HSS Hire HW055 Operating & Safety Manual

The electrode wire stick out from the MIG gun nozzle should

be between 10mm to 20.0mm. This distance may vary

depending on the type of joint that is being welded.

The speed at which the molten pool travels influences the

width of the weld and penetration of the welding run.

STICK WELDING

Place yourself in a comfortable position before beginning to

weld. Get a seat of suitable height and do as much work as

possible sitting down. Don't hold your body tense. A taut

attitude of mind and a tensed body will soon make you feel

tired. Relax and you will find that the job becomes much

easier. You can add much to your peace of mind by wearing

a leather apron and gauntlets. You won't be worrying then

about being burnt or sparks setting alight to your clothes.

Place the work so that the direction of welding is across,

rather than to or from, your body. The electrode holder lead

should be clear of any obstruction so that you can move your

arm freely along as the electrode burns down. If the lead is

slung over your shoulder, it allows greater freedom of

movement and takes a lot of weight off your hand. Be sure

the insulation on your cable and electrode holder is not

faulty, otherwise you are risking an electric shock.

Practice this on a piece of scrap plate before going on to

more exacting work. You may at first experience

contact with the work and failing to withdraw the electrode

quickly enough. A low amperage will accentuate it. This

freezing-on of the tip may be overcome by scratching the

electrode along the plate surface in the same way as a match

is struck. As soon as the arc is established, maintain a 1.6mm

to 3.2mm gap between the burning electrode end and the

parent metal. Draw the electrode slowly along as it melts

down.

assume you have the wrong equipment for the job. Contact

HSS Hire for advice.

Keep the equipment clean - you will find this less of a

chore if you clean it regularly, rather than wait until the end

of the hire period.

When not in use, store the equipment somewhere

clean, dry and secure.

FINISHING OFF

Switch OFF and unplug the unit. Leave everything to

cool then take the earth clamp off the work.

Where applicable remove the welding rod, disconnect

all leads and coil them up neatly.

Collect all parts together and give them a final clean up

ready for return, to HSS Hire.

HW055/01

HW055/01

Operating & Safety Guide HW055

Operating & Safety Guide HW055

TIG WELDING

TIG Welding is generally regarded as a specialised process

that requires operator competency. While many of the

principles outlined in the previous Arc Welding section are

applicable a comprehensive outline of the TIG Welding

process is outside the scope of this Operating Manual. For

further information please contact HSS Hire.

TECHNICAL SPECIFICATIONS

Primary Voltage

Supply Voltage Range

Number of Phases Single Phase

Supply Frequency 50 / 60 Hz

Generator Requirement 7kVA(230V) / 4.5kVA(110V)

Open Circuit Voltage 79V

Input Current 15A (230V) / 18.3A(110V)

Current Range

Wirefeed Speed Range 2.5-18m/min

230VAC / 110VAC

230V±10% / 110V±10%

10-210A (230V)/10-140A (110V)

EQUIPMENT CARE

Never push the equipment beyond its design limits. If it

will not do what you want with reasonable ease and speed,

GENERAL SAFETY

For advice on the safety and suitability of this equipment

contact HSS Hire.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed prior

to the use of this equipment.

Most welding tasks may be considered as hot work in site

situations and may be subject to specific permits to work.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by a competent adult

who has read and understood these instructions.

Anyone with either a temporary or permanent disability,

should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using cones and

either barriers or tape, available for hire from HSS Hire.

Welding screens are also available for hire from HSS Hire.

WARNING

IF YOU ARE WEARING AN ELECTRONIC LIFE

SUPPORT DEVICE (A HEART PACEMAKER) YOU

MUST CONSULT YOUR DOCTOR BEFORE GOING

NEAR OR WORKING WITH THIS EQUIPMENT.

MAGNETIC FIELDS ASSOCIATED WITH HIGH

CURRENTS MAY AFFECT THESE DEVICES.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or drugs.

Cover your skin. Wear practical, dry, hole-free

footwear. Avoid loose garments and jewellery that could

catch in moving parts, tie back long hair.

Insulate yourself from work and ground using dry

insulating mats or covers.

Ensure the work area is well lit and ventilated, a fume

extractor or smoke eliminator should be used. If in doubt,

ask about lighting and ventilation equipment at HSS Hire.

Do not work near flammable gases or liquids, petrol or

paint thinner fumes for example. Keep combustible

materials at a safe distance - at least 5m.

Watch for fire, and keep a fire extinguisher nearby.

regulations, ear defenders must be worn by everyone in

the vicinity.

suitable. Avoid loose garments and jewellery that could

interfere with the work.

If the headshield o r lens becomes damaged, return it to

HSS Hire.

worn when using this equipment. Respiratory protective

equipment is available for hire, contact HSS Hire for

insulating gloves, protective clothing and

This equipment generates potentially harmful

noise levels. To comply with health and safety at work

A head shield with suitable shading MUST be worn

by anyone in the work area – goggles are not

Fumes produced by the welding process, if inhaled,

can be harmful to health. A suitable mask must be

... have you been trained

The law requires that personnel using this type of equipment in

the workplace must be competent and qualified to do so.

Training is available at HSS Training

0845 766 7799

…any comments?

If you have any suggestions to enable us to improve the

information within this guide please e-mail your comments or

write to the Safety Guide Manager at the address below

e-mail: safety@hss.com

©HSS Hire Service Group Ltd 2013 No. HW055/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.com

details.

Do not weld in locations near degreasing, cleaning, or

spraying operations. The heat and rays of the arc can react

with vapours to form highly toxic and irritating gases.

Do not weld on coated metals, such as galvanized lead,

or cadmium plated steel, unless the coating is removed

from the weld area, the area is well ventilated, and if

necessary, while wearing an air supplied respirator. The

coatings and any metals containing these elements can

give off toxic fumes if welded.

Never use welding equipment near computers or any

sensitive electronic equipment. Observe potential

electromagnetic problems in the surrounding area.

Make sure you know how to switch this machine OFF

before you switch it ON in case you get into difficulty.

If working above floor level, wear a safety harness to

prevent falling.

Always switch equipment OFF before making any

adjustments to it. Never leave it switched ON and

unattended.

LET IT COOL

HANDLE WELDING EQUIPMENT AND WORK

WITH CARE – IT WILL BE HOT. LEAVE EQUIPMENT

TO COOL BEFORE CHANGING WELDING RODS,

MOVING EARTH CLAMPS, AND SO ON.

Keep the power unit’s air vents clear of all obstructions.

Always transport, store and operate the machine in an

upright position.

Never dip electrode holder in water to cool it or lay it

down on the ground or the work surface. Do not touch

holders connected to two welding machines at the same

time or touch other people with the holder or electrode.

Do not wrap cables around your body.

Always ground the workpiece to a good electrical (earth)

ground.

Do not touch electrode while in contact with the work

(ground) circuit.

Use protective screens or barriers to protect others from

flash and glare; warn others not to watch the arc.

Turn off all equipment when not in use. Disconnect power

to equipment if it will be left unattended or out of service.

Do not touch live electrical parts.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

HSS Hire.

COSHH information sheets are available from HSS Hire.

VEHICLE SAFETY

BEFORE CARRYING OUT WELDING WORK ON

CARS/LORRIES AND SIMILAR VEHICLES...

REMOVE THE VEHICLE’S BATTERY AND DISCONNECT

THE ALTERNATOR.

REMOVE ALL COMBUSTIBLE MATERIAL AND OTHER

FIRE/EXPLOSION HAZARDS.

200 amp Mig

200 amp Mig

Welder

Welder

Provides excellent welding

performance across a broad

range of applications

Code 55308

GAS CYLINDERS

IF WORKING WITH GAS CYLINDERS HANDLE THEM

WITH CARE. IF DAMAGED, A CYLINDER CAN

PROTECT COMPRESSED GAS CYLINDERS FROM

EXCESSIVE HEAT, MECHANICAL SHOCKS, AND ARCS.

INSTALL AND SECURE CYLINDERS IN AN UPRIGHT

POSITION BY CHAINING THEM TO A STATIONARY

SUPPORT OR EQUIPMENT CYLINDER RACK TO

PREVENT FALLING OR TIPPING.

KEEP CYLINDERS AWAY FROM ANY WELDING OR

OTHER ELECTRICAL CIRCUITS.

NEVER ALLOW A WELDING ELECTRODE TO TOUCH

EXPLODE.

ANY CYLINDER.

SAFETY OUTFIT

Hearing

protection

Gloves

Boots

Welding helmet

Flame-proof

clothing

ELECTRICAL SAFETY

The HSS 200 amp Mig Welder unit must be powered from a

230/110V mains supply, Extension leads must always be

protected by armoured cable.

Keep flexes and leads out of harm’s way. Never run them

through water, over sharp edges, or where they could

trip someone.

If the welder fails, or if its flex or plug (if fitted) gets

damaged, return it. Never try to repair it yourself.

Do not use electrical equipment in very damp or wet

conditions, it can be dangerous.

WARNING

TOUCHING LIVE ELECTRICAL PARTS CAN CAUSE

FATAL SHOCKS OR SEVERE BURNS. THE ELECTRODE

AND WORK CIRCUIT IS ELECTRICALLY LIVE

WHENEVER THE OUTPUT IS ON. THE INPUT POWER

CIRCUIT AND MACHINE INTERNAL CIRCUITS ARE

ALSO LIVE WHEN POWER IS ON.

The ON/OFF switch (front panel) is the main circuit

Push

Vertical

Drag/Pull

breaker. The Power Indicator display illuminates when

the power switch is in the ON position.

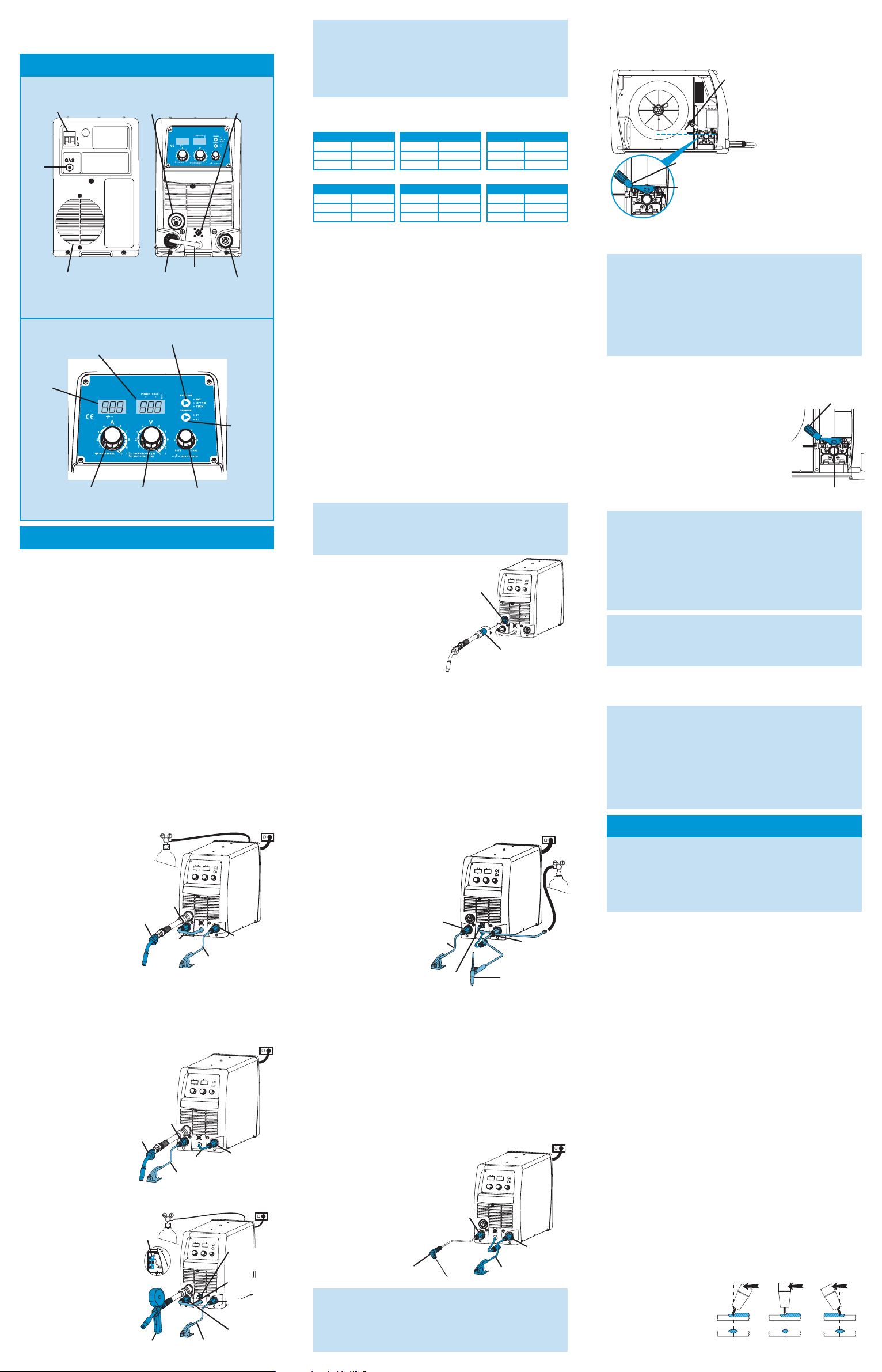

IDENTIFIER

On / Off

Switch

Gas

Inlet

Digital

Amps

Meter

Cooling

Fan

Digital

Voltage

Meter

Amperage/

Wirespeed

switch

MIG

Gun

Adaptor

Positive

Welding

Output

MIG

Polarity

Lead

Terminal

Process Selection

Control

Voltage

switch

(Inductance)

Arc Control

Remote

Control

Socket

Negative

Welding

Output

Terminal

Trigger

Mode

Control

switch

GETTING STARTED

The HSS 200 amp Mig Welder is a self contained single

phase multi process welding inverter that is capable of

performing MIG (GMAW/FCAW), STICK (MMA) and LIFT TIG

(GTAW) welding processes. The unit is equipped with an

integrated wire feed unit, digital voltage and amperage

meters, and a host of other features in order to fully satisfy

the broad operating needs of the modern welding

professional.

Never use the 200 amp Mig Welder until you have fully

read and understood this User Guide and the machine has

been properly set up using the information it contains.

WARNING

WELDING PRODUCTS AND WELDING PROCESSES CAN

CAUSE SERIOUS INJURY OR DEATH, OR DAMAGE TO

OTHER EQUIPMENT OR PROPERTY, IF THE OPERATOR

DOES NOT STRICTLY OBSERVE ALL SAFETY RULES

AND TAKE PRECAUTIONARY ACTIONS.

It is important that the equipment duty cycle is taken

into consideration when in use.

Duty Cycle for 110V Power

MIG DUTY CYCLE

140A 20%

99A 60%

77A 100%

Duty Cycle for 230V Power

MIG DUTY CYCLE

210A 20%

130A 60%

101A 100%

STICK DUTY CYCLE

125A 20%

80A 60%

60A 100%

STICK DUTY CYCLE

200A 20%

130A 60%

101A 100%

TIG DUTY CYCLE

200A 20%

130A 60%

101A 100%

TIG DUTY CYCLE

200A 20%

130A 60%

101A 100%

This welding power source is protected by a self resetting

thermostat. The indicator will illuminate if the duty cycle of

the power source has been exceeded. Should the thermal

overload indicator illuminate the output of the power

source will be disabled. Once the power source cools down

this light will go OFF and the over temperature condition

will automatically reset. Note that the mains power switch

should remain in the on position such that the fan

continues to operate thus allowing the unit to cool

sufficiently. Do not switch the unit off should a thermal

overload condition be present.

TRANSPORTING METHODS

This unit is equipped with a handle for carrying purposes.

Lift unit with handles built into the top of the front and rear

moulded panels.

Use handcart or similar device of adequate capacity.

If using a fork lift vehicle, place and secure unit on a proper

skid before transporting.

PREPARING FOR WORK

Place the unit on the stable, levelled ground at a distance

of 300mm or more from the walls or similar that could

restrict natural air flow for cooling. Make sure the area

is free from moisture, dust, oil, steam and corrosive

gases. It is important to operate the machine in ambient

temperature between 0oC and 40oC.

DANGER!

ALWAYS MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF BEFORE UNDERTAKING ANY TYPE OF

ATTACHING MIG GUN

Fit the MIG gun to the

power source by pushing

the MIG gun connector into

the MIG gun adaptor and

screwing the plastic nut

clockwise to secure the MIG

gun to the MIG gun

adaptor.

INTERVENTION ON THE WELDER

MIG Gun

Adaptor

MIG Gun

Connector

INSERTING WIRE INTO THE WIRE FEED MECHANISM

Release the tension from the pressure roller by turning the

adjustable wire drive tension screw in an anti-clockwise

direction. Then to release the pressure roller arm push

MIG Welding

the tension screw

toward the front of the

Wire

machine which

releases the pressure

roller arm. With the

MIG welding wire

feeding from the

bottom of the spool

Wire Drive

Tension

Screw

Pressure

Roller Arm

through the inlet guide, between

the rollers, through the outlet

guide and into the MIG gun. Resecure the pressure roller arm and

pass the electrode wire

wire drive tension screw and adjust

the pressure accordingly. Remove

the contact tip from the MIG gun. With the MIG gun lead

reasonably straight, feed the wire through the MIG gun by

depressing the trigger switch. Fit the appropriate contact tip.

DANGER!

BEFORE CONNECTING THE WORK CLAMP TO THE

WORK MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

THE WELDING WIRE WILL BE AT WELDING VOLTAGE

POTENTIAL WHILE IT IS BEING FEED THROUGH THE

SYSTEM.

KEEP MIG GUN AWAY FROM EYES AND FACE.

FEED ROLLER PRESSURE ADJUSTMENT

The pressure (top) roller applies pressure to the grooved

feed roller via an adjustable pressure

screw. These devices should be adjusted

Wire Drive

Tension Screw

to a minimum pressure that will provide

satisfactory WIREFEED without slippage. If

slipping occurs, and inspection of the wire

contact tip reveals no wear, distortion or

burn back jam, the conduit liner should be

checked for kinks and clogging by metal

flakes and swarf. If it is not the cause of

slipping, the feed roll pressure can be

increased by rotating the pressure screw

clockwise.

Pressure Roller

Arm

DANGER!

BEFORE CONNECTING THE WORK CLAMP TO THE

WORK MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

SECURE THE WELDING GRADE SHIELDING GAS

CYLINDER IN AN UPRIGHT POSITION BY CHAINING IT

TO A SUITABLE STATIONARY SUPPORT TO PREVENT

FALLING OR TIPPING.

CAUTION!

LOOSE WELDING TERMINAL CONNECTIONS CAN

CAUSE OVERHEATING AND RESULT IN THE MALE

PLUG BEING FUSED IN THE TERMINAL.

MIG (GMAW) WELDING WITH GAS SHIELDED MIG WIRE

The process selection control is used to select the desired

welding mode. Three modes are available, MIG

(GMAW/FCAW), LIFT TIG (GTAW) and STICK (MMA) modes.

Note that when the unit is powered off the mode selection

control will automatically default to MIG mode. This is

necessary so as to prevent inadvertent arcing should an

electrode holder be connected to the unit and mistakenly be

in contact with the work piece during power up.

MIG (GMAW) WELDING WITH GAS SHIELDED MIG WIRE

Select MIG mode with the

process selection control.

Next, connect the MIG

polarity lead to the positive

welding terminal (+).

Fit the MIG gun to the

power source.

Connect the work lead to

the negative welding

terminal (-).

Fit the welding grade

shielding gas regulator /

flow meter to the

Positive

Welding

Terminal (+)

MIG Gun

MIG

Polarit y

Lead

Work Le ad

Negative

Welding

Terminal (-)

shielding gas cylinder, then connect the shielding gas hose

from the rear of the power source to the regulator /

flowmeter outlet.

Refer to the Weld Guide located on the inside of the wirefeed

compartment door for further information.

MIG (FCAW) WELDING WITH GASLESS MIG WIRE

Select MIG mode with the

process selection control.

Connect the MIG polarity

lead to the negative

welding terminal (-).

Connect the work lead to

the positive welding

Positive

Welding

Terminal (+)

terminal(+).

Refer to the Weld Guide

located on the inside of the

wirefeed compartment

door for further

information.

MIG Gun

MIG Polarity

Lead

Work Le ad

Negative

Welding

Terminal (-)

SPOOL GUN MIG (GMAW) WELDING WITH GAS

SHIELDED MIG WIRE

Spool

Gun

Switch

Spool Gun

Work Le ad

Remote

Control

Socket

MIG Polarity

Lead

Negative

Welding

Terminal (-)

Positive

Welding

Terminal (+)

Select MIG mode with the

process selection control.

Connect the MIG polarity

lead to the positive

welding terminal(+).

Fit the Euro Spool Gun to

the power source using

the front panel EURO

adaptor (see Attaching

MIG gun). Connect the 8

pin Remote Control Plug

to the 8 pin Remote

Control Socket on the power source.

Connect the work lead to the negative welding terminal(-).

Fit the welding grade shielding gas regulator / flowmeter to

the shielding gas cylinder, then connect the shielding gas

hose from the rear of the power source to the regulator /

flowmeter outlet.

Refer to the Weld Guide located on the inside of the wirefeed

compartment door for further information.

Select MIG mode with the process selection control.

Set the Spool Gun Switch located inside the wire drive

compartment, to SPOOL GUN.

TIG (GTAW) WELDING

Select LIFT TIG mode with

the process selection

control.

Connect the TIG Torch to

the negative welding

terminal (-).

Connect the work lead to

the positive welding

terminal (+).

Connect the TIG torch

Positive

Welding

Terminal

(+)

Work

Lead

Negative

Welding

Terminal (-)

trigger switch via the 8 pin

socket located on the front

of the power source as

TIG Remote

Control

TIG Torch

shown below. The TIG torch will require a trigger switch to

operate in LIFT TIG Mode.

NOTE: If the TIG torch has a remote TIG torch current control

fitted then it will require to be connected to the 8 pin socket.

Fit the welding grade shielding gas regulator/flowmeter to

the shielding gas cylinder (see MIG Welding With Gas

Shielded Mig Wire) then connect the shielding gas hose from

the TIG torch to the regulator/flowmeter outlet. Note that the

TIG torch shielding gas hose is connected directly to the

regulator/flowmeter. The power source is not fitted with a

shielding gas solenoid to control the gas flow in LIFT TIG

mode therefore the TIG torch will require a gas valve.

STICK (MMA) WELDING

Connect the Electrode

Holder lead to the positive

welding terminal(+).

Connect the work lead to

the negative welding

terminal (-). Select STICK

mode with the process

Positive

Welding

Terminal (+)

selection control.

Negative

Welding

Electrode Holder

Work Le ad

Terminal (-)

DANGER!

BEFORE INSERTING THE ELECTRODE IN THE TIG

TORCH MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

ATTENTION

IF IN DOUBT, WHEN CONNECTING THE WORK LEAD

CONTACT HSS HIRE FOR ADVICE

WELDING CURRENT FLOWS FROM THE POWER

SOURCE VIA HEAVY DUTY BAYONET TYPE

TERMINALS. IT IS ESSENTIAL, HOWEVER, THAT THE

MALE PLUG IS INSERTED AND TURNED SECURELY TO

ACHIEVE A SOUND ELECTRICAL CONNECTION.

BASIC TECHNIQUES

ADVICE

IF YOU HAVE NOT YET DONE ANY WELDING,

PRACTICE ON A PIECE OF SCRAP PLATE BEFORE

GOING ON TO MORE SERIOUS WORK. YOU MAY AT

FIRST EXPERIENCE DIFFICULTY.

MIG WELDING

The easiest welding procedure for the beginner to

experiment with MIG welding is the flat position. The

equipment is capable of flat, vertical and overhead positions.

For practicing MIG welding, secure some pieces of 1.6mm or

1.2mm mild steel plate 150 x 150mm. Use 0.8mm flux cored

gasless wire or a solid wire with shielding gas.

Begin work by setting up power source. Power source has

two control settings that have to balance. These are the

Wirespeed control and the welding Voltage Control. The

welding current is determined by the Wirespeed control, the

current will increase with increased Wirespeed, resulting in a

shorter arc. Less wire speed will reduce the current and

lengthen the arc. Increasing the welding voltage hardly alters

the current level, but lengthens the arc. By decreasing the

voltage, a shorter arc is obtained with a little change in

current level.

When changing to a different electrode wire diameter,

different control settings are required. A thinner electrode

wire needs more Wirespeed to achieve the same current

level.

A satisfactory weld cannot be obtained if the Wirespeed and

Voltage settings are not adjusted to suit the electrode wire

diameter and the dimensions of the work piece.

If the Wirespeed is too high for the welding voltage,

“stubbing” will occur as the wire dips into the molten pool

and does not melt. Welding in these conditions normally

produces a poor weld due to lack of fusion. If, however, the

welding voltage is too high, large drops will form on the end

of the wire, causing spatter. The correct setting of voltage

and Wirespeed can be seen in the shape of the weld deposit

and heard by a smooth regular arc sound. Refer to the Weld

Guide located on the inside of the wirefeed compartment

door for setup information.

The angle of MIG gun to

the weld has an effect

on the width of the

weld. The welding gun

should be held at an

angle to the weld joint.

Hold the gun so that the welding seam is viewed at all times.

Loading...

Loading...