HSS Hire 810 Operating & Safety Manual

Portable Turbine and

Large Volume

Turbine

HVLP Sprayer

Hire Shops

Powerful 3 stage turbine sprayer

suitable for spraying multi-flek,

enamel and acrylic finishes. Two

versions available. Portable turbine

unit complete with cup and gun or a

trolley mounted sprayer complete

with 1.9 litre paint pot for larger

applications.

Operating & Safety Guide 810

Always begin by spraying a test pattern on old

newspaper or the like

and adjust the spray-gun’s

controls as required.

Note that the gun has a two-stage trigger.

To spray

you must fully depress the trigger. Depressing it half-way

delivers air only, allowing you to blow any dust off the

surface before spraying.

To change the spray pattern’s shape click the air-

cap to the appropriate position.

Use the vertical

pattern if spraying from side to side, the horizontal

pattern if working up and down and the round pattern

if spraying small areas.

To change the spray pattern’s size and density,

tighten or loosen the air-cap.

Tightening it produces

a coarser spray but a bigger pattern. Loosening it gives a

finer spray and a smaller pattern.

To fine-tune the spray pattern, adjust the air

and/or fluid controls.

The higher the air-to-fluid ratio,

the better the atomisation and the finer the finish.

Reducing the ratio produces special effects.

Once satisfied with the pattern,

paint the area in a

series of horizontal or vertical strips

, each

overlapping its predecessor by about 50%.

For the best results,

move the gun at an even pace,

keeping it parallel to the surface

being painted and

about 150mm to 200mm away from it.

To ensure even coverage at the beginning and end of

each strip,

start the gun moving before you trigger

it and keep it moving after the trigger has been

released.

To spray edges and corners, simply run the gun

along the edge/corner

, keeping this in the centre of

the spray pattern.

For most jobs, hold the gun at right-angles to the

surface being painted.

In windy conditions, though,

angle the gun to spray into the wind and tackle the area

in vertical strips.

Trouble-Shooting

Always check you have been given the correct needle

and nozzle. If in doubt contact your local HSS Hire

Shop.

Correctly set, the spray-gun should produce a uniform,

symmetrical spray pattern. If the pattern is misshapen,

rotate the air-cap and try again.

If the defect rotates with the cap, remove the air-cap

assembly and clean it. If that doesn’t work, the nozzle

may be defective so return the equipment to your

local HSS Hire Shop.

BASIC TECHNIQUES

If using the Portable Turbine model…

Never turn the spray gun upside down or on its

side when spraying.

DO NOT REMOVE THE PAINT CUP while the

machine is running.

WHATEVER you are using…

Never push the equipment beyond its design

limits.

If it will not do what you want with reasonable

ease, assume you have the wrong tool for the job.

Contact your local HSS Hire Shop for advice.

Handle the equipment with care. Avoid dropping it,

knocking it, or otherwise exposing it to damage.

Do not use the unit continuously. Switch off and

leave it to cool for about ten minutes in every hour.

Clean the turbine’s air-filters before starting and at

regular intervals in use.

Having switched off the

turbine, simply lift out the filter pads and slap them to

remove trapped dust before refitting them.

Never spray at or near the machine. The turbine’s

filters will become clogged, seriously damaging the unit.

Keep the unit about 3 metres from the spray area.

If the spray tip gets blocked,

switch OFF and

depressurize the system, then unscrew the nozzle and

wash it thoroughly in the appropriate solvent.

Never attempt to clear blocked nozzles using a pin

or other metal objects.

EQUIPMENT CARE

Never expose the equipment to dangerous and/or

corrosive chemicals.

Keep the equipment clean.

Even if you are taking only

a short break, clean it out as thoroughly as if you were

returning it at the end of the hire period.

Damaged hoses are dangerous so handle them

with care

and coil them neatly, without kinks, for

storage.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

If using the Portable Turbine model…

Turn OFF the turbine and disconnect the small air

hose from the top of the paint-cup

to release the

internal pressure.

Empty the paint-cup and rinse out with the

appropriate solvent.

If using the Large Volume model…

Turn OFF both the turbine and compressor, then

depressurize the pressure pot by both

disconnecting the red air hose and opening the

pressure safety valve.

WHATEVER you are using…

Reset the system for spraying, this time using an

appropriate solvent rather than paint.

With the air adjuster turned down, flush the

system through by spraying the solvent into a

suitable container, repeating the process until the

solvent emerges clean.

That done, clean the outside of the unit and spraygun using a cloth dipped in the appropriate

solvent.

If using cellulose thinners or white-spirit, always

work in a well ventilated area, away from possible

ignition sources. And DO NOT SMOKE.

Finally, disconnect all air-hoses and carefully coil

them ready for return.

FINISHING OFF

Code 61461, 61464

©HSS Hire Service Group Plc 1998 No. 810/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.co.uk

Contact your local

0845 728 2828

…any comments?

If you have any suggestions

which would improve the

information within this guide

please fax your comments or

write to the Product Manager

at the address below

Fax: 0181-687 5001

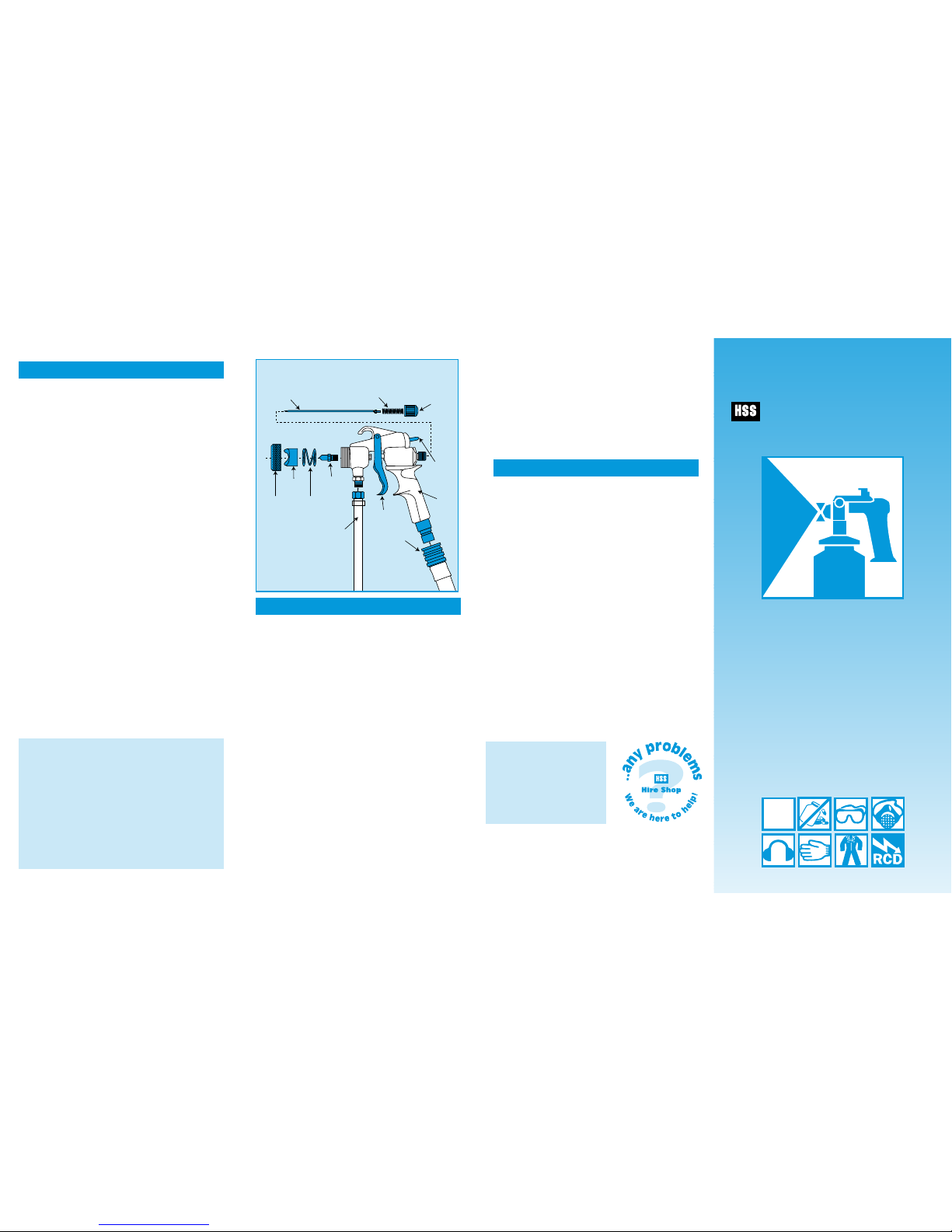

Needle

Needle Spring

Fluid

Adjuster

Retaining

Ring

Air

Cap

Air

Adjuster

Nozzle

Air Cap

Spring

Paint

Hose

Trigger

Compressor

Hose

Handle

Cleaning the Spraygun

For advice on the safety and suitability of this

equipment, contact your local HSS Hire Shop.

Check the equipment before use, paying special

attention to the air hoses.

If it shows signs of damage

or excessive wear, return it.

Keep children, animals and bystanders out of the

work area and never point the spray-gun at anyone.

This equipment should be used only be used by an

able-bodied competent adult

who has read and

understood these instructions. Anyone with either a

temporary or permanent disability should seek expert

advice before using it.

Never use this equipment if you are

feeling tired, ill, or under the influence

of alcohol or drugs.

Wear goggles and a face-mask suitable

for the material you are spraying.

If in

doubt, contact either the material’s manufacturer or your

local HSS Hire Shop for advice.

This equipment generates potentially harmful

noise levels.

To comply with Health & Safety at

Work regulations,

ear defenders must be worn by

everyone in the vicinity.

Wear suitably practical clothing and

footwear.

Tie back long hair and avoid loose

garments and jewellery that could interfere with the work.

Ensure the work area is well lit and well ventilated.

Never spray at or near electrical fittings or equipment.

If spraying flammable materials, DO NOT SMOKE

and make sure there are no potential sources of

ignition in the work area.

Always SWITCH OFF, UNPLUG and DEPRESSURISE

the equipment before changing paints, cleaning

filters and so on

. Never leave it switched on

and unattended.

Most HSS equipment is designed to plug straight

into a standard, 240V 13A power socket.

However, 110V models (with a round yellow plug)

must be provided with a suitable 110V generated

power supply

, or powered from the mains via a suitable

110V transformer.

Extension leads should be fully unwound and

loosely coiled, away from the equipment.

Never run

them through water, over sharp edges or where they

could trip someone.

Keep the equipment dry. Using electrical equipment in

very damp or wet conditions can be dangerous.

ELECTRICAL SAFETY

GENERAL SAFETY

To reduce the risk of electric shock, use a

suitable RCD

(Residual Current-Operated Device)

available from your local HSS Hire Shop.

Never carry or pull the equipment by its flex

and hoses.

Ensure the equipment is switched OFF before

plugging it into the power supply.

If the equipment fails, or if its flex or plug gets

damaged, return it.

Never attempt to repair it yourself.

Prepare the surface you are spraying and the

material to be sprayed

according to the material

manufacturer’s instructions.

Position the turbine unit close to its power source

and well away from the spray area.

With the unit disconnected from its power source, screw

the air-hose hand-tight onto the turbine’s air outlet.

Connect the other end of the air-hose to the spraygun.

Simply pull back the quick-release connector’s outer

sleeve, push the hose onto the gun’s air-inlet and let the

sleeve snap back into place.

GETTING STARTED

If using the Portable Turbine Unit…

Remove the spray-gun’s paint-cup and fill with

whatever you are spraying until about full – that is,

up to the level of the cup’s shoulder.

Refit the paint-cup to the spray-gun, making sure it

is securely fastened.

Finally, connect the unit to its power supply and

switch ON.

If using the Large Volume Turbine Unit...

Stir whatever you are intending to spray and then

pour into the pressure pot’s liner. Never pour paint

directly into pot. If using a paint tin, remove the

liner and place the tin inside the unit’s pressure pot.

It will accommodate standard paint tins of up to 5 litres.

Having ensured the gasket on the underside is clean and

in place,

refit the pressure pot’s lid and clamp

securely in place, tightening the clamps in opposite

pairs to seat the lid correctly.

That done, connect the unit to its power supply

and switch ON.

Now, with the pressure pot’s pressure control turned fully

anti-clockwise,

connect the red air hose to the

pressure pot and adjust the pressure, switch ON

the compressor

control clockwise until the gauge

stabilises at between 10-15psi for most standard paints,

25-30psi for multi-colour finishes.

If you need to reduce the pressure for any reason,

simply open the pressure pot’s safety valve.

Once the desired pressure has been achieved, switch

OFF the compressor and check

the pressure pot’s lid

and air-hose connections

for leaks – you will hear air

hissing out.

WHATEVER you are using…

Remove the spray-gun’s air-cap assembly and

trigger the gun to prime the system.

Ideally, you

should see a jet of paint arc out with a radius of between

150mm and 200mm.

Release the trigger, wipe the gun’s nozzle clean and

refit

the air-cap by screwing it fully home then

loosening it approximately one full turn.

Finally, turn on the unit’s turbine and start spraying.

Nozzles & Air-Caps

Always make sure the spray-gun is fitted with

the correct nozzle and air-cap for the material

being sprayed. If in doubt, contact your local

HSS Hire Shop.

Viscosity Finish Needle/Nozzle Air Cap

Thin Lacquers .029 (0.7mm) #3

Stains

Basecoats

Medium Clearcoat .043 (1.1mm) #2

Cellulose

Stoving Enamels

Red Oxide

Decorator’s Gloss

Medium-Thick Interior Emulsions .051 (1.3mm) #0 or #1

Enamels

Undercoats

Industrial Primers

Thick Exterior Emulsions .073 (1.9mm) #1 or #0

Masonry Paints

H.B.Primer

Thick-Heavy Multi-Colour Coatings .118 (3mm) #4

Textured Coatings

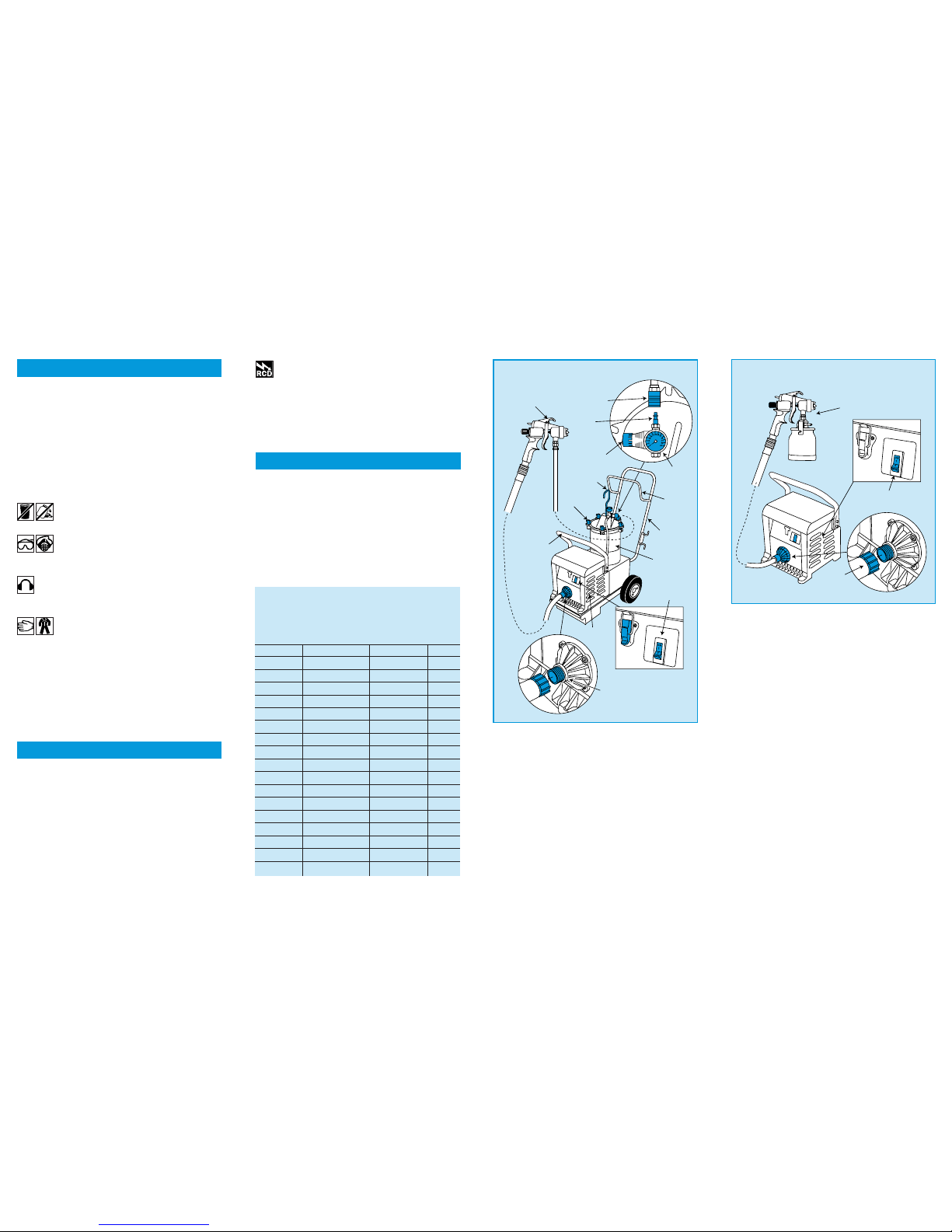

Turbine

Hose Fitting

Turbine

Switch

Control

Knob and

Safety Valve

Hose

Connector

Gauge

Spray Gun

Pressure

Pot

Handle

Cart

Handle

Hose

Holder

Handle

Pressure

Pot

Hose

Outlet

Clamp

Filter

Spray Gun & Cup

Turbine

Hose Fitting

Turbine

Switch

TS40P(61464)

TS40(61461)

Loading...

Loading...