HRS QR-P18 User manual

Rectangular, High-Pin-Count Rack/Panel

Insulation Displacement Connectors (IDC)

QR/P18 Series

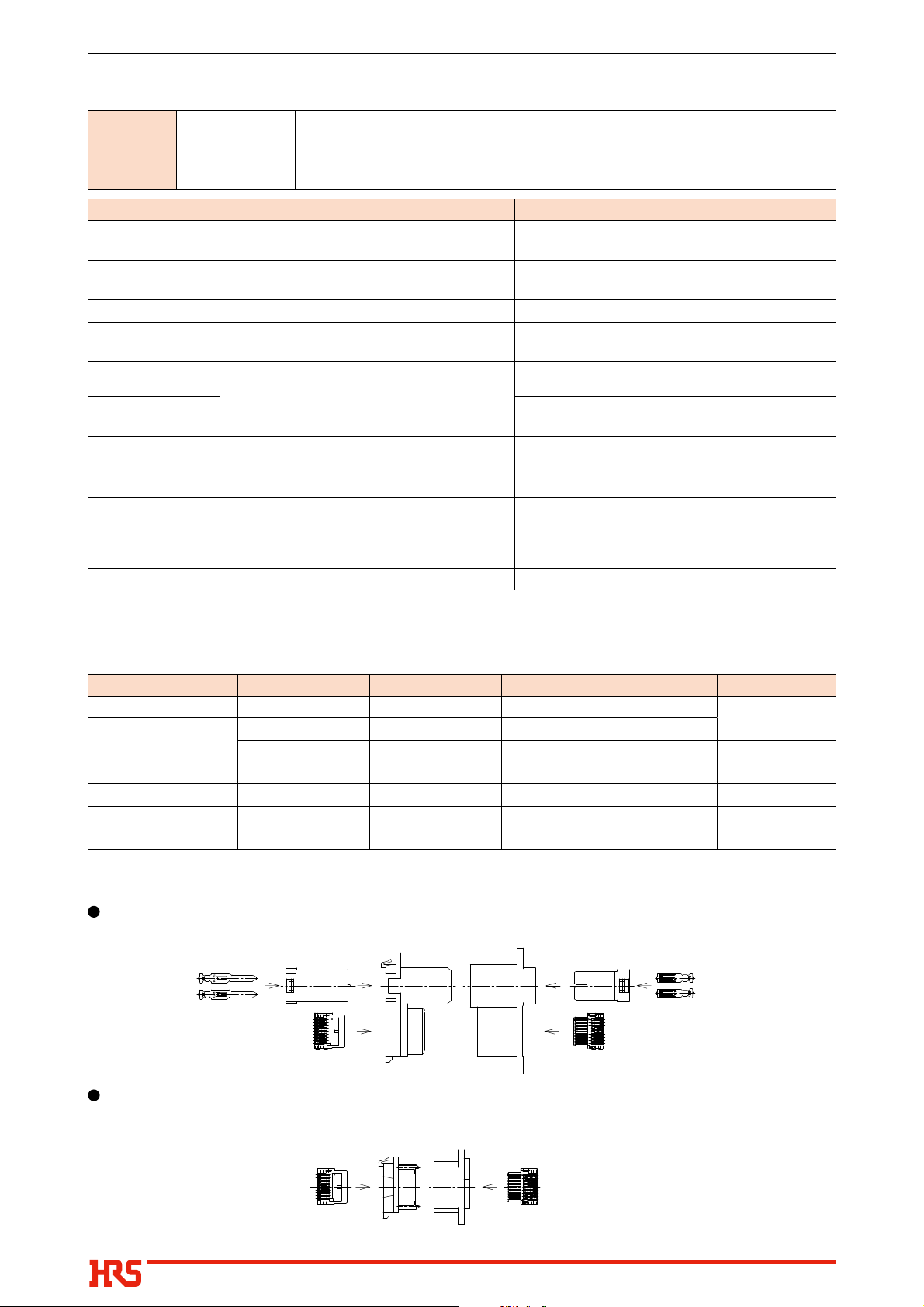

2.5Gbps Eye Diagram

Overview

The QR/P18 Series of miniature rack/panel connectors

2.5Gbps

AWG#28 2m

is designed for the complete segmentation of the

structure of the external holder/terminal units of the

well-received QR/P Series of plug-in rectangular rack/

panel connectors; furthermore, the subsequent

insertion of the harnessed terminal unit affords a more

efficient harness mounting task. These connectors are

configured with 12, 18, or 24 pos.(IDC) in the signal

line, and 4 pos.(crimp) in the power line.

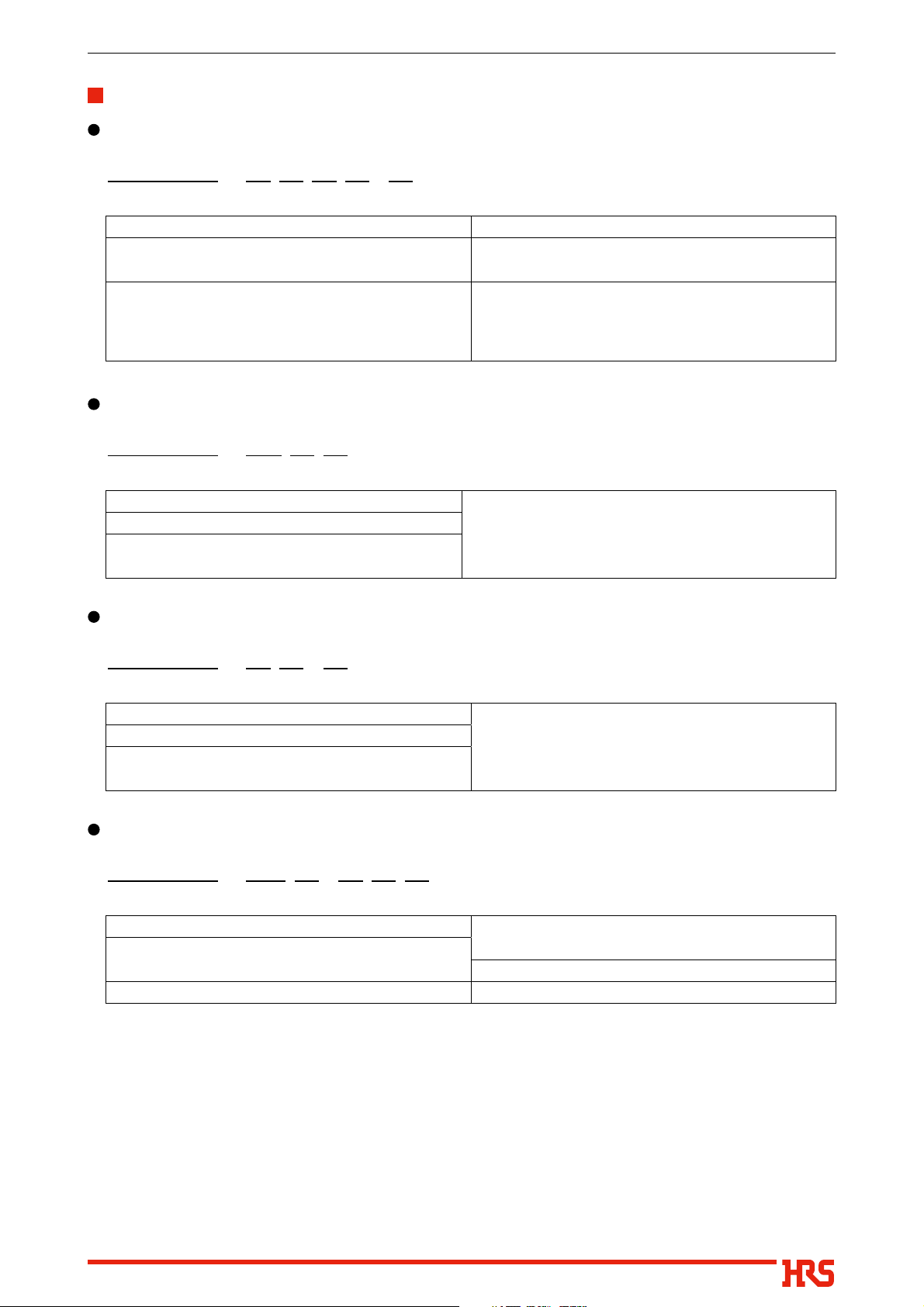

Power supply contact

female unit

Features

1. Completely separated structure of the

external holder/terminal unit

In order to improve the harness procedures, the

connectors are designed for the complete

segmentation of the external holder and the signal/

power supply unit, and inserting the harnessed

contacts aims to improve the workability of the power

supply/signal line harness as well as the mounting to

the set.

2. Signal unit

The signal unit uses the highly reliable insulation

displacement connection method. (The wire is AWG

#26 and the insulation outter diameter is 0.88mm.)

The insulation displacement procedure can now be

used by attaching a special applicator to a

Apr.1.2021Copyright2021HIROSEELECTRICCO.,LTD.AllRightsReserved.

commercially available automatic insulation

displacement machine, or a manual press tool can

also be selected.

3. Power supply

The power supply terminals permit the use of a

crimp harness using wire of AWG#16 to 18 (and

insulation outside diameter of 2.1 to 2.2mm), and

can accommodate a maximum of 12 A.

4. Sequential mating structure

Two sequential contacts in the signal male unit and

one sequential contact in the power supply female unit

are provided for safety operation.

5. Panel installation

Installation to a panel uses a single-action method

on the anchored side and a floating screw structure

on the floating side which permits smooth insertion

and disconnection without forcing.

Power supply

female contacts

External holder

Signal contact

male unit

Scale

X : 100psec/div

Y : 100V/div

Power supply contact male unit

Power supply

male contacts

Signal contact

female unit

Panel

Fig.1

Fig.2

In cases where the application will demand a high level of reliability, such as automotive,

please contact a company representative for further information.

2021.2e

1

QR/P18 Series●Rectangular, High-Pin-Count Rack/Panel Insulation Displacement Connectors (IDC)

Product Specifi cations

■

Voltage rating

Ratings

Current rating

Item Specifi cation Conditions

Contact resistance

1.

Insulation resistance

2.

Withstanding Voltage

3.

4. Durability

(mating / un-mating)

5. Vibration

6. Shock

7. Temperature cycle

8. Humidity

(Steady state)

9. Salt mist No HEAVY corrosions. 5% salt water solution for 48 hours

Note1 : Includes temperature rise caused by current fl ow.

Note2 : Excludes wire conductor resistance.

50mø max. (Signal contacts) (Note 2)

10mø max. (Power contacts) (Note 2)

1000Mø min. (Signal contacts)

5000Mø min. (Power contacts)

No fl ashover or insulation breakdown. 500V AC / 1 minute

Contact resistance : 70mø max. (Signal contacts)

20mø max. (Power contacts)

No electrical discontinuity of 10µs or more.

No damage, cracks or parts dislocation.

Contact resistance : 70mø max. (Signal contacts)

20mø max. (Power contacts)

No damage, cracks or parts dislocation.

Insulation resistance:

100Mø min. (Signal contacts, state)

3000Mø min. (Power contacts, state)

No damage, cracks or parts dislocation.

125V AC (Signal contacts)

300V AC (Power contacts)

1A (Signal contacts)

12A (Power contacts)

Operating temperature range

100mA MAX (DC or 1000Hz)

500V DC

3000 cycles

Frequency: 10 to 55 Hz, single amplitude of 0.75mm,

2 hours in each of the 3 axis.

Acceleration of 490 m/s2, 11 ms duration, sine halfwave waveform, 3 cycles in each of the 3 axis

Temperature : -55ç ➝ +5 to +35ç ➝ +105ç ➝ +5ç to +35ç

Time : 30 ➝ 5 ➝ 30 ➝ 5 (Minutes)

5 cycles

96 hours at 40ç and RH 90% to 95%

-40°C to +105°C

(Note 1)

Materials

■

Product Components Material Finish Remarks

External holder Insulator PBT

Insulator PA

Signal contact unit

Power contact unit Insulator PBT

Power supply contacts

Function Diagram

■

Apr.1.2021Copyright2021HIROSEELECTRICCO.,LTD.AllRightsReserved.

Power supply/signal combination type

QR/P17-PCA-*11(70) QR/P17-SCA-*11(70)

Female contacts

Male contacts

Female contacts

Male contacts

QR/P18-4P-C QR/P18-4S-C

Phosphor bronze Gold plated

Copper alloy Gold plated + Tin plated

QR/P18-S*4P-* QR/P18-P*4S

Signal type

−−−−−

−−−−−

−−−−−

QR/P18-*P*QR/P18-*S*

UL94V-0

−−−−−

−−−−−

UL94V-0

−−−−−

−−−−−

QR/P18-P*QR/P18-S*-*

QR/P18-*S*

QR/P18-*P*

2

QR/P18 Series●Rectangular, High-Pin-Count Rack/Panel Insulation Displacement Connectors (IDC)

Product Number Structure

External holder

QR / P18 - S A 4 P - A

❶ ❷❸❹❺ ❻

Series name

q

Signal contact type S : Female contact

w

P : Male contact

Number of signal contact of external holder

e

A : 12 pos. (Contact pitch 1.5mm)

B : 18 pos. (Contact pitch 1.5mm)

C : 24 pos. (Contact pitch 1.5mm)

Signal Unit

QR / P18 - 12 S A

❶❷❸❹

Series name

q

Number of signal contact

w

Signal contact type S : Female contact

e

P : Male contact

Power Unit

QR / P18 - 4 P - C

❶❷❸❹

Number of power contact

r

Power contact type S : Female contact

t

P : Male contact

Applicable panel thickness

y

A : 2mm

B : 1.5mm

Signal unit size

r

A : 12 pos. (Contact pitch 1.5mm)

B : 18 pos. (Contact pitch 1.5mm)

C : 24 pos. (Contact pitch 1.5mm)

Series name

q

Number of power contact

w

Power contact type S : Female contact

e

P : Male contact

Connector type C : Crimp housing

r

Power contact

QR / P17 - PC A - 1 1 1

❶❷❸❹❺❻

Apr.1.2021Copyright2021HIROSEELECTRICCO.,LTD.AllRightsReserved.

Series name

q

Power contact type PC : Male crimp contact

w

SC : Female crimp contact

Applicable wire style A : UL1015

e

Packaging 1 : Pack packaging

r

2 : Reel packaging

Applicable wire 1 : AWG#16 to 18

t

Contact plating 1 : Gold plated

y

3

Loading...

Loading...