HSS Hire HW038 Operating & Safety Manual

MMA/TIG

AC/DC

Inverter

200 amp

A professional inverter welder with

HF & lift TIG ignition.

Operating & Safety Guide HW038

Set the AC / DC selector as required. Note that

when AC is selected the current wave balance can

be altered via the balance button.

Fit the regulator to an Argon gas cylinder then

connect the gas hose to the regulator and the gas

inlet at the rear of the unit.

STICK WELDING...

Clip the earth clamp to a patch of clean, bright

metal on the workpiece as close to the weld

as possible.

Holding the welding rod at an angle of 60-70

degrees to the surface, move it towards the work

until you strike an arc.

Keep the arc about 3mm long, work slowly along

the weld in a series of semicircular sweeps across

the line of the joint.

Chip off any slag build-up on the weld before

making a second pass along the joint.

Always begin by making a test weld and adjust the

settings as necessary.

TIG WELDING....

Turn on the Argon gas cylinder and adjust the

regulator until the TIG unit’s float gauge registers a

flow of 8-12 litres per minute when you push the

torch button.

Switch the welder ON and adjust the welding

current to the amperage required.

The torch has a dial fitted, which allows the

operator to adjust the amperage while welding. To

use this facility, turn the current control mode selector to

the symbol. The adjuster dial will only decrease the

amperage from the current displayed on the LED, it

cannot increase it.

If the HF setting has been selected, hold the

welding torch at an angle of 60-70 degrees to the

workpiece and about 3mm from the surface, then

press the torch control button to strike an arc.

If the Lift TIG setting has been selected hold the

welding torch with the electrode in contact with

the workpiece press the torch control button and

raise the electrode clear of the surface to strike

the arc.

As soon as a pool of molten metal forms, simply

move the torch slowly along the joint, keeping it at

a constant angle and distance from the surface.

If necessary feed a length of filler rod into the weld

pool’s leading edge as you go.

BASIC TECHNIQUES

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease and speed, assume you have the wrong tool for the

job. Contact your local HSS Hire Shop for advice.

The welders electronic system is protected

against damage from overheating. If overheating

occurs, the system will shut down the welding

process until it has cooled. This is indicated by the

amber temperature lamp.

Keep the equipment clean. You will find this less of a

chore if you clean up regularly rather than wait until the

end of the hire period.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

If TIG welding, replace the gas cylinder as soon as

it runs out. Simply turn OFF and unscrew the regulator

then remove the old cylinder and fit a new one.

Turn off the gas cylinder if leaving the unit

unattended to reduce gas loss through leakage.

IF TIG WELDING…

Turned OFF the Argon gas supply at the cylinder,

switch OFF the welder then disconnect the gas

cylinder.

WHATEVER YOU ARE USING…

Leave everything to cool off before removing the

earth-clamp from the work and disconnecting all

of the unit’s welding leads.

Finally, neatly coil all leads and hoses, ready for

return to your local HSS Hire Shop.

FINISHING OFF

EQUIPMENT CARE

Code 55332/55334

©HSS Hire Service Group Plc 2000 No. HW038/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hireweld.com

Contact your local

0845 728 2828

…any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your

comments or write to the Product Manager at the

address below

Fax: 020 8687 5001

HW038/01

For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Skin must be covered – protective

clothing, footwear and gauntlets must

be worn.

A head shield with a 10 EW shade MUST be

worn by anyone in the work area – goggles

are not suitable.

Fumes produced by the welding process, if

inhaled, can be harmful to health. A suitable

welding mask must be worn when using this

equipment. Respiratory protective equipment is available

for hire, contact your local HSS Hire Shop for details.

A fume extractor or smoke eliminator should be

used in the work area.

If the head shield or lens becomes damaged, return

it to your local HSS Hire Shop for exchange.

Never use welding equipment near any combustible

gases or materials.

Never use welding equipment near computers or

any sensitive electronic equipment.

Always transport, store and operate the machine in

an upright position.

Keep the power unit’s air vents clear of all

obstructions.

Always switch the equipment OFF before making

any adjustments to it. Never leave it switched ON

and unattended.

Let It Cool

Handle welding equipment and work with

care – it will be hot. Leave equipment to cool

before changing welding rods or moving

earth clamps.

GENERAL SAFETY

The HSS 200amp Inverter Welder is available in

two model types, a single voltage 240V PFC

(power fluctuation control) or a dual voltage

240V/415V standard model.

If using a 240V supply the unit can be connected

using a 32A (blue) 240V plug (not supplied) or be

wired direct to a 35A dedicated fuse on the

consumer unit.

If using a 415V 3-phase supply, connect the two

supply wires to two phases and connect the earth

wire to the earth connection.

Whichever you are using, all connections may only

be made or removed by a qualified electrician. Do

ensure the electrician sets the unit’s ON/OFF

switch to suit the supply voltage, failure to do so

could cause the unit to ‘burn out’.

If the equipment fails, or if its power supply cable

becomes damaged, return it. Never try to repair

it yourself.

Keep cables out of harm’s way, and clear of the

work area.

Extension leads should be fully unwound and

loosely coiled, away from the equipment. Never run

them through water, over sharp edges or where they

could trip someone.

Keep the equipment dry, using electrical

equipment in very damp or wet conditions can

be dangerous.

Ensure the welder and the power socket are switched

OFF before plugging into the power supply.

Ensure the workpiece is clean, dry and free from

rust, paint and grease. Aim to weld only bright,

bare metal.

Clamp workpieces securely in their final positions

to stop them moving during welding.

STICK WELDING, (MMA)…

For general purpose welding of mild steel/

fabrication, ideal where applications restrict the

use of gas (oxy-acetylene) systems.

Connect the welding torch and earth clamp to

the terminals on the front of the unit.

The electrode holder to the (+) positive, earth

clamp to the (–) negative.

Attach the earth clamp to the workpiece and fit an

appropriate welding rod to the electrode holder.

GETTING STARTED

ELECTRICAL SAFETY

Turn the function switch to the electrode holder

sign (top) and select the welding mode AC or DC

with the AC/DC switch. Now switch the welder ON

(there is an ON/OFF switch at the rear of the casing).

Turn the current control mode selector to the

then turn the welding current control knob

until the required welding amperage is displayed

on the LED. You are now r eady to stick/MMA weld.

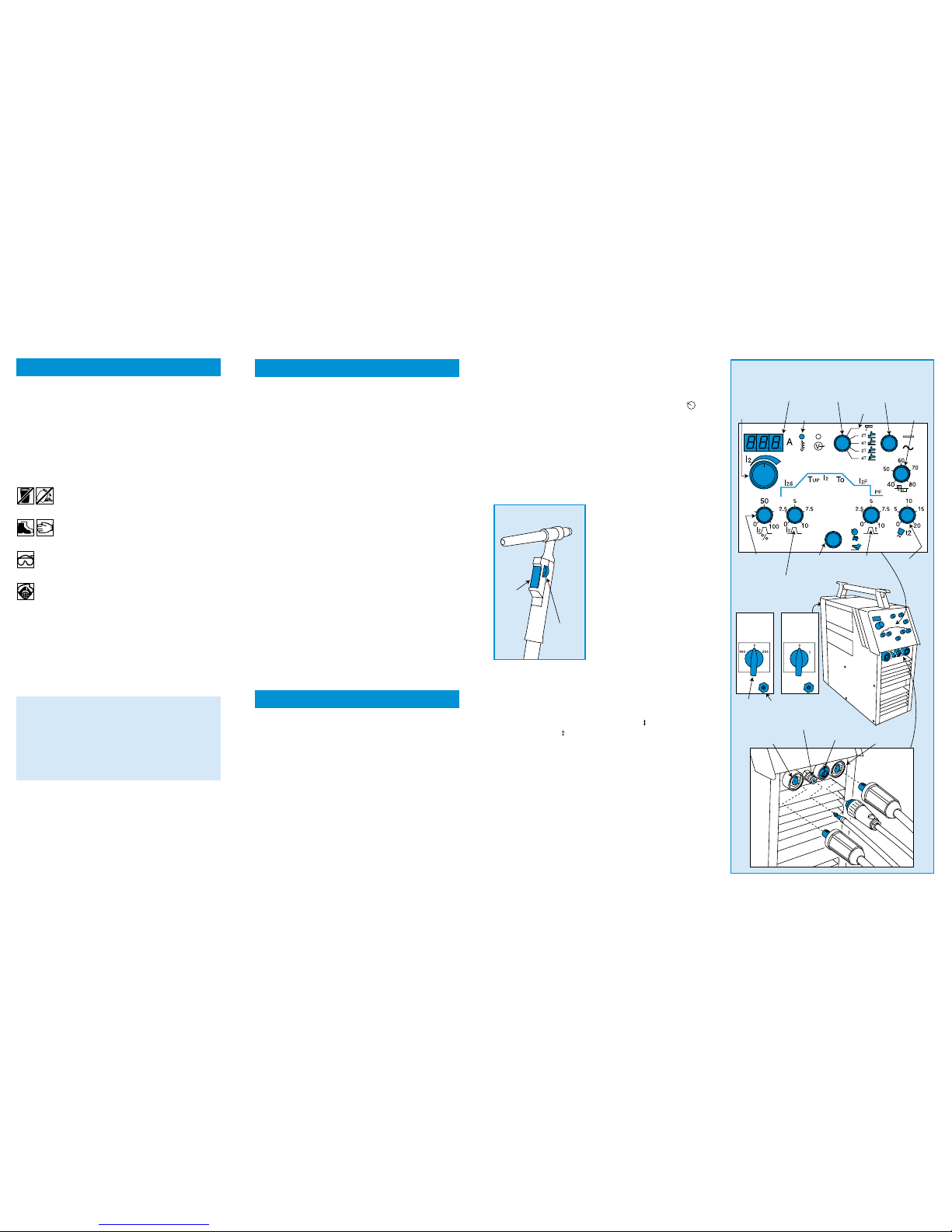

TIG WELDING CONTROLS...

(Tungsten Inert Gas Shield) Used mainly in the

petrochemical industry for welding stainless steel,

aluminium and specialist pipelines.

Ensure the welder is switched OFF and isolated

from its power supply.

Connect the TIG torch and

earth clamp to the

terminals on the front of

the unit, this time with

the earth clamp to the (+)

positive. The TIG torch

has a seven-pin connector

and a gas supply hose,

which should both be

connected.

Set the function switch to

one of the four available

settings.

These settings effect the

way the torch reacts to

each press or release of

the button.

2T (two-touch) press to activate torch, release to

deactivate.

4T (four-touch) press for gas, release to weld, pr ess

again for slope down and release for post flow.

The symbols next to the torch represent the type

of welding current. Either Lift-TIG ( ) or HF-TIG,

high frequency ( ).

If Slope Up (the period of time taken for the current to

increase from establishment of an arc) is to be utilised

set the slope up dial to the required setting (graded

in seconds).

If Slope Down (the period of time taken for the current to

decrease from release of the torch button) is to be utilised

set the slope down dial to the required setting.

When slope is selected, turn the current

percentage dial to select a % of the welding

current, which the slope up will start from and

slope down will close to.

Set the post flow dial (the period of time, after the

welding current has stopped, that gas continues to flow)

as required.

Dual

Voltage

Model

240V

Model

Welding

Current

Control Knob

Current

LCD

Temperature

Lamp

Function

Switch

Stick

Weld

AC/DC

Switch

Balance

Button

Current

Percentage

Dial

Slope

Up

Current

Control

Mode

Selector

Slope

Down

Gas Post

Flow

Gas

Inlet

Gas

Connection

Tig Torch

Socket

+ Connection

– Connection

ON/OFF

Switch

Current

Adjuster

Dial

Torch

Control

Button

TIG Torch

MMA/TIG AC/DC Inverter

Loading...

Loading...