HTC Floor Systems DURATIQ T6, DURATIQ RT6, DURATIQ X6, DURATIQ RX6 User Manual

Original instructions

i

User Manual

HTC DURATIQ

T6 / RT6 / X6 / RX6

Contact information

HTC Sweden AB

Box 69

SE-614 22 Söderköping - Sweden

Tel: +46 (0) 121-294 00

Fax: +46 (0) 121-152 12

www.htc-floorsystems.com

Trademarks

HTC is a trademark owned by HTC Sweden AB. Other names and products mentioned in

this manual may be registered trademarks owned by the relevant companies.

© 2016 HTC Sweden AB. All rights reserved.

EC Declaration of conformity

Manufacturer: HTC Sweden AB

Box 69

SE-614 22 Söderköping

Sweden

+46 (0)121-29400

Type of equipment: Grinding machine

Make: HTC

Trademark: HTC DURATIQ 6

Year of manufacture: See machine name plate

Serial number: See machine name plate

Original of the EC declaration of conformity (Swedish). Other languages are translations of

the original of the EC declaration of conformity.

Söderköping 01/06/2016

Stefan Lind Björn Jeansson

CEO Product Manager

HTC Sweden AB HTC Sweden AB

Standards

As the manufacturer, we hereby declare under our sole responsibility that the above product

with serial numbers from 2016 onward conforms to the applicable regulations in:

EN 60335-1:2012

Household and similar electrical appliances Safety - Part 1: General requirements.

EN 60335-1:2012 + A11:2014

Household and similar electrical appliances Safety - Part 1: General requirements.

EN 60335-2-72:2012

Household and similar electrical appliances Safety - Part 2-72: Particular requirements for

floor treatment machines with or without traction

drive, for commercial use.

EN 62233:2008

Measurement methods for electromagnetic fields

of household appliances and similar apparatus

with regard to human exposure.

EN 61000-6-4:2007 + A1:2001 EMC

FCC CFR 47 Part 15 (2016) EMC

EN 61000-6-2 (2005) EMC

DIRECTIVE 2006/42/EC Machinery directive.

DIRECTIVE 2014/30/EC EMC

DIRECTIVE 2014/35/EC LVD

ISO 5349-1:2001

Mechanical vibration -- Measurement and

evaluation of human exposure to

hand-transmitted vibration -- Part 1: General

requirements.

ISO 5349-2:2001

Mechanical vibration -- Measurement and

evaluation of human exposure to

hand-transmitted vibration -- Part 2: Practical

guidance for measurement at the workplace.

ISO 20643:2005

Mechanical vibration -- Hand-held and

hand-guided machinery -- Principles for

evaluation of vibration emission.

ISO 3744:2010

Acoustics -- Determination of sound power levels

and sound energy levels of noise sources using

sound pressure -- Precision methods for

reverberation test rooms.

ISO 11201:2010

Acoustics -- Noise emitted by machinery and

equipment -- Determination of emission sound

pressure levels at a work station and at other

specified positions applying approximate

environmental corrections.

The product was CE marked in 2016. The technical documentation is available from the

manufacturer.

HTC DURATIQ

D002998, 01.06

www.htc-floorsystems.com 7

Table of contents

1 Introduction................................................................................................. 9

1.1 General...................................................................................................... 9

1.2 Liability....................................................................................................... 9

1.3 Warranty .................................................................................................... 9

2 Safety........................................................................................................... 10

2.1 Symbols that are used............................................................................... 10

2.2 Safety rules................................................................................................ 10

3 Information about the machine................................................................. 13

3.1 Unpacking the equipment.......................................................................... 13

3.2 Transport ................................................................................................... 13

3.2.1 Transport ............................................................................................... 13

3.2.2 Lifting..................................................................................................... 13

3.2.3 Movement.............................................................................................. 13

3.2.4 Hanging the cover ................................................................................. 15

3.2.5 Support wheel....................................................................................... 16

3.3 Storage...................................................................................................... 16

3.4 Machine name plate.................................................................................. 17

3.5 Hand and arm vibrations........................................................................... 18

3.6 Sound power level..................................................................................... 18

4 Machine description................................................................................... 19

4.1 General machine description..................................................................... 19

4.2 Storage compartment................................................................................ 22

4.3 Control cabinet .......................................................................................... 24

4.4 Description of Controls – Control Panel (HMI) .......................................... 25

4.5 Information Panel ...................................................................................... 27

4.6 Connection Panel ..................................................................................... 30

5 Operation..................................................................................................... 31

5.1 General...................................................................................................... 31

5.2 Handle setting............................................................................................ 31

5.3 Handling weights....................................................................................... 33

5.4 Cable and Hose Strain Relief Device ........................................................ 35

5.5 Access to Grinding Tools........................................................................... 35

5.6 Fitting Grinding Tools................................................................................. 36

6 Grinding ...................................................................................................... 38

6.1 Manoeuvring via the Control Panel........................................................... 38

6.1.1 Manual Grinding.................................................................................... 39

6.1.2 Emergency Stop Switch ........................................................................ 39

6.2 Making Operation Easier........................................................................... 40

7 Accessories ................................................................................................ 41

7.1 Radio package........................................................................................... 41

7.1.1 Description of Controls – Remote Control............................................. 41

7.1.2 Radio Receiver...................................................................................... 44

7.1.3 Charging................................................................................................ 45

7.1.4 Operation............................................................................................... 45

7.1.5 Locking the Wheels ............................................................................... 46

HTC DURATIQ

8 www.htc-floorsystems.com

D002998, 01.06

7.2 Radio Control............................................................................................. 47

7.3 Lighting Package....................................................................................... 49

7.4 GPS Tracker.............................................................................................. 50

7.4.1 Start Up................................................................................................. 50

7.4.2 Registration ........................................................................................... 51

7.4.3 Use........................................................................................................ 51

7.4.4 GSM card .............................................................................................. 52

7.4.5 Remote Control ..................................................................................... 52

7.5 Water package........................................................................................... 53

7.5.1 Mist Cooler System ............................................................................... 53

7.5.2 Wet grinding .......................................................................................... 54

8 Maintenance and repair ............................................................................. 56

8.1 General...................................................................................................... 56

8.2 Cleaning.................................................................................................... 56

8.3 Prior to each new grinding process........................................................... 57

8.4 Daily........................................................................................................... 57

8.5 Every week................................................................................................ 57

8.6 Repairs...................................................................................................... 57

8.7 Spare parts................................................................................................ 58

8.8 Warranty .................................................................................................... 58

9 Troubleshooting.......................................................................................... 59

9.1 General...................................................................................................... 59

9.2 The machine will not start ......................................................................... 59

9.3 Fuse or earth fault breaker trip frequently................................................. 60

9.4 The machine cannot cope ......................................................................... 60

9.5 Warnings and Error Messages.................................................................. 61

9.5.1 Warnings ............................................................................................... 61

9.5.2 Error Messages..................................................................................... 63

10 Technical Data ............................................................................................ 65

11 Environment................................................................................................ 75

11.1 Chassis...................................................................................................... 75

11.2 Grinding head............................................................................................ 75

11.3 Electrical system ....................................................................................... 76

11.4 Recycling................................................................................................... 76

HTC DURATIQ Introduction

D002998, 01.06

www.htc-floorsystems.com 9

1 Introduction

1.1 General

HTC's machines are used for processing floor surfaces. The machine's area of application

depends on the choice of tool.

In addition to use and general functions, this manual explains the applications and

maintenance of your HTC machine. Contact your local retailer for further information. For

contact information, see the start of the manual.

1.2 Liability

Even though every effort has been made to make this manual as complete and accurate as

possible, we bear no responsibility for incorrect or missing information. HTC reserves the

right to change descriptions in this manual without giving prior notice.

This manual is protected by the Copyright Act and no part of it may be copied or used in any

other way without the written approval of HTC.

1.3 Warranty

This warranty only covers manufacturing defects. HTC bears no responsibility for damage

that arises or occurs during transportation, unpacking or use. In no instance and under no

circumstances shall the manufacturer be held responsible for damage and defects caused by

incorrect use, corrosion or use outside the prescribed specifications. The manufacturer is not

responsible for indirect damage or costs under any circumstances. For complete information

on the manufacturer's warranty period, see HTC's current warranty terms.

Local distributors may have special warranty terms specified in their terms of sale, delivery

and warranty. If there is any uncertainty regarding warranty terms, please contact your

retailer.

HTC DURATIQ Safety

10 www.htc-floorsystems.com

D002998, 01.06

2 Safety

This chapter includes the safety rules that must be observed when using HTC's machines.

2.1 Symbols that are used

The symbols below are used in this manual to show the need for extra care when using the

machine.

WARNING

This symbol means Warning! and indicates a risk of personal

injury or material damage.

If the warning is not observed, this could result in death or

serious personal injury.

NOTE

This symbol means Note! and indicates a risk of material

damage in the event of incorrect use.

TIP

This symbol means Tips! and indicates tips and advice on

effective use of the machine or ways of reducing wear and tear

to the machine.

2.2 Safety rules

Users of machines from HTC have the ultimate responsibility for ensuring that everybody

who works with or in the vicinity of the equipment follow all applicable safety rules. Safety

measures must meet the requirements that apply for this type of equipment. Apart from the

standard rules that apply in the workplace, the recommendations in this manual shall also be

observed.

All work must be performed by trained personnel. Users of machines from HTC must have

read through the dedicated manual for the machine. Incorrect use of the equipment could

result in situations that could cause harm to the operator, the surroundings or the machine.

HTC DURATIQ Safety

D002998, 01.06

www.htc-floorsystems.com 11

WARNING

Training is required.

Risk for personal injury and mechanical damage.

Children should be kept under supervision to prevent them

from playing with the machine.

The machine must not be operated by children or in the vicinity

of children. The machine must not be used by those with

impaired physical, sensory or mental abilities or by those who

lack the knowledge that is required for using the machine.

Machines from HTC may only be used in the way recommended by HTC.

Machines from HTC may only be used for commercial purposes.

Anyone using the machine shall know about:

• its functions

• location of emergency stops

• the safety rules for the work

The operator shall ensure that:

• No unauthorised person is stationed within the work area when the machine is started up

The workplace shall:

• be suitable for the purpose

• be secured from loose objects that can be thrown out by the machine

• be free from protruding bolts etc. on the surface to be processed

Individuals in the workplace shall always use the recommended personal protective

equipment and wear suitable clothing:

• safety goggles

• protective gloves

• steel toe safety shoes

• hearing protection

• respiratory mask

• do not wear loose fitting clothing or anything that can catch, such as scarves, bracelets,

rings, etc.

General precautions:

• Check the machine is connected to an earthed wall socket.

• Work on live parts shall only be performed by qualified personnel.

• Suitable fire extinguishers shall be clearly marked and close to hand.

• Maintenance of the equipment must not be performed during operation.

HTC DURATIQ Safety

12 www.htc-floorsystems.com

D002998, 01.06

The machine is only tested for use up to 2000 metres above sea level.

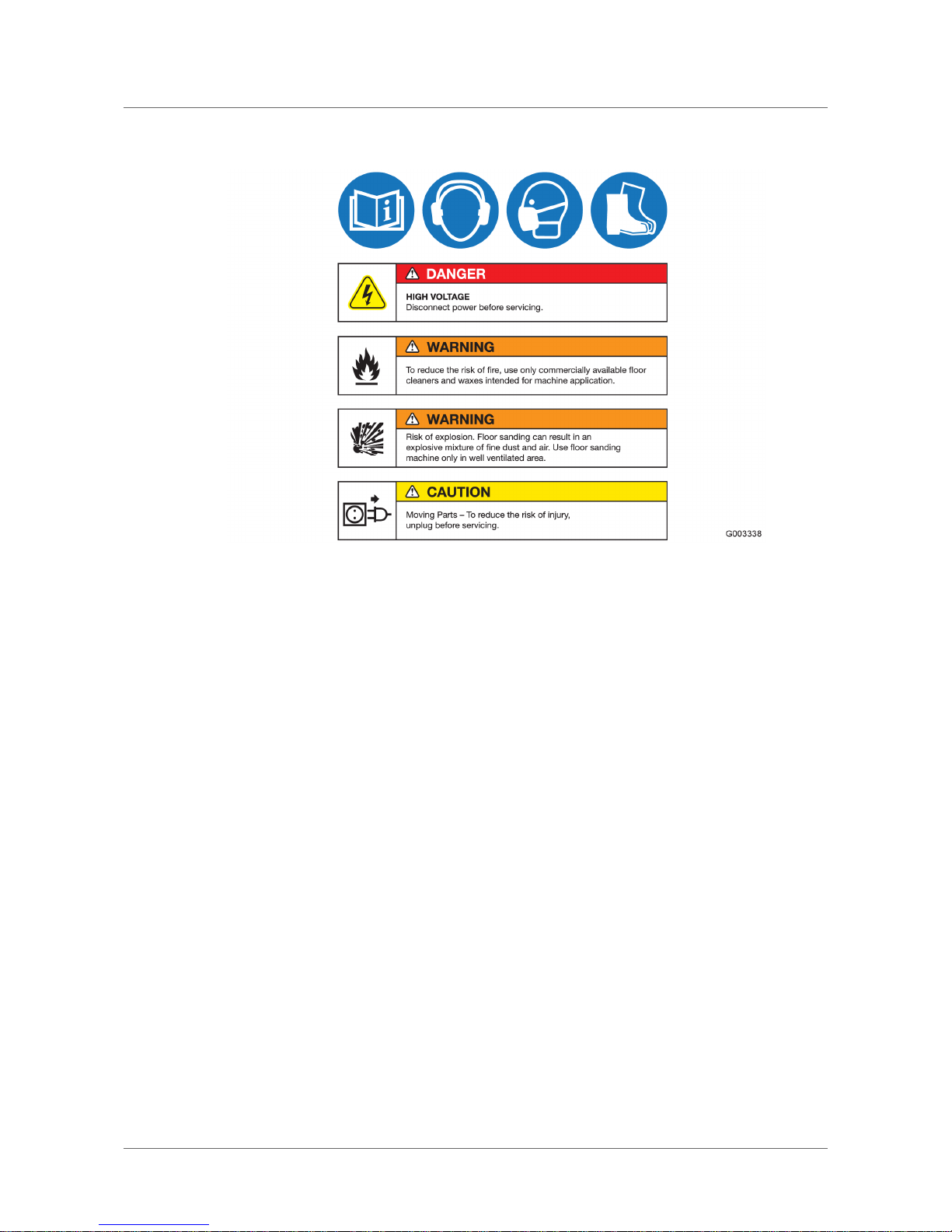

This information decal is affixed clearly visible on the machine's electrical cabinet.

HTC DURATIQ Information about the machine

D002998, 01.06

www.htc-floorsystems.com 13

3 Information about the machine

3.1 Unpacking the equipment

Check the packaging and equipment carefully on delivery for any possible transport damage.

If there is any sign of damage, contact the retailer and report the damage. Report packaging

damage to the transport company as well.

Check that the delivery matches the order. If there are any questions, contact the retailer.

3.2 Transport

WARNING

Risk for personal injury and mechanical damage

NOTE

During moving, transport and lifting, the weights shall be in

position 1, see Handling Weights.

3.2.1 Transport

Always make sure that the machine is securely anchored to its surroundings and that the

grinding head is lowered on to the surface. Tighten the securing straps, or other equipment

used for anchoring during transport over non-moving parts, e.g. the machine's chassis.

3.2.2 Lifting

The machine can also be lifted using the lifting eyes provided or using other approved lifting

equipment. In which case, make sure that the weights are locked in the forward position and

that the handle is in its back position, see Handling weights page 33 and Handle setting

page 31. When lifting the machine, lifting straps must be used.

3.2.3 Movement

When moving on sloping surfaces, e.g. loading ramps, the machine should be secured in the

lifting eyes, for example, using a winch. This is a safety measure in case the machine starts

to roll out of control or tip over. The weights should be in position 1, see Handling weights

page 33. Otherwise, there is a risk that the machine tips backwards. Ensure there is no

one below the machine during movement on sloping surfaces.

HTC DURATIQ Information about the machine

14 www.htc-floorsystems.com

D002998, 01.06

Fixing points for lifting and securing.

HTC DURATIQ Information about the machine

D002998, 01.06

www.htc-floorsystems.com 15

3.2.4 Hanging the cover

During transport or work with HTC grouting, the cover can be hung up so it does not drag on

the surface.

Lift up the cover and secure it with the rubber straps to secure the cover in the raised

position.

WARNING

Moving parts. High noise level.

Risk for personal injury.

Always use the recommended personal protective equipment.

HTC DURATIQ Information about the machine

16 www.htc-floorsystems.com

D002998, 01.06

3.2.5 Support wheel

To ease movement, a support wheel can be firmly mounted on the machine.

The support wheel can be mounted during grinding.

3.3 Storage

The machine should be stored in a heated, dry area when not in use. It may be damaged by

condensation and cold.

HTC DURATIQ Information about the machine

D002998, 01.06

www.htc-floorsystems.com 17

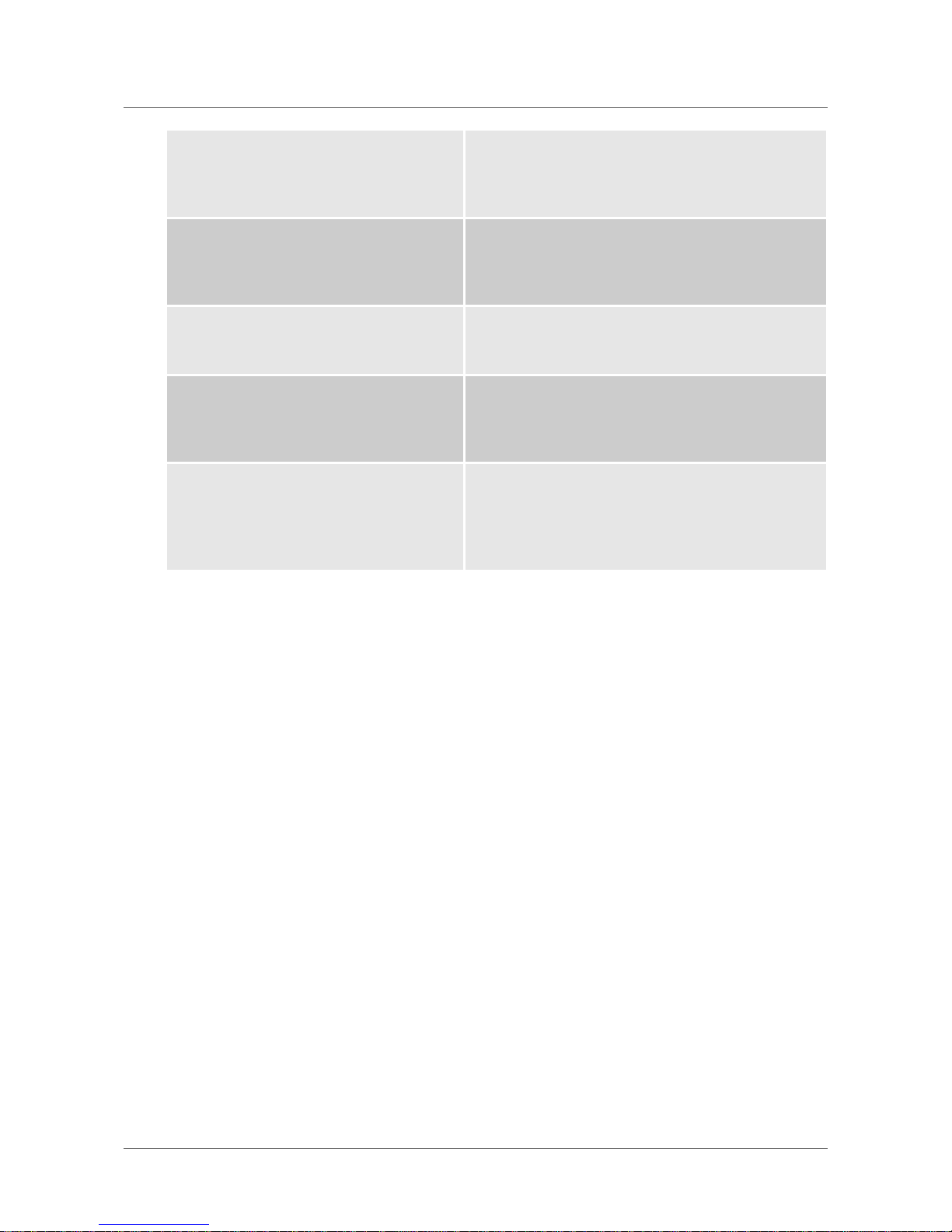

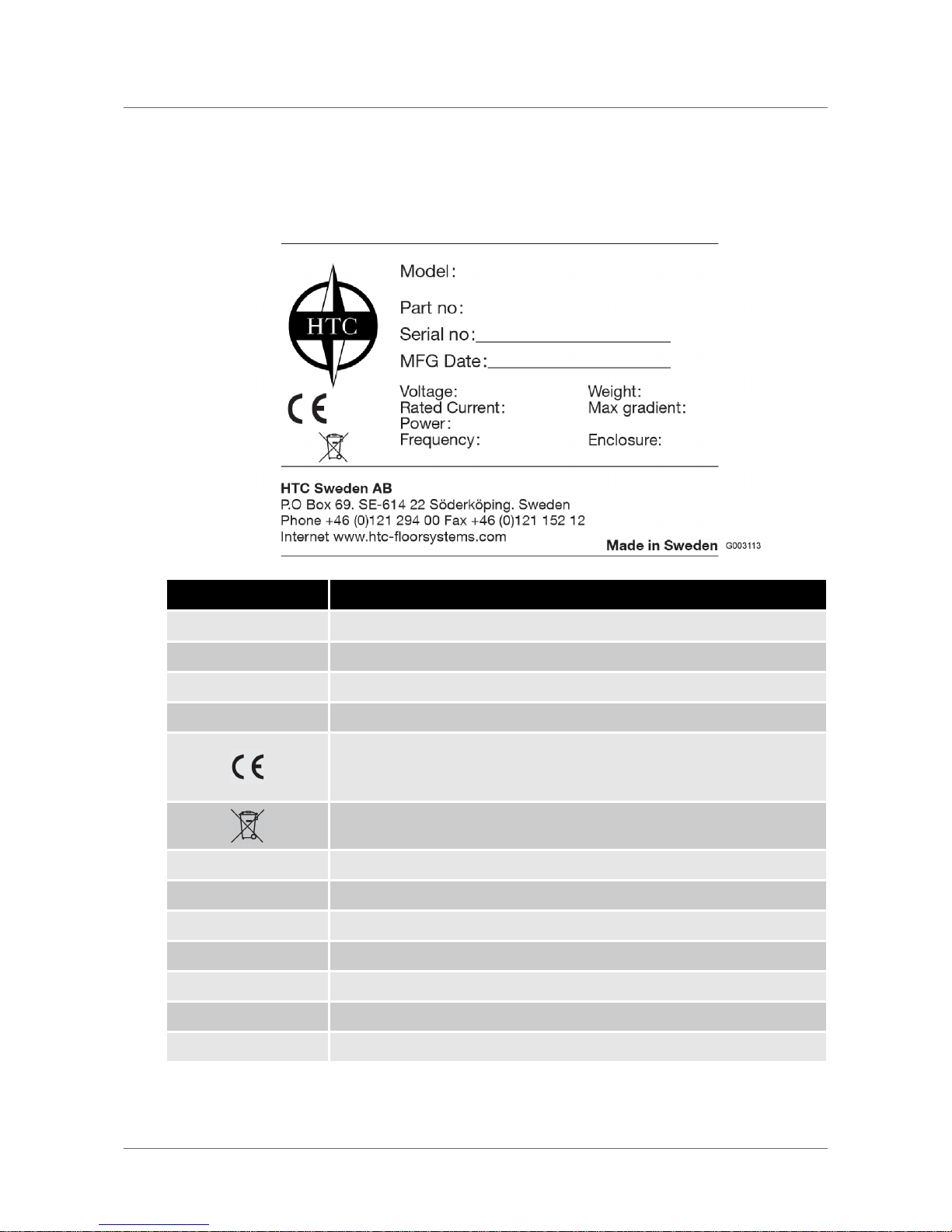

3.4 Machine name plate

The machine name plate provides the following information. The model and serial number

must be specified when ordering spare parts for the machine.

Name Description

Model Model

Part no Part number

Serial no Serial number

MFG date Date of manufacture

Approved standards. Only examples are shown here, the machine

name plate shows the correct approved standards.

See also Standards page 5

Recycling, see Recycling page 76

Power Power (kW)

Voltage Voltage (VAC)

Rated current Current (A)

Frequency Frequency (Hz)

Weight Weight (kg)

Max gradient Max gradient during normal use

Enclosure IP class

HTC DURATIQ Information about the machine

18 www.htc-floorsystems.com

D002998, 01.06

3.5 Hand and arm vibrations

Hand and arm-weighted vibration levels [m/s2] for HTC DURATIQ have been measured using

equipment approved in accordance with ISO 5349-1:2001. The uncertainty of measurement

for the measuring equipment is given as ±2%.

The machine has been tested in accordance with ISO 5349-2:2001 and ISO 20643:2005 in

order to identify the operations that contribute to the most frequent vibration exposures. At

vibration levels > 2.5 m/s2the exposure time should be limited in accordance with the table

below. For vibration levels > 5 m/s2immediate measures must be taken by the employer to

ensure that the exposure time does not exceed the time specified in the table below.

Identified work conditions

Measured values [m/s2]

Daily permitted exposure

(number of hours)

Grinding/polishing

< 2.5 m/s

2

> 10 h

3.6 Sound power level

This machine has been tested for noise in accordance with ISO 3744:2010 and ISO 11201.

Measured using class 1 instruments as sound level meters. For information about sound level

power, see chapter Technical Data page 65.

HTC DURATIQ Machine description

D002998, 01.06

www.htc-floorsystems.com 19

4 Machine description

4.1 General machine description

A grinding machine from HTC has been developed for processing various types of floor. It is

used to grind, coarse grind, prepare and polish concrete, natural stone and terrazzo floors or

other materials specified in this manual or material recommended by HTC.

Some grinding machines can be equipped with radio control. Radio control is an accessory

that eases the work considerably.

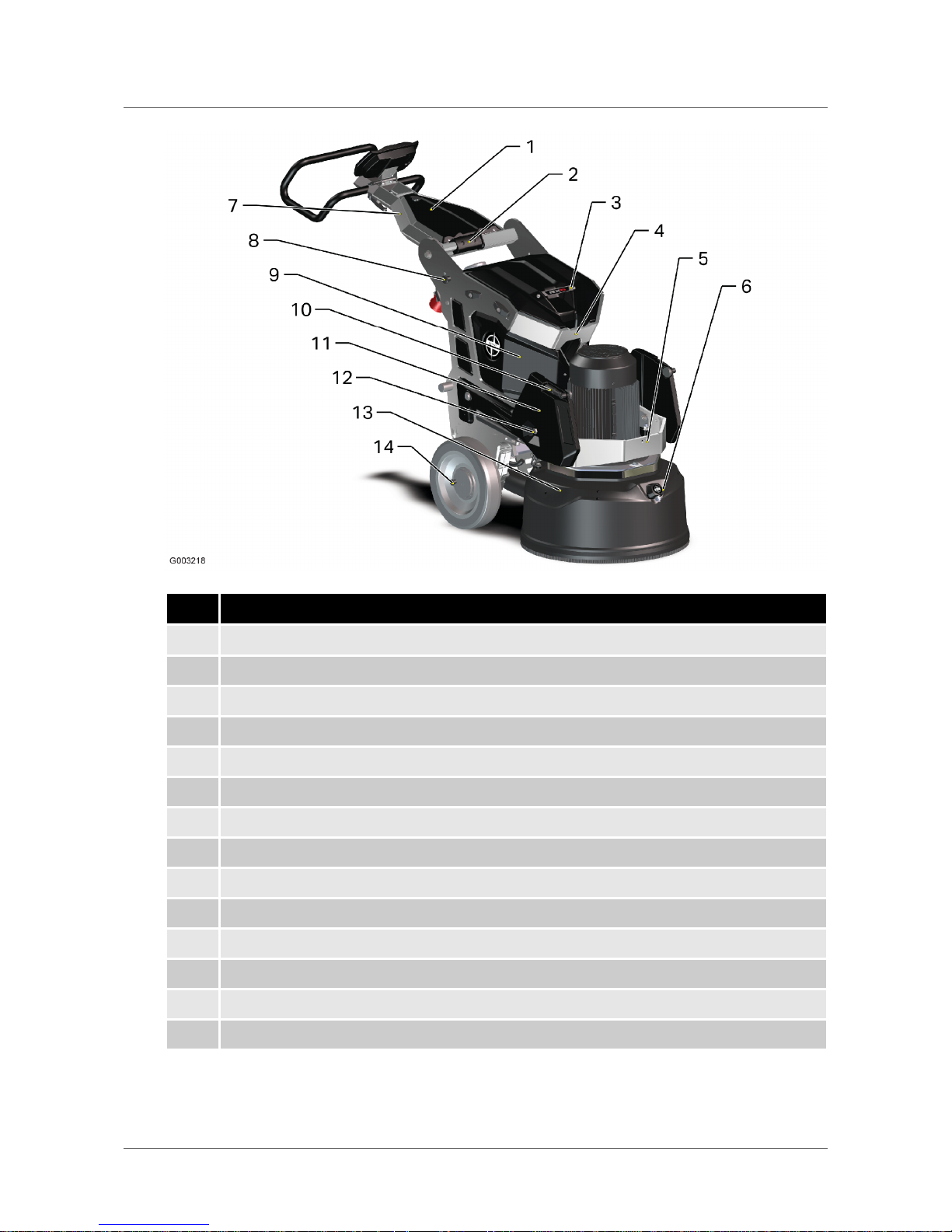

The machine is constructed from a number of main components, see below page 20.

The handle can be set in a number of different tilt positions. Choose a position that suits you

best, when the machinery is to be operated manually.

The machine's grinding head can be equipped with one of several different grinding discs

that are covered by a sealed sloping cover against the floor. The cover together with the

connected vacuum system provide the conditions needed for a good work environment. The

cover ensures that the operator does not come into contact with rotating mechanical parts

and exposure to dust is minimised. Because the cover is floating, the dust uptake is

optimised since it is always in contact with the surface.

Always make sure that a dust extractor is connected to the grinder during dry grinding to

prevent as far as possible exposure to dust particles of operators, people in the vicinity, the

grinder and other equipment.

WARNING

Dust.

Risk for personal injury.

The dust that is sucked up may be harmful if inhaled. Follow

local regulations and use breathing protection.

The machine can be easily equipped with a large number of tools, depending on the floor

material to be ground. For more information about different tools, see HTC's website

www.htc-floorsystems.com.

Some grinding machines can be equipped with a Mist Cooler system for effective cooling of

the grinding tools. This system enables a very fine water mist to be diffused through a nozzle

over the floor surface, which cools the tools and thereby makes the grinding more effective.

HTC DURATIQ Machine description

20 www.htc-floorsystems.com

D002998, 01.06

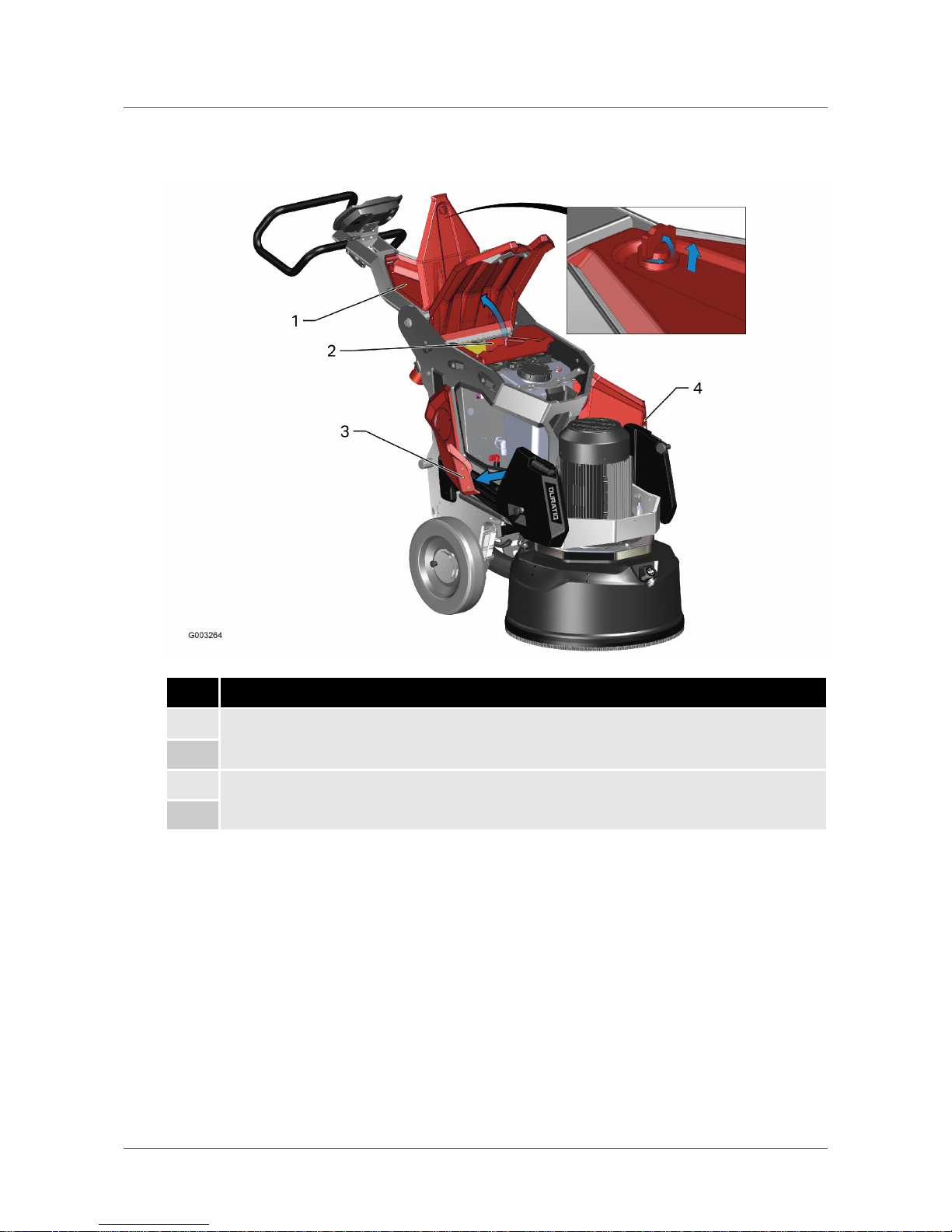

No. Description

1 Storage hatch

2 Handlebar locking rough adjustment

3 Storage hatch

4 Lifting point

5 Fixing point for support wheel and securing the load

6 Nozzle for Mist Cooler System

7 Handlebar

8 Handlebar locking fine adjustment

9 Service hatch

10 Weight handle

11 Weight

12 Weight locking

13 Grinding head

14 Wheel lock for driving

HTC DURATIQ Machine description

D002998, 01.06

www.htc-floorsystems.com 21

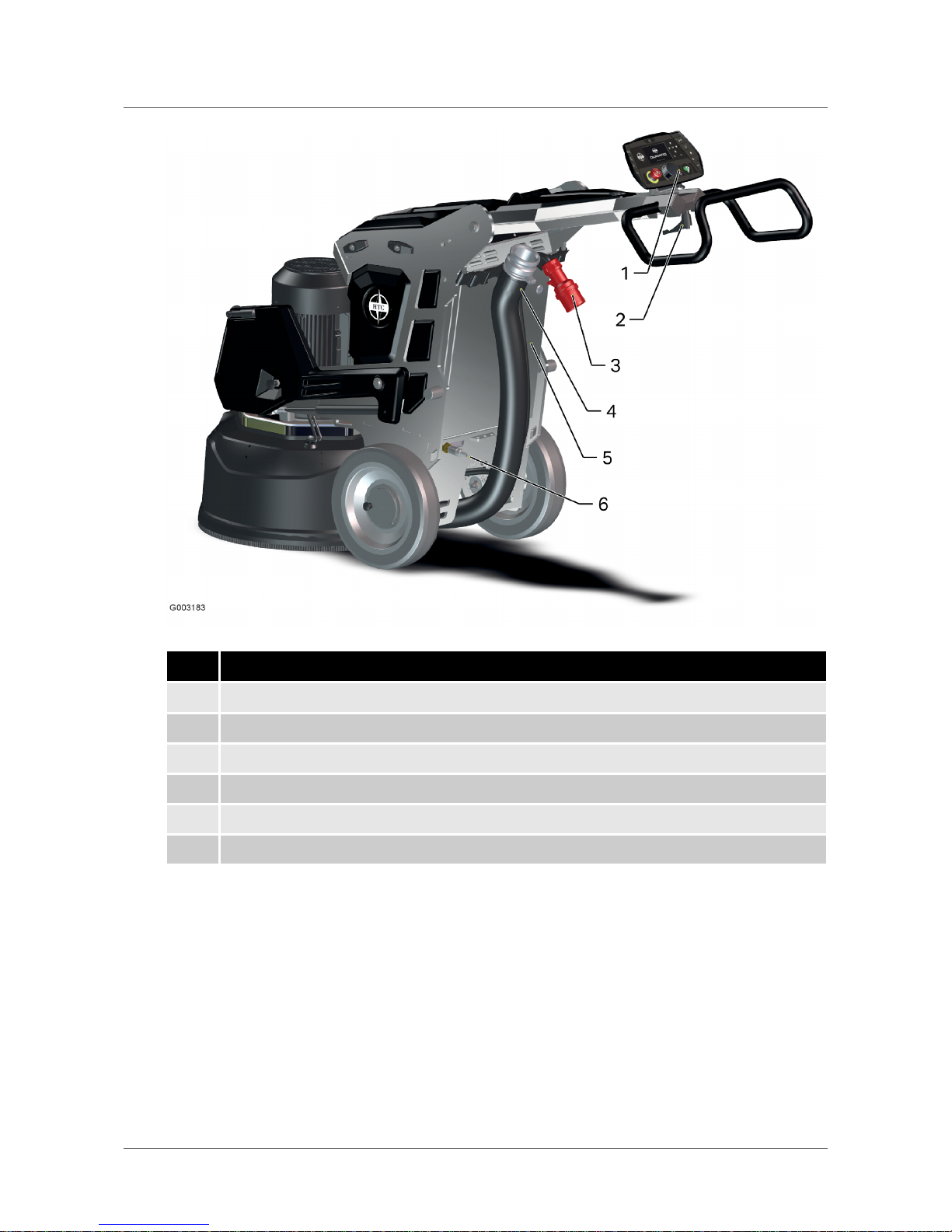

No. Description

1 Control panel

2 Handle lock

3 Electrical connection

4 Connection, dust extractor

5 Control cabinet

6 Water quick release coupling

HTC DURATIQ Machine description

22 www.htc-floorsystems.com

D002998, 01.06

4.2 Storage compartment

No. Description

1

Storage compartment

2

3

Service hatches

4

HTC DURATIQ Machine description

D002998, 01.06

www.htc-floorsystems.com 23

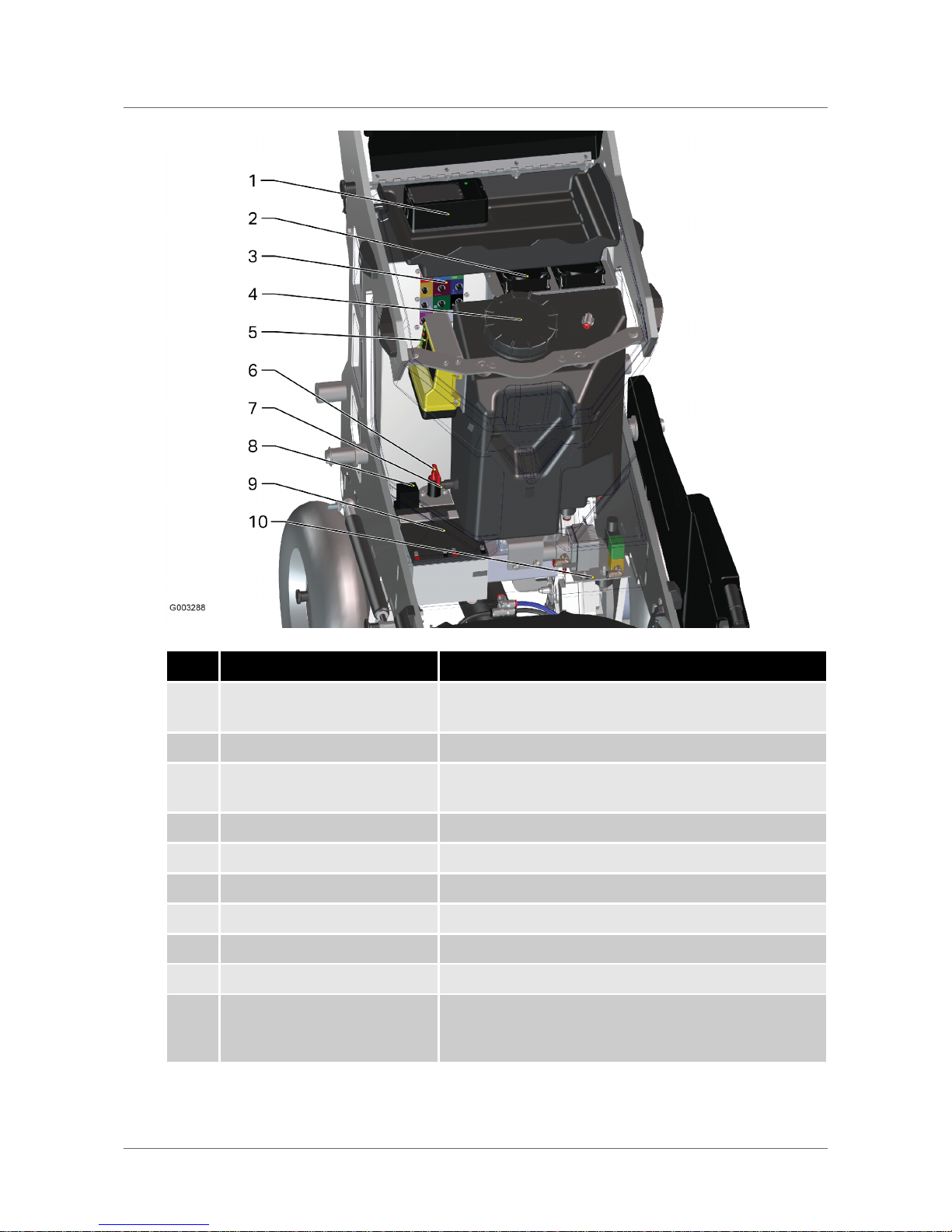

No. Description Accessories

1

Battery charger for remote

control

Radio package

2 Cooling fans

3

Connection panel for

accessories

4 Water tank Water package

5 Radio receiver Radio package

6 Battery disconnector Radio package

7 Water level sensor Water package

8 Relay Radio package

9 Battery Radio package

10

Mist Cooler system pump /

proportional valve water

supply

Water package

Loading...

Loading...