Page 1

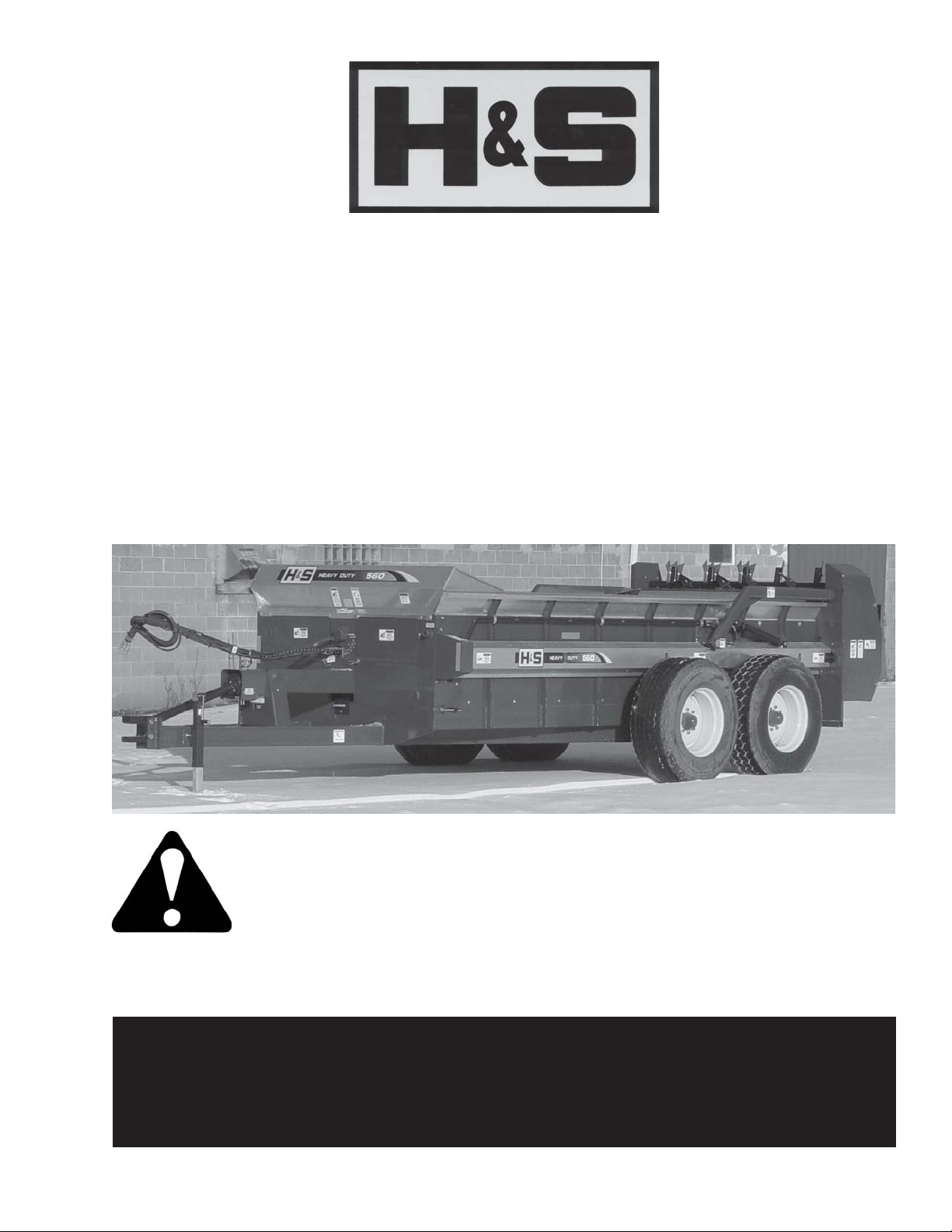

560/660560/660

560/660

560/660560/660

MANURE SPREADERMANURE SPREADER

MANURE SPREADER

MANURE SPREADERMANURE SPREADER

OPERAOPERA

OPERA

OPERAOPERA

W ARNING

Revision #03

560 St arting Serial #210086

660 St arting Serial #210046

TT

OR’S MANUOR’S MANU

T

OR’S MANU

TT

OR’S MANUOR’S MANU

READ AND UNDERSTAND THIS MANUAL

BEFORE OPERATING THIS EQUIPMENT.

UNSAFE OPERA TION OR MAINTENANCE OF

THIS EQUIPMENT CAN RESULT IN SERIOUS

INJURY OR DEATH.

HSMFG0312

ALAL

AL

ALAL

Part #72236

Manufactured By

H&S MANUFACTURING CO.,INC.

P.O. BOX 768 (715) 387-3414 FAX (715) 384-5463

MARSHFIELD, WISCONSIN 54449

Page 2

CONTENTS

Warranty & W arranty Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Dealer Pre-Delivery Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dealer Delivery Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Information - Be Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Information - Explanation of Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Safety Information - Warning - Owner Must Read and Understand . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Cap Screw Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set-Up & Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparing For Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-20

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lubrication Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

Decal Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-28

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Inside Back Cover

Page 3

Page 4

Page 5

DEALER PRE-DELIVERY CHECK LIST

AFTER COMPLETION, DEALER SHOULD REMOVE AND RETAIN FOR RECORDS

After the Manure Spreader has been completely set-up, check to be certain it is in correct operating order

before delivering to the customer . The following is a list of point s to inspect. Check off each item as you

have made the proper adjustments and found the item operating satisfactorily.

Manure spreader was not damaged in shipment. Check for dents and loose or missing

parts. Report damage immediately to H&S Manufacturing Co., Inc.

All bolts and fasteners are tight.

Manure spreader has been correctly assembled according to instructions in this manual.

All grease fittings have been lubricated. Gearbox is filled to proper level.

Hoses and fittings are properly attached and there are no visible leaks.

Guards and shields are secure.

Wheels are properly mounted to torque specifications.

Tires are inflated to correct pressure.

Drive chain tension and alignment is correct.

Decals are in place and legible.

Main apron chains are adjusted properly .

Connect the manure spreader onto a proper horsepower tractor and attach the PTO and connect

(Remove Dealer File Copy At Perforation)

the lights. Connect the hydraulic hoses to the tractor remote outlets. Run the manure spreader

and make sure all components operate properly.

PTO guard turns freely.

Hydraulic end gate operates smoothly .

Main apron operates smoothly .

Hydraulic system does not leak under pressure.

Lights and wiring functioning properly .

Implement and all components are functioning properly .

Model Number

Serial #

Dealer’s Name

Inspection Date

Signature of Pre-Delivery Inspector

-3-

Page 6

Intentionally Left Blank

-4-

Page 7

DEALER DELIVERY CHECK LIST

AFTER COMPLETION, DEALER SHOULD REMOVE AND RET AIN FOR RECORDS

This check list that follows is an important reminder of valuable information that should be passed

on to the customer at the time this Manure Spreader is delivered.

Check off each item as you explain it to the customer.

This delivery check list, when properly filled out and signed assures the customer that the

Pre-delivery service was satisfactorily performed.

(Remove Dealer File Copy At Perforation)

Explain to the customer that the pre-delivery inspection was made.

Explain to the customer all the safety precautions they must exercise when operating

this unit.

Explain recommended loads for different types of materials.

Explain to customer that regular lubrication is required for proper operation and long life of

machine.

Show customer the lubrication section of Owner’s Manual.

Give the customer Owner’s Manual and make sure they read and understand all operating

and service instructions.

Have the customer sign a completed “Warranty Registration”, and mail it.

Date Delivered

Dealer’s Name

By

Signature of Original Buyer

Note: Warranty is not valid until warranty card is completed and returned to H&S Mfg. Co., Inc.

-5-

Page 8

Intentionally Left Blank

-6-

Page 9

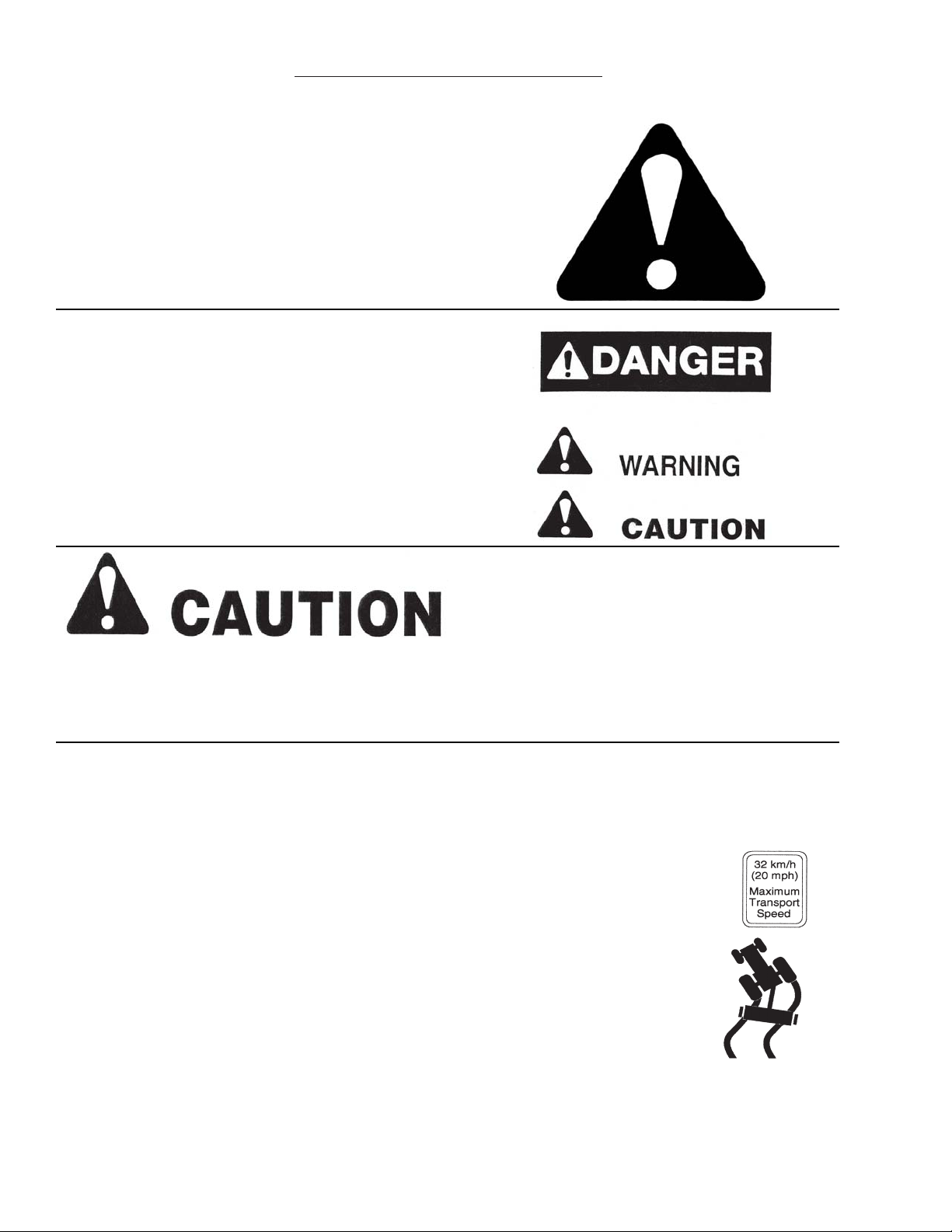

SAFETY INFORMATION

BE

YOUR SAFETY

ALERT!

THIS SYMBOL IS USED THROUGHOUT THIS BOOK WHENEVER YOUR PERSONAL SAFETY

IS INVOLVED. TAKE TIME TO BE CAREFUL. REMEMBER: THE CAREFUL OPERATOR IS THE

BEST OPERATOR. MOST ACCIDENTS ARE CAUSED BY HUMAN ERROR. CERTAIN

PRECAUTIONS MUST BE OBSERVED TO PREVENT THE POSSIBILITY OF INJURY OR

DAMAGE.

H&S MANUF ACTURING CO., INC.

IS INVOL VED.

-7-

Page 10

SAFETY INFORMATION

Keep signs in good condition. Immediately replace any missing or damaged signs.

RECOGNIZE SAFETY INFORMATION

This is the safety-alert symbol. When you see this

symbol on your machine or in this manual, be alert to the

potential for personal injury .

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A single word; DANGER, WARNING, or CAUTION is used

with the safety-alert symbol. DANGER identifies the most

serious hazards.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual, and all safety signs on your machine. Follow all

recommended precautions and safe operating procedures.

OBSERVE MAXIMUM TRANSPORT SPEED

The maximum transport speed for this implement is 32 km/h (20 m.p.h.).

Some tractors are capable of operating at speeds that exceed the maximum

transport speed of this implement. Regardless of the maximum speed capability

of the tractor being used to tow this implement, do not exceed the implement’s

maximum transport speed.

Exceeding the implements maximum transport speed can result in:

* Loss of control of the tractor/implement combination

* Reduced or no ability to stop during braking

* Implement tire failure

* Damage to the implement structure or its components

Use additional caution and reduce speed when towing under adverse surface

conditions, when turning, and when on inclines.

Do not attempt transport if the fully loaded implement weighs more than 1.5 times

the weight of the tractor.

-8-

Page 11

SAFETY INFORMATION

-9-

Page 12

SAFETY INFORMATION

-10-

Page 13

SAFETY INFORMATION

TRACTOR:

This operators manual uses the term “Tractor” when identifying the power or the towing source.

WARNING

TO PREVENT SERIOUS INJURY OR DEATH

BEFORE YOU ATTEMPT TO OPERATE THIS EQUIPMENT, READ AND STUDY THE FOLLOWING

INFORMATION. IN ADDITION, MAKE SURE THAT EVERY INDIVIDUAL WHO OPERATES OR WORKS

WITH THIS EQUIPMENT, WHETHER FAMILY MEMBER OR EMPLOYEE, IS FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

KNOW HOW TO ST OP UNLOADING MECHANISM BEFORE STARTING IT.

If the machine becomes clogged,

and allow all mechanisms to stop before cleaning or working on the machine.

DO NOT get off the tractor while the Manure S preader is in operation.

DO NOT attempt to perform maintenance or repair with tractor running and PTO or hydraulic lines

hooked up.

DO NOT step up on machine at any time.

NEVER manually feed material into the beaters.

DO NOT allow minors to operate or be near the machine.

DO NOT ALLOW PERSONNEL OTHER THAN THE QUALIFIED OPERATOR NEAR THE MACHINE.

Before starting tractor, be sure PTO shields turn freely and PTO is securely locked to tractor.

DO NOT clean, adjust, or lubricate the machine when any part is in operation.

Keep hands, feet, and clothing away from beaters when they are revolving.

Loose or floppy clothing should not be worn by the operator.

Be sure the machine is clear of people, tools, and other objects before engaging PTO.

DO NOT step over power take off shaft. Stay clear of PTO at all times.

disengage the PTO. Stop the tractor engine, remove ignition key,

NEVER start Manure Spreader until all guards and safety shields are secured in place.

STAY CLEAR of Hydraulic Lines. They may be under extreme pressure or heat.

H&S always takes the operator and his safety into consideration and guards exposed moving parts for

his protection. However, some areas cannot be guarded or shielded in order to assure proper ope ration.

In addition, the operators manual and decals on the machine itself warn you of further danger and

should be read and observed closely .

Study The Above Safety Rules

ATTENTION - BE ALERT - YOUR SAFETY IS INVOLVED

-11-

Page 14

-12-

Page 15

SET -UP & ASSEMBLY

Note: Determine right and left side of spreader by viewing it from the rear . If instructions

or parts lists call for hardened bolts, refer to Cap Screw Torque Value p age to identify.

PREPARING MANURE SPREADER

The Manure Spreader may be shipped without the wheels/tires installed.

1. Attach the wheels with tires, using the lug nuts furnished and torque the mounting hardware to

the appropriate torque. The wheel bolts must be tightened at 100 ft./lbs. of torque on the 560, and

300 ft./lbs. of torque on the 660

2. Check the tires and inflate them to the recommended pressure(425/65R-22.5 tires to 85 psi.).

3. Check for proper assembly and adjustment and make sure that all bolts are tightened.

4. Securely retighten after a few hours of operation, as bolts can loosen up on new machinery.

5. Lubricate the machine completely , check the oil level of the gearbox, fill if necessary.

TRANSPORTING

TRANSPORT LIGHTING & REFLECTORS

When transporting on the highway , connect the spreader

to the tractor with a lighting power cord. The lighting

system is to be connected to the 7 pin power receptacle

(per SAEJ560B) on your tractor. If your tractor is not

equipped with the proper receptacle, see your tractor dealer

for details. Make sure lights are functioning properly.

Regularly clean the reflective tape at the rear of the

spreader. There is a holder provided for your SMV sign.

SAFETY CHAIN (Optional)

Follow state and local regulations regarding use of a safety chain and transport lighting when towing farm

equipment on public highways. A proper safety chain should be used to retain the safety connection

between the towing and towed machines, in the event of separation of the primary attaching system.

Check with local law enforcement agencies for your own particular regulations. Unless otherwise prohibited,

use a slow-moving vehicle emblem. Never tow the manure spreader on a public highway at a speed

greater than 20 m.p.h. (32 kph).

1. Chain is sufficiently slack to allow turns and movements of either the tractor or the manure spreader,

without placing tension on the chain.

2. Chain is of sufficient strength to hold the decoupled implement (and its load) and tow it to the

shoulder.

-13-

Page 16

PREPARING FOR OPERA TION

TRACTOR CONNECTIONS

Tractor Hitch

Fasten the spreader hitch to the drawbar with a hitch pin with a safety locking device. Remove the

weight from the jack (jack is not to be used when spreader is loaded). Remove jack from the pipe mount

and place it on the storage mount located on the left front of spreader . This allows protection of the jack

from the tractor tires during turns. The hitch of the spreader is designed for a standardized tractor hitch.

Adjust the drawbar so that it is 13 to 17 inches above the ground. Extend or shorten it so that the

horizontal distance from the end of the tractor power takeoff shaft to the center of the hitch pin hole is 14

inches for 540 PTO and 15-3/4” for 1000 PTO as shown in drawing. An improperly located hitch point

may cause damage to the universal joints of the power takeoff. Secure the drawbar so that the hitch pin

hole is directly below the power drive line.

15-3/4” for 1000 RPM

PTO

Attach the PTO of the spreader to the tractor by sliding the spring loaded locking collar on PTO yoke

rearward, then sliding it onto the tractor PTO shaft. Release the spring loaded collar. Be sure the pins

fall into the groove of the tractor PTO shaft and collar snaps forward into locking position.

CAUTION: Do not use a steel hammer to aid in joining PTO parts.

If this implement is attached to a tractor with a clevis

hitch (hammer-strap) style drawbar, the hammer-strap

must be removed to prevent damage to the IID guarding

and the IID telescoping members. [See Figure 1]

If this implement is attached to a tractor with an offset in

the drawbar, be certain it is in the down position to

prevent damage to the IID guarding and the IID

telescoping members. [See Figure 2]

-14-

Page 17

PREPARING FOR OPERA TION

Hydraulics

The spreader requires a 4 hose hook-up;

Connect the set of hydraulic hoses which operate the hydraulic endgate to a double acting valve on the

tractor.

Connect the set of hydraulic hoses which operate the spreader main aprons from the spreader to a

double acting valve on the tractor.

Securely mount the electrical speed control inside the tractor cab. Attach the pigtail to the tractor

electrical supply , either wired directly from the battery, or by connecting to the convenience plug.

Note: The Hydraulic Endgate must always be raised completely prior to activating the hydraulics

for the main apron.

Operate the tractor valve to fill the hydraulic lines and operate the cylinders. Add hydraulic fluid to the

tractor system, as required.

Before operation, run the machine slowly to make sure that the spreader is operating and lubricated

properly.

-15-

Page 18

OPERATION

EMERGENCY SHUTDOWN

If a foreign object becomes lodged in the beater area and shears the shear bolt, disengage the PTO.

Stop the tractor engine, remove the ignition key, and allow all mechanisms to stop before cleaning or

working on the spreader.

WARNING: Some photographs used in the following pages show guards or shields

removed for clarification. NEVER operate machine until these guards or shields are in

proper operating position.

LOADING

Begin loading the spreader at the front end and work toward the rear until loading is completed. Loading

this way permits the material to be spread uniformly . Loading front to rear is particularly important when

the spreader is loaded by a mechanical loader because this type of load requires more power to spread

than other loads.

When hauling extremely heavy materials with a large portion of dirt, it may be necessary to reduce the

load size to prevent excessive shear bolt breakage. Never dump material onto the beater. Do not use

extra sideboards. Do not overload the Manure Spreader. Overloading decreases the spreading

effectiveness. Do not load more than 15 inches above the beater.

WINTER OPERATION

In freezing weather, make cert ain that hydraulic t ailgate is not frozen to the sides or on the floor of the

spreader. Make sure the push gate is not frozen to the spreader floor or any lump s of manure are frozen

to the floor.

SPREADING

1. Engage the tractor PTO slowly. The beater is always in

the engaged position, therefore, engaging the tractor PTO

will automatically starts the beaters.

2. Raise the hydraulic endgate by engaging the tractor

hydraulics.

Note: The Hydraulic endgate

COMPLETELY prior to engaging the hydraulic main

apron.

3. Engage the tractor hydraulic lever into the detent position

to operate the hydraulic drive main aprons.

4. Control the variable speed main apron by using the

cab-mounted electric control.

5. When the spreader is almost empty, the box can be

cleaned out by disengaging the tractor PTO (which will stop

the beater), and increasing the apron speed.

MUST BE RAISED

6. When the spreader is completely empty , return the apron

speed indicator to the stop position and engage the tractor

hydraulics to close the hydraulic endgate.

-16-

Page 19

ADJUSTMENTS

APRON

Tighten the four adjusting bolts (1 on each side of

spreader and the two below the input shaft shield)

equally so that the apron slats run parallel with the

ends of the bed. The apron will be damaged if the

machine is operated with one end of the apron

slats running ahead of the opposite end.

Adjust the tightener bolts equally on both sides of

each apron until (three) slats are lifted off of the

apron return slides at the front and rear of the

spreader.

Front

Drive

Chain

Adjuster

FRONT DRIVE CHAIN

T o adjust the front drive chain, loosen the jam nut and turn the nut on the adjusting rod (located at the right

hand front side of spreader) clockwise. There should be 1/2” deflection at the center of the drive chain.

Over tightening or too loose of a chain will result in excessive wear on the bearing, chain and sprockets.

After adjusting, lock with the jam nut.

Apron Tightening Bolts

APRON DRIVE

Check the apron drive chain regularly. To adjust, loosen the nut on the tightener and slide the tightener

against the chain until there is approximately 1/8” deflection in the center of the chain opposite the

tightener.

A

Shields Removed for Clarity

-17-

Page 20

ADJUSTMENTS

PRIMARY & SECOND BEATER DRIVE CHAINS

Both chains are spring loaded. Check both chains regularly to

maintain space between the coils of the springs. Adjust the “I” bolt

to increase spring tension. If the space between the coils of the

spring is not able to be maintained by adjusting the I-bolt, a link

may have to be removed in the main aprons to maintain proper

adjustment.

NOTE: PERIODICALL Y LUBRICA TE ALL ROLLER CHAINS

WITH A LIGHT MACHINE OIL.

BE SURE ALL SHIELDS ARE SECURED INTO

PLACE PRIOR TO RE-STARTING MACHINE.

ADJUSTING WHEEL HUBS

T o adjust the wheel hubs, tighten the castellated nut on the spindle

to the point where there is no end-play and a slight drag on the

bearings. Replace the cotter key with a new one of the correct

size.

Shields Removed for Clarity

-18-

Page 21

SERVICE

SHEAR BOLT

Both beaters at the rear of the spreader are protected by one shear bolt located in the PTO at the front of

the spreader. Four spare shear bolts are provided. Shearing of shear bolts is normally due to large

frozen chunks of manure, foreign objects (rocks, chunks of wood, etc.) in the manure, running the apron

too fast when unloading long straw and pen-packed material, or STARTING THE SPREADER PTO

TOO QUICKLY WITH HIGH TRACTOR RPM’S. Always determine the reason for shearing bolt and

eliminate the problem before replacing the shear bolt. Always use the proper H&S shear bolts.

Shear

Bolt

Spare

Shear

Bolts

A

-19-

Page 22

SERVICE

BEATER

When replacing the beater paddles, the sharp edges of

the teeth must lead in the direction of beater travel. On the

right half of the beater the teeth must point to the right side

of the spreader. On the left half of the beater the teeth

must point to the left side of the spreader . Always use H&S

special grade 5 bolts, washers, and nuts when replacing

the tips, and torque to 60 foot lbs.

WHEEL BEARING LUBRICATION, CLEAN

& RE-PACK INSTRUCTIONS

Wheel hubs are equipped with a grease zerk for regular

maintenance. Annually disassemble and clean parts in

solvent. Pack the bearings with grease and reassemble

the bearings, tighten the castellated nut on the spindle to

the point where there is no end-play and a slight drag on

the bearings. Replace the cotter key with a new one of the

correct size, bend cotter pin over and re-install cap.

-20-

Page 23

OPTIONAL EQUIPMENT

REAR PAN

The rear pan is optional equipment on the 560 &

660 manure spreaders. The rear pan and

hydraulic endgate may be used together on both

models.

-21-

Page 24

LUBRICATION GUIDE

GENERAL INFORMATION

IMPORTANT: Catch and dispose of fluid per local waste disposal regulations whenever service is

performed on hydraulic components, valves, cylinders, hoses, etc.

GREASE FITTINGS

There are numerous grease fittings on the spreader. The operator should become familiar with all

lubrication points and establish a systematic routine to insure complete and quick lubrication of the

machine. If these are lubricated properly and often enough, it will prolong the life of the spreader.

(Grease every 10 hours, also before and after power washing.) Make certain that the grease fittings

are free of paint and dirt, force a high-quality grease into them until the grease comes out around the

shaft on the sleeve-type bearings. On the sealed ball bearings, grease should be added slowly until a

slight bead forms at the seals indicating the correct amount of lubricant. Wipe off excess grease to

prevent the accumulation of chaff and grit around the bearings.

PTO ASSEMBLY

Care must be taken to keep the male and female driving elements well lubricated and free sliding. Failure

to observe this precaution will result in excessive pressure being required to collapse or extend the

assembly while subject to operating torque. This excessive force may damage or displace the jackshaft

bearings. DO NOT lubricate the shield surfaces. The shield surfaces must be kept dry, as dirt

accumulation on them will quickly cause these units to bind and not rotate. Care should also be taken to

be certain that the rotating integral shields are not dented or damaged, as this also will result in

excessive force being applied against the jackshaft. Damaged shields also cause obvious difficulties

when installing the assembly. If at any time the shields do not turn freely, they should be checked to

determine the cause, and repaired or cleaned. To avoid damage to the main drive bearings, avoid

turning sharp corners while PTO is running.

Start and Stop PTO slowly to avoid damage to the drive line.

Constant angle applications must have a lube interval of 4 hours.

IMPORTANT

DAMAGE WILL OCCUR

IF 80° C.V . JOINT

ANGLE IS EXCEEDED

-22-

Page 25

LUBRICATION

GREASE ZERK LOCATION

A. (7) PTO Shaft

B. (2) Front jack shaft bearings.

C. (4) Side Shaft Support Bearings

D. (2) Endgate Pivot Points

E. (2) Each Axle Pivot (Remote Zerk)

F. (4) Each Beater End

G. (4) Each Front Idler S procket

H. (3) Apron Drive Shaft Support Bearings

I . (1) Bearing on Apron Reduction

NOTE: Shields removed in some pictures for clarity. DO NOT OPERATE WITH SHIELDS REMOVED.

F

G

H

Shields Removed for Clarity

DE

I

Shields Removed for Clarity

AB

C

(7 Total)

-23-

Page 26

LUBRICATION

GEAR BOX

Before using your new machine, check the oil in

the beater drive gearbox (A) and apron chain

reduction oil bath (B). Keep the gearbox filled to

the oil plug on the side of the gearbox with

#80-90 gear lube. Keep a sufficient amount of

#80-90 gear lube in the oil bath (B).

B

DRIVE CHAINS

Lubricate the drive chains with a light machine

oil. Keeping the chains aligned with the

sprockets will lengthen the life of the sprockets

and chain. Lubricate the chains often.

A

-24-

Page 27

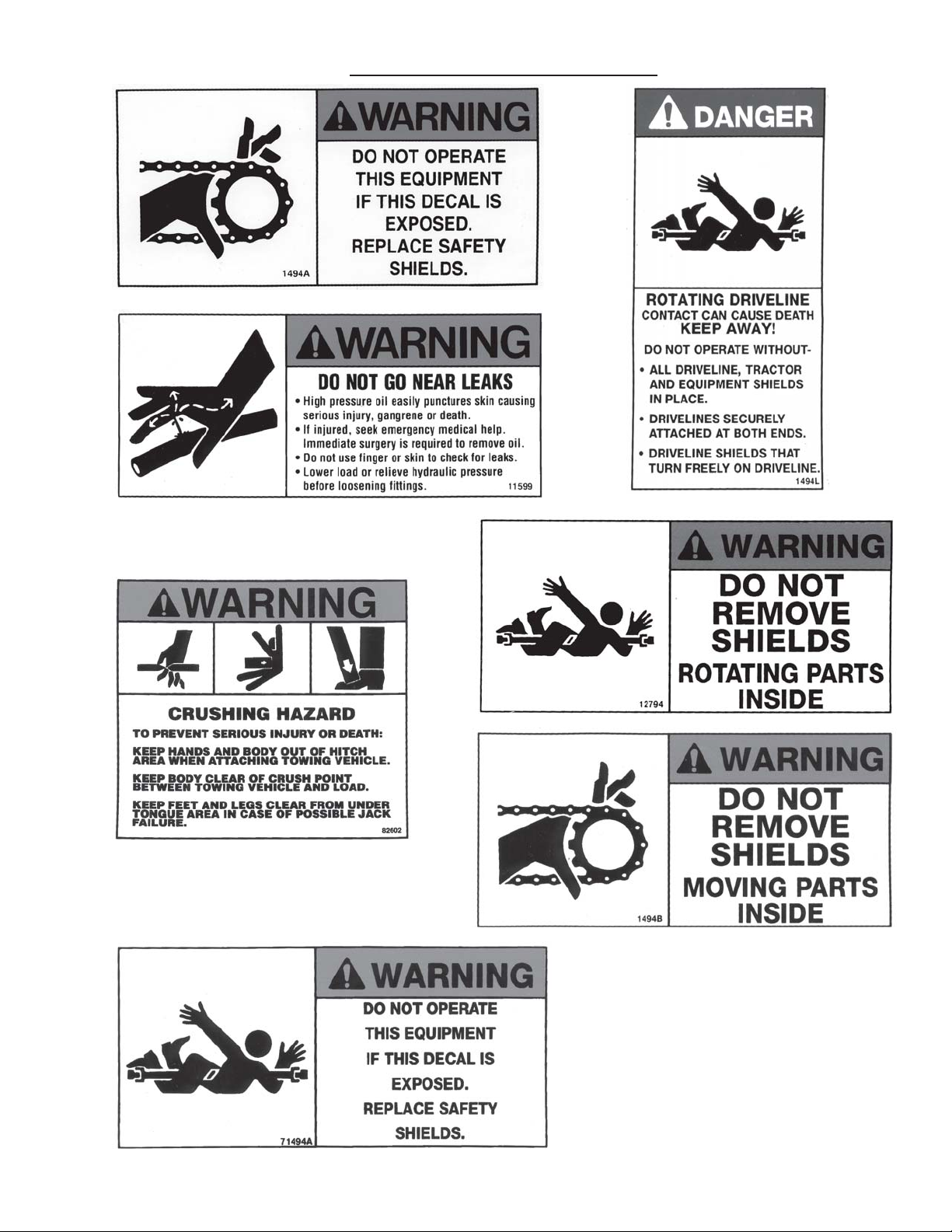

DECAL LOCATION

Your H&S Manure Spreader was manufactured with operator safety in mind. Located on the manure

spreader are various decals to aid in operation, and warn of danger or caution areas. Pay close attention

to all decals on your Manure Spreader.

DO NOT REMOVE ANY OF THESE DECALS. IF DECALS ARE LOST, DAMAGED, OR

IF MANURE SPREADER IS REP AINTED, REPLACE DECALS. REMEMBER: DECALS

ARE FOR YOUR PROTECTION AND INFORMA TION.

Listed below are the decals on your Manure Spreader. These decals may be ordered individually by

part number .

PART # QTY. DESCRIPTION

31 1 1 Patent Pending

1494A 3 Warning - Do Not Operate

1494B 2 Warning - Do Not Remove Shields

1494J 3 Warning - Do Not Work or Clear

1494K 3 Warning - Do Not Remove Shields

1494L 1 Danger - Rotating Driveline (Only on PTO)

3187 1 Speed Indicator

3494A 2 Remote Grease Zerk

66076 4 Grease Zerk Behind Shield Decal

7896B 1 Shear Bolts

8414 1 560 Logo Decal-Left

8415 1 560 Logo Decal-Right

8416 1 560 Logo Decal-Front

8417 1 660 Logo Decal-Left

8418 1 660 Logo Decal-Right

8419 1 660 Logo Decal-Front

8515 1 C.V. Joint Angle (Only on PTO)

9194A 3 Danger - No Step

9194B 1 Danger - Never Allow Riders

1 1599 1 Warning - S t ay Clear of Hydraulic Lines

12794 4 Warning - Do Not Operate

54033 1 Made In USA 3”

71188B 1 Jack Storage Position

71494A 4 Warning - Do Not Operate

72203A 1 Warning - Help Avoid Injury

82602 1 Warning - Crush Hazard

093020 24 Grease Zerk Decal (not shown)

093366 1 Keep Operators Manual Here

102196 1 Lubrication (CV PTO)

1 11593A 2 Danger - Stay Clear of Beater

111593C 2 Danger - Stay Clear of Endgate Arms

123002 2 Warning - Stay Clear of Endgate Arms

DCAMB 6 Amber Reflector

DCRED 2 Red Reflector

JD5922 2 Orange Non Reflector

-25-

Page 28

1 1593A

DCAMB

111593C

DECAL LOCATION

8415 560 RH

123002

8418 660 RH

1494J

TOP

OF

SHIELD

1494K

1494J

1494B

12794

9194A

102196

8515

3494A

BEHIND

TIRE

8416 560 Decal

8419 660 Decal

DCAMB

54033

DCAMB

9194B311

9194A

72203A

71 188B

1494B

1 1599

3187

1494L

82602

7896B

71494A

-26-

9194A

Page 29

DECAL LOCATION

71 188B

DCAMB

12794

71494A

BEHIND

SHIELD

DCAMB

8414 560 LH

8417 660 LH

12794

71494A

BEHIND

SHIELD

3494A

BEHIND

TIRE

111593C123002

DCAMB

1494K

12794

1 1593A

1494J

JD5922

DCAMB

JD5922

DCAMB

-27-

Page 30

DECAL LOCATION

1494A

093366

3187

1494A

1494A

-28-

Page 31

TROUBLE SHOOTING

WARNING:

MAKE SURE THAT THE TRACTOR IS SHUT OFF AND THE MANURE SPREADER

CAN NOT MOVE BEFORE SERVICING. MAINTENANCE AND REPAIR SERVICE

WORK TO BE PERFORMED BY A QUALIFIED SERVICE PERSON ONLY.

TROUBLE... POSSIBLE CAUSE... POSSIBLE REMEDY...

Beater Does Not Turn PTO Not Turning Engage Tractor PTO

PTO Shaft Shear Bolt Sheared Replace PTO Shaft Shear Bolt

Front Drive Chain Off, Replace or Repair Front Drive Chain

Broken, or Missing

Primary Beater Drive Chain Off, Replace or Repair Primary Beater

Broken, or Missing Drive Chain

Key Sheared or Missing on Beater Replace Sheared or Missing Key

Drive or Driven Sprocket

Top Beater Does Not Turn Secondary Beater Drive Chain Replace or Repair Secondary Beater

Off, Broken, or Missing Drive Chain

Apron Does Not Turn Tractor Hydraulics Not Engaged Engage Tractor Hydraulics

Apron Drive Chain Off, Broken, Replace or Repair Apron Drive

or Missing Chain

Insufficient T ractor Hydraulic Change Tractors

Pressure

-29-

Page 32

SERVICE NOTES

-30-

Page 33

SPECIFICATIONS

560 660

T op Flare W idth. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89-1/2”. . . . . . . . . . . . 89-1/2”

Inside Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 80”. . . . . . . . . . . . . . . .80”

Inside Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17’-5”. . . . . . . . . . . . . 17’-5”

Inside Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36” . . . . . . . . . . . . . . .49”

Overall Width w/S tandard T ruck Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . 130”. . . . . . . . . . . . . . 130”

Overall Width w/Optional 21.5L x 16.1 Tires. . . . . . . . . . . . . . . . . . . . .142-1/2”. . . . . . . . . . . . N/A

Spindle Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3”. . . . . . . . . . . . . . . . . 3”

Overall Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26’-10”. . . . . . . . . . . 26’-10”

Overall Loading Height (Top of Flare). . . . . . . . . . . . . . . . . . . . . . . . . . .63-3/8” . . . . . . . . . . . 73-3/4”

Overall Height w/Hyd. Endgate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78”*. . . . . . . . . . . . . . 83”

Diameter of Beater . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 29”. . . . . . . . . . . . . . . 29”

Diameter of Top Beater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20”. . . . . . . . . . . . . . .20”

Weight w/S tandard T ires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8140# . . . . . . . . . . . .9700#

Capacity (Old Rating). . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . 560 Bu . . . . . . . . . . . 660 Bu.

Capacity - Cu. Ft. S truck Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353. . . . . . . . . . . . . . 479

Rear Hydraulic Endgate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . St andard . . . . . . . . . St andard

Semi Liquid Rear Pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional . . . . . . . . . . Optional

Upper Beater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . St andard . . . . . . . . . St andard

V ariable S peed Hydraulic Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Standard . . . . . . . . . S tandard

Front Splash Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S t andard . . . . . . . . . Standard

PTO S peed. . . . . . . . . . . . . . . . . . . . . 1000 RPM St andard/540RPM Optional. . . . . . . . 1000 RPM

Hydraulic Cylinder on Hydraulic Endgate. . . . . . . . . . . . . . . . . . . . . . T wo. . . . . . . . . . . . . . . . T wo

* Overall Height is Height to Top of Upper Beater

* SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

Page 34

H&S MFGH&S MFG

H&S MFG

H&S MFGH&S MFG

products approved

for the

FEMAFEMA

FEMA

FEMAFEMA

..

CO CO

.

CO

..

CO CO

..

.

..

SEAL OF QSEAL OF Q

SEAL OF Q

SEAL OF QSEAL OF Q

UU

ALITYALITY

U

ALITY

UU

ALITYALITY

Loading...

Loading...