HRS MXR User Manual

HARMONIC RESOLUTION SYSTEMS

MXR AUDIO STAND

The Foundation of Great System Performance

Introduction

Thank you for purchasing the Harmonic Resolution Systems MXR Audio Stand.

When used properly, it will give you many years of superior musical or video

signal reproduction.

The MXR Audio Stand significantly reduces the negative impact of structureborne noise on your audio or video component performance. Decades of

engineering experience, custom material development, and listening tests are

incorporated into the design of the MXR Audio Stand. This reference level

product from Harmonic Resolution Systems, Inc. will enable your audio/video

source and amplification components to achieve peak performance.

The MXR Audio Stand, which includes the HRS Isolation Base as the primary

shelf system, is a perfect match for the HRS Damping Plates and Nimbus

Products. While the MXR Audio Stand and Isolation Bases work to significantly

reduce structure-borne noise, the HRS Damping Plates and Nimbus Products

significantly reduce the harmful effects of air-borne noise and structural

resonance on your components.

Please read this manual completely prior to assembly and use of your MXR Audio

Stand. It contains instructions necessary for proper assembly, use, and care of

this system. Proper care of your MXR Audio Stand will ensure optimum

performance and an aesthetically appealing.

Safety Instructions

IMPORTANT WARNINGS!

Do not place any tall objects on the top shelf of the MXR Audio Stand. A tall

object is any object with a height that is greater than the length of the isolation

base. A tall object is also any object that has a height greater than its own width

or length. Tall objects must not be placed on top of the MXR Audio Stand for any

reason. The object may become unstable and tip over causing damage to the

component, adjacent objects, or injury to people.

Never lift or move the MXR Audio Stand with the shelves (M3 Isolation Bases)

installed. You should always move the MXR Audio Stand frame to its final

location prior to loading shelves and components. Moving the MXR Audio Stand

frame with the isolation bases installed (with or without equipment) can

permanently damage the systems adjustable feet or cause the shelves to fall out of

the rack resulting in potential damage or injury. Always take the time to remove

all of the equipment and shelves to relocate the MXR Audio Stand.

Do not lift the M3 Isolation Base (shelf) by the inner plate or the external feet

attached to the bottom of the rectangular frame. Always lift or move the isolation

base with the inner plate facing up and the external support feet facing down

(same orientation as when used to support your component). Always follow

these handling instructions to prevent personal injury or damage to the unit.

Set-Up Instructions

The MXR Audio Stand consists of a frame structure and the isolation bases that

support each component. The standard three and four shelf frame structures

come in three boxes. Each box will be marked with the model number starting

with MXR. There are two longer boxes that contain the left and right vertical

panels. The third box contains the panel brace system, the isolation base support

brackets, the adjustable rack feet, screws, and wrenches required to complete the

assembly process. The only tools not provided for assembly are:

1. Adjustable wrench - to lock the feet after leveling the frame

2. Philips Head Screwdriver - for unpacking crates (electric drive

recommended)

3. Level - 24" minimum length or equivalent

Work Surface - Prior to unpacking any material, locate a very strong and very

stable work surface (capable of supporting 250 lb. load) or area on the floor that

will give you a very soft scratch resistant work area that is at least three feet by

six feet in size. The more space you have the better, as it will give you room to

move around the frame to complete assembly. It is important that the area be free

of all dirt, screws or small pebbles, and that it is covered with a clean soft

protective blanket (min size 24" x 45") that will prevent damage to the relatively

soft external skin of the vertical panels.

Unpacking Assembly Hardware - Remove all the contents from the smaller

cardboard box containing the hardware required to assemble the frame. Place

them on a table adjacent to your selected work surface and remove all the

wrapping material. Be careful not to drop or allow the anodized aluminum parts

to contact each other as they may scratch the surface. Do not stack the parts on

top of each other once they are removed from the protective packaging material.

Unpacking Vertical Panels - Unpack the vertical panel by removing the top

surface of the crate (see Photo 1). This surface will be marked for clarity and you

will need a Philips head screwdriver (manual or electric) to remove the cover.

Photo 1 Photo 2

Lift the panel out of the crate by lifting vertically at each end (see Photo 2). Move

the panel and packing material directly to your damage free work surface. Once

at the work surface, remove and save the two fitted foam end support cushions.

Then open the protective paper covering the panel to expose the unit for

assembly. Saving all the packing material is critical to secure transportation of

the frame in the future. Shipping or moving the panel by any other means may

expose the unit to permanent damage.

Installation of Adjustable Foot System - Unwrap two of the four feet supplied

with the unit. Remove the screw and washer from each of the feet (see Photo 3).

Photo 3

Hands tighten the nut all the way down on each individual foot. Then back the

nut off one half rotation (see Photo 4).

Photo 4

Place the supplied washer on top of the nut and then screw each of the feet into

the threaded inserts on the bottom of the first vertical panel (see Photo 5 & 6).

The feet should be threaded into the insert until the washer/nut come in contact

with the vertical panel threaded insert. (This ensures maximum engagement

between the insert and the foot). Repeat this procedure and install the second foot

to the bottom of the first vertical panel.

Photo 5 Photo 6

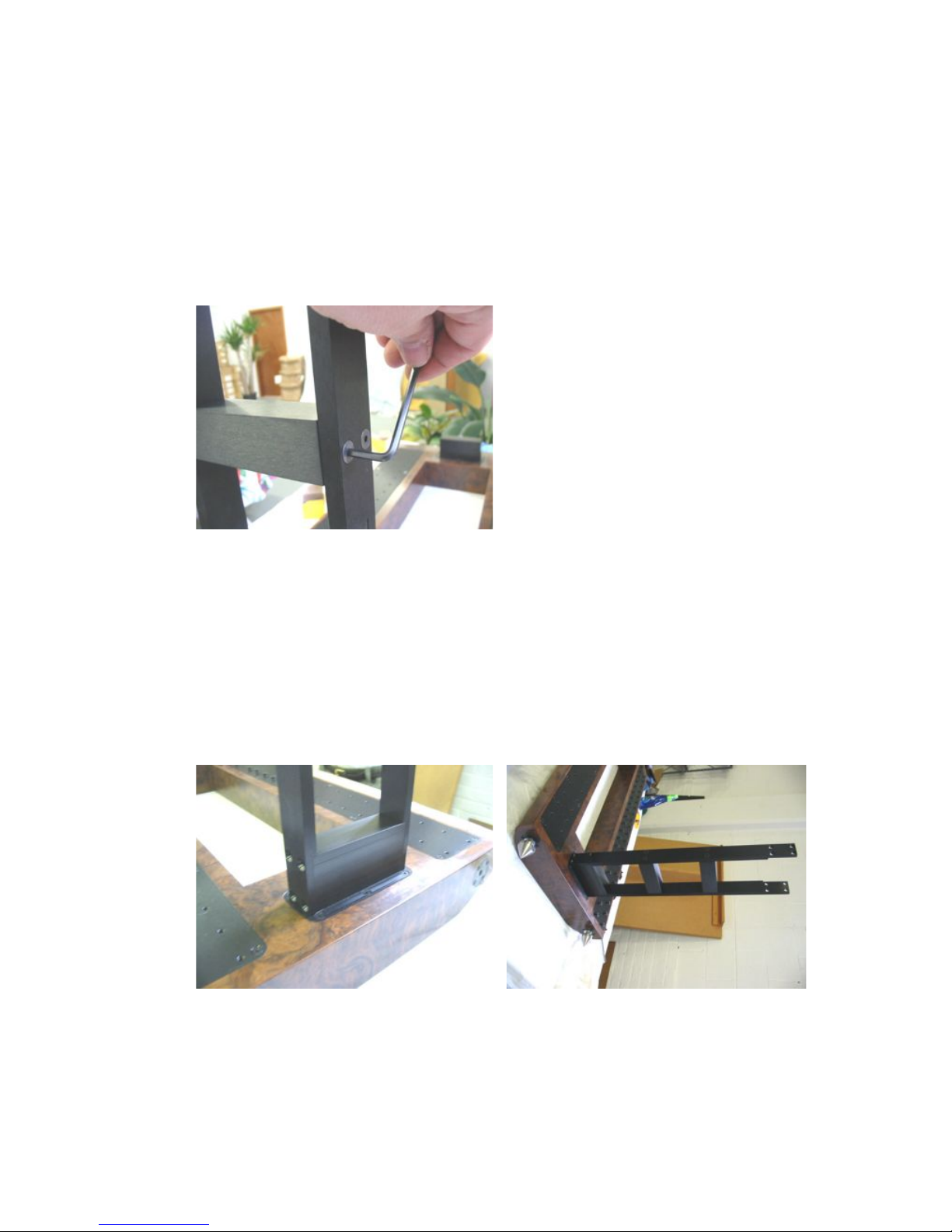

Panel Brace Installation - You are now ready to attach the primary brace system

to the panel. There are two braces that hold the two end panels together to form

the primary MXR Frame Structure. There are two rectangular spacers attached

to each brace system when it is shipped that need to be loosened to complete

assembly. Simply take the T-wrench or Allen wrench supplied with the MXR and

loosen (counter clockwise) each of the eight nuts on the brace assembly (see

Photo 7). You do not want to have lots of play in the assembly, you just want to

break the torque on each nut so that the brace can be properly located.

Photo 7

The HRS logo is machined into the center of each brace. Locate the HRS logo on

the brace and orient it so that when the stand is upright on its feet, the logo will

be in correct orientation. There are two steps at each end of the brace sub

assembly that fit precisely over the attachment block on the panel. Slowly lower

the brace assembly onto the block until the steps in the brace contact the block

(see Photo 8 and Photo 9). Attach at least one of the 1/4-20 x 3/4" screws to the

brace assembly (see Photo 10) prior to removing your hand from the assembly to

insure it stays in place. It is very important that the 3/4" long screws are used at

this location to obtain proper thread engagement.

Photo 8 Photo 9

Loading...

Loading...