Page 1

INSTRUCTION MANUAL

TURBINE POWERHEAD

FOR

P/N 7160, 7161 & T210

HAND HELD

TURBINE

POWERHEAD

FOR

P/N 6970g, 6971g

& 6972g

These Turbine Powerheads have been carefully designed and manufactured for long life, reliable performance

and convenient cleaning. They are designed to do most of the cleaning work for you. They move easily and do

not require downward pressure for thorough cleaning.

As with any tool with moving parts, caution must be exercised while using these Turbine Powerheads. Please

read and save this Instruction Manual.

SAFETY PRECAUTIONS

1. Keep hair, hands and feet away from rotating brush while the Turbine Power Head is running.

2. Remember that Turbine Powerheads operate whenever they are connected to a running vacuum. If children

are present, make sure to turn vacuum system off when leaving Powerhead unit unattended.

3. Do not attempt to service or unclog tool while unit is running.

4. Avoid picking up water or spilled liquids with a Turbine Powerhead. The vacuum system is designed for dry

pick-up only.

Page 1

Page 2

INSTRUCTIONS FOR TURBINE POWERHEAD

(A) ATTACHING THE TURBINE POWERHEAD

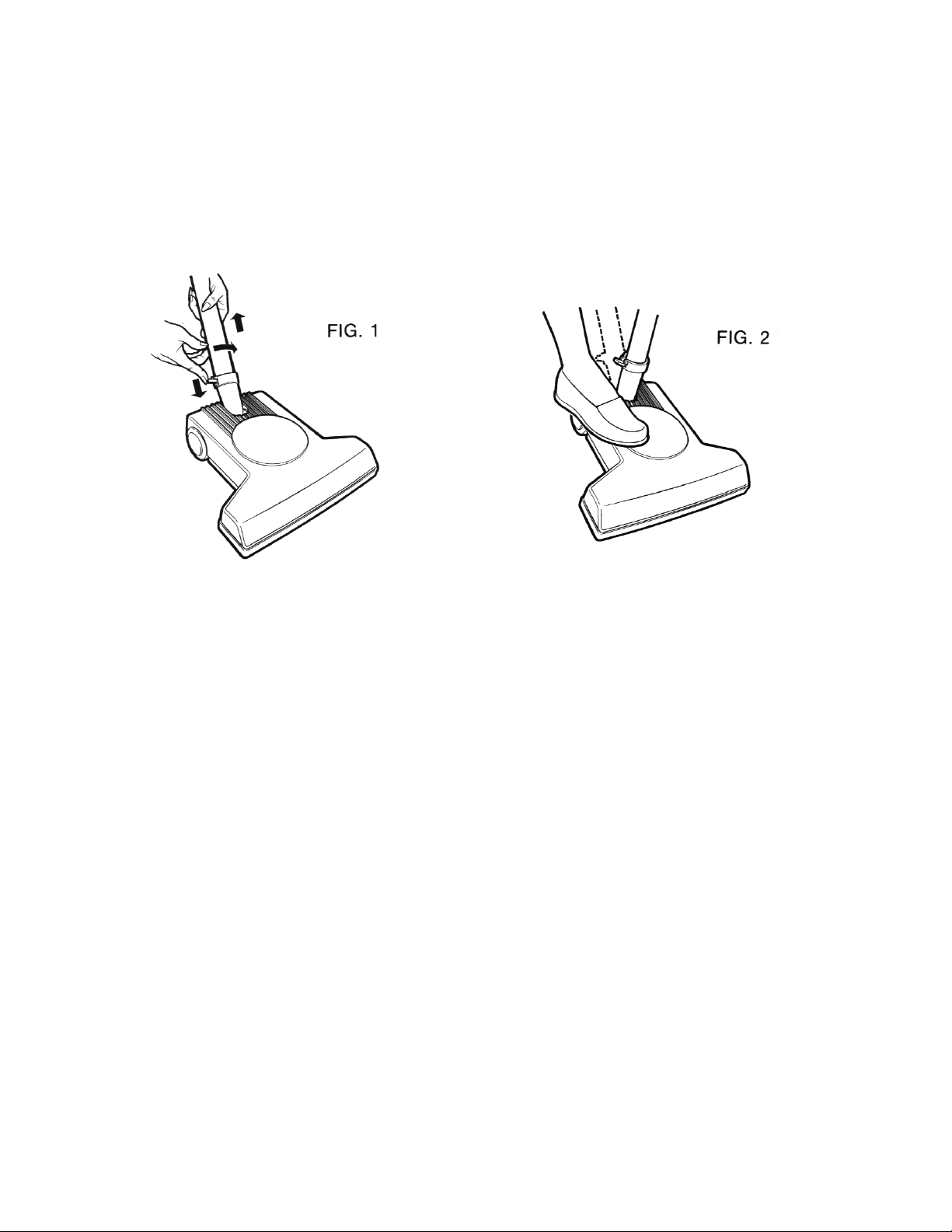

To attach your metal wand, simply twist into Powerhead elbow until it fits snugly. The built-in, locking mechanism

will prevent the wand from coming loose from your Powerhead while in use. To detach wand, depress tab on

side of elbow and twist wand free. (See Fig. 1)

The wand can be locked in an upright position by pushing it forward until the lock is engaged. (See Fig. 2). This

locked position is convenient for storage and for lifting of the Powerhead. To release wand from the vertical

locked position, gently place foot on Powerhead, grasp wand and pull back firmly.

(B) OPERATING PROCEDURES

Your Turbine Powerhead has no on/off switch. Whenever it is attached to an operating vacuum system, it will be

running. No adjustments to the tool are necessary for different types of carpeting.

To ensure maximum efficiency of the Turbine Powerhead, make sure that any filters, bags and cleaning hoses

in your vacuum system are clean and free of blockage.

(C) CLEARING INTAKE NOZZLE

If the Turbine or Intake nozzle become obstructed.

1. Turn off Vacuum System and disconnect the Powerhead from wand and hose.

2. Turn Powerhead over, and remove the clear belt cover, by first rotating the two latches counter clockwise

until they align with the openings in the belt cover. Pull the belt cover away from the housing using the tab

provided, then pull the belt cover out from under the baseplate. (see Fig. 3)

3. Remove debris from the intake or turbine. Rotate brush to ensure the system is clear. Ensure the special

red coloured seal and mating surfaces are clean and free of any dirt particles, before re-assembling belt

cover to unit.

4. To re-assemble the belt cover to the unit: insert the front of the belt cover under the base plate edge, and

press the belt cover into the housing.

5. Check that a proper seal is made: UNIT PERFORMANCE IS DEPENDENT ON A PROPER SEAL!

6. Secure the belt cover in place by rotating the two latches clockwise to the locked position.

(D) CLEANING BRUSH

Tu rn off vacuum system and disconnect Powerhead.

Threads, string, carpet fiber, fuzz, etc. occasionally may become wound around the beater brush. These should

be removed by unwinding them by hand or carefully cutting with scissors or other cutting tool. Keeping the beater brush clean will maintain efficiency.

Page 2

Page 3

(E) REMOVING THE DRIVE BELT AND BRUSH

“It is recommended this procedure be performed by a Qualified Service Technician.”

Should the drive belt or brush become clogged with debris or need replacing:

1. Turn off vacuum system and disconnect powerhead.

2. Remove belt cover as described in procedure C.

3. Remove the 3 screws securing the metal baseplate. (see Fig. 4)

4. Lift front of baseplate up from bumper, then pull baseplate free of unit.

5. Stubborn debris may now be easily removed from the brush area.

6. PLEASE NOTE: Correct brush and belt orientation; they must be re-installed correctly for proper function.

7. Slide the belt up off the end of the drive shaft.

8. Partially remove the bumper by lifting it free from the front and sides of the housing.

9. Lift the lower belt shroud, brush, belt and support assembly out of the housing, and remove the belt from the

brush. Leave upper belt shroud installed in the housing, unless stubborn debris remains lodged below it.

10. (IF REPLACING BRUSH). Pull the right brush support (marked ‘R’) off the assembly and remove the brush

from the shaft.

11. Slide replacement brush onto the shaft so the large recess at one end of the brush goes on first and fits

over the 4 ribs on the shaft support.

12. Push the right shaft support (marked ‘R’) onto the shaft extending through the brush, and check that the

brush spins freely when rotated.

13. Place the belt over one end, onto the brush.

14. Slide the brush/belt assembly back into the housing recesses so the supports seat properly into the housing.

NOTE: The housing and supports are marked L and R and must be assembled accordingly. The ARROWS

on the shaft supports must point toward the rear of the unit, when fitting a new belt. The supports can be

rotated to point the arrows forward to increase belt tension after extensive use (typically several hundred

hours of use).

15. Place the lower belt shroud into the housing, over top of the brush pulley, as shown in FIG. 4. Ensure that

the top of the shroud cylindrical portion is flush with the upper housing screw boss.

16. Stretch the bumper around the housing, over the shaft supports and press the bumper into place.

17. Pull the belt gently up against the pulley teeth, and over the idler bearing. Twist the end of the belt 90° as

illustrated on the lower housing and press the belt over the teeth of the drive shaft.

NOTE: The brush will rotate in the wrong direction and belt damage may occur if the belt is twisted

incorrectly.

18. Tilt baseplate to the rear of brush area and insert the three tabs into the mating slots in the lower housing.

Rotate the front of the base down so it seats into the groove in the bumper.

19. Replace the three screws, and tighten to secure the base.

20. Replace the belt cover as described in procedure ‘C’.

Page 3

Page 4

Page 4

Page 5

INSTRUCTIONS FOR HAND HELD TURBINE POWERHEAD

(A) ATTACHING THE HAND HELD TURBINE

POWERHEAD

To attach your metal wand and/or curved hose handle simply

twist into hand brush neck until it fits snugly. (See Fig. 1). To

detach wand or curved hose handle, simply hold neck of Hand

Held Powerhead and pull apart with a twisting motion.

(B) OPERATING PROCEDURES

Your hand held Turbine Powerhead has no on/off switch.

Whenever it is attached to an operating vacuum system, it will

be running. There is only one adjustment for the Brush. A suction control valve is located on the top left side. Slide the control valve open to reduce suction for cleaning draperies. (See

Fig. 2)

(C) CLEANING BRUSH

Tu rn off vacuum system and disconnect Powerhead Brush.

Threads, string, carpet fiber, fuzz, etc. can wrap around the cleaning brush. These should be removed by

unwinding them by hand or carefully cutting with scissors. (Note: Brown base plate should be removed to clean

properly). Keeping the cleaning brush clean will maintain efficiency of the Powerhead Brush.

(D) CLEANING INTAKE NOZZLE

If turbine or intake nozzle become obstructed:

1. Turn off vacuum system and disconnect Powerhead.

2. Remove brown base plate by first sliding the base plate latch toward the back of the brush. Next, pull the

rear of the plate away from the housing and slide forward to disengage front locking tabs. (See Fig. 3)

3. Remove debris from intake port and/or turbine.

4. Reassemble by inserting the tabs on the front of the base plate into the slots in the base housing, then

secure the back of the brown base plate with the latch.

Page 5

Page 6

(E) BELT REPLACEMENT

Remove brown base plate and belt cover (right side of Powerhead) by removing screw. (See Fig. 4). Next,

remove belt from pulley (may help to turn cleaning brush backwards slightly.) (See Fig. 5).

Pull belt and brush assembly out and replace belt. Before replacing base plate and belt cover, make sure a “2”

is showing at both ends of brush assembly (this number is stamped right on the bearing housing.) (See Fig. 6).

Make sure also that no brush bristles are caught between the belt and brush roll gear. If brush bristles are worn,

see BRUSH ROLLER ADJUSTMENT.

(F) BRUSH ROLLER ADJUSTMENT

To adjust brush to compensate for bristle wear, remove brown base plate. Next, remove the belt cover by removing the screw. Finally, remove the belt from the pulley (it may help to turn cleaning brush backwards slightly).

Pull the brush assembly out. Turn brush assembly over and reinsert so that number “1” is showing at both ends.

(See Fig. 6).

Note: The brush roll comes from the factory with a “2” showing at both ends of the brush roll assembly.

Before replacing base plate and belt cover, make sure no brush bristles are caught between the belt and the

brush roller gear.

Page 6

Page 7

OTHER REPAIRS

For repairs or service beyond those described above, please contact your servicing distributor or dealer.

LIMITED WARRANTY

H-P PRODUCTS, INC. warrants that the turbine powerhead and the hand held turbine powerhead, when used

for household purposes, pursuant to Seller’s instructions, will be free from defects in materials and workmanship for a period of one year from the date of the initial consumer purchase. H-P PRODUCTS, INC. warrants

that the turbine powerhead or the hand held turbine powerhead, when used in a commercial application pursuant to Seller’s instructions, will be free from defects in materials and workmanship for a period of ninety (90)

days from the date of the initial consumer purchase.This warranty is limited to the replacement of defective parts

and any costs of shipping shall be incurred by the purchaser. THIS WARRANTY IS EXCLUSIVE AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED, OR STATUTORY, AND H-P PRODUCTS, INC.

SPECIFICALLY DISCLAIMS RESPONSIBILITY FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES, AND

LIMITS THE IMPLIED WARRANTY OF MERCHANTABILITY TO THE PERIOD OF EFFECTIVENESS OF THIS

EXPRESS WARRANTY.

H-P PRODUCTS, INC.,

Louisville, Ohio

44641 U.S.A.

(216) 875-5556

TROUBLE SHOOTING TURBINE

POWERHEADS

CAUTION

Moving parts – disconnect from vacuum system before servicing unit

PROBLEMS

1. TURBINE RUNS SLOW 3. BRUSH BOUNCES IN USE

2. BRUSH MAKES KNOCKING NOISE 4. BRUSH HARD TO PUSH

POWERHEAD INSTRUCTION MANUAL

FLOOR HAND

BRUSH BRUSH

1. CHECK BOTTOM PLATE PAGE/PAR. 3/(E) 3/(C)(D)

2. CHECK BELT AND TENSION PAGE/PAR. 3/(E) 3/(E)

3. CHECK BEATER BRUSH PAGE/PAR. 3/(E) 4/(F)

4. CHECK ALL INTAKE AREAS PAGE/PAR. 2/(C) 3/(D)

FOR OBSTRUCTIONS AND BRUSH

ROTATION DIRECTION

CENTRAL VACUUM CLEANER SYSTEMS

NON-BAG MODEL BAG MODEL

1. CHECK DIRT RECEPTACLE 1. CHECK PAPER BAG

2. CHECK GUARD SCREEN 2. CHECK CLOTH BAG

3. CHECK ALL FILTER SCREENS 3. CHECK AIR FILTERS

4. CHECK HOSES FOR AIR LEAKS 4. CHECK HOSES FOR AIR

OR OBSTRUCTIONS LEAKS OR OBSTRUCTIONS

READ OPERATION MANUAL PROCEDURES

Page 7

Page 8

Part Number

Turbine Powerhead

Item Part Description 7160 7161 T210

1Lower Housing 7211-01 SAME 7211-02

2 Wheel (2) 7212-01 SAME 7212-02

3 SA Turbine 7213 SAME SAME

4 Belt Cover 7214 SAME SAME

5 Base Plate 7215 SAME SAME

6 Compr. Spring 5958 SAME SAME

7Washer 5974 SAME SAME

8Washer, Elbow Seal 5971 SAME SAME

9 Elbow 7216-01 SAME 7216-02

10 Spring, Wand 5966 SAME SAME

11 Retainer/Cap 7217-01 SAME 7217-02

12 Spring, Latch 7218 SAME SAME

13 SA Tophousing 7219 7220 7221

14 Bumper 7222-01 SAME 7222-02

15 Seal (Large) 7223 SAME SAME

16 Seal (Small) 7224 SAME SAME

17 SA Brush 7330 SAME SAME

18 T Latch (2) 7226 SAME SAME

19 Belt 7227 SAME SAME

20 Screw Base (3) 7228 SAME SAME

21 O-Ring 7229 SAME SAME

22 Screw (9) 5944 SAME SAME

23 Screw, T Latch (2) 7230 SAME SAME

24 D-Washer 7231 SAME SAME

25 Bearing, Needle 7234 SAME SAME

26 Idler Shaft 7233 SAME SAME

27 Sleeve, Flange (2) 7232 SAME SAME

28 SA Shaft Supt 7235 SAME SAME

29 RT Shaft Supt 7236 SAME SAME

30 Rubber Plug 7237 SAME SAME

31 Ballast WT (2) 7238 SAME SAME

32 Foam Pad (2) 7239 SAME SAME

33 Caution Label 7240 SAME SAME

34 Shroud, Belt, Upper 7331 SAME SAME

35 Shroud, Belt, Lower 7332 SAME SAME

Instr. Manual HVS-825 SAME SAME

Page 8

Page 9

Page 9

Page 10

HAND HELD TURBINE POWERHEAD

Item No. Description

1 Swivel 6321-1

2 Sub Assembly 6322

Turbine and Shaft

3 Belt 6323

4 Swivel Seal (2 req.) 6324

5 Latch Spring 6325

6 Latch 6326-1

7 Housing, Assy. Half 6780-1

8 Label 7054

9 Slide Valve 6328-1

10 Sub Assy. Housing, Half/Belt Side 6757-1

11 Belt Cover 6330-1

12 Screw 6-19x.750 (3 req.) 6331

13 Brush Assembly 6332

14 Base Plate with Basket and Bumper 6755

15 Basket 6334

(Avail. only with #6755)

16 Bumper 6335

17 Screw 6-19x1.2 (1 req.) 6336

18 Caution Label 6304

19 Screw 6-19x.500 (1 req.) 6339

20 Rubber Plug 6340

Page 10

Loading...

Loading...