Page 1

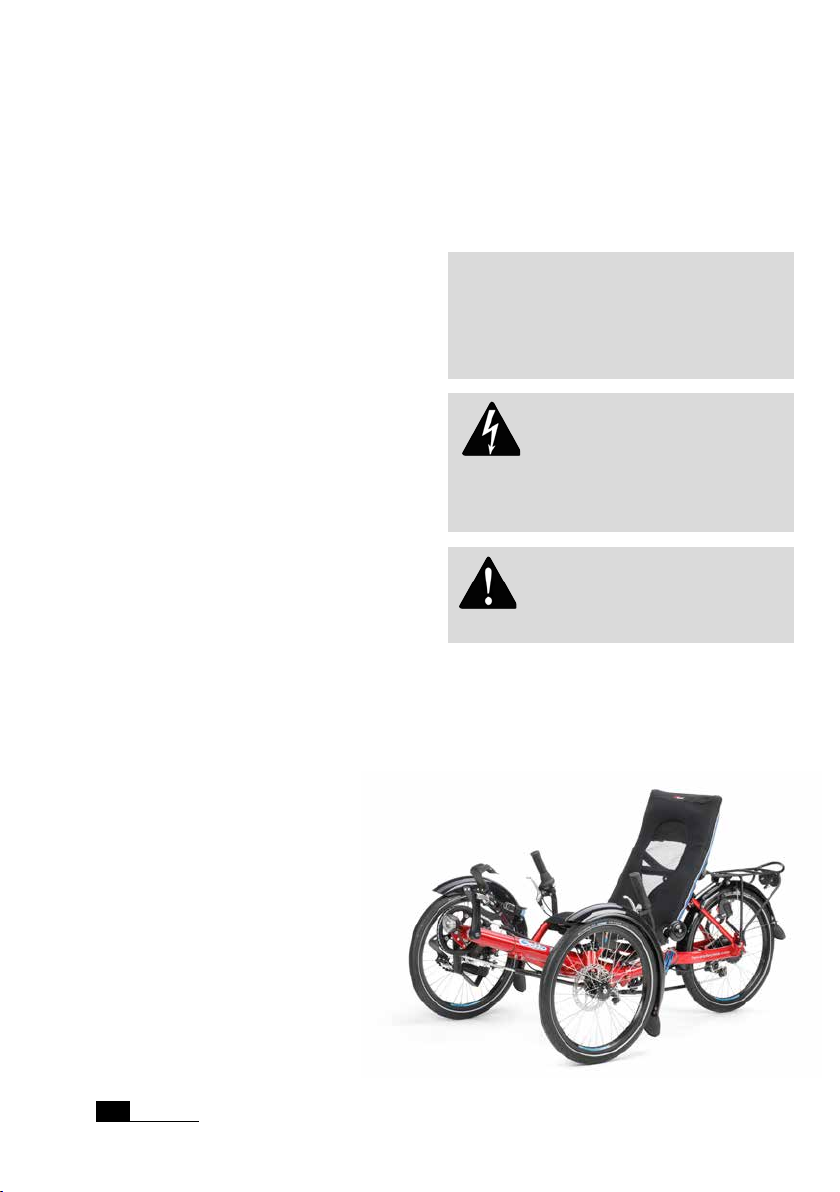

recumbent

2016

technology

... recline in style!

Velotechnik

HP

hpvelotechnik.com

Operating manual

and service instructions

Feb. 2016

Page 2

OrthoFlex-Seat

Handlebar

Trike fender

Rear rack

Rear light and

braking light*

Gearhub

Chain and chaintubes

Idler

Standing-up aid*

Trike fender

Front boom quick adjust*

Companion bar*

Brake lever

Cranks and

chainrings

Headlight

Twist shifter

Pedals with heelstrap

and foot clamp

Track rod

Retention belt system

Mirror*

Front boom

Brake discs

Scheme of the Gekko fxs and its components.

Parts marked with * are options.

Parts marked with ** belong to the optional electric assist system.

Hub motor**

Batterie**

Folding hinge

Page 3

Introduction

Dear customer,

thank you for buying the recumbent bike Gekko fxs designed by HP

Velotechnik and congratulations on the purchase of your new recumbent tricycle!

With this high-quality tricycle, you will enjoy many years of exhilarating riding pleasure.

Your satisfaction and the safety of your child are our main concern.

On the following pages, this manual will inform you about important

safety issues as well as maintenance and care instructions.

Even if you have many years of experience with bicycles please do

take your time to read this manual carefully before the rst ride. Your

recumbent tricycle is designed with the latest recumbent technology

by HP

In this manual you will nd detailed instructions on how to optimize

your tricycle to meet your demands and riding style as well as your

size and weight. In addition to this, we have put together a collection

of information on care and maintenance as well as special technical

advice from our engineers. Important: Please send us the attached

warranty registration form for your extended warranty (see page 76).

Velotechnik that partly needs special treatment and care.

This guide helps you to keep your tricycle in perfect condition so you

will always experience maximum fun, comfort and safety.

Enjoy yourselves and have a great ride!

Paul J.W. Hollants, Dipl.-Ing. Daniel Pulvermüller and the

HP

Velotechnik team

Velotechnik

HP

1

Page 4

Content

Safety instructions 4

General safety instructions 4

Intended use 5

Indications 5

Contraindications 5

Individualisation 5

Load capacity 6

Carrying luggage 6

Final assembly 6

Bolts and nuts 7

Quick release levers 7

The rst miles 8

Safety instructions (bicycle) 9

Legal requirements 9

No alteration of parts 9

Frame number and identication marks 10

Added parts and accessories 10

Replacement of parts 10

Transport of children 11

Pedelec system 11

Trailer 11

Handling instructions 12

Riding a recumbent tricycle 12

Learning the new riding technique 12

How to ride correctly and safely 13

Wear protective clothing 13

Use special pedals 13

Slowly increase the strain 14

Adjusting your new tricycle 15

Basic adjustment of the frame length 15

The OrthoFlex mesh seat 17

Adjusting the seat mesh 18

Adjusting the seat back angle 18

Padding with seat cushion elements 18

Attaching the retention belt system 19

The head rest 21

Adjusting to your size 22

Adjusting the front boom 22

Adjusting the length with front boom quick

adjust 25

Special pedals 27

Heel support pedal 27

Ergonomic pedal / Ergonomic pedal with

lower leg xation 29

Clipless pedal 34

Adjusting the handlebars 36

A good setting for the handlebars 36

Setting the width and angle 36

Adjusting the cable length 38

Handlebar grips 38

Folding 39

Folding of Gekko fxs 39

Lighting system 43

Lighting systems for bicycles 43

Brakes 45

Handling of the brakes 45

One-hand operation for brakes 46

Maintenance of the brakes 47

Hydraulic brakes 48

HP

Velotechnik

2

Page 5

Content

Gear system and chain 50

Handling of the gear system 50

Adjusting the gear system 51

Chain 52

Chain tubes 54

Replacing the tubes 55

Chain roller 55

Go SwiSSDriVe pedelec system 56

Wheels 57

Disassembling the wheels 57

Tyres 57

Front wheels 58

Rear wheel 58

Spokes 58

Headset 59

Adjusting the headset 59

Wheel alignment 60

Measuring toe-setting 60

Adjusting toe setting 60

Mudguards 63

Front mudguards 63

Mounting of front mudguards 63

Rear rack 64

Rear rack 64

Water bottle cages 65

Water bottle cage 65

Comfort and ability options 66

Companion bar 66

Adjustment of the companion bar 66

Standing-up aid 67

Walking aid mount 67

Handling of the walking aid mount 67

Handrest 68

Maintenance and care 70

Maintenance routine 70

Wear and tear 70

Cleaning, conservation and disinfection 70

Storing the bicycle 72

Transport in the car 72

Technical Data 73

Technical Data 73

Tightening torques 74

Tightening torques 74

Warranty and Service 76

Warranty 76

Warranty policy 76

Warranty pass 77

Warranty pass 77

Service plan 85

Revision February 2016. For latest product

information and manuals, please check out

our website at www.hpvelotechnik.com.

hP Velotechnik ohG

Kapellenstraße 49

D-65830 Kriftel

Tel. +49 - 61 92 - 97 99 2-0

Fax +49 - 61 92 - 97 99 2-299

HP

Velotechnik

3

Page 6

General safety instructions

The manuals of component manufacturers

such as the brake manufacturer, the gear

system manufacturer, and the pedal manufacturer also belong to this manual. They give

detailed information on operating and

maintaining these specic parts. Please read

the manuals of the part manufacturers as

carefully as this manual.

Please share the information you have read

with your child and involve it in this process.

Make sure, that it has understood all relevant functions of safety. Please provide this

manual to any other user of your recumbent before using it. Attendants of mentally

handicapped persons have to make them

Safety instructions

understand all safety-related functions prior

to every ride; these drivers are only allowed

to use the Gekko fxs supervised by an adult.

The maintenance and adjustment of this

recumbent partly requires special tools and

skills. Do only works within your limits and,

for the purpose of your own safety, do not

go beyond. Should you be uncertain at any

point, get in contact with your local dealer.

The instructions in this manual apply only to

a completely assembled Gekko fxs tricycle

with standard parts from the series production of HP

The texts in the grey boxes are particularly

important for your safety. Please read them

carefully. The signs explained below will be

used in this document without beeing

explained again!

Danger! Texts that begin with

„Danger!“ mark an immediate danger for

your life and your health. Please read them

carefully.

Attention! Hints with the text

„Attention“ are important for your safety!

Velotechnik.

4

HP

Velotechnik

Page 7

General safety instructions

Intended use

Use your

the intended use.

The Gekko fxs is a bike for the use on

streets and paved roads. This tricycle is not

designed for the use in racing and off-road

riding, for jumping or acrobatics, and you

must not ride across curbs, stairs, etc.

The Gekko fxs allows children and teenager

with specic handicaps (see indications) to

gain individual mobility. Physiotherapy gets

supported, to hold up and keep balance

is trained as well as the coordination of

movements.

The power transmission takes place in a

reclined position. Actuation occurs by a

rotation that the leg muscles transmit on

the pedal cranks. An optional electric motor

can give support.

Using your bike on public roads is only

allowed if it has been equipped with the accessories that are required by the applicable

trafc regulations of the country in which

you are using it.

Never drive without holding on! Before

your rst ride, read the chapter “Riding

a recumbent tricycle” on page 12 and

get carefully used to the different vehicle

performance.

Damage through inappropriate use, assembly errors, accidents or similar activities

and wilful damage results in the loss of any

warranty.

The intended use also includes the precise

observation of the prescribed usage and

maintenance regulations and instructions.

hP Velotechnik tricycle only for

Indications

According to your child‘s therapist suggestion, indications for riding this tricycle may be:

Neuromuscular disorders:

e. g. cerebral palsy or muscular dystrophy

The tricycle can also be used for rehabiltation of the mobility with coordination or

balance disorders and restricted natural

movement.

The tricycle should always be considered

when a child owing to its special physical

conditions is unable to ride standard children bicycles or vehicles, even with training

wheels.

Contraindications

The bike may not be used by persons

who are not able to ride a bike safely and

independent. For example in the case of

blindness or the unability to move necessary extremities controlled.

Individualisation

It is possible to adapte the Gekko fxs to

indivual demands. HP

huge variety of optional accessories. For

example: electric motor, one-hand operation, special pedals, head rest, standing-up aid,

handrest, walking aid mount and companion

ba r.

Velotechnik offers a

Safety instructions

HP

Velotechnik

5

Page 8

General safety instructions

Load capacity

The maximum load (rider + luggage) is

100 kg (220 lbs). The maximum total weight

(bicycle + rider + luggage) is 130 kg

(286 lbs). The lower limit is valid. With a

coupled trailer, the maximum total weight

must not exceed 130 kg (286 lbs).

Carrying luggage

Luggage transport is only allowed with the

special racks designed by HP

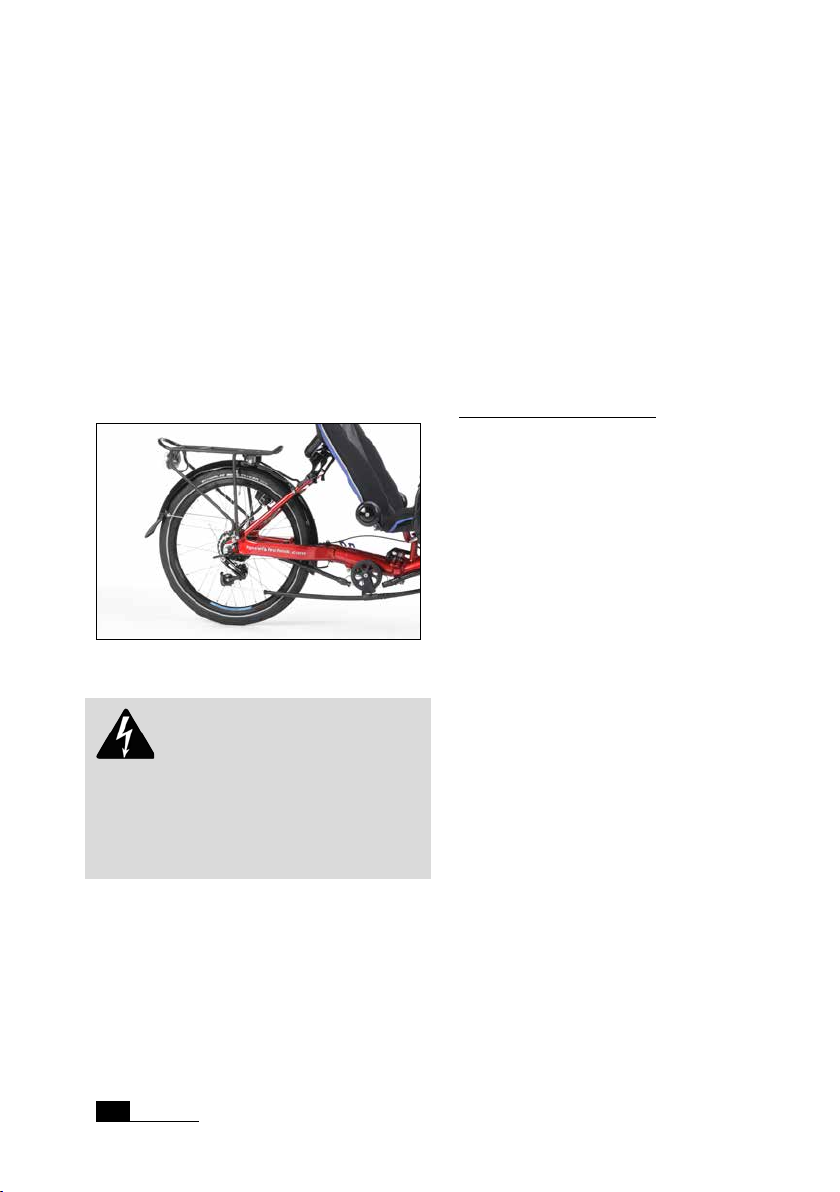

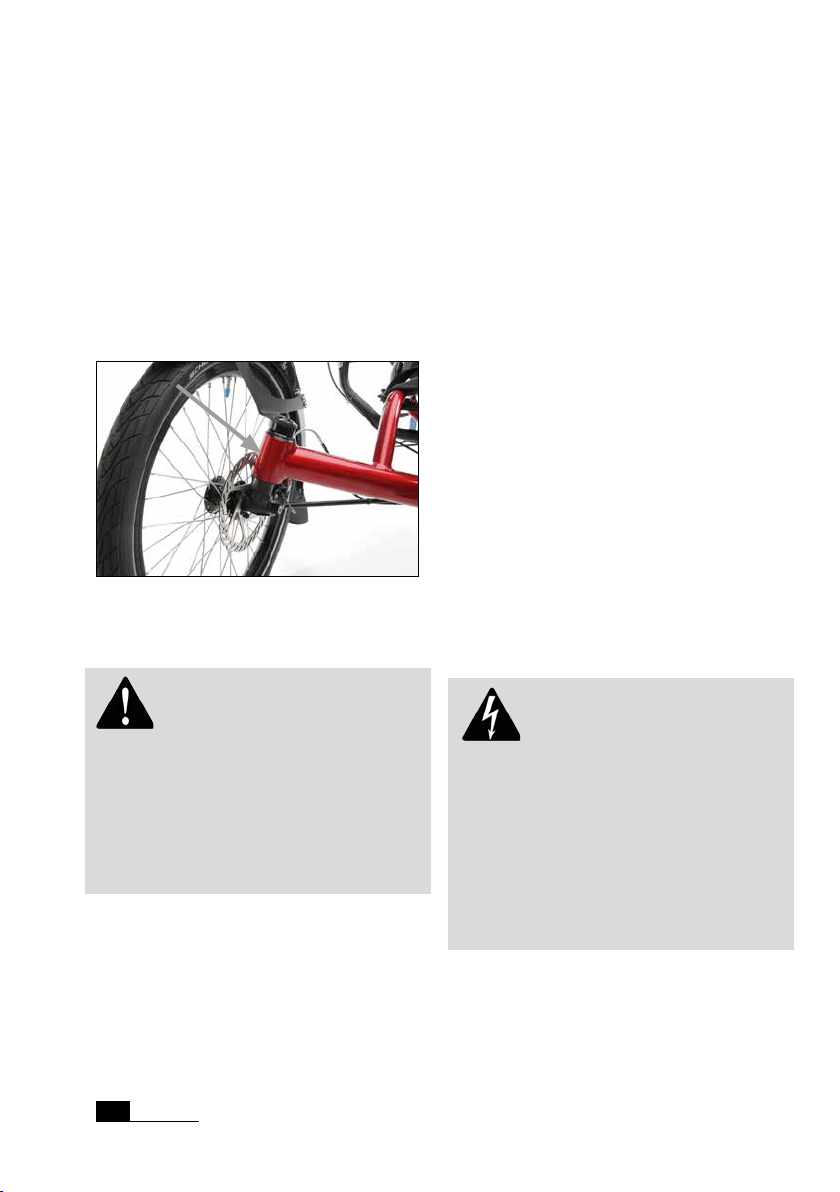

Rear rack on Gekko fxs

Danger! Additional loading can

inuence the handling of your tricycle considerably. If you plan on riding with heavy

luggage we advise you to make a test ride

on a street with no trafc to get used to

the new situation.

Velotechnik.

Take care that your luggage is safely stored

on the racks. Bags must be tightly fastened

to the racks so they can not move. Make

sure that loose parts like straps or belts can

not touch the wheels, the derailleur, or the

suspension.

The rear rack is designed for standard

tricycle panniers. Take care that your luggage

does not cover the lighting system and the

reectors of your tricycle and that they stay

fully functional.

Maximum load for carriers:

The maximum load on the rear rack is 25 kg

(55 lbs).

Final assembly

Your tricycle has been delivered to your

specialist dealer only partly assembled.

Your dealer has to have carefully nished

the assembly, perhaps altered the specica-

tion of your tricycle to meet your special

requirements and has to have performed

a test ride. Please make sure that this predelivery service is recorded in the Warranty

Pass at the end of this manual.

All screws must be checked and tightened,

especially on the handlebar, stem, knuckles,

swing arm pivot and wheels. Please follow

the tightening torque settings listed in the

table on page 74.

The load should be placed as close to the

body of the rider as possible, since this

results in better riding performance. You can

also improve the handling of the tricycle by

positioning the centre of gravity of the luggage as low as possible, so pack heavy items

in the bottom of your panniers.

HP

Velotechnik

6

Derailleurs and brakes must be checked and

adjusted. Please follow the instructions in

the manuals of the parts manufacturers that

come with this manual.

Page 9

General safety instructions

Bolts and nuts

Attention! Screws must be

tightened with prescribed tightening torque.

In this manual tightening torques are given

in „Nm“ (Newton meter). Always use a

torque wrench wherever a torque setting is

given in this manual. Never rely on „feeling“.

Screws tightened too much or not enough

can break, which can lead to dangerous

accidents. In case you don‘t own a torque

wrench have your bicycle mechanic do the

respective work. You will nd tables with

the prescribed torque settings on page 88

and 89 in this manual.

Screws gradually settle in and hence they

can come loose. Therefore check the screws

regularly if they are tightened appropriately

with a torque wrench.

In the tables on page 74 and 75 you will nd

the prescribed tightening torques, they refer

to greased screws!

The grease also prevents your screws from

seizing in their threads so that they won‘t

unscrew anymore. In particular, screws

made of stainless steel are susceptible to

this and therefore have always to be put in

with grease.

Do use high quality acid free grease, if possible a lubricant with added solid particles

like Teon or MoS2. Their ingredients still

work properly after the thinner grease has

been removed from the contact surfaces.

Alternatively you can use thread locker e.g.

loctite, that you apply to the screw before

you put it into the thread.

Always check the screws very diligently for

signs of corrosion. Rust at the screw heads

may also lead to the screw seizing in the

thread. When the metallic and shiny coating

of galvanised screws comes off and discloses

dull, gray-brown steel you have to exchange

the screw.

When you exchange screws please only use

screws of the same type. Screws come in

different strength classes. Please only use

galvanised screws of the same type and

strength, corresponding to the German

strength class 8.8 or stainless steel screws

grade A2-70, when not given any other

recommendation. If you are in doubt please

ask your specialist dealer.

Safety instructions

Quick release levers

Quick release levers hold wheels and seat in

position. A quick release lever consists of

two basic parts: the lever on one side provides the clamping force. With the adjusting

nut on the other side you adjust the clamping tension on the screw thread.

Danger! An incompletely or improperly closed quick release can result in

parts coming loose and hence in a crash,

possibly resulting in serious injury.

To open the quick release, move the lever

away from the frame. In doing so the

inscription „open“ should be visible on the

lever.

To close the quick release, move the lever

with power in the other direction so that

the word „close“ is visible on the outward

side of the lever.

HP

Velotechnik

7

Page 10

General safety instructions

At the start of the lever‘s motion, for, say,

half of its movement, the lever should move

very easily, without any clamping action. In

the second half of the lever‘s movement the

force on the leer should increase considerably, corresponding in the end to 15 – 20 kg

(33 – 40 lbs). In its nal position, the lever

should come parallel with the tricycle and

should not stick out to one side.

Check the security of the lever by attempting to twist the lever. If the lever can

be made to pivot around in a circle the

clamping is too loose. You must re-open the

quick release, hold the lever and increase

the clamping tension. Do this by screwing

the adjustment nut on the other side by

half a turn. Close the lever and check the

clamping anew.

Finally, check that the part being secured is

rmly xed: Lift each wheel several inches

off the ground and give it a slap onto the

tire from above. A properly xed wheel will

remain secure in the frame‘s dropouts. Parts

that are fastened with a quick release open

easily. Thus, they are more susceptible to

theft. Therefore, always secure the wheels

with a lock when you park your tricycle. It

is also possible to exchange the quick releases with special security screws (e.g. from

Pitlock) that can only be opened with a

special tool. For this please consult your

local specialist dealer.

The rst miles

The rst 300 km (186 miles) are important

for breaking in the tricycle. During the rst

use of a new tricycle the screws may settle

and become loose. Cables and spokes may

stretch. Bearings may show play. Please be

very attentive during that period.

After 300 km or after two months at the latest you will have to take your tricycle to a

bicycle mechanic for the rst service. Please

record this rst service and the works

performed in the warranty pass on page

77. This rst service is the prerequisite for

further use of the tricycle and for your

warranty claims.

Danger! Check the proper setting

of quick release levers always before riding,

especially when the bicycle has been unattended.

HP

Velotechnik

8

Page 11

Safety instructions (bicycle)

Legal requirements

When you ride your tricycle on public

roads it must comply with national legislation and guidelines. They will vary from

country to country.

In general, there are minimum standards for

brakes, reectors and lighting systems, as

well as usually a general duty to ensure that

your vehicle is in roadworthy safe condition.

There will also be a duty to ride in a safe

and responsible manner. If you ride your

HP

Velotechnik tricycle in trafc you should

be sure to observe all the applicable laws

and regulations.

In most countries, including Germany and

the UK, two independent braking systems

are required. Do not ride with only one

brake working! Please contact your local

dealer to nd out about your legal obligations.

In the scope of German StVZO your equipment has to meet the following requirements:

• two functional, independent brakes

• a dynamo or battery driven lighting sys-

tem with a white headlight aiming

forward whose beam center touches the

road 10 m ahead

• a red taillight and a red rear reector

which may be combined

• at least one white reector aiming for-

ward and a red large area reector with

“Z” label aiming to the back

• two yellow reectors attached to the

spokes in every wheel; may be substituted

by tires or rims with white reective ring

• yellow pedal reectors on both sides for

the pedals

• a bell

By default the Gekko fxs is equipped accordingly to the current valid StVZO.

As an addition, we recommend to mount a

ag on a pole for better visibility in trafc.

You can nd a bracket for the pole at the

rear rack or the rear light mount.

The safety equipment on your tricycle must

be checked before every ride and maintained in proper condition.

Trafc regulations may change. Please check

currently valid regulations or ask your

specialist dealer.

In Germany, children under the age of eight

only may use a bicycle on sidewalks and

under adult supervision. Take especially care

of pedestrians.

No alteration of parts

Attention! You are not allowed

to perform any work on the parts of the

tricycle, especially frame, fork, handlebar and

seat, which might endanger their solidity.

These works include drilling holes, welding,

brazing, paint methods that add heat or any

other chemical treatment. If any of these

works is done improperly it may result in a

loss of strength by direct damage or increased susceptibility to corrosion.

Safety instructions

HP

Velotechnik

9

Page 12

Safety instructions (bicycle)

Frame number and identication

marks

The frame number is placed on the one side

of the steering tube. If needed, an additional

identication number can be engraved at

the other side of the stering tube.

However, we recommend to use adhesive

stickers for additional identication numbers.

Position for identication mark on the Gekko fxs

Added parts and accessories

Attention! Mounting additional

parts or accessories is at your own risk. It

is important that you carefully read the

installation guide of the manufacturer. Additions to the handlebar like fairings, handle-

bar ttings, bottle holders, etc. may impair

your safety due to additional loading or clips

with sharp edges.

Additional accessories may impair the function of your recumbent tricycle. We advise

you to generally ask your dealer before you

mount any special parts or accessories to

your tricycle.

Take care that the handlebar and the wheels

always stay moveable. You must not add

any parts to the handlebar or the seat that

might endanger the rider through sharp

edged or pointed shapes while steering,

getting on and off the tricycle or bumping

against something.

Before you purchase a bell or a lighting

system make sure that these accessories

conform to your national laws and regulations.

Replacement of parts

The replacement of parts relevant for safety

(especially brakes, lighting system, stem,

handlebar, knuckle, drive train) may only be

done with original parts by a bicycle mechanic, since it requires a certain degree of skill,

suitable tools and mechanical aptitude.

Any technical change you perform on your

own is at your own risk! This can also result

in the loss of any warranty.

Danger! If any part is deformed

(e.g. due to an accident or overload), especially frame, knuckles, handlebar, seat

mountings, pedals, cranks and brakes, it is

not allowed to use it any further or repair

it. Do not try to straighten bent parts. You

must replace them for your own safety. If

you do not replace a damaged part it can

result in a total failure of the part and you

may be seriously injured!

10

HP

Velotechnik

Page 13

Safety instructions (bicycle)

Transport of children

Velotechnik tricycles are not designed

HP

for the transport of children. You are not

allowed to mount a child‘s seat.

It is only allowed to transport children in a

trailer that has been specially designed for

that purpose.

Pedelec system

Instructions for the use and safety of the

optional pedelec systems are referred in the

systems manufacturer‘s manuals. Please read

them carefully before use.

Trailer

You are allowed to use trailers (double trail

only) up to 40 kg (88 lbs).

When using a rear rack, you will need a

weber coupling.

Please make sure the maximum allowed

load on the trailer hitch is not exceeded.

weber offers a special, lowered coupling for

chariot trailers on 20 inch rear wheels.

Safety instructions

HP

Velotechnik

11

Page 14

Riding a recumbent tricycle

Learning the new riding technique

Your new tricycle has been assembled by

your dealer and adjusted together with

you as described on the pages 15 and

following in the chapter „Adjusting your

new tricycle“. Before you sit down on your

tricycle and enjoy your rst ride please

make yourself familiar with the instructions

on riding technique and handling.

To ride this recumbent you will have to

make yourself acquainted with the different

Handling instructions

riding position. Make sure that you and all

other future users of this tricycle will have

read this manual carefully prior to the rst

ride. If you are in doubt please consult your

local dealer.

Before the rst ride the users of this

recumbent have to practice and make themselves familiar with the different handling.

We recommend to practice on a quiet road

away from trafc. Before you ride the tricycle in trafc you must master the handling

completely.

Danger! Never touch the ground

with your feet while the tricycle is still

moving. The feet could be caught on the

ground and be pulled backwards and

dragged under the cross bar which could

lead to a serious injury. We strongly recommend using a pedal binding system like

clipless pedals or toe clips and straps.

Keep all three wheels on the ground while

riding. If you are cornering too fast, your

tricycle can be upset and fall over. Lean into

curves when turning sharply. At high speed,

keep your upper body quiet as any upper

body movements can inuence the steering

of the tricycle.

Practice cornering away from trafc to learn

what speed is safe at a specic turning angle.

If you lift up a front wheel, immediately

steer in the opposite direction to bring it

safely back to the ground.

Attention! When getting on and

off the tricycle, make sure to avoid pulling

at the handle bars or stepping on the tie

rods. To get off the tricycle, sit upright on

the front seat edge and then stand up. Grip

the front wheels or the seat back as extra

support, not the handlebars. If you pull

rmly at the handlebars, the steering can

be damaged.

HP

Velotechnik

12

Danger! Please be aware that due

to your low seat height other road users

may notice you very late. Ride anticipatory

with this in mind.

This is especially important while riding in

darkness. You yourself have a much better

view than others perceive you. Ride defensively. We recommend mounting a well visible

and reecting ag to the tricycle while using

it in trafc. Find more information about

lighting systems on page 43. Please ask your

dealer for more information.

Page 15

Riding a recumbent tricycle

How to ride correctly and safely

Attention! Always carry your

tricycle over stairs and curb stones. Do

not ride through big road holes. Especially

when road holes are lled with water it is

very difcult to guess how deep they really

are.

In case you hit such an obstacle, frame and

steering may be damaged which can result

in a serious fall. At rst, the damage may

be unnoticed. Please check your tricycle

immediately for deformations and cracks. If

you are in doubt please consult your local

dealer.

Do not ride freehand

Danger! In order to ride safely

you have to keep both hands at the handlebar. Even when signalling keep at least one

hand at the handlebar. Otherwise, unforeseen bumps in the road or oscillations of

the steering may lead to a serious fall.

How to ride correctly and safely

Always adjust your speed to the trafc, the

road and the weather conditions. Ride slowly in curves and on unknown roads. Always

ride at a safe distance from other road

users, and when you ride in a group never

ride side by side.

most attentive car driver may not see you

due to your low riding position.

Wear protective clothing

Riding a tricycle is a potentially dangerous

sport where accidents can happen even

when you take care of every safety instruction prescribed.

We recommend you to wear an approved

bicycle helmet that ts well. Protect yourself

by wearing special sports clothing that ts

tight and is reective. If you‘re wearing

wide pants use clips to protect them from

getting caught in the chain – or use an old

fashioned method and put the pants in your

sockets.

When you fall with a recumbent you’ll usually land on the side of your hips and your

hands. Wearing reinforced cycling shorts and

gloves reduces the danger of skin injuries

considerably.

Use special pedals

The Gekko fxs comes with heel support

pedals by default.

If you wish, you can equip your recumbent

tricycle with clippless pedals, ergonomic

safety pedals or ergonomic pedals with

lower leg xation. To accomodate persons

with different physical impairments, the ergonomic versions can optional be choosed

for one side or both side.

Find more information on pages 27 and

following.

Handling instructions

When you approach a trafc light never ride

past the line of waiting cars since even the

HP

Velotechnik

13

Page 16

Riding a recumbent tricycle

Slowly increase the strain

We recommend you to perform only short

rides without much power during the rst

weeks. Always use a low gear and ride with

a high pedalling frequency. Only after having

acquired some training do increase the

strain slowly.

When you ride on a recumbent you use

different muscles than on a conventional

bicycle, and they have to be trained rst. The

very high position of the bottom bracket

requires your muscles and blood transport

system to slowly familiarise with the new

position. In case of an overload the blood

circulation in your legs may be affected

which shows in loss of power, a prickling in

the toes, falling asleep of the legs or cramps.

When you feature a sporty way of riding it

can take up to 6 months until you have become accustomed to your new recumbent.

If there is pain in your knees occuring while

riding this is usually the result of too much

power put into pedalling. The good support

of the back sometimes misleads to putting

the full power of the legs in the pedal, simi-

lar to the leg training machines in a tness

center. When you repeat it regularly it is

harmful for the knees. Pain in the knees often results from an overuse of the muscles

in the knee that can also be strengthened by

exercise.

Please contact your physician if you have

pain over a longer period of time.

Also, a wrong adjustment of the front boom

to the leg length (in most cases too short)

can lead to pain in the knees. Advices for

increasing the training can be found in a lot

of cycling books or magazines. Your pedalling frequency should stay between 80 – 100

revolutions per minute and not fall below

60 while going uphill. If necessary consult

your local dealer and have him adapt the

gear range to your style of riding.

HP

Velotechnik

14

Page 17

Adjusting your new tricycle

Your position on the recumbent bicycle is

essential for your riding comfort, well-being

and efcient cycling. Therefore you should

adjust the frame, seat, handlebar and suspension to your individual requirements.

Find detailed information about the possibilities of adjustment on the following pages.

Danger! All procedures described

here require a certain degree of skill, suitable tools and mechanical aptitude. After

any adjustment perform a static check and

take a test ride on a quiet street, away from

trafc. If you have any doubts please contact

your local dealer.

Basic adjustment of the frame length

For the basic adjustment of the frame length

for different body heights, the rear frame

tube and the seating have to be adjusted

with the blue quick release levers.

Adjusting range of the Gekko fxs

If your tricycle is equipped with the optional

front boom quick adjust, please read the instructions in the separate manual in addition

to the following instructions.

The Gekko fxs can be adapted for riders

between 1,20 m to 1,80 m (3'11" to 5'11").

The basic adjustment takes place by changing the frame length.

In order to adapt the bicycle as closely as

possible to your body dimensions and to

nd your ideal position you need to adjust

the front boom, seat and handlebars.

If you open these quick release levers of the

OrthoFlex-seat, seat depth and frame length

can interdependent be slided in or pulled

out.

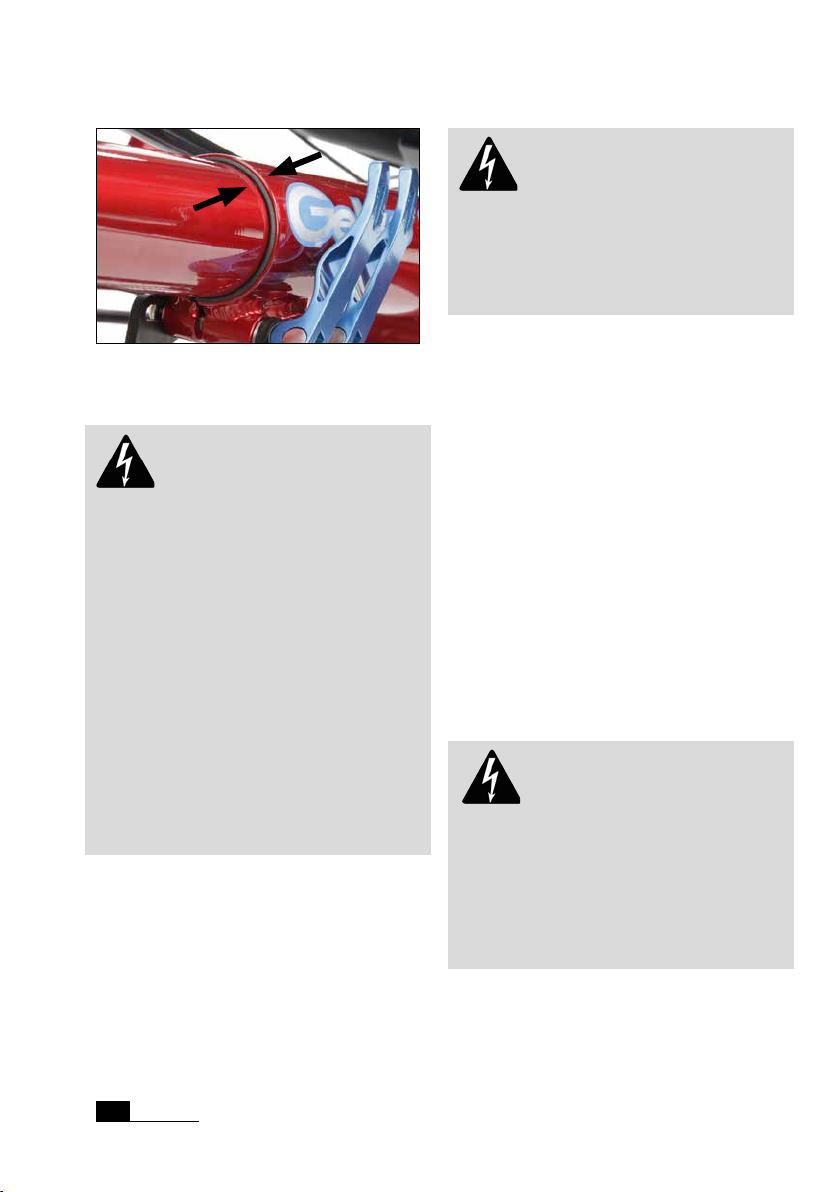

First, open the seatback quick release lever

that allows to adjust the seat angle. Then,

swivel the seatback to the front.

Opening the seat back quick release lever

Velotechnik

HP

15

Handling instructions

Page 18

Adjusting your new tricycle

1

2

Rear frame with frame quick release levers (1) and

seat quick release levers (2)

Now open the frame quick release lever

(on the left side, in front of the rear wheel).

Then, you can slide the rear frame part in

or pull it out to the required lenght.

Make sure, that the end of the frame tube

is not visible in the clamping slot when you

look from below. In the case it is visible,

slide the rear frame part back in until the

tube end is not visible anymore.

If the desired length is reached, align the

rear frame part to a neutral position. Then,

close the quick release lever only half.

Open the two seat quick release levers at

the rear edges of the seating. If necessary,

knock a little on the quick release levers in

order to loosen the wedge inside the seat

tube.

Then, you can slide the seating length in or

pull it out. If the movement is not working

or wedged, you can help with small knocks

on the lower part of the seatback.

Make sure, that the seat net in the front

part slides along as well.

The seating length can be slided in or pulled out.

Next, slide the seating so far in that you can

insert the seat mountings easily back into

the mounting of the seatback quick release

levers.

Check if the seat back is perpendicular to

the riding direction if you look from above.

Correct if not.

Then close the seating quick release levers

and the frame quick release levers completely.

Finally, adjust the desired seat back angle

(see page 18) and close the seat quick

release lever.

You can use the optional adjustable end

stops, that allow an exact positioning of the

seat.

Attention! The minimum insertion

depth of the rear frame part into the main

frame is 6,5 cm (2 1/2"). The end of the

rear frame part must not be visible in the

clamping slot when you look at the main

frame from below, since this may result in a

damage of the frame.

16

HP

Velotechnik

Page 19

Adjusting your new tricycle

The OrthoFlex base length can be be inni-

Attention! Always tightly close

the seatback quick release lever, the seating

quick release levers and the frame quick release levers. The seat is a structural part of

the tricycle frame. An opened quick release

may lead to frame damage. Please pay attention to the instructions about quick release

levers on page 7.

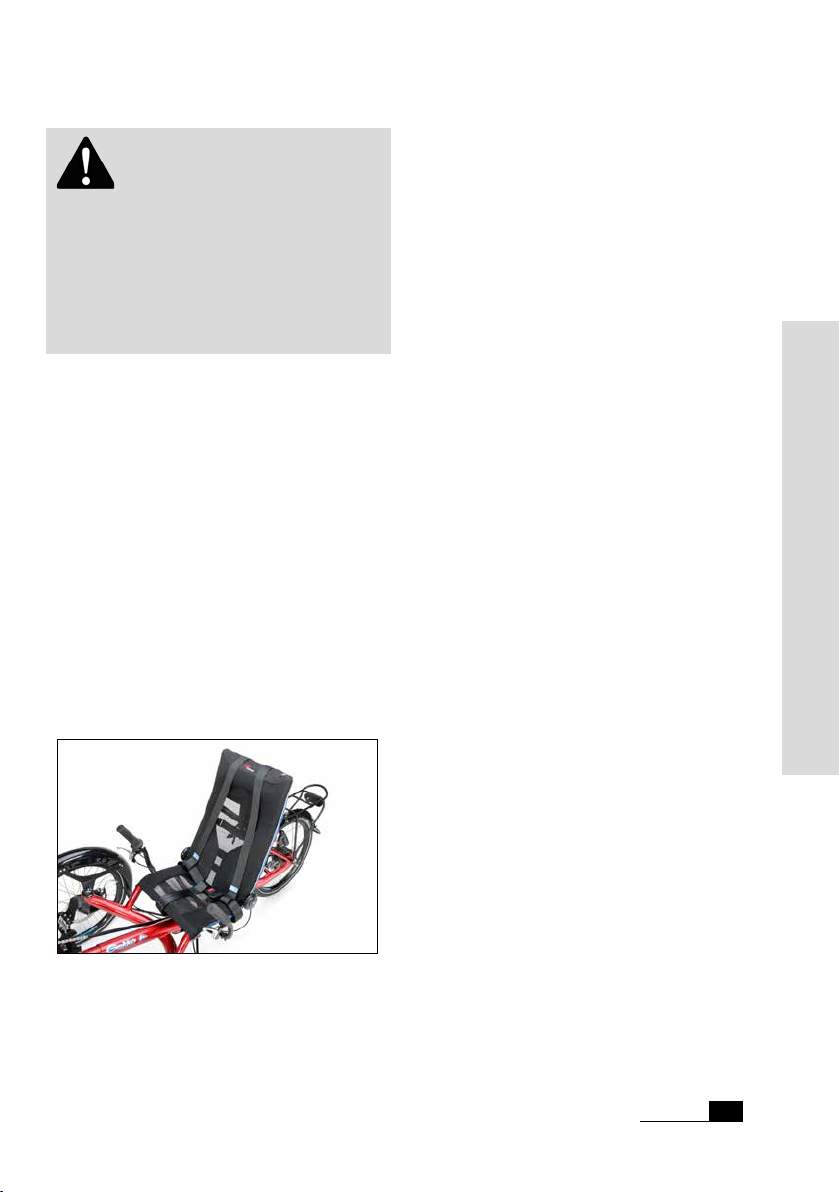

The OrthoFlex mesh seat

The Gekko fxs comes with the OrthoFlex mesh seat. The seat is integrated into

the frame and remains on the tricycle for

folding. The seat cushion and the characteristic of the seat net material the OrthoFlex

mesh seat is slightly cushioned.

The seat mesh is washable and has lateral

reective strips to improve visibility at dusk.

In the top of the backrest is a practical

pouch where you can put small items like

keys, wallet as well as an optional rain protection cover for the seat.

tely adjusted together with the rear frame

to the riders size (see page 15). With a

quick release, the seat angle can be adjusted

between 48 and 64 degrees.

The contour of the seat can be adapted

to the natural S-shape of the spine. The

support of the pedaling forces takes place in

the area of the lumbar vertebrae. By arranging the eight individually adjustable padding

elements in the seat pockets adjustments in

the lordotic area (lower lumbar spine) are

possible.

The OrthoFlex-seat is also a practical base

platform for therapeutic changes by an

orthopaedic technician who can install

custom seat support pads in the pockets.

The adjustment of the seat mesh and the

proper seat angle is crucial for a comfortable feeling while riding your recumbent.

The Gekko fxs has a retention belt system

with customizable straps on the seat. The

adjustable retention belt system can be

used, depending on the therapeutic need, as

lap belt or as 4- or 5-point-belt.

Handling instructions

OrthoFlex mesh seat with retention belt system

The seat can be individually adjusted to

different therapeutic needs.

Riders above 1,40 m (4'7") can install an

optional head-rest, adjustable in height and

angle.

At the left top edge of the seatback is an

adapter for a ag post.

Velotechnik

HP

17

Page 20

Adjusting your new tricycle

Adjusting the seat mesh

Eight tension belts on the back side of the

seat allow the adjustment oft the seat net

to your needs.

Does the seat feel to soft or gives you the

feeling of sitting on the seat frame, increase

the tension of the belts on the back side of

the seat.

Attention! Always tightly close

the seatback quick release lever. The seat is

a structural part of the tricycle frame. An

opened quick release may lead to frame

damage. Please pay attention to the instruc-

tions about quick release levers on page 7.

Is it hard or uncomfortable, or do you feel

like slipping off when going through curves,

release the belts in the relating area.

It may be necessary to put a high force on

the belts to apply sufcient tension to the

belts. If it can not be done by hand, make

use of a at nose pliers and pull the lose

end of the belts rmly. To easily loosen the

belt, pull up the round end of the strap

retainer.

Adjusting the seat back angle

A great advantage of the OrthoFlex mesh

seat on your Gekko fxs is the possibility

to adjust the seat back angle very quickly.

Thus rides in an upright seat position or in

a at position are possible according to the

individual needs.

The seat back is fastened with a quick

release lever on a slotted aluminium seat

mounting. You can adjust the seat back angle

by 16 degrees by simply opening the quick

release lever. Having set up your desired

seat back angle close the quick release tightly to make sure the seat back will not move

during the ride.

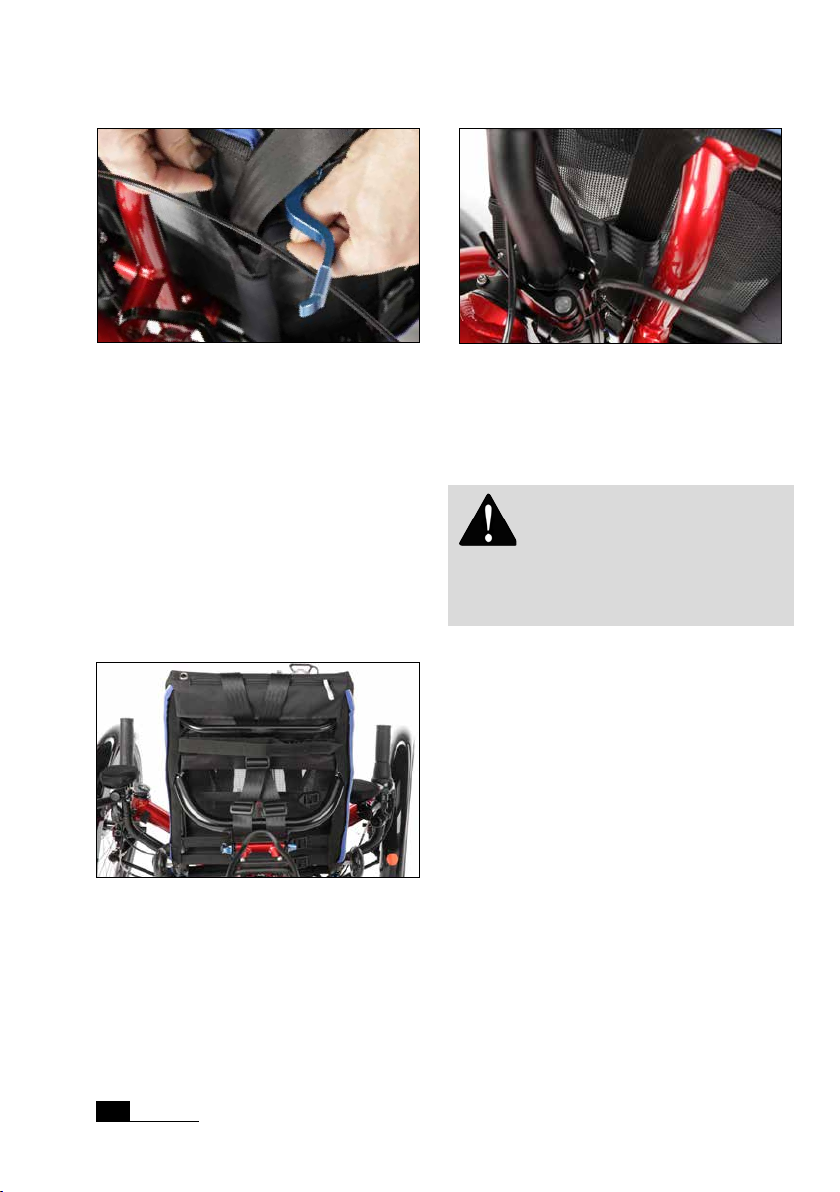

Padding with seat cushion elements

The sides of the seat are equipped with

special pockets – their openings are clearly

marked by blue ribbons. Open the hookand-loop straps of the mesh seat there.

The pockets for the padding are closed with hook-andloop straps.

Now, you can arrange the eight individually

adjustable padding elements in the pockets

according to the rider‘s needs.

You can slightly reduce the tension of the

seat seat net to get more play for inserting

the padding elements.

18

HP

Velotechnik

Page 21

Adjusting your new tricycle

the OrthoFlex seat.

1

The entire seat mesh can be detached from

the seat frame and be washed at 30° C with

the tension belts.

3

Attaching the retention belt system

2

4

The OrthoFlex seat with adjustable padding cushions.

Following areas may be padded:

Head

The padding cushions No. 1 may be adjusted

in distance and height in order to support

the head in an ideal position and give some

orientation.

Lordotic area (lower lumbar spine)

The padding cushions No. 2 may be adjusted

in width and height to form a lumbar

support.

Sides

The padding cushions No. 3 and 4 may be

adjusted in width to give lateral support and

orientation.

Every padding cushion can be individually

cut with a knife. Replacements of padding

cushions may be reordered. When not

needed, the seat can also be used without

padding cushions.

The retention belt system on the Gekko

fxs consists of a lap belt, a harness belt and

a crotch belt. These can be combined as a

single 2-point belt and a 4- or 5-point belt.

5-point retention belt

Depending on the required retaining function, straps may be removed or re-attached

to the seat. The belts can be adapted to the

body proportions.

For attaching the belts to the tricycle, the

tension straps and the seat frame are used.

First attach the lap belt with the two supplied neoprene hook-and-loop sleeves to

the rear seating tension belt.

Handling instructions

After adjusting the padding cushions, close

the sides and press the hook-and-loop

straps tightly together.

Proceed as described above, if you want to

use custom-made orthopedic moldings in

HP

Velotechnik

19

Page 22

Adjusting your new tricycle

Attaching the lap belt

Then the harness belt is looped on the thick

seat frame cross tube between the seat

mountings. The straps then go underneath

the upper seatback tension belt and the

thin seat frame cross tube. The harness belt

parts are connected with a slidable buckle.

With this, the desired width of the harness

belt can be adjusted at the neck. The left

and right side of the lap belt get put through

the loops at the ends of the harness belt.

Positioning of the harness belt

Position of the crotch belt

Open or close the lap belt with the red

press button of the lap belt buckle.

Attention! Loose belt parts can be

caught in the wheel and cause an accident.

Make sure that the belt is always closed and

no loose belt ends are hanging off the bike.

The crotch belt has to be looped around

the middle seating tension belt. It is adjustable in length with a buckle. Before closing

the belt, put the lap belt through the loop

at the end.

HP

Velotechnik

20

Page 23

Adjusting your new tricycle

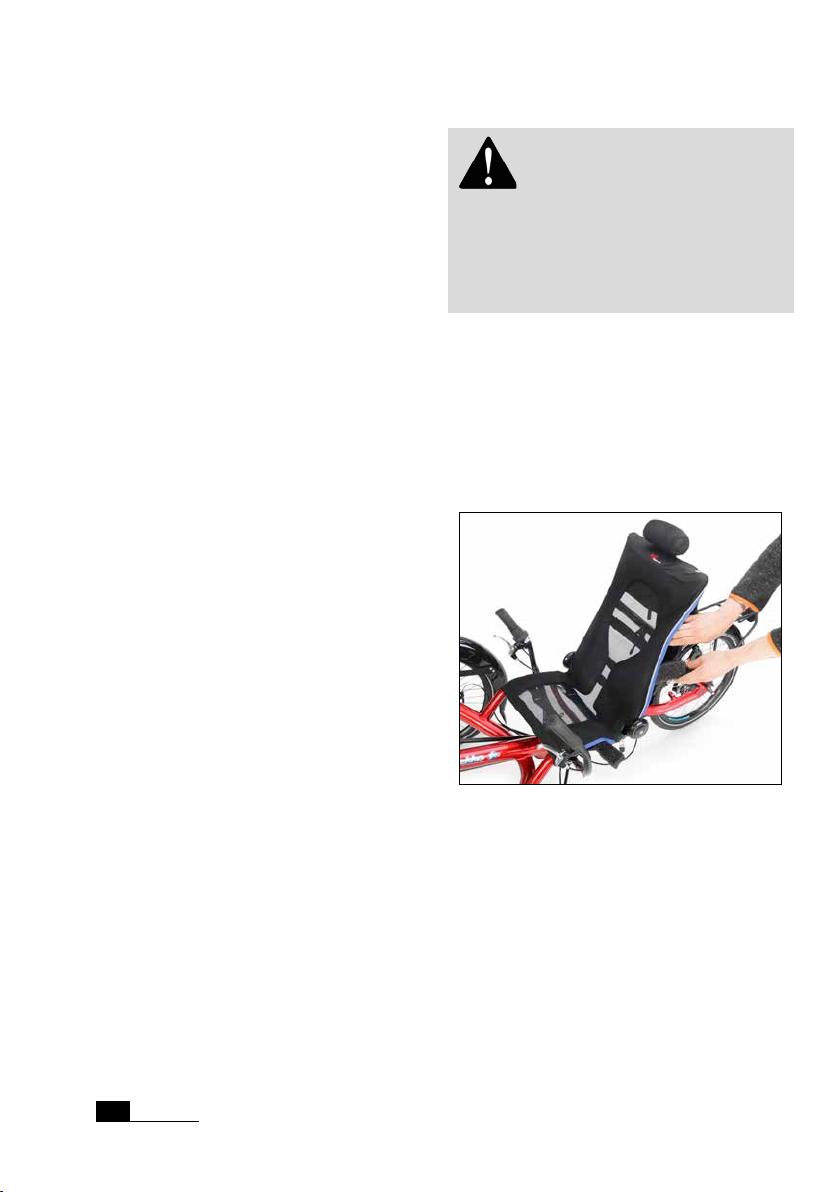

The head rest

OrthoFlex-seats can be equipped with

a head / neck rest which is adjustable in

height and angle. Mounting and adjustment

is possible with two quick-release levers on

the seat frame.

Head rest on the OrthoFlex-seat

Position of the head rest in the neck when using a

helmet.

Attention! Do not push or carry

your tricycle on the head rest, this may

damage the head rest or the seat!

HP

Velotechnik

Handling instructions

21

Page 24

Adjusting to your size

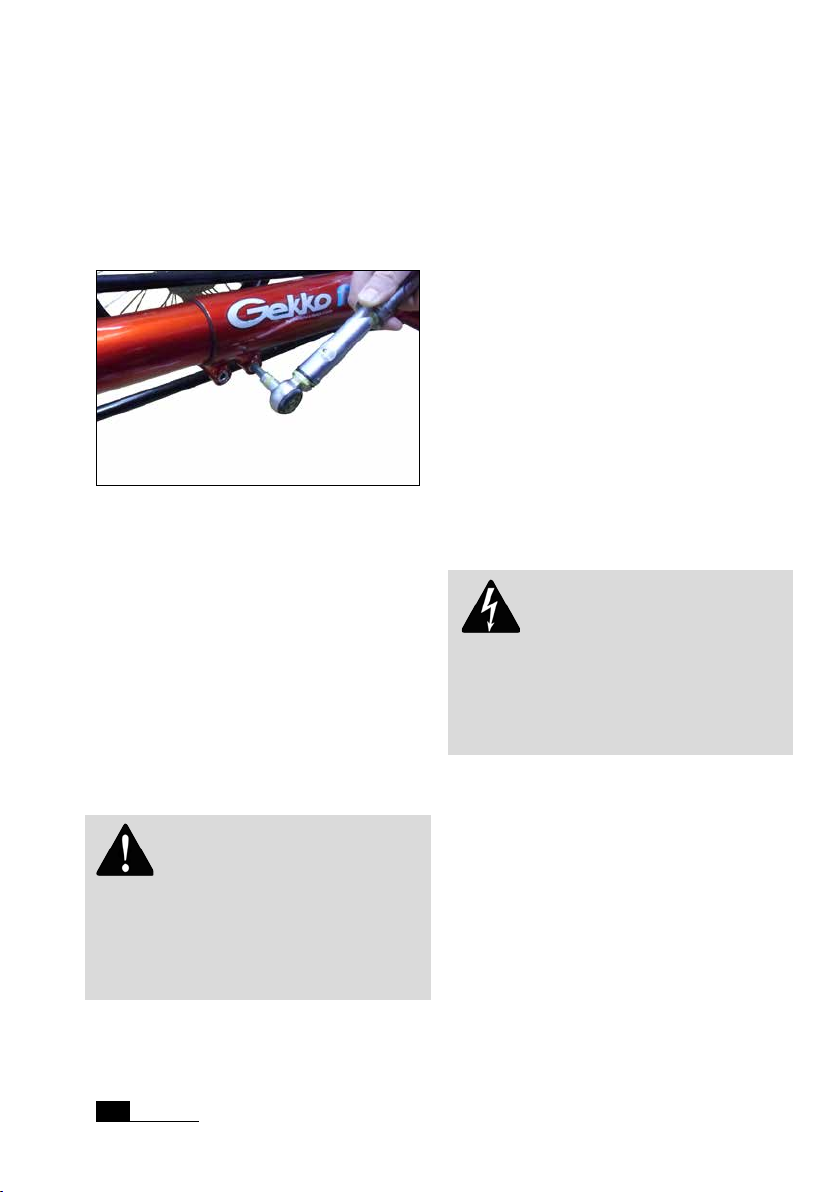

Adjusting the front boom

In order to adjust the leg length you have to

move the front boom (the front part of the

frame where the cranks are mounted) in

the main frame.

Loosing the bolts to adjust the front boom

Unscrew the bolts M8 x 35 under the main

tube with a 6 mm Allen key. Take a grip on

the front derailleur tube or both cranks and

move the front boom further into the frame

or pull it out while cautiously turning it.

Before you pull out the front boom shift the

chain to the smallest chain ring and sprocket. Turn the cranks a little bit backwards

while pulling. Thus the chain is not under

tension.

Adjust the front boom in a way that your

leg is fully extended when your heel (wea-

ring at shoes) is in the foremost position

on the pedal. Experience shows that the

pedal-to-seat distance on a recumbent can

be slightly longer than on a conventional

bicycle.

While you are pedalling, the ball of your

foot should be positioned above the centre

of the pedal axle.

It is important that your leg is not fully

straightened when the crank is in the foremost position. If the distance is too long it is

difcult to overcome this dead point, pedalling becomes uncomfortable and there is

too much strain on the sinews of your feet

and legs. If the distance is too short you may

suffer from knee pain.

Danger! When you insert the

front boom, the front boom and the inner

wall of the tube must be totally free from

grease, otherwise it will not clamp properly

and may turn while you are riding. This can

result in serious accidents.

Attention! After you have unscrewed the clamping bolts take them off and

examine them for deformation. Lubricate

threads and heads thoroughly. Then re-t

the bolts. If they don‘t turn easily you will

have to replace the bolts.

HP

Velotechnik

22

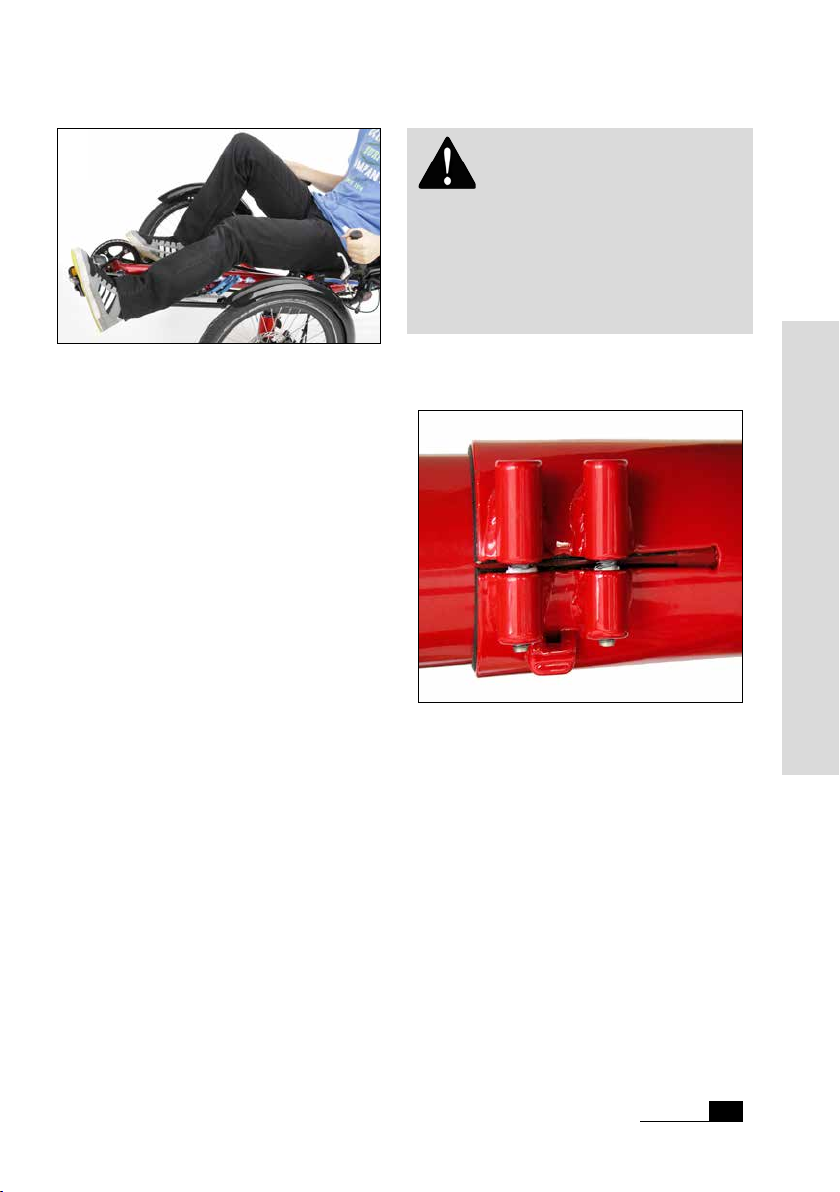

Page 25

Adjusting to your size

Adjust the front boom so that your knee will not be fully

straightened when paddling.

For riders with short leg length the front

boom has to be cut by a bicycle mechanic,

so it can be inserted maximum possible. It

is important to trim the end of the tube

neatly. The bare metal of the shortened tube

end has to be protected against corrosion

with a paint stick or wax spray.

The maximum insertion of the front boom

is limited by possible heel cycle of the

frame’s cross bar, depending on the rider’s

shoe size. Please check before riding your

tricycle that there is enough heel clearance

(depending on insertion depth of the front

boom and your shoe size). If you colide, you

have to choose a shorter crank. There are

cranks in following lengths: 115 mm, 135 mm

and 155 mm.

Look beyond the bottom bracket shell

at the rear wheel axle and align the front

boom parallel to it. Then sit down on your

tricycle and check the position.

Attention! The minimum insertion

depth of the front boom into the main

frame is 8 cm (3 1/5"). The end of the front

boom must not be visible in the clamping

slot when you look at the main frame from

below, since this may result in a damage of

the frame.

The rear end of the front boon must never be visible in

the clamping slot.

Tighten the bolts with a torque wrench

(tightening torque 14 – 16 Nm). On your

rst ride check whether there is sufcient

clamping. There might be the danger otherwise, that a single bolt overloads and the

frame gets damaged.

Handling instructions

HP

Velotechnik

23

Page 26

Adjusting to your size

Danger! If the bolts are tightened

too much or bent, the screw or the frame

can break! If the clamping is insufcient the

front boom can turn during a ride which

may cause your feet to slip from the pedals

and lead to injuries.

The plastic bush between front boom and main frame

must be visible at all time.

Danger! There must be a bushing

(a slotted tube of plastic with edges to the

front and the clamping slot) in the main

frame’s front boom hole that is glued in the

frame. This bush ensures safe clamping of

the front boom and protects the paint. It is

important to take care that this bush is

always visible at the front end of the main

frame. The lower slot has to be aligned in

coincidence with the slot in the main frame.

If this bush is missing or moved to the back

of the tube while inserting the front boom,

safe clamping is no longer guaranteed, even

if it seems to be the case at rst glance. If

the front boom is not clamped properly

it may turn and lead to a fall. A missing or

misaligned bush will lead to frame damage.

After moving the bottom bracket tube your

dealer has to adjust the chain length. By default your recumbent tricycle comes with a

very long chain so the adjustment range of

the tricycle can be fully used without the

need to lengthen the chain.

After the basic adjustment of the leg length

done by your dealer before handing over

the tricycle, the chain has to be shortened so that the derailleur cage is not fully

turned forward while shifting on the largest

chain ring in front and the smallest sprocket

behind. In order to choose the right chain

length, please consult the manual of the

derailleur manufacturer.

Danger! After the chain has been

shortened it must be closed with a special

closing link or a chain riveting tool that expands the rivet while riveting (i.e.

Revolver). A poorly joined chain may break

and thus lead to damage or injury. Chain

length adjustments or chain changes should

be done by your bicycle mechanic.

rohloff-

24

HP

Velotechnik

Page 27

Adjusting to your size

We recommend to slightly readjusting the

front boom every 3 months in order to

provide a slightly different position to your

muscles and ankles. You might also nd a

more comfortable and more efcient riding

position.

A wrong adjustment may lead to pain in

your knees and inefcient pedalling. In

addition we recommend riding with a high

pedalling cadence, which means to pedal fast

and with little pressure. Pedalling with too

much pressure may also lead to pain in the

knees. You will nd more information about

this in the chapter „Slowly increase the

strain“ on page 14.

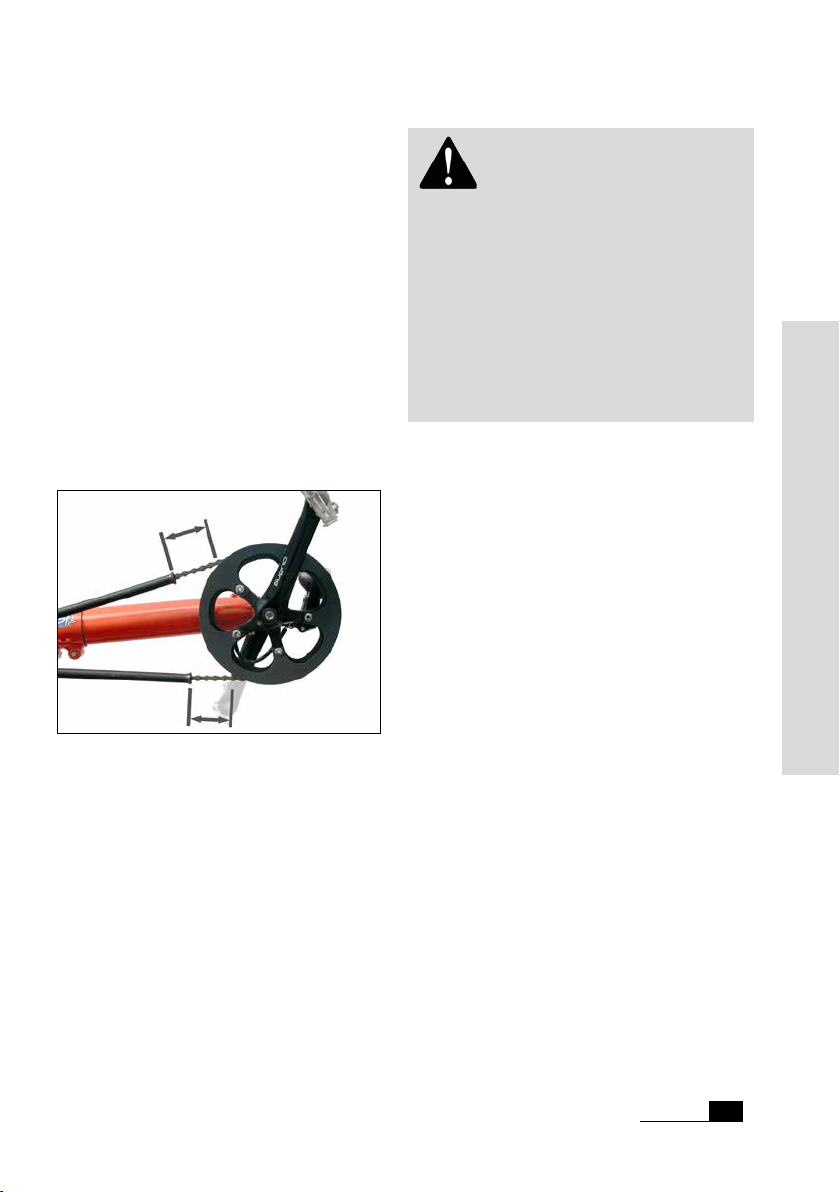

Check that there is at least a 5 cm (2") clearance between the end of the chain tube and other parts of the

drive train.

Attention! Take care that the

chain tubes have a clearance of at least 5 cm

(2") to the rear derailleur and the front

derailleur even under maximum tension of

the chain and make sure that the tubes are

held tight in their fastenings. The front upper

tube can be moved to the rear for length

adjustment. Shorten the tubes if necessary. If

the end of the chain tube gets in touch with

the rotating chain rings it can be locked-up

and destroyed.

Adjusting the length with front boom

quick adjust

The front boom quick adjust is additional

equipment for HP

that feature a telescopic front boom for leg

length adjustment. It replaces the standard

bolts of the front boom clamping by quick

release levers. Two pulleys provide chain

length compensation while moving the front

boom.

The front boom must be clean and free

from wax or tenacious remains of chain

lube to make sure it can be easily slid in and

out.

Velotechnik recumbents

Handling instructions

The chain tubes must be prevented from

moving by a rubber tube over the retention

spring.

After adjusting the front boom, the gap in

the clamping slot between the front boom

and the main frame should be sealed with

wax or silicone in order to protect your

frame from the penetration of water and

dirt and hence damage through corrosion

which may lead to a broken frame.

First, shift the chain to the largest chain ring

and the largest sprocket to check the correct chain length.

Open both quick release levers. Slide the

front boom into the frame or pull it out until you’ve reached the required frame length.

Velotechnik

HP

25

Page 28

Adjusting to your size

Routing of the chain over the idlers of the front boom

quick adjust

To slide the front boom in, grip the cranks

and turn them against the tensioned chain.

The force on the chain helps to move the

front boom into the frame tube.

To pull the front boom out, grip the derailleur tube if available. If you pull at the

cranks, you’ll have to turn them backwards

at the same time, else the tensioned chain

will balk the motion.

adjust the whole adjusting range of the front

boom with the front boom quick adjust.

Moving the front boom is easier when

turning it a little bit from side to side. When

doing this, make sure the pulley bracket

doesn’t scratch the frame and its lug won’t

be bent. That’s why we recommend to only

turn the front boom clockwise (and back

afterwards) when looking from the front.

Align the bottom bracket axis horizontally

when looking from the front. Close both

quick release levers. Please pay attention to

the instructions about quick release levers

on page 7.

Move the chain to the smallest chain ring

and the smallest sprocket. Check the chain

length. The rear derailleur cage should not

be completely swivelled to the back to still

apply tension to the chain. It is possible to

HP

Velotechnik

26

Page 29

Special pedals

Heel support pedal

4

2

5

1

Heel support sheet (1), heel support strap tube (2),

heel support hook (3), pedal toe clip (4), pedal (5)

and heep support strap (6)

The Gekko fxs comes with the

technik heel support pedals by default. This

is a comfortable alternative to clipless pedal

systems.

It offers a safe foothold while riding recumbent tricycles without wearing special

cycling shoes.

Mounting the pedal on your tricycle

The heel support pedal comes completely

assembled and ready to mount on your

tricycle.

Depending on the mounting side, the thread

is a left hand thread (left side) or a right

hand thread (right side). If there are already

pedals on the bike, demount them rst.

Use a little bit of tting grease on the

thread of the pedal. Screw the pedal into

the crank and use a 15 mm open end

wrench or 6 mm Allen wrench to tighten it.

6

3

hP Velo-

Adjustment

The pedal is suitable for shoe lengths

from 22 to 28 cm (8.5 – 11 inches). If you

need larger pedals, there is a version for

shoe lengths from 27 to 35 cm (10.5 – 13.5

inches) available.

As a rst step open the pedal to its maximum length: Loosen the strap by pushing

the buckle mechanism and pulling the strap

through it. Don‘t pull the strap out of the

buckle.

Loosen the M5 screws on the bottom side

that connects the heel support hook with

the heel support sheet with a 4 mm Allen

wrench. Then pull it out to maximum length.

Handling instructions

Adjusting the lenght by sliding heel support sheet and

heel support hook.

Put your shoe into the pedal and pull the

strap until the spring steel sheet in the heel

support tube is under tension. The rear part

bends around the heel. Check if you can pull

out the shoe easily and then put it into the

pedal again. Now tighten the M5 screws on

the bottom side.

HP

Velotechnik

27

Page 30

Special pedals

Get onto the tricycle and test getting into

and out of the pedal as described below.

If the heel support hook does not slip over

the heel easily or if it feels to lose, the setting might be wrong. Try varying the length

of the strap and, if necessary, the length

setting of the heel support hook.

Using the pedal

Getting in:

The heel support pedal aligns itself to the

entering position by its centre of gravity. You

can easily get into it with one movement of

your leg without using a hand.

When you have reached completely inside

the pedal toe clip, push a little bit onto the

pedal.

The heel support hook will slip over your

heel and hold your foot safely in the riding

position.

Getting out:

To get out of the pedal, push the heel support hook a little bit with your hand and lift

the foot from the pedal.

Now you can move your foot downwards

out of the pedal toe clip.

Move the tip of you toes from the bottom

side into the pedal toe clip.

HP

Velotechnik

28

Page 31

Special pedals

Attention! Take care that the heel

support strap will not get in contact with

the crank. If necessary bend the steel spring

sheet in the strap support hook slightly

away from the crank.

Danger! Do not use the heel

support pedal with other than recumbent

tricycles. Using the pedal on two wheeled

bicycles may cause crashes and serious

injuries.

Ergonomic pedal / Ergonomic pedal

with lower leg xation

Attention! HP

nomic Pedals can be used for medical rehabilitation and therapeutic purpose. Please

consult your doctor for a complete list of

indications, warnings, precautions or adverse

effects. Make sure you can use this product

and ride your tricycle safely in all situations

without affecting your health negatively.

Attention! When using the

Ergonomic Pedal, make sure that it does not

affect the functionality and safety of your

tricycle.

Velotechnik Ergo-

Velotechnik

HP

29

Handling instructions

Page 32

Special pedals

strap spring sheet

(inside the retaining strap)

holes for retaining

strap

cleat nut

base plate

strap bracket

side part

retaining strap with

hook-and-loop strap

SPD-cleat

M5 nuts and washers

cleat stabilising

adapter

holes for SPD-cleat/

pedal mount

The HP Velotechnik ergonomic pedal is

available with or without lower leg xation

and ts for shoe sizes from approx. 32 to

41 (UK 1 – 8 ½) or in a lager version from

approx. 37 to 45 (UK 5 – 11 ½) depending

on the shoe length.

It is used for positioning and xing of the

foot and allows active or passive movement and mobilisation of the leg while

riding tricycles. It also helps to compensate

misalignment of leg or foot. Due to a spring

steel sheet inside the foot straps, the entry

is easy and only one hand is needed to open

and close the straps safely. The ergonomic

pedal without lower leg xation will be

connected via

Shimano SPD-System witch

allows a joint-friendly heel movement of approx. +/- 3° while pedalling and plus a safety

release functionality.

The ergonomic pedal comes as a pre-assembled top piece and is ready to use with

the

Shimano SPD-System.

The ergonomic pedal with lower leg xation

allows a comfortable support of the leg by

xing the calf. For safety and stability

reasons, the top piece of this version is

xed rigidly to a pedal and will be used

instead of a standard pedal.

Mounting

Ergonomic pedal without lower leg xation

To apply the ergonomic pedal with foot xation to your bike, please mount a

Shimano

SPD-compatible pedal to the crank of your

tricycle. The SPD-cleat on the underside of

the base plate will connect the pedal pod to

the binding of the pedal.

Please pay attention to the instructions of

the SPD-pedal manufacturer

Shimano about

mounting and adjusting the release strength

of the SPD-pedals.

The easiest way to engage the pedal pod

to the SPD-pedal is by xing it to your foot

rst and the step into the pedal binding as

shown in gure 1. The cleat stabilising adapter will help you to easily nd the correct

position.

30

HP

Velotechnik

Page 33

Special pedals

This version of the ergonomic pedal can

be also be xed rigidly to a standard pedal:

After removing the SPD-cleat and cleat

stabilising adapter and follow the steps

explained in „Adjusting the medial position

of the pedal axle – ergonomic pedal with

lower leg xation“.

gure 1: engaging the pedal pod to the SPD-pedal

Ergonomic Pedal with lower leg xation

This version of the ergonomic pedal will be

mounted instead of a standard pedal. The

base plate and the lower leg support are

xed rigidly to a pedal body.

Depending on the mounting side the turning

direction of the thread will be clockwise on

the right side or counter clockwise on the

left side for tightening.

With a 6 mm Allen key or with a 15 mm

open end wrench, screw the pedal into

the crank and tighten the axle of the pedal

in the crank with a tightening torque

35 – 55 Nm (304 – 477 in. lbs.).

Adjustment of the ergonomic pedal

The base plate is the same for both versions

and allows the adjustment of the

(1) shoe size and shape

(2) medial position of the pedal axle

(3) angle of the pedal axle

The version with lower leg support additionally allows the adjustment of

(4) lateral position of the calf padding

(5) orientation of the calf padding

(6) height of the calf padding

(7) distance of the calf padding

(see gure 2)

To adjust the lower leg support, loosen

the clamps of the lower part, set up the

preferred position and x the clamps with a

torque of 5 - 6 Nm.

Adjustment of the retaining straps

You can use one or two hook and loop

straps on various positions. The longer one

is designed for the rear position.

Loosen the M5 self locking nuts and remove

the washers, the retaining strap and the

strap brackets (gure 2 (8)).

Loosen the pressed in threaded bolt with a

light tap of a hammer and the place it in the

position you prefer.

Prevent the bolt from falling out again by

xing it with your nger while re-assembling

the strap, the strap bracket, the washers

and the nuts. The bolt should lock himself

against rotation.

Handling instructions

Make sure that the at rear part of the bolt

will not be pulled too far into the material

by not exceeding the tightening torque of

3 - 5 Nm.

Velotechnik

HP

31

Page 34

Special pedals

If the threaded bolt rotates while tightening

the self locking nut, you can use a standard

M5 nut to pull it into the hole until it locks

itself.

Adjusting the medial position of the

pedal axle

Ergonomic pedal without lower leg xation

To adjust the Ergonomic Pedal to your shoe

size and to your preferred medial foot position above the pedal axle, there are 6 pairs

of holes where the SPD-Cleat can be xed.

Loosen the M5 bolts that x the SPD-cleat

and remove the cleat nut from the base

plate. Choose the preferred cleat position

and put the cleat nut back into the respective holes. Now place the cleat stabilising

adapter, the cleat nut and the cleat washer

on the underside and x them with the M5

bolts. Make sure the SPD-cleat has correct

orientation.

Please pay attention to the instructions of

the SPD-pedal manufacturer

mounting of the SPD-system.

Shimano about

medial as well as lateral to mount the base

plate on the pedal body (gure 2, pos. 2). To

change the pre-mounted position, put the

two cleat nuts into the base plate at the

preferred position with two holes between.

1a 1b

2 3

4

5

calf padding

lower leg support

(upper part, g. w/o strap)

6

(lower part)

8

Make sure that there will be no contact between the parts of the pedal and the cranks

or other parts of your tricycle. If necessary,

reposition only the orientation of the cleat.

Ergonomic pedal with lower leg xation

Try to adjust the base plate to your shoe

size and preferred foot position above

the pedal axle by loosing the bolts on the

underside slightly. If the adjustment range is

too low, disassemble the system by removing the 4 M5 bolts that connect the pedal

adapter with the base plate on the underside. You can choose out of three 3 positions

HP

Velotechnik

32

7

gure 2: adjustment options of the ergonomic pedals

Place the pedal adapter on the underside of

the base plate. Screw the M5 countersunk

bolts into the threads of the cleat nuts. Use

the washers with d

parts. Tighten the bolts hand tight to adjust

the orientation of the ground plate to t

your needs.

= 8,4 mm to mount the

i

Page 35

Special pedals

cleat nut

washer d

pedal adapter + countersunk

bolt M5 x 8

gure 3: re-assembling the pedal with lower leg

xation

=8,4 mm

i

You may need to loosen the pedal body

from the pedal adapter to reach the bolt

heads depending on the position you chose.

When the pedal is mounted to the crank

arm of your tricycle, make sure that there

is enough space between all parts while

pedalling and no collision can occur.

Finally tighten all four bolts with a torque of

5 – 7 Nm until the base plate can not move

any more.

Using the ergonomic pedal

Getting in and out

To get into the Ergonomic Pedal sit down

on your tricycle rst. Open the hook-and-

loop strap(s) by pulling the blue coloured

end. Due to the integrated spring steel, the

straps will rise and open the way to easily

place your foot and shoe through it on the

base plate.

gure 4: guiding of the opened hook and loop retaining strap through the strap bracket

Handling instructions

lower leg

retaining strap

calf padding

gure 5: laying of the hook-and-loop retaining strap

for calf xation

The strap does not need to be pulled out of

the strap bracket. Once your foot is in position, tighten the strap by pulling the blue

coloured end and close it by laying the free

end with the hook part over the loop part

(gure 4).

Velotechnik

HP

33

Page 36

Special pedals

To x your lower leg to the support, open

the retaining strap on the calf pad. Place

your calf on the support, guide the retaining

strap around your lower leg and x it with

the hook-and-loop.

You can cut the end of the strap if it is too

long.

Pushing the trike with lower leg xation

mounted

Attention! When using the lower

leg xation the parts of the pedal can collide with the frame or touch the oor.

To protect the pedal parts when the tricycle

is standing, you can apply the round hook

and loop adhesive part to the frame. Place it

on the most forward position of the main

frame above the front boom clamping.

Turn the crank into the lowest position

and x the retaining strap of the lower leg

support in a way that the telescopic part

remains in horizontal position and no parts

are touching the oor.

gure 6: position of the adhesive hook-and-loop part

Clipless pedal

The selectable clipless pedal of

lightweight, multi-purpose pedal for normal

and SPD-shoes. These are special cycling

shoes with a metal plate (cleat) screwed underneath, which locks into the pedal. When

the foot is placed on the pedal with enough

pressure, the shoe locks in - to release the

connection the foot has to be turned slightly to the side. The required release force

can be variably adjusted.

Shimano is a

Pushing forward will be no problem then

either. The cranks can rotate and the pedals

or parts of them will not touch the ground.

When pushing the tricycle backwards, you

still have to be careful, but it is possible

without producing collisions of pedal parts

with the frame or the oor.

HP

Velotechnik

34

Multi-purpose pedal on Gekko fxs

Page 37

Special pedals

With the rm connection between shoe

and pedal you do not need any power to

keep the foot on the pedal. Thereby a more

relaxed and round pedaling movement is

possible in which you even can pull the

pedals a little with your feet.

Without pedal binding, your feet might suddenly slip off the pedals, which can lead to

a fall. Therefore, modern pedal system with

binding contribute to safe riding. However,

using these pedals have to be practiced rst,

so that you can get out from the pedals

quickly in dangerous situations. Please read

the manual of the pedal manufacturer and

let yourself explain the usage of the pedals

from your bicycle dealer. Adjust the release

force of the binding to a low value to make

sure to get out of it securely.

Use only the supplied cleats of the binding

system manufacturer, no third-part products. Using unapproved cleats, the binding

system might noth operate safely.

HP

Velotechnik

Handling instructions

35

Page 38

Adjusting the handlebars

A good setting for the handlebars

While riding you should allow your arms to

rest in a relaxed position on the handlebars.

Do not push or pull on the handlebars. If

the handlebars turn in the stem clamping

during the ride stop immediately and tighten the clamping screw of the handlebars. If

the handlebars are not sufciently clamped

the handlebars or the stem may be damaged

or deformed. In this case, safe clamping can

no longer be guaranteed, not even with the

correct tightening torque, and handlebars

and stem have to be replaced.

Attention! When getting on and

off the tricycle, make sure to avoid pulling

at the handle bars or stepping on the tie

rods. To get off the tricycle, sit upright on

the front seat edge and then stand up. Grip

the front wheels or the seat back as an

extra support, not the handlebars. If you pull

rmly at the handlebars, the steering

mechanism can be damaged.

Setting the width and angle

The grip position can be tted to your body

and arm length by adjusting the handlebar.

1

2

The handlebar allows adjustment in width (1) and

angle (2)

Most riders are comfortable with an 85°

angle so that the bent grips point upwards

and slightly forward. The more upright the

grip position and the narrower the handlebar width, the larger the minimum possible

turning circle as the handlebars touch your

legs or the seat earlier.

Danger! If the handlebar grips

are adjusted pointing too far forward or

too wide, your hands or the brake levers

can touch the front wheels or mudguards

when cornering sharp, leading to injury.

Make sure you have at least 5 cm (2")

clearance between brake levers and front

wheels / mudguards at all steering angles.

The handlebar consists of two parts. They

are mounted to the stem by a slotted clamp

on each side. The adjustment range in width

is 3,5 cm on each side, giving a total range of

7 cm (aprox. 2 ¾").

HP

Velotechnik

36

Page 39

Adjusting the handlebars

The handlebar angle is individually adjustable.

Danger! Do not exceed the

handlebar width beyond the „Max“-mark,

otherwise a safe clamping is not possible

In order to change the angle or the width,

loosen the screws of the stem/handlebar

clamping. Move the handlebars until they are

in your favourite position. Tighten the

clamping screws with 5 – 6 Nm. Check the

correct clamping of the handlebars by sitting

down on your tricycle and pulling the handlebars. The handlebars must not turn in the

stem.

Your bike shop can supply a special tting

lubricant that increases friction between

handlebar and stem.

Danger! Please take care that the

clamping area of the stem is thoroughly

trimmed and there are no sharp edges

which may cause handlebar failure.

Handlebar stem clamp with quick release lever

Handling instructions

HP

Velotechnik

37

Page 40

Adjusting the handlebars

Adjusting the cable length

You can make smaller adjustments by moving the cables in their guides at the frame

and the stem, so there is enough clearance

for all movements. If this is not the case

you will have to have your specialist dealer

shorten the cables or replace them by

longer ones.

Attention! After having adjusted

the handlebar position you have to readjust

the length of the brake cables and shifter

cables. The cables have to run smoothly

without any sharp turns and they should

not be bent sharply or stretched when the

handlebar is at maximum angle. Also avoid

large bows that could be caught up by

the front wheels or other parts or touch

objects under your tricycle.

Cover all contact areas where cables move

and touch the frame with sturdy transparent tape. This protects the paint against

scratching and wear.

Handlebar grips

The grips on the handlebar are susceptible

to wear and tear. Have your grips replaced

by your bike shop once they don‘t feel comfortable any more. The grips always need to

be attached rmly to the handlebar.

HP

Velotechnik

38

Page 41

Folding

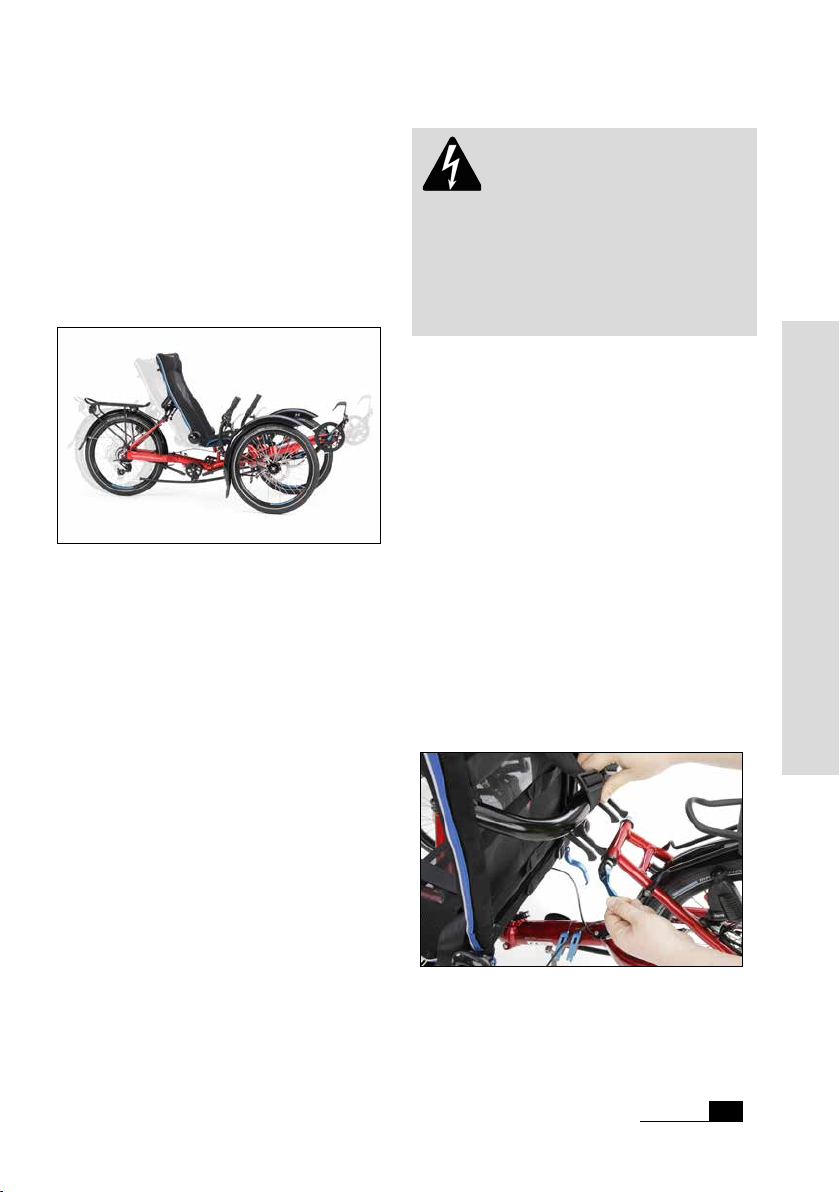

Folding of Gekko fxs

Thanks to the Dual-Flat-Fold (D.F.F.) technology, your Gekko fxs folds from a comfortable touring tricycle to a compact package

in a few steps. Then it can be stored upright

or towed on its integrated rollers.

To fold the Gekko fxs stand on the right

side next to the seatback.

1. Open the quick release behind the seat

(a) and swivel the seatback to the front

(b). Make sure, that the seating quick

release levers show downwards, because

they are used as stand later on.

2. Take the Velcro strap off the second

strap and apply it to the soft Velcro

under the cross tube to secure the

seatback in its position.

3. If your tricycle is equipped with a front

boom quick adjust, the rod of the front

boom quick adjust and the main frame

rear end could collide.

In order to avoid a collision, stand in

front of the Gekko fxs, open the quick

adjust levers of the front boom quick

adjust and turn the front boom a little

to the right. Then close the quick release

levers slightly.

4. Turn the tricycle on the right front

wheel.

Attention! Don’t rest the tricycle

on the rear rack. It may become deformed.

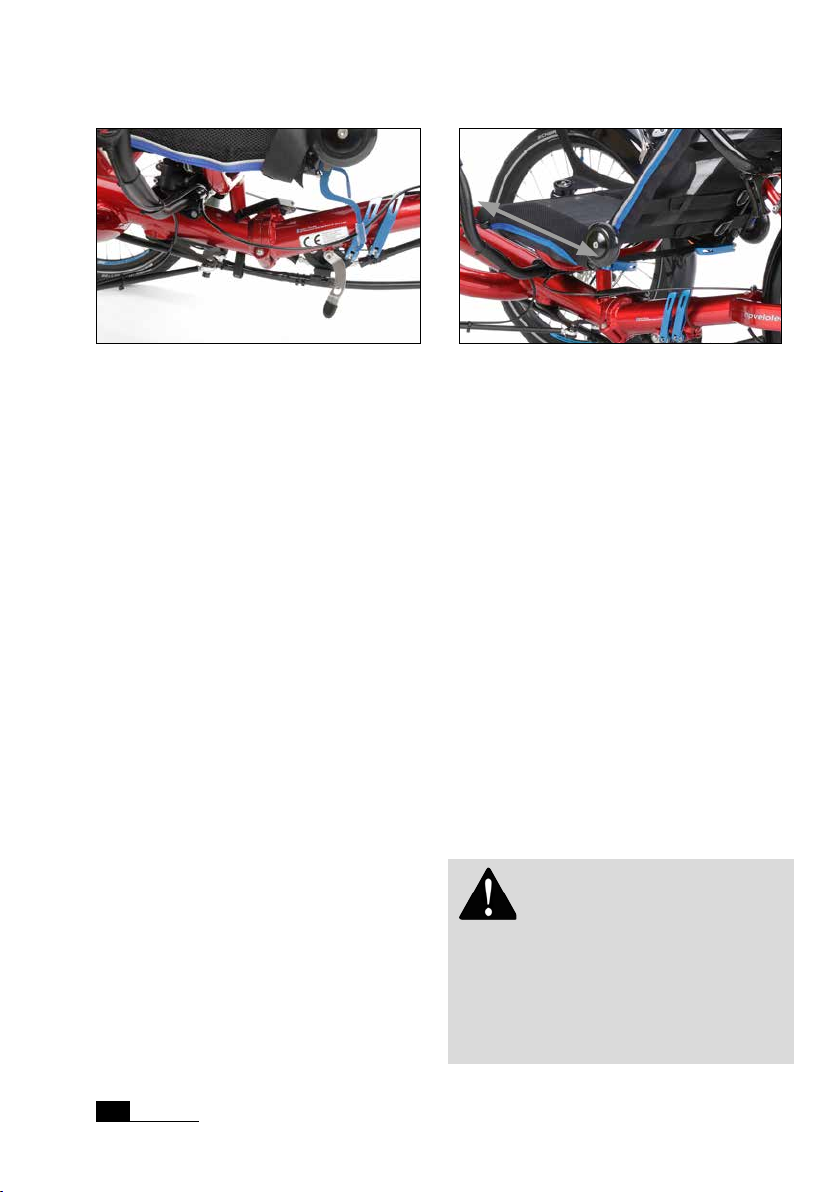

5. Open the quick release at the folding

hinge.Turn the quick release axis about

90° towards the handlebar. Release the

safety bolt against spring pressure.

Slightly open the folding hinge. Swivel

the quick release lever to the upside so

that it is held in an upright position by

the sheet metal.

Handling instructions

HP

Velotechnik

39

Page 42

Folding

6. Swivel the rear part forward comfor-

tably. Make sure the main frame tube

gets placed betwwen the two black

centre sleeves of the steering.

Attention! Do not deform the

track rod, because the steering will be

affected and a safe steering is not possible

anymore.

7. Push the Gekko fxs frame together until

you can hear the locking sheet metal

snaps in.

Attention! Make sure that the