Page 1

Operating manual

and service instructions

NEW

recumbent

technology

2011

HPVelotechnik

August 2011

Page 2

General safety instructions

Intended use – 3

The first miles – 3

Legal requirements – 3

Load capacity – 4

Carrying luggage – 4

Transport in the car – 5

Do not take kids with you – 5

Trailers – 5

Added parts and accessories – 5

Fairings – 5

Replacement of parts – 6

No alteration of parts – 6

Final assembly – 6

Screws and bolts – 6

Adjusting your new bike

Adjusting the leg length – 7

Adjusting the seat position – 11

Adjusting the handlebars – 13

Adjusting the suspension – 16

Handling instructions

Learning the new riding technique – 24

Wear protective clothing – 25

Use clipless pedals – 25

Slowly increase the strain – 26

Do not ride freehand – 26

How to ride correctly and safely – 26

Quick release levers, Seat – 27

Brakes – 28

Gear system – 30

Light system – 31

Prop stand – 32

Content

-

HP

Velotechnik

Maintenance and care

Wear and tear – 33

Brakes – 33

Gear system – 35

Chain – 36

Chain tubes – 38

Chain roller – 40

Suspension fork – 41

Rear suspension element – 46

Swing arm pivot – 48

Seat cushion – 49

Water bottle cage – 50

Mudguards – 51

Wheels – 51

Cleaning and conservation – 52

Storing the bicycle – 54

Screws and bolts – 54

Tightening torques for screws – 55

Warranty Pass

Warranty – 56

Warranty Pass – 57

Service Plan – 58

Proofs of service – 62

Revision August 2011. For latest product information, please check out our website at

www.hpvelotechnik.com. All trademarks belong to their respective owners.

HP V

ELOTECHNIK

Bleichstrasse 5

65830 Kriftel / Germany

Tel. ++49 (0) 61 92 - 97 99 2-0

Fax ++49 (0) 61 92 - 91 02 18

Page 3

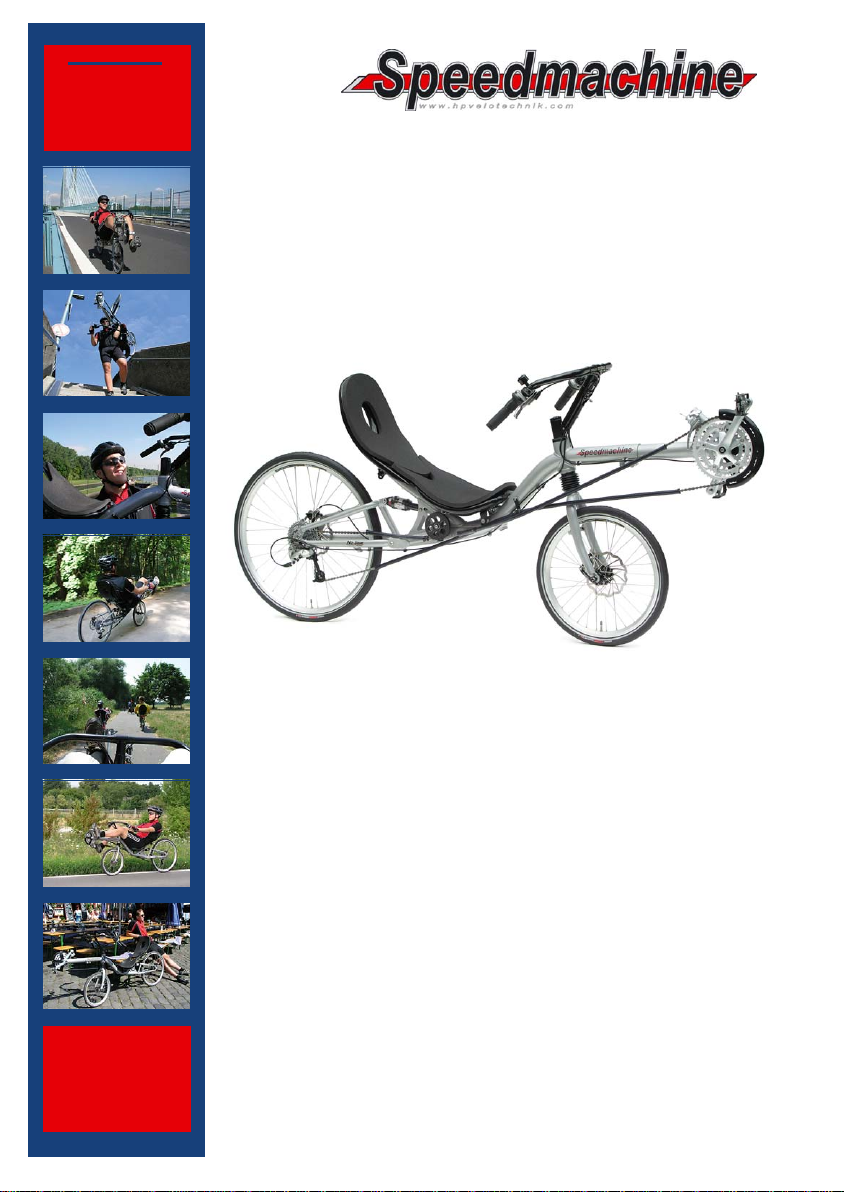

thank you for buying a recumbent bike designed by

HP VELOTECHNIK and congratulations on the purchase of your

new Speedmachine! With the Speedmachine, a high-quality

sports bike, you will enjoy many years of exhilarating riding

pleasure.

Your safety and your satisfaction are our main concern. On the

following pages, this manual will inform you about important

safety issues as well as maintenance and care instructions.

Even if you have many years of experience with bicycles please

do take your time to read this manual carefully.Your recumbent

bike is designed with the latest bicycle technology by

HP V

ELOTECHNIK that partly needs special treatment and care.

In this manual you will find detailed instructions on how to

optimize your Speedmachine to meet your demands and riding

style as well as your size and weight. In addition to this, we have

put together a collection of information on care and maintenance as well as special technical advice from our engineers.

Important: Please send us the attached warranty registration

form for your extended warranty (see page 56.)

This guide helps you to keep your Speedmachine in perfect

condition so that you will always have maximum fun, comfort

and safety.

Enjoy yourselves and have a great ride!

Paul J.W. Hollants, Dipl.-Ing. Daniel Pulvermüller

and the HP V

ELOTECHNIK team

1

HP

Velotechnik

Introduction

Dear customer,

Page 4

The manuals of component manufacturers

such as the brake manufacturer, the gear system manufacturer, and the pedal manufacturer

also belong to this manual.They give detailed

information on operating and maintaining

these specific parts. Please read the manuals of

the part manufacturers as carefully as this

manual. Please provide this manual to any other user of your recumbent before using it.

The maintenance and adjustment of this recumbent partly requires special tools and

skills. Do only works within your limits and,

for the purpose of your own safety, do not go

beyond. Should you be uncertain at any point,

get in contact with your local dealer.

The instructions in this manual apply only to a

completely assembled Speedmachine with

standard parts from the series production of

HP VELOTECHNIK.

On special demand HP V

ELOTECHNIK delivers

frame kits to put a specialist dealer in a position to assemble a bicycle individually. In this

case the manuals on the operation and maintenance of the parts only represent a guideline,

please read every manual of every part manufacturer separately.The specialist dealer is responsible for the expert assembly, please contact him for detailed information! A bicycle

that has been assembled from a frame kit must

always be tested and approved by a qualified

bicycle mechanic before your first ride.

Introduction

2

HP

Velotechnik

Caution! The texts in the grey boxes are

particularly important for your safety.Texts

that begin with "Danger!" mark an immediate danger for your life and your health.

Please do read them carefully.

Page 5

General safety instructions

Legal requirements

When you ride your bike on the public road it

must comply with national legislation and

guidelines.These will vary from country to

country.

In general, there are minimum standards for

brakes, reflectors and lighting systems, as well

as usually a general duty to ensure that your

vehicle is in roadworthy safe condition.There

will also be a duty to ride in a safe and responsible manner. If you ride your HP V

ELOTECHNIK

bike in traffic you should be sure to observe

all the applicable laws and regulations.

In most countries, including Germany and the

UK, two independent braking systems are required. Do not ride with only one brake working!

Please contact your local dealer to find out

about your legal obligations.

General safety instructions

Intended use

Your Speedmachine is a bicycle for the use on

streets and surfaced roads.

This bicycle is not designed for the use in racing and off-road riding, for jumping or acrobatics, and you must not ride across curbs, stairs,

etc.

Damage through inappropriate use, assembly

errors, accidents or similar activities and wilful

damage results in the loss of any warranty.

The intended use also includes the precise observation of the prescribed usage and maintenance regulations and instructions.

The first miles

The first 300 km (186 miles) are an important

phase in which you break in the bicycle.

During the first use of a new bicycle the

screws may bed in and come loose. Cables and

spokes may stretch. Bearings may show play.

Please be very attentive during that period.

After 300 km or after two months at the latest you will have to take your bicycle to a bicycle mechanic for the first service. Please

record this first service and the tasks performed in the warranty pass on page 57.This

first service is the prerequisite for further use

of the bicycle and for your warranty claims.

Page 6

4

HP

Velotechnik

Load capacity

The maximum load (rider + luggage) is 130 kg

(286 lbs).The maximum total weight (bicycle +

rider + luggage) is 150 kg (330 lbs).The lower

limit is valid. It is important to adjust the

spring stiffness of the suspension according to

the load, see the chapter about adjusting the

suspension in this manual, page 16.

With an attached trailer, the maximum total

weight must not be higher than 150 kg

(330 lbs).

Carrying luggage

Luggage transport is only allowed with the

special rear racks or lowrider racks offered by

HP Velotechnik .The maximum load of the

rear rack is 25 kg (57 lbs), the maximum load

of the lowrider rack is 25 kg (57 lbs).

When a rear rack is mounted you have to

make sure that when the rear suspension is

fully compressed there is at least a 1 cm (app.

1

/2") distance between the rear tire (or mudguard) and the rear rack. In order to adjust

this distance you can clip spacers onto the piston rod of the spring at the rear end between

the spring retention disc and the bottom-out

elastomer.These spacers are available from

your local HP Velotechnik dealer.You will find

further information in the chapter on suspension adjustment on page 20.

Additional loading can influence the handling of

your bike considerably. If you plan on riding

with heavy luggage we advise you to make a

test ride on a street with no traffic to adjust

to the new situation.

The load should be placed as close to the

body of the rider as possible, since this leads

to more stable performance.

You can also improve the handling of the bike

by positioning the center of gravity of the luggage as low as possible, so pack heavy items in

the bottom of your panniers and hang them

on the lowrider racks.

Be careful that your luggage on the rack is

safely stored. Bags must be tightly fastened to

the rack so they can not move. In no case may

loose parts like straps or belts touch the

wheels, the derailleur or the suspension.

We recommend waterproof bicycle bags by

the German manufacturer O

RTLIEB.You can buy

them with extra large hooks matching the

oversized tubes of the rack.You can also refit

those largs hooks later.

Take care that your luggage does not cover

the lighting system and the reflectors of your

bicycle and that they stay fully functional.

In case you want to park your bicycle take

care to lean it on a wall or any other solid object.With the kickstand alone it is not possible

to safely park a bicycle loaded with luggage, it

could fall down and be damaged.

General Safety Instructions

Page 7

General safety instructions

5

HP

Velotechnik

Transport in the car

The best way of transporting your bicycle is

inside the car.Take care that it does not lie on

the derailleur.

If you want to transport it outside the car we

recommend a roof-rack or a rear carrier.Take

care to fasten your bicycle at the frame only.

Please remove any part that could come loose

during transport (seat cushion, water bottles,

luggage bags, pumps, pennants, etc.).

Do not take kids with you

The Speedmachine is not designed for the

transport of children.You are not allowed to

mount a child's seat. It is only allowed to

transport children in a trailer that has been

specially designed for that purpose.

Trailers

You are allowed to use trailers up to 40 kg

(88 lbs) with the Speedmachine.We recommend to assemble it with the W

EBER-coupling

Type E.Always check that the suspension and

the trailer still work properly after you have

mounted the trailer.Take care that the trailer

does not damage the frame in case the bicycle

falls over.

Added parts and accessories

Additional accessories may impair the function

of your Speedmachine.We advise you to generally ask your dealer before you mount any

special parts or accessories to your bicycle.

Take care that the handlebar and the suspension always stay mobile.You may not add any

parts to the handlebar or the seat that might

endanger the rider through sharp edged or

pointed shapes while steering, getting on and

off the bike or bumping against something.

Before you purchase a bell or a lighting system

make sure that these accessories conform to

your national laws and regulations.

Fairings

We advise you against using front fairings for

the Speedmachine, since the high position of

the bottom bracket impairs the vision over a

fairing to the front.

Please take into account that any fairing makes

the bicycle more prone to crosswind influences. In strong wind or gusts of wind unsafe

situations may occur, please take off the fairing

in such weather conditions before the ride.

Caution! Do not fasten your bicycle at the

handlebar or, with disassembled wheels, at

the dropouts.The wind causes violent forces

that can stress the parts and therefore may

cause damage. Such a damage may not be

noticed immediately.

Caution! Mounting additional parts or accessories is at your own risk. It is important

that you carefully read the installation guide

of the manufacturer.Additions to the handlebar like fairings, handlebar fittings, bottle

holders etc. may impair your safety due to

additional loading or clips with sharp edges.

Page 8

6

HP

Velotechnik

Replacement of parts

The replacement of parts relevant for safety

(especially brakes, lighting system, stem, handlebar, fork, drive train, suspension elements)

should only be done with original parts by a

bicycle mechanic, since it requires a certain degree of skill, suitable tools and mechanical aptitude.

Any technical change you perform on your

own is at your own risk!

No alteration of parts

Final assembly

Your bike has been delivered to your specialist

dealer only partly assembled.

Your dealer has carefully finished the assembly,

perhaps altered the specification of your bike

to meet your special requirements and performed a test ride. Please make sure that this

pre-delivery service is recorded in the warranty document at the end of this manual.

All screws must be checked and tightened, especially on the handlebar, stem, fork, swing arm

pivot and wheels. Please follow the tightening

torque settings listed in the table on page 55.

Rear derailleur and brakes must be checked

and adjusted. Please follow the instructions in

the manuals of the parts manufacturers that

come with this manual.

Screws and bolts

General Safety Instructions

Danger! If any part is deformed (e.g. due to

an accident or overload), especially frame,

fork, handlebar, seat mounts, pedals, cranks

and brakes, it is not allowed to use it any

further or repair it. Do not try to straighten

bent parts.You must replace them for your

own safety. If you do not replace a damaged

part it can result in a total failure of the part

and you may be seriously injured!

Caution! You are not allowed to perform

any work on the parts of the bicycle, especially frame, fork, handlebar and seat, which

might endanger their solidity.

These works include drilling holes, welding,

brazing, painting methods that add heat or

any other chemical treatment. If any of these

works is done improperly it may result in a

loss of strength through direct damage or

increased susceptibility to corrosion.

Caution! Screws must be tightened with

prescribed tightening torque. In this manual

tightening torques are given in Nm

(Newtonmeter).Always use a torque

wrench wherever a torque setting is given in

this manual. Never rely on "feel". Screws

tightened too much or not enough can

break, which can lead to dangerous accidents. In case you don't own a torque

wrench have your bicycle mechanic do the

respective work.You will find a table with

the prescribed torque settings on page 55 in

this manual.

Page 9

Adjusting your new bike

7

HP

Velotechnik

Before the first ride: adjusting your

new Speedmachine

The seating position is essential for your riding

comfort, well-being and efficient cycling on the

Speedmachine.Therefore you should adjust the

frame, seat, handlebar and suspension to your

individual requirements.

In order to adapt the Speedmachine as closely

as possible to your body dimensions and to

find the ideal seating position you need to adjust the front boom, seat and handlebars.

Adjusting the leg length: moving the

front boom

In order to adjust the leg length you have to

move the front boom (the front part of the

frame where the cranks are mounted) within

the main frame.

Unscrew both screws M8x35 under the main

tube with an 6 mm Allen key.Take a grip on

both cranks and move the front boom into the

frame or pull it out while cautiously turning it.

Before you pull out the front boom shift the

chain to the smallest chain ring and sprocket.

Turn the cranks a little bit backwards while

pulling.Thus the chain is not under tension.

Adjusting the leg length

Danger! In case of wrong adjustment your

legs will bump against the handlebar.You may

hence hurt yourselves or even loose control

over the bicycle and fall!

Danger! All procedures described here require a certain degree of skill, suitable tools

and mechanical aptitude.After any adjustment perform a static check and take a testride on a quiet street, away from traffic. If

you have any doubts please contact your local dealer.

Caution! After you have unscrewed the

clamping bolts take them off and examine

them for deformation. Lubricate threads and

heads thoroughly.Then re-fit the bolts. If

they don't turn easily you will have to replace the bolts.

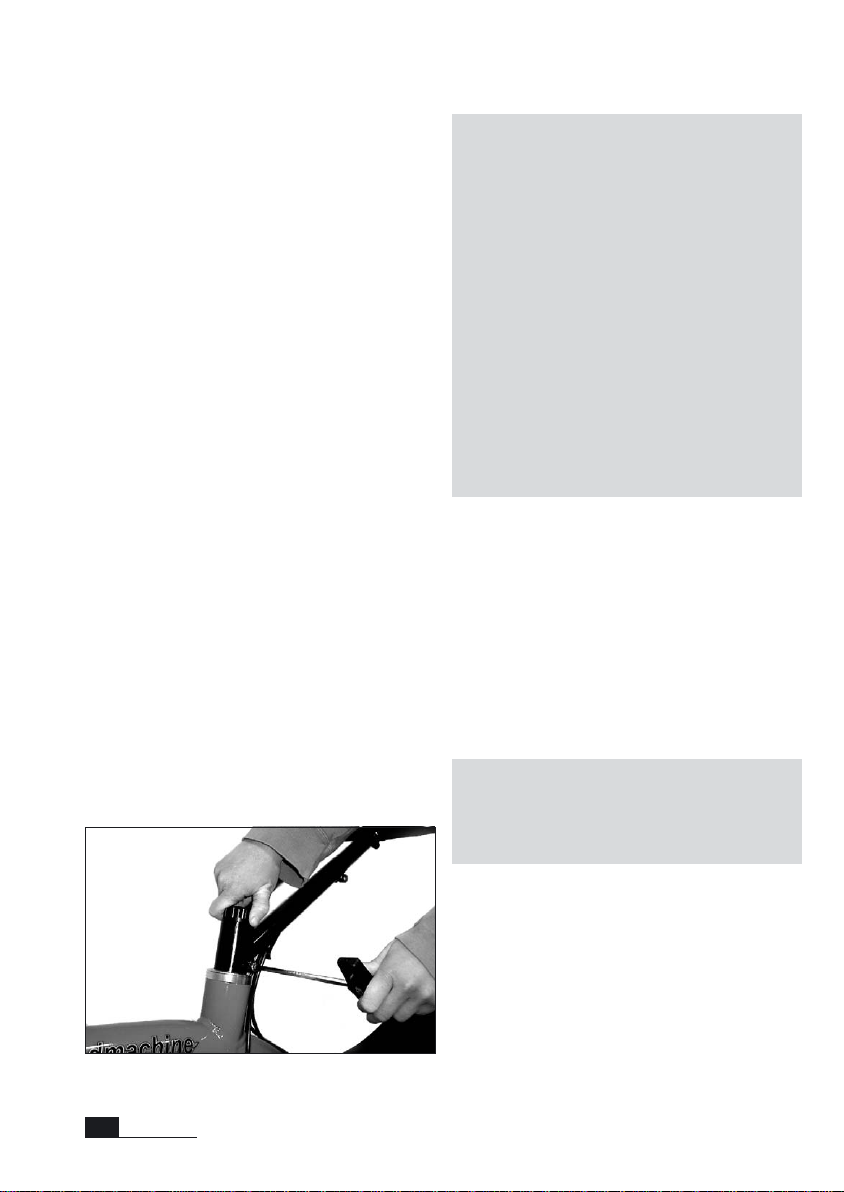

Unscrew the clamping bolts to adjust the front boom.

Page 10

8

HP

Velotechnik

In order to check the adjustments have another person hold the bicycle while you are sitting on the recumbent.

Adjust the front boom in such a way that your

leg is fully extended when your heel (wearing

flat shoes) is in the foremost position on the

pedal. Experience shows that the pedal-to-seat

distance on a recumbent can be slightly longer

than on a conventional bike.

While you are pedaling the ball of your foot

should be positioned over the center of the

pedal axle.

It is important that your leg is not fully

straightened when the crank is in the foremost

position. If the distance is too great it is difficult to overcome this dead point, pedaling becomes uncomfortable and there is too much

strain on the sinews of your feet and legs. If

the distance is too short you may suffer from

knee pain or your legs bump on the handlebar.

For riders with a short leg length the front

boom has to be cut by a bicycle mechanic, so

that it can be inserted to the maximum. It is

important to trim the end of the tube neatly.

The bare metal of the shortened tube end has

to be protected against corrosion with a paint

stick or wax spray.

On the left underside of the front boom there

is a fine line.Align this line with the sticker on

the main tube’s front end right above the

clamping bolts to adjust the bottom bracket

axle to a horizontal position.Additionally, you

can look beyond the bottom bracket shell at

the rear wheel axle and align the front boom

parallel to it.Align your eyes with the bottom

bracket axle and not the front derailleur tube.

Then sit down on your bicycle and check the

position.

Tighten the bolts with a torque wrench (tightening torque 14–16 Nm). On your first ride

check whether there is sufficient clamping.

Adjusting the leg length

Caution! When you move the front boom

take care that its end does not damage any

light cables that possibly come out of the

main frame near the fork. Please inform

yourself about the length of the front boom

on your bike before you do any work.While

moving the front boom you also have to

move the light cables The light cable must

never be stressed by pulling.

Adjust the front boon so that your knee will not be fully straightened when pedaling.

Danger! When you insert the front boom,

the front boom and the inner wall of the

tube must be totally free from grease, otherwise it won’t clamp properly and turn while

you are riding.

Page 11

Adjusting your new bike

9

HP

Velotechnik

Caution! The minimum insertion depth of

the front boom into the main frame is 10

cm (4"). In no case may the end of the front

boom be visible in the clamping slot when

you look at the main frame from below,

since it may result in a damage of the frame.

Danger! In the opening of the main frame

there must be a spacer (a slotted tube of

black plastic with edges to the front and the

clamping slot) that is glued into the frame.

This spacer ensures safe clamping of the

front boom and protects the paint. It is important that you take care that this spacer is

always visible at the front end of the main

frame.The lower slot has to be aligned in

accordance with the slot in the main frame.

If this spacer is missing or is moved to the

back of the tube while inserting the front

boom, secure clamping is no longer guaranteed, even if it seems to be the case at first

glance. If the front boom is not clamped

properly it may turn and lead to a fall. A

missing or misaligned spacer will lead to a

frame damage.

The rear end of the front boon may never be visible in the

clamping slot.

The plastic spacer between front boom and main frame must be

visible at all time.

Danger! If the bolts are tightened too

much or bent, the screw or the frame can

break! If the clamping is insufficient the front

boom can turn during a ride which may

cause your feet to slip from the pedals and

lead to a dangerous fall.

If the spacer is missing or not alligned properly or the screws are

tightened too much, the frame can break.!

Page 12

10

HP

Velotechnik

When moving the bottom bracket tube your

dealer has to adjust the chain length. By default

the Speedmachine comes with a very long

chain so that the adjustment range of the bicycle can be fully used without the need to

lengthen the chain.

After the first adjustment of the leg length that

you have done together with your dealer while

handing over the bicycle, the chain has to be

shortened so that the arm of the derailleur is

not fully turned forward while shifting on the

big chain ring in front and the big sprocket behind.The derailleur must still be able to compensate a length change of the chain of at least

4 cm (1 1/2"). In order to choose the right

chain length, please consult the manual of the

derailleur manufacturer.

After you have adjusted the front boom you

should seal the gap in the clamping slot between the front boom and the main frame

with wax or silicone in order to protect your

frame from the penetration of water and dirt

and hence damage through corrosion which

may lead to a broken frame. (The clamped

tube has to stay grease free, see above).

We recommend to slightly readjust the front

boom every 3 months so that knees, muscles

and ankles will be used differently, and you

might find a more comfortable and more efficient riding position.

A wrong adjustment may lead to pain in your

knees and inefficient pedaling. In addition we

recommend to ride with a high pedaling cadence, which means to pedal fast and with little pressure. Pedaling with too much pressure

may also lead to pain in the knees.You will find

more information about this on page 26.

Adjusting the leg length

Danger! After the chain has been short-

ened it has to be closed with a special closing link or a chain riveting tool that expands

the rivet while riveting (i. e. ROHLOFF-

Revolver).A poorly joined chain may break

and thus lead to a fall. Have adjustments of

the chain length or the changing of the chain

be done by your bicycle mechanic.

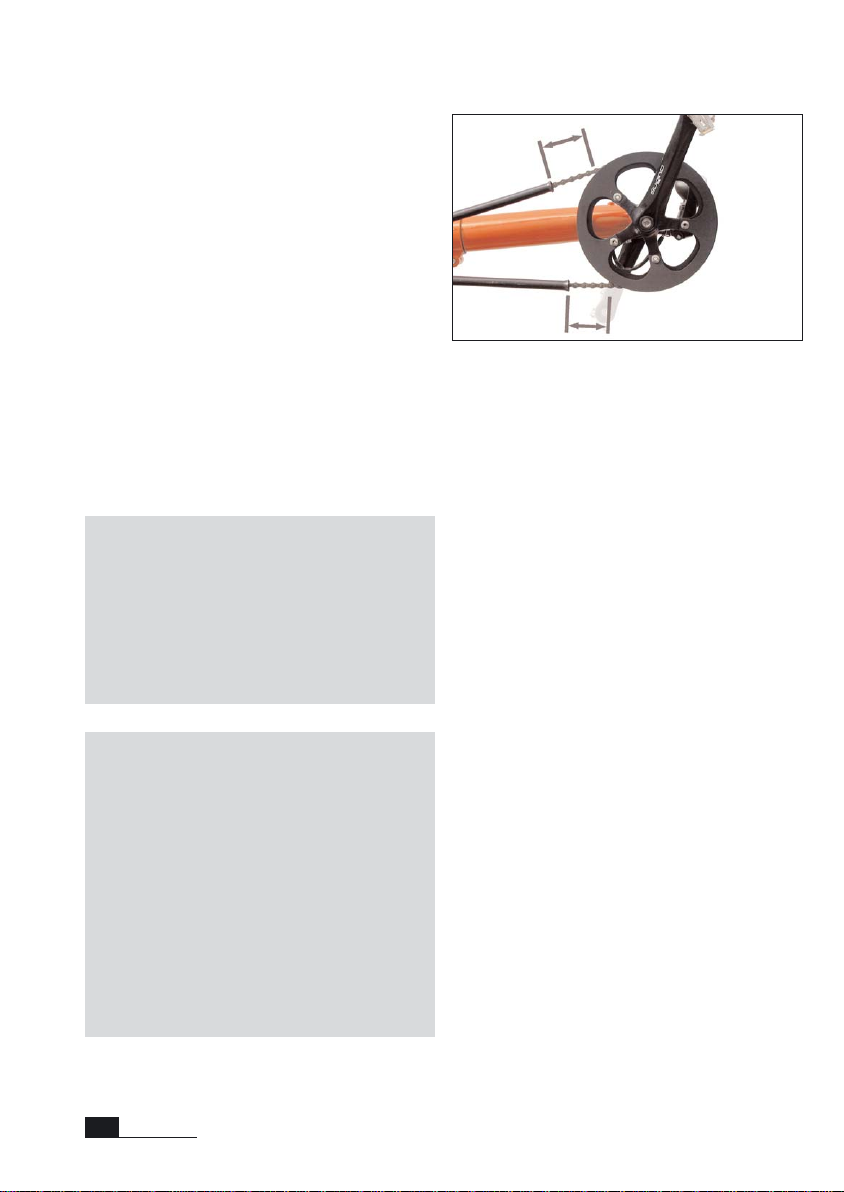

Check that thre is at least a 5 cm (2")clearance between the

end of the chain tube and other parts of the drive train.

Caution! Take care that the chain tubes

have at least a clearance of 5 cm (2") to the

rear derailleur and the front changer even

under maximum tension of the chain and

that the tubes stay tight in their fastenings.

The front upper tube can be moved to the

rear for length adjustment. Shorten the

tubes if necessary. If the end of the chain

tube gets into the rotating drive train it

could be locked-up and destroyed.The end

of the chain tubes have to be tightly secured

with a rubber tube over the retention

spring.

Page 13

Adjusting your new bike

11

HP

Velotechnik

Adjusting the seat position

Adjusting the seat length

Your Speedmachine is equipped either with

the ErgoMesh®mesh seat or the adjustable

BodyLink

®

seat from HP VELOTECHNIK.

The following instructions refer to the

BodyLink seat. Length, seat back angle and

lower seat angle are adjustable for this seat.

The adjustment of the seat length and the

proper seat angle is crucial for a comfortable

feeling while riding your recumbent.

The upper curve of the seat back in the area

of the shoulder blades determines the correct

seat length:Through this shape the shoulder

and neck area is lifted from the recumbent position so that the head rests in a natural and

relaxed position. For this reason you shouldn't

need a head rest if you have the right seat position. On long rides, a head rest can increase

your riding comfort as you can relax your

neck for a few seconds by leaning back.You

can mount our custom headrest to your existing seat.

The seat is too small when you have the impression that your back is pressed too much

into a "hunchback". It is too large when you

have the impression that the seat angle is too

far back when you are in the most upright position, or when you hit the upper seat edge

with the back of your head when you look upwards.

Adjusting the seat length

Take off the seat cover (see page 49). Open

the quick release lever for the seat back angle

adjustment, so that the seat is not bent with

inner tension. Loosen the 4 screws at the inner side of the seat back with an allen key

SW4 a few turns. Step behind your bike and

hold the seat back with both hands. Pull or

push the seat back to achieve the preferred

seat length.To achieve the smallest possible

seat length, move the 2 upper screws from the

top to the middle holes.

Tighten all 4 screws with 5–6 Nm. Move the

seat back rest to the preferred angle and close

the quick release lever firmly. Reinstall the seat

cover

Length adjustment of the Airflow cushion

The optional Airflow-cushion consits of two

parts, that connect in a V-type shape. Loosen

the velcro mount of the upper part, and place

it in the desired position, than fasten the velcro.

Adjusting the seat back angle

A big advantage of the BodyLink® seat on your

Speedmachine is that you can adjust the seat

back angle very quickly. For beginners or rides

in the city you can choose an upright seat position for a better view, and for longer rides

you can choose a flat position for better aerodynamics.

The seat back is fastened with a quick release

lever on a slotted aluminum seat mount.You

can adjust the seat back angle by 10 degrees

by simply opening the quick release lever. In

the medium seat position the angle is about

33° from horizontal.

Caution! Do not loosen or tighten the 4

screws in the lower seat part to adjust the

seat length. Maximum tightening torque of

these screws is 3–4 Nm.

Caution! To avoid noise from the seat when

loaded, the contact surfaces between the

two seat halfs need to be seperated by selfadhesive plastic sheets and all contact surfaces of seat and seat mounts and frame

need to be lubricated with grease.

Page 14

12

HP

Velotechnik

Adjusting the seat position

Adjusting the seat back angle is easy when you

push the seat closely to the seat mount into

the desired position. By pulling at the upper

seat edge, you would twist the seat, creating

tension and locking up the adjustment mechanism.

Because of the flexibility of the BodyLink

®

seat

and the special cam shape of the seat mounts,

the seat effectively pivots around a central axis, approximately in the area of the lower lumbar vertebrae.This is the place where you support the biggest part of your pedaling force

while riding, so this point determines the distance to the pedals.The advantage of this design is that you adjust the distance from the

seat to the bottom bracket only once as described above, a change in the seat angle does

not require an adjustment of the front boom.

Adjusting the front seat edge

The front seat edge can be slightly lowered to

accommodate smaller riders.With a lower

front seat edge, it is easier to put your feet on

the ground without pressure from the seat

edge on the back of your legs.With a higher

front seat edge, the seat will give more support and avoid the feeling of „sliding down the

seat“ that occurs with upright seat angles.

To adjust the front seat edge, open the quick

release lever at both the lower and the upper

seat half, so that the seat has no inner tension.

Thus you need less force for the adjustment.

Push or pull the seat front edge firmly until

you reach the desired position and close the

quick release lever firmly.Then adjust the seat

back angle as described above.

If the quick release lever pressure is to loose

when closed, open the lever and turn the

screw on the end of the quick release axle

clockwise.The low profile design of the screw

head gives more clearance for the drive train.

Adjusting the lumbar support

The BodyLink®seat is ergonomically shaped

and supports the natural S-curve of your

spine. Forces from pedaling are supported in

the area of your lower back just above your

hips.The amount of support in this area (lumbar support) is adjustable by moving the seat

back and lower seat opposite to each other.

To get more lumbar support, lower the seat

front edge and put the seat back in a more reclined position.

To get less lumbar support, rise the front seat

edge and put the seat back more upright.

For more extreme adjustments, loosen the 4

screws for the seat length adjustment in the

seat back.Thus the seat back can expand and

bend into the desired shape.Tighten the

screws and quick releases as described above.

Adjustment of the head rest

Both seat types can be equipped with a head /

neckrest which is adjustable in height and angle. Use the long holes and the screw hidden

under the cushion (BodyLink-seat) or the

mounting clamp (ErgoMesh-seat) for setting up

the correct position.

Caution! The three quick releases have to

be closed firmly (tightening force 15-20 kg /

45 lbs) to safely hold the seat.You are not

allowed to open them while riding.After

they have been closed the imprint "close"

must be visible. If the quick releases are not

tightened appropriately the seat can move

while riding so that you may no more be

able to control your bicycle.

Caution! Do not push or carry your bike

on the head rest, this could damage the

head rest or your seat!

Page 15

Adjusting your new bike

13

HP

Velotechnik

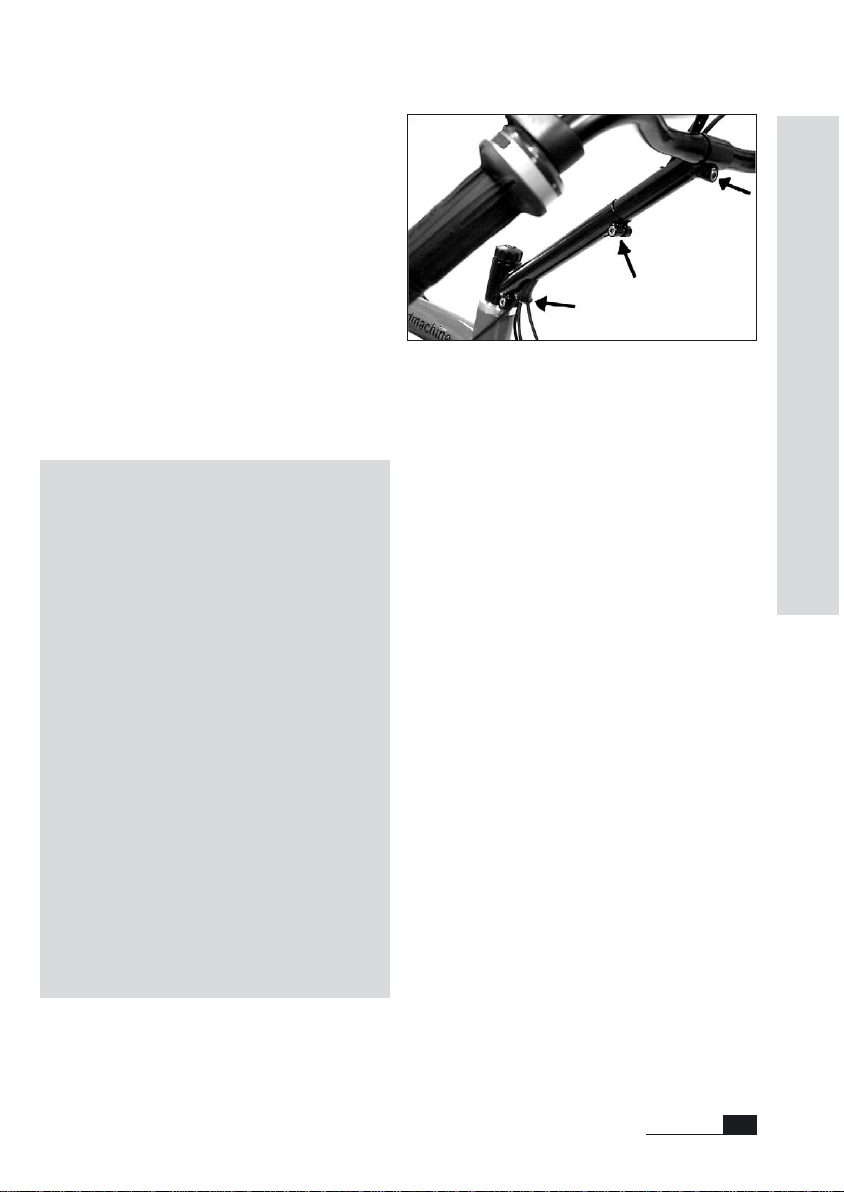

Adjusting the above seat steering

There are two versions of above seat steering

available for the Speedmachine: Tiller steering

(pictured) and Aerobar steering. Both feature a

length-adjustable stem which fixes the handlebars to the fork.

The stem has three clamping connections

where the tubes are slotted and connected

with a clamping screw.The connections are in

particular the connection stem/fork, the connection of the upper half of the stem with the

lower part of the stem for telescopic adjustment of the length, and the connection

stem/handlebar.

Danger! Every time you undo one of the

clamping connections you have to check the

clamping screw.You also have to check the

welded-on thread nut.The thread must not

be damaged and the screw must turn easily.

Once a year you have to dismount the

screw completely and check it. In case of

damage or deformation you have to change

the clamping screw immediately.When you

refit the screw it has to be lubricated carefully and tightened with the required tightening torque (see table on page 55).

In case you tighten the screws too much the

clamping may deform and break.When you

bend the screws while tightening they may

break and the clamping can loosen.When

you tighten the screws with an insufficient

tightening torque the clamping does not

reach the necessary strength and this can

result in a twisting of the handlebar or the

stem while riding.All these assembly errors

can lead to dangerous falls!

Adjusting the handlebars

On the stem you will find 3 clamping screws for adjustment.

At first align the stem parallel to the front

wheel. For this purpose loosen the lower

clamping screw M8 with an Allen key SW6.

Get on your bike, secure the front wheel with

your feet and bring the stem into line.Tighten

the screw with a tightening torque of 13-14

Nm. Check the safe clamping by trying to twist

the stem against the front wheel. Due to the

manufacturing process the upper end of the

short tube which is attached onto the fork's

steerer tube is slightly oval, this is not a defect.

With the tiller steering, the grips of the handlebar should show to the front in riding direction, away from the rider.This results in the

most comfortable position to grip the handlebar since all you have to do is "hook in" your

hands to the handlebar.This position allows for

easy cornering as it gives the rider the most

space between handlebar and belly.

The adjustable stem should preferably be set

to the shortest possible position while taking

care that the legs don't touch the handlebars

when riding.To check this make sure that you

you have correctly adjusted the leg length as

described above and sit down on your bicycle.

Now, by loosening the clamping screw a little

bit you can adjust the length of the stem.

Page 16

Adjusting the under seat steering

handlebars

Your Speedmachine with under seat steering is

equipped with an „indirect“ steering.The handlebars are supported by a stem that pivots in

the frame.The front fork is connected to the

stem by a connection rod.

Horiz

ontal alignment of the handlebars

The stem is made of two parts that telescopically slide into each other.The connection is

made by 2 clamping screws. Loosen both

clamping screws, sit on the bike and align the

handlebars horizontally, so that both bar ends

are at same height.Tighten both clamping

screws with 6–8 Nm.

Check the safe clamping by trying to turn the

handlebars in the stem.This should only be

possible with high forces.The ability to turn is

designed on purpose: In case the bike drops

over the handlebars can turn without being

bent or broken immediately.

We suggest to fully insert the stem half. If you

move the handlebars further back, the turning

cycle will increase as the handlebars contact

the frame or lowrider earlier.

Alignment of the handlebar

s to the wheel

Remove the screw between rear connection

rod end and stem. Loosen the counterlock nut

at the rod end.Adjust the steering rod length

by screwing the rod end in or out to align the

handlebars perpendicular to the front wheel.

Adjust both rod ends parallel to each other.

Make sure that the centerline of the connection rod is in a plane perpendicular to the

ground, i.e. parallel to the frame.Tighten the

counterlock nut against the steering rod with

6–8 Nm.

14

HP

Velotechnik

Pull the handlebar together with the upper

part of the stem towards yourself so that

there is enough room between your thighs

and the handlebar for pedaling.Then check the

clamping screw as described above and tighten

the screw.

Tightening torques:

length adjustment screw M8

(Allen key 6 mm ) 8–10 Nm

handlebar clamping screws M6

(Allen key 5 mm) 6–8 Nm

Adjusting the handlebars

Danger! Only pull out the stem so far as

not to fall below the minimum insertion

depth of 4 cm (1

3

/4"). In no case may the

lower end of the inserted tube be visible in

the clamping slot! When the stem is pulled

out too far the clamping may be damaged or

the stem may come loose while riding,

which can result in a dangerous fall.

The end of the upper stem half must not be visible in the clamping slot.

Danger! The minimum insertion depth of

the stem half is 5 cm (2"). In no case may

the rear end of the inserted stem half become visible in the clamping slot.

Page 17

Position the rear rod end on top of the mount

at the stem and reassemble the screw and selfsecuring nut with 6–8 Nm. Check the correct

assembly of the indirect steering by turning

the handlebars in both directions until the

handlebars make contact with frame.The rod

ends must moove freely without hitting the

frame or getting twisted.

Adjusting the handlebar angle

By changing the angle of the handlebars you

can adjust the position of the grip to the

length of your upper body and your arms.

To change the angle, loosen the screws of the

handlebar clamping.Turn the handlebars until

they are in your favourite position. Check that

the stem clamps the handlebars exactly in the

center.Tighten the clamping screws with 6–8

Nm. Check the correct clamping of the handlebars by sitting down on your bike and

pulling the handlebars. Doing so the handlebar

must not turn.

Please take care that the clamping area of the

stem is thoroughly trimmed and does not

show any sharp edges which may lead to a

rupture of the handlebars.

While riding you should allow your arms to

rest in a relaxed position on the handlebars.

Do not pull on the handlebars. If the handlebars turn in the stem clamping during the ride

stop immediately and tighten the clamping

screw of the handlebars.

Adjusting your new bike

15

HP

Velotechnik

Danger! The adaptor for the connection of

front rod end and front fork must be seated

firmly in the slots of the outer steering tube

and be firmly secured between adjustment

ring and counter lock ring. Before every

ride, check that there is no play in the steering system. Play will destroy your front fork

and lead to unsecure riding conditions.

If the handlebars turn in a stem that is not sufficiently clamped the handlebars or the stem

might be damaged or deformed. In that case a

safe clamping can no longer be guaranteed,

even with the correct tightening torque, and

handlebars and stem have to be exchanged.

Adjusting the cable length

You can make smaller adjustments by moving

the cables in their guides at the frame and the

stem, so that there is enough room at all mobile parts. If this proves not to be sufficient

you will have to have your specialist dealer

shorten the cables or replace them by longer

cables.

Cover all contact areas where cables move

and touch the frame with protection stickers

or sturdy transparent tape.This protects the

paint against scratching and wear.

Handlebar grips

The grips on the handlebar are susceptible to

wear and tear. Have your grips replaced by

your bike shop once they don't feel comfortable anymore.The grips always need to be attached firmly to the handlebar.

Caution! After adjusting the handlebar position you have to adjust the length of the

brake cables and shifter cables.The cables

have to run smoothly without any sharp

turns and they may not be bent sharply or

stretched when the handlebar is at maximum cramping or the above seat steering

stem is folded forwards. Also avoid large

arches that could be caught up in other

parts.

Page 18

16

HP

Velotechnik

Purpose of the adjustment of the

suspension

Your Speedmachine is fitted with a rear swing

arm for the suspension of the rear wheel and

optionally with a suspension fork for the front

wheel.This system compensates slight bumps

on the road so that riding is comfortable and

strain on your bicycle is reduced.

A well-adjusted suspension improves the traction of your bicycle on uneven roads.

Especially when cornering this allows a higher

speed and also increases safety.

In order to achieve maximum riding comfort,

the suspension settings have to match your

weight as well as the road condition.

The goals of the adjustment are:

● maximum use of the available suspension

travel without the suspension frequently

bottoming out

● quick reaction of the suspension without

obvious oscillation after having passed a

bump

● avoiding self enforcing oscillations, that means

increasing oscillations of the suspension

system due to pedaling influence, rhythmic

body movements or permanent wavy underground

Suspension and damping

The suspension systems of the suspension fork

and the rear swing arm are fitted with the actual spring and a seperate damper. Often, the

terms suspension and damping are used inappropriately in everyday language.

The spring is the elastic element that compresses and decompresses through the load

which occurs on bumpy roads.While decompressing the spring releases the same energy it

has stored during compression.

The Speedmachine is fitted with coil springs of

steel at the suspension fork and the rear fork

swing arm.The optional rear shock DT-S

WISS

XM180 uses air as spring medium.

The damper slows down the process of compression and decompression.That means that

the bicycle does not immediately "spring" back

to the initial position or even further than that

after having passed a bump.The damper converts spring energy into friction and finally into

heat, and thus takes away energy from the suspension system.This way the damper prevents the spring from swinging uncontrolled after an initial stimulation. In addition the damper helps to avoid self enforcing oscillations of

the suspension system that may be caused by

reoccurring stimulation like pedaling forces

within a crank revolution or the rhythmic up

and down movement of the legs.

The suspension fork of the Speedmachine is

dampened through a friction damper in the

fork, the rear suspension through a hydraulic

damping unit. Some models have an adjustable

damping.

Adjusting the suspension

Page 19

Adjusting to load

The luggage rack of the Speedmachine is

mounted to the suspended part of the frame.

That way your luggage is also fully suspended

and it spares the material. Most notably, even

under heavy load the suspension will compensate an uneven road much better and quicker

compared to a design where the luggage carrier would be mounted to the unsuspended

parts, e.g. the rear swing arm.

Additional luggage changes the load of the

wheels and their suspension.The suspension

system is more compressed through the load.

That way, there is less suspension travel for

bumps while riding.Your suspension could seize up more often.

The suspension of the front wheel is less affected since luggage at the rear rack almost only

puts weight on the rear wheel. Only in case of

heavy luggage on the lowrider under the seat

there is an influence on the front wheel.

In order to compensate the variations in the

load you can change the preload. For details

see the following chapter.

Theoretically this can compensate for a load

change of approx. 10 kg (23 lbs) at the rear

wheel. In case of higher variations in the load

you would have to exchange the spring for another spring with another spring stiffness. In

practice you can often do without it: the

Speedmachine offers with 60 mm a lot of suspension travel for a sports bike. When you

choose the spring stiffness so that the full 60

mm are at your disposal when your recumbent

is under maximum load, you will have a somewhat smaller but still very comfortable suspension travel when you ride without luggage.

The optional air shock DT-S

WISS XM180 can

be easily pumped up to compensate load.

Adjusting your new bike

17

HP

Velotechnik

You should always set the damping as low as

possible to give the bicycle the possibility to

quickly react even to several bumps in a row.

You can ride the Speedmachine with a considerably lower damping than for example a MTB:

Due to the relaxed and steady position of the

body the recumbent does not experience extreme variations in the load as it is known

from dancing on the pedals while riding uphill

on a mountain bike.

In addition to this, varying pedaling forces have

very little influence on the suspension of the

bicycle due to the No Squat design of the suspension system of the Speedmachine. So when

you adjust the damping, always start with a low

damping rate.

It is necessary to choose the correct spring

stiffness to have a well operating suspension

system.The spring stiffness is a measure for

the compression of a spring at a certain load.

It is either given in "N/mm" (Newton per

Millimeters) or "lbs./inch" (Pounds per Inch).

Sometimes you only find "lbs." printed on the

springs.

The spring stiffness of the optional air shock

DT-S

WISS XM180 is set by adjusting the air

pressure.

The suspension is designed in a way that the

spring compresses considerably when you

mount your bicycle.This is called negative suspension travel (or "sag") and enables the suspension to decompress on bumpy roads.

(Which is in fact a definitely positive feature.)

You should choose a spring stiffness with

which this negative suspension travel takes up

around 30% of the overall suspension travel.

This value usually provides a very comfortable

ride on your recumbent bike designed by HP

V

ELOTECHNIK.

Page 20

18

HP

Velotechnik

Caution! When you turn the cap take care

that it is always screwed into the outer tube

with at least 5 complete turns.To check unscrew the cap completely anti-clockwise.

Then put the cap back on the outer tube

and tighten it at least by 5 threads. In no

case may the threaded lower end of the cap

be visible.This thread passes on the total

load of the front wheel to the frame. In case

you don't take care of the minimum threaded depth the thread can come off and destroy your fork permanently.

Do not turn the cap as far as it will go into

the outer tube, there has always to be a

small gap of at least half a turn.Thus you

have an adjusting range of 3,5 turns.

Adjusting the suspension: suspension fork

Adjust the damping to the smallest value possible.That way the fork reacts sensitively and

stable. In case of high damping rate the suspension can rub and compress not as smoothly as

with low damping rate.The up and down

movement of the legs while pedaling can make

the fork oscillate at certain pedaling frequencies and certain leg lengths; you can reduce

this influence by choosing a higher damping

rate.

Caution! After having adjusted the damping

rate you have to tighten the lower clamping

of the stem as described in the chapter

"Adjusting the handlebar", see page 13.

Adjusting the suspension fork

The front fork of the Speedmachine comes

with a "Concept S2" suspension system.The

suspension travel is about 54 mm.The fork

features a simple adjustment of the damping

and exchangeable steel springs.

Adjusting the damping of the suspension

fork

To adjust the damping you turn the threaded

cap at the upper end of the fork.The damping

results from friction between an elastomer

ring that lies between the outer tube and the

inner fork steerer tube. By tightening the cap

the elastomer ring is compressed, the friction

to the side walls of the inner fork steerer tube

is increased and thus gives more damping.

Both compression and rebound damping are

affected at the same time by turning the cap.

In order to adjust the damping you have to undo the clamping screw of the stem.Afterwards

you can turn the cap either by hand. If you

look at it from above the damping increases

while turning clockwise, it decreases while

turning anti-clockwise.

After unduing the stem clamping, you can adjust the damping.

Page 21

Adjusting your new bike

19

HP

Velotechnik

If the spring stiffness should not meet your requirements you can order a spring with another spring stiffness through your dealer and

have it mounted there.

For more information for your specialist dealer on changing springs, see "Maintenance and

Care" on page 41.

You can distinguish the dismounted springs by

their color:

medium, 19 N/mm: black

hard, 24 N/mm, red

(Values are valid for Concept-Suspension from

10/2005 on.)

Choosing the spring stiffness of the

suspension fork

Your suspension fork comes standard with a

medium spring that covers a wide range of

load and riding styles.The preload is fixed to

about 3 mm.

In order to follow our advice for about 30%

compression of the suspension while mounting

the bike (negative travel) , the suspension

should compress by 14-18 mm.To check this

value you will need a second person and a

ruler. First measure the distance between fork

and frame.

Let the second person hold the bicycle while

you sit down on the bike and put your feet on

the pedals. Now have the second person

measure the distance at the same spot.

The value taken should be smaller by 14-18

mm than the value taken before. Repeat this

several times and calculate an average value.

Due to the stiction caused by the friction

damping of the fork and the low preload the

fork will not always spring back to its initial

position when compressed by hand. However,

it will while you are actually riding and the full

suspension travel is used.

Measuring is easier when you set the damping

rate of the suspension fork to a small amount.

It is not important to exactly follow the recommended values for the negative travel,

rather follow your feeling how the bicycle behaves during a ride, depending on the road situation.While riding you should only seldom

feel the suspension bottoming out. However, in

case this never occurs the spring might be to

hard which means you don't use the total suspension travel.

Page 22

20

HP

Velotechnik

Adjusting the suspension: rear swing arm

Adjusting the rear suspension element

For the rear suspension of the Speedmachine

a spring element is combined with a hydraulic

damping unit in a suspension element.The

damping results from fluid friction of an oil

flow through thin holes of a throttle valve in

between two chambers inside the damper.A

slightly noticeable sound that may occur from

this oil flow is normal. Due to the fluid friction

the spring element may heat up, therefore don’t touch the suspension element directly after

a ride.

The Speedmachine comes standard with a

steel spring rear shock D

NM DV-22.As an op-

tion you can get the air shock DT-SWISS

XM180 that uses air as spring medium.

Danger! While adjusting the rear suspension element never load the bicycle e.g.

through resting on the seat or loading the

rear rack when your hands or tools are close to the suspension element. Otherwise

your hands may get caught and squeezed

when the suspension compresses.

Danger! The suspension elements are filled

with gas under high pressure. Never try to

open the damper or to remove the screw at

the gas tank. Inside the damper there are no

user serviceable parts. In case of damage

you will have to take the complete suspension element to your dealer.

Steel spring rear shock DNM DV-22

The preload determines how far the suspension compresses when you are sitting on the

bicycle while standing still.

For the rear wheel the same guidelines as for

the suspension fork are valid: for maximum riding comfort the suspension should compress

by about 30% of the total suspension travel

while you mount the bicycle in driving position.

For that purpose measure (similar to the method described for the suspension fork) the distance between the two suspension element

bolts or between rear rack and rear wheel

while the bike is unloaded as well as while sitting on the bicycle in riding position.Also take

into account possible luggage. Find out the total suspension travel possible for your bicycle,

depending on the mounted add-on parts and

clips on the piston rod.The static compression

should about one third of the overall suspension travel.

You can affect this negative suspension travel

depending on how much you weigh and how

much you load your bike either by adjusting

the suspension preload for fine tuning or by

replacing the spring by a spring with a different

stiffness in the rough tuning.

In order to adjust the suspension preload turn

the knobby adjustment ring on the threaded

part of the suspension element by hand.

Turning the adjustment ring clockwise (looking

at it from behind) reduces the preload, turning

it anti-clockwise you screw the adjustment

ring towards the spring and increase the spring

preload. It is helpful to turn the spring together with the adjustment ring.

Page 23

Adjusting your new bike

21

HP

Velotechnik

The adjustment ring should be turned no more than five turns (measured from the relaxed

position) towards the spring. If the suspension

compresses still too far even after six turns,

the spring is too soft and has to be replaced

by a harder spring.A too high preload of a too

soft spring does not take advantage of the full

comfort potential.

You will find more information on changing

springs in this manual under "Maintenance and

Care", page 45.

Suspension element DV-22 with fixed damping rate.

Danger! The adjustment ring has always to

be screwed so far towards the spring that

the spring has no play when unloaded.

Otherwise the adjustment ring could come

loose through shocks while riding so that

the slotted rear spring retention disc comes

off. In that case the suspension element may

be damaged or the rear wheel could hit the

frame or rear rack, which may lead to serious falls.

Always have an initial preload of at least half

a turn on the spring.

The suspension travel is adjusted by adding clips to the piston

rod of the spring element.

Danger! Take care that the rear wheel or

mudguard or suspension element never hit

the frame, seat, rear rack or luggage box

while the suspension is fully compressed.

Therefore relax the spring completely by

turning the spring retention disc on the

thread of the spring element as far as possible (before this, take out the possibly existing safety spring ring of its slot in the threaded section). Have a second person mount

the bicycle and make the suspension bottom

out by leaning on the seat or the rear rack.

If the distance between the wheel or mudguard and the frame or rear rack or

Speedbag is smaller than 1 cm you will have

to mount an additional spacer. In case you

don't, the mudguard may break suddenly or

the rear wheel might be blocked which can

lead to serious crashes.

Page 24

22

HP

Velotechnik

Adjusting the suspension: rear swing arm

Air shock DT.SWISS XM180

Please follow the instructions in the separate

manual from the rear shock manufacturer.

This rear shock contains pressurized air in a

main („positive“) air chamber as suspension

medium.Air shocks are lighter than steel

spring rear shocks.Another advantage is that

the spring stiffness can be easily adjusted with

an air pump: By increasing the pressure the

spring becomes harder.

Air shocks have a progressive spring behaviour,

whereas steel springs have a linear spring behaviour. This means that the air shock gets

progressively harder, e.g. it is much stiffer when

fully compressed than when only slightly compressed.

The advantage of this progressive spring behaviour is the good bottom-out protection

when heavily loaded.

The valve for the air chamber is located at the

back end of the air shock.The valve is protected by a metal valve cap.

To pump up the air shock you need a special

air pump designed for bicycle air shocks. It

must have a fitting schrader valve adaptor and

a pressure indicator.

When attaching or removing the pump

to/from the valve, you will loose some air

(about 0,5-1 bar).Take off the pump quickly.

Recommended pressure settings

load pressure

– 80 kg (183 lbs) 7,5 bar

–100 kg (230 lbs) 9,0 bar

–130 kg (286 lbs) 10,5 bar

Maximum allowed pressure is 18 bar.

Danger! Take care that the rear wheel or

mudguard or suspension element never hit

the frame, seat or rear rack box while the

suspension is fully compressed.

Therefore fully deflate the air shock. Have a

second person sit down on the bicycle and

make the suspension bottom out by pushing

on the seat or the rear rack.

If the distance between the wheel or mudguard and the frame, seat or rear rack is

smaller than 1 cm you will have to have your

bike dealer mount an additional spacer inside the air shock. In case you don't, the

mudguard may break suddenly or the rear

wheel might be blocked which can lead to

serious crashes.

Page 25

Adjusting your new bike

23

HP

Velotechnik

Adjusting the damping

By adjusting the damping you can adjust the

performance of the suspension precisely to

your individual riding situation.A rough street

with many harsh bumps that occur in a row or

even cobblestones needs a low damping rate

while a road with long stretched bumps that

occur more regularly needs a stronger damping to achieve a smooth road holding.

When you add a lot of luggage you will need

to adjust the spring stiffness; in that case an

adjustment of the damping may even give you

more riding comfort.

Finally, the oil used in the damper becomes

thicker and more viscous at lower temperatures, which can be compensated through a

change in the damper setting.

Please note that you can seriously spoil the

riding comfort by a bad damper setting, especially through unsystematic playing with the

knobs that may result in much to high damping

rates. In the worst case the suspension element will neither compress nor decompress. If

you are in doubt please consult your local

dealer.

The rebound damping prevents an eventual

"jumping" of the rear wheel and provides a

good traction. By improving the road surface

contact the suspension of the Speedmachine

also increases your riding safety.

A higher damping value prolongs the time until

the decompression movement is finished. Only

then can the suspension compensate the next

shock with the full suspension travel.

Therefore, when you ride on very bumpy

streets with shocks that occur fast in a row

you might want to use a lower damping value.

A good setting for maximum comfort is

achieved when the rear wheel decompresses

completely after a shock and then oscillates

only once. In order to check the adjustment

you will need a second person that compresses the suspension by pushing the bicycle down

while you are sitting on the bicycle in the riding position.The other person can then observe the suspension movements.

In order to adjust the damping during decompression, turn the adjustment knob on top of

the rear end of the suspension element.

If you turn the knob in direction of the „-“ you

will get less damping and thus faster decompression.Turning the knob in direction of the

„+“ will give you more damping and thus slower decompression.

Air Shock DT-Swiss XM180. Damping is adjusted with the red

knob at the rear end.The shock must be installed with the lockout lever facing down to avoid a collision of lever and frame

when the suspension is moving.

Page 26

24

HP

Velotechnik

Learning the new riding technique

Your new bicycle has been assembled by your

dealer and adjusted together with you as described on the previous pages under

"Adjusting your new bicycle". Before you

mount your bike and enjoy your first ride

please make yourself familiar with the instructions on the riding technique and the handling.

To ride this recumbent you will have to make

yourself acquainted with the different riding

position. Make sure that you and all other future users of this bicycle will have read this

manual carefully prior to the first ride. If you

are in doubt please consult your local dealer.

Before the first ride the users of this recumbent have to practice and make themselves familiar with the different handling.We recommend to practice on a quiet road away from

traffic. Before you ride the bicycle in traffic you

must master the handling completely.

Go to a road where you can ride straight

ahead without being hindered. Hold your bike

at the handlebar and pull a break.Then sit

down on your bicycle and lean back. Leave one

foot on the ground and put one on the pedal.

Therefore rotate the crank in the top position

so that you can pedal immediately with power.

Try to keep your balance in that position.

Assure yourself that you can stop whenever

you want to and hold the bicycle with one

foot on the ground.When you feel safe put

pressure on the pedal, loosen the brake, pedal

with a lot of force and immediately put your

second foot on the other pedal. Do not care

on which side of pedal you are currently pedaling in the beginning. Hold the handlebar

loose but steady and accelerate with a few

pedal strokes.Your bicycle needs speed to stabilize.

Look ahead in the direction where you want

to ride, not on the handlebar, at your feet or

the front wheel.

In order to stop brake carefully with both

brakes until the bicycle has come to a complete stop. Only then do you put a foot on the

ground and keep the balance.

Learning the new riding technique

Danger! Never touch the ground with your

feet while the bicycle is still moving.The feet

could be caught on the ground and be pulled

backwards which could lead to a serious injury.

Danger! With a compact recumbent like

the Speedmachine it is possible that a foot

of the rider contacts the front wheel when

riding sharp corners with a pedal in a low

position.You will have to avoid this situation

at all times since in extreme situations it

may lead to a fall and injuries.

To control the bicycle you will therefore

have to apply the following cornering technique: when you ride a curve stretch the leg

on the inside of the curve, stop pedaling, only then start steering into the curve. Only

when you ride straight ahead again may you

resume pedaling.

Page 27

Handling instructions

25

HP

Velotechnik

Wear protective clothing

Riding a bicycle is a potentially dangerous

sport where accidents can happen even when

you take care of every safety instruction prescribed.

We recommend you to wear an approved bicycle helmet that fits well. Protect yourself by

wearing special sports clothing that fits tightly

and is reflective.

When you fall with a recumbent you usually

land on the side of your hips and your hands.

Wearing reinforced cycling shorts and gloves

reduces the danger of skin injuries considerably.

Use clipless pedals

The pedals of your recumbent bike can be upgraded on demand with a binding system.As

soon as you are comfortable with riding your

recumbent bike you should use those clipless

pedals. Due to the rigid connection between

shoe and pedal you don't have to keep your

foot on the pedals with pressure anymore. This

enables a more relaxed and round pedaling

movement where you may even pull a little on

the pedals.Without this connection to the pedals your feet may come off suddenly which

may result in a fall. Modern system pedals with

binding therefore contribute to safe riding.

At first you will have to practice with these

pedals to make sure that you can get off quikkly in a dangerous situation. Please read the

manual of the pedal manufacturer that comes

with this manual and have your dealer explain

the use of the pedals to you. In the beginning

set the release force of the binding to a low

value to make sure you can get off safely.

Please exclusively use the original shoe plates

(cleats) from the pedal manufacturer. Do not

use any other brand. If you're using shoe plates

that are not authorized the binding system

won't work properly.

Protective clothing, cleatless pedals

Danger! Please note that you may be no-

ticed very late by other road users due to

the low seat height and ride anticipatory according to this.This is especially important

while riding in darkness.You yourself have a

much better view than others perceive you.

Ride defensively.We recommend you to

mount a well visible and reflecting flag to the

bicycle while using it in traffic. Please ask

your dealer for more information.

Page 28

26

HP

Velotechnik

Slowly increase the strain

We recommend you to perform only short

rides without much power during the first

weeks.

Always use a low gear and ride with a high

pedaling frequency. Only after having acquired

some training do increase the strain slowly.

When you ride on a recumbent you use other

muscles than on a conventional bicycle, and

they have to be trained first. The very high position of the bottom bracket requires your

muscles and blood transport system to slowly

familiarize with the new position.

In case of an overload the blood circulation in

your legs may be affected which shows in loss

of power, a prickling in the toes, falling asleep

of the legs or cramps.When you have a sporty

way of riding it can take up to 6 months until

you have become accustomed to your new recumbent.

Should you have pain in your knees while riding this is usually the result of too much power put into pedaling.The good support of the

back sometimes misleads to putting the full

power of the legs in the pedal, similar to the

leg training machines in a fitness center.When

you repeat it regularly it is harmful for the

knees. Pain in the knees often results from an

overuse of the muscles in the knee that can also be strengthened through exercise.

Also, a wrong adjustment of the front boom to

the leg length (in most cases too short) can

lead to pain in the knees.

Your pedaling cadence should stay between

80-100 revolutions per minute and not fall below 60 revolutions when going uphill. If necessary have your specialist dealer adjust the gear

range to your riding style and the terrain you

usually ride.

You will find many tips on proper training for

cyclists in miscellaneous books and magazines

for cyclists.

In case of persistent problems please consult

your doctor.

Do not ride freehand

How to ride correctly and safely

Always adjust your speed to the traffic, the

road and the weather conditions. Ride slowly

in curves and on unknown roads.Always ride

at a safe distance from other road users, and

when you ride in a group never ride side by

side.

When you approach a traffic light never ride

past the line of waiting cars since even the

most attentive car driver may not see you due

to your low seating position.

Strain, riding freehand, way of riding

Danger! In order to ride safely you have to

keep both hands at the handlebar. Even

when signaling keep at least one hand at the

handlebar. Otherwise, unforeseen bumps in

the road or oscillations of the steering may

lead to a serious fall.

Caution! Always carry your bicycle over

stairs and curbstones. Do not ride through

big road holes. Especially when road holes

are filled with water it is very difficult to

guess how deep they really are. In case you

hit such an obstacle frame and fork may be

damaged which can result in a serious fall.At

first, the damage may be unnoticed. Please

check your bicycle immediately for deformations and cracks. If you are in doubt please

consult your local dealer.

Page 29

Handling instructions

27

HP

Velotechnik

Quick release levers

Quick release levers hold wheels and seat in

position.

A quick release lever consists of two basic

parts: the lever on one side provides the

clamping force.With the adjusting nut on the

other side you adjust the clamping tension on

the screw thread.

To open the quick release move the lever away

from the frame. In doing so the inscription

"open" will become visible on the lever.

To close the quick release move the lever with

power in the other direction so that the word

"close" is visible on the outward side of the

lever. At the start of the lever's motion, for, say,

half of its movement, the lever should move

very easily, without any clamping action. In the

second half of the lever's movement the force

on the lever should increase considerably, corresponding in the end to 15-20 kg (46 lbs).

In its final position the lever should lie parallel

with the bicycle and should not stick out to

one side.

Check the security of the lever by attempting

to twist the lever. If the lever can be made to

pivot around in a circle the clamping is too

loose.You must re-open the quick release,

hold the lever and increase the clamping tension. Do this by screwing the adjustment nut

on the other side further by half a turn. Close

the lever and check the clamping anew.

Finally, check that the part being secured is

firmly fixed: Lift each wheel several inches off

the ground and give it a slap onto the tire

from above.A properly fixed wheel will remain

secure in the frame's dropouts.

The dropouts of the fork of your

Speedmachine are designed as safety dropouts.

Therefore you always have to loosen the

clamping nut of the quick release when you

take off the front wheel.When you reassemble

it do not forget to tighten the nut again!

Parts that are fastened with a quick release

open easily.Thus, they are more susceptible to

theft.Therefore, always secure the wheels with

a lock when you park your bicycle. It is also

possible to exchange the quick releases with

special security screws (e.g. from P

ITLOCK) that

can only be opened with a special tool. For

this please consult your local specialist dealer.

Take off the seat

Open all three quick release levers of the seat

mounts. Unscrew the nut of the upper seat

quick release approximately 4 turns. Turn the

quick release levers of the middle and lower

seat quick release counter clockwise approximately 4 turns.

Eventually it may be easier to hold the quick

release lever and turn the flat nut on the right

side (chainside) of the seat mounts with a 5

mm allen key.

Pull the lower seat half out of its mounts, then

the upper seat half.

Quick release levers, Seat

Danger! An incompletely or improperly

closed quick release can result in parts coming loose, and hence in a crash, possibly resulting in serious injury.

Caution! When storing the seat, please take

care not to bend or break the seat mounts.

Protect the edges of the seat mounts with

padding to avoid scratching other objects

with the seat mounts.

Page 30

Do not brake in a bend, always brake before a

bend. Braking increases the risk of slipping.

Especially when it is wet the rear wheel immediately slides out of the bend while braking

and this can result in a serious fall!

If you should hear any unusual sounds while

braking the braking pads might be worn. Do

not use your bike any further until you have

checked the braking pads according to the manual of the brake manufacturer or ask your local dealer.

28

HP

Velotechnik

Brakes

The Speedmachine is equipped with a powerful disc brake system.This system features an

excellent braking performance and little wear

of the brake pads.You can choose between cable-operated disc brakes or hydraulic disc

brakes. Please read the separate manual that

comes with your bike for details.

Make yourself familiar with the braking system.

Remember which lever pulls the front brake

and which the rear brake.

If the arrangement of the levers does not correspond to what you are used to, please have a

bicycle mechanic change it. Please contact your

local bike dealer to find out if there exists any

legal requirement for the arrangement of the

brake levers in your country.

For optimum handling you can adjust the distance between the brake grip and the handlebar with a small hex-headed screw at the grip,

please see the respective manual for details.

Note that the front brake is the most effective

brake on the Speedmachine.With the front

brake, you achieve a much higher braking effect than with the rear brake.The rear wheel

has a tendency to lock up and slip on the pavement even under low braking forces.The

braking effect of modern brake systems can be

more powerful than what you have been used

to until now. Do brake carefully. When you

brake too much with the front brake the rear

wheel may lift off the street and the bike may

tumble over.

Brakes

Danger! Please note that the braking di-

stance is much longer when it is wet or

when the bike is heavily loaded. When riding

on wet, sandy, icy or slippery roads you have

to use the front brake very carefully to avoid

that your front wheel slips. If it does so you

will no longer be able to handle your bike,

which might lead to a serious fall.