HSS Hire 527 Operating & Safety Manual

Electric Heavy

Duty Breakers

©HSS Hire Service Group Plc 1998 No. 527/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Hire Shops

For breaking concrete up to 300mm

(12 in) thick.

Operating & Safety Guide 527

Begin carefully, allowing the steel to mark the surface,

this will stop the steel from wandering over the work

surface and causing unnecessary and expensive damage.

Never apply too much pressure, let the breaker/steel

work at its own pace.

Lift it clear before turning OFF, and wait for moving parts

to stop before putting it aside.

If the steel becomes jammed in the work DO NOT use

the breaker as a lever. Tease the steel from the work

by pushing then pulling.

If the steel strikes a hidden object, stop the breaker

immediately then check to make sure it is safe to

continue.

Where possible, concentrate on weak spots in the

structure you are breaking - mortar joints, cracks etc.

Alternatively, start close to an edge and gradually

work inward.

Take your time, rushing a job tends to produce poor results

and increases the risk of a serious accident.

Don’t over do it - you are more likely to have an accident if

you are suffering from fatigue.

Never push the breaker beyond its capabilities. If it will

not do the job you want with reasonable ease, change it for

a more powerful model.

Regularly check that the air vents in the breakers

body are clear. If these become blocked with dust, isolate

the unit from its power supply. Clean them out using a soft

brush before continuing, taking care not to push dirt into

the drill body.

Avoid hitting or dropping the breaker. Its casing will be

damaged by a heavy blow.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

Remove the steel and clean up the breaker ready

for return.

Neatly coil the flex and place on the transport trolley

ready for return to your local HSS Hire Shop.

FINISHING OFF

EQUIPMENT CARE

Code 02111

Contact your local

0990 282828

For advice on the safety and suitability of this

equipment contact your local HSS Hire Shop.

This equipment has been designed to be used by an

able bodied adult. If you suffer from either a

temporary or permanent disability, you must seek

expert advice before using this equipment.

Keep children, animals and bystanders away from the

work area.

Never use this equipment if you are ill, feeling tired,

or under the influence of alcohol or drugs.

This equipment should only be used by a competent

person who has read and understood these

instructions.

Safety Goggles MUST be worn by everyone in

the work area.

Some materials contain substances that, when

inhaled, can be harmful to health. A suitable

mask must be worn when using this equipment.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, protective clothing,

gloves and footwear. Avoid loose

garments and jewellery that could catch in moving parts,

tie back long hair.

Always switch OFF the equipment when not in use.

Check the condition of the equipment before use. If it

shows signs of damage or excessive wear, return it to your

local HSS Hire Shop.

Never lift or pull the equipment by its power

supply cable.

Make sure you know how to switch this

machine OFF before you switch it ON, in case you get

into difficulty.

Take special care when breaking into floors, they may

contain hidden pipework, reinforcing bars or electrical

cables. If in doubt, hire a Cable Avoiding Tool or metal

locater, to determine the exact position of such hazards.

Stop the machine if you experience discomfort or numbness

during use.

Watch your footing. Take special care if working other

than on firm, level ground.

Most HSS Breakers plug into a standard 240v 13amp

power socket. However, 110v models (with a round yellow

plug) must be provided with a suitable 110v generated supply,

or powered from the mains via a suitable 110v transformer.

If the equipment fails, or if its flex or plug becomes

damaged, return it. Never try to repair it yourself.

Keep flexes out of harm’s way, and clear of the

work area.

ELECTRICAL SAFETY

GENERAL SAFETY

Extension leads should be fully unwound and loosely

coiled, away from the equipment. Never run them

through water, over sharp edges or where they could

trip someone.

Keep the equipment dry, using electrical equipment

in very damp or wet conditions can be dangerous.

To reduce the risk of electric shock, use a

suitable RCD (Residual Current-Operated Device)

available from your local HSS Hire Shop. Or power the

equipment from a mains circuit with a built in RCD.

Ensure the breaker and power socket are switched

OFF before plugging into the power supply.

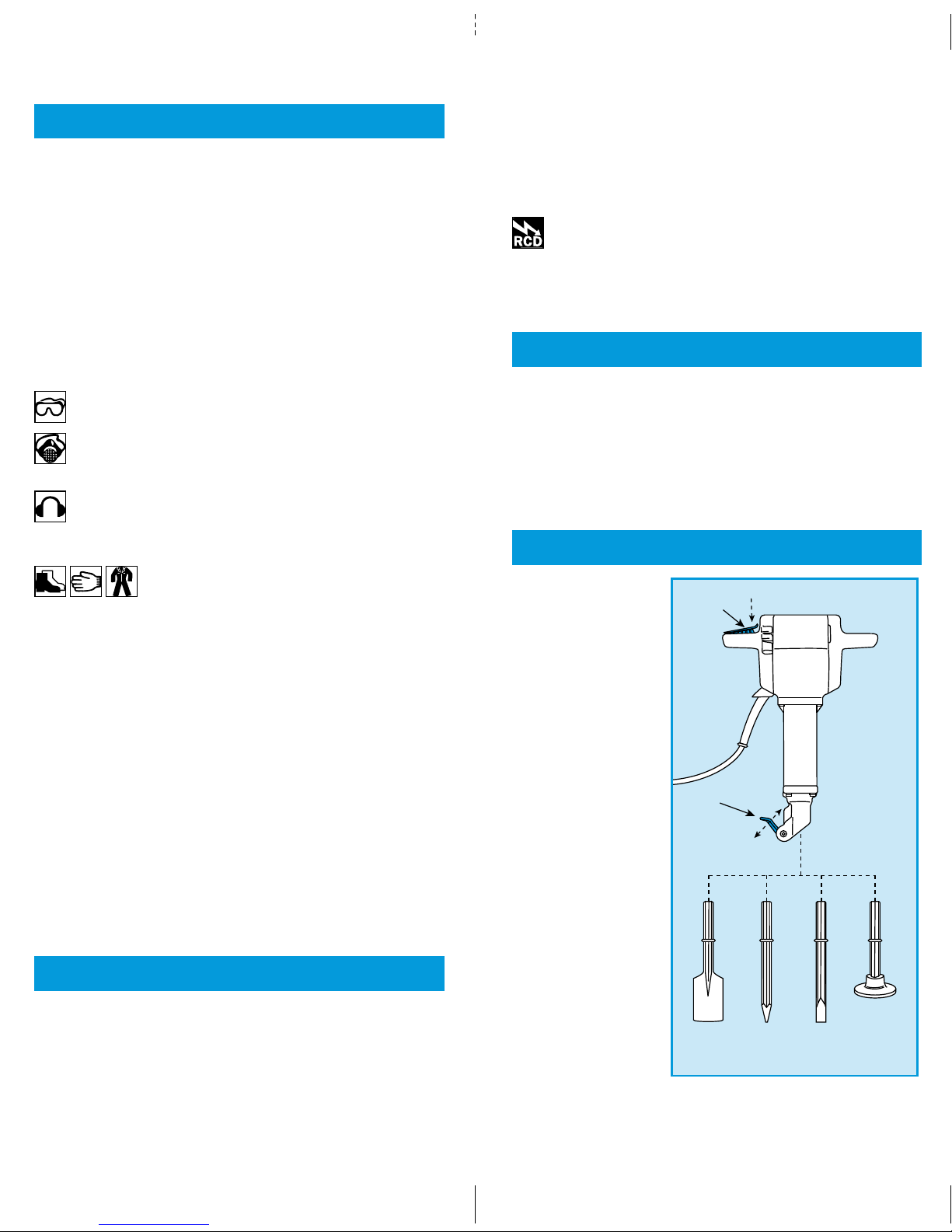

Fit the breaker with a point, chisel or tarmac cutter as

appropriate. Our staff will advise you on the best tool for

the job.

To fit the steel, cock the chuck lever into the open

position, push in the steel as far as it will go, then snap

the lever back to lock it.

Take care, never force the steel in. If the fit is at all tight,

return the equipment to us.

Plug the machine

into its power

supply and switch

the supply ON.

To start the breaker,

depress the ON/OFF

lever, to stop simply

release the lever.

Hold the breaker

with both hands

and adopt a stable

stance that gives a

good view of the

work while keeping

you clear of the bit.

Do not work in

areas where you

are forced to stand

on loose debris or

on a slippery

uneven surface.

If possible, drape the

breaker’s flex over

one shoulder to

keep it clear of the

steel, but make sure

there is still enough

slack so you are not

restricted in movement.

On first contact with the surface, the breaker/steel

will try to wander off line. Take great care until you

become familiar with the tool.

BASIC TECHNIQUES

GETTING STARTED

ON/OFF

Lever

Point

Clay

Spade

Chissel

Compactor

Chuck

Lever

OPEN

CLOSE

Loading...

Loading...