HSS Hire 530 Operating & Safety Manual

Code 07115/9/20

12” Portable

Cut-Off Saw

For on site cutting of bricks, blocks,

concrete, stone, roof tiles and metalwork.

Operating & Safety Guide 530

530/02

©HSS Hire Service Group Plc 2003 No. 530/02

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.com

...any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your

comments or write to the Product Manager at the

address below

Fax: 020 8687 5001

BASIC TECHNIQUES

Trolley Tip

If you wish to use the trolley-mounted version as

a normal cut-off saw, stop the engine and simply

de-mount it from the trolley. It is held in place

with two clamps; one for the saw’s main handle,

the other for the bottom of its front bar grip.

Merely slacken off the clamps’ bolts and lift the

cut-off saw clear. But take care when remounting. Make absolutely sure the cut-off saw

is clamped firmly to the

trolley (without overtightening the clamp

bolts). And check that the

saw’s trigger is operated

by the linkage from the

trolley’s throttle control

and give the unit a final

clean up ready for return,

to your local HSS Hire

Shop.

Adjust the angle of the safety guard to suit the

work using the adjustment knob on the top.

Take special care if the cut-off saw is trolley

mounted. The guard should be set to remain just

clear of the ground (i.e. the surface you are cutting

into) at all times.

Adopt a comfortable, balanced stance that allows

a good view of the cut. Never use a cut-off saw when

standing on an unstable platform, or on slippery, uneven

ground.

Hold the machine firmly with both hands and

squeeze the throttle trigger to bring the wheel up

to speed before starting the cut. Do not release the

trigger again until the saw is clear of the work.

On the trolley-mounted version, the throttle

control is located on the trolley handle and you

simply tilt the trolley backwards or forwards to raise or

lower the wheel as required.

When using the trolley-mounted version, always make

the cut by moving the trolley forwards.

Use the dust suppression kit to control the dust created

during the cut. NOTE: THE DUST SUPPRESSION KIT

MUST ONLY BE USED WITH DIAMOND WHEELS,

NOT WITH STANDARD ABRASIVE WHEELS

Let the Cut Off Saw do the work – don’t try to force

it through the material.

Keep the machine and/or work as steady as possible.

Keep the cut straight and do not allow the cutting

wheel to twist in the cut.

EQUIPMENT CARE

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease and speed, assume you have the wrong tool for the

job. Contact your local HSS Hire Shop for advice.

Keep the equipment clean - you will find this less of a

chore if you clean it regularly, rather than wait until the

end of the hire period.

If working with very dusty materials, or if using the

trolley-mounted version, stop work and clean the saw

more frequently.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

FINISHING OFF

Set the ON/OFF switch into the OFF position. Wait for

the engine to stop and for the cutting wheel to stop

rotating.

If the machine is not to be used again, remove the

cutting wheel by simply reversing the fitting procedure

(see Getting Started).

All that remains is to give the unit a final clean before

returning it to your local HSS Hire Shop.

Once the engine has warmed up release the trigger

lock (squeeze and release the throttle) to set the throttle in

the idling position.

If restarting after a short break, you need only set the

throttle trigger half-open using the throttle lock button. If

the engine floods, push the choke fully in to its off position,

hold the throttle trigger full on, then pull the starter cord

repeatedly until the engine starts.

Now stop the engine

and prepare the work area.

If using the water feed system, connect the unit’s

water connector to a fresh water supply or pressurised

water container.

For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all necessary

risk assessments have been completed prior to the use

of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using either cones,

barriers or tape, available for hire from your local HSS Hire

Shop.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety goggles MUST be worn by everyone in the

work area.

This equipment generates potentially harmful

noise levels. To comply with health and safety at work

regulations, ear defenders must be worn by everyone in

the vicinity.

Some materials when cut contain substances

which, when inhaled, can be harmful to health. A

suitable mask must be worn when using this equipment.

Respiratory protective equipment is available for hire, contact

your local HSS Hire Shop for details.

Wear practical, protective clothing,

gloves and footwear. Avoid loose

garments and jewellery that could catch in moving parts, tie

back long hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at your

local HSS Hire Shop.

Do not work near flammable gases or liquids, petrol or

paint thinner fumes for example. Keep combustible

materials at a safe distance - at least 5m.

Make sure you know how to switch this machine OFF

before you switch it ON in case you get into difficulty.

Never leave the unit running and unattended.

Always switch the engine off and wait for moving

parts to come to rest before making adjustments to it.

Engines, especially the exhausts, get very hot so

switch OFF and allow to cool before touching

them.

GENERAL SAFETY

Pullstart

Exhaust Danger

NEVER operate petrol engines indoors or in a

confined space.

The exhaust contains gases that can kill.

Fuel Safety

NEVER refuel while the engine is hot or running.

Never smoke or allow naked lights into the area

while refuelling.

Never inhale fuel vapour.

ALWAYS mop up spillage’s as quickly as possible, and

change your clothes if you get fuel on yourself.

ALWAYS store fuel in a purpose-made sealed

container, in a cool, safe place well away from

the work area.

Make sure that everyone is warned of what you

are doing.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Hire Shop.

Ensure the guard is correctly fitted and secure

before starting work.

COSHH information sheets are available from your local

HSS Hire Shop.

GETTING STARTED

A range of diamond blades is available on sale or return

to suit most applications. Contact your local HSS Hire Shop.

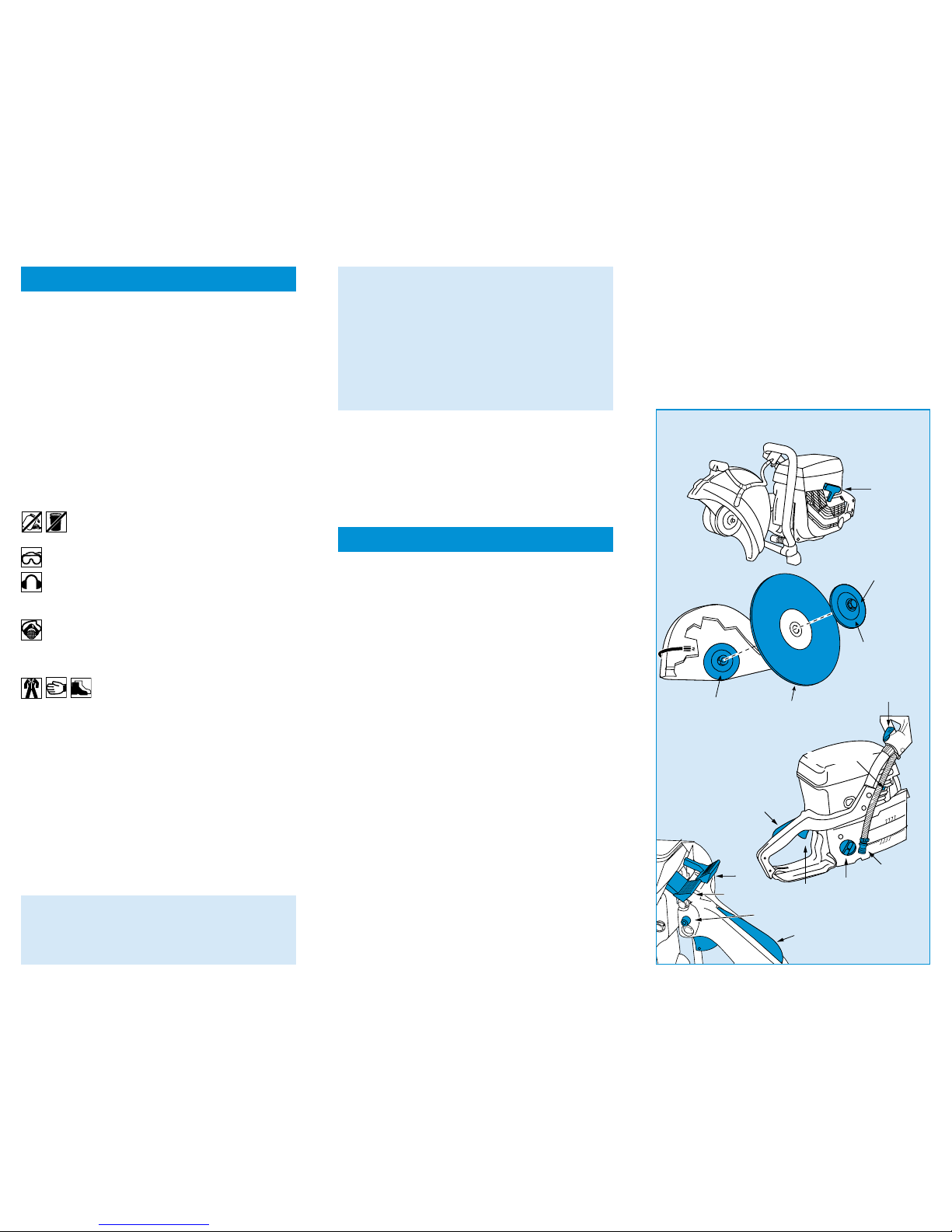

To fit the 300mm abrasive or diamond wheel, immobilize

the rear flange plate by inserting a locking pin into the

hole in the drive belt housing.

Unscrew the flange retaining bolt with the spanner

provided, remove the outer flange and seat the new

wheel onto the inner flange.

Refit the outer flange and screw the flange retaining

bolt back into place, DO NOT OVERTIGHTEN.

Double check that both flanges are secure, the wheel is

central and spins freely.

Finally, ensure that the safety guard is in the normal

operating position.

Mix 5 Litres of unleaded petrol with 1 bottle of HSS 2-

Stroke oil in a suitable container, and fill the fuel tank.

Each tank full gives about 30 minutes use. Never add the oil

and petrol to the tank unmixed.

Set the red ON/OFF control to the ON position by

pushing fully in, to switch OFF pull the switch back out again.

If starting from cold, set the blue choke control to ON by

pulling out, then push in the de-compressor button.

The unit is fitted with an operators presence lever

(OPL), the throttle cannot be operated unless the OPL is

firstly depressed.

Now, depress the OPL and operate the throttle trigger,

set the throttle half on and hold using the trigger lock

button.

Set the machine on a firm level surface with the

blade clear of the ground and clear of any obstruction,

as it will rotate as soon as the engine starts.

Pull the starter cord a few times until the engine

'coughs', then push the choke in to it's off position and

pull the starter once more. The engine should start.

12” Portable Cut-Off Saw

Outer Flange

Inner Flange

Abrasive Or

Diamond

Wheel

Flange Retaining Bolt

Water Feed Tap

Decompressor

Water Feed

Connector

Fuel Tank

Throttle Trigger

Trigger Lock

Button

Operator

Presence

Lever

Operator

Presence

Lever

ON/OFF

Choke

Loading...

Loading...