HSD ES915, ES919 NL, ES919 L NC, ES919 NC, ES919 L NL Installation, Operation And Maintenance Manual

Page 1

Installation, Operation and Maintenance Manual

5801H0017

Revision 02

ELECTRO-SPINDLES

for automatic tool changing

HSD S.p.a.

TECHNOLOGICAL EQUIPMENT FOR AUTOMATION

Via della Meccanica 16

Loc. Chiusa di Ginestreto

61100 PESARO (ITALIA)

Tel. (+39)0721.439.612

Fax(+39)0721.441.606

E-mail hsd.sales@hsd.it

Web: www.hsd.it

ES915

ES919 NC

WHITH BELT DRIVEN "C" AXIS UNIT

ES919 NC

ES919 NL

ES919 L NC

ES919 L NL

Page 2

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 2/98

TABLE OF CONTENTS

§ 1 DOCUMENTS DELIVERED WITH THE ELECTRO-SPINDLE......................................... 5

§ 2 DOCUMENT INFORMATION ........................................................................................... 5

§ 3 CUSTOMER ASSISTANCE SERVICE............................................................................. 5

§ 4 TERMS OF WARRANTY.................................................................................................. 6

§ 5 WARNINGS AND SAFETY PRECAUTIONS.................................................................... 7

5.1 Distribution of this manual .................................................................................................. 7

5.2 General safety symbols ....................................................................................................... 7

5.3 Risks associated with the electro-spindle.......................................................................... 8

5.4 Risks associated with improper use and handling............................................................ 8

5.5 Risks specific to maintenance............................................................................................. 9

§ 6 GENERAL INFORMATION............................................................................................... 9

6.1 Proper use of the product.................................................................................................... 9

6.2 Identification of manufacturer and part ............................................................................ 10

6.3 Description of the main parts of the electro-spindle........................................................ 11

6.4 Glossary.............................................................................................................................. 12

§ 7 TECHNICAL SPECIFICATIONS..................................................................................... 13

7.1 Available models................................................................................................................ 13

7.1.1 ES915 / ES915 L ........................................................................................................ 13

7.1.2 ES919 / ES919 L ........................................................................................................ 13

7.2 Technical specifications of ES915 .................................................................................... 14

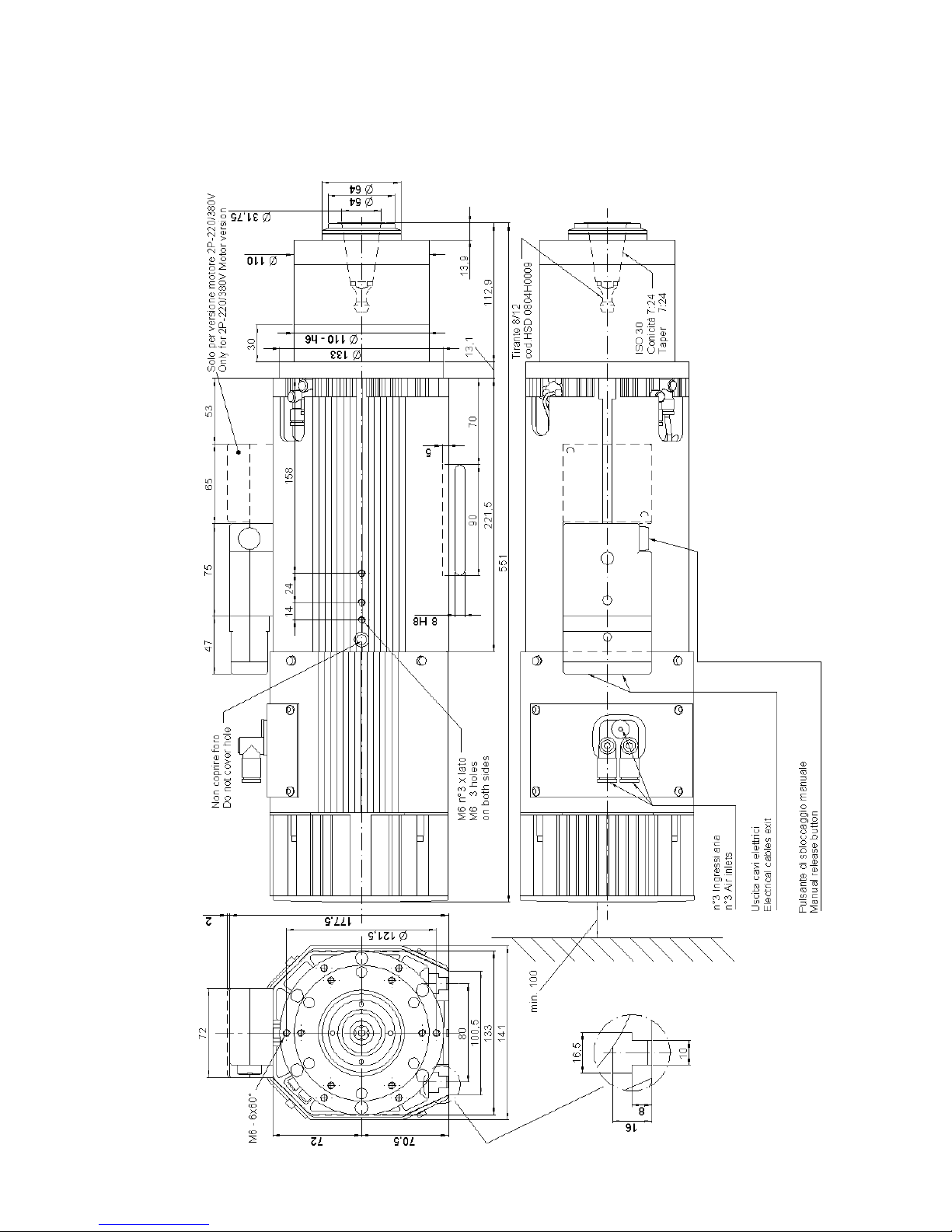

7.2.1 Overall dimensions of ES915........................................................................................ 14

7.2.2 Specifications and performance of ES915 2 Pole, 3.8 kW units.................................... 15

7.2.3 Specifications and performance of ES915 4 Pole, 5 kW units....................................... 16

7.3 Technical specifications of ES915 L................................................................................. 17

7.3.1 Overall dimensions of ES915 L HSK F63 Long Nose.................................................. 17

7.3.2 Specifications and performance of ES915 L 4 Pole, 7.5 kW units ................................. 18

7.4 Technical specifications of ES919 .................................................................................... 19

7.4.1 Overall dimensions of ES919 ISO30 Short Nose .......................................................... 19

7.4.2 Overall dimensions of ES919 ISO30 Long Nose........................................................... 20

7.4.3 Overall dimensions of ES919 HSK F63 Short Nose...................................................... 21

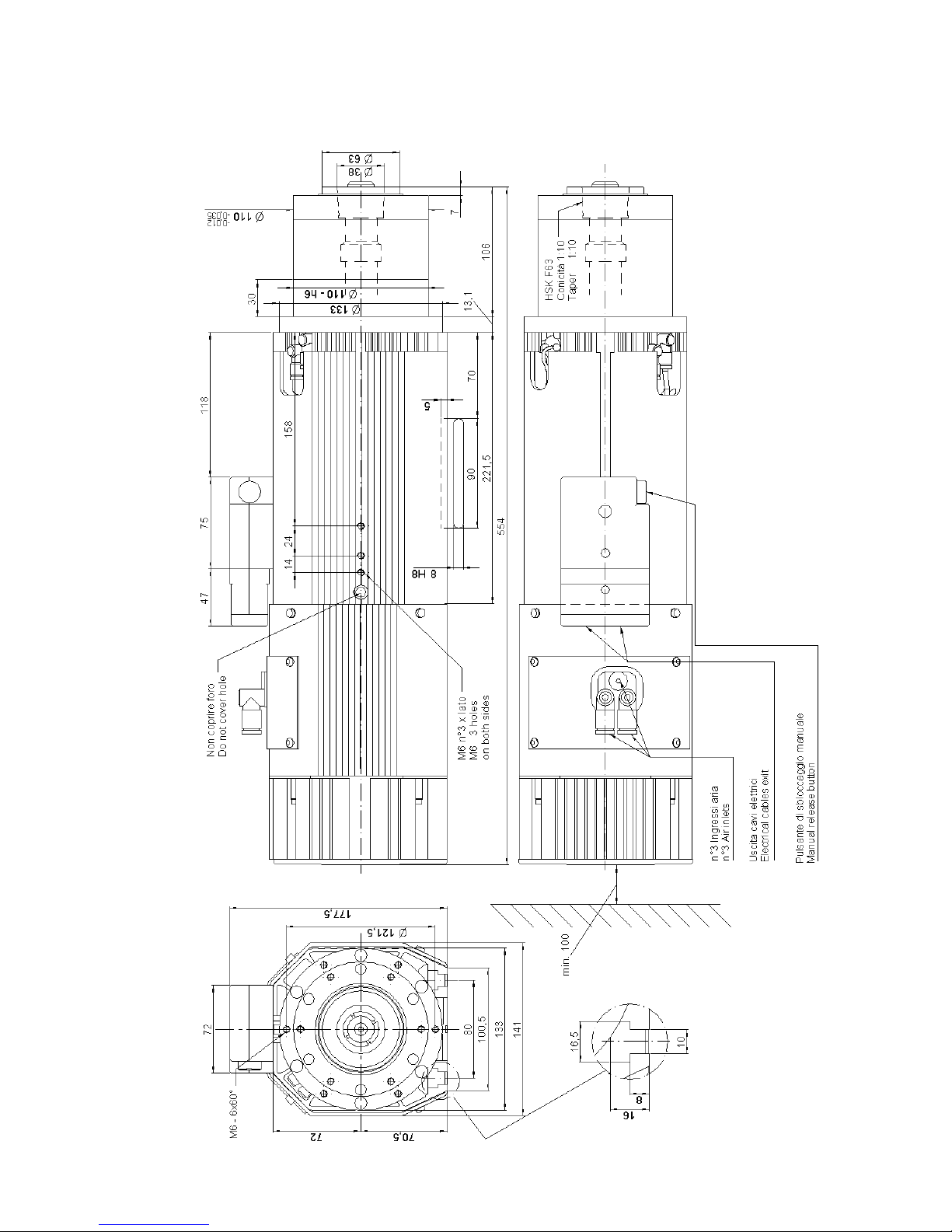

7.4.4 Overall dimensions of ES919 HSK F63 Long Nose....................................................... 22

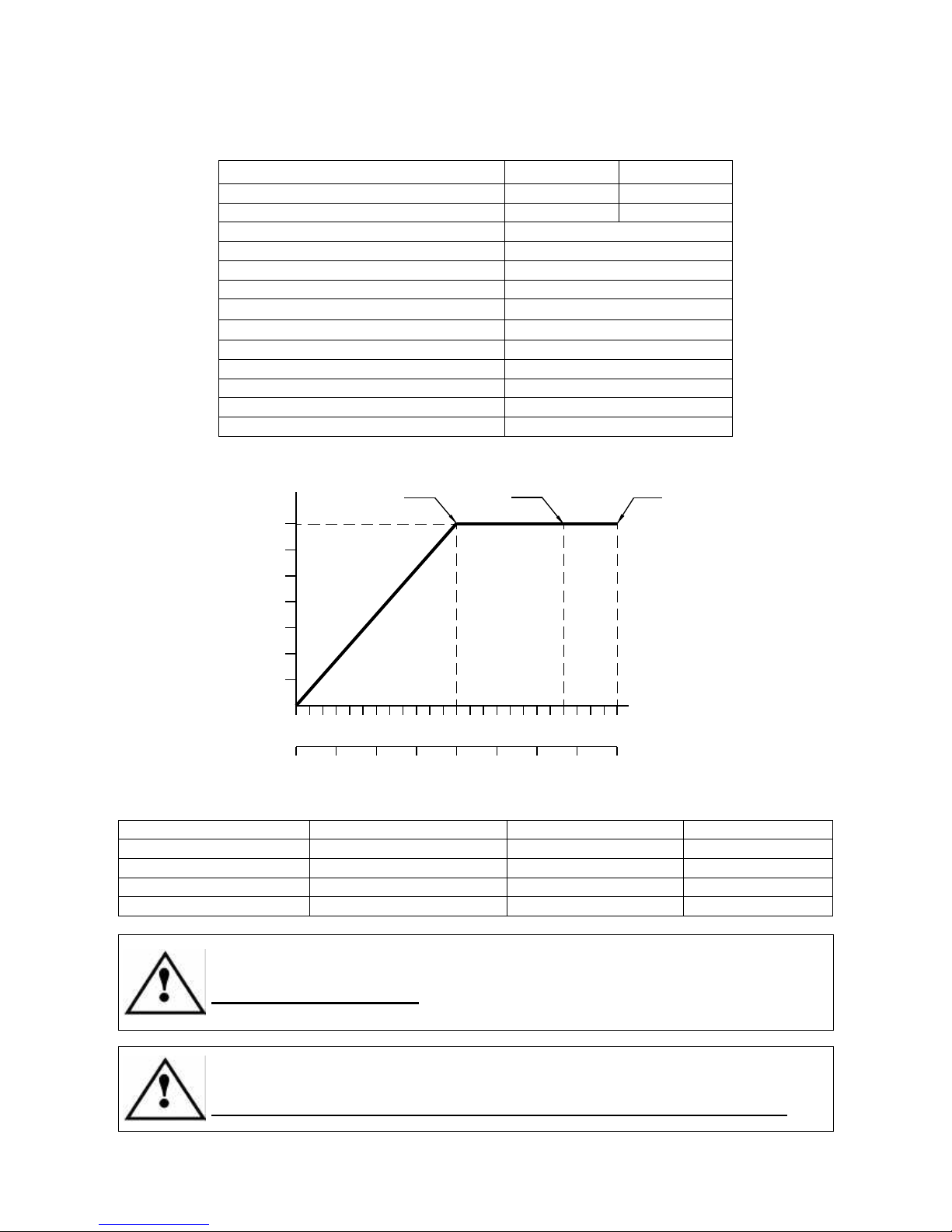

7.4.5 Specifications and performance of ES919 2 Pole, 7 kW units....................................... 23

7.4.6 Specifications and performance of ES919 2 Pole, 8 kW units....................................... 24

7.4.7 Specifications and performance of ES919 4 Pole, 5.5 kW units.................................... 25

7.4.8 Specifications and performance of ES919 4 Pole, 7.5 kW units.................................... 26

7.5 Technical specifications of ES919 L................................................................................. 27

7.5.1 Overall dimensions of ES919 L ISO30 Short Nose ...................................................... 27

7.5.2 Overall dimensions of ES919 L ISO30 Long Nose....................................................... 28

7.5.3 Overall dimensions of ES919 L HSK F63 Short Nose.................................................. 29

7.5.4 Overall dimensions of ES919 L HSK F63 Long Nose ................................................... 30

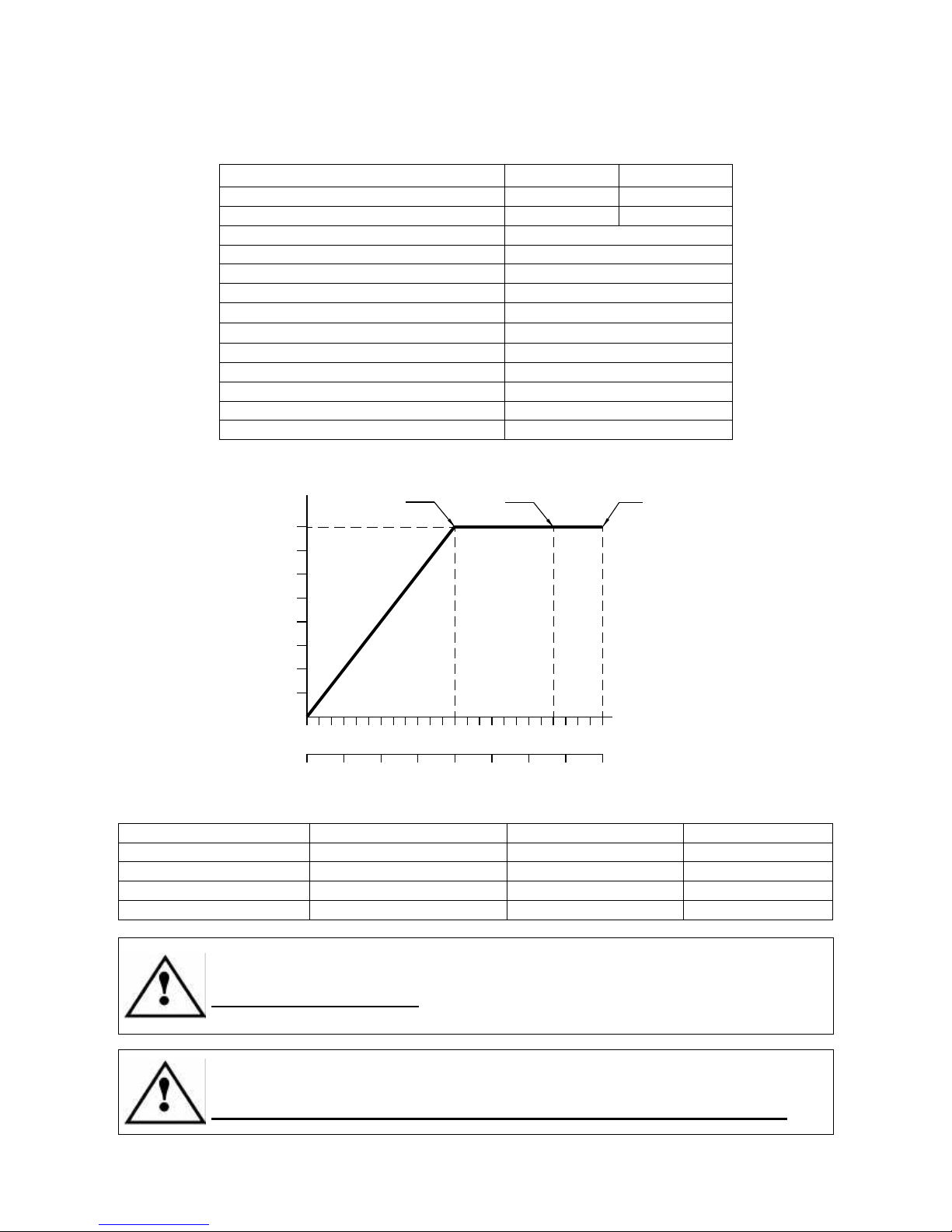

7.5.5 Specifications and performance of ES919 L 4 Pole, 12 kW units ................................. 31

7.6 Technical specifications of Belt driven C axis unit.......................................................... 32

7.6.1 Overall dimensions of ES919 ISO30 Short Nose with belt driven C Axis unit................ 32

7.6.2 Overall dimensions of gear units................................................................................... 33

7.6.3 Technical specifications for belt driven C axis unit ........................................................ 34

7.7 Technical specifications of components.......................................................................... 35

7.7.1 Bearings........................................................................................................................ 35

7.7.2 Tool holder locking and release device ......................................................................... 35

7.7.3 Automatic cleaning of the tool holder and internal pressurization.................................. 36

7.7.4 Proximity sensors.......................................................................................................... 36

Page 3

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 3/98

7.7.5 Tool release button....................................................................................................... 36

7.7.6 Thermal switch.............................................................................................................. 37

7.7.7 Cooling fan.................................................................................................................... 37

§ 8 TRANSPORT AND MOVING.......................................................................................... 38

8.1 Storage................................................................................................................................ 38

8.2 Lifting the electro-spindle in its crate............................................................................... 38

§ 9 INSTALLATION.............................................................................................................. 40

9.1 First Check .......................................................................................................................... 40

9.2 Preparation of the equipment required for installation on site ....................................... 40

9.3 Mechanical installation ...................................................................................................... 40

9.3.1 The supporting surface ................................................................................................. 40

9.3.2 Positioning the electro-spindle ...................................................................................... 40

9.3.3 Mechanical fixing of the electro-spindle ......................................................................... 41

9.3.4 Threaded service holes................................................................................................. 42

9.4 Compressed air connections............................................................................................. 43

9.4.1 Compressed air unions................................................................................................. 43

9.4.2 Functional diagram of electro-spindle compressed air connections............................... 44

9.5 Cooling circuit .................................................................................................................... 45

9.5.1 Cooler specifications..................................................................................................... 45

9.6 Electrical connections........................................................................................................ 46

9.6.1 Connectors ................................................................................................................... 46

9.6.2 Pin layout of fixed signals connector - ISO 30 version................................................... 46

9.6.3 Pin layout of fixed signals connector - HSK F63 version ............................................... 47

9.6.4 Pin layout of fixed power connector............................................................................... 47

9.6.5 Tool holder release system electrical wiring diagram for electro-spindles not controlled by

CNC.............................................................................................................................. 48

9.6.6 Configurable power terminals (optional)........................................................................ 49

§ 10 GENERAL CHECKS AFTER INSTALLATION AND DURING START-UP.................. 50

10.1 Checking the electro-spindle before start-up................................................................. 50

10.2 Checking the electro-spindle on first start-up................................................................ 51

§ 11 OPERATING THE ELECTRO-SPINDLE...................................................................... 52

11.1 Climatic conditions .......................................................................................................... 52

11.2 Running in......................................................................................................................... 52

11.3 Warming up....................................................................................................................... 52

11.4 Selecting the tool holder and tool ................................................................................... 53

11.4.1 ISO 30 tool holders ..................................................................................................... 53

11.4.2 HSK F63 tool holders.................................................................................................. 54

11.4.3 General safety precautions for tool holders................................................................. 55

11.4.4 Choosing tools............................................................................................................ 56

11.5 Speed limitations.............................................................................................................. 57

11.5.1 Content of graphs ....................................................................................................... 57

11.5.2 Reading the graphs..................................................................................................... 57

11.5.3 ES915 ISO30............................................................................................................. 58

11.5.4 ES919 ISO30 Short Nose , ES919 L ISO30 Short Nose ...................................... 59

11.5.5 ES919 ISO30 Long Nose , ES919 L ISO30 Long Nose........................................ 60

11.5.6 ES919 HSK F63 Short Nose , ES919 L HSK F63 Short Nose.............................. 61

11.5.7 ES919 HSK F63 Long Nose , ES919 L HSK F63 Long Nose............................... 62

11.6 Sensor functioning........................................................................................................... 63

11.6.1 ISO 30 versions .......................................................................................................... 63

11.6.2 HSK F63 versions....................................................................................................... 64

11.7 Thermal switch ................................................................................................................. 65

§ 12 MAINTENANCE............................................................................................................ 66

12.1 Scheduled maintenance................................................................................................... 67

12.1.1 Checking the cleanliness of the tool holder cone and of the spindle shaft tool housing67

Page 4

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 4/98

12.1.2 Cleaning the tool holder cone...................................................................................... 69

12.1.3 Protecting the spindle shaft's conical housing ............................................................. 69

12.1.4 Lubricating HSK fingers .............................................................................................. 70

12.1.5 Bearings...................................................................................................................... 70

12.2 Replacing parts................................................................................................................. 71

12.2.1 Changing the spindle shaft kit ..................................................................................... 72

12.2.2 Replacing the cooling fan............................................................................................ 74

12.2.3 Replacing the tool change push-button....................................................................... 74

12.2.4 Replacing sensors S1, S2, S3 and S4......................................................................... 75

12.2.4.1 Wiring of sensors in ISO 30 versions...............................................................................75

12.2.4.2 Wiring of sensors in HSK versions...................................................................................75

12.2.4.3 Accessing the sensors.....................................................................................................76

12.2.4.4 Location of sensors..........................................................................................................76

12.2.4.5 The sensor assembly.......................................................................................................77

12.2.4.6 Replacing a sensor assembly..........................................................................................77

12.2.4.7 Calibrating sensors S1, S2, and S3 on ISO 30 electro-spindles .....................................78

12.2.4.8 Calibrating sensors S1, S2, S3 and S4 on HSK F63 electro-spindles ............................78

12.2.4.8.1 Procedure for S1..............................................................................................78

12.2.4.8.2 Procedure for S2..............................................................................................78

12.2.4.8.3 Procedure for S3..............................................................................................79

12.2.4.8.4 Procedure for S4..............................................................................................79

12.2.4.9 Gauge and shim kit for calibrating S1 and S4 sensors on HSK F63 electro-spindles

(HSD code 3811H0110).......................................................................................................80

12.2.4.10 Calibrating sensors S1 and S4 on F63 HSK electro-spindles using the 3811H0110 kit80

12.2.4.10.1 Procedure for S1............................................................................................81

12.2.4.10.2 Procedure for S4............................................................................................81

12.2.5 Replacing the cylinder assembly................................................................................. 82

§ 13 ACCESSORIES AND OPTIONS .................................................................................. 85

13.1 "Spindle shaft stopped" sensor S3................................................................................. 85

13.2 Bearing temperature sensor............................................................................................ 85

13.2.1 Installing the bearing temperature sensor ................................................................... 86

13.2.2 Characteristic curve of the temperature sensor referred to 1 mA............................... 86

13.3 “C” axis unit...................................................................................................................... 87

13.3.1 Belt driven “C” axis unit............................................................................................... 87

13.3.2 Gear driven “C” axis unit ............................................................................................. 87

13.3.3 SC sensor for the belt driven “C” axis unit................................................................... 88

13.3.4 Replacing and calibrating the SC sensor in belt drive versions.................................... 89

13.4 Forced air cooling ............................................................................................................ 91

13.4.1 Installing the forced air cooling kit ............................................................................... 91

§ 14 TROUBLE SHOOTING................................................................................................. 92

§ 15 SPARE PARTS LIST.................................................................................................... 96

§ 16 DISPOSING OF THE ELECTRO-SPINDLE.................................................................. 97

Page 5

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 5/98

§ 1 DOCUMENTS DELIVERED WITH THE ELECTRO-SPINDLE

The following documents are delivered with the electro-spindle:

• this manual containing the safety warnings and instructions for installation, operation and

maintenance

• a series of other documents including:

1. The Manufacturer's Declaration of conformity to attachment IIB of Directive 98/37/CE

2. Attachments containing information on special parts of the electro-spindle. All such

attachments must be consulted in conjunction with the main document to which they refer in

order to avoid missing important information.

Make sure that all the above documents are delivered with the electrospindle. If any are missing, ask HSD S.p.a. for a replacement copy.

§ 2 DOCUMENT INFORMATION

This manual has been written by the Electro-spindle department of the Technical Office at HSD

S.p.a. for use by all the installers, operators and service engineers who work with the electrospindle.

ISSUED BY CODE REVISION APPROVED BY

HSD S.p.a.

Via della Meccanica 16

Loc. Chiusa di Ginestreto

61100 PESARO (ITALIA)

5801H0017 02 UTE 005 / 03

Record of updates

Revision Added § Deleted § Changed §

00 First issue First issue First issue

01 General revision General revision General revision

02 ES 915 L HSK F63 Long Nose ---- Overall dimensions of ES 919 L HSK F63 Long Nose

This manual is delivered as an essential part of the electro-spindle and at the time of revision was

the most up to date documentation on the product.

§ 3 CUSTOMER ASSISTANCE SERVICE

HSD HSD HSD

Via della Meccanica 16

61100 PESARO (ITALIA)

Loc. Chiusa di Ginestreto

Tel. (+39)0721.439.638

Fax (+39)0721.441.606

E-mail hsd.service@hsd.it

Web www.hsd-hitec.com

HSD Deutschland GmbH

Brückenstrasse 2

D-73333 Gingen

Tel. +49(0)7162 / 9323436

Fax +49(0)7162 / 9323439

HSD USA Inc.

3764 SW, 30th Avenue

Hollywood, Florida 33312 USA

Phone no. (+1) 954 587 1991

Fax (+1) 954 587 8338

E-mail service@hsdusa.com

Web www.hsdusa.com

Page 6

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 6/98

§ 4 TERMS OF WARRANTY

HSD S.p.a. guarantees that this electro-spindle has been QC passed in testing in the factory. HSD

S.p.a. accepts responsibility only for defects in electrical and mechanical parts. The warranty does

not cover defects caused by the normal use of parts subject to continuous or rapid wear (e.g.

seals, belts, bearings, etc.). In particular HSD S.p.a. offers no guarantee as to the duration of

bearings, since bearing wear depends on various factors including: tool balancing precision, type

of machining operation, impacts and/or mechanical stress in excess of the manufacturer’s declared

limits.

HSD S.p.a. declines all responsibility for non-compliance of the electro-spindle caused by failure to

follow the precautions and instructions given in this manual or by improper use or handling of the

electro-spindle. The customer has the right to replacement of all parts shown to be defective,

unless the said defects are caused by unauthorized tampering, including the fitting of non-original

HSD spare parts and/or the replacement of parts not described or authorized in this manual unless

authorized beforehand and in writing by HSD S.p.A..

In no case shall HSD S.p.A. or its suppliers accept any responsibility for damage (including

damage to the unit, damage incurred for lost production and income, down-time in manufacturing,

loss of information or other economic losses) deriving from the use of HSD products, even if HSD

has been advised of such risks in advance.

The warranty becomes automatically null and void if the customer fails to notify HSD S.p.A. in

writing of any faults found in the electro-spindle within 15 days of their occurrence. The warranty

likewise becomes null and void if the customer fails to permit the seller to perform all necessary

checks and tests, and if, when the seller requests the return of a defective part, the customer fails

to do so within two weeks of the request.

Dimensioned drawings and photographs are provided only for information purposes and to

facilitate understanding of text.

HSD S.p.A. has a policy of constant development and improvement, and reserves the right to

make functional and stylistic modifications to its products, to change the design of any functional or

accessory part, and to suspend manufacturing and supply without notice and without obligation to

third parties. Furthermore, HSD S.p.A. reserves the right to make any structural or functional

change to the units, and to change the supply of spare parts and accessories without any prior

notice.

Page 7

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 7/98

§ 5 WARNINGS AND SAFETY PRECAUTIONS

5.1 DISTRIBUTION OF THIS MANUAL

This manual contains important instructions and precautions, and must accompany the electrospindle at all times since it is essential for the safe operation of the electro-spindle.

Keep this manual safe, and ensure that all persons involved with the electro-spindle know of it and

have access to it.

The safety precautions contained herein are designed to ensure the safety of all persons

exposed to the residual risks associated with the electro-spindle.

The instructions contained herein provide information necessary for the correct operation of the

electro-spindle, as required by the manufacturer.

If any information given in this manual is found to be in conflict with applicable safety regulations,

contact HSD S.p.A. on +39 0721 439612 to request the necessary corrections and/or adaptations.

Make sure that you read and fully understand all the documentation supplied with the electrospindle to avoid incorrect operation of the unit and unnecessary risks of personal injury.

Keep this manual in a suitable place near the machine, where it will always be readily available to

operators for consultation.

IMPORTANT: The information given in this manual is essential to

ensure that the electro-spindle is installed and used safely and

correctly.

5.2 GENERAL SAFETY SYMBOLS

In this manual, important instructions or precautions are marked with the following symbols:

WARNING: Identifies situations that could lead to

personal injury.

WARNING: Live electrical parts.

i

IMPORTANT: Identifies particulary important

information.

Page 8

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 8/98

5.3 RISKS ASSOCIATED WITH THE ELECTRO-SPINDLE

HSD does not and can not know how end users will install their electro-spindles. The

installer or customer must therefore perform risk assessment specific to each installation

and application.

It is also the responsibility of the installer to ensure that adequate guards are provided to prevent

accidental contact with moving parts.

The installer and the operator must also bear in mind other types of risk, particulary those

associated with foreign bodies, explosive, inflammable, toxic or high temperature gasses.

Risks associated with maintenance operations must also be guarded against. Maintenance must

be performed in conditions of maximum safety, and only with the electro-spindle fully stationary

and switched off.

Once the electro-spindle has been installed in the way decided upon by the installer and/or

customer, the machine becomes a “finished machine” as defined for the purposes of the Machinery

Directive. Overall risk assessment must therefore be performed on the finished machine and a

declaration of conformity produced in compliance with Appendix IIA of the 98/37/CE Machinery

Directive.

5.4 RISKS ASSOCIATED WITH IMPROPER USE AND HANDLING

• Never impede the functioning of, remove, modify or in any way interfere with any safety device,

guard, or control of individual parts or of the electro-spindle as a whole.

• Never place your hands, arms, or any other part of your body near moving machinery.

• Do not use the electro-spindle in atmospheres or environments where there is a risk of

explosion.

• Unless you are duly authorized, never attempt to repair faults or electro-spindle malfunctions

and never interfere in any way with the electro-spindle’s operation or installation.

• On completion of servicing work for which guards, covers, or any other protections have been

removed, always make sure that they have been correctly and securely replaced and are fully

functional before re-starting the electro-spindle.

• Keep all protection and safety devices in perfect working order. Also make sure that all warning

labels and symbols are correctly positioned and perfectly legible.

• When troubleshooting the electro-spindle always adopt all the safety precautions listed in this

manual for the purpose of preventing injury or damage to persons and things.

• After adjusting any mechanical part, make sure that you fully tighten all screws, bolts or ring

nuts you may have slackened or removed.

• Before you start the electro-spindle, make sure that all the safety devices are installed and

perfectly functional. Do not start the electro-spindle if this is not the case, but immediately

inform the person responsible for machine safety or your direct superior.

• Make sure that you have and use all the personal protective equipment (PPE) required by law.

Do not wear loose or hanging clothing (ties, wide sleeves, etc.).

• Never use tool holders of different types to those specified in this manual. To do so could

damage the tool holder cone or lead to unsafe tool holder locking.

Page 9

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 __________________________________________________________ 9/98

5.5 RISKS SPECIFIC TO MAINTENANCE

• Take great care not to cut yourself on the tools while servicing or cleaning the electro-spindle.

Ideally, tools should be removed prior to these operations.

• Rotating parts may continue to spin under the effect of inertia even when the electro-spindle

has been switched off. Make absolutely sure that the spindle is not spinning before accessing

it.

• Perform all scheduled maintenance as described in this manual. Failure to do so may lead to

mechanical failures and breakage through wear or inadequate maintenance.

WARNING: NEVER:

• Start any maintenance before making absolutely sure that the tool in the

electro-spindle is completely stationary.

• Start any maintenance on the electro-spindle before disconnecting it from

the main power supply.

• Attempt to clean the electro-spindle while it is operating.

§ 6 GENERAL INFORMATION

6.1 PROPER USE OF THE PRODUCT

Electro-spindles are used as parts of machines.

The machine structure to which the electro-spindle is secured must be rigid and strong enough to

support the weight of the electro-spindle and withstand the machining operations to be performed.

The electro-spindles described in this manual are designed for milling and drilling wood, plastic,

aluminium and fiber-board.

They are all designed for operation in an S1 duty type. Technical specifications vary as detailed in

section § 7.

All ES919 and ES915 variants can be fitted with a gear driven C axis unit as an optional.

Model ES919 ISO30 Short Nose (7 kW or 8 kW version, 2 poles) is also available with a belt driven

C axis unit. (C axis belt drive is not available as an option for retro-fitting.)

Some models have their power terminals configured in either star or delta configuration.

A spindle shaft kit is available for rapid changes of the complete spindle shaft with bearing

assembly on all models except models with belt driven C axis units.

To prevent damage to the precision bearings, all electro-spindles are fitted with a

mechanical reaction system that counteracts the axial force that the piston applies to the

spindle shaft during tool change operations.

Page 10

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 10/98

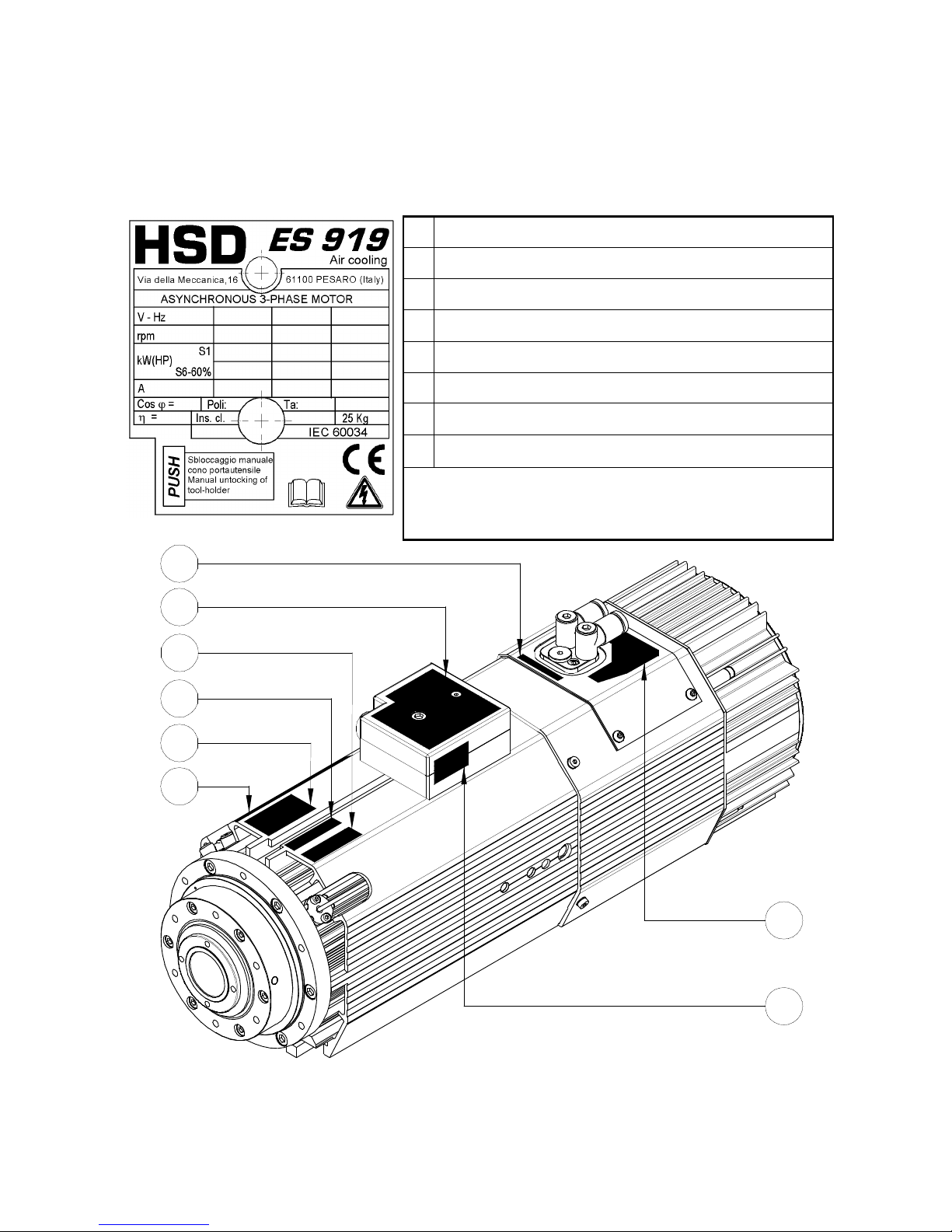

6.2 IDENTIFICATION OF MANUFACTURER AND PART

The data label shown below is the only form of electro-spindle identification recognised by the

manufacturer, and must be kept in its original legible condition. Figure 6.1 shows the electrospindle data label, while Figure 6.2 shows its location on the electro-spindle (Position 2).

1

Commercial part name and HSD code

2

CE label

3

“CERAMIC” (models with ceramic bearings only)

4

Serial number

5

Description of the tool holder cone

6

Commercial name of electro-spindle

7

Description of air inlets

8

HSD code for stator group

Figure 6.1 The CE label

NOTE:

Some of the symbols shown here may not be

present on your particular electro-spindle.

6

5

4

3

7

8

2

1

Figure 6.2 Location of the CE label and other symbols on the electro-spindle

Page 11

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 11/98

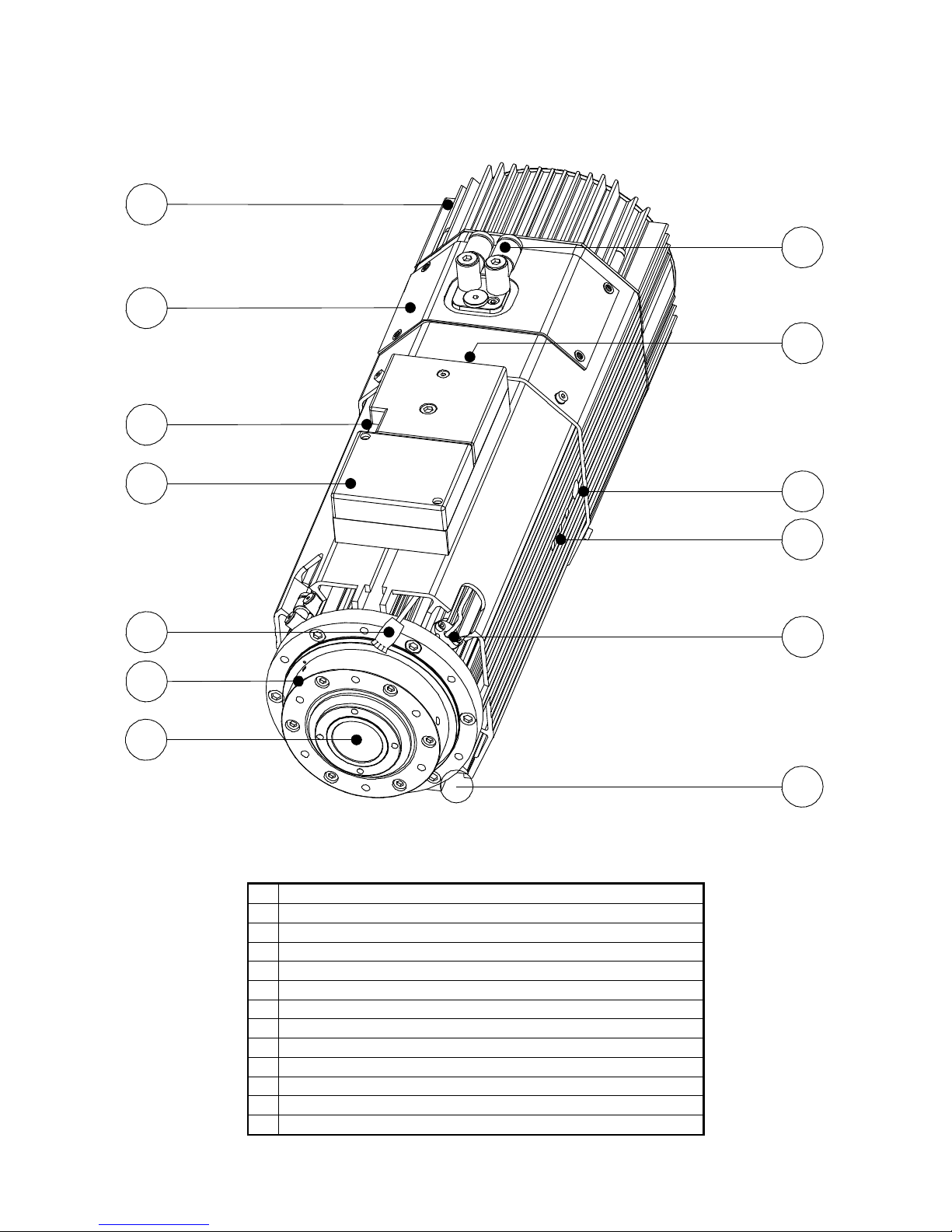

6.3 DESCRIPTION OF THE MAIN PARTS OF THE ELECTRO-SPINDLE

1

2

3

4

5

6

7

8

10

11

12

13

9

Figure 6.3 General view of the electro-spindle

1

Cooling fan

2

Sensor compartment

3

Manual tool holder release button

4

Configurable terminal block (optional)

5

C axis sensor connector (optional C axis)

6

Spindle nose

7

Spindle shaft

8

Compressed air connectors

9

Electrical terminals

10

Exhaust air silencer (one on each side)

11

Threaded service holes (see section 9.3.4 )

12

Temperature sensor for front bearings (optional)

13

“T” slots for anchoring to support

Page 12

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 12/98

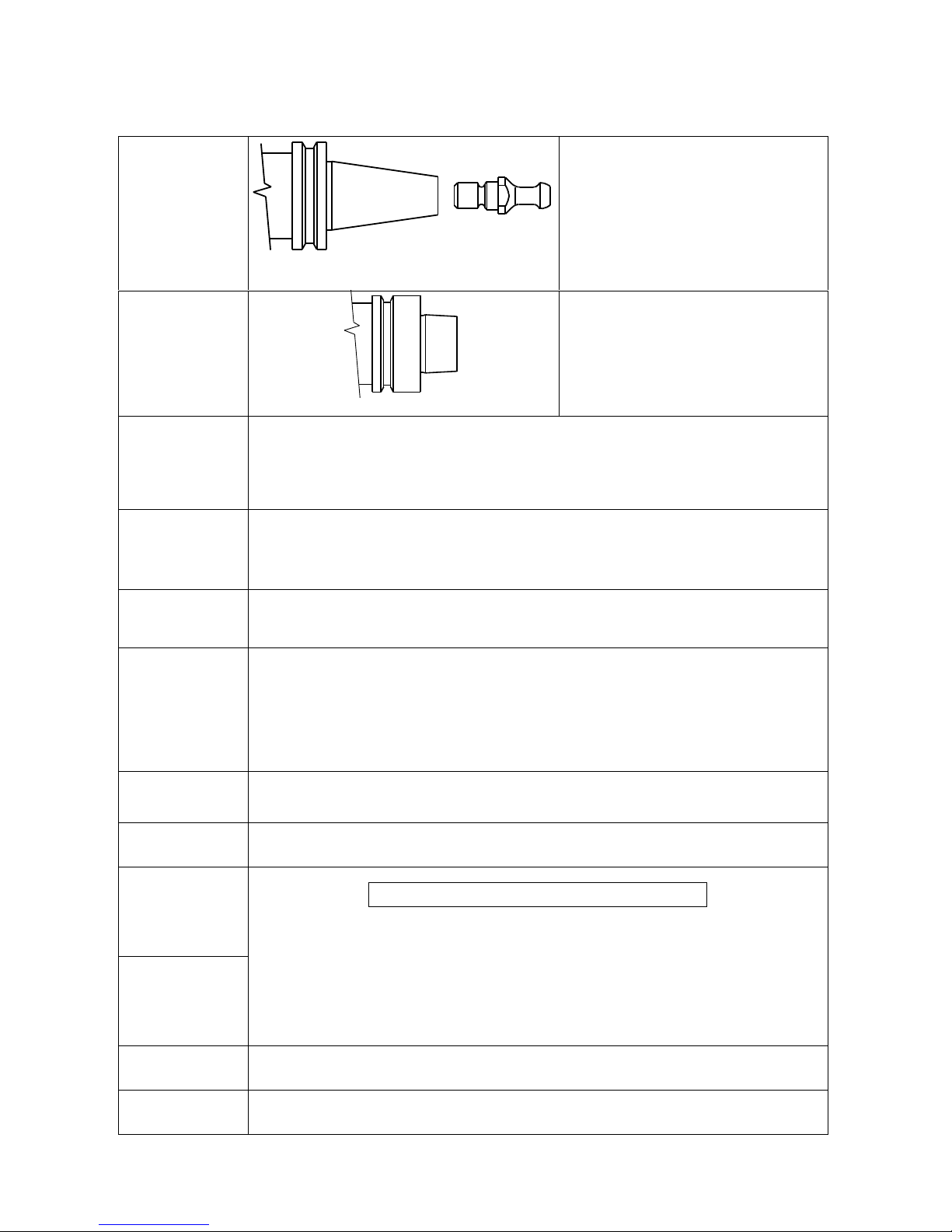

6.4 GLOSSARY

ISO 30

ISO30, DIN69871 CONE

HSD PULL STUD

0804H0009

The locking system for the tool holder

cone complies with DIN standard 69871.

The electro-spindle has a label showing

the type of tool holder mechanism (ISO

or HSK), bearing a symbol like that

shown at left.

HSK

DIN69893 HSK F63 CONE

The locking system for the tool holder

cone complies with DIN standard 69893.

The electro-spindle has a label showing

the type of tool holder mechanism (ISO

or HSK), bearing a symbol like that

shown at left.

Dynamic

balancing

class

The degree of balancing of a rotating object according to ISO standard 1940/1, defined

as the G rating.

Low G values mean better balancing. G = 0.4 specifies maximum balancing precision.

G assumes discrete values that increment in multiples of 2.5 (G=0.4 , G=1 , G=2.5 ,

etc.).

Scheduled

maintenance

Actions required to maintain the electro-spindle in the original condition, as specified by

HSD S.p.a..

Maintenance can include scheduled adjustments, repairs and part replacements.

Duty type S1

Functioning at constant load for enough time to bring the electro-spindle to a state of

thermal equilibrium.

Abbreviated as S1.

Duty type S6

A sequence of identical operating cycles, each comprising a period of functioning at

constant load and a period of functioning at no load but at the same rotation speed,

without any intermediate rest times.

Abbreviated as S6 followed by the percentage ratio between the period of functioning

under load and the duration of the cycle.

Example: S6 40%.

(40% functioning under load, 60% no load rotation).

Rated voltage

The maximum voltage permissible for electrical power to the electro-spindle.

Rated

frequency

The minimum frequency at which power at rated voltage must be delivered.

Torque

Power

..Torque (Nm) = [ 60 · power (W) ] : [ 2 · Π · rpm]..

Precise definition of torque and power goes beyond the scope of this manual.

Nevertheless, torque can be adequately understood as being related to the force with

which the tool bites into the work piece. (For the same torque, force increases as tool

diameter decreases.) Power on the other hand is proportional to torque and rotation

speed. Power limits the maximum machining speed (within the limits dictated by tool

performance, the characteristics of the material being machined, and the type of

machining involved).

Ratings

The set of rated values declared at rated frequency.

Coolants

Liquids or gases (including air), used as the medium for transferring heat from the

spindle into the environment.

Page 13

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 13/98

§ 7 TECHNICAL SPECIFICATIONS

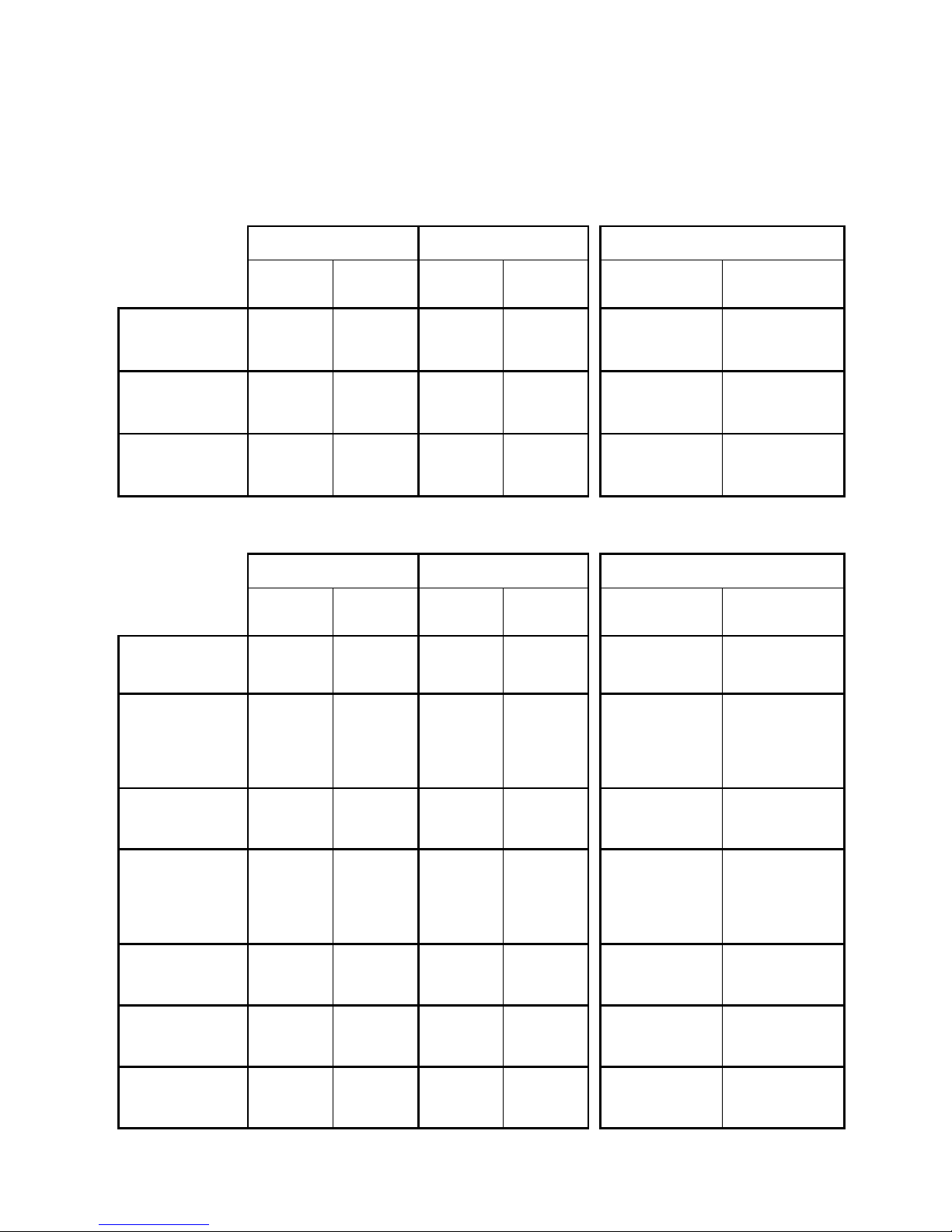

7.1 AVAILABLE MODELS

7.1.1 ES915 / ES915 L

ISO 30 HSK F63 RATED VOLTAGE

SHORT

NOSE

LONG

NOSE

SHORT

NOSE

LONG

NOSE

380 V

CONFIGURABLE

380 V / 220 V

3.8 kW

2 poles

air cooling

¦ ¦ ¦

5 kW

4 poles

air cooling

¦ ¦

7.5 kW

4 poles

liquid cooling

¦ ¦

7.1.2 ES919 / ES919 L

ISO 30 HSK F63 RATED VOLTAGE

SHORT

NOSE

LONG

NOSE

SHORT

NOSE

LONG

NOSE

380 V

CONFIGURABLE

380 V / 220 V

7 kW

2 poles

air cooling

¦ ¦ ¦ ¦

7 kW

2 poles

air cooling

whith belt-driven

"C Axis" unit

¦ ¦ ¦

8 kW

2 poles

air cooling

¦ ¦ ¦ ¦

8 kW

2 poles

air cooling

whith belt-driven

"C Axis" unit

¦ ¦ ¦

5.5 kW

4 poles

air cooling

¦ ¦ ¦

7.5 kW

4 poles

air cooling

¦ ¦ ¦ ¦ ¦

12 kW

4 poles

liquid cooling

¦ ¦ ¦ ¦ ¦

Page 14

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 14/98

7.2 TECHNICAL SPECIFICATIONS OF ES915

7.2.1 Overall dimensions of ES915

Page 15

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 15/98

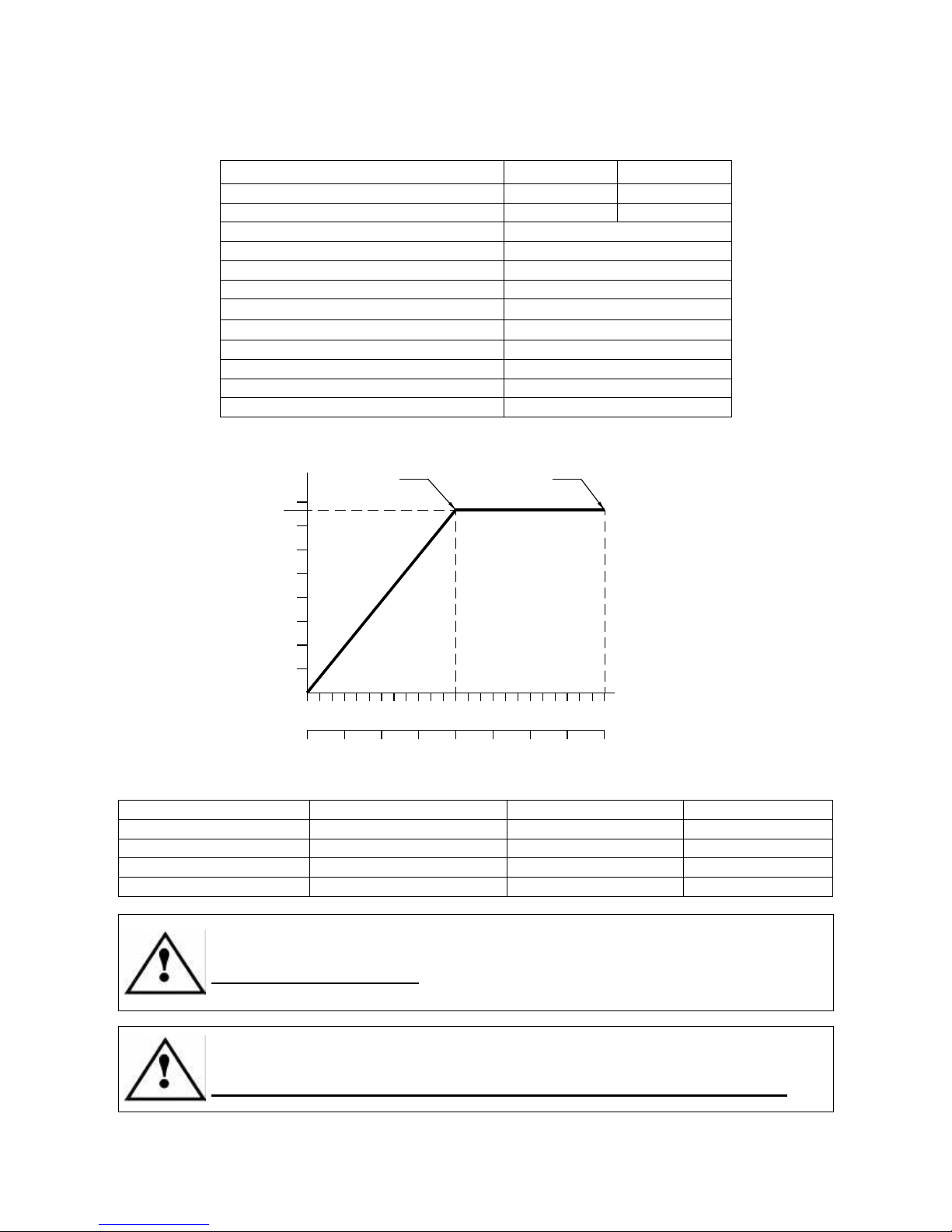

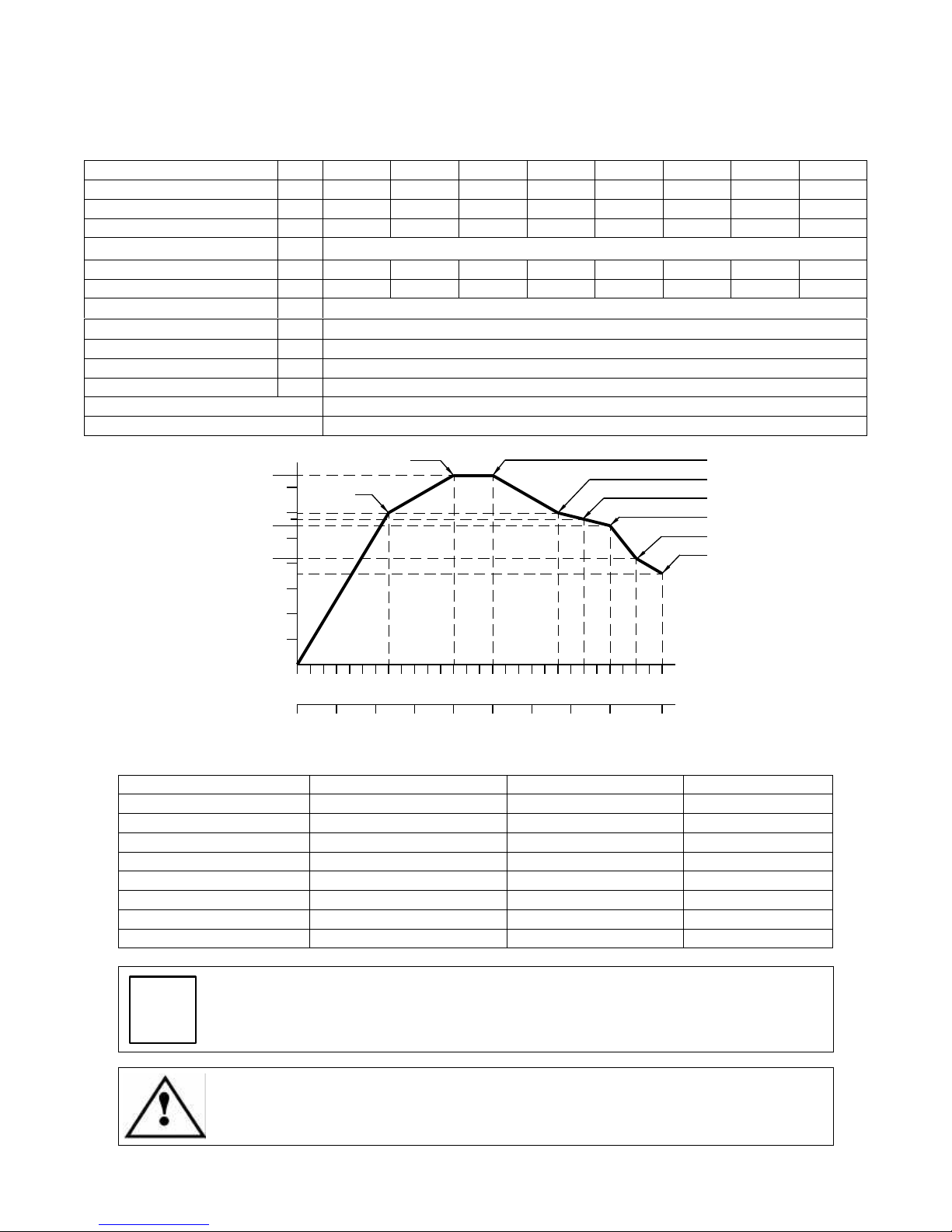

7.2.2 Specifications and performance of ES915 2 Pole, 3.8 kW units

Terminal connection type

Star Delta

Rated voltage (*)

380 V ± 10% 220 V ± 10%

Rated current

8.3 A 14.4 A

Rated speed

12000 rpm (200 Hz)

Rated power

3.8 kW

Duty type

S1

Rated torque

3 Nm

Rated efficiency η

0.8

Power factor cos ϕ

0.8

Number of poles

2

Insulation class

H

Type of cooling

Cooling fan

Weight

~ 21 kg

[(*) from inverter]

kW (S1)

Hz

0

3 6 9 12 15 18 21 2 4

1

2

3

4

0

50

100

150

200

250

300

350

400

3,8

3 Nm1,5 N

m

rpm x 1000

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

ISO30 STEEL STEEL 20000rpm / 333Hz

ISO30 CERAMIC STEEL 24000rpm / 400Hz

ISO30 CERAMIC CERAMIC 24000rpm / 400Hz

ISO30 CRONIDUR / CHROMEX CERAMIC 28000rpm / 467Hz

The 3.8 kW 2 Pole motor is also available in a configurable double voltage

version.

Configurable models only: Check that the power terminals are correctly wired

for the supply voltage before installing the unit.

The maximum continuous current inverter parameter must match the rated

current value in the table above (also stated on the motor’s data label).

Select the right value depending on whether the connection is star or delta.

Page 16

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 16/98

7.2.3 Specifications and performance of ES915 4 Pole, 5 kW units

Rated voltage (*)

V 225 ±10% 380 ±10% 380 ±10% 380 ±10% 380 ±10% 380 ±10%

Rated frequency

Hz 233 400 500 667 800 933

Rated speed

rpm 7000 12000 15000 20000 24000 28000

Rated power

kW 3 5 5 3.9 3 2,1

Duty type

S1

Rated torque

Nm 4 4 3.2 1.7 1.2 0.7

Rated current

A 12 12 10,5 9.2 7 4

Rated efficiency η

0.8 0.8 0.8 0.8 0.8 0.8

Power factor cos ϕ

0.85 0.85 0.85 0.8 0.8 0.75

Number of poles

4

Insulation class

F

Type of cooling

Cooling fan

Weight

kg ~ 21

[(*) from inverter]

kW (S1)

Hz

0

rpm x 1000

3 6 9 12 15 18 21 24 28

2,1

3,9

5

0

100

200

300

400

500

600

700

933

4

1

3

4 Nm

4 Nm

3,2 Nm

1,7 Nm

0,7 Nm

800

1,2 Nm

2

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

ISO30 STEEL STEEL 20000rpm / 667Hz

ISO30 CERAMIC STEEL 24000rpm / 800Hz

ISO30 CERAMIC CERAMIC 24000rpm / 800Hz

ISO30 CRONIDUR / CHROMEX CERAMIC 28000rpm / 933Hz

i

The 5 kW, 4 Pole motor is not available with configurable double voltage power

terminals.

The maximum continuous current inverter parameter must match the maximum

value of the rated current in the table above (also stated on the motor’s data

label).

Page 17

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 17/98

7.3 TECHNICAL SPECIFICATIONS OF ES915 L

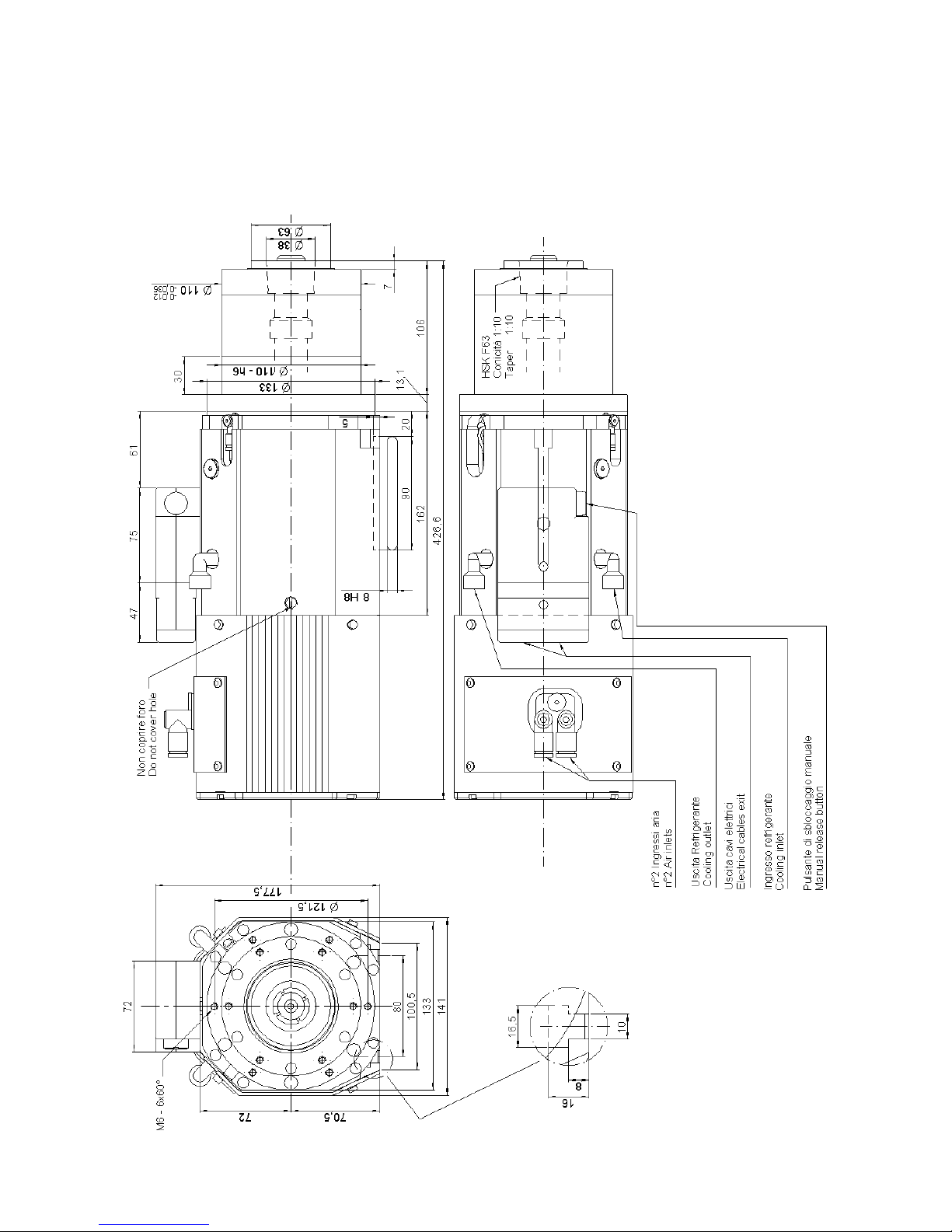

7.3.1 Overall dimensions of ES915 L HSK F63 Long Nose

Page 18

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 18/98

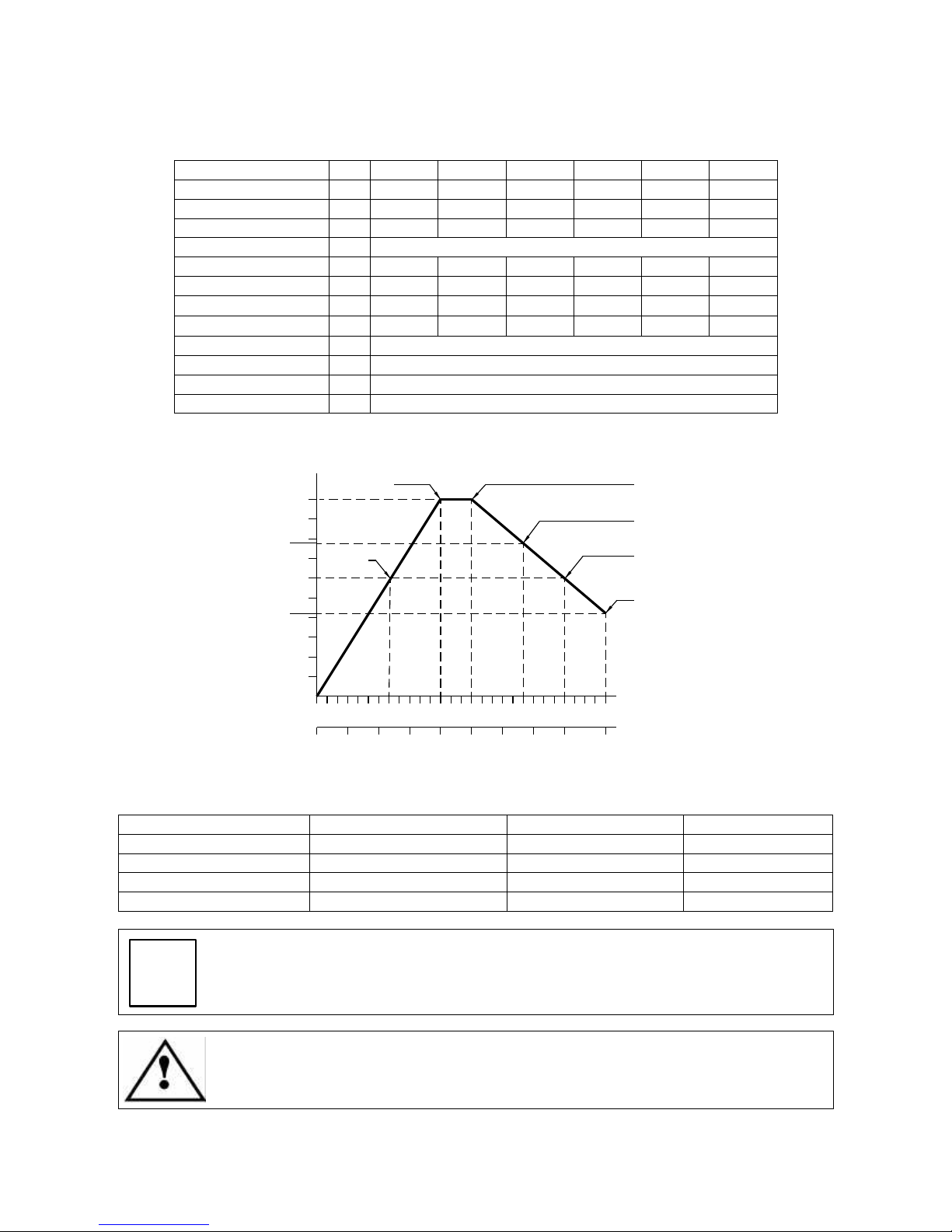

7.3.2 Specifications and performance of ES915 L 4 Pole, 7.5 kW units

Rated voltage (*)

V

380 ±10% 380 ±10% 380 ±10% 380 ±10% 380 ±10% 380 ±10%

Rated frequency

Hz 400 500 600 667 733 933

Rated speed

rpm 12000 15000 18000 20000 22000 28000

Duty type

S1

contS650%S1contS650%S1contS650%S1contS650%S1contS650%S1contS650%

Rated power

kW

6,5 7,5 6,5 7,5 6,1 6,7 5,8 6,4 5,5 6 3 3

Rated torque

Nm 5,2 6 4,1 4,8 3,2 3,6 2,8 3,1 2,4 2,6 1 1

Rated current

A

15 18 15 18 14 15,7 13 16 13,1 14,1 7,5 7,5

Rated efficiency η

0,82

Power factor cos ϕ

0,74

Number of poles

4

Insulation class

F

Type of cooling

Liquid cooling

Weight of

LONG NOSE variant

kg ~ 29

[(*) from inverter]

kW (S6 50%)

Hz

0

rpm x 1000

3 6 9 12 15 18 21 24 28

1

2

3

4

5

6

6,7

0

100

200

300

400

500

600

700

933

7,5

6 Nm

4,8 N

m

3,6 Nm

800

2,6 Nm

1 Nm

6,4

3,1 N

m

Note:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

HSK F63 STEEL STEEL 18000rpm / 600Hz

HSK F63 CERAMIC STEEL 20000rpm / 667Hz

HSK F63 CERAMIC CERAMIC 22000rpm / 733Hz

HSK F63 CRONIDUR / CHROMEX CERAMIC 28000rpm / 933Hz

i

The 7.5 kW, 4 Pole motor is not available with configurable double voltage

power terminals.

The maximum continuous current inverter parameter must match the maximum

value of the rated current in the table above (also stated on the motor’s data

label).

Page 19

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 19/98

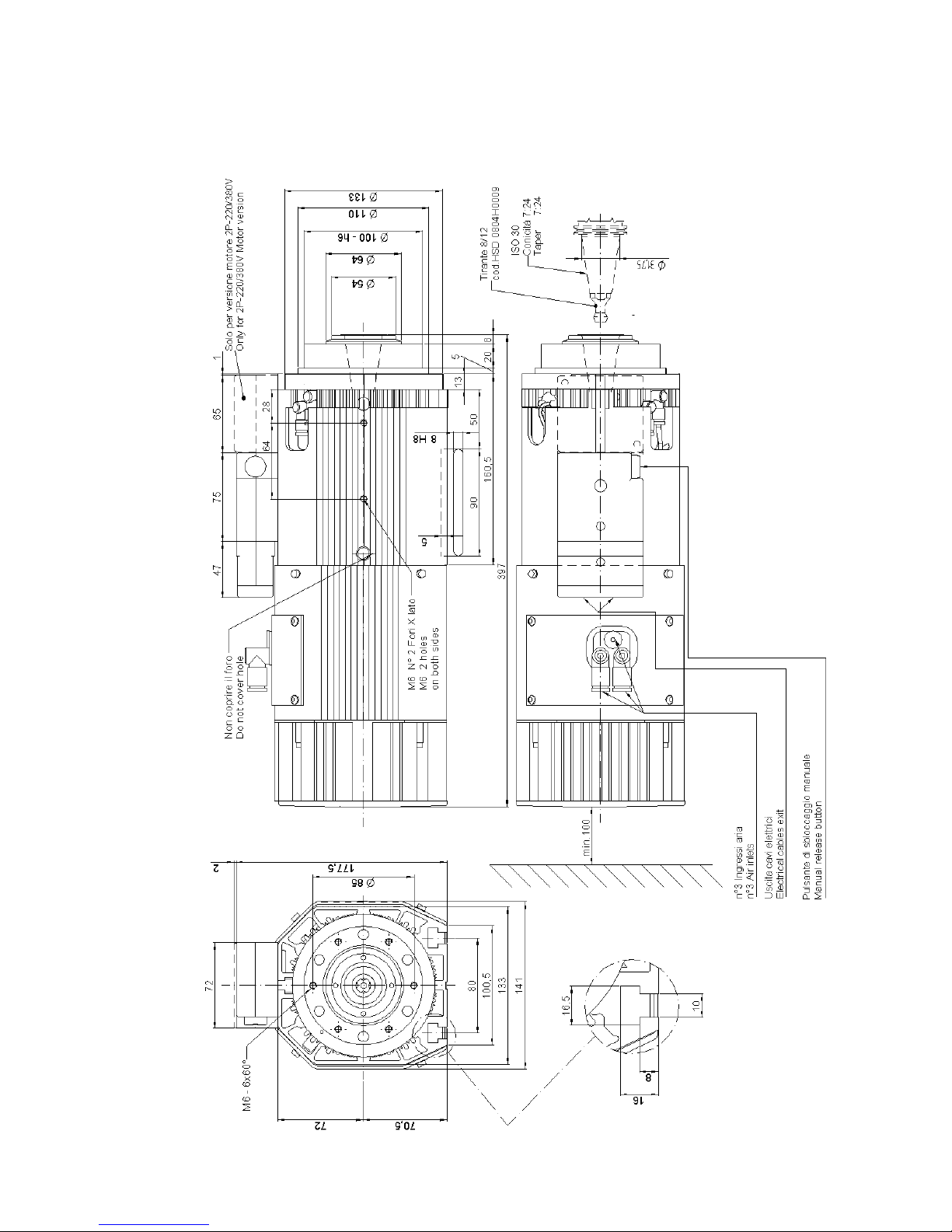

7.4 TECHNICAL SPECIFICATIONS OF ES919

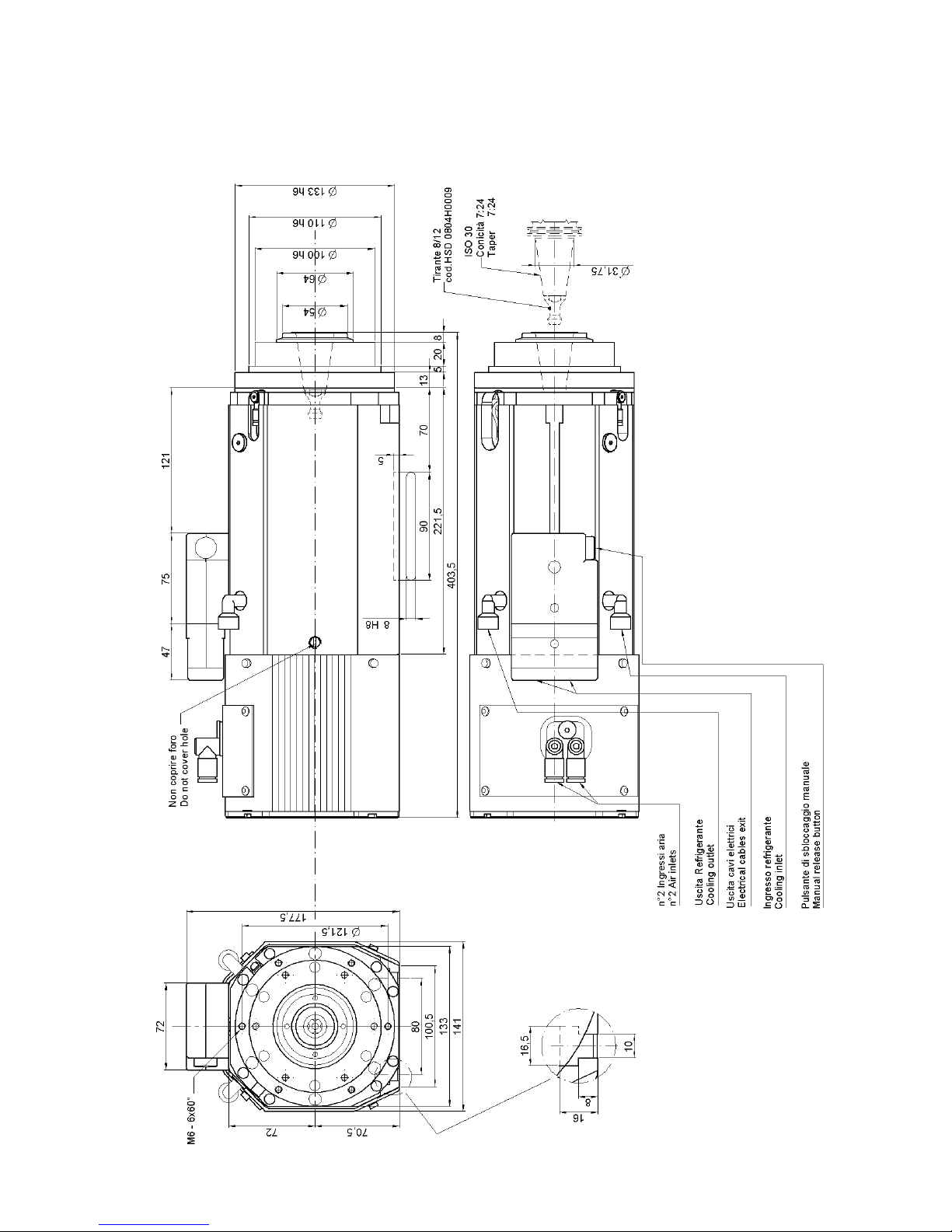

7.4.1 Overall dimensions of ES919 ISO30 Short Nose

Page 20

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 20/98

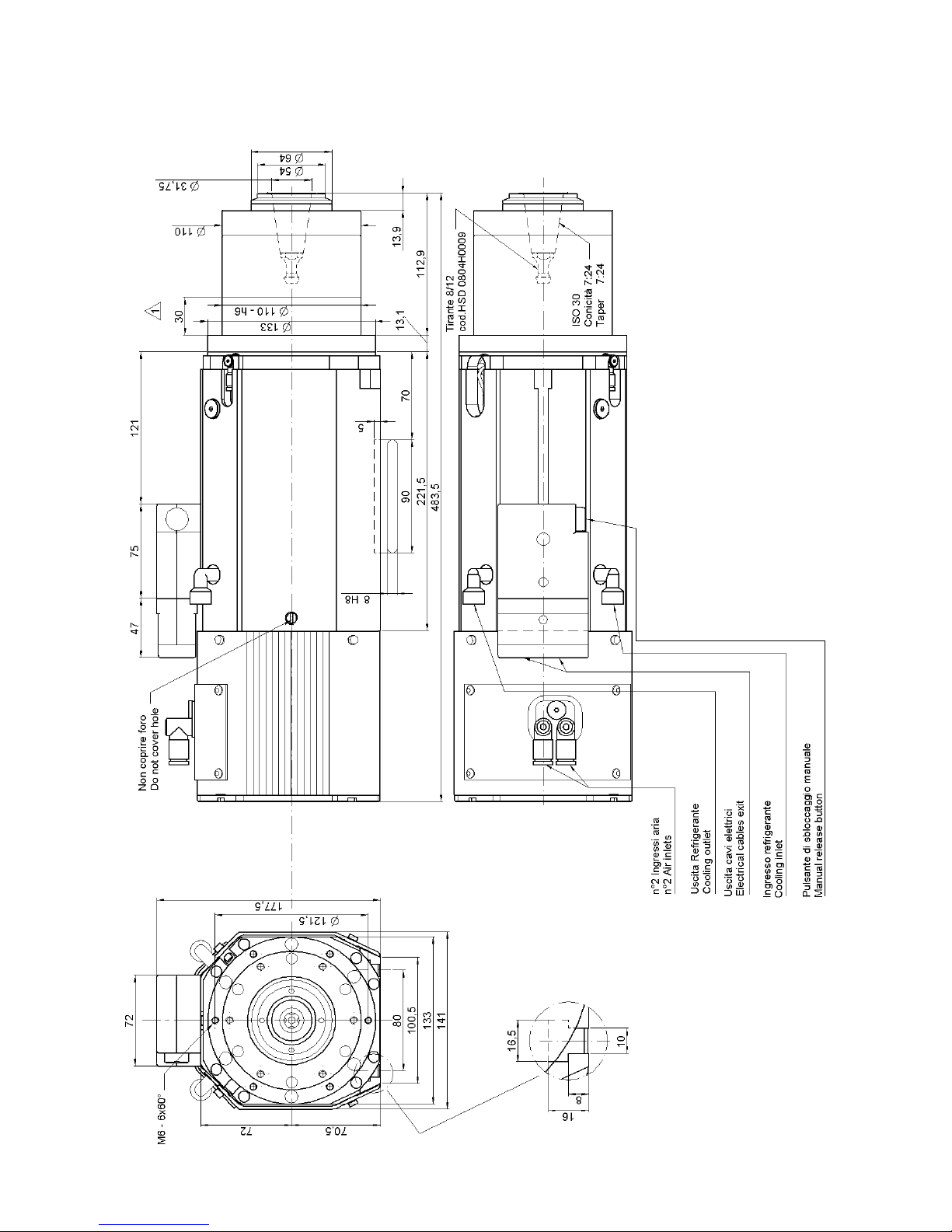

7.4.2 Overall dimensions of ES919 ISO30 Long Nose

Page 21

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 21/98

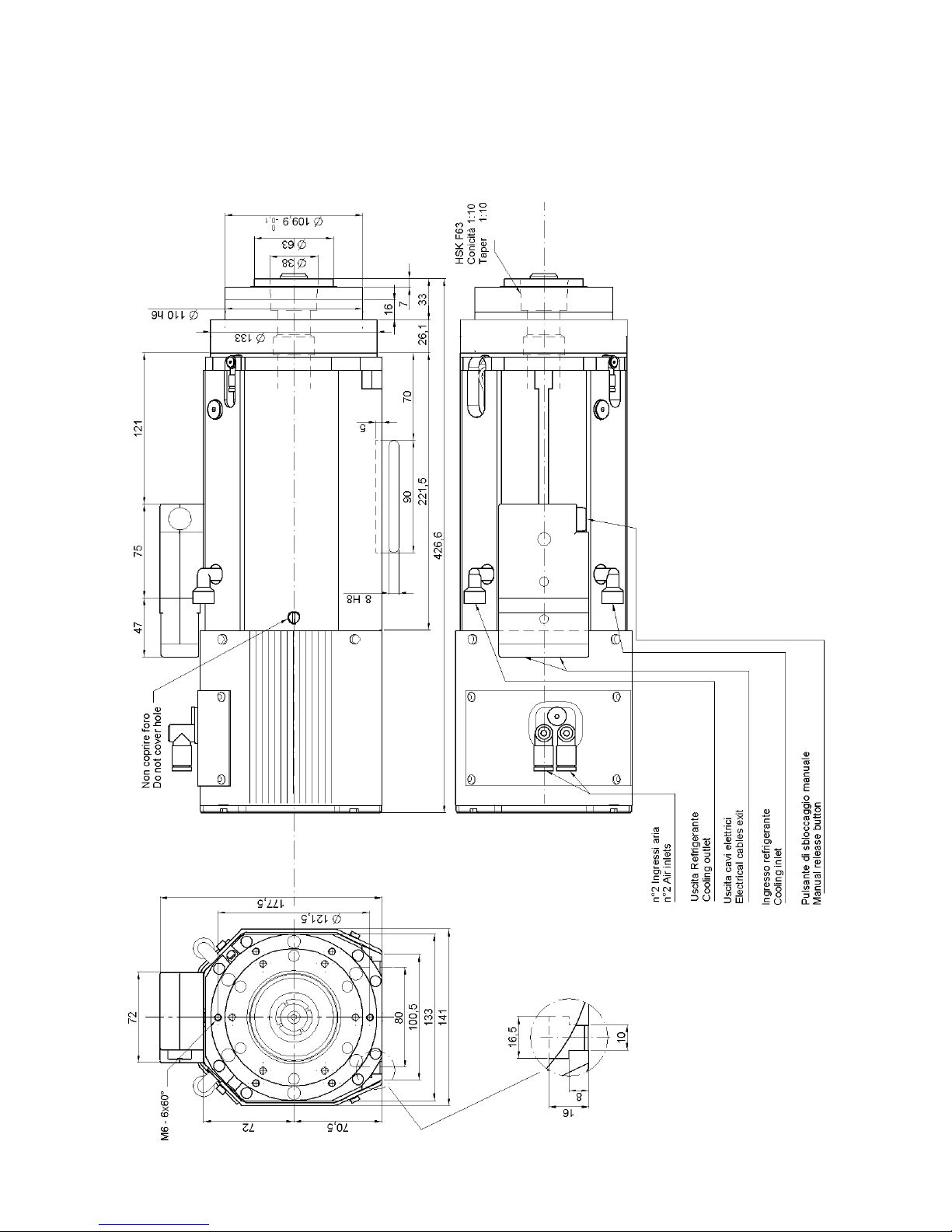

7.4.3 Overall dimensions of ES919 HSK F63 Short Nose

Page 22

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 22/98

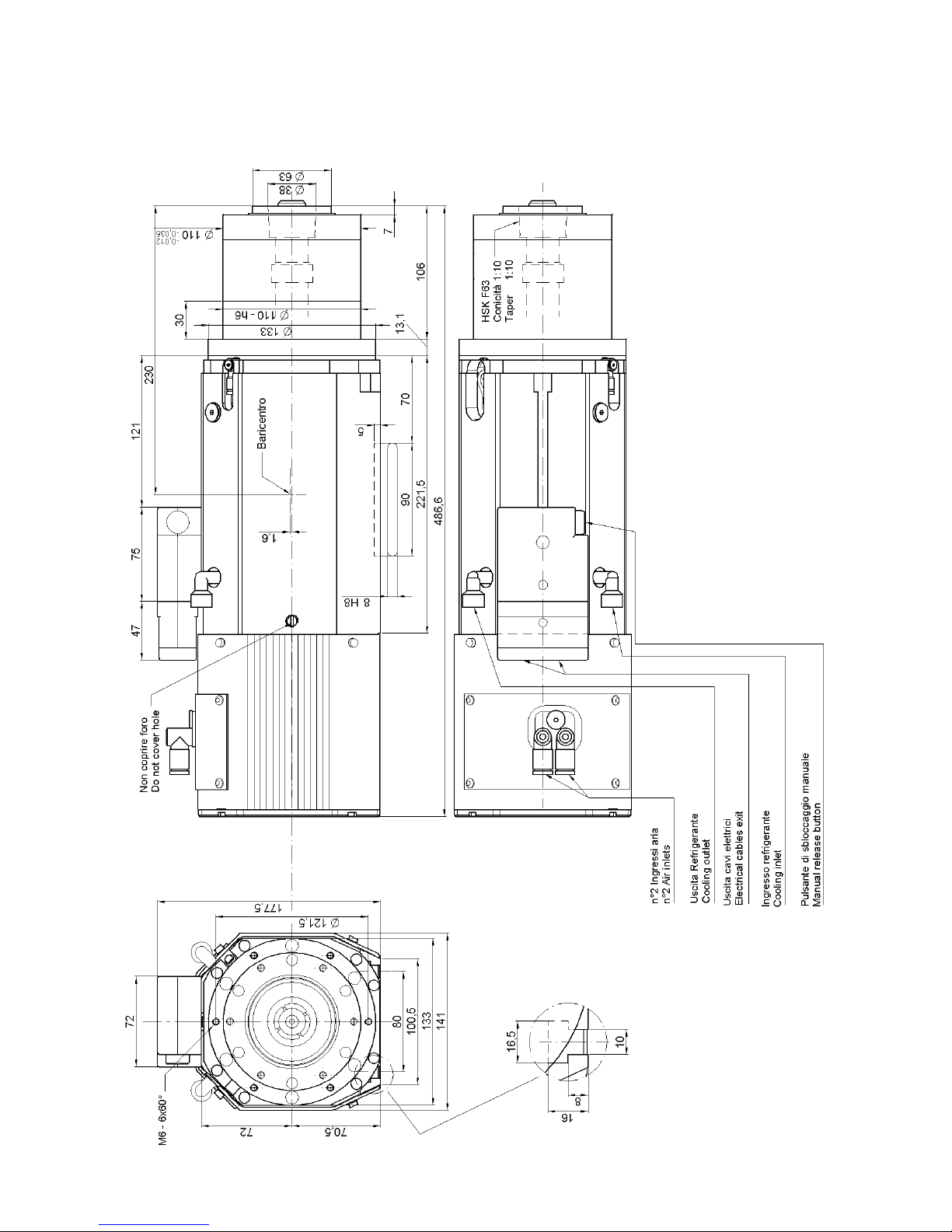

7.4.4 Overall dimensions of ES919 HSK F63 Long Nose

Page 23

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 23/98

7.4.5 Specifications and performance of ES919 2 Pole, 7 kW units

Terminal connection type

Star Delta

Rated voltage (*)

380 V ± 10% 220 V ± 10%

Rated current

16 A 28 A

Rated speed

12000 rpm (200 Hz)

Rated power

7 kW

Duty type

S1

Rated torque

5.6 Nm

Rated efficiency η

0.8

Power factor cos ϕ

0.8

Number of poles

2

Insulation class

H

Type of cooling

Cooling fan

Weight of SHORT NOSE variant

~ 26 kg

Weight of LONG NOSE variant

~ 31 kg

[(*) from inverter]

kW (S1)

Hz

0

rpm x 1000

3 6 9 1 2 15 18 21 2 4

1

2

3

4

5

6

7

0

50

100

150

200

250

300

350

400

5,6 Nm3,3 Nm2,8 N

m

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

ISO30 STEEL STEEL 20000rpm / 333Hz

ISO30 CERAMIC STEEL 24000rpm / 400Hz

ISO30 CERAMIC CERAMIC 24000rpm / 400Hz

ISO30 CRONIDUR / CHROMEX CERAMIC 28000rpm / 467Hz

The 7 kW 2 Pole motor is also available in a configurable double voltage

version.

Configurable models only: Check that the power terminals are correctly wired

for the supply voltage before installing the unit.

The maximum continuous current inverter parameter must match the rated

current value in the table above (also stated on the motor’s data label).

Select the right value depending on whether the connection is star or delta.

Page 24

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 24/98

7.4.6 Specifications and performance of ES919 2 Pole, 8 kW units

Terminal connection type

Star Delta

Rated voltage (*)

380 V ± 10% 220 V ± 10%

Rated current

18 A 32 A

Rated speed

12000 rpm (200 Hz)

Rated power

8 kW

Duty type

S1

Rated torque

6.4 Nm

Rated efficiency η

0.8

Power factor cos ϕ

0.8

Number of poles

2

Insulation class

H

Type of cooling

Cooling fan

Weight of SHORT NOSE variant

~ 26 kg

Weight of LONG NOSE variant

~ 31 kg

[(*) from inverter]

kW (S1)

Hz

0

rpm x 1000

3 6 9 12 15 18 21 24

1

2

3

4

5

6

7

8

0

50

100

150

200

250

300

350

400

6,4 N

m

3,6 Nm 3,2 Nm

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

ISO30 STEEL STEEL 20000rpm / 333Hz

ISO30 CERAMIC STEEL 24000rpm / 400Hz

ISO30 CERAMIC CERAMIC 24000rpm / 400Hz

ISO30 CRONIDUR / CHROMEX CERAMIC 28000rpm / 467Hz

The 8 kW 2 Pole motor is also available in a configurable double voltage

version.

Configurable models only: Check that the power terminals are correctly wired

for the supply voltage before installing the unit.

The maximum continuous current inverter parameter must match the rated

current value in the table above (also stated on the motor’s data label).

Select the right value depending on whether the connection is star or delta.

Page 25

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 25/98

7.4.7 Specifications and performance of ES919 4 Pole, 5.5 kW units

Rated voltage (*)

380 V ± 10% 380 V ± 10% 380 V ± 10%

Rated frequency

233 Hz 400 Hz Hz 600

Rated speed

7000 rpm 12000 rpm 18000 rpm

Rated power

5.5 kW 4.5 kW 1.5 kW

Duty type

S1

Rated torque

7.5 Nm 3.6 Nm 0.8 Nm

Rated current

15 A 14 A 6.5 A

Rated efficiency η

0,8

Power factor cos ϕ

0,8

Number of poles

4

Insulation class

H

Type of cooling

Cooling fan

Weight

~ 26 kg

[(*) from inverter]

kW (S1)

Hz

0

rpm x 1000

3 6 9 12 15 18

1

2

3

4

5

0

100

200

300

400

500

600

5,5

4,5

1,5

7,5 N

m

3,6 Nm

0,8 Nm

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

ISO30 STEEL STEEL 18000rpm / 600Hz

ISO30 CERAMIC STEEL 18000rpm / 600Hz

i

The 5.5 kW, 4 Pole motor is not available with configurable double voltage

power terminals.

The maximum continuous current inverter parameter must match the maximum

value of the rated current in the table above (also stated on the motor’s data

label).

Page 26

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 26/98

7.4.8 Specifications and performance of ES919 4 Pole, 7.5 kW units

Rated voltage (*)

V 225 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10%

Rated frequency

Hz 233 400 500 667 733 800 867 933

Rated speed

rpm 7000 12000 15000 20000 22000 24000 26000 28000

Rated power

kW 6 7.5 7.5 6 5.75 5.5 4.2 3.6

Duty type

S1

Rated torque

Nm 8.2 6 4.8 2.9 2.5 2.2 1.5 1.2

Rated current

A 25 20 17 15 13 13 10 11.5

Rated efficiency η

0,8

Power factor cos ϕ

0,8

Number of poles

4

Insulation class

F

Type of cooling

Cooling fan

Weight of SHORT NOSE variant

~ 26 kg

Weight of LONG NOSE variant

~ 31 kg

[(*) from inverter]

kW (S1)

Hz

0

rpm x 1000

3 6 9 12 15 18 21 24 28

1

2

3

4

5

6

7

0

100

200

300

400

500

600

700

933

4,2

7,5

8,2 Nm

6 Nm4,8 N

m

2,9 Nm

2,2 Nm

800

5,5

1,5 Nm

5,5

2,5 Nm

1,2 Nm

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

HSK F63 STEEL STEEL 18000rpm / 600Hz

HSK F63 CERAMIC STEEL 20000rpm / 667Hz

HSK F63 CERAMIC CERAMIC 22000rpm / 733Hz

HSK F63 CRONIDUR / CHROMEX CERAMIC 26000rpm / 867Hz

ISO30 STEEL STEEL 20000rpm / 667Hz

ISO30 CERAMIC STEEL 24000rpm / 800Hz

ISO30 CERAMIC CERAMIC 24000rpm / 800Hz

ISO30 CRONIDUR / CHROMEX CERAMIC 28000rpm / 933Hz

i

The 7.5 kW, 4 Pole motor is not available with configurable double voltage

power terminals.

The maximum continuous current inverter parameter must match the maximum

value of the rated current in the table above (also stated on the motor’s data

label).

Page 27

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 27/98

7.5 TECHNICAL SPECIFICATIONS OF ES919 L

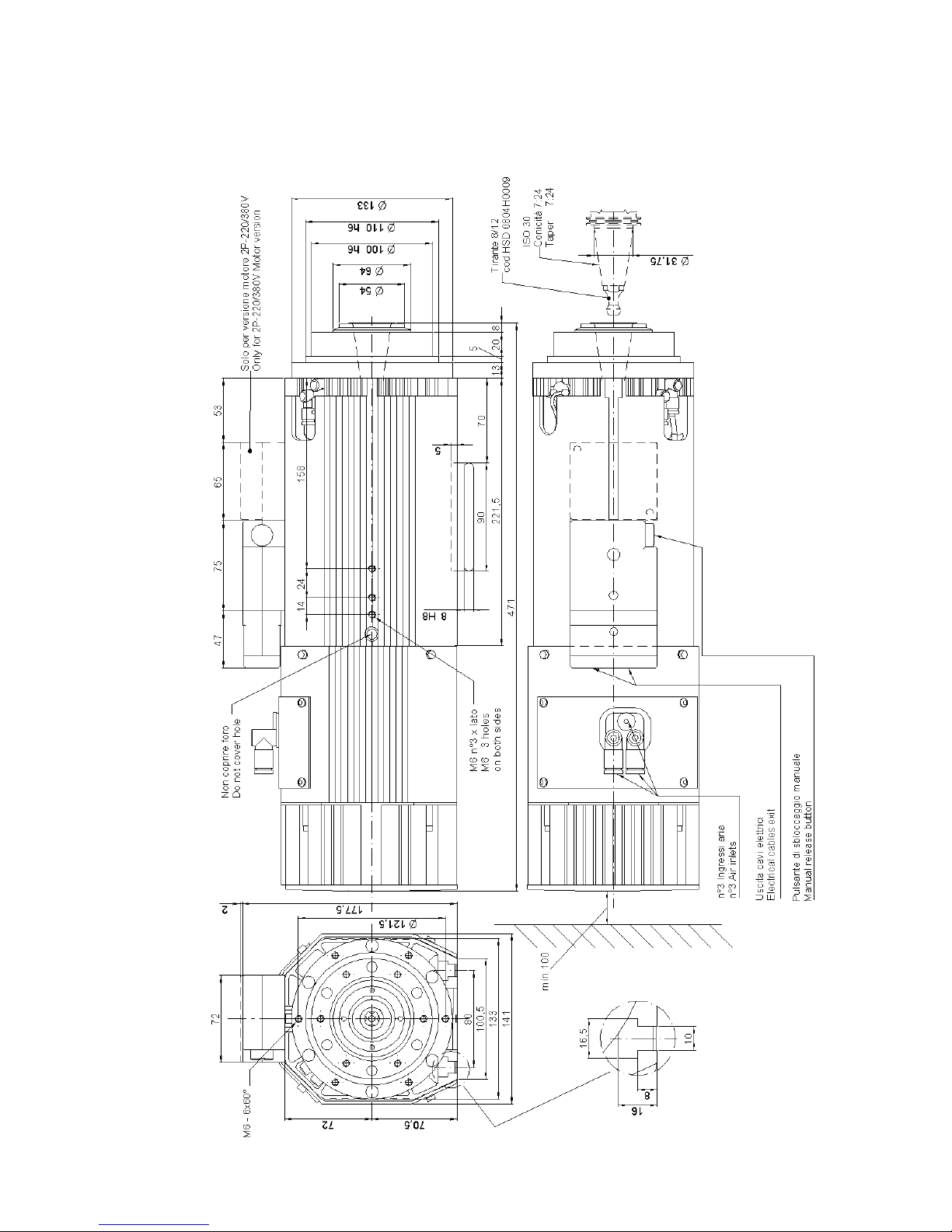

7.5.1 Overall dimensions of ES919 L ISO30 Short Nose

Page 28

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 28/98

7.5.2 Overall dimensions of ES919 L ISO30 Long Nose

Page 29

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 29/98

7.5.3 Overall dimensions of ES919 L HSK F63 Short Nose

Page 30

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 30/98

7.5.4 Overall dimensions of ES919 L HSK F63 Long Nose

Page 31

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 31/98

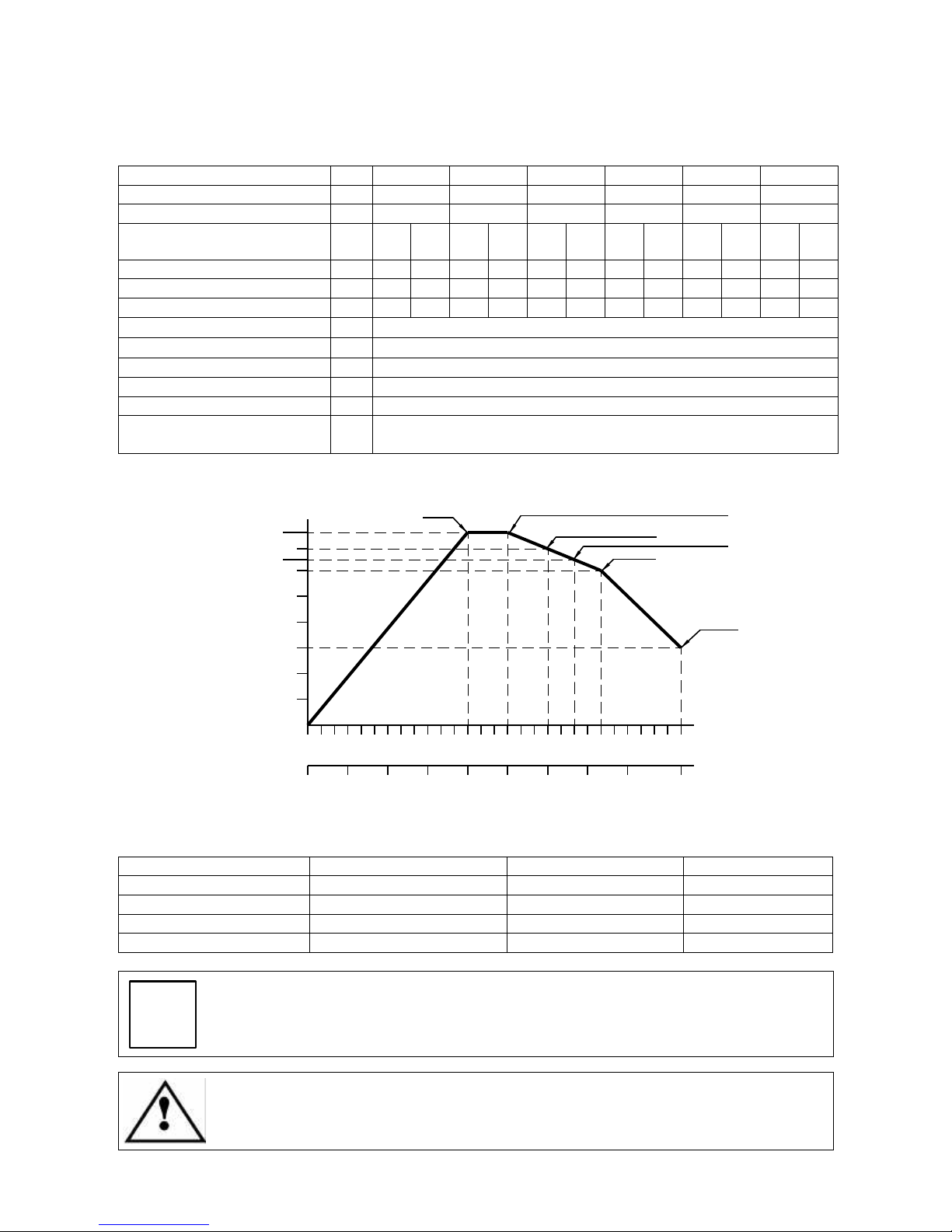

7.5.5 Specifications and performance of ES919 L 4 Pole, 12 kW units

Rated voltage (*)

V 225 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10% 380 ± 10%

Rated frequency

Hz 233 400 500 667 733 800 867

Rated speed

rpm 7000 12000 15000 20000 22000 24000 26000

Rated power

kW 7 12 9,5 7,3 6,4 5,5 4,6

Duty type

S1

Rated torque

Nm 9,5 9,5 6 3,5 2,8 2,2 1,7

Rated current

A 27 27,5 22 17 16,5 14 11,8

Rated efficiency η

0,8

Power factor cos ϕ

0,8

Number of poles

4

Insulation class

F

Type of cooling

Liquid

Weight of SHORT NOSE variant

~ 30 kg

Weight of LONG NOSE variant

~ 34 kg

[(*) from inverter]

kW (S1)

Hz

0

rpm x 100

0

3 6 9 12 15 18 21 24 26

2

4

6

8

10

12

0

100

200

300

400

500

600

700

867

5,5

9,5 Nm

2,2 N

m

6 N

m

3,5 N

m

9,5 Nm

7

6,4

9,5

800

7,3

1,7 N

m

2,8 N

m

Notes:

TOOL HOLDER FRONT BEARINGS REAR BEARINGS MAX SPEED

HSK F63 CERAMIC STEEL 20000rpm / 667Hz

HSK F63 CERAMIC CERAMIC 22000rpm / 733Hz

HSK F63 CRONIDUR / CHROMEX CERAMIC 26000rpm / 867Hz

ISO30 CERAMIC CERAMIC 24000rpm / 800Hz

i

The 12 kW, 4 Pole motor is not available with configurable double voltage power

terminals.

The maximum continuous current inverter parameter must match the maximum

value of the rated current in the table above (also stated on the motor’s data

label).

Page 32

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 32/98

7.6 TECHNICAL SPECIFICATIONS OF BELT DRIVEN C AXIS UNIT

7.6.1 Overall dimensions of ES919 ISO30 Short Nose with belt driven C Axis

unit

Page 33

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 33/98

7.6.2 Overall dimensions of gear units

Page 34

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 34/98

7.6.3 Technical specifications for belt driven C axis unit

Syncroflex ATS5 transmission belt drive.

Main specifications for a servomotor giving 1.27 Nm at 3000 rpm (*)

Rated torque

60 Nm (*)

Starting torque

80 Nm (*)

Overall gear ratio

1 / 60

Total mechanical efficiency

0.8

Epicyclic gear backlash

5’

Positioning precision

10’

Gearbox input rpm

3000 rpm (4000 rpm max)

Rated gearbox input torque

2.5 Nm

Starting gearbox input torque

4 Nm

Weight

4 Kg (without servomotor)

(*) Technical specifications depend on the type of servomotor installed by the customer.

i

Use of the belt driven C axis unit is described in section 13.3

i

ONLY FOR UNITS WITH BELT DRIVEN C AXIS:

On models with belt driven C axis, the spindle shaft kit must be replaced by HSD

technical assistance. Replacement by the customer is not permitted.

Page 35

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 35/98

7.7 TECHNICAL SPECIFICATIONS OF COMPONENTS

7.7.1 Bearings

The front of the shaft is supported by a pair of precision angular contact ball bearings, 40 mm

diameter for versions with ISO 30 tool fittings and 45 mm diameter for versions with HSK F63

fittings.

The rear of the shaft is supported by a pair of precision angular contact ball bearings of 30 mm

diameter.

All bearing pairs are pre-loaded and lubricated for life with special high speed grease.

The bearings are lubricated for life and do not require greasing.

7.7.2 Tool holder locking and release device

The tool holder is mechanically locked by springs that develop an axial force of:

ELECTRO-SPINDLE

MODEL

AXIAL SPRING

FORCE

AXIAL FORCE

ON TOOL HOLDER

ES915 ISO 30--- 3200 N ± 10% _3000 N ± 10%

ES919 ISO 30--- 3500 N ± 10% _3200 N ± 10%

ES919 HSK F63 3850 N ± 10% 11000 N ± 10%

Tool release is achieved by the movement of a single acting, double stage, compressed air

cylinder operating at a pressure of 7 bar (100 PSI).

i

The axial force applied to the tool holder by the locking springs is

guaranteed to remain constant for a minimum of 2,000,000 tool change

cycles.

1 tool change cycle = tool locked / tool released / tool locked

Page 36

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 36/98

7.7.3 Automatic cleaning of the tool holder and internal pressurization

The tool holder cone and its conical housing in the spindle shaft are automatically cleaned by the

air purge during the tool change phase.

This prevents dirt from building up on the mating surface. The condition of the surface should

nevertheless be regularly checked as described in section 12.1 on scheduled maintenance.

The pneumatic circuit for internal pressurization prevents dirt from entering the electro-spindle.

This system is fed at 4 bar (58 PSI). Waste air is exhausted through the forward facing labyrinth

ports in the spindle nose.

Compressed air at 4 bar (58 PSI) must always be delivered to the electrospindle even when it is not operating.

7.7.4 Proximity sensors

Sensor type: PNP proximity; NO (Normally Open)

Voltage 10 - 30 V (DC)

Maximum load 200 mA

No-load consumption < 10 mA

Rated read distance 0.8 MM

7.7.5 Tool release button

Push-button specifications Lamp specifications

Rated voltage (DC) 24 V Rated voltage (DC) 24 V

Maximum current 100 mA Rated power 0.7 W

Rated current 29 mA

Page 37

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 37/98

7.7.6 Thermal switch

The electro-spindle motor windings are protected by a normally closed bi-metallic switch encased

in the stator. A second bi-metallic switch protects the cooling fan motor.

The two switches are connected in series (see Figure 11.3).

The switches open if temperature reaches a potentially damaging level and close again when

temperature drops to normal operating levels.

This thermal switch system must be connected in series to the machine's safety stop system as

shown in section 9.6.4 .

The series of bi-metallic switches has the following specifications:

DC power 48 VDC MAX

AC power 230 VAC MAX

Current 1.6 A MAX

7.7.7 Cooling fan

The electro-spindle is cooled by a rear

mounted fan.

The fan must be powered up even when the

spindle is not operating.

The fan is independent of the spindle shaft.

This solution gives improved efficiency

compared to shaft mounted fans.

If the fan motor overheats, the fan's own

thermal switch, wired in series with the main

electro-spindle switch, shuts the unit down.

Operation is re-enabled when the fan's

motor drops to a safe operating temperature

again.

Power

230 ± 10% VAC

Cycles/second 50 Hz 60 Hz

Consumption 45 W 39 W

Thermal switch: Bi-metallic switch

i

The fan's thermal switch only detects fan motor overheating. It cannot detect that

the fan is prevented from turning, unless this causes overheating. For this

reason, check the condition of the fan regularly.

The fan must remain on at all times when the machine is active even if the

electro-spindle is not operating.

Page 38

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 38/98

§ 8 TRANSPORT AND MOVING

Lifting and moving electro-spindles can create situations of risk to persons nearby. Always follow

the instructions provided by HSD and always use suitable lifting equipment.

Installation and assembly work must be performed only by specialist technicians.

Always use great care in lifting and moving electro-spindles and their components. Avoid impacts

that can damage the body which could cause malfunctions.

IT IS THE RESPONSIBILITY OF THE CUSTOMER TO ENSURE THAT THE LIFTING EQUIPMENT,

CABLES, SLINGS AND CHAINS USED IS SUITABLE FOR THE PURPOSE IN TERMS OF

FUNCTIONING AND LOAD CAPACITY.

8.1 STORAGE

If the electro-spindle is to be stored for any length of time, make sure that it is protected against the

elements and in particular against damp, dust, and other forms of damage by the atmosphere or

storage environment.

Check on the general condition of the electro-spindle periodically to prevent deterioration. Turn the

spindle shaft by hand about once a month to keep the bearings free.

STORAGE TEMPERATURE: from –5°C (+23°F) to +55°C (+131°F)

NON-CONDENSING RELATIVE HUMIDITY: from 5% to 90%

8.2 LIFTING THE ELECTRO-SPINDLE IN ITS CRATE

The electro-spindle is shipped in a wooden crate packed with expanded polystyrene foam. The

electro-spindle itself is packed in a VCI plastic bag and is coated in protective grease to prevent

corrosion. Use a clean cloth to wipe the protective grease off the new electro-spindle.

(Note: The expanded polystyrene and the protective bag are plastics and must be disposed of as

such).

Figure 8.1 Example of how to lift the crate

Page 39

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 39/98

A label, shown in figure 7.2, is applied to the crate, stating its weight. The box corresponding to the

correct weight is checked (25 kg in the example shown).

GROSS WEIGHT

15 90

25

√

110

35 130

45 160

55 215

65 270

75 …

Figure 8.2 Label showing weight of crate

Do not lift the electro-spindle by the cooling fan cover. The cover could break and the

electro-spindle could fall, causing serious damage to the unit and injury to the operator.

The lifting diagrams reproduced here are merely examples of possible ways of lifting the

electro-spindle. HSD S.p.a. cannot foresee all possible lifting methods and

configurations for its electro-spindles.

THIS SYMBOL IS USED TO IDENTIFY POTENTIAL LIFTING POINTS.

Page 40

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 40/98

§ 9 INSTALLATION

9.1 FIRST CHECK

Before starting installation, check:

q That no part of the electro-spindle has been damaged during transport and/or handling.

q That the connectors are not damaged in any way.

9.2 PREPARATION OF THE EQUIPMENT REQUIRED FOR INSTALLATION ON

SITE

All work in preparation for installation of the electro-spindle is the responsibility of the customer

(e.g. preparation of electrical power supplies, compressed air etc.).

Make sure that the electrical power line to the electro-spindle is of adequate gauge and power.

Connection of the unit to the power supply must only be done by qualified electricians. The

customer is responsible for all parts of the electrical power supply to the electro-spindle.

The customer is expressly reminded that the electro-spindle must be correctly connected to earth.

Furthermore, the earth connection must comply with applicable regulations in the country in which

the unit is installed and must be duly checked and tested by a qualified electrician.

See below for the installation layout and connection diagrams.

9.3 MECHANICAL INSTALLATION

9.3.1 The supporting surface

i

The supporting surface on which the

electro-spindle is fixed must have a

flatness better than 0.02 mm.

0,02

9.3.2 Positioning the electro-spindle

100

Figure 9.1 Minimum clearance of fan

The electro-spindle must be

installed with at least 100 mm

of free space behind the

cooling fan cover to ensure an

adequate flow of cooling air.

Page 41

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 41/98

9.3.3 Mechanical fixing of the electro-spindle

80

100,5

10

8

16

16,5

Figure 9.2 T slots for anchoring the electro-spindle

Fix the electro-spindle to the carriage or spindle mounting using M8 bolts and nuts fitted in the T

slots and tightened to a torque of 20 Nm. Maximum permitted protrusion of the fixing bolts is 15

mm, as shown in Figure 9.3. Greater protrusion can deform the electro-spindle body and lead to

incorrect fixing, reduced machining precision and reduced machining safety.

(16)

15 MAX 1 MIN

Figure 9.3 Maximum permitted protrusion of bolts in T slots

Maximum protrusion of bolt: 15 mm.

Leave a clearance of at least 1 mm.

Excessive protrusion can deform the

electro-spindle body and reduce machining

precision and safety.

Page 42

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 42/98

9.3.4 Threaded service holes

There are a number of M6 threaded holes in the electro-spindle body, located as shown in Figure

9.4.

Attention: never to block the silenced exhaust air holes

(Position 4 in Figure 9.4).

4

3

1

2

1

Frontal service holes 6

2

C axis fixing holes 6

3

Side service holes

3 (ES919) per side

2 (ES915) per side

4

Silenced exhaust air hole 1 per side

Figure 9.4 Service holes and silenced exhaust air hole

Page 43

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 43/98

9.4 COMPRESSED AIR CONNECTIONS

9.4.1 Compressed air unions

The compressed air unions are quick-fit unions. They are located as shown in Figure 9.5 and are

described in the table below.

2 1

Figure 9.5 Location of the compressed air quick-fit unions

DESCRIPTION

PRESSURE

( bar / PSI )

EXTERNAL

HOSE Ø (mm)

1

Inlet for pressurization and cone

cleaning air

4 / 58 8

2

Tool release air inlet - outlet

7 / 100 8

Page 44

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 44/98

9.4.2 Functional diagram of electro-spindle compressed air connections

Figure 9.6 shows typical compressed air system connections, to be prepared by the customer. The

use of two solenoid valves connected in series reduces the risk of system malfunctions. Though it

is very rare for this type of fault to occur, it can have very serious consequences if it does.

Redundancy is therefore recommended.

5 µ

0,1 µ

1

2

3

5

6 7

4 bar (58 PSI)

4

7 bar (100 PSI)

7 bar (100 PSI)

Figure 9.6 Typical compressed air connection diagram

1

Cone cleaning and internal pressurization air inlet (see also n°1 in Figure 9.5)

2

Tool holder release air inlet (see also n°2 in Figure 9.5)

3

Factory air supply inlet

4

Compressed air filtration/drying group with automatic condensate drain: first stage 5µ and

second stage 0.1µ

5

4 bar (58 PSI) pressure regulator

6

Pressure switch

7

Pair of 3 way, mono-stable solenoid valves

Use 2 separate circuits to connect the solenoid valves (pos. 7 in Figure 9.6) to the

numeric control unit or manual control system.

IMPORTANT:

The air supply to the compressed air circuit

must be dry and filtered

When the machine is powered on, pressurized air must be delivered even when the

electro-spindle is stopped, to prevent dust and dirt from the machining area from

entering the electro-spindle (see section7.7.3 ).

With the spindle stopped, make sure that there is uniform flow of air around the spindle

shaft (pressurization air). If there is not, check the compressed air circuit and

connections.

Page 45

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 45/98

9.5 COOLING CIRCUIT

Liquid-cooled models must be connected to a coolant circuit to dissipate the heat generated during

machining. Coolant must be: water with 10% ethylene glycol.

Out

In

CONNECTION DESCRIPTION THREAD

Out

Coolant circuit outlet G 1/4”

In

Coolant circuit inlet G 1/4”

Hose internal diameter (at least) 8 mm ( 5/16 in. - 315 mils )

9.5.1 Cooler specifications

Cooling capacity 1600 W

Minimum delivery 3 litres/minute ( 0.11 cfm )

Coolant type H2O + 10% ethylene glycol

Cooler set temperature +25°C ( +77°F )

Page 46

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 46/98

9.6 ELECTRICAL CONNECTIONS

9.6.1 Connectors

The electro-spindle is fitted with two connectors, one for power and the other for signals.

Figure 9.7 Location of electrical connectors

9.6.2 Pin layout of fixed signals connector - ISO 30 version

PIN DESCRIPTION

1

Sensor S2 (tool ejected) output

2

Sensor S1 (tool locked) output

3

Sensor S3 (shaft stopped) output

4

+24V DC power to S1, S2, S3

5

+24V DC power to push-button lamp

6

0V power to S1, S2, S3

7

+24V DC power to push-button and

C axis zeroing sensor (SC sensor)

8

Push-button output

7

14

1

2

13

15

12

3

16

8

21

22

20

4

17

11

18

5

19

10

6

9

9

Temperature sensor for front bearings

10

Temperature sensor for front bearings

11

0V power to push-button, lamp, and SC

i

Use AWG22 wires.

12

C axis zeroing sensor output (SC sensor)

Page 47

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 47/98

9.6.3 Pin layout of fixed signals connector - HSK F63 version

PIN DESCRIPTION

1

Sensor S2 (tool ejected) output

2

Sensor series S1 + S4 (tool locked)

output

3

Sensor S3 (shaft stopped) output

4

+24V DC power to S1, S2, S3

5

+24V DC power to push-button lamp

6

0V power to S1, S2, S3, S4

7

+24V DC power to push-button and C

axis zeroing sensor (SC sensor)

8

Push-button output

7

14

1

2

13

15

12

3

16

8

21

22

20

4

17

11

18

5

19

10

6

9

9

Temperature sensor for front bearings

10

Temperature sensor for front bearings

11

0V power to push-button, lamp, and SC

12

C axis zeroing sensor output (SC sensor)

i

Use AWG22 wires.

14

For maintenance

9.6.4 Pin layout of fixed power connector

PIN DESCRIPTION

1

Thermal switch: normally closed bimetallic switch to be connected in series

to machine safety stop system.

230V AC MAX; 48V DC MAX; 1.6A MAX

2

W PE common to pin 7

3

230V AC 50/60 Hz cooling fan

4

U Motor phase

5

Thermal switch (see pin 1)

2

5

3

4

6

1

8

9

7

6

V Motor phase

7

W PE common to pin 2

8

W Motor phase

i

Use AWG10 wires for the

even pins and AWG18 for

odd pins.

9

230V AC 50/60 Hz cooling fan

Page 48

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 48/98

9.6.5 Tool holder release system electrical wiring diagram for electro-spindles

not controlled by CNC

• The control system must disable the tool release push-button

signal while the spindle is rotating.

• The push-button must only be enabled when the spindle is

completely stationary.

• Only use the push-button to lock/release tools on manually

controlled machines.

7 - 8

Pins 7 and 8 of the signals

connector

B

Tool release button

(See section 7.7.5 for technical

specifications.)

P

Pressure switch to prevent tool

release in case of insufficient air

pressure

C

Safety check (spindle stopped

check device)

E

Tool release solenoid valves (See

pos. 7 in Figure 9.6 and the

warnings for it.)

• When button “B” on the electrospindle is pressed, the coils of

solenoids “E” (not supplied) are

energized and the tool holder is

released.

• Press button “B” to release the tool

holder.

24V

7

B

8

P

C

0 V

E

Page 49

______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 49/98

9.6.6 Configurable power terminals (optional)

On request, some models can

be provided with power

terminals that can be

configured either for delta or

star connections, for use with

rated voltages of 380 V or 220

V.

See section § 7 for details of

models available with

configurable power terminals.

The figure on the left shows the

location of the power terminals,

under a protective cover fixed in

place by two screws.

Check what type of connections have been made

in the terminal block before installing the unit.

CONNECTION DIAGRAM

STAR CONNECTIONS

(rated voltage 380V)

DELTA CONNECTIONS

(rated voltage 220V)

RED (STATOR)

380V - PIN6

BLACK (STATOR)

WHITE (STATOR)