Page 1

HSD

MECHATRONIC

DIVISION

Instructions for use

ES884 – ES888

5801H0056

Rev.02

EN

ES915

ES919 – ES929 – ES939

ES983 – ES988

5801H0056 Rev.02 __________________________________________________________ 1/181

Page 2

HSD

Information about the document

ISSUED BY CODE REVISION APPROVAL

HSD S.p.A.

Via della Meccanica 16

Loc. Chiusa di Ginestreto

5801H0056

61100 PESARO (ITALIA)

List of updates

Revision Modified paragraph Description of the modification

00 (12.02.2007) First issue First issue

01 (06.03.2007)

02 (02.06.2008)

§12.7

§12.7.2

General

§ 5.2

§ 6.2

§ 6.4

§ 9

§ 10.3

§ 10.4

§ 10.6

§ 10.8.5

§ 13.2.2

§ 13.2.2.9

§ 15

Elimination of the note “respect the number of rotations ...”; elimination of the phrase “on the basis of the type and

quality ...” (both the eliminated parts are already present in paragraph §12.7.1).

Additional explanation of the simplified calculation for the centre of gravity.

Added ES884, ES888, ES915, ES919, ES939, ES983, ES988 models

Symbols updated

Wording on shaft kits corrected

Glossary: generalised wording “ISO” and “HSK”

Motor identification plates and equivalent electrical networks of all motors added

Fixing specifications added

Pressurisation values added

Electrical connections of encoder models and with military connectors added

Note on possible tie-rod breakage added

Sensor connections and positions updated

Sensor adjustment procedure for HSK E63 models added

List of spare parts and note on shaft kit updated

This manual has been drawn up by the Electrospindles Technical Office of HSD S.p.A. and is to be

used by all installers, users and maintenance engineers working with the electrospindle.

This manual is supplied together with the product; it is the most updated documentation available

at the revision date.

For the updates, visit the website www.HSD.it

or contact HSD Customer Service.

The manual must be kept in a suitable place that is easily accessed and known to the personnel

using the product. In addition, it must be kept carefully for the entire lifespan of the product, and

must accompany the product if this is ceded to third parties.

This publication is the English translation of the original Italian version of the manual HSD.

In case of discrepancies between this translation and the original version, refer to the original

version in Italian.

02

UTE 002 / 07

5801H0056 ________________________________________________________________ 2/181

Page 3

HSD

TABLE OF CONTENTS

1 PRELIMINARY INFORMATION ....................................................................................6

1.1 DOCUMENTS SUPPLIED WITH THE ELECTROSPINDLE ............................................. 6

1.2 PURPOSE OF THE MANUAL .......................................................................................... 6

1.3 GENERAL SAFETY SYMBOLS ....................................................................................... 6

1.4 RISKS ASSOCIATED WITH THE USE OF THE ELECTROSPINDLE.............................. 7

1.5 RISKS ASSOCIATED WITH INCORRECT USE AND/OR OPERATION.......................... 7

1.6 SPECIFIC RISKS DURING ELECTROSPINDLE MAINTENANCE................................... 8

1.7 RESIDUAL RISKS............................................................................................................ 8

1.8 PURPOSE OF THE PRODUCT ........................................................................................ 8

1.9 RANGE OF APPLICATIONS............................................................................................ 8

1.10 IDENTIFICATION OF THE PRODUCT AND THE MANUFACTURER.............................. 8

1.11 GLOSSARY...................................................................................................................... 9

1.12 GUARANTEE CONDITIONS .......................................................................................... 10

2 TECHNICAL SPECIFICATIONS..................................................................................11

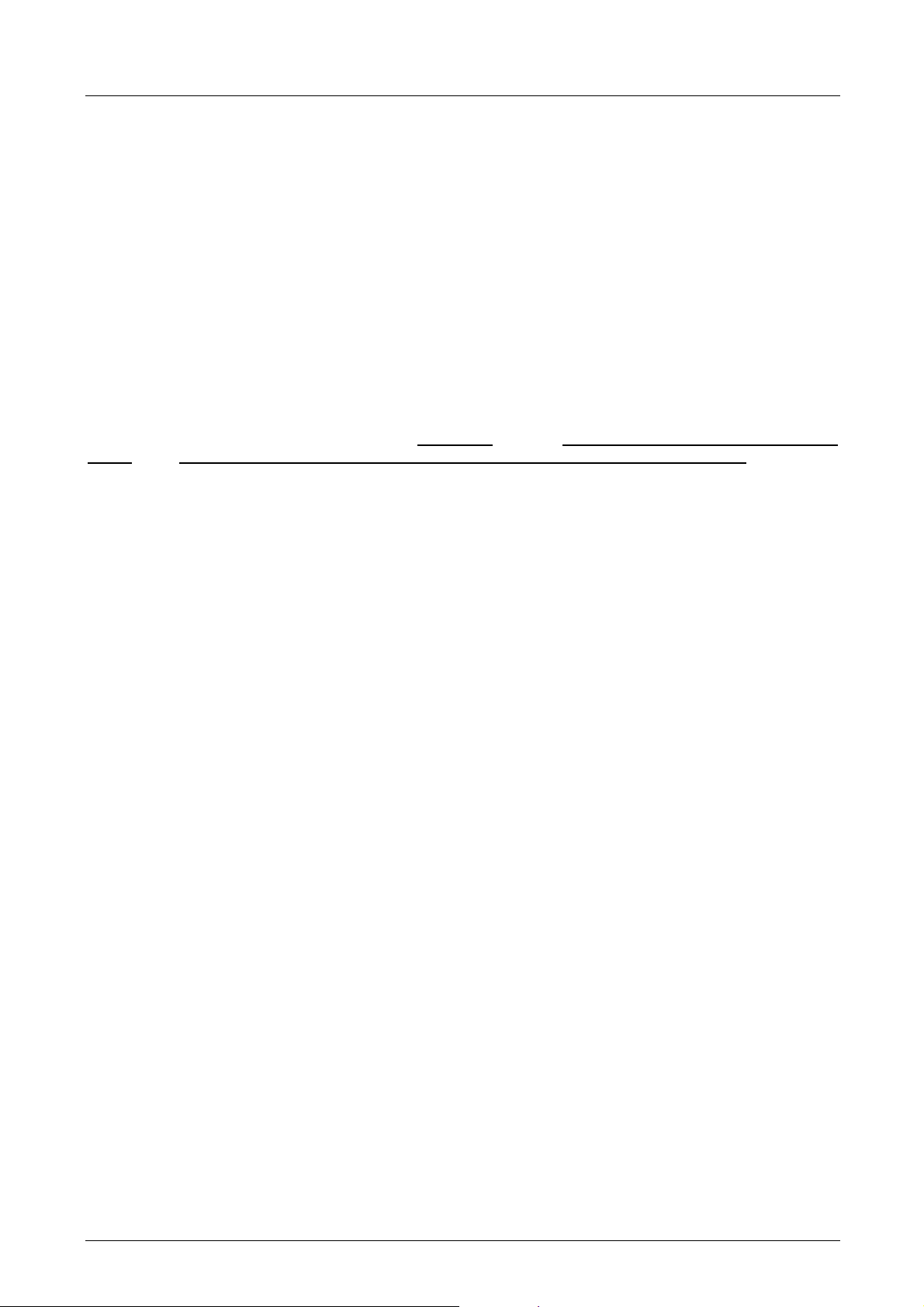

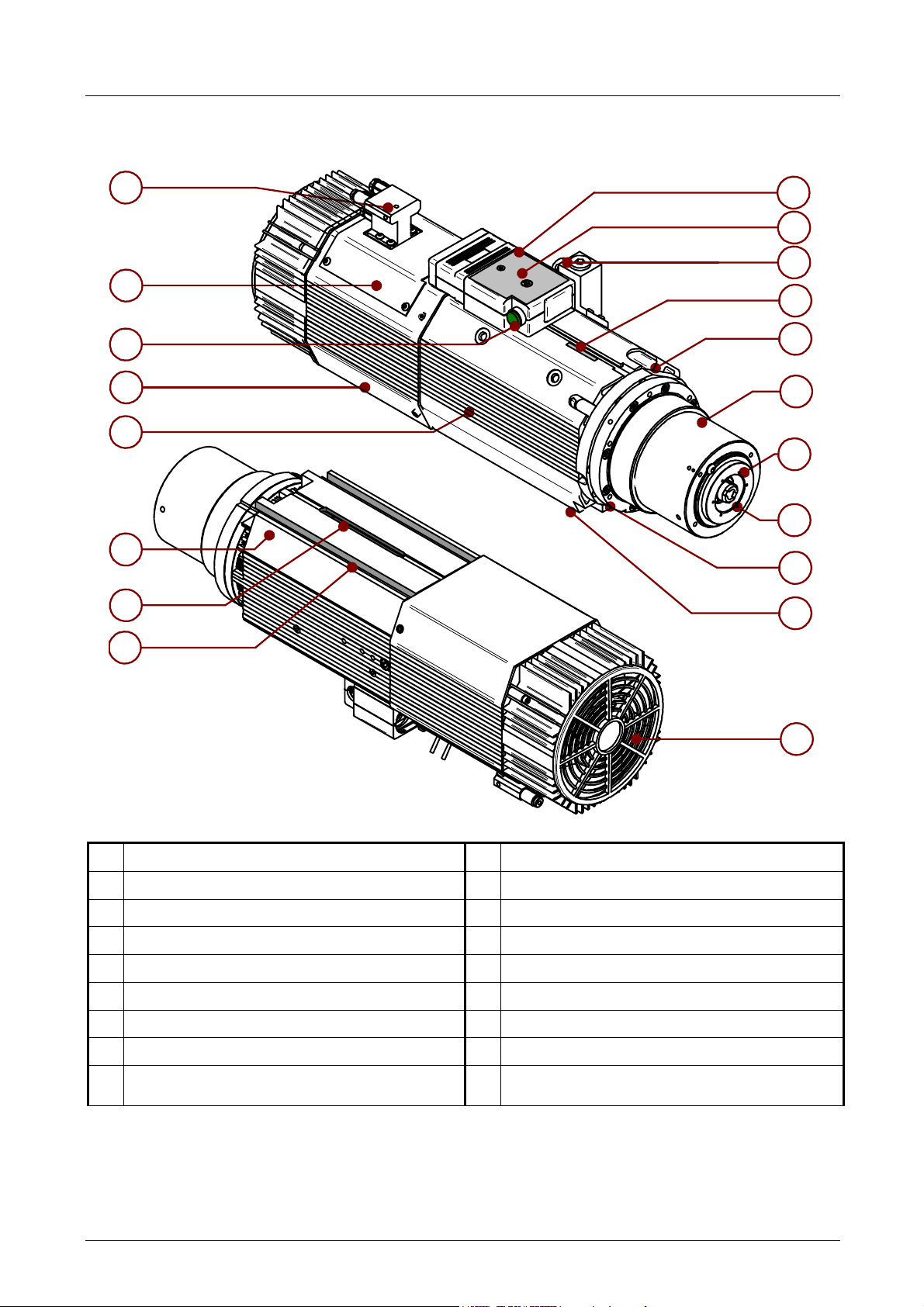

2.1 MAIN PARTS OF ES915/ES919/ES929/ES988.............................................................. 11

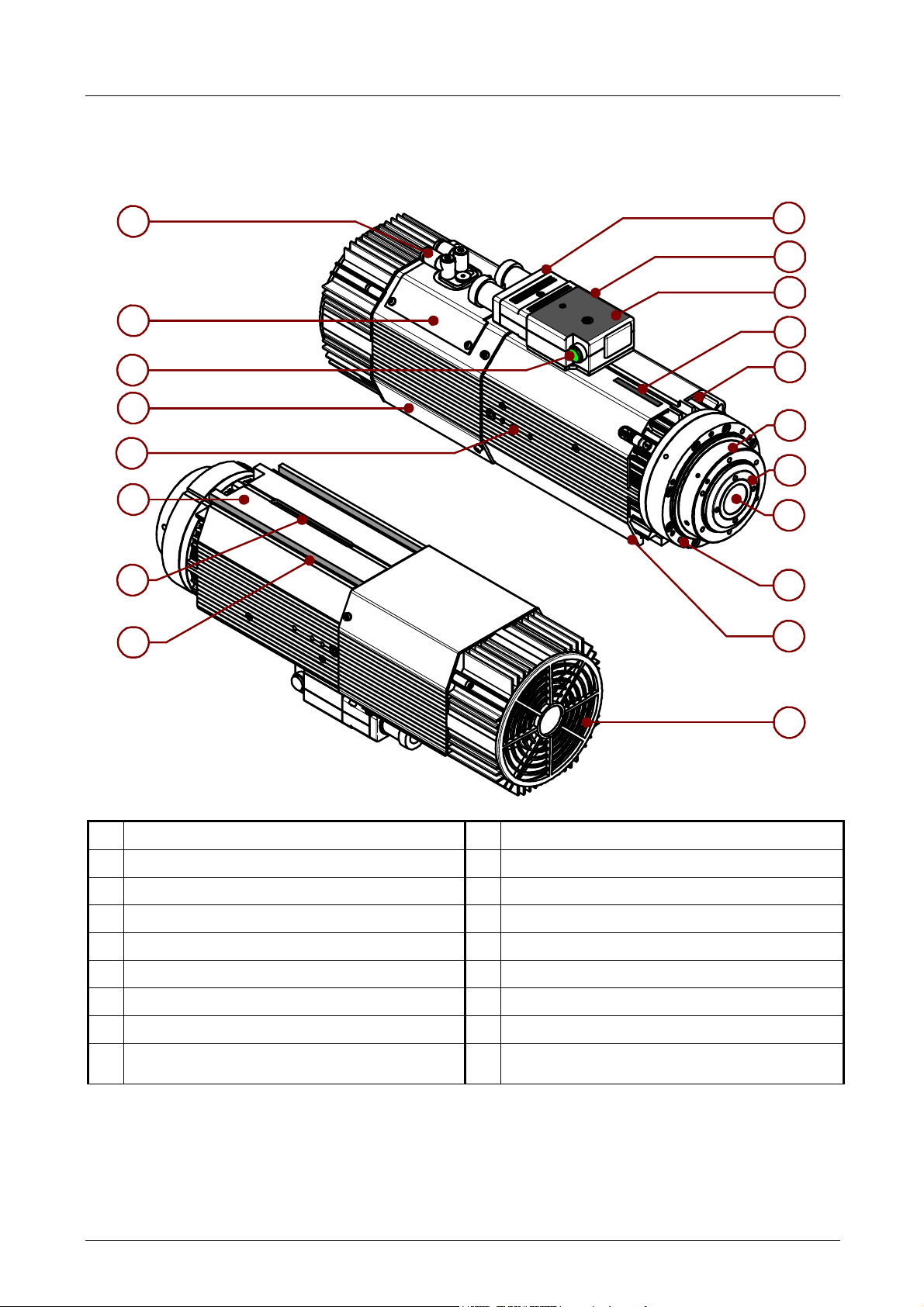

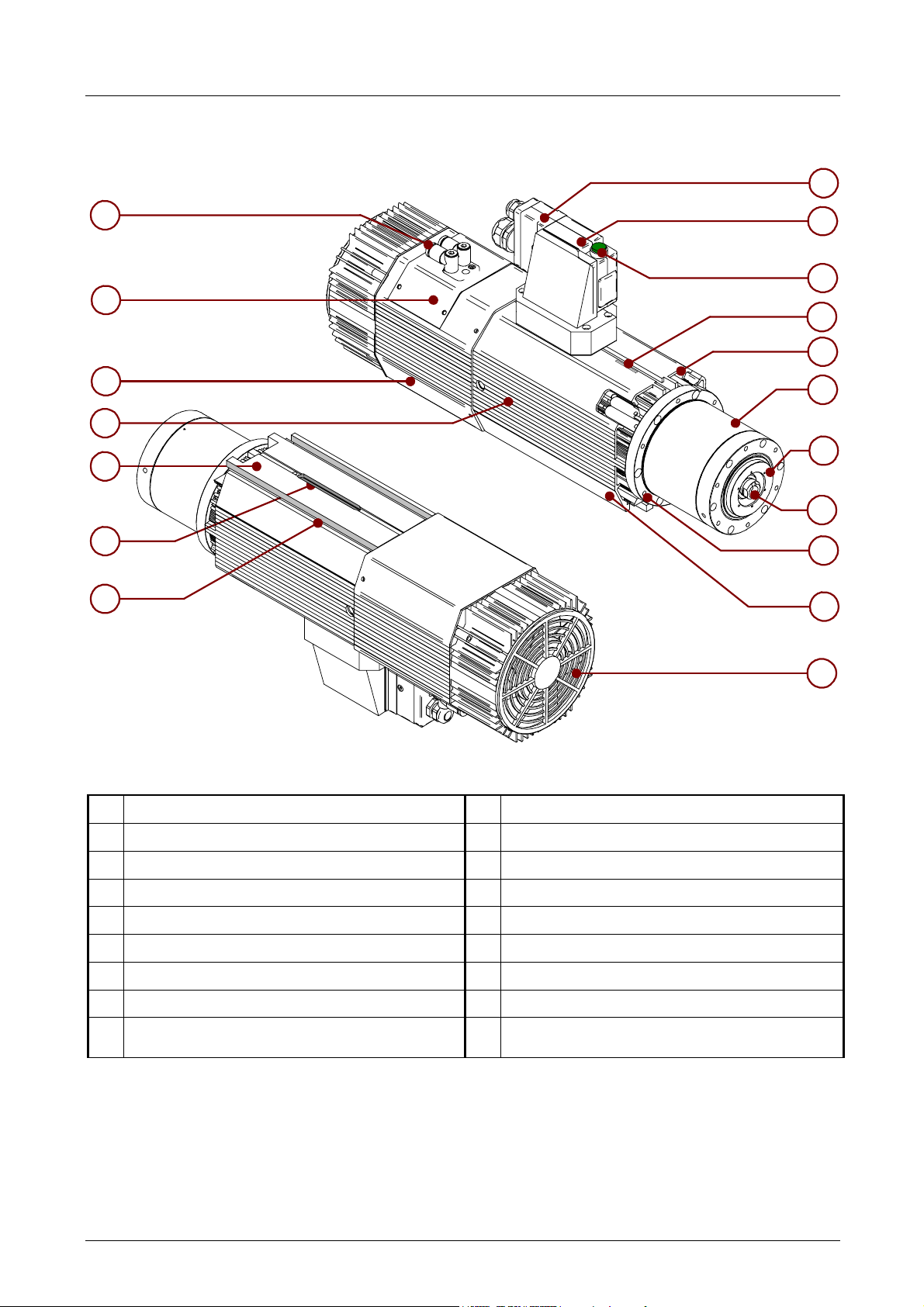

2.2 MAIN PARTS OF MODELS ES884 - ES888................................................................... 12

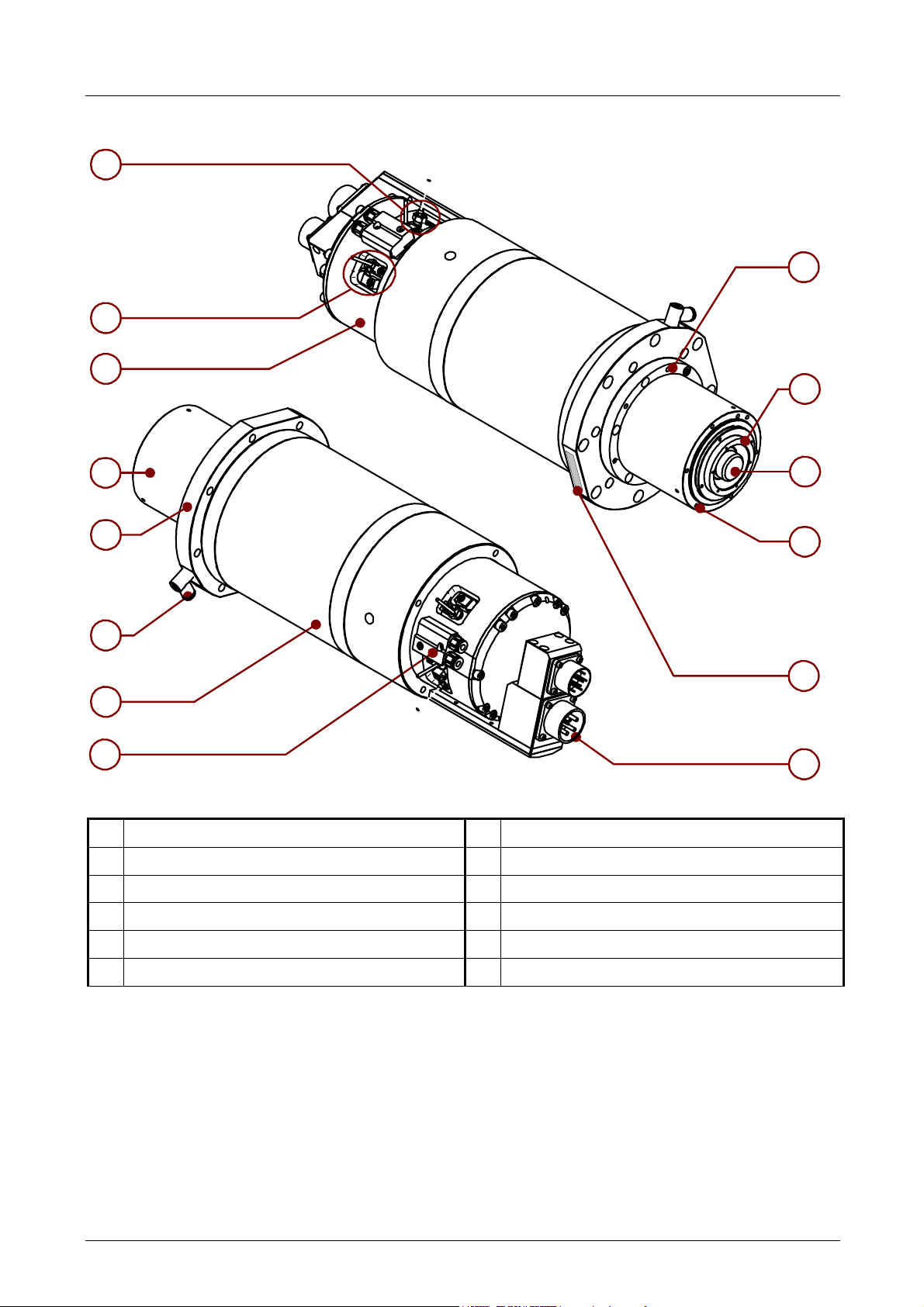

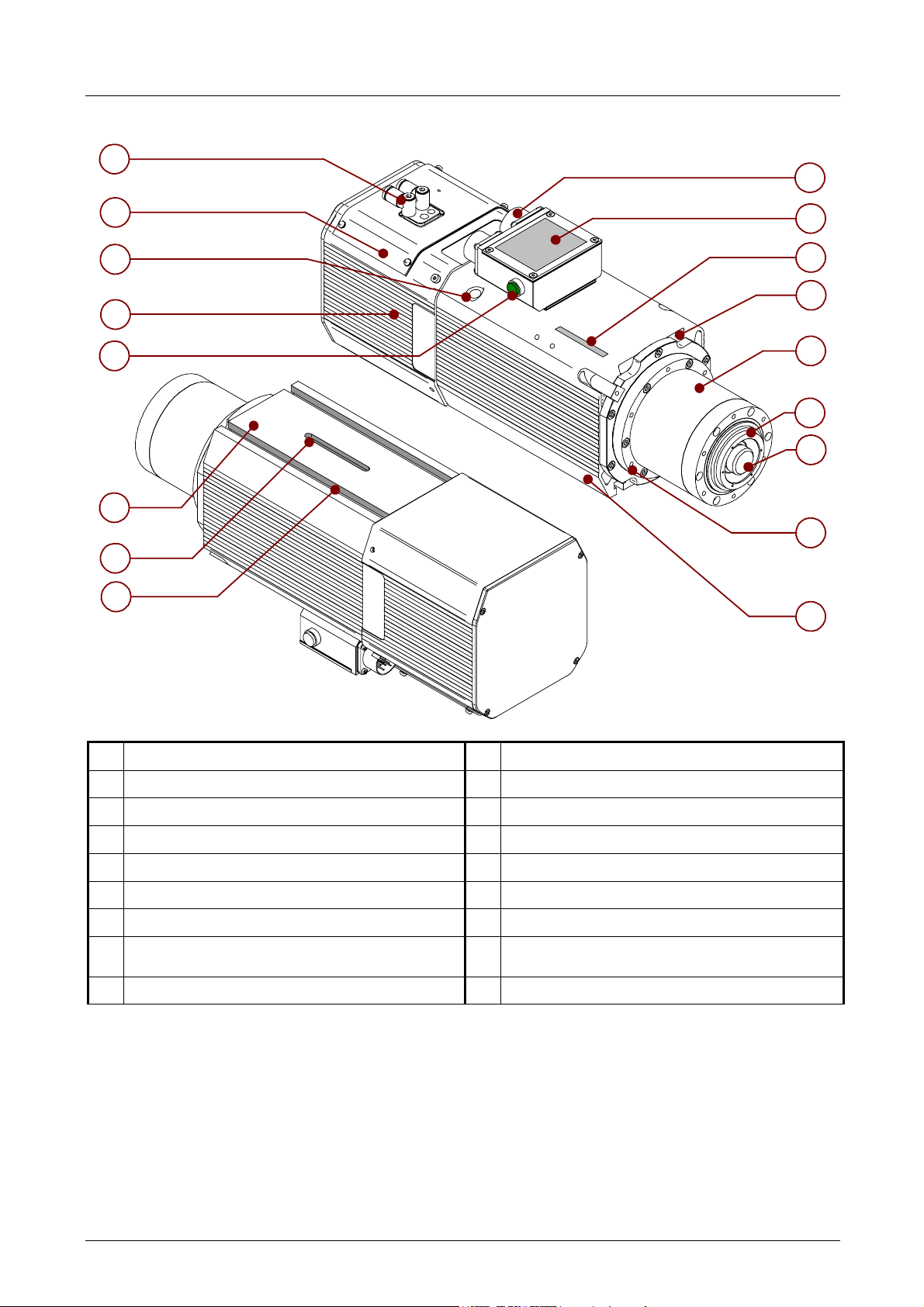

2.3 MAIN PARTS OF MODEL ES939................................................................................... 13

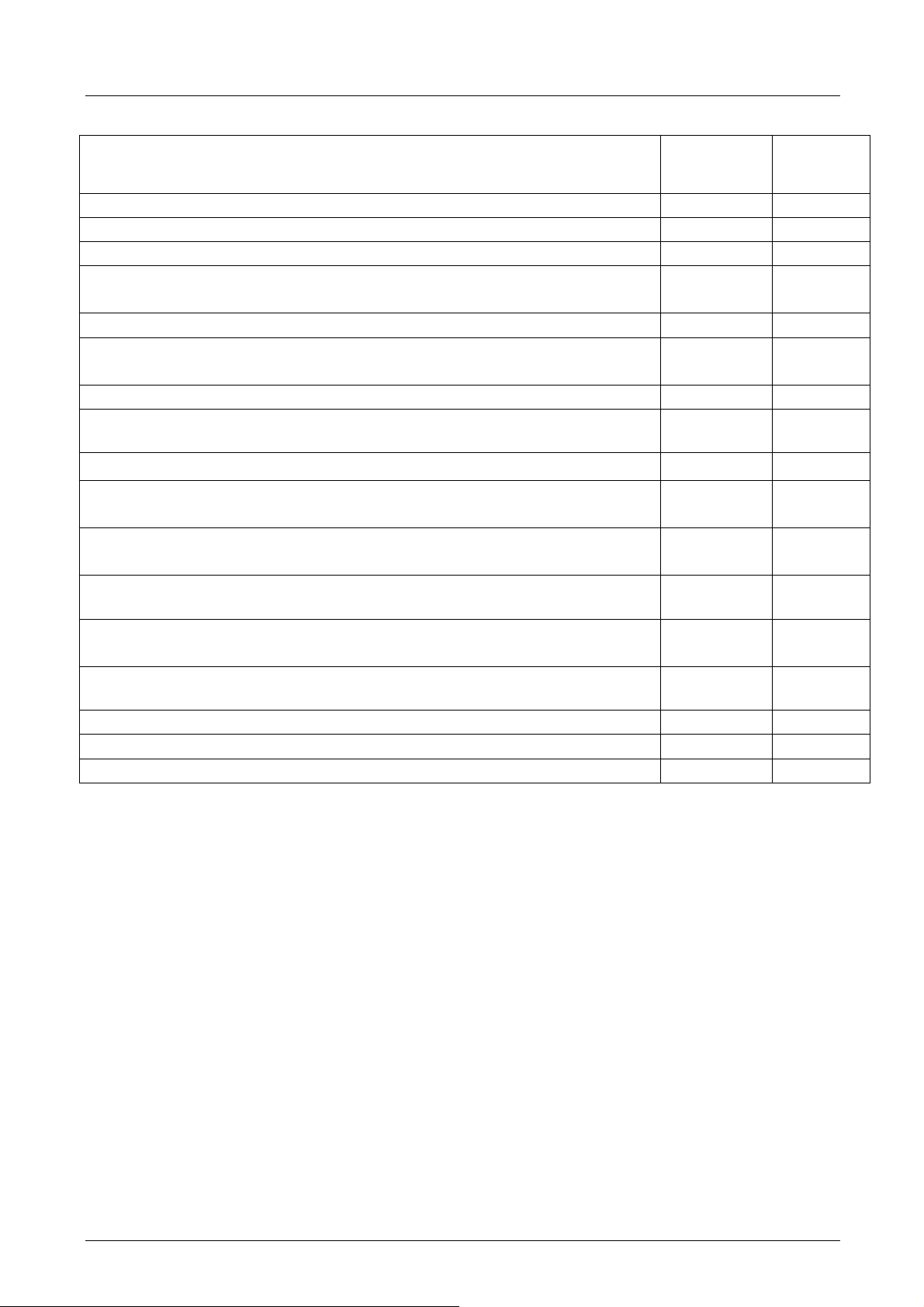

2.4 VARIATIONS WITH VERTICAL MOUNTING PLATE..................................................... 14

2.5 VARIATIONS WITH MILITARY CONNECTORS ............................................................ 15

2.6 TECHNICAL CARDS ES884 .......................................................................................... 16

2.7 TECHNICAL CARDS ES888 .......................................................................................... 18

2.8 TECHNICAL CARDS ES915 .......................................................................................... 20

2.9 TECHNICAL CARDS ES919 .......................................................................................... 26

2.10 TECHNICAL CARDS ES929 .......................................................................................... 40

2.11 TECHNICAL CARDS ES939 .......................................................................................... 44

2.12 TECHNICAL CARDS ES983 .......................................................................................... 52

3 TRANSPORT, PACKAGING, UNPACKING, STORAGE............................................65

3.1 WARNINGS.................................................................................................................... 65

3.2 DIMENSIONS AND WEIGHTS ....................................................................................... 65

3.3 TRANSPORT AND PACKAGING CONDITIONS ........................................................... 65

3.4 UNPACKING PROCEDURE........................................................................................... 65

3.5 STORAGE ...................................................................................................................... 66

4 INSTALLATION AND INITIAL START-UP..................................................................67

4.1 CHECK ...........................................................................................................................67

4.2 PREPARATION OF THE AUXILIARY SYSTEMS OF THE PLANT................................ 67

4.3 MECHANICAL CONNECTIONS..................................................................................... 67

4.3.1 Positioning of electrospindle (versions with electric fan)............................................. 67

4.3.2 Electrospindle resting surface (versions with rectangular framework) ........................ 68

4.3.3 Fixing structure for spindles with round framework .................................................... 68

4.3.4 Tool change system................................................................................................... 69

4.3.5 Fixing electrospindles with rectangular framework..................................................... 70

4.3.6 Fixing electrospindles with round framework.............................................................. 70

4.3.7 Threaded bores for accessories................................................................................. 70

4.4 PNEUMATIC CONNECTIONS........................................................................................ 71

4.4.1 Air purity .................................................................................................................... 71

4.4.2 Pneumatic connection points for spindles with single-acting cylinder......................... 72

4.4.3 Variation with vertical block (single-acting cylinder) ................................................... 72

4.4.4 Pneumatic connection points ES939 or variations with “T-block” (double-acting

cylinder) ................................................................................................................................. 74

4.4.5 Pneumatic connection points for spindles ES884 - ES888 (single-acting cylinder)..... 76

4.4.6 Internal volumes of the pneumatic cylinders .............................................................. 78

4.4.7 Internal pressurisation ............................................................................................... 78

5801H0056 ________________________________________________________________ 3/181

Page 4

HSD

4.4.8 Cleaning the tool-holder cone.................................................................................... 78

4.5 HYDRAULIC CONNECTIONS AND SPECIFICATIONS OF THE COOLER................... 79

4.5.1 Specifications for the cooler....................................................................................... 79

4.6 ELECTRICAL CONNECTIONS ...................................................................................... 80

4.6.1 Connectors ................................................................................................................ 80

4.6.2 Military connectors..................................................................................................... 83

4.6.3 Configurable power supply terminal board 220/380 V (optional) ................................ 84

4.6.4 ES988 with configurable terminal board 220/440 V (optional).................................... 85

4.7 BUTTON FOR MANUAL COMMAND OF TOOL RELEASE .......................................... 86

4.7.1 Electrical layout for tool-holder manual release circuit ............................................... 86

5 GENERAL CHECKS AFTER INSTALLATION............................................................87

5.1 CHECKS BEFORE THE START-UP .............................................................................. 87

5.1.1 Positioning................................................................................................................. 87

5.1.2 Pneumatic connections.............................................................................................. 87

5.1.3 Electrical connections................................................................................................ 87

5.1.4 Programming the inverter .......................................................................................... 87

5.2 START-UP CHECKS...................................................................................................... 87

6 USE AND ADJUSTMENT............................................................................................88

6.1 ENVIRONMENTAL CONDITIONS.................................................................................. 88

6.2 RUNNING-IN................................................................................................................... 88

6.3 PREHEATING................................................................................................................. 88

6.4 ELECTRIC FAN.............................................................................................................. 88

6.4.1 Technical characteristics of the electric fan................................................................ 89

6.5 TOOL-HOLDER LOCKING AND EXPULSION DEVICE................................................. 89

6.6 TOOL-HOLDER CONE................................................................................................... 89

6.6.1 Installation of the tie-rod HSD 0804H0009 in the cone ISO30 DIN69871................... 90

6.6.2 General recommendations for the tool-holder cones.................................................. 90

6.7 TOOL.............................................................................................................................. 90

6.7.1 Speed limits............................................................................................................... 91

6.7.2 Maximum speed and shape of the tool ...................................................................... 91

6.8 WHAT TO DO IF THE TOOL IS BLOCKED ON THE PIECE BEING WORKED .......... 111

6.9 SENSORS .................................................................................................................... 113

6.9.1 Technical characteristics of the inductive sensors ................................................... 113

6.9.2 Status modes of the electrospindle and corresponding outputs ............................... 114

6.9.3 Output of sensor S3: “shaft idle” signal .................................................................... 114

6.9.4 Use and technical characteristics of the thermal alarm ............................................ 115

6.10 ENCODER (OPTIONAL)............................................................................................... 115

6.10.1 General description.................................................................................................. 115

6.10.2 Technical characteristics of the HSD Square Wave encoder ................................... 116

6.10.3 Output of the HSD Square Wave encoder ............................................................... 116

6.10.4 Technical characteristics of the Lenord+Bauer Square Wave encoder .................... 117

6.10.5 Output of the Lenord+Bauer Square Wave encoder ................................................ 117

6.10.6 Technical characteristics of the Lenord+Bauer sinusoidal encoder.......................... 118

7 MAINTENANCE.........................................................................................................124

7.1 SCHEDULED MAINTENANCE..................................................................................... 125

7.1.1 Checking the cleaning of the tool-holder cone and the conical housing in the spindle

shaft 125

7.1.2 Purging the filters of the pneumatic circuit ............................................................... 126

7.1.3 Protecting the conical seat in the spindle shaft ........................................................ 127

7.1.4 Cleaning the tool-holder cone.................................................................................. 127

7.1.5 Lubricating the HSK collet........................................................................................ 127

7.1.6 Checking the connections........................................................................................ 128

7.1.7 Replacing the filters of the pneumatic circuit............................................................ 128

7.1.8 Bearings .................................................................................................................. 128

5801H0056 ________________________________________________________________ 4/181

Page 5

HSD

8 REPLACING COMPONENTS....................................................................................129

8.1 REPLACING THE ELECTRIC FAN.............................................................................. 129

8.2 REPLACING THE SHAFT KIT FOR MODELS ES884, ES888..................................... 129

8.2.1 Disassembly procedure ........................................................................................... 129

8.2.2 Assembly procedure................................................................................................ 131

8.3 REPLACING THE SHAFT KIT FOR MODELS ES915,ES919,ES929,ES988............... 133

8.3.1 Disassembly procedure ........................................................................................... 133

8.3.2 Assembly procedure................................................................................................ 138

8.4 REPLACING THE SHAFT KIT FOR MODELS ES919 ENCODER............................... 142

8.4.1 Disassembly procedure ........................................................................................... 142

8.4.2 Assembly procedure................................................................................................ 145

8.5 REPLACING THE SHAFT KIT FOR MODELS ES939 ................................................. 148

8.6 REPLACING THE SHAFT KIT FOR MODELS ES939 WITH ENCODER..................... 149

8.6.1 Cylinder unit disassembly ........................................................................................ 149

8.6.2 Disassembly of shaft kit and phonic wheel............................................................... 151

8.7 REPLACING THE ENCODER READERS .................................................................... 154

8.7.1 Replacing the HSD optical encoder reader .............................................................. 154

8.8 REPLACING THE SENSORS....................................................................................... 158

8.8.1 Wiring the sensors of ISO30 models with single-acting piston ................................. 158

8.8.2 Wiring the sensors of HSK models with single-acting piston.................................... 158

8.8.3 Wiring the sensors of ISO30 models with double-acting piston................................ 159

8.8.4 Wiring the sensors of HSK models with double-acting piston................................... 159

8.8.5 Wiring the sensors of HSK models with boosted mounting plate.............................. 160

8.8.6 Accessing the sensors............................................................................................. 161

8.8.7 Position of the sensors ............................................................................................ 161

8.8.8 Accessing the ES939 sensors ................................................................................. 162

8.8.9 Position of the ES939 sensors................................................................................. 162

8.8.10 Position of the sensors in models ES884/ES888 ..................................................... 163

8.8.11 Description of the sensor unit .................................................................................. 163

8.8.12 Replacing the sensor unit ........................................................................................ 164

8.8.13 Adjusting sensor S1 (both ISO and HSK versions) .................................................. 165

8.8.14 Adjusting sensor S2 in ISO versions........................................................................ 166

8.8.15 Adjusting sensor S2 in HSK versions....................................................................... 167

8.8.16 Adjusting sensor S3 (both ISO and HSK versions) .................................................. 167

8.8.17 Adjusting sensor S4 (HSK versions only)................................................................. 168

8.8.18 Kit of gauges to adjust sensors S1 and S4 HSK F63 (code HSD 3811H0110)......... 169

8.8.19 Kit of gauges to adjust sensors S1 and S4 HSK E63 (code HSD 3811H0739) ........ 171

9 OPTIONAL PARTS....................................................................................................173

9.1 COOLING WITH FORCED AIR .................................................................................... 173

9.2 INSTALLATION OF THE KIT FOR COOLING WITH FORCED AIR ............................ 174

10 TROUBLESHOOTING...............................................................................................175

11 LIST OF SPARE PARTS ...........................................................................................179

12 DISPOSAL.................................................................................................................180

13 CUSTOMER SERVICE ..............................................................................................181

5801H0056 ________________________________________________________________ 5/181

Page 6

HSD

i

1 PRELIMINARY INFORMATION

1.1 DOCUMENTS SUPPLIED WITH THE ELECTROSPINDLE

The documentation supplied with the product consists of:

• the Manufacturer's Declaration in accordance with Appendix IIB of Directive 2006/42/EC

• the product inspection certificate.

• this manual, containing the warnings and instructions for transport, installation, operation,

1.2 PURPOSE OF THE MANUAL

• The manual is an integral part of the electrospindle and must compulsorily accompany it,

• The manual must be handled with care, distributed and made available to all persons

• The purpose of the warnings is to protect the safety of the persons exposed to residual risks.

maintenance and disposal of the product.

Check that all the documents defined above are present at the time of delivery; if

necessary, request a new copy from HSD S.p.A.

otherwise the electrospindle would be without one of its essential safety requirements.

concerned.

• The instructions provide tips on the proper behaviour for the correct use of the product, as

intended by the manufacturer.

• In the event that contradictions are discovered between these instructions and the safety

standards, please contact HSD S.p.A. for any corrections and/or amendments, on +39 0721

439638.

• In order to avoid incorrect operations that could cause danger for people, it is important to read

and understand all the documentation supplied with the electrospindle.

• It is important to keep this manual in a suitable place and always within reach for consultation.

1.3 GENERAL SAFETY SYMBOLS

In this manual, some information of particular interest may be preceded by one of the following

symbols:

Indicates a procedure, practice or any other similar

measure that, if not observed or correctly followed, may

cause personal injuries.

Indicates an operational procedure, practice or any other

similar measure that, if not observed or correctly

followed, can damage or completely destroy the product.

Indicates that the marked part may be red-hot and must

not be touched without due care.

Indicates information of particular general interest that

i

5801H0056 ________________________________________________________________ 6/181

must not be ignored.

Page 7

HSD

1.4 RISKS ASSOCIATED WITH THE USE OF THE ELECTROSPINDLE

• HSD S.p.A. does not know, and cannot know, the conditions of installation of the

product, so the installer or end user must carry out an analysis of the risks, relating

specifically to the method and typology of installation.

• It is, however, the responsibility of the party conducting the installation to guarantee an

adequate degree of protection against the risk of accidental contact with moving parts and

elements.

• The installer and user must also bear in mind other types of risk, in particular those arising from

the presence of foreign bodies and from the transport of explosive, inflammable or toxic gases at

high temperatures.

• Furthermore, consideration must be given to the risks inherent in the maintenance operations

that must be carried out under conditions of maximum safety by isolating the electrospindle and

with the tool at a standstill.

• The finished machine on which the HSD product is to be integrated will be subject to an overall

risk evaluation, and a conformity declaration must be granted, according to Directive

2006/42/EC, appendix IIA, and successive amendments.

• It is forbidden to put the product into operation before the machine into which it is to be

incorporated complies with the provisions of Directive 2006/42/EC and successive

amendments.

1.5 RISKS ASSOCIATED WITH INCORRECT USE AND/OR OPERATION

• It is absolutely forbidden to disconnect, remove, modify or in any other way deactivate any

safety, protection or monitoring device, both relating to individual devices and to the

electrospindle as a whole.

• Do not place your hands, arms or any other parts of the body in the vicinity of moving parts.

• The use of the electrospindle in atmospheres or environments with the risk of explosion is

forbidden.

• It is forbidden for an unauthorised operator to eliminate possible defects or faults in the

functioning of the electrospindle and/or to change the type of operation and installation.

• After carrying out any special operations involving the removal of guards, barriers or other

protective devices, install these again before restarting the electrospindle and check that they

are correctly positioned and functioning efficiently.

• All the protective and safety devices must be maintained in a perfect and efficient condition at all

times. The plates with indications, recommendations and danger warnings must be kept in place

and fully efficient.

• When looking for the cause of any fault or malfunction of the electrospindle, take all the

precautions described in the manual in order to avoid personal injury or damage to equipment.

• Remember to tighten all screws, bolts or ring nuts of all mechanical control or adjustment

elements.

• Before starting up the electrospindle, ensure that all the safety devices are installed and in

proper functional order; if this is not the case, it is absolutely forbidden to start it up, and the

person responsible for internal safety or the section head must be informed immediately.

• The operator must be equipped with Personal Protective Equipment (PPE) in accordance with

the provisions of the laws in force; wearing loose clothes and various accessories (ties, wide

sleeves, etc.) is forbidden.

• It is absolutely forbidden to use types of tool holder that do not correspond to the models defined

in the manual; this would cause the risk of breakage or imperfect hook-up of the tool holder

cone.

5801H0056 ________________________________________________________________ 7/181

Page 8

HSD

1.6 SPECIFIC RISKS DURING ELECTROSPINDLE MAINTENANCE

To safely operate an HSD product fitted on the machine, refer to the manual of the

machine itself.

• Disconnect the product from the main power supply before carrying out any maintenance

operations!

• Even when the product is disconnected from the power supply, the rotating parts (and moving

parts in general) can nevertheless move, due to their inertia; before carrying out maintenance

operations therefore, check that the moving parts of the product are at a standstill.

1.7 RESIDUAL RISKS

The product has been analysed on the basis of Directives 2006/95/EC and 2006/42/EC in order to

identify possible sources of risk. The risks that still remain (residual risks) and the respective

countermeasures are described in the relevant sections of this manual.

1.8 PURPOSE OF THE PRODUCT

The product cannot work independently: it is a part of a machine, and is designed to be assembled

with other machine parts, or to be incorporated in a machine, so as to form a machine in

accordance with Directive 2006/42/EC.

It is forbidden to set the product into operation before the machine into which it is to be

incorporated complies with the provisions of Directive 2006/42/EC and subsequent

amendments.

1.9 RANGE OF APPLICATIONS

The product has been designed to carry out milling and boring operations in the field of wood and

its derivatives, plastic, fibre, aluminium, and light machining operations on other metals.

The quick replacement of the shaft unit complete with bearings is possible on some models, using

the “shaft kit”. For further information see section 11 List of spare parts

All the electrospindles have a mechanical reaction system that neutralises the axial force of the

piston on the shaft during the tool changing phase, guaranteeing the integrity of the precision

bearings.

1.10 IDENTIFICATION OF THE PRODUCT AND THE MANUFACTURER

The EC marking plate and the serial number represent the only elements to identify the product

acknowledged by HSD S.p.A. The user of the product is obliged to maintain the integrity of these

signs.

In section 2 you can see the position of the EC mark and the serial number of the product.

5801H0056 ________________________________________________________________ 8/181

Page 9

HSD

1.11 GLOSSARY

ISO

HSK

Value of the balancing of a rotating object according to the standard ISO 1940/1,

Degree or type

of dynamic

balancing

indicated by the letter G.

Low G values correspond to higher balancings; the maximum balancing precision is

G=0.4.

G takes on discrete values in relation to multiples of 2.5 (G=0.4 G=1 G=2.5 …).

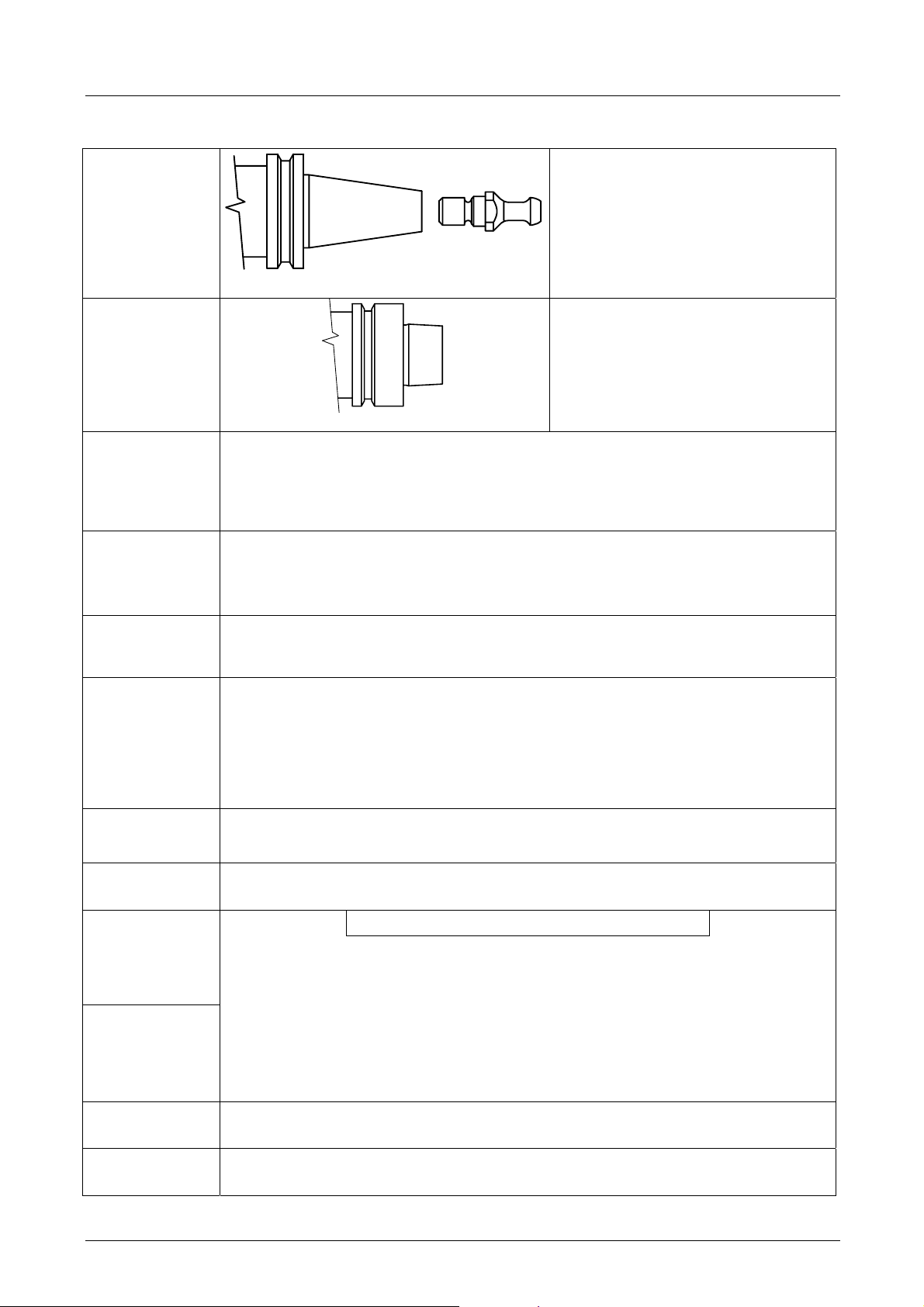

ISO DIN69871 CONE HSD TIE-ROD

HSK DIN69893 CONE

Tool-holder cone hooking system,

described by the standard DIN 69871.

On the electrospindle there is a plate

similar to that alongside, indicating the

type of hook-up (ISO or HSK) and the

type of HSD tie-rod (see paragraph

6.6).

Tool-holder cone hooking system,

described by standard DIN 69893.

The electrospindle has a plate similar to

that alongside, indicating the type of

hook-up (ISO or HSK).

Routine

maintenance

Service S1

Service S6

Rated voltage

Rated

frequency

Torque

Power

All the activities intended to maintain the operating and functioning conditions of the

electrospindle as provided for by HSD S.p.A. at the moment of its launch on the market;

it is carried out through scheduled operations to adjust, repair and replace parts.

Function under constant load, of a duration sufficient to allow the electrospindle to attain

a thermal equilibrium.

The corresponding abbreviation is S1.

Sequence of identical operating cycles, each comprising a period of operation under

constant load and a period of operation without load while maintaining the rotational

speed; there is no rest period.

The corresponding abbreviation is S6, followed by the percentage ratio between the

period of operation under load and the length of the cycle.

Example: S6 40%.

40% period of operation under load, 60% period of operation in rotation without load).

(

Maximum power supply voltage of the electrospindle.

Minimum frequency at which rated voltage is supplied.

..Torque (Nm) = [ 60 · power (W) ] : [ 2 · Π · rpm ]..

Providing a precise physical definition of torque and power would be going beyond the

scope and possibility of this manual. Nevertheless the torque can be roughly

correlated to the force with which the tool contacts the piece being machined (and for

the same torque value, the force increases as the diameter of the tool decreases). The

power, on the other hand, is proportional to the torque and the rotational speed and

determines the maximum machining speed (taking into consideration the performance

of the tool, the characteristics of the material being machined and the type of

machining).

Nominal

characteristics

Coolant

All the various rated values reached in relation to the rated frequency.

Fluid, liquid or gas (including air) by means of which the heat is transferred from the

spindle to the atmosphere.

5801H0056 ________________________________________________________________ 9/181

Page 10

HSD

1.12 GUARANTEE CONDITIONS

HSD S.p.A. guarantees that the electrospindle has been inspected at its plant with a positive result.

Works under warranty shall be performed free at the HSD S.p.A. facilities, transport at the

customer's expense; HSD S.p.A. shall not be liable for termination of production during the

warranty period.

The warranty does not cover faults due to normal wear of those parts which, by their nature, are

subject to rapid and continuous wear (e.g. gaskets, belts, bearings, etc.). In particular, HSD S.p.A.

gives no guarantee as to the working life of the bearings, as this depends on various factors

including: the degree of balancing of the tools, the types of machining operation, collisions and/or

mechanical stresses beyond the values indicated by the manufacturer.

HSD S.p.A. accepts no liability for faults in the conformity of the electrospindle caused by a failure

to observe the standards of the instruction manual or the incorrect operation or handling of the

electrospindle.

only if the faults have not been caused by tampering

parts and/or replacing components not provided for and not authorised in this manual and, in any

case, without the prior written approval of HSD S.p.A.

On no account shall HSD S.p.A. or its suppliers be responsible for damage (including but not limited

to damage to the physical integrity of the product or damages due to loss or reduced earnings,

stoppages in production, loss of information or other economic losses) resulting from the use of

HSD products, even in cases where HSD S.p.A. has been warned of the possibility of such damage.

The buyer shall therefore have a right to replacement of parts found to be defective

, namely by installing non-original HSD spare

The buyer's warranty shall be voided if HSD S.p.A. is not notified in detail, in writing, of the nature

of any faults discovered in the electrospindle within 15 days of the fault being discovered. The

buyer's warranty shall also be voided in the event that he does not allow the seller to carry out any

requested inspections, or if the seller requests the return of the defective parts and the buyer fails

to return them within two weeks of the request.

Measured drawings and photographs are provided purely as reference examples for a simpler

understanding of the text.

In line with its policy of continuous development and advancement of the product, the company

reserves the right to modify both its functional and aesthetic characteristics, to vary the design of

any functional element or accessory, or to suspend production and delivery; this without

undertaking to give notice to anyone and without incurring any other obligation. Furthermore, HSD

S.p.A. reserves the right to make any structural or functional modifications, as well as the

modification of the supplied spare parts and accessories, without the obligation of communicating

these changes to anyone or assuming any other obligation.

5801H0056 _______________________________________________________________ 10/181

Page 11

HSD

2 TECHNICAL SPECIFICATIONS

2.1 MAIN PARTS OF ES915/ES919/ES929/ES988

12

13

14

15

9

16

17

18

1

2

3

4

5

6

7

8

9

10

11

1 Movable electrical connectors 10 Framework

2 Fixed electrical connectors 11 Electric fan (air-cooled versions only)

3 EC marking plate 12 Pneumatic connectors

4 Serial number 13 Cover of the sensor area

5 Connector for sensor on accessories (e.g. C-axis) 14 Button for the manual release of the tool-holder

6 “Nose” 15 Pneumatic cylinder

7 Shaft 16 Resting surface

8 Tool hooking system 17 Seat for centring tang

Threaded bores for accessories

9

(on the sides and the front flange)

18 “T” slot for fixing

5801H0056 _______________________________________________________________ 11/181

Page 12

HSD

2.2 MAIN PARTS OF MODELS ES884 - ES888

1

1

2

8

9

3

4

5

6

7

1 Sensor area 7 Pneumatic connections

2 Pneumatic cylinder 8 M6 threaded bores for accessories

3 “Nose” 9 Shaft

4 Fixing surface 10 Tool hooking system

10

8

11

12

5 Pressurisation connector 11 Serial number

6 Framework 12 Electrical connectors

5801H0056 _______________________________________________________________ 12/181

Page 13

HSD

2.3 MAIN PARTS OF MODEL ES939

12

13

14

15

9

16

17

1

2

3

4

5

6

7

8

9

10

18

1 Fixed electrical connectors 10 Framework

2 EC marking plate 11 Electric fan (air-cooled versions only)

3 Encoder connector 12 Pneumatic connectors

4 Serial number 13 Cover of the sensor area

5 Connector for sensor on accessories (e.g. C-axis) 14 Button for the manual release of the tool holder

6 “Nose” 15 Pneumatic cylinder

7 Shaft 16 Resting surface

8 Tool hooking system 17 Seat for centring tang

Threaded bores for accessories

9

(on the sides and the front flange)

18 “T” slot for fixing

11

5801H0056 _______________________________________________________________ 13/181

Page 14

HSD

2.4 VARIATIONS WITH VERTICAL MOUNTING PLATE

1

12

13

14

9

15

16

17

2

3

4

5

6

7

8

9

10

1 Movable electrical connectors 10 Framework

2 Fixed electrical connectors 11 Electric fan (air-cooled versions only)

3 Button for the manual release of the tool-holder 12 Pneumatic connectors

4 Serial number 13 Cover of the sensor area

5 Connector for sensor on accessories (e.g. C-axis) 14 Pneumatic cylinder

6 “Nose” 15 Resting surface

7 Shaft 16 Seat for centring tang

8 Tool hooking system 17 “T” slot for fixing

Threaded bores for accessories

9

(on the sides and the front flange)

11

5801H0056 _______________________________________________________________ 14/181

Page 15

HSD

2.5 VARIATIONS WITH MILITARY CONNECTORS

10

1

11

12

13

14

15

16

17

2

3

4

5

6

7

8

9

1 Fixed electrical connectors 10 Pneumatic connectors

2 EC marking plate 11 Cover of the sensor area

3 Serial number 12 Motor cooling liquid inlet / outlet

4 Connector for sensor on accessories (e.g. C-axis) 13 Pneumatic cylinder

5 “Nose” 14 Button for the manual release of the tool-holder

6 Shaft 15 Resting surface

7 Tool hooking system 16 Seat for centring tang

Threaded bores for accessories

8

(on the sides and the front flange)

9 Framework

17 “T” slot for fixing

5801H0056 _______________________________________________________________ 15/181

Page 16

HSD

2.6 TECHNICAL CARDS ES884

H1423H0292 Rev.02 (120.150.4A )

Rated voltage (*)

Rated frequency Hz 267 333 500 600

Rated speed rpm 8,000 10000 15,000 18,000

Duty type

Rated power kW 16.0

Rated torque Nm 19

Rated current A 34.5

Rated output η 0.8

Power factor cos φ 0.7

Number of poles 4

Type of insulation F

IP rating 54

Type of cooling Raffreddamento a liquido / Flüssigkeit / Liquid cooling

Weight of

LONG NOSE version

[(*) supplied by inverter]

V 380 380 380 380

S1

cont

kg ~ 57

S6

60%

18.0

21.5

45

S1

cont

16.0

15.3

34.5

S6

60%

18.0

17.2

45

S1

cont

11.0

7.0

23.7

S6

60%

13.0

8.3

32.6

S1

cont

8.0

4.2

18.0

S6

60%

10.0

5.3

26.0

5801H0056 _______________________________________________________________ 16/181

Page 17

HSD

SP120.150.4A

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage / leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

16

34.5

380

7810

267

370

11

0.12

0.2

1

1.7

19

8000

18000

0.8

0,0025

Y

5801H0056 _______________________________________________________________ 17/181

Page 18

HSD

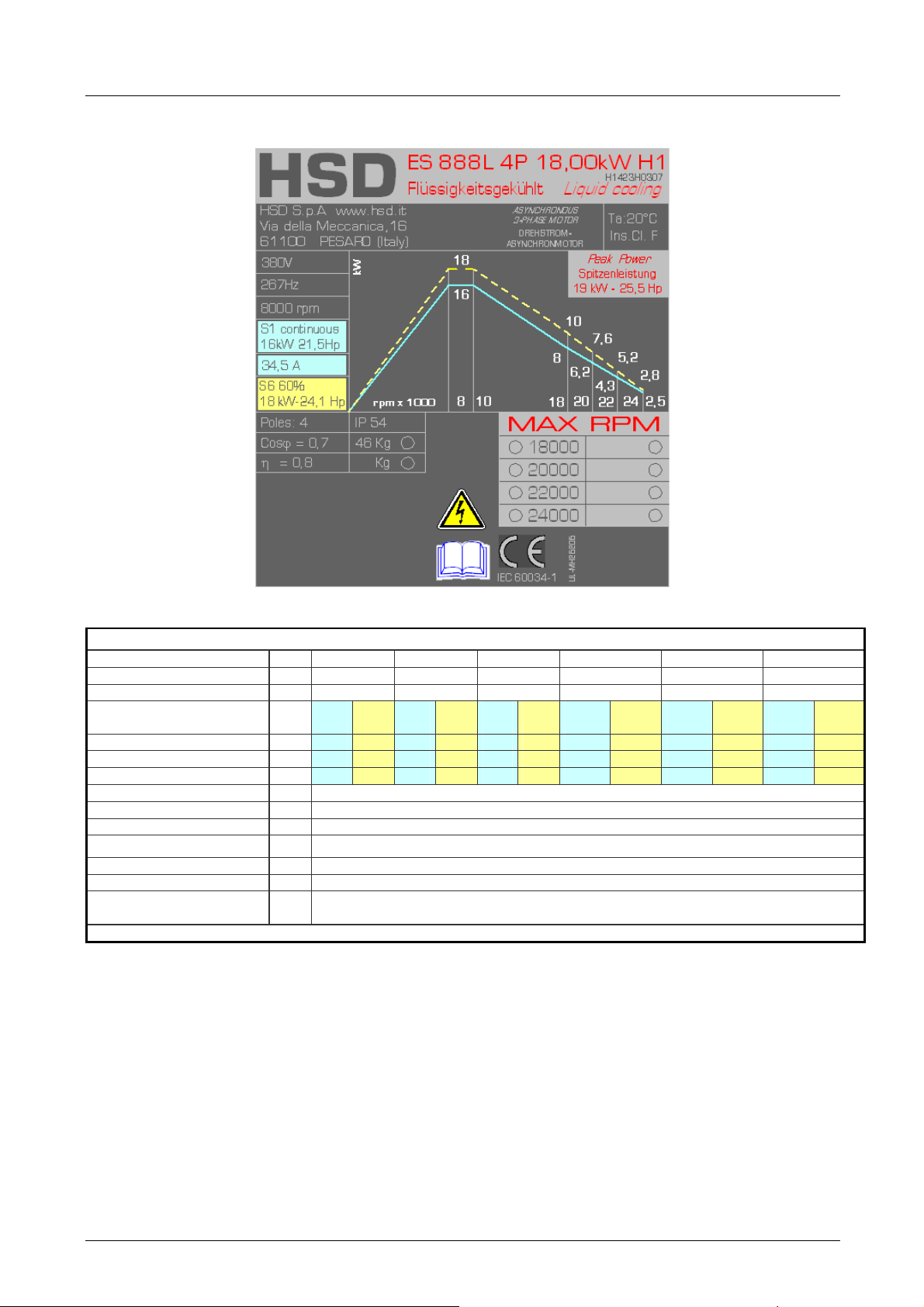

2.7 TECHNICAL CARDS ES888

H1423H0307 Rev.00 ( Ref.: H2120H0120 / SP.120.150.4A )

Rated voltage (*) V

Rated frequency Hz

Rated speed rpm

Duty type

Rated power kW

Rated torque Nm

Rated current A

Rated output η

Power factor cos φ

Number of poles

Type of insulation

IP rating

Type of cooling

Weight of

LONG NOSE version

[(*) supplied by inverter]

kg

380 380 380 380 380 380

267 333 600 667 733 800

8,000 10000 18,000 20,000 22000 24,000

S1

cont

16

19

34.5

4

S6

60%

18

21.5

45

S6

S1

60%

cont

18

16

17.2

15.3

45

34.5

Raffreddamento a liquido / Flüssigkeit / Liquid cooling

S1

cont

8

4.2

18

S6

60%

10

5.3

26

S1

cont

6.2

3

14.3

0.8

0.7

F

54

~ 46

S6

60%

7.6

3.6

17.2

S1

cont

4.3

1.9

8

60%

S6

5.2

2.3

11

S1

cont

2.5

1.0

4.6

S6

60%

2.8

1.1

5

5801H0056 _______________________________________________________________ 18/181

Page 19

HSD

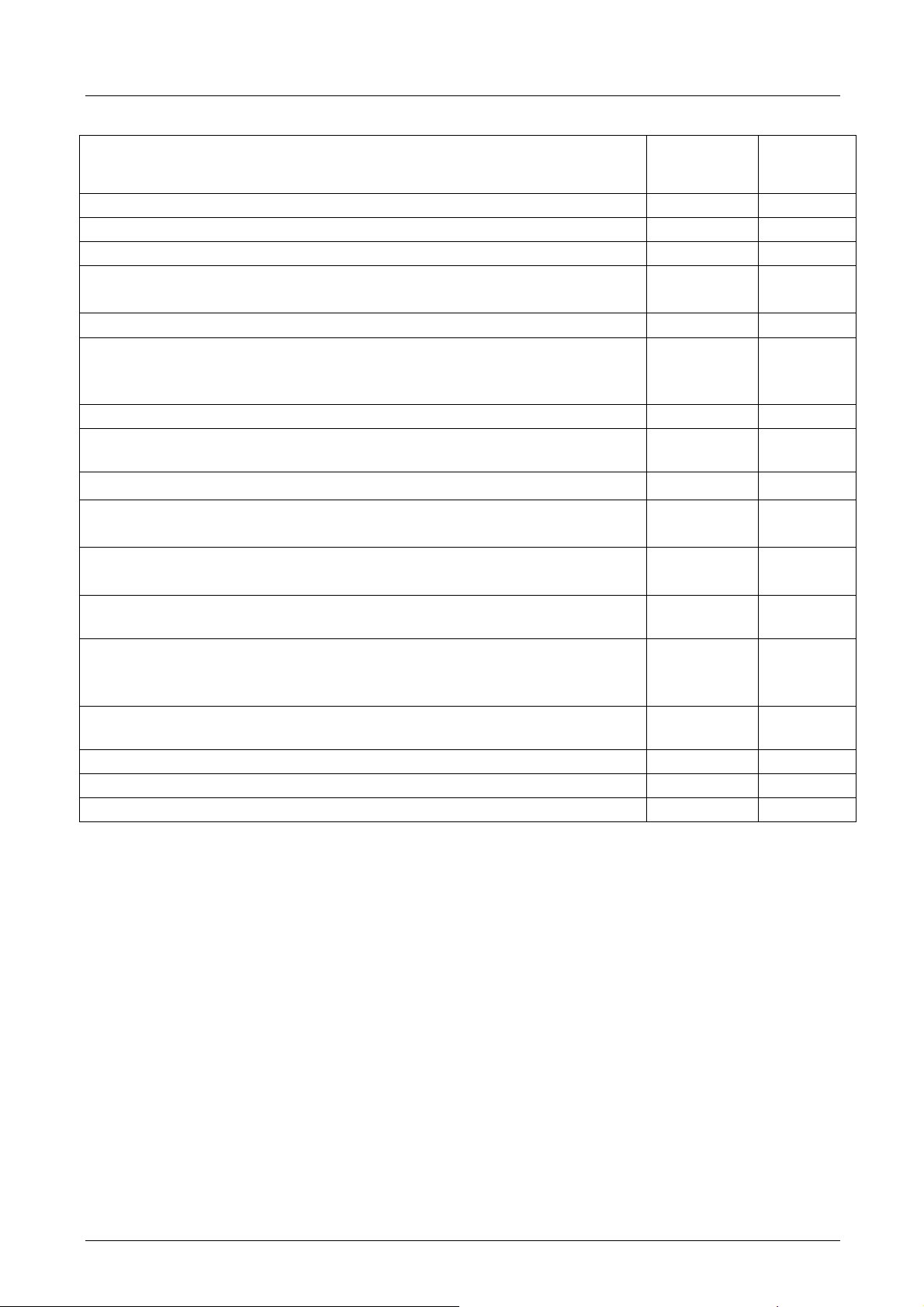

SP120.150.4A

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

16

34.5

380

7810

267

370

11

0.12

0.2

1

1.7

19

8000

18000

0.8

0.0025

Y

5801H0056 _______________________________________________________________ 19/181

Page 20

HSD

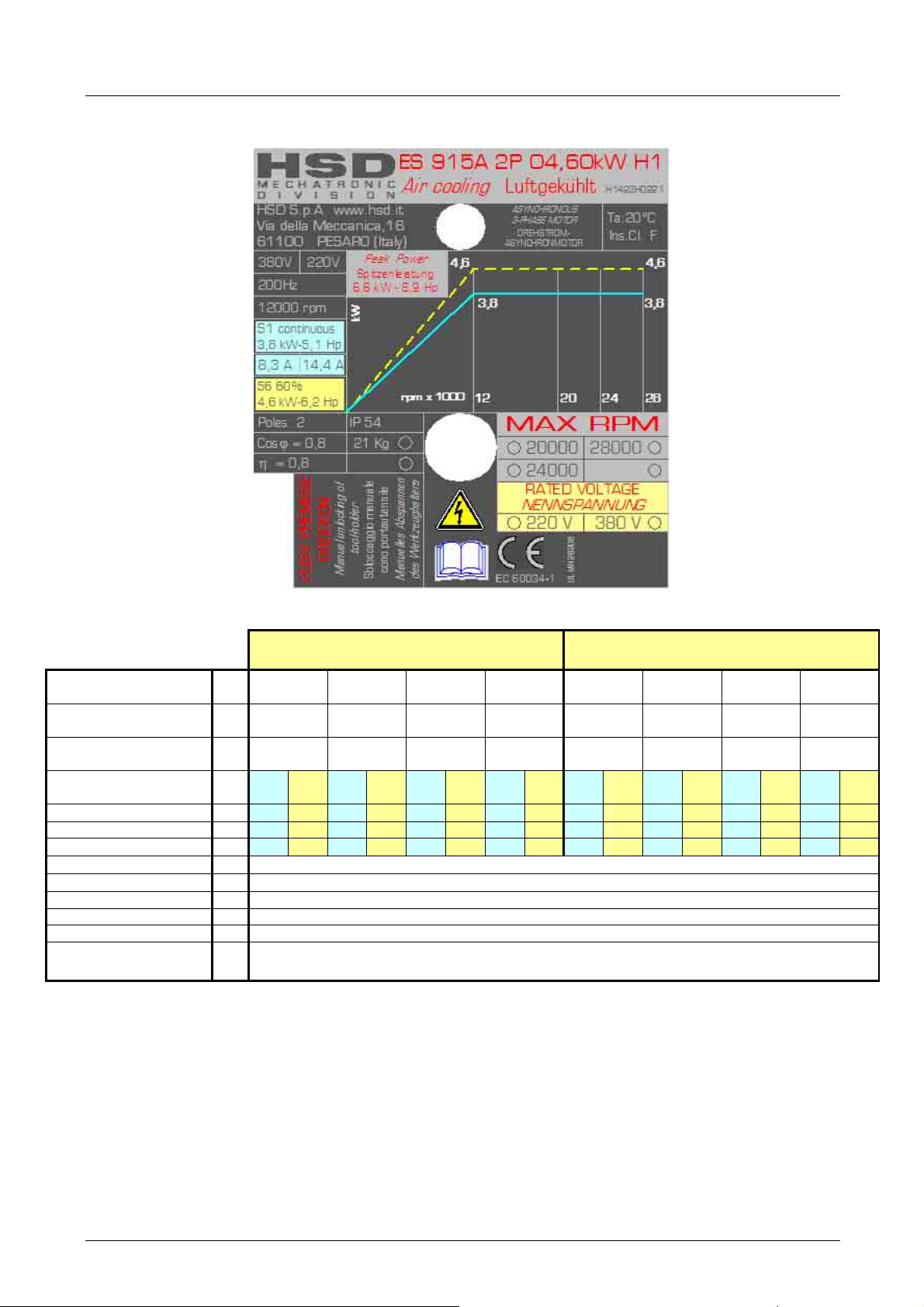

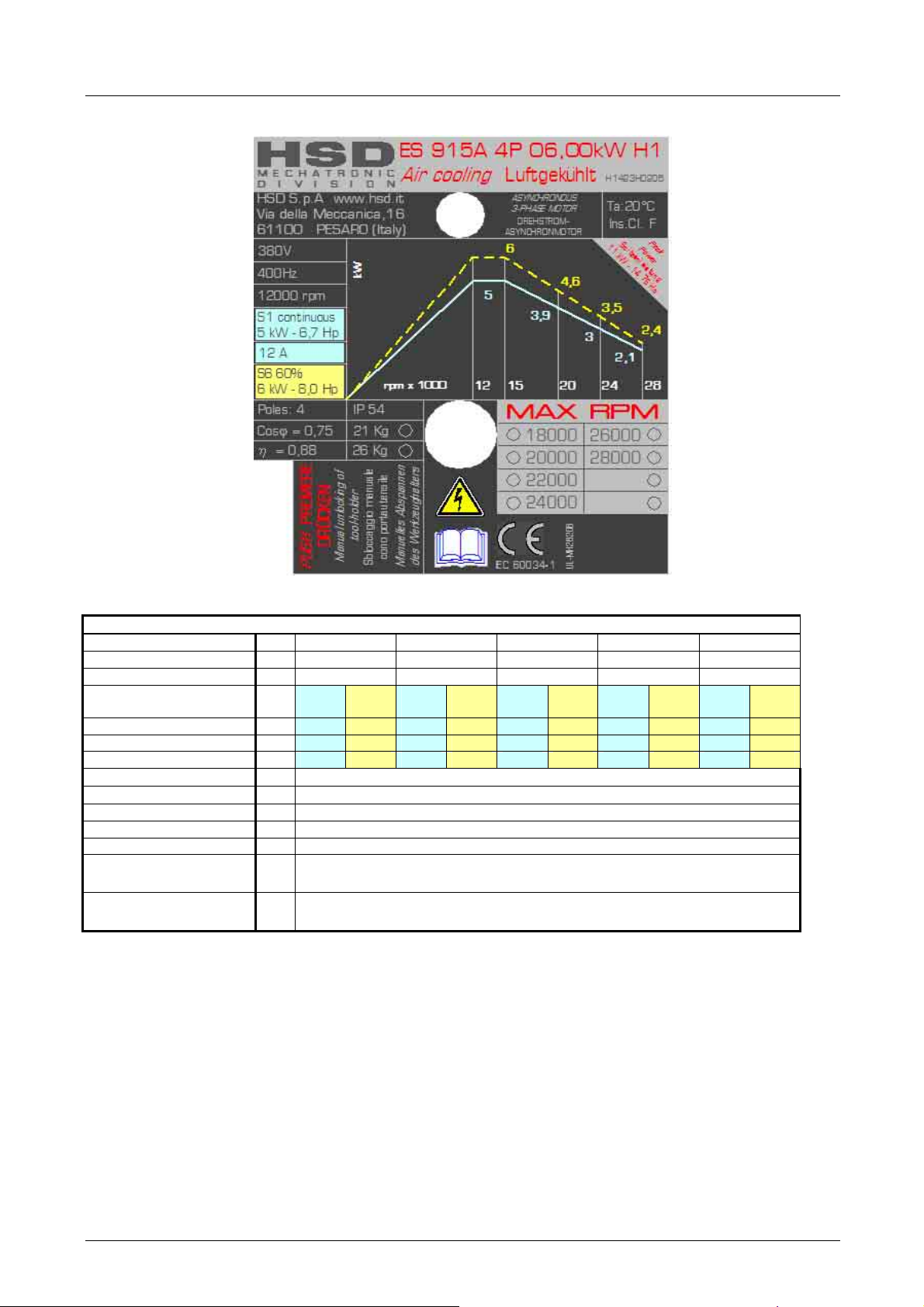

2.8 TECHNICAL CARDS ES915

H1423H0221 Rev.04

(SP.110.70.24)

Rated voltage (*) V 380 380 380 380 220 220 220 220

Rated frequency Hz 200 333 400 466 200 333 400 466

Rated speed rpm 12000 20000 24000 28000 12000 20000 24000 28000

Duty type

Rated power kW 3.8 4.6 3.8 4.6 3.8 4.6 3.8 4.6 3.8 4.6 3.8 4.6 3.8 4.6 3.8 4.6

Rated torque Nm 3 3.7 1.8 2.2 1.5 1.8 1.3 1.6 3 3.7 1.8 2.2 1.5 1.8 1.3 1.6

Rated current A 8.3 10 8.3 10 8.3 10 8.3 10 14.4 17.3 14.4 17.3 14.4 17.3 14.4 17.3

Rated output η

Power factor cosϕ

Number of poles 2

Type of insulation F

Type of cooling Elettroventola / Elektrolüfter / Cooling fan

Weight of

SHORT NOSE version

[(*) supplied by inverter]

STAR CONNECTION DELTA CONNECTION

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

0.8

0.8

kg ~ 21

5801H0056 _______________________________________________________________ 20/181

Page 21

HSD

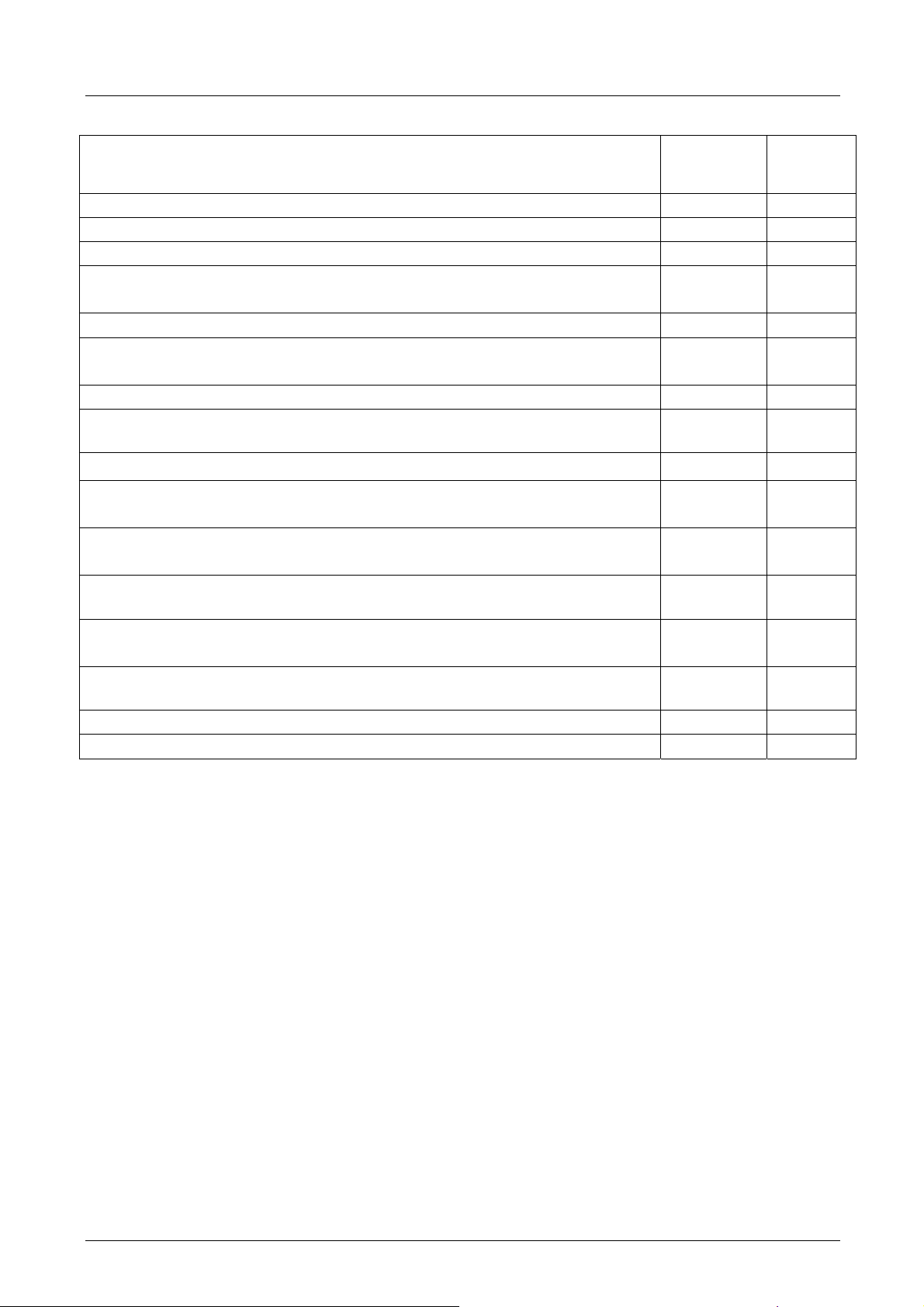

SP 110.70.24

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage / leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Y or D

Value

3.7

8.3

380

11800

200

370

2.6

0.67

0.65

2.1

3.8

82

12000

12000

0.8

Y

5801H0056 _______________________________________________________________ 21/181

Page 22

HSD

H1423H0206_Rev02 SP.110.070.42

Rated voltage (*)

Rated frequency

Rated speed

Duty type

Rated power

Rated torque

Rated current

Rated output η

Power factor cosϕ

Number of poles

Type of insulation

Type of cooling

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by inverter]

V 380 380 380 380 380

Hz 400 500 667 800 933

rpm 12,000 15,000 20,000 24,000 28,000

kW

Nm

A

0.86

0.82

4

F

kg ~ 21

kg ~ 26

S1

cont

5

4

12

S6

60%

6

4.8

14

S1

cont

3.2

10.5

Elettroventola / Elektrolüfter / Cooling fan

S6

60%

5

3.8

14

S1

cont

6

3.9

1.7

9.2

S6

60%

4.6

2.2

10.5

S1

cont

3

1.2

7

60%

3.5

1.4

S6

8

S1

cont

2.1

0.7

4

S6

60%

2.4

0.8

4.5

5801H0056 _______________________________________________________________ 22/181

Page 23

HSD

SP110.70.42_Air

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

5

10.5

380

11850

400

370

4.3

0.27

0.24

1.6

3.2

50

12000

24000

0.85

1.1E-03

Y

5801H0056 _______________________________________________________________ 23/181

Page 24

HSD

H1423H0207 Rev.02 (ST 110.070.42)

Rated voltage (*) V 380 380 380 380 380 380

Rated frequency Hz 400 500 600 667 733 933

Rated speed rpm 12,000 15,000 18,000 20,000 22000 28,000

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

Duty type

Rated power kW 6.5

Rated torque Nm 5.2

Rated current A 15

Rated output η

Power factor cosϕ

Number of poles 4

Type of insulation F

Type of cooling

Weight of

LONG NOSE version

[(*) supplied by inverter]

cont

50%

cont

50%

cont

50%

7.5

6

18

0.82

0.74

kg ~ 29

7.5

6.5

4.8

4.1

18

15

Raffreddamento a liquido / Flüssigkeit / Liquid cooling

6.1

3.2

14

6.7

3.6

15.7

cont

5.8

2.8

13

50%

6.4

3.1

16

cont

5.5

2.4

13.1

50%

6

2.6

14.1

cont

7.5

S6

50%

3

3

1

1

7.5

5801H0056 _______________________________________________________________ 24/181

Page 25

HSD

SP110.70.42_Liquid

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

6.5

13.2

380

11850

400

370

4.3

0.27

0.24

1.6

3.2

50

12000

24000

0.85

1.1E-03

Y

5801H0056 _______________________________________________________________ 25/181

Page 26

HSD

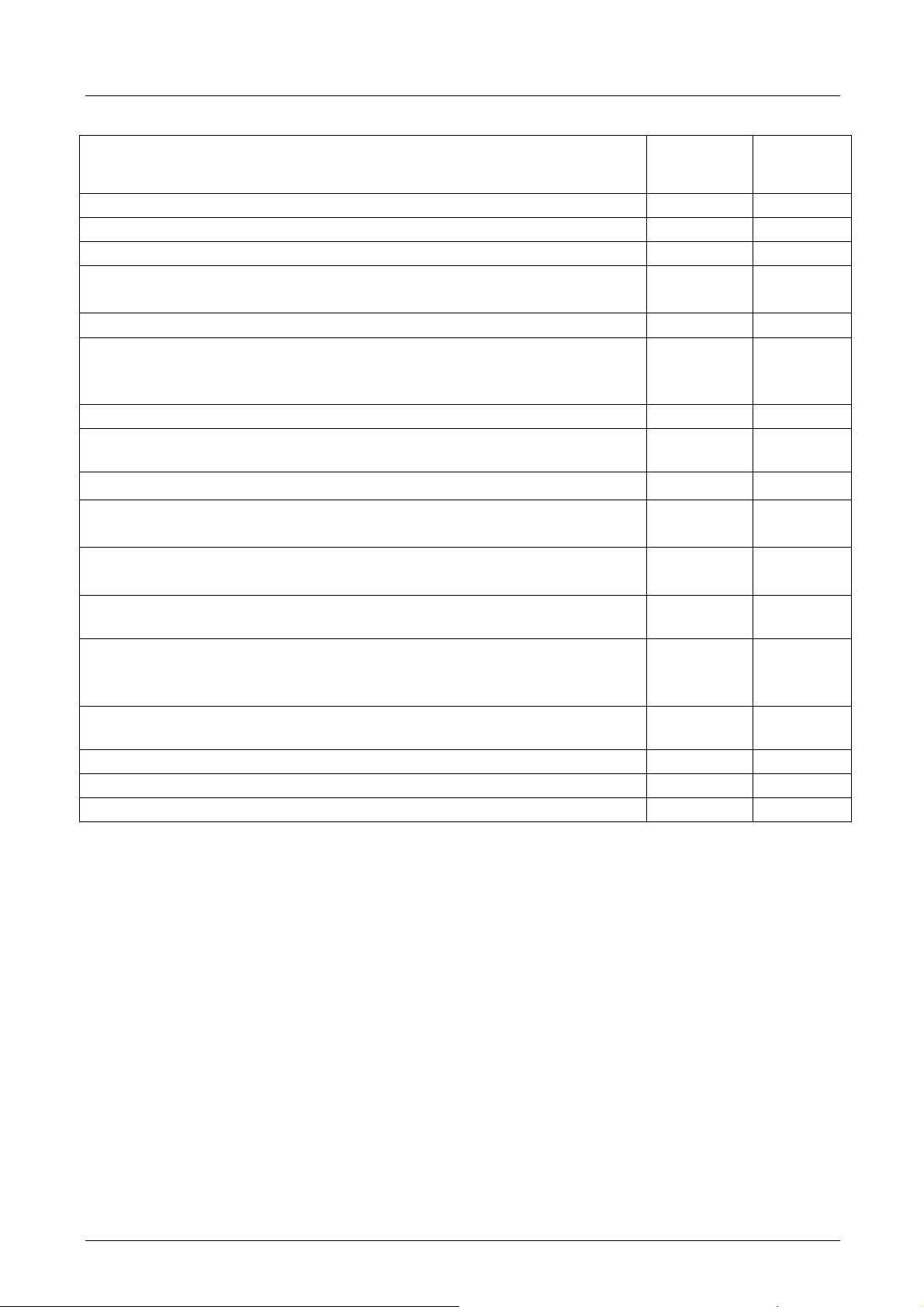

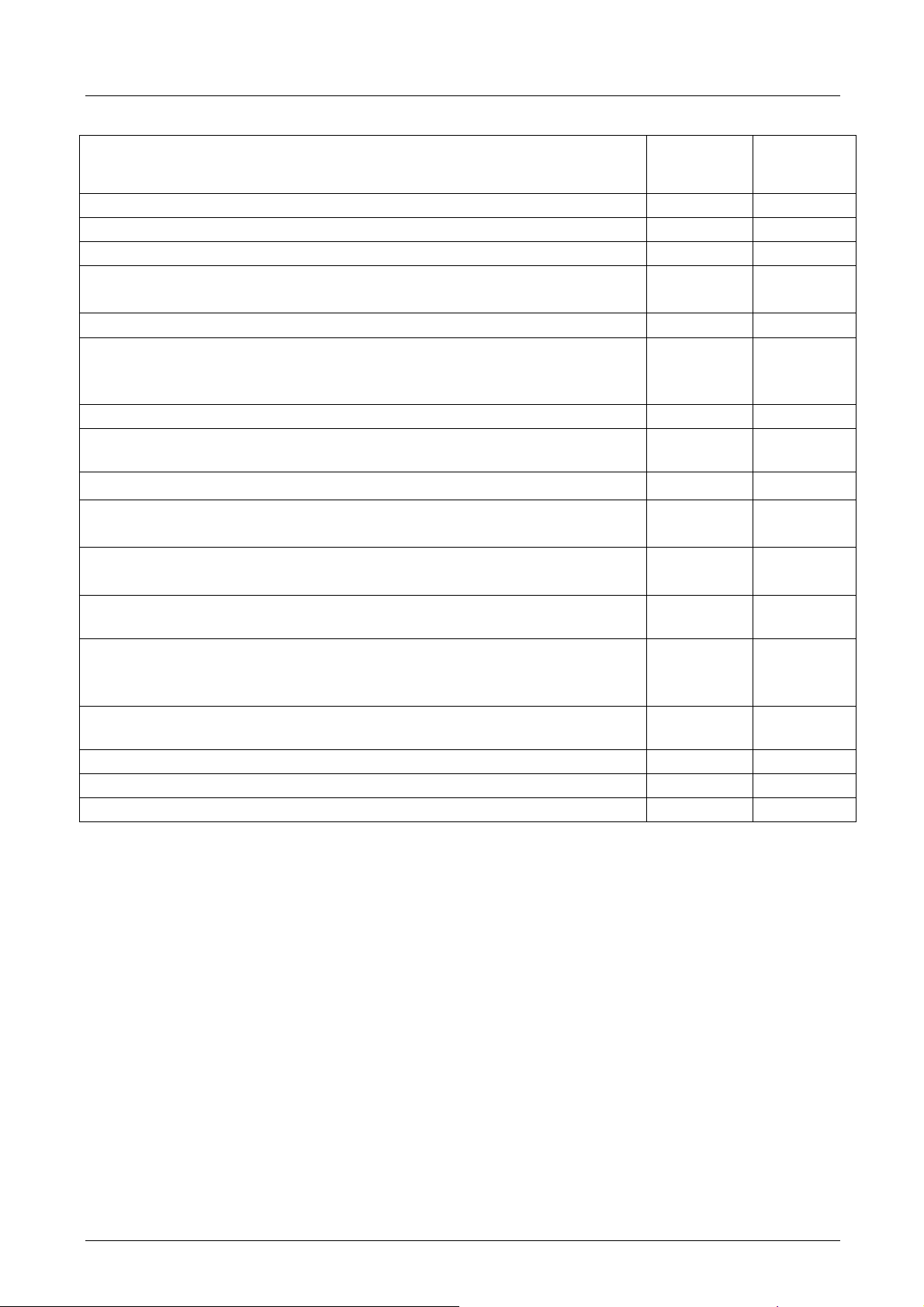

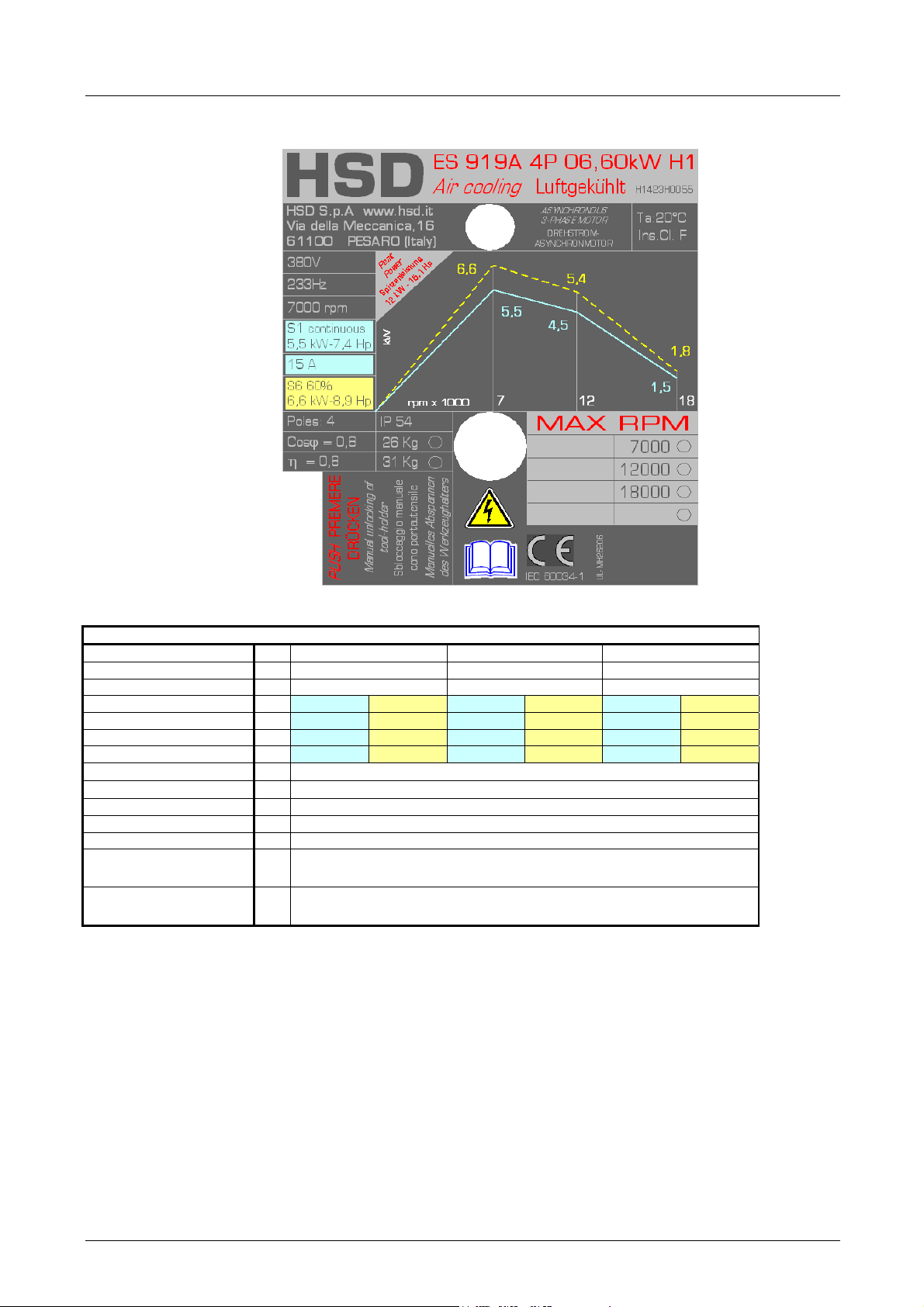

2.9 TECHNICAL CARDS ES919

H1423H0055 Rev.03 (SP.110.130.45)

Rated voltage (*) V 380 380 380

Rated frequency Hz 233 400 600

Rated speed rpm 7000 12,000 18,000

Duty type S1 cont S6 60% S1 cont S6 60% S1 cont S6 60%

Rated power kW 5.5

Nm 7.5

Rated current A 15

Rated output η

Power factor cosϕ

Number of poles 4

Type of insulation F

Type of cooling

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by inverter]

0.8

0.8

kg ~ 26

kg ~ 31

6.6

9

18

Elettroventola / Elektrolüfter / Cooling fan

4.5

3.6

14

5.4

4.3

17

1.5

0.8

6.5

1.8

1

8

5801H0056 _______________________________________________________________ 26/181

Page 27

HSD

SP110.130.45

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

5.5

15

380

6870

233

355

4.2

0.38

0.4

3.4

2.6

49

7000

18000

0.85

1.8E-03

D

5801H0056 _______________________________________________________________ 27/181

Page 28

HSD

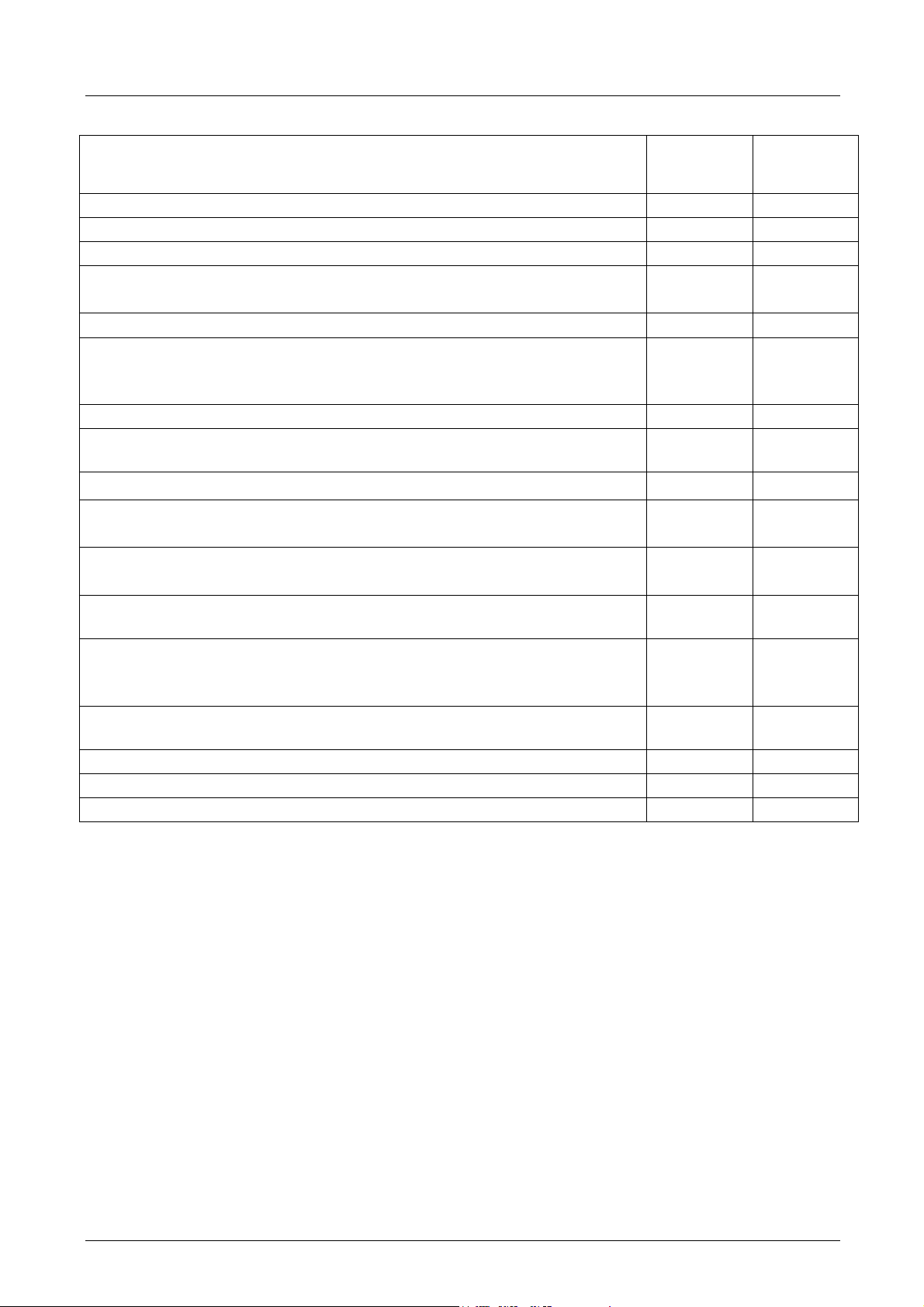

H1423H0196 Rev.01 (SP.110.130.48)

Rated voltage (*) V 380 380 380 380 380 380 380 380

Rated frequency Hz 400 500 600 667 733 800 867 933

Rated speed rpm 12,000 15,000 18,000 20,000 22000 24,000 26000 28,000

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

S6

S1

Duty type

Rated power kW 7.5 9 7.5 9 6.6 8 6 7.3 5.8 6.7 5.5 6 4.2 5.3 3.6 4.7

Rated torque Nm 6 7.2 4.8 5.7 3.5 4.2 2.9 3.5 2.5 2.9 2.2 2.4 1.5 2 1.2 1.6

Rated current A 20 22.5 17 20.5 16 18.5 15 17.5 13 15 13 14 10 12.6 11.5 15

Rated output η

Power factor cosϕ

Number of poles 4

Type of insulation F

Type of cooling Elettroventola / Elektrolüfter / Cooling fan

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by inverter]

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

cont

60%

0.85

0.8

kg ~ 26

kg ~ 31

cont

S6

60%

5801H0056 _______________________________________________________________ 28/181

Page 29

HSD

SP110.130.48 (air-cooled)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Kg m2

Y or D

Value

7.5

20

380

11910

400

360

12

0.12

0.14

1.2

1.9

25

12000

0.85

1.8E-03

Y

5801H0056 _______________________________________________________________ 29/181

Page 30

HSD

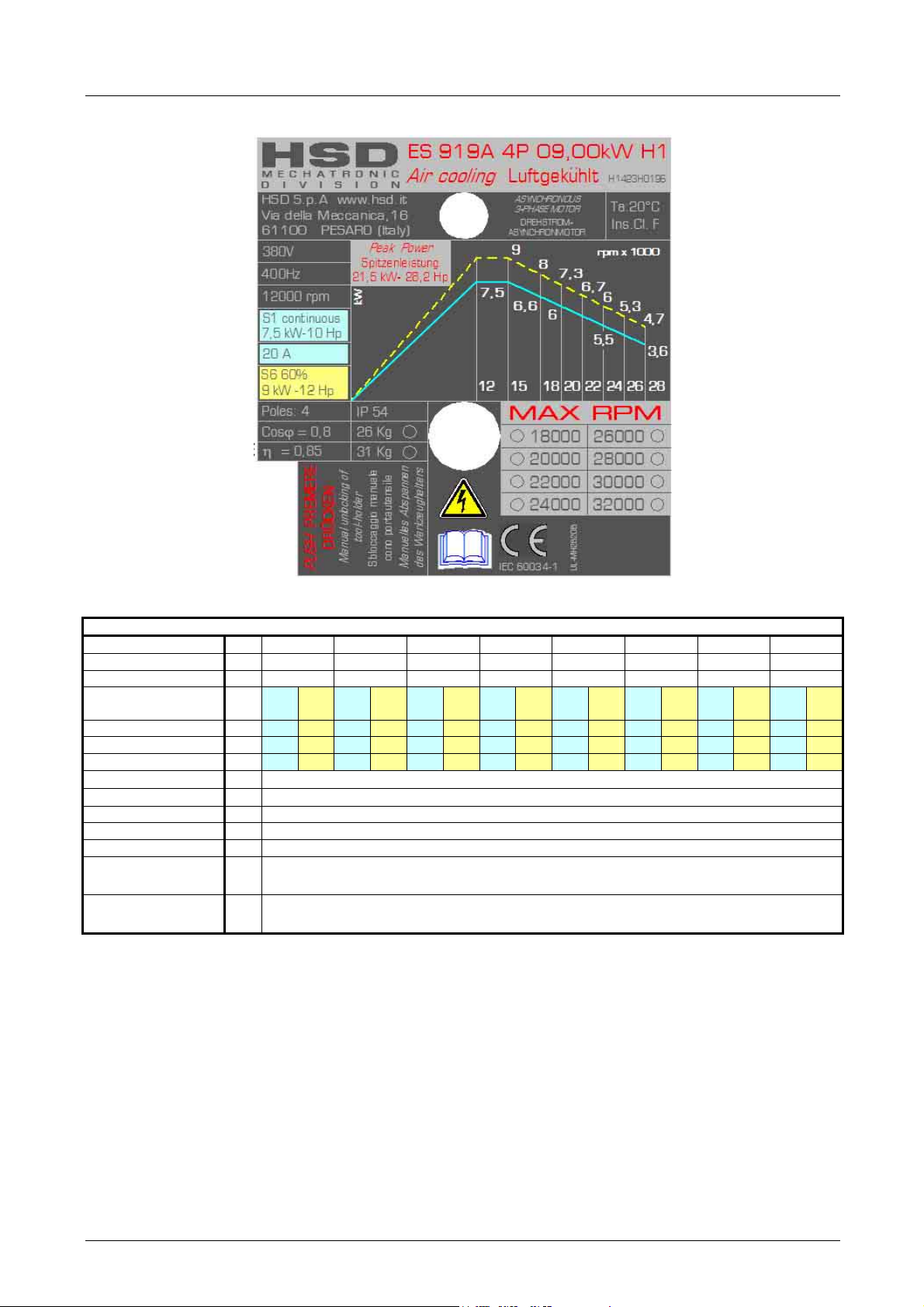

H1423H0223 Rev.01

(SP.110.130.29)

Rated voltage (*) V 380 380 380 380 220 220 220 220

Rated frequency Hz 200 333 400 466 200 333 400 466

Rated speed rpm 12,000 20,000 24,000 28,000 12,000 20,000 24,000 28,000

Duty type

Rated power kW 6.6 7 6.6 7 6.6 7 5 5.5 6.6 7 6.6 7 6.6 7 5 5.5

Rated torque Nm 5.3 5.6 3.2 3.3 2.6 2.8 1.7 1.9 5.3 5.6 3.2 3.3 2.6 2.8 1.7 1.9

Rated current A 15.8 18 15.8 18 15.8 18 15 17 27.4 31.2 27.4 31.2 27.4 31.2 26 29.4

Rated output η

Power factor cosϕ

Number of poles 2

Type of insulation F

Type of cooling Elettroventola / Elektrolüfter / Cooling fan

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by inverter]

S1

cont

0.8

0.8

kg ~ 26

kg ~ 31

COLLEGAMENTO STELLA

STERNSCHALTUNG

STAR CONNECTION

S6

S1

S6

S1

60%

cont

60%

cont

60%

S6

S1

cont

S6

60%

COLLEGAMENTO TRIANGOLO

DREIECKSCHALTUNG

DELTA CONNECTION

S1

S6

S1

S6

S1

cont

60%

cont

60%

cont

S6

60%

S1

cont

S6

60%

5801H0056 _______________________________________________________________ 30/181

Page 31

HSD

SP110.130.29 (delta connection)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage /

nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand

kalt (20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt

(20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

6.6

27.4

220

11840

200

211

17

0.07

0.09

0.29

0.6

7

12000

24000

0.65

1.6E-03

D

5801H0056 _______________________________________________________________ 31/181

Page 32

HSD

SP110.130.29 (star connection)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

6.6

15.8

380

11840

200

364

10

0.2

0.28

0.87

1.8

22

12000

24000

0.72

1.6E-03

Y

5801H0056 _______________________________________________________________ 32/181

Page 33

HSD

H1423H0224

Rev.02

(SP.110.130.29)

Rated voltage (*) V

Rated frequency Hz

Rated speed rpm

Duty type

Rated power kW

Rated torque Nm

Rated current A

Rated output η

Power factor

cos

ϕ

Number of poles

Type of insulation

Type of cooling

Weight of

SHORT NOSE

version

Weight of

LONG NOSE

version

[(*) supplied by

inverter]

kg

kg

COLLEGAMENTO STELLA

STERNSCHALTUNG

STAR CONNECTION

380 380 380 380 380 220 220 220 220 220

200 333 400 466 500 200 333 400 466 500

12,000 20,000 24,000 28,000 30000 12,000 20,000 24,000 28,000 30000

S1

S6

S1

S6

S1

S6

S1

S6

S1

cont

60%

cont

60%

cont

60%

cont

60%

6.6 8 6.6 8 6.6 8 5 5.5 4.2 4.3 6.6 8 6.6 8 6.6 8 5 5.5 4.2 4.3

5.3 6.4 3.2 3.8 2.6 3.2 1.7 1.9 1.3 1.4 5.3 6.4 3.2 3.8 2.6 3.2 1.7 1.9 1.3 1.4

15.8 18 15.8 18 15.8 18 15 17 12.3 13.4 27.4 31.2 27.4 31.2 27.4 31.2 26 29.4 23 23.3

cont

S6

60%

0.8

0.8

2

F

Elettroventola / Elektrolüfter / Cooling fan

~ 26

~ 31

COLLEGAMENTO TRIANGOLO

DREIECKSCHALTUNG

DELTA CONNECTION

S1

S6

S1

S6

S1

cont

60%

cont

60%

cont

S6

60%

S1

cont

S6

60%

S1

cont

S6

60%

5801H0056 _______________________________________________________________ 33/181

Page 34

HSD

SP110.130.29 (delta connection)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

6.6

27.4

220

11840

200

211

17

0.07

0.09

0.29

0.6

7

12000

24000

0.65

1.6E-03

D

5801H0056 _______________________________________________________________ 34/181

Page 35

HSD

SP110.130.29 (star connection)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

6.6

15.8

380

11840

200

364

10

0.2

0.28

0.87

1.8

22

12000

24000

0.72

1.6E-03

Y

5801H0056 _______________________________________________________________ 35/181

Page 36

HSD

H1423H0225 Rev.01 (SP.110.130.4H)

Rated voltage (*) V 380 380 380 380 380 380

Rated frequency Hz 400 500 600 667 733 800

Rated speed rpm 12,000 15,000 18,000 20,000 22000 24,000

Duty type

Rated power kW 9

Rated torque Nm 7.2

Rated current A 21

Rated output η

Power factor cosϕ

Number of poles 4

Type of insulation F

Type of cooling

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by inverter]

S1

cont

0.85

0.85

kg ~ 26

kg ~ 31

S6

60%

10.5

8.7

25.3

S1

S6

S1

S6

S1

cont

60%

cont

60%

10.5

9

5.7

19.2

6.7

22.5

Elettroventola / Elektrolüfter / Cooling fan

8

4.2

17.5

9.4

5

20

cont

7.2

3.4

15.8

S6

60%

8.6

4.1

19

S1

cont

6.3

2.7

14

S6

60%

7.5

3.3

17

S1

cont

5.4

2.2

12.9

S6

60%

6.3

2.5

14.7

5801H0056 _______________________________________________________________ 36/181

Page 37

HSD

SP110.130.4H

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage /

leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial

speed

speed / Einsatzdrehzahl feldschwachung

Velocità massima del motore / motor maximum speed /

Maximaldrehzahl

Fattore di potenza / power factor / nennleistungsfactor

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Rpm

Kg m2

Y or D

Value

7.5

16

380

11910

400

360

8.5

0.12

0.14

1.2

1.9

25

12000

20000

0.85

1.8E-03

Y

5801H0056 _______________________________________________________________ 37/181

Page 38

HSD

H1423H0204 Rev.01 (SP.110.130.48)

Rated voltage (*) V

Rated frequency Hz

Rated speed rpm

Duty type

Rated power kW

Rated torque Nm

Rated current A

Rated output η

Power factor cosϕ

380 380 380 380 380 380 380 380

400 500 600 667 733 800 867 933

12,000 15,000 18,000 20,000 22000 24,000 26000 28,000

S1

S6

cont

60%

12 14 9.5 12 8.2 10 7.3 8.8 6.4 7.5 5.5 6.2 4.6 4.9 3.5 3.6

9.5 11.1 6 7.6 4.6 5.3 3.5 4.2 2.8 3.3 2.2 2.5 1.7 1.8 1.2 1.2

27.5 32 22 26.4 16.5 20 17 20.5 16.5 19 14 15.7 11.8 12.5 8.9 9.2

Number of poles

Type of insulation

Type of cooling

Weight of

SHORT NOSE version

Weight of

LONG NOSE version

[(*) supplied by

inverter]

kg

kg

S1

cont

S6

60%

S1

S6

S1

S6

S1

S6

cont

60%

cont

60%

cont

0.86

0.8

4

F

Raffreddamento a liquido / Flüssigkeit / Liquid cooling

30

34

60%

S1

cont

S6

60%

S1

cont

S6

60%

S1

cont

S6

60%

5801H0056 _______________________________________________________________ 38/181

Page 39

HSD

SP110.130.48 (liquid-cooled)

Description

Potenza nominale / rated power / nennleistung (S1)

Corrente nominale / rated current / nennstrom (S1)

Tensione nominale concatenata / line rated voltage / nennspannung

Velocità nominale al carico nominale/ rated speed at rated load /

nenndrehzahl bei nennlast

Frequenza nominale / rated frequency / nennfrequenz

Tensione a vuoto concatenata / no-load line voltage / leerlaufspannung

bei nennflussu

Corrente a vuoto / no-load current / leerlaufstrom

Resistenza dello statore / stator resistance / standerwiderstand kalt

(20°C)

Resistenza del rotore /rotor resistance / lauferwiderstand kalt (20°C)

Reattanza di dispersione dello statore / stator leakage reactance /

standerstreureaktanz

Reattanza di dispersione del rotore /rotor leakage reactance /

lauferstreureaktanz

Reattanza del campo principale / main field reactance /

hauptfeldreaktanz

Velocità di inizio indebolimento del campo / field weakening initial speed

speed / Einsatzdrehzahl feldschwachung

Momento di inerzia del rotore / moment of inertia

Collegamento / circuit connection / schaltungsart

Unit of

measur

ement

kW

A

V

Rpm

Hz

V

A

Ω

Ω

Ω

Ω

Ω

Rpm

Kg m2

Y or D

Value

12

27.5

380

11760

400

360

12

0.12

0.14

1.2

1.9

25

12000

1.8E-03

Y

5801H0056 _______________________________________________________________ 39/181

Page 40

HSD

2.10 TECHNICAL CARDS ES929

H1423H0248 Rev.04 (SP.110.131.43)

Rated voltage (*)

Rated frequency

Rated speed

Duty type

Rated power

Rated torque

Rated current

Rated output η

Power factor cosϕ

Number of poles

Type of insulation

Type of cooling

Weight of

SHORT NOSE version

Weight of

LONG NOSE version