Page 1

Copyright HT ITALIA 2017 Release EN 1.02 - 16/05/2017

GSC60

User manual

Page 2

Page 3

GSC60

EN - 1

Table of contents:

1. PRECAUTIONS AND SAFETY MEASURES ............................................................... 3

1.1. Preliminary instructions ..................................................................................................... 3

1.2. During use ......................................................................................................................... 4

1.3. After use ............................................................................................................................ 4

1.4. Definition of measurement (overvoltage) category ............................................................ 4

2. GENERAL DESCRIPTION ........................................................................................... 5

2.1. Foreword ........................................................................................................................... 5

3. PREPARATION FOR USE ........................................................................................... 6

3.1. Initial checks ...................................................................................................................... 6

3.2. Instrument power supply ................................................................................................... 6

3.3. Storage .............................................................................................................................. 6

4. NOMENCLATURE ........................................................................................................ 7

4.1. Instrument description ....................................................................................................... 7

4.2. Description of measuring leads ......................................................................................... 7

4.3. Keyboard description ......................................................................................................... 8

4.4. Display description ............................................................................................................ 8

4.5. Initial screen ...................................................................................................................... 8

5. GENERAL MENU ......................................................................................................... 9

5.1. Instrument settings ............................................................................................................ 9

5.1.1. Language ................................................................................................................................. 9

5.1.2. Reference country .................................................................................................................. 10

5.1.3. Automatic Power OFF for display and key sound ................................................................. 10

5.1.4. System ................................................................................................................................... 10

5.1.5. Operator name entry .............................................................................................................. 11

5.1.6. System date/time setting ........................................................................................................ 11

5.2. Information ...................................................................................................................... 11

6. OPERATING INSTRUCTIONS ................................................................................... 12

6.1. RPE: Continuity of protective conductors ........................................................................ 12

6.1.1. Anomalous situations ............................................................................................................. 15

6.2. M: Measurement of insulation resistance ..................................................................... 16

6.2.1. Anomalous situations ............................................................................................................. 19

6.3. RCD: Test on differential switches .................................................................................. 20

6.3.1. AUTO mode ........................................................................................................................... 24

6.3.2. x½, x1, x2, x5 modes ............................................................................................................. 25

6.3.3. Mode x1 – Test on RCDs with delay time .............................................................................. 25

6.3.4. Mode ................................................................................................................................. 26

6.3.5. Test on earth leakage relay RCD .......................................................................................... 27

6.3.6. Anomalous situations ............................................................................................................. 28

6.4. LOOP: Line impedance/Loop and overall earth resistance ............................................. 31

6.4.1. Test types ............................................................................................................................... 33

6.4.2. STD Mode – Generic test ...................................................................................................... 35

6.4.3. Mode kA – Verify of breaking capacity of protection device .................................................. 37

6.4.4. Mode I2t – Verify of protection against short-circuit ............................................................... 39

6.4.5. Mode - Verify of protection coordination ..................................................................... 42

6.4.6. Mode - Verify of protection coordination – Norvay country ......................................... 44

6.4.7. Verify of protection against indirect contacts (TN system) .................................................... 46

6.4.8. Verify of protection against indirect contacts (IT systems) .................................................... 48

6.4.9. Verify of protection against indirect contacts (TT systems) ................................................... 49

6.4.10. Impedance measurement by means of the accessory IMP57 .............................................. 51

6.4.11. Anomalous situations ............................................................................................................. 53

6.5. SEQ: Phase sequence and phase concordance test ...................................................... 55

6.5.1. Anomalous situations ............................................................................................................. 58

6.6. LEAKAGE: Leakage current measurement and recording .............................................. 59

6.7. EARTH: Measurement of earth resistance ...................................................................... 62

6.7.1. 3-wire or 2-wire earth measurement and 4-wire ground resistivity ....................................... 62

6.7.2. 3-wire or 2-wire earth measure – USA, Extra Europe and Germany countries .................... 68

6.7.3. Earth measurement with optional clamp T2100 .................................................................... 71

Page 4

GSC60

EN - 2

6.7.4. Anomalous situations in 3-wire and 2-wire earth measurements .......................................... 74

6.8. AUX: Measure and recording of ambient parameters ..................................................... 75

6.9. ∆V%: Voltage drop of main lines ..................................................................................... 78

6.9.1. Anomalous situations ............................................................................................................. 82

6.10. PQA: Measurement and recording of main parameters .................................................. 84

6.10.1. Connections types ................................................................................................................. 84

6.10.2. General settings ..................................................................................................................... 88

6.10.3. Display of measurements ...................................................................................................... 90

6.10.4. Start recording ....................................................................................................................... 92

6.11. List of message at display ............................................................................................... 94

7. OPERATIONS WITH THE MEMORY ......................................................................... 95

7.1. Saving measurements ..................................................................................................... 95

7.1.1. Saving safety tests and snapshots ........................................................................................ 95

7.1.2. Recall and delete safety measurements and snapshots ....................................................... 96

7.1.3. Recall and delete saved recordings....................................................................................... 97

7.1.4. Anomalous situations ............................................................................................................. 98

8. CONNECTING THE INSTRUMENT TO A PC OR MOBILE DEVICES ...................... 99

8.1. Connection to iOS/Android devices through WiFi ........................................................... 99

9. MAINTENANCE ........................................................................................................ 100

9.1. General information ....................................................................................................... 100

9.2. Recharging and replacement of the batteries ............................................................... 100

9.3. Cleaning the instrument ................................................................................................ 100

9.4. End of life ...................................................................................................................... 100

10. TECHNICAL SPECIFICATIONS ............................................................................... 101

10.1. Technical characteristics safety section ........................................................................ 101

10.2. Technical characteristics PQA section .......................................................................... 105

10.3. Reference guidelines ..................................................................................................... 107

10.4. General characteristics .................................................................................................. 107

10.5. Environment .................................................................................................................. 108

10.5.1. Environmental conditions for use ......................................................................................... 108

10.6. Accessories ................................................................................................................... 108

11. SERVICE .................................................................................................................. 109

11.1. Warranty conditions ....................................................................................................... 109

11.2. Service .......................................................................................................................... 109

12. THEORETICAL APPENDIXES ................................................................................. 110

12.1. Continuity of protective conductors ............................................................................... 110

12.2. Insulation resistance...................................................................................................... 111

12.3. Checking circuit separation ........................................................................................... 112

12.4. Test on differential switches (RCD) ............................................................................... 114

12.5. Verify of the breaking capacity of protection devices .................................................... 115

12.6. Verify of protection against indirect contacts in TN systems ......................................... 116

12.7. Verify of protection against indirect contacts in TT systems ......................................... 118

12.8. Verify of protection against indirect contacts in IT systems ........................................... 119

12.9. Verify of protection coordination L-L, L-N and L-PE ...................................................... 120

12.10. Verify of the protection against short circuits – Test I2t ................................................. 122

12.11. Verification of voltage drop on main lines ...................................................................... 123

12.12. Measurement of earth resistance in TN systems .......................................................... 124

12.13. Voltage Anomalies ........................................................................................................ 129

12.14. Supply voltage unbalance ............................................................................................. 129

12.15. Voltage and current Harmonics ..................................................................................... 130

12.16. Definitions of powers and power factors ....................................................................... 133

12.17. Measuring method: outlines .......................................................................................... 136

12.18. Description of typical configurations .............................................................................. 137

Page 5

GSC60

EN - 3

1. PRECAUTIONS AND SAFETY MEASURES

The instrument is been designed in compliance with directives IEC/EN61557 and

IEC/EN61010-1, relevant to electronic measuring instruments. Before and after carrying

out measurements, carefully observe the following instructions:

Do not carry out any voltage or current measurement in humid environments.

Do not carry out any measurements in case gas, explosive materials or flammables are

present, or in dusty environments.

Avoid any contact with the circuit being measured if no measurements are being

carried out.

Avoid contact with exposed metal parts, with unused measuring probes, etc.

Do not carry out any measurement in case you find anomalies in the instrument such

as deformations, breaks, substance leaks, absence of display on the screen, etc.

Pay special attention when measuring voltages higher than 25V in special

environments (such as construction sites, swimming pools, etc.) and higher than 50V in

normal environments, since a risk of electrical shock exists.

Only use original HT accessories.

The following symbols are used in this manual:

CAUTION: observe the instructions given in this manual; improper use could

damage the instrument, its components or create dangerous situations for the

operator.

High voltage danger: electrical shock hazard.

Double insulation

AC voltage or current

DC voltage or current

Connection to earth

1.1. PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in the environmental conditions specified in

§ 10.5.1. Do not use in different environmental conditions.

The instrument may be used for measuring and verifying the safety of electrical

systems. Do not use on systems exceeding the limit values specified in § 10.4.

We recommend following the normal safety rules devised to protect the user against

dangerous currents and the instrument against incorrect use.

Only the accessories supplied with the instrument (in particular the external adapter

A0060) guarantee compliance with safety standards. They must be in good conditions

and be replaced with identical models, when necessary.

Make sure the batteries are correctly installed.

Before connecting the test leads to the circuit being measured, check that the desired

function has been selected

Page 6

GSC60

EN - 4

1.2. DURING USE

Please carefully read the following recommendations and instructions:

CAUTION

Failure to comply with the caution notes and/or instructions may damage

the instrument and/or its components or be a source of danger for the

operator.

Before changing function, disconnect the test leads from the circuit under test.

When the instrument is connected to the circuit under test, never touch any terminal,

even if unused.

Avoid measuring resistance if external voltages are present. Even if the instrument is

protected, excessive voltage could cause damage.

While measuring current, place the clamp jaws as far as possible from the conductors

not involved in the measurement, as the magnetic field they produce could interfere

with the measuring operations and place the conductor as much as possible in the

center of the jaws to maximize accuracy.

1.3. AFTER USE

When measurements are completed, turn off the instrument by pressing and holding the

ON/OFF key for some seconds. If the instrument is not to be used for a long time, remove

the batteries and follow the instructions given in § 3.3.

1.4. DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard "IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements” defines what measurement

category, commonly called overvoltage category, is. § 6.7.4: Measured circuits, reads:

circuits are divided into the following measurement categories:

Measurement Category IV is for measurements performed at the source of a low-

voltage installation.

Examples are electricity meters and measurements on primary overcurrent protection

devices and ripple control units.

Measurement Category III is for measurements performed on installations inside

buildings.

Examples are measurements on distribution boards, circuit breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in fixed installation, and

equipment for industrial use and some other equipment, for example, stationary motors

with permanent connection to fixed installation.

Measurement Category II is for measurements performed on circuits directly

connected to the low-voltage installation.

Examples are measurements on household appliances, portable tools and similar

equipment.

Measurement Category I is for measurements performed on circuits not directly

connected to MAINS.

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the standard requires that the transient withstand capability of

the equipment is made known to the user.

Page 7

GSC60

EN - 5

2. GENERAL DESCRIPTION

2.1. FOREWORD

The instrument is equipped with a TFT color LCD display, with capacitive "touch-screen"

that can be handled simply with the touch of a finger by the user and is structured with an

icon-based menu allowing the direct selection of measurement functions for quick and

intuitive use.

The instrument can perform the following tests:

RPE Continuity test of earth, protective and equipotential conductors with test

current higher than 200mA and open-circuit voltage between 4V and 24V

M Measurement of insulation resistance with continuous test voltage of 50V,

100V, 250V, 500V or 1000V DC

RCD Test on molded case RCD (Standard – STD) and on earth leakage relay

RCD ( ) General (G), Selective (S) and Delayed ( ) of type A ( )

and AC ( ) and B ( ) of the following parameters: tripping time,

tripping current, contact voltage

LOOP Measurement of line impedance/Loop P-N, P-P, P-E with calculation of

the assumed short-circuit current, also with high resolution (0.1m) (by

means of optional accessory IMP57), overall earth resistance without

causing the RCD tripping, check of the interruption capacity of

magnetothermal protections (MCB) and fuses, I2t test, protection check

in case of indirect contacts

EARTH Measurement of earth impedance and ground resistivity by

voltammetric method and by an external clamp connected to the

instrument (optional accessory T2100)

SEQ Indication of phase sequence with 2- or 1-terminal method

AUX Measurement and recording of environmental parameters (illuminance, air

temperature, humidity) by means of optional external probes and DC voltage

signals

LEAKAGE Measurement and recording of leakage current (by means of the

optional transducer clamp HT96U)

ΔV% Measurement of percentage voltage drop on main lines

PQA Real-time measurement and recording of mains parameters, harmonic

analysis, voltage anomalies (sags, swells), power/energy consumption

in single-phase and three-phase generic systems

Page 8

GSC60

EN - 6

3. PREPARATION FOR USE

3.1. INITIAL CHECKS

Before shipping, the instrument has been checked from an electric as well as mechanical

point of view. All possible precautions have been taken so that the instrument is delivered

undamaged. However, we recommend checking it to detect any damage possibly suffered

during transport. In case anomalies are found, immediately contact the Dealer.

We also recommend checking that the packaging contains all the components indicated in

§ 10.6. In case of discrepancy, please contact the Dealer. In case the instrument should

be returned, please follow the instructions given in § 11.

3.2. INSTRUMENT POWER SUPPLY

The instrument is powered by 6x1.2V NiMH rechargeable batteries type AA LR06 supplied

with the instrument or by 6x1.5V alkaline batteries type AA LR06. Rechargeable batteries

must be recharged by using the external charger A0060, also provided with the instrument.

The green “ ” symbol indicates a sufficient charge level for the correct performance of the

tests. The red “ ” symbol indicates an insufficient charge level for the correct performance

of the tests. In this case, recharge the batteries (see § 9.2).

CAUTION

If the external adapter is used, it is necessary to connect it first to the

instrument, then to the mains, then please connect the instrument to the

circuit to be tested

The external adapter A0060 can be used both for verification tests

(SAFETY) and for network analyses (PQA)

While recording it is recommended to use both the external adapter and

the rechargeable batteries, in order to guarantee the instrument’s supply

in case of voltage interruption

With low battery indication, stop the tests and recharge or replace the

batteries (see § 9.2)

The instrument is capable of keeping data stored even without batteries

The instrument has an AutoPower OFF function (which can be

deactivated) after 5 minutes’ idling (the Auto Power OFF is inactive while

recording – see § 5.1.3)

3.3. STORAGE

In order to guarantee precise measurement, after a long storage time under extreme

environmental conditions, wait for the instrument to come back to normal condition (see §

10.5.1).

Page 9

GSC60

EN - 7

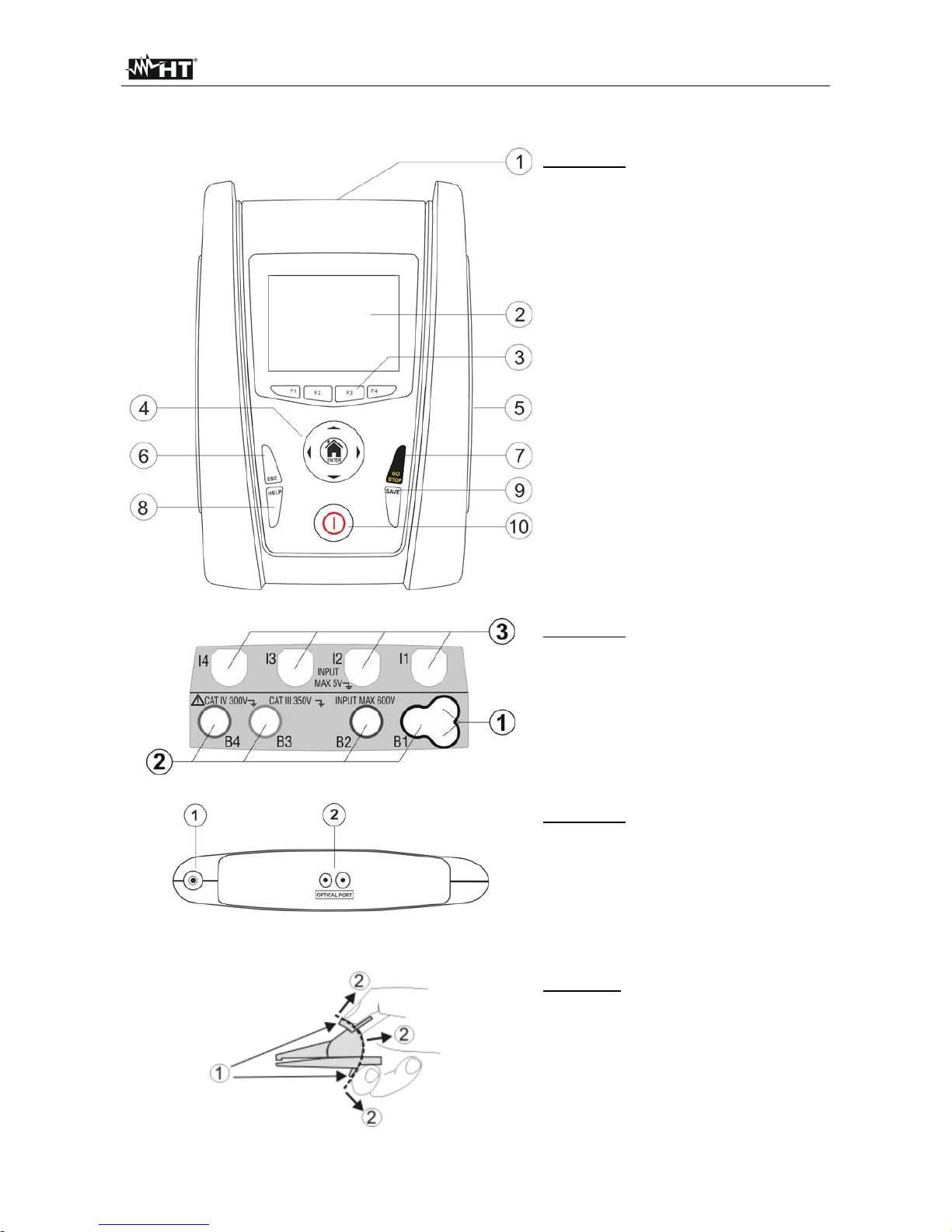

4. NOMENCLATURE

4.1. INSTRUMENT DESCRIPTION

CAPTION:

1. Inputs

2. LCD Touch screen display

3. Function keys F1, F2, F3, F4

4. ,, , / ENTER keys

5. Compartment of the connector

for optical cable/USB port

6. ESC key

7. GO/STOP key

8. HELP key

9. SAVE key

10. ON/OFF key

Fig. 1: Description of the front part of the instrument

CAPTION:

1. Connector for remote probe

2. B1, B2, B3, B4 inputs

3. I1, I2, I3, I4 inputs

Fig. 2: Description of the upper part of the instrument

CAPTION:

1. Connector for external adapter

2. Connector for optical/USB cable

Fig. 3: Description of the instrument's side

4.2. DESCRIPTION OF MEASURING LEADS

CAPTION:

1. Hand protection

2. Safe area

Fig. 4: Description of measuring leads

Page 10

GSC60

EN - 8

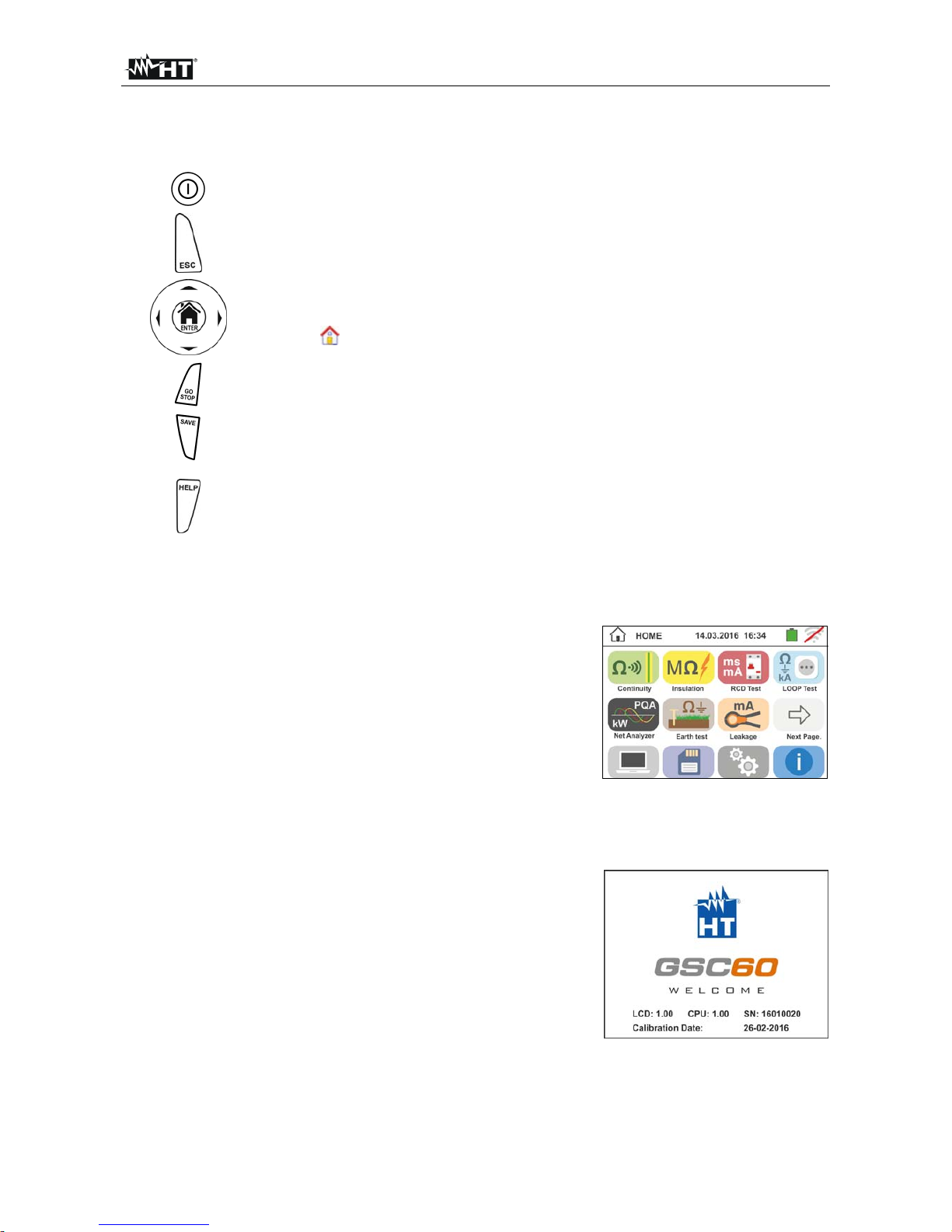

4.3. KEYBOARD DESCRIPTION

The keyboard includes the following keys:

ON/OFF key to switch on/off the instrument

ESC key to exit the selected menu without confirming

keys to move the cursor through the different screens in order

to select the desired programming parameters

HOME / ENTER key to back to general Menu on each moment

GO/STOP key to start the measurement

SAVE key to save the measured values

HELP key to access the online help and display the possible connections

between the instrument and the system for each selected function

F1, F2, F3, F4

Function keys corresponding to the activation of the four icons on the

bottom of the screen as an alternative to direct touch on the display

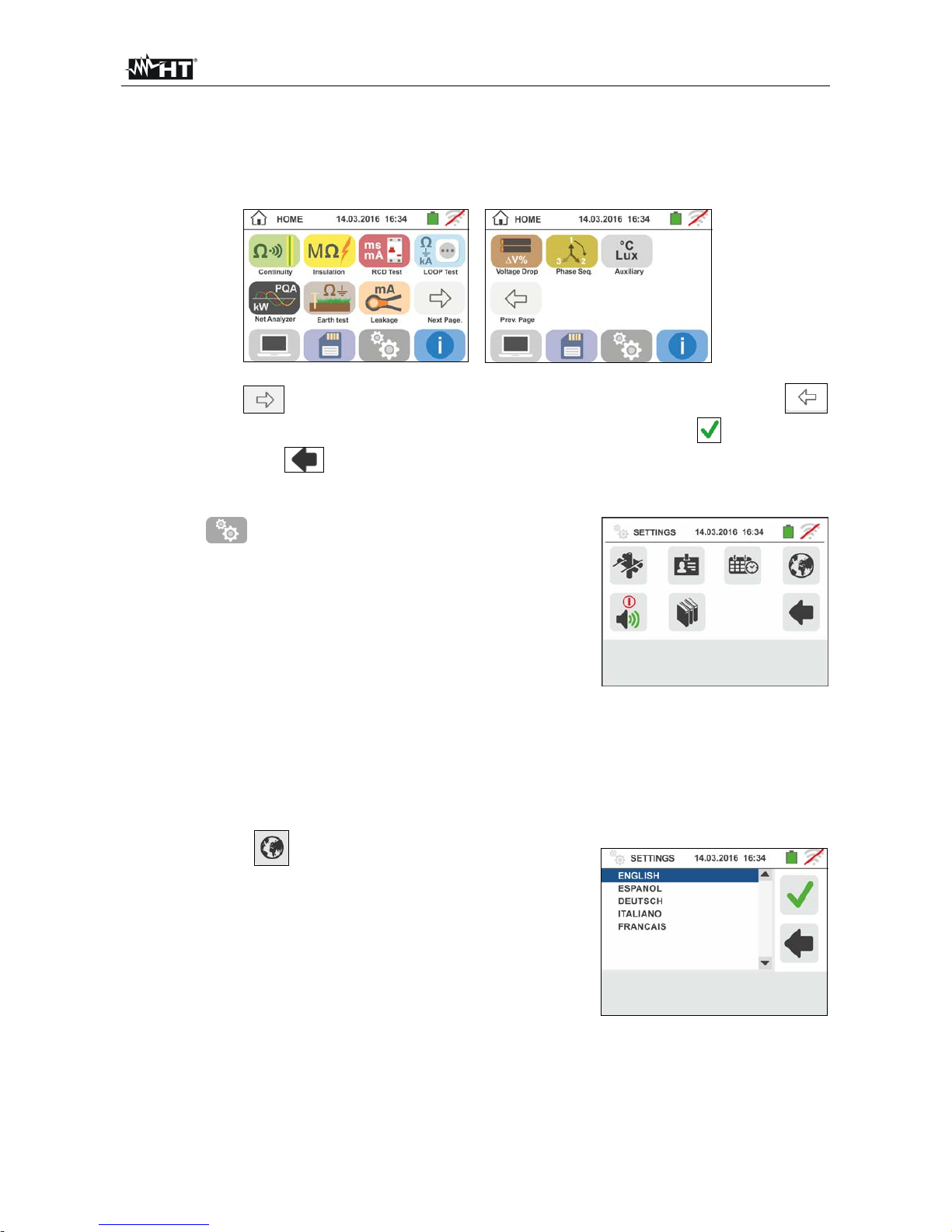

4.4. DISPLAY DESCRIPTION

The display is an LCD, 320x240pxl TFT color display with

capacitive touch screen whose icon-structure can be directly

selected with a simple touch. The first line of the display

indicates the type of active measurement, the date/time and

the battery charge indication.

4.5. INITIAL SCREEN

When switching on the instrument, the initial screen appears

for a few seconds. It shows:

The HT manufacturer's logo

The instrument model

The Firmware version (LCD and CPU)

The serial number (SN:) of the instrument

The date of instrument calibration (Calibration date:)

After a few seconds, the instrument switches to the general menu.

Page 11

GSC60

EN - 9

5. GENERAL MENU

Pressing the ENTER key in any condition of the instrument allows to go back to the

general menu in which internal parameters may be set, the saved measures can be

displayed and the desired measuring function may be selected.

Fig. 5: General menu of the instrument

Touch the icon to move to the following page of the general menu and the icon

to go back to the previous page. Inside the screens, touch the icon

to confirm a

selection or the icon

to exit without confirming.

5.1. INSTRUMENT SETTINGS

Touch the icon. The screen to the side appears on the

display. The following settings are available:

System language setting

Setting of the type of electrical system

Setting of the country

Operator name setting

System date/time setting

Activation/deactivation of display AutoPower OFF and of

key sound

Settings will be maintained also after switching off the

instrument.

5.1.1. Language

Touch the icon

to select the system language. The

screen to the side appears on the display.

Select the desired language, confirm the choice and return

to the previous screen.

Page 12

GSC60

EN - 10

5.1.2. Reference country

Touch the icon to select the reference country. This

choice have influence on the LOOP and EARTH

measurements (see § 6.4 and § 6.7) as shown in Table 1.

The screen to the side appears on the display.

Select the desired country, confirm the choice and return to

the previous screen

Europe Extra Europe USA Germany Norvay

LOOP

TT Europe mode Europe mode

Not available Europe mode Europe mode

TN Europe mode Europe mode Europe mode Europe mode Norvay mode

IT Europe mode Europe mode Not available Europe mode Norvay mode

EARTH Ra

TT Europe mode

Europe mode Not available Europe mode Europe mode

TN Europe mode USA mode USA mode USA mode Europe mode

IT Europe mode Europe mode Not available Europe mode Europe mode

EARTH

(measure with

T2100)

TT Europe mode

Europe mode Not available Europe mode Europe mode

TN Europe mode USA mode USA mode USA mode Europe mode

IT Europe mode Europe mode Not available Europe mode Europe mode

Table 1: LOOP and EARTH measurements depending on reference countries

5.1.3. Automatic Power OFF for display and key sound

Touch the icon. The screen to the side appears on the

display.

Move the slide bar reference of section " " down/up to

turn off/on the Automatic Power OFF of the instrument after

a period of inactivity of 5 minutes.

Move the slide bar reference of section " " down/up to

disable/enable the sound key when pressed. Confirm the

choices made and go back to the previous screen.

5.1.4. System

Touch the icon

to select the type of electrical system

(TT, TN or IT), of the mains frequency (50Hz, 60Hz), of the

limit value for contact voltage (25V, 50V) and rated voltage

value to be used for calculating the assumed short-circuit

current. The screen to the side appears on the display.

NOTE: for “USA” country this icon is not displayed and

the electrical system is fixed to TN

Move the slide bar references to select the options. Confirm

the choices made and go back to the previous screen.

Page 13

GSC60

EN - 11

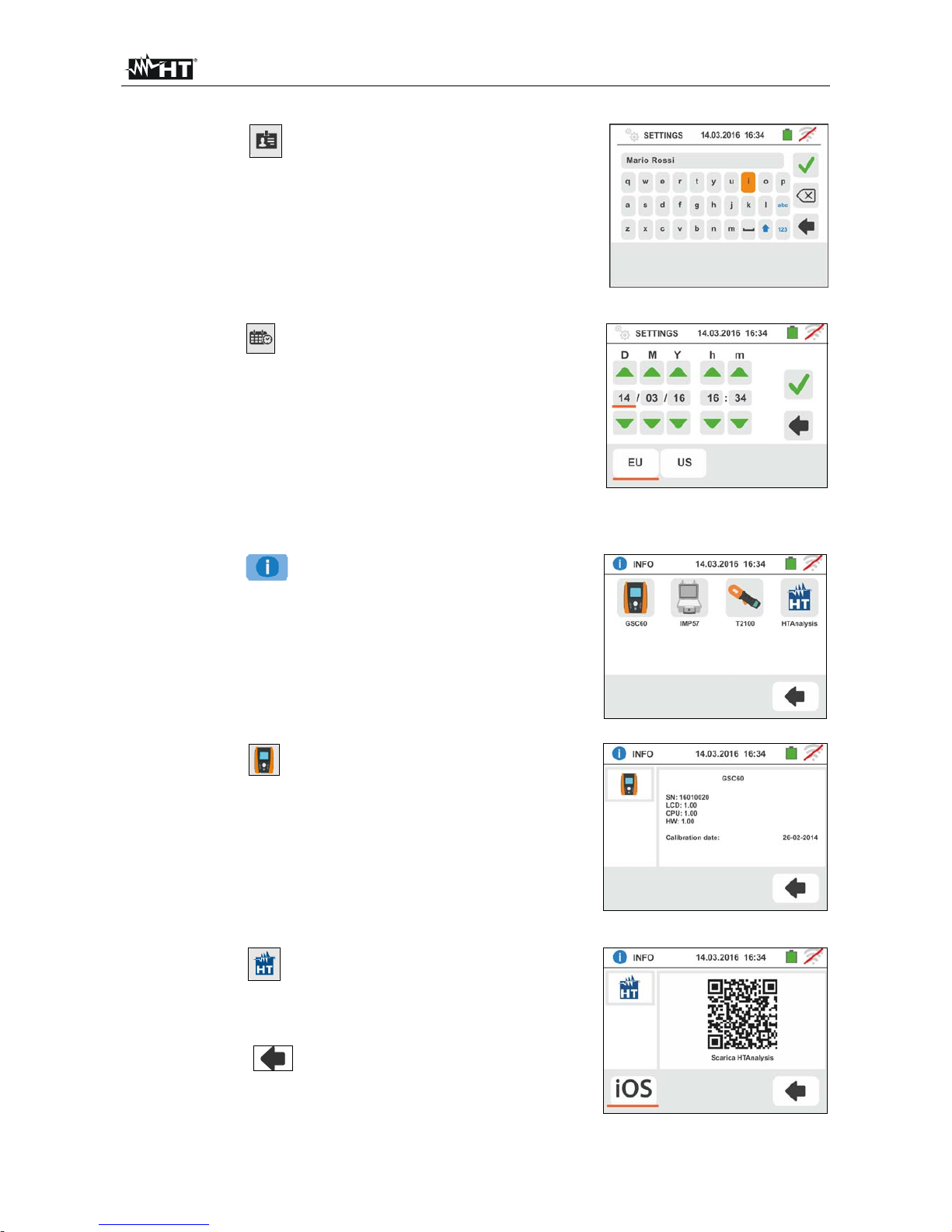

5.1.5. Operator name entry

Touch the icon to enter the name of the operator that

will be displayed in the header of each measurement

downloaded to PC. The screen to the side appears on the

display.

Set the desired name using the virtual keyboard (max 12

characters).

Confirm the settings or exit without saving.

5.1.6. System date/time setting

Touch the icon to set the system date/time. The screen

to the side appears on the display.

Touch the "EU" icon for the European date/time system in

the format "DD/MM/YY hh:mm" or the "US" icon for the

American system in the format "MM/DD/YY hh:mm AM/PM".

Touch the up/down arrow keys to set the desired value.

Confirm the settings or exit without saving.

Current date/time is kept inside the instrument without

batteries for approximately 12 hours.

5.2. INFORMATION

Touch the icon . The display shows the screen on the

right with the icons relative to the properties of the

instrument, the optional accessories IMP57 and T2100 and

the HTAnalysis APP

Touch the icon . The display shows the screen on the

right as well as following information:

Serial number

Internal version of Firmare and Hardware (for the

accessories IMP57 and T2100 these informations are

available only after the connection to the instrument)

Last calibration date

Touch the icon . The display shows the screen on the

right with the QR code of HTAnalysis APP (see § 8.1) in

iOS and Android systems. This code permits an easy

access to the Apple Store to download the APP

Touche the icon to exit and return to the general menu

Page 14

GSC60

EN - 12

6. OPERATING INSTRUCTIONS

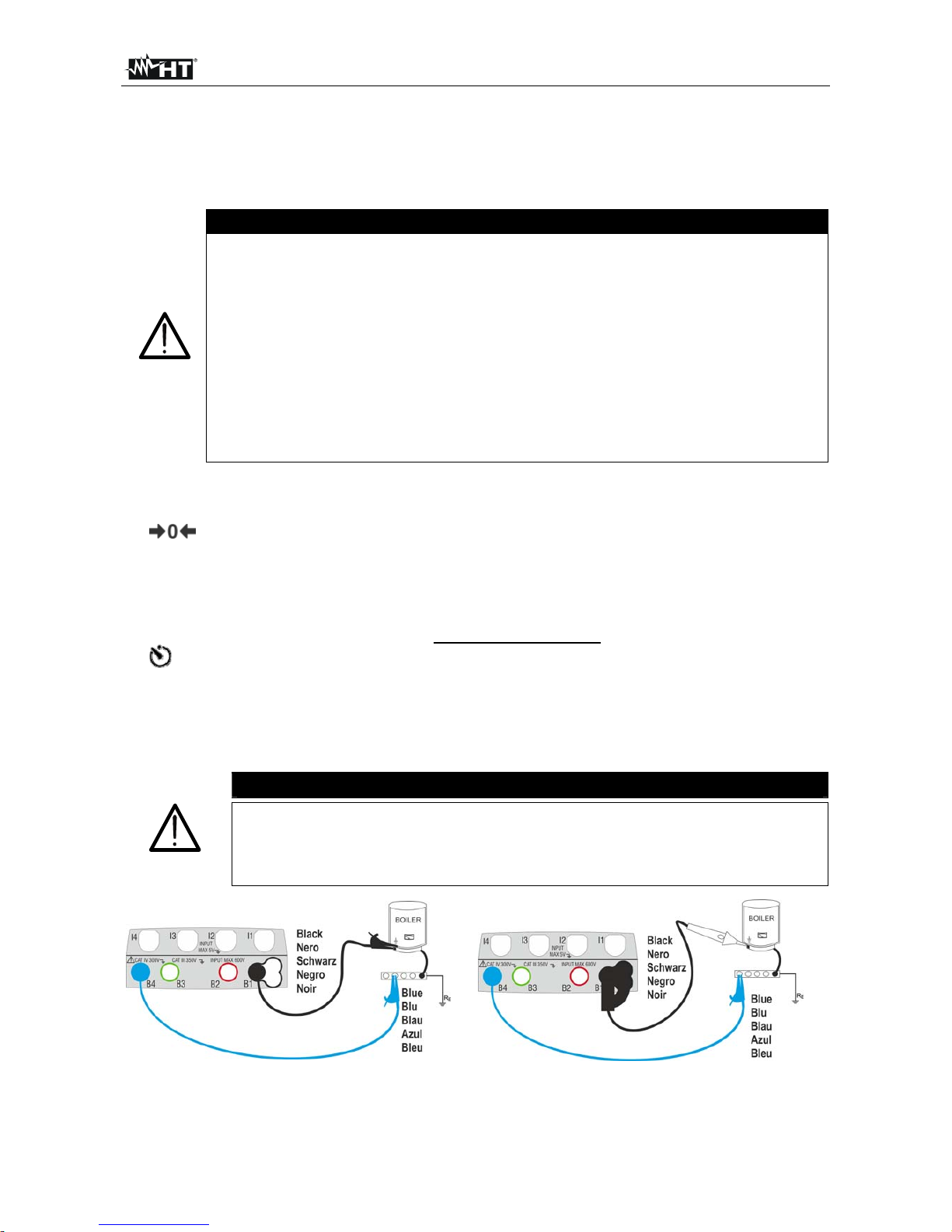

6.1. RPE: CONTINUITY OF PROTECTIVE CONDUCTORS

This function is performed in compliance with standards IEC/EN61557-4 and allows

measuring the resistance of protective and equipotential conductors.

CAUTION

The instrument can be used for measurements on installations with

overvoltage category CAT IV 300V to earth and max 600V between inputs.

Do not connect the instrument on installations with voltage exceeding the

limits indicated in this manual. Exceeding these limits could cause electrical

shock to the user and damage to the instrument.

We recommend holding the alligator clip respecting the safety area created

by the hand protection (see § 4.2).

Check that no voltage is present at the ends of the item to be tested before

carrying out a continuity test.

The results may be influenced by the presence of auxiliary circuits

connected in parallel with the item to be tested or by transient currents.

The following operating modes are available:

Compensation of the resistance of the cables used for measurement. The

instrument automatically subtracts the value of cable resistance from the

measured resistance value. Therefore, it is necessary that this value is

measured each time the measuring cables are changed or extended.

AUTO The instrument carries out two measurements with inverted polarity and

displays their average value. Recommended mode

The instrument carries out the measurement with the possibility of setting a

duration time for testing. The operator may set a sufficiently long measuring

time (between 1s and 99s) to be able to move the protective conductors while

the instrument is carrying out the test, in order to find out a possible bad

connection.

CAUTION

Continuity test is carried out by supplying a current higher than 200mA

in case the resistance does not exceed ca. 2 (including resistance of

the test cables). For higher resistance values, the instrument carries out

the test with a current lower than 200mA.

Fig. 6: Continuity test by means of single cables and remote lead

Page 15

GSC60

EN - 13

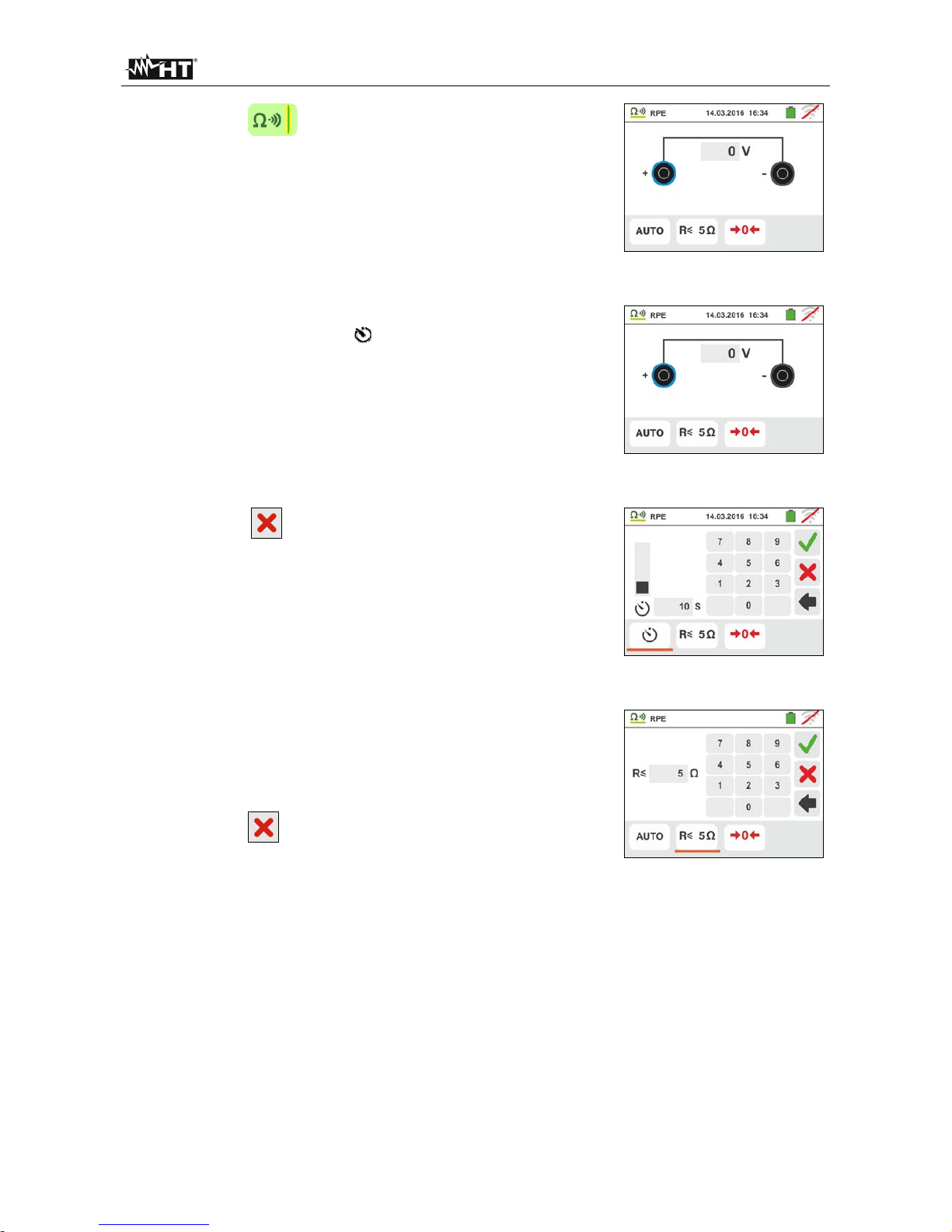

1.

Touch the icon. The screen to the side appears on

the display. The instrument automatically carries out the

test for the presence of voltage between the inputs

(shown on the display) and blocks the test in case of

voltage higher than 10V

Touch the “AUTO” icon to set the measuring mode. The

following screen appears on the display:

2. Move the slide bar reference in the positions "AUTO"

(Automatic mode) or "

" (Timer mode). Confirm the

choice by going back to the previous screen.

If Timer mode is selected, the following screen is shown:

3.

Touch the icon to zero the value in the Timer field

and use the virtual keyboard to set the value in seconds

between 1s and 99s. Confirm the choice by going back to

the initial measurement screen.

4.

Touch the icon "Rxx" to set the maximum limit value of

the resistance on which the instrument makes the

comparison with the measured value. The screen to the

side appears on the display.

Touch the

icon to zero the value in the “R” field.

Use the virtual keyboard to set the value between 1 and

99.

Confirm the choice by going back to the initial

measurement screen. Note the presence of the set limit

value.

Page 16

GSC60

EN - 14

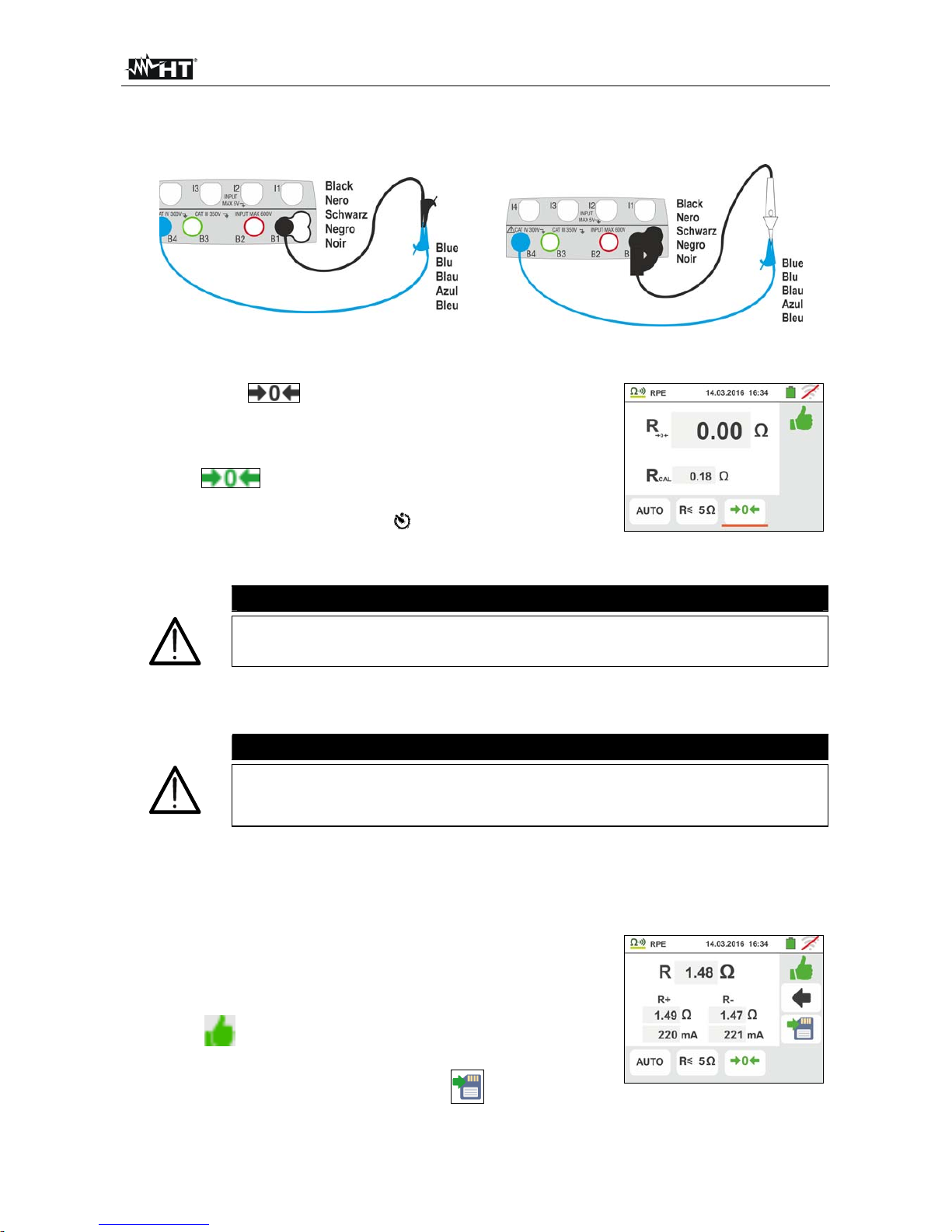

5. Perform, if necessary, the compensation of the measuring leads resistance by

connecting the cables or the remote lead as shown in Fig. 7.

Fig. 7: Compensation of single cables and remote lead resistance

6.

Touch the icon to activate the measurement. After

a few seconds, the instrument provides the screen to the

side if the operation is successful (Rcables 2); the

indication of the value is shown in the "Rcal" field and the

icon is shown on the display.

Touch the "AUTO" icon or " " to go back to the main

measurement screen.

CAUTION

Before connecting the test leads, make sure that there is no voltage at

the ends of the conductor to be tested.

7. Connect the alligator clips and/or test leads and/or remote lead to the conductor to

be tested as in Fig. 6.

CAUTION

Always make sure, before any measurement, that the compensation

resistance value is referred to the cables currently used. In case of

doubt, repeat points 5 and 6.

8.

Press the GO/STOP key on the instrument or the START key on the remote lead.

The instrument will start the measurement. During this whole stage, do not

disconnect the test leads of the instrument from the conductor under test. The

following screen appears on the display:

9. The value of the result is shown in the upper part of the

screen, while the partial values of the test with inverted

polarity of the test source in addition to the real test

currents are reported in the fields "R+" and "R-".

The symbol indicates the positive result of the

measurement.

Press the SAVE button or touch the icon to save the

measurement (see § 7.1).

Page 17

GSC60

EN - 15

10. At the end of the test, if the value of the measured

resistance is higher than the set limit, the screen to the

side is shown on the display.

The value is shown in red and the symbol indicates

the negative result of the measurement. The "> 99.9"

message indicates the instrument overload status.

Press the SAVE button or touch the icon to save the

measurement (see § 7.1).

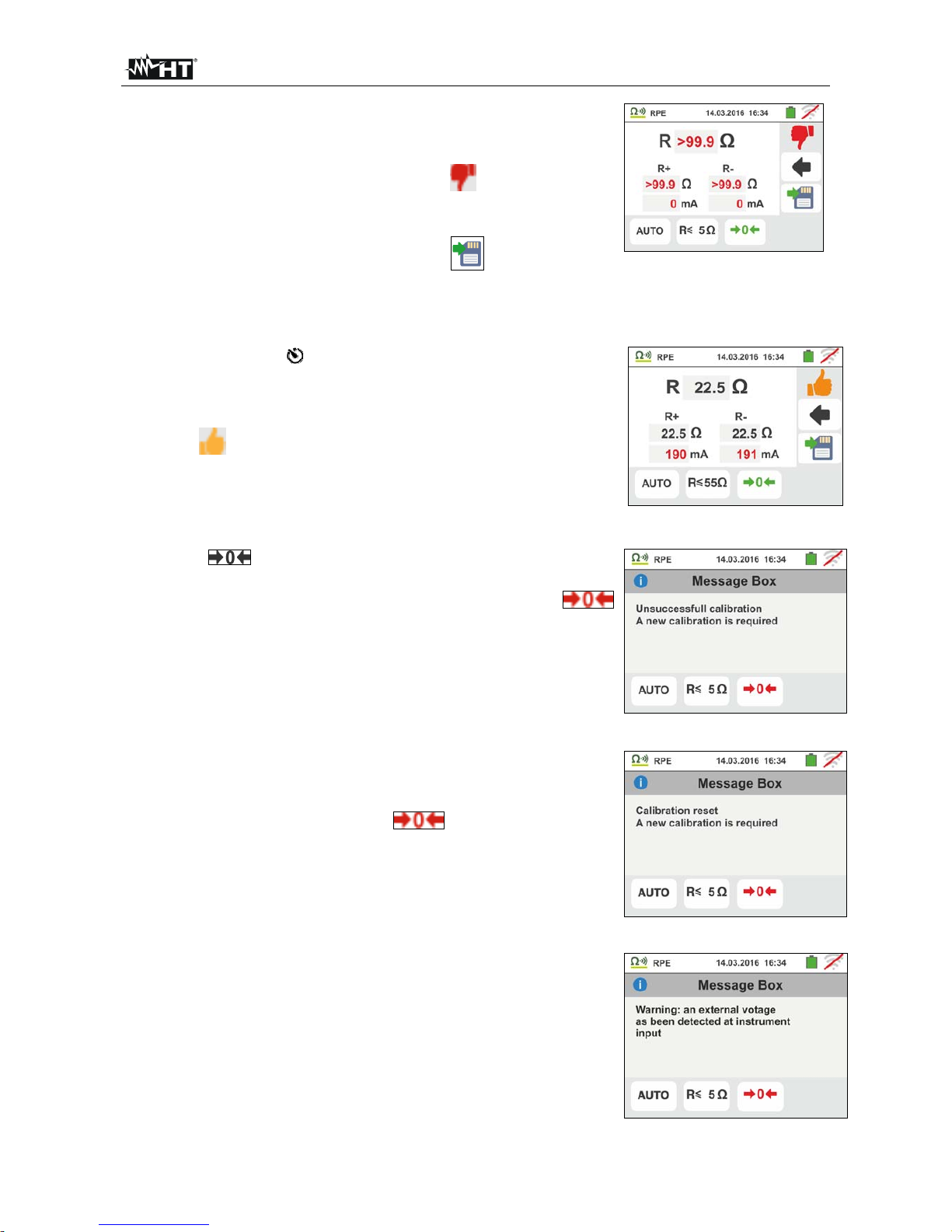

6.1.1. Anomalous situations

1.

In AUTO or " " modes if the instrument detects a

resistance lower than the set limit value but for which is it

not able to generate a current of 200mA, the screen to

the side is displayed.

The symbol is shown on the display and the values of

the real test current are indicated in red.

2. If in mode the instrument detects a resistance

higher than 2 at its terminals, it resets the offset value

and displays a screen like the one to the side. The

icon is shown on the display to indicate the calibration

reset value (i.e. performing the operation with open

terminals).

3. In case the instrument detects that the calibrated

resistance is higher that the measured resistance, the

instrument gives out a long sound and displays a screen

like the one to the side. The icon is shown on the

display to indicate the calibration reset value.

4. If the instrument detects a voltage value higher than

approx. 10V at its terminals, it does not carry out the test,

gives out a long sound and the screen reported here to

the side is displayed

Page 18

GSC60

EN - 16

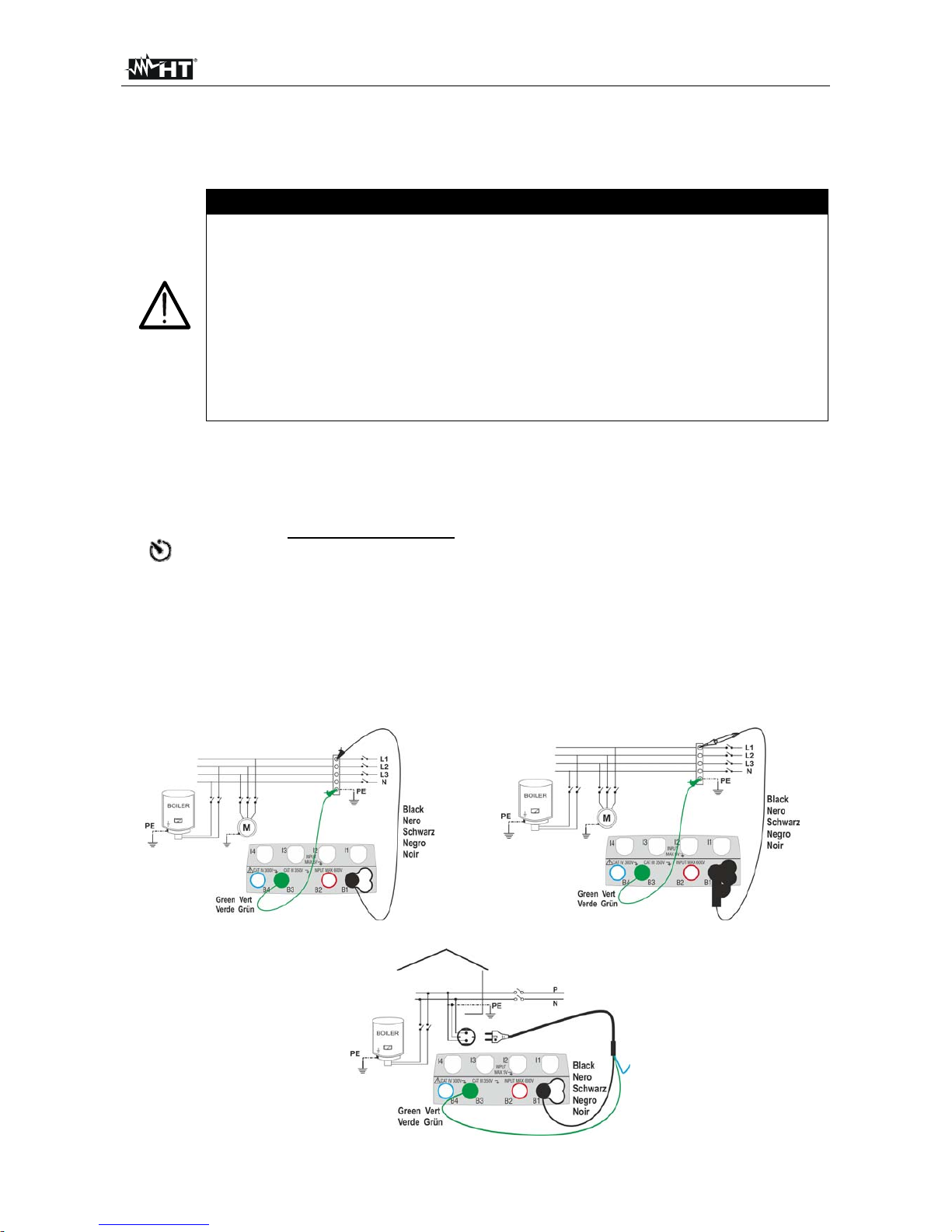

6.2. M: MEASUREMENT OF INSULATION RESISTANCE

This function is performed in compliance with standards IEC/EN61557-2 and allows

measuring the insulation resistance between the active conductors and between each

active conductor and the earth.

CAUTION

The instrument can be used for measurements on installations with

overvoltage category CAT IV 300V to earth and max 600V between inputs.

Do not connect the instrument on installations with voltage exceeding the

limits indicated in this manual. Exceeding these limits could cause electrical

shock to the user and damage to the instrument.

We recommend holding the alligator clip respecting the safety area created

by the hand protection (see § 4.2).

Check that the circuit being tested is not live and that all possible loads

normally connected to it are disconnected before carrying out insulation

measurement.

The following operating modes are available:

AUTO The test is activated by the GO/STOP key of the instrument (or START of the

remote lead). The instrument automatically detects the presence of possible

capacitance and waits until test nominal voltage is reached (typically approx. 2

seconds). Recommended mode

The operator may set a sufficiently long measuring time (1s 999s) to be able

to move the test lead on the conductors being tested, while the instrument is

carrying out the test. For the whole measurement duration, the instrument will

give out a short sound every second. While measuring, if the insulation

resistance reaches a lower value than the set limit, the instrument will give a

continuous acoustic signal. To stop the test, press again the GO/STOP key on

the instrument or the START key on the remote lead. At the end of test, the

lowest value of insulation (worst case) detected during the test will be shown by

the instrument

Fig. 8: Insulation test by means of single cables and remote lead

Fig. 9: Insulation test by means of shuko plug

Page 19

GSC60

EN - 17

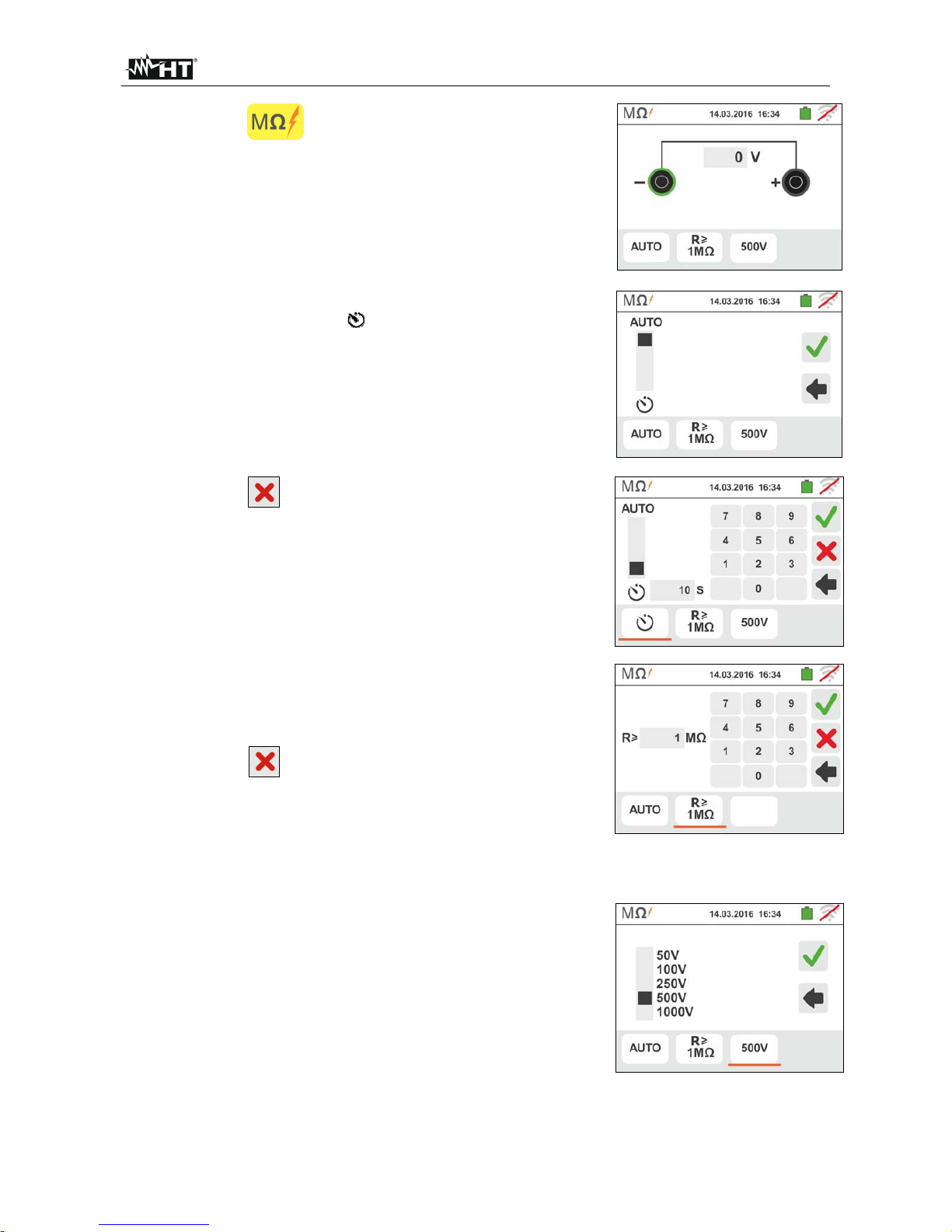

1.

Touch the icon. The screen to the side appears

on the display. The instrument automatically carries out

the test for the presence of voltage between the inputs

(shown on the display) and blocks the test in case of

voltage higher than approx. 10V

Touch the “AUTO” icon to set the measuring mode. The

following screen appears on the display:

2. Move the slide bar reference in the positions "AUTO"

(Automatic mode) or " " (Timer mode). Confirm the

choice by going back to the previous screen.

If Timer mode is selected, the following screen is

shown:

3.

Touch the icon to zero the value in the Timer field

and use the virtual keyboard to set the value in seconds

between 1s and 999s. Confirm the choice by going

back to the initial measurement screen.

4.

Touch the icon "Rxx" to set the minimum limit value

of the insulation resistance on which the instrument

makes the comparison with the measured value. The

screen to the side appears on the display.

Touch the

icon to zero the value in the “R” field.

Use the virtual keyboard to set the value between

0.01M and 999M.

Confirm the choice by going back to the initial

measurement screen. Note the presence of the set limit

value.

5. Touch the "xxxxV" icon to set the test DC voltage in the

insulation measurement. The screen to the side

appears on the display.

Move the slide bar reference to the desired value for

test voltage by choosing among 50, 100, 250, 500,

1000VDC.

Confirm the choice by going back to the initial

measurement screen. Note the presence of the set limit

value.

Page 20

GSC60

EN - 18

CAUTION

Disconnect any cable not strictly involved in measurement and especially

check that no cable is connected to In1 input.

Before connecting the test leads, make sure that there is no voltage at the

ends of the conductors to be tested.

6. Connect the alligator clips and/or test leads and/or remote lead to the ends of the

conductors to be tested as in Fig. 8 and Fig. 9.

7.

Press the GO/STOP key on the instrument or the START key on the remote lead. The

instrument will start the measurement.

CAUTION

During this whole stage, do not disconnect the test leads of the instrument

from the conductor under test. It could remain charged with a dangerous

voltage due to the stray capacitances in the circuit being tested.

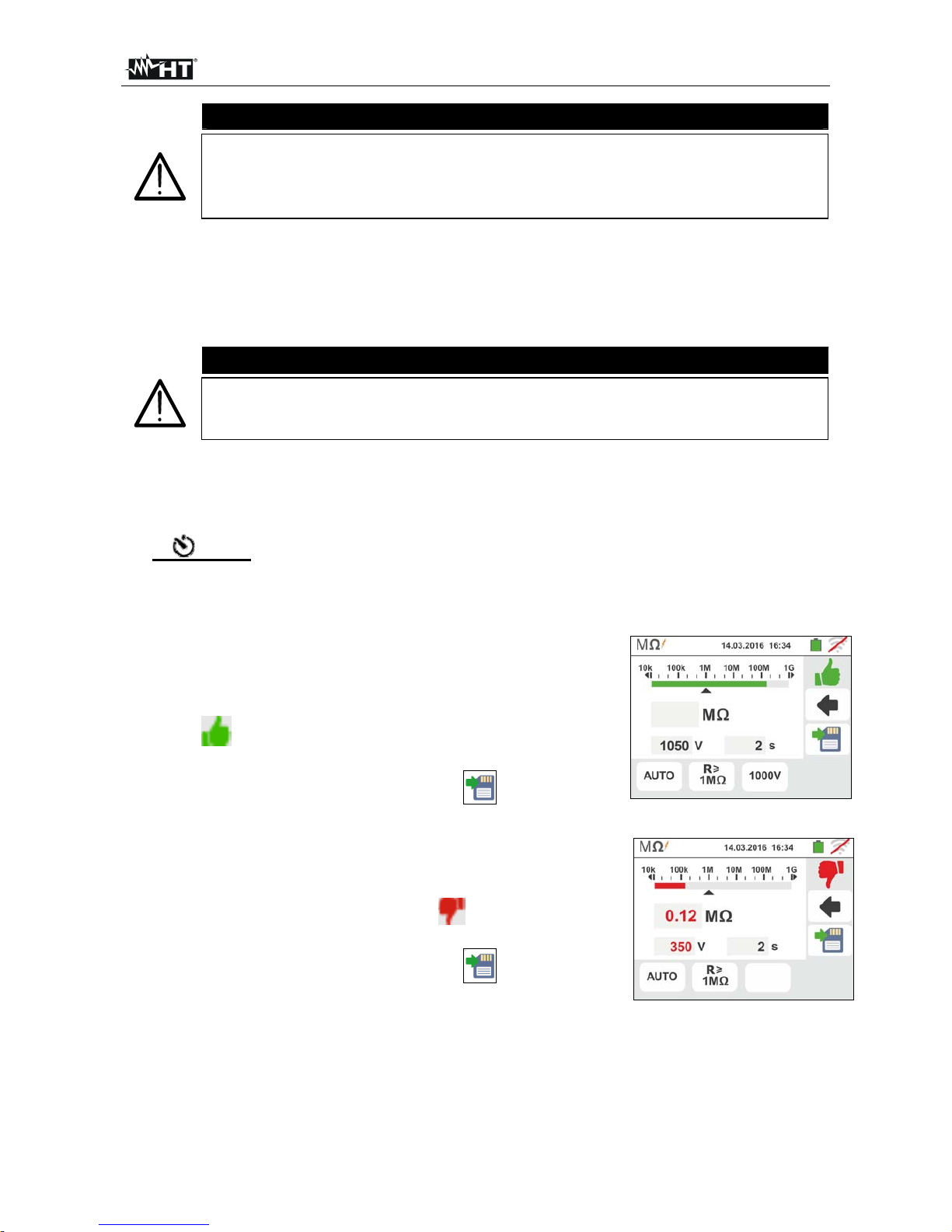

8. Regardless of the operating mode selected, at the end of the measurement, the

instrument applies a resistance to the output leads to discharge the capacitances in the

circuit.

9.

In mode:

The final result is the minimum insulation value measured during the test

Pressing a second time the GO/STOP key or the START key on the remote lead

stops the test before the set time has elapsed.

10. The measurement result is shown both as a numeric

value and in the analog bar graph as shown in the

screen to the side. The values of the real test voltage

and the measurement time are present on the display.

The symbol indicates the positive result of the

measurement.

Press the SAVE button or touch the

icon to save

the measurement (see § 7.1).

11. At the end of the test, if the value of the measured

resistance is lower than the set limit, the screen to the

side is shown on the display.

The value is shown in red and the symbol indicates

the negative result of the measurement.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

Page 21

GSC60

EN - 19

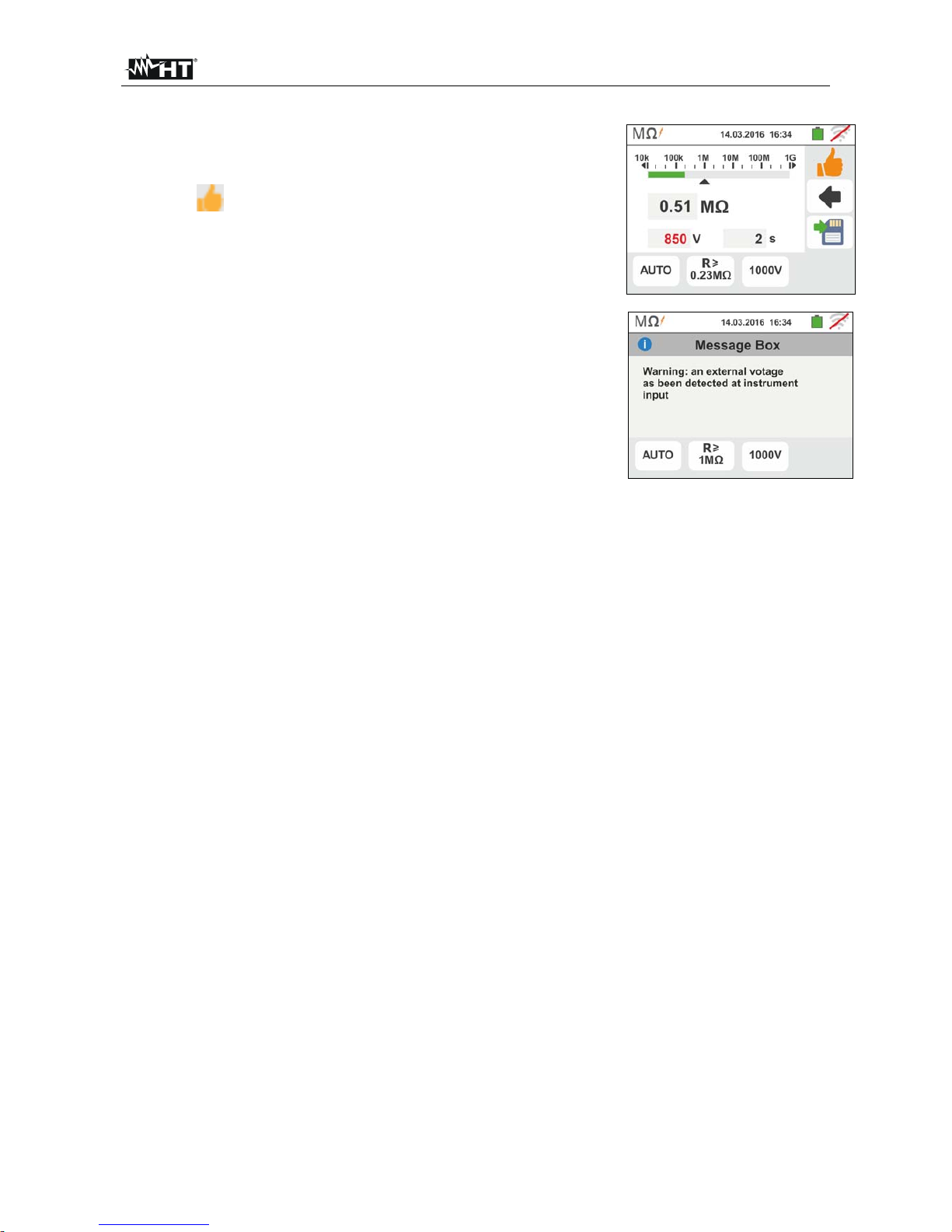

6.2.1. Anomalous situations

1. If the instrument measures a resistance higher than

the set limit value but for which it is not able to generate

the rated voltage, the screen to the side is displayed.

The symbol is shown on the display and the values

of the real test voltage are indicated in red.

2. If the instrument detects a voltage value higher than

approx. 10V at its terminals, it does not carry out the

test, gives out a long sound and the screen reported

here to the side is displayed.

Page 22

GSC60

EN - 20

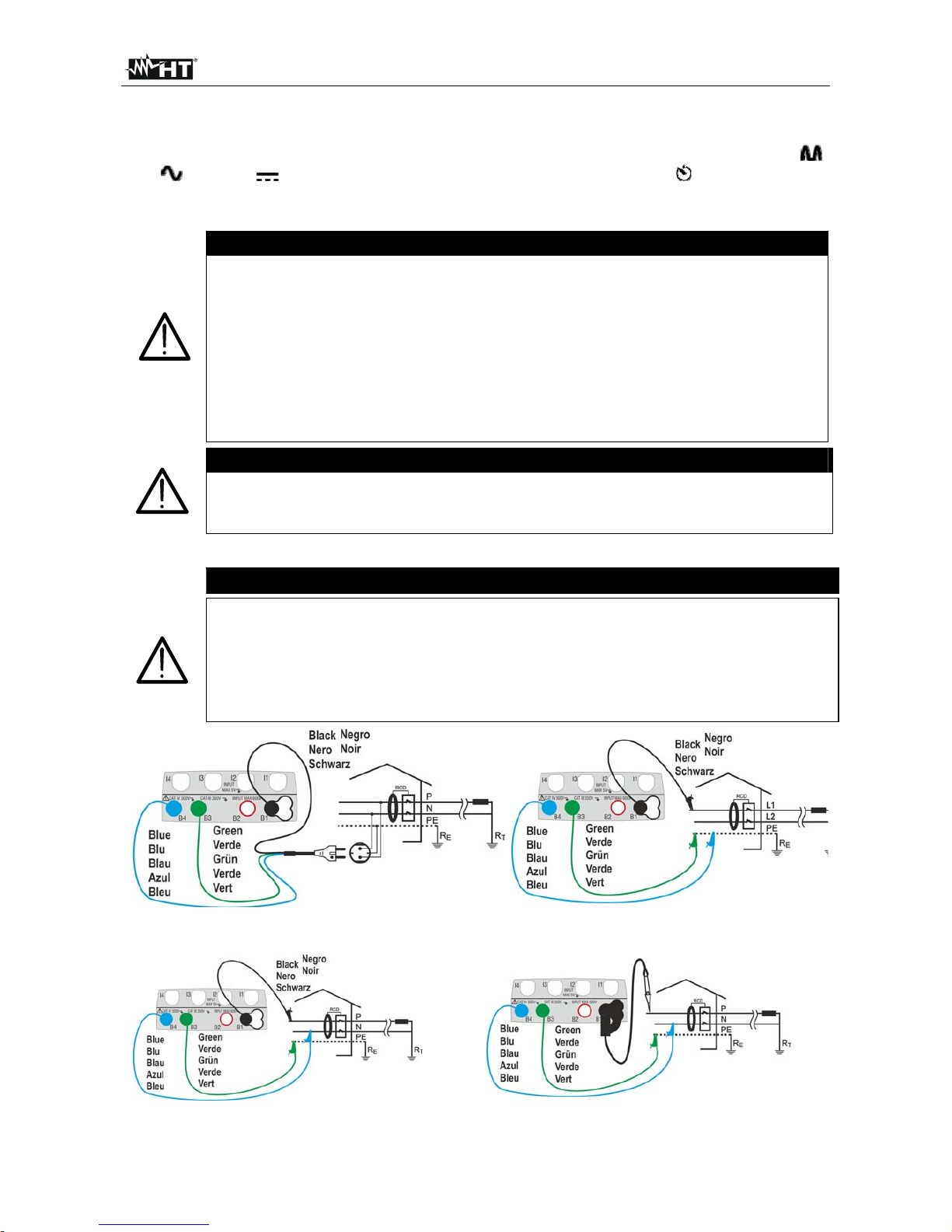

6.3. RCD: TEST ON DIFFERENTIAL SWITCHES

This function is performed in compliance with standard IEC/EN61557-6 and allows

measuring the tripping time and current of molded case differential switches of type A ( ),

AC ( ) and B ( ), being General (G), Selective (S) and Delayed ( ). The instrument

allows performing tests on earth leakage relay RCDs with currents up to 10A (with optional

accessory RCDX10).

CAUTION

The instrument can be used for measurements on installations with

overvoltage category CAT IV 300V to earth and max 600V between inputs.

Do not connect the instrument on installations with voltage exceeding the

limits indicated in this manual. Exceeding these limits could cause electrical

shock to the user and damage to the instrument.

Always connect the measuring cables to the instrument and to the alligator

clips with the accessories disconnected from the system

We recommend holding the alligator clip respecting the safety area created

by the hand protection (see § 4.2).

CAUTION

Some combinations of test parameters can be not available in compliance with

the technical specification of the instrument and the RCD tables (see § 10.1 –

the empty cells of RCD tables means not available situations)

The following operating connections are available to perforn the RCD test:

CAUTION

Testing the RCD tripping time causes its tripping. Therefore, check that there

are NO users or loads connected downstream of the differential switch

being tested which could be damaged by a system downtime.

Disconnect all loads connected downstream of the differential switch as they

could produce leakage currents further to those produced by the instrument,

thus invalidating the results of the test.

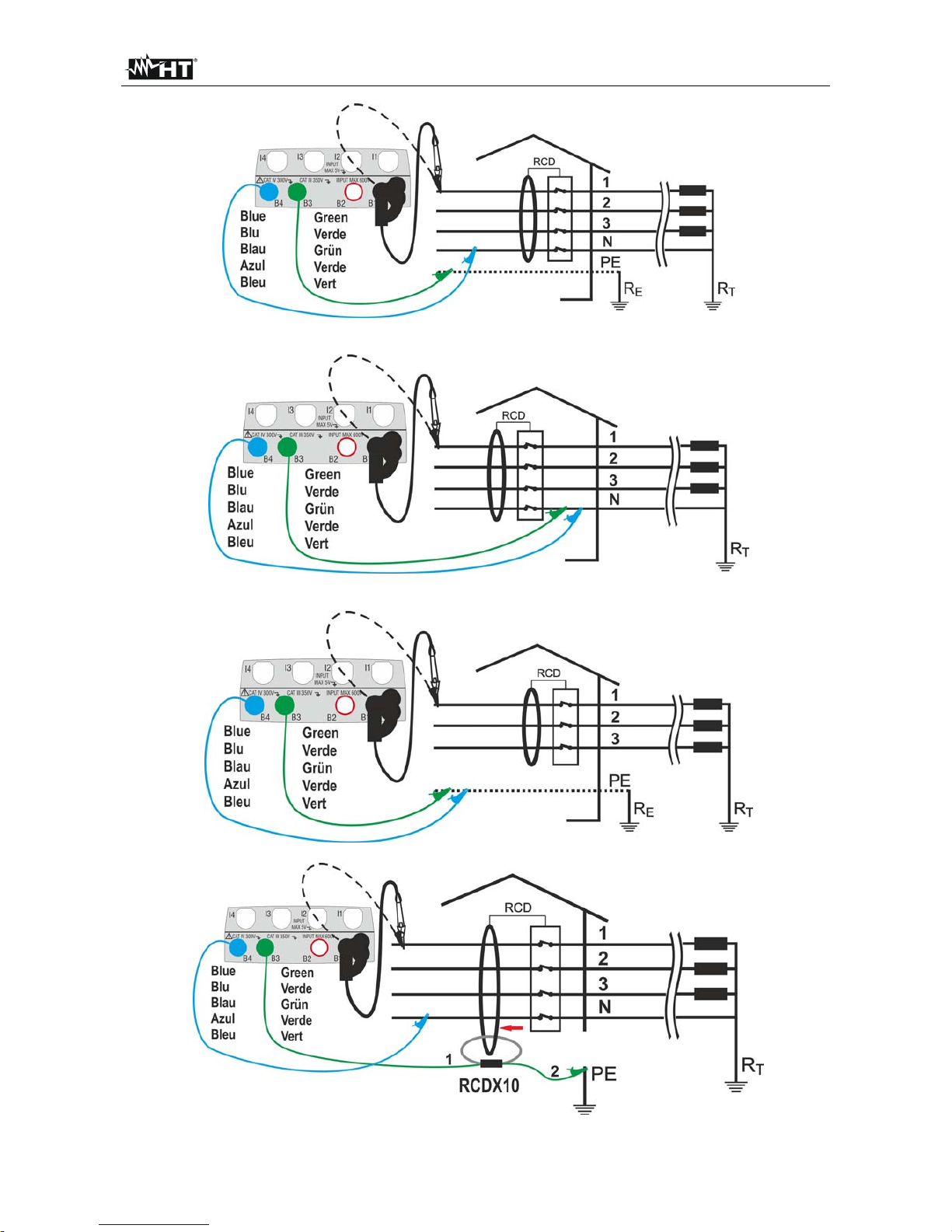

Fig. 10: Connection for single-phase 230V

system by means of shuko plug

Fig. 11: Connection for double-phase

230V with no neutral (no RCD B type)

Fig. 12: Connection for single-phase 230V system with single cables and remote lead

Page 23

GSC60

EN - 21

Fig. 13: Connection for a 400V + N + PE by means of single cables and remote lead

Fig. 14: Connection for a 400V + N (no PE), single cables, remote lead (no RCD B type)

Fig. 15: Connection for a 400V + PE (no N) single cables, remote lead (no RCD B type)

Fig. 16: Connection to earth leakage relay RCDs with optional accessory RCDX10

Page 24

GSC60

EN - 22

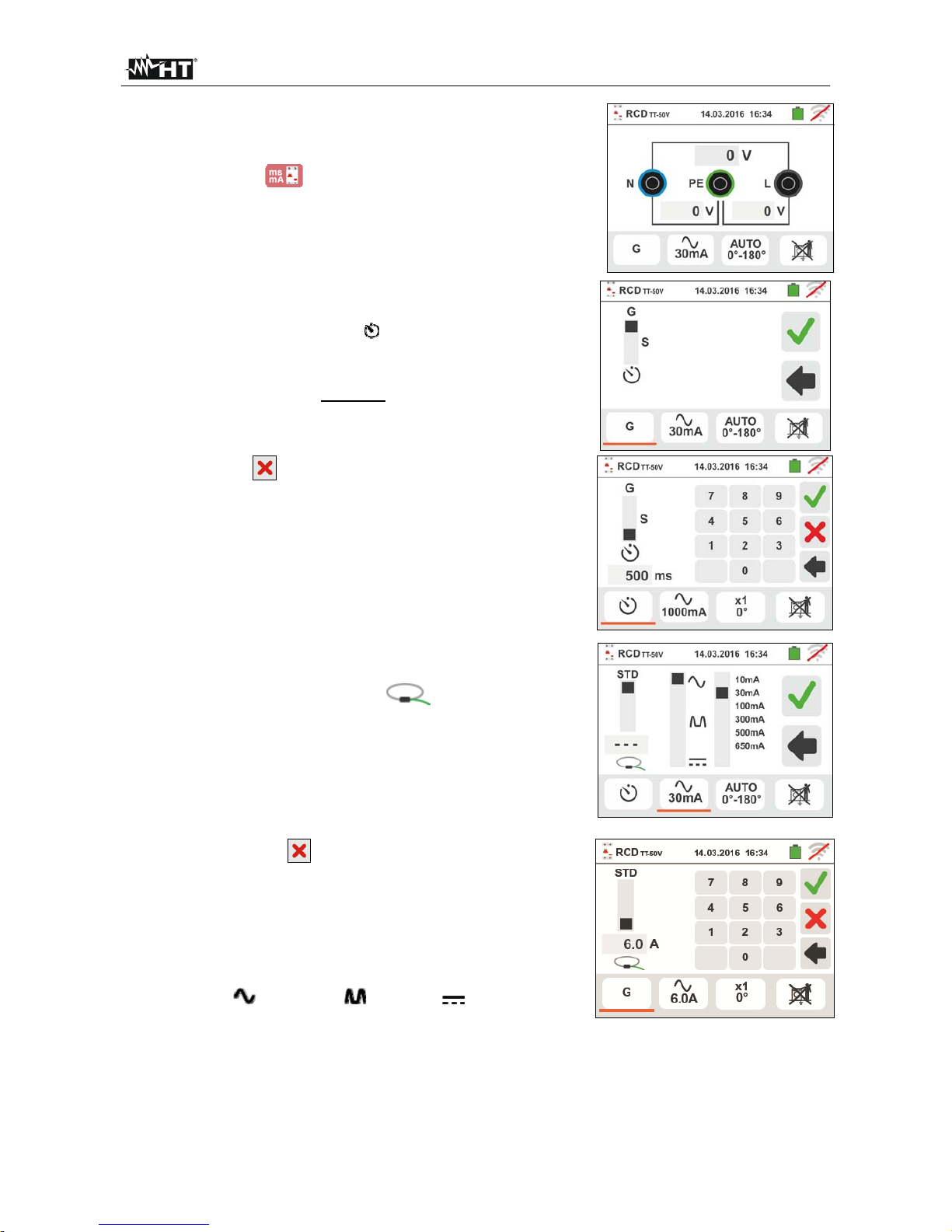

1. Select the options “TN, TT or “IT”, “25 or 50V”,

“50Hz or 60Hz” and the reference voltage in the

general settings of the instrument (see § 5.1.4).

Touch the icon. The screen to the side

appears on the display. Touch the icon to the left to

set the RCD operating mode. The following screen

appears on the display:

2. Move the slide bar reference by selecting the

desired operating mode between the options: G

(General), S (Selective), (Delayed). Confirm the

choice by going back to the initial measurement

screen. Note the presence of the chosen selection.

When selecting a Delayed RCD, the instrument

displays the following screen.

3.

Touch the icon to zero the value in the Timer

field and use the virtual keyboard to set the value

of RCD delay time in seconds between 1ms and

500ms. Confirm the choice by going back to the

initial measurement screen. Touch the second icon

to set the type of RCD, the waveform and the

tripping current. The following screen appears on

the display.

4. Move the left slide bar reference and select the

type of RCD between the following options: STD

(molded case RCD) and “ ” (earth leakage

delay RCD with use of optional accessory

RCDX10). In case of earth leakage relay RCD the

following screen appears on the display

5.

Touch the icon

to zero the value in “A” field and

use the virtual keyboard to set the value of rated

current of earth leakage relay RCD. The maximum

rated current is 10.0A. Confirm the choice by going

back to the previous screen.

Move the second slide bar reference by selecting

the waveform of the differential switch between the

options:

(type AC), (type A), (type B).

For RCD of molded case type STD move the third

slide bar reference by selecting the desired rated

current of the differential switch between the

options: 10, 30, 100, 300, 500, 650, 1000mA

Confirm the choice by going back to the initial

measurement screen. Note the presence of the

chosen selections

Page 25

GSC60

EN - 23

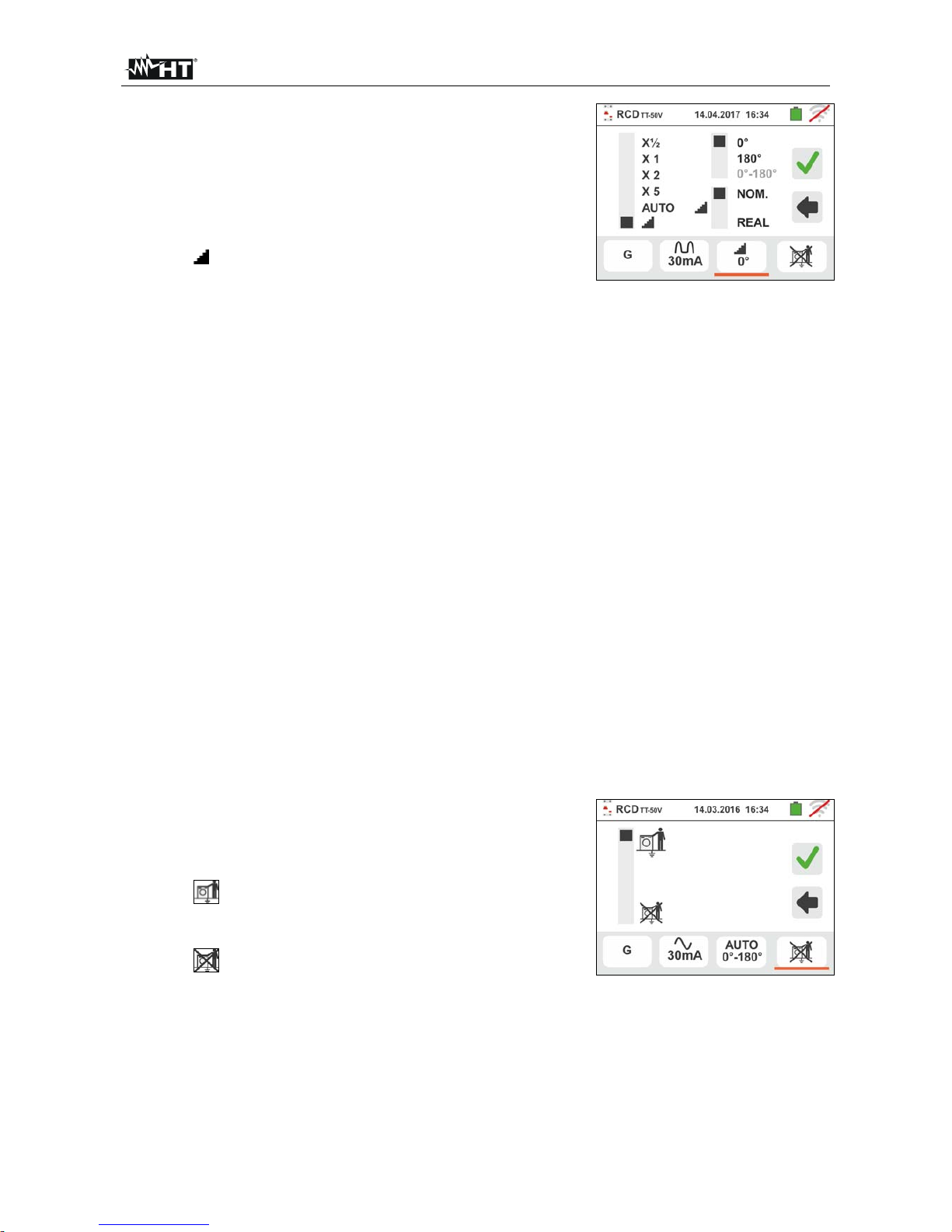

6. Touch the third icon at the bottom of display and

select the desired type of test among the options::

x ½ Manual with multiplier ½ Idn

x 1 Manual with multiplier 1Idn

x 2 Manual with multiplier 2Idn

x 5 Manual with multiplier 5Idn

AUTO Auto mode (6 tests in sequence)

Ramp (real tripping current measurement)

Move the right slide bar reference by selecting the

polarity of the test current between the options: 0°

(direct polarity), 180° (inverted polarity), 0°-180°

(for Automatic mode only). Move the lower right

slide bar reference by selecting (for Ramp mode

only) the kind of the trip out current visualization

between the followed options:

NOM the instrument shows the normalized

value of trip out current (referred to the nominal

current). Example: for RCD type A with

Idn=30mA the effective value of normalized trip

out current can be up to 30mA

REAL the instrument shows the effective

value of the trip out current by considering the

coefficients indicated by the IEC/EN61008 and

IEC/EN61009 guidelines (1.414 for RCD type

A, 1 for RCD type AC, 2 for RCD type B).

Example: for RCD type A with Idn=30mA the

effective value of trip out current can be up to

30mA * 1.414 = 42mA

NOTE: The selection of the two option involves

only the choose of the trip out current

visualization but not influence the outcome

test (OK/NO)

Confirm the choice by going back to the initial

measurement screen

7. Touch the fourth icon at the bottom of the display

and select the possible visualization of the contact

voltage value at the end of measurement. The

following options are possible:

The value of contact voltage is shown on

the display at the end of measurement (the test

time will be slightly longer)

The value of contact voltage is not

shown on the display at the end of

measurement. The symbol “- - -“ is shown

8. Insert the green, blue and black connectors of the three-pin shuko plug into the

relevant instrument input terminals B3, B4, B1. As an alternative, use the single cables

and apply the relevant alligator clips to the free ends of the cables. It is also possible to

use the remote lead by inserting its multipolar connector into the input lead B1.

Connect the shuko plug, the alligator clips or the remote lead to the electrical mains

according to Fig. 10, Fig. 12, Fig. 13, Fig. 14 and Fig. 15.

Page 26

GSC60

EN - 24

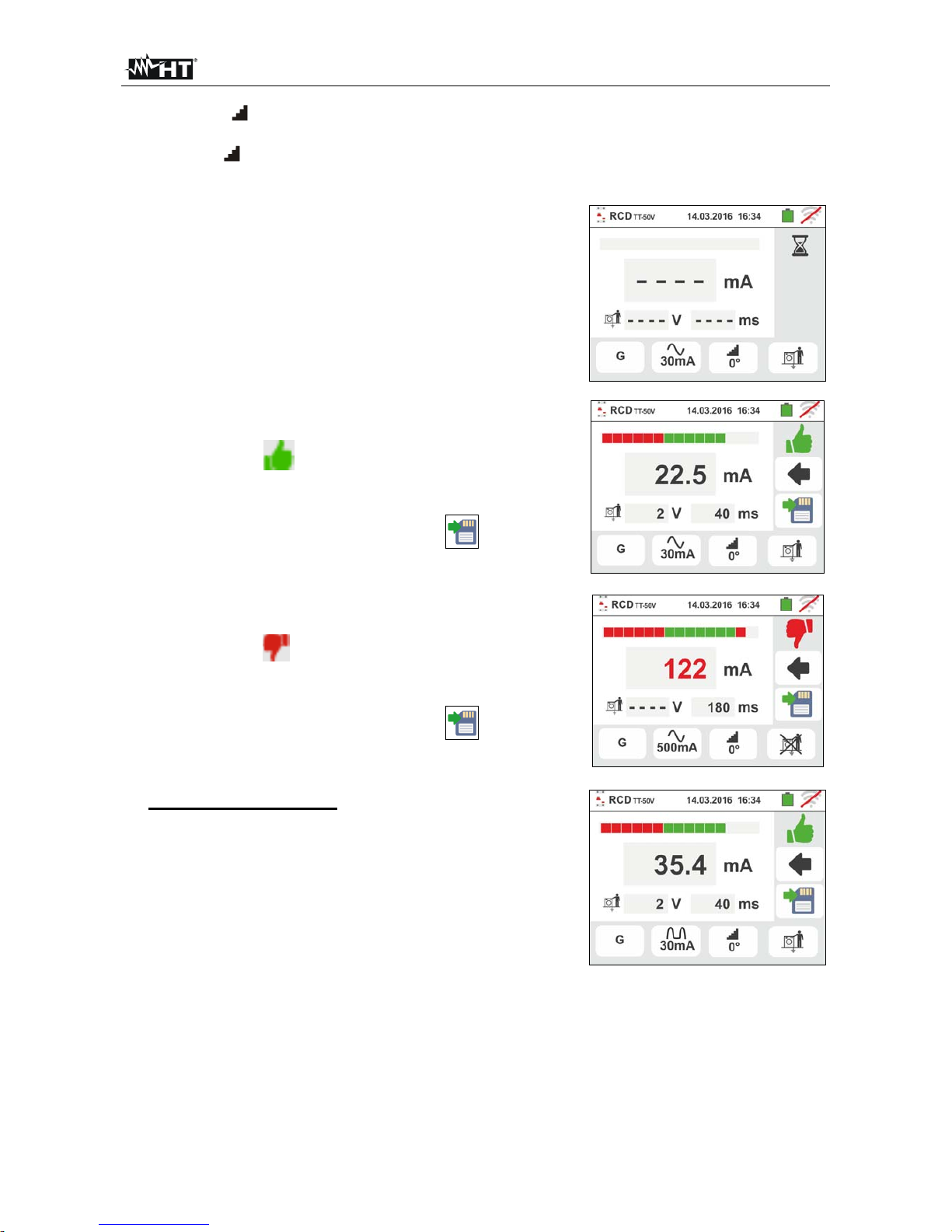

6.3.1. AUTO mode

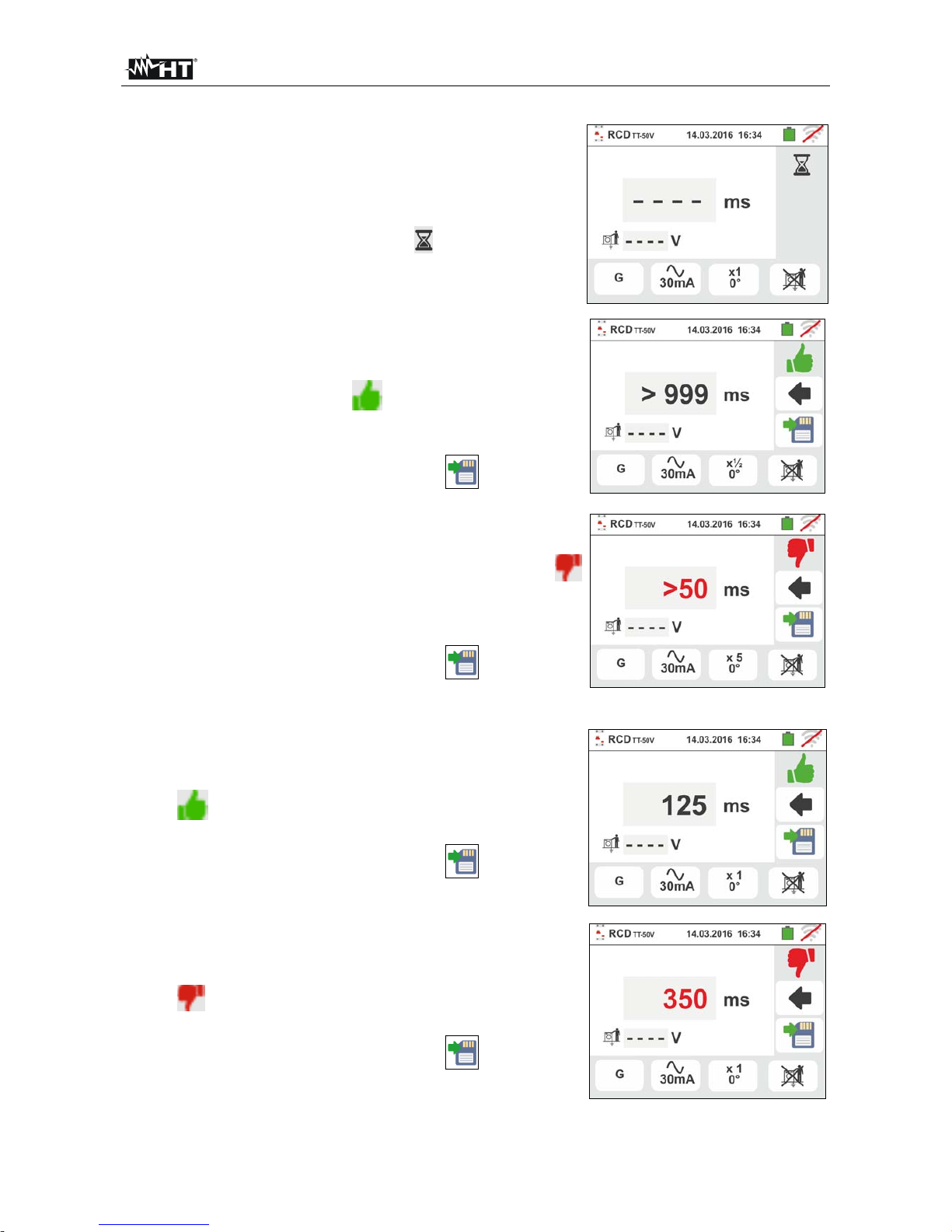

9.

Press the GO/STOP key for 2s on the instrument or the

START key on the remote lead. The instrument will

start the measurement.

The screen to the side is shown on the display when

the icon indicates the performance of the test.

10 The AUTO mode foresees the automatic execution of 6

measurements in a sequence:

IdN x 1 with phase 0° (the RCD must trip,reset the

switch, icon )

IdN x 1 with phase 180° (the RCD must trip,reset

the switch, icon )

IdN x 5 with phase 0° (the RCD must trip,reset the

switch, icon )

IdN x 5 with phase 180° (the RCD must trip,reset

the switch, icon )

IdN x½ with phase 0° (RCD must not trip)

IdN x½ with phase 180° (RCD must not trip, end of

test)

11

The test has a positive result if all tripping times of molded case type STD comply with

what indicated in Table 4 (see § 12.4). The test has a negative result when one of the

values is out of range. During this whole stage, do not disconnect the measuring leads

of the instrument from the system on test.

12 At the end of the test, if the tripping time of each test

complies with what is indicated in Table 4 (see § 12.4)

the instrument shows the symbol to signal that the

test has been completed successfully, and displays a

screen similar to the one reported here to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

13 At the end of the test, if the tripping time of a test does

not comply with what is indicated in Table 4 (see §

12.4). the instrument shows the

symbol to signal

that the test has not been completed successfully, and

displays a screen similar to the one reported here to the

side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

CAUTION

A

ccording to standard EN61008, the test for Selective differential switches

requires an interval of 60 seconds between the tests (30s for tests with ½ Idn).

The instrument display shows a timer indicating the time remaining before the

instrument can automatically perform the test.

Page 27

GSC60

EN - 25

6.3.2. x½, x1, x2, x5 modes

9.

Press the GO/STOP key for 2s on the instrument or the

START key on the remote lead. The instrument will

start the measurement.

The screen to the side (concerning multiplier x1) is

shown on the display when the icon indicates the

performance of the test.

10

At the end of the test with multiplier x1/2, x1, x2 or x5 if

the tripping time, for molded case type STD, is as

listed in Table 4

the instrument shows the symbol to signal that the

test has been completed successfully, and displays a

screen similar to the one reported here to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

11

At the end of the test, for molded case type STD, if the

tripping time of a test does not comply with what is

indicated in Table 4the instrument shows the

symbol to signal that the test has not been completed

successfully, and displays a screen similar to the one

reported here to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

6.3.3. Mode x1 – Test on RCDs with delay time

9. At the end of the test, if the measured tripping time is

within the interval: [limit delay = set delay time +

value indicated in Table 4] the instrument displays

the

symbol to indicate the positive outcome of the

test and displays a screen like the one to the side.

Press the SAVE button or touch the

icon to save

the measurement (see § 7.1).

10 At the end of the test, if the measured tripping time is

external the interval: [limit delay = set delay time +

value indicated in Table 4] the instrument displays

the symbol to indicate the negative outcome of the

test and displays a screen like the one to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1)

Page 28

GSC60

EN - 26

6.3.4. Mode

The standard defines, for molded case type STD, the tripping times for RCDs at nominal

current. The mode is used to detect the minimum tripping current (which could also be

lower than the nominal voltage).

9.

Press the GO/STOP key for 2s on the instrument or the

START key on the remote lead. The instrument will

start the measurement.

The screen to the side is shown on the display when

the hourglass icon indicates the performance of the

test.

10 At the end of the test, if the tripping current is within the

values of the table in the relevant §, the instrument

displays the

symbol to indicate the positive

outcome of the test and displays a screen like the one

to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

11 At the end of the test, if the tripping current is not within

the values of the table in the relevant §, the instrument

displays the symbol to indicate the negative

outcome of the test and displays a screen like the one

to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

12

For RCD type A and B it is possible to have a positive

outcome also if the result is higher then the selected

nominal current. This is due to the “REAL” option

visualization selected (see § 6.3 – point 6)

Page 29

GSC60

EN - 27

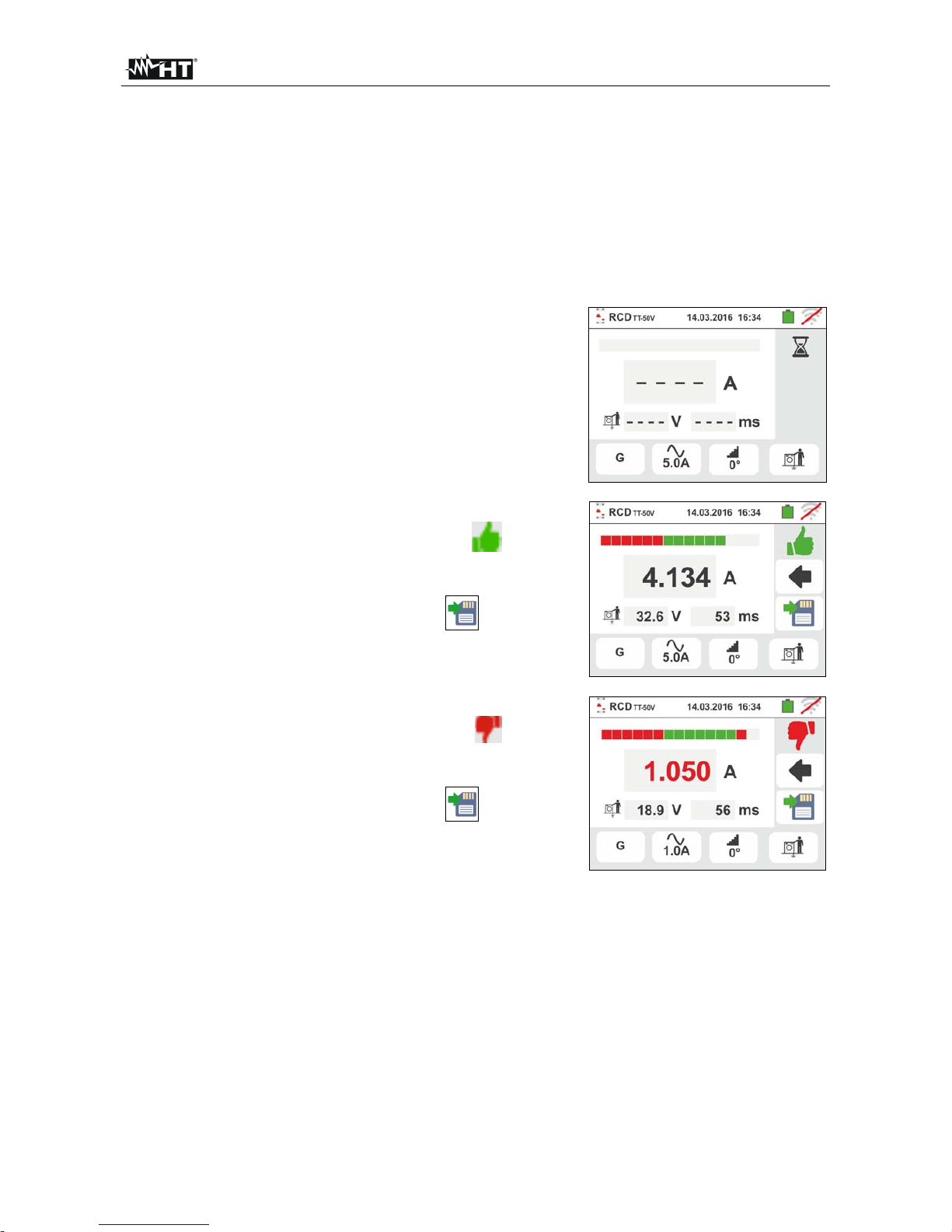

6.3.5. Test on earth leakage relay RCD

The instrument allows performing tests on earth leakage relay RCD with currents up to

10A (with optional accessory RCDX10)

8. Connect the instrument and the optional accessory RCDX10 to the installation (see Fig.

16). Pay attention to the connection of cables “1” and “2” of the RCDX10 accessory

and to the direction of the current indicated by the arrow printed on the accessory. It is

also possible to use the remote lead by inserting its multipolar connector into input lead

B1

9.

Press the GO/STOP key for 2s on the instrument or the

START key on the remote lead. The instrument will

start the measurement.

The screen to the side is shown on the display when

the hourglass icon indicates the performance of the

test.

10 At the end of the test, if the tripping current is lower to

the set value, the instrument displays the symbol to

indicate the positive outcome of the test and displays a

screen like the one to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1)

11 At the end of the test, if the tripping current is higher to

the set value, the instrument displays the symbol to

indicate the negative outcome of the test and displays a

screen like the one to the side.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1)

Page 30

GSC60

EN - 28

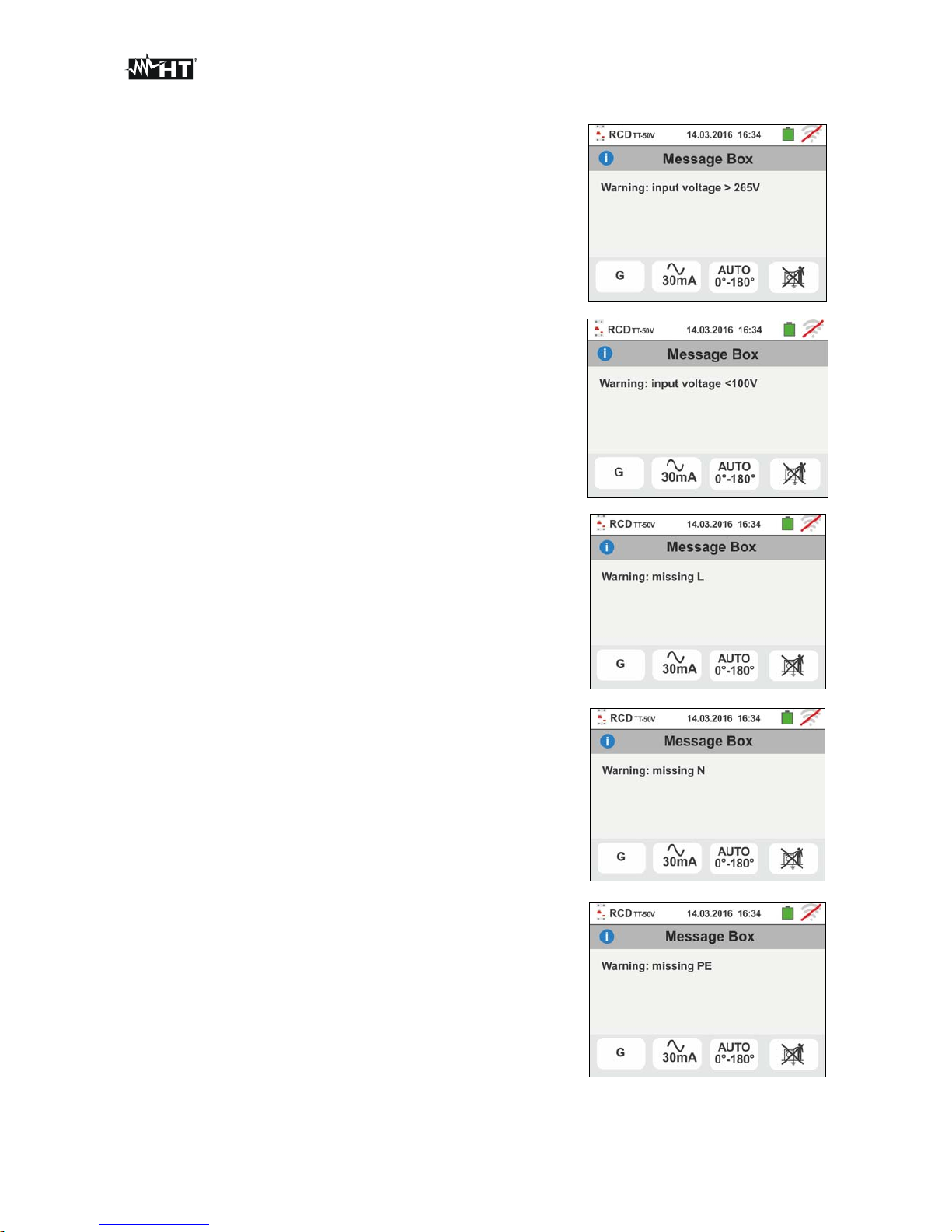

6.3.6. Anomalous situations

1. If the voltage between inputs B1 and B4 and inputs B1

and B3 is higher than 265V, the instrument provides the

warning screen shown to the side and blocks the

execution of the tests.

2. If the voltage between inputs B1 and B4 and inputs B1

and B3 is lower than 100V, the instrument provides the

warning screen shown to the side and blocks the

execution of the tests.

3. If the instrument detects the absence of the signal to

terminal B1 (phase conductor), it provides the warning

screen shown to the side and blocks the execution of

the tests.

4. If the instrument detects the absence of the signal to

terminal B4 (neutral conductor), it provides the warning

screen shown to the side and blocks the execution of

the tests.

5. If the instrument detects the absence of the signal to

terminal B3 (PE conductor), it provides the warning

screen shown to the side and blocks the execution of

the tests.

Page 31

GSC60

EN - 29

6. If the instrument detects that the phase and neutral

leads are inverted, it does not carry out the test and a

screen similar to the one reported to the side is

displayed. Rotate the shuko plug or check the

connection of measuring cables.

7. If the instrument detects that the phase and PE leads

are inverted, it does not carry out the test and a screen

similar to the one reported to the side is displayed.

Check the connection of measuring cables.

8. If the differential switch being tested trips during the

preliminary checks (performed automatically by the

instrument before executing the selected test), the

instrument does not carry out the test and displays a

screen like the one to the side. Check that the IdN set

value is consistent with the differential switch in

question and that all loads connected downstream of it

are disconnected.

9. If the instrument detects a dangerious voltage on PE

conductor it provides the warning screen shown to the

side and blocks the execution of the tests. Check the

PE conductor and earth plant efficiency. This message

can also appair in case of an insufficient pressure of the

GO/STOP key

10 If the instrument detects a dangerious contact voltage

Ut (over the set limit 25V or 50V) in the starting pretest, it provides the warning screen shown to the side

and blocks the execution of the tests. Check the PE

conductor and earth plant efficiency

Page 32

GSC60

EN - 30

11 If the instrument detects a voltage Vn-pe > 50V (or the

analogue Vn-pe >25V) it provides the warning screen

shown to the side and blocks the test for safety

reasons. Check the PE conductor and earth plant

efficiency

12 If the instrument detects in the input terminals a too

high external impedance such that it can not provides

the nominal current, it provides the warning screen

shown to the side and blocks the test. Disconnect the

possible loads downstream the LCD before perform the

test

13

For only RCD type B if the instrument is not able to

provide for the charging of the internal capacitors of the

RCD, it provides the warning screen shown to the side

and blocks the test. Check that the VL-N voltage should

be more than 190V

14

For only RCD type B if the instrument detects a input

voltage VL-N <190V, it provides the warning screen

shown to the side and blocks the test. Chech the values

of the voltages on the installation

15

For test on earth leakage relay RCD if the value set

for the rated current of the protection device is out of

the allowed range, the instrument provides the warning

screen shown to the side and stops the tests. Change

the value of the rated current of the protection device

Page 33

GSC60

EN - 31

6.4. LOOP: LINE IMPEDANCE/LOOP AND OVERALL EARTH RESISTANCE

This function is performed in compliance with standard IEC/EN61557-3 and allows

measuring the line impedance, the fault loop impedance and the prospective short-circuit

current.

CAUTION

The instrument can be used for measurements on installations with

overvoltage category CAT IV 300V to earth and max 600V between inputs.

Do not connect the instrument on installations with voltage exceeding the

limits indicated in this manual. Exceeding these limits could cause electrical

shock to the user and damage to the instrument.

Always connect the measuring cables to the instrument and to the alligator

clips with the accessories disconnected from the system

We recommend holding the alligator clip respecting the safety area created

by the hand protection (see § 4.2).

CAUTION

Depending on the selected electrical system (TT, TN or IT) some kind of

connection and function modes are disabled by the instruments (see Table 2 )

The following operating modes are available

L-N Standard (STD) measurement of the line impedance between the phase

conductor and the neutral conductor and calculation of the assumed phase-toneutral short-circuit current. This measurement is carried out even with high

resolution (0.1m) through the optional accessory IMP57.

L-L Standard (STD) measurement of the line impedance between the two phase

conductors and calculation of the assumed phase-to-phase short-circuit current.

This measurement is carried out even with high resolution (0.1m) through the

optional accessory IMP57.

L-PE Standard (STD) measurement of the fault loop impedance between the phase

conductor and the earth conductor and calculation of the assumed phase-toearth short-circuit current. This measurement is carried out even with high

resolution (0.1m) through the optional accessory IMP57.

Ra Global earth resistance without causing the differential protections tripping in

systems with and without neutral (see § 12.11)

CAUTION

The measurement of line impedance or fault loop impedance involves the

circulation of a maximum current according to the technical specifications of

the instrument (see § 10.1). This could cause the tripping of possible

magnetothermal or differential protections at lower tripping currents.

Fig. 17: P-N/P-PE measure for single-phase/two-phase 230V systems with shuko plug

Page 34

GSC60

EN - 32

Fig. 18: P-N/P-PE measure for single-phase/two-phase 230V with cables and remote lead

Fig. 19: P-N/P-PE test for 400V+N+PE by means of single cables and remote lead

Fig. 20: P-P test for 400V+N+PE three-phase systems

Fig. 21: P-PE/P-N test for 400V + PE (no N) by means of single cables and remote lead

Fig. 22: P-PE measurement for IT systems by means of single cables and remote lead

Page 35

GSC60

EN - 33

6.4.1. Test types

The protection of electrical lines is the essential part of a project so as to guarantee the

correct functionality and avoid damages to persons or property. To this purpose, the safety

guidelines impose on electrical designers also to design the electrical installation in order to

reach:

1. The protection from short-circuits, that’s to say:

The breaking capacity of the protection device must be not lower than the supposed

short-circuit current in the point in which the device is installed

In case of short-circuit in any point of the protected line, the protection device must

trip on quickly enough to avoid that the insulation materials assume excessive

temperatures

2. The protection from indirect contacts.

In order to verify the a.m. conditions, the instrument performs the following functions:

Check of protection from indirect contact – According to the type of

distribution system (TT, TN, IT) set by the user, the instrument performs the

measurement and verifies the condition imposed by the guidelines. Should it

be reached, the instrument gives a positive outcome (see § 12.6, § 12.7,

§12.8)

kA Check of protection’s breaking capacity – The instrument detects the value

of the line impedance upstream to the measurement point, calculates the

maximum value of short-circuit current and gives a positive outcome if the

value is lower than the limit set by the user (see § 12.5)

I2t Check of protection from short-circuits – The instrument detects the value

of the line impedance upstream to the measurement point, calculates the value

of short-circuit current and the corresponding value of the trip out time (t) of the

protection device and gives a positive outcome if the value of specific energy

passing through the protection device is lower than the specific short-circuit

energy bearable by the cables according to the known relationship (see §

12.10):

tISK

2

2

*

where K and S are parameters of the cable, set by the user, that’s to say:

K= parameter indicated by the guideline depending on the type of conductor

material and on the material of the insulating sheath

S = section of the cable

To completion of the above checks, the instrument performs also:

Check of the coordination of protections – The instrument detects the value

of the line impedance upstream to the measurement point, calculates the

minimum value of short-circuit current and the corresponding value of the trip

out time (t) of the protection device and gives a positive outcome if the value is

lower than the limit set by the user (see § 12.9)

STD

Generic test

The IMP57 optional accessory allows the instrument to perform both individual and high

resolution (0.1m) Line/Loop impedance measurements

Page 36

GSC60

EN - 34

The following table summarizes the possible measures executable depending on the type of

system (TT, TN and IT), of selected modes and the relationships that define limit values

TT TN IT

Mode Condition x OK outcome Condition x OK outcome Condition x OK outcome

L-L

STD

No outcome No outcome No outcome

kA

Isc L-L max < BC Isc L-L max < BC Isc L-L max < BC

I2t

(Isc L-L 3F)

2

* t < (K * S)2 (Isc L-L3F)2 * t < (K * S)2 (Isc L-L3F)2 * t < (K * S)2

(IscL-Lmin 2F) Tmax Tmax < Tlim (IscL-L min 2F) Tmax Tmax < Tlim (IscL-Lmin 2F) Tmax Tmax < Tlim

L-N

STD

No outcome No outcome No outcome

kA

Isc L-N max < BC Isc L-N max < BC Isc L-N max < BC

I2t

(Isc L-N)

2

* t < (K * S)2 (Isc L-N)2 * t < (K * S)2 (Isc L-N)2 * t < (K * S)2

(Isc L-N min ) Tmax Tmax < Tlim (Isc L-N min ) Tmax Tmax < Tlim (Isc L-N min ) Tmax Tmax < Tlim

L-PE

STD

No outcome

kA

Isc L-PE max< BC

I2t

(Isc L-PE)

2

* t < (K * S)2

(Isc L-PE min ) Tmax Tmax < Tlim

Tlim Ia Isc L-PE MIN > Ia Utmeas < Utlim

Ra

(No for

IMP57)

STD

kA

I2t

(Rameas * Idn) < Utlim Isc L-PE MIN > Idn

Table 2: Conditions of positive outcome depending on the test parameters

Where:

Empty cells Not available mode for this particular combination of electric system

Isc L-L_3F Prospective short circuit current three-phase Phase-Phase (see § 12.5)

Isc L-L_Min2F Prospective short circuit current minimum two-phase Phase-Phase (see § 12.9)

Isc L-N_Max Prospective short circuit current maximum Phase-Neutral (see § 12.5)

Isc L-N_Min Prospective short circuit current minimum Phase-Neutral (see § 12.9)

Isc L-PE_Max Prospective short circuit current maximum Phase-PE (see § 12.5)

Isc L-PE_Min Prospective short circuit current minimum Phase-PE (see § 12.9)

BC Breaking Capacity of the protection device - kA)

K Constant relative to the I2t measurement (vedere § 12.10)

S Section of conductor

Tmax Maximum trip out time of the protection device

Tlim Limit time of fault extinction by the protection set by the user

Ut meas Contact voltage measured

Ut lim Contact voltage limit (25V or 50V)

Ra meas Global earth resistance measured

Idn Trip out current of RCD devices

Page 37

GSC60

EN - 35

6.4.2. STD Mode – Generic test

This mode performs the impedance measurement and the calculation of prospective short

circuit current without applying any evaluation. Therefore, at the end of the test, no outcome

is given by the instrument.

1. Select the options “TN, TT or “IT”, “25 or 50V”, “50Hz or

60Hz” and the reference voltage in the general settings

of the instrument (see § 5.1.4).

Touch the icon. The screen to the side appears

on the display.

Touch the lower icon. The following screen appears on

the display:

2.

Move the left slide bar reference by selecting the icon

to execute the measurement only with the instrument or

the icon to execute the measurement with the

instrument + optional accessory IMP57 (see § 6.4.10).

Move the central slide bar reference by selecting the "

L-L, L-N or L-PE” options. Move the right slide bar

reference by selecting the "STD" option. Confirm the

choice by going back to the previous screen.

3. If possible, disconnect all loads connected downstream of the measuring point, as the

impedance of these users could distort the test results.

4. Connect the shuko plug, the alligator clips or the remote lead to the electrical mains

according to Fig. 17, Fig. 18, Fig. 19 and

Fig. 21.

5. Note the presence of the correct voltage values

between L-N and L-PE corresponding to the selections

carried out in the initial phase (see § 5.1.4) as shown in

the screen to the side.

Press the GO/STOP key for 2s or the START key on

the remote lead. During this whole stage, do not

disconnect the measuring leads of the instrument from

the system under test. The following screen appears on

the instrument's display:

Page 38

GSC60

EN - 36

6. The value of the assumed short-circuit current (Isc) is

shown in the upper part of the display, while the

Line/Loop ZPE impedance is shown at the bottom of the

display.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

The Standard (Std) assumed short-circuit current (Isc)

is calculated using the following formula:

MEAS

NOM

SC

Z

U

I

Z

MEAS

= measured L-L,L-N,L-PE loop impedance

U

NOM

= nominal voltage (depend on the system)

Page 39

GSC60

EN - 37

6.4.3. Mode kA – Verify of breaking capacity of protection device

1. Select the options “TN, TT or “IT”, “25 or 50V”, “50Hz or

60Hz” and the reference voltage in the general settings

of the instrument (see § 5.1.4).

Touch the icon. The screen to the side appears

on the display.

Touch the lower icon. The following screen appears on

the display:

2.

Move the left slide bar reference by selecting the

icon to execute the measurement only with the

instrument or the icon to execute the

measurement with the instrument + optional accessory

IMP57 (see § 6.4.10).

Move the central slide bar reference by selecting the

“L-L”, “L-N” or “L-PE” options (for TN systems only).

Move the right slide bar reference by selecting the "kA"

option.

Touch the icon in the lower right corner to set the

maximum tripping current expressed in "kA" that the

protection must interrupt. The following screen appears

on the display:

3.

Touch the icon to zero the value in the kA field and

use the virtual keyboard to set the value of the breaking

capacity of the protection between 1kA and 9999kA

Confirm the choice by going back to the initial

measurement screen.

4. If possible, disconnect all loads connected downstream

of the measured point, as the impedance of these users

could distort the test results. Connect the shuko plug,

the alligator clips or the remote lead to the electrical

mains according to Fig. 17, Fig. 18, Fig. 19 and

Fig. 21 in the nearest possible point to the protection

device

Note the presence of the correct voltage values

between L-L and L-PE corresponding to the selections

carried out in the initial phase (see § 5.1.4) as shown in

the screen to the side.

Page 40

GSC60

EN - 38

5.

Press the GO/STOP key for 2s or the START key on

the remote lead. During this whole stage, do not

disconnect the measuring leads of the instrument from

the system under test.

In case of positive outcome, the screen to the side is

shown by the instrument.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

6. In case of test failure (measured Isc Max current > set

threshold), the screen to the side is displayed by the

instrument.

Note the presence of the measurement result

highlighted in red.

Press the SAVE button or touch the icon to save

the measurement (see § 7.1).

Page 41

GSC60

EN - 39

6.4.4. Mode I2t – Verify of protection against short-circuit

CAUTION

The verify of conductor protection against the thermic effect of short-circuit is

performed under the following conditions:

Ambient temperature of 25°C