HSS Hire 765 Operating & Safety Manual

765/01 Page 1 Black PMS Pro. Blue

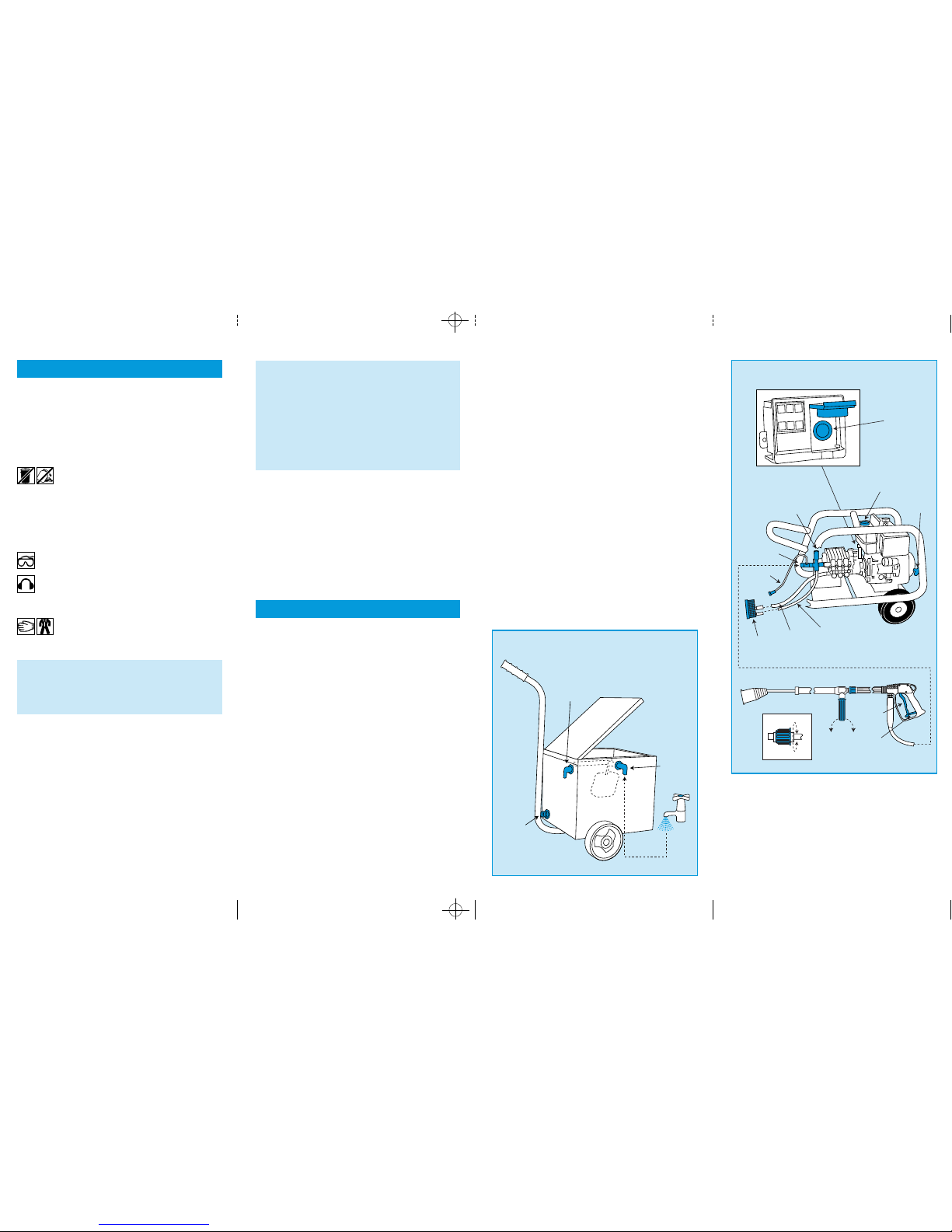

High Pressure

Diesel Washer,

Water Break

Tank and Rotary

Jetwash Head

Hire Shops

A powerful diesel engined cold water

washer. The Water Break Tank for use

with HSS pressure washers which have

a syphoning ability. The rotary Jetwash

Head, for cleaning large floor areas.

Operating & Safety Guide 765

Release the trigger lock on the lance then squeeze

the trigger to begin work.

The spray pressure can be adjusted at the spray

lance. For low pressure turn the lances side handle

anti-clockwise.

The Jetwash head has no pressure adjustment.

The pressure can also be adjusted at the pump, to

increase pressure turn the pressure regulator clockwise,

to decrease, turn anti-clockwise.

Pump Performance

A pump’s performance depends mainly on a sufficient

supply of water. If the pump gives intermittent high or

low spray pressure during use, check the inlet hose

connections for kinks, damage and secure connection

to the pump and mains tap. Also check the water

pressure at the tap, in case the pressure has dropped

due to other services being supplied.

If syphoning, check that the supply hose and filter are

fully submerged in water, and that the filter cage has

not become blocked.

If using a break tank, check that the tanks supply is

sufficient for the demand.

If in doubt, contact your local HSS Hire Shop for advice.

BASIC TECHNIQUES

If a detergent is to be sprayed, reduce the spray

pressure at the side handle. Triggering the lance will

now draw the chemical into the system automatically.

If you then wish to spray without detergent, screw the

side handle clockwise as far as it will go, high pressure

will return. The chemicals will continue for a short while

as the residue is cleared.

Be prepared for the lance to give a kick each time

it is triggered, due to the high pressure delivered.

Start with the lance about 1.5m away from the

surface being cleaned. Squeeze the trigger and allow

the unit to build up to pressure.

Slowly move closer to the work, then increasing

the pressure if required by turning the side handle

clockwise. Note when adjusting the pressure do not

trigger the lance.

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease or within the time required, assume you have the

wrong size or type of washer for the job. Ask at your local

HSS Hire Shop for advice.

Keep the equipment clean. You will find this less of a

chore if you clean up regularly rather than wait until the

end of the hire.

When not in use, store the equipment somewhere

clean, dry and safe from thieves. And where it will

be protected from frost at all times.

Handle hoses with care. Never run them over sharp

edges or anywhere else that exposes them to the risk

of damage.

Keep the engine upright at all times. If it should be

tipped over, mop up oil and fuel spillage’s and contact

your local HSS Hire Shop for advice.

Regularly check the fuel level and top up as

required using the correct fuel: DERV.

Check the engine oil level daily. Let the engine cool,

stand it on level ground, withdraw the dip stick and wipe

clean. Now, replace the dip stick, withdraw it a second

time and verify that the oil level is between Min and Max.

Top up as required.

To STOP the engine, push and hold the STOP lever until

the engine dies.

Shut off the water supply and trigger the lance to

drain any remaining water.

If you have finished with the unit completely,

disconnect the pressure, suction and return hoses

FINISHING OFF

EQUIPMENT CARE

as applicable, drain out any water they contain and

coil them neatly ready for return to your local HSS

Hire Shop.

Code 59227/59259/59248

Jetwash Head

©HSS Hire Service Group Plc 1998 No. 765/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.co.uk

Contact your local

0990 282828

…any comments?

If you have any suggestions

which would improve the

information within this guide

please fax your comments or

write to the Product Manager

at the address below

Fax: 0181-687 5001

765/01 Page 2 Black PMS Pro. Blue

For advice on the safety and suitability of this

equipment contact your local HSS Hire Shop.

This equipment has been designed to be used by

an able bodied adult. If you suffer from either a

temporary or permanent disability, you must seek

expert advice before using this equipment.

Keep children, animals and bystanders away from

the work area.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

This equipment should only be used by a

competent person who has read and understood

these instructions.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

Safety Goggles MUST be worn by everyone in

the work area.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, waterproof protective

clothing, gloves and footwear. Avoid

loose garments and jewellery that could get in the way of

the work, tie back long hair.

Never carry, lift or pull the equipment by its hoses.

Check the equipment before use. If it shows signs of

damage or excessive wear, return it.

Pressure washing equipment can cause serious injury,

so take care. Never point the spray lance at anyone or

invert the jetwash head and always engage the

trigger safety lock when not actually washing.

Never direct the spray at or near anything electrical.

Take care where you lay hoses. Avoid running them

where there is a risk of someone tripping over them.

Always switch OFF the equipment when not in use.

Engines, especially the exhausts, get very hot so

switch OFF and allow to cool before touching them.

Keep flammable materials well away from engine

and exhaust.

Exhaust Danger

NEVER operate diesel engines indoors or in a

confined space.

The exhaust contains gases that can Kill.

GENERAL SAFETY

Do not run the pump, with the lance trigger in the

closed position, for more than 5 minutes. The pump

needs a good flow of water to keep it cool. Without

water movement, the pump will over heat and expensive

damage will be caused.

If working above ground-level, work from a

suitable, stable platform, an access tower for

example. Never work from ladders or steps.

Watch your footing. Take special care if working other

than on firm, level ground.

Information on COSHH regulations is available from your

local HSS Hire Shop.

Place the unit on firm level ground, as far from the

work area as the pressure hose will allow.

Screw the pressure hose finger tight onto the unit’s

water outlet.

Two versions are available for hire.

The first has just one supply hose from the pump and may

be connected direct to a mains water supply, a water

break tank or can syphon from a suitable water butt.

The second has both a supply and return hose from the

pump, which in turn are both fitted to the same syphon

filter (see illustration).This unit cannot be connected

directly to a mains water supply, if a mains supply is to be

used it MUST be connected via a water break tank.

Either connect the unit’s water inlet to a suitable

tap using a hose secured to the unit’s inlet

connector with a Jubilee clip. Or where a break tank is

to be used, connect the tanks water inlet to a suitable tap

using a hose secured to the break tanks inlet connector.

Make sure it is free from kinks and sharp turns that could

impede the flow of water.

Make sure the hose has an internal diameter is of at least

15mm (1/2in).

If the Break Tank is to be used, remove the supply and

return hoses from the syphon filter and reconnect them

to the respective ports on the break tank (see illustration).

GETTING STARTED

Fuel Safety

NEVER refuel while the engine is hot or running.

Never smoke or allow naked lights into the area while

refuelling. Never inhale fuel vapour.

ALWAYS mop up spillages as quickly as possible, and

change your clothes if you get fuel on yourself.

ALWAYS store fuel in a purpose-made sealed container,

in a cool, safe place well away from the work area.

If a mains water supply is not available, the unit is

able to syphon water from a tank provided it not

more than 2m away. If the syphon method is to be used,

the pump MUST be protected by using the correct hose

pipe and filter. Ask at your local HSS Hire Shop for details.

If a mains water supply to the unit or the break

tank is established, turn ON the water supply.

Flush out the air in the system by squeezing the

lance’s trigger until water flows freely from the nozzle.

Not that if using a break tank or syphoning the

supply, the pump can only be primed when the

engine is running.

This unit can be used to spray a mixture of water and

detergent. Simply place the chemical suction hose into

the detergent’s container.

Lock the lances trigger OFF using the trigger lock

bar (see illustration).

You may now start the engine. NOTE: The engine

MUST NOT be run without a water supply

connected, as the pump uses the water to keep it

cool and will quickly overheat if dry.

HSS diesel pressure washers come with electric

start, and a manual start backup.

For PUSH BUTTON START…

Simply push and hold the button until the engine

fires, then release. The battery will be recharged during

use, automatically.

To STOP the engine, push and hold the STOP lever until

the engine dies.

For MANUAL backup START…

To start the engine, take a firm hold of the pull

start handle with both hands. Pull the pull cord

until slight resistance is felt, then let the cord

return to the starter.

Give the pull cord a firm pull and the engine

should start, (you may have to repeat the process a

couple of times if the unit has been inactive for a while).

Push Button

Start

Fuel Tank

Pull Start

Pressure

Regulator

Pressure Hose

Connector

Syphon

Filter

Chemical

Suction

Hose

Return

Hose

Supply

Hose

Trigger

Trigger

Lock

Low

Low

High

High

Return Hose

Connector

Water

Inlet

Water

Outlet

Water Break Tank

Diesel Washer

Loading...

Loading...