Page 1

ENGLISH

User manual

Copyright HT ITALIA 2018 Release EN 1.00 - 31/10/2018

Page 2

Page 3

NEPTUNE

TABLE OF CONTENTS

1. PRECAUTIONS AND SAFETY MEASURES ............................................................... 2

1.1. Preliminary instructions ..................................................................................................... 2

1.2. During use ......................................................................................................................... 3

1.3. After use ............................................................................................................................ 3

1.4. Definition of Measurement (Overvoltage) category ........................................................... 3

2. GENERAL DESCRIPTION ........................................................................................... 4

2.1. Measuring average values andTRMS values .................................................................... 4

2.2. Definition of true root mean square value and Crest factor ............................................... 4

3. PREPARATION FOR USE ........................................................................................... 5

3.1. Initial checks ...................................................................................................................... 5

3.2. Instrument power supply ................................................................................................... 5

3.3. Storage .............................................................................................................................. 5

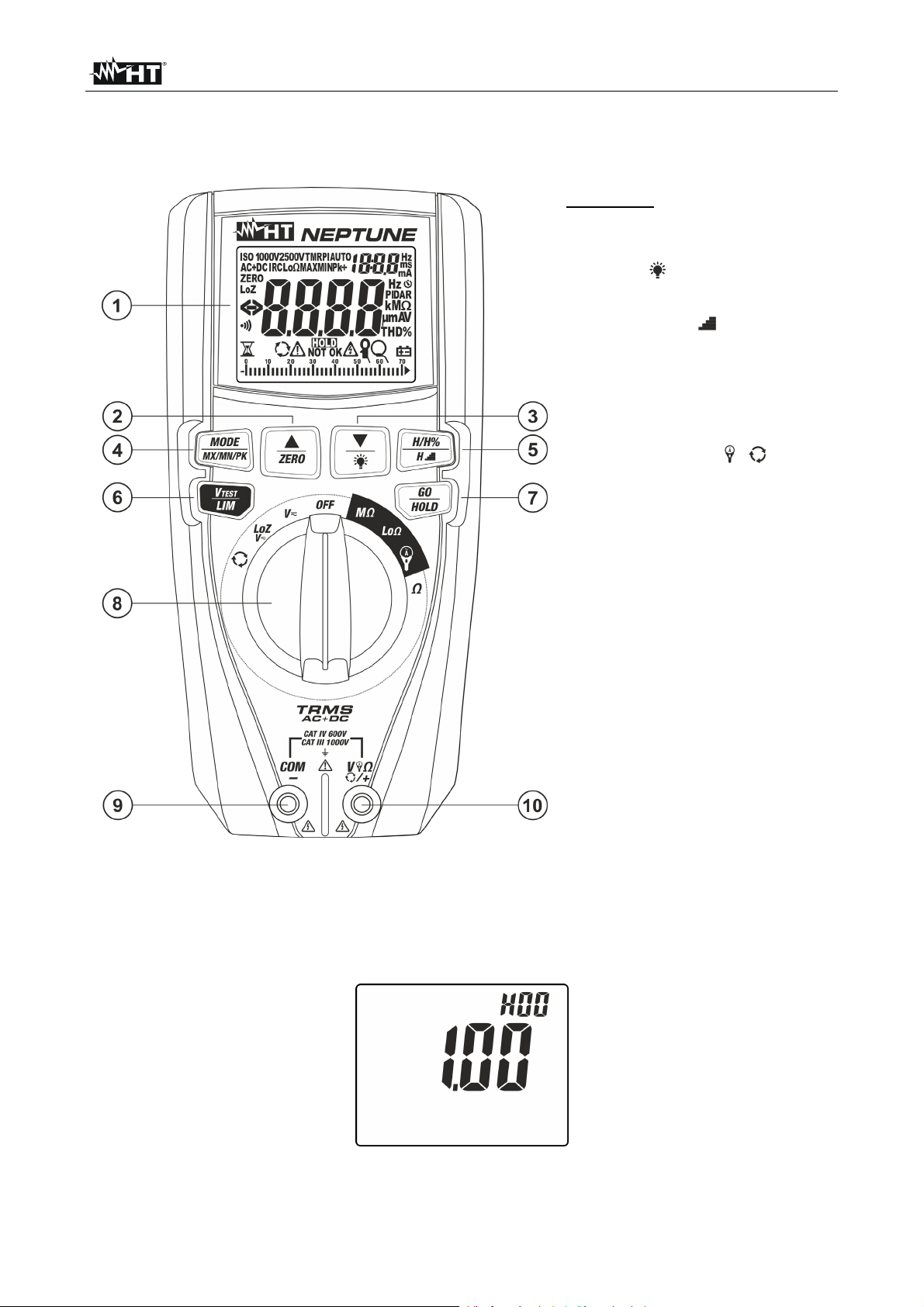

4. NOMENCLATURE ........................................................................................................ 6

4.1. Description of the instrument ............................................................................................. 6

4.1.1. Instrument’s initial screen ........................................................................................................... 6

4.2. Description of function keys .............................................................................................. 7

4.2.1. Key GO/HOLD ............................................................................................................................ 7

4.2.2. Key H/H%/H ............................................................................................................................ 7

4.2.3. Key MODE/MXMNPK ................................................................................................................. 8

4.2.4. Keys / e / ZERO .............................................................................................................. 8

4.2.5. Key VTEST/LIM .......................................................................................................................... 8

4.2.6. LoZ function ................................................................................................................................ 9

4.2.7. AC+DC function .......................................................................................................................... 9

4.2.8. Inrush current function (INRUSH) .............................................................................................. 9

4.2.9. Disabling the Auto Power Off function ........................................................................................ 9

4.2.10. Setting the full scale for flexible clamp transducer ................................................................... 10

5. OPERATING INSTRUCTIONS ................................................................................... 11

5.1. DC voltage measurement ................................................................................................ 11

5.2. AC, AC+DC voltage measurement ................................................................................. 12

5.3. AC, DC, AC+DC voltage with low impedance (LoZ) ....................................................... 13

5.4. Resistance measurement and continuity test .................................................................. 14

5.5. Phase sequence and phase concordance with 1 terminal .............................................. 15

5.6. Measurement of insulation resistance ............................................................................. 17

5.7. Continuity of protective conductors with 200mA ............................................................. 23

5.7.1. Function ZERO – Zeroing of test cable resistance ................................................................... 27

5.8. Measurement of DC, AC, AC+DC, INRUSH current with clamp transducers ................. 29

6. MAINTENANCE ......................................................................................................... 33

6.1. Battery replacement ........................................................................................................ 33

6.2. Cleaning the instrument .................................................................................................. 33

6.3. End of life ........................................................................................................................ 33

7. TECHNICAL SPECIFICATIONS ................................................................................ 34

7.1. Technical characteristics ................................................................................................. 34

7.1.1. General characteristics ............................................................................................................. 36

7.2. Environmental conditions for use .................................................................................... 36

7.3. Accessories ..................................................................................................................... 36

8. ASSISTANCE ............................................................................................................. 37

8.1. Warranty conditions ......................................................................................................... 37

8.2. Assistance ....................................................................................................................... 37

9. THEORETICAL APPENDIXES ................................................................................... 38

9.1. Continuity of protective conductors ................................................................................. 38

9.2. Measurement of insulation resistance ............................................................................. 39

9.2.1. Polarization Index (PI) .............................................................................................................. 42

9.2.2. Dielectric Absorption Ratio (DAR) ............................................................................................ 42

9.3. Voltage and current harmonics ....................................................................................... 43

EN - 1

Page 4

NEPTUNE

1. PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with directive IEC/EN61010-1 relevant to

electronic measuring instruments. For your safety and in order to prevent damaging the

instrument, please carefully follow the procedures described in this manual and read all

notes preceded by symbol with the utmost attention.

Before and after carrying out measurements, carefully observe the following instructions:

Do not carry out any measurement in humid environments.

Do not carry out any measurements in case gas, explosive materials or flammables are

present, or in dusty environments.

Avoid any contact with the circuit being measured if no measurements are being

carried out.

Avoid contact with exposed metal parts, with unused measuring probes, etc.

Do not carry out any measurement in case you find anomalies in the instrument such

as deformation, breaks, substance leaks, absence of display on the screen, etc.

Pay special attention when measuring voltages higher than 50V, since a risk of

electrical shock exists.

In this manual, and on the instrument, the following symbols are used:

Warning: observe the instructions given in this manual; improper use could

damage the instrument or its components.

High voltage danger: electrical shock hazard.

Double-insulated meter

AC voltage or current

DC voltage or current

Connection to earth

1.1. PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in environments of pollution degree 2.

It can be used for VOLTAGE and CURRENT measurements on installations with CAT

IV 600V, CAT III 1000V to earth and between inputs.

We recommend following the normal safety rules devised by the procedures for

carrying out operations on live systems and using the prescribed PPE to protect the

user against dangerous currents and the instrument against incorrect use.

In case the lack of indication of the presence of voltage may represent a danger for the

operator, always carry out a continuity measurement before carrying out the

measurement on the live system, in order to confirm the correct connection and

condition of the leads.

Only the leads supplied with the instrument guarantee compliance with the safety

standards. They must be in good conditions. If necessary, only replace them with

original HT accessories.

Do not test circuits exceeding the specified voltage limits.

Do not perform any test under environmental conditions exceeding the limits indicated

in § 6.2.1

Check that the battery is correctly inserted.

Make sure that the LCD display and the rotary switch indicate the same function.

EN - 2

Page 5

NEPTUNE

1.2. DURING USE

Please carefully read the following recommendations and instructions:

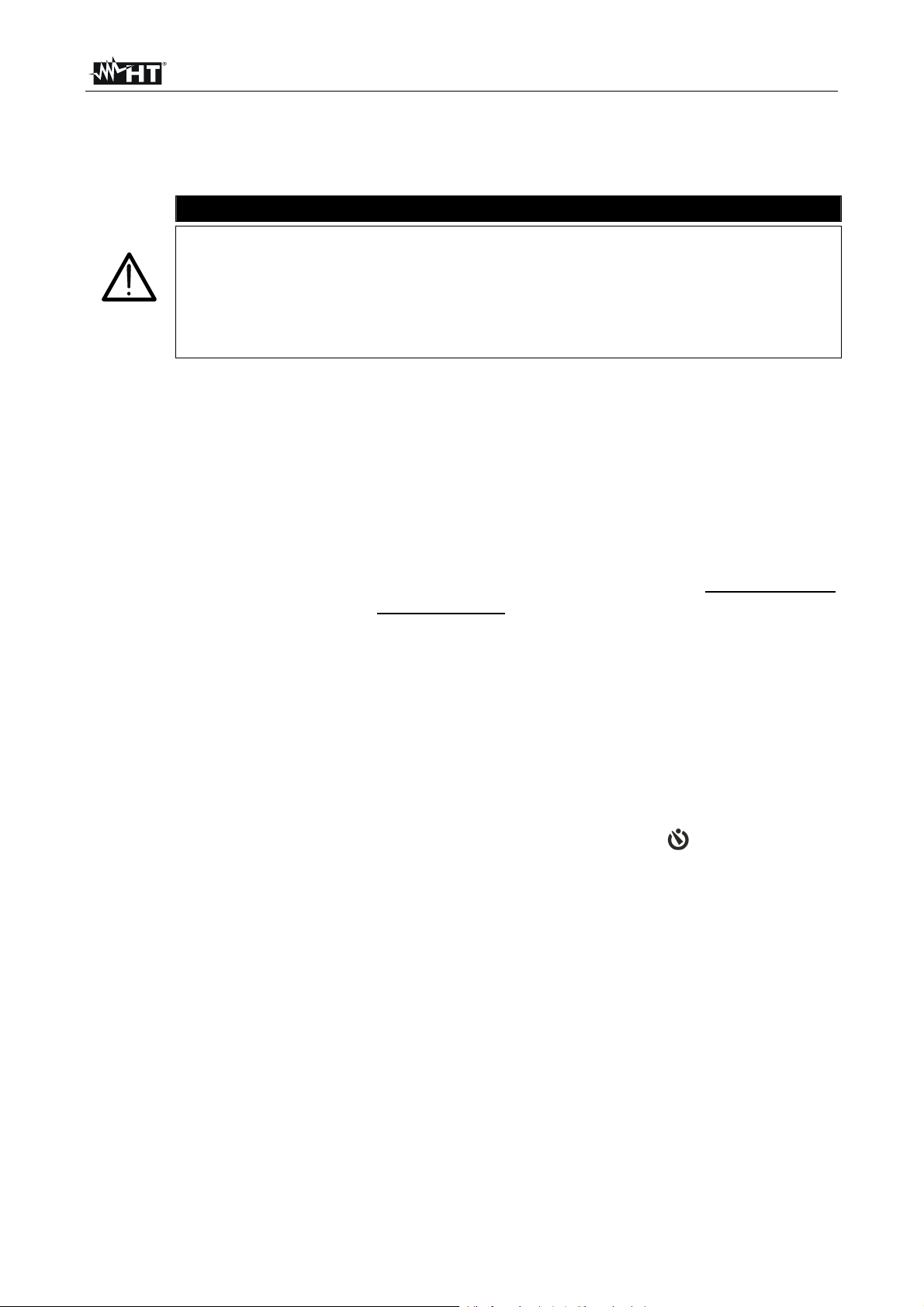

CAUTION

Failure to comply with the caution notes and/or instructions may damage

the instrument and/or its components or be a source of danger for the

operator.

Before activating the rotary switch, disconnect the test leads from the circuit being

measured.

When the instrument is connected to the circuit being measured, do not touch any

unused terminal.

During current measurement, any other current near the clamps may affect

measurement precision.

When measuring current, always put the conductor as near as possible to the middle of

the clamp jaw, to obtain the most accurate reading.

Do not measure resistance in case external voltages are present; even if the

instrument is protected, an excessive voltage may cause malfunction.

Before attempting any resistance measurement, cut off power supply from the circuit to

be measured and make sure that all capacitors are discharged, if present.

While measuring, if the value or the sign of the quantity being measured remain

unchanged, check if the HOLD function is enabled.

1.3. AFTER USE

When measurement is complete, set the rotary switch to OFF

If the instrument is not to be used for a long time, remove the batteries

1.4. DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard “IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements”, defines what measurement

category, commonly called overvoltage category, is. § 6.7.4 reads: Circuits are divided into

the following measurement categories:

Measurement category IV is for measurements performed at the source of the low-

voltage installation.

Examples are electricity meters and measurements on primary overcurrent protection

devices and ripple control units.

Measurement category III is for measurements performed on installations inside

buildings.

Examples are measurements on distribution boards, circuit breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and

equipment for industrial use and some other equipment, for example, stationary motors

with permanent connection to fixed installation.

Measurement category II is for measurements performed on circuits directly

connected to the low-voltage installation.

Examples are measurements on household appliances, portable tools and similar

equipment.

Measurement category I is for measurements performed on circuits not directly

connected to MAINS.

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the standard requires that the transient withstand capability of

the equipment is made known to the user.

EN - 3

Page 6

NEPTUNE

2. GENERAL DESCRIPTION

The instrument carries out the following measurements:

DC / AC, AC+DC TRMS voltage

DC / AC / AC+DC TRMS voltage with low impedance (LoZ)

DC / AC / AC+DC TRMS current with standard clamp transducer

AC TRMS current with flexible clamp transducers

Automatic recognition of AC and DC quantities

Inrush current (Dynamic INRUSH - DIRC)

Current/voltage harmonics up to the 25th and THD% calculation

Resistance and Continuity test

Current and voltage frequency

Insulation resistance with test voltage 50,100,250,500,1000VDC

Measurement of Polarization Index (PI) and Dielectric Absorption Ratio (DAR)

Continuity of protective conductor with 200mA

Phase sequence with 1 terminal

Each of these functions can be selected by means of the appropriate switch. The

instrument is also equipped with function keys (see § 4.2), an analogue bargraph and

backlight. The instrument is also equipped with an Auto Power OFF function (which can be

disabled), which automatically switches off the instrument 15 minutes after the last time a

function key was pressed or the rotary switch was turned. To switch on the instrument

again, turn the rotary switch.

2.1. MEASURING AVERAGE VALUES ANDTRMS VALUES

Measuring instruments of alternating quantities are divided into two big families:

AVERAGE-VALUE meters: instruments measuring the value of the sole wave at

fundamental frequency (50 or 60 Hz).

TRMS (True Root Mean Square) VALUE meters: instruments measuring the TRMS

value of the quantity being tested.

With a perfectly sinusoidal wave, the two families of instruments provide identical results.

With distorted waves, instead, the readings shall differ. Average-value meters provide the

RMS value of the sole fundamental wave; TRMS meters, instead, provide the RMS value

of the whole wave, including harmonics (within the instruments bandwidth). Therefore, by

measuring the same quantity with instruments from both families, the values obtained are

identical only if the wave is perfectly sinusoidal. In case it is distorted, TRMS meters shall

provide higher values than the values read by average-value meters.

2.2. DEFINITION OF TRUE ROOT MEAN SQUARE VALUE AND CREST FACTOR

The root mean square value of current is defined as follows: “In a time equal to a period,

an alternating current with a root mean square value of 1A intensity, circulating on a

resistor, dissipates the same energy that, during the same time, would be dissipated by a

direct current with an intensity of 1A". This definition results in the numeric expression:

Tt

0

1

2

dttg

G=

T

The Crest Factor is defined as the relationship between the Peak Value of a signal and its

RMS value: CF (G)=

sinusoidal wave it is 2=1.41. In case of distortion, the Crest Factor takes higher values

as wave distortion increases.

)(

t

0

The root mean square value is indicated with the acronym RMS.

G

p

This value changes with the signal waveform, for a purely

G

RMS

EN - 4

Page 7

NEPTUNE

3. PREPARATION FOR USE

3.1. INITIAL CHECKS

Before shipping, the instrument has been checked from an electric as well as mechanical

point of view. All possible precautions have been taken so that the instrument is delivered

undamaged.

However, we recommend generally checking the instrument in order to detect possible

damage suffered during transport. In case anomalies are found, immediately contact the

forwarding agent.

We also recommend checking that the packaging contains all components indicated in §

6.3.1. In case of discrepancy, please contact the Dealer.

In case the instrument should be returned, please follow the instructions given in § 7.

3.2. INSTRUMENT POWER SUPPLY

The instrument is supplied with 4x1.5V alkaline batteries type AAA IEC LR03, included in

the package. When batteries are flat, the symbol

the batteries, see § 6.1.

3.3. STORAGE

In order to guarantee precise measurement, after a long storage time, wait for the

instrument to come back to normal condition (see § 6.2.1).

“ ” is shown on the display. To replace

EN - 5

Page 8

NEPTUNE

4. NOMENCLATURE

4.1. DESCRIPTION OF THE INSTRUMENT

CAPTION:

1. LCD display

2. Key / ZERO

3. Key/

4. Key MODE/MXMNPK

5. Key H/H%/H

6. Key V

TEST/LIM

7. Key GO/HOLD

8. Rotary selector switch

9. Input terminal COM/

10. Input terminal V /+

Fig. 1: Description of the instrument

4.1.1. Instrument’s initial screen

1. Turn the rotary switch to any position to switch on the instrument. The following initial

screen is shown on the display for a few seconds to identify the internal Hardware and

Firmware version.

Fig. 2: Instrument’s initial screen

2. Turn the rotary switch to OFF to switch off the instrument.

EN - 6

Page 9

NEPTUNE

4.2. DESCRIPTION OF FUNCTION KEYS

4.2.1. Key GO/HOLD

Pressing the key GO/HOLD (for functions V , LoZV , and ) makes the instrument

hold the value of the quantity shown on the display. The message “HOLD” appears on the

display. Press the key again to exit the function. Pressing key GO/HOLD (for functions

M, Lo, , IRC) activates the corresponding measurement.

4.2.2. Key H/H%/H

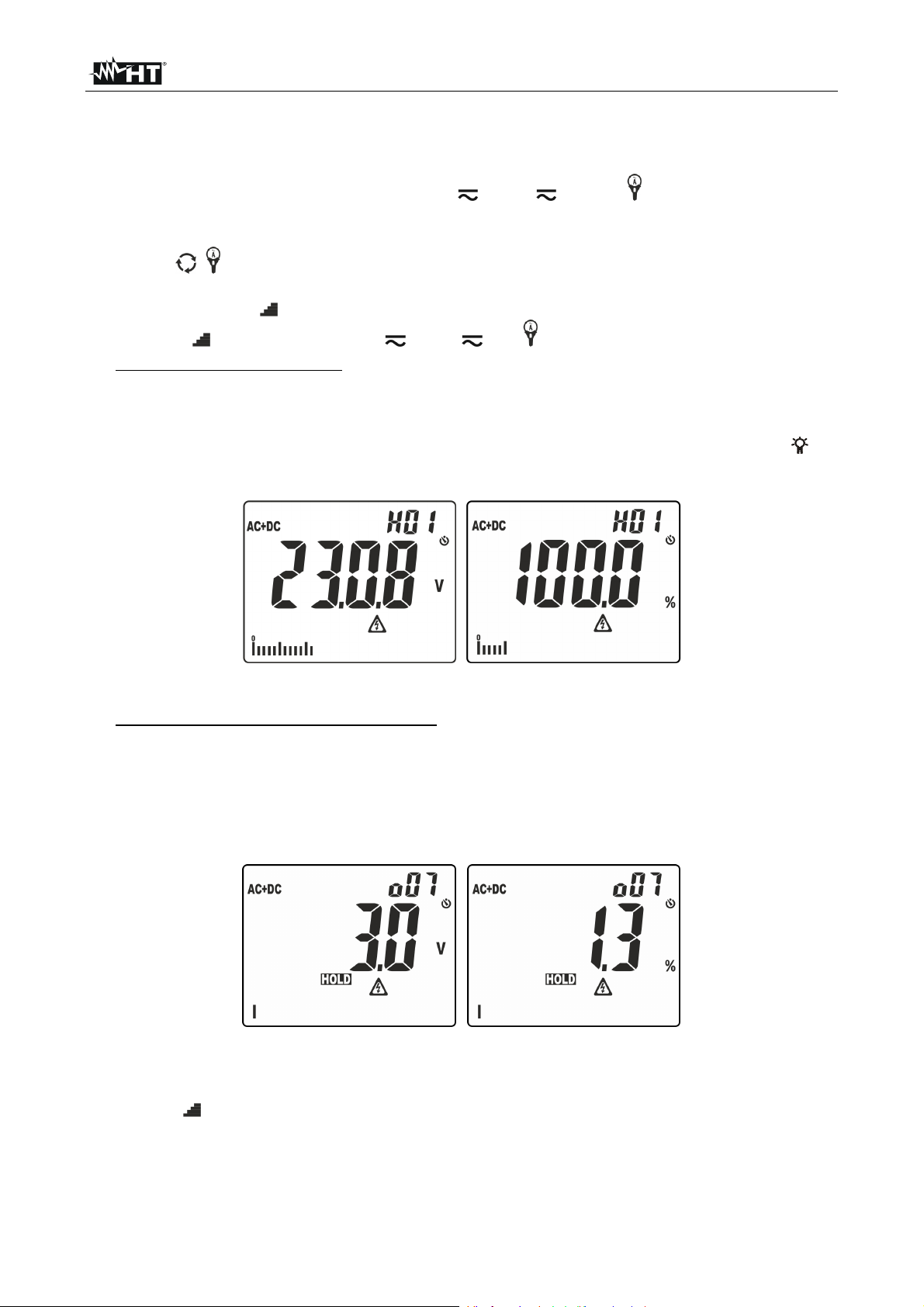

Key H/H%/H (active in positions V , LoZV and ) allows the following operations:

Simple pressing of the key to display the amplitude of voltage and current harmonics

up to the 25th (Hdc, H01… H25) in absolute or percentage format in relationship with

the fundamentals of input signals (for voltage values VAC >0.5V and current values AC

> 0.5A and frequency in the range 42.5Hz ÷ 69Hz) and the percentage value of

parameter THD% (see § 9.3) as shown in Fig. 3. Use keys /ZERO and /

to

increase/decrease the order of the harmonic.

Fig. 3: Display of amplitude of harmonic analysis

Long pressing of the key (at least 2s) in order to activate the H2O (Higher Harmonic

Ordering) ordering function of the amplitude of harmonics. In these conditions, function

“HOLD” is automatically activated and symbol “o” appears next to the displayed

harmonic order to indicate that the Ordering function is activated. The bargraph is

disabled and the instrument shows the value of amplitude of all the harmonics between

the DC value and the 25th, fundamental harmonic excluded, in a decreasing order

starting from the harmonic with the highest amplitude, as shown in Fig. 4

Fig. 4: Display of ordering of amplitude of harmonic analysis

In the example in Fig. 4, the harmonic with the highest value corresponds to the 7th.

Press key to observe the amplitude of the remaining harmonics and press key

H/H%/H again to switch between display in absolute and percentage values. Turn

the rotary switch to exit the function.

EN - 7

Page 10

NEPTUNE

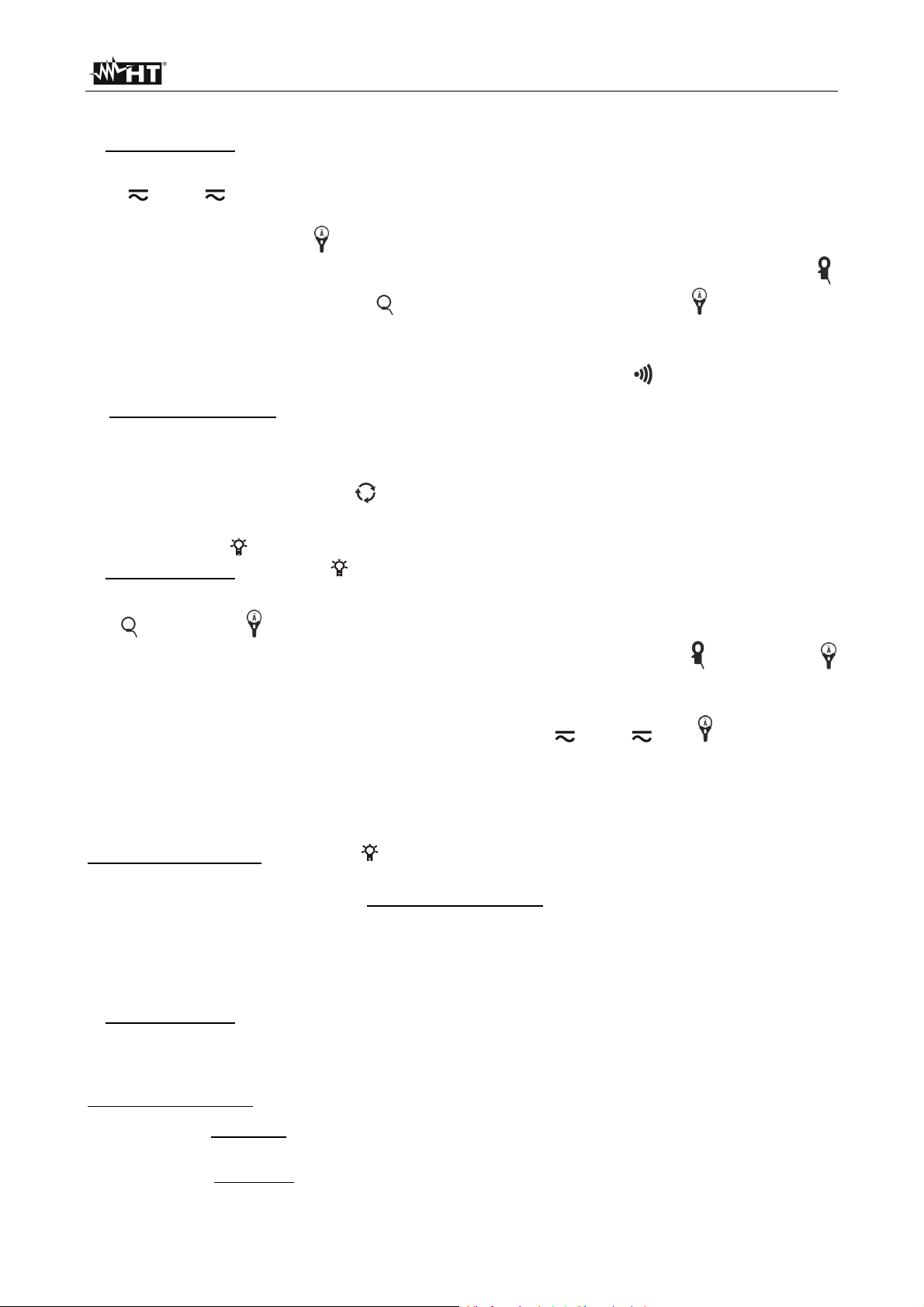

4.2.3. Key MODE/MXMNPK

A simple pressing of key MODE/MXMNPK allows for the following operations:

Selection of measuring modes “AUTO”, “AC”, “DC”, “AC+DC” and “FREQ” in positions

V , LoZV

Selection of measuring modes “AUTO”, “AC”, “DC” and “AC+DC”, “FREQ” and “IRC”

(see § 4.2.8) in position

Selection of clamp transducer type in current measurement between options “ ”

(optional standard clamp) and “ ” (optional flexible clamp) in position

Selection of measurements “AUTO” “TMR” and “PI” in position M (see § 5.6).

Selection of measurements “AUTO” and “TMR” in position Lo (see § 5.7).

Selection of measurement of Resistance “” or Continuity test “ ” in position

A long pressing (>2s) of key MODE/MXMNPK allows for the activation/deactivation of

continuous detection of maximum value (MAX), minimum value (MIN), positive peak (Pk+),

negative peak (Pk-) of the quantity (voltage or current) to be measured. The values are

constantly updated and are displayed cyclically every time the same key is pressed. This

function is not active in position . Press and hold key MODE/MXMNPK (>2s) or use the

selector to exit the function.

4.2.4. Keys / e / ZERO

A simple pressing of keys / and / ZERO allows for the following operations::

Setting of the full scale value of flexible clamp transducer (optional accessory - option

“ ” ) in position among values: 30A, 300A, 3000A for AC current measurement.

Setting of the full scale value of standard clamp transducer (option “ ” ) in position

among values: 1A, 10A, 30A, 40A, 100A, 200A, 300A, 400A, 1000A, 2000A, 3000A

for AC and DC current measurement.

Selection of harmonic order “DC ÷ 25°” in positions V , LoZV and

Selection of calculation time of RMS value in DIRC function (see § 4.2.8).

Setting of threshold values in positions M and Lo.

Once insulation measurement is complete, the results appear on the display (M,

Vgen, PI, DAR).

Long pressing (>2s) of key / allows activating/deactivating display backlight. This

function is activated in any position of the rotary switch and is automatically deactivated

after approx. 2 minutes

following operations:

’ idling. Long pressing (>2s) of key / ZERO allows for the

Zeroing of cable resistance in position Lo (see § 5.7)

Zeroing of cable resistance in position (see § 5.4)

4.2.5. Key VTEST/LIM

A simple pressing of key VTEST/LIM allows for the following operations:

Selecting test voltage in insulation measurement among the following options: 50V,

100V, 250V, 500V, 1000VDC in position M

Long pressing (>2s) of key VTEST/LIM allows for the following operations:

Setting the minimum threshold in insulation measurement among the following options:

no (no threshold), 0.10M, 0.230M, 0.50M, 1.00M, 100M in position M.

Setting the maximum threshold for continuity test in range: 0.05 ÷ 9.99 in position

Lo.

EN - 8

Page 11

NEPTUNE

4.2.6. LoZ function

This mode allows carrying out AC/DC voltage measurement with a low input impedance, in

order to eliminate wrong readings due to parasite voltages for capacitive couplings.

CAUTION

By plugging the instrument between the phase and earth conductor,

because of the low impedance of the instrument during measurement,

RCD protections may trip while carrying out the test. If this test is to be

carried out, first carry out a measurement of at least 5s between phase

and neutral in the presence of voltage

Do not leave the instrument connected for more than 1min

4.2.7. AC+DC function

The instrument is capable of measuring a possible presence of overlapping alternating

components on a generic direct waveform (voltage or current). This can be useful when

measuring typical impulsive signals of non-linear loads (e.g. welding machines, ovens,

etc.).

4.2.8. Inrush current function (INRUSH)

Measurement of inrush current (see § 5.8) is intended as the recognition of an event

detected upon exceeding of a trigger threshold. If the instant value exceeds this threshold

(fixed, equal to 1%FS clamp), the instrument shows on the display the maximum Peak

value (calculated in 1ms) and the maximum RMS value calculated with a time which can

be selected among options: 16.7ms, 20ms, 50ms, 100ms (default), 150ms, 175ms and

200ms.

4.2.9. Disabling the Auto Power Off function

In order to preserve internal batteries, the instrument switches off automatically

approximately 15 minutes after it was last used. Press key MODE/MXMNPK or turn the

rotary switch from position OFF to switch on the instrument again. To disable the Auto

Power Off function, proceed as follows:

Switch off the instrument (OFF)

Press and hold key to switch on the instrument. The symbol

“ ” disappears from

the display

Switch off and then on again the instrument to enable the function.

EN - 9

Page 12

NEPTUNE

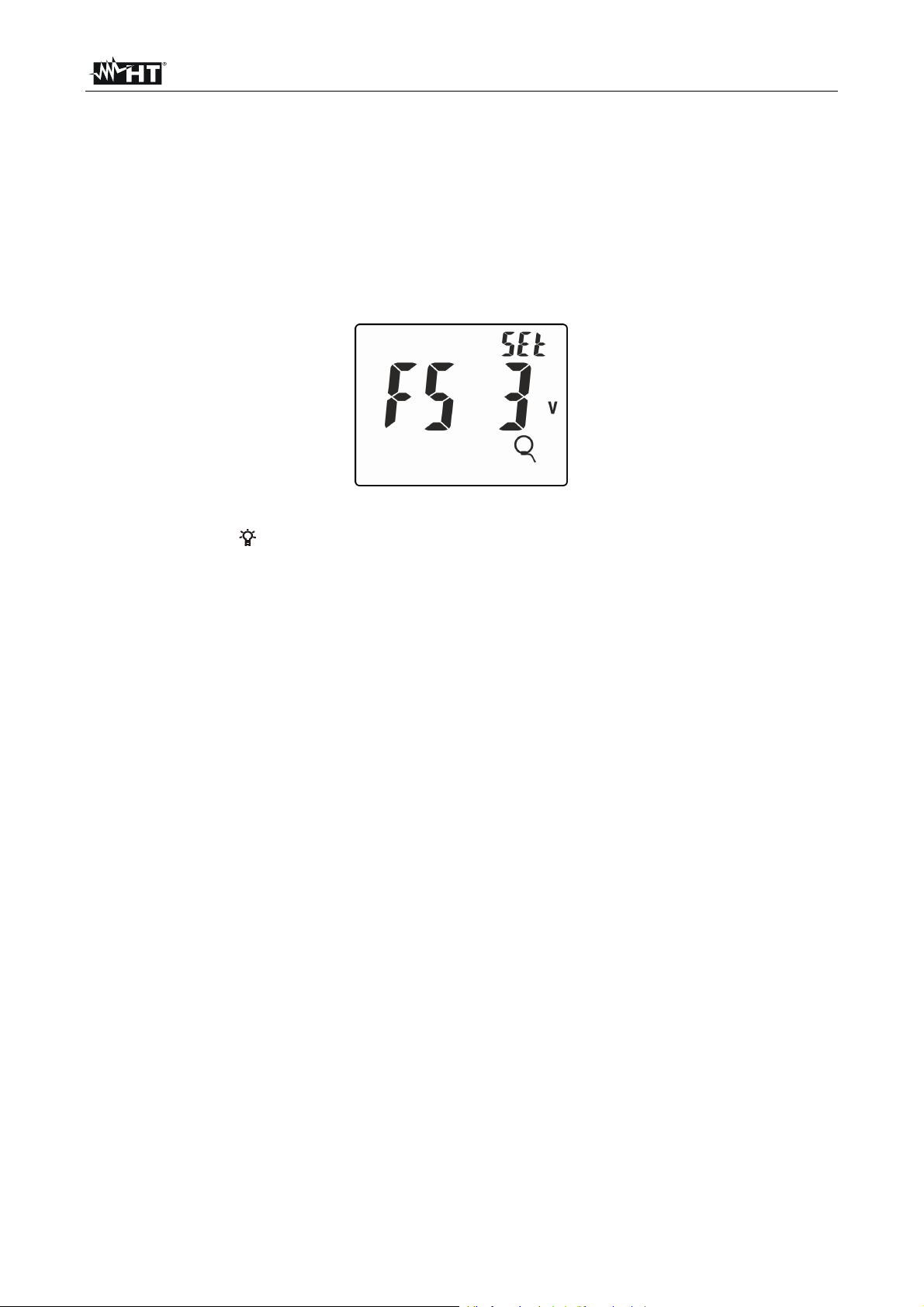

4.2.10. Setting the full scale for flexible clamp transducer

The instrument can be used with a flexible clamp transducer (optional accessory). For a

correct current measurement, it is necessary to set the full scale of voltage for the clamp

in use (please refer to the transducer’s user manual for the correct full scale value to be

set). Proceed as follows:

1. Switch off the instrument (OFF)

2. Press and hold key MODE/MXMNPK and switch on the instrument by turning the

rotary switch. The following screen appears on the display:

Fig. 5: Setting the full scale for flexible clamp transducer

3. Press keys /

or to set the full scale value of the clamp in use among the options:

3VAC (model F3000U) or 1VAC (other models).

4. Press key GO/HOLD to confirm and go back to measuring screen.

5. Settings are maintained very time the instrument is switched on.

EN - 10

Page 13

NEPTUNE

5. OPERATING INSTRUCTIONS

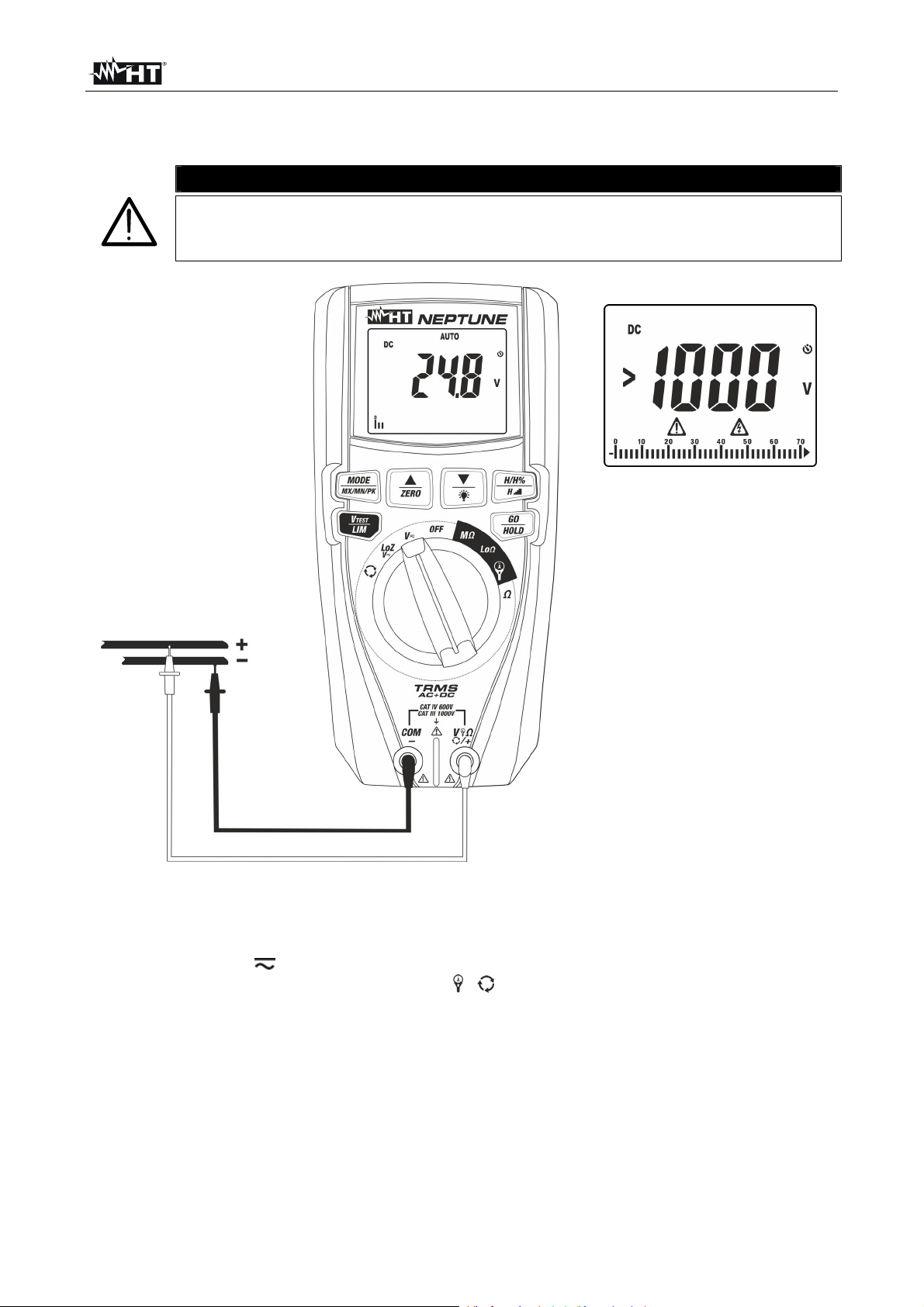

5.1. DC VOLTAGE MEASUREMENT

The maximum input DC voltage is 1000V. Do not measure voltages

exceeding the limits given in this manual. Exceeding voltage limits could

result in electrical shocks to the user and damage to the instrument.

CAUTION

Fig. 6: Use of the instrument for DC voltage measurement

1. Select position V

2. Insert the red cable into input terminal V /+ and the black cable into input terminal

COM.

3. Position the red lead and the black lead respectively in the spots with positive and

negative potential of the circuit to be measured (see Fig. 6). The display shows the

value of voltage.

4. If the display shows the message “>1000V” (see Fig. 6), the maximum measurable

value has been reached.

5. When symbol "-" appears on the instrument’s display, it means that voltage has the

opposite direction with respect to the connection in Fig. 6.

6. To use functions HOLD, MAX/MIN/PK, see § 4.2

EN - 11

Page 14

NEPTUNE

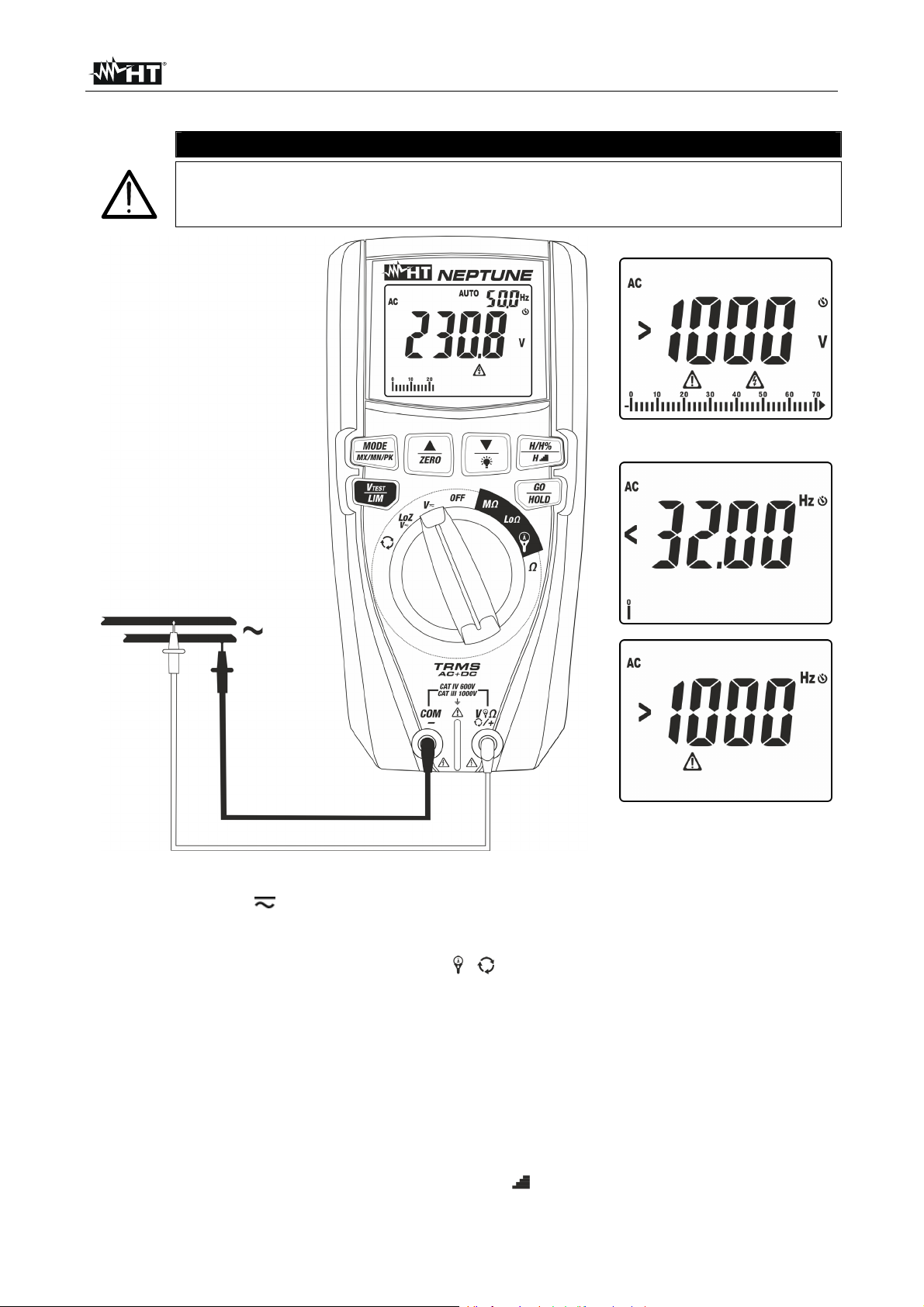

5.2. AC, AC+DC VOLTAGE MEASUREMENT

CAUTION

The maximum input AC voltage is 1000V to earth. Do not measure voltages

exceeding the limits given in this manual. Exceeding voltage limits could

result in electrical shocks to the user and damage to the instrument.

Fig. 7: Use of the instrument for AC voltage measurement

1. Select position V

2. Press the MODE/MXMNPK key until symbol “AC” or “AC+DC” is displayed. The

instrument automatically recognizes AC or DC signals.

3. Insert the red cable into input terminal V /+ and the black cable into input terminal

COM/.

4. Position the red lead and the black lead respectively in the spots of the circuit to be

measured (see Fig. 7). The display shows the value of voltage. On the top of the

display on the right side, the value of voltage frequency is displayed. Press key

MODE/MXMNPK to display the value of frequency with a higher resolution.

5. If the display shows the message “>1000V” (see Fig. 7), the maximum measurable

value has been reached.

6. If the display shows the messages “<32Hz” or “>1000Hz” (see Fig. 7), the value of

frequency is out of the measuring range 32Hz ÷ 1000Hz.

7. To use functions HOLD, MAX/MIN/PK, H/H%/H, see § 4.2

EN - 12

Page 15

NEPTUNE

5.3. AC, DC, AC+DC VOLTAGE WITH LOW IMPEDANCE (LOZ)

CAUTION

The maximum input AC/DC voltage is 1000V to earth. Do not measure

voltages exceeding the limits given in this manual. Exceeding voltage limits

could result in electrical shocks to the user and damage to the instrument.

Fig. 8: Use of the instrument for AC/DC voltage measurement with LoZ function

1. Select position LoZV . The symbols “LoZ” and “DC” appear on the display.

2. Press key MODE/MXMNPK to select

“AC” or “AC+DC” measurement. Anyway, the

instrument automatically recognizes AC or DC signals.

3. Insert the red cable into input terminal V

/+ and the black cable into input terminal

COM/.

4. Position the red lead and the black lead respectively in the positions of the circuit to be

tested (see Fig. 8) for AC voltage measurement or in the positions with a positive or

negative potential of the circuit to be tested (see Fig. 6) for DC voltage measurement.

The display shows the value of voltage. On the top of the display on the right side, the

value of voltage frequency is displayed. Press key MODE/MXMNPK to display the

value of frequency with a higher resolution.

5. If the display shows the messages “<32Hz” or “>1000Hz” (see Fig. 8), the value of

frequency is out of the measuring range 32Hz ÷ 1000Hz.

6. When symbol “-” appears on the instrument's display, it means that voltage has the

opposite direction with respect to the connection in Fig. 6

7. To use functions HOLD, MAX/MIN/PK, H/H%/H, see § 4.2

EN - 13

Page 16

NEPTUNE

5.4. RESISTANCE MEASUREMENT AND CONTINUITY TEST

CAUTION

Before attempting any resistance measurement, cut off power supply from

the circuit to be measured and make sure that all capacitors are discharged,

if present.

Fig. 9: Use of the instrument for resistance measurement and continuity test

1. Select the position.

2. Insert the red cable into input terminal V /+ and the black cable into input terminal

COM.

3. If necessary, short-circuit the measuring leads and press key /ZERO to zero the

resistance of the measuring cables. The symbol “ZERO” appears on the display.

4. Position the test leads in the desired spots of the circuit to be measured (see Fig. 9).

The display shows the value of resistance.

5. If the display shows the message “>2000” (see Fig. 9) the maximum measurable

value has been reached.

6. Press key MODE/MXMNPK to select “ ” measurement, relevant to the continuity test,

and position the test leads in the desired positions of the circuit to be measured.

7. The value of resistance (which is only indicative) is displayed in and the instrument

sounds if the value of resistance is <30.

8. To use functions HOLD, MAX/MIN, H/H%/H , see §. 4.2

EN - 14

Page 17

NEPTUNE

5.5. PHASE SEQUENCE AND PHASE CONCORDANCE WITH 1 TERMINAL

CAUTION

Input AC voltage to carry out this test must be in range 100V ÷ 1000V with

a frequency in range 42.5Hz ÷ 69Hz.

This test can only be performed by touching the metal parts of the

conductors.

Fig. 10: Use of the instrument for phase sequence and phase concordance test

1. Select position

. Message “PH 1” flashes on the display.

2. Insert the red lead into input terminal V /+.

3. Position the red lead onto phase L1 of the three-phase system to be tested (see Fig.

10). The following messages may appear on the display (see Fig. 11) to identify the

presence of a voltage signal with frequency out of range 42.5Hz ÷ 69Hz. In these

conditions, the instrument does not perform the test.

Fig. 11: Signal of voltage with wrong frequency

EN - 15

Page 18

NEPTUNE

4. In conditions of correct voltage and frequency, the instrument shows message “HOLD”,

symbols and “PH1” and the buzzer sounds continuously, waiting for a stable voltage

value on phase L1 to be detected (see Fig. 12 – left side).

Fig. 12: Detecting phase L1 and waiting for phase L2

5. Do not remove the lead from phase L1 until message “PH 2” appears flashing on the

display (see Fig. 12 – right side)

Fig. 13: Detecting phase L1 and waiting for phase L2

6. Position the red lead onto phase L2 of the three-phase system to be tested (see Fig.

10). In case passage between phase L1 and phase L2 takes more than 10s, the

instrument shows message “t.out” on the display (see Fig. 13 – left side). In conditions

of correct voltage and frequency, the instrument shows message “HOLD”, symbols

“PH2” and the buzzer sounds continuously, waiting for a stable voltage value on

and

phase L2 to be detected (see Fig. 13

– right side).

7. Upon detection of a stable voltage value on phase L2, the instrument automatically

shows message “1.2.3.” (test OK) or message “2.1.3” (test NOT OK) as shown in Fig.

14

Fig. 14: Results of phase sequence and phase concordance test

8. In case it is necessary to check phase concordance between two parallel three-phase

systems, after detection of phase L1 of the first system, position the lead on phase L1

of the second system. The correct final result is message “1.1-” (see Fig. 14 – right side)

EN - 16

Page 19

NEPTUNE

5.6. MEASUREMENT OF INSULATION RESISTANCE

This function is performed in compliance with standard IEC/EN61557-2 and allows

measuring insulation resistance in electric installations and industrial applications where it

is necessary to carry out duration tests (see § 9.2). The following operating modes are

available:

AUTO the test continues until a stable result is obtained (minimum duration 3s, max

15s) or until key GO/HOLD is pressed. Recommended mode

TMR the test is carried out in a continuous mode for the duration (timer) set, among

the values: 15s, 30s, 1min, 5min, 10min

PI the test is carried out in a continuous mode for the duration (timer) set, among

the values: 1min,10min. If the set time is 1min, the instrument will display the

value of parameter DAR (Dielectric Absorption Ratio) (see § 9.2.2).

1min,10min. If the set time is 10min, the instrument will display the value of

AUTO mode

parameter PI (Polarization Index) (see § 9.2.1).

CAUTION

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

We recommend holding the alligator clip respecting the safety area created

by the hand protection.

Fig. 15: Use of the instrument for insulation resistance measurement in AUTO mode

1. Select position M

2. Press key MODE/MXMNPK and select option “AUTO”

3. Press key VTEST/LIM to set the test voltage choosing among the values: 50V, 100V,

250V, 500V, 1000VDC. Please note the value in the top part of the display.

4. Press and hold key VTEST/LIM (>2s) to set the minimum limit threshold for

measurement. The symbol “Set” flashes on the display.

EN - 17

Page 20

NEPTUNE

5. Press keys / or /ZERO to select the value among the options: 0.10M,

0.230M, 0.50M, 1.00M, 100M, no. Option “no” indicates that no threshold was

set (see Fig. 16).

Fig. 16: Setting the limit threshold for insulation measurement

6. Press key GO/HOLD to confirm and quit the setting section. The buzzer gives a short

continuous sound.

7. Insert the red lead into input terminal V /+ and the black lead into input terminal

COM/ and possible alligator clips, and connect the instrument to the system to be

tested (see Fig. 15).

8. Press key GO/HOLD to activate the test. The following screen may appear on the

display to signal the presence of a voltage >10V found on the input terminals,

preventing the test to be carried out.

Fig. 17: Presence of voltage on the input terminals

9. In case no anomalous conditions are found, the instrument performs the test until key

GO/HOLD is pressed and held. Otherwise, the test has a duration of approx. 3s if the

key is immediately released, symbol flashes on the display and the buzzer gives out

an intermittent sound. At the end of the test, the following screens appear on the

display.

Fig. 18: Results of insulation measurement in AUTO mode

10. In the screen in Fig. 18

“>999” indicates the out-of-range condition) with positive result “OK” (value higher than

– left side, the value of insulation resistance is present (symbol

the set threshold). In the screen in Fig. 18 – right side, the value of insulation resistance

is present with negative result “NOT OK” (value lower than the set threshold).

11. Press keys / or /ZERO to display the real applied voltage.

EN - 18

Page 21

NEPTUNE

TMR mode

CAUTION

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

We recommend holding the alligator clip respecting the safety area created

by the hand protection.

Fig. 19: Use of the instrument for insulation resistance measurement in TMR mode

1. Select position M

2. Press key MODE/MXMNPK and select option

3. Press key V

TEST/LIM to set the test voltage choosing among the values: 50V, 100V,

“TMR”

250V, 500V, 1000VDC. Please note the value in the top part of the display.

4. Press and hold key V

TEST/LIM (>2s) to set the minimum limit threshold for

measurement. The symbol “Set” flashes on the display. Press keys / or /ZERO

to select the value among the options: 0.10M, 0.230M, 0.50M, 1.00M, 100M,

no. Option “no” indicates that no threshold was set (see Fig. 16).

5. Press keys / or /ZERO to select the measuring time (timer) choosing among

the options: 15s, 30s, 1min, 5min, 10min. Please note the value in the top part of the

display on the right (see Fig. 20).

Fig. 20: Setting the measuring time in TMR mode

EN - 19

Page 22

NEPTUNE

6. Insert the red lead into input terminal V /+ and the black lead into input terminal

COM/ and possible alligator clips, and connect the instrument to the system to be

tested (see Fig. 19).

7. Press key GO/HOLD to activate the test. The screen in Fig. 17 may appear on the

display to signal the presence of a voltage >10V found on the input terminals,

preventing the test to be carried out.

8. In case no anomalous conditions are found, the instrument performs the test in a

continuous mode with a countdown of time (until time “0:00”) for the entire duration of

the set timer, symbol flashes on the display and the buzzer gives out an intermittent

sound. At the end of the test, the following screens appear on the display.

Fig. 21: Results of insulation measurement in TMR mode

9. In the screen in Fig. 21 – left side, the value of insulation resistance is present (symbol

“>1999” indicates the out-of-range condition) at the end of measurement with positive

result “OK” (value higher than the set threshold). In the screen in Fig. 21 – right side, the

value of insulation resistance is present at the end of measurement with negative result

“NOT OK” (value lower than the set threshold).

10. Press keys / or /ZERO to display the real applied voltage.

PI mode

The PI mode is used to carry out diagnostic duration tests on materials (appliances,

electric cables, etc.) in order to evaluate the quality of insulation. The purpose is the

evaluation of the following coefficients:

Polarization Index (PI) defined as:

Riso

PI

Riso

min)10(

min)1(

Dielectric Absorption Ratio (DAR) defined as:

DAR

See § 9.2.1 and § 9.2.2 for further details.

Riso

min)1(

)30(

sRiso

CAUTION

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

We recommend holding the alligator clip respecting the safety area created

by the hand protection.

EN - 20

Page 23

NEPTUNE

Fig. 22: Use of the instrument for insulation resistance measurement in PI mode

1. Select position M

2. Press key MODE/MXMNPK and select option “PI”

3. Press key VTEST/LIM to set the test voltage choosing among the values: 50V, 100V,

250V, 500V, 1000VDC. Please note the value in the top part of the display.

4. Press and hold key VTEST/LIM (>2s) to set the minimum limit threshold for

measurement. The symbol “Set” flashes on the display. Press keys / or /ZERO

to select the value among the options: 0.10M, 0.230M, 0.50M, 1.00M, 100M,

no. Option “no” indicates that no threshold was set (see Fig. 16).

5. Press keys / or /ZERO to select the measuring time (timer) choosing among

the options: 1min (for DAR measurement) or 10min (for PI measurement). Please note

the value in the top part of the display on the right (see Fig. 20).

6. Insert the red lead into input terminal V

COM/

and possible alligator clips, and connect the instrument to the appliance to be

/+ and the black lead into input terminal

tested (see Fig. 22).

7. Press key GO/HOLD to activate the test. The screen in Fig. 17 may appear on the

display to signal the presence of a voltage >10V found on the input terminals,

preventing the test to be carried out.

8. In case no anomalous conditions are found, the instrument performs the test in a

continuous mode with a countdown of time (until time “0:00”) for the entire duration of

the set timer, symbol flashes on the display and the buzzer gives out an intermittent

sound. At the end of the test, the following screens appear on the display.

Fig. 23: Results of insulation measurement in PI mode

EN - 21

Page 24

NEPTUNE

9. In the screen in Fig. 23 – left side, the value of insulation resistance is present at the

end of measurement with positive result “OK” (value higher than the set threshold). In

the screen in Fig. 23 – right side, the value of insulation resistance is present at the end

of measurement with negative result “NOT OK” (value lower than the set threshold).

10. Press keys / or /ZERO to display the real applied voltage, the value of

parameter PI or the value of parameter DAR (see Fig. 24).

Fig. 24: Results of PI and DAR measurements

EN - 22

Page 25

NEPTUNE

5.7. CONTINUITY OF PROTECTIVE CONDUCTORS WITH 200MA

This function is performed in compliance with standard IEC/EN61557-4 and allows

measuring the continuity of protective and equipotential conductors. The following

operating modes are available:

AUTO the test is activated by pressing key GO/HOLD and the result is immediately

displayed after comparing it with the set maximum threshold value.

Recommended mode

TMR the test is carried out in a continuous mode for the duration (timer) set in range

1s ÷ 30s, and the result is shown on the display after comparing it with the set

maximum threshold value.

ZERO compensation of the resistance of the cables used for measurement. The

instrument automatically subtracts the value of cable resistance from the

measured resistance value. It is therefore necessary that this value is measured

(by means of the ZERO function) each time the test cables are changed or

extended.

AUTO mode

CAUTION

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

The continuity test is performed by supplying a current higher than 200mA for

resistances not higher than 5 (including the resistance of the measuring

cables). For higher resistance values, the instrument carries out the test with

a current lower than 200mA.

Fig. 25: Use of the instrument for continuity test in AUTO mode

EN - 23

Page 26

NEPTUNE

1. Select position Lo

2. Press key MODE/MXMNPK and select option “AUTO”

3. Press and hold key VTEST/LIM (>2s) to set the maximum limit threshold for

measurement. The symbol “Set” flashes on the display.

4. Press keys / or /ZERO to select the value in the range: 0.05 ÷ 9.99 (see Fig.

26).

Fig. 26: Setting the limit threshold for continuity test

5. Press key GO/HOLD to confirm and quit the setting section. The buzzer gives a short

continuous sound.

6. If necessary, compensate the test cables (see § 5.7.1).

7. Insert the red lead into input terminal V /+ and the black lead into input terminal

COM/, and connect the instrument to the system to be tested (see Fig. 25).

8. Press key GO/HOLD to activate the test. The following screen may appear on the

display to signal the presence of a voltage >10V found on the input terminals,

preventing the test to be carried out.

Fig. 27: Presence of voltage on the input terminals

9. In case no anomalous conditions are present, the instrument carries out the test and

symbol

the display.

flashes on the display. At the end of the test, the following screens appear on

Fig. 28: Results of continuity test in AUTO mode

10. In the screen in Fig. 28 – left side, a positive test result “OK” is shown (value lower than

the set threshold and test current >200mA). In the screen in Fig. 28

– middle, a

negative test result “NOT OK” is shown (value higher than the set threshold and test

current <200mA). In the screen in Fig. 28 – right side, a negative test result “NOT OK” is

shown, corresponding to the out-of-range condition (symbol “>200.0”).

EN - 24

Page 27

NEPTUNE

TMR mode

CAUTION

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

The continuity test is performed by supplying a current higher than 200mA for

resistances not higher than 5

(including the resistance of the measuring

cables). For higher resistance values, the instrument carries out the test with

a current lower than 200mA.

Fig. 29: Use of the instrument for continuity test in TMR mode

1. Select position Lo

2. Press key MODE/MXMNPK and select option “TMR”

3. Press and hold key VTEST/LIM (>2s) to set the maximum limit threshold for

measurement. The symbol “Set” flashes on the display.

4. Press keys / or /ZERO to select the value in the range: 0.05 ÷ 9.99 (see Fig.

26).

5. Press keys / or /ZERO to select the measuring time (timer) in range: 1s ÷ 30s.

Please note the value in the top part of the display on the right (see Fig. 30).

Fig. 30: Setting the measuring time in TMR mode

EN - 25

Page 28

NEPTUNE

6. If necessary, compensate the test cables (see § 5.7.1).

7. Insert the red lead into input terminal V /+ and the black lead into input terminal

COM/, and connect the instrument to the system to be tested (see Fig. 29).

8. Press key GO/HOLD to activate the test. The screen in Fig. 27 may appear on the

display to signal the presence of a voltage >10V found on the input terminals,

preventing the test to be carried out.

9. In case no anomalous conditions are found, the instrument performs the test in a

continuous mode with a countdown of time (until time “0”) for the entire duration of the

set timer, and symbol flashes on the display. At the end of the test, the following

screens appear on the display:

Fig. 31: Results of continuity test in TMR mode

10. In the screen in Fig. 31 – left side, a positive test result “OK” is shown (value lower than

the set threshold and test current >200mA). In the screen in Fig. 31 – middle, a

negative test result “NOT OK” is shown (value higher than the set threshold and test

current <200mA). In the screen in Fig. 31 – right side, a negative test result “NOT OK” is

shown, corresponding to the out-of-range condition (symbol “>200.0”).

EN - 26

Page 29

NEPTUNE

5.7.1. Function ZERO – Zeroing of test cable resistance

In every operating mode (AUTO, TMR) it is possible to zero the resistance of the test

cables before carrying out continuity tests. This operation is recommended upon the first

use of the provided test cables and in case different cables must be used (e.g. cable

extensions). The operation is only possible for test cable resistance <5.00.

1. Select position Lo

2. Insert the test cables into input terminal V /+ and COM/, connect the alligator clips

and shot-circuit the cable ends between each other (see Fig. 32).

Fig. 32: Connection of the cables in compensation function

3. Press and hold (>2s) key /ZERO. The instrument starts the compensation procedure

of cable resistance, immediately followed by the verification of the compensated value.

The following screens are displayed in a quick sequence:

Fig. 33: Results of a correctly performed zeroing

4. The instrument performs the first measurement, detecting the resistance of the test

cables (see Fig. 33 – left side). If the compensated value (ZERO) is ≤5.00, the

instrument keeps it saved and carries out the following test by performing a second

EN - 27

Page 30

NEPTUNE

measurement and comparing this new value to the compensated one. If the difference

between the values is ≤0.01, calibration is confirmed and the message “OK” is

displayed (see Fig. 33 – middle). Subsequently, the instrument goes back to the

measuring screen with the message “ZERO” displayed to indicate that cable

compensation is present.

5. In case the first measurement detects a resistance of test cables >5.00, the

instrument shows the following screens in a quick sequence:

Fig. 34: Results of zeroing not correctly performed

6. Messages “>5.00” and “NOT OK” are initially shown on the display (see Fig. 34 – left

side). Subsequently, message “CLr” is shown, to indicate that calibration has been

cancelled (see Fig. 34 – middle) and the message “ZERO” is not shown in the

measuring screen (see Fig. 34 – right side).

7. To zero a cable calibration in the instrument, carry out the procedure with open input

terminals V /+ and COM/ and press and hold (>2s) key /ZERO. The following

screens are displayed in a quick sequence:

Fig. 35: Zeroing calibration

EN - 28

Page 31

NEPTUNE

5.8. MEASUREMENT OF DC, AC, AC+DC, INRUSH CURRENT WITH CLAMP

TRANSDUCERS

CAUTION

Maximum measurable current in this function is 3000A AC or 1000A DC.

Do not measure currents exceeding the limits given in this manual.

The instrument carries out the measurement both with flexible clamp

transducers (optional accessories) and with other standard clamp

transducers in the HT family (optional accessories). With transducers

having an Hypertac output connector, the optional adapter NOCANBA is

necessary to obtain the connection.

Fig. 36: Use of the instrument for current measurement with clamp transducer

1. Select the position.

2. Press key MODE/MXMNPK to select the type of clamp transducer among the options:

“ ” (flexible clamp transducer – only AC) or “ ” (standard clamp transducer – AC or DC).

3. Press keys / or and, on the instrument, select the same range set on the

clamp, among the options: 30A, 300A, 3000A (AC current measurement with flexible

clamp) or: 1A, 10A, 30A, 40A, 100A, 200A, 300A, 400A, 1000A, 2000A, 3000A for

AC, DC, AC+DC current measurement with standard clamp).

4. For flexible clamp transducers, set the relevant full scale value of voltage (see §

4.2.10).

5. Press key GO/HOLD to confirm settings.

EN - 29

Page 32

NEPTUNE

6. For standard clamp transducers, press key MODE/MXMNPK to select “AC”, “DC” or

“AC+DC” measurement. Anyway, the instrument automatically recognizes AC or DC

quantities.

7. Insert the red cable into input terminal V /+ and the black cable into input terminal

COM/.. For standard transducers with Hypertac connector, use optional adapter

NOCANBA. For information on the use of clap transducers, please refer to the relevant

user manual.

8. Insert the cable into the center of the jaws (see Fig. 36). The value of current is shown

in Fig. 37

Fig. 37: Result of AC current measurement with standard and flexible clamp

9. Press key MODE/MXMNPK to display the value of frequency of AC current with a high

resolution (see Fig. 38).

Fig. 38: Result of frequency measurement with standard and flexible clamp

10. The following screens may be shown on the display:

Fig. 39: Anomalous situations on current measurement with clamp transducers

11. Message

full scale (300A in case of Fig. 39). If the display shows the messages

“>1000Hz”, the measured value of current frequency is out of the measuring range

“>300A” indicates that the value of current measured is higher than the set

“<32.00Hz” or

32Hz ÷ 1000Hz.

12. To use functions HOLD, MAX/MIN/PK, H/H%/H, see § 4.2

EN - 30

Page 33

NEPTUNE

Inrush current measurement (DIRC)

CAUTION

Maximum measurable current in this function is 3000A AC or 1000A DC.

Do not measure currents exceeding the limits given in this manual.

The instrument carries out the measurement both with flexible clamp

transducers (optional accessories) and with other standard clamp

transducers in the HT family (optional accessories). For inrush currents

containing a high DC component, the use of AC/DC clamps is

recommended. With transducers having an Hypertac output connector,

the optional adapter NOCANBA is necessary to obtain the connection.

1. Select the position.

2. Press key MODE/MXMNPK to select the type of clamp transducer among the options:

“ ” (flexible clamp transducer – only AC) or “ ” (standard clamp transducer – AC or DC).

3. Press the keys / or and, on the instrument, select the same range set on the

clamp, among the options: 30A, 300A, 3000A (AC current measurement with flexible

clamp) or: 1A, 10A, 30A, 40A, 100A, 200A, 300A, 400A, 1000A, 2000A, 3000A for AC

or AC+DC current measurement with standard clamp.

4. For flexible clamp transducers, set the relevant full scale value (see § 4.2.10).

5. Press key GO/HOLD to confirm settings.

6. Press key MODE/MXMNPK to select “IRC” measurement. The following screens are

shown on the display according to the type of clamp used:

Fig. 40: Initial screens of inrush current measurement

7. Connect the clamps to the system to be tested as indicated in § 5.8

8. Press key GO/STOP to activate the function. The instrument waits for the event to be

recognized (measured value higher than the fixed trigger threshold equal to 1%FS

clamp: e.g. 30A with FS = 3000A) and shows symbol

“ ” on the display (see Fig. 41 –

left side).

Fig. 41: Recognition of inrush current event

EN - 31

Page 34

NEPTUNE

9. Upon recognition of the event, measurement stops automatically and the instrument

shows, in its main display, the Max RMS value calculated according to the evaluation

time of 100ms (default) indicated on the secondary display (see Fig. 41 – right side).

10. Press keys / or to select the display of the following parameters:

Peak value “Pk” calculated in 1ms (see Fig. 42 – left side)

Max RMS value calculated in 16.7ms

Max RMS value calculated in 20ms

Max RMS value calculated in 50ms

Max RMS value calculated in 100ms

Max RMS value calculated in 150ms

Max RMS value calculated in 175ms

Max RMS value calculated in 200ms

Fig. 42: Examples of display of inrush current

11. If the measured current is higher than the set FS of the clamp, a message like the one

in Fig. 42 – right side (relevant to FS = 3000A) is shown on the display.

12. Press key GO/HOLD again to start a new measurement or turn the rotary switch to quit

the function.

EN - 32

Page 35

NEPTUNE

6. MAINTENANCE

CAUTION

Only expert and trained technicians should perform maintenance

operations. Before carrying out maintenance operations, disconnect all

cables from the input terminals.

Do not use the instrument in environments with high humidity levels or

high temperatures. Do not expose to direct sunlight.

Always switch off the instrument after use. In case the instrument is not to

be used for a long time, remove the battery to avoid liquid leaks that could

damage the instrument’s internal circuits.

6.1. BATTERY REPLACEMENT

When the LCD display shows symbol “ ” and the indication “bAtt” (see Fig. 43), batteries

need to be replaced, operating as follows:

Fig. 43: Screen with low battery indication

1. Position the rotary switch to OFF and remove the cables from the input terminals.

2. Turn the fastening screw of the battery compartment cover from position “ ” to position

“ ” and remove it.

3. Remove the battery and insert a new battery of the same type (see § 7.1.1), respecting

the indicated polarity.

4. Restore the battery compartment cover into place and turn the fastening screw from

position

“ ” to position “ ”.

5. Do not scatter old batteries into the environment. Use the relevant containers for

disposal.

6.2. CLEANING THE INSTRUMENT

Use a soft and dry cloth to clean the instrument. Never use wet cloths, solvents, water, etc.

6.3. END OF LIFE

WARNING: the symbol on the instrument indicates that the appliance and its

accessories must be collected separately and correctly disposed of.

EN - 33

Page 36

NEPTUNE

7. TECHNICAL SPECIFICATIONS

7.1. TECHNICAL CHARACTERISTICS

Accuracy calculated as [%reading + (no. digits*resolution)] at 23°C 5°C <80%RH.

DC Voltage (Autorange)

Range

[V]

0.0 999.9

AC, AC+DC, Loz TRMS Voltage (Autorange)

Range

[V]

0.5 999.9

Input impedance function VAC: 5M,

Input impedance function LoZ: 3.5k for 10s (@ 110V/50Hz), 4.5s (@ 230V/50Hz), 1s (@ 400V/50Hz). For higher

voltage values, input impedance becomes higher than 10k. WARNING: do not leave the instrument connected for

more than 1min.

Automatic selection DC mode, Max crest factor: 1.5

Current and Voltage frequency (Autorange)

Range [Hz] Resolution [Hz] Accuracy

32.00 99.99

100.0 999.9

Voltage range: 0.5V ÷ 999.9V, Current field: 0.5A ÷ 3000A (Flexible clamp F3000U), 1mV ÷ 1000mV (STD clamp)

AC TRMS Current (Flexible clamp F3000U) – (Autorange)

Range [mV] Resolution [mV] Accuracy (*)

1 3000

(*) For frequency >100Hz accuracy is: (1.5%reading + 5digits)

Max crest factor: 3 ; Frequency bandwidth: 1kHz ; Current zeroed for value <1%FS [A]

AC TRMS Current (flexible clamp FS 1V) and DC, AC, AC+DC (STD clamp) – (Autorange)

Range [mV] Resolution [mV] Accuracy (*)

1 1000

(*) For frequency >100Hz accuracy is: (1.5%reading + 5digits)

Max crest factor: Frequency bandwidth: 1kHz;

Current zeroed for value <1%FS [A] (Flex clamp 1V), Current zeroed for value <1%FS [A] (STD clamp)

AC TRMS inrush current (Flexible clamp F3000U)

Range [mV] Resolution [mV] Accuracy (*)

1 3000

(*) Accuracy declared for frequency: DC, 42.5 ÷ 69Hz

Max crest factor: 3, Sampling frequency: 4kHz

Detection threshold: 1%FS [A] fixed

Response time: 1ms (Peak), 16.7ms, 20ms, 50ms, 100ms, 150ms, 175ms, 200ms (max RMS)

AC TRMS inrush current (Flexible clamp 1V) and DC, AC, AC+DC TRMS (STD clamp)

Range [mV] Resolution [mV] Accuracy (*)

1 1000

(*) Accuracy declared for frequency: DC, 42.5 ÷ 69Hz

Max crest factor: 3, Sampling frequency: 4kHz

Detection threshold: 1%FS [A] fixed

Response time: 1ms (Peak), 16.7ms, 20ms, 50ms, 100ms, 150ms, 175ms, 200ms (max RMS)

Resistance and continuity test (Autorange)

Range [] Resolution []

0.0 199.9

200 1999

Resolution

[V]

0.1

Resolution

[V]

(0.5%rdg + 2digits) 5M

Frequency Accuracy Overload protection

0.1 32Hz ÷ 1kHz

Accuracy

0.01

0.1

0.1

1

Input

impedance

(0.5%reading + 2digits)

1

1

1

1

Accuracy Buzzer

(1.0%reading +

5digits)

Overload protection

1000VDC/ACrms

1000VDC/ACrms

(0.1%rdg +1digit)

(0.5%rdg + 2digits)

(0.5%rdg + 2digits)

(2%reading + 2digits)

(2%reading + 2digits)

<30

EN - 34

Page 37

NEPTUNE

Harmonic voltage and current (Autorange)

Harmonic order

DC

1 25 (5.0rdg+10digits)

Fundamental

frequency

42.5Hz 69Hz

Resolution

0.1V / 0.1A /0.1%

THD% 0.1%

Accuracy of harmonic amplitudes expressed in % is evaluated considering the accuracy of parameters’ ratio

(*) Harmonic voltages will be zeroed under the following conditions:

1st harmonic: value <0.5V

DC, 2nd to 25th harmonic: harmonic value <0.5% fundamental value or value <0.5V

(*) Harmonic currents will be zeroed under the following conditions

1st harmonic: value <1%FS[A]

DC, 2nd to 25th harmonic: harmonic value <0.5% fundamental value or value <1%FS[A].

Accuracy (*)

(non-zeroed values)

(5.0rdg+20digits)

(10.0rdg+10digits)

Insulation resistance (M)

Test voltage [V]

50

100

250

500

1000

Open-circuit voltage: rated test voltage (-0% ÷ 10%)

Short-circuit current: < 6mA (peak) with each rated test voltage

Rated test current: >1mA with 1k x Vnom (50V, 100V, 250V, 1000V), >2.2mA with 230k @ 500V

Input protection: error message for voltage > 10V

Range [M] Resolution [M]

0.01 9.99

10.0 99.9

0.01 9.99

10.0 99.9

100.0 199.9 (5.0read. + 2digits)

0.01 9.99

10.0 99.9

100 499

0.01 9.99

10.0 199.9

200 499

500 999 (5.0read. + 2digits)

0.01 9.99

10.0 199.9

200 999

1000 1999 (5.0read. + 2digits)

0.01

0.1

0.01

0.1

0.01

0.1

1

0.01

0.1

1

0.01

0.1

1

Accuracy

(5.0read. + 2digits)

(2.0read. + 2digits)

(2.0read. + 2digits)

(5.0read. + 2digits)

(2.0read. + 2digits)

(2.0read. + 2digits)

Continuity of protective conductors (Lo)

Range [] Resolution []

0.00 9.99

10.0 199.9

Test current: >200mA DC up to 5 (cables included), resolution 1mA, accuracy (5.0%reading + 5digits).

Open-circuit voltage: 4 < V

Input protection: error message for voltage > 10V

< 12V

0

0.01

0.1

(2.0%reading + 2digits)

Accuracy

Phase sequence with 1 terminal (*)

Voltage range L-N, L-PE [V] Frequency range

100.0 999.9

(*) Measurement possible by direct contact on the metallic parts of the conductors (not on the insulating sheath)

42.5 ÷ 69Hz

EN - 35

Page 38

NEPTUNE

Reference guidelines

Instrument safety: IEC/EN61010-1,IEC/EN61010-2-030,

IEC/EN61010-2-033

EMC: IEC/EN 61326-1

M test: IEC/EN 61557-2

Lo test: IEC/EN 61557-4

Phase sequence: IEC/EN 61557-7

Insulation: double insulation

Pollution level: 2

Measurement category: CAT IV 600V, CAT III 1000V to earth and

between inputs

7.1.1. General characteristics

Mechanical characteristics

Size (L x W x H): 175 x 85 x 55mm (7 x 3 x 2in)

Weight (batteries included): 420g (15ounces)

Mechanical protection: IP40

Power supply

Battery type: 4x1.5V batteries type AAA IEC LR03

Low battery indication: symbol “” ” on the display

Battery life: V, A, , approx. 132h (backlight OFF)

V, A, , approx. 68h (backlight ON)

M (@500V) approx. 400 tests (backlight

OFF).

Lo approx. 2000 tests (backlight OFF).

Auto Power Off: after 15 minutes’ idling (can be disabled)

Display

Type of display: 4 dgt LCD, max 9999 dots, decimal sign, point

backlight and bargraph, indication of polarity

Sampling frequency: 2 times/s

Conversion: RMS

7.2. ENVIRONMENTAL CONDITIONS FOR USE

Reference temperature: 23°C

5°C (73°F ± 41°F)

Operating temperature: 5°C ÷ 40°C (41°F ÷ 104°F)

Allowable relative humidity: <80%RH

Storage temperature: -20°C ÷ 60°C (-4°F ÷ 140°F)

Storage humidity: <80%RH

Max operating altitude: 2000m (6562ft)

This instrument satisfies the requirements of Low Voltage Directive 2014/35/EU

(LVD) and of EMC Directive 2014/30/EU.

This instrument satisfies the requirements of European Directive 2011/65/EU (RoHS)

and 2012/19/EU (WEEE).

7.3. ACCESSORIES

See the attached packing list.

EN - 36

Page 39

NEPTUNE

8. ASSISTANCE

8.1. WARRANTY CONDITIONS

This instrument is warranted against any material or manufacturing defect, in compliance

with the general sales conditions. During the warranty period, defective parts may be

replaced. However, the manufacturer reserves the right to repair or replace the product.

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer's charge. However, shipment will be agreed in advance. A report will

always be enclosed to a shipment, stating the reasons for the product's return. Only use

original packaging for shipment. Any damage due to the use of non-original packaging

material will be charged to the Customer. The manufacturer declines any responsibility for

injury to people or damage to property.

The warranty shall not apply in the following cases:

Repair and/or replacement of accessories and battery (not covered by warranty).

Repairs that may become necessary as a consequence of an incorrect use of the

instrument or due to its use together with non-compatible appliances.

Repairs that may become necessary as a consequence of improper packaging.

Repairs which may become necessary as a consequence of interventions performed

by unauthorized personnel.

Modifications to the instrument performed without the manufacturer's explicit

authorization.

Use not provided for in the instrument's specifications or in the instruction manual.

The content of this manual cannot be reproduced in any form without the manufacturer's

authorization.

Our products are patented and our trademarks are registered. The manufacturer

reserves the right to make changes in the specifications and prices if this is due to

improvements in technology.

8.2. ASSISTANCE

If the instrument does not operate properly, before contacting the After-sales Service,

please check the conditions of battery and cables and replace them, if necessary. Should

the instrument still operate improperly, check that the product is operated according to the

instructions given in this manual. Should the instrument be returned to the After-sales

Service or to a Dealer, transport will be at the Customer's charge. However, shipment will

be agreed in advance. A report will always be enclosed to a shipment, stating the reasons

for the product's return. Only use original packaging for shipment; any damage due to the

use of non-original packaging material will be charged to the Customer.

EN - 37

Page 40

NEPTUNE

9. THEORETICAL APPENDIXES

9.1. CONTINUITY OF PROTECTIVE CONDUCTORS

Purpose of the test

Checking the continuity of:

Protective conductors (PE), main equalizing potential conductors (EQP), secondary

equalizing potential conductors (EQS) in TT and TN-S systems.

Neutral conductors having functions of protective conductors (PEN) in TN-C systems.

This test is to be preceded by a visual check verifying the existence of yellow-green

protective and equalizing potential conductors as well as compliance of the sections used

with the standards’ requirements.

Parts of the system to be checked

Connect one of the test leads to the

protective conductor of the socket

and the other to the equalizing

potential node of the earth

installation.

Connect one of the test leads to the

external mass (in this case the water

pipe) and the other to the earth

installation using for example the

protective conductor of the closest

socket.

Fig. 44: Examples of continuity measures of conductors

Check continuity between:

Earth poles of all the plug sockets and earth collector or node.

Earth terminals of class I appliances (boilers, etc.) and earth collector or node.

Main external masses (water tubes, gas tubes, etc.) and earth terminal or node.

Additional external masses between each other and to earth terminal.

Allowable values

The standards do not require the measurement of continuity resistance and the

comparison of the results with limit values. The standards simply require that the

instrument in use warns the operator if the test was not carried out with a current of at

least 200mA and an open-circuit voltage ranging from 4 to 24V. The resistance values

may be calculated according to the sections and lengths of the conductors being tested. In

general, if the instrument detects values of some ohms, the test may be considered as

successful.

EN - 38

Page 41

NEPTUNE

9.2. MEASUREMENT OF INSULATION RESISTANCE

Purpose of the test

Check that the insulation resistance of the installation complies with the requirements of

the applicable standard. This test has to be performed with the circuit being tested not

powered and with the possible loads it supplies disconnected.

Description Test voltage [V]

SELV or PELV systems

Systems up to 500V (private inst.)

Systems over 500V

250VDC

500VDC

1000VDC

Minimum allowable value [M]

> 0.250 M

> 1.00 M

> 1.00 M

Table 1: Most common test types, test voltages and relevant limit values.

Parts of the system to be checked

Check the insulation resistance between:

Each active conductor and the earth (the neutral conductor is considered as an active

conductor except in TN-C power supply systems, where it is considered as part of the

earthing (PEN)). During this measurement, all active conductors may be connected to

each other. Should the measured result not be within the limits prescribed by the

standards, the test must be repeated separately for each single conductor.

Active conductors. Guidelines recommends also checking the insulation between

active conductors when it is possible.

Allowable values

The values of the measured voltage and of the minimum insulation resistance can be

taken from the following table:

Rated voltage of circuit [V]

SELV and PELV * 250

Up to/equal to 500 V, except for the abovementioned circuits

Over 500 V 1000

* The terms SELV and PELV replace, in the standard’s new wording, the old definitions of “very

low safety voltage

” or “very low functional voltage”.

Test voltage

[V]

500

Insulation resistance

[M]

0.250

0.500

1,000

Table 2: Most common test types, insulation resistance measurement

If the system includes electronic devices, it is necessary to disconnect them from the

system. Should this not be possible, only perform the test between active conductors

(which, in this case, must be connected to each other) and the earth connection.

EN - 39

Page 42

NEPTUNE

EXAMPLE OF HOW TO MEASURE THE INSULATION OF A SYSTEM

Fig. 45: Example of an electric system

Switches D and E are the switches installed near the load which have the function of

separating the load from the system. Should these switches not be provided, or should

they be single-pole switches, it is necessary to disconnect the users from the system

before performing the insulation resistance test.

An indicative procedure of how to measure the insulation resistance of a system is given in

the table below:

EN - 40

Page 43

NEPTUNE

4

Spot where to

Switch conditions

Open switches A, D

1.

and E

2. Open switch B On switch A

3. On switch B

. Open switch C On switch B

5. On switch C

perform

measurement

On switch A

Measureme

nt

If RR

If RR

If RR

If RR

If RR

If RR

If RR

If RR

If RR

If RR

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

LIMITE

System evaluation

OK (end of test)

Proceed to 2

Proceed to 3

Insulation between switches

A and B is too low. Restore

insulation and measure again.

OK (end of test)

Insulation is too low

downstream of switch B.

Proceed to 4

Proceed to 5

Insulation between switches

B and C is too low. Restore

insulation and measure again.

OK (end of test)

Downstream of switch B,

insulation is too low. Restore

insulation and measure again.

Table 3: Procedure for measuring insulation in he system reported in Fig. 45

In the presence of a very extended circuit, wires running side by side constitute a capacity

that the instrument must load in order to obtain a correct measurement; in this case it is

advisable to hold the start button of the measurement (in case you run the test in manual

mode) until the result is stable.

When performing measurements between active conductors, it is absolutely necessary to

disconnect all users (alarm lights, intercom transformers, etc.), otherwise the instrument

will measure their resistance instead of the system

’s insulation. Moreover, an insulation

resistance test between active conductors may damage them.

The

“> full scale” message indicates that the insulation resistance measured by the

instrument is higher than the maximum measurable resistance value. This result is

obviously much higher than the minimum limits in the standard table above, so the

insulation in that spot is to be considered as compliant with the standards.

EN - 41

Page 44

NEPTUNE

9.2.1. Polarization Index (PI)

The purpose of this diagnostic test is to evaluate the influence of the polarization effects.

Upon the application of a high voltage to insulation, the electric dipoles distributed in the

insulation align in the direction of the applied electric field. This phenomenon is called

polarization. Because of the polarized molecules, a polarization (absorption) current

generates, which lowers the total value of insulation resistance.

Parameter PI consists in the ratio between the value of insulation resistance measured

after 1 minute and after 10 minutes. The test voltage is maintained throughout the whole

duration of the test and, at the end, the instrument provides the value of ratio:

PI

Riso

Riso

min)10(

min)1(

Some reference values:

PI Value Insulation condition

from 1.0 to 1.25 Not acceptable

from 1.4 to 1.6 Good

>1.6 Excellent

9.2.2. Dielectric Absorption Ratio (DAR)

Parameter DAR consists in the ratio between the value of insulation resistance measured

after 30s and after 1 minute. The test voltage is maintained throughout the whole duration

of the test and, at the end, the instrument provides the value of ratio:

DAR

Riso

min)1(

)30(

sRiso

Some reference values:

DAR Value Insulation condition

< 1.0 Dangerous

from 1.0 to 2.0 Questionable

from 2.0 to 4.0 Good

> 4.0 Excellent

EN - 42

Page 45

NEPTUNE

9.3. VOLTAGE AND CURRENT HARMONICS