HTC Floor Systems 280 Operator's Manual

EN Operator's manual 2-18

ES-MX Manual del usuario 19-36

FR-CA Manuel d’utilisation 37-54

HTC 280

Contents

Introduction..................................................................... 2

Safety..............................................................................4

Operation........................................................................ 8

Maintenance................................................................. 14

Introduction

Owner responsibility

WARNING: Cutting, especially when DRY

cutting, generates dust that comes from the

material being cut, which frequently contains

silica. Silica is a basic component of sand,

quartz, brick clay, granite and numerous

other minerals and rocks. Exposure to

excessive amount of such dust can cause:

Respiratory disease (affecting your ability to

breath), including chronic bronchitis, silicosis

and pulmonary fibrosis from exposure to

silica. These diseases may be fatal;

Skin irritation and rash.

Cancer according to NTP* and IARC* */

National Toxicology Program, International

Agency for Research on Cancer.

Take precautionary steps:

Avoid inhalation of and skin contact with

dust, mist and fumes.

Wear and ensure that all bystanders wear

appropriate respiratory protection such as

dust masks designed to filter out

microscopic particles. (See OSHA 29 CFR

Part 1926.1153)

To minimize dust emissions, wet cut when

feasible. If dry cutting is necessary, use an

appropriate dust extractor.

Troubleshooting............................................................ 15

Transportation and storage...........................................16

Technical data.............................................................. 18

read and understood the Operator’s Manual. They must

be aware of:

• The products’s safety instructions.

• The products’s range of applications and limitations.

• How the product is to be used and maintained.

National/Local regulations could restrict the use of this

product. Find out what regulations are applicable where

you work before you start using the product.

Product description

The product is a power grinder for concrete surfaces of

different hardness. The grind range is from rough

surfaces through to smoother finish.

For example, the product has these functions:

• A frame that can be folded for easier transport.

• A grinding head cover that adjusts the movement to

the surface layer.

• The product can be used to grind at edges.

• The power plug can be changed to 1-phase or 3phase.

• A grind area of 280 mm.

Intended use

Use the product to grind concrete surfaces with different

hardness such as terazzo and stone tiles.

The product is used for light commercial operations at

private properties and small commercial spaces.

It is the owner’s/employer’s responsibility that the

operator has sufficient knowledge about how to use the

product safely. Supervisors and operators must have

2 917 - 001 -

WARNING: Do not use the product for other

tasks.

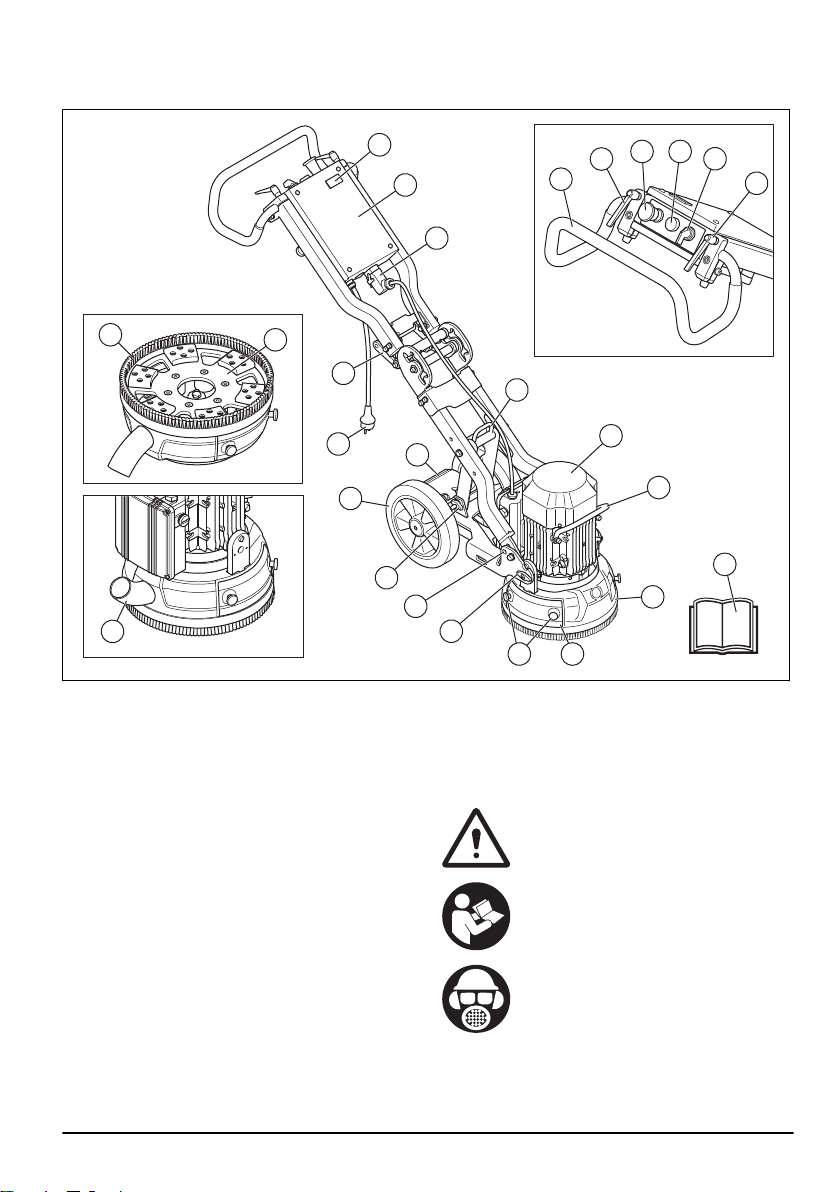

Product overview

22

23

24

4

5

2

3

2

1

9

10

12

6

7

8

21

14

11

15

19

18

20

25

13

16

17

1. Handle/Handlebar

2. Lock knobs for handlebar adjustment

3. Emergency stop

4. Overload lamp

5. ON/OFF switch

6. Hour meter

7. Electrical enclosure

8. Connection for motor cable

9. Angle joint handle

10. Power plug

11. Rubber wheels

12. Foot pedal

13. Lock knob

14. Lock function

15. Lock bolt to attach the motor/grinding head

16. Edge grinder, screws

17. Edge grinder, hatch

18. Grinding head cover

19. Lift handle, motor

20. Electric motor

21. Lifting eye

22. Brush strip

23. Tool plate

24. Connection, vacuum hose

25. Operator's manual

Symbols on the product

917 - 001 - 3

WARNING: Not careful or incorrect use can

result in injury or death to the operator or

others.

Read the manual carefully and make sure

that you understand the instructions before

you use the product.

Always put on hearing protection, eye

protection and breathing protection.

WARNING! The dust can cause breathing

problems. Use breathing protection. Do not

breathe exhaust fumes. Always make sure

that there is good airflow.

Note: Other symbols/decals on the product refer to

special certification requirements for some markets.

Product liability

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not from

the manufacturer or not approved by the

manufacturer.

• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product. Save

all warnings and instructions. Refer to the

warnings and instructions for future work, if it

is necessary.

• The safety section gives basic directions on how to

use the product correctly. This information is not an

alternative for professional knowledge and

experience. If you are in a situation where you do not

feel safe, stop and get professional support. Speak

to your dealer, service agent or an operator with

experience. Do not try a task where you do not feel

sure.

• Keep work area clean and bright, this will decrease

the risk of accidents.

Safety instructions for operation

WARNING:

that follow before you use the product. Save

all warnings and instructions for future

operations.

Read the warning instructions

WARNING: Overexposure to vibration can

cause circulatory damage or nerve damage

to persons with decreased blood circulation.

Get medical aid if you have symptoms of

overexposure to vibration. These symptoms

include numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes in

skin color or condition. These symptoms

usually show in the fingers, hands or wrists.

• Only use the product for operations that are given in

this manual. Refer to

• Use personal protective equipment. Refer

to

Personal protective equipment on page 5

• Do not go away from the product when the motor is

on.

• Connect the motor cable to the electrical enclosure

before you connect the plug.

• Do not let other operators use the product if they

have not read and understood the contents of this

operators manual.

• Only start the product with the brush strip attached.

Brush strip must seal tightly to the surface,

especially during dry surface operations.

• Make sure that the brush strip is not damaged and is

clean. Replace damaged brush strip.

• Keep the motor on until the fan comes to a complete

stop.

• Lift the grinding head if a check of the start

procedure is necessary.

• Only start the product when the grinding head is put

on the surface.

• Make sure that only approved persons are in the

work area.

• Do not use the product in areas where fire or

explosions can occur.

• Always disassemble the diamond tool after each

operation.

• Make sure that the tool plate does not rotate if you

lift up the product. The tool plate continues to rotate

for a while after the motor stops.

Intended use on page 2

.

.

4

917 - 001 -

• When you remove diamond tools, let the product

become cool and use protective gloves. Diamond

tools are very hot after use.

• Make sure to connect the product to a dust extractor

for removal of the dust.

• Make sure that the product is assembled correctly.

• To lift the product always use the lifting eye of the

product.

• Do not use the product if there are signs of damage.

• Only start the product when the grinding head

touches the surface, unless you do a check of the

ON/OFF switch.

• Only operate the product from behind with your 2

hands on the handle.

• Do not operate the product unless you receive

training before use. Make sure that all operators

receive training.

• Make sure that only approved persons are in the

work area, because there is a risk of serious injury.

• Make sure that clothing, long hair and jewelry do not

get caught in moving parts.

• Make sure that you are in a safe and stable position

during operation.

• Sudden appearance of persons and animals can

prevent safe operation of the product. Always

operate the product carefully and be prepared to

stop the product if it is necessary.

• Do not let children use or come near the product.

• Make sure that there is always one more person

near when you use the product. If an accident

occurs, you can receive help when it is necessary.

• Do not operate this product when you are tired, ill, or

if you use alcohol, drugs or medicine. This can

decrease your vision, your judgment or your

coordination.

• Do not use a product that has been changed from its

factory specification.

• Always use approved accessories. Speak to your

dealer for more information.

Personal protective equipment

WARNING: Read the warning instructions

that follow before you use the product.

• Always use correct personal protective equipment

when you operate the product. The personal

protective equipment does not erase the risk of

injury. The personal protective equipment decreases

the grade of injury if an accident occurs. Let your

dealer help you select the right equipment.

• Use approved eye protection while you operate the

product.

• Do not use loose, heavy and not applicable clothing.

Use clothes that let you move freely.

• Use approved protective gloves that enables a solid

hold.

• Use rubber protective gloves that prevents skin

irritation from wet concrete.

• Use an approved protective helmet.

• Always use approved hearing protection while you

operate the product. Noise for a long period can

cause noise-induced hearing loss.

• The product makes dust and fumes that contain

dangerous chemicals. Use an approved breathing

protection.

• Use boots with steel toe-caps and non-slip soles.

• Make sure that you have a first aid kit near.

• Sparks can occur when you operate the product.

Make sure that you have a fire extinguisher near.

Electrical safety

WARNING: There is always a risk of shocks

from electrical products. Do not use the

product in bad weather conditions. Do not

touch lightning conductors and metal

objects. Always use the product as given in

this operator’s manual to prevent injury.

CAUTION: The product obeys the

requirements in EN61000-3-11 and is a

subject for conditional connection to the

power mains. Speak with the supply

authority for instructions on how to connect

the product.

Only connect the product to the power

mains with resistance lower than 0.28 Ω.

Get the interface point of the system

resistance from the supply authority.

If the power mains has higher system

resistance, short voltage drop can occur

when the product is started. This can

influence the operation of other products, for

example flicker on the lights.

• Make sure that the power, fuse and mains voltage

are the same as the voltage shown on the rating

plate of the product.

• Always stop the product before you disconnect the

power plug.

• Do not use the product if the cord or plug is

damaged. Hand it in to an approved service center

for repair. A damaged cable can cause serious injury

and death.

• Use the cord correctly. Do not use the cord to move,

pull or disconnect the product. Hold the plug to

disconnect the power cord.

• Do not operate the product in water depths where

the equipment of the product gets wet. The

equipment can be damaged and the product can

become live and cause injury.

• Do not get more moisture into the product than that

is supplied by the water system. Prevent rain to

917 - 001 -

5

come in touch with the product. Water that enters a

power tool increases the risk of electrical shock.

• Always have the power cord disconnected when you

connect or disconnect the connection for the motor

cable and the electrical enclosure.

Safety devices on the product

WARNING: Read the warning instructions

that follow before you use the product.

Grounded product instructions

WARNING: Incorrect connection can result

in electrical shock. Speak to an approved

electrician if you are not sure if the product

is correctly grounded.

Do not change the power plug from its

factory specification. If the power plug is not

correct for the mains outlet, let an approved

electrician install a correct mains outlet.

Obey local regulations and laws.

If you do not fully understand the

instructions about the grounded product,

speak to an approved electrician.

The product has a grounded cord and power plug.

Always connect the product to a grounded mains outlet.

This decreases the risk of electrical shock if there is a

malfunction.

Do not use adapters with the product.

Extension cables

• The mark on the extension cable must be the same

or higher than the value written on the rating plate of

the product.

• Use grounded extension cables.

• When you operate a power tool outdoor, use

extension cable that is applicable for outdoor

operation. Use of a power cord applicable for

outdoor operations decreases the risk of electrical

shock.

• Keep the connection to the extension cable dry and

off the ground.

• Keep cable away from heat, oil, sharp edges or

moving parts. Damaged or too large cable increases

the risk of electrical shock.

• Check that the cables are not damaged and in good

condition. Do not use the product if a cable is

damaged. Let an approved service center repair the

product.

• To prevent overheating, do not use the extension

cable while it is folded.

• Make sure that the power cord is behind you when

you use the product. This is to prevent damage to

the power cord.

• If you use an extension cable, use only approved

extension cables with sufficient length.

• Do not use a product with defective safety devices.

• Do a check of the safety devices regularly, refer to

Daily maintenance on page 14

are defective, speak to your HTC Floor Systems

approved service agent.

• Do not change the safety devices.

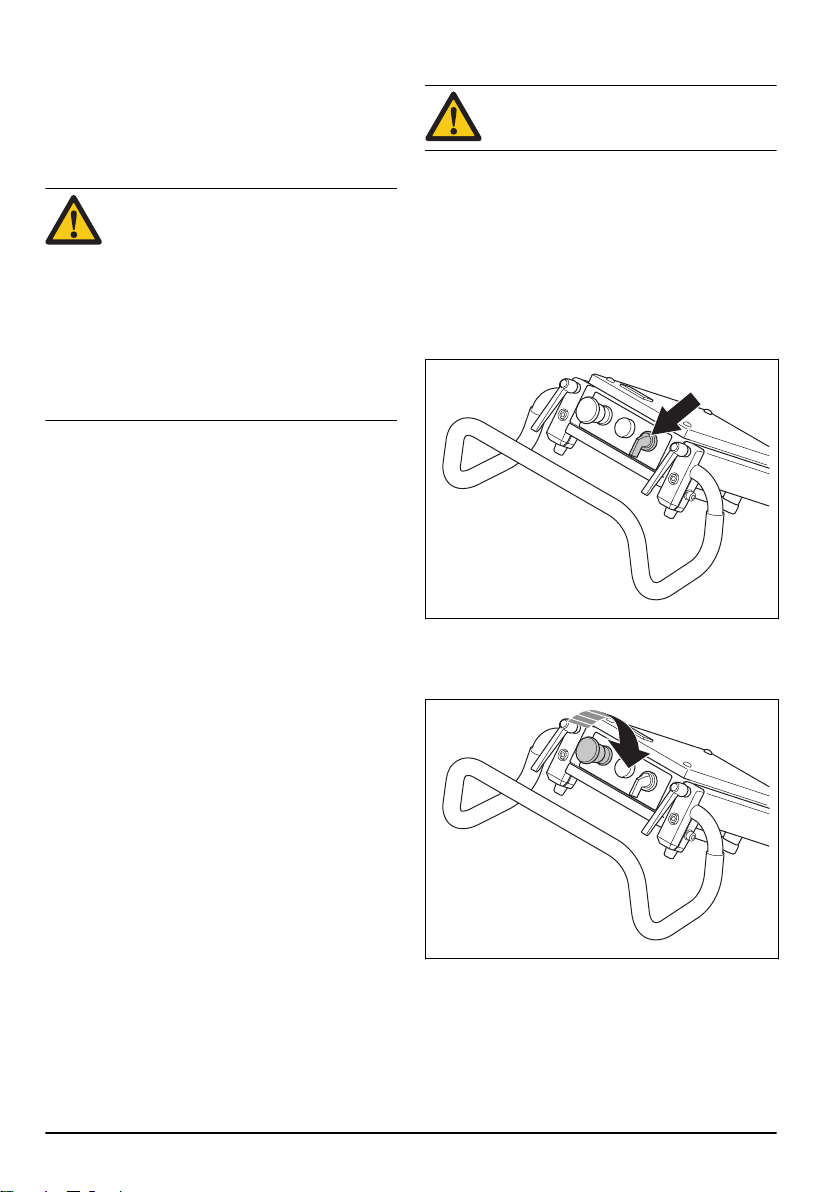

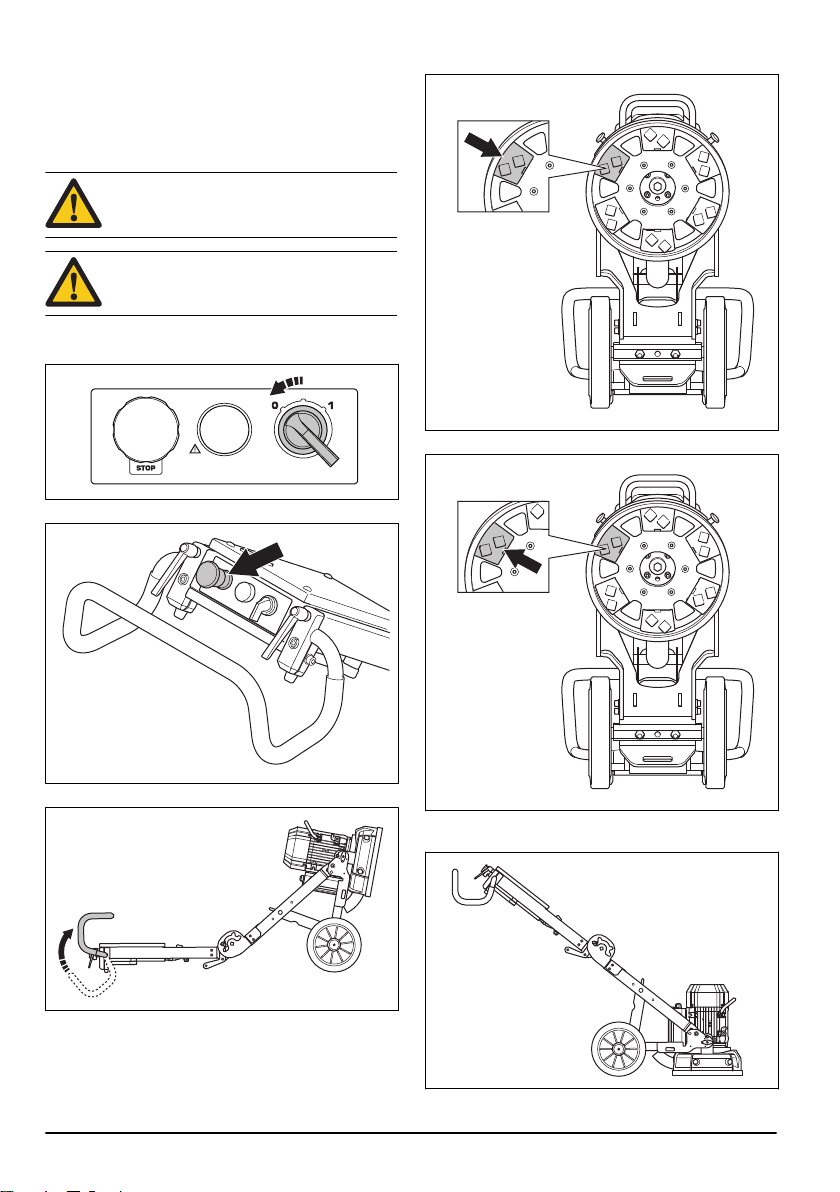

ON/OFF switch

The ON/OFF switch is used to start and stop the

product.

To do a check of the ON/OFF switch

1. Turn the emergency stop button clockwise to make

sure that emergency stop button is disengaged.

. If the safety devices

6

917 - 001 -

2. Push down the handle to lift the grinding head from

A

B

the floor.

3. Turn the ON/OFF switch to 1 to start the product.

4. Wait for 5 seconds, this is to let the product operate

at the idle speed.

5. Turn the ON/OFF switch to 0 to stop the product.

Emergency stop

The emergency stop is used to quickly stop the motor.

The emergency stop at the product breaks the mains

power supply.

To do a check of the emergency stop

1. Push the emergency stop button (A) and make sure

that the motor stops.

917 - 001 -

2. Turn the emergency stop button clockwise (B) to

disengage.

Safety instructions for maintenance

• Keep all parts in good condition and make sure that

all fixtures are correctly tightened.

• Do not use a product that is defective. Do the safety

checks, maintenance and the servicing as given in

this manual. All other maintenance work must be

done by an approved service agent.

• Stop the product when you replace the diamond

tools. Turn the ON/OFF switch to 0 and push the

emergency stop button.

• Do the inspection and/or maintenance with the motor

stopped and the power plug disconnected.

• Do the maintenance to make sure that the product

operates correctly. Refer to

Maintenance on page

14

7

Introduction

WARNING: Before you operate the product,

you must read and understand the safety

chapter.

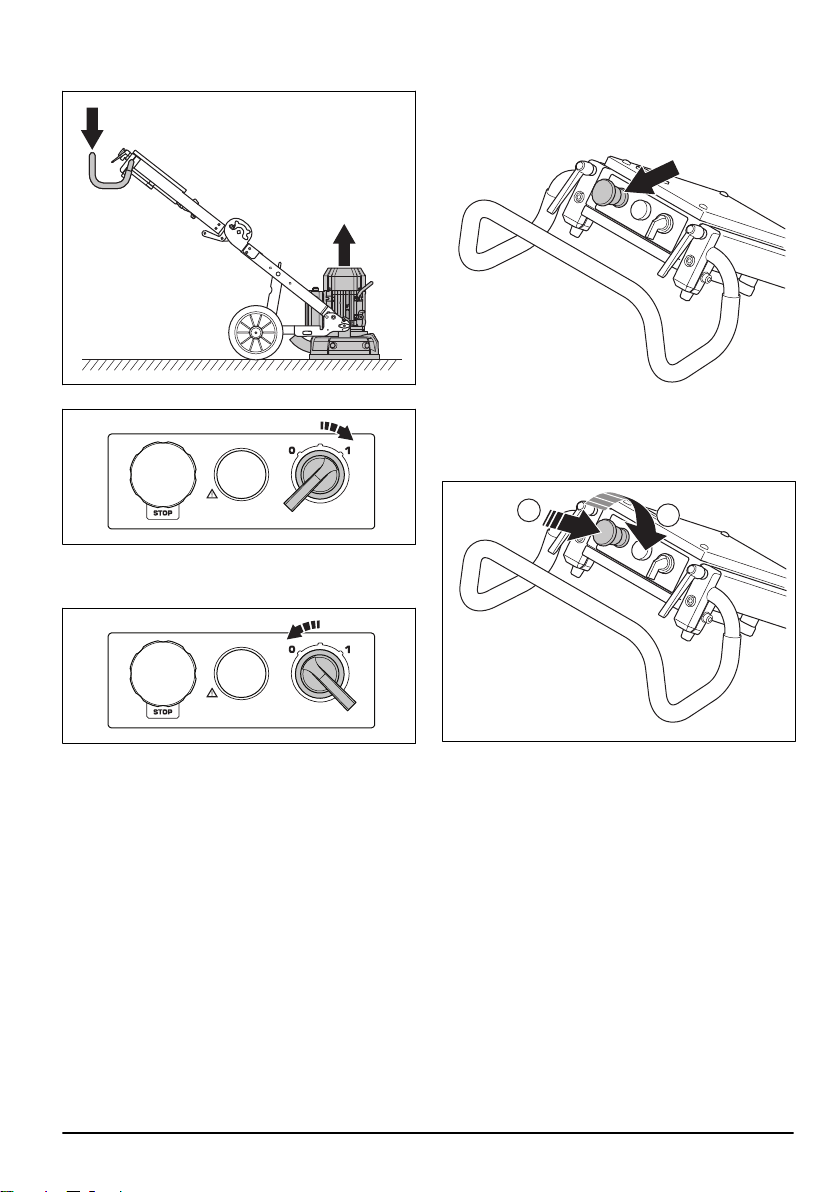

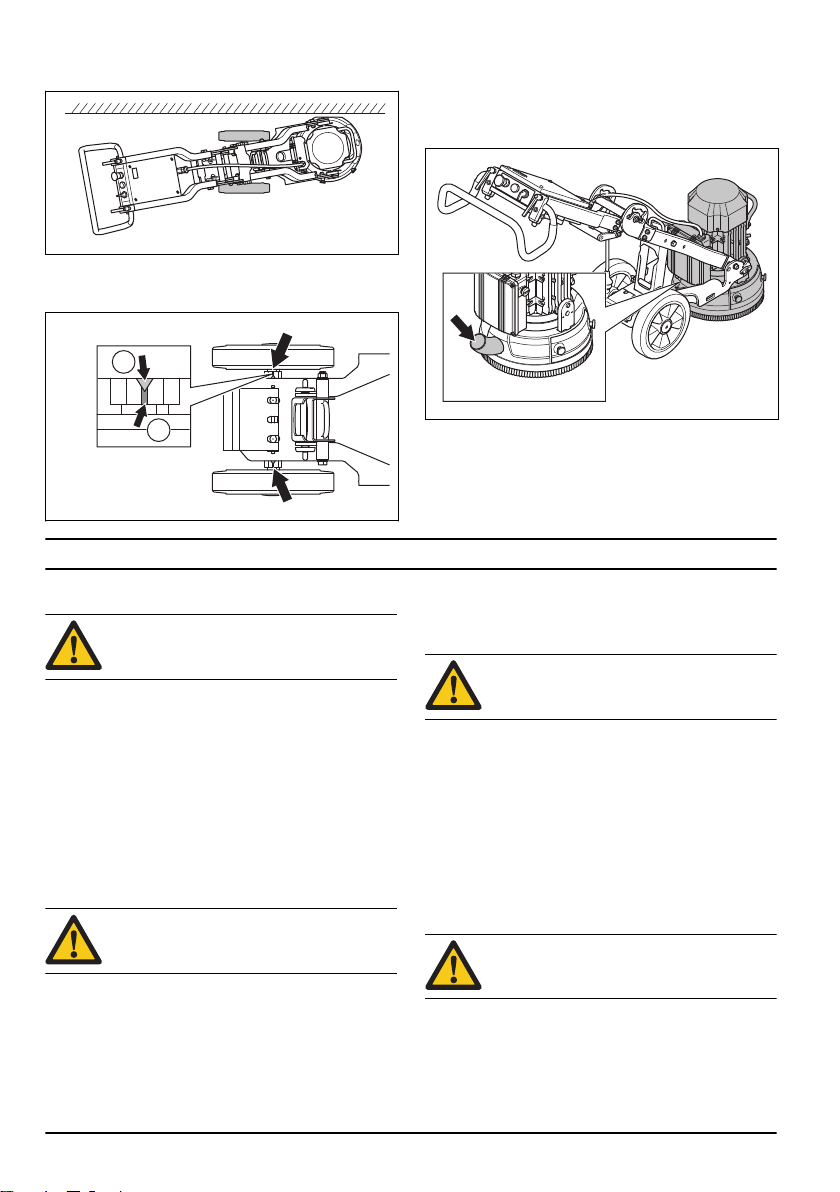

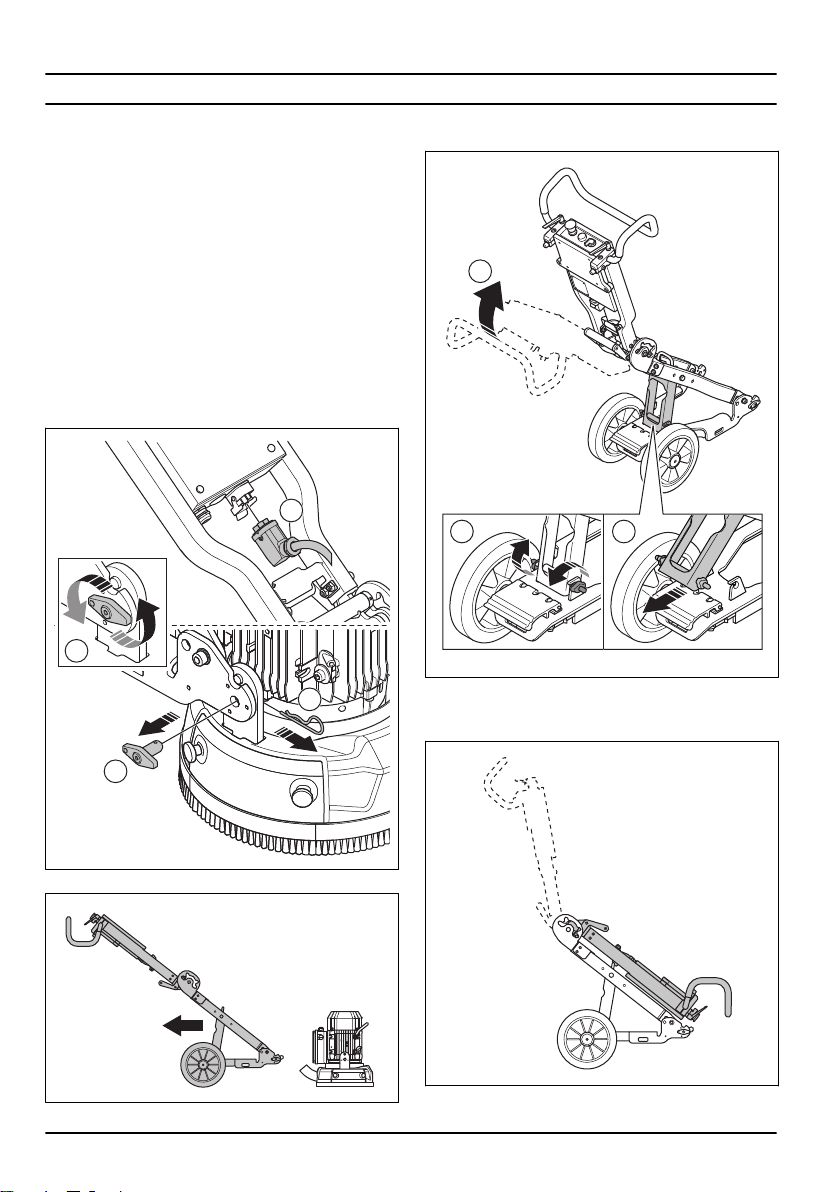

Product positions

Operation position

Servicing position

CAUTION: Only put the product in the

servicing position on a horizontal surface.

Operation

Tilted transport position

Lift transport position

Put a protection between the motor and the electrical

enclosure to prevent damage to the product.

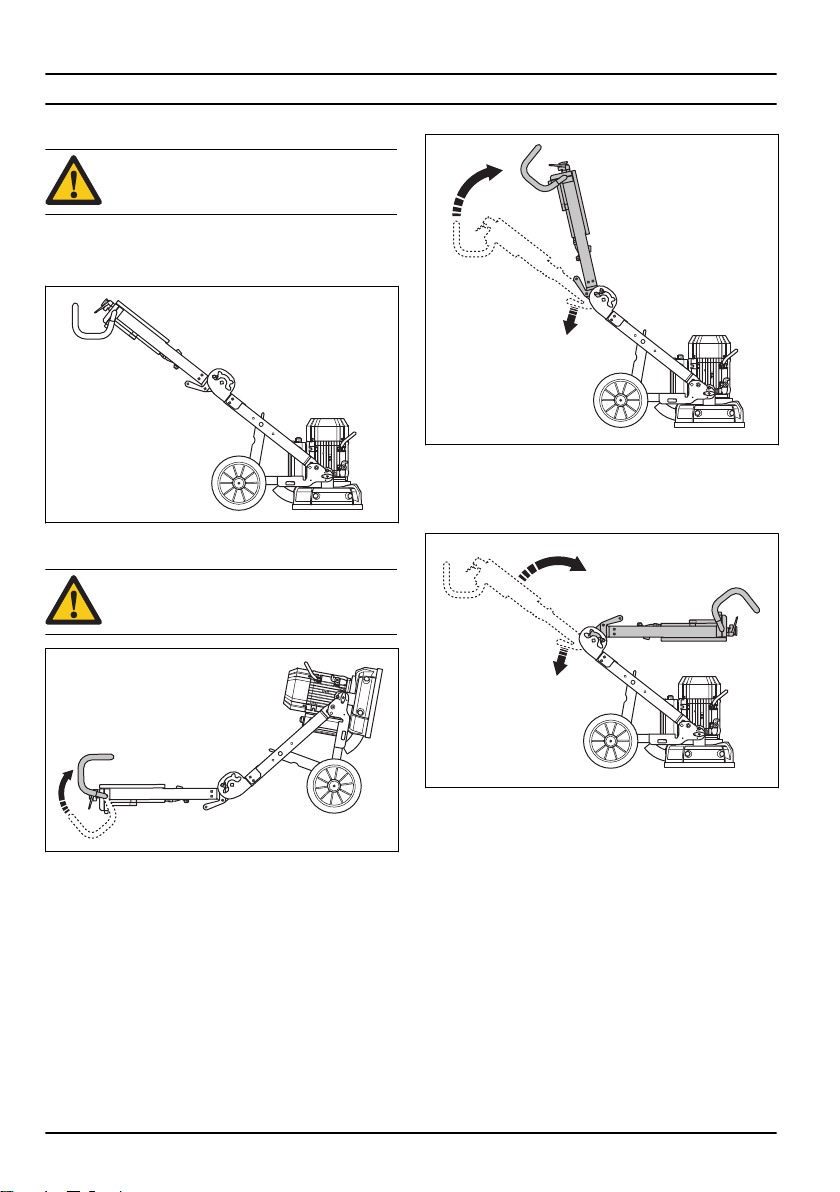

To adjust the handlebar

The handle lock knobs are operated clockwise,

counterclockwise or put in idle position.

8

917 - 001 -

1. Loosen the lock knobs (A) and adjust the handle (B)

A

B

A

A

B

A

B

B

A

C

to idle position.

2. Tighten the lock knobs to set the position.

3. When the handle position is set, pull the handle lock

knobs up (A) and put them into idle position (B).

Adjust the angle to set up a good work position for

different operators.

1. Disconnect the motor cable (A) from the electrical

enclosure.

2. Remove the lock knob (B).

3. Select the applicable position (C) for the operation

and put the lock knob (B) in correct hole. The bottom

hole increases the grinding pressure and the height

of the handlebar. The top hole decreases the

grinding pressure and the handlebar.

Handle heights

Hole position

To adjust the frame height

The angle of the frame can be changed to divide the

weight of the chassis. This is to decrease or increase

the grinding pressure against the surface.

917 - 001 - 9

Top 835/33

Center 925/36

Lower 1000/39

Grinding pressure

Refer to the tables for the grinding pressure against the

surface for each hole position.

Low, kg/lbs

23/51 25/55* 27/60

With accessory counterweight

17/37 20/44* 23/51

*Factory setting

Handle height, mm/inch

Center, kg/lbs Top, kg/lbs

Diamond tools

There are many types of diamond tools for the product.

Speak to your approved service center or go to

www.htc-floorsystems.com to select correct diamond

tool.

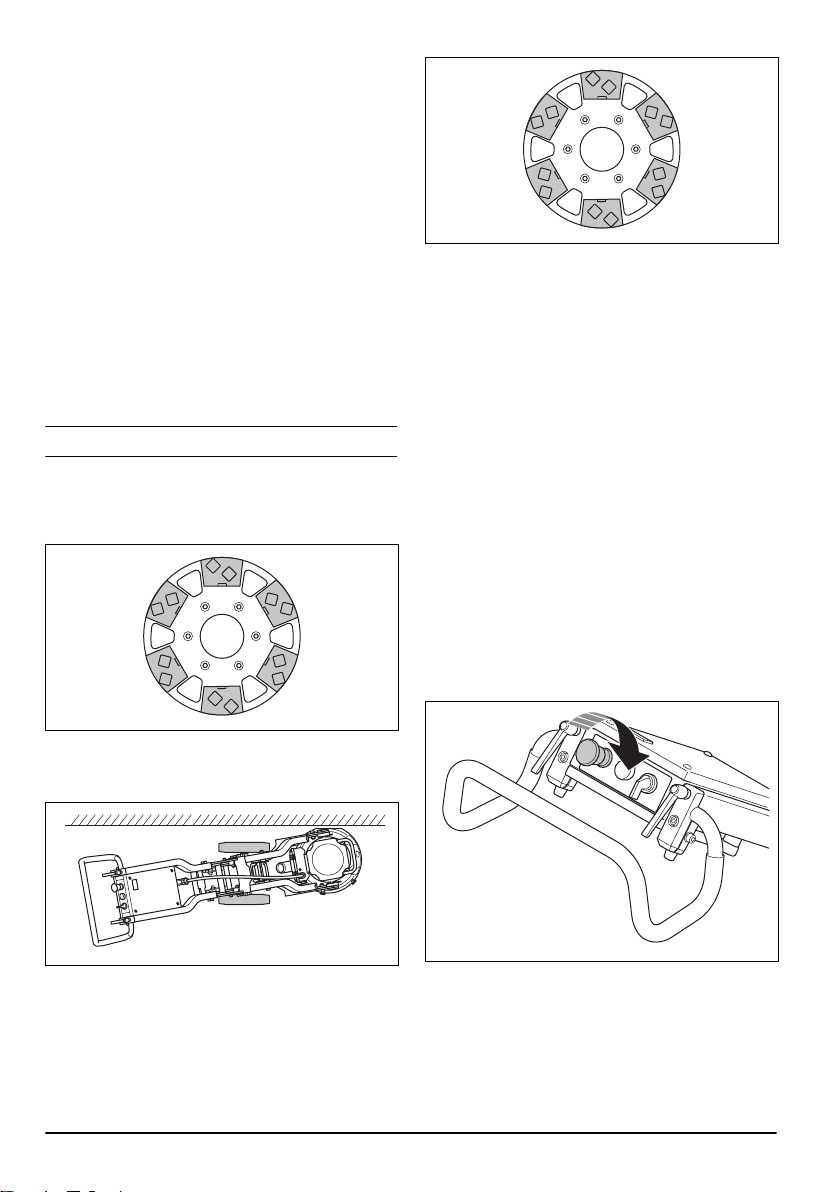

Installation of the diamond tools

The installation of the diamond tools on the tool plate

has effect on the performance of the product. The

diamond tool type together with the number of segments

on the diamond tool is important.

Use metal bond diamond tools with 2 segments for

usual grind operations, to make the surface level or light

removal.

Use metal bond diamond tools with 1 diamond segment

to increase the diamond tool pressure. This installation

is for heavy removal with much force.

For the heaviest removal, we recommend to use tools

that only run in one direction with PCD diamond tops.

Note: T-Rex tools are made to run only in one direction.

Metal bond diamond tools

• Full set - outer row. This installation removes the

surface layer with much force.

To do before you operate the product

1. Read the operator's manual carefully and make sure

that you understand the instructions.

2. Do daily maintenance. Refer to

on page 14

3. Make sure that the product is assembled correctly

and is not damaged.

4. Put the product on the work area.

5. Make sure that there are diamond tools on the tool

plate and that they are tightly attached.

6. Connect the dust extractor to the product. Refer to

.

To connect a dust extractor on page 14

7. Adjust the handlebar to set the necessary work

height.

8. Make sure that the motor cable is connected to the

electrical enclosure before the product is connected

to an electric socket.

9. Connect the power plug of the product into the mains

outlet.

10. Turn the emergency stop button clockwise to make

sure that the emergency stop is disengaged.

Daily maintenance

Installation for edge grinding

This product can grind at an edge.

• Full set - outer row.

10

11. Make sure that you know in which direction the

motor rotates.

917 - 001 -

To change in which direction the motor rotates

CAUTION: The T-Rex tools are made to

rotate in only one direction.

1. Look at the arrow to see in which direction the motor

rotates.

To start the product

1. Push down the handle lightly to lift the grinding head

from the surface, approximately 1 mm. This

decreases the pressure against the surface. Do not

lift the grinding head fully from the surface.

2. Turn the 2 pins in the power plug in the opposite

direction to change in which direction the motor

rotates. This is only applicable for 3-phase.

2. Turn the ON/OFF switch to 1 to start the product. In

less than 5 seconds the product operates at the idle

speed.

To stop the product

CAUTION:

surface when you stop the motor. The tool

plate rotates for a while after the motor

stops. Much off the dust can blow off in to

the air and the surface can be damaged.

CAUTION: If you grind adhesive asphalt,

paint or equivalent material, lift up the front

of the product slightly when the tool plate

stops. The product can attach to the

adhesive surface if not lifted.

1. Turn the ON/OFF switch to 0 to stop the motor.

Do not lift the tool plate from the

917 - 001 -

11

2. Keep the tool plate against the surface. Make sure

that the tool plate does not rotate before you lift up

the front.

3. Pull out the power plug.

To replace the diamond tools

WARNING: Disconnect the power plug.

WARNING: Use protective gloves, as

diamond tools can become very hot.

1. Turn the ON/OFF switch to 0 and disconnect the

power plug to stop the product.

2. Push the emergency stop.

4. Use a hammer to remove the diamond tools.

5. Attach new diamond tools on the tool plate.

3. Put the product into servicing position.

12

6. When the diamond tools are replaced, put the

product into operation position.

917 - 001 -

To grind at an edge

A

B

1. Remove the screws (A) and the hatch (B).

2. Attach the hatch onto the holder.

3. A guard behind the hatch prevents damage to the

wall. Remove the 2 screws and the guard if it is

necessary to grind near the wall.

4. Lift the foot pedal.

5. Use your foot to give the wheels the right angle.

917 - 001 -

6. If it is necessary to grind on the right side, the

wheels must point in the left direction.

13

7. If it is necessary to grind on the left side, the wheels

A

B

must point in right direction.

8. For straight wheel direction, align the red mark on

the wheel axle (A) with the red mark on the frame

(B).

Maintenance

Introduction

WARNING: Before you do maintenance,

you must read and understand the safety

chapter.

For all servicing and repair work on the product, special

training is necessary. We guarantee the availability of

professional repairs and servicing. If your dealer is not a

service agent, speak to them for information about the

nearest service agent.

Daily maintenance

Daily maintenance means that you clean the product.

Also that you do a check of the electrical supply, the

brush strip and the grind holder.

To clean the product

CAUTION: A blocked air intake decreases

the performance of the product and can

cause the motor to become too hot.

• Always pull out the plug from the mains outlet before

you clean, do maintenance or assemble the product.

• Always clean all the equipment at the end of the

work day. Do not use a high pressure washer to

clean the product.

To connect a dust extractor

Use a HTC Floor Systems dust extractor system.

1. Connect the dust extractor to the product. Use a 50

mm (2 inch) hose.

2. Make sure that the filters in the dust extractor are

clean and not damaged. Monitor the dust during the

operation.

• Remove blockage from all air openings. The product

must always have sufficiently cool temperature.

To do a check of the electrical supply

WARNING: Do not use damaged cables. A

damaged cable can cause serious injury or

death.

• Make sure that the power cord and extension cable

are not damaged and in good condition.

• Do not use the product if the power cord is

damaged. Let an approved service center repair the

product.

To do a check of the brush strip

• Make sure that the brush strip is full.

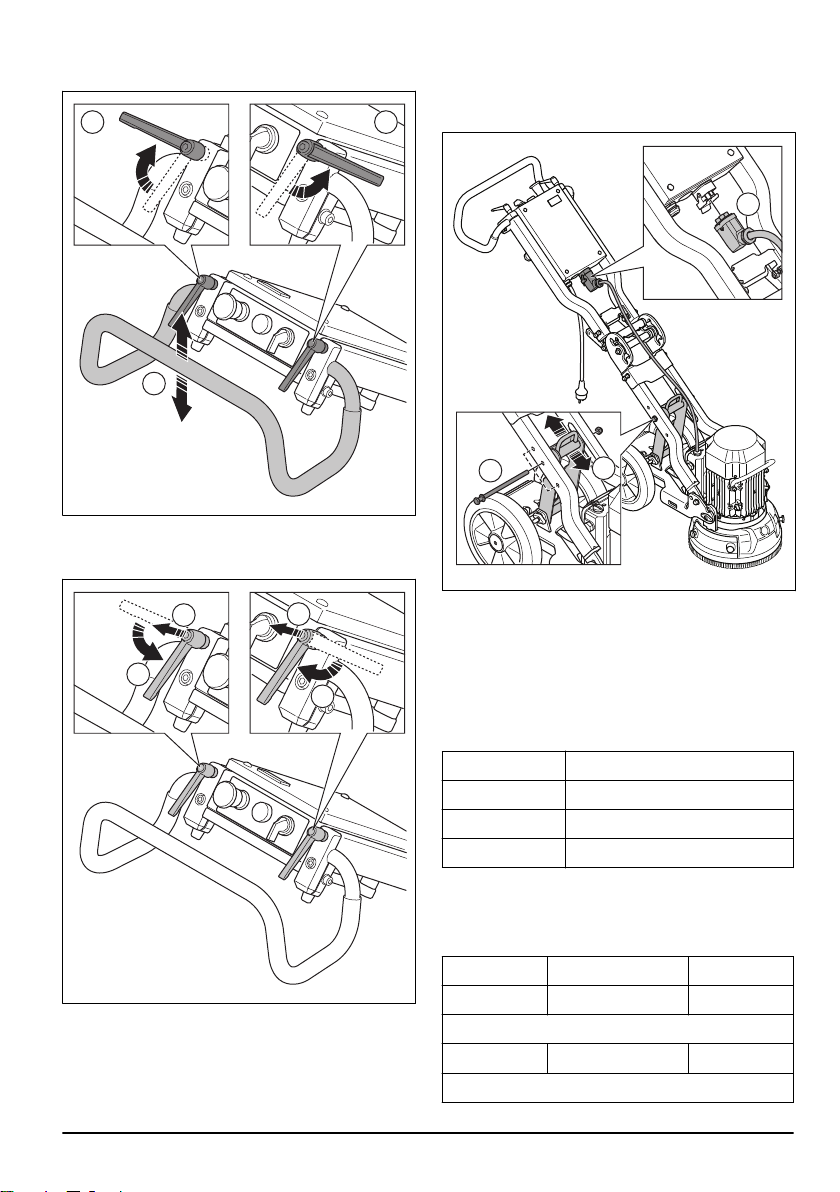

• Make sure that the brush strip touches the surface.

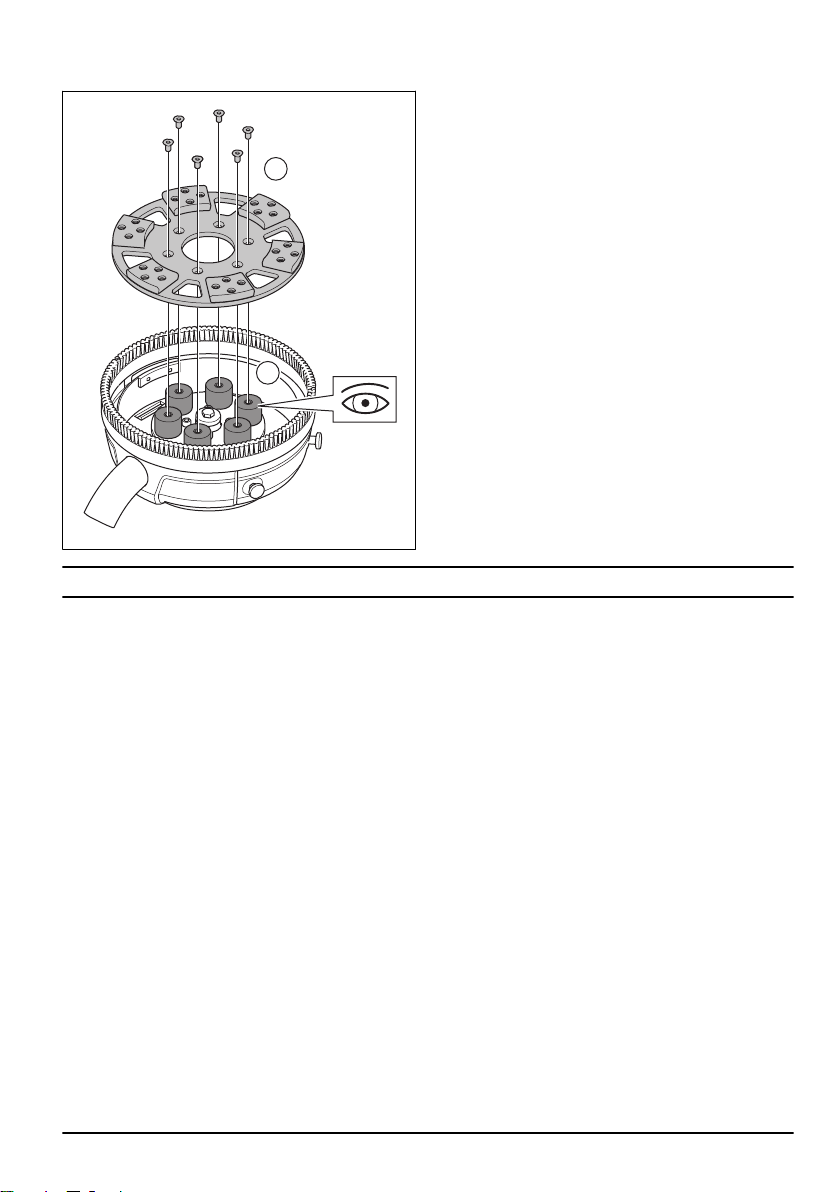

To do a check of the grind holder

CAUTION: The condition of the grind holder

is important for the performance and the

safety.

• Remove the tool plate (A).

14 917 - 001 -

• Examine the grind holder for damages and the wear

A

B

of the rubber cylinders (B).

Troubleshooting

• Replace the rubber cylinders if it is necessary.

The product does not start

• Make sure that the power supply and the power

cords are not damaged.

• Examine the emergency stop button, turn the button

clockwise to release the emergency stop.

• Examine the overload lamp. If the overload lamp is

on, let the motor cool down for some minutes until

the product is automatically reset.

The product is not easy to hold on to

• Too small number of diamond tools are installed on

the product.

• The selected type of diamond tool is not correct for

the surface.

• High current is used by the motor for the operation.

• Use the number of diamond tools that is

recommended to decrease the force on the product

and the operator. Refer to

on page 10

Metal bond diamond tools

.

The product has sudden movements

• Make sure that all diamond tools are installed

correctly and that all have the same height.

917 - 001 - 15

The product stops after only a while

• If the product overloads, the overload protection

engages and stops the motor.

• Decrease the load. The lower hole is for a higher

handlebar and increased grind pressure. The top

hole is for a lower handlebar and decreased grind

pressure.

• The product restarts after approximately a minute,

when the temperature of the motor is decreased to

usual level.

• Make sure that the extension cables are not too

short.

The product stops during startup

Correct voltage supply is necessary for a good motor

performance. Too long extension cables and/or a too

small gage decreases the power of the motor during

operation.

• If the motor overloads, the overload lamp comes on.

Wait 2 minutes and try again. When this does not

help, speak to an approved service workshop.

• Make sure that the extension cables are not too

short.

Transportation and storage

B

A

C

D

A

B

C

To set the product in transport position

Put some type of protection on the product during

transportation. The protection keeps natural elements

such as rain and snow away from the product.

The product can be divided into 2 components. This

makes the transportation easier.

Always move the product with the lifting eye and the

handlebar.

1. Disconnect the motor cable from the electric

enclosure (A).

2. Loosen the lock bolts some turns to release the

pressure (B).

3. Pull out the lock pins (C) and remove the lock bolts

(D) on each side of the grinding head.

5. Put the product in tilted transport position (A).

Loosen the lock knobs (B) on the support foot.

4. Remove the wheel chassis from the grinding head.

16

6. Fold the support foot (C).

7. Hold down the handle on the angle joint. At the same

time push the top part of the frame carefully forward.

917 - 001 -

8. Fold down the product carefully.

A B

3X

9. Lock the product with the lock pin and bolt (B).

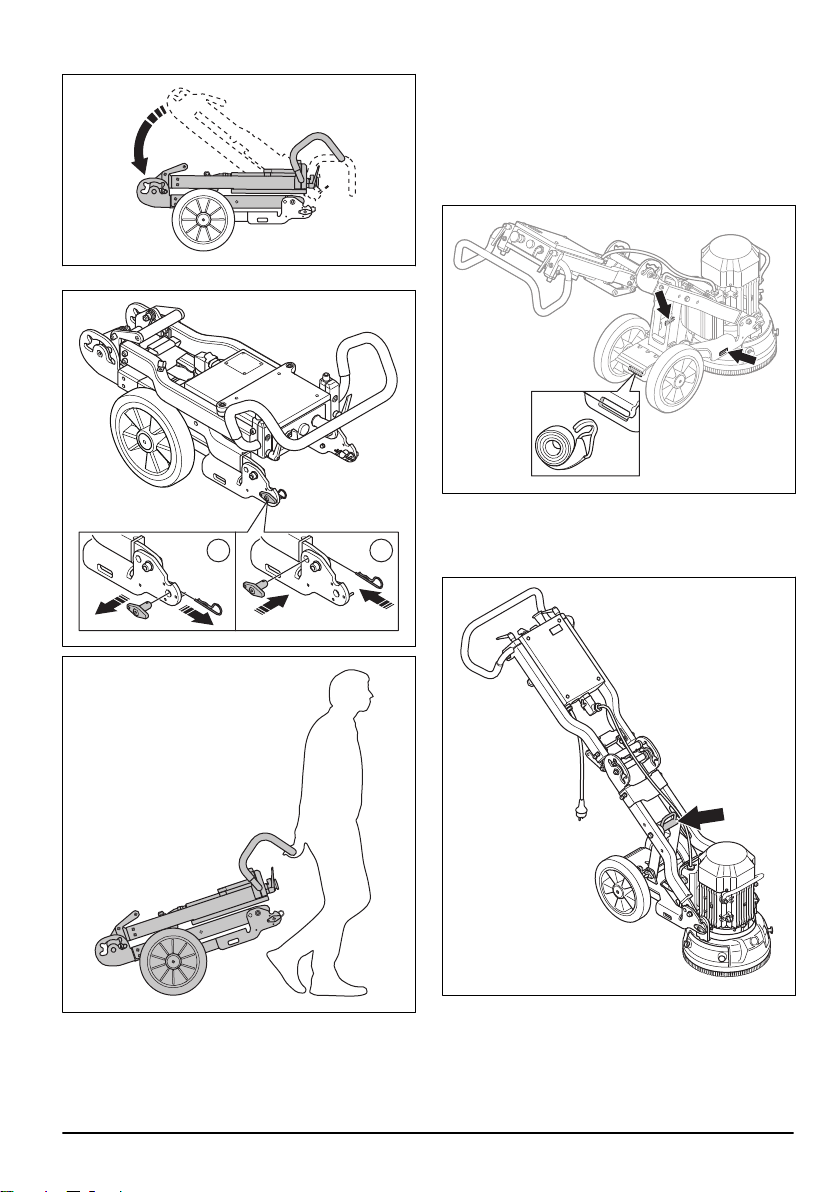

To attach the product to a vehicle for transportation

Attach the product during transportation in order to

prevent accidents and damage to the equipment. The

product has holes that are used with straps to attach the

product to the vehicle.

1. Attach the strap into the holes.

2. Attach and tighten the strap to the vehicle.

To lift the product

1. Use the lifting eye to lift the product.

917 - 001 -

2. Make sure that the product is balanced when you lift

it. Let a bystander help you when you lift the product.

17

Loading...

Loading...