hpmont HD5L-2T5P5, HD5L-4T5P5, HD5L-2S2P2, HD5L-2T7P5, HD5L-2T011 User Manual

...

FOREWORD

Thank you for purchasing HD5L series elevator controller manufactured by

Shenzhen Hpmont Technology Co., Ltd.

This User Manual describes how to use HD5L series elevator controller and

their installation wiring, parameter setting, troubleshooting and daily maintenance

etc. Before using the product, please read through this User Manual carefully. In

addition, please do not use this product until you have fully understood safety

precautions.

Note:

Preserve this Manual for future.

Due to product upgrade or specification change, and for the purpose of improving

convenience and accuracy of this manual, this manual’s contents may be modified.

If you need the User Manual due to damage, loss or other reasons, please contact

the regional distributor of our company or directly contact our company Technical

Service Center.

For the first time using, the user should carefully read this manual.

If you still have some problems during use, please contact our company Technical

Service Center.

Telephone: 4008-858-959 or 189 4871 3800

The product warranty is on the last page of this Manual, please preserve it for future.

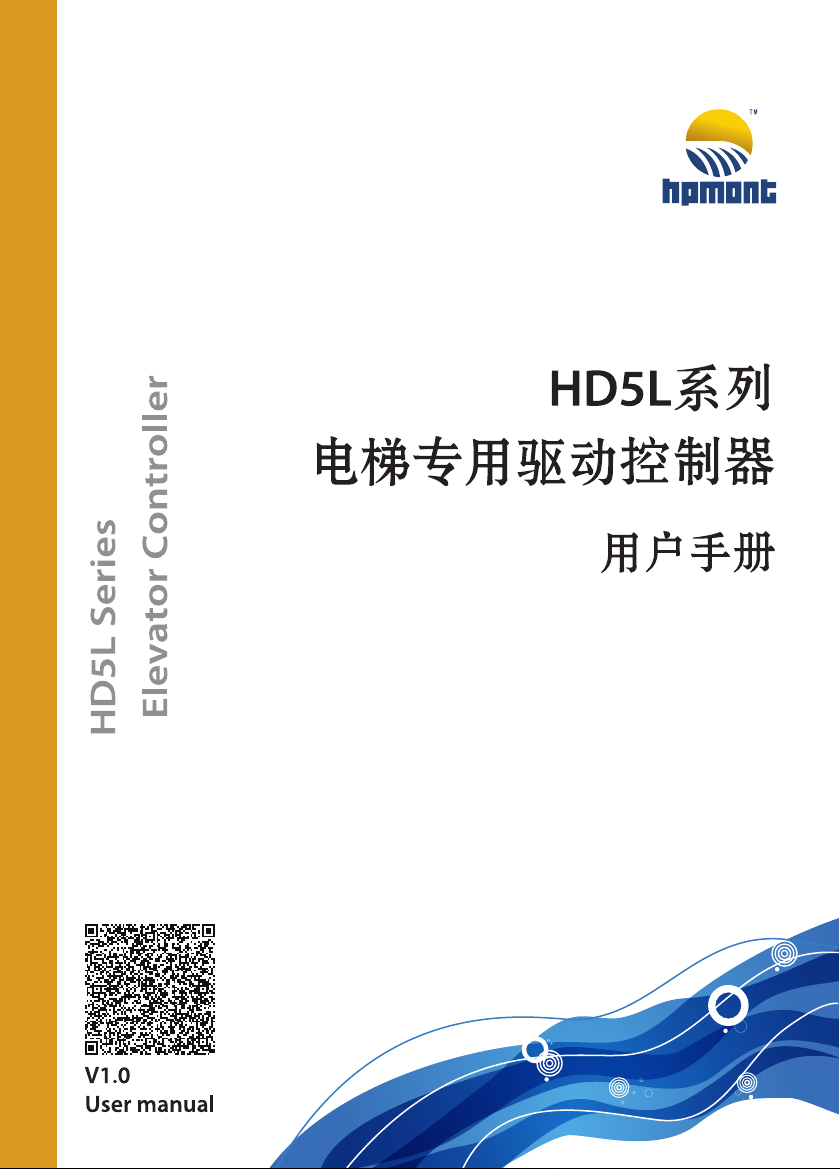

Three-phase AC power supply

MCCB

Contactor

Controller

Ground connection

Connection with peripheral devices

AC input reactor

EMI filter

EMI filter

AC output reactor

Motor

DC reactor

Braking resistor

(optional)

(optional)

Ground connection

CONTENTS

Chapter 1 Safety Information and Precautions ............................................................................ 1

1.1 Safety Definiti on ............................................................................................................... 1

1.2 About Motor and Load ...................................................................................................... 1

1.3 Installation Limitation ........................................................................................................ 2

Chapter 2 Product Information ...................................................................................................... 3

2.1 Model Explanation ............................................................................................................ 3

2.2 Nameplate ....................................................................................................................... 3

2.3 Specifications ................................................................................................................... 4

2.4 Ratings............................................................................................................................. 6

2.5 Parts of Controller ............................................................................................................ 7

Chapter 3 Mechanical Installation ................................................................................................. 9

3.1 Instal la tion Prec autions .................................................................................................... 9

3.2 Requirement for the Installation Site ................................................................................. 9

3.3 Installation Direction and Space Requirements ............................................................... 10

3.4 Dimensions and Mounting Size ...................................................................................... 10

3.5 Panel Installation and Dismantle ..................................................................................... 12

3.6 Plastic C over Disma ntle ................................................................................................. 13

Chapter 4 Electrical Installation .................................................................................................. 15

4.1 Wiring Precautions ......................................................................................................... 15

4.2 Selection of Main Ci rcuit Per ipheral Devices ................................................................... 16

4.3 Main Circuit Terminals and Wiring ................................................................................... 16

4.3.1 Terminals Description......................................................................................... 17

4.3.2 Wiring Terminals ................................................................................................ 17

4.4 Control Terminals and Wire Connection .......................................................................... 18

4.4.1 Control Terminal Description .............................................................................. 19

4.4.2 Wire Jumper De s crip tion .................................................................................... 20

4.4.3 SCI Communicati on Terminal Description .......................................................... 20

4.4.4 Control Terminal Connection .............................................................................. 21

4.5 I/O Terminals and Wiring Connection .............................................................................. 26

4.5.1 I/O Card Terminal Description ............................................................................ 26

4.5.2 I/O Card Wire Jumper Description ...................................................................... 27

4.5.3 I/O Card Terminal Connection ............................................................................ 27

4.6 Encoder Card ................................................................................................................. 28

4.6.1 Encoder Cards Introduction ............................................................................... 28

4.6.2 FD Description ................................................................................................... 28

4.6.3 DB15 Terminal ................................................................................................... 29

4.6.4 HD-PG2-OC-FD ................................................................................................ 29

4.6.5 HD-PG5-SINCOS-FD ........................................................................................ 32

4.6.6 HD-PG6-UVW-FD .............................................................................................. 34

4.6.7 HD-PG9-SC-FD ................................................................................................. 36

4.7 Meet EMC Requirement of Installation ............................................................................ 37

4.7.1 Correct E MC In stallation .................................................................................... 37

4.7.2 Wiring Requirement ........................................................................................... 38

4.7.3 Wiring Motor ...................................................................................................... 38

4.7.4 Ground Connections .......................................................................................... 39

4.7.5 EMI Filter ........................................................................................................... 39

4.7.6 Conduction, Radiation and Radio Frequency Interference Countermeasures ..... 40

4.7.7 Input and Output R eactor ................................................................................... 41

Chapter 5 Operation Instructions ................................................................................................ 43

5.1 Function Description ....................................................................................................... 43

5.1.1 Operation Mode ................................................................................................. 43

5.1.2 Control Mode ..................................................................................................... 44

5.1.3 Controller Sta te .................................................................................................. 44

5.1.4 Controller Running Mode ................................................................................... 44

5.2 Operating Instructions .................................................................................................... 45

5.2.1 Panel Description .............................................................................................. 45

5.2.2 Display State ..................................................................................................... 46

5.2.3 Panel Operation Exa mple s ................................................................................ 48

5.3 Initial Power On .............................................................................................................. 52

Chapter 6 Function Introduction ................................................................................................. 53

6.1 Group D: Display Parameters ......................................................................................... 54

6.1.1 Group D00 System State Par ameters ................................................................ 54

6.1.2 Group D01 Drive State Parameters .................................................................... 55

6.1.3 Group D02 Analogue State Display Parameters ................................................. 56

6.1.4 Group D03 Running State Parameters ............................................................... 57

6.1.5 Group D04 Encode r State Para meters ............................................................... 58

6.2 Group F: General Function Parameters .......................................................................... 59

6.2.1 Group F00 Basic Parameters ............................................................................. 59

6.2.2 Group F01 Protection of Pa rameters .................................................................. 61

6.2.3 Group F02 Start & Stop Parameters .................................................................. 62

6.2.4 Group F03 Acceleration/Deceleration Parameters .............................................. 63

6.2.5 Group F04 Analogue Curve Parameters ............................................................ 64

6.2.6 Group F05 Speed Para mete rs ........................................................................... 65

6.2.7 Group F06 Weighin g C ompensation Param eters ............................................... 67

6.2.8 Group F07 Asynchrono us Motor Parameters...................................................... 68

6.2.9 Group F08 Motor Vector Control Speed-loop Param eters ................................... 71

6.2.10 Group F09 Current-loop Parameters ................................................................ 72

6.2.11 Group F10 Synchronous M ot or Parameters ..................................................... 72

6.2.12 Group F11 PG Parameters............................................................................... 73

6.2.13 Group F12 Di gital I/O Terminal Param eters ...................................................... 74

6.2.14 Group F13 Analo gue I/O Terminal Parameters ................................................. 77

6.2.15 Group F14 SCI Communication Parameters .................................................... 79

6.2.16 Group F15 Display Control Parameters ............................................................ 79

6.2.17 Group F16 Enhance Function Parameters ....................................................... 81

6.2.18 Group F17 Fa ult Protect Paramet ers ................................................................ 82

6.2.19 Group F18 PWM Parameters ........................................................................... 85

6.2.20 Group F19 Reserved ....................................................................................... 85

6.2.21 Group F20 Reserved ....................................................................................... 85

6.3 Group Y Manufacturer Func tio n Para me ter s ................................................................... 85

Chapter 7 Elevator Application Guidance ................................................................................... 87

7.1 Basic Debug Procedures ................................................................................................ 87

7.1.1 System Analy sis and Wire.................................................................................. 87

7.1.2 Set Basic Parameters ........................................................................................ 87

7.1.3 Motor Parameter Auto-tuning ............................................................................. 88

7.1.4 Inspection Running ............................................................................................ 92

7.1.5 Run Fast ............................................................................................................ 92

7.2 Terminal MS Run Mode Application ................................................................................ 93

7.2.1 Control Part Connection ..................................................................................... 93

7.2.2 Set Parameter ................................................................................................... 94

7.3 T erminal Analogue Run Mode Application ....................................................................... 96

7.3.1 Control Part Connection ..................................................................................... 96

7.3.2 Set Parameter ................................................................................................... 97

7.4 Power-off Battery Driven Run Mode Application .............................................................. 98

7.4.1 Basic Connection ............................................................................................... 98

7.4.2 Running Time Sequence .................................................................................... 98

Chapter 8 Troubleshooting .......................................................................................................... 99

Chapter 9 Maintenance .............................................................................................................. 103

9.1 Daily Maintenance ........................................................................................................ 104

9.2 Periodical Maintenance ................................................................................................ 104

9.3 Replacing Damaged Parts ............................................................................................ 105

9.4 Unwanted Controller Recycling ..................................................................................... 105

Chapter 10 Accessories ............................................................................................................. 107

10.1 Panel Installation Assembly ........................................................................................ 107

10.1.1 Mounting Base ............................................................................................... 107

10.1.2 Extension Cable ............................................................................................ 107

10.2 Braking Resistor Selectio n .......................................................................................... 108

10.3 Protect ive Cover ......................................................................................................... 108

10.4 Power Regenerative Unit ............................................................................................ 108

Appendix A Parameters ............................................................................................................. 109

Appendix B Communication Protocol ...................................................................................... 129

Communication Protocol

Elevator A pplicat ion Guidan ce

Troubleshooting

Maintenance

Accessories

Safety Information and Precautions

Product Information

Mechanical Installation

Electrical Installation

Operation Instructions

Function Introduction

Parameters

1

2

3

4

5

6

7

8

9

10

A

B

Shenzhen Hpmont Technology Co., Ltd Chapter 1 Safety Inform a ti on a nd Prec a uti ons

A Danger contains information which is critical for avoiding safety

a

Danger

Warning

Note

Chapter 1 Safety Information and Precautions

1.1 Safety Definition

Danger:

hazard.

Warning: A Warning contains information w hich is essential for avoiding

risk of damage to product or other equipments.

Note: A Note contains inf ormation wh ich helps t o ensure co rrect oper ation

of the product.

1.2 About Motor and L oad

Compared to the standar d frequency operation

The HD5L series controllers are voltage-type controllers and their output is PWM wave with

certain harmonic wave. T herefore, the temperature, noi se and vibration of the motor will be a little

higher than that at standard frequency operation.

Motor’s overload protecting threshold

When choose the adaptive motor, the controller can effectively implement the motor thermal

protection. Otherwise it must adjust the motor protection parameters or other protection

measures to ensure t hat the mot or is at a safe a nd reliab le operation.

Lubrication of mechanical devices

At long time low-speed operation, it should provide periodical lubrication maintenance for the

mechanical devices such as gear box and geared motor etc. to make sure the drive results meet

the site need.

Check the insulation of the motor

For the first time using of the motor or after long time storage, it need check the insulation of the

motor to avoid damage the controller because of the worse insulation motor.

Note:

Please use a 500V Mega-Ohm-Meter to tes t and the in s u lation resistanc e m ust be higher than

5Mohm.

1

HD5L Series Controller User Manual ―1―

Chapter 1 Safety Inform a ti on a nd Prec a uti ons S he nzhen Hpmont Technology Co., Ltd

80%

100%

1000 4000

Controller’s rat ed cu r r ent

Altitude(m)

1.3 Installation Limitation

No capacitor or varistor on the output side

Since the controller outpu t is PWM wave, it is strictly forbidden to connect capacitor for improving

the power factor or varistor for lightning protection to the output terminal s so as to avoid the

controller fault tripping or component damage.

Contactors and circuit breakers connect e d t o the out put of t he controller

If circuit breaker or contactor needs to be connected between the controller and the motor, be

sure to operate these circuit breakers or contactor when the controller has no output, so as to

avoid any damage to the controller.

Rated voltage

The controller i s prohibited to be us ed bey ond the speci fied range o f oper ation voltage. If need ed,

please use the suitable voltage regulation device to change the vol tage.

Change three-phase input to single-phase input

For three-phase input controller, the users should not change it to be single-phase input.

If you have to use s ingle-phase power supply, you should disable the in put phase-loss protection

function. And the bus-voltage and current ripple will increase, which n ot only influences the life of

electrolytic capacitor but also deteriorates the performance of the controller. In that case, the

controller must be derating and should be within the controller 60% rated value.

Lightning surge protection

The controller internal design has lightning surge overcurrent protection circuit, and has certain

self-protection capacity against the lightning.

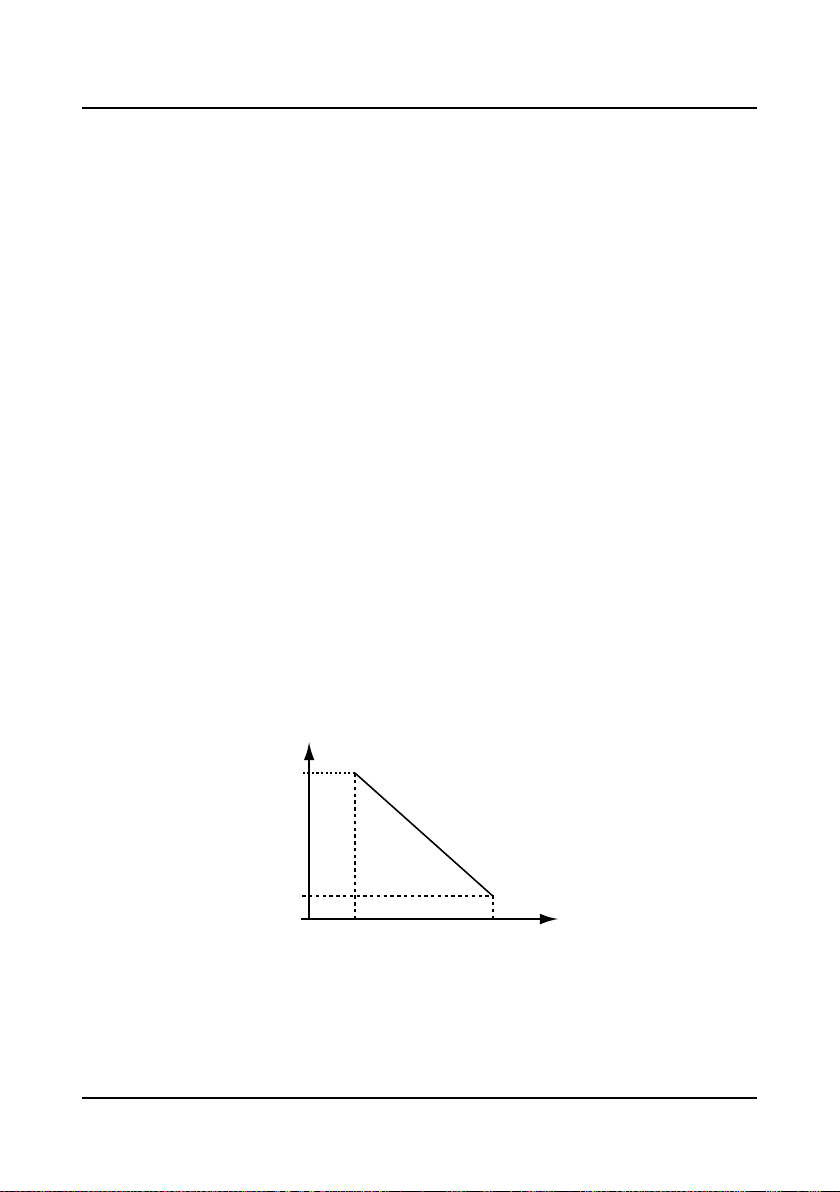

Altitude and derating

In the altitude exceeded 1000 meters area, since the heatsink efficiency will be reduced because

of the tenuous air, the controller should be derating. Figure 1-1 is the derating curve of the

controller rated current and the altitude.

Figure 1-1 Derating curve of controller rated current and altitude

―2― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 2 Product Information

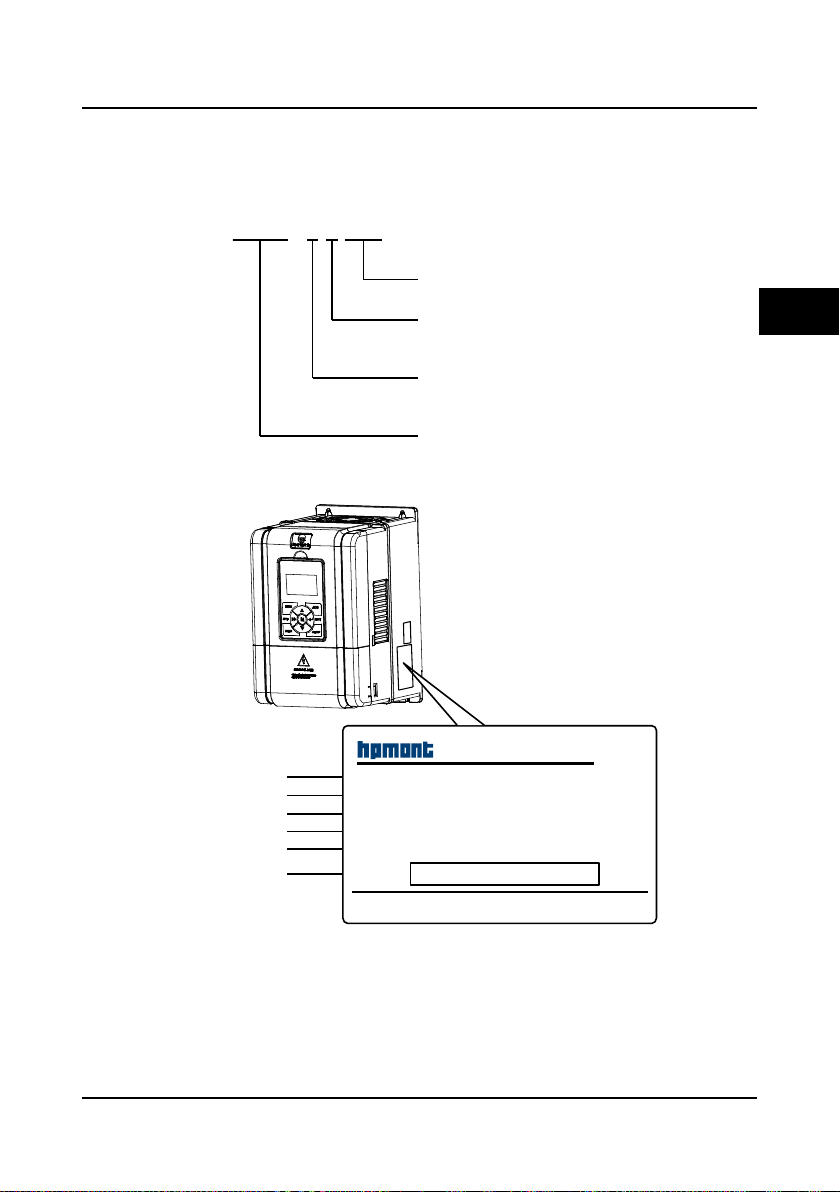

HD5L - 4 T 5P5

2 : 200-240V

4 : 380-460V

Refer to section 2.4 about rati ng

S : single-phase

T : three-phase

Elevator c ontroller

Adaptive motor power

Input phases

Voltage ratings

Product seri es

Shenzhen Hpmont Technology Co., Ltd

HD5L-4T5P5

MODEL:

POWER:

INPUT:

OUTPUT:

Version:

S/N:

5.5kW

3PH380-460V15A50/60Hz

1.00

8.5kVA0-460V 13A0-100Hz

Barcode

Productmodel

Adaptivemotor

Inputspecification

Outputspecification

Softwareversion

Serialnumber

Chapter 2 Product Information

2.1 Model Explanation

2.2 Nameplate

2

HD5L Series Controller User Manual ―3―

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd

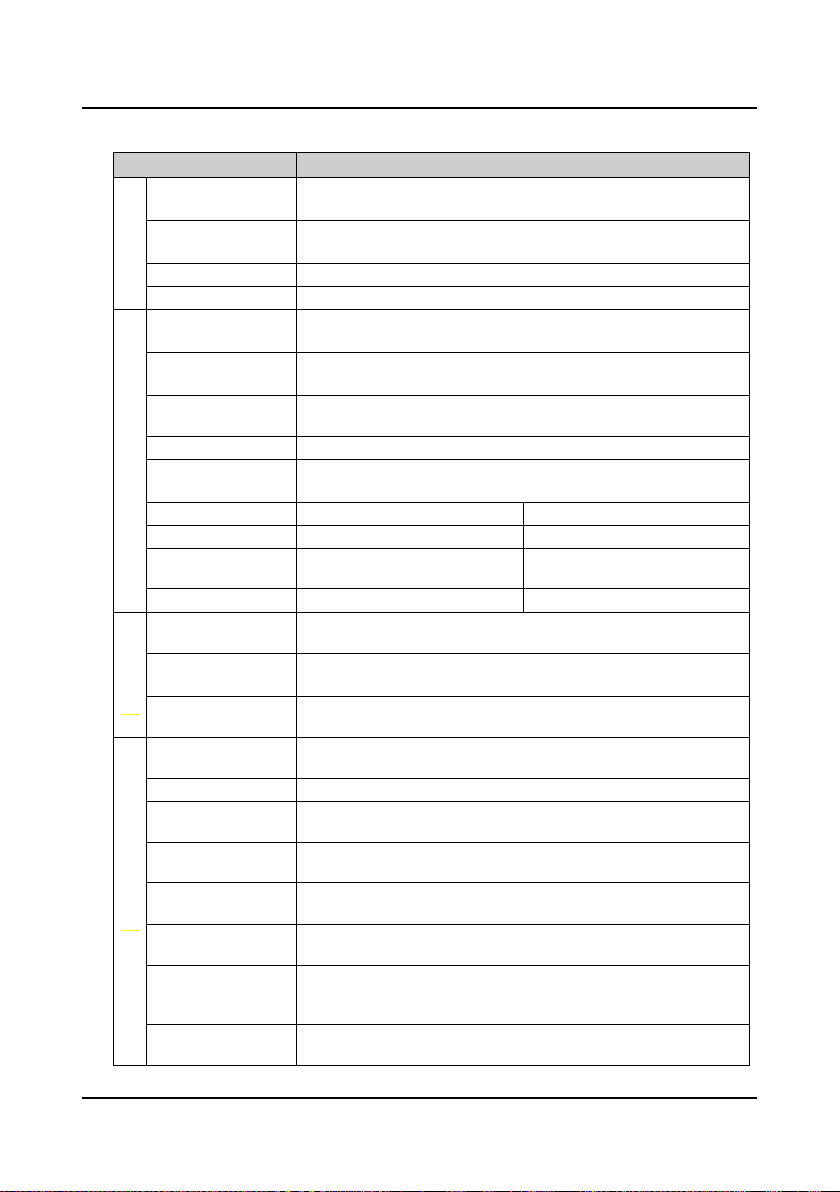

2.3 Specifications

Item Specification

Rated voltage and

frequency

Electrical

Accuracy

Output voltage 0-input voltage

Output frequency 0-100.00Hz

Maximum current

Control mode

Operation command

Performance

control mode

Speed setting mode Digital setting, analogue setting, SCI communication setting

Speed setting

resolution

Speed control accuracy SVC: ± 0.5% VC: ± 0.05%

Speed control range SVC: 1:100 VC: 1:1000

Torque control

response

Start torque SVC: 180% rated-torque /0.5Hz VC: 200% rated-torque /0Hz

Parameter upload and

Characteristic

download function

Programmable I/O

interface

Communication

protocol

Auto-inspection

Over-speed protection To make sure safe running, elevator over-speed protection is provided

Speed deviation

protection

Up/down forced

Protection

deceleration function

I/O phase loss

protection

Motor temperature

detection

Power output

grounding fault

protection

Power output short

circuit protection

Single-phase: 200-240V, 50/60Hz

Three-phase: 380-460V, 50/60Hz

Voltage: fluctuation within ± 10%, imbalance rate < 3%

Frequency: ± 5%

150% rated output current for 2 minutes

180% rated output current for 10 seconds

V/f control; Open-loop vector control (SVC);

Closed-loop vector control (VC)

Panel control; external terminal control; host computer communication

control via SCI communication port

Digital setting: 0.01Hz

Analogue setting: 0.1% × max-frequency

SVC: < 200ms VC: < 50ms

To achieve parameters uploading or downloading

The programmable input interface has up to 34 functions

The pragrammable output interface has up to 19 functions

Controller is built-in MODBUS communication protocol

To eliminate the potential safety problems, safety inspection for the

peripheral devices is provided when power is on

To eliminate the potential safety problems, speed deviation detection

protection is provided

Up/down forced deceleration function, to avoid climbing elevator or plunging

elevator

I/O phase loss auto-detect and alarm function

Real time detection for the motor temperature

Power output grounding fault protection is enabled

Power output short circuit protection is enabled

―4― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 2 Product Information

cation

Item Specification

Analogue supply

Digital supply +24V, maximum current 200mA

I/O feature

Analogue input

Analogue output AO1, AO2: 0-10V/0-20mA (voltage/current is selectable)

Digital input DI1-DI6 (control board); DI7-DI12 (I/O card)

Digital output DO1, DO2

Programmable relay

output

Communi-

SCI communication RS-485 interface

+10V, maximum current 100mA

-10V, maximum current 10mA

AI1 (control board): voltage 0-10V

AI2, AI3 (control board): -10V-+10V/0-20mA (voltage/current is

selectable)

AI4 (I/O card): -10V-+10V/0-20mA (voltage/current is selectable, and

differential input is supported)

R1A/R1B/R1C (control board)

R2A/R2B/R2C; R3A/R3B/R3C; R4A/R4B/R4C (I/O card)

Contact rating 250VAC/3A or 30VDC/1A

2

Panel

LCD display

Parameter copy To achieve quick parameter copy

Operation temperature

Environment

Storage temperature -40-+70℃

Location for use

Altitude Less than 1000 meters, otherwise should be derating use

Humidity Less than 95%RH, non-condensing

Ocsillation Less than 5.9m/s2 (0.6g)

Encoder card

Options

About panel

Enhanced protection Protective cover (HD-CK-Frame4)

Power unit Power regenerative unit (HDRU)

Function parameter setting, check the state parameters and the fault code

etc.

-10-+40℃, air temperature fluctuation is less than 0.5℃/min

The derating value of the output current of the controller shall be 2% for each

degree centigrade above 40℃. Max. allowed temperature is 50℃

Indoor, preventing from direct sunlight, no dust, corrosive, flammable gases,

oil mist, water vaper, dripping or salt etc.

OC encoder card with frequency demultiplication output (HD-PG2-OC-FD)

SINCOS encoder card with frequency demultiplication output

(HD-PG5-SINCOS-FD)

Line drive encoder card with frequency demultiplication output

(HD-PG6-UVW-FD)

Serial Communication encoder card with frequency demultiplication output

(HD-PG9-SC-FD) (support Endat)

Mounting base to panel (HD-KMB)

1 meter extension cable to panel (HD-CAB-1M)

2 meter extension cable to panel (HD-CAB-2M)

3 meter extension cable to panel (HD-CAB-3M)

6 meter extension cable to panel (HD-CAB-6M)

HD5L Series Controller User Manual ―5―

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd

(kVA)

(A)

(A)

(kW)

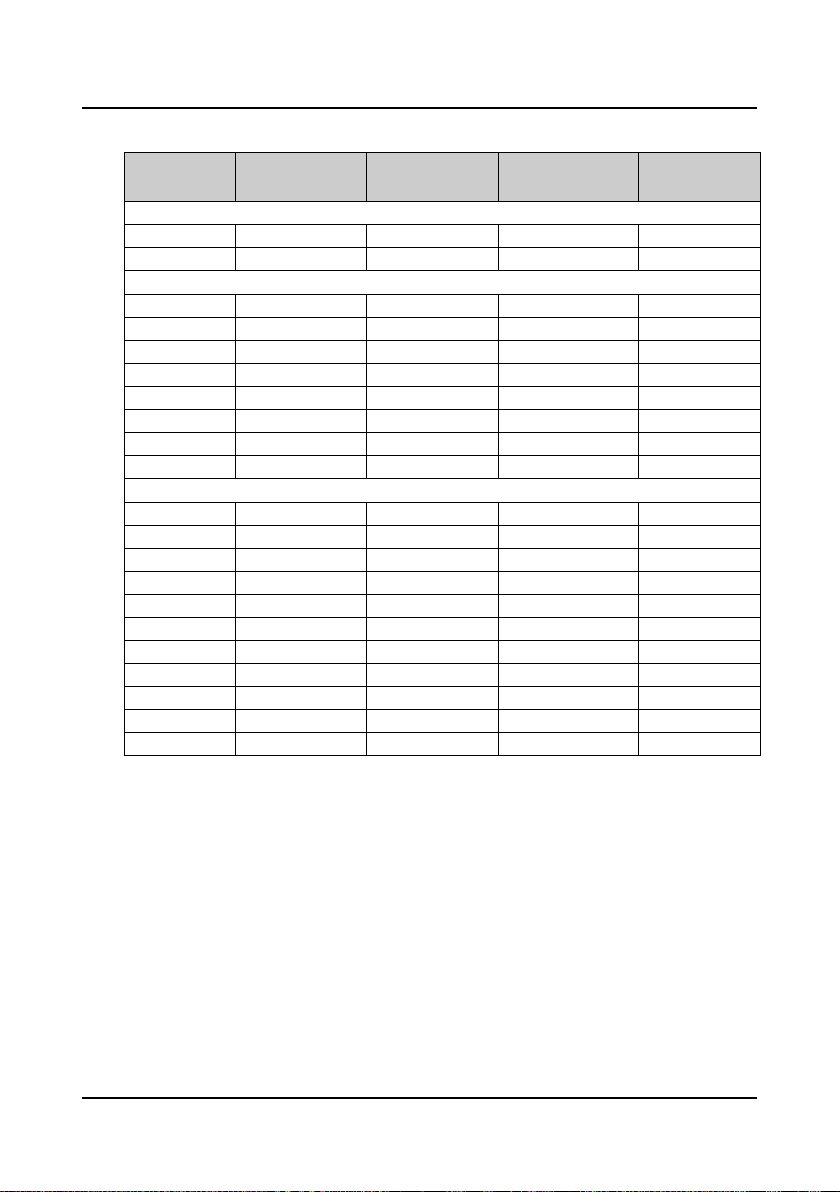

2.4 Ratings

Model

HD5L-2S2P2 3.8 24.1 10 2.2

HD5L-2S3P7 5.9 40 17 3.7

HD5L-2T3P7 5.9 19 17 3.7

HD5L-2T5P5 8.5 28 25 5.5

HD5L-2T7P5 11 35 32 7.5

HD5L-2T011 16 47 45 11

HD5L-2T015 21 62 55 15

HD5L-2T018 24 77 70 18.5

HD5L-2T022 30 92 80 22

HD5L-2T030 39 113 110 30

HD5L-4T2P2 3.4 7.3 5.1 2.2

HD5L-4T3P7 5.9 11.9 9.0 3.7

HD5L-4T5P5 8.5 15 13 5.5

HD5L-4T7P5 11 19 17 7.5

HD5L-4T011 16 28 25 11

HD5L-4T015 21 35 32 15

HD5L-4T018 24 39 37 18.5

HD5L-4T022 30 47 45 22

HD5L-4T030 39 62 60 30

HD5L-4T037 49 77 75 37

HD5L-4T045 59 92 90 45

Rated capacity

Single-phase power supply: 200-240V, 50/60Hz

Three-phase power supply: 200-240V, 50/60Hz

Three-phase power supply: 380-460V, 50/60Hz

Rated input current

Rated output current

Motor power

―6― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 2 Product Information

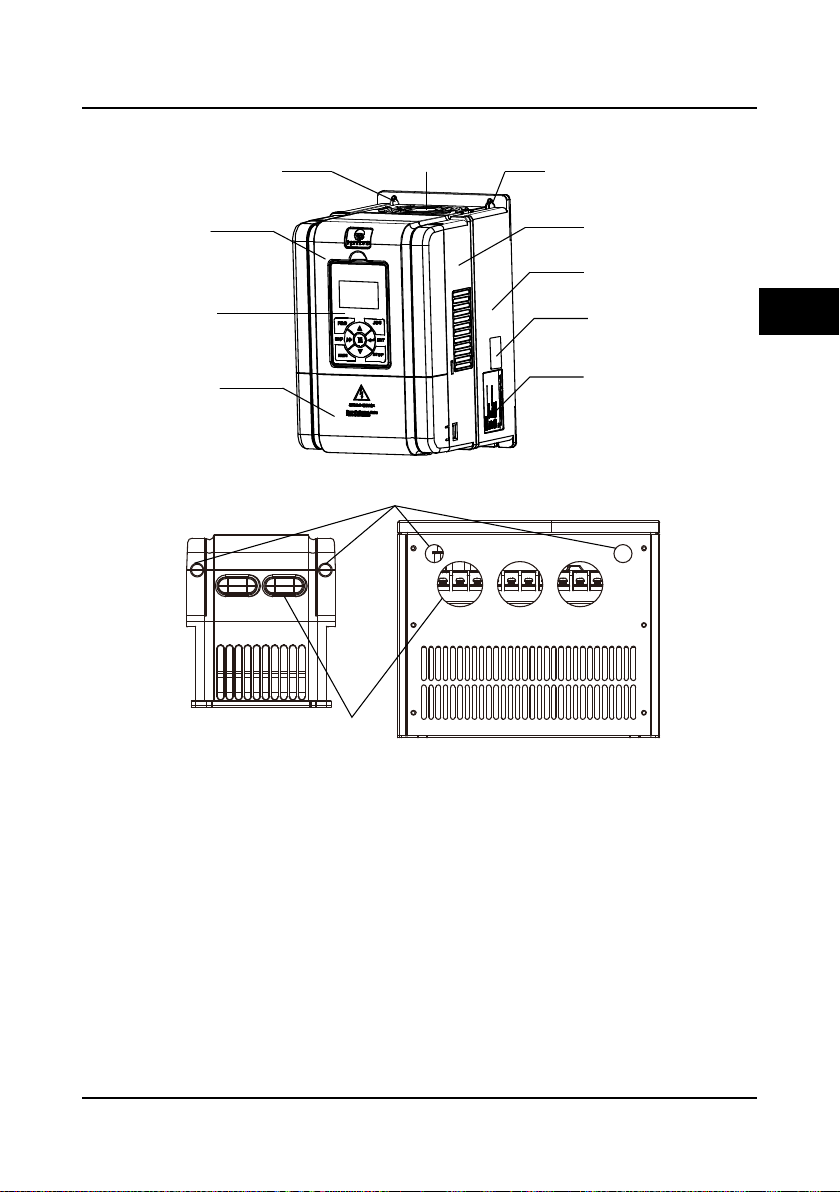

Mountinghole

Certification

Bottomenclosure

Middleenclosure

Displaypanel

Uppercover

Fancover

Lowercover

Mountinghole

Nameplate

Controlterminalconnectionhole

Plastic structure Metal structure

Powerterminal

connectionhole

2.5 Parts of Controller

2

HD5L Series Controller User Manual ―7―

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd

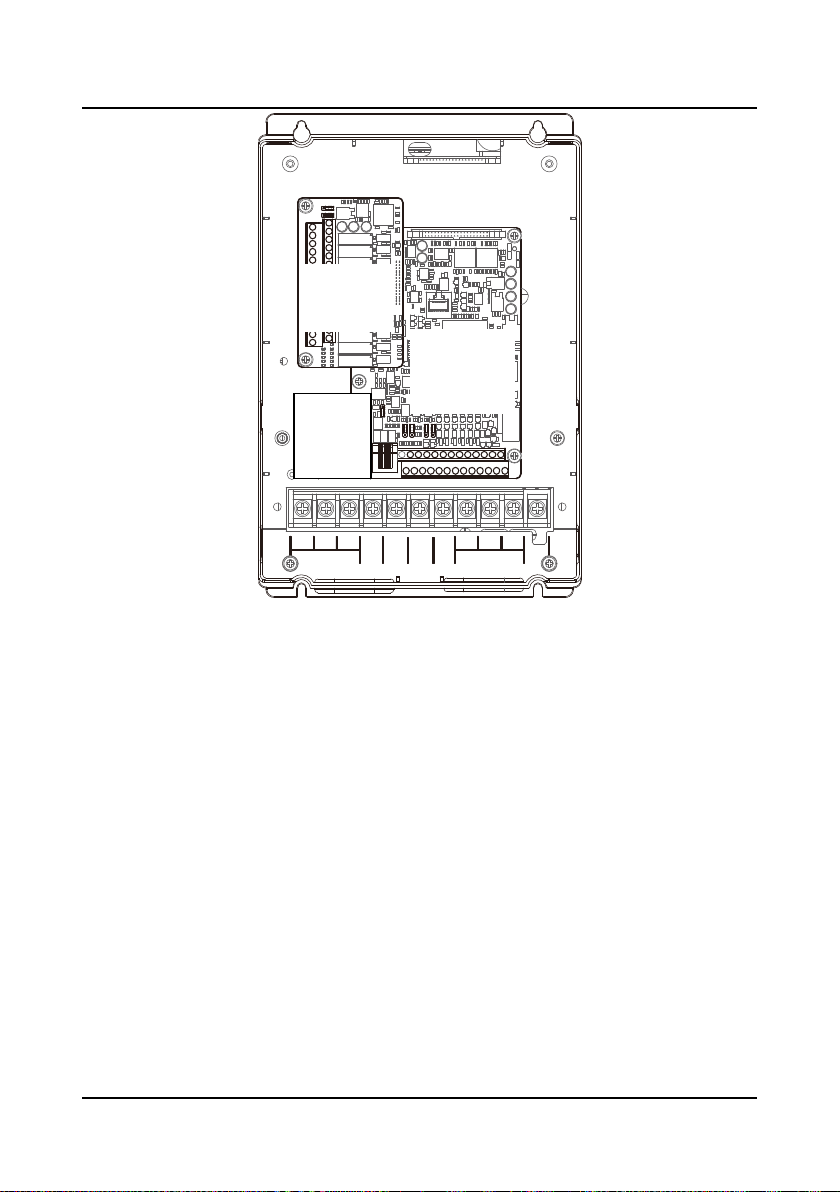

PE

BR

P1

(+)

(-)

U

V W

MOTOR

L1

L2

L3

POWER

I/O card

Refer to section4.5

Control board

Refer to section4.4

Encoder card

(optional)

Refer to section4.6

―8― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 3 Mechanical Installation

Danger

Warning

Chapter 3 Mechanical Installation

3.1 Installation Precautions

• Do not install if the controller is imcomplete or impaired.

• Make sure that the controller is far from the explosive and combustible things.

• Do not operate the controller until the power is cut-off 10 minutes later.

• It is required not only carry the panel and the cover but also the controller bottom enclosure.

• Do not play metal into the controller when insta l ling.

123

3.2 Requirement for the Installation Site

Ensure the installation site mee ti ng the foll ow ing requirements:

• Do not instal l at the direc t sunlight, moisture, water droplet location;

• Do not install at the combustible, explosive, corrosive gas and liquid location;

• Do not install at the oily dust, fiber and metal powder location;

• Be vertical installation on fire-retardant material with a strong support;

• Make sure adequate cooling space for the controller so as to keep the ambient temperature

between - 10-+ 40℃;

• Install at where the vibration is less than 5.9m/s

Note:

1. It needs derating use if the controller operation temperature excee ds 40℃ . The derating value

of the output current of the controller shall be 2% for each degree centigrade. Max. allowed

temperature is 50℃.

2. Keep ambient temperature between -10-+40℃. It can improve the controller operation

perform ance if install at the location with good ventilation or cooling devices.

2

(0.6g).

3

HD5L Series Controller User Manual ―9―

Chapter 3 Mechanical Installation Shenzhen Hpmont Technology Co., Ltd

≥30

≥50

≥30

≥50

W

H

H2

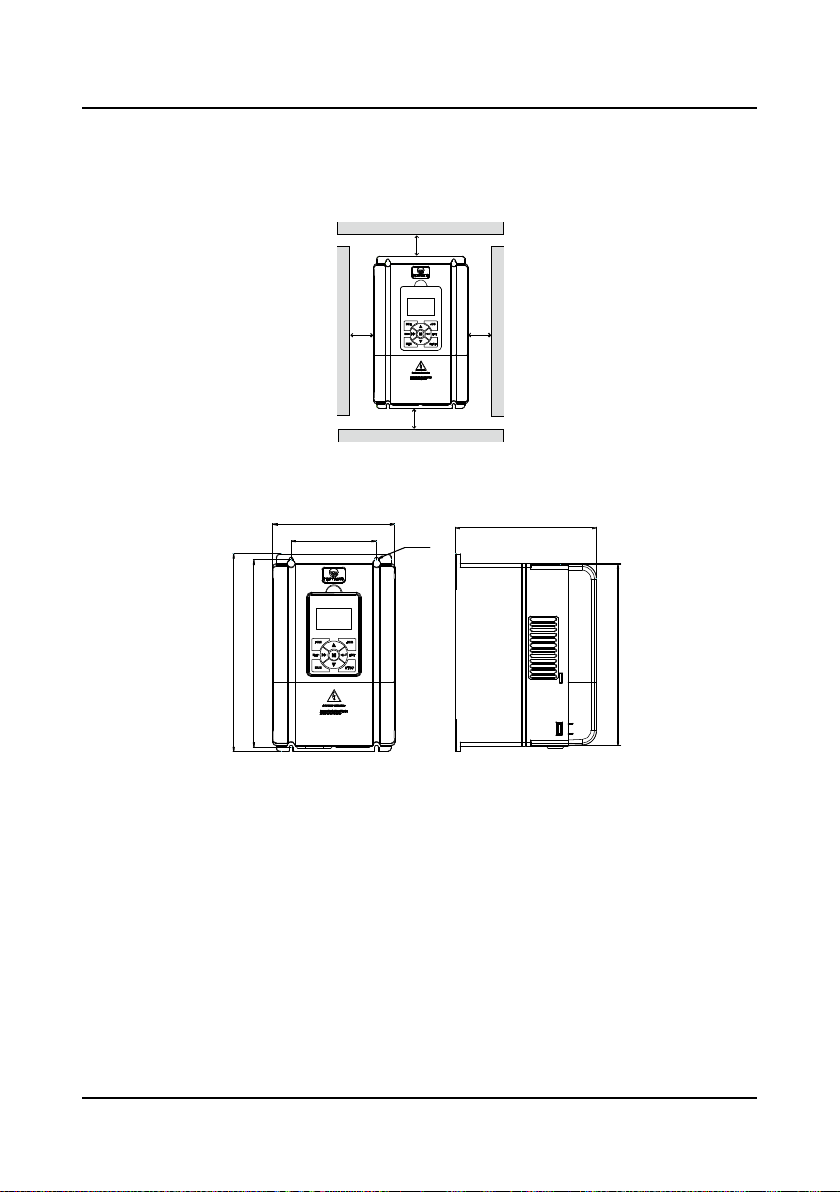

3.3 Installation Direction and Space Requirem ent s

To achieve good cooling efficiency, install the controller perpendicularly and always provide the

following space to allow normal heat dissipation. The requirements on mounting space and

clearance are shown in Figure 3-1.

Figure 3-1 Installation of the controller

3.4 Dimensions and Mounting Size

W1

H1

4-Ød

Dimensions figure 1

D

―10― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 3 Mechanical Installation

W

H

H2

W1

4-Ød

D

H1

3

(kg)

Figure

Dimensions figure 2

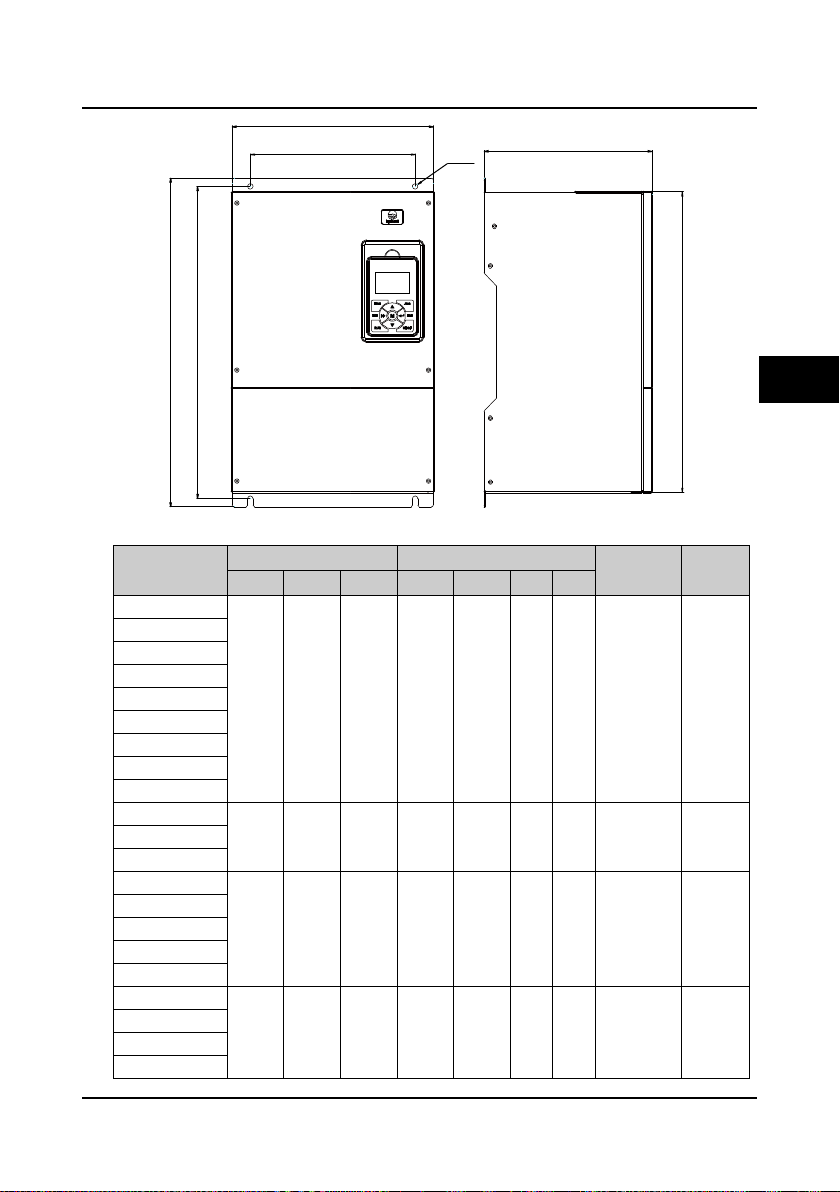

Table 3-1 HD5L dimensions

Model

HD5L-2S2P2

HD5L-2S3P7

HD5L-2T3P7

HD5L-2T5P5

HD5L-4T2P2

HD5L-4T3P7

HD5L-4T5P5

HD5L-4T7P5

HD5L-4T011

HD5L-2T7P5

HD5L-4T015

HD5L-4T018

HD5L-2T011

HD5L-2T015

HD5L-2T018

HD5L-4T022

HD5L-4T030

HD5L-2T022

HD5L-2T030

HD5L-4T037

HD5L-4T045

Dimensions (mm) Mounting size (mm)

W H D W1 H1 H2 d

200 299 210 146 286 280 5 5.8 1

235 353 222 167 337 330 7 8.2 1

290 469 240 235 445 430 8 20.4 2

380 598 290 260 576 550 10 48 2

Gross weight

HD5L Series Controller User Manual ―11―

Chapter 3 Mechanical Installation Shenzhen Hpmont Technology Co., Ltd

ENT

JOG

PRG

RUN

STOP

SHF

ENT

JOG

PRG

RUN

STOP

SHF

1

2

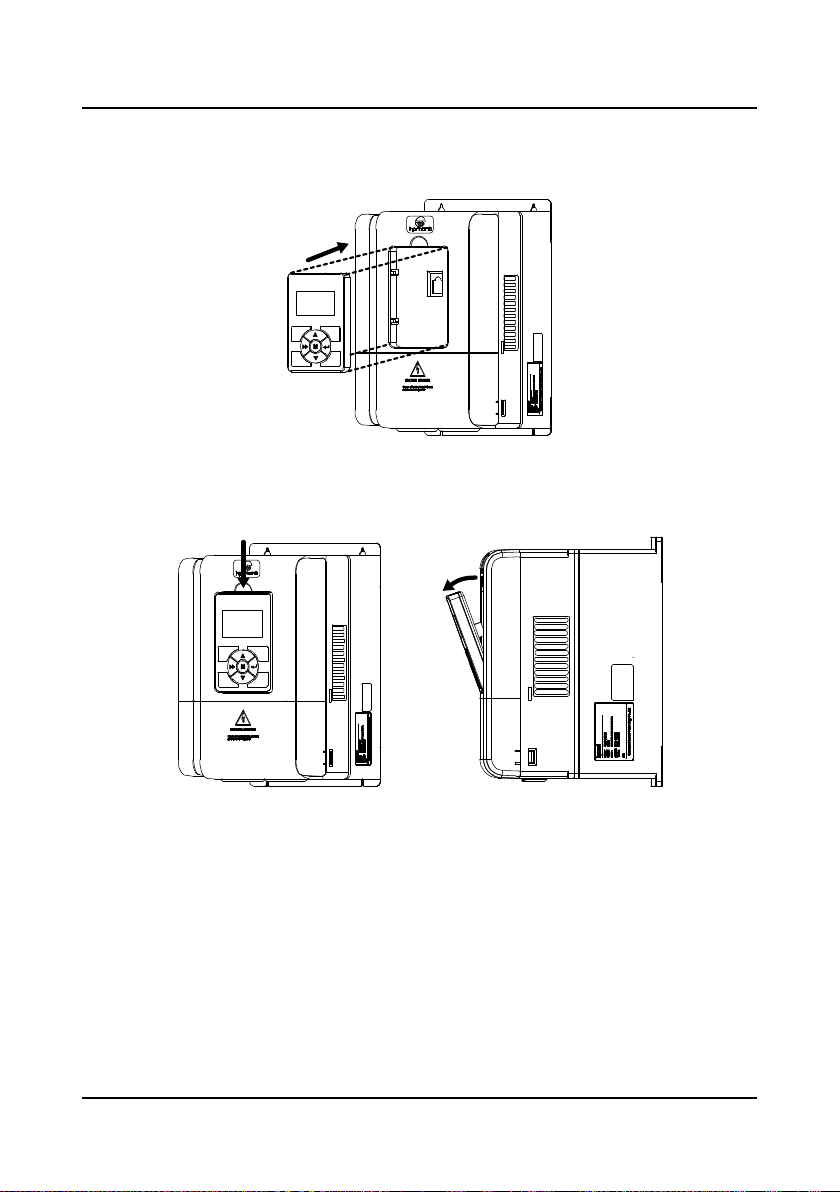

3.5 Panel Installation and Dismant l e

According to the direction of the Figure 3-2, press the panel until hear a “click” sound. Do not

install the panel from other dir ections or it wil l cause p oor contact.

Figure 3-2 Installation of the panel

There are two steps in Figure 3-3.

First, press the hook of the panel according to the direction 1.

Second, take out of the panel according to the direction 2.

Figure 3-3 Dismantle of the panel

―12― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 3 Mechanical Installation

(a)

1.Extrude the hooks at both side together,

take off the lower cover, as (a).

2.Dismantle the screws of upper cover, as (b).

3.Extrude the hooks at both side together,

take off the upper cover, as(c).

The removing proceeses

of plastic coverboard:

(b)

(c)

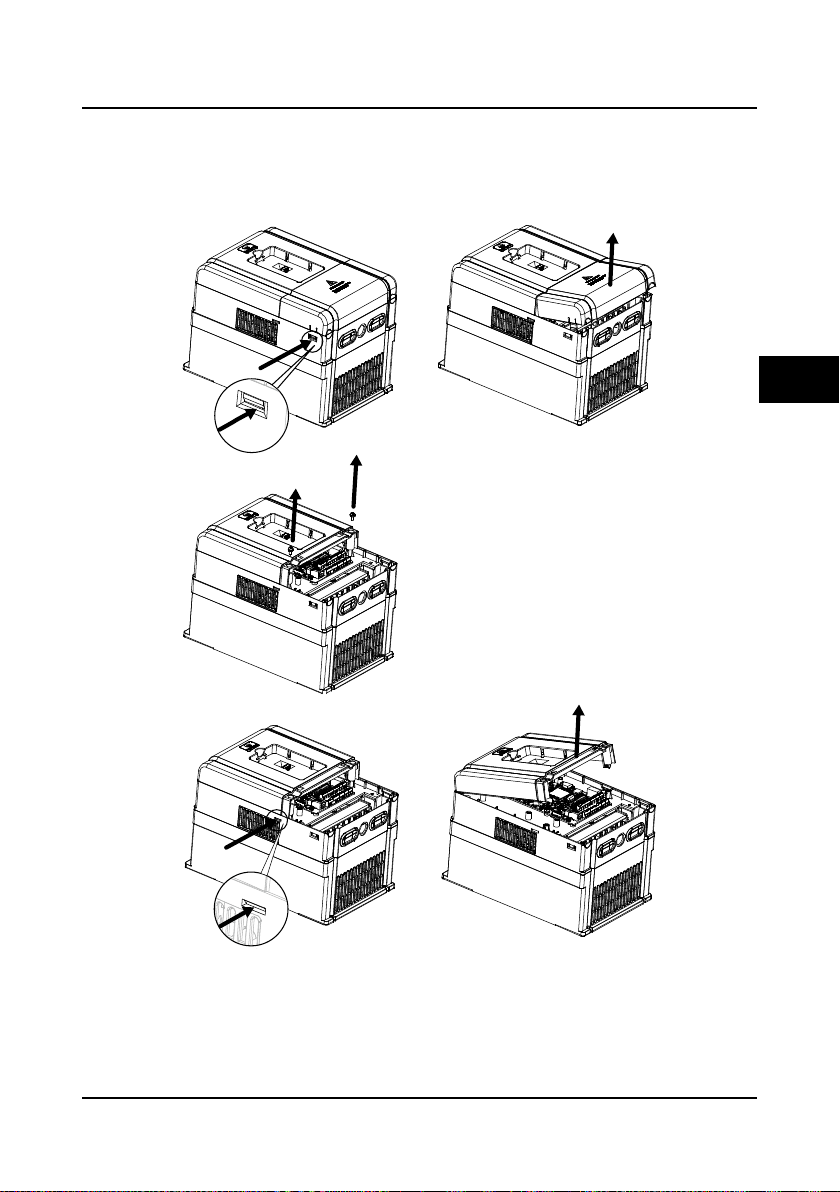

3.6 Plastic Cover Dismantle

The upper cover and the lower cover of the HD5L series controller are removable. The dismantle

step is shown as Figure 3-4.

Before removing the upper cover, please take away the panel.

3

Figure 3-4 Dismantle of the plastic cover

HD5L Series Controller User Manual ―13―

Shenzhen Hpmont Technology Co., Ltd Chapter 4 Electrical Installation

Danger

Warning

Chapter 4 Electrical Installat ion

4.1 Wiring Precautions

• Only qualified electrical engineer can perform wiring job.

• Only when the power supply switch is completely off can you do the wiring job.

• You can’t open the controller cover to do wiring operation until the power is cut-off 10 minutes later. Do

not wire or detach the controller internal devices at power-on situation.

• Do not do wiring operation until the internal charge indicator of the controller is off and the voltage

between (+) and (-) of the main circuit terminals is below 36V.

• Check the wiring carefully before connecting emergency stop or safety circuit.

• The earth terminal PE of the controller must be reliable earthing. It must use two separate earth wire due

to the leakage current from the controller to ground.

• It must use Type B mode when utilize earth leakage protection devices(ELCB/RCD).

• Do not touch the wire terminals of the controller when it is live. The main circuit terminals is neither

allowed connecting to the enclosure nor short-circuiting.

• Do not do dielectric strength test on the controller.

• Do wiring connection of the braking resistor or the braking unit according to the wiring figure.

• Make sure the terminals are fixed tightly.

• Do not connect the AC supply cable to the output terminals U/V/W of the controller.

• Do not connect the phase-shifting capacitors to the output circuit.

• The controller DC bus terminals must not be short-circuited.

4

HD5L Series Controller User Manual ―15―

Chapter 4 Electri c al I ns tallation Shenzhen Hpmont Technology Co., Ltd

Danger

Warning

4.2 Selection of Main Circuit Peripheral Devices

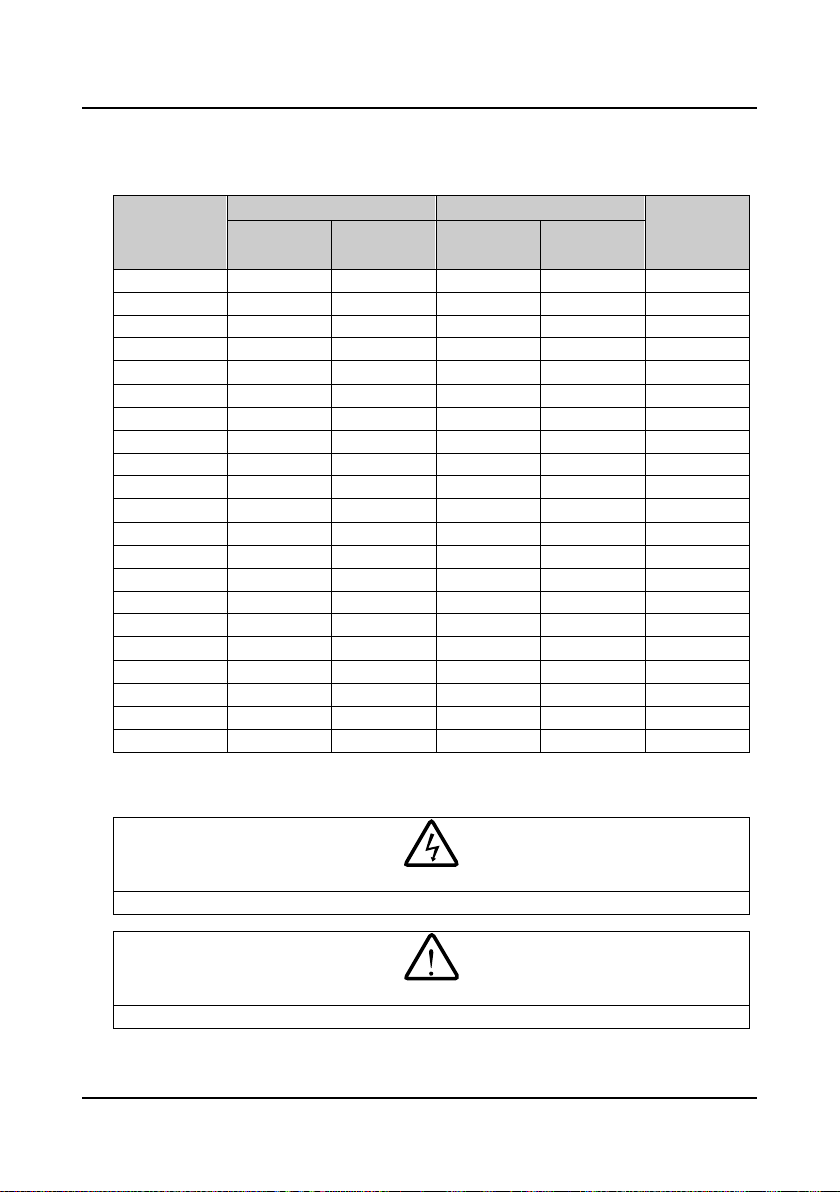

Please r efer to the Table 4-1 for the recommended specification s.

Table 4-1 HD5L series controller I/O wiring specification

Input Protection Main Circuit

Model

HD5L-2S2P2 32 20 4.0 2.5 ≥0.5

HD5L-2S3P7 63 32 4.0 4.0 ≥0.5

HD5L-2T3P7 40 32 4.0 4.0 ≥0.5

HD5L-2T5P5 63 40 6.0 6.0 ≥0.5

HD5L-2T7P5 63 40 6.0 6.0 ≥0.5

HD5L-2T011 100 63 16 16 ≥0.5

HD5L-2T015 125 100 25 25 ≥0.5

HD5L-2T018 160 100 25 25 ≥0.5

HD5L-2T022 200 125 35 35 ≥0.5

HD5L-2T030 200 125 50 50 ≥0.5

HD5L-4T2P2 16 10 1.5 1.5 ≥0.5

HD5L-4T3P7 25 16 2.5 2.5 ≥0.5

HD5L-4T5P5 32 25 4.0 4.0 ≥0.5

HD5L-4T7P5 40 32 4.0 4.0 ≥0.5

HD5L-4T011 63 40 6.0 6.0 ≥0.5

HD5L-4T015 63 40 6.0 6.0 ≥0.5

HD5L-4T018 100 63 10 10 ≥0.5

HD5L-4T022 100 63 16 16 ≥0.5

HD5L-4T030 125 100 25 25 ≥0.5

HD5L-4T037 160 100 25 25 ≥0.5

HD5L-4T045 200 125 35 35 ≥0.5

MCCB

(A)

Contactor

(A)

Supply Cables

(mm2)

Motor Cables

(mm2)

Control Circuit

(mm2)

4.3 Main Circuit Terminals and Wiring

• The bare portions of the power cables must be bound with insulation tapes.

• Ensure that AC supply voltage is the same as controller’s rated input voltage.

―16― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 4 Electri c al I ns tallation

MOTOR

PE

L3

L1 L2

W

U V

P1

L1 L2 L3 (+) (-) BR U V W PE

P1

Optional EMIfilter

Optional ACreactor

Mains supply

Braking resistor

Fuses

DC reactor

(external)

Supply ground

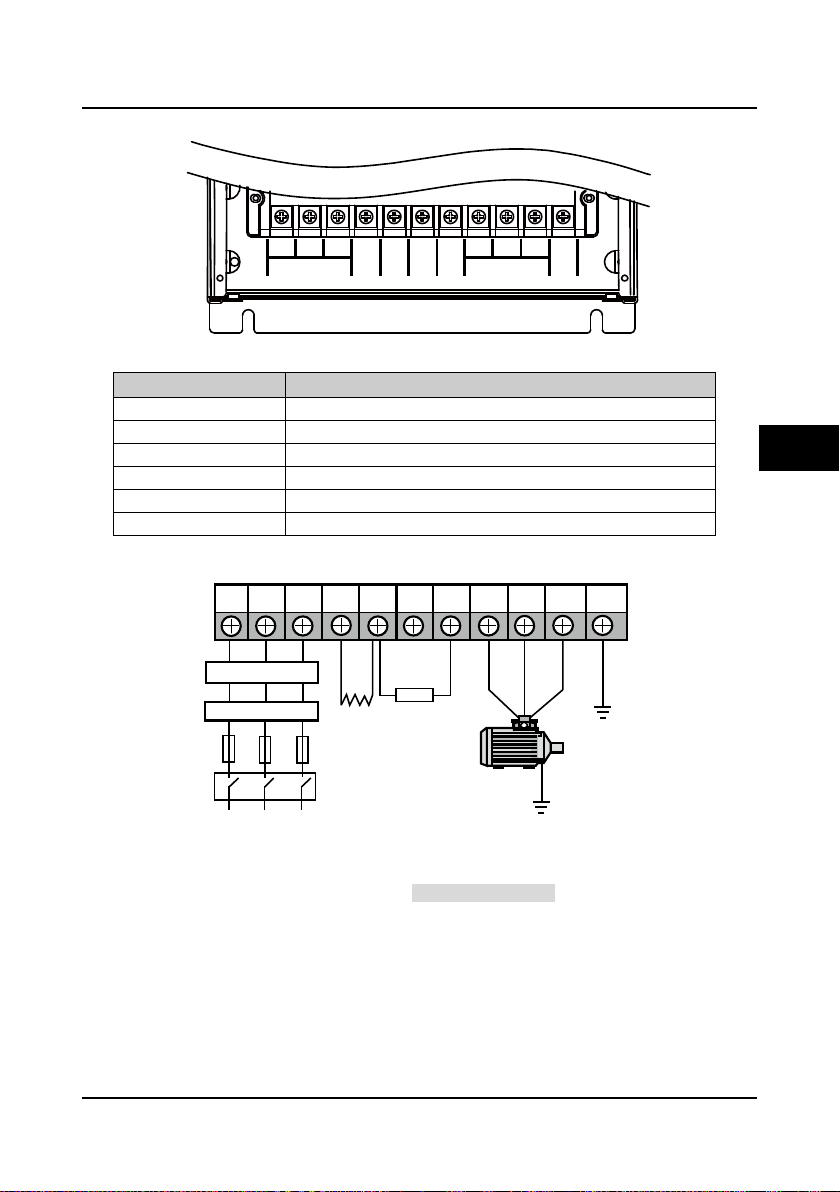

4.3.1 Terminals Description

(+) (-)

POWER

BR

Figure 4-1 Power terminal layout of HD5L controller

Table 4-2 HD5L power terminal function description

Terminal Function Description

L1、L2、L3 Three-phase AC power input terminals

U、V、W Output terminals, connect to three-phase AC motor

P1、(+) DC reactor connection terminals

(+)、(-) DC supply input terminals; DC input terminals of power regenerative unit

(+)、BR Braking resistor connection terminals

PE Earth terminal, connect to the ground

4.3.2 Wiring Terminals

Figure 4-2 HD5L power terminal connection

During trial operation, make sure that the elevator will go up when the UP command is enabled.

If the elevator goes down, set the parameter F00.08 (run direc tion) to be the reverse value.

4

HD5L Series Controller User Manual ―17―

Chapter 4 Electri c al I ns tallation Shenzhen Hpmont Technology Co., Ltd

Danger

Warning

SCI communicationterminal

Wirejumper

CN5andCN6

WirejumperCN9

Controlterminal

Wirejumper

CN7 andCN8

4.4 Control Terminals and Wire Connection

• The control circuit is designed as ELV (Extra Low Voltage) circuit and basically isolated with the

power circuit. Do not touch the control circuit when the controller is on power.

• If the control circuit is connected to the external devices with live touchable port (SELV circuit), it

should increase an additional isolating barrier to ensure that SELV classification of external devices

not be changed.

• If connect the communication terminal of the control circuit to the PC, you should choose the

RS485/232 isolating converter which meets the safety requirement.

In order to efficiently suppress the interference to control signals, the length of signal cables

should be less than 50m and keep a distance of at least 0.3m from the power lines. Please use

twisted-pair shie lded cable s for analogue input and output signals.

The positions of control terminal, wire jumper and SCI commu nicati on port in the control board

are shown in Figure 4-3.

Figure 4-3 Positions of control terminal, wire jumper and SCI port in the control board

―18― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 4 Electrical Install a ti on

+10

-10

AI1 AI2

AI3

DI1 DI2 DI3 DI4 DI5 DI6 COM R1ACOM

GND

AO1 AO2

P24 SEL DO1 R1C

GND COM CME DO2 R1B

4.4.1 Control Terminal Description

Figure 4-4 Control terminal layout

Table 4-3 Control terminal function description

Item Terminal Name Function Description

AI1 Anglogue input 1 Input voltage: 0-10V (input impedance: 34kΩ)

Analogue

input

Analogue

output

Digital

input

Digital

output

Relay

output

Power

source

AI2 Anglogue input 2 Input voltage/current is selectable;

AI3 Anglogue input 3

AO1 Anglogue output 1

AO2 Anglogue output 2

DI1-DI6 Digital input 1-6

DO1 Digital output 1 Programmable optical-coupled isolation, open

DO2 Digital output 2

CME DO1 reference ground Isolated from COM, default short connected COM

R1A/ R1B/ R1C Relay contact output

+10V +10V power supply

-10V -10V power supply

GND

P24 +24V power supply

SEL

COM

+/-10V power

reference ground

Digital input common

terminal

Digital reference

ground

Input voltage: -10V-10V (input impedance: 34kΩ);

Input current: 0-20mA (input impedance: 500Ω)

Output voltage/current signal: 0-10V/0-20mA;

Programmable output

Programmable bipolar optional input signal

Input voltage: 0-30VDC

DI1-DI5 input impedance: 4.7kΩ;

DI6 input impedance: 1.6kΩ

collector output

Output voltage: 0-30VDC, max-output current 50mA

Programmable output, contact rating: 250VAC/3A or

30VDC/1A

R1B,R1C: normally closed; R1A,R1C: normally open

Analogue input use +10V as reference supply,

maximum output current is 100mA

Analogue input use -10V as reference supply,

maximum output current is 10mA

Analogue site, isolated from COM

Digital input use +24V as supply, maximum output

current is 200mA

Factory settings default SEL and P24 are connected.

Disconnected SEL and P24 when use external power

to drive DI1-DI6

Digital site, isolated from CME

4

HD5L Series Controller User Manual ―19―

Chapter 4 Electri c al I ns tallation Shenzhen Hpmont Technology Co., Ltd

CN5

1

3

CN6

1

3

CN7

1

3

CN8

1

3

CN9

13

Port pin

Port signal

RJ45

1

+5V2485+3+5V4GND5GND6GND7485-8Reserved

1 8

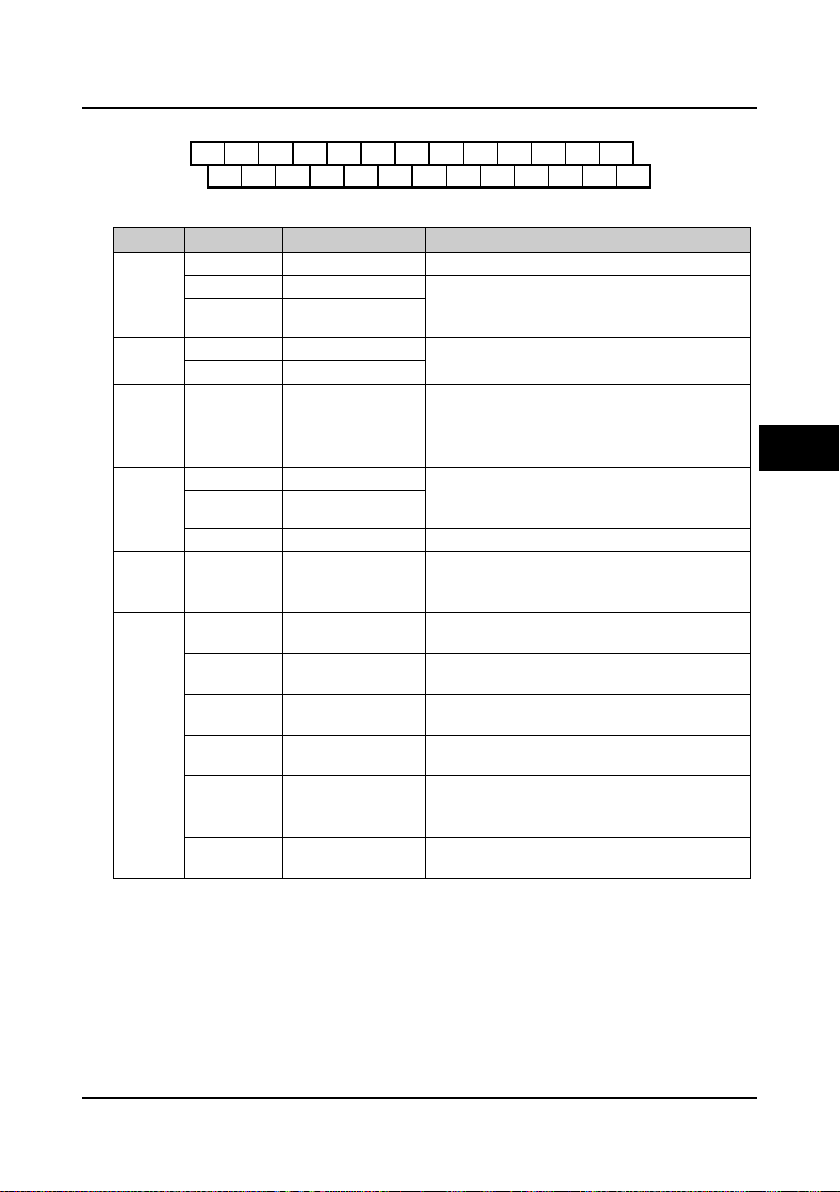

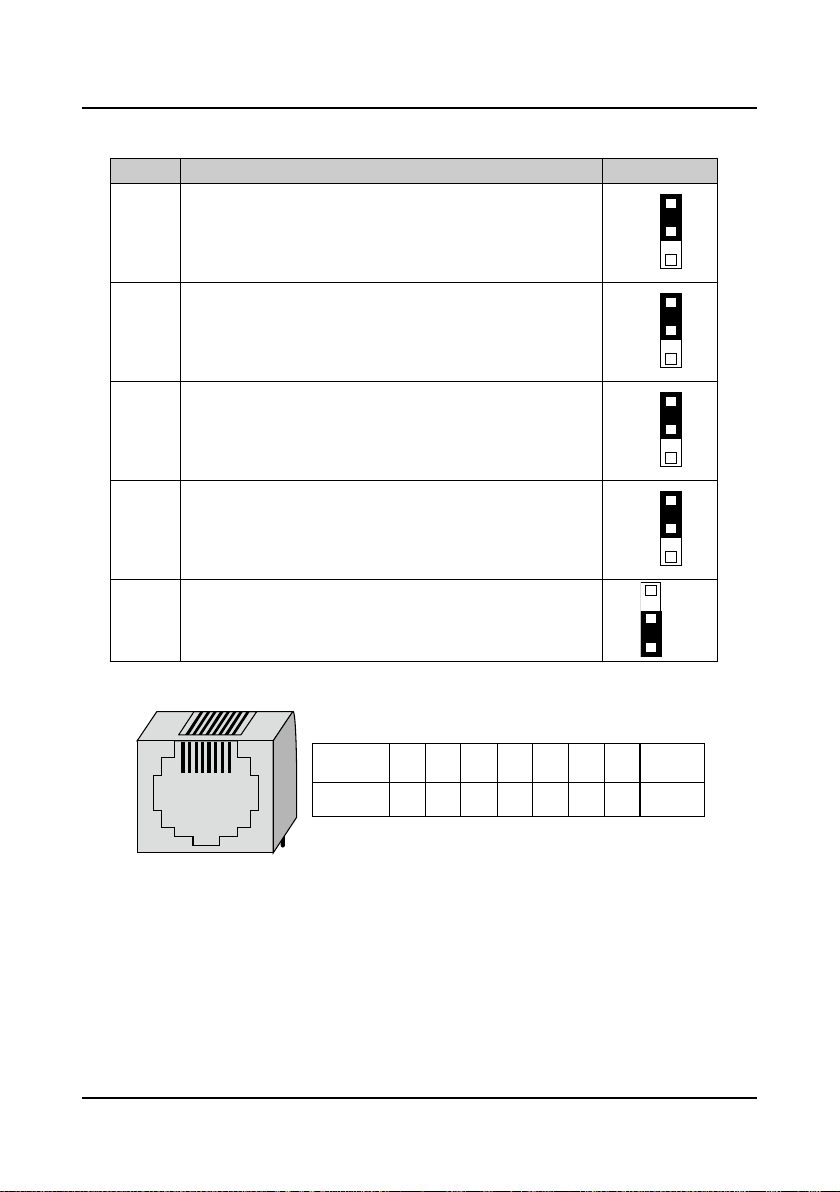

4.4.2 Wire Jumper Description

Table 4-4 Wire jumper function and setting description on the control board

Jumper Function and setting description Factory setting

AI2 analogue input channel can select voltage or current signal.

When pin 1 and pin 2 of the CN5 are short-circuited, AI2 channel

CN5

inputs voltage signal;

When pin 2 and pin 3 of the CN5 are short-circuited, AI2 channel

inputs current signal.

AI3 analogue input channel can select voltage or current signal.

When pin 1 and pin 2 of the CN6 are short-circuited, AI3 channel

CN6

inputs voltage signal;

When pin 2 and pin 3 of the CN6 are short-circuited, AI3 channel

inputs current signal.

AO1 analogue output channel can select voltage or current signal.

When pin 1 and pin 2 of the CN7 are short-circuited, AO1 channel

CN7

outputs voltage signal;

When pin 2 and pin 3 of the CN7 are short-circuited, AO1 channel

outputs current signal.

AO2 analogue output channel can select voltage or current signal.

When pin 1 and pin 2 of the CN8 are short-circuited, AO2 channel

CN8

outputs voltage signal;

When pin 2 and pin 3 of the CN8 are short-circuited, AO2 channel

outputs current signal.

SCI communication can select proper resistance.

When pin 2 and pin 3 of the CN9 are short-circuited, no resistance;

CN9

When pin 1 and pin 2 of the CN9 are short-circuited, select the proper

resistance.

4.4.3 SCI Communication Terminal Description

Figure 4-5 SCI communication terminal and description

―20― HD5L Series Controller User Manual

Shenzhen Hpmont Technology Co., Ltd Chapter 4 Electri c al I ns tallation

DI1

DO2

DO1

CME

R1A

R1C

R1B

GND

AO1

AO2

DI2

DI3

DI4

DI5

DI6

COM

AI1

AI2

+10

HD5L

Control board

AI3

GND

COM

PE

CN5

1

3

CN6

1

3

CN7

1

3

CN8

1

3

Multi-function inputterminal1

Multi-function inputterminal2

Multi-function inputterminal3

Multi-function inputterminal4

Multi-function inputterminal6

Multi-function inputterminal5

Digital ground

DO1 referenceground

DO2 reference ground

AI 1

AI 2

Analogue ground

Analogue ground

Analogue outputchannel2

Analogue outputchannel1

Programmable relayoutput

Programmable open-collector

output channel1

Programmable open-collector

output channel2

AI

3

Shielded cable

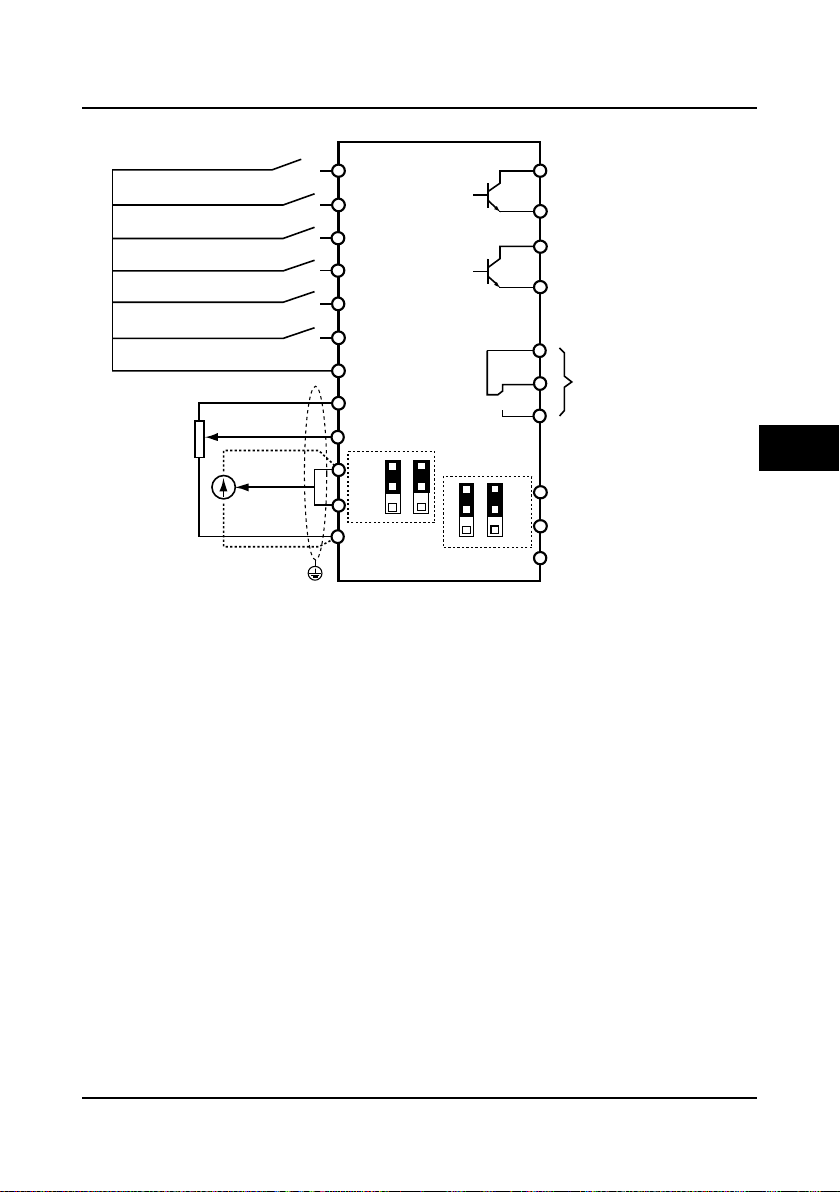

4.4.4 Control Terminal Connection

4

HD5L Series Controller User Manual ―21―

Figure 4-6 HD5L control circuit connection diagram

Loading...

Loading...