HSS Hire 609 Operating & Safety Manual

Portable Band

Saw

©HSS Hire Service Group Plc 1997 No. 609/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Hire Shops

For cutting wood, steel or alloy,

with a choice of 100mm or 150mm

depth of cut.

Operating & Safety Guide 609

To start the unit, push the green button, if the unit

does not start, reset the red STOP button by turning it

clockwise and try again.

To STOP the unit press the red STOP button (reset

by turning clockwise).

Always start the saw and let it get up to speed

before bringing the workpiece into contact with

the blade.

Adopt a stable stance that gives a good view of

the off-cut while keeping you clear of the saw

blade. In particular, avoid placing your hands and

fingers close to the blade.

Holding the workpiece firmly, guide it into the

blade using any pre-marked cutting line, supplying

just enough pressure to ensure reasonable progress.

If the workpiece is narrow or small, push it through the

blade using a piece of waste timber. Never allow your

hands or fingers to get close to the blade.

Remove the work from the cut before switching

OFF and wait for the blade to stop before clearing

any waste off-cut.

Never force the work through the saw. If it jams in

the cut, switch OFF, free it and check the blade for

damage before going on.

Regularly clean out the tool’s ventilation slots. If

these clog with dust, the tool’s motor could burn out.

Never work with a blunt or dirty blade. It not only

produces poor work but could overload the saw’s motor.

When cleaning or changing blades, though, do

remember to switch OFF and unplug the machine.

When not in use store the equipment somewhere

clean, dry and safe from thieves.

Never over-tighten nuts, knobs and screws when

making adjustments, particularly when adjusting

guides and guards, you could damage the unit.

Never use the saw to cut through timber

containing nails, screws and other obstacles, unless

the blade fitted is designed to do so.

Switch the unit OFF and unplug from the power

supply, remove the table and the legs.

Give the unit a final clean then neatly coil the

cable ready for return to your local HSS Hire Shop.

FINISHING OFF

EQUIPMENT CARE

Quick Tip

Because band saws cut on the ‘down stoke’, the

workpiece’s lower face may be marred by chipping

or splintering. Marking cut lines with a knife may

reduce damage, but it is still best to saw with the

work face up.

Code 03512

Contact your local

0990 282828

Guide

Wheels

Tension

Lever

Guide

Bearings

Direction

of Cut

Replacing the Blade

Having double-checked that it is unplugged and

switched OFF, fit the band saw with the appropriate

blade for the job.

Undo the 2 clips on the left hand side of the body

and swing the front cover fully back, to reveal the

4 guide wheels.

Lower the tension lever (situated between the two

top wheels), then slip the blade on to the wheels,

ensuring the direction of cut is correct (teeth facing

down) and that it passes between both upper and

lower guide bearings.

Raise the tension lever and check again that the

blade is correctly positioned. Then close and lock the

front cover.

For advice on the safety and suitability of this

equipment contact your local HSS Hire Shop.

This equipment is designed for operation by an

able-bodied adult. Anyone with either temporary

or permanent disability must seek expert advice

before using it.

Keep children, animals and bystanders away from

the work area.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or drugs.

This equipment should only be used by a

competent person who has read and understood

these instructions.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

Safety Goggles MUST be worn by everyone in

the work area.

Some materials when cut contain substances

which, when inhaled, can be harmful to

health. A suitable mask must be worn when using

this equipment.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery that

could catch in moving parts, tie back long hair.

This equipment is heavy, never attempt to lift

a bandsaw by yourself. Always get help.

Make sure you know how to switch this machine

OFF before you switch it ON, in case you get

into difficulty.

Always unplug the saw before moving it or making

adjustments to it.

NEVER start the saw with the blade in contact with

the workpiece.

Ensure the work area is well lit and adequately

ventilated. Dust extraction and ventilation

equipment is available for hire, contact your local

HSS Hire Shop for information and advice.

Do not work near flammable gasses or liquids.

Always switch OFF and unplug the equipment

when not in use. Never leave it switched ON

and unattended.

Never carry or pull the equipment by its flex.

Never remove or otherwise interfere with any

safety guards fitted to the saw.

Never use the saw to cut asbestos sheeting, it may

yield hazardous dust.

GENERAL SAFETY

Keep the work area tidy, do not work in areas where

you are forced to stand on loose debris or on a slippery

uneven surface.

Ensure all guards are correctly adjusted and secure

before starting work.

And take care when fitting blades – they are sharp.

Information on COSHH regulations is available from your

local HSS Hire Shop.

Most HSS Band Saws plug into a standard 13amp

power socket. However, 110V models (with a round

yellow plug) must be provided with a suitable 110V

generated supply, or powered from the mains via a

suitable 110V transformer.

If the equipment fails, or if its flex or plug gets

damaged, return it. Never try to repair it yourself.

Keep flexes out of harm’s way, and clear of the

work area.

Extension leads should be fully unwound and

loosely coiled, away from the equipment.

Never run leads through water, over sharp edges

or where they could trip someone. Don’t let them

disappear under a pile of off cuts.

Keep the equipment dry, using electrical

equipment in very damp or wet conditions can

be dangerous.

To reduce the risk of electric shock, use a

suitable RCD (Residual Current-Operated Device)

available from your local HSS Hire Shop, or power the

equipment from a mains circuit with a built-in RCD.

Ensure the band saw and power socket

are switched OFF before plugging into the

power supply.

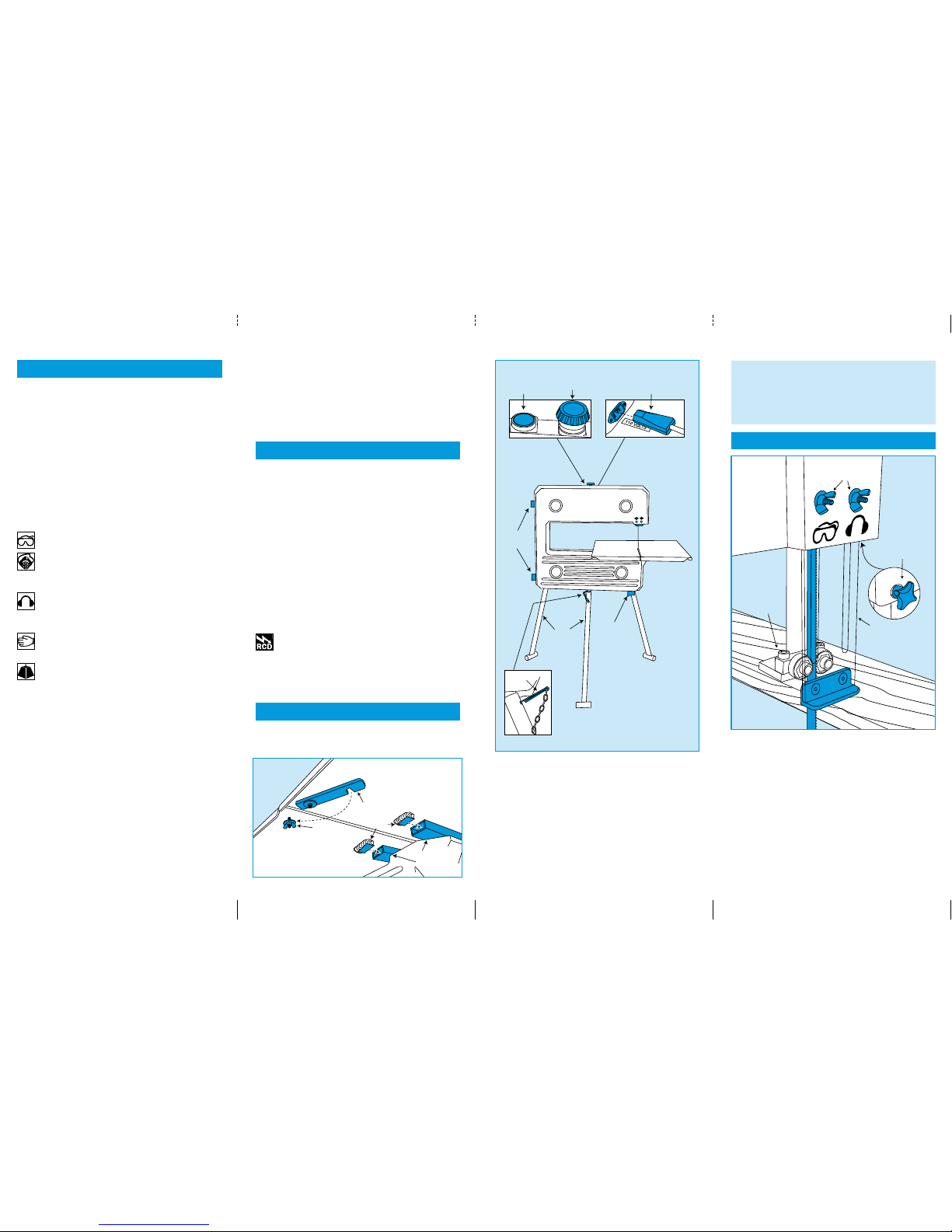

Lay the saw on its side and insert the 3 legs into

their respective slots, ensuring the split-pins are

correctly located.

GETTING STARTED

ELECTRICAL SAFETY

Lift the unit up onto its legs and make sure it

is level.

To fit the table, loosen and swing the table bar clear,

then slide the table from the back of the unit, making

sure you don’t twist the blade.

Slide the table forward and over the two lugs so

that they are inserted into the table support tubes,

then secure in place with the 2 rear catches.

Now re-position the table bar and tighten the wing nut.

All that now remains is to plug the supply lead into

the rear of the saw, then plug in and switch ON

the power.

The unit is fitted with an NVR (no volt return) switch,

if the power supply is interrupted the unit will

switch OFF and will need to be switched back ON

once the power is restored.

If this should occur during a cutting operation

DO NOT switch back ON until the workpiece has

been removed.

Lower the upper blade guide (by loosening the

thumb screw at the rear of the head stock) so that it is

about 5 mm above the thickest part of the material

to be cut then tighten securely in position.

Lower the safety guard by loosening the 2 wing

nuts at the front of the head stock, to leave the

minimum amount of blade necessary to make the cut.

BASIC TECHNIQUES

Blade Choice

If in doubt, ask at your local HSS Hire shop about the

right blade for the job. Blade selection may depend

on the material you are cutting, its thickness, whether

you are cutting wood along or across the grain.

Thumb

Screw

Wing

Nuts

Safety

Guard

Upper

Blade

Guide

Table

Bar

Wingnut

Lugs

Support

Tubes

Clips

Table

Legs

Dust

Extraction

Port

Mains Lead

Supply

Split

Pin

Green

ON

Red

OFF

Loading...

Loading...