HSS Hire 429 Operating & Safety Manual

230mm

Concrete

Grinder & Dust

Extractor

Powerful portable concrete grinder

fitted with dust extraction shroud for

use with HSS dust extraction units.

Operating & Safety Guide 429

Apply just enough pressure to ensure reasonable

progress. Too much pressure will damage the disc, the

work area, and the machine’s motor.

Keep an eye on the wear rate of the disc

remembering to inspect it with the machine OFF.

The disc has diamond cutters, these will wear down

during normal use. If you use the equipment as

described the cutters should wear evenly. When the

disc has worn out replace it with a new one,

following the instructions in GETTING STARTED.

Discs are available sale or return from your local HSS Hire

Shop.

To turn OFF the Grinder, let the trigger switch go.

Be aware of the gyroscopic effect created by the machine

once it has been switched OFF. Hold the Grinder still

until the disc has stopped spinning.

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease, assume you have the wrong tool or blade for the

job. Ask at your local HSS Hire Shop for advice.

Keep the equipment clean, (especially the motor’s

ventilation slots). You will find this less of a chore if you

do it regularly rather than wait until the end of the hire

period. Always switch OFF and unplug the tool prior to

cleaning.

Regularly check that the disc and extractor shroud

have not become loose, if either have, STOP work

and contact your local HSS Hire Shop for advice.

When not in use, remove disc and store the

equipment somewhere clean, dry and safe from

thieves.

Switch OFF and unplug the Grinder then remove

the disc (simply reverse the fitting procedure explained

in GETTING STARTED).

Clean the tool up as far as possible, paying special

attention to the motor’s ventilation slots.

Finally, neatly coil the cable and collect all the

components ready for return to your local HSS Hire Shop.

FINISHING OFF

EQUIPMENT CARE

Code 06333

©HSS Hire Service Group Plc 2002 No. 429/01

Group Office: 25 Willow Lane, Mitcham, Surrey CR4 4TS

Web Site: http://www.hss.com

Contact your local

0845 728 2828

…any comments?

If you have any suggestions to enable us to improve

the information within this guide please fax your

comments or write to the Product Manager at the

address below

Fax: 020 8687 5001

429/01

ON/OFF

Trigger

Lock OFF

Button

1

2

Handle

Alternative Position

for Handle

Spindle

Lock

To Dust

Extractor

Grinding Operation

Dust

Extrator

Disc

90°

Concrete Grinder

For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Hire Shop.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety Goggles MUST be worn by everyone in

the work area.

This equipment can create residual dust

which, when inhaled, can be harmful to

health. A suitable mask must be worn when using

this equipment.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, protective clothing,

gloves and footwear. Avoid loose garments

and jewellery that could catch in moving parts, tie back

long hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about dust extraction and ventilation

equipment at your local HSS Hire Shop.

Do not work near flammable gasses or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance – at least 5m.

If working above ground level, work from a

suitable, stable platform – an access tower for

example. Never work from ladders or steps.

Always switch OFF and unplug the equipment

when not in use. Never leave it switched ON and

unattended.

Caution

This machine vibrates during use, DO NOT use

for prolonged periods.

GENERAL SAFETY

Make sure you know how to switch this equipment

OFF before using it, in case you get into difficulties.

Always switch OFF and unplug the tool prior to

cleaning, checking or changing discs.

Having switched OFF the tool, always wait for the

disc to come to rest before putting it down.

never start the Grinder with the disc in contact

with the work piece.

Never carry or pull the equipment by its power cable.

When working, adopt a stable, well-balanced

stance that lets you see what you are doing while

leaving your hands and body behind the cutting

edge at all times.

Never use the Grinder to cut asbestos sheeting, nor

any other material that may yield hazardous dust.

Take care when handling or fitting discs – they are

sharp.

Check the equipment before use. If it shows signs of

damage or excessive wear, return it to your local HSS

Hire Shop.

COSHH information sheets are available from your local

HSS Hire Shop.

Most HSS Grinders plug into a standard 230V

13amp power socket. However, 110V models (with a

round yellow plug) must be provided with a suitable

110V 16amp generated supply, or powered from the

mains via a suitable 110V transformer.

If the equipment fails, or if its power cable or plug

becomes damaged, return it. Never try to repair it yourself.

Keep cables out of harm’s way, and clear of the work area.

Extension leads should be fully unwound and

loosely coiled, away from the equipment.

Never run them through water, over sharp edges or

where they could trip someone.

Using electrical equipment in very damp or wet

conditions can be dangerous.

To reduce the risk of electric shock, use a

suitable RCD (Residual Current-Operated Device)

available from your local HSS Hire Shop.

Ensure the Grinder and power socket is switched

OFF before plugging into the power supply.

To set up the machine, screw handle into appropriate

position.

Select a suitable disc for grinding concrete, if you are

in any doubt ask for advice at your local HSS Hire Shop.

Use only approved discs, if in doubt ask at you local

HSS Hire Shop. NEVER use old or part worn discs.

Before installing a new disc ensure that it is

distortion free, and undamaged and that the

diamond cutters are not worn.

GETTING STARTED

ELECTRICAL SAFETY

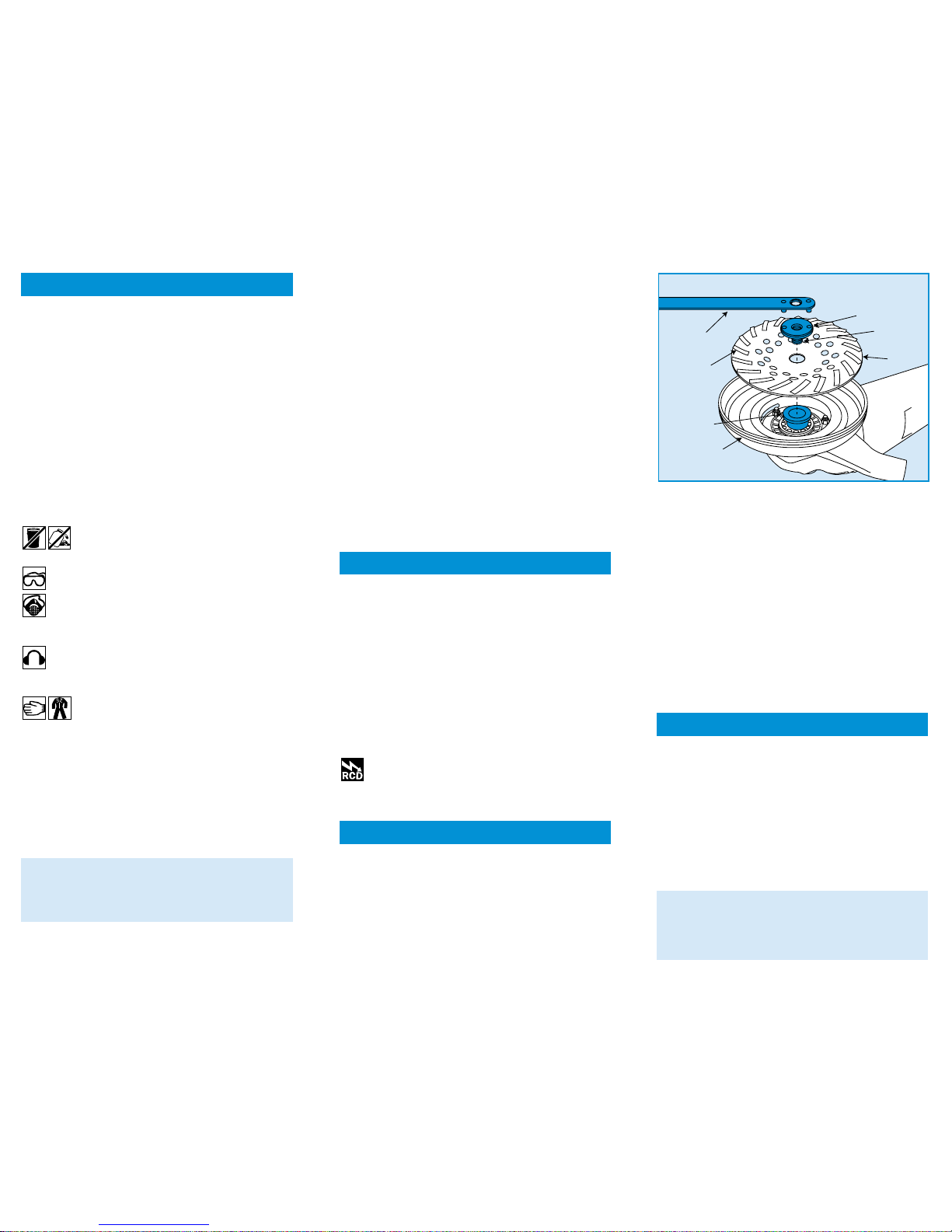

To fit a disc, switch OFF and unplug the tool, then

immobilise the back flange plate by depressing the

spindle lock button.

Turn the Grinder over and remove the lock nut with

the pin spanner provided.

Inspect the flange faces of the lock nut and the

back flange plate, if they appear to be damaged, return

the unit to you local HSS Hire Shop for replacement.

Place the new disc over the back flange plate

ensuring that the diameter and the centre hole of the

disc are the correct size for the machine.

Finally, secure the disc by screwing on the lock nut

and front flange with the boss inner most.

Immobilise the back flange plate again and tighten the

lock nut with the pin spanner.

Attach dust extractor to the exit duct on the dust

extractor shroud.

The Grinder is ready to use.

Take the Grinder and dust extractor equipment to

the work area.

Before each work session ensure that the dust

extractor shroud is securely fastened to the

Grinder. If it is loose or damaged, return the unit to your

local HSS Hire Shop for replacement.

To switch on the Grinder, either, depress or push

forward the lock OFF button and squeeze the

ON/OFF trigger.

Bring the grinder to the surface with the disc

spinning and work the tool back and forth across

the surface, holding flat against the surface.

Warning

Do not use the grinder at an angle against

the surface. This will cause the disc to

wear prematurely.

BASIC TECHNIQUES

Pin

Spanner

Lock Nut &

Front Flange

Diamond

Cutters

Boss

Grinding

Disc

Back

Flange

Dust Extractor

Shroud

Fitting a Disc

Loading...

Loading...