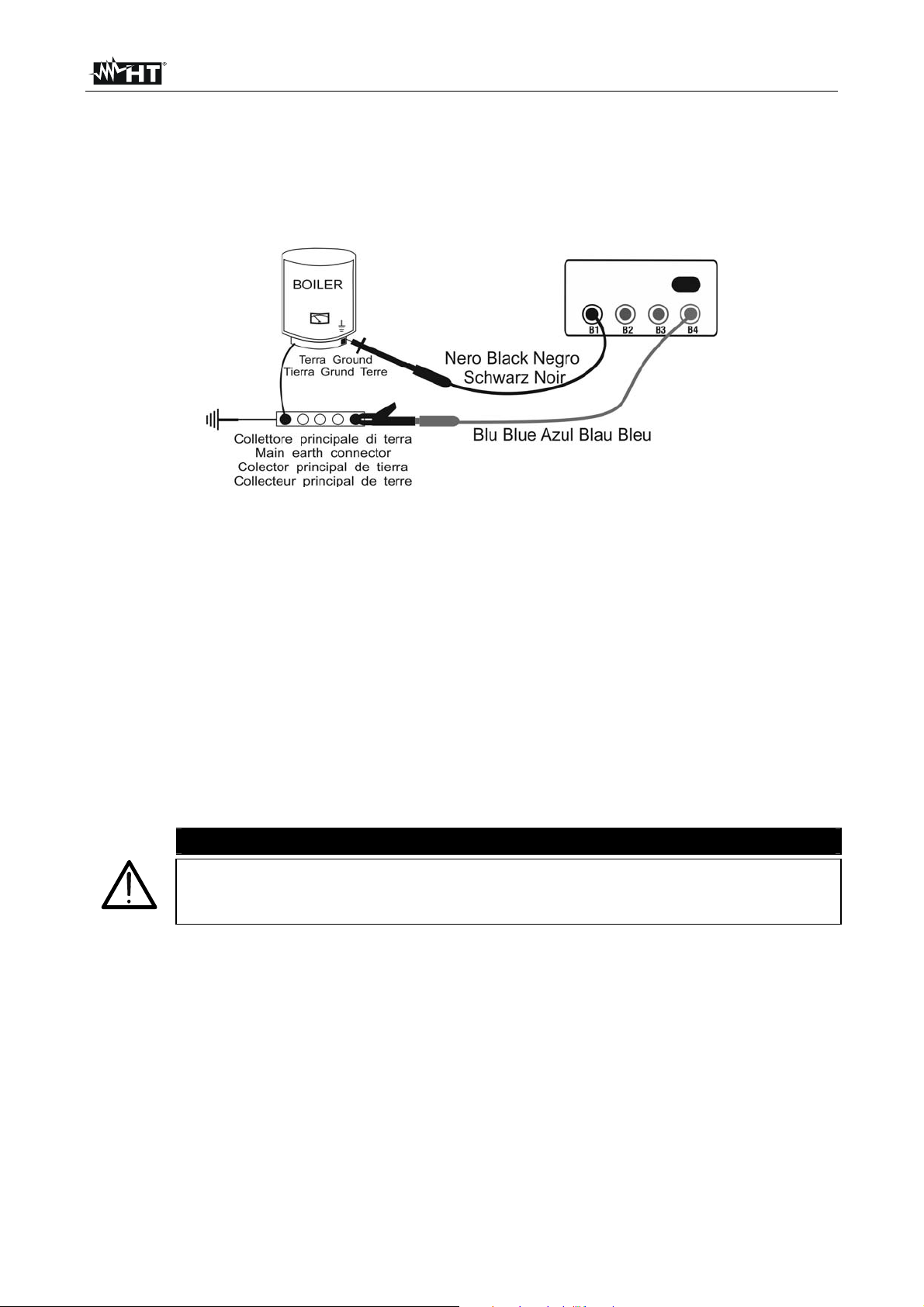

range 0.001 0.999. Keep the function keys pressed for a quick setting of the

desired value

3. Supply the instrument by connecting it to the 230V/50Hz electric mains (see Fig. 2 –

position 2) by means of the cable provided.

4. Connect the connectors of the measuring cables C7000 provided to the instrument’s

input terminals B1 (Black), B2 (Red), B3 (Red), B4 (Black) and the alligator clips to the

item to be tested as indicated in Fig. 5

EN - 14

Page 17

EQUITEST 5071

A

Fig. 5: Instrument connection for LOW10A test

5. Press the START key. The instrument starts testing.

CAUTION

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

t the end of the test, the

instrument gives out a

double sound to indicate

that test has been

correctly performed and

the following screen

appears on the display.

LOW 10A 31.11.12

0.107

13.4A

RLIM:0.100

Measured resistance

Test current

6. The displayed results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 15

Page 18

EQUITEST 5071

R

6.2.2. Anomalous situations

If the instrument does not

detect any power supply

at connector "230V 50Hz",

it displays the message

reported to the side.

LOW 10A 31.11.12

-----

----A

NO POWER SUPPLY

LIM=0.100

If the instrument detects

a resistance higher than

the limit set, it gives out

a long sound and the

following screen

appears on the display.

LOW 10A 31.11.12

0.323

9.12A

RLIM=0.100

Symbol indicates a

resistance higher than the

limit set.

Test current

The displayed results can be saved by pressing the SAVE key twice (see § 7.1).

If the instrument detects

a resistance higher than

the maximum

measurable value, it

gives out a long sound

and the following screen

appears on the display.

LOW 10A 31.11.12

>0.999

9.12A

RLIM=0.100

Symbol ">" indicates a

resistance higher than the

maximum measurable

value.

Test current

The displayed results can be saved by pressing the SAVE key twice (see § 7.1)

EN - 16

Page 19

EQUITEST 5071

6.3. LOW10AE204: CONTINUITY 10A IN COMPLIANCE WITH IEC/EN602041:2006

Measurement is carried out in compliance with standard IEC/EN60204-1:2006, which

states that measurement result must be compatible with the protective conductor’s length,

section and material.

The instrument evaluates the limit threshold of measured resistance according to the

following formula:

L

lim

R

S

in which:

L = length in m of the protective conductors being tested, decided by the user

according to design calculations;

S= section in mm2 of the protective conductor being tested;

= resistivity of copper set to the standard average value of 0.017mm2/m.

Measurement is carried out by voltammetric method with 4 wires. Therefore, the calculated

value is not influenced by the value of resistance of the measuring cables, so it is not

necessary to carry out any preventive calibration of the cables used for measuring (unlike

with function LOW).

CAUTION

Before carrying out the continuity test, make sure there is no voltage at the

ends of the conductor to be analyzed.

Measurement may be influenced by parallel impedance of additional

circuits or by transient currents. Make sure none of these parasite

elements is present before measuring and always keep test cables

outstretched in order to prevent “coil effects”.

CAUTION

The instrument performs the test with a current 10A only if resistance is

lower than approx. 0.45.

EN - 17

Page 20

EQUITEST 5071

6.3.1. Measuring

1. Turn the rotary switch to LOW10AE204. The following screen appears on the display:

LOW10AE204 30.11.12

-----

LEN: 10.0 SEC: 4.0

----A

2. Use the F1 and F2 keys to set the length in range 0.1m 999.9m and keys F3 and F4

to set the section of the protective conductor being tested, selecting the values 0.5, 1,

1.5, 2.5, 4, 6, 10, 16mm2. Keep the function keys pressed for a quick setting of the

desired values

3. Supply the instrument by connecting it to the 230V/50Hz electric mains (see Fig. 2 –

position 2) by means of the cable supplied.

4. Connect the connectors of the measuring cables C7000 provided to the instrument’s

input terminals B1 (Black), B2 (Red), B3 (Red), B4 (Black) and the alligator clips to the

item to be tested as indicated in Fig. 6

Fig. 6: Instrument connection for LOW10AE204 test

EN - 18

Page 21

EQUITEST 5071

A

5. Press the START key. The instrument starts testing.

CAUTION

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

t the end of the test, the

instrument gives out a

double sound to indicate

that test has been

correctly performed and

the following screen

appears on the display.

LOW 10A 31.11.12

0.012

22.7A

LEN: 10.0 SEC: 4.0

Measured resistance

Test current

6. The displayed results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 19

Page 22

EQUITEST 5071

6.3.2. Anomalous situations

If the instrument does not

detect any power supply

at connector "230V 50Hz",

it displays the message

reported to the side.

LOW10AE204 30.11.12

-----

----A

NO POWER SUPPLY

LEN: 10.0 SEC: 4.0

If the instrument detects

a resistance higher than

the limit set, it gives out

a long sound and the

following screen

appears on the display.

LOW10AE204 30.11.12

0.323

9.12A

LEN: 10.0 SEC: 4.0

Symbol indicates a

resistance higher than the

limit set.

Test current

The displayed results can be saved by pressing the SAVE key twice (see § 7.1).

If the instrument detects

a resistance higher than

the maximum

measurable value, it

gives out a long sound

and the following screen

appears on the display.

LOW10AE204 30.11.12

>0.999

9.12A

LEN: 10.0 SEC: 4.0

Symbol ">" indicates a

resistance higher than the

maximum measurable

value.

Test current

The displayed results can be saved by pressing the SAVE key twice (see § 7.1)

EN - 20

Page 23

EQUITEST 5071

6.4. LOOP/RA : LOOP IMPEDANCE, OVERALL EARTH RESISTANCE AND

PHASE SEQUENCE

Measurement is carried out in compliance with standards IEC/EN61557-3 and

IEC/EN60204-1:2006.

Turn the rotary switch to LOOP/Ra .

With the F1 key it is possible to select one of the following measuring modes

(which cyclically appear when pressing the key):

“P-N” mode (the instrument measures impedance between Phase

conductor and Neutral conductor and calculates the assumed PhaseNeutral short-circuit current. This test is usually carried out to evaluate if

the breaking power of switches is higher than short-circuit current in the

installation point).

“P-P” mode (the instrument measures impedance between two Phase

conductors and calculates the assumed Phase-Phase short-circuit

current. This test is usually carried out to evaluate if the breaking power

of switches is higher than short-circuit current in the installation point).

“P-PE” mode (the instrument measures the overall earth resistance and

calculates the assumed Phase-Earth short-circuit current. This test is

usually carried out to evaluate the coordination of the protections against

indirect contact by means of an automatic interruption of power supply

and to measure the value of Earth resistance).

“RA” mode (the instrument measures the overall earth resistance and

calculates the assumed Phase-Earth short-circuit current. This test is

usually carried out to evaluate the coordination of the protections against

indirect contact by means of an automatic interruption of power supply

and to measure the value of Earth resistance. This test has a lower

resolution than “P-PE” test, but has the advantage that it can be carried

out without making a possible residual current protection, installed

upstreams of the measuring point, trip).

“ ” mode (the instrument detects phase sequence).

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

CAUTION

EN - 21

Page 24

EQUITEST 5071

3

6.4.1. High-resolution impedance measurement (0.1 m)

The instrument allows measuring impedance with a high resolution next to a MT/BT

transformer by using the optional accessory IMP57. Measurement is selectable in modes

LOOP P-P, P-N, P-PE by means of the F2 key (Z2). In case high-resolution impedance

measurement is selected with no connection of the accessory IMP57, the instrument shows a

screen similar to the following one (e.g.: Loop P-N):

LOOP

V1-2= 0V FRQ= 0.0Hz

P-N Z2

Z=-----

R=----- X=-----

IkSTD=----A

NO IMP57

FUNC ZSTD ICAL RMT

0.11.12

For any detail regarding the use and the technical specifications of accessory IMP57,

please refer to the relevant user manual or visit the website www.ht-instruments.com.

6.4.2. "P-N" mode: measurement procedure and results

1. Select the P-N mode using the F1 key.

2. Insert the 3 Black, Green, Blue connectors of the three-pin shuko cable or of the separate

cables into the relevant instrument input terminals B1, B3, B4 (see F ig. 7, Fig. 8). In case

separate cables are used, insert alligator clips on the free cable ends.

Fig. 7: Connection for measuring Loop

impedance of single-phase/two-phase

Fig. 8: Connection for measuring Loop

impedance of three-phase 400V system

230V system

3. Insert the Shuko plug into a 230V 50Hz socket or the alligator clips onto the conductors

of the three-phase system (see Fig. 7, Fig. 8)

4. When possible, disconnect all loads connected downstreams of the measuring point since

the impedance of these users may alter test results.

5. Press the START key. The instrument carries out the test.

EN - 22

Page 25

EQUITEST 5071

A

3

CAUTION

The following test entails the circulation of a maximum current of approx. 6A

between phase and neutral. This could cause the tripping of possible

magnetothermal protections with lower tripping currents. In this case, carry

out the measurement upstreams of the protections.

CAUTION

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

t the end of the test,

the instrument gives out

a double sound to

indicate that test has

been correctly

performed and the

following screen

appears on the display.

LOOP

1.07

FRQ=50.0HZ

VP-N=231V VP-PE=231V

P-N

FUNC Z2

215A

0.11.12

Value of Phase-Neutral Line

impedance expressed in

Ohm

Value of the assumed PhaseNeutral short-circuit current

calculated using the formula

reported below

Formula used for calculating the assumed short-circuit current:

U

I

CC

N

Z

PN

where U

= Phase-Neutral voltage 127 if V

N

230 if 150V< V

150

mis

mis

260

Z

= measured Phase-Neutral impedance

PN

6. The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 23

Page 26

EQUITEST 5071

A

3

6.4.3. "P-P" mode: measurement procedure and results

1. Select the P-P mode using the F1 key.

2. Insert the 3 Black, Green, Blue connectors of the separate cables into the relevant

instrument input terminals B1, B3, B4.

Fig. 9: Instrument connection for measuring Phase-Phase impedance

3. Insert the alligator clip s onto the conductors of the three-phase system (see Fig. 9)

4. When possible, disconnect all loads connected downstreams of the measuring point

since the impedance of these users may alter test results

5. Press the START key. The instrument carries out the test.

CAUTION

The following test entails the circulation of a maximum current of approx.

12A (400V) between phase and phase. This could cause the tripping of

possible magnetothermal protections with lower tripping currents. In this

case, carry out the measurement upstreams of the protections.

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s

leads during this phase.

t the end of the test,

the instrument gives out

a double sound to

indicate that test has

been correctly

performed and the

following screen

appears on the display.

Operating mode

Formula used for calculating the assumed short-circuit current:

where UN = Phase-Phase voltage 127 if V

Z

LOOP

0.57

FRQ=50.0HZ

VP-P=402V VP-PE=231V

P-P

FUNC Z2

= measured Phase-Phase impedance

PP

701A

0.11.12

230 if 150V< V

400 if V

Value of Phase-Phase Line

impedance expressed in

Ohm

Value of the assumed PhasePhase short-circuit current

calculated using the formula

reported below

U

N

Z

PP

mis

> 260

mis

150

mis

260

I

CC

3. The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 24

Page 27

EQUITEST 5071

6.4.4. "P-PE" mode: measurement procedure and results

1. Select the P-PE mode using the F1 key.

2. Insert the 3 Black, Green, Blue connectors of the shuko cable or of the separate cables into

the relevant instrument input terminals B1, B3, B4 (see Fig. 10, Fig. 11, Fig. 12). In case

separate cables are used, insert alligator clips on the free cable ends.

Fig. 10: Connection for measuring P-PE

impedance of single-phase/two-phase

230V system

Fig. 11: Connection for measuring P-PE

impedance of three-phase 400V + N

system

Fig. 12: Connection for P-PE impedance of three-phase 230V o 400V system without N

3. Insert the Shuko plug into a 230V 50Hz socket or the alligator clips onto the conductors

of the three-phase system (see Fig. 10, Fig. 11, Fig. 12)

4. The F4 key allows setting the limit value for contact voltage. The instrument carries out

the test, checking that the contact voltage found on the system masses, with regard to

the actual current applied, does not exceed the limit value set. You may select one of

the two possible values: 50V (default), 25V

5. Press the START key once. The instrument carries out the test by circulating a current

of type "0°". Otherwise, press the START key twice before the dashes disappear. The

instrument carries out the test by circulating a current of type "180°".

CAUTION

The following test entails the circulation of a current of approx. 6A

between phase and earth. This could cause the tripping of possible

magnetothermal or residual current protections. In this case, carry out the

measurement upstreams of the protection. In case of AC residual current

protections you may try and detect what kind of waveform (type 0° or type

180°) does not cause the protection’s tripping.

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s

leads during this phase.

EN - 25

Page 28

EQUITEST 5071

A

3

t the end of the test,

the instrument gives out

a double sound to

indicate that test has

been correctly

performed and the

following screen

appears on the display.

LOOP

1.07

Freq=50.0HZ

VP-N=231V Vp-PE=231V

P-PE

FUNC Z2

215A

0.11.12

Value of Phase-Earth

impedance expressed in .

Value of the assumed PhasePhase short-circuit current

calculated using the formula

reported below

Operating mode

N.B.: In TT systems, the value of impedance measured by the instrument may only be

attributed to the value of overall earth resistance. Therefore, in compliance with

standard CEI 64-8, the measured value may be taken as the value of the system’s

earth resistance.

U

Formula used for calculating the assumed short-circuit current:

I

CC

N

Z

PE

where: UN = Phase-Earth voltage 127 if

100< V

Z

150

mis

230 if 150V< V

= measured Phase-Earth impedance

PE

mis

260

6. The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 26

Page 29

EQUITEST 5071

6.4.5. "RA" mode: measurement procedure and results

1. Select the RA mode using the F1 key.

2. Insert the 3 Black, Green, Blue connectors of the shuko cable or of the separate cables into

the relevant instrument input terminals B1, B3, B4 (see Fig. 13, Fig. 14, Fig. 15). In case

separate cables are used, insert alligator clips on the free cable ends.

Fig. 13: Connection for Ra measuring of

single-phase/two-phase 230V system

Fig. 14: Connection for Ra measuring of

three-phase 400V + N system

Fig. 15: Connection for Ra measuring of three-phase 230V o 400V system without N

3. Insert the Shuko plug into a 230V 50Hz socket or the alligator clips onto the conductors

of the three-phase system (see Fig. 13, Fig. 14, Fig. 15)

4. The F4 key allows setting the limit value for contact voltage. The instrument carries out

the test, checking that the contact voltage found on the system masses, with regard to

the actual current applied by the instrument, does not exceed the limit value set for

contact voltage. You may select one of the two possible values: 50V (default), 25V

5. Press the START/STOP key once. The instrument carries out the test by circulating a

current of type "0°". Otherwise, press the START/STOP key twice before the dashes

disappear. The instrument carries out the test by circulating a current of type "180°".

CAUTION

The following test entails the circulation of a current of approx. 15mA

between phase and earth. This could cause the tripping of possible

residual current protections with rated current of 10mA. In this case, carry

out the measurement upstreams of the protection.

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s

leads during this phase.

EN - 27

Page 30

EQUITEST 5071

A

3

A

t the end of the test,

the instrument gives out

a double sound to

indicate that test has

been correctly

performed and the

following screen

appears on the display.

Operating mode

LOOP

1.07

Freq=50.0HZ

VP-N=231V Vp-PE=231V

R

FUNC

215A

0.11.12

Value of Phase-Earth

resistance expressed in

Value of the assumed PhaseEarth short-circuit current

calculated using the formula

reported below

N.B. In TT systems, the value of overall earth resistance may be considered similar to

the value of Phase-Earth fault loop impedance, measured by the instrument.

Therefore, in compliance with standards, the measured value may be taken as the

value of the system’s earth resistance.

Formula used for calculating the assumed short-circuit current:

U

I

CC

N

Z

PE

where: UN = Phase-Earth voltage 127 if

100< V

Z

150

mis

230 if 150V< V

= measured Phase-Earth impedance

PE

mis

260

6. The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 28

Page 31

EQUITEST 5071

A

3

6.4.6. " " mode: measurement procedure and results

1. Select the " " mode using the F1 key.

2. Insert the 3 Black, Blue, Green connectors of the separate cables into the relevant

instrument input terminals B1, B2, B3.

Fig. 16: Instrument connection for phase sequence test

3. Insert the alligator clips onto the conductors of the three-phase system (see Fig. 16)

4. Press the START key. The instrument carries out the test.

CAUTION

When message "MEASURING…" is displayed, this indicates that the

instrument is carrying out the test. Never disconnect the instrument’s leads

during this phase.

t the end of the test,

the instrument gives out

a double sound to

indicate that test has

been correctly

performed and the

following screen

appears on the display.

Operating mode

123

FRQ=50.0HZ V1-2=391V

V2-3=401V V3-1=399V

PHASE ROTATION

FUNC

OK

0.11.12

Phase sequence indication

123

Phase-Phase voltage values

Correct phase sequence

5. The results can be saved by pressing the SAVE key twice (see § 7.1).

CAUTION

Message “123” DOES NOT mean that Input B1 is connected to phase L1,

Input B2 is connected to phase L2 and Input B3 is connected to phase L3,

but it only indicates that the phases of the electric system being tested

respect the correct sequence.

EN - 29

Page 32

EQUITEST 5071

6.4.6.1. Anomalous situations in "P-P", "P-N", "P-PE","RA", " " mode

If the instrument detects

a Phase-Neutral voltage

and a Phase-Earth

voltage lower than

100V, the following

message appears on

the display. Check that

the system being tested

is supplied.

If the instrument detects

a Phase-Neutral voltage

and a Phase-Earth

voltage higher than

250V, or a Phase-Phase

voltage higher than

440V, the following

message appears on

the display. Check that

the instrument is not

connected phase to

phase.

If the instrument detects

that the Phase and

Neutral terminals have

been exchanged, the

following message

appears on the display.

Rotate the Shuko plug

or check the connection

of the separate cables.

If the instrument detects

that the Phase and

Earth terminals have

been exchanged, the

following message

appears on the display.

Rotate the Shuko plug

or check the connection

of the separate cables.

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N= 1V VP-PE= 0V

P-PE 50V

FUNC Z2 UL

LOOP 30.11.12

- - -

Freq=50.0HZ

VP-N=401V VP-PE=230V

HIGH VOLTAGE

P-PE 50V

FUNC Z2 UL

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N=231V VP-PE= 0V

P-PE 50V

FUNC Z2 UL

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N= 1V VP-PE= 230V

P-N

FUNC Z2

---A

LOW VOLTAGE

---A

---A

CHANGE P-N

---A

CHANGE P-PE

Insufficient voltage

Voltage too high

Phase and Neutral

conductors have been

exchanged.

Phase and Earth

conductors have been

exchanged.

EN - 30

Page 33

EQUITEST 5071

A

If in a 230V system, the

instrument detects that

terminals B3 and B4

have been exchanged,

the following message

appears on the display.

Check the connection of

the separate cables.

If the instrument detects

that, in case test is

carried out, a Contact

Voltage higher than the

limit value set would be

found in the system

being tested, it does not

perform the test and the

following message

appears on the display.

Check for the efficiency

of the PE conductor and

of the grounding system.

If the instrument detects

an Earth resistance so

high that the Earth

conductor of the

grounding system itself

may be considered

missing, the following

message appears on

the display. Check for

the efficiency of the PE

conductor and of the

grounding system.

If, after repeated tests,

the instrument has

overheated, the

following message

appears on the display.

Wait for the message to

disappear before

carrying out other tests.

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N=131V VP-PE= 227V

P-N

FUNC Z2

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N= 1V Vp-PE= 0V

R

50V

FUNC UL

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N=231V Vp-PE= 40V

P-PE 50V

FUNC Z2 UL

LOOP 30.11.12

- - -

FRQ=50.0HZ

VP-N=231V Vp-PE= 40V

P-PE 50V

FUNC Z2 UL

---A

CHANGE N-PE

---A

Ut DANGEROUS

---A

NO PE

---A

HIGH TEMP

Phase and Earth

conductors have been

exchanged.

The instrument detects a

dangerous Contact Voltage

Inefficient grounding

system

The instrument has

overheated

EN - 31

Page 34

EQUITEST 5071

3

A

Using modes "P-P", "P-

N", if the instrument

detects an impedance

higher than 199.9, the

following screen

appears on the display.

LOOP 30.11.12

>199.9

FRQ =50.0HZ

VP-N= 1V VP-PE= 0V

P-N

FUNC Z2

---A

Symbol ">" indicates that

the value of impedance is

higher than the maximum

measurable value

The results can be saved by pressing the SAVE key twice (see § 7.1).

Using modes "P-PE",

"RA", if the instrument

detects an impedance

higher than 1999, the

following screen

appears on the display.

LOOP

>1999

FRQ =50.0HZ

VP-N= 1V VP-PE= 0V

R

50V

FUNC UL

---A

0.11.12

Symbol ">" indicates that

the value of impedance is

higher than the maximum

measurable value

The results can be saved by pressing the SAVE key twice (see § 7.1).

EN - 32

Page 35

EQUITEST 5071

3

In " " mode, if one of

the Phase-Phase

voltages does not reach

the minimum threshold

value of 100V, the

instrument does not

perform any test and

displays the following

screen.

Check that all phases of

the electric system

being tested have

30.11.12

- - -

FRQ =50.0HZ V1-2=391V

V2-3= 0 V V3-1= 0V

LOW VOLTAGE L3

PHASE ROTATION

FUNC

Phase "L3" does not reach

the minimum voltage value

voltage.

Using the " " mode, if

two phases of the

electric system coincide,

the instrument does not

perform any test and

displays the following

screen.

Check that all phases of

the electric system

being tested have

voltage.

30.11.12

- - -

FRQ =50.0HZ V1-2=407V

V2-3= 0 V V3-1=407V

PHASE DOUBLED

PHASE ROTATION

FUNC

Two phases of the threephase system being tested

are connected to each

other

Using mode " ", if

phase sequence is

incorrect, the symbol

"132" is displayed.

Exchange two phases of

the electric system being

tested and repeat the

test.

132

FRQ=50.0HZ VR-S= 391V

VS-T= 392V VT-R= 398V

FUNC

INCORRECT

PHASE ROTATION

0.11.12

This symbol DOES NOT

indicate that input B1 is

connected to phase L1,

input B2 is connected to

phase L3, input B3 is

connected to Phase L2. It

ONLY indicates that the

detected phase sequence

is incorrect

Incorrect sequence

EN - 33

Page 36

EQUITEST 5071

7. OPERATIONS WITH THE MEMORY

7.1. STORAGE OF MEASUREMENT RESULTS

1. With displayed result, press the SAVE key. The following screen appears on the

display:

The parameter "LAST REF"

(numerical marker) may be

used to help the operator

find out the point in which a

measurement has been

carried out. The value of

this parameter can be freely

modified and is not bound

to the memory location in

which the results shall be

saved, which progressively

increases. There are up to

255 markers available.

SAVE IN LOC. 038

OK? (SAVE/ESC)

LAST REF: 007

2. Use the F3 or F4 keys to set the mnemonic reference marker.

3. Press the SAVE key again to save the result in the indicated memory location,

associating the displayed value of parameter "REF". The message “OK” immediately

appears on the display to confirm operation.

4. Press the ESC key to exit without saving.

7.2. RECALLING AND DELETING DATA FROM THE MEMORY

1. Press the MENU key to access the instrument’s general menu. Select item “SAFETY

TEST MEMORY” and confirm with ENTER. The following screen appears on the

display:

SAFETY TEST MEMORY

MEM

001 LOW

002 LOW10A 001

003 LOWE204 002

004 LOOP 003

TOT:004 FREE:995

TYPE REF

2. Use the F1 or F2 keys to select the desired measurement among those available in the

list. Press the ENTER key to recall the measurement on the display and the ESC key

to go back to the list of measurements.

3. Press the F3 key to delete the last measuring result saved in the memory. The

instrument shows the message “CLEAR LAST? (Enter)”. Confirm the operation with

ENTER or press ESC to go back to the list of measurements.

4. Press the F4 key to delete the whole memory content. The instrument shows the

message “CLEAR ALL? (Enter)”. Confirm the operation with ENTER or press ESC to

go back to the list of measurements

30.11.12

001

LAST TOT.

Memory location

Mnemonic parameter

EN - 34

Page 37

EQUITEST 5071

8. CONNECTING THE INSTRUMENT TO THE PC

To transfer data to the PC, follow this procedure:

1. Install the TopView software found in the provided CD-ROM.

2. Install the C2006 cable driver found in the provided CD-ROM.

3. Launch TopView software. The following initial screen appears on the PC screen:

4. Switch on the instrument and leave it in any reading screen.

5. Connect the optical connector of the C2006 cable to the instrument (side in the shape

of an “8”) and the other end to a USB port of the PC.

6. Click on key “PC-InstrumentConnection” of the TopView software. The following

screen appears on the display:

7. Use the keys “Detect instrument” and “ Autoset” until the instrument is detected.

8. Click on key “Forward” and follow the guided procedure of the software.

For any detail regarding the analysis of the results, please refer to TopView ON-LINE

HELP

EN - 35

Page 38

EQUITEST 5071

9. MAINTENANCE

9.1. GENERAL INFORMATION

1. The instrument you purchased is a precision instrument. While using and storing the

instrument, carefully observe the recommendations listed in this manual in order to

prevent possible damage or danger during use.

2. Do not use the instrument in environments with high humidity levels or high

temperatures. Do not expose to direct sunlight.

3. Always switch off the instrument after use. For long-term storage, remove the batteries

to avoid leakage of battery fluid that can damage the internal components.

9.2. BATTERY REPLACEMENT

The symbol “ ” indicates a full charge level of the batteries. The symbol " "

indicates that the batteries are almost flat. In this case, stop testing and replace the

batteries.

The instrument is capable of keeping data stored even without batteries.

The date/time settings remain unchanged only if replacement is

carried out within 24 hours.

Only expert and trained technicians should perform this operation. Before

carrying out this operation, make sure you have disconnected all cables

from the input terminals.

1. Switch off the instrument using the ON/OFF key.

2. Remove all the cables from the input terminals.

3. Loosen the battery compartment cover fastening screw and remove the cover.

4. Remove all batteries and replac e them with six new batteries of the same type (see §

10.2), respecting the indicated polarity.

5. Position the battery cover back over the compartment and fasten it with the relevant

screw.

6. Do not scatter old batteries into the environment. Use the relevant containers for

battery disposal.

9.3. CLEANING THE INSTRUMENT

Use a soft and dry cloth to clean the instrument. Never use wet cloths, solvents, water, etc.

9.4. END OF LIFE

CAUTION

CAUTION: the symbol on the instrument indicates that the appliance and its

accessories must be collected separately and correctly disposed of.

EN - 36

Page 39

EQUITEST 5071

10. TECHNICAL SPECIFICATIONS

Accuracy indicated as [%reading + (number of digits)* resolution] at 23°C±5°C, <60%RH

Continuity of protective conductors with 200mA (LOW)

Mode

AUTO, R+TIMER, R-TIMER

(*) Considering the calibration of measuring cables

Test current >200mA DC up to 5 (including calibration value)

Current measurement resolution 1mA ; Open-circuit voltage: 4V < V

Measuring range

()

0.01 9.99

10.0 99.9

Continuity of protective conductors with 10A (LOW10A)

Measuring range () Resolution ()

0.001 0.999

Test current > 10A AC up to 0.45

Current measurement resolution 0.1A

Open-circuit voltage < 12V AC

Measuring mode 4 terminals

Power supply 230V AC / 50/60Hz

0.01

Continuity of PE conductors in compliance with IEC/EN60204-1:2006 (LOW10AE204)

Measuring range () Resolution ()

0.001 0.999

Test current > 10A AC up to 0.45 ; Current measure resolution: 0.1A ; Open-circuit voltage < 12V AC

Length measuring range 0.1m 999.9m ;

Selectable section 0.5, 1, 1.5, 2.5, 4, 6, 10, 16mm2 ; Copper resistivity 0.017 mm

Measuring mode 4 terminals

Power supply 230V AC / 50/60Hz

0.01

Contact voltage (Ut)

Range (V) Resolution (V) Accuracy

0.1 -0%, +(10%rdg + 3digits)

Ut lim (U

0 2U

): 25V or 50V

L

t lim

Frequency

Range (Hz) Resolution (Hz) Accuracy

47.0 63.6

LOOP measurement is only active for 50Hz ±0.5Hz

0.1

AC voltage measurement (LOOP, )

Measuring range (V) Resolution (V) Accuracy

15 460

1

Line impedance (Phase – Phase / Phase - Neutral)

Range () Resolution () (*)

0.01 9.99

10.0 199.9

(*) 0.1m in range 0.0 199.9 m (with IMP57)

Maximum peak current at test voltage: 3.65A (127V) ; 6.64A (230V) ; 11.5A (400V)

Phase – Phase test voltage: 100 460V 50Hz 0.5Hz ; Phase – Neutral test voltage: 100 265V 50Hz 0.5Hz

0.01

0.1

Fault ring impedance (Phase – Earth)

Range ()

0.01 9.99

10.0 199.9

200 1999

(*) 0.1 m in range 0.0 199.9 m (with IMP57)

Maximum peak current at test voltage: 3.65A (127V) ; 6.64A (230V)

Phase – Earth test voltage 100 265V 50Hz 0.5Hz

Resolution () (*)

0.01

0.1

1

Global earth resistance (Ra ) without RCD tripping

Range () Resolution ()

1 1999

Test current: 15mA ; Phase – Earth test voltage : 100 265V 50Hz 0.5Hz

1

Resolution ()

< 12V

0

0.01

0.1

(2%rdg + 2digits)

Accuracy

(1%rdg + 2digits)

Accuracy

(1%rdg + 2digits)

2

/m

(0.1%reading+1digit)

(3%rdg + 2digits)

Accuracy

(5%rdg + 3digits)

Accuracy

(5%rdg + 3digits)

Accuracy

(5%rdg + 3digits)

Accuracy (*)

EN - 37

Page 40

EQUITEST 5071

10.1. REFERENCE STANDARDS

Safety: IEC/EN61010-1, IEC/EN61557-1, -3, -4, -7

Insulation: double insulation

Pollution level: 2

Measurement category: CAT II 600VAC (inputs) / 350VAC to earth

CAT III 600VAC (inputs) / 300VAC to earth

LOW (200mA): IEC/EN61557-4

10A: IEC/EN60439-1

LOW

LOW

10AE60204: IEC/EN60204-1:2006

LOOP P-P, P-N, P-PE, Ra: IEC/EN61557-3

PHASE SEQUENCE: IEC/EN61557-7

10.2. GENERAL CHARACTERISTICS

Mechanical characteristics

Size (L x W x H): 225 x 165 x 105mm ; (9 x 6 x 4in)

Weight (batteries included): 1.7kg (35lv)

Power supply

Internal power supply: 6x1.5V alkaline batteries type AA LR6 AM3

Battery life: LOW: >80 test;

LOOP:>1000test; Ra :>1000 test;

PHASE SEQUENCE: > 1000 test

External power supply: 230V / 50/60Hz (only for continuity test with 10A)

Display

Characteristics: Dot matrix graphic module, backlit

Resolution 128x128pxl

Visible area 73mmx73mm ; (3 x 3in)

Memory:

Memory 2MByte (non-expandable)

Verification tests max 999 measurements

Interface: Serial port RS232, opto-isolated

10.3. ENVIRONMENTAL CONDITIONS

Reference temperature 23°

5°C ; (73° 41°C)

Operating temperature 0° 40°C ; (32° 104°F)

Operating relative humidity < 80%RH

Storage temperature -10 60°C; (14° 140°F)

Storage humidity < 80%RH

Max operating altitude: 2000m (6562ft)

10.4. ACCESSORIES

See the attached packing list.

EN - 38

Page 41

EQUITEST 5071

11. SERVICE

11.1. WARRANTY CONDITIONS

This instrument is warranted against any material or manufacturing defect, in compliance

with the general sales conditions. During the warranty period, defective parts may be

replaced. However, the manufacturer reserves the right to repair or replace the product.

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer’s charge. However, shipment will be agreed in advance.

A report will always be enclosed to a shipment, stating the reasons for the product’s return.

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer.

The manufacturer declines any responsibility for injury to people or damage to property.

The warranty shall not apply in the following cases:

Repairs that may become necessary as a consequence of an incorrect use of the

instrument or due to its use together with non-compatible appliances.

Repairs that may become necessary as a consequence of improper packaging.

Repairs which may become necessary as a consequence of interventions performed

by unauthorized personnel.

Modifications to the instrument performed without the manufacturer’s explicit

authorization.

Use not provided for in the instrument’s specifications or in the instruction manual.

The content of this manual cannot be reproduced in any form without the manufacturer’s

authorization.

Our products are patented and our trademarks are registered. The manufacturer

reserves the right to make changes in the specifications and prices if this is due to

improvements in technology.

11.2. SERVICE

If the instrument does not operate properly, before contacting the After-sales Service,

please check the conditions of batteries and cables and replace them, if necessary.

Should the instrument still operate improperly, check that the product is operated

according to the instructions given in this manual.

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer’s charge. However, shipment will be agreed in advance.

A report will always be enclosed to a shipment, stating the reasons for the product’s return.

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer.

EN - 39

Page 42

Page 43

Page 44

YAMUM0055HT0

Via della Boaria 40

48018 – Faenza (RA) - Italy

Tel: +39-0546-621002 (4 linee r.a.)

Fax: +39-0546-621144

email: ht@htitalia.it

http://www.ht-instruments.com

Loading...

Loading...