Page 1

INSTALLATION AND

OPERATING INSTRUCTIONS

OWNERS MANUAL

MODEL 6200

LOW VOLTAGE CONTROL CHAIR

Page 2

SERIAL NUMBER

For your future reference, mark the serial number

in the space provided.

QUALITY MANAGEMENT

SYSTEM

REGISTERED TO

ISO 9001:2008

ISO 13485:2003

MADE I N AM ER IC A

Reliance® Medical Products • 3535 Kings Mills Road • Mason, Ohio 45040-2303 • 1-800-735-0357 • www.reliance-medical.com

Page 3

TABLE OF CONTENTS

4. LOCATING AND REPLACING FUSES..........................11

IMPORTANT INFORMATION.............................................4

1. INTRODUCTION.........................................................5

TECHNICAL SPECIFICATIONS.........................................6

2. INSTALLATION...........................................................7

2.1. Unpacking.......................................................7

Chair......................................................................7

2.2. Assembly.........................................................7

Headrest......................................................................7

Power Receptacle...................................................7

3. OPERATION..............................................................7

3.1. Stop Switch.....................................................7

3.2. Chair Lift........................................................8

Rais ing & Low erin g the Cha ir Lift fro m the

Footswitch...............................................................8

3.3. Chair Top........................................................9

4.1. Fuse Replacement..........................................11

TROUBLESHOOTING GUIDE..........................................12

CLEANING AND MAINTENANCE ....................................13

PARTS LIST.................................................................14

Model 6200 Chair Assembly..................................15

Chair Top Assembly...............................................16

Chair Base Assembly.............................................20

Lift Assembly.........................................................22

#18, 22 Headrest Assembly...................................24

#10 Headrest Assembly.........................................26

#11 Headrest Assembly.........................................28

#21 Headrest Assembly.........................................30

Wiring Diagram - 6200 .........................................32

LIMITED WARRANTY.....................................................35

Posistioning the Chair Back.....................................9

3.4. Revolving/Rotation..........................................9

3.5. Arm Movement................................................9

3.6. Footrest..........................................................10

3.7. Headrest.........................................................10

Operation-No. 18, 22 Headrest................................10

Adjustment-No. 18, 22 Headrest............................10

Operation-No. 10 Headrest....................................10

Operation-No. 11, 21 Headrest..............................10

Adjustment-No. 11, 21 Headrest............................11

IN-6200

3

Page 4

IMPORTANT INFORMATION

SAFETY SYMBOLS

Protective Earth Ground

“DANGER”, “WARNING”, or “CAUTION”

The exclamation point within an equilateral

triangle is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions in this

Installation and Operating Instructions.

« DANGER », « AVERTISSEMENT », ou

«PRÉCAUTION »

Le point d’exclamation à l’intérieur d’un

triangle équilatéral vise à alerter l’utilisateur

à la présence d’importantes instructions

de fonctionnement et de maintenance

(service) dans ce manuel d’installation et

d’instructions de fonctionnement.

“NOTE”

Amplifies a procedure, practice, or condition.

“NOTE”

Amplifie une procédure, pratique ou condition.

Type B, Applied Part

Alternating Current-AC

Safe Working Load

“Attention, Consult Accompanying

Documents”

!

TRANSPORTATION / STORAGE CONDITIONS

Temperature: Operating: 59 to 104º F

15 to 40º C

Storage: -22 to +140º F

-30 to +60º C

Relative Humidity: Operating: 5%RH to 95%RH

without condensation

Storage: 10%RH to 100%RH,

including condensation

Atmospheric Pressure: Operating: 700hPa - 1060hPa

Storage: 500hPa - 1060hPa

Dangerous Voltage / Shock Hazard

Fuse Rating Specification

IN-62004

Page 5

1. INTRODUCTION

1.1. This manual contains information applicable only

to the Reliance® Model 6200 Chair.

1.2. Whenever you see the symbols shown below,

heed their instructions! Always follow safe operating

and maintenance practices.

“DAN GE R”-

IDENTIFIES SPECIAL INSTRUCTIONS OR

PROCEDURES WHICH, IF NOT CORRECTLY

FOLLOWED, COULD RESULT IN LOSS OF

LIFE OR PERSONAL INJURY.

THE DANG ER SYMBO L

« DANGER » : LE SYMBOLE DANGER

ID ENT IF IE DE S I NST RU CTI ON S O U

PROCÉDURES SPÉCIALES QUI, SI ELLES

NE SONT PAS SUIVIES CORRECTEMENT,

POURRAIENT CAUSER UNE PERTE DE VIE

OU UNE BLESSURE.

“WARNING”-

IDENTIFIES SPECIAL INSTRUCTIONS

OR PROCEDURES WHICH, IF NOT

CORRECTLY FOLLOWED, COULD RESULT

IN PERSONAL INJURY.

THE WARNING SYMBOL

« AVERTISSEMENT » : LE SYMBOLE

AV E R T I S S EM EN T ID E N T I F I E DE S

INSTRUCTIONS OU PROCÉDURES SPÉCIALES

QUI, SI ELLES NE SONT PAS SUIVIES

CORRECTEMENT, POURRAIENT CAUSER

UNE BLESSURE.

“CAUTION”-

special instructions or procedures which,

if not strictly observed, could result in

damage to or destruction of equipment.

This caution symbol identifies

“NOTE”-

additional information.

Note indicates points of particular or

« REMARQUE » : Remarque indique des points

d’intérêt particulier ou des renseignements

additionnels.

d’information particulière ou supplémentaire.

1.3. Should your product not perform properly, or if

you have any questions concerning the use and care

of any Reliance® product, contact the Reliance®

Distributor, where you purchased this product or contact

the Technical Service Department, Reliance® Medical

Products, Inc., 3535 Kings Mills Road, Mason, Ohio

45040-2303, or call (800) 735-0358.

NOTE:

serial number available before contacting

Reliance® or your Authorized Reliance®

Distributor.

la note indique des remarques

Always have the model number and

REMARQUE : Ayez toujours le numéro de

modèle et le numéro de série à portée de la

main avant de contacter Reliance® ou votre

distributeur Reliance® autorisé.

“CLASSIFIED BY CANADIAN STANDARDS

ASSOCIATION® WITH RESPECT TO ELECTRIC

SHOCK, FIRE AND MECHANICAL HAZARDS

ONLY IN ACCORDANCE WITH UL 60601-1.”

According to Clause 5 in IEC 60601-1, sec 6.8.1, this

unit is classified by the following:

• The type of protection against electric shock:

EQUIPMENT energized from an external electrical

power source: CLASS I EQUIPMENT

• The degree of protection against electric shock:

TYPE B EQUIPMENT

IN-6200

« PRÉCAUTION » : Ce symbole de

précaution identifie des instructions ou

procédures spéciales qui, si elles ne sont pas

strictement suivies, pourraient causer un

dommage ou la destruction de l’équipement.

• The degree of protection against harmful ingress of

water: ORDINARY DEGREE

• The degree of safety of application in the presence

of a FLAMMABLE ANAESTHETIC MIXTURE WITH AIR

or WITH OXYGEN OR NITROUS OXIDE: EQUIPMENT

not suitable for use in the presence of a FLAMMABLE

ANAESTHETIC MIXTURE WITH AIR or WITH OXYGEN

OR NITROUS OXIDE

• The mode of operation: CONTINUOUS OPERATION

5

Page 6

WARNING: TO PREVENT FIRE OR ELECTRICAL

SHOCK HAZARD, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE.

AVERTISSEMENT : POUR ÉVITER UN

IN CENDIE OU U N RIS QU E DE CH OC

ÉL E CTR I QUE , N’ E XPO S EZ PA S CE T

ÉQUIPEMENT À LA PLUIE OU À L’HUMIDITÉ.

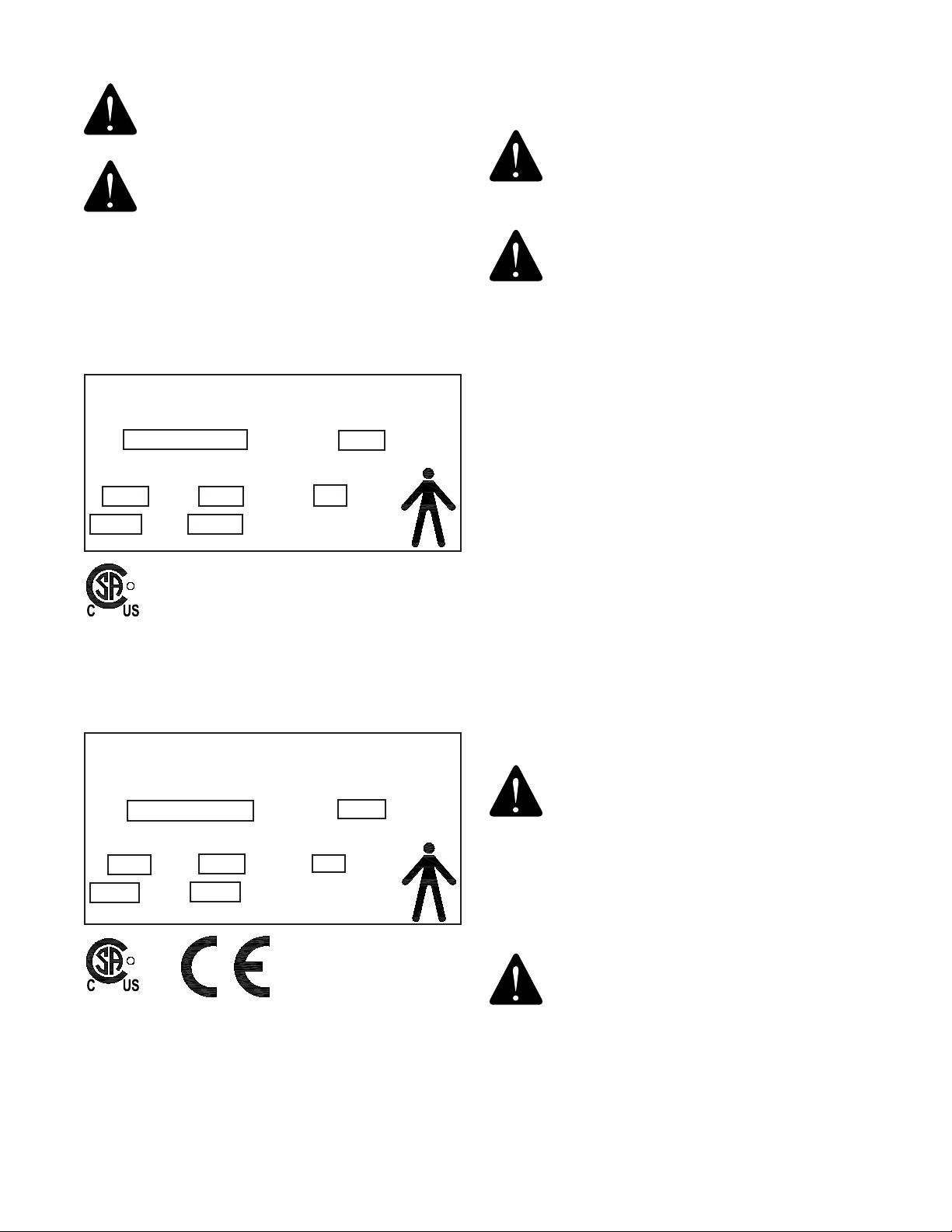

TECHNICAL SPECIFICATIONS

Rating for 120V Low Voltage Chair

This equipment is rated Class I, Type B

Equipment Model

Low Voltage Chair 6200

Volts Hertz Amps

120V 50/60 8.0

Class I Type B

IMPORTANT USER WARNINGS

WARNING: EXPLOSION HAZARD. THIS EQUIP-

MENT MUST NOT BE USED IN THE PRESENCE

OF FLAMMABLE ANESTHETICS.

AVERTISSEMENT : RISQUE D’EXPLOSION.

CET ÉQUIPEMENT NE DOIT PAS ÊTRE UTILISÉ

EN PRÉSENCE D’ANESTHÉSIQUES INFLAMMABLES.

POT ENTIAL ELEC TROMAGNETIC or OTHER

INTERFERENCE

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to other devices

in the vicinity. However, there is no guarantee that interference

will not occur in a particular installation.

If this equipment does cause harmful interference to other

devices, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving device.

Rating for 230V Low Voltage Chair

This equipment is rated Class I, Type B

Equipment Model

Low Voltage Chair 6200

Volts Hertz Amps

230V 50 3.0

Class I Type B

U.S. Patent No.

3,661,421

3,792,905

5,467,002

• Increase the separation between the equipment.

• Connect the equipment into an outlet on a circuit different

from that to which the other device(s) are connected.

• Consult the manufacturer or field service technician for

help.

WARNING - STORAGE OF THIS EQUIPMENT

BELOW 40°F (4.4ºC) WILL CAUSE THE

HYDRAULIC OIL TO BECOME THICK. THIS

MAY CAUSE UNU SUAL NOISES WHEN

THE BASE MOTOR IS OPERATED. IT IS

RECOMMENDED THAT THE EQUIPMENT

STAY AT A TEMPERATURE OF 60°F (15.6ºC)

OR ABOVE FOR AT LEAST 8 HOURS BEFORE

OPERATING.

AVERTISSEMENT : L’ENTREPOSAGE DE

CET ÉQUIPEMENT À MOINS DE 4,4°C (40°F)

FERA EN SORTE QUE L’HUILE HYDRAULIQUE

DEVIENDRA ÉPAISSE. CECI POURRAIT

CAUSER DES BRUITS INHABITUELS LORSQUE

LE MOTEUR DE LA BASE FONCTIONNE. ON

RECOMMANDE QUE L’ÉQUIPEMENT DEMEURE

À UNE TEMPÉRATURE DE 15,6°C (60°F) OU

PLUS DURANT AU MOINS 8 HEURES AVANT

DE L’UTILISER.

IN-62006

Page 7

2. INSTALLATION

2.1. Unpacking

2.1.1. Chair

2.1.1.1. Cut the shipping bands, open the top of the

shipping carton, and remove all packing material and boxes

that can be easily reached. Remove (4) nuts and remove

both base clamping boards.

2.1.1.2. It is recommended that the skid be positioned as

close as possible to the desired chair location.

2.1.1.3. Remove at least two small shipping blocks stapled

to the top of the skid. The chair can now be slid and/or

tipped from the skid onto the floor.

2.1.1.4. Do not lift the chair by the upper structure.

However, the chair may be tipped or slid into position by

pushing or pulling on the upper structure.

2.1.1.5. With the chair in positon, remove all remaining

paper pads, plastic, tape, strings, etc.

2.2. Assembly

2.2.2.2. To disconnect power to Chair unplug power cord

from Instrument Stand or from wall receptacle.

NOTE: If this chair is purchased in conjunction

with a Reliance® instrument stand, the chair control

cable supplied will provide proper operation. Refer

to the instrument stand manual for connection to

the stand.

REMARQUE : Si cette chaise est achetée avec

un support à instruments Reliance®, le câble

de commande de la chaise fourni permettra un

fonctionnement adéquat. Se référer au manuel du

support d’instrument pour savoir comment faire la

connexion au support.

3. OPERATION

CAUTION: Caution should be taken to ensure

there are no obstructions (instruments, trays,

tables) impeding movement of the Chair.

PRÉCAUTION : On devrait faire attention

pour s’assurer qu’il n’y a pas d’obstructions

(instruments, plateaux, tables) empêchant le

mouvement de la chaise.

2.2.1. Headrest

2.2.1.1. Remove the headrest from its carton, and mount

it into position onto the chair back. Using the proper hex

key wrench, tighten the cap screw to clamp the headrest

securely into its mounting bracket.

2.2.2. Power Receptacle

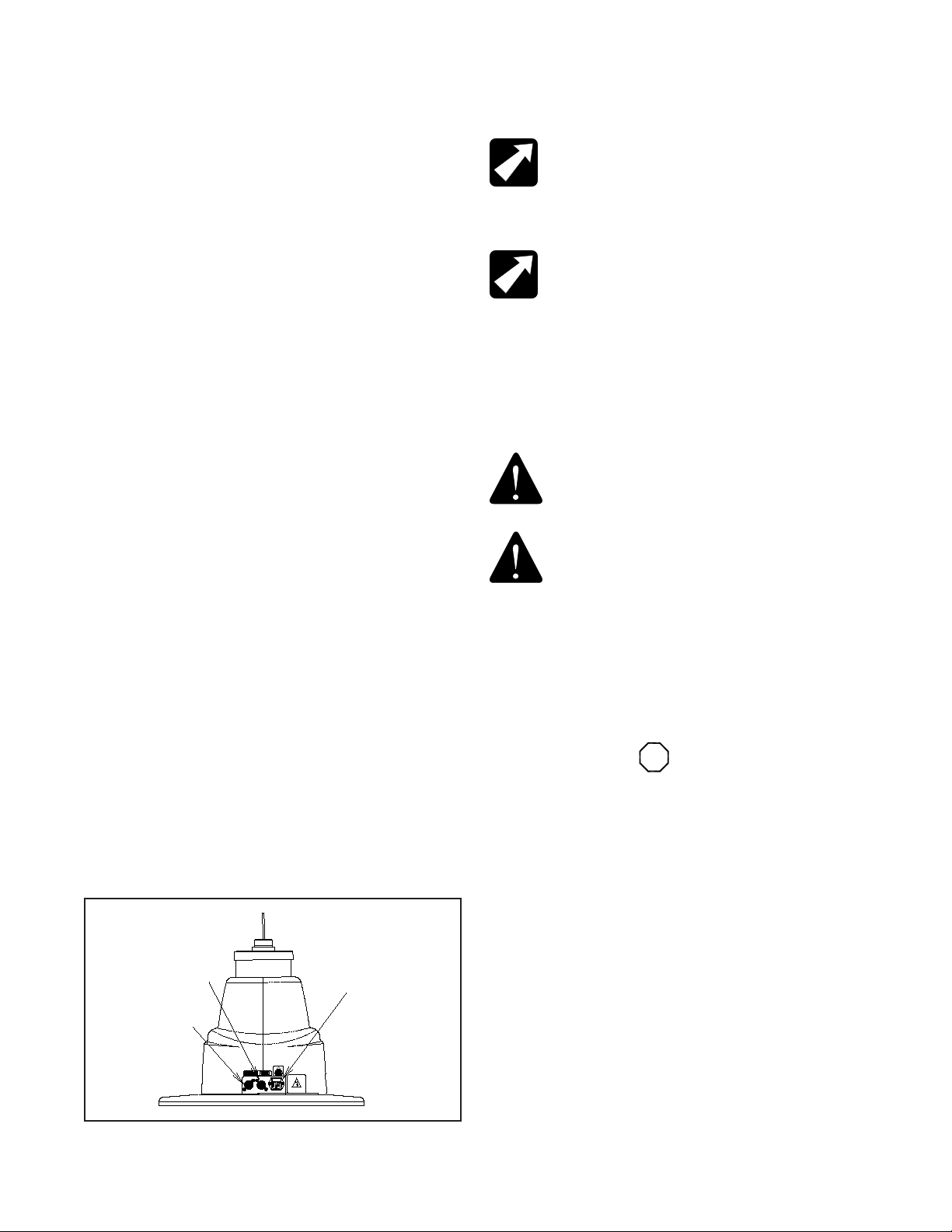

2.2.2.1. Locate the footswitch assembly, chair control

cable, and the power cord assembly. Refer to Figure 1 for

receptacle location and attach all cables.

Footswitch

Cable

Chair Control

Cable

Power Cord &

Fusedrawer

Each time main power is applied to the chair, the circuit

board inside the chair will respond with a one second

beep. The beep indicates the electronics are functioning

properly.

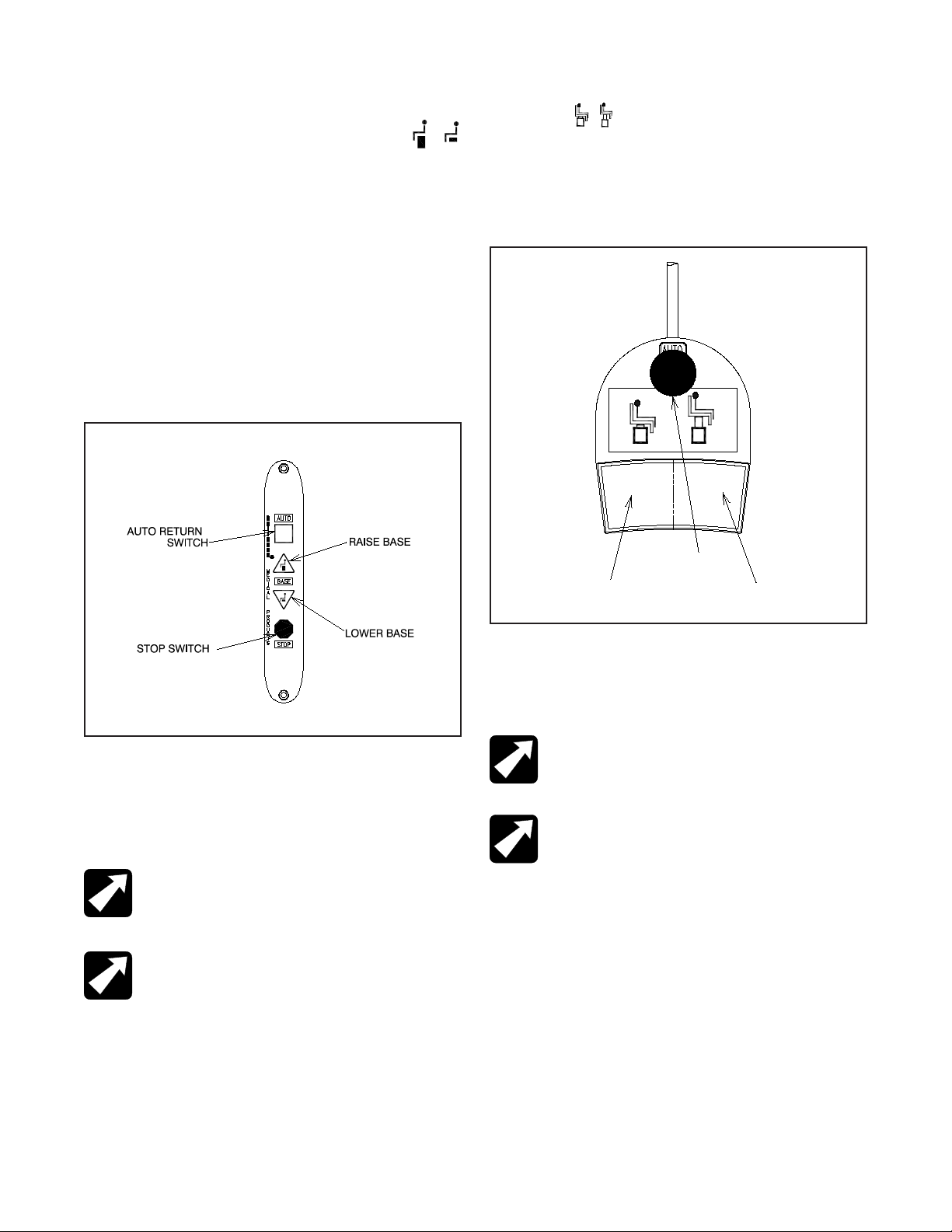

3.1. Stop Switch

3.1.1. Depressing the STOP switch on either side of the chair

back will STOP ALL movement of the chair. The STOP switch

is shaped like a stop sign, and should be ORANGE in color. It

is located above the text “STOP”. (Refer to Figure 2).

IN-6200

FIGURE 1

BASE

7

Page 8

3.2. Chair Lift

3.2.1. Raising & Lowering the Chair Lift with

Membrane Switches

• The chair lift may be raised or lowered by Membrane

Switches on either side of the chair back (Figure 2).

• To raise the chair lift from these switches, depress the

triangular-shaped UP arrow located ABOVE the text ”BASE”.

This is called the RAISE BASE switch.

• To lower the chair lift, depress the triangular-shaped DOWN

arrow located BELOW the text “BASE”. This is called the

LOWER BASE switch.

3.2.2. Raising & Lowering the Chair Lift from the

Footswitch

• For operation from the footswitch (Figure 3), depress the

right side of the pedal to raise the chair lift.

• Depress the left side of the right-hand pedal to lower the

chair lift.

FIGURE 2

MEMBRANE SWITCH

NOTE:

By design, the motion of the Chair will

STOP when the RAISE or LOWER BASE switch is

released.

REMARQUE : Selon la conception initiale,

le mouvement de la chaise S’ARRÊTE lorsque

l’interrupteur RAISE (LEVER) ou LOWER (BAISSER)

la base est relâché

AUTO

RETURN

LIFT

DOWN

LIFT

UP

FIGURE 3

Footswitch Operation

NOTE:

By design, the motion of the Chair will

STOP when the RAISE or LOWER BASE switch is

released.

REMARQUE : Selon la conception initiale,

le mouvement de la chaise S’ARRÊTE lorsque

l’interrupteur RAISE (LEVER) ou LOWER (BAISSER)

la base est relâché

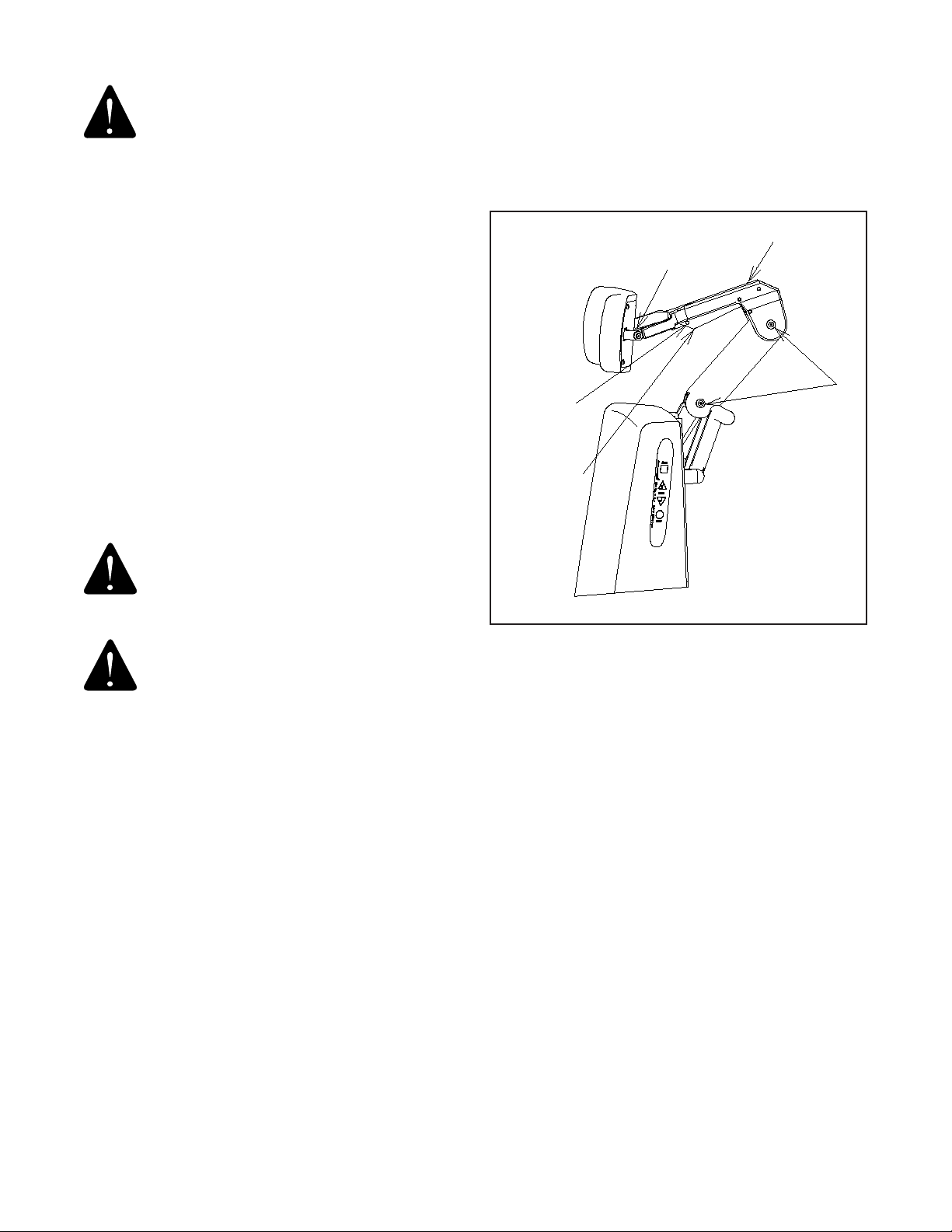

3.3. Chair Top

3.3.1. Positioning The Chair Back

• The chair back may be reclined or raised by either

pushing downward or pulling upward on the release lever

(Figure 4)

• If the chair is equipped with an articulating leg rest, the

foot-step and apron will rise when the back is reclined

• In the extreme reclined position these surfaces form a

flat table.

.

.

IN-62008

Page 9

FIGURE 4

Release Lever.

RELEASE LEVER

CAUTION: This exam Chair is designed

for use in a specific position called the

Intended Use Position. Prior to reclining a

patient, ensure the Chair Back is aligned

with the Chair’s power receptacle and

that the Chair Swivel is locked. The safe

working load is reduced if the Chair is

swiveled away from this Intended Use

Position, and may result in insufficient

stability.

PRÉCAUTION : Cette chaise d’examen

est conçue pour utilisation dans une

position spécifique appelée la position

d’utilisation prévue. Avant d’incliner un

patient, assurez-vous que le dossier de

la chaise est aligné avec le réceptacle

d’alimentation de la chaise et que le pivot

de la chaise est verrouillé. La charge

de travail sécuritaire est réduite si la

chaise est tournée hors de sa position

d’utilisation prévue et cela pourrait causer

une stabilité insuffisante.

3.4. Revolving/Rotation

3.4.1. The chair upper structure may be revolved 350°,

with a built-in stop to prevent continuous rotation. The lock

for revolving is controlled by a hand lever with chrome plated

knob located below the seat at the center and on either

side. Push the lever backward to release the lock and pull

upward to apply the lock.

3.5. Arm Movement

3.5.1. The chair arms may be raised to provide better

access to the patient or to permit entrance to or exit from

the chair.

3.5.2. The movements of both arms are identical and

completely independent of each other.

3.5.3. To raise an arm, push rearward on the middle joint

of the arm support link while raising upward on the arm.

A stop limits upward motion of the arm to a point parallel

to the plane of the back. Lowering the arm automatically

locks it in place against vertical motion in either direction.

CAUTION: This exam Chair is designed

for use with a specific maximum patient

weight as a static (non-moving) load.

Sudden weight shifts or impact loads

can exceed the safe static load rating of

the Chair, and may result in insufficient

stability.

PRÉCAUTION : Cette chaise d’examen

est conçue pour utilisation avec un poids

de patient maximum spécifique comme

charge statique (sans mouvement). Les

déplacements de poids soudains ou les

charges dynamiques peuvent excéder

la norme de charge statique sécuritaire

de la chaise, ce qui pourrait causer une

stabilité insuffisante.

CAUTION: This exam Chair is designed

for use with a patient properly positioned

in the Chair. Prior to reclining the Chair,

ensure that the patient is seated in the

Chair and that the patient position does

not move to an extreme position either

toward the head of the Chair or toward

the foot of the Chair, since this may result

in insufficient stability.

IN-6200

9

Page 10

PRÉCAUTION : Cette chaise d’examen est

conçue pour utilisation avec un patient

correctement positionné dans la chaise.

Avant d’incliner la chaise, assurez-vous

que le patient est assis dans la chaise et

que la position du patient ne se déplace

pas vers une position extrême soit vers

la tête, soit vers le pied de la chaise,

puisque cela pourrait causer une stabilité

insuffisante

3.6. Footrest

with a 3/32” hexagon key wrench. Next, tighten the pivot

screw on the other side of the pivot, with a 1/8” hexagon

key wrench. Now, retighten the set screw to retain the

pivot screw at the new adjustment. Either pivot may be

adjusted.

2

ACORN NUTS

3.6.1. The footrest may be retracted by lifting near its

outer edge. When fully retracted the footstep will stay in

place.

3.7. Headrest

3.7.1. The No. 18 headrest is the standard headrest for

the Model 6200 Chair.

WARNING- IF THE NO. 18 HEADREST

RECEIVES A IMPACT OR STRIKES AN OBJECT

WITH FORCE CONTACT RELIANCE® TECH

SERVICE IMMEDIATELY.

AVERTISSEMENT : SI L’APPUIE-TÊTE

# 18 REÇOIT UN CHOC OU FRAPPE

UN OBJET AVEC FORCE, CONTACTEZ

IMMÉDIATEMENT LE SERVICE TECHNIQUE

RELIANCE®.

3.7.2. Operation-No. 18, 22 Headrest

3.7.2.1. The No. 18, 22 headrest is designed so it can be

operated with just one hand. To unlock, squeeze the clear

plastic actuator into lock housing. This will allow both pivots

of the articulating arm to rotate so the headrest can be

moved to a new desired position. Once in the new position,

release the actuator. Make sure the actuator expands to its

original position fully exposing black dot on handle to insure a

positive lock. The headrest pad is free to rotate at all times.

(See Figure 5).3.7.3.

1

BLACK DOT

ACTUATOR

FIGURE 5

No. 18, 22 Headrest

3.7.3.2. The third adjustment is for proper clearance of the

block dot to indicate that the headrest is properly locked.

If the dot does not fully clear the lock housing when the

headrest is locked securely, turn the set screw located at the

top of the lock housing (Figure 5, item 2) counterclockwise

until the dot on the actuator is fully exposed.

3.7.4. Operation-No. 10 Headrest

3.7.4.1. The No. 10 headrest has a fixed, rigid upholstered

backboard which supports a sliding, center pillow section.

For patient comfort simply move this pillow to a desired

position.

Adjustment-No. 18, 22 Headrest

3.7.3.1. There are three adjustments provided on the No.

18, 22 headrest. The first is the tension on the pad rotation.

By tightening the two hex acorn nuts on the pad pivots with

a 3/8” open end wrench, the tension will be increased. To

adjust the drag on the pivots of the articulating arm, loosen

the set screw in the center of the pivot (Figure 5, item 1)

3.7.5. Operation-No. 11, 21 Headrest

3.7.5.1. A single handle on the rear of the No. 11, 21

headrests controls the locking mechanism. To unlock,

grasp the handle and turn counter-clockwise. Change the

tilt of the headrest until it is in the desired position. To lock,

turn the handle clock-wise until snug. (See Figure 6, No. 11

Headrest shown)

IN-620010

Page 11

3.7.6. Adjustment-No. 11, 21 Headrest

3.7.6.1. The handle on the outermost knob can be adjusted

to any preferred, locked position. Simply push in on the large

screw while pulling out on the handle. Rotate as desired, and

release. (See Figure 6, No. 11 Headrest shown)

3.7.6.2. The No. 21 headrest pillow assembly will slide

to a preferred patient position. Simply slide pillow on the

attached headrest strap to the desired position. (Not Shown)

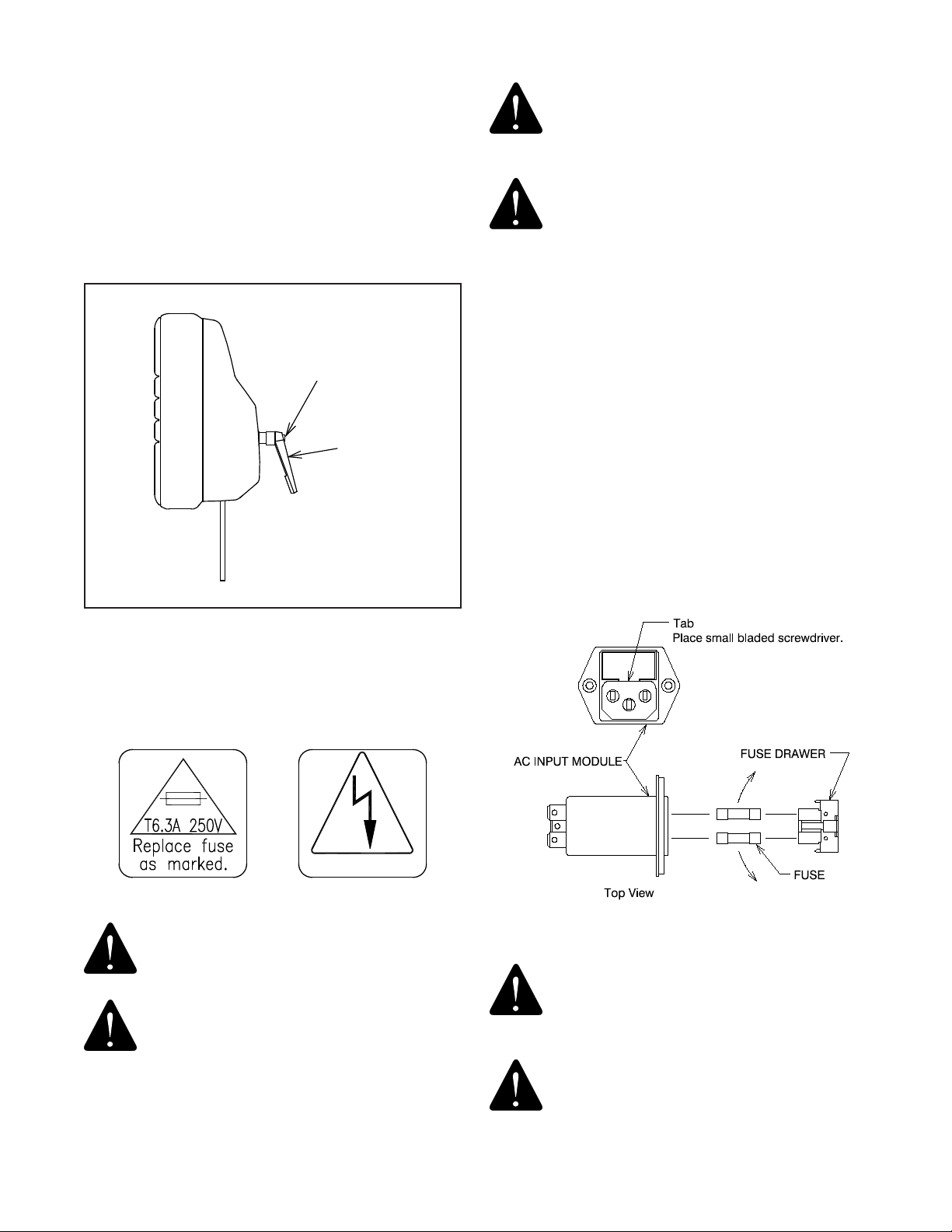

CAUTION: Replace fuse(s) as marked. All

fuses must be replaced with a fuse of the same

size and rating. Refer to the Wire Diagrams

at the end of this Manual.

PRÉCAUTION : Remplacez le(s) fusible(s)

comme indiqué. Tous les fusibles doivent

être remplacés par un fusible de la même

dimension et de la même valeur. Se référer

aux schémas de câblage à la fin de ce manuel

The chair contains two fuses located inside the AC Input

Module in the Base Assembly.

SCREW

HANDLE

FIGURE 6

No. 11 Headrest

4.0 LOCATING AND REPLACING FUSES

4.1. Fuse Replacement (AC Input Module)

4.1.1. Unplug the power cord from the AC power input

module. Referring to Figure 7, locate tab. With a tool similar

to a small common screwdriver placed under tab, pry fuse

drawer out. Remove the drawer by pulling it out with your

fingers.

4.1.2. To remove fuses from fuse drawer, tilt fuses in direction

of arrows as shown in Figure 7. Examine the fuses, replace

as necessary.

WARNING: DISCONNECT EQUIPMENT FROM

MAIN INPUT POWER BEFORE PROCEEDING WITH

ELECTRICAL INSPECTIONS OR MAINTENANCE.

AV ERT ISS EME N T : D ÉCONN EC TE Z

L’É QUI PEM EN T D E L’ A LI MEN TATI ON

ÉLECTRI QU E P RI NCIPAL E AVANT DE

PROCÉDER À DES INSPECTIONS ÉLECTRIQUES

OU À DE L’ENTRETIEN.

IN-6200

FIGURE 7

AC INPUT MODULE

CAUTION: To avoid a bind of the Fuse Drawer

within the AC Input Module, never install the

Fuse Drawer into the AC Input Module without

fuses.

PRÉCAUTION : Pour éviter que le tiroir à

fusible reste bloqué dans le module d’entrée

CA, n’installez jamais le tiroir à fusible

à l’intérieur du module d’entrée CA sans

fusibles.

11

Page 12

TROUBLESHOOTING GUIDE

PROBLEM PROBLEM CAUSE SOLUTION

CHAIR WILL NOT OPERATE. 1) POWER CORD NOT PLUGGED IN.

2) NO AC POWER AT WALL RECEPTACLE.

3) BLOWN LINE FUSE.

1) CHECK ALL WIRING CONNECTIONS.

2) RESTORE OUTLET POWER.

3) REPLACE FUSE.

OUTLET POWER OK, BUT NO

BEEP IS HEARD WHEN POWER

IS APPLIED.

1) BLOWN LINE FUSE.

2) LOOSE WIRING IN BASE.

3) OTHER.

1) REPLACE FUSE.

2) CHECK ALL WIRING CONNECTIONS.

3) CONTACT FACTORY

FOOTSWITCH FUNCTIONS NOT

OPERATING.

1) FOOTSWITCH CORD NOT CONNECTED. 1) CHECK ALL INTERNAL AND

EXTERNAL FOOTSWITCH WIRING

BACKSWITCH FUNCTIONS NOT

OPERATING.

1) DAMAGED OR DISCONNECTED WIRES

IN CHAIR BACK, UNDER CHAIR SEAT,

OR IN CHAIR BASE

1) CHECK ALL WIRING CONNECTIONS.

CHAIR BASE WILL NOT STAY UP 1) SOLENOID VALVE NOT CLOSED.

(DIRT IN VALVE.)

2) CONSTANT POWER APPLIED TO

SOLENOID.

3) OTHER

1) REPAIR OR REPLACE SOLENOID

VALVE.

2) CHECK FOR SWITCHES STUCK

"CLOSED" .

3) CONTACT FACTORY.

CHAIR BASE WILL NOT LOWER. 1) NO POWER TO PUMP MOTOR ASS'Y.

2) SOLENOID COIL BURNED-OUT

3) OTHER

1) CHECK FOR VOLTAGE.

2) REPLACE SOLENOID COIL.

3) CONTACT FACTORY.

CHAIR BASE WILL NOT RAISE.

PUMP MOTOR DOES NOT RUN.

1) NO POWER TO PUMP MOTOR ASS'Y

2) UP-LIMIT SWITCH STUCK "OPEN".

3) PUMP MOTOR BURNED-OUT.

4) OTHER

1) CHECK FOR VOLTAGE.

2) RE-ADJUST OR REPLACE SWITCH.

3) REPLACE PUMP MOTOR ASS'Y.

4) CONTACT FACTORY.

CHAIR BASE WILL NOT RAISE.

PUMP MOTOR RUNS.

1) SOLENOID VALVE NOT CLOSED.

(DIRT IN VALVE.)

2) CONSTANT POWER APPLIED TO

SOLENOID.

3) OTHER.

1) REPAIR OR REPLACE SOLENOID

VALVE.

2) CHECK FOR SWITCHES STUCK

"CLOSED".

3) CONTACT FACTORY.

BASE "STUTTERS" DURING

ASCENT.

1) HYDRAULIC FLUID LEVEL IS LOW. 1) CONTACT DEALER OR FACTORY

FOR INFORMATION ON ADDING OIL.

CHAIR BASE WILL NOT RAISE

OR LOWER FROM FLOOR UNIT.

1) CHAIR CONTROL CABLE NOT PLUGGED

IN.

2) BLOWN FUSE IN CHAIR BASE.

1) CHECK CABLE CONNECTIONS AT

STAND CHAIR

2) REPLACE FUSE.

CHAIR TOP "WOBBLES" ON

CHAIR BASE

1) LOCK NUT IS LOOSE.

(UNDER SEAT BOARD.)

1) TIGHTEN LOCK NUT.

CHAIR BACK RECLINES FULLY

WITHOUT HANDLE BEING

ACTIVATED.

1) BACK SPRING FAILURE 1) ADJUST GAS SPRING

2) REPLACE GAS SPRING

CHAIR BACK SPONGY WHEN

PATIENT PUTS PRESSURE ON

CHAIR BACK.

1) BACK SPRING FAILURE 1) REPLACE GAS SPRING

IN-620012

Page 13

CLEANING AND MAINTENANCE

Cleaning the Upholstery

When cleaning upholstery, it is suggested that you use all

recommended commercial cleaning agents in an inconspicuous spot to check for potential damage to the upholstery

material before applying to the entire area to be cleaned.

Day to Day soil:

Remove ordinary dirt and smudges with a mild soap and

warm water solution. Dry with a soft, lint-free cloth or towel.

For more difficult stains, use of a stronger detergent is

recommended; however, follow the detergent manufacturer’s

instructions closely.

Disinfecting Material:

In order to disinfect, use a 1:9 solution of bleach and water (1

part bleach to 9 parts water). Wipe surface with damp cloth

then rinse with water immediately, using a damp cloth.

Special cleaning problems:

The following methods are recommended to clean stains

on PreFixx-protected vinyl upholstery. Most stains will be

removed when these cleaning agents are used in the following order.

Type 1 Cleaners: Nonabrasive household cleaners to be

used with water and a soft cloth.

• Formula 409~ All-Purpose Spray Cleaner

• Fantastik® Spray Cleaner

PRÉ C AUTI O N : C e s s olv an t s s ont

extrêmement inflammables. Faites très

attention lors du nettoyage et avisez le

personnel dans la zone de tout danger.

Portez des gants de caoutchouc durant toute

activité de nettoyage. Faites attention en

nettoyant autour des boutons, des coutures

et autres finitions de bois ou décoratives,

puisque ces solvants pourraient endommager

sérieusement ces endroits.

Cleaning Painted Surfaces

The painted metal surfaces are covered in durable, powdercoated paint which is resistant to scratching and scuffing.

It may be cleaned with a clean cloth dampened with mild,

soapy water or equivalent household product that uses spray

application.

Recommended Infection Control Products

The disinfectant/cleaner products that we have tested and

recommend for our upholstery, painted items and plastic

covers are as follows.

• Cavicide® Hospital Disinfectant

• Precise® Hospital Foam Cleaner Disinfectant

• Other similar household cleaners and bleaches

Type 2 Cleaners: Solvent-type cleaner to be liberally

applied with a soft cloth. Dry area with another cloth, rinse

with clean water and dry.

• Rubbing alcohol (isopropyl alcohol)

• Lighter fluid (naptha)

Type 3 Cleaners: Strong, active solvent cleaners such as

nail polish remover (acetone/water) to be applied with a soft

cloth. Stain should be removed with less than six (6) rubs; if

stain persists after six rubs, contact manufacturer. Dry area

with another cloth, rinse with clean water and dry.

CAUTION- These solvents are highly

flammable. Exercise proper care in cleaning

and notify personnel in area of danger. Wear

rubber gloves during all cleaning activity. Use

caution in cleaning around buttons, stitching

and wooden or other decorative trim, since

these solvents could seriously damage such

areas.

CAUTION : Follow manufacturer’s directions for

concentration and application of disinfecting

cleaner. Avoid prolonged application of any

disinfectant/cleaner products, because

they may cause staining or discoloration of

material.

PRÉCAUTION : Suivez les instructions

du fabricant pour la concentration et

l’application de nettoyeurs désinfectants.

Évitez une application prolongée de tout

produit désinfectant/nettoyant, parce que

ceux-ci pourraient causer des taches ou une

décoloration du matériel.

WARNING: REFER TO LOCAL OR

HEALTHCARE PROFESSION GUIDELINES

FOR SELECTING EFFECTIVE INFECTION

CONTROL PRODUCTS.

AV E R T ISSEM E N T : SE RÉ F ÉRER

AUX DIRECTIVES LOCALES OU DES

PROFESSIONS DE LA SANTÉ POUR

SÉLECTIONNER DES PRODUITS DE

CONTRÔLE D’INFECTION EFFICACES.

IN-6200

13

Page 14

PARTS LIST

RELIANCE® MODEL 6200

EXAMINATION AND TREATMENT CHAIR

Note: When ordering parts, please:

1. Advise dealer or factory of model and serial number of unit. These numbers are on the

plate that is located at rear, near bottom, of chair back.

2. Specify color of painted parts. Painted parts have an asterisk(*) behind the part description.

Note : Quand pièces de commande, s’il vous plaît :

1. Informez le distributeur ou l’usine du modèle et du numéro de série de l’ensemble. Ces

numéros sont de la plaque qui est située à l’arrière, près du bas, de l’arriére de présidence.

2. Indiquez la couleur des pièces peintes. Les pièces peintes ont un astérisque (*) derrière la

description de pièce.

Should your chair not perform properly, or if replacement parts are

needed, contact the Reliance® Distributor, where you purchased this

product or contact the Technical Service Department, Reliance® Medical

Products, Inc., 3535 Kings Mills Road, Mason, Ohio 45040-2303, or call

(800) 735-0358.

IN-620014

Page 15

ITEM PART NO. DESCRIPTION ITEM

PART NO. DESCRIPTION

1 Chair Top Assembly* (See Figure 8) 7 1479473 Upholstered Apron Assembly**

2 Base Assembly* (See Figure 9) 8 1467673 Upholstered Arm Assembly-Right**

3 Headrest Assemblies (See Figures 11 thru 14) 9 1467773 Upholstered Arm Assembly-Left**

4 1760403 Footstep* 10 0667873 Upholstered Arm Pad Assembly**

5 1715073 Upholstered Back Assembly** 11 1765073 Scuff Pad**

6 1479373 Upholstered Seat Assembly** 12

M

ODEL AND SERIAL

N

UMBER PLATE

FIGURE 7

6200 CHAIR ASSEMBLY

5

8, 9

10

6

2

7

4

11

** Please specify upholstery color when ordering.

To order complete Upholstery Set use P/N.

2727873 Designer Upholstery Set With No. 18 Headrest Pad - 6200

*Please specify paint color when ordering.

IN-6200

15

Page 16

47

FIGURE 8

6200 CHAIR ASSEMBLY

46

(2)

32

31

27

(2)

30

33

58

38

28

39

83

58

24

77

56

40

20

(2)

23

34

43

41, 42

45

50

45

72

51

49

82

53

70

6,58

68

7

(4)

52

69

5

8

9, 10

71

12

11

66

84

71

14

75

44

13, 22

76

(4)

17

15

16

1

48

29

81

22

79, 80

19

18

57

68

65

64

21

78

3

2

69

55, 59

26

25

69, 73, 74

35

60

37

(2)

54

36

61, 62, 63

IN-620016

Page 17

ITEM

PART NO. DESC RIPTION ITEM

PART NO. DESCRIPTION

1546699 Hinge Cable Assembly 23

1

1472195 Gas Spring Pivot Block 24

2

0978499 5/8 Dia. Steel Ball 25

3

4

1471995 Gas Spring Rease Actuator 27

5

1509199 Pivot Block Pin 28

6

1475685 Back Plate Weldment 29

7

1604095 Gas Spring Release Pivot 30

8

1477503 Side Plate Assembly - Right* 31

9

1477603 Side Plate Assembly - Left* 32

10

0396299 Spring Washer 33

11

0725999 S.H.S.S. 1/4-20 x 3/4 34

12

0761899 3/16 x 1 Roll Pin 35

13

0556285 Armrest Cover 36

14

0136703 Headrest Bracket* 37

15

1573503 Gas Spring Release Bar* 38

16

26

0729699

1472795

0722899

1760403

0609699

1471882

1734099

0614299

0606099

0605999

1473803

1473903

0605299

0605399

0569499

1473203

1/2 Washer

Apron Tie Bar

S.S.H.S. 1/4-20 x 3/8

Footrest*

Fiber Washer

Footrest Link

Snap Bushing

Footstep Pin Assembly

9/32 Dia Steel Ball

Spring

Apron Bracket - Right*

Apron Bracket - Left*

Lock Handle Assembly - Right

Lock Handle Assembly - Left

Roll Pin 3/16 x 3/4

Apron Control Link*

1473472 Back Cover - With ENT* 39

17

1472672 Back Cover - Without ENT* 40

0605499 Lock Shaft 41

18

0411199 Fiber Washer 42

19

0603803 Back Hinge Assembly - Right* 43

20

0603903 Back Hinge Assembly - Left* 44

21

22 0732699

1/2 Retaining Ring 45

For Items 46 thru 84 see page 18.

0401299

1472203

1842692

1842792

0122203

0122303

0563299

3/8 x 1 Shoulder Bolt

Apron Control Arm*

Armrest Link Assembly - Right

Armrest Link Assembly - Left

Armrest Bracket - Right*

Armrest Bracket - Left*

Linkage Pin

*Please specify paint color when ordering.

IN-6200

17

Page 18

ITEM PART NO.

DESC RIPTION

ITEM PART NO.

DESC RIPTION

46 2027099 Membrane Switch Assembly 66 0706399 H.H.C.S. 1/4-20 x 1 1/2

47 1546299 Ribbon Cable 67 0527899 1/4-20 Flex Lock Nut

48 0387303 Plug Button* 68 0758599 R.H.M.S. #10-24 x 5/8

49 0603399 Truarc Ring 69 0703299 #10-24 Hex Nut

50 1472999 10mm x 30mm Shoulder Bolt 70 0569699 O.H.W.S. #6 x 3/4 Phil

51 0307999 H.H.C.S. 5/16-18 x 3/4 71 0808699 F.H.C.S. 1/4-20 x 1 Sck't

52 0643599 Lock Plug 72 0929199 F.H.M.S. #10-24 x 3/4 Phil

53 0722899 S.H.S.S. 1/4-20 x 3/8 73 0728199 #10 Split Lock Washer

54 0561799 Locking Cam 74 0729999 1/4 Washer

55 1036799 H.H.C.S. 5/16-18 x 5/8 75 0704099 1/4-20 Hex Nut

56 1504185 Seat Plate Weldment 76 0716499 T.H.M.S. #10-24 x 3/8

57 2014399 Gas Spring 77 0704899 5/16-18 Hex Nut

58 0732599 Truarc Ring 78 0713599 F.H.M.S. 1/4-20 x 1.25 Phil

59 0728399 5/16 Washer 79 0729199 1/4 Lock Washer

60 1964085 Seat Support 80 0703699 1/4-20 Keps Nut

61 0708599 H.H.C.S. 3/8-16 x 1 1/2 81 1475399 M8 x 1.25 Hex Nut

62 0728499 3/8 Lock Washer 82 1660799 4 Circuit Cap

63 0705199 3/8-16 Nut 83 1660899 6 Circuit Cap

64 1586899 6 in Extention Spring 84 0299899 F.H.M.S. 1/4-20 x 2 1/2 Phil

65 1655599 6 1/2 in Flexible Tubing 85

*Please specify paint color when ordering.

Part List for Figure 8 page 16

IN-620018

Page 19

(NOTES)

IN-6200

19

Page 20

FIGURE 9

6200 BASE ASSEMBLY

20

33

18

9

21

34

35

3, 4

11

10

19

7

25

26

8

15

24

36

29

12

32

27

22

30, 17

31

23

5

38

30, 17

6

13

16, 17

37, 36

39

14

36

1

2

IN-620020

Page 21

ITEM

PART NO.

DESCRIPTION

ITEM PART NO.

DESCRIPTION

1

2081203 Base

20

0560099 Thrust Washer

2

2065599 Base Cover

21

0123885 Lock Nut

3

2065199 Base Housing - Low - RH

22

1548195 Wiring Tube-High

2065399 Base Housing - High - RH 1548395 Wiring Tube-Low

4

2065299 Base Housing - Low - LH

23

1127599 Union Tee

2065499 Base Housing - High - LH 24 1659299 Power Cord Assembly

5

Lift Assembly (See Figure 10) 25 1550599 Chair Control Cable-LV To LV

6

1707792 Solenoid Valve Assembly-120V

26

1608292 Footswitch Assembly

1707892 Solenoid Valve Assembly-230V

27

1634299 Fuse, 6.3 A / 250V-120V

7

1702892 Keyshield Assembly-Low* 1634999 Fuse, 4 A / 250V-230V

1702992 Keyshield Assembly-High*

28

1976799 Power Entry Module W/ Filter

8

2720092 Pump/Motor Assembly-120V 29 Fusedrawer, 2 Pole (In Item 28)

2720192 Pump/Motor Assembly-230V 30 0458999 Tubing-5 in

9

1547899 Piston Rod Bolt

31

1597299 Capacitor, Starting-120V

10

1525899 Set Screw-#10-24 x 1/4 2002199 Capacitor, Starting-230V

11

0607299 Washer

32

1993592 Ent Transformer Assembly - 120V

12

2721092 Hose Assembly 1994392 Ent Transformer Assembly - 230V

13

1596292 Pressure Tube Assembly

33

2722099 Base Cable Grey

14

2025599 P.C. Board Assembly 34 1643899 6 Circuit Plug

15

2720892 AC Input Assembly

35

1643799 4 Circuit Plug

16

0458999 Tubing-5-1/2 in

36

1720399 PH Phil w/Lock Washer-#10-24 x 1/2

17

1081999 Tubing Insert

37

2081099 Housing Mount Bracket

18

1547999 Snap Bushing

38

0708599 HHCS 3/8-16 x 1.5

19

0559999 Thrust Bearing

39

1569999 Circuit Board Support

To order complete Base Assembly use P/N’s.

2716292 Chair Base Assembly - Low - 120V*

2716392 Chair Base Assembly - High - 120V*

2716492 Chair Base Assembly - Low - 230V*

2716592 Chair Base Assembly - High - 230V*

*Please specify paint color when ordering.

NOTE- Power cord for 230V base does not

include a plug.

NOTE- Le cordon de secteur pour la base

230V ne comprend pas une fiche.

IN-6200

21

Page 22

1

2

10

9

3

4

6

5

7

8

11

41

38

26

42

40

43

20

30

31

32

33 & 37

34

27

28

29

35

36

12

13

15

16

19

18

14

17

25

24

23

22

21

18

39

FIGURE 10

LIFT ASSEMBLY

IN-620022

Page 23

ITEM

PART NO.

DESCRIPTION

ITEM

PART NO.

DESCRIPTION

1 1012795 Lift Base 22 0733299 Retaining Ring

2 1019095 Lift Top 23 0512599 Backup Ring

3 0439979 Switch Plate 24 0730899 U - Pack

4 0929699 Insulator 25 0512499 Piston Ring

5 1011399 Switch 26 0353199 Cylinder Gasket

6 0727599 Drive Screw 27 0569299 Pin - Roll

7 0731499 "O" Ring 28 0466399 Filter Screen

8 1454699 Pin 29 0446099 Snap Ring

9 0485199 Nut - Acorn 5/16 30 0741799 Valve Ball

10 0365799 Gasket - Tie Rod 31 0731199 "O" Ring

11 0432599 Base Column Seal 32 0441999 Valve Seat

12

0903292 Cylinder Assembly - High 33 1012499 Valve Housing

0526792 Cylinder Assembly - Low 34 0363299 Relief Valve Plunger

13 Spacer - Cylinder (in Item 12) 35 0784699 Relief Valve Spring

14 Bushing (in Item 12) 36 1012399 Set Screw

15 Ring - Quad (in Item 12) 37 0731299 "O" Ring

16

0902285 Base Column - High 38 0442499 Valve Spring

0563885 Base Column - Low 39 2720799 Elbow - 45°

17 0432599 Base Column Seal 40 1081899 Elbow - 90°

18

0901999 Tie Rod - High 41 0447199 Elbow - 90°

0563699 Tie Rod - Low 42 0303699 Plug - Pipe 1/8-27 Sckt Head

19 Pin - Roll (in Item 12) 43 1060392 Tubing Assembly

20 0422899 Disc - Valve

21

1183592 Piston Rod - High

1183692 Piston Rod - Low

To order complete Lift Assembly use P/N’s.

2721192 Lift Assembly - Low

2721292 Lift Assembly - High

IN-6200 23

Page 24

FIGURE 11

# 18 & # 22 HEADREST ASSEMBLY

16

1

11

8

5

9

2

6

7

9

3

18

17

14

15

4

13

12

10

IN-620024

Page 25

ITEM PART NO. DESCRIPTION

1

0475673 Pad Assembly - No. 18*

1680073 Pad Assembly - No. 22*

2 1460492 Yoke Assembly*

3 1460592 Gear & Bracket Assembly*

4 1470692 Actuator & Lock Gear Assembly

5 1425299 Pivot Cap, Right

6 1425399 Pivot Cap, Left

7 0307599 Screw, Shoulder 1/4 x 1

8 0726099 S.H.S.S. #10-24 x 3/16

9 1424999 Washer, 2" OD

10 1454799 B.H.C.S. 1/4-28 x 1/2

11 1456399 S.H.S.S. #10-24 x 3/8

12 1427099 Spring Plunger

13 1538899 Spring

14 1454999 L.H.C.S. #10-24 x 3/4 - Socket

15 1434799 Pivot Cap, Pad

16 0467195 Bushing .188 I.D x .312 O.D.

17 1456199 Nut, Acorn 1/4-20 Low Crown

18 1425699 Screw, Shoulder .25 x .50

To order complete Headrest Assembly use P/N. To order complete Screw Assembly use P/N.

144080 #18 Headrest Assembly* 2721692 Middle Joint Screw Assembly

144070 #22 Headrest Assembly* Includes: Item’s 5, 6, 7 & 8.

*Please specify paint color when ordering. 2721792 Bottom Joint Screw Assembly

** Please specify upholstery color when ordering.

Includes: Item’s 5, 6, 8 & 18

IN-6200

25

Page 26

FIGURE 12

# 10 HEADREST ASSEMBLY

3

1

4

2

7

9

6

(4)

11

(4)

12

8

10

5

(4)

IN-620026

Page 27

ITEM PART NO. DESCRIPTION

1

0665073 Uph # 10 Board Assembly**

2 0574173 Pillow Assembly - #10**

3 0567903 High Back Cover*

4 0568003 Pillow Back Cover*

5 0845199 F.H.W.S. #6 x .50 - Phil

6 0569699 O.H.W.S. #6 x 3/4

7 0569799 #6 Finishing Washer

8 0557499 Mounting Plate Assembly

9 0123203 Bracket Cover*

10 0808699 F.H.C.S 1/4-20 x 1.00 - Socket

11 0788699 S.H.C.S. 1/4-20 x 1.00

12 1454799 B.H.C.S. 1/4-28 x 1/2

To order complete Headrest Assembly use P/N.

665200 #10 Headrest Assembly*

*Please specify paint color when ordering.

** Please specify upholstery color when ordering.

IN-6200

27

Page 28

13

11

FIGURE 13

# 11 HEADREST ASSEMBLY

2

12

(4)

18

16, 17

(4)

4

14

1

7

3

8

10, 17

9

15

5

6

IN-620028

Page 29

ITEM PART N O. DESCRIPTION

1

1557573 Uph # 11 Pad Assembly**

2 1558897 Headrest Cover

3 1562499 3/8" Adjustable Handle

4 1558903 Mounting Plate*

5 1559295 Headrest Lock Block

6 1559395 Headrest Pad Mounting Plate

7 1207199 3/4 O.D x 3/8 I.D x 3/4 Spacer

8 1562899 S.H.S.S. 3/8-16 x 2 1/2

9 0472999 Retaining Ring

10 1559599 R.H.M.S 1/4-20 x 2 1/2

11 1523699 T.H.M.S. 5/16-18 x 3/8

12 1571799 Short Standoff

13 1559092 Stud Mount Assembly

14 0712999 F.H.M.S

1/4-20 x 3/4

15 1559499 F.H.M.S 3/8-16 x 3/4

16 0713199 R.H.M.S 1/4-20 x 3/4

17 0728299 1/4 Lockwasher

18 1454799 B.H.C.S., 1/4-28 x 1/2

To order complete Headrest Assembly use P/N.

155720 #11 Headrest Assembly*

*Please specify paint color when ordering.

** Please specify upholstery color when ordering.

IN-6200

29

Page 30

FIGURE 14

11

# 21 HEADREST ASSEMBLY

2

12

(4)

13

21

16, 20

(4)

5

14

(2)

1

3

4

19

(4)

15

17

6

18

10, 20

9

8

7

IN-620030

Page 31

ITEM PART NO. DESCRIPTION

1

1846373 Uph # 21 Pad Assembly**

2 1558897 Headrest Cover

3 0574173 Pillow Assembly**

4 0568003 Pillow Board Back Cover*

5 1558903 Mounting Plate*

6 1562499 3/8" Adjustable Handle

7 1559395 Headrest Pad Mounting Plate

8 1559295 Headrest Lock Block

9 0472999 Retaining Ring

10 1559599 R.H.M.S 1/4-20 x 2 1/2

11 1523699 T.H.M.S. 5/16-18 x 1/2

12 1571799 Short Standoff

13 1559092 Stud Mount Assembly

14 0712999 F.H.M.S 1/4-20 x 3/4

15 1559499 F.H.M.S 3/8-16 x 3/4

16 0713199 R.H.M.S 1/4-20 x 3/4

17 1207199 3/4 O.D x 3/8 I.D x 3/4 Spacer

18 1562899 S.H.S.S. 3/8-16 x 2 1/2

19 0845199 F.H.W.S. #6 x 1/2 - Phil

20 0728299 1/4 Lockwasher

21 1454799 B.H.C.S., 1/4-28 x 1/2

To order complete Headrest Assembly use P/N.

184640 #21 Headrest Assembly*

*Please specify paint color when ordering.

** Please specify upholstery color when ordering.

IN-6200

31

Page 32

FIGURE 15

WIRING DIAGRAM

LED 1

3

4

2 1

AUTO

PART # 1546299

RIBBON CABLE

LED 2

3

4

2 1

BASE

RAISE

LOWER

OUTPUT

1

1

LED 3

3

4

12

BASE

STOP

PART NO. - 2027099

MEMBRANE SWITCH

INPUT

1

GYO

R

BL V

GSH

W

B

Y

1

1546699

HINGE CABLE ASSY

W/B

BR

V

1

W/B

BR

B

G

W

R

BL

O

SH

1

G/B

1

B

R/B

W/B

BL

R

W

SH G

1

O

STRIPE TO PIN-1 BOTH ENDS

1

OUTPUT

1

AUTO

BASE

RAISE

14 2

3

LED 1

LED 2

STOP

BASE

LOWER

214

14 2

3

3

INPUT

1

LED 3

TO ENT LIGHT

(P/N 1736992)

PART NO. - 2027099

MEMBRANE SWITCH

IN-620032

Page 33

230V - 2720192

120V - 2720092

PUMP MOTOR ASSY.

PUMP

MOTOR

120V - 1707792

230V - 1707892

SOLENOID ASSY.

B

W

B

230V - 1994392

120V - 1993592

R

W

Y

B

CAPACITOR

230V - 2002199

120V - 1597299

COLOR

BLACK

BLUE

WIRE COLOR

BL

B

ABBREVIATIONS

ABBR

ORANGE

BROWN

GREEN

GRAY

BR

GYGOVR

WHITEW

VIOLET

RED

Y YELLOW

ENT TRANSFORMER ASSY (OPT)

Y

Y

Y

1

1

1

2722099

BASE CABLE

B

W/B

R/B

R

BL

O

G/B

W

G

SH

1

1

TIMER

CIRCUIT BOARD

2025599 - 120V & 230V

1

1

1

ENT

SOL

1

1

RELAY

DRIVER

1

1

POWER

SUPPLY

1

BUFFER

OPTICAL

W

PUMP

LIMIT

ENT IN

AC IN

FOOT

CONSOLE

1038992

LIMIT SWITCH

B

B

1

B

W

1

1

B

O

1

G

R/W

BL

W

R

1

O/B

G/B

R/B

B/W

CABLE ASSY, AC INPUT

1993392

G/Y

B

W

(1)BR

R

W

R/W

O

BBL

G

O/B

B/WG/B

R/B

(3)R

(4)G

(6)O

(7)BL

(5)W

(2)B

RECEPTACLE

CHAIR CONTROL

1607899

CABLE ASS'Y

LV FOOTSWITCH

LINE FUSES

B

W

O

BL

3

UP

6

G

11

4

AUTO

7

BR

DOWN

B

POWER ENTRY MODULE W/FILTER 1976799

230V-4.0A/250V - 1634999

120V-6.3A/250V - 1634299

L

N

CHAIR BASE

FOOTSWITCH ASS'Y - 1608292

POWER CORD ASSEMBLY 1659299

(OPTIONAL)

IN-6200

FOOT/CONSOLE CABLE-1993199

33

Page 34

(NOTES)

IN-620034

Page 35

LIMITED WARRANTY

The Reliance® product must be used only for the purposes and in the manner described in the literature

distributed with the product. The products are warranted against defective materials and workmanship for the

period set forth in the warranty provided with each product. Products or parts thereof will be repaired or replaced

as required at Reliance® Medical Products, Inc. Such repair or replacement shall be the sole remedy under

this warranty. This warranty extends only to the original purchaser from an authorized Reliance® dealer and is

subject to the following conditions:

1. The warranty card must be completed and returned to Reliance® Medical Products, Inc. within two(2)

weeks from the date of installation.

2. Installation and servicing of the products must be performed by trained Reliance® equipment dealer service

personnel in accordance with the appropriate instructions manual for the products.

3. The products have not sustained breakage or other type damage due to accident or misuse.

4. This warranty will not apply to Reliance® products which have had the serial number removed, altered or

effaced.

EXCEPT FOR THE EXPRESS WARRANTY SET FORTH ABOVE, RELIANCE® DOES NOT GRANT ANY

WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILTY

OR FITNESS FOR A PARTICULAR USE.

Reliance® Medical Products neither assumes nor authorizes any person to assume for it, any other liability

in connection with the sale and use of its products.

REMEDIES ARE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT OF PARTS. RELIANCE®

MEDICAL PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGE RESULTING FROM THE USE OF THE EQUIPMENT.

Claims covered by this warranty will be honored when presented within one (1) month from discovery of a defect.

IN-6200

35

Page 36

MADE IN AMERICA

3535 Kings Mills Road

Mason, Ohio 45040-2303

1-800-735-0357(Customer Service)

1-800-735-0358 (Technical Service)

(513) 398-3937

Http://www.reliance-medical.com

P/N 27168 REV E

© Copyright 2006

Printed in U.S.A.

Revised 02-2012-7925

Loading...

Loading...