HSS Hire 453 Operating & Safety Manual

Electric Floor

Grinder

An electrically powered grinding

machine for removing surface

imperfections, sealants and mastics

from concrete slabs.

Operating & Safety Guide 453

Please note that strip-serts are not suitable for use

on wet surfaces.

Gently lower the machine back onto its wheels

and check that it is level. If the grinder is not level,

or the wheels are left in the transport position,

attempting to use it will damage your floor.

You MUST use either water or dust extraction to

comply with health and safety regulations.

For wet grinding attach a water hose to the water

inlet at the rear of the machine. Do not allow water

to flow until you are ready to start work.

Water supply hoses and suitable wet pick up vacuum

cleaners are available for hire from your local HSS Hire Shop.

For dry grinding attach a dust extraction unit to

the dust extraction port at the rear of the machine.

Dust extraction units are available for hire from your local

HSS Hire Shop.

Position the grinder at the start of the work and

uncoil the power supply cable.

All that remains is to plug the Floor Grinder into its

power supply and switch the supply ON.

Always position yourself so you can control the

Floor Grinder while staying clear of the grinding

head.

When wet grinding, turn the water supply on at

the tap and open the water inlet valve on the

machine. Only use enough water to reduce dust as

excess water can create a hazardous working area and

will cause clean up problems.

When dry grinding switch on the dust extraction

system.

Keeping one hand on the control handle, tilt the

machine back, enough to raise the inserts off the floor

and switch the machine ON by moving the

ON/OFF switch to the ON position.

Gently lower the machine to the floor. On first

contact with the surface the machine may jolt, use

extra care until you are familiar with this characteristic.

When grinding, work in straight, overlapping

strips until the entire area has been covered. Do

not pause in one spot or you will damage the floor .

Take your time and don’t over do it. You are more

likely to have an accident if you are tired or rushing.

When you have finished, tilt the machine back to

raise the inserts from the floor and switch the unit OFF

by moving the ON/OFF switch to the OFF

position.

When the grinding head has come to a rest lower

the machine back to the floor.

BASIC TECHNIQUES

When wet grinding, close the water inlet valve on

the machine and turn the water supply off at the

tap.

When dry grinding, turn the dust extraction

unit off.

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease and speed, assume you have the wrong tool for the

job. Contact your local HSS Hire Shop for advice.

Replace the inserts as soon as they become worn.

Use only inserts supplied by HSS, any others could

damage the machine and your floor.

Keep the equipment clean - you will find this less of a

chore if you clean it regularly, rather than wait until the

end of the hire period.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

Switch OFF and unplug the floor grinder.

If dry grinding detach the extraction hose from the

machine and coil it away.

If wet grinding detach the water hose from the

machine and coil it away.

Remove any inserts fitted to the grinding head,

then neatly coil the power supply cable and give

the machine a final clean up ready for return, to

your local HSS Hire Shop.

FINISHING OFF

Cutter Replacement

Strip-sert cutters have four sides and can be

rotated as sharpness deteriorates.

Using an allen key undo the cutter retaining

screw. Rotate the cutter to present a sharp

edge. When all four edged are blunt replace

with a new cutter. Use only cutters supplied

by HSS, any others could damage the machine

or your floor.

EQUIPMENT CARE

Code 06521 / 06551/2

©HSS Hire Service Group Plc 2001 No. 453/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.co.uk

Contact your local

0845 728 2828

…any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your

comments or write to the Product Manager at the

address below

Fax: 020 8687 5001

453/01

For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or

permanent disability, should seek expert advice before

using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Hire Shop.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety goggles MUST be worn by everyone in

the work area.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Some materials, when ground, contain

substances which, when inhaled, can be

harmful to health. A suitable mask must be worn

when using this equipment. Respiratory protective

equipment is available for hire, contact your local HSS

Hire Shop for details.

Wear practical, protective clothing, gloves and

footwear . Avoid loose garments and jewellery that

could catch in moving parts, tie back long hair.

This equipment is heavy (80Kg without inserts

fitted), never attempt to lift it on your own,

always get help.

Always switch OFF and unplug the machine before

making adjustments to it.

Having switched OFF, always wait for the grinding

head to come to rest.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire Shop.

GENERAL SAFETY

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance - at least 5m.

Make sure you know how to switch this machine

OFF before you switch it ON in case you get into

difficulty.

Never lift or pull the equipment by its power

supply cable.

Make sure that anyone in the immediate work area

is warned of what you are doing.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear , return it to

your local HSS Hire Shop.

COSHH information sheets are available from your local

HSS Hire Shop.

HSS Floor Grinders must be provided with a

suitable 110V 32AMP generated supply, or

powered from the mains via a suitable 110v transformer

(minimum 3Kva tool rating).

If the equipment fails, or if its power supply cable

or plug becomes damaged, return it. Never try to

repair it yourself.

Only use suitable three core earthed extension

leads to power this equipment.

Keep cables out of harm’s way,and clear of the work

area.

Extension leads should be fully unwound and

loosely coiled, away from the equipment. Never run

them through water, over sharp edges or where they

could trip someone.

This machine is designed to be used with water

and is perfectly safe to use provided you do not

allow water to contact the motor, switchgear,

cables, transformer or other electrical components.

To reduce the risk of electric shock, always

use a suitable RCD (Residual Current-Operated

Device) available from your local HSS Hire Shop. Or power

the equipment from a mains circuit with a built in RCD.

Ensure the floor grinder and power socket are

switched OFF before plugging into the power

supply.

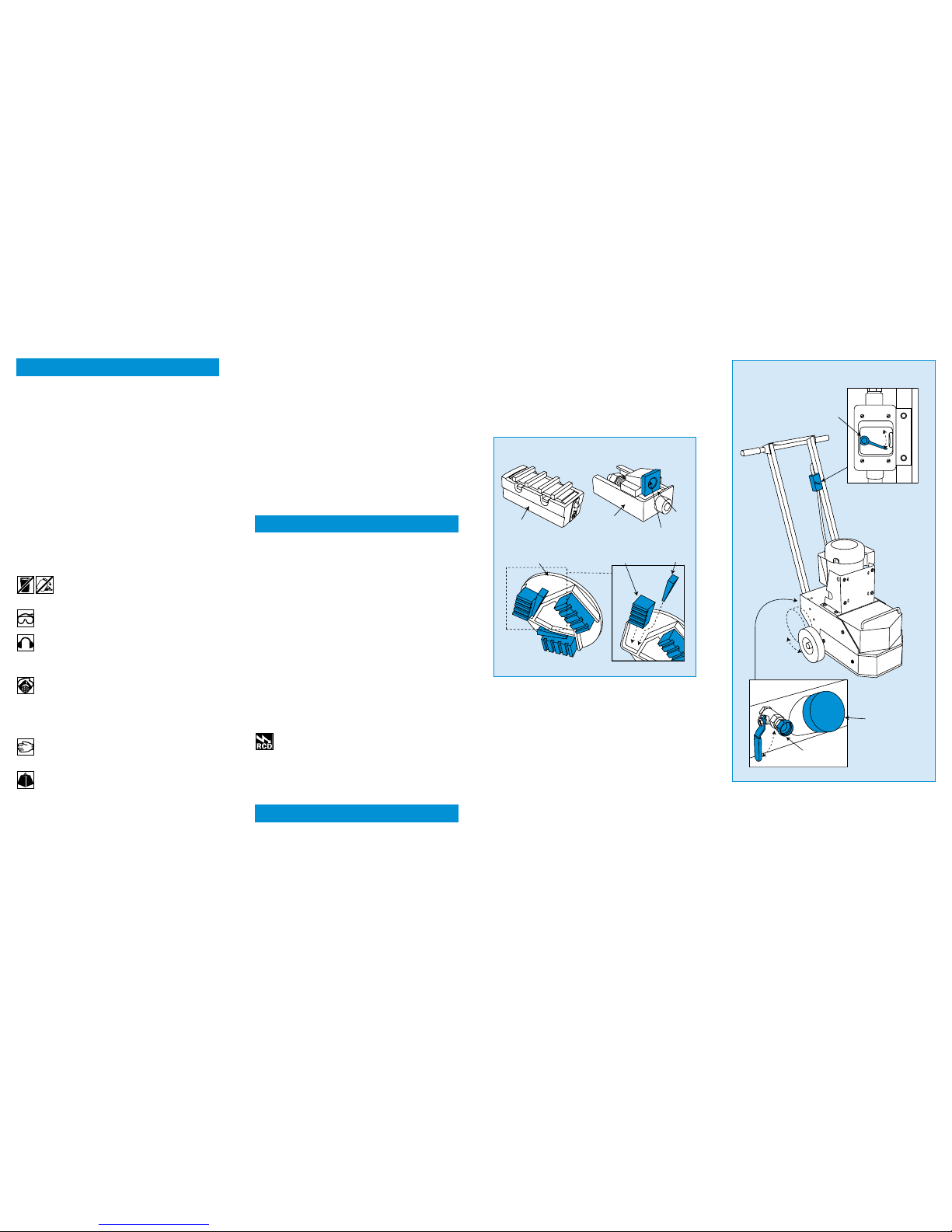

Familiarise yourself with the machines ON/OFF

switch and its location so that you can operate it

quickly in an emergency.

Fit the machine with the correct insert for the job.

There are two options, dyma-serts and strip-sert.

GETTING STARTED

ELECTRICAL SAFETY

Dyma-serts are concrete grinding inserts for wet/dry

grinding of epoxies, sealers, glues and concrete.

Strip-serts are carbide tipped inserts for stripping concrete

of paint, glue, rubber and tar.

Both are fittedto the grinding head in the same way.

Note that the strip-serts cutting edge must face the

direction of rotation (see illustration).

The grinding head will require the fitting of 3 inserts. Do

not attempt to use the machine unless all 3 are

fitted.

To fit the inserts, tilt the machine back to reveal the

underside of the grinding head.

Take the first insert and hold it in the recess with

the insert positioned tightly against the outer and

rear wall (see illustration). Next insert the wood

wedge between the insert and the inner wall, then

secure in place with a few light hammer blows.

Only use the wood wedges provided by HSS, anything

else may damage the inserts and the machine. Make sure

that you do not hit the insert as this may result in

irreparable damage.

Repeat this with the remaining 2 inserts.

Check that the inserts are fitted correctly and that

they are all in line (and in the case of the strip-serts, facing

the correct way). Set the machine back in the

upright position.

If you are using dyma-serts, turn them around after

each work session so that the current leading edge

becomes the trailing edge. This will allow the inserts

to wear evenly.

Move the wheels from the transport position to

the grinding position by tilting the machine

forward until the wheels are off the floor and then

swinging the wheels back towards the rear of the

grinder.

ON/ OFF

Switch

ON

OFF

Water

Inlet

Dust

Extraction

Port

ON

OFF

Transport

Position

Grinding

Position

Grinding Block

Wedge

Grinding

Head

Strip-Sert

Dyma-Sert

Cutte

r

Retaining

Screw

Grinding Inserts

Electric Floor Grinder

Loading...

Loading...