HST HD102B Installation And Maintenance Instructions Manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

HD102B

Conventional Heat Detector

Before Installing

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: This detector used with the HD10X base must be tested and maintained regularly following NFPA 72

requirements. The detector should be cleaned at least once a year.

General Description

This detector can be used in all areas where heat detector is required. It is suited for fires ranging from heat to flaming fires.

This detector is designed to provide open area protection and to be used with most conventional fire alarm control panel.

Two LEDs on each detector provide local 360° visible for indication of status. In the normal condition the LEDs flash red

every 5 seconds. When the detector senses heat goes into pre-alarm sensitivity the LEDs will flash red every 1 second. When

the detector senses heat and goes into alarm the LEDs will latch on red.

The alarm can be reset only by a momentary power interruption.

Base Terminals

No. Function

1 Remote Indicator (-)

2 Power (-), In

3 Power (-), Out

4 Power (+), Remote Indicator (+)

Specifications

Operating Voltage Range: 16 to 28VDC Volts Non-polarized

Standby Current: 40µA @ 28 VDC(Maximum)

Alarm Current (LED on: ) 30mA @ 28 VDC(Maximum)

Temperature Class: A2R

Operating Temperature Range: 14°F to 122°F (-10°C to50°C)

Operating Humidity Range: 10% to 93% Relative Humidity, Non-condensing

Height: 2.2˝ (55 mm) installed in Base

Diameter: 4.0˝ (103 mm)

Weight: 5.5 oz. (155 g)

Color & Material White/ ABS

Bases HD10X

Compatible control panels Conventional fire alarm control panel

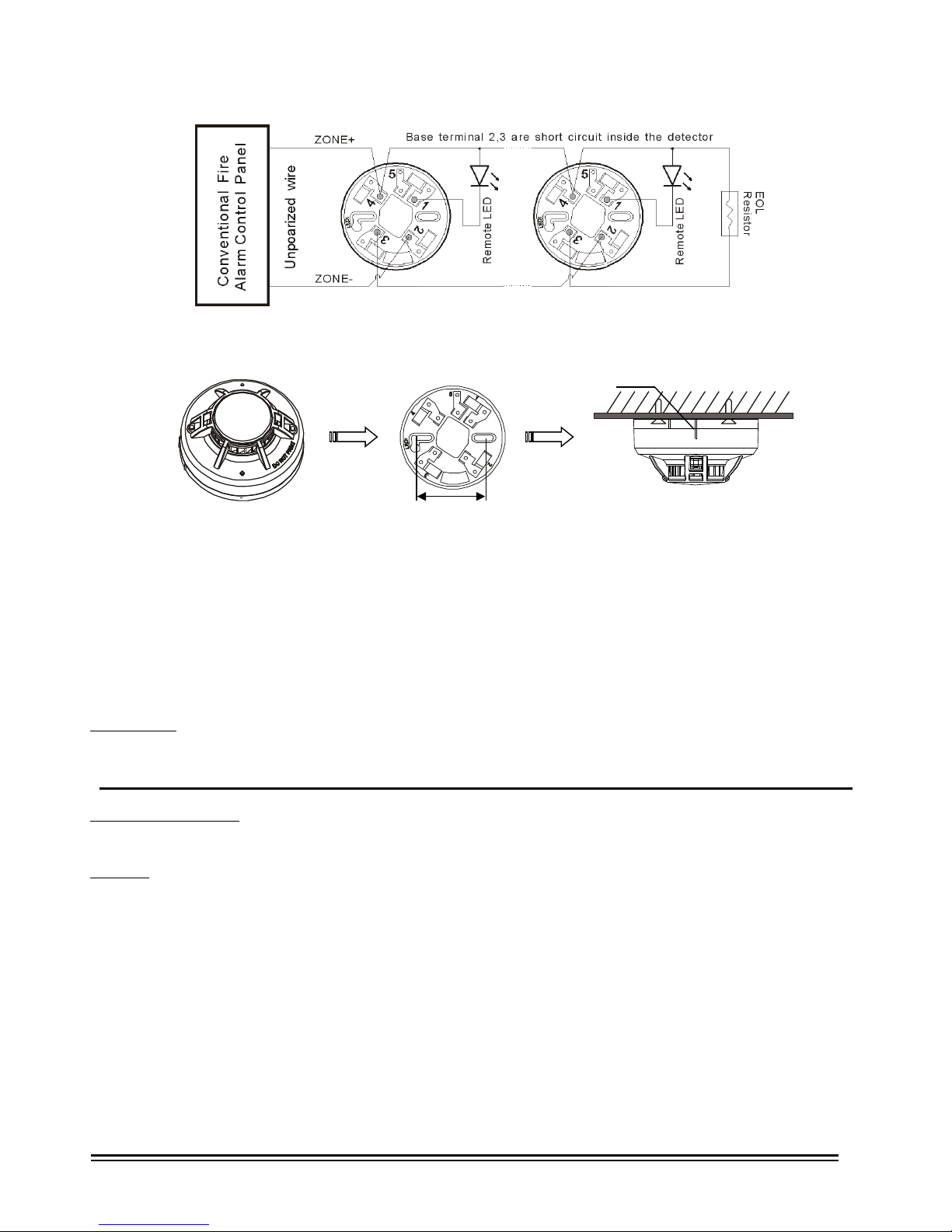

Installation Guidelines (See Figure 2)

All wiring must be installed in compliance with the local codes having jurisdiction. Proper wire gauges should be used. The

conductors used to connect heat detectors to control panels and accessory devices should be color-coded to reduce the

likelihood of wiring errors. Improper connections can prevent a system from responding properly in the event of a fire.

For signal wiring (the wiring between interconnected detectors), it is recommended that the wire be no smaller than 1.0

square mm. Wire sizes up to 2.5 square mm may be used with the base. For best system performance. The Power (+) and

Power(-) wires should be twisted pair and installed in separate grounded conduit to protect the loop from extraneous

electrical interference.

Heat detector and fire alarm system control panels have specifications for allowable loop resistance. Consult the control

panel manufacturer’s for the total loop resistance allowed for the particular model control panel being used before are made

by simply stripping about 3/8 inches (9.5 mm) insulation from the end of the wire. Sliding the bare end of the wire under the

HLogic Security Technology Co., Ltd www. hstfire .com Document Ref: M2115-04 Issue: 5.3 07/2015

Base Terminal

Figure 1. Terminal layout of HD10X base

©

clamping plate.

The wiring of the detector base should be checked before the detector heads are installed in them. The wiring should be

checked for continuity ,polarity in the base, and dielectric tests.

Note: During the installation, Make the rib of the detector align with the rib on the base until it drops into place.(see figure 3)

Note: Dust covers are an effective way to limit the entry of dust into smoke detector sensing chambers. However, they may

not completely prevent airborne dust particles from entering the detector. Therefore, We recommends the removal of

detectors before beginning construction or other dust producing activity.

Be sure to remove the dust covers from any sensors that were left in place during construction as part of returning the system

to service.

Remote LED

The remote indicator is connected between terminals 1 and 4 as showing Figure 2. The remote indicator must be current

limited to 20mA @24V. Maximum. Not limiting current could result in damage to the detector or cause a no alarm condition.

Tamper-Resistance

The detector include a tamper-resistant capability that prevents their removal from the bracket without the use of a tool.

Testing

Before testing, notify the proper authorities that the system is undergoing maintenance, and will temporarily be out of

service. Disable the system to prevent unwanted alarms.

All sensors must be tested after installation and periodically thereafter. Testing methods must satisfy the Authority Having

Jurisdiction (AHJ). Sensors offer maximum performance when tested and maintained in compliance with NFPA 72.

The sensor can be tested in the following ways:

Direct Heat Method (Hair dryer of 1000 – 1500 watts)

1. From the side of the detector, direct the heat toward the sensor. Hold the heat source about 6 inches (15cm)

away to prevent damage to the cover during testing.

2. The LEDs on the detector should light when the temperature at the detector reaches the alarm set point. If the LEDs fail to

light, check the power to the detector and the wiring in the detector base.

3. Reset the detector at the system control panel.

HLogic Security Technology Co., Ltd www. hstfire .com Document Ref: M2115-04 Issue: 5.3 07/2015

Figure 2. Typical wiring diagram

60mm

Figure 3. Install the detector

Rib

Detector Base Installed

Loading...

Loading...