HSS Hire HW011 Operating & Safety Manual

300AMP MIG

Compact

Welder

A compact MIG Unit featuring

standard, spot and stitch welding

facilities.

Operating & Safety Guide HW011

Feed the wire through the wire feed roller and into

the guide. Close the tensioning roller and set the

tension. Feed the wire through to the gun until

25mm of wire is exposed then re-fit the tip.

The welder offers a range of different settings to

suit the type of welding task being performed.

Work through the following list of options selecting the

settings best suited to the work.

Welding Mode Selector Switch…

This allows you to select one of four welding types.

2-times. Squeeze the torch trigger to begin

welding, release to stop.

Spot. Squeeze the torch trigger to begin

welding, then release. Welding will

stop automatically within the time

selected. See Welding Time.

4-times. Squeeze the torch trigger then release

to begin welding, squeeze the trigger

then release a second time to stop.

Burn Back

(fitted inside the wire feed compartment).

Adjusts the time that the wire continues

to be fed after the welding current has

stopped. The time can be set between

0.05 seconds and 0.5 seconds.

Set the welding voltage and wire speed

appropriate to the total thickness of the metal

being welded.

Clamp the workpieces securely in their final

positions.

Ensure the metal to be welded is clean, dry and

free from rust, paint and grease. Aim to weld only

bright, bare metal.

Clip the earth clamp to

the work, as close to the

proposed weld as

possible to ensure good

electrical contact.

Open the gas regulator

to give a flow rate to suit

the wire speed.

Expose about 25mm of

wire before striking an

arc. Hold the welding

gun at an angle of 60-70

degrees to the surface,

squeeze the trigger to strike an arc.

If you have difficulty in striking an arc, snip off all

but about 25mm of exposed wire and try again.

BASIC TECHNIQUES

Continue holding the

trigger, keeping the arc

about 3mm long and

work slowly along the

line of the joint.

DO NOT allow the tip to

touch the work. At the

end of the weld simply

release the trigger.

Never push the equipment beyond its design

limits. If it will not do what you want with

reasonable ease and speed, assume you have the

wrong type or size of welder for the job. Ask at

your local HSS Hire Weld Depot for advice.

When not in use, store the equipment somewhere

clean, dry and safe

from thieves.

Keep the equipment clean. You will find this less of a

chore if you clean it up regularly rather than wait until

the end of the hire period.

Switch OFF and unplug the unit. Leave everything

to cool then take the earth clamp off the work.

Disconnect all leads and coil them up neatly ready

for return

, to your local HSS Hire Weld Depot.

FINISHING OFF

EQUIPMENT CARE

Code 55165

©HSS Hire Service Group Plc 2000 No. HW011/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hireweld.com

…any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your

comments or write to the Product Manager at the

address below

Fax: 020 8687 5001

HW011/01

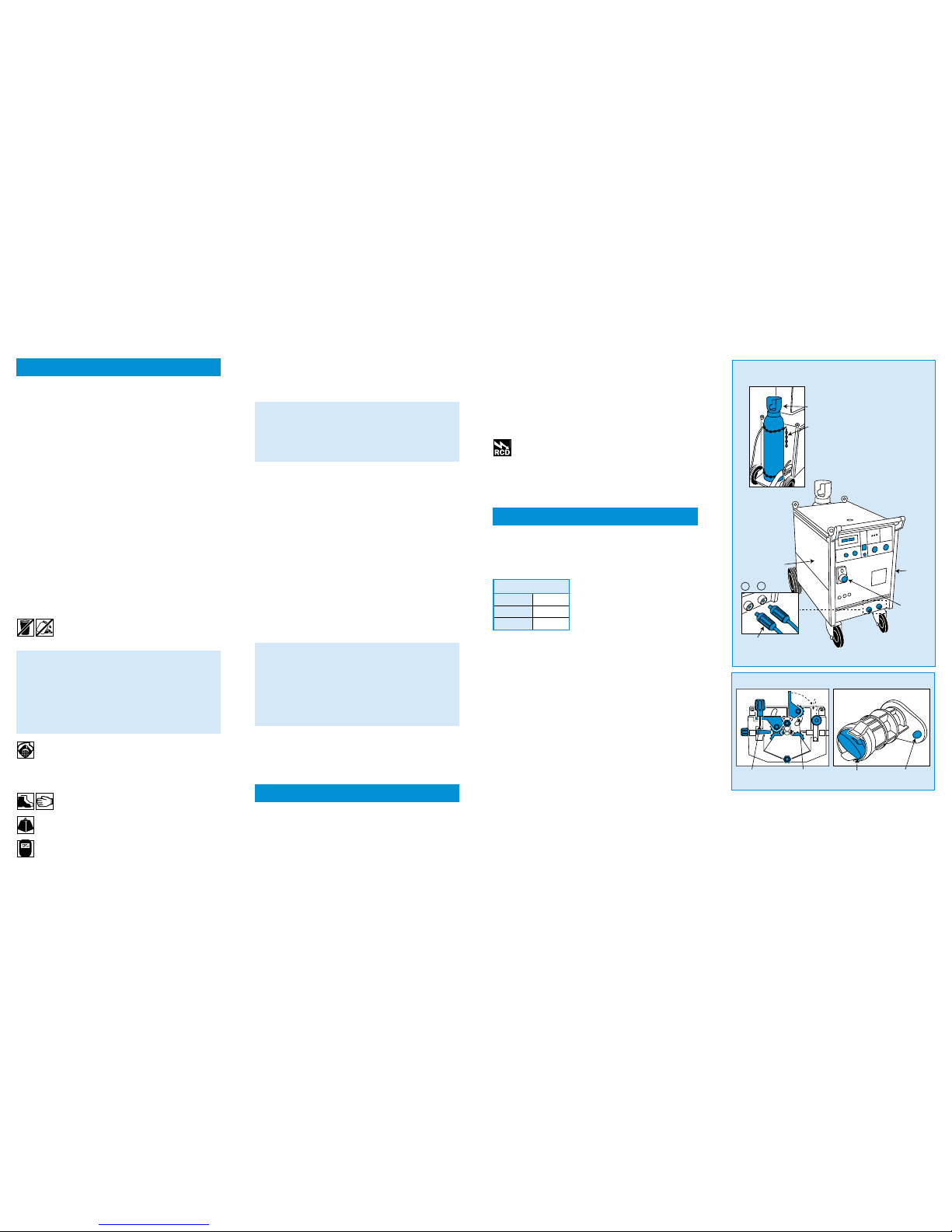

Wire Feed

Speed Dial

Welding

Voltage

ON / OFF

Switch

Welding

Mode

Selector

Welding AMP

& Wire Speed

Welding Voltage

Selector – Coarse

Welding Voltage

Selector – Fine

Control Panels

Trigger

Tip Shield

Torch

Earth Clamp

For advice on the safety and suitability of this equipment

contact your local HSS Hire Weld Depot.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

Most welding tasks may be considered as hot work

in site situations and may be subject to specific

permits to work.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment should be used by an able bodied,

competent adult

who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Hire Weld Depot.

Welding screens are also available for hire from

your local HSS Hire Weld Depot.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Fumes produced by the welding process, if

inhaled, can be harmful to health.

A suitable

mask must be worn when using this equipment.

Respiratory protective equipment is available for

hire

, contact your local HSS Hire Weld Depot for details.

Skin must be covered – wear practical,

protective clothing, gloves and footwear .

This equipment is heavy

(132kg), never attempt

to lift it on your own, always get help.

A head shield with an 11 EW shade MUST be

worn by anyone in the work area – goggles

are not suitable.

Avoid loose garments and jewellery

that could interfere with the work.

Warning

If you are wearing an electronic life support

device (a heart pacemaker) you must consult

your doctor before going near or working with

this equipment. Magnetic fields associated with

high currents may affect these devices.

GENERAL SAFETY

If the headshield or lens becomes damaged, return

it to your local HSS Hire Weld Depot.

Never use welding equipment near computers or

any sensitive electronic equipment.

Always transport, store and operate the machine

in an upright position.

Keep the power unit’s air vents clear of all

obstructions.

Always switch equipment OFF before making any

adjustments to it. Never leave it switched ON and

unattended.

Ensure the work area is well lit and ventilated,

a

fume extractor or smoke eliminator should be used. If in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire Weld Depot.

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example

. Keep combustible

materials at a safe distance -

at least 5m.

Make sure you know how to switch this machine

OFF before you switch it ON

in case you get into

difficulty.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear , return it to

your local HSS Hire Weld Depot.

COSHH information sheets are available from your local

HSS Hire Weld Depot.

The HSS 300A Welding power unit must be

powered from a 415V-3 Phase NO neutral mains

supply, and all mains connections may only be

made by a qualified Electrician.

If the equipment fails, or if its power supply cable

or plug becomes damaged, return it.

Never try to

repair it yourself.

ELECTRICAL SAFETY

Vehicle Safety

Before carrying out welding work on cars/lorries

and similar vehicles...

Remove the vehicle’s battery and disconnect the

alternator.

Remove all combustible material and other

fire/explosion hazards.

Let It Cool

Handle welding equipment and work with care

– it will be hot. Leave equipment to cool before

changing welding rods, moving earth clamps,

and so on.

Keep cables out of harm’s way,

and clear of the

work area

.

Extension leads should be fully unwound and

loosely coiled, away from the equipment.

Never run

them through water, over sharp edges or where they

could trip someone.

Keep the equipment dry, using electrical equipment

in very damp or wet conditions can be dangerous.

To reduce the risk of electric shock, always use

a suitable RCD

(Residual Current-Operated Device)

available from your local HSS Hireweld Depot. Or power

the equipment from a mains circuit with a built in RCD.

Ensure the welder and the power socket are

switched OFF before plugging into the power

supply.

This guide is designed to help the user to safely set

up and dismantle the welder. It is not intended as

a guide to welding techniques as it is assumed

that the user already has the necessary

training/knowledge and experience.

It is important that the

equipment duty cycle is taken

into consideration when in use.

DO NOT use the unit in the

rain or in extremely damp

environments.

Place the unit on a suitable surface and make sure

that there is a minimum of 200mm clearance

around the unit to allow a good circulation of air.

Ensure that the unit is switched OFF and isolated

from the power supply.

Connect the argon gas supply hose to the

regulator then fit the regulator to the argon

cylinder and secure with the spanner supplied.

Chain the cylinder securely to the rear of the unit.

Attach the MIG torch to the connection socket on

the units’ front panel. Simply align the pipes and

pins, insert and lock in place by turning the collar

clockwise.

Connect the earth clamp cable to the negative (–)

terminal 1 or 2 depending on the wire diameter

being used. Terminal 1 for wire sizes from 0.6mm

to 1.0mm and terminal 2 for wire sizes from1.2mm

to 1.6mm.

Remove the wire feed compartment cover.

Remove the welding guns shield and tip, pull

through any remaining wire and remove any

empty roll.

Place a new roll of wire onto the spool holder

making sure that the wire is fed from the bottom of

the roll.

GETTING STARTED

Ensure the brake location pin fits correctly to the

wire roll.Turn the spool holder securing cap by 90°

to retain the wire roll.

You must now switch the welder ON.

Pull approximately 150mm of wire from the roll

ensuring you DO NOT let go of the wire

(as the wire

will spring loose).

Snip the end of the wire to leave a

straight leading piece.

Duty Cycle

335A 35%

300A 60%

240A 100%

Wire Feed

Compartment

Torch

Connection

Socket

Main

Power

Unit

2

1

Earth

Clamps

Chain

Cylinder

300AMP MIG Welder

Tension

Roller

Tension

Adjuster

Securing

Cap

SPOOL HOLDER

Brake

Location Pin

Wire Feed

Loading...

Loading...