Page 1

BOILER

GUN

BG44 BOILER GUN

OPERATING MANUAL

P/N 100190

April 2017

Revision 1

Page 2

Page 3

TABLE OF CONTENTS

CHAPTER/SECTION PAGE

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 HOW TO USE THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 S

1.3 G

1.4 M

1.5 R

1.6 R

1.7 L

AFETY ALERTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ENERAL SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ACHINE-SPECIFIC SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ISK ASSESSMENT AND HAZARD MITIGATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ISK ASSESSMENT CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7.1 Label identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7.2 Label location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 FEATURES AND COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 C

ONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Pneumatic motor controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Electric motor controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 S

2.5 I

PECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TEMS REQUIRED BUT NOT SUPPLIED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

13 SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 RECEIPT AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 M

3.3 M

3.4 I

3.5 M

ACHINE SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Wedge locking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Collet locking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.3 Tool holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ACHINE MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

NSTALLING THE CUTTING TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.1 Pneumatic motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5.2 Electric motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

21 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 PRE-OPERATION CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 O

PERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.1 Pneumatic motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2 Electric motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

23 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 MAINTENANCE CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

P/N 100190, Rev. 1 Page i

Page 4

TABLE OF CONTENTS (CONTINUED)

CHAPTER/SECTION PAGE

5.2 APPROVED LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 M

5.4 T

27 STORAGE AND SHIPPING

6.1 STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 S

6.3 D

AINTENANCE TASKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Checking and filling the in-line oiler reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 Servicing the filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.3 Adjusting the oil flow rate of the in-line oiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.4 Tool holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.5 Greasing the drive and pinion gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.1 The machine isn’t turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.2 The machine isn’t feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.3 The machine is performing poorly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.1 Short-term storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.2 Long-term storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

HIPPING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ECOMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

29 APPENDIX A ASSEMBLY DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

51 APPENDIX B SDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Page ii BG44 Boiler Gun Operating Manual

Page 5

LIST OF FIGURES

FIGURE PAGE

1-1 BG44 Boiler Gun- crank feed, pneumatic label location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2 BG44 Boiler Gun- wrench feed, pneumatic label location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 BG44 Boiler Gun- wrench feed, electric label location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1 BG44 and shipping container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-2 Pneumatic motor throttle lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-3 Speed selector and Trigger controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-4 BG44 Boiler gun pneumatic dimensions (P/N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-5 BG44 Boiler Gun electric dimensions (P/N PB06EL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-1 BG44 Boiler Gun main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-2 Wedge extensions installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-3 Installed wedge set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-4 The .875 wedge set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-5 The 1.25” collet set installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-6 The .875” collet set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-7 Tool holder set screw and key slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-8 BG44 installed in workpiece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-9 Locking rod wrench with speed wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-10 Fixed (L) and sliding (R) tool holders with cutting bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3-11 Cutting bit installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3-12 Universal coupler (top) and quick disconnect (bottom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-13 Speed control set to low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4-1 Hand positioning on the pneumatic BG44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-2 BG44 with electric motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5-1 In-line oiler sight glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6-1 BG44 shipping container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

A-1 BG44 Boiler Gun - high velocity, crank feed assembly (P/N BG44HVCR) . . . . . . . . . . . . . . . . . . . . . . 30

A-2 BG44 Boiler Gun - high velocity, crank feed parts list (P/N BG44HVCR) . . . . . . . . . . . . . . . . . . . . . . . 31

A-3 BG44 Boiler Gun - high velocity, wrench feed assembly (P/N BG44HVWR) . . . . . . . . . . . . . . . . . . . . 32

A-4 BG44 Boiler Gun - high velocity, wrench feed parts list (P/N BG44HVWR) . . . . . . . . . . . . . . . . . . . . . 33

A-5 BG44 Boiler Gun - low velocity, crank feed assembly (P/N BG44LVCR) . . . . . . . . . . . . . . . . . . . . . . . 34

A-6 BG44 Boiler Gun - low velocity, crank feed parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A-7 BG44 Boiler Gun - low velocity, wrench feed assembly (P/N BG44LVWR) . . . . . . . . . . . . . . . . . . . . . 36

A-8 BG44 Boiler Gun - low velocity, wrench feed parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A-9 BG44 Boiler Gun - electric, crank feed assembly (P/N BG44CR-E) . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

A-10 BG44 Boiler Gun - electric, crank feed parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A-11 BG44 Boiler Gun - wrench feed, electric assembly (P/N BG44WR-E) . . . . . . . . . . . . . . . . . . . . . . . . 40

A-12 BG44 Boiler Gun - wrench feed, electric parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A-13 Collet Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A-14 Wedge sets and wedge extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A-15 Center shafts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A-16 Locking rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A-17 Tool holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A-18 HV air motor assembly and parts list (P/N 100105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

A-19 LV air motor assembly and parts list (P/N CML3488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

P/N 100190, Rev. 1 Page iii

Page 6

LIST OF FIGURES (CONTINUED)

FIGURE PAGE

A-20 Air hose assembly and parts list (P/N HS 50-509) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

A-21 Electric motor assembly and parts list (P/N EMB003610) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Page iv BG44 Boiler Gun Operating Manual

Page 7

LIST OF TABLES

TABLE PAGE

1-1 Sound levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 Risk assessment checklist before set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Risk assessment checklist after set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 BG44 Boiler Gun labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1 Sub-component mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-1 Maintenance intervals and tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5-2 Approved lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

P/N 100190, Rev. 1 Page v

Page 8

This page intentionally left blank

Page vi BG44 Boiler Gun Operating Manual

Page 9

©2017 Climax Portable Machining and Welding Systems or its subsidiaries.

All rights reserved.

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted, disseminated,

downloaded, or stored in any storage medium, without the express prior written consent of Climax. Climax hereby

grants permission to download a single copy of this manual and of any revision hereto onto an electronic storage

medium to be viewed and to print one copy of this manual or any revision hereto, provided that such electronic or

printed copy of this manual or revision must contain the complete text of this copyright notice and provided further

that any unauthorized commercial distribution of this manual or any revision hereto is prohibited.

At Climax Portable Machining and Welding Systems, we value your opinion.

For comments or questions about this manual or other Climax documentation, please e-mail

documentation@cpmt.com.

For comments or questions about Climax products or services, please call Climax or e-mail

quick and accurate service, please provide your factory representative with the following:

•Your name

• Shipping address

• Telephone number

• Machine model

• Serial number (if applicable)

•Date of purchase

info@cpmt.com. For

Climax World Headquarters

Climax Portable Machining and Welding Systems

2712 South Second Street Newberg, Oregon 97132 USA

Telephone (worldwide): (503) 538-2815

Toll-free (North America):1-800-333-8311

Fax: 503.538.7600

E-mail:

info@cpmt.com

Climax UK Headquarters

Climax Portable Machine Tools Ltd

Unit 10 Heather Close

Lyme Green Business Park

Macclesfield, Cheshire SK11 0LR, UK

Telephone: +44 (0) 161 406 1720

E-mail:

info@cpmt.com

Climax European Headquarters

Climax GmbH

Am Langen Graben 8

52353 Düren, Germany

Telephone: +49 (0) 2421-9177-12

E-mail:

info@cpmt.de

P/N 100190, Rev. 1 Page A

Page 10

CLIMAX GLOBAL LOCATIONS

Page B

Page 11

CE DOCUMENTATION

CE Certification is pending

P/N 100190, Rev. 1 Page C

Page 12

LIMITED WARRANTY

Climax Portable Machine Tools, Inc. (hereafter referred to as “Climax”) warrants that all new machines are free

from defects in materials and workmanship. This warranty is available to the original purchaser for a period of one

year after delivery. If the original purchaser finds any defect in materials or workmanship within the warranty

period, the original purchaser should contact its factory representative and return the entire machine, shipping prepaid, to the factory. Climax will, at its option, either repair or replace the defective machine at no charge and will

return the machine with shipping prepaid.

Climax warrants that all parts are free from defects in materials and workmanship, and that all labor has been performed properly. This warranty is available to the customer purchasing parts or labor for a period of 90 days after

delivery of the part or repaired machine or 180 days on used machines and components. If the customer purchasing

parts or labor finds any defect in materials or workmanship within the warranty period, the purchaser should contact its factory representative and return the part or repaired machine, shipping prepaid, to the factory. Climax

will, at its option, either repair or replace the defective part and/ or correct any defect in the labor performed,

both at no charge, and return the part or repaired machine shipping prepaid.

These warranties do not apply to the following:

• Damage after the date of shipment not caused by defects in materials or workmanship

• Damage caused by improper or inadequate machine maintenance

• Damage caused by unauthorized machine modification or repair

• Damage caused by machine abuse

• Damage caused by using the machine beyond its rated capacity

All other warranties, express or implied, including without limitation the warranties of merchantability and fitness

for a particular purpose are disclaimed and excluded.

Terms of sale

Be sure to review the terms of sale which appear on the reverse side of your invoice. These terms control and limit

your rights with respect to the goods purchased from Climax.

About this manual

Climax provides the contents of this manual in good faith as a guideline to the operator. Climax cannot guarantee

that the information contained in this manual is correct for applications other than the application described in this

manual. Product specifications are subject to change without notice.

Page D

Page 13

1 INTRODUCTION

DANGER

WARNING

CAUTION

NOTICE

IN THIS CHAPTER:

1.1 HOW TO USE THIS MANUAL - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

1.2 S

AFETY ALERTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

ENERAL SAFETY PRECAUTIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

1.3 G

ACHINE-SPECIFIC SAFETY PRECAUTIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

1.4 M

1.5 R

ISK ASSESSMENT AND HAZARD MITIGATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

ISK ASSESSMENT CHECKLIST - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1.6 R

ABELS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

1.7 L

1.7.1 L

ABEL IDENTIFICATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

ABEL LOCATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

1.7.2 L

1.1 HOW TO USE THIS MANUAL

This manual describes information necessary for the

setup, operation, maintenance, storage, shipping, and

decommissioning of the BG44 Boiler Gun.

The first page of each chapter includes a summary of

the chapter contents to help you locate specific information. The appendices contain supplemental product

information to aid in setup, operation, and maintenance

tasks.

1.2 SAFETY ALERTS

Pay careful attention to the safety alerts printed

throughout this manual. Safety alerts will call your

attention to specific hazardous situations that may be

encountered when operating this machine.

Examples of safety alerts used in this manual are

defined here

1

:

indicates a hazardous situation which, if not

avoided, WILL result in death or severe

injury.

Read this entire manual to familiarize yourself with the

BG44 Boiler Gun before attempting to set it up or operate it.

indicates a hazardous situation which, if not

avoided, COULD result in death or severe

injury.

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

1. For more information on safety alerts, refer to ANSI/NEMA

Z535.6-2011, Product safety Information in Product

Manuals, Instructions, and Other Collateral Materials

P/N 100190, Rev. 1 Page 1

indicates a hazardous situation which, if not

avoided, could result in property damage,

equipment failure, or undesired work

results

.

Page 14

1.3 GENERAL SAFETY PRECAUTIONS

H&S leads the way in promoting the safe use of portable

machine tools. Safety is a joint effort. You, the end

user, must do your part by being aware of your work

environment and closely following the operating procedures and safety precautions contained in this manual,

as well as your employer’s safety guidelines.

Observe the following safety precautions when operating or working around the machine.

Training – Before operating this or any machine

tool, you should receive instruction from a qualified trainer. Contact H&S for machine-specific

training information.

Risk assessment – Working with and around this

machine poses risks to your safety. You, the end

user, are responsible for conducting a risk

assessment of each job site before setting up

and operating this machine.

Intended use – Use this machine in accordance with

the instructions and precautions in this manual.

Do not use this machine for any purpose other

than its intended use as described in this manual.

Personal protective equipment – Always wear

appropriate personal protective gear when

operating this or any other machine tool.

Flame-resistant clothing with long sleeves and

legs is recommended when operating the

machine. Hot chips from the workpiece may

burn or cut bare skin.

Work area – Keep the work area around the

machine clear of clutter. Restrain cords and

hoses connected to the machine. Keep other

cords and hoses away from the work area.

Lifting – Many H&S machine components are very

heavy. Whenever possible, lift the machine or

its components using proper hoisting equipment

and rigging. Always use designated lifting points

on the machine. Follow lifting instructions in

the setup procedures of this manual.

Lock-out/tag-out – Lock-out and tag-out the

machine before performing maintenance.

Moving parts – H&S machines have numerous

exposed moving parts and interfaces that can

cause severe impact, pinching, cutting, and

other injuries. Except for stationary operating

controls, avoid contact with moving parts by

hands or tools during machine operation.

Remove gloves and secure hair, clothing, jewelry, and pocket items to prevent them from

becoming entangled in moving parts.

Sharp edges – Cutting tools and workpieces have

sharp edges that can easily cut skin. Wear protective gloves and exercise caution when handling a cutting tool or workpiece.

Hot surfaces – During operation, motors, pumps,

HPUs, and cutting tools can generate enough

heat to cause severe burns. Pay attention to hot

surface labels, and avoid contact with bare skin

until the machine has cooled.

Page 2 BG44 Boiler Gun Operating Manual

Page 15

1.4 MACHINE-SPECIFIC SAFETY PRECAUTIONS

Eye hazard – This machine produces metal chips

during operation. Always wear eye protection

when operating the machine.

Hazardous environments – Do not operate the

machine in environments where potentially

explosive materials, toxic chemicals, or radiation may be present.

Sound level – This machine produces potentially

harmful sound levels. Hearing protection is required

when operating this machine or working around it.

During testing, the machine produced the sound

1

levels

listed in Table 1-1.

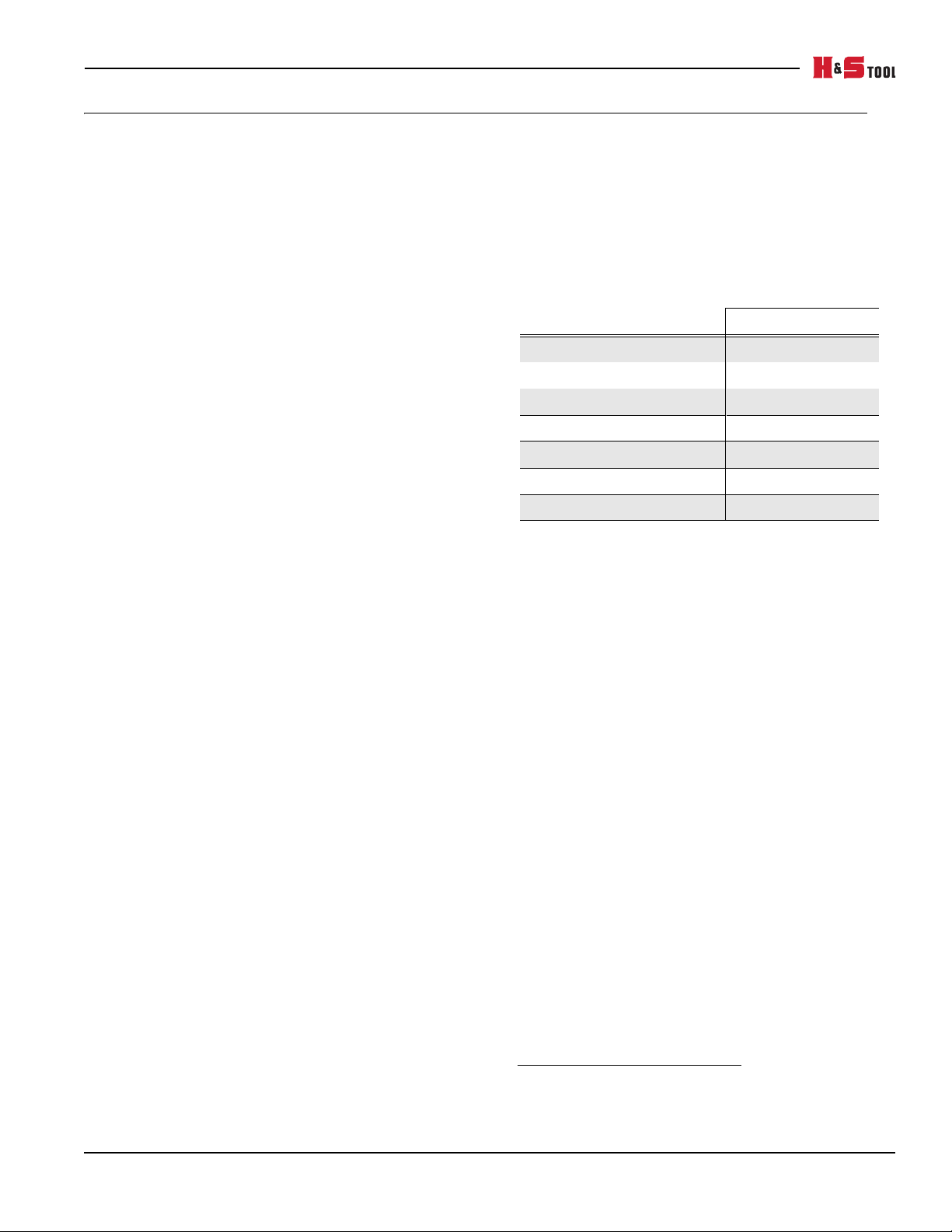

TABLE 1-1. SOUND LEVELS

S

Pneumatic Motor

Average sound pressure 90.6 dBA

Operator sound pressure 91.5 dBA

Bystander sound pressure 89.4 dBA

Electric Motor

Average sound pressure 85 dBA

Operator sound pressure 85 dBA

Bystander sound pressure 85 dBA

1. Machine sound testing was conducted in accordance with European Harmonized Standards EN ISO 3744:2010 and EN 11201:2010.

P/N 100190, Rev. 1 Page 3

Page 16

1.5 RISK ASSESSMENT AND HAZARD MITIGATION

Machine Tools are specifically designed to perform precise material-removal operations.

Stationary Machine Tools include lathes and milling

machines and are typically found in a machine shop.

They are mounted in a fixed location during operation

and are considered to be a complete, self-contained

machine. Stationary Machine Tools achieve the rigidity

needed to accomplish material-removal operations from

the structure that is an integral part of the machine

tool.

In contrast, Portable Machine Tools are designed for onsite machining applications. They typically attach

directly to the workpiece itself, or to an adjacent structure, and achieve their rigidity from the structure to

which it is attached. The design intent is that the Portable Machine Tool and the structure to which it is

attached become one complete machine during the

material-removal process.

To achieve the intended results and to promote safety,

the operator must understand and follow the design

intent, set-up, and operation practices that are unique

to Portable Machine Tools valve testers.

The operator must perform an overall review and onsite risk assessment of the intended application. Due to

the unique nature of portable machining applications

hydrostatic testing, identifying one or more hazards

that must be addressed is typical.

When performing the on-site risk assessment, it is

important to consider the Portable Machine Tool valve

tester and the workpiece as a whole.

Page 4 BG44 Boiler Gun Operating Manual

Page 17

1.6 RISK ASSESSMENT CHECKLIST

The following checklist is not intended to be an all

inclusive list of things to watch out for when setting up

and operating this Portable Machine Tool.

TABLE 1-2. RISK ASSESSMENT CHECKLIST BEFORE SET-UP

Before set-up

I took note of all the warning labels on the machine.

I removed or mitigated all identified risks (such as tripping, cutting, crushing, entanglement, shearing, or falling objects).

I considered the need for personnel safety guarding and installed any necessary guards.

I read the machine setup instructions (Section 3.2) and took inventory of all the items required but not supplied (Section 2.5).

I considered how this machine operates and identified the best placement for the controls, cabling, and the operator.

I evaluated and mitigated any other potential risks specific to my work area.

ABLE 1-3. RISK ASSESSMENT CHECKLIST AFTER SET-UP

T

After set-up

I checked that the machine is safely installed (according to Section 3) and the potential fall path is clear. If the machine is installed at

an elevated position, I checked that the machine is safeguarded against falling.

I identified all possible pinch points, such as those caused by rotating parts, and informed the affected personnel.

However, these checklists are typical of the types of

risks the assembler and operator should consider. Use

these checklists as part of your risk assessment:

I planned for containment of any chips or swarf produced by the machine.

I followed the required Maintenance Intervals (Section 5.1) with the recommended lubricants (Section 5.2).

I checked that all affected personnel have the recommended personal protective equipment, as well as any site-required or regulatory

equipment.

I checked that all affected personnel understand and are clear of the danger zone.

I evaluated and mitigated any other potential risks specific to my work area.

P/N 100190, Rev. 1 Page 5

Page 18

1.7 LABELS

1.7.1 Label identification

The following warning labels should be on your

machine. If any are defaced or missing, contact H&S

Tool immediately for replacements.

TABLE 1-4. BG44 BOILER GUN LABELS

P/N 100196

HV Boiler gun label

P/N 100197

LV Boiler gun label

P/N 100199

H&S company label

P/N 100198

H&S serial plate

crank feed only

P/N 87259

H&S serial plate

wrench feed only

P/N 87271

Warning label: use

eye and ear protection, and read the

operating manual

P/N 802112

Multi-Prep label

P/N 100200

H&S serial plate

crank feed only

P/N 100248

Wedge and pad

chart label

Page 6 BG44 Boiler Gun Operating Manual

Page 19

1.7.2 Label location

FIGURE 1-1. BG44 BOILER GUN- CRANK FEED, PNEUMATIC LABEL LOCATION

FIGURE 1-2. BG44 BOILER GUN- WRENCH FEED, PNEUMATIC LABEL LOCATION

The following figures display the location of the labels on each of the components of the BG44 Boiler Gun.

Label P/N: 100196 or 100197, 100198, 100199, 802112, 100200, 87271

Label P/N: 87271

P/N 100190, Rev. 1 Page 7

Page 20

Label P/N: 87259

FIGURE 1-3. BG44 BOILER GUN- WRENCH FEED, ELECTRIC LABEL LOCATION

Page 8 BG44 Boiler Gun Operating Manual

Page 21

2 OVERVIEW

FIGURE 2-1. BG44 AND SHIPPING CONTAINER

IN THIS CHAPTER:

2.1 FEATURES AND COMPONENTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

2.2 C

ONTROLS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

NEUMATIC MOTOR CONTROLS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

2.2.1 P

LECTRIC MOTOR CONTROLS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

2.2.2 E

2.3 D

IMENSIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11

PECIFICATIONS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -12

2.4 S

TEMS REQUIRED BUT NOT SUPPLIED - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -12

2.5 I

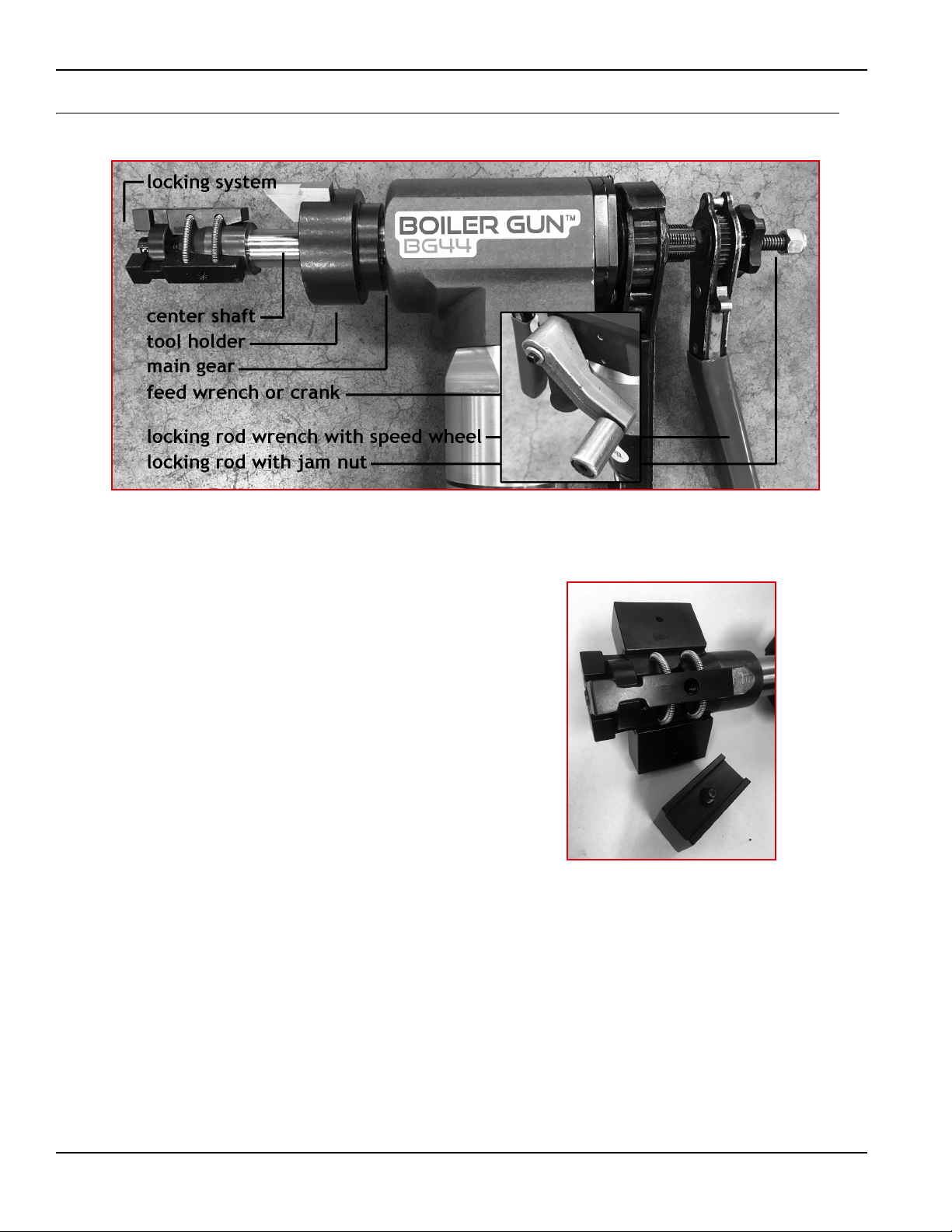

2.1 FEATURES AND COMPONENTS

The BG44 is a portable, gear-driven, inside-diameter

(ID)-mounted, single or dual-point beveling and facing

machine for use on workpieces with a range of .875”

(22.2mm) I.D. to 5.00” (127mm) O.D.

Principle components include the following:

Drive options: Available with either a 1.625 HP

pneumatic motor or a 1.5 HP electric motor.

High Velocity (HV) or Low Velocity (LV) gearing—

HV delivers higher speeds to turn specialty carbide insert cutters while LV is geared for heavy

wall and hard alloys.

Mounting systems—Either a wedge or collet mounting system secures the BG44 to the workpiece. They

are both self-centering and adapt to a wide range of

pipe sizes.

Tool holders—Available with either fixed or sliding

tools holders, in multiple sizes.

Torque free operation—Once securely mounted the

BG44 requires no additional effort to operate

aside from feeding the cutting tool.

Wrench feed—Advances the cutting tools in con-

fined areas with a ratcheting system. This system has a smaller footprint.

Crank feed—Advances the cutting tools with a fast

and convenient side-mounted crank.

Speed wheel—Provides a quicker way advance the

locking rod nut before fully tightening with the

wrench.

P/N 100190, Rev. 1 Page 9

Page 22

2.2 CONTROLS

WARNING

WARNING

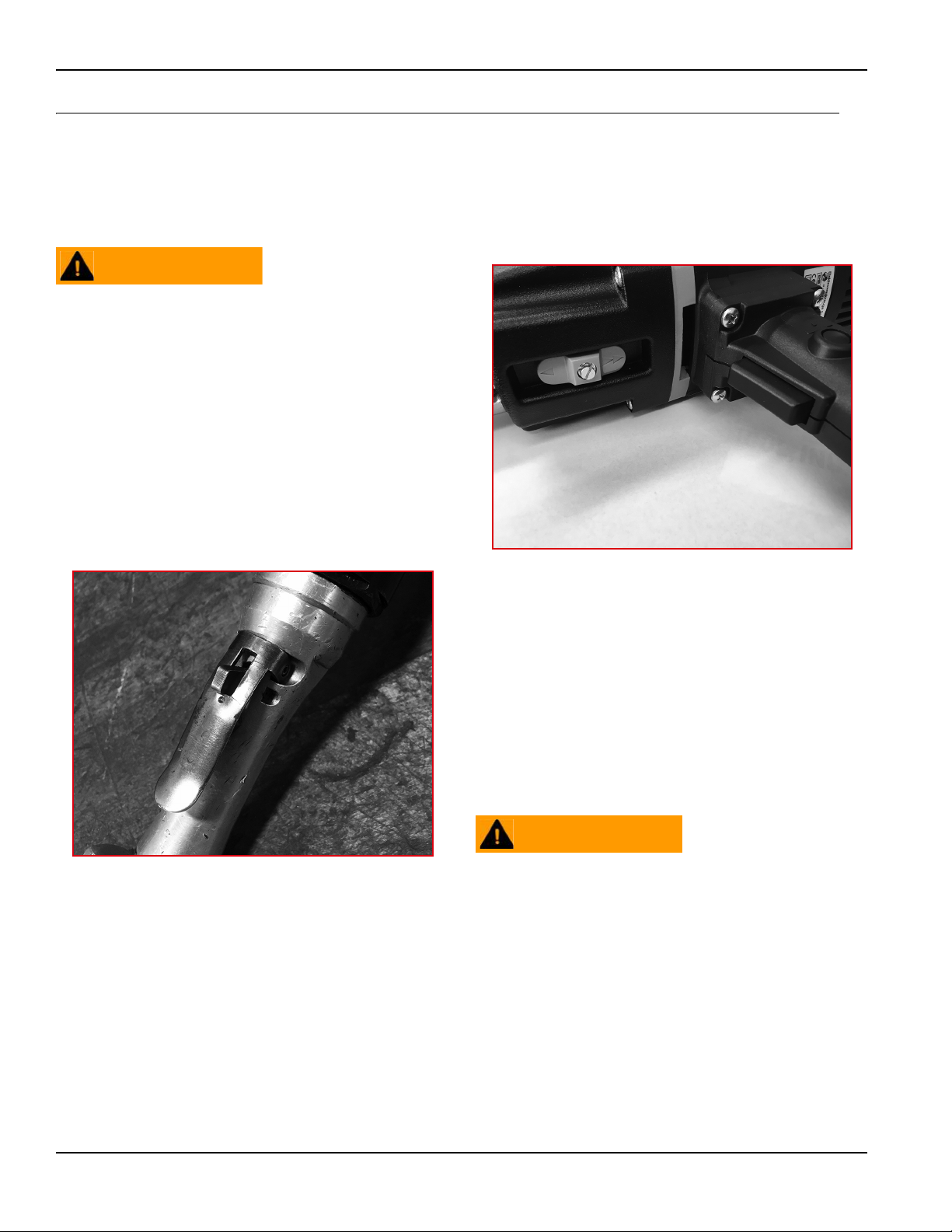

FIGURE 2-2. PNEUMATIC MOTOR THROTTLE LEVER

FIGURE 2-3. SPEED SELECTOR AND TRIGGER CONTROLS

Depending on the users requirements, the BG44 Boiler

Gun can be powered by either a pneumatic or electric

motor. The controls for each type of motor follow.

Always stop the machine and disconnect

any power supply before making

adjustments to controls or machine

components. Failure to follow this safety

precaution may result in severe injury.

2.2.1 Pneumatic motor controls

The pneumatic motor used on the BG44 features a

throttle lever. The safety lock must be disengaged by

pressing and holding up while depressing the throttle

lever. The throttle lever actuates the motor; when

released, the motor will stop and the safety lock will reengage.

This is an on or off control only.

2.2.2 Electric motor controls

The electric motor controls are similar to a drill or drill

driver. The trigger is squeezed to actuate the motor,

when released the motor will stop.

This is an on and off control only.

A two speed gearing selector is located at the front of

the motor. The BG44 is designed to be used with the

electric motor in the low setting ONLY.The low setting is

indicated with a single arrow while the high setting is

indicated with two arrows.

To adjust, if the motor is not in the low setting, push in

and slide the selector. The spindle may need turned by

hand to fully engage, when fully engaged the selector

will spring back up. If not fully engaged the drive motor

will not function properly.

Do not take any measures to lock the

throttle or the trigger in the on position.

Failure to follow this safety precaution may

result in severe injury.

Page 10 BG44 Boiler Gun Operating Manual

Page 23

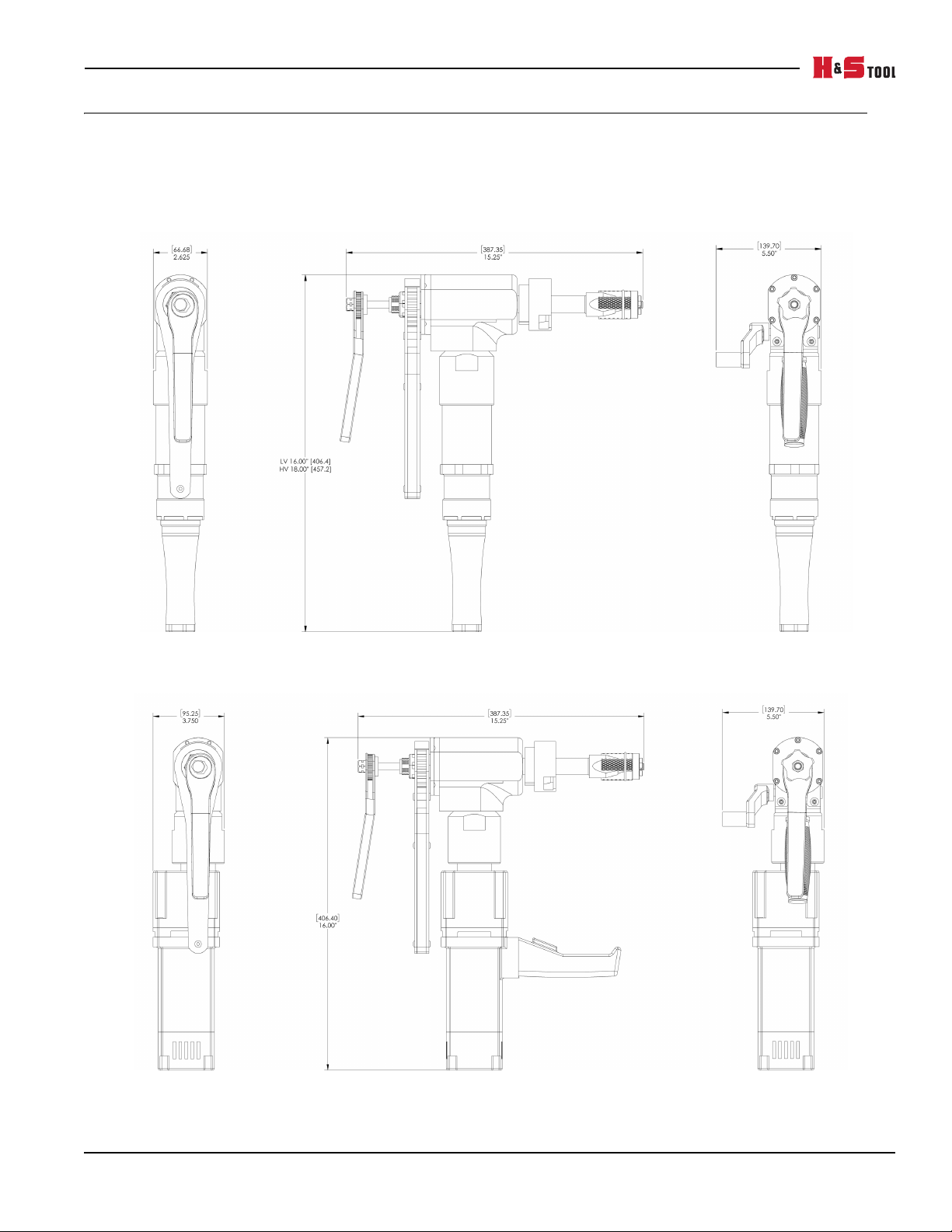

2.3 DIMENSIONS

Figures 2-4 and 2-5 show the machine and operating

dimensions.

FIGURE 2-4. BG44 BOILER GUN PNEUMATIC DIMENSIONS

FIGURE 2-5. BG44 BOILER GUN ELECTRIC DIMENSIONS

P/N 100190, Rev. 1 Page 11

Page 24

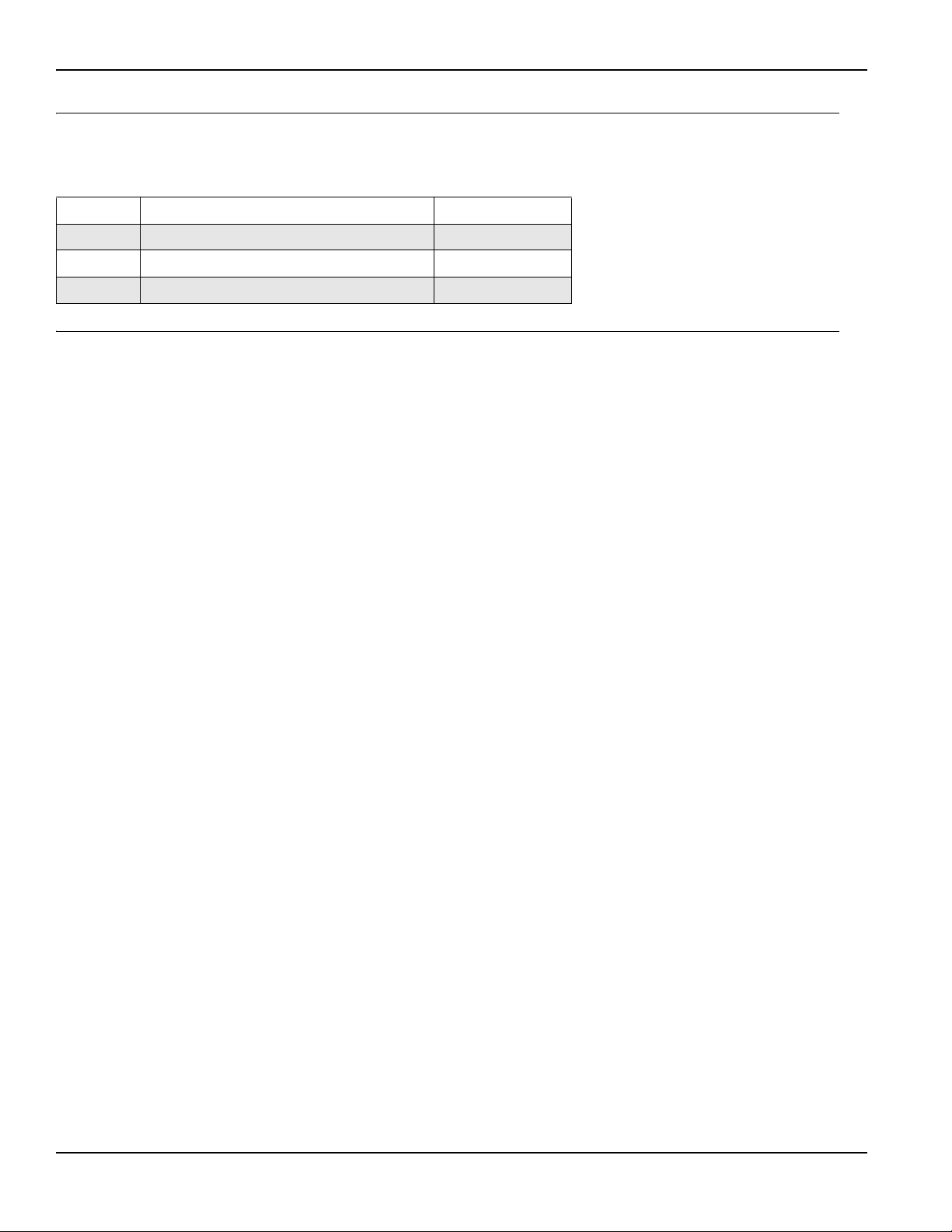

2.4 SPECIFICATIONS

TABLE 2-1. SUB-COMPONENT MASS

P/N Component Mass in lbs (kg)

BG44 BG44 Boiler Gun Pneumatic 21 (9.5)

BG44 BG44 Boiler Gun Electric 25 (11.3)

2.5 ITEMS REQUIRED BUT NOT SUPPLIED

The following items may be required but not supplied in

your H&S product kit:

• Tape measure or steel ruler

• Rubber mallet

•Pliers

Page 12 BG44 Boiler Gun Operating Manual

Page 25

3SETUP

NOTICE

IN THIS CHAPTER:

3.1 RECEIPT AND INSPECTION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

ACHINE SETUP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -14

3.2 M

3.2.1 W

WEDGE SETS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -14

WEDGE MOUNTING SYSTEMS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

3.2.2 C

3.2.3 T

3.3 M

3.4 I

NSTALLING THE CUTTING TOOLS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -19

3.5 M

3.5.1 P

3.5.2 E

This section describes the setup procedures for the

BG44 Boiler Gun.

EDGE LOCKING SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -14

3.2.1.1 I

3.2.1.2 I

3.2.2.1 I

ACHINE MOUNTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -18

OTORS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -20

NTERCHANGING THE M-01 AND M-02 BASE

NTERCHANGING THE .875” AND 1.200”

OLLET LOCKING SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

NTERCHANGING THE COLLET SETS - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

OOL HOLDERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -17

NEUMATIC MOTOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -20

LECTRIC MOTOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -20

3.1 RECEIPT AND INSPECTION

Your H&S product was inspected and tested prior to

shipment then packaged for normal shipment conditions. H&S does not guarantee the condition of your

machine upon delivery.

When you receive your H&S product, perform the following receipt checks:

1. Inspect the shipping containers for damage.

2. Check the contents of the shipping containers

against the included invoice to make sure that

all components have been shipped.

3. Inspect all components for damage.

Contact H&S immediately to report damaged or missing

components.

Keep the shipping container and all packing

materials for future storage and shipping of

the machine.

P/N 100190, Rev. 1 Page 13

Page 26

3.2 MACHINE SETUP

FIGURE 3-1. BG44 BOILER GUN MAIN COMPONENTS

FIGURE 3-2. WEDGE EXTENSIONS INSTALLATION

Do the following to setup the BG44 Boiler Gun:

4. If installing wedge extensions, secure three of

the same size range onto the base wedges with

the screws.

3.2.1 Wedge locking system

1. Complete the risk assessment checklist in Table

1-2 on page 5.

2. Position the machine on a solid support for

installation of the wedge set.

3. Measure the I.D. of the pipe to be machined and

determine the size of the wedge extension set

to be used, if required. The wedge bases can

also be used without extensions.

3.2.1.1 Interchanging the M-01 and M-02 base

wedge sets

The M-01 and M-02 wedge sets can use the same center

shaft. Do the following to change between the wedge

set sizes:

1. Return the machine to a solid support for

removal and installation of the wedge sets.

2. To remove: Pull out on the wedge set enough to

slide them up and over the wedge guide.

3. To install: Expand the wedge bases enough to

slide the wedge set over the wedge guide and

onto the center shaft.

Page 14 BG44 Boiler Gun Operating Manual

Page 27

4. Align the wedges sets with the slots in the cen-

FIGURE 3-3. INSTALLED WEDGE SET

FIGURE 3-4. THE .875 WEDGE SET

ter shaft and seat the other ends on the wedge

guide.

3.2.1.2 Interchanging the .875” and 1.200”

wedge mounting systems

The .875” wedge mounting system uses a dedicated

center shaft.

Do the following to change between a 1.200” wedge set

and the .875” wedge set:

1. Return the machine to a solid support for

removal and installation of the wedge sets.

2. Remove the jam nut from the end of the locking

rod.

3. Remove the locking rod wrench from the locking

rod. The direction of the ratchet mechanism

may need to be switched to feed off instead of

on.

4. Slide the wedge set with locking rod out of the

center shaft from the wedge end of the

machine.

5. On the crank feed machine, turn the crank

opposite of the feed direction until the threads

of the center shaft are free of the feed nut.

On the wrench feed machine, turn the wrench

opposite of the feed direction until the threads

of the center shaft are free of the feed nut.

6. Slide the center shaft out from the front of the

machine.

7. Insert the center shaft of the .875” wedge set,

threaded end first, through the tool holder and

into center shaft lock, aligning the slots in the

threaded shaft with splines in the center shaft

lock. Continue to insert the center shaft until it

stops against the feed nut.

8. On the crank feed machine, turn the crank to

advance the center shaft.

On the wrench feed machine, turn the wrench

to advance the center shaft. The direction of

the ratchet mechanism may need switched to

feed in instead of off.

9. Advance the center shaft until approximately

.50” (12.7mm) of threads protrude past the rear

of the machine or the feed wrench.

10. Reinstall the locking rod wrench until .50”

(12.7mm) of the locking rod protrudes.

P/N 100190, Rev. 1 Page 15

Page 28

11. Reinstall the jam nut on the end of the locking

FIGURE 3-5. THE 1.25” COLLET SET INSTALLED

FIGURE 3-6. THE .875” COLLET SET

rod.

3.2.2 Collet locking system

1. Complete the risk assessment checklist in Table

1-2 on page 5.

2. Position the machine on a solid support for

installation of the collet set.

3. Measure the I.D. of the pipe to be machined and

determine the size of the collet set to be used.

4. Based on size, locate the center shaft that

matches the collet set required.

5. To install the center shaft:

a) Insert the center shaft through the tool

holder and into the center shaft lock,

aligning the slots in the threaded shaft

with the splines on the center shaft lock.

Continue to insert the center shaft until it

stops against the feed nut.

b) On the crank feed machine, turn the

crank to advance the center shaft.

On the wrench feed machine, turn the

wrench to advance the center shaft. The

direction of the ratchet mechanism may

need switched to feed in instead of off.

6. Slide a locking rod into the center shaft from

the rear of the machine.

7. Thread the required collet set on the end of the

locking rod until the collets begin to engage the

center shaft. If flat are present on the center

shaft, align the collets with the flats.

8. Insert a cotter pin through the hole in the locking rod and open the splines to secure.

9. If not installed, slide the locking rod wrench

onto the locking rod nut and secure with a

retaining clip.

10. To remove the center shaft, reverse steps 5-8.

3.2.2.1 Interchanging the collet sets

The .875” collet system has a range of .875 to 1.25”. It

uses three collet sets, in .125” increments and the

.875” center shaft.

The 1.25” collet system has a range of 1.25 to 4.75”.

The collet sets are in .125” increments and use the

1.25” center shaft.

Do the following to change between the collet sets:

1. Return the machine to a solid support.

2. Remove the cotter pin from the end of the locking rod.

3. Remove the collet set from the locking rod.

4. Install the collet set on the locking rod. If flats

are present on the center shaft, align the collet

segments with the flats.

5. Reinstall the cotter pin.

6. See Section 3.2.2, Steps 5-8 to interchange the

center shafts.

Page 16 BG44 Boiler Gun Operating Manual

Page 29

3.2.3 Tool holders

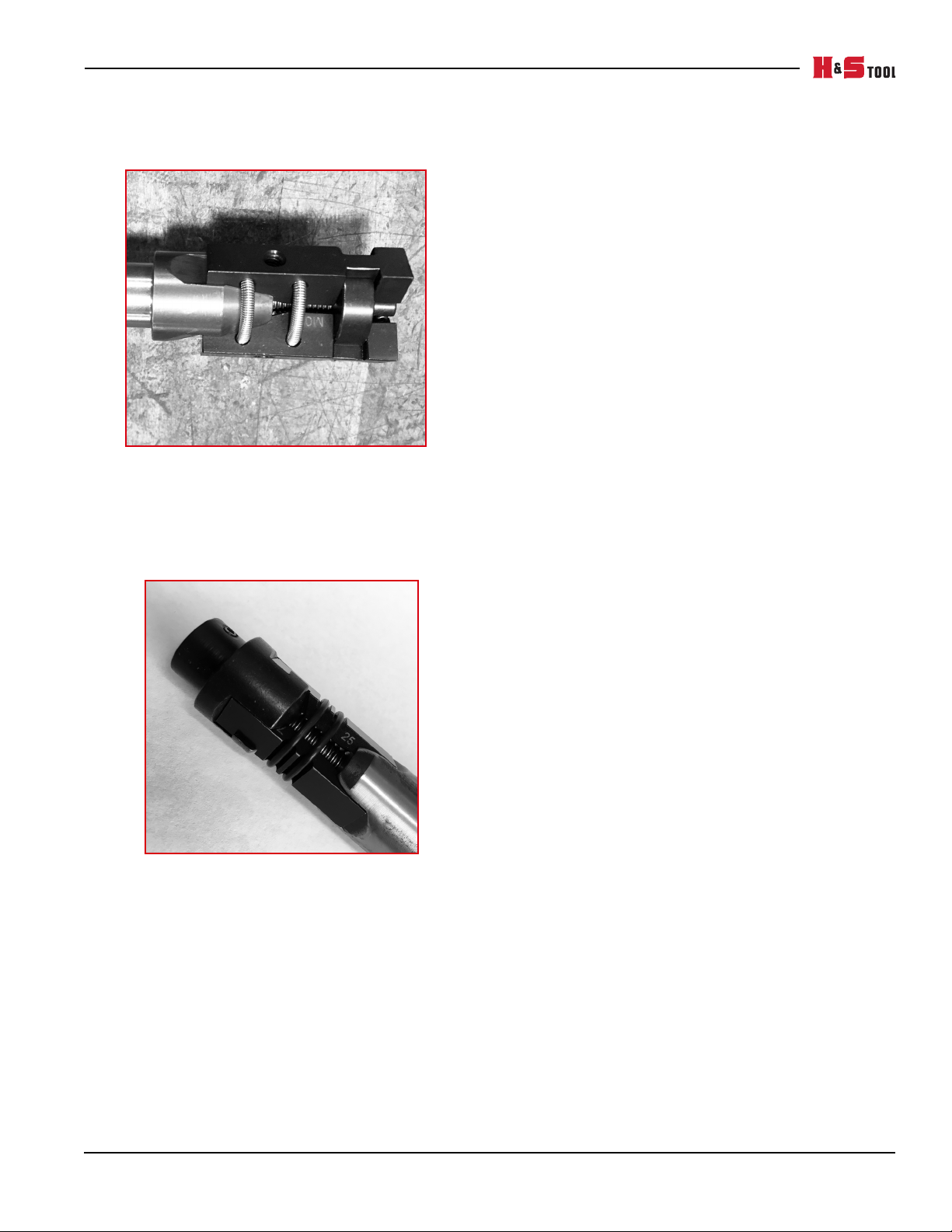

FIGURE 3-7. TOOL HOLDER SET SCREW AND KEY SLOT

The BG44 Boiler Gun can be used with two styles of tool

holders in several different sizes.

Do the following to switch between tool holders:

To remove:

1. Loosen the set screw in the body of the tool

holder.

2. The tool holder has an interference fit with the

main gear. Strike the back face of the tool

holder to remove it towards the front of the

machine.

3. The shaft key may come loose from the main

gear during removal. Retain it for reuse.

To install:

1. Check that the set screw in the body of the tool

holder is backed out or remove completely.

2. Install the shaft key in the key slot on the main

gear.

3. Slide the tool holder onto the main gear, aligning the key way with the shaft key.

4. Tap into place until seated against the shoulder

on the main gear.

5. Reinstall or tighten the set screw in the tool

holder body until secure.

P/N 100190, Rev. 1 Page 17

Page 30

3.3 MACHINE MOUNTING

WARNING

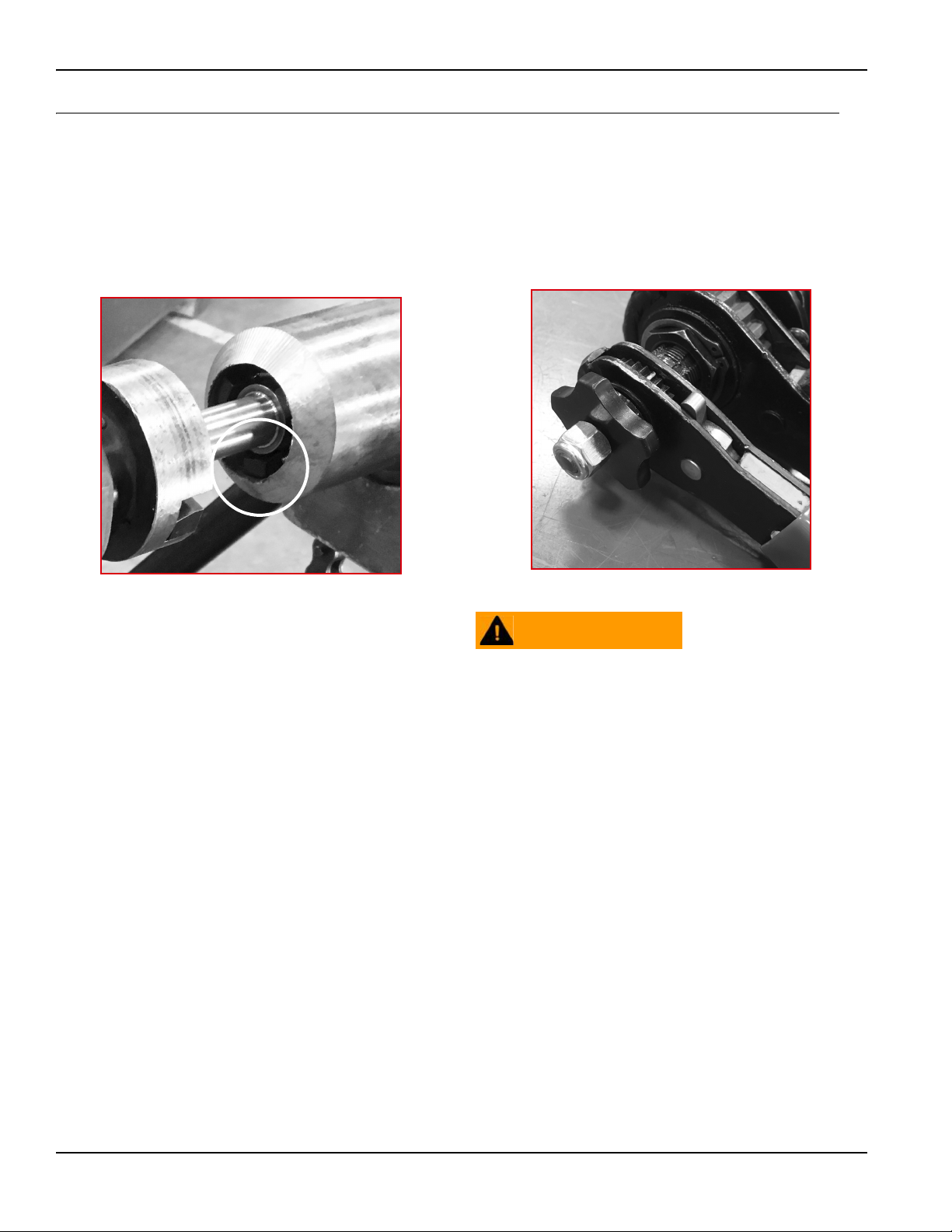

FIGURE 3-8. BG44 INSTALLED IN WORKPIECE

.50”

FIGURE 3-9. LOCKING ROD WRENCH WITH SPEED WHEEL

Do the following to mount the BG44 on the workpiece:

1. Insert the mounting system end of the BG44 into

the workpiece until there is approximately .50”

(12.7mm) between the end of the mounting system and the face of the workpiece. This will

provide enough material for most procedures.

2. Tighten the mounting system by turning the lock

rod clock-wise using either the rod wrench or

the speed wheel. Once snug, verify that the

mounting system position in the workpiece has

been maintained. Completely tighten the

mounting system using the locking rod wrench.

Check that the mounting system has been

fully tightened. After the machine has made

2-3 revolutions during operation, recheck

the mounting system for tightness in the

pipe. If loose, the machine itself could

rotate causing severe injury to the operator.

Page 18 BG44 Boiler Gun Operating Manual

Page 31

3.4 INSTALLING THE CUTTING TOOLS

TIP:

FIGURE 3-10. FIXED (L) AND SLIDING (R) TOOL HOLDERS

WITH CUTTING BITS.

FIGURE 3-11. CUTTING BIT INSTALLED

Do the following to install the cutting bit(s):

1. Advance the tool holder towards the workpiece

to help with alignment of the cutting bit(s).

2. On a fixed tool holder:

a) Loosen the set screw for the cutting tool

slot.

b) Fully insert the cutting bit into the slot

with the beveled cutting edge facing the

direction of rotation.

c) Tighten the set screw(s).

3. On a sliding tool holder:

a) Loosen the set screws in the blade locks.

b) Slide the cutting bit into the channel with

the beveled cutting edge facing the direction of rotation.

c) Align the cutting edge of the tool to cut

the full width of the workpiece wall.

4. Tighten the set screw(s) to secure the cutting

bit(s) to the tool holder.

5. If using two blades, install the second blade

opposite (180°) to the first. Orientate the beveled cutting edge facing the direction of rotation.

The BG44 Boiler Gun can be operated

with one blade. Smoother operation on

harder materials or thicker pipe walls

will result with the use of two blades.

P/N 100190, Rev. 1 Page 19

Page 32

3.5 MOTORS

FIGURE 3-12. UNIVERSAL COUPLER (TOP) AND QUICK

DISCONNECT (BOTTOM)

FIGURE 3-13. SPEED CONTROL SET TO LOW

The BG44 Boiler Gun is powered by either a pneumatic

motor or an electric motor. The following subsections

explain how to set up each for operation.

3.5.1 Pneumatic motor

Do the following to prepare the pneumatic motor for

use (See Section 2.2 for controls):

1. Connect the air supply line to the in-line oiler/

filter end of the air hose assembly with the universal coupler. Secure with the lock pin.

2. Connect the air hose assembly to the pneumatic

drive motor using the quick disconnect coupler.

3.5.2 Electric motor

Do the following to prepare the electric motor for use

(See Section 2.2 for controls):

1. Verify that the speed control is set to low. The

selector switch should be at the single arrow

position.

2. Plug the drive into an OSHA certified power

source or consult a licensed electrician for additional power supply options.

Page 20 BG44 Boiler Gun Operating Manual

Page 33

4 OPERATION

FIGURE 4-1. HAND POSITIONING ON THE PNEUMATIC BG44.

IN THIS CHAPTER:

4.1 PRE-OPERATION CHECKS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

PERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

4.2 O

4.2.1 P

NEUMATIC MOTOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

LECTRIC MOTOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -22

4.2.2 E

4.1 PRE-OPERATION CHECKS

Do the following checks before operating the machine:

1. Complete the risk assessment checklist in

Table 1-3 on page 5.

2. Check that the work area is clear of non-essential personnel and equipment.

3. Check that the machine control/observation

area will not be in the path of hot flying chips

during machine operation.

4. Check the machine is securely mounted to the

workpiece, according to Section 3.3 on page 14.

4.2 OPERATION

The BG44 Boiler Gun can machine both O.D. and I.D.

bevels and face or shorten pipes. Aside from the use of

different blades, operation is the same for all the

machining processes. See Section 2.2 for controls information.

4.2.1 Pneumatic motor

To operate the BG44 Boiler Gun with the pneumatic

motor do the following:

1. Actuate the motor by unlocking the safety lock

then squeeze and hold the throttle lever.

2. With the other hand turn the crank handle or

the feed wrench to advance the cutting tool

into the workpiece.

3. Continue to turn either the crank handle or feed

wrench until the required machining is complete. Base the feed rate on the motor’s feedback, if the RPMs drop or the machine stalls

slow the feed rate.

4. Once complete, allow the machine to make a

few revolutions without feeding the cutting tool

to clean up the machined surface.

5. Check that hoses and electric cords are routed

and secured to avoid tripping, entanglement,

damage from hot chips, or other damage should

an air hose or connection fail.

6. Check the cutting tool condition and sharpness.

7. On the in-line air lubricator, verify that oil is

present in the sight glass. (See Section 5.3.1)

8. Check that all hand tools are removed from

inside the machine and the work area.

5. Release the throttle lever to stop the machine.

6. Reverse the rotation of the crank handle or feed

wrench 2-3 revolutions to back the cutting tool

away from the workpiece.

7. To remove the BG44 from the workpiece do the

following:

P/N 100190, Rev. 1 Page 21

Page 34

a) Turn off the air supply at the source. Dis-

WARNING

WARNING

FIGURE 4-2. BG44 WITH ELECTRIC MOTOR

connect the air hose assembly from the

machine.

b) Turn the locking wrench to loosen the

locking system from the workpiece.

c) Slide the BG44 straight out from the

workpiece using the body of the machine

to support it’s weight.

Always pick up and move the BG44 Boiler

Gun by body of the machine. Never pick up

the BG44 Boiler Gun by the throttle lever

section of the air motor, actuation of the

motor could occur and lead to severe injury.

Never pick up the BG44 Boiler Gun by the

air hose assembly as it could become

detached and result in injury or damage to

the machine. Do not pick up and move the

machine by either of the wrenches as

damage to the machine could occur.

4.2.2 Electric motor

To operate the BG44 Boiler Gun with the electric motor

do the following:

1. Start the motor by squeezing and holding the

trigger.

2. With the other hand turn either the crank handle or feed wrench to advance the cutting tool

into the workpiece.

3. Continue to turn either the crank handle or feed

wrench until the required machining is complete. Base the feed rate on the machine’s

feedback, if the RPMs drop or the motor stalls

slow the feed rate.

4. Once complete, allow the machine to make a

few revolutions without feeding the cutting tool

to clean up the machined surface.

5. Release the trigger to stop the machine.

6. Reverse the rotation on the crank handle or

feed wrench 2-3 revolutions to back the cutting

tool away from the workpiece. The ratchet

mechanism on the feed wrench will need

switched to feed out instead of in.

7. To remove the BG44 from the workpiece do the

following:

a) Unplug or disconnect the power supply

from drive motor. Lock out/tag out where

applicable.

b) Turn the locking wrench to loosen the

locking system from the workpiece.

c) Slide the BG44 straight out from the

workpiece using the body of the machine

to support it’s weight.

Always pick up and move the BG44 Boiler

Gun using the body of the machine or

combination of the center shaft and

machine body. Never pick up the BG44

Boiler Gun by the handle section of the

electric driver, actuation of the motor could

occur and lead to severe injury. Never pick

up the BG44 Boiler Gun by electrical cord as

it could result in damage to the machine.

Do not pick up and move the machine by

either of the wrenches as damage to the

machine could occur.

Page 22 BG44 Boiler Gun Operating Manual

Page 35

5 MAINTENANCE

IN THIS CHAPTER:

5.1 MAINTENANCE CHECKLIST - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

PPROVED LUBRICANTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

5.2 A

5.3 M

AINTENANCE TASKS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

HECKING AND FILLING THE IN-LINE OILER RESERVOIR - - - - - - - - - - - - - - - - - - - - - -24

5.3.1 C

ERVICING THE FILTER ELEMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

5.3.2 S

5.3.3 A

DJUSTING THE OIL FLOW RATE OF THE IN-LINE OILER - - - - - - - - - - - - - - - - - - - - - -24

OOL HOLDERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

5.3.4 T

REASING THE DRIVE AND PINION GEARS - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

5.3.5 G

5.4 T

ROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

HE MACHINE ISN’T TURNING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

5.4.1 T

HE MACHINE ISN’T FEEDING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

5.4.2 T

5.4.3 T

HE MACHINE IS PERFORMING POORLY - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

5.1 MAINTENANCE CHECKLIST

Table 5-1 lists maintenance intervals and tasks

TABLE 5-1. MAINTENANCE INTERVALS AND TASKS

Interval Task Reference

Check that oil is present in the sight glass on the in-line oiler, refill as needed. 5.3.1

Before each use

Before and after each use Remove debris, oil, and moisture from machine surfaces. --

Every ten operation cycles Lubricate center shaft threads. --

Check air lines for damage and wear. --

Check the cutting tool for sharpness. Replace as necessary. --

Adjustment of the oil flow rate 5.3.3

Filter element service 5.3.2

5.2 APPROVED LUBRICANTS

H&S recommends using the following lubricants at the

locations indicated.

Failure to use the appropriate lubricants can result in

damage and premature machine wear.

P/N 100190, Rev. 1 Page 23

Page 36

CAUTION

Avoid damage, premature machine wear,

WARNING

and protect your warranty by using only

approved lubricants.

TABLE 5-2. APPROVED LUBRICANTS

Application Area Lubricant

Threads of the center shaft

In-line oiler

Unpainted Surfaces LPS1 or LPS2 N/A 38 @ 25C As required

Drive and pinion

gears

WD-40 or lightweight spray lube

MOBIL ALMO 525 or

10W SAE oil

NOOK PAG-1 grease N/A 113 @ 100C

Biodegradable Lubri-

cant

N/A

N/A 46 @ 40C

Viscosity (cSt) Quantity Frequency

5.3 MAINTENANCE TASKS

Maintenance tasks are described in the following sections.

5.3.1 Checking and filling the in-line

oiler reservoir

Do the following to check and fill the in-line oiler:

1. Check sight glass on the oil reservoir for the

presence of oil.

2. To refill: Remove the cap, fill the reservoir and

replace the cap.

5.3.2 Servicing the filter element

See Figure A-20.

Do the following service the filter element:

1. Remove the filter nut to access the filter element.

2. Slide the filter element out of the filter housing.

3. Clean the filter element with a solvent and

compressed air.

4. Reassemble the filter and replace the filter nut.

Light coating

applied by

spray

Fill oil lubricator body

Light coating

applied by hand

Daily during machine

use

Each use

Each use, and before

storage

Weekly during machine

use

5.3.3 Adjusting the oil flow rate of the

in-line oiler

To adjust the oil flow rate the machine must

be mounted as if being used. ALL operating

and safety precautions must be taken to

avoid injuries.

Different lubricants and environments may effect the

rate of the in-line oiler.

Do the following to adjust the oil flow rate:

FIGURE 5-1. IN-LINE OILER SIGHT GLASS

Page 24 BG44 Boiler Gun Operating Manual

1. Remove the cap and check the oil level. Refill as

needed.

Page 37

2. Set the oiler valve to ‘3’ as a baseline for the

flow rate.

3. Replace the cap.

4. Mount and setup the machine (see Section 3.2-

3.5)

5. Squeeze and hold the throttle lever to run the

machine.

6. Hold a sheet of white paper approximately 4”

(101mm) in front of the exhaust ports on the

pneumatic motor. If adjusted correctly, there

will be a light splatter of oil on the paper after

a few seconds of operation.

7. If the oil rate needs adjusted, disconnect the

air supply line from the air filter end of the air

hose assembly.

8. Repeat Step 1.

9. The larger the number on the oiler valve the

higher the oil flow rate. Adjust as required.

10. Replace the cap and retest the machine for corrected oil flow rate.

5.4 TROUBLESHOOTING

5.3.4 Tool holders

Do the following to service the tool holders:

1. Monitor and replace as necessary, the o-rings on

the I.D. of the tool holder.

2. Monitor and replace as necessary, the key stock

between the main gear and the tool holders.

5.3.5 Greasing the drive and pinion

gears

Do the following to grease the drive and pinion gears:

1. On either drive type, remove the four screws in

the gearbox adapter.

2. Slide the entire motor, gearbox and gearbox

adapter out of the machine housing.

3. Both the drive and pinions gears are now accessible and can be greased.

4. Reverse the process to reassemble.

This section is intended to help you solve basic machine

performance problems. For serious maintenance or if

you have questions on the following procedures, contact

H&S.

5.4.1 The machine isn’t turning

If the machine is not rotating, check the following:

1. The air supply line is connected and sufficient

air pressure is present (pneumatic motor only).

2. The power source is connected and energized

(electric motor only).

3. The Low/High setting on the electric motor is

not in the neutral position (between gears).

5.4.2 The machine isn’t feeding

If the machine isn’t feeding properly, check the following:

1. The center shaft is properly installed in the

machine and 1/2” (12.7mm) projects through

either the back of the machine or the back of

the feed wrench.

2. The feed wrench or crank handle are being

turned the wrong direction.

5.4.3 The machine is performing poorly

If the machine is performing poorly, check the following:

1. The cutting tool is installed correctly.

2. That the set screw on the tool holder is tight to

the center shaft.

3. The machine is tight to the workpiece.

4. The cutting tool or insert is sharp and has the

correct geometry for the material and type of

cut.

5. Electric motor:

a) The low/high gear is set correctly.

6. Pneumatic motor:

a) There is oil in the in-line oiler.

b) The air supply to the machine is sufficient

in both quantity and pressure. Optimal

levels are: 90PSI at 38CFM.

7. After 40 hours of use, monitor the wear of the

bronze bushings. Replace when play is observed

between the components for best performance.

P/N 100190, Rev. 1 Page 25

Page 38

This page intentionally left blank

Page 26 BG44 Boiler Gun Operating Manual

Page 39

6 STORAGE AND SHIPPING

IN THIS CHAPTER:

6.1 STORAGE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

HORT-TERM STORAGE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

6.1.1 S

6.1.2 L

ONG-TERM STORAGE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

HIPPING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

6.2 S

ECOMMISSIONING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

6.3 D

6.1 STORAGE

Proper storage of the BG44 Boiler Gun will extend its

usefulness and prevent undue damage.

Store the BG44 Boiler Gun in its original shipping container. Keep all packing materials for repackaging the

machine (see Figure 6-1).

6.1.1 Short-term storage

Do the following for short-term storage (three months

or less):

1. Remove the tooling.

2. Remove hoses.

3. Clean the machine to remove dirt, grease,

metal chips, and moisture.

4. Drain all liquids from the in-line pneumatic

oiler.

5. Spray all unpainted surfaces with LPS-2 to prevent corrosion.

6. Store the BG44 Boiler Gun in its original shipping box (see Figure 6-1).

6.1.2 Long-term storage

Do the following for long-term storage (longer than

three months):

1. Follow the short-term storage instructions, but

use LPS-3 instead of LPS-2.

2. Add a desiccant pouch to the shipping container. Replace according to manufacturer

instructions.

3. Store the shipping container in an environment

out of direct sunlight with temperature < 70ºF

(21ºC) and humidity < 50%.

P/N 100190, Rev. 1 Page 27

Page 40

6.2 SHIPPING

The BG44 Boiler Gun can be shipped in its original shipping container, as shown in Figure 6-1.

FIGURE 6-1. BG44 SHIPPING CONTAINER

6.3 DECOMMISSIONING

To decommission the BG44 Boiler Gun prior to disposal,

remove the drive motor and dispose of it separately

from the rest of the machine components. Refer to

Appendix A for component assembly information.

Page 28 BG44 Boiler Gun Operating Manual

Page 41

APPENDIX A ASSEMBLY DRAWINGS

Drawing list

FIGURE A-1. BG44 BOILER GUN - HIGH VELOCITY, CRANK FEED ASSEMBLY (P/N BG44HVCR) - - - - - - - -30

IGURE A-2. BG44 BOILER GUN - HIGH VELOCITY, CRANK FEED PARTS LIST (P/N BG44HVCR) - - - - - - - -31

F

F

IGURE A-3. BG44 BOILER GUN - HIGH VELOCITY, WRENCH FEED ASSEMBLY (P/N BG44HVWR) - - - - - - -32

IGURE A-4. BG44 BOILER GUN - HIGH VELOCITY, WRENCH FEED PARTS LIST (P/N BG44HVWR) - - - - - - -33

F

IGURE A-5. BG44 BOILER GUN - LOW VELOCITY, CRANK FEED ASSEMBLY (P/N BG44LVCR) - - - - - - - - -34

F

F

IGURE A-6. BG44 BOILER GUN - LOW VELOCITY, CRANK FEED PARTS LIST - - - - - - - - - - - - - - - - - -35

IGURE A-7. BG44 BOILER GUN - LOW VELOCITY, WRENCH FEED ASSEMBLY (P/N BG44LVWR) - - - - - - - -36

F

IGURE A-8. BG44 BOILER GUN - LOW VELOCITY, WRENCH FEED PARTS LIST - - - - - - - - - - - - - - - - -37

F

F

IGURE A-9. BG44 BOILER GUN - ELECTRIC, CRANK FEED ASSEMBLY (P/N BG44CR-E) - - - - - - - - - - -38

IGURE A-10. BG44 BOILER GUN - ELECTRIC, CRANK FEED PARTS LIST - - - - - - - - - - - - - - - - - - -39

F

IGURE A-11. BG44 BOILER GUN - WRENCH FEED, ELECTRIC ASSEMBLY (P/N BG44WR-E) - - - - - - - - - -40

F

F

IGURE A-12. BG44 BOILER GUN - WRENCH FEED, ELECTRIC PARTS LIST - - - - - - - - - - - - - - - - - -41

IGURE A-13. COLLET SETS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

F

IGURE A-14. WEDGE SETS AND WEDGE EXTENSIONS - - - - - - - - - - - - - - - - - - - - - - - - - - -43

F

IGURE A-15. CENTER SHAFTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -44

F

F

IGURE A-16. LOCKING RODS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

IGURE A-17. TOOL HOLDERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -46

F

IGURE A-18. HV AIR MOTOR ASSEMBLY AND PARTS LIST (P/N 100105) - - - - - - - - - - - - - - - - - - -47

F

F

IGURE A-19. LV AIR MOTOR ASSEMBLY AND PARTS LIST (P/N CML3488) - - - - - - - - - - - - - - - - - -48

IGURE A-20. AIR HOSE ASSEMBLY AND PARTS LIST (P/N HS 50-509) - - - - - - - - - - - - - - - - - - - -49

F

IGURE A-21. ELECTRIC MOTOR ASSEMBLY AND PARTS LIST (P/N EMB003610) - - - - - - - - - - - - - - -50

F

F

IGURE A-22. TOOL KIT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

P/N 100190, Rev. 1 Page 29

Page 42

Page 30

FIGURE A-1. BG44 BOILER GUN - HIGH VELOCITY, CRANK FEED ASSEMBLY (P/N BG44HVCR)

Page 43

20 1 KEY, 1/4 X 1/2" 100124 40 1 MALE PLUG, 3/8" NPT 100143

19 1 THRUST BEARING 100123 39 1 DROP SWIVEL, 3/8" NPT 100142

18 1 HELICAL GEAR 100122 38 1 CRANK SHAFT 100141

17 1 FEED NUT 100121 37 1 SOCKET HEAD CAP SCREW, 8-32 X 1/2" 100140

16 1 BEARING CUP 100120 36 1 WASHER, #8 (SAE) 100139

15 1 TAPERED ROLLER BEARING 100119 35 2

SOCKET HEAD CAP SCREW

1/4-20 X 1/4"

100464

14 1 CENTERPIECE 100118 34 1 KEY, 1/8 X 3/4" 100138

13 1 MAIN GEAR 100117 33 1 HELICAL GEAR 100137

12 1 KEY, 3/16 X 5/8" 100116 32 1 KEY, 1/8 X 1/2" 100136

11 2 NEEDLE BEARING 100115 31 2 THRUST BEARING 100135

10 1 TAPERED ROLLER BEARING 100114 30 2 NEEDLE BEARING 100134

9 1 BEARING CUP 100113 29 1 SHOULDER BOLT, 3/8 X 1" 100133

8 1 NEEDLE BEARING 100112 28 1 FEED HANDLE KNOB 100132

7 1 HOUSING 100111 27 1 FEED HANDLE 100131

6 1 ADAPTER 100110 26 1 RUBBER GRIP 100130

5 1 NEEDLE BEARING 100109 25 1 O-RING 100129

4 1 PINION GEAR 100108 24 1 HANDLE 100128

3 1 KEY, 3/16 X 5/8" 100107 23 2

BUTTON HEAD CAP SCREW

1/4-20 X 3/4"

100127

2 1 DRIVE SHAFT 100106 22 6 SOCKET HEAD CAP SCREW 10-24 X 1" 100126

1 1 AIR MOTOR 100105 21 1 CENTERSHAFT LOCK 100125

ITEM NO. QTY. PART NAME

PART

NUMBER

ITEM NO. QTY. PART NAME

PART

NUMBER

FIGURE A-2. BG44 BOILER GUN - HIGH VELOCITY, CRANK FEED PARTS LIST (P/N BG44HVCR)

P/N 100190, Rev. 1 Page 31

Page 44

Page 32

FIGURE A-3. BG44 BOILER GUN - HIGH VELOCITY, WRENCH FEED ASSEMBLY (P/N BG44HVWR)

Page 45

FIGURE A-4. BG44 BOILER GUN - HIGH VELOCITY, WRENCH FEED PARTS LIST (P/N BG44HVWR)

P/N 100190, Rev. 1 Page 33

Page 46

Page 34

FIGURE A-5. BG44 BOILER GUN - LOW VELOCITY, CRANK FEED ASSEMBLY (P/N BG44LVCR)

Page 47

20 1 CENTERSHAFT LOCK 100125

19 1 KEY, 1/4 X 1/2" 100124 39 1 MALE PLUG, 1/2" NPT DCP2504

18 1 THRUST BEARING 100123 38 1 DROP SWIVEL, 1/2" NPT 95462

17 1 HELICAL GEAR 100122 37 1 CRANK SHAFT 100141

16 1 FEED NUT 100121 36 1 SOCKET HEAD CAP SCREW, 8-32 X 1/2" 100140

15 1 BEARING CUP 100120 35 1 WASHER, #8 (SAE) 100139

14 1 TAPERED ROLLER BEARING 100119 34 2

SOCKET HEAD CAP SCREW

1/4-20 X 1/4"

100464

13 1 CENTERPIECE 100118 33 1 KEY, 1/8 X 3/4" 100138

12 1 MAIN GEAR 100117 32 1 HELICAL GEAR 100137

11 1 KEY, 3/16 X 5/8" 100116 31 1 KEY, 1/8 X 1/2" 100136

10 2 NEEDLE BEARING 100115 30 2 THRUST BEARING 100135

9 1 TAPERED ROLLER BEARING 100114 29 2 NEEDLE BEARING 100134

8 1 BEARING CUP 100113 28 1 SHOULDER BOLT, 3/8 X 1" 100133

7 1 NEEDLE BEARING 100112 27 1 FEED HANDLE KNOB 100132

6 1 HOUSING 100111 26 1 FEED HANDLE 100131

5 1 ADAPTER 100110 25 1 RUBBER GRIP 100130

4 1 NEEDLE BEARING 100109 24 1 O-RING 100129

3 1 PINION GEAR 100108 23 1 HANDLE 100128

2 1 WOODRUFF KEY MB003489 22 2

BUTTON HEAD CAP SCREW

1/4-20 X 3/4"

100127

1 1 AIR MOTOR CML3488 21 6 SOCKET HEAD CAP SCREW 10-24 X 1" 100126

ITEM NO. QTY . PART NAME

PART

NUMBER

ITEM NO. QTY . PART NAME

PART

NUMBER

FIGURE A-6. BG44 BOILER GUN - LOW VELOCITY, CRANK FEED PARTS LIST

P/N 100190, Rev. 1 Page 35

Page 48

Page 36

FIGURE A-7. BG44 BOILER GUN - LOW VELOCITY, WRENCH FEED ASSEMBLY (P/N BG44LVWR)

Page 49

14 TAPERED ROLLER BEARING 100119

13 CENTERPIECE 100145 40 SPRING WASHER 100061

12 MAIN GEAR 100117 26 MALE PLUG, 3/8" NPT DCP2504

11 KEY, 3/16 X 5/8" 100116 25 DROP SWIVEL, 3/8" NPT 95462

10 NEEDLE BEARING 100115 24 HOUSING O-RING 100129

9 TAPERED ROLLER BEARING 100114 23 FEED NUT SNAP RING 100152

8 BEARING CUP 100113 22 FEED WRENCH, 1-1/4" 100151

7 NEEDLE BEARING 100112 21

BUTTON HEAD CAP SCREW

10-24 X 3/8"

100150

6 HOUSING 100144 20 RETAINER PLATE 100149

5 ADAPTER 100110 19 FEED NUT 100148

4 NEEDLE BEARING 100109 18 THRUST BEARING 100123

3 PINION GEAR 100108 17

SOCKET HEAD CAP SCREW

10-24 X 1/2"

100147

2 WOODRUFF KEY 911-0012 16 CENTERSHAFT LOCK 100146

1 AIR MOTOR CML3488 15 BEARING CUP 100120

ITEM NO. PART NAME

PART

NUMBER

ITEM NO. PART NAME

PART

NUMBER

FIGURE A-8. BG44 BOILER GUN - LOW VELOCITY, WRENCH FEED PARTS LIST

P/N 100190, Rev. 1 Page 37

Page 50

Page 38

FIGURE A-9. BG44 BOILER GUN - ELECTRIC, CRANK FEED ASSEMBLY (P/N BG44CR-E)

Page 51

21 1 HELICAL GEAR 100122 42 SOCKET HEAD CAP SCREW 500-1074

20 1 FEED NUT 100121 41 1 CRANK SHAFT 100141

19 1 BEARING CUP 100120 40 1 SOCKET HEAD CAP SCREW 100140

18 1 TAPERED ROLLER BEARING 100119 39 1 WASHER 100139

17 1 CENTERPIECE 100118 38 2 SOCKET HEAD SET SCREW 100464

16 1 MAIN GEAR 100117 37 1 KEY STOCK 100138

15 1 SHAFT KEY 100116 36 1 HELICAL GEAR 100137

14 1 NEEDLE BEARING 100115 35 1 KEY STOCK 100136

13 1 TAPERED ROLLER BEARING 100114 34 2 THRUST BEARING 100135

12 1 BEARING CUP 100113 33 2 NEEDLE BEARING 100134

11 2 NEEDLE BEARING 100112 32 1 SHOULDER BOLT 100133

10 1 HOUSING 100111 31 1 FEED HANDLE KNOB 100132

9 1 SOCKET HEAD SET SCREW 903-0003 30 1 FEED HANDLE 100131

8 1 O-RING MB003572 29 1 RUBBER GRIP 100130

7 1 TOOL HOLDER A/R 28 1 O-RING 100129

6 1 ADAPTER EMB003613 27 1 HANDLE 100128

5 1 NEEDLE BEARING 100109 26 2 BUTTON HEAD CAP SCREW 100127

4 1 PINION GEAR 100108 25 6 SOCKET HEAD CAP SCREW 100126

3 1 SHAFT KEY EMB003612 24 1 CENTERSHAFT LOCK 100125

2 1 DRIVE SHAFT EMS003511 23 1 SHAFT KEY 100124

1 1 AIR MOTOR EMB003610 22 1 THRUST BEARING 100123

ITEM NO. Q TY. PART NA ME

PART

NUMBER

ITEM NO. Q TY. PART NA ME

PART

NUMBER

FIGURE A-10. BG44 BOILER GUN - ELECTRIC, CRANK FEED PARTS LIST

P/N 100190, Rev. 1 Page 39

Page 52

Page 40

FIGURE A-11. BG44 BOILER GUN - WRENCH FEED, ELECTRIC ASSEMBLY (P/N BG44WR-E)

Page 53

,7(012 3$571$0(

,7(012 3$571$0(

FIGURE A-12. BG44 BOILER GUN - WRENCH FEED, ELECTRIC PARTS LIST

3$57

180%(5

3$57

180%(5

P/N 100190, Rev. 1 Page 41

Page 54

2 2.875" COLLET SET MC2-78

2 2.75" COLLET SET MC2-34 2 4.875" COLLET SET MC4-78

2 2.625" COLLET SET MC2-58 2 4.75" COLLET SET MC4-34

2 2.50" COLLET SET MC2-12 2 4.625" COLLET SET MC4-58

2 2.375" COLLET SET MC2-38 2 4.50" COLLET SET MC4-12

2 2.25" COLLET SET MC2-14 2 4.375" COLLET SET MC4-38

2 2.125" COLLET SET MC2-18 2 4.25" COLLET SET MC4-14

2 2" COLLET SET MC2 2 4.125" COLLET SET MC4-18

2 1.875" COLLET SET MC1-78 2 4" COLLET SET MC4

2 1.75" COLLET SET MC1-34 2 3.875" COLLET SET MC3-78

2 1.625" COLLET SET MC1-58 2 3.75" COLLET SET MC3-34

2 1.50" COLLET SET MC1-12 2 3.625" COLLET SET MC3-58

2 1.375" COLLET SET MC1-38 2 3.50" COLLET SET MC3-12

2 1.25" COLLET SET MC1-14 2 3.125" COLLET SET MC3-38

1 1.125-1.25" COLLET SET MC1-18 2 3.25" COLLET SET MC3-14

1 1-1.125" COLLET SET MC1 2 3.125" COLLET SET MC3-18

1 .875-1" COLLET SET MC78 2 3" COLLET SET MC3

ITEM NO. PART NAME

PART

NUMBER

ITEM NO. PART NAME

PART

NUMBER

Page 42

FIGURE A-13. COLLET SETS

Page 55

,7(012 47< 3$571$0(

,7(012 47< 3$571$0(

3$57

180%(5

FIGURE A-14. WEDGE SETS AND WEDGE EXTENSIONS

P/N 100190, Rev. 1 Page 43

3$57

180%(5

Page 56

8 1.25" WRENCH FEED, WEDGE 100160

7 1.25" CRANK FEED, WEDGE 100159

6 1.25" CRANK FEED, COLLET MB003549

5 1.25" WRENCH FEED, COLLET MB003550

4 .875" CRANK FEED, COLLET MB003545

3 .875" WRENCH FEED, COLLET MB003546

2 .875 WRENCH FEED, WEDGE 100154

1 .875" CRANK FEED, WEDGE 100153

ITEM NO. PART NAME

PART

NUMBER

FIGURE A-15. CENTER SHAFTS

Page 44

Page 57

FIGURE A-16. LOCKING RODS

P/N 100190, Rev. 1 Page 45

Page 58

6 SET SCREW (BLADE AND SHAFT) 903-0003

5B 5" FIXED TOOL HOLDER MB003586

5A 4" FIXED TOOL HOLDER MB003581

5 3" FIXED TOOL HOLDER MB003570

4 O-RING MB003572

3 DIFFERENTIAL SCREW 917-0001

2 BLADE LOCK 000875

1C 5.5" SLIDING TOOL HOLDER MB003583

1B 4" SLIDING TOOL HOLDER MB003584

1A 3" SLIDING TOOL HOLDER MB003573

1 2.625" SLIDING TOOL HOLDER 100186

ITEM NO. PART NAME

PART

NUMBER

Page 46

FIGURE A-17. TOOL HOLDERS

Page 59