HRS Vortex User Manual

HARMONIC RESOLUTION SYSTEMS

VORTEX

Introduction

Thank you for purchasing the Harmonic Resolution Systems Vortex. When used properly, they will give you many years of superior

musical or video signal reproduction. The HRS Vortex is designed to significantly reduce the negative impact of air and structureborne vibration on your audio or video component performance. The Vortex is specifically designed for use with components that

have stiffer (plate and billet) metal chassis construction and yields targeted performance improvements when used in conjunction

with the HRS isolation bases. The HRS Vortex was designed specifically for used in combination with the HRS Isolation Bases.

Using the HRS Vortex in conjunction with another shelf that does not have the same capabilities as the HRS Isolation Bases could

limit the performance benefits achieved by the HRS Vortex. The HRS Vortex can be used in combination with the HRS Damping

Plates. While the Vortex significantly reduces bottom chassis noise, the Damping Plates will work to reduce top chassis noise if

present in the component.

Safety Instructions IMPORTANT!

Do not place the Vortex over ventilation holes of any electronic component. The ventilation holes will be blocked and the internal

operating temperature of the component may be increased.

Set Up Instructions

The HRS Vortex should be placed directly on the HRS Isolation Base supporting your component. HRS recommends using a pattern

of at least three HRS Vortexes to support a component. If the component is larger (over 100 sq inch), using four or five Vortexes

will often significantly improve performance. The HRS vortex was design to provide exceptional performance on a standard size

component using the 4 vortex set up. See the diagrams below for the recommended Vortex placements. HRS recommends that

every Vortex beyond the third unit is the model with adjustable height (example V150A, all adjustable Models have “A” at end of

model number). The bottom chassis (not the feet) of the component should be placed in direct contact with the HRS Vortex. The

point of the vortex is to be placed in contact with the HRS Isolation Base surface. Proper setup and contact with the chassis will

control bottom panel resonance and transfer energy from the chassis into the Vortex energy dissipation system. Moving the

Vortexes in small increments to find optimal performance for a specific component chassis based on listening tests is often

beneficial but the general guide shown below is excellent starting point. IF you have a drive, motor, or other noise source inside

the unit then placing the closest vortex directly under the noise source is often excellent starting location as well.

When setting up adjustable Vortexes HRS recommends placing them towards the front of the component for easy access. Use the

1/8” T-wrench (provided by HRS) to set the height of the adjustable Vortex model. Start with the adjustable Vortex just slightly

shorter than the non-adjustable model, then with the component placed on top of all the Vortexes, turn (using the wrench inserted

into one of the four catch holes on the adjustable center element) the adjustable vortex center element counter clockwise (viewed

from below vortex) to raise the Adjustable Vortex until in contacts the chassis and resist movement equally (this means there is

equal pressure on the chassis at all locations). You can easily check the pressure by conducting a simple test at each Vortex

location. Pushing on outside diameter of each vortex and observe the resistance to movement relative to the chassis. When there is

equal resistance to relative motion between the Vortex and the Chassis then there is the desired equal contact pressure at each

location.

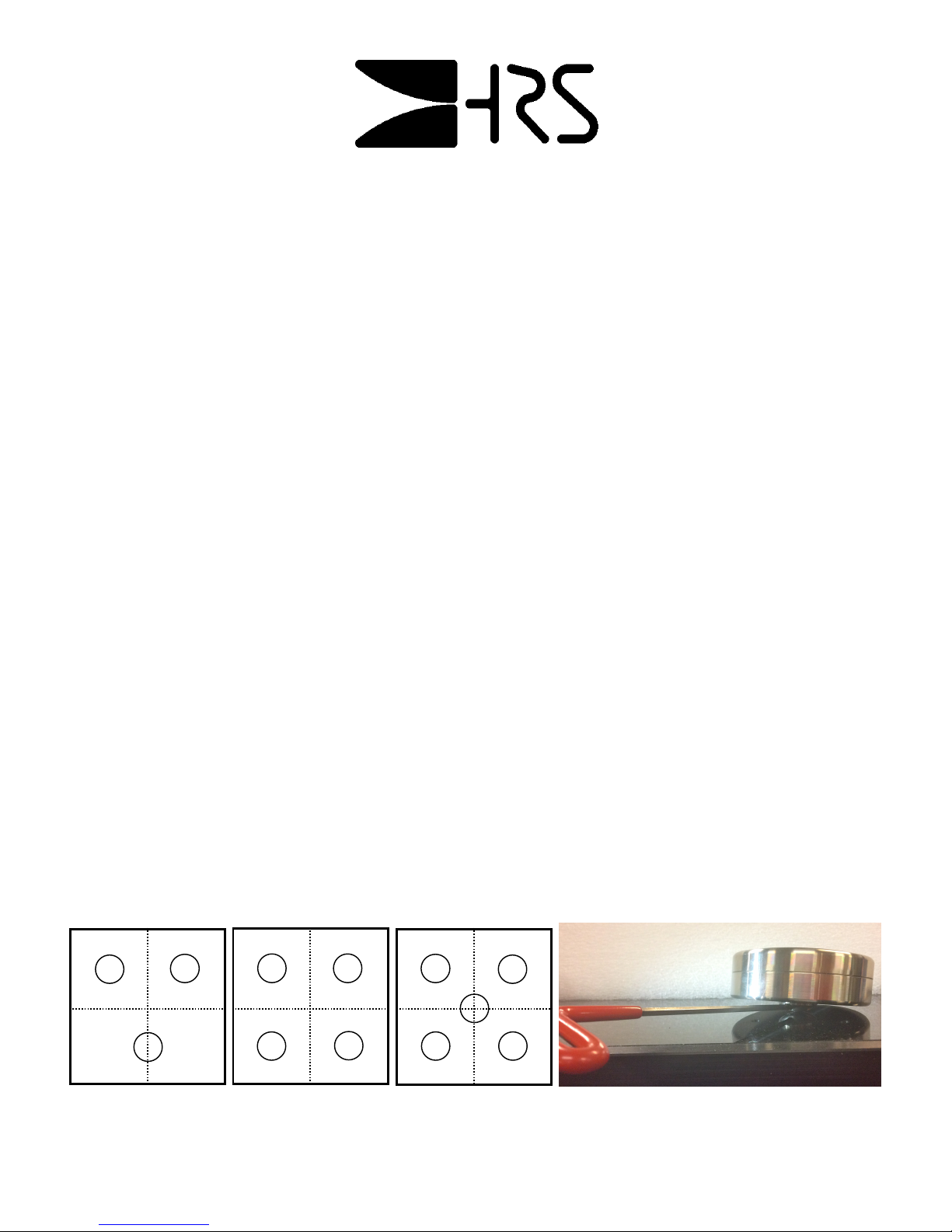

3 Vortexes (All Fixed) 4 Vortexes (1 Adjustable) 5 Vortexes (2 Adjustable) Adjusting the V-150A model using a 1/8” T-wrench

Adjustable

Adjustable

Adjustable

Care and Maintenance

The HRS Vortex is a very low maintenance item that will provide many years of trouble free performance by applying these basic

care instructions. Clean the HRS Vortex using a lint-free soft (non-abrasive) cloth. Use a damp cloth with water or mild soap if

required. Do not spray with or immerse in water.

Warnings!

Do not place objects with sharp or pointed feet directly on the Vortex as they may cause nicks, scratches or tear the custom HRS

materials used in the Vortex.

Do not use an abrasive cleaner or abrasive sponge to clean the Vortex, as they may scratch the metallic surface.

Do not wash with any solvent based cleaning solutions.

Warranty

Limited Five-Year Warranty

Harmonic Resolution Systems warrants to the purchaser that each Vortex is free of manufacturing defects for a period

of five (5) years from the date of purchase. This warranty is subject to the following conditions and limitations.

1. A copy of the original purchase receipt from a certified Harmonic Resolution Systems authorized retailer is used to

verify the date of original purchase and ownership.

2. This warranty is void and inapplicable if the product has been handled other than in accordance with the

instruction specified within this document, abuse or misused, damaged by accident or neglect or in being

transported, or the defect is due to the product being tampered with, modified or repaired by anyone other then

Harmonic Resolution Systems.

3. Warranty does not cover normal recommended care and maintenance.

4. Harmonic Resolution Systems shall not be responsible in any way for consequential or indirect damages or

liabilities resulting from the use of the product covered herein or resulting from any breach of this warranty or any

implied warranty relating to said product.

During this period, Harmonic Resolution Systems will repair or replace any defective components free of charge. A

Return Authorization Number (RA Number) is required before any product is returned to Harmonic Resolution Systems

for any reason. This number must be visible on the exterior of the shipping container(s) for Harmonic Resolution

Systems to accept the return. Units shipped to Harmonic Resolution Systems without a visible RA Number on the

exterior of the shipping container(s) are subject to be returned to the sender, freight collect.

Units to be repaired by Harmonic Resolution Systems must be sent shipping and insurance prepaid by the original

purchaser in the original packaging material. A returned product should be accompanied by a written description of the

defect. Repaired units will be returned by Harmonic Resolution System shipping and insurance prepaid.

All other warranties or conditions either written or implied are void.

(MADE IN USA)

All Harmonic Resolution Systems Inc. products are 100% Made In The United States of America by

skilled craftsmen using only the finest materials and our personal dedication to the highest

workmanship standards.

HARMONIC RESOLUTION SYSTEMS INC.

2495 Main Street, Suite 227

Buffalo, NY 14214

Telephone: 716-873-1437

Web: www.avisolation.com

E-mail: info@avisolation.com

Loading...

Loading...