Page 1

EN

MANUAL

MANUAL

HTC D60

Translation of manual from original language

Page 2

Page 3

HTC D60

Contact information

HTC Sweden AB Box 69

SE-614 22 Söderköping, Sweden Tel: +46 (0) 121-294 00

Fax: +46 (0) 121-152 12

You can nd addresses for our retailers and service partners on our website:

www.htc-oorsystems.com

Always specify the model and serial number when asking questions about your machine.

Trademarks

HTC is a trademark owned by HTC Sweden AB. Other names and products mentioned in this manual may be registered trademarks owned by the relevant companies.

© 2017 HTC Sweden AB. All rights reserved.

3

www.htc-oorsystems.com

V 1.0

Page 4

EC Declaration of conformity

Manufacturer: HTC Sweden AB

Box 69

SE-614 22 Söderköping, Sweden

+46 (0)121-29400

Type of equipment: Dust extractor

Make: HTC

Model: HTC D60

Year of manufacture: See machine name plate

Serial number: See machine name plate

Original of the EC declaration of conformity (Swedish).

Other languages are translations of the original of the EC declaration of conformity.

HTC D60

Söderköping 21.11.2017

Peter Lundgren

Development Manager

HTC Sweden AB

Björn Jeansson

Production Manager

HTC Sweden AB

www.htc-oorsystems.comV 1.0

4

Page 5

HTC D60

1. Standards

As the manufacturer, we hereby declare under our sole responsibility that the above product with

serial numbers from 2017 onward conforms to the applicable regulations in:

Standard Description

60335-1

60335-2-69

UL73 UL STANDARD FOR SAFETY MOTOR-OPERATED APPLIANCES

CAN/CSA

E60335-2-69-01 R2010,

DIRECTIVE 2014/30/EU Electromagnetic Compatibility (EMC) Directive

DIRECTIVE 2014/35/EU The Low Voltage Directive (LVD)

ISO 3746:2010

ISO 11203:2010 Acoustics -- Noise emitted by machinery and equipment

This product was CE marked in 2017.

The technical documentation is available from the manufacturer.

Houshold and similar electrical appliances - Safety - Part 1: General requirements

Household and similar electrical appliances - Safety - Part 2-69: Particular

requirements for wet and dry vacuum cleaners, including power brush, for

commercial use

Safety of Household and Similar Electrical Appliances - Part 2: Particular

Requirements for Wet and Dry Vacuum Cleaners, Including Power Brush,

for Industrial and Commercial Use (Adopted CEI/IEC 60335-2-69:1997,

second edition, 1997-02, including Amendment 1:2000, with Canadian deviations)

Acoustics -- Determination of sound power levels and sound energy levels

of noise sources using sound pressure

5

www.htc-oorsystems.com

V 1.0

Page 6

HTC D60

Table of contents

1. Standards 5

2. Introduction 7

2.1 General information 7

2.2 Liability 7

2.3 Manual 7

2.4 Machine name plate 8

3. Machine description 9

3.1 General information 9

3.2 Machine overview 10

4. Transport & storage 11

4.1 Handling and storage 11

4.2 Transport & lifting 11

5. Operation 12

5.1 Safety 12

5.2 General information 12

5.3 Various positions of the pre-separator & dust extractor 12

5.4 Control panel 13

5.5 Display use menu 14

5.6 Dust ltration 15

5.7 Filter cleaning 17

5.8 Replacing the dust bag 18

5.9 Display information menu 19

6. Accessories 20

6.1 Automatic lter cleaning 20

6.2 Remote control 21

7. Maintenance 22

7.1 General information 22

7.2 Cleaning the dust extractor 22

7.3 Daily maintenance 22

7.4 Weekly maintenance 23

7.5 Filter replacement 24

7.6 Control cabinet 25

8. Service 26

8.1 Repairs 26

8.2 Spare parts 26

8.3 Motor protection 26

8.4 Function checks 27

9. Troubleshooting 28

9.1 Warnings and error messages 29

10. Technical data 31

11. Environment 33

www.htc-oorsystems.comV 1.0

6

Page 7

HTC D60

2. Introduction

2.1 General information

Together with HTC's oor grinders, HTC's dust extractor is designed to create as dust-free environment as possible in conjunction with the dry grinding of stone and concrete oors. The dust sucked

up is collected in, for example, a bag system.

Read the manual carefully so that you know how to use and maintain the dust extractor before using

it. Contact your local retailer for further information. For contact information, see Contact Information

at the start of the manual.

2.2 Liability

Even though every effort has been made to make this manual as complete and accurate as possible, we bear no responsibility for incorrect or missing information. HTC reserves the right to change

descriptions in this manual without giving prior notice.

This manual is protected by the Copyright Act and no part of it may be copied or used in any other

way without the written approval of HTC.

2.3 Manual

In addition to general functions, this manual contains information on areas of use and care of the dust

extractor.

Safety Instructions – Explanation of Symbols

The following symbols are used in the document to indicate where special attention is needed.

Warning!

This symbol means Warning! and indicates a risk of personal injury or material

damage in the event of incorrect use of the dust extractor. If you see this symbol

next to a section of text, you must be particularly careful when reading through

the text and not carry out any stages of which you are unsure. This is for your own

and other users’ safety and to avoid damage to the dust extractor.

Note!

This symbol means Note! and indicates a potential risk of material damage in

the event of incorrect use of the dust extractor. If you see this symbol next to a

section of text, you must be particularly careful when reading through the text and

must not carry out any stages of which you are unsure. This is to avoid damage to

the dust extractor.

Tip!

This symbol means Tip! You can get tips and advice on ways to make operating

your dust extractor easier, and ways to avoid wear. When you see this symbol you

should read the accompanying text to facilitate your work and prolong the service

life of the dust extractor.

7

www.htc-oorsystems.com

V 1.0

Page 8

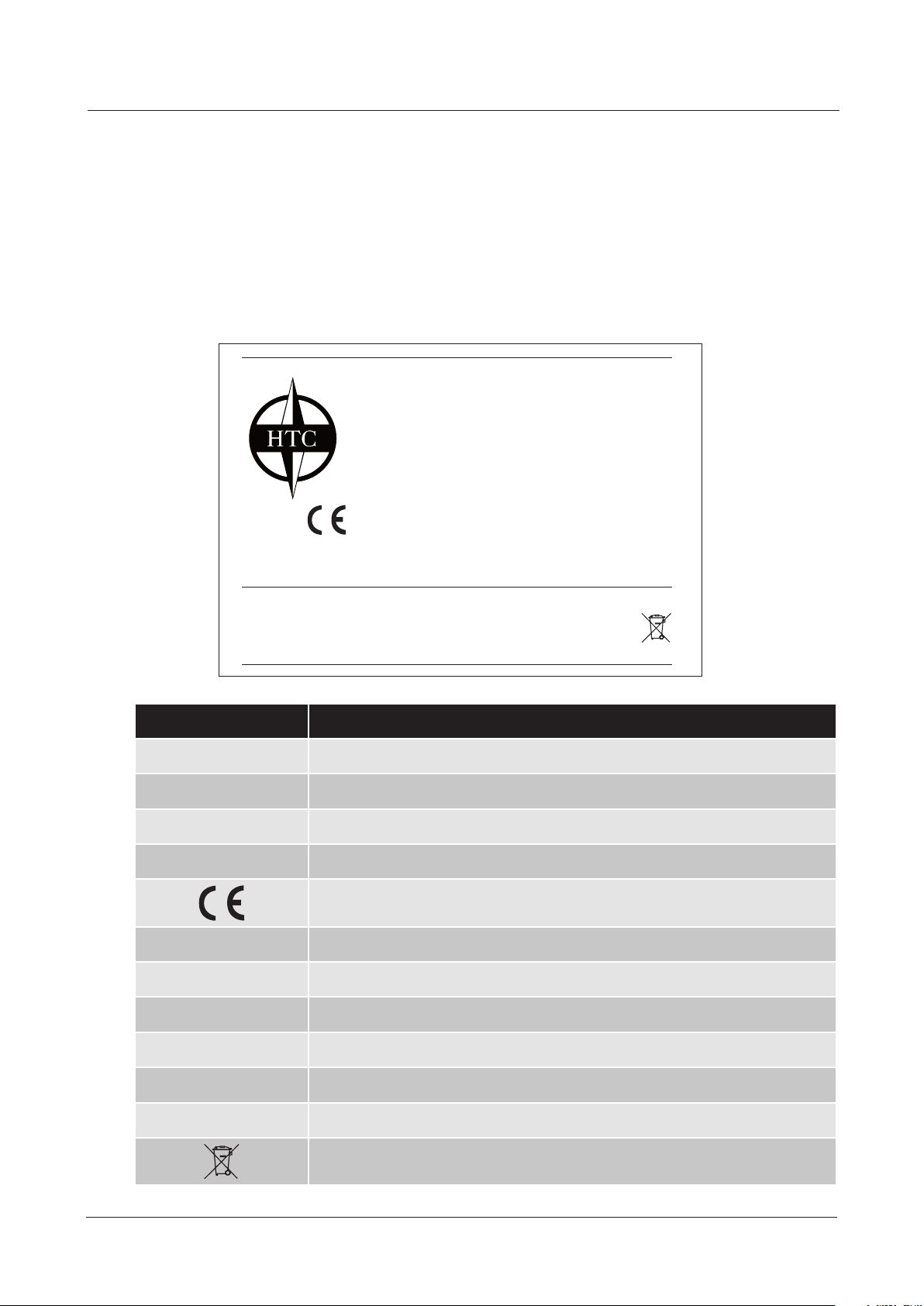

2.4 Machine name plate

The machine name plate provides the following information. The model and serial number must be

specied when ordering spare parts for the machine.

HTC D60

Model

Part no :

Serial no

MFG Date

Voltage :

Rated Current :

Power :

HTC Sweden AB

P.O Box 69. SE-614 22 Söderköping. Sweden

Phone +46 (0)121 294 00 Fax +46 (0)121 152 12

Internet www.htc-floorsystems.com

Name Description

Model Model

Part no Part no

Serial no Serial no

:

:

:

Frequency :

Weight :

Enclosure :

Made in Sweden

MFG date MFG date

Approved standards. Only one example is shown here, the machine name

plate shows the correct approved standards. Also see standards page 5

Voltage Voltage (VAC)

Rated current Rated current (A)

Power Power (kW/hp)

Frequency Frequency (Hz)

Weight Weight (kg/Ibs)

Enclosure Enclosure

Recycling. See Recycling page 33

www.htc-oorsystems.comV 1.0

8

Page 9

HTC D60

3. Machine description

3.1 General information

The machine is a dust extractor with an integrated pre-separator for industrial and building use

intended for the dry vacuuming of dust particles, e.g. concrete, wood, stone etc. The dust extractor

is equipped with a pre-separator, where the majority of the dust is collected instead of being sucked

into the actual vacuum cleaner, as well as a two-stage lter system, a coarse lter followed by a ne

lter.

It is also equipped with a lter cleaning system that unloads the vacuum cleaner's lter increasing the

service life and maintaining the performance of the dust extractor.

To handle the collected dust, a bag system is used on the pre-separator and dust extractor. To prevent bags from being sucked into the pre-separator or dust extractor, they are equipped with a rubber

valve that closes during operation.

The pre-separator can be raised and lowered with a simple movement and easily removed from the

chassis if necessary.

The dust extractor can also be controlled from HTC DURATIQ grinder.

9

www.htc-oorsystems.com

V 1.0

Page 10

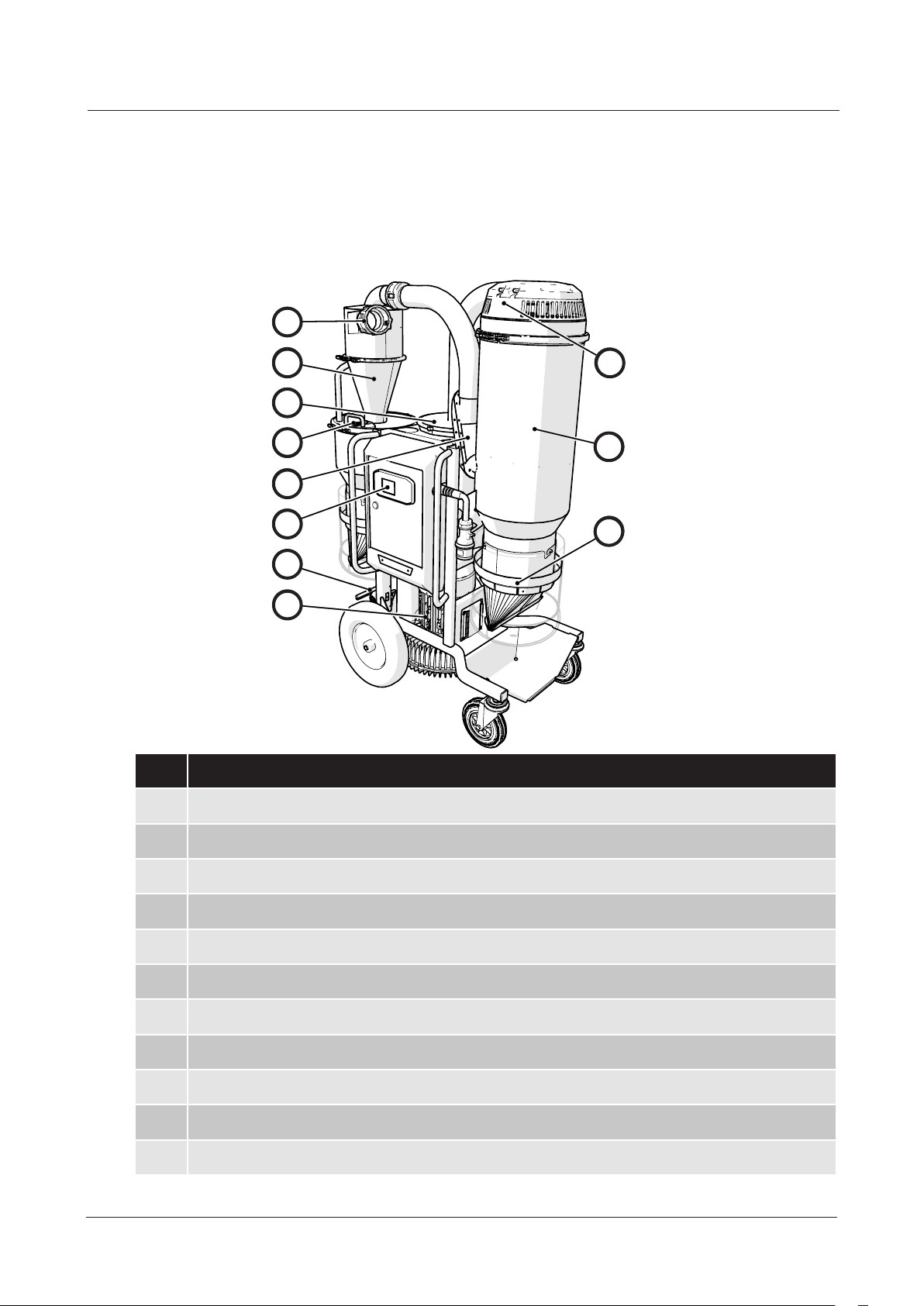

3.2 Machine overview

1

1

1

HTC D60

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

Pos. Description

1 3” camlock inlet connection

9

9

9

10

10

10

11

11

11

2 Pre-separator

3 Fine lter

4 Bypass valve

5 Inlet valve

6 Control cabinet with control panel

7 Parking brake

8 Side duct fan

9 Filter cleaning valve

10 Coarse lter container

11 Bag connection with lip valve

www.htc-oorsystems.comV 1.0

10

Page 11

HTC D60

4. Transport & storage

4.1 Handling and storage

The dust extractor should be stored in a heated, dry area when not in use.

Otherwise it may be damaged by condensation and cold.

The dust extractor's dimensions and weight are given in chapter Technical data.

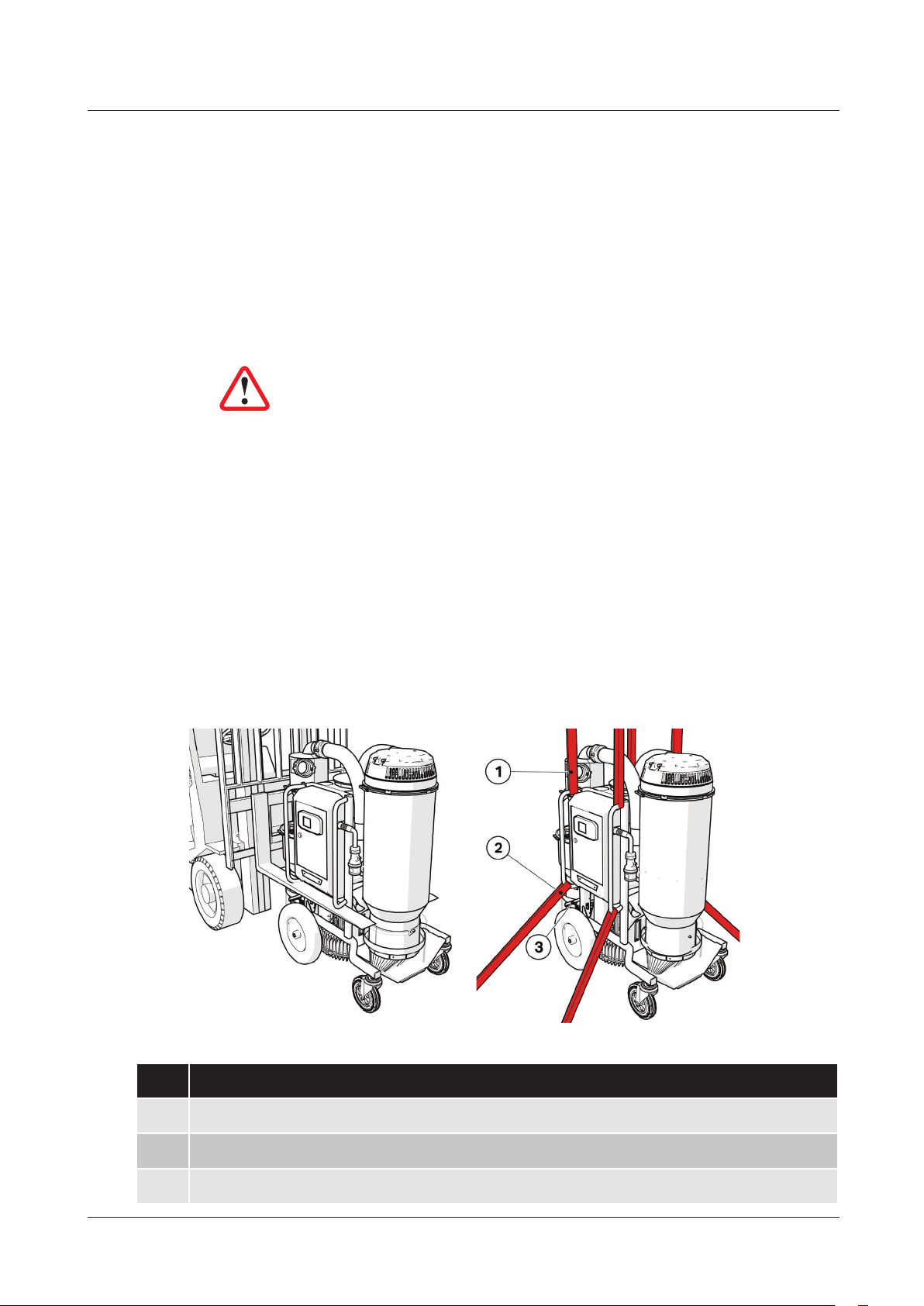

4.2 Transport & lifting

Warning!

If handled carelessly, the dust extractor can overturn and cause both

personal injury and damage to the equipment.

Always ensure that the dust extractor is emptied of dust and other particles before it is transported,

lifted or hoisted. When being moved with a forklift, always place the forks under the protection bar.

Always make sure that the dust extractor is securely anchored to its surroundings and that the parking brake is in the locked position during transport to prevent it from moving during transport. Ensure

that the securing straps, or other equipment used for anchoring during transport, are tightened in

lashing points and tensioned downwards as illustrated.

When lifting the machine, use 4 approved lifting straps at the lifting points on the machine.

When the dust extractor is to be hoisted, it must be securely anchored at two lashing points.

11

Pos. Description

1 Lifting points

2 Lashing points

3 Parking brake

www.htc-oorsystems.com

V 1.0

Page 12

5. Operation

5.1 Safety

This chapter contains all the warnings and notes that must be considered for the dust extractor.

5.2 General information

Warning!

Use protective equipment such as safety shoes, safety goggles, protective gloves, mouth mask and hearing protection.

5.3 Various positions of the pre-separator & dust extractor

Warning!

The dust extractor may only be used or repaired by personnel who

have received the requisite theoretical and practical training and who

have read the user manual.

HTC D60

Warning!

The dust extractor may only be used and moved on level surfaces.

There is a risk for crush injuries, if it should start to roll.

Tip!

Check the minimum recommended cable area before using an extension cord. You will nd the recommended cable area under Technical

Data.

The pre-separator and the dust extractor can be lowered during transport but can also be removed with a simple movement.

www.htc-oorsystems.comV 1.0

12

Page 13

HTC D60

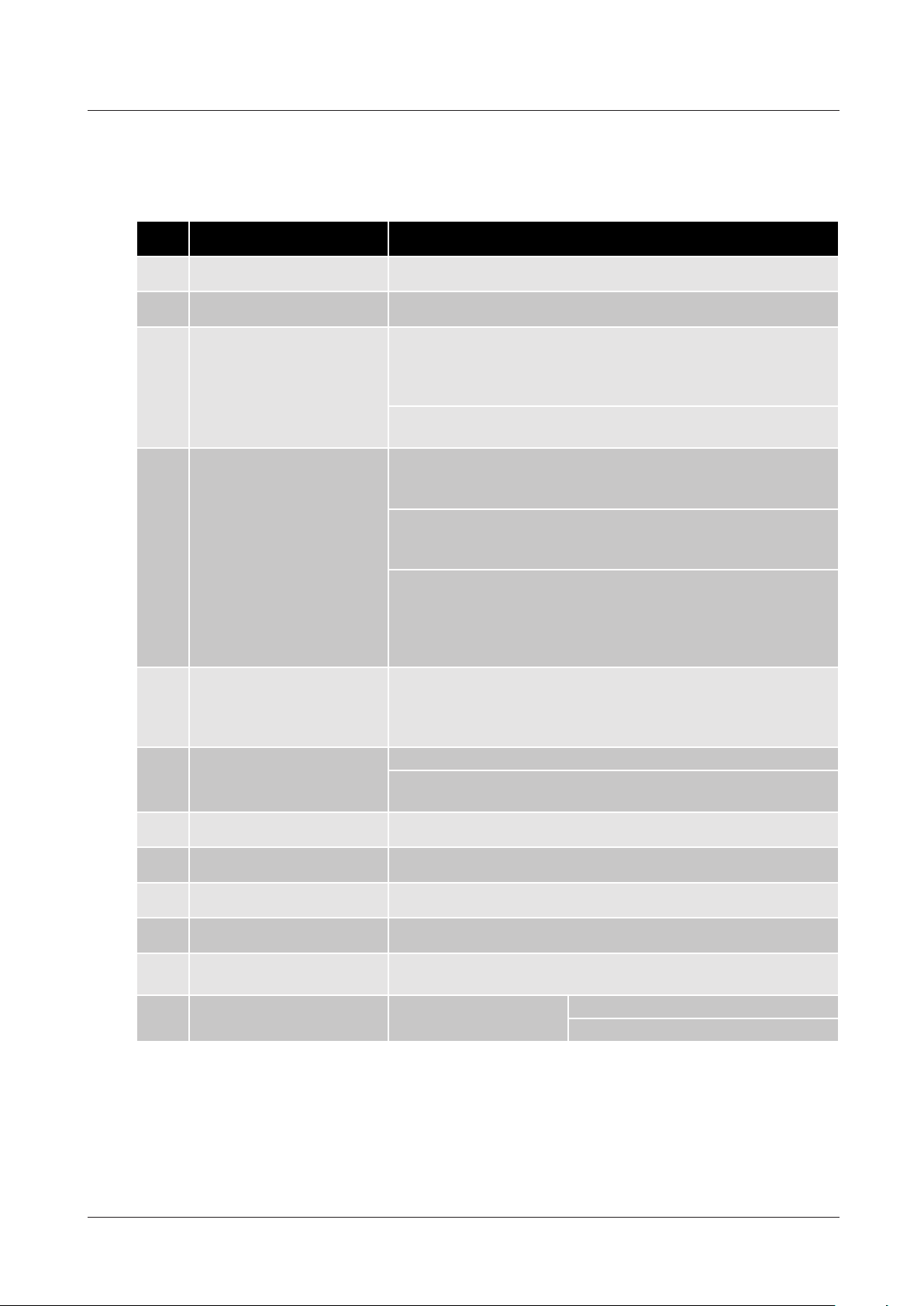

5.4 Control panel

NO. Icon Function Description

Indicates ow (m³ or cfm).

1 Display

2 On/Standby

3 Remote connection Indicates status for DURATIQ remote connection.

4 Accessory off/on Switches the accessory off and on

Dust emptying

5

6

7 Alarm / Warning

8 Menu navigation

9 Start / stop

(accessory, automat-

ic)

Filter cleaning

(accessory, automat-

ic)

Indicates pressure (total pressure mbar or in Aq).

Filter status, 0% clean lter, 100% blocked lter.

Starts up or places the machine in standby mode.

The machine wakes up when power is supplied. To place

the machine into standby mode, hold the button in. To

wake the machine press once.

Keeps the lter cleaning valve open for a time so that the

dust can fall down in the dust bags.

Runs lter cleaning (closes inlet valve and opens lter

cleaning valve) once.

Alarm, red LED. The machine cannot be operated due to

an error

Warning, yellow LED. The machine has restricted functionality.

Controls menu selection etc.

When you are not in the menus these buttons control other

functions.

Arrow up/down - switches between which value on the

screen is to be dominating (large).

Starts and stops the side duct fan.

Automatic phase switching (direction of rotation) of the

side duct fan, In the event of incorrect direction of rotation,

the side duct fan stops, the phases switch and the side

duct fan starts in the correct direction.

13

www.htc-oorsystems.com

V 1.0

Page 14

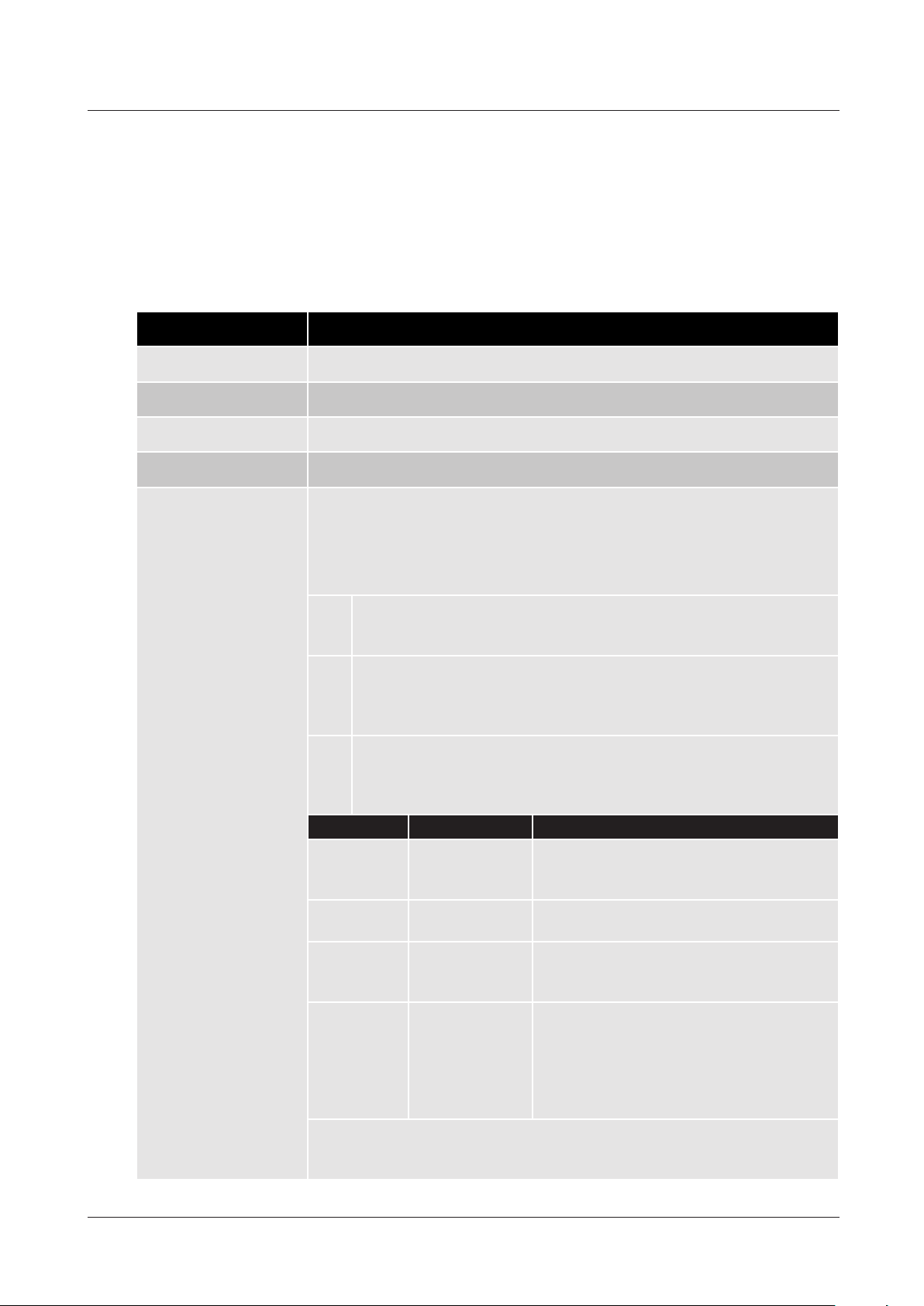

5.5 Display use menu

HTC D60

1

2

3

4

NO. Icon Function Description

Service Service

Dust emptying Dust emptying

Filter cleaning Filter cleaning

1

Direction of rotation Direction of rotation

Automatic Automatic

Lighting Lighting

Use the up or down

arrows to change

display mode.

Time and date Time and date

2 Flow

3 Pressure

4 Filter status

Indicates ow in (m³ or cfm) turns yellow when the ow is

low.

Indicates pressure (total pressure mbar or mm/Aq) turns yellow when the negative pressure is too great, suction blocked.

Risk of the motor shutting off due to overheating.

0% = Clean lter.

100% = Blocked lter, yellow bar, time to clean lter

www.htc-oorsystems.comV 1.0

14

Page 15

HTC D60

5.6 Dust ltration

Hose connection

The suction system is equipped with a 3" connector

for quick, easy and safe connection of the suction

hose between the grinding machine and dust extractor or other accessories that are to be used for

dust collection.

Pre-separator

The task of the pre-separator is to separate the

majority of the dust from the airow that passes the

machine.

The separated dust is collected in the space under

the actual pre-separator.

15

Bypass valve

To empty the space down in the bag, close the bypass valve by turning counter clockwise.

Note!

The valve should not be closed for more than a short interval, because the risk

of dust building up and blocking the pre-separator increases signicantly.

www.htc-oorsystems.com

V 1.0

Page 16

When the valve is closed, the dust falls into

the space down into the bag and if the bag is

full, it can now be replaced. When the valve is

closed, the dust is not separated but instead

continues directly to the coarse lter container. To start separating the dust, turn the valve

back.

HTC D60

When the air enters the vacuum tank, the

speed reduces, so the remaining dust in the

airow falls down into the bag. The airow

then passes a coarse lter in the coarse lter

container.

Air cleaning

To achieve a high degree of cleanliness, the

air also passes a ne lter before it passes the

side duct fan and ows out through the exhaust.

www.htc-oorsystems.comV 1.0

16

Page 17

HTC D60

5.7 Filter cleaning

NO. Icon Name Description

1 Button 1

2 Button 2 Opens the cleaning valve to clean the coarse lter

To clean the coarse lter, hold button 1 in

so that the inlet valve closes and the airow

into the coarse lter container ceases. The

side duct fan then starts to build up a greater

negative pressure.

Closes the inlet valve to build up a negative pressure in the

coarse lter container

Keep button 1 held in and then press button 2 to open the cleaning valve and clean

the coarse lter.

On the display, check that the desired

lter status is achieved after cleaning.

Otherwise, clean again.

If the lter status is above 30%,

dust is stuck in the lter and the lter

must be cleaned or replaced. See Filter

replacement 6.8

17

www.htc-oorsystems.com

V 1.0

Page 18

HTC D60

5.8 Replacing the dust bag

The dust extractor is equipped with a bag system that makes it possible to minimise dust exposure when

changing dust bags. This bag system can be ordered. Please contact your HTC retailer.

Warning!

Use protective equipment such as safety shoes, safety

goggles, protective gloves, mouth mask and hearing protection.

Place the bags in the holder and install on the container. Pull up the inner part of the bag and tighten

with the strap. Seal the lower part with a tie.

When the bag is full, pull out the bag and install two

ties and cut off the bag.

Tip!

Pull out a new length of empty bag down to the collection plate. This

is to create the best conditions for the waste to fall into the bag.

www.htc-oorsystems.comV 1.0

18

Page 19

HTC D60

5.9 Display information menu

MENUS

SETTINGS

TIME/DATE Time and date settings

Metric m³/h & mbar

UNITS

Imperial CFM & in Aq

FREQUENCY

FILTER PURGE

RADIO SYSTEM Group id

HTC SUPPORT

50Hz

60Hz

Auto Purge AUTO ON/OFF

Purge Time

Filter Status 50% — 100%

Flow

Link to webpage

(QR code and web address)

SERIAL NO.

For calculating ow

TIMER

3/5/10/15/20/30 MIN

150m³/h — 500m³/h

100cfm — 300cfm

19

SERVICE

INFORMATION

www.htc-oorsystems.com

FIRMWARE VERSION

MACHINE HOURS

COMMISIONING DATE

NEXT SERVICE

V 1.0

Page 20

6. Accessories

6.1 Automatic lter cleaning

Automatic lter cleaning automatically cleans the dust extractor's coarse lter when it becomes

blocked. This occurs by electromagnets connecting to buttons 1 and 2, whereupon the dust extractor's control panel can perform lter cleaning automatically or via a button push. Filter cleaning

occurs when one or more of the following conditions are met:

HTC D60

• Set time between lter cleans reached.

• Filter status - Standard is 100%.

Lower values giver more frequent pulses.

• Flow limit - Standard is 240 m³/h (150cfm).

Higher values give more frequent pulses.

To adjust pre-set values, see 4.9 Display information menu.

Filter cleaning from the control panel

Function button Description

Bag emptying

Filter cleaning Performs a lter cleaning cycle

Performs a slower lter clean so that the dust has

time to fall down into the bag

www.htc-oorsystems.comV 1.0

20

Page 21

HTC D60

6.2 Remote control

DURATIQ Remote Connection connects the dust extractor to a DURATIQ grinding machine.

To pair a dust extractor and DURATIQ grinding machine go to Radio System in the menu and select

the same ID in the grinding machine and dust extractor.

By doing this, the dust extractor can be controlled from a DURATIQ grinding machine and can also

send data between the devices.

2

1

Information and control from DURATIQ grinding machine

Pos. Icon Name Description

Gray icon:

Machine and vacuum cleaner are connected

Vacuum cleaners

1

Warning Yellow ashing icon in the event of warning.

Error Message

Vacuum cleaner

values

2

Change display using arrow-right or

arrow-left on the

control panel.

Red ashing icon in the event of error mes-

Vacuum cleaner is running.

to each other.

White icon:

sage.

Flow

Negative pressure

Filter status

Function button Description

21

Dust extractor Starts and stops the dust extractor

Quick press performs one lter clean

Filter cleaning

Button held in performs one dust empty

www.htc-oorsystems.com

V 1.0

Page 22

7. Maintenance

7.1 General information

We recommend regular inspection of the dust extractor.

Warning!

During maintenance and repair work, the machine must be disconnected from the mains power supply.

Warning!

Use protective equipment such as safety shoes, safety goggles,

protective gloves, mouth mask and hearing protection.

Warning!

HTC D60

Do not rinse off the dust extractor, as moisture can penetrate to the

electrical parts and damage the side duct fan.

7.2 Cleaning the dust extractor

• Vacuum the dust extractor.

• Perform lter cleaning and empty the machine of dust.

• Then clean the dust extractor after use with a damp sponge or cloth.

• Only use water.

7.3 Daily maintenance

• Check that the dust bags are intact.

• Check that the lip valves are not damaged.

• Check the lter status.

• Check that accessories such as hoses, that connect to the dust ex-

tractor are intact and do not have any cracks.

• In addition, make sure that the air ow is unobstructed and that there

are no blockages.

www.htc-oorsystems.comV 1.0

22

Page 23

HTC D60

7.4 Weekly maintenance

Check for leaks

• Place your hand over the inlet and make sure it goes up to 370mbar.

Check pre-separator

• Inspect sealing strips and surfaces for cracks or damage.

• Check for unusual dust build up.

• Also check for cracks or other irregularities.

• Adjust the quick fasteners on the pre-separator if necessary.

Check bypass valve

• Check the buttery damper can move without jamming.

• Visually check that there is no damage on the buttery damper's seal

surfaces.

Check lter cleaning valve

• Perform a normal cleaning cycle and check that the pulse valve is working

distinctly and does not leak in the closed position.

Check side duct fan

• If necessary, vacuum up any dust on visible parts of the side duct fan.

Dust around the fan can cause overheating.

• Also listen for noise from the

side duct fan.

23

www.htc-oorsystems.com

V 1.0

Page 24

7.5 Filter replacement

Warning!

The dust that is sucked up may be harmful if inhaled. Follow local

regulations and use breathing protection.

HTC D60

To check the lter, start by disconnecting the hose to the ne lter and checking in the hose connection for dust on the inside of the ne lter. In the event of dust, remove the lock ring, pull a bag

over to reduce contact with dust particles and replace the lter.

If there is dust in the ne lter, it has passed the coarse lter, which must then be replaced.

Also use a bag here to protect against dust particles.

www.htc-oorsystems.comV 1.0

24

Page 25

HTC D60

7.6 Control cabinet

2

1

4

5

3

6

7 8 9

10

No. Designation Description

1 K1

2 K2

3 Fuse 4A 24V DC

4 USB USB Port

5 PLC Control panel

Contact

(Clockwise)

Contact

(Counter clockwise)

No. Designation Description

6 K3 Contact (Black, Y)

7 K4

8 Q1 Motor protection

9 F1

10 U1 Power supply

Contact (Operation, D)

Miniature circuit

breaker

25

www.htc-oorsystems.com

V 1.0

Page 26

8. Service

8.1 Repairs

Any repairs that may be required must be carried out by a HTC Service Centre that has trained service personnel and uses HTC original parts and accessories. Contact your retailer if your machine

requires servicing. For contact information, see Contact Information at the start of the manual.

8.2 Spare parts

To ensure rapid delivery of spare parts, always specify the model, the machine's serial number and

the spare part number when ordering. Information on the model and serial number can be found on

the machine's name plate.

Information on spare part numbers can be found in the machine's spare parts list which is available to

read or print out from the accompanying digital media or HTC's website: www.htc-oorsystems.com.

Only original tools and spare parts from HTC may be used. Otherwise, neither the CE marking nor the

warranty will be valid.

8.3 Motor protection

Automatic reset of motor protection

See warning message on the screen, when it disappears, the motor protection has been reset.

HTC D60

• The motor protection trips when the motor draws too much current or if

the motor protection gets hot.

• Check whether the suction system is blocked (negative pressure is displayed on the screen).

• Disconnect the machine from the mains power supply.

• Clean the motor/control cabinet (wait a while before opening the control

cabinet).

• Close the control cabinet, connect the machine to the mains power supply and start the machine.

www.htc-oorsystems.comV 1.0

26

Page 27

HTC D60

8.4 Function checks

Check point Action

1 The dust bags Check that the bags are intact

2 The lip valves Check that they are not damaged

3 Pre-separator

4 Inlet valve

5 Cleaning valve

6 Side duct fan

Plug the inlet and check on the display that a negative pressure

is reached.

Perform the checks with the bypass valve in the open position

and in the closed position

Open the cover and check for wear on the bypass valve and

wear rubber.

Ensure that the dust extractor is off.

Remove the hose from in the inlet valve and visually inspect the

inside of the rubber membrane for wear and holes.

Start the dust extractor and hold in button 1 on the lter cleaning valve and after 3 seconds check that a negative pressure of

at least 33mbar is reached.

Switch off the suction system and remove the hose for the ne

lter.

Check for dust on the inside of the 3” hose. If dust is present,

then there is damage to the coarse lter or pilot hoses (Ø 10mm)

which can cause damage to the inlet valve's membrane.

Perform a normal cleaning cycle and check that the valve is

working distinctly and does not leak.

During normal cleaning, the display shows a max. value of ap-

prox. 280 - 330mbar.

Listen for noise.

Clean the side duct fan.

Dust around and on the fan can cause overheating.

27

7 Wheels Check for wear. Check the bearings and suspension.

8 Hose connections Check for leaks.

9 Brakes Function checks

10 Lifting points Check for cracks

11 Function of the guides

DURATIQ remote connec-

12

tion

Check all position locations and check for any wear to suspen-

sion lugs.

Check functions

Automatic lter cleaning

Lighting

www.htc-oorsystems.com

V 1.0

Page 28

9. Troubleshooting

This chapter describes some of the errors that may occur and how to deal with them. If

the error cannot be corrected, or if errors arise other than those described here, contact

your nearest retailer. See Contact Information at the front of the manual.

Symptoms Cause/Action

The dust extractor will not start.

The connected accessory does not work.

HTC D60

Check electrical connections.

Check miniature circuit breaker.

Check power supply (does the LED light?).

Check circuit board fuse. LED lights red

when the fuse has blown.

Is the symbol on the screen lit?

Check the voltage at the accessory.

Inlet valve constantly open/closed.

Filter cleaning valve not working.

The pump will not start.

Check the ow on the outputs.

Check that it works manually.

See chapter 4, Dust ltration.

Check that the membrane in the valve is intact.

Check the ow on the outputs.

Is it sealed? Check using a vacuum pump.

Is the membrane intact?

Motor protection tripped. Error message appears on screen.

Error message appears on screen.

Open-circuit motor cable.

www.htc-oorsystems.comV 1.0

28

Page 29

HTC D60

9.1 Warnings and error messages

Warnings

Warnings appear on a yellow background at the top of the screen. A warning does not usually stop

operation but the machine may have restricted functionality. Actions to ensure operation may need to

be taken. A warning can normally be minimized using the OK key and the warning is then minimized

to an icon in the icon eld. When the problem has been solved, the warning disappears.

Error Message Description

5V POWER PROBLEM Circuit board internal voltage error.

Duratiq Rmt no resp DURATIQ Remote Connection internal error.

PTC Short Circuit Short-circuit in PTC circuit

USB/PTC Overcurrent Overload on USB or PTC. Short-circuit?

Pressure sensor error.

Causes automatic pulsing to only work on time and not on lter status/

ow. Some display values also stop working, see below.

Each pressure sensor error has a three digit error code, each sensor has

its own place in the three digit code that indicates which sensor is faulty.

PSens Err 000

Sensor diff error

1xx

The values of the sensors do not correspond.

May be due to defective sensor or one of the following errors.

Error in pressure sensor P_in (pressure sensor in coarse lter container)

x#x

Error in pressure sensor P_in means lter status does not work.

Automatic pulsing only occurs on time.

Error in pressure sensor P_tot (Pressure sensor after ne lter)

Error in pressure sensor P_tot means ow meter, negative pressure

xx#

meter and lter status do not work. Automatic pulsing only occurs

on time.

Error code Designation Description

SENSOR

1

2

4

8

Example:

Error code 4 on sensor P_in and error 1 on pressure sensor P_tot, the error

message will be: PSens Err 041

SHORT TO

GND

SENSOR

SHORT TO REF

SENSOR LIMIT

HIGH

SENSOR LIMIT

LOW

Internal error on circuit board/sensor

Internal error on circuit board/sensor

The sensor gives a value that is greater

than what is normal/possible. Pressure

sensor error.

The sensor gives a value that is less than

what is considered normal.

May be due to leakage in the dust bag,

lter, seals,

pressure sensor hose etc. for example.

May also be due to a defective sensor.

29

www.htc-oorsystems.com

V 1.0

Page 30

HTC D60

Error Message

Error messages appear on a red background at the top of the screen. An error usually stops one or

more functions of the machine. Action may need to be taken to resume operation.

Error Message Description Cause

May be due to suction system stoppage

Motor Overload

Terminal xx

Overload

The overcurrent protection has

tripped.

Resets automatically when the

machine has cooled

Short circuit on terminals 1-12.

xx indicates to which terminal the short

(high negative pressure).

Low voltage.

Excessive heat.

Defective motor.

circuit applies.

Alternativ

Pump Direction

Ctrl Failure

After three failed start-up attempts three alternatives are

displayed.

The machine struggles to read

the phase sequence.

Is the

pump

direction

correct?

Yes

No

Try Again

www.htc-oorsystems.comV 1.0

30

Page 31

HTC D60

10. Technical data

The tables and pictures below show the technical data and dimensions for the dust extractor.

160601 160602 160603

HTC D60

Motor power

Current 30 A 15 A

Frequency 50Hz – 60Hz 60Hz

Voltage 180 – 240V 3

Total machine weight

50 Hz

Max. theoretical airow

60 Hz

50 Hz

Machine’s initial airow

60 Hz

Max. vacuum machine

Filter area, main lter

HEPA lter class H13

5.5kW

7.5 hp

~

380 – 415V 3

179 kg

395 Ibs

530 m³/h

312 cfm

620 m³/h

365 cfm

440 m³/h

260 cfm

500 m³/h

295 cfm

375 mbar

150 inH2O

4 m²

43 ft²

~

6.3kW

8.5 hp

440 – 480V 3

620 m³/h

365 cfm

500m³/h

295 cfm

~

31

Filter area, Hepa 13 lter

Recommended minimum cable area

Storage temperature

Working temperature

Humidity 5-90%

Sound pressure level, according to ISO

11203, measured using class 1 precision

sound level meters.

Sound power level, according to ISO 3746,

measured using class 1 precision sound

level meters.

Transmitter frequency, remote start 2.45GHz band (2400 – 2483 Mhz)

Transmitter power, remote start >1.26mW (max1dBm)

6.0 mm²

AWG10

6 m²

64.6 ft²

2.5 mm²

AWG14

-20 — +50 °C

-4 — +122 °F

-5 — +40 °C

+23 — +104 °F

82 dBA

89 dBA

www.htc-oorsystems.com

V 1.0

Page 32

HTC D60

A

C

Height and length of the dust extractor, in the operating position and transportation position.

Dimensions A B C D

1920 mm 1400 mm 1235 mm 680 mm

75.6” 55.1” 46.6” 26.8”

D

B

www.htc-oorsystems.comV 1.0

32

Page 33

HTC D60

11. Environment

HTC products are mainly constructed of recyclable metal and plastic.

The main materials used are listed below.

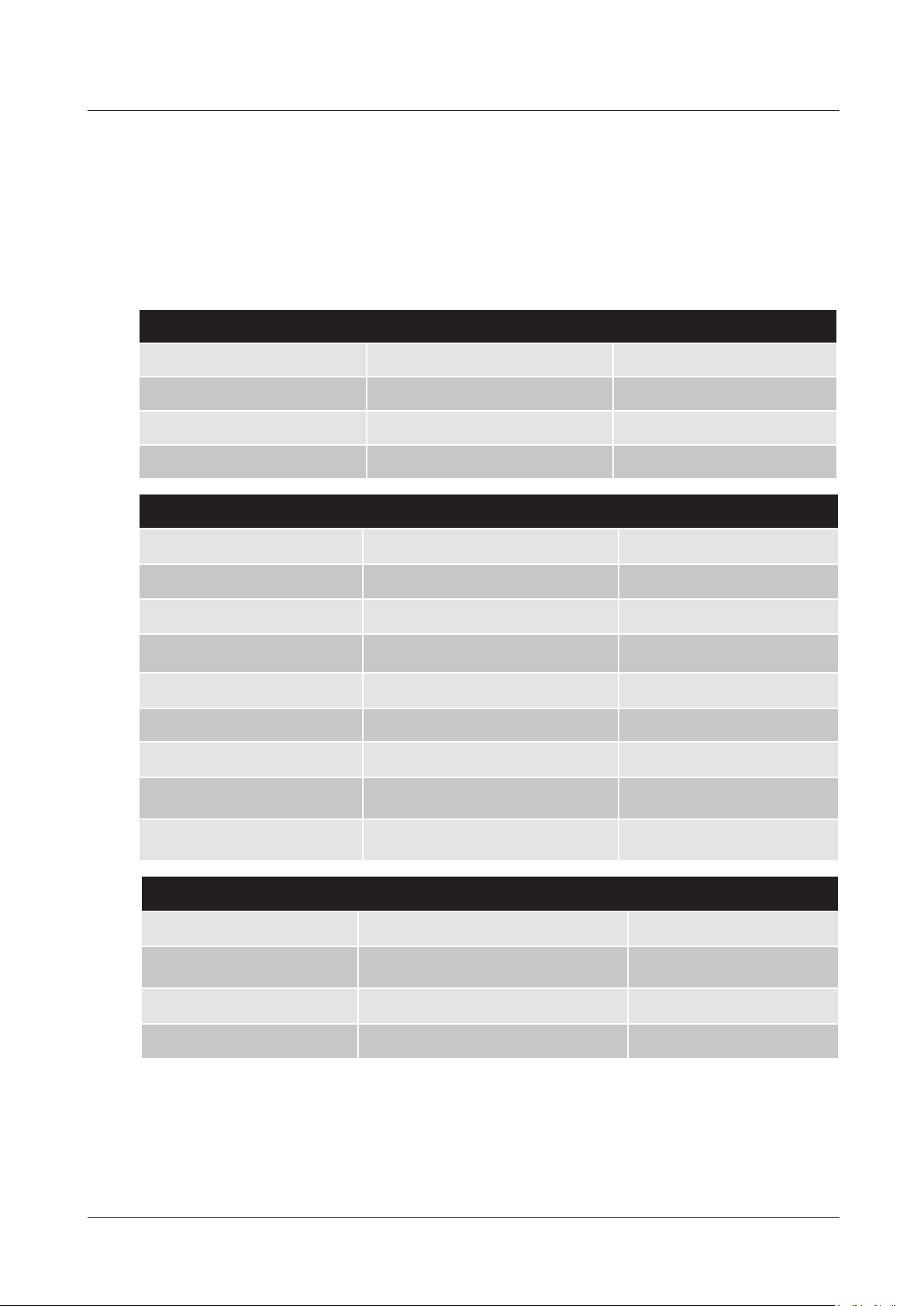

Machine part Material Waste management

Frame Metal, powder-coated Metal recycling

Front wheels Metal, plastic and rubber Metal recycling

Back wheels Plastic and rubber Combustible

Chassis

Dust extractor

Machine part Material Waste management

Cylinder Metal, powder-coated Metal recycling

Longopac holder Plastic, ABS Plastic recycling/Combustible

Cover Metal, powder-coated Metal recycling

Camlock Metal incl. aluminium Metal recycling 1)

Rotation joint pre-separator Plastic (nylon) Plastic recycling/Combustible

Hose Plastic (PUR) and metal wire Plastic recycling/Combustible

HEPA lter Hepa 13

Pre-lter

Metal, glass ber reinforced paper

and hot-melt adhesive

Metal, polyester and hot-melt adhesive

Metal recycling 2)

Metal recycling 2)

Electrical system

Machine part Material Waste management

Cables

Copper conductors with Neoprene

and PVC coating

Waste cable

33

Motor Metal: Steel, aluminium and copper Electronic waste

Electrical components Metal and plastic Electronic waste

1) If possible, different metals should be separated.

2) If the lter contains any hazardous substance from the grinding dust, it

must be treated as hazardous waste.

For recycling and scrapping of components, see the applicable national

regulations for each country.

www.htc-oorsystems.com

V 1.0

Page 34

Head ofce

HTC Sweden AB

Box 69

SE-614 22 Söderköping

Sweden

Street (delivery) address:

Klevvägen 7

SE-614 92 Söderköping

Sweden

Tel.: +46 (0)121-29400

Fax: +46 (0)121-15212

E-mail: info@htc-sweden.com

www.htc-oorsystems.com

HTC Floor Systems Ltd.

Unit 4 Kingston Business Park

Dunfermline Court

Maidstone Road

Kingston

Milton Keynes

MK10 0BY

United Kingdom

Tel.: +44 (0 ) 845 460 2500

Fax: +44 (0) 845 460 1500

E-mail: info@htc-europe.co.uk

www.htc-oorsystems.com

HTC Floor Systems GmbH

Hinter dem Entenpfuhl 17

65604 Elz

Deutschland

Tel.: +49 (0)6431 – 97658-0

Fax: +49 (0)6431 – 97658-22

E-Mail: order@htc-europe.de

www.htc-oorsystems.com

HTC Inc.

5617 Tazewell Pike

Knoxville, TN 37918

USA

Tel.: +1 865 689 2311

Fax: +1 865 689 3991

E-mail: info@htc-america.com

www.htc-oorsystems.com

HTC France S.A.S.

ZI Mondeville Sud

10 Rue Nicéphore Niepce

14120 Mondeville

France

Tel.: +33 (0)2 31 34 27 00

Fax: +33 (0)2 31 34 09 29

E-mail: info@htc-europe.fr

www.htc-oorsystems.com

www.htc-oorsystems.com/support

Loading...

Loading...