HSS Hire 42CFM Operating & Safety Manual

42CFM

Compressor

A single tool compressor, driven by a

petrol engine.

Operating & Safety Guide 444

Anchor the delivery end of the air hose so that it is

not aimed at any person or property then, taking great

care, slightly open the air supply valve to clear the

hose of any debris. Then fully close the valve.

NOW TURN THE COMPRESSOR OFF, by moving

the ignition key to the ‘0’ position.

You can now connect the hose/s between the com-

pressor and whatever it is supplying.

Confirm that the tools air valve is in the closed

position then connect the delivery hose to the tool

in the same way as to the compressor.

All that now remains is to check that the air supply

valve is closed and to start the compressor.

This model of compressor is fitted with a thermostatic temperature

gauge which shuts

down the compressor

unit if the air discharge

temperature reaches

110ºC. If during the

course of your work the

air supply stops but the

engine continous running, check the temperature gauge.

If the compressor has

overheated, stop the

engine and allow the

compressor to cool

before restarting and

continuing your work.

Make sure you read and

fully understand the

operating instructions supplied with the tool you

are using, if in doubt, contact your local HSS Hire

Shop for advice.

Even if you are only stopping work for a short

break, shut down the compressor completely.

Never push the equipment beyond its design limits. If it will not do what you want with reasonable ease,

assume you have the wrong equipment for the job. Ask

at your local HSS Hire Shop

for advice.

Regularly check the fuel

level and top up as necessary with unleaded petrol.

Regularly check the oil

level – when the engine is

cold and on level ground.

Withdraw the dipstick, wipe

it clean, then replace it,

remove it a second time and

verify that the oil level is

EQUIPMENT CARE

between the min and max

lines, top up as necessary.

Keep the equipment clean.

You will find this less of a chore if

you clean up regularly, rather

than wait until the end of the hire

period.

When not in use, store the

equipment somewhere clean,

dry and safe from thieves.

Switch OFF the compressor by turning the ignition

key to the ‘0’ position, close all air taps and operate

the equipment fed by the compressor to release the

pressure in the hoses.

If you have finished with the equipment completely, you should now clean up the compressor as thor-

oughly as possible, disconnect the air hoses and

tools then coil them neatly ready for return to your

local HSS Hire Shop.

FINISHING OFF

Code 20046

©HSS Hire Service Group Plc 2001 No. 444/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.com

Contact your local

0845 728 2828

…any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your comments or write to the Product Manager at the address

below

Fax: 020 8687 5001

444/01

Closed

Open

Oil

Fill

Choke

Pressure

Gauge

Temperaure

Gauge

Hour

Meter

Gauges

Dipstick

For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all necessary risk assessments have been completed prior

to the use of this equipment.

This equipment should only be used by an operator who has been deemed competent to do so by

his/her employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Hire Shop.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety goggles MUST be worn by everyone in

the work area.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery that

could catch in moving parts, tie back long hair.

This equipment is heavy (163Kg), never attempt

to lift it, always use suitable lifting equipment.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire Shop.

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance – at least 5m.

Make sure you know how to switch this machine

OFF before you switch it ON in case you get into dif-

ficulty.

Never leave the unit running and unattended.

Always switch the engine off and wait for moving

parts to come to rest before making adjustments

to it.

Exhaust Danger

NEVER operate petrol engines indoors or in a

confined space.

The exhaust contains gases that can kill.

GENERAL SAFETY

Engines, especially the exhausts, get very hot so

switch OFF and allow to cool before touching

them.

Choose a site for the compressor that keeps flammable materials well away from the engine and

exhaust.

Make sure that anyone in the immediate work area

is warned of what you are doing.

Always double-check the unit’s general condition

before use, paying special attention to hose connec-

tions, air taps and hoses. If it shows signs of damage

or excessive wear, DO NOT USE IT. Return it to your

local HSS Hire Shop for a replacement.

The air connections used are the claw type quick

action couplings.

If the tool fails, or if its hose or coupling gets damaged, return it. Never try to repair it yourself.

Damaged hoses are dangerous, so always handle

them with care and coil them neatly, without kinks, for

storage.

Keep the air hose/s out of harm’s way, keep it clear

of moving parts. Never run them through water, over

sharp edges or where they could trip someone.

Never allow compressed air to travel down an air

hose which is not connected to an air tool, this may

cause personal injury.

Never carry or pull the equipment by its air hose.

Ensure the air supply is turned OFF before con-

necting or disconnecting it from the air hose.

Isolate it from the air supply before making any

adjustments.

As a safety precaution, this compressor is fitted with

an air fuse, which cuts out the air flow if the hose

becomes disconnected or damaged during use.

Stand the compressor on a firm, level surface

strong enough to bear its weight. DO NOT use on

slopes, soft ground or where there is a risk of subsidence.

GETTING STARTED

AIR SAFETY

Fuel Safety

NEVER refuel while the engine is hot or running.

Never smoke or allow naked lights into the area

while refuelling.

Never inhale fuel vapour.

ALWAYS mop up any spillage as quickly as pos-

sible, and change your clothes if you get fuel

on yourself.

ALWAYS store fuel in a purpose-made sealed

container, in a cool, safe place well away from

the work area.

With the machine on firm level ground, check fuel

and oil levels (see EQUIPMENT CARE).

To start the compressor,

firstly, open the air supply valve.

Open the fuel tap and

apply approximately one

quarter choke if starting

from cold, no choke if

starting from warm.

Turn the ignition key fully

to the right, then, once

the engine has fired,

return the key to the ‘I’ position.

You can now close the air supply valve and let the

engine warm up for a few minutes.

With the compressor warmed up, and the air sup-

ply valve CLOSED, connect the air hose by pushing

it on to the valve and turning clockwise.

Fuel

Fuel

Tap

Tap

Fuel

Tap

Ignition

Ignition

Key

Key

Ignition

Key

ONONON

OFF

OFF

OFF

Start

Start

Start

Closed

Closed

Closed

Open

Open

Open

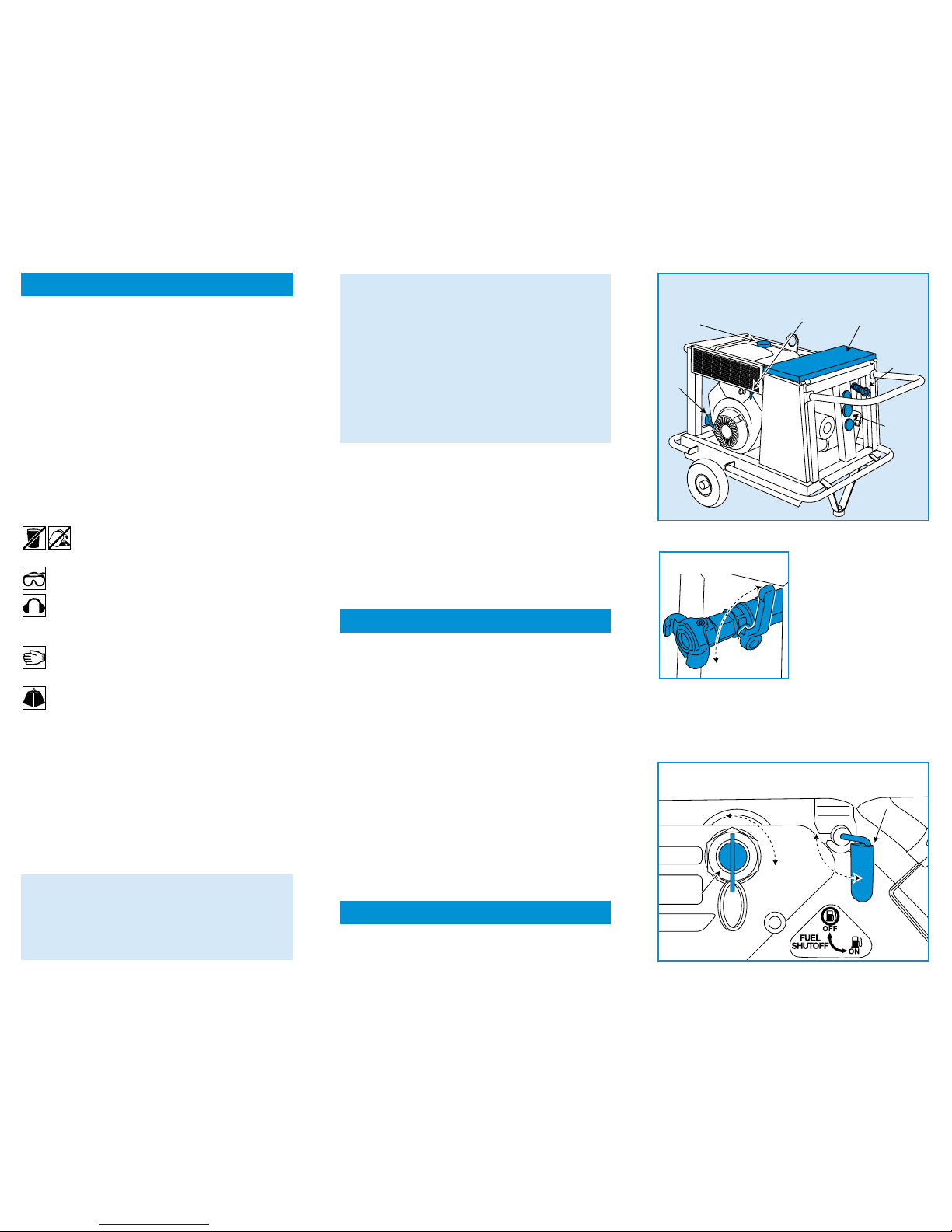

Fuel

Tank

Engine

Cover

Pull

Start

Air

Supply

Valve

Gauges

Ignition/

Fuel Tap

42CFM Compressor

Ignition Key & Fuel Tap

Open

Closed

Air Supply Valve

Loading...

Loading...