Page 1

ENGLISH

User’s manual

© Copyright HT ITALIA 2006 Release EN 2.00 - 22/08/2006

Page 2

MULTITEST M72 - M73 - M74 - M75

1. SAFETY PRECAUTIONS AND PROCEDURES ....................................................................................................... 2

1.1. Preliminary instructions ....................................................................................................................................2

1.2. During use........................................................................................................................................................ 3

1.3. After use........................................................................................................................................................... 3

1.4. Overvoltage categories - definitions ................................................................................................................. 3

2. GENERAL DESCRIPTION ........................................................................................................................................4

2.1. Working............................................................................................................................................................ 4

2.2. TRMS value and mean value - definitions........................................................................................................ 4

2.3. TRUE ROOT MEAN SQUARE VALUE and CREST FACTOR - definitions.....................................................4

3. PREPARATION FOR USE ........................................................................................................................................5

3.1. Preliminary checks ...........................................................................................................................................5

3.2. Power supply.................................................................................................................................................... 5

3.3. Calibration........................................................................................................................................................5

3.4. Storage ............................................................................................................................................................ 5

4. OPERATING INSTRUCTIONS.................................................................................................................................. 6

4.1. Instrument - Description ................................................................................................................................... 6

4.1.1. Turning on ................................................................................................................................................... 7

4.1.2. Auto Power Off ............................................................................................................................................ 7

4.1.3. Current measurement through external transducer..................................................................................... 7

4.1.4. Phase sequence and phase conformity measurement................................................................................ 7

4.2. HOLD, MAX/MIN/AVG, PEAK±........................................................................................................................ 8

4.2.1. HOLD .......................................................................................................................................................... 8

4.2.2. MAX/MIN/AVG ............................................................................................................................................8

4.2.3. PEAK±......................................................................................................................................................... 8

4.3. V

4.3.1. Frequency measurement .......................................................................................................................... 10

4.3.2. Anomalous cases which may occur during V

4.4. A

4.4.1. Frequency measurement .......................................................................................................................... 13

4.4.2. Anomalous cases which may occur during A

4.5. Ω

4.5.1. "CAL" mode............................................................................................................................................... 15

4.5.2. Anomalous cases which may occur during Ω

4.6.

4.6.1. Anomalous cases which may occur during

4.7. LAN: Cabling test (M75) ................................................................................................................................. 21

4.7.1. Anomalous cases which may occur during LAN tests ............................................................................... 22

4.7.2. SPLIT PAIRS - explication note................................................................................................................. 22

4.7.3. Cabling errors............................................................................................................................................ 23

4.8. Ω 0.2A: Continuity test on earth, protective and equalizing potential conductors (M72, M74, M75) ............... 24

4.8.1. "CAL" mode............................................................................................................................................... 25

4.8.2. Anomalous cases which may occur during Ω 0.2A tests............................................................................. 27

4.9. MΩ: Insulation resistance measurement test voltage 500V

4.9.1. Anomalous cases which may occur during MΩ tests ................................................................................29

4.10. RCD: Tests on AC type RCDs (M73, M74, M75) ........................................................................................... 30

4.10.1. Anomalous cases which may occur during RCD tests............................................................................. 31

4.11. Ra

4.11.1. Anomalous cases which may occur during Ra

4.12. AUTO: Automatic cycle of measurements to test a plant (M74, M75)............................................................ 37

5. MAINTENANCE ...................................................................................................................................................... 39

5.1. General .......................................................................................................................................................... 39

5.2. Battery replacement ....................................................................................................................................... 39

5.3. Cleaning......................................................................................................................................................... 39

5.4. End of life ....................................................................................................................................................... 39

6. TECHNICAL SPECIFICATIONS ............................................................................................................................. 40

6.1. Characteristics ...............................................................................................................................................40

6.1.1. Electrical.................................................................................................................................................... 42

6.1.2. Safety standards ....................................................................................................................................... 42

6.1.3. General specifications ............................................................................................................................... 42

6.2. ENVIRONMENT............................................................................................................................................. 42

6.2.1. Environmental conditions ..........................................................................................................................42

6.2.2. EMC .......................................................................................................................................................... 42

6.3. ACCESSORIES ............................................................................................................................................. 42

7. SERVICE................................................................................................................................................................. 43

7.1. Warranty conditions .......................................................................................................................................43

7.2. After-sale service ...........................................................................................................................................43

Hz: DC/AC voltage and frequency measurement (M73 and M75).......................................................... 9

Hz measurements ............................................................ 11

Hz: DC/AC current and frequency measurement ................................................................................. 12

Hz measurements ...........................................................14

: Resistance measurement and continuity test ....................................................................................... 15

measurement ................................................................ 16

: Phase sequence and conformity measurement ...................................................................................... 17

tests................................................................................. 20

..................................................................... 28

: Measurement of global earth resistance (M73, M74, M75)................................................................. 33

tests............................................................................ 35

EN - 1

Page 3

MULTITEST M72 - M73 - M74 - M75

1. SAFETY PRECAUTIONS AND PROCEDURES

This instrument complies with safety Standards EN61557 and EN61010-1 related to

electronic measuring instruments.

CAUTION

For your own safety and to avoid damaging the instrument follow the

procedures described in this instruction manual and read carefully all notes

preceded by this symbol .

When taking measurements:

) avoid doing that in humid or wet places - make sure that humidity is within the limits

indicated in section “environmental conditions”.

) avoid doing that in rooms where explosive gas, combustible gas, steam or excessive

dust is present.

) keep you insulated from the object under test.

) do not touch exposed metal parts such as test lead ends, sockets, fixing objects,

circuits etc.

) avoid doing that if you notice anomalous conditions such as breakages, deformations,

fractures, leakages of battery liquid, blind display etc.

) be particularly careful when measuring voltages exceeding 25V in particular places

(building yards, swimming pools, etc.) and 50V in ordinary places to avoid risks of

electrical shocks.

The following symbols are used:

CAUTION - refer to the instruction manual - an improper use may damage the

instrument or its components

DC or AC voltage or current

CAUTION for dangerious voltage. Risk of electric shock

Meter with double insulation

1.1. PRELIMINARY INSTRUCTIONS

) This instrument has been designed for use in environments of pollution degree 2.

) It can be used for tests on electrical installations of overvoltage category III 265V and

550V maximum rated interlinked voltage (and to earth).

) You are recommended to respect the usual safety regulations aimed at protecting you

against dangerous currents and protecting the instrument against improper use.

) Only the original test leads supplied along with the instrument guarantee compliance

with the safety Standards in force. They must be in a good conditions and, if

necessary, replaced with identical ones.

) Do not test nor connect to any circuit exceeding the specified overload protection.

) Do not take measurements under environmental conditions exceeding the limits

indicated in this manual.

) Make sure that batteries are correctly installed.

) Before connecting the test probes to the installation make sure that the right function is

chosen.

EN - 2

Page 4

MULTITEST M72 - M73 - M74 - M75

1.2. DURING USE

CAUTION

An improper use may damage the instrument and/or its components or injure

the operator.

) Before selecting any function, first disconnect the test leads from the circuit under test.

) When the instrument is connected to circuits never touch any unused terminal.

) Do not measure resistance in presence of external voltages; although the instrument is

protected, an excessive voltage may cause malfunctioning.

CAUTION

If the “low battery” symbol is displayed during use interrupt testing and replace

batteries following the procedure described in paragraph 5.2.

1.3. AFTER USE

) Disconnect the test leads from the circuit under test and switch off the instrument.

) If you expect not to use the instrument for a long period remove batteries.

1.4. OVERVOLTAGE CATEGORIES - DEFINITIONS

Standard EN61010-1 (Safety requirements for electrical equipment for measurement, control

and laboratory use, Part 1: General requirements) defines what a measurement category

(usually called “overvoltage category”) is. At paragraph 6.7.4: Measuring circuits it says:

(OMISSIS)

Circuits are divided into the following measurement categories:

• Measurement category IV is for measurements performed at the source of the

low-voltage installation.

Examples are electricity meters and measurements on primary overcurrent

protection devices and ripple control units.

• Measurement category III is for measurements performed in the building

installation.

Examples are measurements on distribution boards, circuit breakers, wiring,

including cables, bus-bars, junction boxes, switches, socket-outlets in the fixed

installation, and equipment for industrial use and some other equipment, for

example, stationary motors with permanent connection to fixed installation.

• Measurement category II is for measurements performed on circuits directly

connected to the low voltage installation.

Examples are measurements on household appliances, portable tools and similar

equipment.

• Measurement category I is for measurements performed on circuits not directly

connected to MAINS.

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the norm requires that the transient withstand capability of

the equipment is made known to the user.

EN - 3

Page 5

MULTITEST M72 - M73 - M74 - M75

2. GENERAL DESCRIPTION

Dear Customer, the instrument you have purchased, whether used according to the

instructions given in this manual, will grant you accurate and reliable measurements.

Thanks to a development of newest conception assuring double insulation and overvoltage

category III you will enjoy the highest safety. This manual refers to the entire range of

MULTITEST family including M72, M73, M74 e M75 models. Except where otherwise

expressly indicated, this manual refers to all these models.

2.1. WORKING

) V Hz: DC and AC TRMS voltage measurement, frequency measurement.

) A

) Ω : measurement of resistance / continuity with sound signal

Hz: DC and AC TRMS current measurement, frequency measurement by means

of current transducer (clamp) with max. full scale of 1V.

)

: phase sequence detection at one or two terminals

) LAN: wire mapping for cables UTP, STP, FTP (SCTP), SFTP, SSTP in any

category (Cat. 3, 5, 5E, 6, etc.) with connector RJ45 capable of measuring

through connection to remote unit (M75 only).

) Ω 0.2A: continuity test on earth, protective and potential equalising conductors with a test

current higher than 200mA and open voltage ranging from 4V to 24V (M72, M74,

M75 only)

) MΩ: insulation resistance measurement with test DC voltage of 250, 500VDC (M72,

M74, M75 only).

) RCD: measurement on RCDs type AC (

)(M73, M74, M75 only)

) Ra measurement of total earth resistance (M73, M74, M75 only)

) AUTO performance of measurements in Ra , RCD and MΩ with automatic sequence (

M74, M75 only)

2.2. TRMS VALUE AND MEAN VALUE - DEFINITIONS

Safety testers for alternate quantities are divided into two categories:

• MEAN VALUE instruments: instruments measuring only the value of the wave at the

fundamental frequency (50 or 60Hz);

• True Root Mean Square (TRMS) instruments: instruments measuring the true root

mean square value of the quantity under test.

Mean value instruments provide only the value of the fundamental wave while TRMS

instruments provide the value of the entire wave, including harmonics (within the passband

of the instrument). Accordingly, the measured values are identical only if the wave is

purely sinusoidal.

2.3. TRUE ROOT MEAN SQUARE VALUE AND CREST FACTOR - DEFINITIONS

The current effective value is defined as follows: “In an interval of time equivalent to a

period, an alternate current with effective value having an intensity of 1A, by passing on a

resistor, disperses the same energy which would be dispersed in the same period of time

by a direct current having an intensity of 1A”. From this definition we get the numerical

expression: G=

0

1

T

The effective value is indicated as RMS (root mean square).

2

dttg

)(

∫

t

0

+Tt

The crest factor is defined as the ratio between the peak value of a signal and its effective

G

value: CF (G)=

p

. This value varies according to the waveform of the signal, for a purely

G

RMS

sinusoidal wave it’s worth 2 =1.41. In presence of distortions, the higher the wave

distortion is, the higher the crest factor values get.

EN - 4

Page 6

MULTITEST M72 - M73 - M74 - M75

3. PREPARATION FOR USE

3.1. PRELIMINARY CHECKS

This instrument was checked both mechanically and electrically prior to shipment. All

possible cares and precautions were taken to let you receive the instrument in perfect

conditions. Notwithstanding we suggest you to check it rapidly (eventual damages may

have occurred during transport – if so please contact the local distributor from whom you

bought the item).

Make sure that all standard accessories mentioned in paragraph 6.3 are included.

Should you have to return back the instrument for any reason please follow the

instructions mentioned in paragraph 7.

3.2. POWER SUPPLY

The instrument is powered by batteries (refer to paragraph 6.1.3 for details on model, no.

and battery life). When batteries are low, a low battery indication is displayed.

To replace/insert batteries follow the instructions indicated in paragraph 5.2.

3.3. CALIBRATION

The instrument complies with the technical specifications contained in this manual and

such compliance is guaranteed for 1 year. Annual recalibration is recommended.

3.4. STORAGE

After a period of storage in extreme environmental conditions exceeding the limits

mentioned in paragraph 6.2.1 let the instrument resume normal measuring conditions

before using it.

EN - 5

Page 7

MULTITEST M72 - M73 - M74 - M75

4. OPERATING INSTRUCTIONS

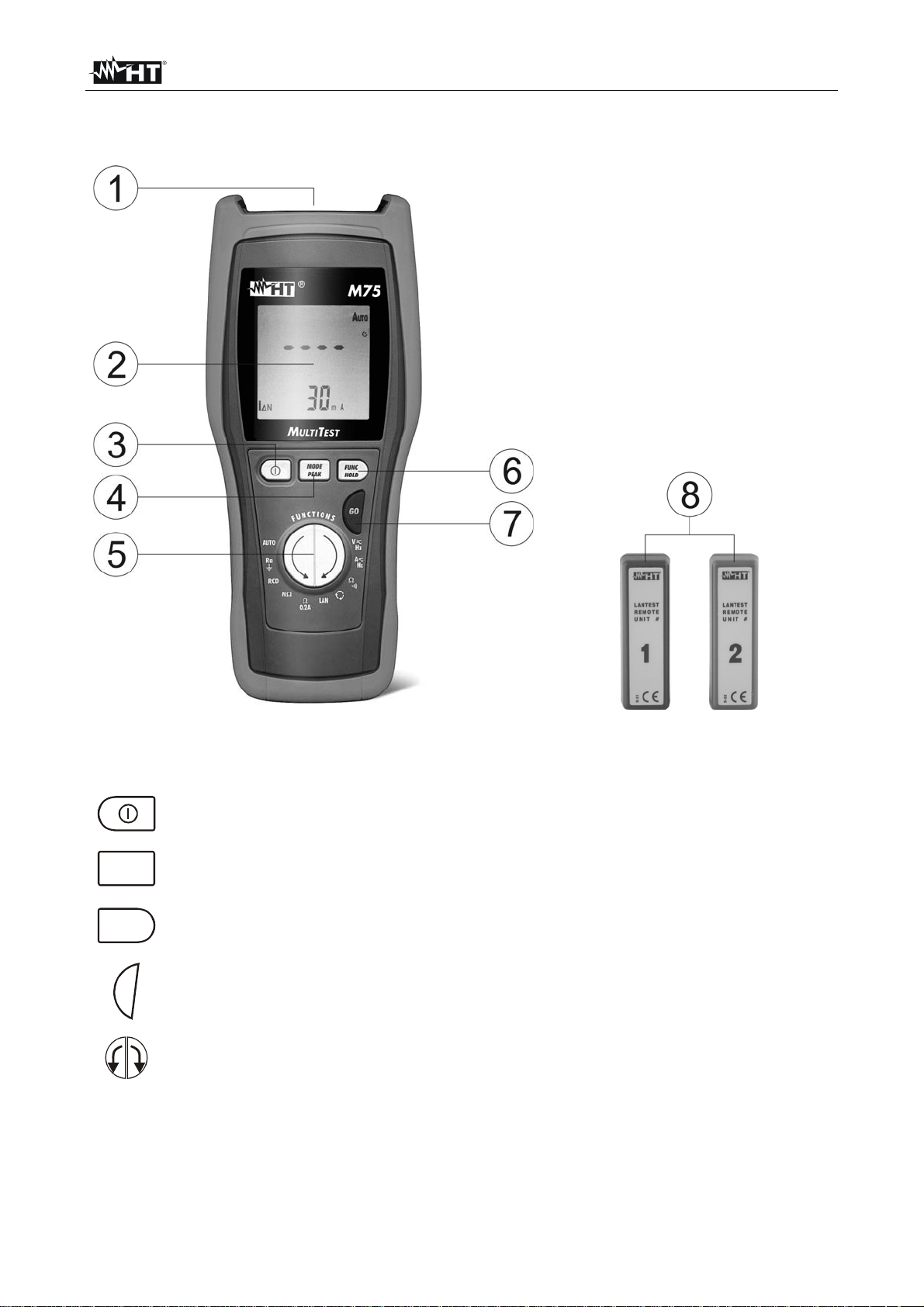

4.1. INSTRUMENT - DESCRIPTION

LEGEND:

1. Inputs

2. Display

3. ON/OFF key

4. MODE PEAK key

5. Arrows key

6. FUNC HOLD key

7. GO key

8. Remote units for LAN tests

(M75 only)

MODE

PEAK

FUNC

HOLD

GO

Fig. 1: Instrument description

to switch on/off the instrument

MODE key to select working mode

PEAK key to select peak measurement

FUNC key to select working mode

HOLD key to stop display updating

to start a measurement

Arrow keys to select measurements

EN - 6

Page 8

MULTITEST M72 - M73 - M74 - M75

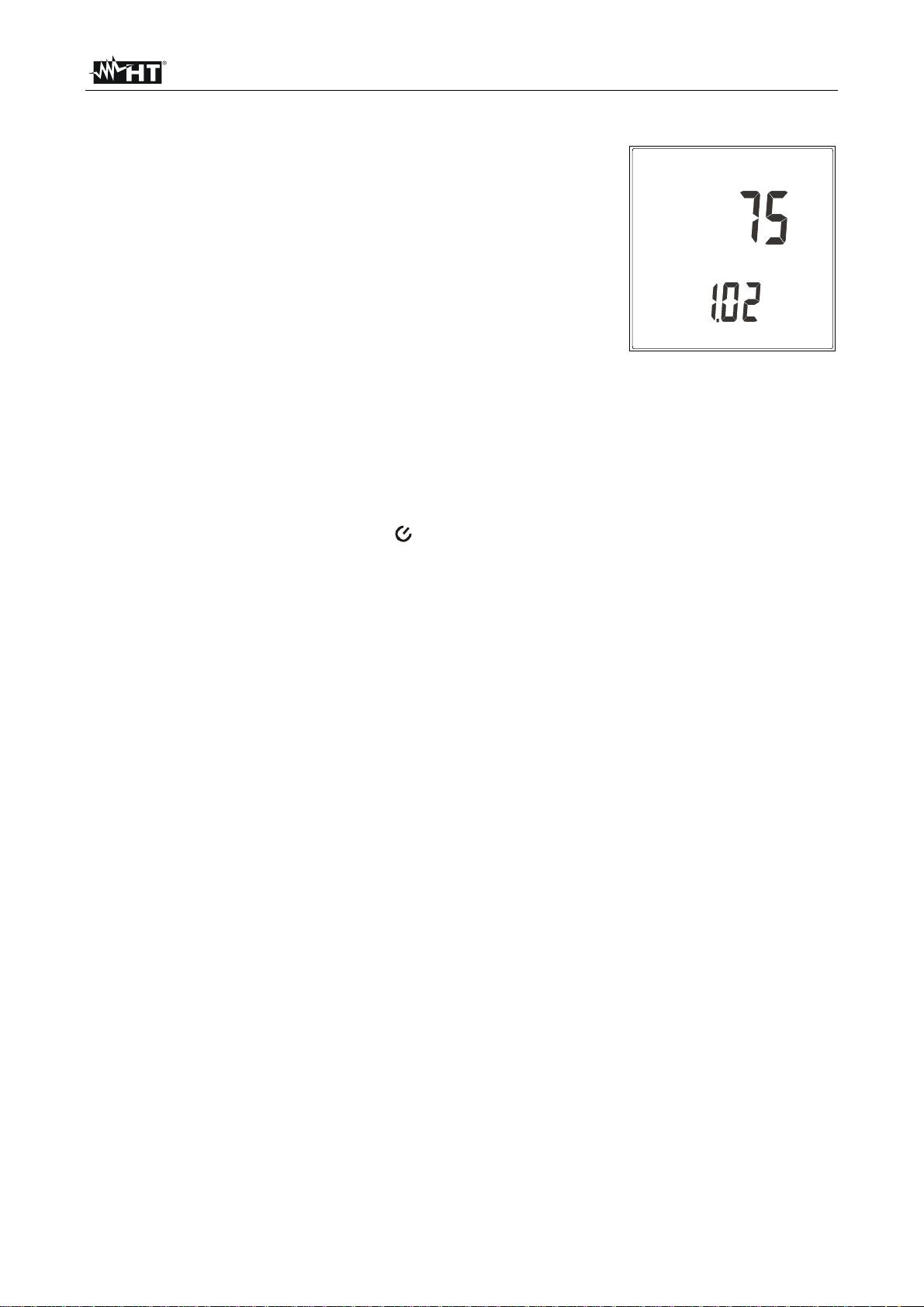

4.1.1. Turning on

When the instrument is turned on, it emits a brief sound and all

display segments are lit for just one second. Then the model

number and the firmware release appear on the display (see

picture referred to M75). Finally the instrument is ready for

operation.

4.1.2. Auto Power Off

The instrument automatically turns off 10 minutes after last pressure of keys. To resume

operation turn on the instrument again. When the instrument must be used for long

periods, the operator may need to disable the Auto Power Off function. In order to do so:

keep pressed the FUNC HOLD key and turn on the instrument; this way the Auto Power

Off function is deactivated. On next switch on autopower off will be automatically restored.

On the instrument’s LCD the symbol is displayed only when auto power off is active.

4.1.3. Current measurement through external transducer

The instrument measures current through a clamp transducer to be connected to the input

terminals. Unlike traditional multimeters it’s therefore not necessary to interrupt the current

circuit to insert the measuring device. Besides it’s possible to use more clamps having

different full scales according to the current to be measured from time to time. To set the

full scale of the clamp being used, turn on the instrument by keeping pressed MODE

PEAK: the instrument displays the value of the set full scale. To modify such value press

the arrow keys to select the desided full scale, then press MODE PEAK to validate the

modification.

The instrument is supplied with full scale already pre-set for the provided clamp.

4.1.4. Phase sequence and phase conformity measurement

Additional functions (patented) distinguishing this instrument from other multimeters

available on the market are phase sequence and phase conformity measurements

(indispensable to interconnect two three-phase triads) with one test probe.

The instrument performs tests by simply touching the cable under test with the built in test

probe. Note! The instrument performs test by only touching the conductors under voltage

with the single test probe, therefore without having to connect both test probes. The

traditional 2-terminal measurement is however available.

EN - 7

Page 9

MULTITEST M72 - M73 - M74 - M75

4.2. HOLD, MAX/MIN/AVG, PEAK±

The following functions are available for measurements of AC and DC voltage, AC current,

frequency and resistance.

4.2.1. HOLD

The HOLD function permits to block on the display the detected value during

measurements of AC and DC voltage, AC current, frequency and resistance. Just press

FUNC HOLD for at least one second. The symbol HOLD is displayed. To escape this

function press again FUNC HOLD or the arrow keys.

This function is not available when MAX/MIN/AVG or PEAK± functions are active.

4.2.2. MAX/MIN/AVG

During measurements of AC and DC voltage, AC current, frequency and resistance it’s

possibile to measure and display the maximum (MAX), minimum (MIN) and average

(AVG) valus of the quantity under test. Press FUNC HOLD for more than one second to

enter this function and press it repeatidly for less than one second to run through MAX,

MIN or AVG. The corresponding symbol is displayed.

Maximum, minimum and average values are detected since this function is activated and

are continuously updated even if not displayed. For example, while the AC current average

value is displayed, the maximum and minimum values of the same quantity are

continuously updated.

To escape the MAX/MIN/AVG function press again FUNC HOLD for more than one

second or the arrow keys.

The MAX/MIN/AVG function is not available when HOLD or PEAK± functions are active.

4.2.3. PEAK±

During measurements of AC and DC voltage and AC current it’s possibile to measure and

display the maximum (PEAK+) and minimum (PEAK-) peak values of the quantity under

test with a resolution of 1ms. Press MODE PEAK for more than one second to enter this

function and press it repeatidly for less than one second to run through PEAK+ or PEAK-.

The corresponding symbol is displayed.

Maximum and minimum peak values are detected since this function is activated and are

continuously updated even if not displayed. For example, while the maximum peak values

of AC current is displayed, the minimum peak value of the same quantity is continuously

updated.

When displaying maximum and minimum peaks it’s not mentioned whether the

corresponding quantity is AC or DC: a peak value is absolutely a peak value, regardless of

the quantity at which it’s detected.

To escape this function press again MODE PEAK for more than one second or the arrow

keys.

The HOLD and MAX/MIN/AVG functions are not available when when PEAK± is active.

EN - 8

Page 10

MULTITEST M72 - M73 - M74 - M75

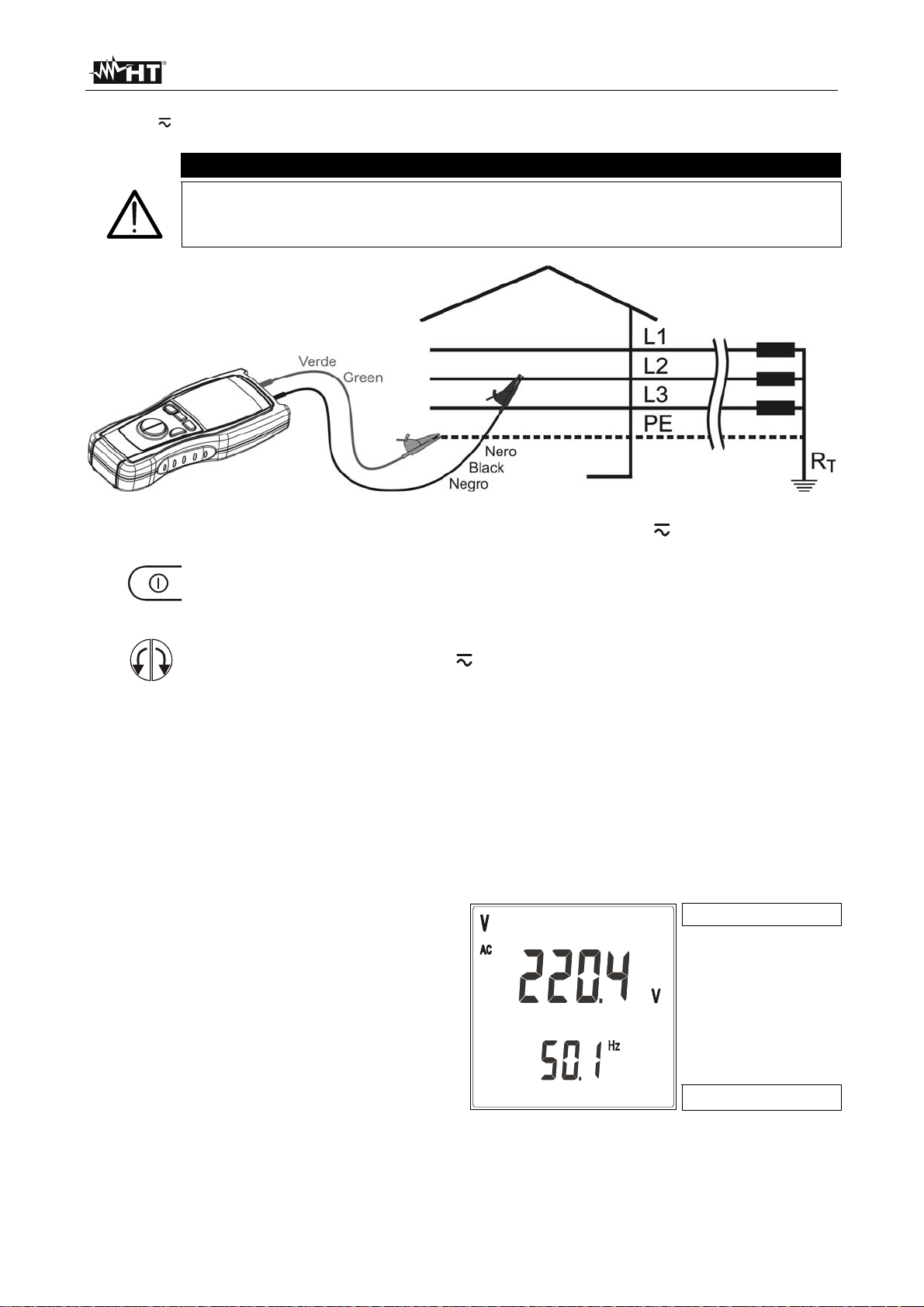

4.3. V Hz: DC/AC VOLTAGE AND FREQUENCY MEASUREMENT (M73 AND M75)

CAUTION

The maximum input voltage is 550+10%V. Don’t try to measure higher

voltages to avoid risks of electrical shocks or serious damages to the

instrument.

Fig. 2: Connection of the instrument’s terminals during V Hz test

1.

Turn on the instrument

2.

Insert the black and green cables in the corresponding input terminals of the

3.

instrument

Press the arrow keys to select V Hz

4. If necessary, insert the croco clips on the test probes

5. Connect the cables to the desired points of the circuit under test as shown in Fig. 2. The

voltage and frequency values will be displayed with automatic range selection.

6. The instrument automatically switches from AC to DC voltage basing on the signal applied

to terminals.

7.

Example of display of AC voltage and

AC voltage value

frequency values. The minimum reading

limit of AC voltage is 0.5V. Lower input

values are displayed as 0.0V.

EN - 9

Frequency value

Page 11

MULTITEST M72 - M73 - M74 - M75

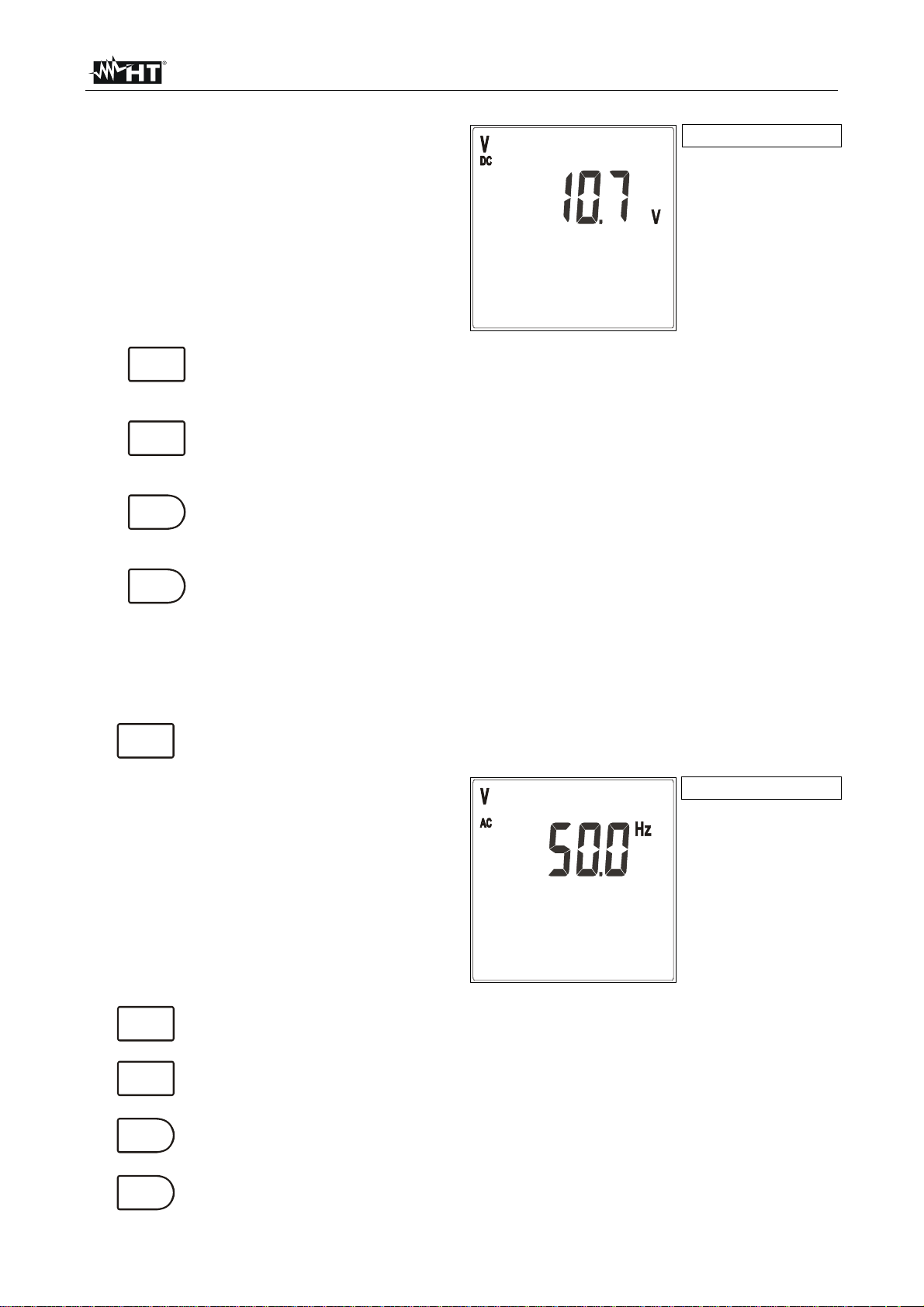

8.

Example of display of DC voltage. The

minimum reading limit of DC voltage is

1.2V. Lower input values are displayed

as 0.0V.

DC voltage value

MODE

9.

10.

11.

12.

PEAK

MODE

PEAK

FUNC

HOLD

FUNC

HOLD

Press MODE PEAK for less than 1 second to pass to frequency

measurement (only during AC measurements, see paragraph 4.3.1)

Press MODE PEAK for more than 1 second to detect the voltage peak value

(see paragraph 4.2.3)

Press FUNC HOLD for less than 1 second to block the detected values on the

display (see paragraph 4.2.1)

Press FUNC HOLD for more than 1 second to detect maximum, minimum

and average voltage values (see paragraph 4.2.2)

4.3.1. Frequency measurement

1. In order to detect minimum, average, maximum and peak values of frequency it's

necessary to pass to this measuring parameter.

MODE

2.

PEAK

3.

Example of display of frequency value.

During AC measurements it’s possible to pass to frequency measurement by

pressing MODE PEAK for less than 1 second

Frequency value

The minimum reading limit of frequency

is 30.0Hz. Lower input values are

displayed as <30.0Hz

4.

5.

6.

7.

MODE

PEAK

MODE

PEAK

FUNC

HOLD

FUNC

HOLD

To resume voltage measurement press MODE PEAK for less than 1 second

To detect the frequency peak value press MODE PEAK for more than 1

second (see paragraph 4.2.3)

To block the detected frequency value on the display press FUNC HOLD for

less than 1 second (see paragraph 4.2.1)

To detect maximum, minimum and average frequency values press FUNC

HOLD for more than 1 second (see paragraph 4.2.2)

EN - 10

Page 12

MULTITEST M72 - M73 - M74 - M75

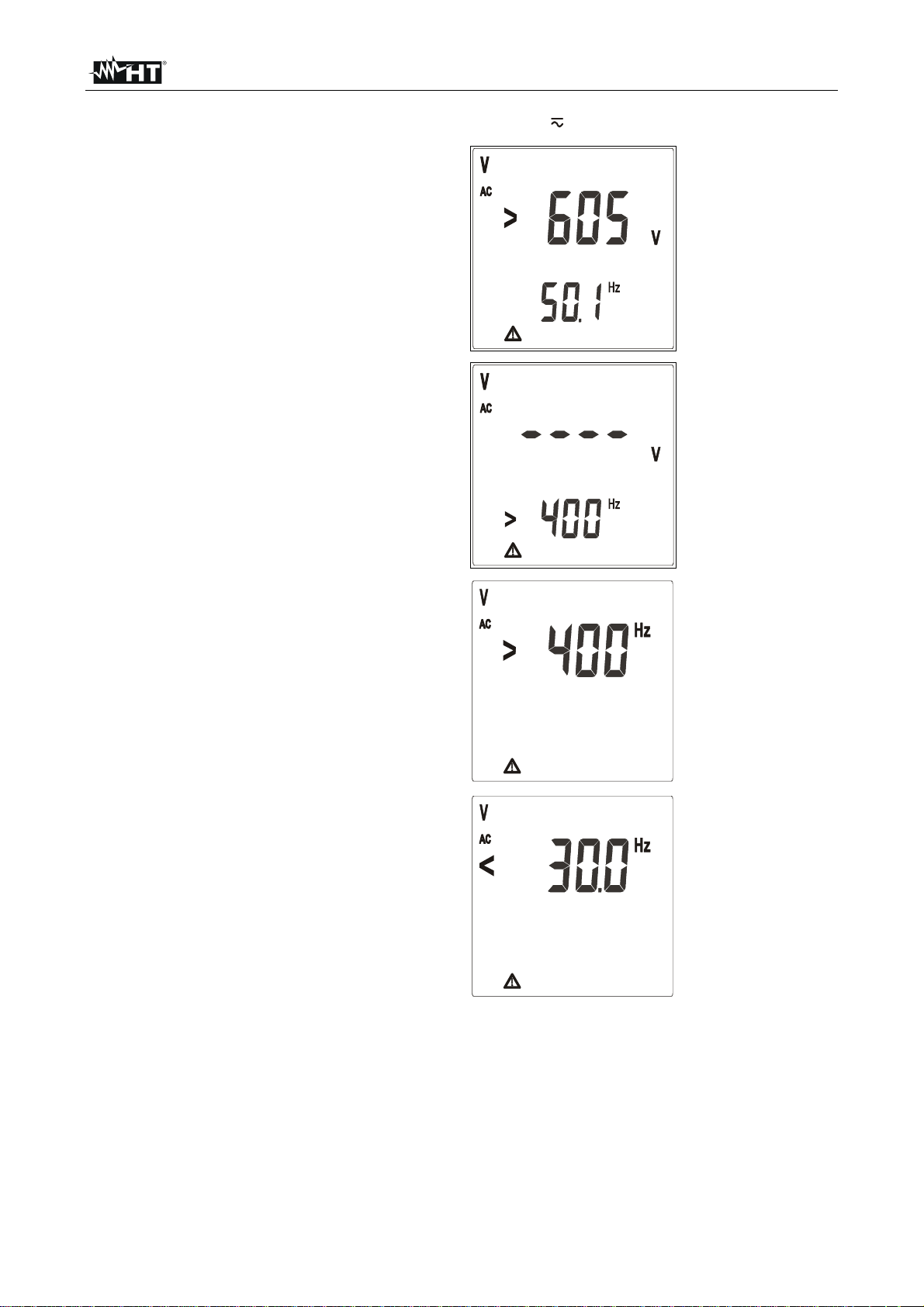

4.3.2. Anomalous cases which may occur during V Hz measurements

1.

The maximum input voltage is

550+10%V.

If the detected voltage value exceeds

605V TRMS the instrument displays the

screen beside.

Disconnect immediately the instrument

from the circuit under test to avoid

electrical shocks and damages to the

instrument.

2.

If during a voltage measurement the

detected frequency value exceeds 400Hz

the instrument displays the screen

beside.

3.

If during a frequency measurement the

detected value exceeds 400Hz the

instrument displays the screen beside.

4.

If during a frequency measurement the

detected value does not reach 30.0Hz

the instrument displays the screen

beside.

EN - 11

Page 13

MULTITEST M72 - M73 - M74 - M75

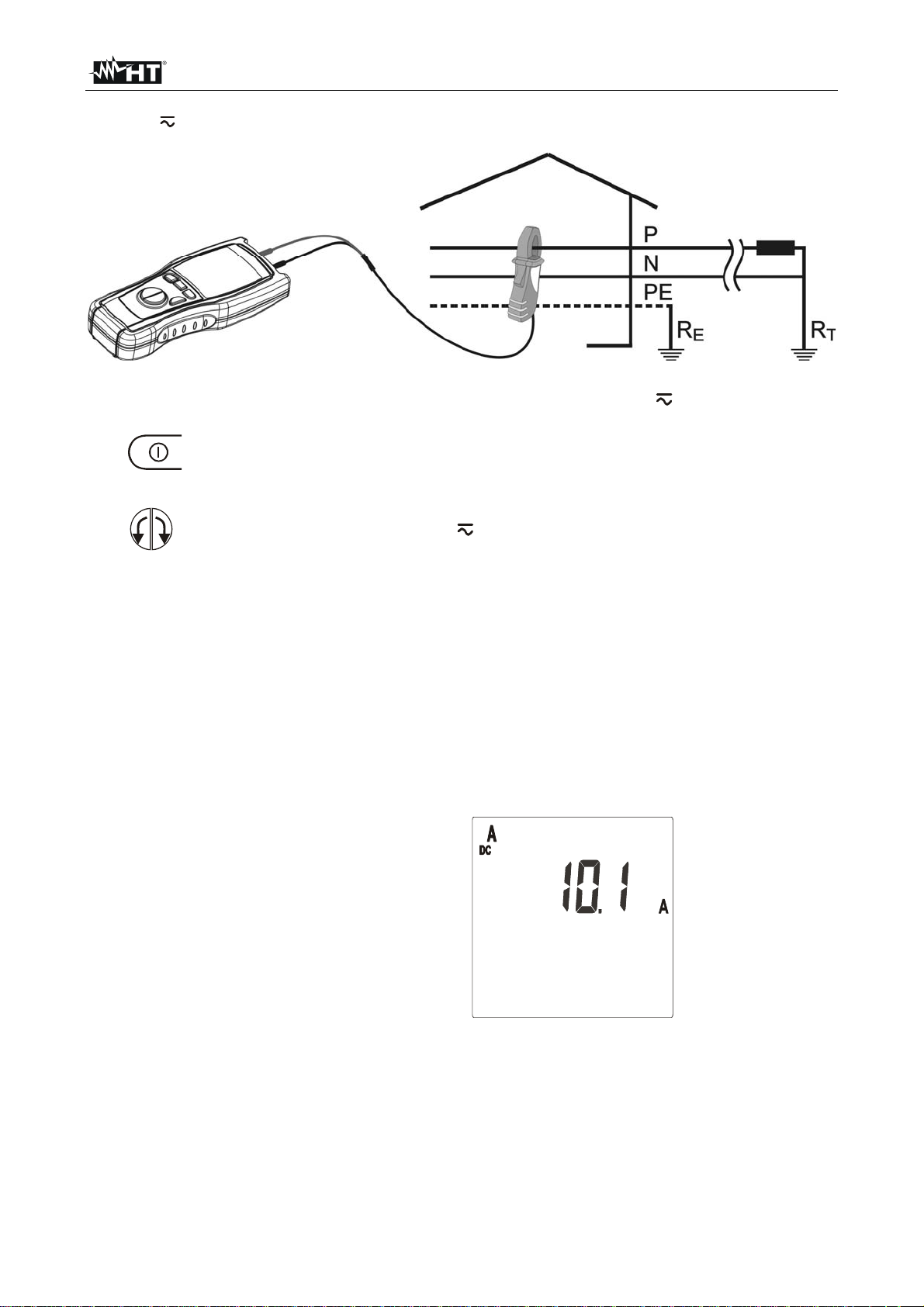

4.4. A Hz: DC/AC CURRENT AND FREQ UENCY MEASUREMENT

1.

Turn on the instrument

Fig. 3: Connection of the instrument’s terminals during A

Hz test

2.

Press the arrow keys to select A Hz

3. Insert the banana connectors of the clamp transducer in the corresponding input

terminals of the instrument (black with black, green or red with green)

4. Make sure that the clamp full scale and the instrument full scale do correspond. If they

do not, the measured value will be wrong. To set the clamp full scale refer to

paragraph 4.1.3

5. Open the jaws and insert the cable in the very middle as shown in Fig. 3. Current and

frequency values will be displayed.

6. The instrument automatically switches from AC to DC current basing on the signal applied

to terminals.

7.

Example of DC current displaying. The

DC current value

minimum limit of DC current is:

1.0mV x transduction ratio of the clamp

lower values are nullified.

EN - 12

Page 14

MULTITEST M72 - M73 - M74 - M75

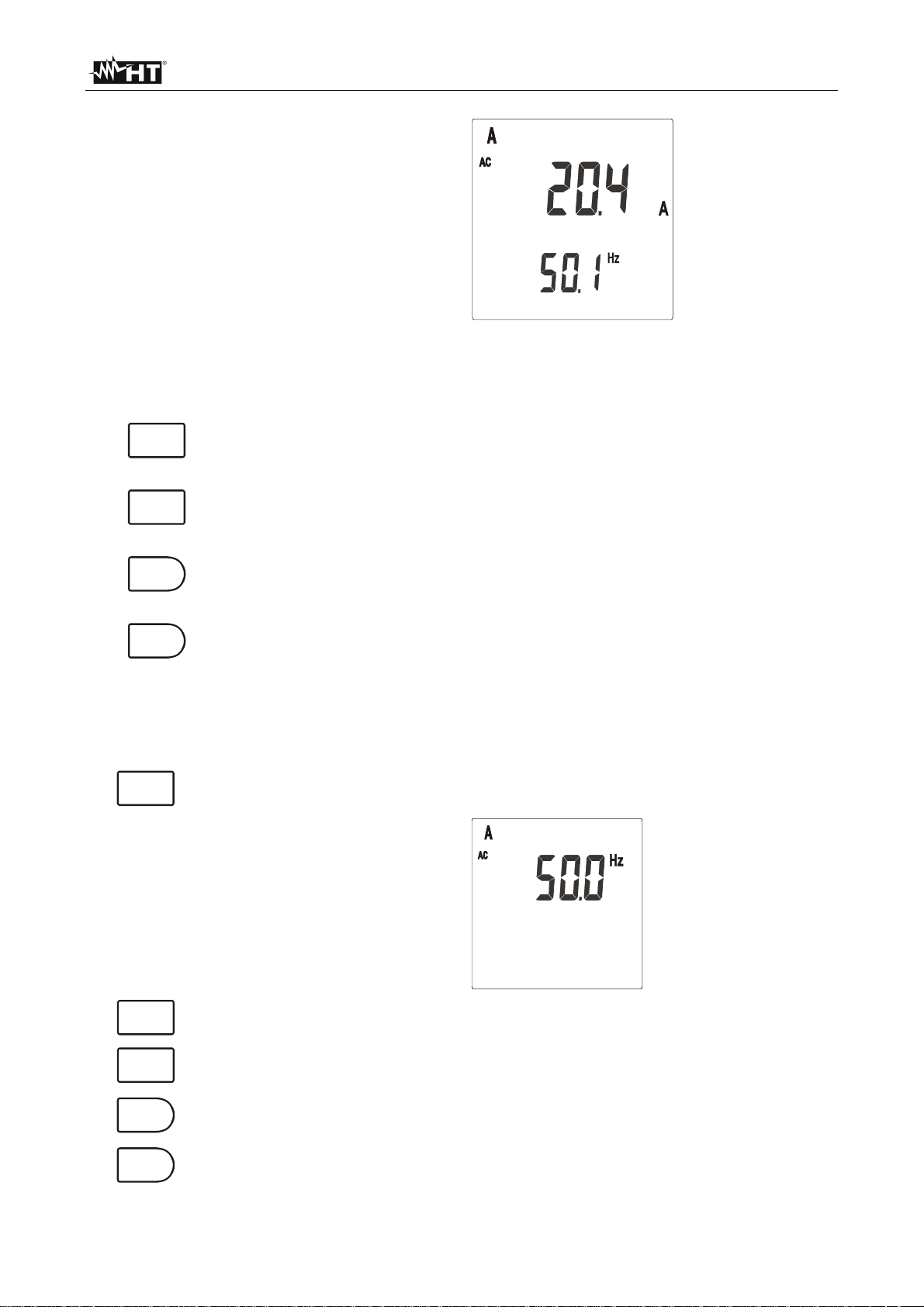

8.

Example of AC current displaying. The

minimum limit of AC current is:

1.0mV x transduction ratio of the clamp

lower values are nullified.

AC current value

Frequency value

The minimum reading value of AC and DC current is given by the herewith:

1mV x transduction ratio of the clamp

Therefore, with a clamp 400A/400mV, the minimum measurable current is 1.0A.

Lower input values are displayed as 0.0A

MODE

9.

10.

11.

12.

4.4.1. Frequency measurement

PEAK

MODE

PEAK

FUNC

HOLD

FUNC

HOLD

To pass to frequency measurement press MODE PEAK for less than 1

second (only during AC current measurements, see paragraph 4.4.1)

To detect the current peak value press MODE PEAK for more than 1 second

(see paragraph 4.2.3)

To block the detected values on the display press FUNC HOLD for less than

1 second (see paragraph 4.2.1)

To detect maximum, minimum and average current values press FUNC

HOLD for more than 1 second (see paragraph 4.2.2)

1. In order to detect minimum, average, maximum and peak values of frequency it's

necessary to pass to this measuring parameter.

MODE

2.

PEAK

3.

Example of display of frequency value.

It’s possible to pass to frequency measurement by pressing MODE PEAK for

less than 1 second

Frequency value

The minimum reading limit of frequency

is 30.0Hz. Lower input values are

displayed as <30.0Hz.

MODE

4.

PEAK

MODE

5.

PEAK

FUNC

6.

HOLD

FUNC

7.

HOLD

To resume voltage measurement press MODE PEAK for less than 1 second

To detect the frequency peak value press MODE PEAK for more than 1

second (see paragraph 4.2.3)

To block the detected frequency value on the display press FUNC HOLD for

less than 1 second (see paragraph 4.2.1)

To detect maximum, minimum and average frequency values press FUNC

HOLD for more than 1 second (see paragraph 4.2.2)

EN - 13

Page 15

MULTITEST M72 - M73 - M74 - M75

4.4.2. Anomalous cases which may occur during A Hz measurements

1.

If the detected current value exceeds the

clamp full scale the instrument displays

Example of clamp full

scale set at 400A AC

the screen beside.

Disconnect immediately the clamp from

the circuit under test to avoid electrical

shocks and damages to the instrument

The instrument is 20% overchargeable

than the clamp full scale

2.

If during a current measurement the

detected frequency value exceeds 400Hz

the instrument displays the screen beside

3.

If during a frequency measurement the

detected value exceeds 400Hz the

instrument displays the screen beside

4.

If during a frequency measurement the

detected value does not reach 30.0Hz

the instrument displays the screen beside

EN - 14

Page 16

MULTITEST M72 - M73 - M74 - M75

4.5. Ω : RESISTANCE MEASUREMENT AND CONTINUITY TEST

CAUTION

Before taking resistance measurements make sure that the circuit under test is

not powered and that eventual condensers are discharged.

Fig. 4: Connection of the instrument’s terminals during Ω test

1.

2.

Turn on the instrument

Press the arrow keys to select Ω

3. If the measuring cables being used have not been calibrated, first calibrate them as

described in paragraph 4.5.1

4. Insert the black and green cables in the

corresponding input terminals of the

instrument

5. Position the test probes on the desired

points of the circuit under test (see Fig. 4)

Resistance value

6. Example of display of resistance value. If

such value is lower than 40Ω the

instrument emits an acoustic signal

FUNC

7.

HOLD

FUNC

8.

HOLD

To block the detected value on the display press FUNC HOLD for less than 1

second (see paragraph 4.2.1)

To detect maximum, minimum and average values press FUNC HOLD for

more than 1 second (see paragraph 4.2.2)

9. The measured value is out of accuracy if an input voltage is present

4.5.1. "CAL" mode

1. Any addition or replacement of cables, extensions and croco clips nullify the previous

calibration and make necessary a new calibration before performing further

measurements. Therefore the instrument must be calibrated in the same conditions at

which it will operate during measurements

2. Short-circuit the cable ends with each other as shown in Fig. 5 making sure that the

metallic parts of test probes and crocodiles are in good touch

EN - 15

Page 17

MULTITEST M72 - M73 - M74 - M75

Fig. 5: Connection of the instrument’s terminals during calibration procedure

MODE

3.

PEAK

CAUTION

Press MODE PEAK for more than 1 second. The instrument resets the

resistance of the cables, the symbol "CAL" is displayed

While MODE PEAK is pressed the instrument is measuring. During this phase

never disconnect test leads.

4.

The instrument performs the calibration of cables with resistance lower than 5Ω.

5. At the end of the test the measured value is stored by the instrument and used as

OFFSET, which means it’s deducted from all continuity tests performed) for all further

measurements until a new calibration is made

6.

If the value measured during the calibration phase is higher than 5Ω the instrument

interruptus the calibration, removes the offset value previously stored and does not

display the CAL symbol until the next positive calibration.

This method can be used to nullify the last calibration performed

7. Each time the instrument is switched off the calibrated value is lost

4.5.2. Anomalous cases which may occur during Ω measurement

1. The full scale of the instrument is

39.99kΩ.

If the resistance value is higher than this

value, or in case of open or interrupted

probes, the instrument displays the screen

beside.

EN - 16

Page 18

MULTITEST M72 - M73 - M74 - M75

4.6. : PHASE SEQUENCE AND CONFORMITY MEASUREMENT

CAUTION

The maximum input voltage is 550+10%V. Don’t try to measure higher

voltages to avoid risks of electrical shocks or serious damages to the

instrument. Do not use the instrument on plants whose interlinked rated

voltage is higher than 550V.

Fig. 6: Connection of the instrument’s terminals during test

1.

2.

MODE

3.

PEAK

CAUTION

Turn on the instrument

Press the arrow keys to select

Press MODE PEAK to select function 1W (1-terminal measurement) or 2W (2-

terminal measurement)

Mode 1W requires the operator to touch the measuring key (without gloves)

and be at the earth potential, and the star centre of the system under test to be

at the earth potential. Only if these conditions are met mode 1W provides

correct results. In absence of just one of the above mentioned conditions

(operator wearing protective gloves or mounting a ladder, IT systems etc.)

select mode 2W.

4. Insert the black wire in the corresponding input terminal of the instrument. If necessary

install the croco-clip on the test probe

5. If mode 2W has been selected, insert the green wire in the corresponding input

terminal of the instrument and connect the test probe to the neutral wire or to the

neutral wire of the plant under test. If necessary install the croco-clip on the test probe

6. Following messages are displayed:

EASURING…" the instrument is ready to measure the first phase voltage

"M

"PH1" (secondary display): the operator is invited to connect the measuring cable to the

cable of the first phase voltage

EN - 17

Page 19

MULTITEST M72 - M73 - M74 - M75

CAUTION

For a correct functioning of mode 1W it’s necessary that the star centre of the

three-phase triad under test is at the earth potential.

In plants with insulated neutral wire, like IT systems (often present in hospitals,

airports etc.) it’s necessary to select mode 2W and connect the green probe to

the neutral conductor (not to the protective conductor). In this kind of plants

mode 1W may not provide correct results.

Only for mode 1W press and keep pressed GO, or simply touch the surface of

7.

8.

GO

the key for the entire duration of the measurement. Connect the test probe to

the first wire of the three-phase triad to be tested

When a higher voltage than 110V is detected, the symbol "

PH" is displayed and the

buzzer emits a prolonged sound

CAUTION

During measurement:

• GO must be always kept pressed or at least its surface must be always

touched (only for mode 1W)

• the test probe, except for the phase cable under test, must not be in touch

or close to any voltage source which may block the measurement due to

the instrument’s sensitivity

• the test probe must be kept in touch with the phase cable

9. At the end of the measurement the wordings "MEASURING…" and "PH1" disappear.

The buzzer emits and intermitting sound until the test probe is disconnected drom the

phase cable

10.

Disconnect the test probe from the cable of the first phase voltage. The wording "PH"

(present only when the input voltage is detected) disappears from the display

Only for mode 1W keep pressed GO, or simply touch its surface, for the entire

duration of the measurement. An eventual release and new pressure on the

11.

GO

key cancels all performed measurements. In this case repeat all previous

passages starting from point 6

12. Following messages are displayed:

"MEASURING…" the instrument is ready to measure the second phase voltage

"PH2" (secondary display): the operator is invited to connect the measuring cable to

the cable of the second phase voltage

CAUTION

If more than 10 seconds pass between the first and the second measurement,

a message "t.out" is displayed. In this case it’s necessary to repeat the entire

procedure. Press GO and re-start from point 6.

Only for mode 1W keep pressed GO, or simply touch its surface, for the entire

13.

14.

GO

duration of the measurement. Connect the test probe to the second cable of

the three-phase triad to be tested

When a higher voltage than 110V is detected, the symbol "PH" is displayed and the

buzzer emits a prolonged sound

EN - 18

Page 20

MULTITEST M72 - M73 - M74 - M75

A

A

A

A

CAUTION

During measurement:

• GO must be always kept pressed or its surface must be always touched

(only for mode 1W)

• the test probe, except for the phase cable under test, must not be in touch

or close to any voltage source which may block the measurement due to

the instrument’s sensitivity

• the test probe must be kept in touch with the phase cable

15.

t the end of the test, if two tested

cables are in a correct phase sequenze,

the instrument emits a double sound to

signal the positive outcome of the test

and displays a screen like this

Correct phase

sequence

16.

t the end of the test, if two cables

belong to the same phase, the

instrument emits a double sound to

sigla the positive outcome of the test

and displays a screen like this

17.

t the end of the test, if two tested

cables are not in the correct phase

sequenze, the instrument emits a

prolonged sound to signal the negative

outcome of the test and displays a

screen like this

18. To perform a new measurement press GO, then re-start from point 6

CAUTION

lthough two cables are in sequence it doesn’t mean that the third cable is in

sequence too. It’s not excluded that the cabling was made by mistake with a

double phase cable. To clear any possible doubt always perform at least two

measurements by testing the cables two by two.

Phase rotation

Cables belonging to

the same phase

Compliance between

one cable and

another

Wrong phase

sequence

Phase rotation

EN - 19

Page 21

MULTITEST M72 - M73 - M74 - M75

4.6.1. Anomalous cases which may occur during tests

1.

If you wait more than 10 seconds

between the first measurement and the

second one, the instrument emits a

prolonged sound to signal the negative

outcome of the test and displays a screen

like this. It’s necessary to repeat the

entire procedure. Press GO and re-start

from point 6

2.

If mode 1W is selected and the

instrument detects the connection of the

second probe like in mode 2W, a screen

like this is displayed to signal the error. A

prolonged sound is emitted until the error

condition is removed

3.

If mode 2W is selected and the

instrument detects an input voltage

(between the two bushes) higher than

605V, a screen like this is displayed and

a prolonged sound is emitted until the

error condition is removed. Disconnect

the instrument promptly

EN - 20

Page 22

MULTITEST M72 - M73 - M74 - M75

4.7. LAN: CABLING TEST (M75)

CAUTION

Before taking any measurement make sure that the circuit under test is not

powered. Connections to phone lines or active networks could damage the

instrument.

Fig. 7: Connections of the instrument’s terminals during LAN tests

1.

2.

MODE

3.

PEAK

Turn on the instrument

Press the arrow keys to select LAN

Select the type of cable under test by pressing MODE PEAK: set STP whether

shielded, UTP whether unshielded

Note: STP must be chosen for all shielded cables such as:

- FTP (Foiled Twisted Pair cable) - SSTP (Shielded/Shielded Twisted Pair cable)

- STP (Shielded Twisted Pair cable) - SFTP (Shielded/Foiled Twisted Pair cable)

4. Connect the cable under test to MULTITEST 75 and to the remote unit if necessary

through patch cables (see Fig. 7)

CAUTION

The remote unit must be necessarily connected to the other end of the cable

being tested, otherwise no measurement is performed.

GO

Press GO to perform all tests related to the selected type of cable

Identification number

of the remote unit

5.

6.

If cabling is correct, a screen like this is

displayed. The identification number (02)

refers to the remote unit connected to the

other end of the cable being tested

EN - 21

Page 23

MULTITEST M72 - M73 - M74 - M75

7.

If cabling is not correct, a screen like this

is displayed (NOT OK). Referring to this

example, “FAULT 1/4” means that the

Identification number

of the remote unit (if

possible to find it)

detected errors are 4, of which the first

one is currently displayed. Details on the

detected error are given on the right side:

the couple 1-2 is open. By pressing

FUNC HOLD key it’s possible to run over

the remaining screens and display other

cabling errors (“FAULT 2/4”, “FAULT

3/4”, “FAULT 4/4”). The number of the

Number of the

displayed error /

number of the

detected errors

remote unit can be not displayed

CAUTION

It’s indispensable to select the right type of cable. If UTP is selected although

a STP cable is tested, test results may be not reliable due to the shield

affecting the measurement.

4.7.1. Anomalous cases which may occur during LAN tests

If the voltage present at the terminal is

higher 0.2V the instrument does not

perform the test and emits a sound to

signal the anomalous situation. The

screen beside is displayed.

CAUTION

Before taking any measurement make sure that the circuit under test is not

powered. Connections to phone lines or active networks could damage the

instrument.

4.7.2. SPLIT PAIRS - explication note

A LAN cable contains 8 conductors, twisted two by two thus forming 4 pairs: 1-2, 3-6,

4-5, 7-8. The error “SPLIT PAIRS” consists in the exchange of two conductors

belonging to different pairs. The pin to pin correspondence seems intact, but physically

the conductors of two couples are split. Such interaction hardly affects (or even makes

impossible) the exchange of data at high frequency/speed

CAUTION

The error condition “SPLIT PAIRS” is verified only when the cable mapping is

fully correct. For a correct detection of such error condition it’s necessary that

the cable under test is at least 1m long.

EN - 22

Page 24

MULTITEST M72 - M73 - M74 - M75

4.7.3. Cabling errors

Cabling errors Description Visualization Mapping

OPEN PAIR

REVERSED PAIR

SHORTED CABLES

TRANSPOSED

(CROSSED) PAIRS

MISWIRE

SPLIT PAIRS

One or both conductors

of the pair are interrupted

(open)

The conductors of the

same pair are reversed

Two conductors are in

short circuit between

each other

Two pairs are crossed

Generic cabling error,

such as for example two

conductors belonging to

different pairs are

exchanged

The pin to pin

correspondence is hold,

but physically the

conductors of two pairs

are crossed

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

1

2

3

4

5

6

7

8

S

EN - 23

Page 25

MULTITEST M72 - M73 - M74 - M75

4.8. Ω 0.2A: CONTINUITY TEST ON EARTH, PROTECTIVE AND EQUALIZING

POTENTIAL CONDUCTORS (M72, M74, M75)

The measurement is performed with a test current higher than 200 mA (R<5Ω) and open

circuit voltage ranging from 4 to 24V DC according to EN 61557-2 and VDE 0413 part 4.

CAUTION

Before performing the continuity test make sure that no voltage is present at the

ends of the conductor under test.

Fig. 8: Connection of the instrument’s terminals during Ω 0.2A test

1.

2.

Turn on the instrument

Press the arrow keys to select Ω 0.2A

3. Insert the black and green cables in the corresponding input terminals of the instrument

4. If the cable length is not sufficient to perform the test, extend the black one

5. If necessary insert the croco clips on the test probes

6. If the measuring cables being used have not been calibrated, first calibrate them as

described in paragraph 4.8.1

7. Connect the instrument’s terminals to the ends of the conductor on which the continuità test

must be performed (see Fig. 8)

8.

GO

Press GO to perform the measurement

EN - 24

Page 26

MULTITEST M72 - M73 - M74 - M75

A

CAUTION

The message “Measuring” on the display means that the instrument is

measuring. During this phase never disconnect test leads. Connect the

instrument just BEFORE measuring and do not change connections while the

message “Measuring” is present on the display.

9. The continuity test is performed by supplying a current higher than 200mA if the

resistance value is lower than 5Ω (including the cable resistance stored as offset after

calibration). For higher resistance values the instrument performs the test with

decreasing current

10.

t the end of the test, if it has been

Resistance value

possible to generate at least 200mA

(not particularly high resistance value),

the instrument emits a double sound to

signal the positive outcome of the test.

The screen beside is displayed

11.

At the end of the test, if it has not been

Test current value

Resistance value

possible to generate 200mA due to the

high resistance value, the instrument

emits a prolonged sound to signal the

negative outcome of the test. The

screen beside is displayed

Test current value

4.8.1. "CAL" mode

Fig. 9: Connection of the instrument’s terminals during calibration procedure

EN - 25

Page 27

MULTITEST M72 - M73 - M74 - M75

MODE

1.

PEAK

By pressing MODE select CAL

2. Any addition or replacement of cables, extensions and croco clips nullify the previous

calibration and make necessary a new calibration before performing further

measurements. Therefore the instrument must be calibrated in the same conditions at

which it will operate during measurements

3. Short-circuit the cable ends with each other as shown in Fig. 9 making sure that the

metallic parts of test probes and crocodiles are in good touch

4.

GO

CAUTION

Press GO to start the calibration procedure

The message “Measuring” on the display means that the instrument is

measuring. During this phase never disconnect test leads.

5.

The instrument performs the calibration of cables with resistance lower than 5Ω

6.

At the end of the test the measured

value is stored by the instrument and

used as OFFSET, which means it’s

deducted from all continuity tests

performed) for all further measurements

until a new calibration is made.

The instrument emits a double sound to

signal the positive outcome of the

calibration procedure and displays a

screen similar to this for 2 seconds.

Then, the default screen corresponding

to the Ω 0.2A test is displayed

7.

If the value measured during the

CAL message:

it means that the

instrument has been

calibrated. This

symbol remains

displayed during any

further measurement

even in case the

instrument is turned

off and on.

Current supplied by

the instrument during

calibration procedure

calibration phase is higher than 5Ω the

instrument interruptus the calibration,

removes the offset value previously

stored and does not display the CAL

symbol until the next positive calibration.

The instrument emits a prolonged sound

to signal the negative outcome of the

calibration and displays a screen similar

to this for 2 seconds. Then, the default

screen related to the Ω 0.2A test is

displayed. This method can be used to

nullify the last calibration performed.

EN - 26

Page 28

MULTITEST M72 - M73 - M74 - M75

4.8.2. Anomalous cases which may occur during Ω 0.2A tests

1.

If the following condition occur:

R

MEASURED

- R

CALIBRATION

< -0.02Ω

the instrument displays the screen beside

and emits a prolonged sound to signal

the anomalous situation

2.

If the voltage present at the terminals is

higher than 10V the instrument does not

perform the test and emits a prolonged

sound to signal the anomalous situation.

The screen beside is displayed for 5

seconds, after which the instrument

displays the default value related to the Ω

0.2A test

3.

If the resistance value is higher than the

full scale the instrument emits a

Input voltage

prolonged sound to signal the anomalous

situation. A screen similar to this is

displayed. The same message may also

mean that mesuring cables are

disconnected or open

EN - 27

Page 29

MULTITEST M72 - M73 - M74 - M75

4.9. MΩ: INSULATION RESISTANCE MEASUREMENT TEST VOLTAGE 500V

The measurement is performed according to EN 61557-2 and VDE 0413 part 1.

CAUTION

• before performing the insulation test make sure that the circuit under test is

not energized and all relative loads are disconnected

• the insulation measurement requires particolar care and attention to avoid

providing wrong test results and causing damages to third parties

• before the insulation test prepare the plant adequately by disconnecting

everything must not be tested. During the insulation test continuously make

sure that the applied voltage is not accessible to third parties

• a measurement with a cable disconnected by mistake may provide a good

result also in presence of a faulty insulation. It’s necessary to take all

possibile cares to avoid that. Once prepared the plant and connected the

measuring cables, make sure that they are correctly connected. In case of

doubt, bifore performing an insulation test, perform a Ω 0.2A measurement

by short-circuiting the cables under test at a point of the plant which is as

far as possibile from the measuring clips. Remove the short circuit before

performing the insulation test

Fig. 10: Connection of the instrument’s terminals during MΩ test

1.

2.

Turn on the instrument

Press the arrow keys to select MΩ. Select test voltage pressing MODE PEAK

key between 250 and 500VDC

3. Insert the black and green cables in the corresponding input terminals of the instrument

4. If the cable length is not sufficient for the measurement extend the black one with an

adequately insulated cable, as its insulation is in parallel to the resistance to be measured. It

must be suspended and not laid to earth and all supports must be of insulated material

5. If necessary insert the croco clips on the test probes

6. Disconnect the circuit or the part of plant under test from power and all eventual loads

7. Connect the instrument’s terminals to the end of the conductors on which the insulation test

must be performed (see Fig. 10)

GO

8.

Press GO to start the measurement

EN - 28

Page 30

MULTITEST M72 - M73 - M74 - M75

A

A

A

CAUTION

The message “Measuring” on the display means that the instrument is

measuring or discharging eventual capacitors. During this phase never

disconnect nor touch test leads.

9. At the end of the test, before giving the result of the measurement, the instrument

automatically discharge eventual capacitors and parasite capacitances present among the

conductors involved in the measurement

10.

t the end of the test, if the resistance

Resistance value

value is higher than 0.5MΩ (or 0.25MΩ

for 250V), the instrument emits a double

sound to signal the positive outcome of

the test. A screen similar to this is

displayed

11.

t the end of the test, if the resistance

Test voltage value

Resistance value

value is higher than 999MΩ, so higher

than the full scale, the instrument emits

a double sound to signal the positive

outcome of the test. A screen similar to

this is displayed. Note! An insulation

value higher than 999MΩ is an excellent

insulation value, generally much higher

than the minimum requirements

prescribed by Standards

12.

t the end of the test, if the resistance

Test voltage value

Resistance value

value is lower than 0.5MΩ (or 0.25MΩ

for 250V) the instrument emits a

prolonged sound to signal the negative

outcome of the test. A screen similar to

this is displayed

Test voltage value

4.9.1. Anomalous cases which may occur during MΩ tests

If, during measurement, the voltage

present at terminals is higher than 10V

the instrument does not perform the test

and emits a prolonged sound to signal

the anomalous situation. The screen

beside is displayed for 5 seconds after

which the instrument displays the default

screen related to the MΩ test

Input voltage value

EN - 29

Page 31

MULTITEST M72 - M73 - M74 - M75

4.10. RCD: TESTS ON AC TYPE RCDS (M73, M74, M75)

The test is performed in compliance with CEI 64.8 612.9, CEI 64.8/6 appendix D,

EN61008, EN61009, EN 60947-2 part B 4.2.4.1 and VDE 0413 part 6.

CAUTION

Testing an RCD involves the tripping of the RCD itself. Therefore, before taking

this measurement, make sure that no loads are connected to the RCD under

test to avoid damaging them. Disconnect all loads connected to the RCD as

they could add further leakage currents to those moved by the instrument, thus

nullifying the test results.

Fig. 11: Connection of the instrument’s terminals during RCD test

1.

2.

MODE

3.

PEAK

CAUTION

Turn on the instrument

Press the arrow keys to select RCD

By pressing MODE select the test current among the possible values 30mA,

30mA x5, 100mA, 300mA which turn cyclically at each key pressure

Pay attention when setting the test current of the RCD to make sure that the

correct one is selected. In case a higher current than the nominal one of the

device under test is selected, the RCD would be tested at a higher current

than the correct one, thus favouring a quicker tripping of the RCD itself.

As an alternative:

4. Insert the black and green cables in the corresponding input terminals of the

instrument. If necessary insert the croco clips on the test probes

5. Connect the green cable to the protective conductor (earth) and the black cable to

the phase conductor at the lower end of the RCD under test (Fig. 11)

Or:

4. Insert the Shuko cable in the input terminals of the instrument

5. Insert the Shuko cable in a socket at the lower end of the RCD under test (Fig. 11)

EN - 30

Page 32

MULTITEST M72 - M73 - M74 - M75

A

A

Keep GO pressed for at least one second to perform the leakage current

measurement in phase with the positive semiwave of the network voltage (0°),

6.

GO

or keep GO pressed for at least one second and, when the hyphens on the

display start disappearing, press GO again to perform the measurement with

the leakage current in phase with the negative semiwave of the network

voltage (180°)

CAUTION

The message “Measuring” on the display means that the instrument is

measuring. During this phase never disconnect test leads.

7.

tripping time is lower than 300ms (40ms

t the end of the test, if the detected

for I∆n=30mA x5), the instrument emits a

double sound to signal the positive

outcome of the test and displays a screen

like this

Tripping time

8.

t the end of the test, if the detected

tripping time is higher than 300ms (40ms

Test current value

Tripping time

exceeding the limit

for I∆n=30mA x5), or in case the RCD

does not trip, the instrument emits a

prolonged sound to signal the negative

outcome of the test and displays a screen

like this

Test current value

4.10.1. Anomalous cases which may occur during RCD tests

1.

If during measurement a higher input

voltage than 265V is detected (for

example, both cables connected to the

phase conductors of a 400V threephases plant) the instrument does not

perform the test and emits a prolonged

sound to signal the anomalous situation.

The screen beside is displayed for 5

seconds after which the instrument

displays the default screen of RCD test

EN - 31

Page 33

MULTITEST M72 - M73 - M74 - M75

2.

If during measurement a lower input

voltage than 110V is detected, the

instrument does not perform the test and

emits a prolonged sound to signal the

anomalous situation. The screen beside

is displayed for 5 seconds after which the

instrument displays the default screen of

RCD test

This can happen for example if the black cable is erroneously connected to the neutral

conductor instead of the phase one. If a Shuko cable is used, rotate the plug and

repeat the test

3.

If during measurement the green probe is

connected to the phase conductor and

the black probe is connected to the

protective conductor, the instrument does

not perform the test and emits a

prolonged sound to signal the anomalous

situation. The screen beside is displayed

for 5 seconds after which the instrument

displays the default screen of RCD test

4.

If during measurement an excessive

contact voltage is detected (higher than

50V) the instrument does not perform the

test and emits a prolonged sound to

signal the anomalous situation. The

screen beside is displayed for 5 seconds

after which the instrument displays the

default screen of RCD test

5.

If during measurement an excessive

earth resistance is detected, such to

prevent the instrument from generatine

the test current, the instrument does not

perform the test and emits a prolonged

sound to signal the anomalous situation.

The screen beside is displayed for 5

seconds after which the instrument

shows the default screen related to RCD

test

EN - 32

Page 34

MULTITEST M72 - M73 - M74 - M75

4.11. RA : MEASUREMENT OF GLOBAL EARTH RESISTANCE (M73, M74, M75)

CAUTION

Disconnect all loads connected to the lower end of the RCD as they could

introduce additional leakage currents, thus nullifying the test results. Is possible to

perform measurement on plants whose phase to earth rated voltage is up to

265V. Do not use the instrument on plants whose interlinked rated voltage is

higher than 550V.

Fig. 12: Connection of the instrument’s terminals during Ra test

1.

2.

MODE

3.

PEAK

CAUTION

Turn on the instrument

Press the arrow keys to select Ra

By pressing MODE select the test current among the possible values 15mA

and 100mA which turn cyclically at each key pressure

If a RCD is present, select a lower current value than the nominal current

value of the device. Otherwise the RCD could trip during the measurement

and therefore prevent it from being executed.

By selecting a test current of 100mA you will get also the value of the prospective short

4.

U

circuit current phase to earth, calculated according to the formula ICC=

N

Z

where:

PE

ZPE is the global earth resistance value

U

is the nominal phase to earth voltage whose value is: 127V if 100V ≤ V

N

230V if 150V ≤ V

measured

measured

< 150V

< 265V

As an alternative:

5. Insert the black and green cables in the corresponding input terminals of the

instrument. If necessary insert the croco climps on the test probes

6. Connect the green cable of the instrument to the protective conductor (earth) and

the black cable to the phase conductor (as shown in Fig. 12)

EN - 33

Page 35

MULTITEST M72 - M73 - M74 - M75

A

A

Or:

5. Insert the Shuko cable in the input terminals of the instruments

6. Insert the Shuko cable in a power socket (as shown in Fig. 12). The picture

represents the connection to power socket

7.

GO

CAUTION

Keep pressed GO for at least one second, the instrument performs the

measurement

The message “Measuring” on the display means that the instrument is

measuring. During this phase never disconnect test leads.

8.

t the end of the test, if the earth

resistance value is lower than 1999Ω,

the instrument emits a double sound

and displays a screen like this reporting

the value of the measured global earth

resistance and the current at which the

measurement has been performed

9.

If a test current of 100mA has been

selected and the earth resistance value

is lower than 1999Ω, by pressing FUNC

you will display alternatively the values

of the global earth resistance and the

prospective short circuit current phase

to earth, as well as the current at which

the measurement has been performed

10.

t the end of the test, if the global earth

resistance value is higher than 1999Ω,

the instrument emits a double sound

and displays a screen like this

Measured value of

global earth

resistance

The symbol HOLD

remains on until a

new measurement

can be taken

Current used during

the measurement

Measured value of

global earth

resistance

The symbol HOLD

remains on until a

new measurement

can be taken

Current used during

the measurement

Measured value of

global earth

resistance higher

than full scale

CAUTION

To guarantee the correctness of measurements, a certain interval of time is

necessary between a measurement and the following. During this period the

symbol HOLD is displayed and no measurement can be taken. When the

symbol HOLD disappears, the instrument is ready for a new measurement.

EN - 34

The symbol HOLD

remains on until a

new measurement

can be taken

Page 36

MULTITEST M72 - M73 - M74 - M75

4.11.1. Anomalous cases which may occur during Ra tests

1.

If during measurement the RCD

protecting the line trips, the instrument

interrupts the test and emits a prolonged

sound to signal the anomalous situation.

The screen beside is displayed for 5

seconds after which the instrument

displays the default screen of Ra test

2.

If during measurement a higher input

voltage than 265V is detected (for

example, if both cables connected to

phase conductors of a 400V three-phase

plant) the instrument does not perform

the test and emits a prolonged sound to

signal the anomalous situation. The

screen beside is displayed for 5 seconds

after which the instrument displays the

default screen of Ra

3.

If during measurement a lower input

test

voltage than 110V is detected, the

instrument does not perform the test and

emits a prolonged sound to signal the

anomalous situation. The screen beside

is displayed for 5 seconds after which the

instrument displays the default screen of

Ra test

This can happen for example if the black cable is erroneously connected to the neutral

conductor instead of the phase one. If a Shuko cable is used, rotate the plug and

repeat the test

4. If during measurement an excessive

contact voltage is detected (higher than

50V) the instrument does not perform the

test and emits a prolonged sound to

signal the anomalous situation. The

screen beside is displayed for 5 seconds

after which the instrument displays the

default screen of Ra

test

EN - 35

Page 37

MULTITEST M72 - M73 - M74 - M75

5.

If during measurement the green probe is

connected to the phase conductor and

the black probe is connected to the

protective conductor, the instrument does

not perform the test and emits a

prolonged sound to signal the anomalous

situation. The screen beside is displayed

for 5 seconds after which the instrument

displays the default screen of Ra

This can happen even if the wrong connection is performed on the back side of the

test

power socket

EN - 36

Page 38

MULTITEST M72 - M73 - M74 - M75

4.12. AUTO: AUTOMATIC CYCLE OF MEASUREMENTS TO TEST A PLANT (M74,

M75)

This function permits to test an electrical plant in a completely automatic way without any

intervention of the operator.

CAUTION

Testing an RCD involves the tripping of the RCD itself. Therefore, before taking

this measurement, make sure that no loads are connected to the RCD under

test to avoid damaging them. Disconnect all loads connected to the RCD as

they could add further leakage currents to those moved by the instrument, thus

nullifying the test results.

Fig. 13: Connection of the instrument’s terminals during AUTO test

1.

2.

MODE

3.

PEAK

CAUTION

Turn on the instrument

Press the arrow keys to select AUTO

By pressing MODE select the test current among the possible values 30mA,

30mA x5, 100mA, 300mA which turn cyclically at each key pressure

Pay attention when setting the test current of the RCD to make sure that the

correct one is selected. In case a higher current than the nominal one of the

device under test is selected, the RCD would be tested at a higher current

than the correct one, thus favouring a quicker tripping of the RCD itself.

4. Insert the black and green cables in the corresponding input terminals of the

instrument. If necessary insert the alligator clips on the test probes or use the shuko

cable

5. Connect the green cable to the protective conductor (earth) and the black cable to the phase

conductor (Fig. 13) or insert the Shuko cable in a power socket

Keep GO pressed for at least one second, the instrument performs

6.

GO

measurements without any intervention of the operator in the following

sequenze: Ra (15mA), RCD, MΩ (phase to earth)

EN - 37

Page 39

MULTITEST M72 - M73 - M74 - M75

A

A

CAUTION

The message “Measuring” on the display means that the instrument is

measuring. During this phase never disconnect test leads.

7. During measurements, at the end of each test, the partial values are displayed for 5

seconds, then the instrument passes to the following test

8.

At the end of the Ra test, if the earth

resistance value is lower than 50V/I

the instrument displays for 5 seconds a

screen like this, then it passes to the

∆n

Measured value of

global earth

resistance

following measurement. Refer to

paragraph 4.11 for further details or

information regarding the negative

outcome of the test or anomalous

situations

9.

t the end of the test, if the detected

tripping time is lower than the maximum

admittable limit, the instrument displays

Measured value of

tripping time

for 5 seconds a screen like this, then it

passes to the following screen. For

further details or information regarding

the negative outcome of the test or

anomalous situations refer to paragraph

4.10

10.

At the end of the MΩ test, if the

detected resistance value is higher than

0.5MΩ, the instrument displays for 5

Value of test current

Measured value of

resistance

seconds a screen like this, then it

passes to the following screen. For

further details or information regarding

the negative outcome of the test or

anomalous situations refer to paragraph

4.9

11.

t the end of the AUTO test, if all tests

have a positive outcome, the instrument

emits a double sound to signal the

Value of test voltage

positive outcome and displays a screen

like this. To display partial results press

FUNC HOLD. The single test results

are dislayed cyclically by any new

pressure on this key

EN - 38

Page 40

MULTITEST M72 - M73 - M74 - M75

5. MAINTENANCE

5.1. GENERAL

This is a precision instrument. Strictly follow the instructions for use and storage reported

in this manual to avoid any possible damage or danger during use.

Do not use this tester under unfavorable conditions of high temperature or humidity. Do

not expose to direct sunlight.

Be sure to turn off the tester after use. If the instrument is not to be used for a long period

you are recommended to remove batteries to avoid leakages of battery liquid which may

damage its internal circuits.

5.2. BATTERY REPLACEMENT

When the low battery indication (refer to paragraph 6.1.3) is displayed the batteries are to

be replaced.

CAUTION

Only skilled technicians can open the instrument and replace batteries. Before

removing batteries disconnect the test leads from the input terminals to avoid

electrical shocks.

1. Switch off the instrument

2. Remove test leads from the input terminals

3. Remove the battery compartment cover by using a screwdriver

4. Remove all batteries replacing them with new ones all of the same type (refer to

paragraph 6.1.3) respecting the polarity signs

5. Re-allocate the battery pack taking care that the part from which the black and red

wires come out is positioned backwards

6. If the battery pack is re-allocated in a wrong way, the battery compartment can not be

closed. In this case do not force the plastic parts, but re-position the battery pack