Page 1

TP801/TP805/TP806 User Manual

www.hprt.com 1

Desktop POS Printer

TP801/TP805/TP806

User Manual

Xiamen Hanin Electronic Technology Co.,Ltd.

ADD: Room 305A,Angye Building, Pioneering Park,

Torch High-tech Zone, Xiamen, China 361009

Tel.:+86-(0)592-5885993

Fax: +86-(0)592-5885992

Web: www.hprt.com

TP805

TP801

TP806

Page 2

TP801/TP805/TP806 User Manual

www.hprt.com 2

REVISION RECORDS

REV.

DATE

DESCRIPTION

Drawn

Checked

Approved

1.0

2013.04.10

1.Added the warnings of using crash

drawer

Chen weihua

Lin yang

Ren xiaowei

1.1

2013.04.19

1.Added the setting of Ethernet IP

Chen weihua

Lin yang

Ren xiaowei

1.2

2013.04.20

1.Added the warnings of using power

adaptor

Chen weihua

Lin yang

Ren xiaowei

1.3

2013.04.23

1.Modified some error descriptions

Chen weihua

Lin yang

Ren xiaowei

1.4

2013.05.11

1.Added the description of Parameters

checking and resetting illustration of

the Ethernet and Wi-Fi cards

Chen weihua

Lin yang

Ren xiaowei

1.5

2013.06.01

1.Modified the packing list

Chen weihua

Lin yang

Ren xiaowei

1.6

2013.11.05

1.Modified the printer’s driver

Chen weihua

Lin yang

Ren xiaowei

1.7

2014.01.13

1.Added the description of Wi-Fi

setting

2. Modified the description of print

self-test page

3. Modified the layout of user manual

Chen weihua

Lin yang

Ren xiaowei

Page 3

TP801/TP805/TP806 User Manual

www.hprt.com 3

CONTENTS

Statement .................................................................................................................... 5

Important Safety Instructions ...................................................................................... 6

POS printer packing-case ............................................................................................. 7

1 Overview ................................................................................................................... 8

1.1 Introductions .................................................................................................. 8

1.2 The main features .......................................................................................... 8

2 Specification ............................................................................................................. 9

2.1 Printer specification ....................................................................................... 9

2.2 Printing media specification ......................................................................... 10

2.2.1 Continuous thermal paper specification ............................................ 10

2.2.2 Black mark paper specification .......................................................... 10

2.2.3 Notices .............................................................................................. 10

2.3 Printing and cutting position ........................................................................ 11

2.3.1 Printing position ................................................................................ 11

2.3.2 Cutting position ................................................................................. 11

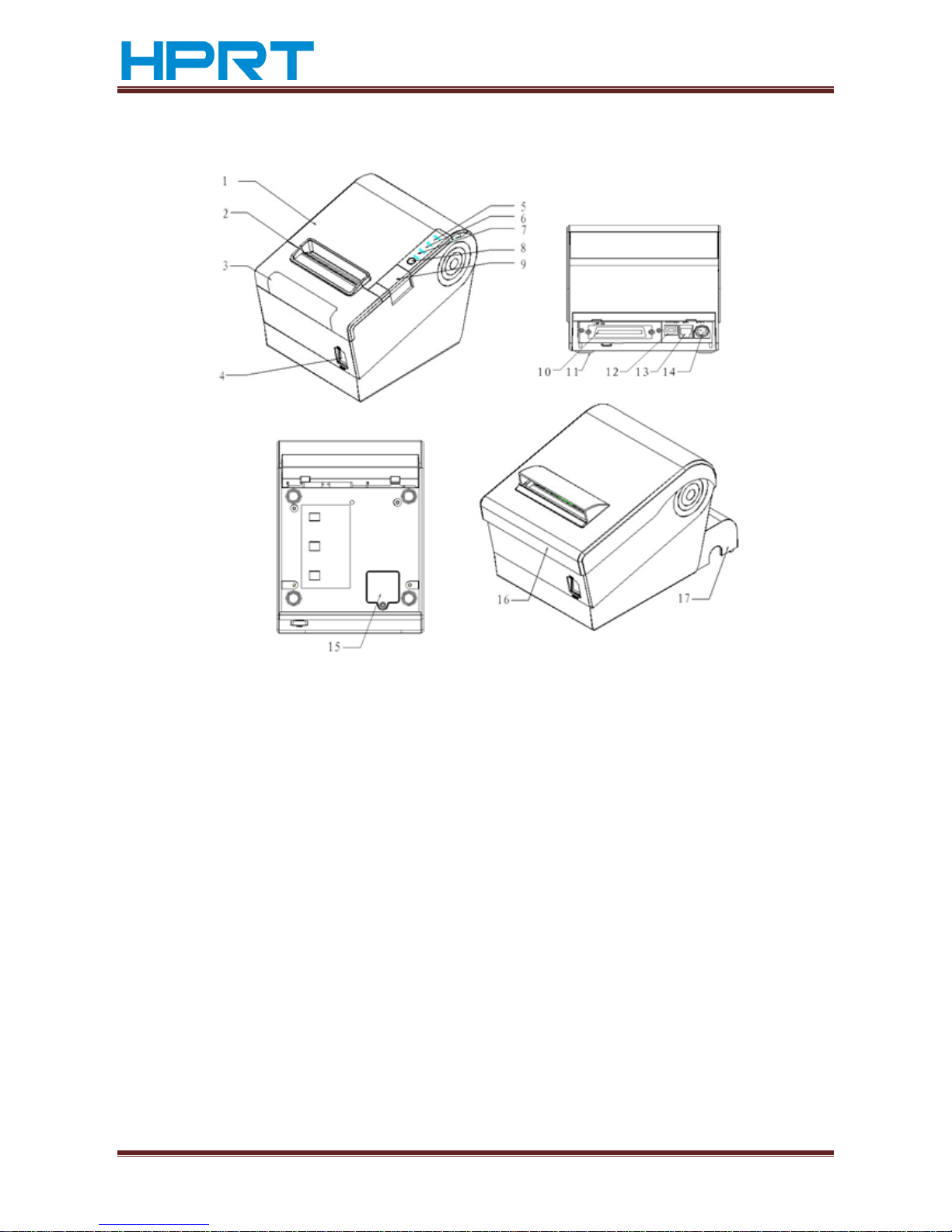

3 Printer components ................................................................................................ 12

3.1 Appearance and component ........................................................................ 12

3.1.1 TP801 ................................................................................................ 12

3.1.2 TP805 ................................................................................................ 13

3.1.3 TP806 ................................................................................................ 14

3.2 Specification of Indicated light and beeper .................................................. 15

4 Printer packing ........................................................................................................ 16

4.1 Open packing ............................................................................................... 16

4.2 Choice installation site and direction of printer ............................................ 16

4.3 Connect the printer power adaptor ............................................................. 16

4.4 Connecting the Interface Cable .................................................................... 17

4.5 Connecting the Cash Drawer ........................................................................ 17

4.6 Paper roll installation ................................................................................... 17

4.6.1 Confirmation of printing paper .......................................................... 17

4.6.2 TP801/TP805/TP806 installation/Change Paper ................................ 17

4.7 Setting DIP switch ......................................................................................... 19

4.7.1 Serial interface(RS-232C) .............................................................. 19

4.7.2 Interfaces of Parallel and USB2.0 ....................................................... 19

4.7.3 The choice of auto cutter................................................................... 20

4.8 Print self testing ........................................................................................... 20

4.9 Installation of Windows driver ..................................................................... 20

4.9.1 The driver installation instruction of USB /serial port /parallel

interface ..................................................................................................... 20

4.9.2 The driver installation instruction of Ethernet and Wi-Fi ................... 22

Page 4

TP801/TP805/TP806 User Manual

www.hprt.com 4

4.9.3 Parameters checking and resetting illustration of the Ethernet and Wi-

Fi cards ....................................................................................................... 24

4.9.4 Setting of Ethernet IP ........................................................................ 25

4.9.5 Wi-Fi settings ..................................................................................... 29

5 Interfaces signal ...................................................................................................... 40

5.1 Parallel interface .......................................................................................... 40

5.2 Serial interface ............................................................................................. 41

5.3 Power Supply interface definition ................................................................ 41

5.4 Cash Drawer interface signal ........................................................................ 42

5.5 Serial interface and Ethernet interface ......................................................... 42

6 Troubleshooting ...................................................................................................... 44

6.1 Printer not working ...................................................................................... 44

6.2 LED indicator on the control panel and beeper alarm .................................. 44

6.3 Troubles occur during printing ..................................................................... 44

6.4 Problems emerge during the paper cutting processes ................................. 45

6.5 Removing Jammed Paper ............................................................................. 45

Page 5

TP801/TP805/TP806 User Manual

www.hprt.com 5

Statement

This manual content may be altered without permission, and Xiamen Hanin

Electronic Technology Co., Ltd. reserves the rights to make changes without notice in

technology, spare parts, hardware and software of the products. If more information

is needed about the products, please contact Xiamen Hanin Electronic Technology

Co., Ltd. Without any written permission from the company, any section of this

manual is prohibited to be copied or transferred in any form.

Copyright

This manual is printed in 2013, the copyright belongs to Xiamen Hanin Electronic

Technology Co. Ltd.

Printed in China

1.0 Version

Warnings :

This must be complied with in order to avoid any damage to the human body

and to the equipment.

This is showing the important information and tips for the printer operating.

Page 6

TP801/TP805/TP806 User Manual

www.hprt.com 6

Important Safety Instructions

1. Safety warning

1) Warnings: The print head will become very hot during printing; avoid contact

with the print head after printing has finished.

2) Warnings: Do not touch the printer head and connector in case static damage

the printer head.

2. Instructions

Read the following instructions thoroughly before starting up your printer.

1) Place the printer on a solid and even base so that it cannot fall.

2) Leave enough space around printer for operation and maintenance.

3) Keep all liquids away from the printer.

4) Do not expose the printer to high temperatures, direct sunlight or dust.

5) Protect the printer from shock, impact and vibration.

6) Ensure the printer is connected to a socket with the correct mains voltage.

7) Switch off the printer power supply when won’t use it for a long time.

8) Do not printing when there is no paper, or it will damage printer head.

9) To ensure the printing quality and reliability, suggest use the same quality or

recommend paper supplier.

10) Pls switch off the power supply when connect/disconnect all the ports or it will

cause damage to the printer control circuit.

11) Never carry out maintenance or repair work yourself. Always contact a

qualified service technician.

12) Keep this Operator’s Manual in a place which is easily accessible at all times.

Page 7

TP801/TP805/TP806 User Manual

www.hprt.com 7

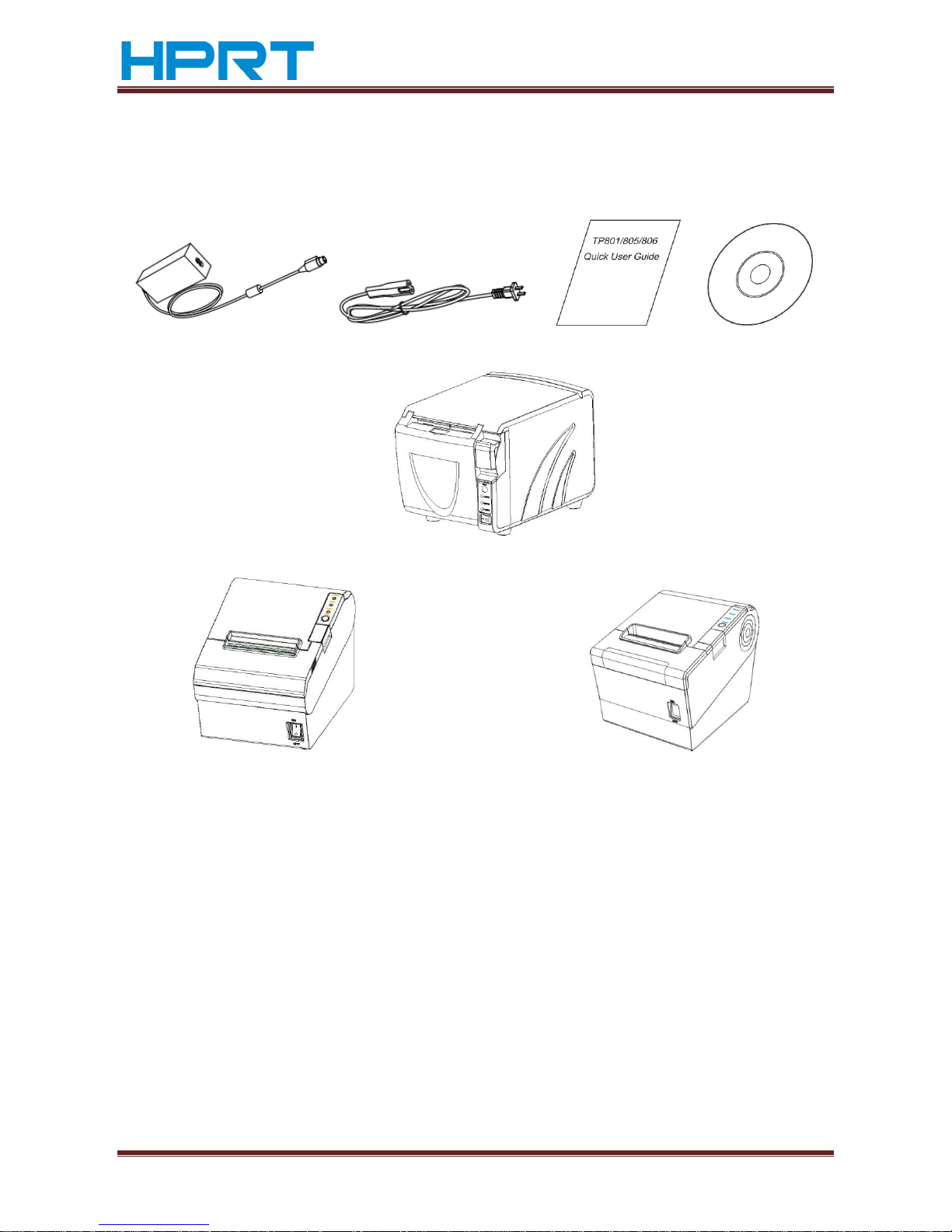

POS printer packing-case

Pls. check you get all in carton as pic. 1

Power adapter Power line Quick start guide CD

pic.1

TP806

TP805

TP801

Page 8

TP801/TP805/TP806 User Manual

www.hprt.com 8

1 Overview

1.1 Introductions

TP801/805/806 is a thermal receipt printer with auto-cutter, featured by high

printing quality, high printing speed, high stability, etc. It can be used in commercial

POS system, food industry and occasions which need real-time field print receipts.

TP801/805/806 can connect with other equipments through parallel, serial, USB, and

Ethernet interfaces. And the printer drivers are available for the WINDOWS

XP/WINDOWS 7 32 bit/WINDOWS 7 64bit operating system.

1.2 The main features

1) Automatic paper cutting

2) Low noise

3) High printing speed

4) Easy paper loading

5) User convenient maintenance

6) Support label paper and continuous paper printing

7) Compatible with various width paper

8) Cash drawer interface

9) Communication interfaces optional

Page 9

TP801/TP805/TP806 User Manual

www.hprt.com 9

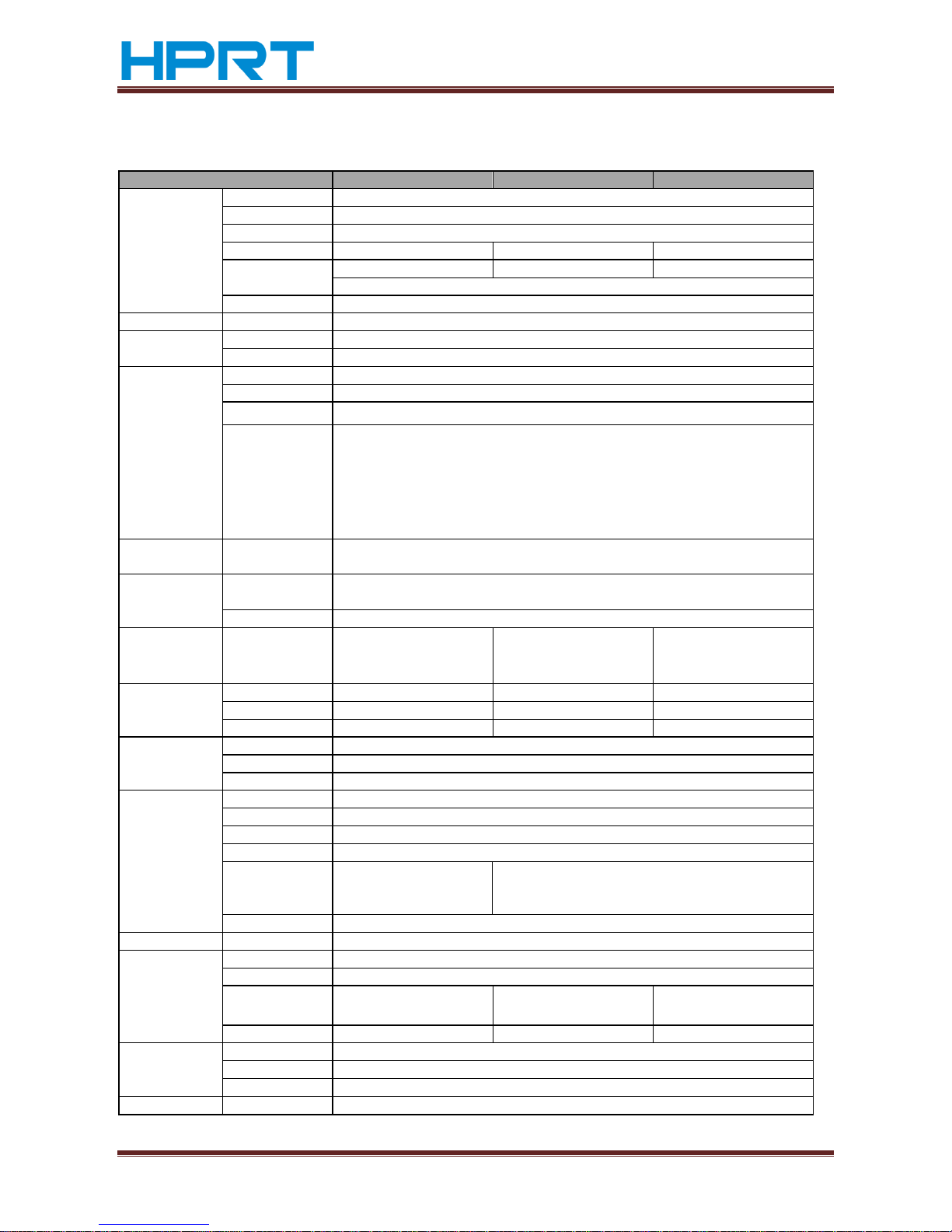

2 Specification

2.1 Printer specification

Model

TP801

TP805

TP806

Printing Parameter

Print method

Direct thermal line printing

Resolution

203DPI,8dots/mm

Printing width

72mm(576dots)

Print speed

Interface

Wi-Fi Wi-Fi

Serial, Parallel, Ethernet, USB

Print density

Adjustable from level 1 to level 4

Page Mode

support

Memory

RAM

1Mb

Flash

4Mb

Fonts

Chinese

GB18030 24×24 (Simplified/Traditional Chinese)

Alphanumeric

ASCⅡ9×17,12×24.

User-defined

support

Code page

Optional international character sets 32:

(PC437,Katakana,PC850,PC860,PC863,PC865,ABICOMP,PC857,PC737,

ISO8859-7 , WPC1252 , PC866,PC852,PC858,KU42,TIS11,TIS18,PC720 , WPC775 ,

PC855 , PC862 , PC864 , ISO8859-2 , ISO8859-15 , WPC1250 , WOC1251 ,

WPC1253,WPC1254,WPC1255,WPC1256,WPC1257,WPC1258)

Graphics

Support varied density bitmap as and download bitmap printing

Max size of each bitmap is 40K, the total size of bitmap is 256k

Barcode

1D

UPC-A、UPC-E、EAN8、EAN13、CODE39、ITF、CODEBAR、CODE128、CODE93

2D

PDF417、QR code

Detect Function

Sensors

Paper end, paper near end,

take paper and cover open

sensors

Paper end, paper near end

and cover open sensors

Paper end, paper near end,

paper jam and cover open

sensors

LED Indicator

Power indicator

Green LED

Green LED

Green LED

Paper indicator

Blue LED

Red LED

Red LED Error indicator

Red LED

Red LED

Red LED

Power Supply

External power adapter

Input

AC100V-240V 50-60HZ

Output

DC 24V, 2A

Paper

Paper type

Standard Thermal Paper

Paper width

79.5

±0.5mm/

57.5

±0.5mm

Paper thickness

0.056~0.1mm

Paper roll diameter

Max. OD ф83mm

Paper load

Forward cover open and Easy

paper loading

Upward cover open and Easy paper loading

Paper cut

Manual tear or Auto-cutter

Command

ESC/POS

Physical Spec.

Operating condition

Storage condition

Dimensions

L×W×H

190×127 ×126mm

195×177×147mm

197×145×146mm

Weight

1580g

1.8kg

1.8kg

Reliability

TPH lifetime

150km

Cutter lifetime

2,000,000 cuts

MTBF

360, 000 hours

Software Function

Driver program

Windows (Win7/Win8/Vistal/XP/2000)

Page 10

TP801/TP805/TP806 User Manual

www.hprt.com 10

2.2 Printing media specification

2.2.1 Continuous thermal paper specification

Paper type: thermal continuous paper/thermal black mark paper/thermal label

paper.

Paper width: 80±0.5 mm, 57.5±0.5 mm.

Paper outer diameter:Max. 83 mm.

Paper roller inner diameter: paper roll mandril inner diameter 12mm, paper roll

mandril outer diameter 18mm.

Paper thickness:0.065 ~ 0.10mm.

2.2.2 Black mark paper specification

When using the black mark paper, the black mark paper must be at the front side of

the receipt paper, and the reflectivity should be less than 15%, and the reflectivity of

other part of the paper should be more than 85%. There must not be any graphics in

the black mark space, such as advertising. The black mark should be qualified for the

below requirement:

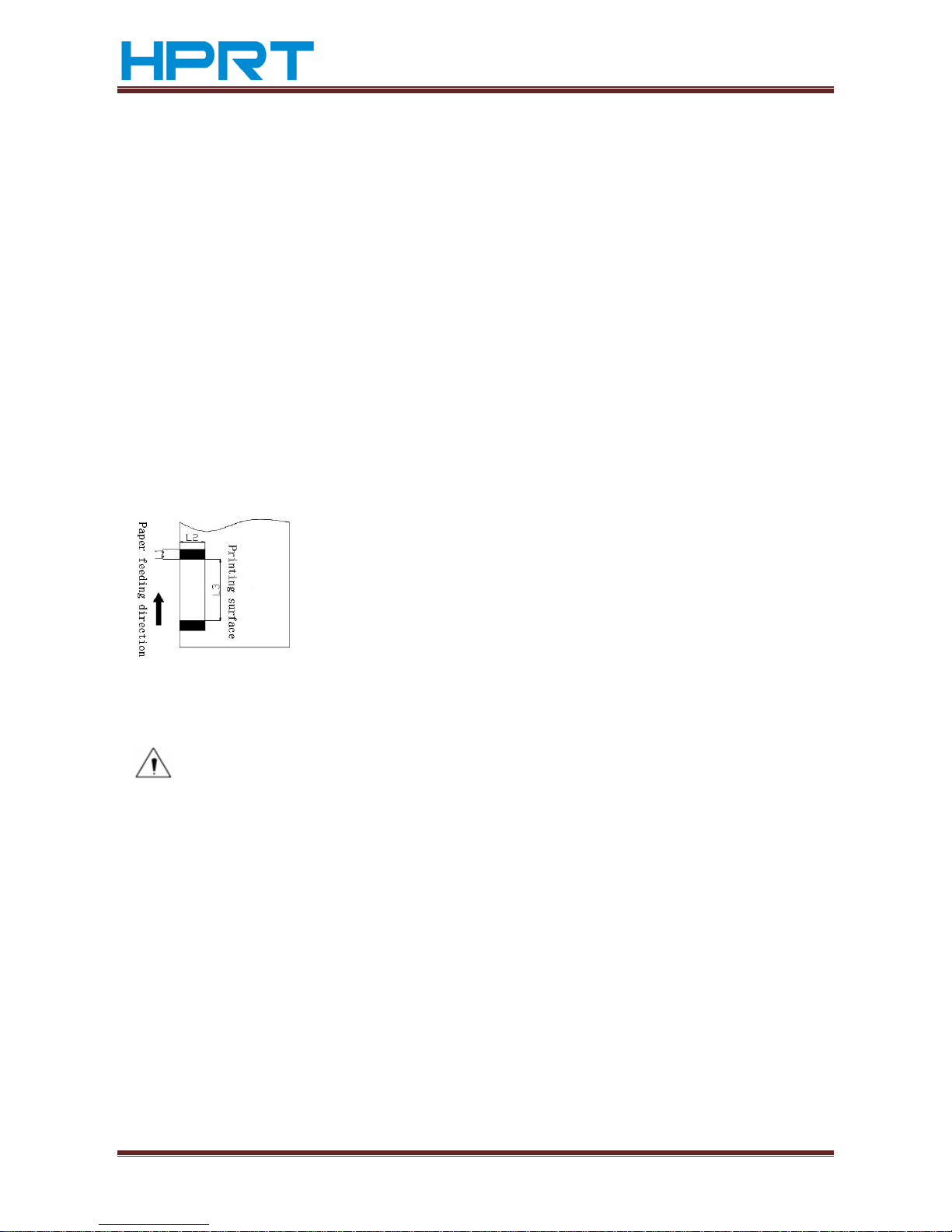

Fig 2.2.1

2.2.3 Notices

Notes:

Pls. use the high quality thermal paper, otherwise it will influence

the printing quality and decrease the thermal printer head life;

Don’t stick the paper on the paper roll mandril;

If the thermal paper is polluted by chemical or oil, the thermal paper

heat sensibility decreases, which will influence the printing quality;

Don’t use finger nail or hard articles to touch the surface o f thermal

paper, otherwise it will cause color fading ;

When the environment temperature is higher than 70°C, the

thermal paper color will fade, so pay attention to the influence of

temperature, humidity and sunlight.

5mm<L1(black mark width)<10mm

L2(black mark length)>12mm

20mm<L3(the distance between two black mark)<500mm

Page 11

TP801/TP805/TP806 User Manual

www.hprt.com 11

2.3 Printing and cutting position

2.3.1 Printing position

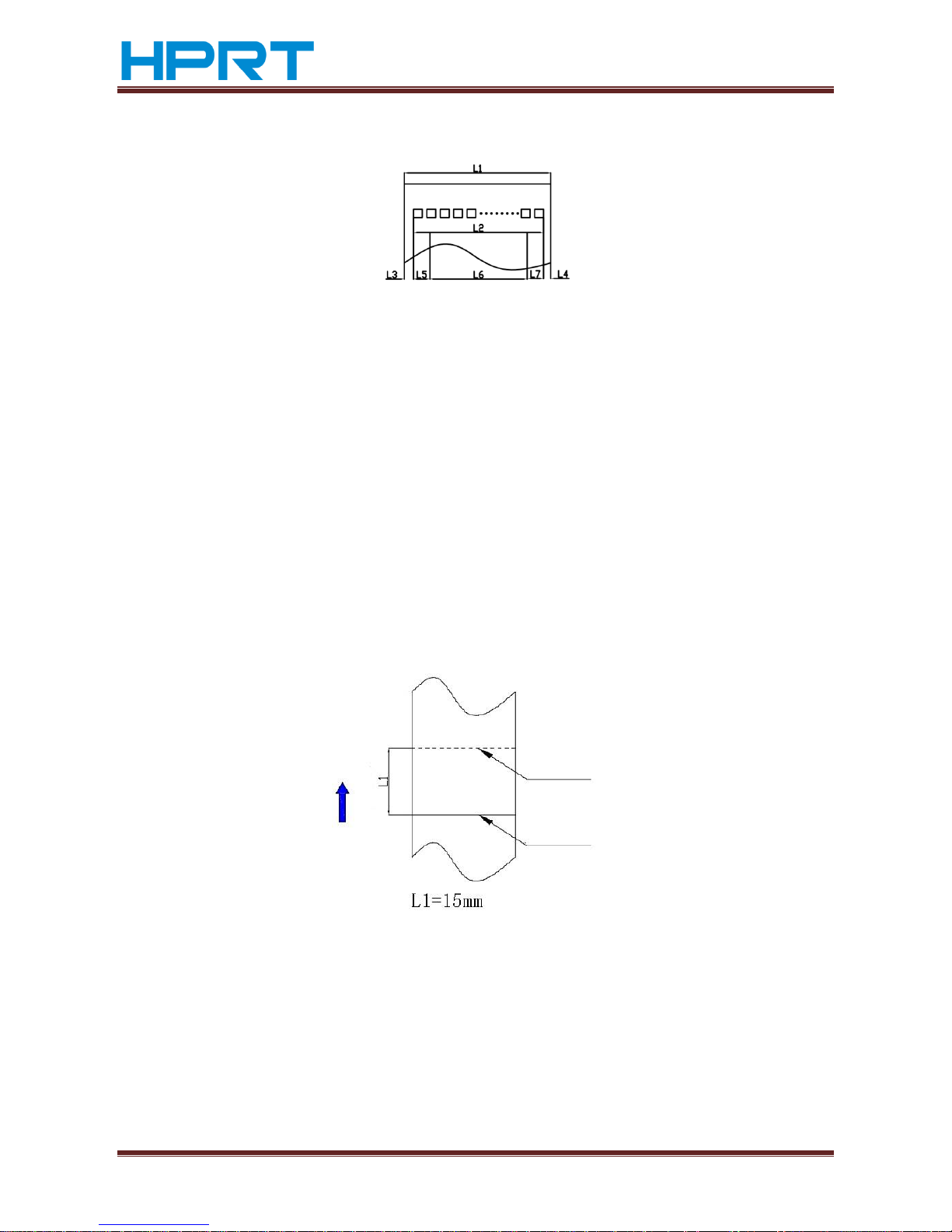

Fig 2.3.1

1) L1 Paper house width:TP801/805-83mm,TP806-81±0.5mm

2)

L2 Valid printing width: 80mm

3) L3 The distance between the thermal printer head and the left side of the paper

house(fixed width):3.5±0.3mm

4) L4 The distance between the thermal printer head and the right side of the paper

house(fixed width):3.5±0.3mm

5) L5 The left side:default 4 mm

6) L6 Printing width: decided by the command (see the program guide), and the

default is 72mm.

7) L7 Te right side:default 4mm

2.3.2 Cutting position

Fig 2.3.2

Cutting position

Paper feeding direction

Page 12

TP801/TP805/TP806 User Manual

www.hprt.com 12

3 Printer components

3.1 Appearance and component

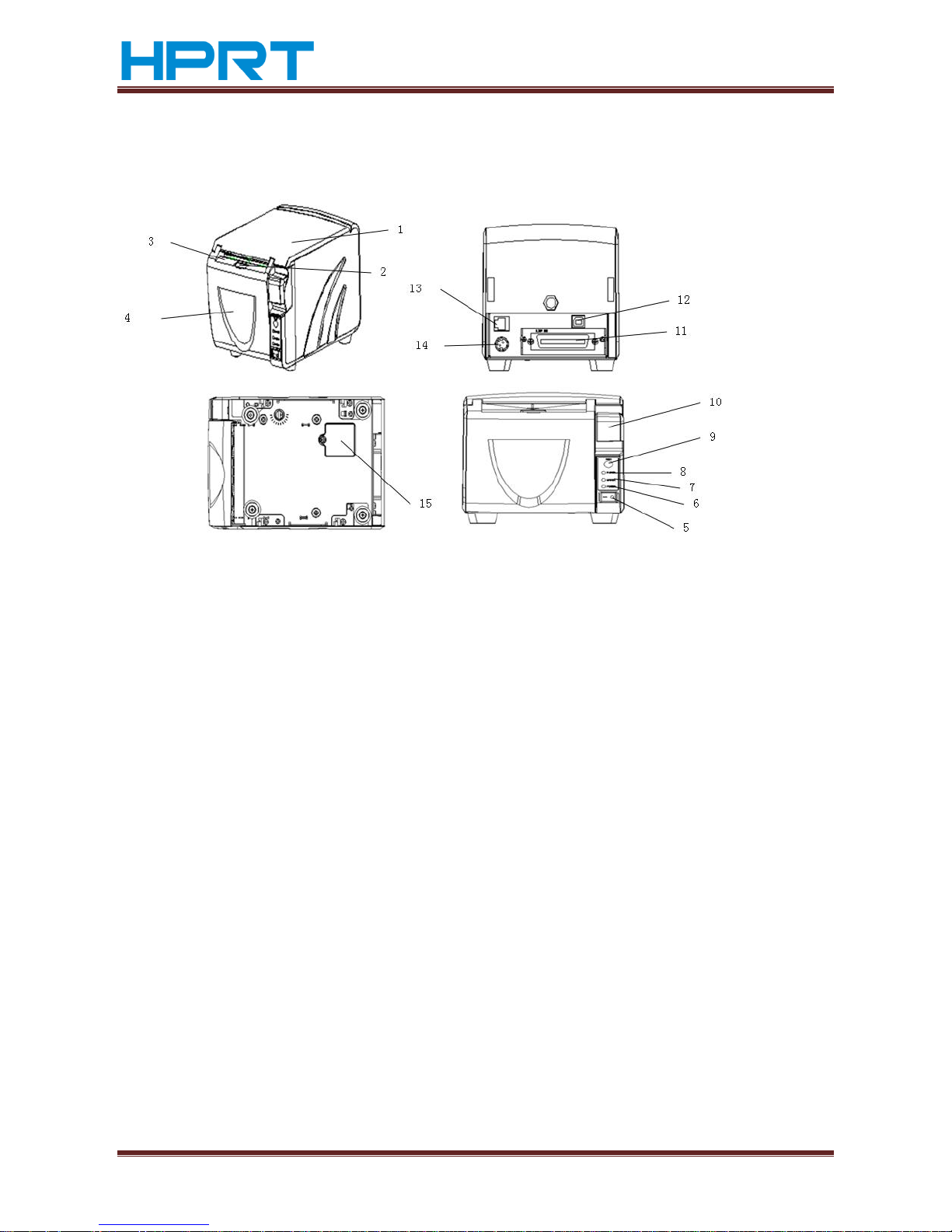

3.1.1 TP801

1.Printer Cover

9.Feed LED

2.Paper Detection

10.Cover Open Button

3.Paper Mouth

11. Flexible Interface Board (Serial/Parallel/Ethernet/Wi-Fi)

4.Front Cover

12.USB Interface

5.Power Switch

13.Cash Drawer Interface

6.Power LED

14.Power Interface

7.Error LED

15.DIP Switch Cover

8.Paper near end LED

Page 13

TP801/TP805/TP806 User Manual

www.hprt.com 13

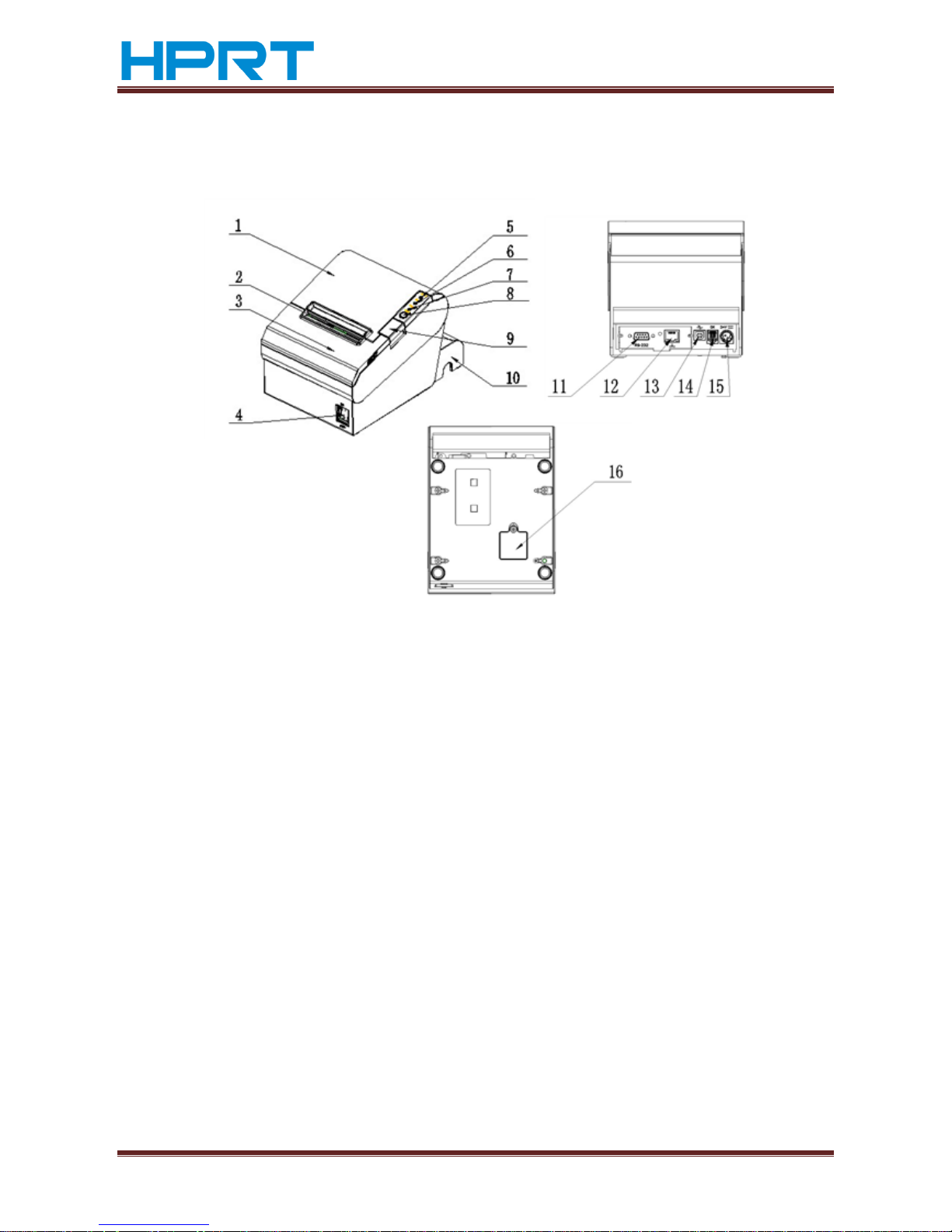

3.1.2 TP805

1.Printer Cover

9.Cover Open Button

2.Paper Mouth

10.Cable cover

3.Front Cover

11/12. Flexible Interface Board

(Serial/Parallel/Ethernet)

4.Power Switch

5.Power LED

13.USB Interface

6.Error LED

14.Cash Drawer Interface

7.Paper nerd end LED

15.Power Interface

8.Feed LED

16.DIP Switch cover

Page 14

TP801/TP805/TP806 User Manual

www.hprt.com 14

3.1.3 TP806

1.Printer Cover

10.Flexible Interface Board (Serial/Parallel/Ethernet/Wi-Fi)

2.Paper Mouth

11.Rubber Pads

3.Front Cover

12.USB Interface

4.Power Switch

13.Cash Drawer Interface

5.Power LED

14.Power Interface

6.Error LED

15.DIP Switch cover

7.Paper nerd end LED

16.Waterproof Cover

8.Feed LED

17.Cable Cover

9.Cover Open Button

Page 15

TP801/TP805/TP806 User Manual

www.hprt.com 15

Specification of some part elements

1) Power switch

Press “0” to turn off power and press “1” to turn on power supply;

2) Paper out indicator light

Detect the status of paper .when warming light fast blink, it means paper will run out,

you should change paper soon; Under this status, printer will keep working until

paper out ;

3) Unusual indicator light

During operation the if some abnormality has occurred, unusual light will flash, which

indicates the printer is in an error state, should turn off power and check it .

3.2 Specification of Indicated light and beeper

Function specification of Indicated light and beeper

Name

Status Specification

POWER

Indicator light

(Green)

Bright

The printer work well

Extinguish

The printer does not work

ERROR

Indicator light

(Red)

Flashed

The printer in an error state

Extinguish

The printer in an normal state

PAPER

Indicator light

(TP801 Blue)

(TP805/TP806 Red)

TP801 Flashed

The printer in paper out state

TP805/TP806 Bright

Extinguish

The printer in an normal state

Notes:

The printer uses a thermistor to detect the temperature of the print head, if the print

head is overheated, the circuit will cut off the power to the print head, and stop

printing; The print head overheat protection temperature is 70 ° C

Description

Power

Unusual

Paper out

Beeper

Open the cover of

printer

bright

bright

bright

Two short voice“ Beep ,Beep”,one

long voice“ Beep”

Full of paper

bright

Extinguish

Extinguish

Silent

No paper

bright

bright

bright

Three short voice “Beep Beep Beep”.

Paper will out

bright

Extinguish

bright

Silent

Page 16

TP801/TP805/TP806 User Manual

www.hprt.com 16

4 Printer packing

4.1 Open packing

When opening the package, according to the packing list to check if items are missing

or damaged, if so, please contact the dealer or manufacturer.

4.2 Choice installation site and direction of printer

1) Install the printer on a flat, stable place; recommend to install it at horizontal

line, angle of inclination should not exceed ± 10 °(paper feed direction)if tilt

install printer, it does not allow to tilt by other direction.

2) Keep printer far away from source of water;

3) Avoid the printer on place where it is vibration and shock

4) Ensure printer ground connect is sate;

5) When the printer is at operation and maintenance, it is recommended to

retain the space as below to ensure the printer can work in reliability and ease

of operation.

4.3 Connect the printer power adaptor

1) Make sure the printer's power switch is turned off;

2) Put the cable plug of power adapter facing up at flat side, insert the rear of

the printer power connector;

3) Turn the power adapter input power;

4) Pay attention about disconnecting or connect the AC adapter at right method,

or likely to cause damage.

The plug of power adapter is designed in a switch type, when accessing power

adapter and uttered the voice "click", it means the connected socket switch is locked

the adapter connect well, otherwise please connect again .

When pull out the adapter, please pinch the shell of power adaptor and pull the

switch up, when the switch is fully opened then pull out the power adapter.

Don’t put forth your strength to pull the plug by squeeze at any of place of power

adaptor .Because, it is more difficult to pull it out and easy to damage the cable.

Page 17

TP801/TP805/TP806 User Manual

www.hprt.com 17

Notes:

► Please only use the power adapter are recommended by supplied or equivalent

products;

► When disconnecting the AC adapter plug, handheld plug connector housing, to

avoid the pulling on the cable in force;

► Avoid drag the power adapter cable, otherwise it will damage the cables, causing

fire and shock;

► Avoid put power adapter around a heating device, otherwise the cable may melt,

causing fire and shock;

► If you do not use the printer in a long time, disconnect the power supply of printer

power adapter.

4.4 Connecting the Interface Cable

1) Make sure the printer's power switch is turned off;

2) Put the interface cable into the matched interface and fixed with screws (or spring)

on the plug;

3) Connect the other end of the interface cable to the host.

4.5 Connecting the Cash Drawer

1) Make sure the printer's power switch is turned off;

2) Connect the cash drawer cable into the cash drawer interface on the rear side of

the printer.

Warning:

Cash drawer interface can only be connected to a voltage of 24V cash drawer

device (can’t connect to the phone line, etc.)

4.6 Paper roll installation

4.6.1 Confirmation of printing paper

After connecting the power adapter and interface cable, you can install media for

printing. Confirm the type of paper used by the printer before printing. The default

paper type is continuous paper. If you need to set the marked paper, please contact

your dealer or manufacturer.

4.6.2 TP801/TP805/TP806 installation/Change Paper

1) Turn off printer power supply;

2) Flipping switch knob, open the top cover of TP805\TP806 and front cover of

TP801(Like figure 4.6.1)

Page 18

TP801/TP805/TP806 User Manual

www.hprt.com 18

Figure 4.6.1

3) Put the paper into printer(Like figure 4.6.2)

Figure 4.6.2

Notes:

► According to the paper size to adjust the paper holder;

► Make sure the end of the paper roll fit for the graphics requirements;

Figure 4.6.3

► Make sure the paper inside is at tight status, or it will tissue paper or other

obstacle.

4) Pull out of the end of paper roll, closed the cover and tear up sheet of paper.

TP805

TP801

TP806

TP801

TP806

TP805

Page 19

TP801/TP805/TP806 User Manual

www.hprt.com 19

4.7 Setting DIP switch

4.7.1 Serial interface(RS-232C)

·DIP switch 1

Switches

Functions

Turn on

Turn off

Default

1-1

Line feed automatic

Yes

Prohibit

Turn off

1-2

Handshaking

XON/XOFF

DTR/DSR

Turn off

1-3

Data length

7 bit

8 bit

Turn off

1-4

Odd-even verify

Yes

No

Turn off

1-5

Odd-even choice

EVEN

ODD

Turn off

1-6

Choice baud rate(bps)

Reference form 1

Turn off

1-7

Turn on

1-8

Turn off

DIP switch 2

Switches

Functions

Turn on

Turn off

Default

2-1

The mode switch in both

Chinese and English

English

Chinese

Turn on

2-2

Internal control beeper

Permit

Prohibit

Turn off

2-3

Auto cutter

Prohibit

Permit

Turn off

2-4

Busy condition

Receive buffer is full

*Off-line

* Receive buffer is full

Turn off

2-5

Printer density

Reference form 2

Turn off

2-6

Turn off

2-7

Turn off

2-8

Paper out sensor status

Prohibit

Permit

Turn off

4.7.2 Interfaces of Parallel and USB2.0

DIP switch 1

Switches

Function

Turn on

Turn off

Default

1-1

Line feed automatic

Permit

Prohibit

Turn off

1-2~1-8

Reserve

- - Turn off

DIP switch 2

Switches

Functions

Turn on

Turn off

Default

2-1

The mode switch in both

Chinese and English

English

Chinese

Turn on

2-2

Internal control beeper

Prohibit

Permit

Turn off

2-3

Auto cutter

Prohibit

Permit

Turn off

2-4

Busy condition

Receive buffer is full

*Off-line

* Receive buffer is full

Turn off

2-5

Printer density

Reference form 2

Turn off

2-6

Turn off

2-7

Turn off

2-8

Paper out sensor status

Prohibit

Permit

Turn off

Page 20

TP801/TP805/TP806 User Manual

www.hprt.com 20

Form 1—The Choice of Baud rate

Baud rate

1-6

1-7

1-8

Default

2400

Turn on

Turn off

Turn off

9600

4800

Turn on

Turn off

Turn on

9600

Turn off

Turn on

Turn off

19200

Turn off

Turn off

Turn off

38400

Turn off

Turn on

Turn on

57600

Turn off

Turn off

Turn on

115200

Turn on

Turn on

Turn on

Form 2—The choice of print density

2-5

2-6

2-7

Printer density

Default

Turn on

Turn on

Reserve

1(diluted)

2

Turn off

Turn off

Reserve

2

Turn on

Turn off

Reserve

3

Turn off

Turn on

Reserve

4(dense)

4.7.3 The choice of auto cutter

DIP Switch setting 2

Switch2-3

Turn on

Automatic paper cutting is

prohibited

Turn off

Automatic paper cutting is

permitted

Application program

Ignore the automatic paper cutting error continuous printing

4.8 Print self testing

1) Make sure the printer has been installed paper roll and turn off the top cover;

2) Press on FEED button and turn on power switch, the printer will print out

self-test page.

4.9 Installation of Windows driver

Give an example of TP806, in printer’s CD has attached windows driver program,

open the driver program and run “DriverSetup.exe”.

4.9.1 The driver installation instruction of USB /serial port /parallel

interface

1) Double click” HPRTTPPrinterDriver-v-1.0.2.6.exe”, Choice “English” and click “OK”.

Page 21

TP801/TP805/TP806 User Manual

www.hprt.com 21

2) Click “Install”.

3) Choice the port and type you want(the installation program will recognize the usable

printer ports automatically, USBxxx is for USB port ,COMx is for serial port,LPTx is for

parallel port),click “Next” to next step.

4) Click “Finish” , it is successful to install.

Page 22

TP801/TP805/TP806 User Manual

www.hprt.com 22

4.9.2 The driver installation instruction of Ethernet and Wi-Fi

1) Install printer driver program just as USB installation.

2) Click “Control Panel”→”Hardware and Sound”→”Devices and Printers”.

3) Right click “HPRT TP806” and choice “Printer properties”, click “Ports”,choice”COM1”,

Click “Add Port…” button.

4) Choice “Standard TCP/IP Port” and click “New Port…” button.

Page 23

TP801/TP805/TP806 User Manual

www.hprt.com 23

5) Click “Next>”.

6) Finishing the writing of printer name (or IP address)and port name ,Clicking

“Next >”.

“Printer Name or IP Address”: Depends on the display of printer’s self-test page.

“Port Name”: Users can customize the name of the port.

7) Clicking “Next >”.

Page 24

TP801/TP805/TP806 User Manual

www.hprt.com 24

8) Click “Finish”.

9) Click Click “Control Panel”→”Hardware and Sound”→”Devices and Printers”., right click

“Printer Properties” of printer HPRT TP806 and choice “Ports”→“Configure Port…”,

finish the setting of related parameter, click “OK”.

4.9.3 Parameters checking and resetting illustration of the Ethernet and

Wi-Fi cards

Ethernet parameter checking:

Press the button on the communication card round hole when the printer is power on,

the printer will print the current Ethernet parameters.

Ethernet card parameter resetting:

Press the button on the communication card round hole then power on. After you

power on, the parameter on the communication card is renew to the original

situation.

Page 25

TP801/TP805/TP806 User Manual

www.hprt.com 25

Wi-Fi card parameter checking:

Press the button on the interface card round hole when the printer is power on, he

printer will print software edition and the TCP/IP setting information of the interface

card.

Wi-Fi card parameter resetting:

Press the button on the communication card round hole then power on. he

parameter on the communication card is renew to the original situation.

4.9.4 Setting of Ethernet IP

1) Ethernet IP can be set through Web page, the operating steps are followed:

2) Connect the printer to computer, please refer to the USB, Serial interface and

Parallel User Manual 4.9.1.

3) Connect Ethernet to the printer, please refer to the Ethernet driver installation in

User Manual 4.9.2.

4) Print self- test page after power on. You can find the IP information in the self-test

page IP address line. IP address: 192.168.0.31 //indicates the IP address is

192.168.0.31

5) Click Start-Operate in the computer and key in “cmd” in the input box then click

Sure, see the following figure:

6) Key in ping 192.168.0.31 after “Administrator>”, see the following figure:

Page 26

TP801/TP805/TP806 User Manual

www.hprt.com 26

7) Click “Enter”, if the following figure is presented, you can sure that the Ethernet

have been connected to the printer, if not presented, please check the

connection between the Ethernet and the printer.

8) Then please input http://192.168.0.31, in the brower see the following figure:

Page 27

TP801/TP805/TP806 User Manual

www.hprt.com 27

9) Press “Enter”, the browser will skip to the IP setting interface, click Configuration

in the left side then enter to the address modify page, 192.168.0.31 is the current

IP address, see the following figure:

10) Modify the IP in the IP Address. For example, modify the IP to 192.168.0.32,see

the following figure:

Page 28

TP801/TP805/TP806 User Manual

www.hprt.com 28

11) Click SUBMIT in the middle of the upper page then enter to the following

webpage:

12) Click RESET in the middle of the upper webpage then enter to the following

webpage:

Page 29

TP801/TP805/TP806 User Manual

www.hprt.com 29

13) Reboot the printer to effect the new IP, then you can print self-test page and find

the new IP address 192.168.xx.xx.

4.9.5 Wi-Fi settings

Wi-Fi work mode:

AP mode:when printer under AP mode, it works as an access point.

STA mode: when printer under STA mode, it works as a wireless terminal, which

could find and connect to AP.

To allow users to conveniently make WIFI setting change, AP mode has been set to

default. User could use PC to connect to the printer by web browser. After entering

WIFI setting page, users could switch to STA mode accordingly and make other

setting changes, for example IP address, SSID.

1. Entering Wi-Fi setting page:

1) Power on the printer.

2) Enable Wi-Fi on the PC, and search for “TP806_WIFI”.

Page 30

TP801/TP805/TP806 User Manual

www.hprt.com 30

3) Open web browser, and enter http://192.168.0.XXX( this IP address is printed on

the Wi-Fi configuration page).

How to print Wi-Fi configuration page: power on the printer, long press the

WIFI reset button (see below picture), then printer will print the configuration

page.

NOTE: hold Wi-Fi reset button, at same time power on the printer, Wi-Fi

settings will be set to factory default.

Example of Wi-Fi configuration page, which shows the IP address of

192.168.0.33.

Page 31

TP801/TP805/TP806 User Manual

www.hprt.com 31

4) Use Internet Explorer or other web browser to open http://192.168.0.33,

input

user name: admin;

password: admin

5) After entering user name and password, click on OK to enter Wi-Fi setting page.

Page 32

TP801/TP805/TP806 User Manual

www.hprt.com 32

2. STA mode settings

1) Click on “Work Mode” on the left-hand side, rolling down to STA mode.

2) Click on “SAVE” and below window will pop up.

Page 33

TP801/TP805/TP806 User Manual

www.hprt.com 33

3) Do not click on “RESTART” button at this moment, instead click on the “STA

Setting” on the left side to make more STA settings.

4) Click on “SCAN” button to search for access points

For example, below picture shows there are several access points available

Page 34

TP801/TP805/TP806 User Manual

www.hprt.com 34

5) Choose the correct access point.

For example: ”embedded” , see below picture.

Page 35

TP801/TP805/TP806 User Manual

www.hprt.com 35

NOTE: settings in the above pictures are just for examples, not for your actual onsite network settings. Please refer to your IT and network engineer for the correct

network settings.

Page 36

TP801/TP805/TP806 User Manual

www.hprt.com 36

6) After setting, click on “SAVE”.

7) If users want to make other changes, click on “ BACK” , otherwise click on

“RESTART” button.

8) Above settings will take into effect after power off/on the printer, user could print

the Wi-Fi configuration page to check whether settings have been success fully

made.

Page 37

TP801/TP805/TP806 User Manual

www.hprt.com 37

NOTE: after changing to STA mode, access point will assign an IP address to the

printer, by printing WIFI configuration page, users could see the IP address, and

use it for entering WIFI setting page in the future.

3. AP mode settings:

1) Click on the “Work Mode”, roll down to “AP mode”, click on “Save”.

2) Do not click on “Restart”, and instead click on “AP Setting” on the left side.

Page 38

TP801/TP805/TP806 User Manual

www.hprt.com 38

3) According to user’s actual needs to change network mode, SSID, IP address and

other settings ( please refer to IT or network engineer for the correct settings).

4) Click on “Save” and “restart” button to confirm the settings.

Page 39

TP801/TP805/TP806 User Manual

www.hprt.com 39

5) Power off and power on the printer, above settings will take into effect. Users

could print WIFI configuration page to check whether setting have been

successfully made.

Page 40

TP801/TP805/TP806 User Manual

www.hprt.com 40

5 Interfaces signal

Printer TP801/TP805/TP806 supports cash drawer interface and many other various

communicate interfaces, such as Serial interface, parallel interface, USB interface,

Ethernet interface (TP801/TP806 also support Wi-Fi interface). The printer has the

communication board with the default USB interface and cash drawer interface, and

the other communication boards with the Ethernet interface, parallel interface,

RS232 interface are optional.

5.1 Parallel interface

Parallel interface (TP801/TP805/TP806 support TM-T88IV protocol) supports protocol

with 36 pin CENTRONICS socket.

Pin No.

Signal

Source

Signal Definition

1 H Data latch pulse, latch the data to the printer at the rising edge of the negative pulse

2

H

Data 0(The lowest bit)

3

H

Data 1

4

H

Data

2Si

5

H

Data 3

6

H

Data 4

7

H

Data 5

8

H

Data 6

9

H

Data

7 (

The highest bit)

10

P

Printer response signal, indicates that the printer has received the last byte of data; A

negative pulse of about 1us.

11

P

Busy Signal; The printer is busy; High level indicates that the printer can’t receive data.

12

P

PE Signal; paper end signal; High level indicates that the printer is paper end.

13

-

Unconnected

14

-

Unconnected

15

-

Unconnected

16

Logic Ground

17

Frame Ground, separated from logic ground

18

-

Unconnected

19~30

Logic Ground

31

-

Unconnected

32

P

Printer error signal, low level indicates that error occurs in the printer, the error signal will

output along with paper end signal.

33

Logic Ground

34~35

-

Unconnected

36

-

Unconnected

Page 41

TP801/TP805/TP806 User Manual

www.hprt.com 41

Note:H indicates that signal comes from Host computer, P indicates that signal

comes from Printer

Figure 5.1.1

5.2 Serial interface

Pin definition

PIN No.

Signal name

Classic wire color

1

VBUS

Red 2 D-

White

3

D+

Green

4

GND

Black

Figure 5.2.1

5.3 Power Supply interface definition

1) Pin definition

Figure 5.3.1

2) Interface type

Printer end-Unetop DC-002 or similar products, user end-Unetop DC-002 or similar

products

PIN No.

Signal Name

1

+24V

2

GND 3 N.C

SHELL

F.G

Page 42

TP801/TP805/TP806 User Manual

www.hprt.com 42

5.4 Cash Drawer interface signal

1)

Electrical characteristics

Driving voltage:DC 24 V

Driving current:maximum 0.8 A ( In 510 ms)

Drawer check signal:“L” = 0~0.5 V “H” = 3~5 V

2)

Cash Drawer interface sing RJ-11 connector

Figure 5.4.1

Interface signal definition

Pin No.

Signal

Function

1

FG

Frame Ground

2

DRAWER 1

Drawer kick-out drive signal 1

3

DRSW

Drawer open/close signal

4

VDR

Drawer driving source

5

DRAWER 2

Drawer kick-out drive signal 2

6

GND

GND

Note:

Strictly prohibit to hot plug the plug.

When arranging the line of communication, you have to avoid paralleling with the

strong current.

you have to use the shielded communication line.

5.5 Serial interface and Ethernet interface

Printer TP 805 serial interface is compatible with RS-232 standard, with 9 pin (D hole

type) socket.

Page 43

TP801/TP805/TP806 User Manual

www.hprt.com 43

Serial interface definition Ethernet interface definition

Printer TP 801 and TP806 serial interface are all compatible with RS-232 standard,

with 25 pin (D hole type) socket.

User can gain the setting of interface via printing configuration sample; the default

setting of serial interface is as follow, 9600 bps (baud rates), 8 bit (data bit), 1 bit

(stop bit), no parity, support RTS/CTS handshaking protocol.

Serial interface definition Ethernet interface definition

TP805 TP801/TP806

Figure 5.4.1

PIN No.

Signal definition

1

TX+

2

TX- 3 RX+

4

n/c 5 n/c

6

RX- 7 n/c

8

n/c

PIN No.

Signal definition

PIN1

Frame Ground

PIN2

TXD

PIN 3

RXD

PIN 4

RTS

PIN 5

Unconnected

PIN 6

DSR

PIN 7

GND

PIN 8~19

Unconnected

PIN 20

DTR

PIN 21~25

Unconnected

PIN No.

Signal definition

1

TX+ 2 TX-

3

RX+ 4 n/c 5 n/c 6 RX- 7 n/c 8 n/c

PIN No.

Signal definition

PIN 1

CD

PIN 2

TD

PIN 3

RD

PIN 4

DSR

PIN 5

GND

PIN 6

DTR

PIN 7

CTS

PIN 8

RTS

PIN 9

RI

Page 44

TP801/TP805/TP806 User Manual

www.hprt.com 44

6 Troubleshooting

Your printer is very reliable, but occasionally problems may occur. This chapter

provides information on some common problems you may encounter and how to

solve them. If you encounter problems that you can not resolve, contact your dealer

for assistance

6.1 Printer not working

Problem description

Probable reason

Solution

LED indicator not light, printer not

working

Printer No power

Connecting the power supply

Printer not on

Turn on the printer

Circuit board broken

Contact with the dealer

6.2 LED indicator on the control panel and beeper alarm

Problem description

Probable reason

Solution

Paper LED always on

Paper near end

The roll paper is near end, the printer can

work normally

Error LED always on and beeper alarms

Printer Cover open

Close the printer cover

Paper Error LED always on and beeper alarms

Paper end

Reload the roll paper

Error LED blinks and beeper alarms

Thermal print head overheated

Turn the printer off and resume when it cools

overvoltage

Print with specified voltage

Low-voltage

Print with specified voltage

6.3 Troubles occur during printing

Problem description

Probable reason

Solution

Coloured stripe in the paper

Paper near end

Reinstall the roll paper

Blurred printing or spot

Incorrect roll paper installation

Check if the roll paper is installed

Unqualified roll paper

Use recommended thermal roll paper

Dirty thermal head or print rooler

Clean the thermal head or print rooler

Low print density

Increase the print density level

Paper Jam

Paper stucked

Open the printer cover, check the paper

path and remove jammed paper

Vertical print words missing

Dirty thermal head or print rooler

Clean the thermal head or print rooler

Thermal head damaged

Contact your dealer for assistance

Page 45

TP801/TP805/TP806 User Manual

www.hprt.com 45

6.4 Problems emerge during the paper cutting processes

Problem description

Probable reason

Resolution

Cutter jam, the movable

cutter cannot back

Cutter abrasion, insufficient

cutting

replace the cutter

Worm gear and worm wheel

abrasion

Replace the worm gear and worm wheel

Motor burnt

Replace the motor

Paper scraps

Clean the paper scraps on the transmission system

Insufficient cutting

Cutter edge abrasion, paper

too thick

Replace the cutter

Paper jam

Thermal printer head over

heat

Reduce the thermal printer head heating power

Driving too fast

Reduce the printer speed to the limit of thermal printer head

Wrong paper feeding

position

Put the paper parallel with the paper mount and insert into the

space between platen roller and the thermal printer head

6.5 Removing Jammed Paper

Do not touch the thermal print head because it becomes very hot after printing.

Turn the printer off and press the cover open button.

Remove jammed paper, reinstall the roll, and close the cover.

Page 46

TP801/TP805/TP806 User Manual

www.hprt.com 46

If the auto cutter jam occurs on printer TP805 and TP806 and you cannot open

the printer cover, open the cutter cover as shown on the left below.

Turn the knob until the cutter blade returns to the normal position.

Close the cutter cover.

Open the printer cover and remove the jammed paper.

TP805 TP806

Loading...

Loading...