HSS Hire 433 Operating And Safety Manual

Sand Glider

For sanding or preparing floor

ready for varnishing/polishing

Code 05426

Sand Glider

Operating & Safety Guide 433

Operating & Safety Guide 433

433/01

433/01

©HSS Hire Service Group Ltd 2012 No. 433/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.com

…any comments?

If you have any suggestions to enable us to improve the

information within this guide please e-mail your comments or

write to the Safety Guide Manager at the address below

e-mail: safety@hss.com

... have you been trained

The law requires that personnel using this type of equipment in

the workplace must be competent and qualified to do so.

Training is available at HSS Training

0845 766 7799

Never push the equipment beyond its design limits. If it

will not do what you want with reasonable ease and speed,

assume you have the wrong equipment for the job. Contact

HSS Hire for advice.

Dust bags must be emptied when indicated via the full

line on the bag and before leaving the sander for any

length of time.

Dispose of wood dust carefully.

Never use a sander that has not got an sanding disc

fitted. Always use the right sanding disc for the job and

change it as soon as it becomes clogged or damaged.

Keep the equipment clean - you will find this less of a

chore if you clean it regularly, rather than wait until the end

of the hire period.

When not in use, store the equipment somewhere

clean, dry and secure.

EQUIPMENT CARE

FINISHING OFF

Release ON/OFF levers and unplug the sander.

Remove and dispose of the dust bag and clean the

sander.

Neatly coil its flex ready for return to HSS Hire.

BASIC TECHNIQUES

OPERATING THE SANDER

The HSS Sand Glider is designed to be operated in the

upright position with all sanding discs in contact with

the floor. DO NOT tilt the unit

back before switching it ON.

Having fitted a full set of four

sanding discs, wheel the machine

to the far corner of the floor,

placing it as close to the corner as

possible. You will be walking

backwards when you first

progress. Connect the power

supply lead to the sander then

to the power supply and switch the supply ON.

Drape the cable over your shoulder to prevent it being

damaged by the sanding action.

With all four sanding discs in contact with the floor surface,

take a firm hold of the control handles. Squeeze in the

lock off lever followed by ON/OFF lever to start the

motor.

Once the sander motor reaches operating speed, slowly

walk backwards manoeuvring the unit over the floor

surface.The machine will try to move around when in

contact with the floor so be prepared.

Try to overlap the previous strip to ensure that you do not

have ‘unsanded’ areas.

The slower you move the sander the greater the removal so

keep a close eye on the surface finish and adjust your speed

as necessary.

Do not exert pressure on the machine, let it work at its

own pace. Rushing the job will result in a poor finish and

will wear out the sanding discs quicker.

Periodically stop and inspect the condition of the

sanding discs. Discs should be replaced when the abrasive

is worn, damaged or clogged.

Once the entire floor area has been sanded, release the

ON/OFF lever to switch the sander OFF.

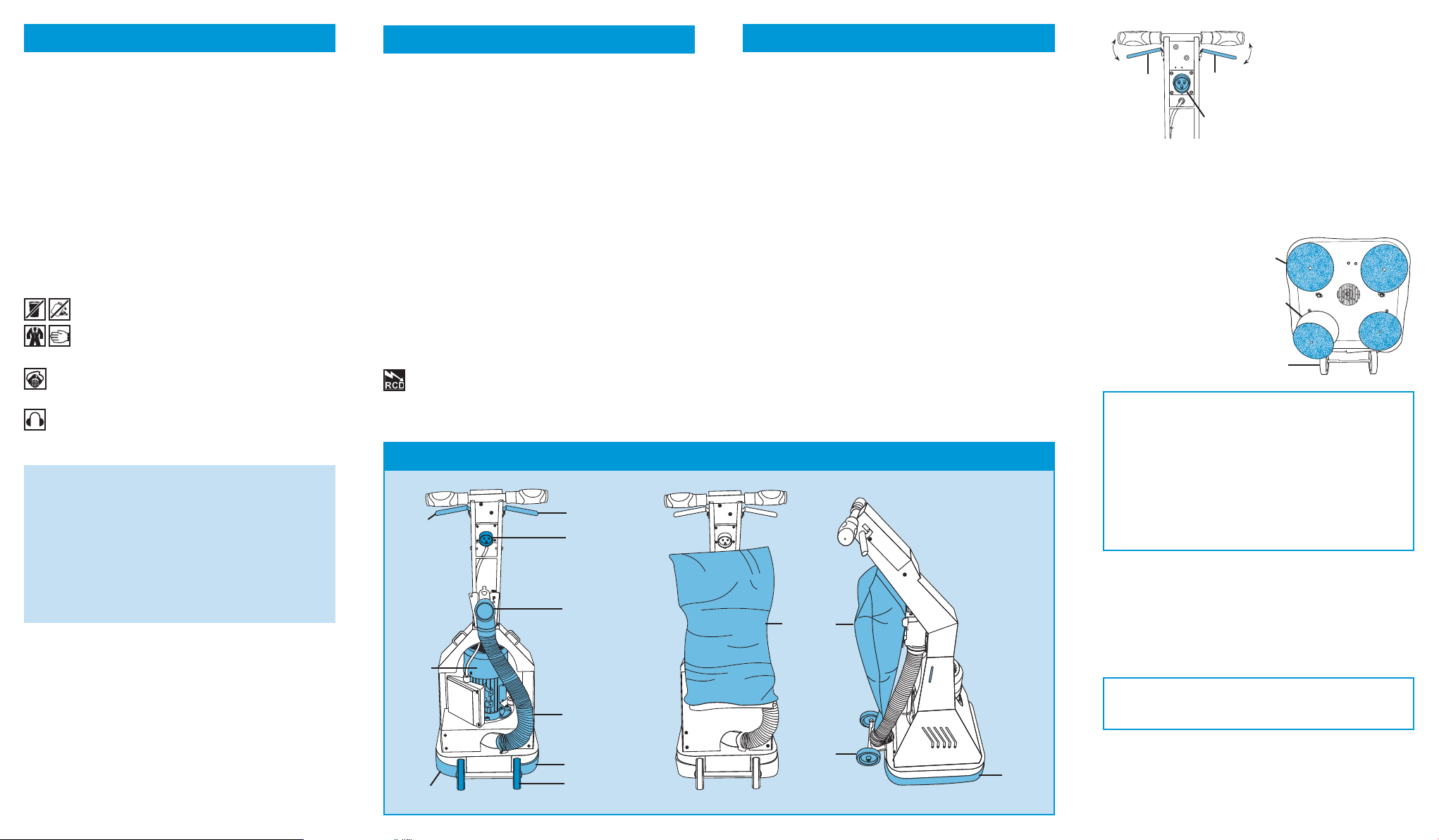

edge of the card on to the outlet’s lower hook.

Pivot the card to bring the bags centre opening over the

outlet until card and outlet are flush. Finally, lower the

two tabs over the outlets clips to retain the bag in place.

Removal is simply a reverse of the fitting instruction.

There is also a dust

skirt which fits

onto the outer

edge of the base

and is used to

contain the dust.

The skirt is held in

place by a

continuous velcro

strip which allows

for the skirt to be

adjusted as its

leading edge

wears. The skirt MUST be fitted and correctly positioned

whenever the sander is in use.

Clips

Tabs

Lower

Hook

Dust

Collection

Outlet

Dust

Collection

Bag

SandGlider ©

Before fitting the next grade of disc, thoroughly vacuum

the floor and give a visual inspection to ensure the floor has

been correctly sanded.

If you rush into the job your floor may be damaged.

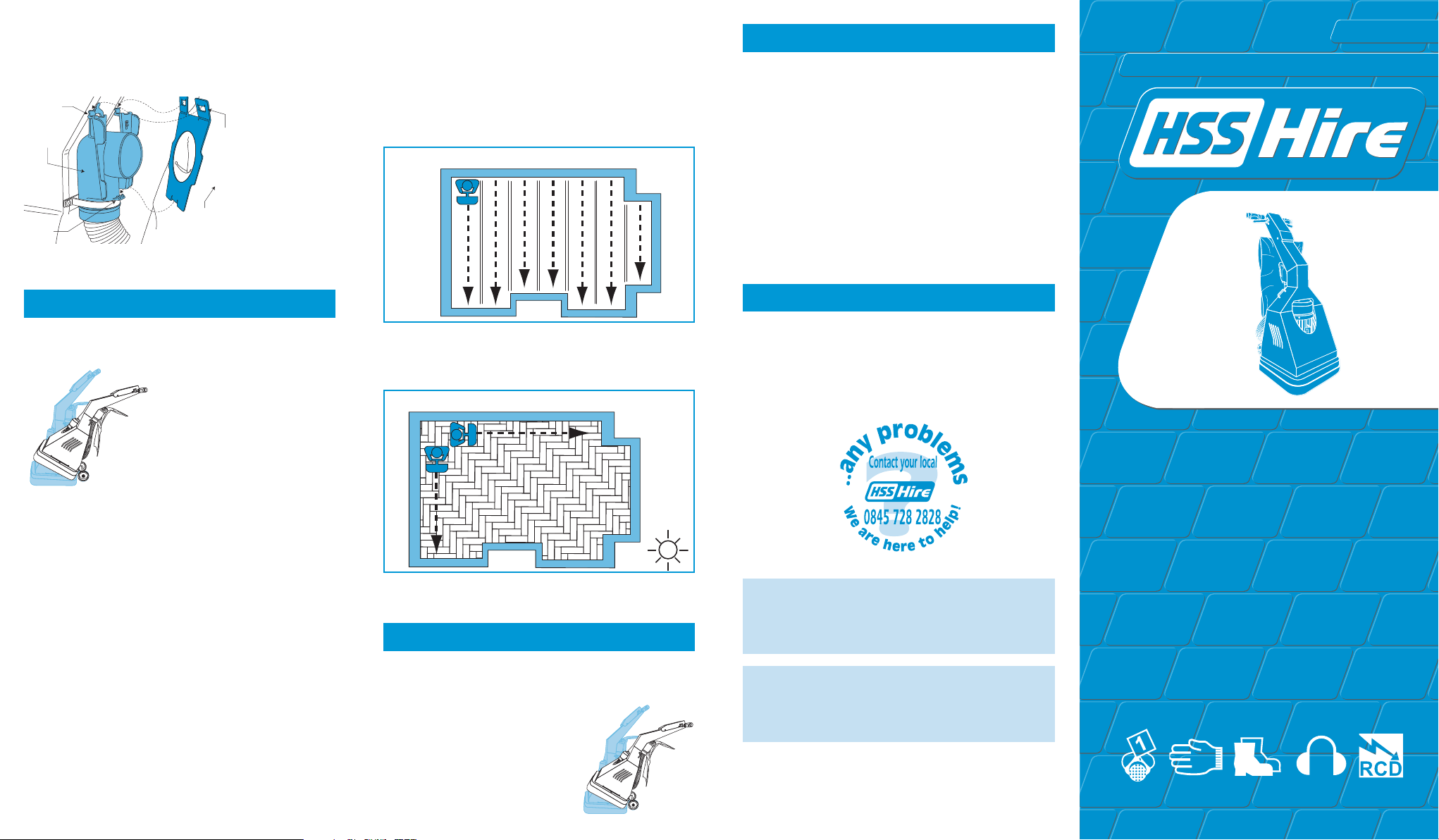

SANDING TECHNIQUES

The following information is for guidance only and is not

necessarily suited to your particular floor. No responsibility

will be accepted for flooring damaged by this technique.

Where the floor is in a bad condition or the boards have

warped, you can rough sand diagonally from top left to

bottom right then top right to bottom left. Once rough

sanded, continue sanding along the grain for a finish.

Always sand towards the source of light, never across or

diagonally from it. The light will show all imperfections

when sanded in any other direction.

Floor Boards

Parquet

TRANSPORTING

VEHICULAR

When transporting the machine, do not lay the unit down,

always keep the sander upright with all four protected

backing pads in contact with the

floor. Do not transport on an open

vehicle in adverse weather.

PEDESTRIAN

Tilt the sander back onto its

transport wheels, making sure that

the dust collection bag is kept clear

of the ground and the wheels.

For advice on the safety and suitability of this equipment

contact HSS Hire.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed prior

to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using cones and

either barriers or tape, available for hire from HSS Hire.

Never use this equipment if you are ill, feeling

tired, or under the influence of alcohol or drugs.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery

that could catch in moving parts, tie back long hair.

Some materials contain substances which, when

sanded, can be harmful to health. A suitable mask

must be worn when using this equipment.

This equipment generates potentially harmful noise

levels. To comply with Health and Safety at Work

regulations, ear defenders must be worn by everyone in

the vicinity.

Keep the equipment dry and protect this equipment

from damp or wet conditions.

Ensure the work area is well ventilated and free from

anything that could ignite wood dust.

Never carry or pull the machine by its power supply

cable. Check the equipment before use, if it shows signs

of damage or excessive wear, return it.

Make sure you know how to switch this equipment OFF

before you switch it ON in case you get into difficulty.

Make sure you know how to operate this equipment

safely and are aware of its limitations before you use it.

Always switch OFF and unplug the machine before

making any adjustments to it.

GENERAL SAFETY

IDENTIFIER

ELECTRICAL SAFETY

FIRE WARNING

WOOD DUST IS EXPLOSIVE!

Never store wood dust it can be dangerous. Dispose

of the bag when indicated to do so via the full line on

the bag and before leaving or storing the machine.

Never tip wood dust into a fire or incinerator

it may explode.

Never leave it packed in a dust-bag or similar

container it can ignite spontaneously.

To dispose of it safely, mix it with general rubbish.

Dust

collection

outlet

GETTING STARTED

The HSS Sand Glider is designed for sanding and

polishing the floor. It is able to sand a floor right up to the

edge, eliminating the need for an edging sander.

Never use the HSS Sand Glider until you have fully read

and understood this User Guide and the machine has

been properly set up using the information it contains.

Prior to using this equipment you must prepare the room.

It is advisable to have the room empty of all furniture,

curtains and wall hangings.

Clear the room and thoroughly vacuum the floor. If you

do not, you risk damaging the machine backing discs.

If there are nails, screws, tacks, staples or any other type

of fixing in the floor make sure they are all either removed

or driven 2mm below the floor surface.

Pipework passing through flooring to a radiator will be

vulnerable to damage by the sanding discs/disc and must

be protected to avoid water leakage and property damage.

This precaution must also be taken with cables and wires.

Ideally, all windows should be opened and all doors

closed and sealed with tape. The HSS Sand Glider will

collect up to 95% of wood dust but not all, so sealing the

doors will help prevent dust travelling throughout the

building.

CONTROLS

To safeguard the operator, the The HSS Sand Glider is

fitted with a switch that must be held in the ON position

by the operator. If the switch is released, the machine

The HSS Sand Glider plugs into a standard 230V 13amp

socket. The lead then simply connects to the captive

male plug fitted to the underside of the main control

handle.

If the equipment fails, or if its power supply cable or

plug becomes damaged, return it. Never try to repair it

yourself.

Keep cables out of harm’s way, and clear of the work area.

The maximum overall length of cable you can use with this

machine is 30M and any extension used must be at least

2.5mm 3 core.

Extension leads should be fully unwound and loosely

coiled, away from the equipment. Never run them

through water, over sharp edges or where they could trip

someone.

Always remove the plug from the power socket before

undertaking any type of intervention on the HSS Sand

Glider or if it is left unattended or within children or

people’s reach not quite conscious of their own actions.

Ensure the machine and power socket are switched OFF

before plugging into the power supply.

Before removing the plug, switch off the machine.

To reduce the risk of electric shock, always use a

suitable RCD (Residual Current-Operated Device)

available from HSS Hire.

Dust

collection

tube

will stop. In addition, there

is a lock off lever, which will

prevent the ON/OFF lever

being operated on its own.

To switch the machine ON

you must firstly operate the

lock off lever. This lever

prevents the ON/OFF lever

from being accidentally

operated. Next, squeeze and hold the ON/OFF lever to

start the motor.

You must hold the control handles with both hands

during operation.

If you release the ON/OFF lever, the machine will stop.

FITTING A SANDING DISC

Fit the sander with the

appropriate abrasive.

In general, start with a

medium grade, then

work through to a fine

grade until the desired

finish is achieved.

Isolate the sander from

the power supply and

carefully tilt the sander

back until its handles are

touching the floor.

The machine should remain in position but it is advisable to

have someone hold it in case it tips back up.

Sanding discs are fitted with the Velcro fastening system.

Firstly, remove any fitted disc by pulling it from the

backing pad. Simply align the new disc with the backing

pad and press on firmly.

It is also advisable to keep a set of sanding discs fitted to

the backing pads when not in use, to protect the pads

Velcro surface from damage.

DISPOSABLE BAG

The disposable bag fits to the outlet at the upper rear of the

machine and requires no tools to release or fit.The inlet is

fitted with stiff card, which attaches to the dust

extraction outlet.

Take a new bag and fully unfold it. Position the bottom

ONON

OFF

OFF

230V 16amp

connector

Lock

OFF

Lever

ON/

OFF

Lever

SANDING DISC SELECTION

Selection of the correct grade of sanding disc is very

important. Generally you can start with a medium grade

but care must be taken in case this is too coarse.

If unsure, start with fine and change to a coarse grade if

required. If you start with a coarse grade and remove too

much material you will have to sand the entire floor to

the same level.

Work through the grades until the desired finish is

achieved.

Offset

Rotating

Head

Abrasive

Disc

Transport

Wheels

DUST CONTROL

The HSS Sand Glider is designed with its own dust

collection system.

16A 230V

Captive

Connector

ON/OFF

Lever

Lock OFF

Lever

Disposal

Dust

Collection

Bag

Dust Skirt

Dust Skirt

Transport

Wheels

Transport

Wheels

Electric

Motor

Dust Skirt

Loading...

Loading...