HD31 Series

Aqua Inverter

HD31 Series

Aqua Inverter

User Manual

V1.1 2017.07

FOREWORD

Thank you for purchasing HD31 series aqua inverter manufactured by Shenzhen

Hpmont Technology Co., Ltd.

This User Manual describes how to use HD31 series inverters and their installation

wiring, parameter setting, troubleshooting and daily maintenance etc.

Before using the product, please read through this User Manual carefully. In addition,

please do not use this product until you have fully understood safety precautions.

Note:

Preserve this Manual for future.

Due to product upgrade or specification change, and for the purpose of

improving convenience and accuracy of this manual, this manual’s contents may

be modified.

If you need the User Manual due to damage, loss or other reasons, please contact

the regional distributor of our company or directly contact our company Technical

Service Center.

For the first time using, the user should carefully read this manual.

If you still have some problems during use, please contact our company Technical

Service Center.

Email address: overseas_1@hpmont.com

n

n

p

h

Co

ectionwithperi

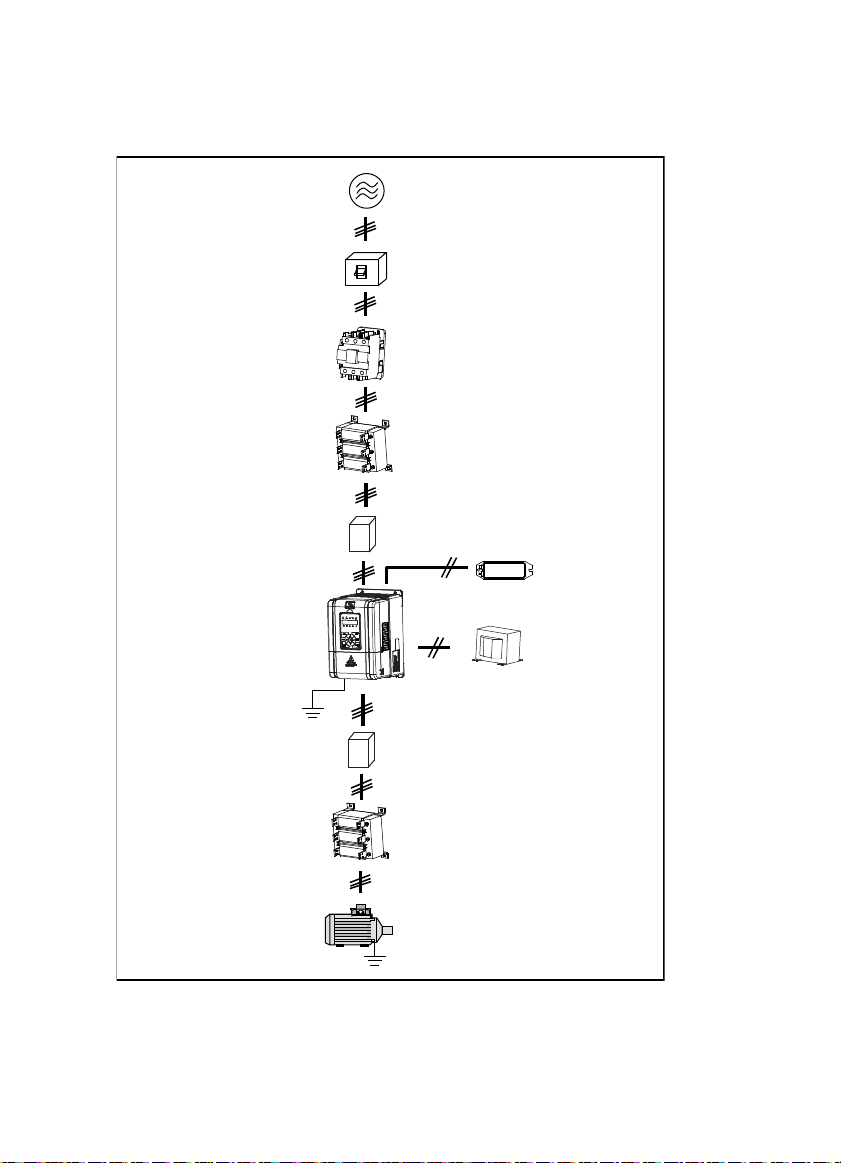

Three-phase AC power supply

AC input r eactor

eral devices

MCCB

Contactor

(accessory)

EMI filter

Braking resistor

(accessory)

HD31

EMI filter

AC output reactor

(accessory)

Motor

DC reactor

(accessory)

Version and Revision Records

The version information is on top of the backbone and the bottom left of the cover.

Time: 2017/07

Version: V1.1

Revised chapter Revised contents

• New model: HD31-4T2P2P, HD31-4T3P7P

• Refer to 2.3 Rated Value, 4.2.1 Wiring specifications of input and output, 9.3 Braking

Resistor and Braking Unit for details

• Modify the input and output lines, see 4.2.1

• New content: 4.2.2 Power terminal lug.

• Add adjustment in switching from variable frequency to power frequeny, see 7.2

• Add fault: E00.37 (Input wrong phase), see Chapter 8

Chapter 6

Appendix A

• Change the pressure unit to: kg/cm2

• Concrete parameter: P00.05, P02.01, P02.04, P02.06, P02.08, P02.10, P02.12, P02.14, P02.16,

P02.18, P02.20, P02.22, P02.24, P02.26, P04.00, P04.02

• Add d00.42 (Set water supply pressure), d00.43 (Actual water supply pressure)

• Add F00.04 (Extension card selection)

• F15.00 – F15.08 (DI function) add: 54 Clear fault records

• F18.02 – F18.13 (Set parameter of run/stop status) modify:

• Add: 35 (Content water supply pressure setting), 36(Actula feedback pressure)

• F18.04, F18.12, F18.13 modify default

• P00.07 (Dormancy enable) add: 3 (No flow dormancy 1), 4 (No flow dormancy 2)

• Modify defination of P00.13, P00.14

• Add P00.23 – P00.30 ((no-flow power function), P00.31 – P00.38 (function of switching from

variable frequency to power frequency), P00.39 – P00.50 (pump contactor function)

• P02.28 (Proportional gain of pressure closed-loop) modify default and range: 0.00 – 10.00

[0.01]

• Add P02.35 (Digital setting for saving selection when power failure)

• Add P05.03 – P05.04 (pressure sensor function), P05.05 ( Water supply method)

CONTENTS

Chapter 1 Safety Information and Precautions .................................................................................................... 1

1.1 Safety Definition ............................................................................................................................... 1

1.2 About Motor and Load ..................................................................................................................... 1

1.3 About HD31 ....................................................................................................................................... 2

Chapter 2 Product Information ............................................................................................................................... 5

2.1 Model .................................................................................................................................................. 5

2.2 Nameplate .......................................................................................................................................... 5

2.3 Rated Value ........................................................................................................................................ 6

2.4 Technical Data ................................................................................................................................... 6

2.5 Parts of Inverter ................................................................................................................................. 8

Chapter 3 Machenical Installation .......................................................................................................................... 9

3.1 Precautions ........................................................................................................................................ 9

3.2 Installation Site Requirement ......................................................................................................... 9

3.3 Installation Direction and Space Requirements ........................................................................ 10

3.4 Dimensions and Weight ................................................................................................................. 11

3.5 Install and Dismantle Keypad ....................................................................................................... 12

3.6 Dismantle Plastic Cover ................................................................................................................. 13

Chapter 4 Electrical Installation ............................................................................................................................ 15

4.1 Precautions ...................................................................................................................................... 15

4.2 Peripheral Accessories Selection .................................................................................................. 15

4.2.1 Wiring specifications of input and output......................................................................................... 15

4.2.2 Power terminal lug .................................................................................................................................... 16

4.3 Main Circuit Terminals and Wiring ............................................................................................... 16

4.3.1 Supply and Motor Terminal .................................................................................................................... 17

4.3.2 Supply and Motor Connection .............................................................................................................. 18

4.4 Control Board and I/O Board ......................................................................................................... 19

4.4.1 Control Board Terminal ............................................................................................................................ 20

4.4.2 I/O Board Terminal ..................................................................................................................................... 21

4.4.3 Modbus Communication Terminal ...................................................................................................... 21

4.4.4 Jumper ........................................................................................................................................................... 22

Chapter 5 Keypad .................................................................................................................................................... 23

Chapter 6 Function Introduction .......................................................................................................................... 25

6.1 Group d: Display Parameters ........................................................................................................ 26

6.1.1 d00: Status Display Parameters ............................................................................................................. 26

6.2 Group F: General Parameters ........................................................................................................ 29

6.2.1 F00: Basic Parameters ............................................................................................................................... 29

6.2.2 F01: Protection of Parameters................................................................................................................ 32

6.2.3 F03: Acc / Dec Parameters ....................................................................................................................... 33

6.2.4 F05: External Setting Curve Parameters ............................................................................................. 33

6.2.5 F08: Asynchronous Motor Parameters................................................................................................ 35

6.2.6 F09: V/f Control Parameters .................................................................................................................... 36

6.2.7 F15: Digital I/O Terminal Parameters ................................................................................................... 38

6.2.8 F16: Analogue I/O Terminal Parameters ............................................................................................. 41

6.2.9 F17: SCI Communication Parameters .................................................................................................. 43

6.2.10 F18: Display Control Parameters ........................................................................................................ 44

6.2.11 F19: Function-boost Parameters ........................................................................................................ 45

6.2.12 F20: Fault Protection Parameters ....................................................................................................... 47

6.2.13 F23: PWM Control Parameters ............................................................................................................. 50

6.3 Group P: Special Parameter for Multi-pump Water Supply ...................................................... 51

6.3.1 P00: Water Supply Logic Parameter ..................................................................................................... 51

6.3.2 P01: Water Supply Pump Parameter .................................................................................................... 56

6.3.3 P02: Water Supply PID Parameter ......................................................................................................... 57

6.3.4 P03: Water Supply AIO Function Parameter ..................................................................................... 59

6.3.5 P04: Water Supply Fault Protection Parameter ................................................................................ 61

6.3.6 P05: Water Supply Time Parameter ...................................................................................................... 61

Chapter 7 Application Reference .......................................................................................................................... 63

7.1 Take one-to-six inverter as an example. ...................................................................................... 63

7.2 Debugging for Switching between VF and IF ............................................................................ 66

Chapter 8 Troubleshooting ................................................................................................................................... 67

Chapter 9 Accessories ............................................................................................................................................. 71

9.1 Keypad Installation Assembly ...................................................................................................... 71

9.2 Reactor Selection ............................................................................................................................ 71

9.3 Braking Resistor and Braking Unit ............................................................................................... 72

Appendix A Parameters ......................................................................................................................................... 73

Safety Information and Precautions

Product Information

Machenical Installation

Electrical Installation

Keypad

Function Introduction

Application Reference

Troubleshooting

Accessories

Parameters

1

2

3

4

5

6

7

8

9

A

Shenzhen Hpmont Technology Co., Ltd. Chapter 1 Safety Information and Precautions

W

Chapter 1 Safety Information and Precautions

1.1 Safety Definition

Danger

arning

Note

A Danger contains information which is critical for avoiding safety hazard.

Danger:

A Warning contains information which is essential for avoiding a risk of damage to products or other

Warn ing:

equipements.

A Note contains information which helps to ensure correct operation of the product.

Note:

1.2 About Motor and Load

Compared to the industrial frequency running

The HD31 series inverters are voltage-type frequency inverters and their output is PWM wave with

certain harmonic wave. Therefore, the temperature, noise and vibration of the motor will be a little

higher than that at industrial frequency running.

Constant torque at low-speed running

When HD31 drives a standard motor at low-speed running for a long time, the output torque ratings

will become worse due to the motor cooling is less effective. In that case, we suggest that you should

choose variable frequency motor.

Thermal protection of motor

When choose the adaptive motor, HD31 can effectively implement thermal protection of motor.

Otherwise it must adjust the motor protection parameters or other protection measures to ensure that

the motor is at a safe and reliable running.

Running above the rated frequency of motor

If the motor runs exceeding its rated frequency, the noise will increase. Pay attention to the motor

vibration as well as ensure the motor bearings and mechanical devices to meet the requirement of

running speed range.

Lubrication of mechanical devices

At long time low-speed running, provide periodical lubrication maintenance for the mechanical

devices such as gear box and geared motor etc. to make sure the drive results meet the site need.

1

HD31 Series User Manual V1.1 ―1―

Chapter 1 Safety Information and Precautions Shenzhen Hpmont Technology Co., Ltd.

Mechanical resonance point of load

Set the skip frequency (F05.17 - F05.19) to avoid the load device or the motor mechanical resonance

point.

Start and stop HD31

User should use the control terminal to start and stop HD31.

It is strictly forbidden to use contactor or other switches on the input side of HD31 to start and stop

directly, or it will damage the device.

Check the insulation of the motor

For the first time using of the motor or after long time storage, it needs checking the insulation of the

motor. Worse insulation can cause damage to HD31.

Note:

Use a 500V Mega-Ohm-Meter to test and the insulation resistance must be higher than 5Mohm.

Load and negative torque

For the occasion to boost load and the like, negative torque often occurs. Consider setting proper

parameters of the braking unit if HD31 is prone to overcurrent or overvoltage fault trip.

Requirement for leakage current protector RCD

Since the device generates high leakage current which goes through the protective grounding

conductor, please install B type leakage current protector RCD on one side of the power supply.

For the selection of RCD, users need to consider the possible problems of ground leakage current in

both transient status and steady status at start and during running. It is recommended to choose

either special RCD that can suppress the higher harmonics, or general RCD that has more aftercurrent.

Warning for ground mass leakage current

The device generates mass leakage current, so users need to confirm the reliable grounding before

connect to the power supply. The grounding should comply with the local relative IEC standard.

1.3 About HD31

No capacitor or varistor on the output side

Since HD31 output is PWM wave, it is strictly forbidden to connect capacitor for improving the power

factor or varistor for lightning protection to the output terminals so as to avoid HD31 fault trip or

component damage.

Contactors and circuit breakers connected to the output of HD31

If circuit breaker or contactor needs to be connected between HD31 and the motor, be sure to operate

these circuit breakers or contactor when HD31 has no output, so as to avoid any damage to HD31.

Running voltage

HD31 is prohibited to be used beyond the specified range of running voltage. If needed, please use

suitable voltage regulation device to change the voltage.

―2― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 1 Safety Information and Precautions

Capacitor energy storage

When the AC power supply is cut off, capacitor of HD31 sustains deadly power for a while. So to

disassemble HD31 that is powered, please cut off the AC power supply for more than 10 minutes,

confirm the internal charge indicator is off and the voltage between (+) and (-) of the main circuit

terminals is below 36V.

Generally, the internal circuit enables the capacitor to discharge. However, the discharging may fail in

some exceptions. In these cases, users need to consult Hpmont or our regional distributor.

Lightning surge protection

HD31 internal design has lightning surge overcurrent protection circuit, and has certain self-protection

capacity against the lightning.

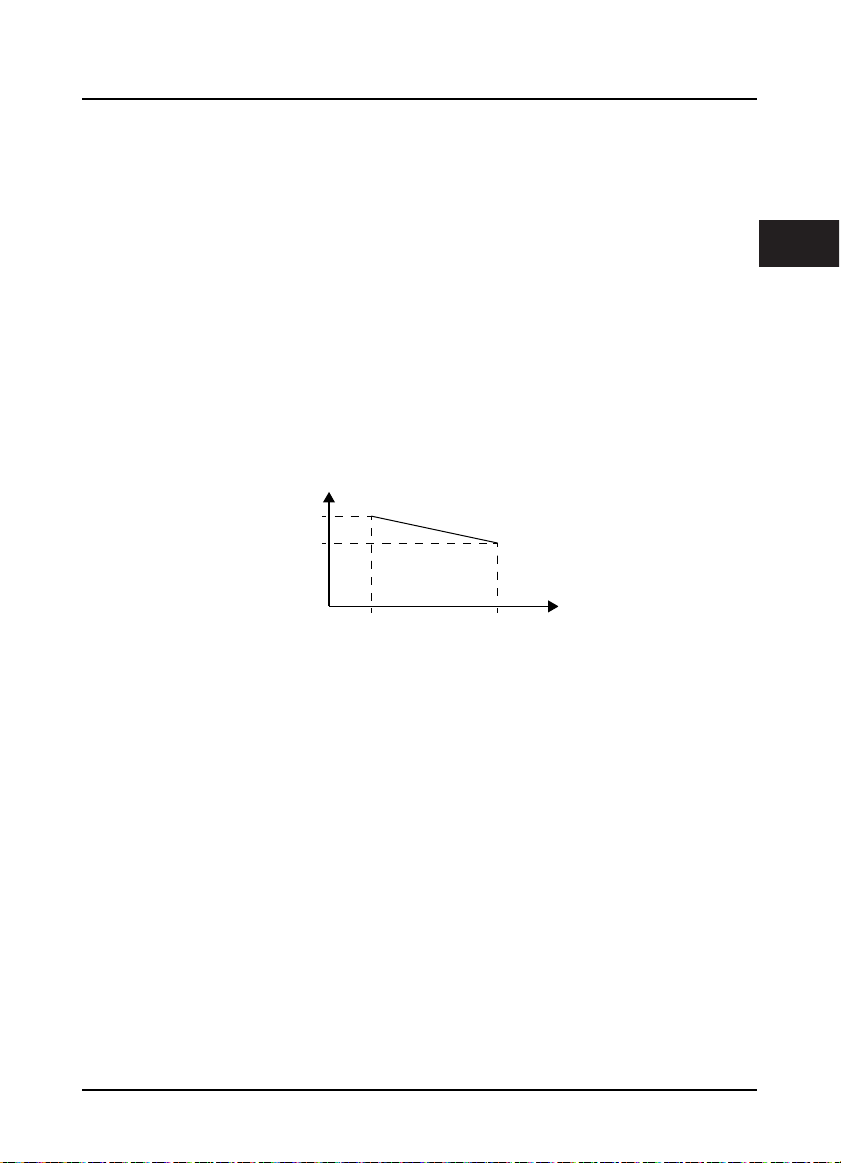

Altitude and derating

In area where altitude exceeds 1000 meters, HD31 should be derating since the heatsink efficiency will

be reduced because of the tenuous air.

The rated value of output current derates by 1% for each 100m increase of the altitude. I.e. for the

altitude of 4000m, derated rate is 30% for rated current of HD31. Figure 1–1 is the derating curve of

rated current and the altitude.

Rated current of HD31

100%

70%

Altitude

1000m 4000m

Figure 1–1 Derating curve of rated current and altitude

1

HD31 Series User Manual V1.1 ―3―

Shenzhen Hpmont Technology Co., Ltd. Chapter 2 Product Information

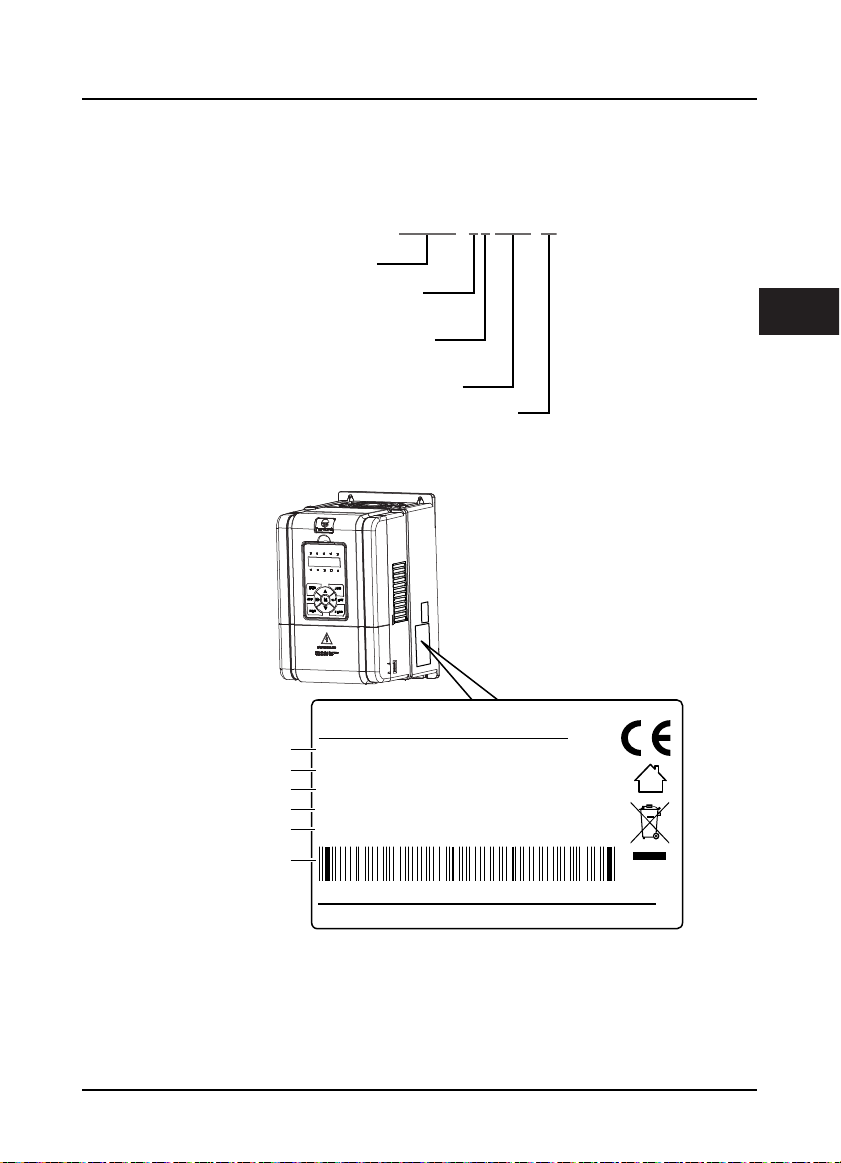

Chapter 2 Product Information

2.1 Model

HD31-4T7P5-P

Product Series

Power Supply Voltage

380 - 460VAC = 4

Input Phase

Three-phase input = T

Power

Product Type

2.2 Nameplate

Fan and pump = P

FWD

REV

ALM

LOCK

LO/RE

HZ

A

V

RPM %

2

Product model

Motor power

Input specification

Output specification

Software version

MODEL:

POWER:

INPUT:

OUTPUT:

HD31-4T7P5P

7.5kW

3PH 380-460V 19A 50/60Hz

11kVA 0-460V 17A 0-400Hz

1.00Version:

Serial number

HD31 Series User Manual V1.1 ―5―

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd.

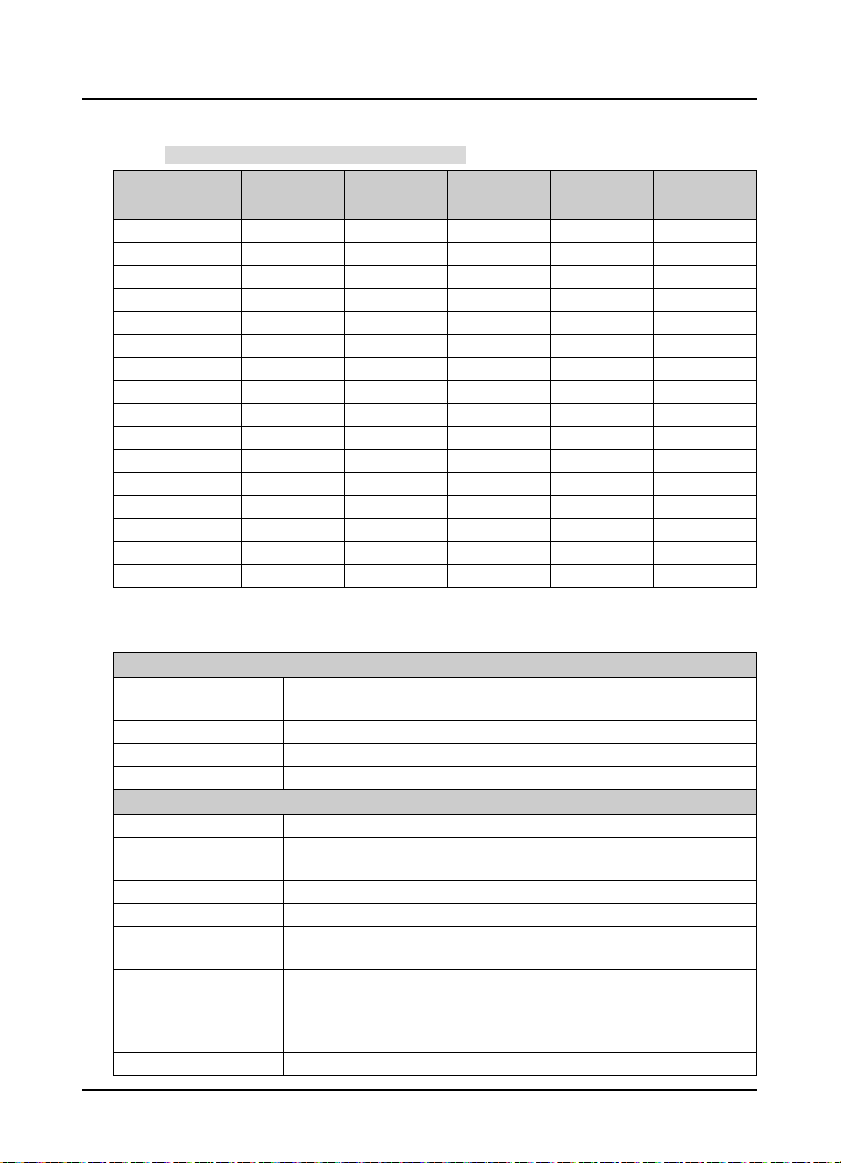

2.3 Rated Value

Refer to section 3.4 Dimensions and Weight (on page 11) for size information.

Model

HD31-4T2P2P 2.2 3.4 7.3 5.1 F2

HD31-4T3P7P 3.7 5.9 11.9 9.0 F2

HD31-4T5P5P 5.5 8.5 15 13 F2

HD31-4T7P5P 7.5 11 19 17 F2

HD31-4T011P 11 16 28 25 F3

HD31-4T015P 15 21 35 32 F3

HD31-4T018P 18.5 24 39 37 F4

HD31-4T022P 22 30 47 45 F4

HD31-4T030P 30 39 62 60 F5

HD31-4T037P 37 49 77 75 F5

HD31-4T045P 45 59 92 90 F6

HD31-4T055P 55 72 113 110 F6

HD31-4T075P 75 100 156 152 F6

HD31-4T090P 90 116 180 176 F7

HD31-4T110P 110 138 214 210 F7

HD31-4T132P 132 167 256 253 F7

Motor

(kW)

Rated Capacity

(kVA)

Rated Input

Current (A)

Rated Output

Current (A)

Size

2.4 Technical Data

Electrical

Input voltage

Input frequency 50/60Hz ± 5%

Output voltage 0 - input voltage

Output frequency 0 - 400.00Hz

Perf orman ce

Control mode V/f, SVC

Max. current

Running command Keypad; Terminals; Communication

Speed setting Digital; Analogue; Communication

Speed resulotion

SVC

Torque control accuracy ±5%

Three-phase: 380 - 460V, 50/60Hz

Fluctuating within ± 10%, imbalance rate < 3%

120% rated output current for 5 minutes;

135% rated output current for 35 seconds

Digital setting: 0.01Hz

Analogue setting: 0.1% × max-frequency

Speed cont rol accuracy: ± 0 .5%

Speed control range: 1:100

Torque control response: < 200ms

Start torq ue: 180% rated torque / 0.5Hz

―6― HD31 Series User Manual V1.1

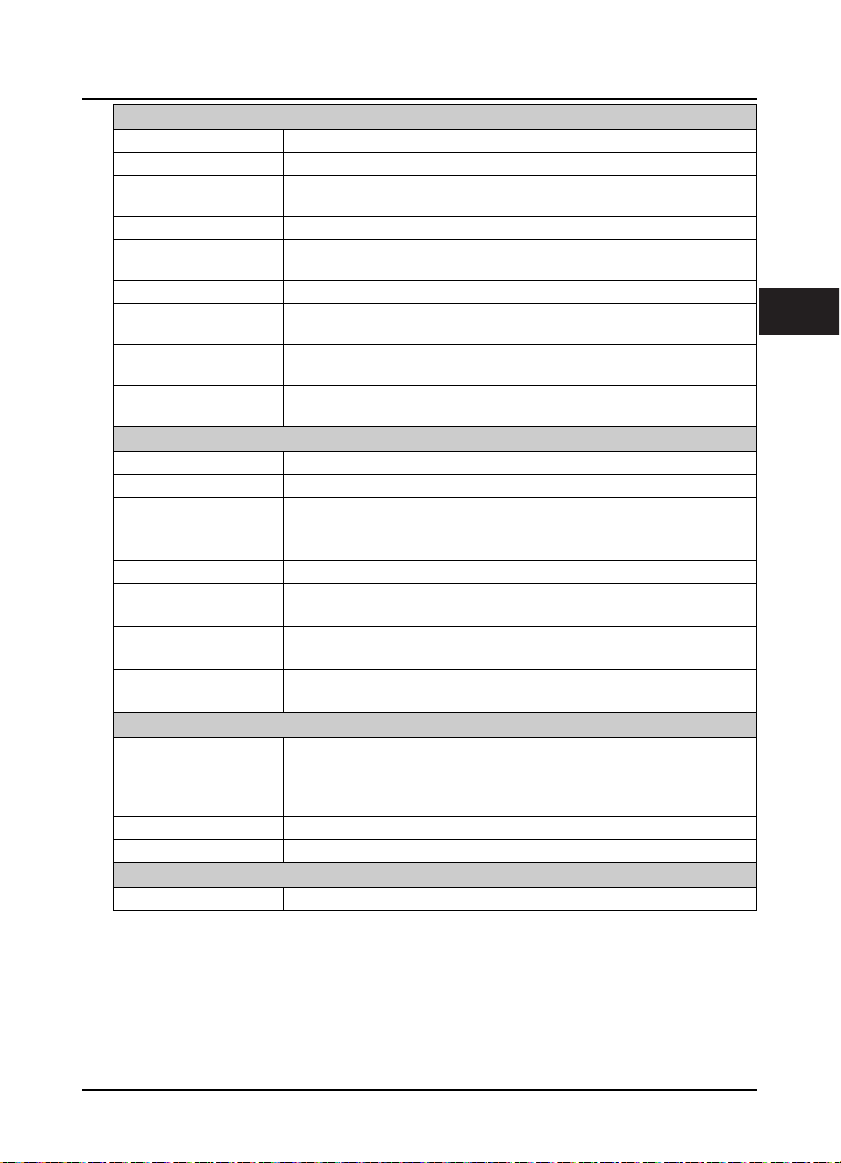

Shenzhen Hpmont Technology Co., Ltd. Chapter 2 Product Information

Protection Functions

Stall overvoltage Bus voltage can auto-control against overvoltage fault

Auto-limit current protection Output current can auto-limit against overcurrent fault

Overload pre-alarm and

alarm

Load loss protection Load loss alarm function

Input / Output voltage

phase loss protection

Braking fault protection Braking detection and alarming function

PID commands and

feedback loss detection

Power output grounding

fault protection

Power output short circuit

protection

Input / Outpot

Analogue power supply +10V, max. current 100mA

Digital power supply +24V, max. current 200mA

Analogue input

Analogue output AO1, AO2: 0 - 10V/0 - 20mA (selectable voltage/current)

Digital input

Digital output

Relay output

Keypad

LED display

LCD display Optional [HD-LCD], display contents in Chinese or English

Parameter copy Both LED and LCD keypad can achieve quick parameter copy

Communication

SCI communication RS-485 interface; Terminal

Overload early pre-alarm and protect

Input / Output voltage phase loss auto-detec t and alarm function

PID can auto-identify whether loss the setting and feedback or the alarm function

Power output grounding fault protection is enabled

Power output short circuit protection is enabled

AI1 (control board): voltage 0 - 10V

AI2 (control board): -10 - +10V/0 - 20mA (selectable voltage/current)

AI3, AI4 (I/O board): -10 - +10V/0 - 20mA (selectable voltage/cu rrent)

DI1 - DI6 (control board); DI7 - DI9 (I/O board)

DI6 can be selectable for high-frequency input

DO1, DO2

DO2 can be selectable for high-frequency output

R1A/R1B/R1C(control board), R2A/R2C - R10A/R10C(I/O board)

Contact rating: 250VAC/3A or 30VDC/1A

Five LEDs display, 5 unit indicators, 5 status indicators

Setting frequency, output frequency, output voltage, output current, motor speed,

output torque, switching value terminal, status parameter, programm menu

parameter and fault code etc.

2

HD31 Series User Manual V1.1 ―7―

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd.

e

C

C

Environment

Running temperature

Storage temperature -40 - +70℃

Location for use

Altitude Less than 1000 meters, otherwise should be derating use

Humidity Less than 95%RH, non-condensing

Vibration Resistance It is 3.5m/s2 in 2 - 9Hz, it is 10m/s2 (IEC60721-3-3) in 9 - 200Hz

Protection class IP20

Pollution level Level 2 (Dry, non conducting dust pollution)

Accessorie s

Bus communication

About keypad

Power units Dynamic braking unit [HDBU]

-10 - +40℃, max. 50℃, air temperature fluctuation is less than 0.5℃/min

The derating value of the output current of HD31 shall be 2% for each degree

centigrade above 40℃. Max. allowed temperature is 50℃

Indoor, preventing from direct sunlight, no dust, corrosive, flammable gases, oil mist,

water vaper, dripping or salt etc.

PROFIBUS option [HDFB-PROFIBUS-DP]

DeviceNet option [HDFB-DeviceNet]

CAN option [HDFB-CAN]

LCD k eypad ( HD-LCD)

Mounting base to keypad (HD-KMB)

1m/2m/3m/6m extension cable to keypad (HD -CAB-1M/2M/3M/6M)

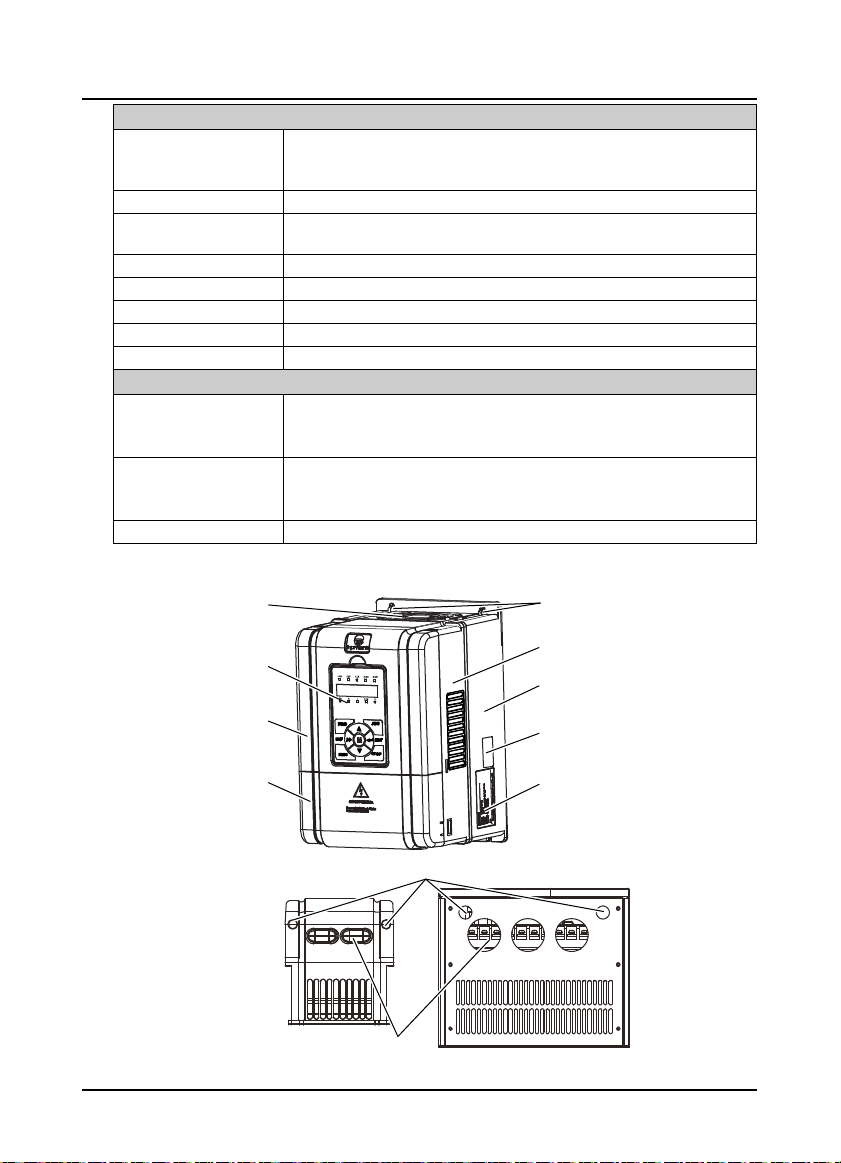

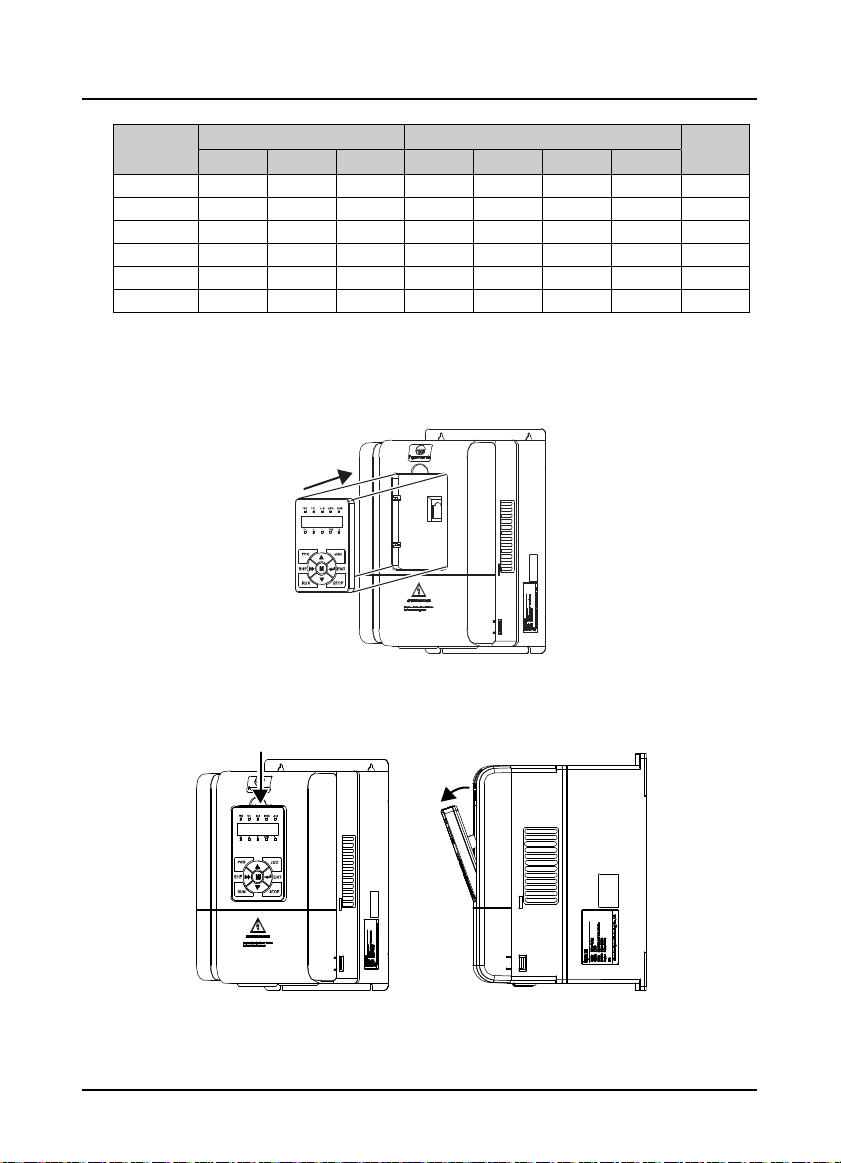

2.5 Parts of Inverter

Fan cover

Keypad

Mounting hole

Middle enclosure

Bottom enclosur

Upper cover

Lower cover

onnection holesofcontrolterminal

Size F2 - F4

onnection holesofpower terminal

Certification

Nameplate

Size F5 - F7

―8― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 3 Machenical Installation

W

Chapter 3 Machenical Installation

3.1 Precautions

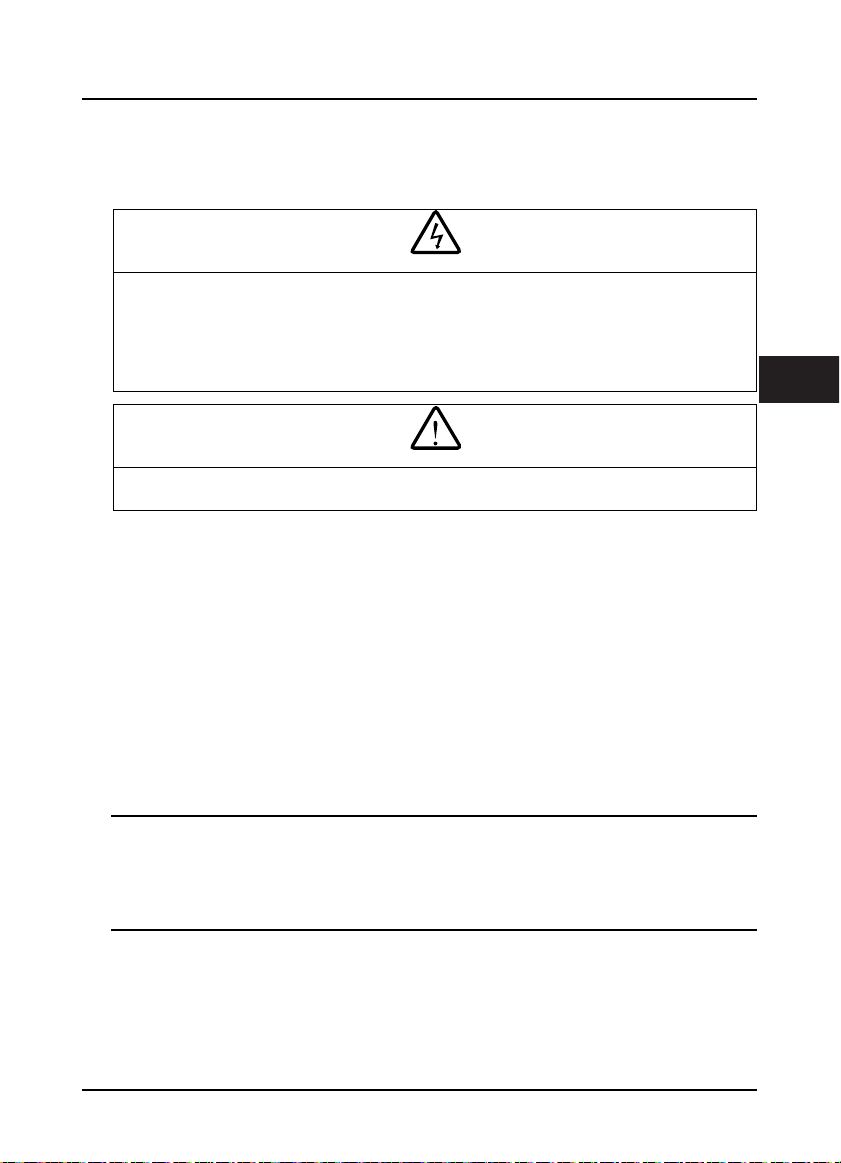

Danger

arning

• Do not install if HD31 is incomplete or impaired.

• When conveying HD31, please employ suitable tools according to its weight. Avoid scratch to the product. Be

careful: rollover and drop may cause hurt.

• Make sure that HD31 is far from explosive and flammable things.

• Do not do wiring operation until power supply is cut off for more than 10 minutes, the internal charge indicator of

HD31 is off and the voltage between (+) and (-) of the main circuit terminals is below 36V.

• It is required not only carry the keypad and the cover but also bottom enclosure of HD31.

• Do not let wires, screws or residues fall into HD31 when installing.

3.2 Installation Site Requirement

Ensure the installation site meets the following requirements:

• Do not install at direct sunlight, moisture, water droplet location;

• Do not install at flammable, explosive, corrosive gas and liquid location;

• Do not install at oily dust, fiber and metal powder location;

• Be vertical installed on fire-retardant material with a strong support;

• Make sure adequate cooling space for HD31 so as to keep ambient temperature between

- 10 - + 40℃;

• Install at where the vibration is 3.5m/s2 in 2 - 9Hz, 10m/s2 in 9 - 200Hz (IEC60721-3-3);

• Install at where the humidity is less than 95%RH and non-condensing location;

• Protection level of HD31 is IP20 and pollution level is 2 (Dry, non-conducting dust pollution).

Note:

1. It needs derating use if running temperature exceeds 40℃. The derating value of the output current of

HD31 shall be 2% for each degree centigrade. Max. allowed temperature is 50℃.

2. Keep ambient temperature between -10 - +40℃. It can improve the running performance if install at

location with good ventilation or cooling devices.

3

HD31 Series User Manual V1.1 ―9―

Chapter 3 Machenical Installation Shenzhen Hpmont Technology Co., Ltd.

D

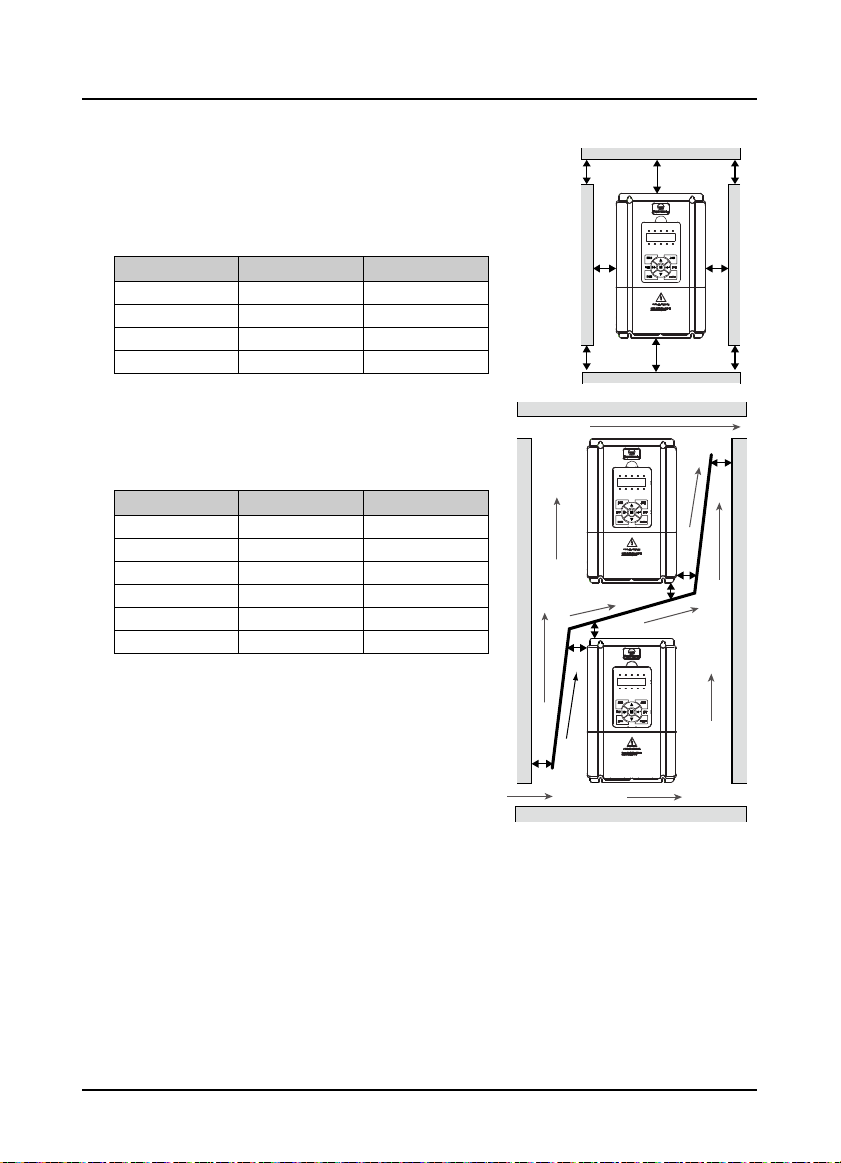

3.3 Installation Direction and Space Requirements

To achieve good cooling efficiency, install the inverter

perpendicularly and always provide the following space to

allow normal heat dissipation. The requirements on mounting

space and clearance are shown in Table 3-1.

Table 3-1 Installation space

HD31 power 5.5 - 75kW 90 - 132kW

A (left and right)

B (up and down)

C (upper vent)

D (lower vent)

123

≥

50mm

≥

100mm

≥

50mm

≥

50mm

≥

150mm

≥

350mm

≥

100mm

≥

100mm

When one inverter is mounted on top of another, an air flow

diverting plate should be fixed between them. Just as shown

in Table 3-2.

Table 3-2 Installation of several inverters

HD31 power 5.5 - 75kW 90 - 132kW

123

A

B

C

a

b

c

≥

≥

≥

≥

≥

≥

50mm

50mm

50mm

50mm

50mm

50mm

≥

100mm

≥

100mm

≥

100mm

≥

100mm

≥

100mm

≥

100mm

C C

B

AA

D

B

a

b

c

C

B

A

―10― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 3 Machenical Installation

H

H

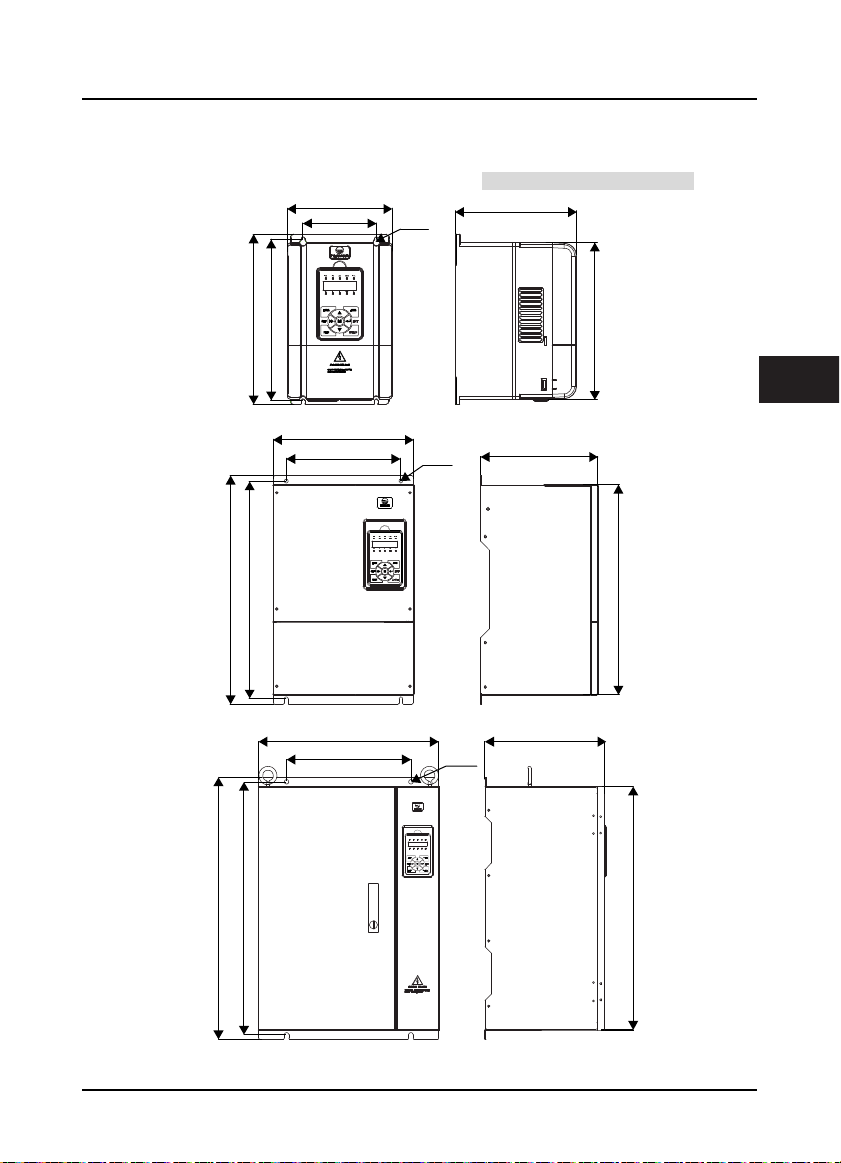

3.4 Dimensions and Weight

The dimensions and weight of HD31 are as shown in Table 3-3.

For the corresponding model of the mounting size, refer to section 2.3 Rated Value, on page 6.

W

W1

4-Ød

D

H1

H1

W

W1

W

W1

Size F2 - F4

4-Ød

Size F5 - F6

H2

3

D

H2

D

4-Ød

H

H1

H2

Size F7

HD31 Series User Manual V1.1 ―11―

Chapter 3 Machenical Installation Shenzhen Hpmont Technology Co., Ltd.

Table 3-3 HD31 dimensions and weight

Size

F2 165 266 190 115 253 245 5 4.4

F3 200 299 210 146 286 280 5 5.8

F4 235 353 222 167 337 330 7 8.2

F5 290 469 240 235 445 430 8 20.4

F6 380 598 290 260 576 550 10 48

F7 500 721 330 343 696 670 12 80

Dimension (mm) Mounting size (mm)

W H D W1 H1 H2 d

GW

(kg)

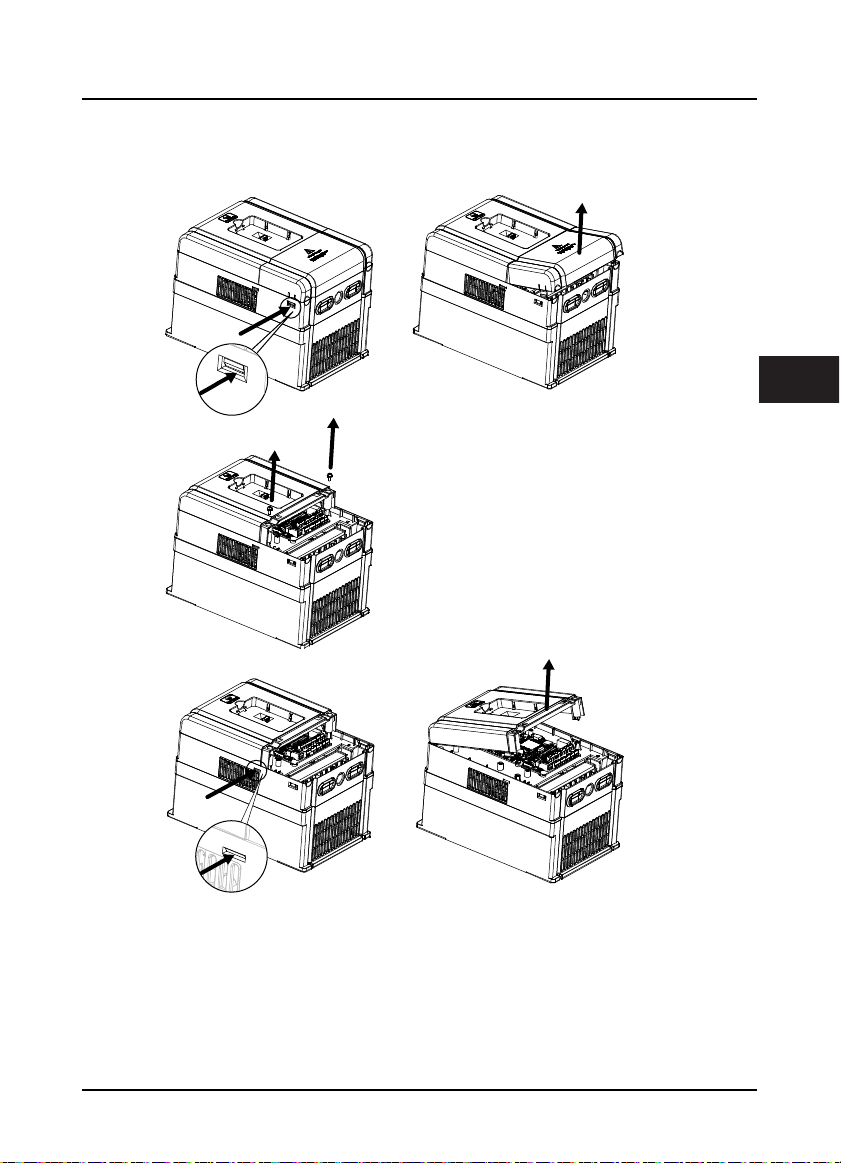

3.5 Install and Dismantle Keypad

According to the direction of Figure 3–1, press the keypad until hear a “click” sound.

Do not install the keypad from other directions or it will cause poor contact.

Figure 3–1 Install keypad

There are two steps in Figure 3–2.

First, press the hook of the keypad according to direction 1. Second, take out of the keypad according

to direction 2.

1

2

Figure 3–2 Dismantle keypad

―12― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 3 Machenical Installation

3.6 Dismantle Plastic Cover

The upper cover and lower cover of HD31 are removable. The dismantle steps are shown as Figure 3–3.

Before removing the upper cover, please take away the keypad.

(a)

3

The removing processes of plastic

cover board:

1. Extrude the hooks at both sides together,

take off the lower cover, as (a).

2. Dismantle the screws of upper cover, as (b).

3. Extrude the hooks at both sides together,

take off the upper cover, as (c).

(b)

(c)

Figure 3–3 Dismantle the plastic cover

HD31 Series User Manual V1.1 ―13―

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

W

Chapter 4 Electrical Installation

4.1 Precautions

Danger

arning

• Only qualified electrical engineer can perform wiring job.

• Only when the power supply switch is completely off can you do the wiring job.

• You can’t open the inverter cover to do wiring operation until the power is cut-off 10 minutes later. Do not wire or

detach the inverter internal devices at power-on situation.

• Do not do wiring operation until the internal charge indicator of the inverter is off and the voltage between (+)

and (-) of the main circuit terminals is below 36V.

• Check the wiring carefully before connecting emergency stop or safety circuit.

• The earth terminal PE of the inverters must be reliable earthing. It must use t wo separate earth wire due to the

leakage current from the inverter to ground.

• It must use Type B mode when utilize earth leakage protection devices(ELCB/RCD).

• Do not touch the wire terminals of the inverter when it is live. The main circuit terminals is neither allowed

connecting to the enclosure nor short-circuiting.

• Do not do dielectric strength test on the inverter.

• Do wiring connection of the braking resistor or the braking unit according to the wiring figure.

• Make sure the terminals are fixed tightly.

• Do not connect the AC supply cable to the output terminals U, V, W of the inverter.

• Do not connect the phase-shifting capacitors to the output circuit.

• Be sure the inverter has ceased output before switching motor or change-over switches.

• The inverter DC bus terminals must not be short-circuited.

4

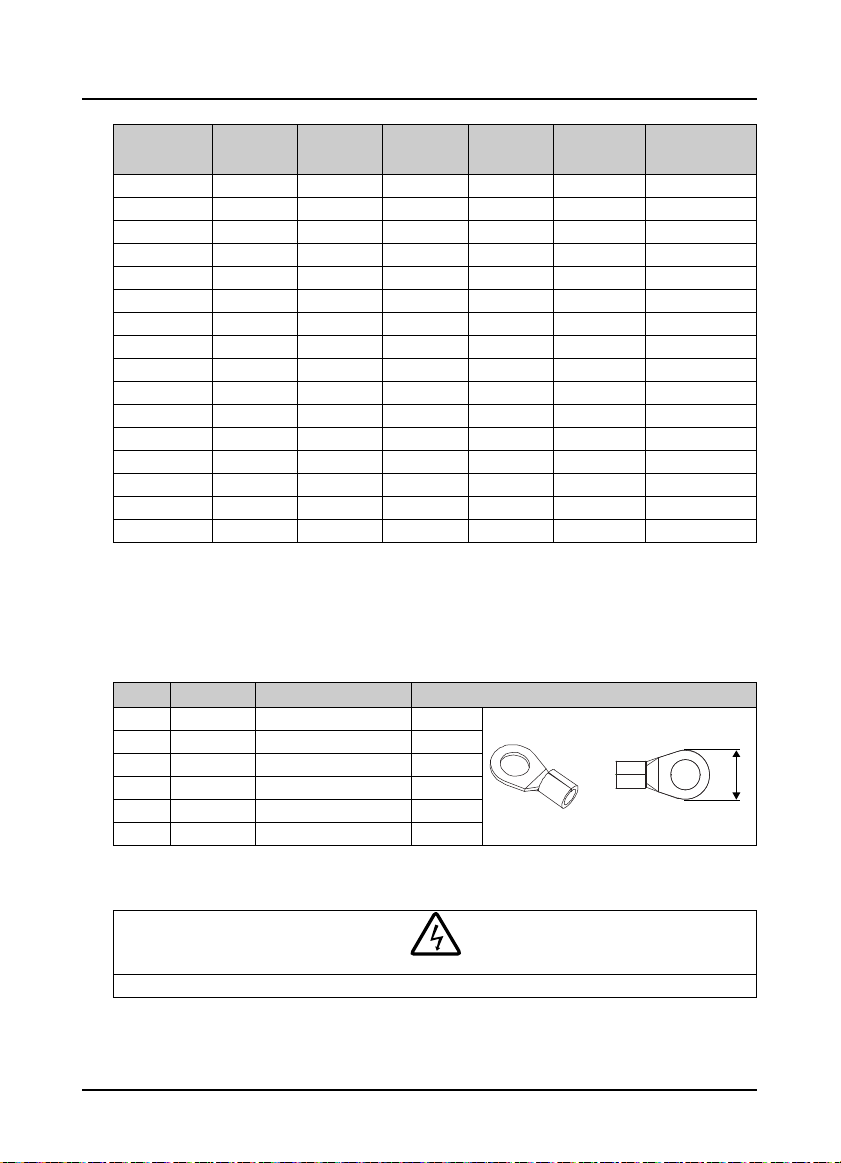

4.2 Peripheral Accessories Selection

4.2.1 Wiring specifications of input and output

The AC supply to HD31 must be installed with suitable protection against overload and short-circuits,

i.e. MCCB (molded case circuit breaker) or equivalent device.

The recommended specification of MCCB, contactor & cables are shown as Table 4-2.

The size of ground wire should accord with the requirement in 4.3.5.4 of IEC61800-5-1, as shown in

Table 4-1.

Table 4-1 Sectional area of ground protective conductor

Sectional area S of phase conductor (power supply

cable) while installing (mm2)

Min. sectional area Sp of relative protective conductor

(ground cable) (mm2)

HD31 Series User Manual V1.1 ―15―

S ≤ 2.5 2.5 < S ≤ 16 16 < S ≤ 35 S > 35

2.5 S 16 S/2

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

Table 4-2 HD31 I/O wiring specification

Model

HD31-4T2P2P 16 10 1.5 0.75 2.5 F2

HD31-4T3P7P 16 10 2.5 1.5 2.5 F2

HD31-4T5P5P 25 16 2.5 2.5 2.5 F2

HD31-4T7P5P 32 25 4 4 4 F2

HD31-4T011P 40 32 6 6 6 F3

HD31-4T015P 63 40 10 10 10 F3

HD31-4T018P 63 40 10 10 10 F4

HD31-4T022P 100 63 16 16 16 F4

HD31-4T030P 100 63 25 25 16 F5

HD31-4T037P 125 100 35 35 16 F5

HD31-4T045P 160 100 35 35 16 F6

HD31-4T055P 200 125 35 35 16 F6

HD31-4T075P 200 125 50 50 25 F6

HD31-4T090P 250 160 95 70 50 F7

HD31-4T110P 250 160 120 120 50 F7

HD31-4T132P 350 350 120 120 50 F7

MCCB Contacto r Power Cable Motor Cable Ground Cable Size

(A) (A) (mm2) (mm2) (mm2)

4.2.2 Power terminal lug

Select the lug of power terminal according to the size of terminal, screw size and max. outer diameter

of lug. Refer to Table 4-3.

Take the round terminal as an example.

Table 4-3 Selection of power terminal lug

Size Screw size Tightening torque (N. M) Max. outer diameter of lug d (mm)

F2 M4 1.2 - 1.5 9.9

F3 M5 2.5 - 3.0 12

F4 M5 2.5 - 3.0 12

F5 M6 4.0 - 5.0 15.5

F6 M8 9.0 - 10.0 24

F7 M10 17.6 - 22.5 30

d

4.3 Main Circuit Terminals and Wiring

Danger

• The bare portions of the power cables must be bound with insulation tapes.

―16― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

W

arning

• Ensure that AC supply voltage is the same as rated input voltage of HD31.

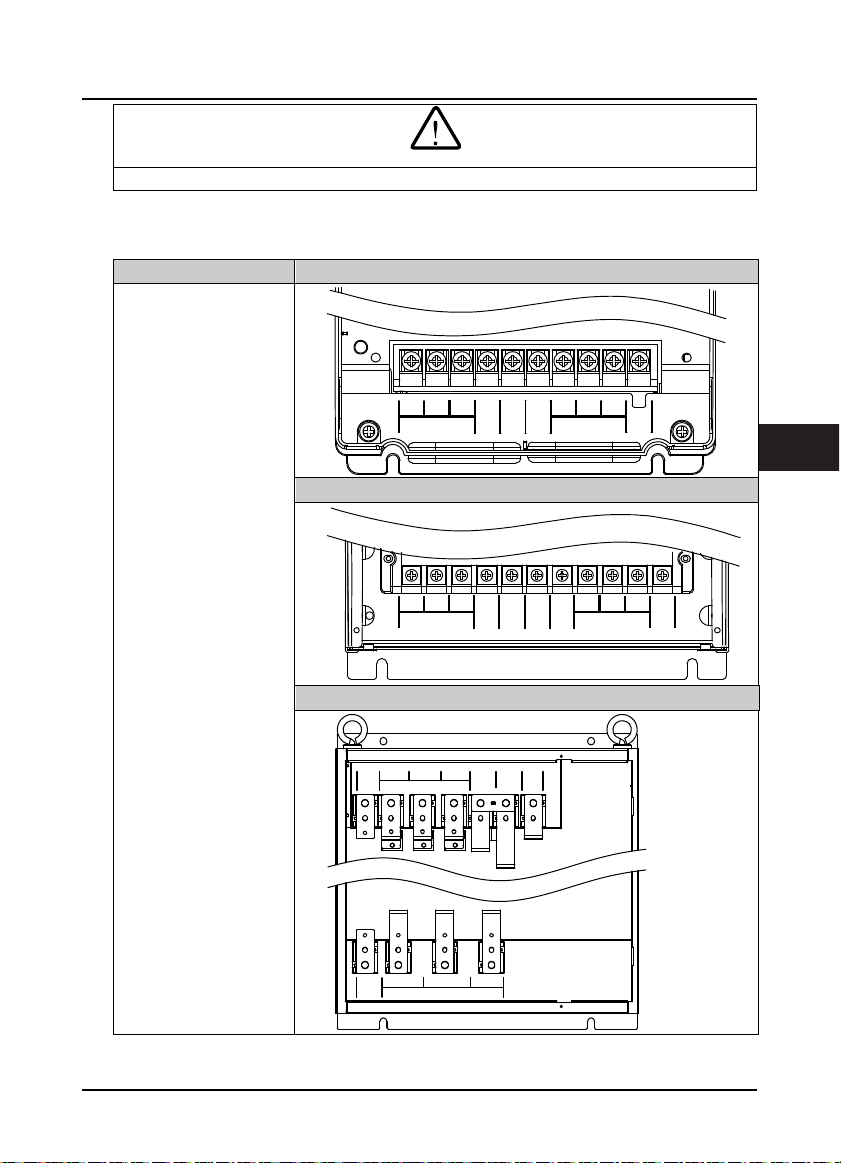

4.3.1 Supply and Motor Terminal

Table 4-4 Supply and motor terminal description

Terminal description Fram e 2

•

L1, L2, L3: Three-phase AC

power input terminals

•

U, V, W: O utput termina ls,

connect to three-phase AC

motor

•

P1, (+):DC reactor

connecti on terminals

•

(+), (-):DC supply input

terminals; DC input

terminals of power

regenerative unit

•

(+), BR: Braking resistor

connecti on terminals

•

PE: Ground terminal,

connect to the ground

Frame 3-Frame 6

Frame 7

L1 L2

PE

PE

L1 L2

L3

L3

MOTOR

(+) (-)

L3

P1

P1

POWER

L1 L2

POWER

POWER

UV

W

(+) (-)

(+) (-)

BR

UV

MOTOR

BR

W

UV

MOTOR

PE

4

W

PE

HD31 Series User Manual V1.1 ―17―

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

4.3.2 Supply and Motor Connection

During trial running, make sure HD31 runs forward when the forward command is enabled.

If not, switch any two of the output terminals (U/V/W) or modify parameter F00.17 to change the

motor direction.

The supply and motor connection are shown as Figure 4–1.

Refer to section 4.2 Peripheral Accessories Selection (on page 15) for product options.

Refer to section 9.3 Braking Resistor and Braking (on page 72) for braking resistors and braking units.

Refer to section 9.2 Reactor Selection (on page 71) for AC reactors and DC reactors.

Size F2 connection Size F3 - F6 connection

L1 L2 L3 (+) (-) BR U V W PE

L1 L2 L3 (+) (-) BR U V W PEP1

EMI filter

AC reactor

Mains supply

Braking resistor

MCCB

Contactor Contactor

Supply

ground

L1 L2 L3 (+) (-)PE P1 UV WPE

EMI filter

Supply

ground

AC reactor

Mains supply

DC

reactor

MCCB

Contactor

Figure 4–1 Supply and motor connection

EMI filter

AC reactor

Mains supply

Size F7 connection

Braking

resistor

BR1 BR2(+) (-)

Braking unit

reactor

MCCB

DC

Supply

ground

Braking

resistor

Supply

ground

―18― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

W

C

4.4 Control Board and I/O Board

Danger

arning

• The control circuit is basically isolated with the power circuit. Do not touch HD31 after it is powered.

• If the control circuit is connected to the external devices with live touchable port, it should increase an additional

isolating barrier to ensure that classification of external devices not be changed

• If connect the communication terminal of the control circuit to the PC, choose RS485/232 isolating converter

which meets the safety requirement.

• Only connect the relay terminal to AC 220V voltage signal. Other control terminal are strictly forbiden for this

connection.

HD31 includes control board and I/O board, as shown in Figure 4–2.

I/O Board

ontrol Board

4

Figure 4–2 Control board and I/O board

HD31 Series User Manual V1.1 ―19―

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

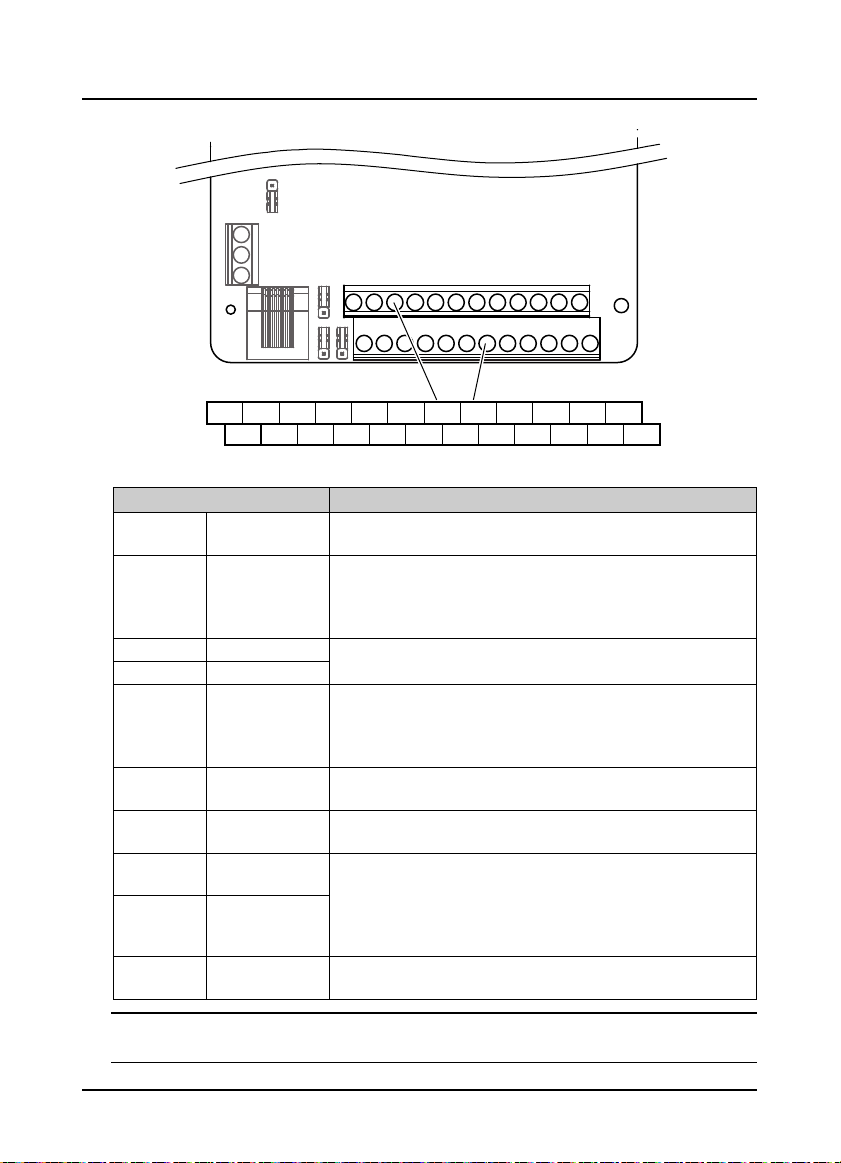

4.4.1 Control Board Terminal

Control Board

Ter min al

+10 A I1 AI2 DI1 DI2 DI3 DI 4 DI5 DI6 COM R1ACOM

GND

Ter mi na l Description

+10, GND

AI1, AI2 Analogue input

AO1, AO2 Analogue output

GND Analogue ground

DI1 - DI6 Digital input

P24, COM

SEL

DO1, CME Digital output

DO2, COM Digital output

R1A/R1B/R1C Relay output

Analogue power

supply

Digital power

supply

Digital input

common terminal

Note:

Limit the current within 3A if the relay terminal is to connect to AC 220V voltage signal.

―20― HD31 Series User Manual V1.1

AO1 AO2

Table 4-5 Control board terminal description

P24 SEL DO1 R1CGND COM CME DO2 R1B

Figure 4–3 Control board term inal

Analogue input use +10V power supply, max. output current is 100mA

GND is isolated to COM

AI1 Input voltage: 0 - 10V (input im pedance: 32kΩ)

AI2 Input voltage: -10 - +10V (input impedance: 32kΩ)

AI2 Input current: 0 - 20mA (input impedance: 500Ω)

• AI2 can be voltage / current selectable

Output voltage / current signal: 0 - 10V/0 - 20mA

Program mable output

Programmable bipolar optional input signal

Input voltage: 0 - 30VDC

DI1 - DI5 input impedance 4.7kΩ, DI6 input i mpedance 1.6kΩ

• DI6 can be selectable for high-frequency input, max-frequency 50kHz

Analogue input use +24V power supply, max. output current is 200mA

COM is isolated to CME

SEL and P24 are connected by default

• Disconnected SEL and P24 when use external power to drive DI

Programmable optical-couple isolation, open collector output

• Output voltage: 0 - 30VDC, max-output current 50mA

• DO2 can be selectable for pulse frequency output, max. frequency 50kHz

CME is isolated to COM, connected to COM by default

• Disconnect CME and COM when they are isolating output

Programmable output, contact rating: 250VAC/3A or 30VDC/1A

• R1B, R1C: normally closed; R1A, R1C: normally open

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

C

A

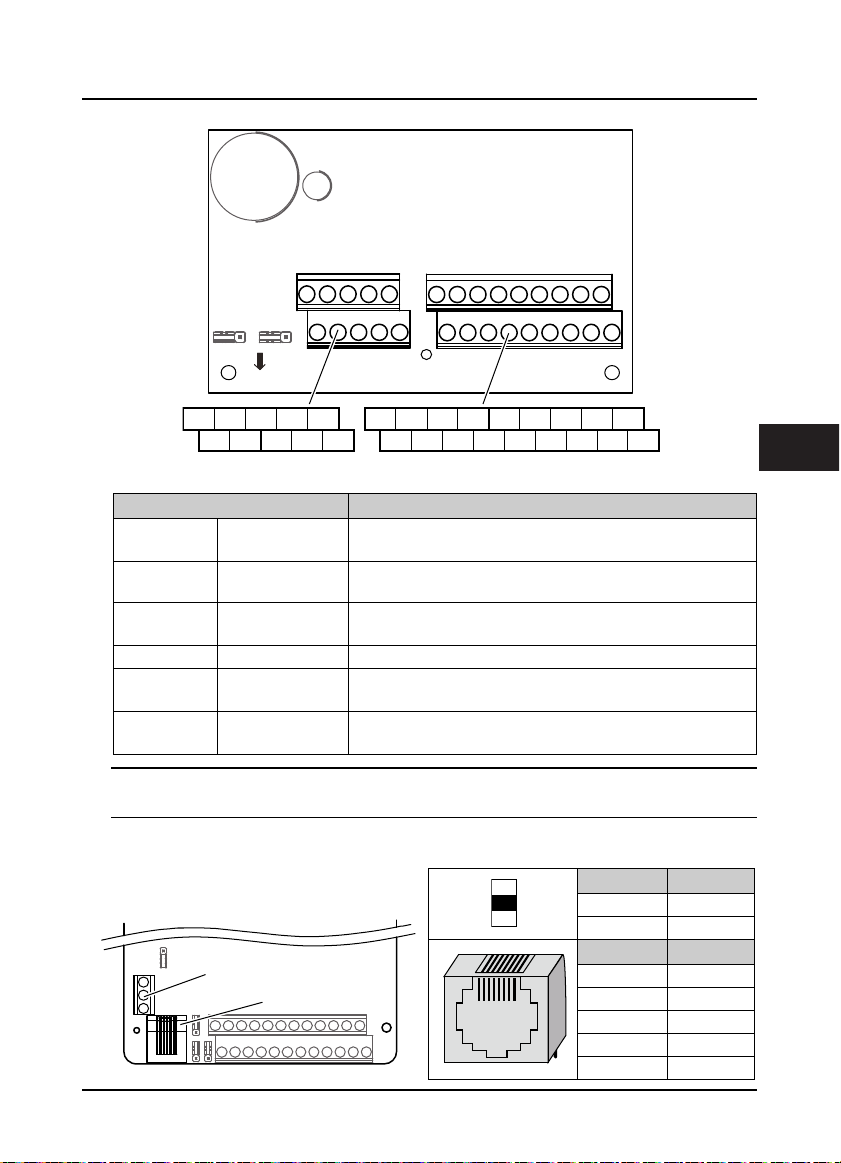

4.4.2 I/O Board Terminal

I/O Board

Ter min alTer min al

R10AR9AR2A R3A R4A R5A R6AR2A R3A R4A R5A R6A R7A R8A

R2A R3A R4A R5A R6A R10

Figure 4–4 I/O board ter minal

Table 4-6 I/O board terminal description

Ter mi na l Funct ion Des cription

AI3 / AI4 Analogue input

+10 / GND

DI7 - DI9 Digital input

P24, COM Digital power supply Digital input use +24V as supply, max. output current is 200mA

SEL

R2A/R2C R10A/R10C

Analogue power

supply

Digital input

common terminal

Relay output

Input voltage: -10 - +10V (input impedance: 32kΩ)

Input current: 0 - 20mA (input impedance: 500Ω)

Analogue input use +10V as supply, max. output current is 100mA

Programmable bipolar optional input, low le vel is effective by default.

Input voltage: 0 - 30VDC (input im pedance: 4.7kΩ)

SEL and P24 are connected by default

• Disconnected SEL and P24 when use external power to drive DI7 - DI9

Programmable normally open output

Contact rating: 250VAC / 3A or 30VDC / 1A

R9CR2C R3C R4C R5C R6C R7C R8C

Note:

Limit the current within 3A if the relay terminal is to connect to AC 220V voltage signal.

4.4.3 Modbus Communication Terminal

Do not use communication terminal and RJ45

simultaneously.

Ter min al

Control Board

RJ45

B

18

RJ45

Ter mi na l Description

A 485+

B 485-

Pin Difinition

1,3 +5V

2 485+

4,5,6 GND

7 485-

8 Unused

4

HD31 Series User Manual V1.1 ―21―

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

4.4.4 Jumper

CN9

CN6

CN7

Jumper Description

Control Board

CN8

Figure 4–5 Jumper posi tion

Table 4-7 Jumper description

1

Control

board

CN6

3

AI2 can select voltage or current signal.

• Pin 1 & 2 are short-connected, AI2 inputs voltage signal (factory setting).

• Pin 2 & 3 are short-connected, AI2 inputs cu rrent signal.

1

Control

board

CN7

3

AO1 can select voltage or current signal.

• Pin 1 & 2 are short-connected, AO1 outputs voltage signal (factory setting).

• Pin 2 & 3 are short-connected, AO1 outputs current signal.

1

Control

board

CN8

3

AO2 can select voltage or current signal.

• Pin 1 & 2 are short-connected, AO2 outputs voltage signal (factory setting).

• Pin 2 & 3 are short-connected, AO2 outputs current signal.

1

Control

board

CN9

I/O board

CN2

3

VI

SCI communication can select proper resistance.

• Pin 1 & 2 are short-connected, select the proper resistance.

• Pin 2 & 3 are short-connected, no resistance (factory setting).

31

AI3 can select voltage or current signal.

• Pin 1 & 2 are short-connected, AI3 inputs voltage signal (factory setting).

• Pin 2 & 3 are short-connected, AI3 inputs cu rrent signal.

CN2

I/O Board

CN3

31

AI4 can select voltage or current signal.

• Pin1 & 2 are short-connected, AI4 inputs voltage signal (factory setting).

• Pin2 & 3 are short-connected, AI4 inputs current signal.

I/O board

CN3

VI

―22― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 5 Keypad

W

Chapter 5 Keypad

Danger

• Only when the terminal cover of HD31 has been fitted can user switch on AC power source. Do not remove the

cover after power is switched on.

• Ensure the motor and the mechnical device are in the use application before HD31 starts.

• Keep away from HD31 if the auto-restart function is enabled at power outage.

• To change the PCBA, correctly set the parameters before running.

• Do not check or detect the signal during HD31 running.

• Do not randomly change HD31 parameter setting.

• Please thoroughly complete all control commissioning and testing, make all adjustments and conduct a full safety

assessment before switching the running command source of HD31.

• Do not touch the energy-depletion braking resistor due to the high temperature.

The standard HD31 are installed with LED keypad which is shown as Table 5-1.

Table 5-1 Key description of keypad

REVFWD ALM LO/RE LOCK

AVRPM%

Hz

Key Description

JOGPRG

ENTSHF

STOPRUN

arning

Entry or exit programming key

In the keypad control, jog start HD31

In the keypad control, press this key to run HD31

a. In the keypad control, press this key to stop HD31

b. In the detection fault, press this key to reset at fault

Set certain function by F00.12

Increase value or parameter

Decrease value or parameter

a. Select display parameter and shift bit

b. Stop in loop/Display the parameter during running

a. Enter lower menu

b. Confirm saving the data

5

HD31 Series User Manual V1.1 ―23―

Chapter 5 Keypad Shenzhen Hpmont Technology Co., Ltd.

The kaypad consists of 5 status indicators and 5 unit indicators and shown as Table 5-2.

Table 5-2 Indicator description of the keypad

Mark Name : Lighting : Flashing : Lightless

Forward status

Reverse status

Alarm status

Remote/Local

status

Password locked

status

Frequency unit

Current unit

Volt age un it

Rotary speed unit

% unit

HD31 is forward running

at the moment

HD31 is reverse running

at the moment

HD31 is faulty at the

moment

Indicate HD31 isn’t in

keypad control mode

The user password lock

of HD31 is avail

The unit of the present

parameter is Hz

The unit of the present

parameter is A

The unit of the current

parameter is V

The unit of the present

parameter is rpm

The unit of the present

function parameter is %

The start of HD31 is forward

running next time

The start of HD31 is reverse

running next time

The present parameter is

output frequency

The present parameter is

rotary speed unit

HD31 is well at the

moment

HD31 is in keypad

control mode

There is no user

password or unlocked

The keypad of HD31 has five LED displays and their meanings are shown in Table 5-3.

Table 5-3 LED display description

LED display Meaning LED display Meaning LED display Meaning LED display Meaning

0 A J U

1 b L u

2 C n y

3 c o -

4 d P Point

5 E q Full display

6 F r No display

7

8 h T

9 i t

H

S

Flash

modifiable

―24― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

Chapter 6 Function Introduction

This chapter will provide user with detail function introduction of each group.

Display Parameters:

d00: Status Display Parameters, on pages 26 - 29

General Parameters:

F00: Basic Parameters, on pages 29 - 31.

F01: Protection of Parameters, on pages 31 - 32.

F03: Acc / Dec Parameters, on page 33.

F05: External Setting Curve Parameters, on pages 33 -35.

F08: Asynchronous Motor Parameters, on page 35.

F09: V/f Control Parameters, on pages 35 - 36.

F15: Digital I/O Terminal Parameters, on pages 36 - 38.

F16: Analogue I/O Terminal Parameters, on pages 38 - 43.

F17: SCI Communication Parameters, on page 43.

F18: Display Control Parameters, on pages 43 - 44.

F19: Function-boost Parameters, on pages 44 - 45.

F20: Fault Protection Parameters, on pages 45 - 47.

F23: PWM Control Parameters, on page 47.

Specialized parameter for multi-pump water supply:

P00: Water Supply Logic Parameter, on pages 51 - 56.

P01: Water Supply Pump Parameter, on pages 56 - 57.

P02: Water Supply PID Parameter, on pages 57 -59.

P03: Water Supply AIO Function Parameter, on pages 59 - 61.

P04: Water Supply Fault Protection Parameter, on page 61.

P05: Water Supply Time, on page 61.

6

HD31 Series User Manual V1.1 ―25―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

6.1 Group d: Display Parameters

Users can directly check the status parameters by checking the function code of Group d.

6.1.1 d00: Status Display Parameters

Ref. Code Function Description Setting Range [Default]

d00.00 Inverter series [Actual value]

d00.01 Software version of the control board [Actual value]

d00.03 Special software version of the control board [Actual value]

d00.05 Software version of the keypad [Actual value]

d00.06 Customized series No. [Actual value]

d00.08 Rated current of the inverter [Actual value]

d00.09 Extended function of the inverter [Actual value]

Display extended function of HD31.

0: No extended function.

1: Constant pressure water supply function.

d00.10 Inverter status [Actual value]

Display HD31 status, as shown in the following table:

Bit13: Current limit

Bit15: Unused Bit14: Unused

Bit10: Speed limit value

Bit11: Unused

Bit7: DC braking

0: Invalid

1: Valid

Bit3: Zero speed

running

0: Invalid

1: Valid

123

d00.14 Setting frequency [Act ual value]

d00.15 Setting frequency (after Acc / Dec) [Actual value]

d00.16 Output frequency [Actual value]

d00.17 Setting RPM [Actual value]

d00.18 Running RPM [Actual value]

d00.19 Three -phase power supply input sequence phase [Actual value]

Display sequence phase of the three-phase input.

• 0: Positive sequence: L1 (R) preceding L2 (S) preceding L3 (T) .

• 1: Negative sequence: L1 (R) preceding L3 (T) preceding L2 (S).

d00.20 Output voltage [Actual value]

d00.21 Output current [Actual value]

d00.23 Output torque [Actual value]

Display output torque which is the relative percentage of the motor rated torque.

d00.24 Output power [Actual value]

Display present actual output power whose unit is 0.1kW.

0: Invalid

1: Valid

Bit6: Unused

Bit2: Forward / reverse

0: Forward

1: Reverse

0: Invalid

1: Valid

Bit9: Unused

Bit5&Bit4: Acc / Dec / Constant

00: Constant

11: Constant

Bit1: Run / stop

0: Stop

1: Run

―26― HD31 Series User Manual V1.1

Bit12: Stall overvoltage

0: Invalid

1: Valid

Bit8: Auto-tuning

0: Not in auto-tuning

1: In auto-tuning

01: Acc

10: Dec

Bit0: Inverter fault

0: No fault

1: Fault

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

Ref. Code Function Description Setting Range [Default]

d00.25 DC bus voltage [Actual value]

d00.26 Potentiometer input voltage of the keypad [Actual value]

Display potentiometer input voltage of the keypad.

d00.27 AI1 voltage [Actual value]

Display AI1 input voltage.

d00.28 AI1 voltage (after calculating) [Actual value]

Display A1 input voltage which is calculated by the gain, bias and filter.

d00.29 AI2 voltage [Actual value]

Display AI2 input voltage.

When selects current input, 0V corresponds to 0m A and 10.00V corresponds to 20mA.

d00.30 AI2 voltage (after calculating) [Actual value]

Display AI2 input voltage which is calculated by the gain, bias and filter.

d00.31 AI3 voltage [Actual value]

Display AI3 input voltage.

When selects current input, 0V corresponds to 0m A and 10.00V corresponds to 20mA.

d00.32 AI3 voltage (after calculating) [Actual value]

Display AI3 input voltage which is calculated by the gain, bias and filter.

d00.33 AI4 voltage [Actual value]

Display AI4 input voltage.

When selects current input, 0V corresponds to 0m A and 10.00V corresponds to 20mA.

d00.34 AI4 voltage (after calculating) [Actual value]

Display AI4 input voltage which is calculated by the gain, bias and filter.

d00.35 DI6 pulse input frequency [Actual value]

Display DI6 terminal pulse input frequency (Hz).

d00.36 AO1 output [Actual value]

Display AO1 output. When selects current output, 0V corresponds to 0mA and 10.00V corresponds to 20mA.

d00.37 AO2 output [Actual value]

Display AO2 output. When selects current output, 0V corresponds to 0mA and 10.00V corresponds to 20mA.

d00.38 High-speed output pulse frequency [Actual value]

Display high-speed output pulse frequency (Hz).

d00.39 Heatsink temperature [Actual value ]

Display heatsink temperature.

d00.42 Set water supply pressure [Actual value]

When the system is supplying water at constant pressure, the current supply pressure will be displayed.

d00.43 Actual water supply pressure [Actual value]

When the system is supplying water at constant pressure, system pressure value detected by remote

pressure gauge will be displayed.

d00.44 PID setting [Actual value]

Display PID setting relative to full scale (10.00V) percentage.

d00.45 PID feedback [Actual value]

Display PID feedback relative to full scale (10.00V) percentage.

d00.46 PID tolerance [Actual value]

Display PID tolerance relative to full scale (10.00V) percentage.

6

HD31 Series User Manual V1.1 ―27―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

Ref. Code Function Description Setting Range [Default]

d00.47 PID integral item [Actual value]

d00.48 PID output [Actual value]

d00.49 External counting value [Actual value]

d00.50 Input terminal status [Actual value]

Display input terminal status. Each bit (binary) of this parameter stands for different physical sources which

d00.51 Output terminal status [Actual value]

Display output terminal status. Each bit (binary) of this parameter stands for different physical sources

d00.55 Total time at power-on [Actual value]

d00.56 Total time at running [Actual value]

d00.55 displays total time at power-on; d00.56 displays total time at running. The unit is hour.

d00.57 High bit of motor total energy consumption [Actual value]

d00.58 Low bit of motor total energy consumption [Actual value]

Display high bit (d00.57) and l ow bit (d00.58) of the motor total energy consumption.

d00.59 High bit of energy consumption at this time running [Actual value]

d00.60 Low bit of energy consumption at this time running [Actual value]

Display high bit (d00.59) and low bit (d00.60) of energy consumption at this time running.

d00.61 Present fault [Actual value]

Display present fault.

Display PID integral item relative to full scale (10.00V) percentage.

Display PID output to full scale ( 10.00V) percentage.

are in the below table.

• 0: Input terminals disconnect with common terminals.

• 1: Input terminals connect with common terminals.

Bit11 Bit10 Bit9 Bit8 Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

- - - DI9 DI8 DI7 DI6 DI5 DI4 DI3 DI2 DI1

123

which are in the below table.

• 0: Output terminals disconnect with common terminals.

• 1: Output terminals connect with common terminals.

Bit11 Bit10 Bit9 Bit8 Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

RLY10 RLY9 RLY8 RLY7 RLY6 RLY5 RLY4 RLY3 RLY2 RLY1 DO2 DO1

123

• Displaying 100 means undervoltage.

―28― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

6.2 Group F: General Parameters

6.2.1 F00: Basic Parameters

Ref. Code Fun ction De scripti on Setting Range [Default]

F00.01 Motor control mode 0 - 2 [0]

0: V/f control. Constant voltage/frequency ratio control.

• It is specially applicable for occasions when one inverter drives more than one motors to achieve

proper efficiency.

• When select V/f control, please properly set the V/f control Group F09 to achieve proper efficiency.

1: Unused.

2: SVC control. Sensorless vector control.

• It is applicable for application with high requirement on inverter performance and torque.

• At first, it must perform motor parameter auto-tuning. And then adjust the settings of F08.00 - F08.04

according to the nameplate of the motor. Start the motor parameter auto-tuning function and

properly set Group F10 parameters, so as to achieve excellent vector control efficiency.

F00.02 Inverter type setting 0,1 [1]

0: G type, to drive heavy and general motor.

F00.04 Extension card selection 0,2 [2]

0: Invalid.

F00.05 HD31 extended function 0,1 [0]

0: No extended.

F00.06 Max. output frequency of HD31 50.00 - 400.00 [50.00Hz]

Defines the max. frequency that HD31 is allowed to output.

F00.07 Upper limit of running frequency setting source 0 - 2 [0]

Defines the highest frequency that user can set, and select setting sources to set the upper limit frequency

F00.08 Upper limit of running frequency 0 - F00.06 [50.00Hz]

F00.07 = 0, the upper limit frequency is set by F00.08.

F00.09 Lower limit of running frequency 0 - F00.08 [0.00Hz]

Use F00.09 to limit the actual output frequency. When the setting frequency value < F00.09, it will operate

1: P type, to drive pump and fan.

2: HD30-WIO extension valid.

1: Constant pressure water supply.

• Be careful to set reasonable parameters accordin g to the nameplate of the motor and the actual running

condition s.

via F00.07.

0: Digital setting. Set the upper limit frequency by F00.08.

1: Analogue input setting. Refer to Group F16.

2: DI6 pulse setting. Set by F16.17, and its max. pulse input frequency corresponds to F00.06 (max. output

frequency of HD31).

at lower limit frequency.

• Properly set the parameters according to the nameplate of the motor and actual running conditions.

• No limitation on the motor parameter auto-tuning function.

• Besides the lower /upper limit frequency, the running frequency of inverter is also limited by the

parameter settings of skip frequency (F05.17 - F05.19).

6

HD31 Series User Manual V1.1 ―29―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

Ref. Code Fun ction De scripti on Setting Range [Default]

F00.10 Frequency setting sources 0 - 4 [0]

0: Keypad setting. Change the value by pressing the or key of the keypad.

F00.11 Command setting source 0 - 2 [0]

0: Keypad setting. Start and stop the inveter by pressing , and .

F00.12 M key function 0 - 2 [2]

0: Switch running direction. Switch the keypad running direction by key.

F00.13 Starting frequency digital setting 0 - upper limit [50.00Hz]

F00.10 = 0 or 1, F00.13 sets the initial frequency value.

F00.14 UP / DOWN digital setting 000 - 111 [000]

Only valid when F00.11 = 0 or 1.

Initial value is set by F00.13.

1: Terminal digital setting. Change the value by using the terminals UP / DN, F00.13 sets initial value.

2: SCI communication setting. Change the setting frequency by SCI communication frequency command.

• The initial value of the SCI communication frequency is 0.

3: Analogue setting. Set by the analogue input voltage.

• Refer to Group F16.

• Refer to Group F5 for the corresponding relationship between the analogue value and the running

frequency of HD31.

4: DI6 pulse setting.

• The specification of input pulse signal: voltage range 15 - 30V; frequency range 0 - 50.0kHz.

• Refer to Group F05 for the corresponding relationship between the pulse terminal frequency and the

running frequency of HD31.

1: Terminal setting. Start and stop by using the corresponding external terminals.

• DI terminal is set as FWD (No. 2 function), REV (No. 3 function), refer to Group F15.

2: SCI communication setting. Start and stop by SCI communication port according to communication

protocol.

• F00.11 = 0, it is valid. Do not save when power is off.

1: Switch local and remote control. Switch the local and remote control by key.

• F00.11 = 0 or 1, it is valid.

2: Invalid.

• The current setting frequency value will be replaced by a new one when the value of the F00.13 has been

changed by setting the parameter.

Units: Save selection of frequency setting at power outage

• 0: Do not save at power outage.

• 1: Save to F00.13 at power outage.

Tens: Control selection of frequency setting at stop

• 0: Do not restore to F00.13 at stop.

• 1: Restore to F00.13 at stop.

Hundreds: Save selection of communication setting frequency

• 0: Do not save when power is off.

• 1: Save to F00.13 when power is off.

―30― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

J

Ref. Code Fun ction De scripti on Setting Range [Default]

F00.15 Jog running frequency digital setting 1 0 - upper limit frequency

F00.16 Interval of jog running 0.0 - 100.0 [0.0s]

After cancel the jog command, HD31 will not

respond to the jog command at the interval of jog

running set by F00.16.

• After the interval of jog is completed, it

immediately executes the arrived jog

command. As show in figure.

F00.17 Running direction 0,1 [0]

0: The same as running command.

1: Opposite to running command.

F00.18 Reverse 0,1 [0]

This function is valid when F00.11 = 0,1,2.

0: Permitted.

1: Prohibitted. It can respond to the FWD / REV commands. When the analogue value is set to positive /

negative voltage and the negative voltage corresponds to the reverse frequency, HD31 will run in

accordance with the zero -frequency run.

F00.19 Dead time of direction switch 0.0 - 3600.0 [0.0s]

Defines the dead time of direction switch, namely, the time of

zero-frequ ency output in th e process of direction switch sho wn as

the right figure.

F00.20 Key enable of optional keypad 0,1 [0]

0: Enabled. When HD31 connects to two keypads, the keys of optional display using the communication

port can be operated.

1: Invalid. When HD31 connects to two keypads, the keys of optional display using the communication port

can not be operated.

F00.21 Dormant function 0,1 [0]

0: Disabled. This function is invalid.

1: Enabled. At running status, when the setting frequency ≤ lower limit of running frequency (F00.09), HD31

coasts to stop and enters dormant status.

F00.22 Dormancy wake up time 0.0 - 360.0 [0.0s]

When HD31 is at dormanc y status, and the setting frequency > lower limit of running frequency (F00.09),

and the duration achieves the setting time of F00.22, then HD31 wakes up from dormancy status, and starts

at the mode of F02.00.

og running

frequency

Jog command

Frequ ency

Acc Dec

Frequ ency

FWD

0

F00.16

F00.19

[5.00Hz]

Time

Time

Time

REV

6

HD31 Series User Manual V1.1 ―31―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

H

6.2.2 F01: Protection of Parameters

Ref. Code Fun ction De scripti on Setting Range [Default]

F01.00 User’s password 00000 - 65535 [00000]

XXXXX: To enable the password protection function, set any non-zero numbe r as the password.

• Once the password is set, to change any parameter, input correct password. Otherwise, all the

parameters cannot be changed but only read.

• When input correct password, by pressing key to exit to stop / run display status or by detecting

no press on the keypad within 5 minutes, the user’s password will be valid. To change parameters, input

correct password. It will restart when there is no press on the keypad within 5 minutes.

00000 : The factory setting of F01.00 is 00000, namely the password protection function is disabled.

• If user unlocks the password, it means clearing the user’s password.

F01.01 Menu mode 0,1 [0]

0: Full menu mode. All function parameters can be displayed.

F01.02 Function code parameter initialization (download) 0 - 6 [0]

0: No operation. HD31 is in regular parameter read / write status.

F01.03 Keypad EEPROM parameter initialization (upload) 0 - 2 [0]

0: No operation. HD31 is in regular parameter read / write status.

1: Checking menu mode. Only parameters different from factory setting can be displayed.

• Whether can change the parameter depends on user’s password

status and the actual running condition of HD31.

1: Restore to factory settings.

• Except F01.00, F01.02, F01.03, F19.19, F19.24, F20.08, F20.09, F20.21 -

F20.37, F23.00.

• Steps: If set F01.02 = 1, press to ensure and the parameters are

restored to factory settings. The keypad dispalys “rESEt”. Then the

keypad will display parameters in stop status after finish restoring to

factory setting.

2: Download the keypad EEPROM parameter 1 to the current function code settings.

3: Download the keypad EEPROM parameter 2 to the current function code settings.

4: Clear fault information. The fault history of F20.21 - F20.37 will be clear.

5: Download the keypad EEPROM parameter 1 to the current function code settings (including the motor

parameters).

6: Download the keypad EEPROM parameter 2 to the current function code settings (including the motor

parameters).

1: Upload the current function code settings to the keypad EEPROM

parameter 1.

2: Upload the current function code settings to the keypad EEPROM

parameter 2.

Note: F01.00, F01.02, F01.03, F20.21 - F20.37 and Group y do not upload or

download

Download

Keypad store d

functionparameter

F01.02 = 2 / 3 / 5 / 6

Upload

D31 pr esent s etti ng

function parameter

F01.0 3 = 1 /2

Keypad

HD31

Keypad

HD31

―32― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

e

6.2.3 F03: Acc / Dec Parameters

Ref. Code Funct ion Des cription Setting Range [Default]

F03.01 Acc time 0.1 - 6000.0

[18.5kW and below: 10.0s]

F03.02 Dec time

Acc time is the time that output frequency accelerates from

0 Hz to F00.06 (the max-output frequency) in linear form.

Dec time is the time that output frequency decelerates from

F00.06 (the max-output frequency) to 0 Hz in linear form.

F03.15 Acc time of jog running 0.1 - 6000.0 [6.0s]

F03.16 Dec time of jog running 0.1 - 6000.0 [6.0s]

F03.15 and F03.16 define the Acc / Dec time of jog running.

F03.17 Dec time of emergency stop 0.1 - 6000.0 [10.0s]

Defines the Dec time of emergency stop.

Frequ ency

F00.06

0

F03.01 F03.02

[22 - 75kW: 30.0s]

[90kW and above: 60.0s]

Tim

6.2.4 F05: External Setting Curve Parameters

Ref. Code Func tion Des criptio n Setting Range [Default]

F05.00 External setting curve 00000 - 22222 [00000]

Units: AI1 curve.

Ten s: A I2 c urv e.

Hundreds: AI3 curve.

Thousands: AI4 curve.

Ten thousands: Pulse input curve.

Each bit setting:

• 0: Line 1.

• 1: Line 2.

• 2: Polyline.

F05.01 Min. setting of line 1 0.0 - F05.03 [0.0%]

F05.02 Min. setting corresponding value of line 1 0.0 - 100.0 [0.0%]

F05.03 Max. setting of line 1 F05.01 - 100.0 [100.0%]

F05.04 Max. setting corresponding value of line 1 0.0 - 100.0 [100.0%]

F05.05 Min. setting of line 2 0.0 - F05.07 [0.0%]

F05.06 Min. setting corresponding value of line 2 0.0 - 100.0 [0.0%]

F05.07 Max. setting of line 2 F05.05 - 100.0 [100.0%]

F05.08 Max. setting corresponding value of line 2 0.0 - 100.0 [100.0%]

F05.09 Max. setting of polyline F05.11 - 100.0 [100.0%]

F05.10 Max. setting corresponding value of polyline 0.0 - 100.0 [100.0%]

F05.11 Inflection point 2 setting of polyline F05.13 - F05.09 [100.0%]

F05.12 Inflection point 2 corresponding value 0.0 - 100.0 [100.0%]

F05.13 Inflection point 1 setting of polyline F05.15 - F05.11 [0.0%]

F05.14 Inflection point 1 corresponding value 0.0—100.0 [0.0%]

F05.15 Min. setting of polyline 0.0 - F05.13 [0.0%]

6

HD31 Series User Manual V1.1 ―33―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

Ref. Code Func tion Des criptio n Setting Range [Default]

F05.16 Min. setting corresponding value of polyline 0.0 - 100.0 [0.0%]

F05.01 - F05.04 define line 1. F05.05 - F05.08 define line 2. F05.09 - F05.16 define the polyline.

• Line 1, line 2 and the polyline can independently achieve positive and negative characteristics as shown

in following figure.

• If the curve min. setting is the same as max. setting, it is a line. The default frequency is the corresponding

frequency of the curve min. setting.

Setting

corresponding value

F05.04

F05.08

Positive and negative characteristic of line

Setting

corresponding value

F05.02

F05.06

F05.02

F05.06

F05.01

F05.10

F05.12

F05.14

F05.16

In the figure:

• P / A is terminal pulse / analogue setting.

• Pulse frequency (P) is 100% corresponding to F16.17 max. input pulse frequency.

• Analogue input (A) is 100% corresponding to 10V or 20mA.

F05.17 Skip frequency 1 F00.09 - upper limit [0.00Hz]

F05.18 Skip frequency 2

F05.19 Skip frequency 3

F05.20 Range of skip frequency 0.00 - 30.00 [0.00Hz]

The setting of skip frequency is for output frequency of HD31 to avoid resonance with the load.

• HD31 will skip the above frequencies as shown in

figure. Up to 3 skip frequency ranges can be set.

• During the process of Acc / Dec, HD31 will run with

countinous frequency output, ignoring the skip

frequency ranges. But HD31 will not run at

constant speed in the skip frequency ranges.

• Frequency setting is uncontinuous, while

frequency output is continuous.

F05.05

Setting corresponding value Setting corresponding value

Inflection point 2

Inflection point 1

F05.15

F05.13 F05.11 F05.09 F05.15 F05.13 F05.11 F05.09

P/A(setting) P/A(setting)

F05.03

F05.07

Positive and negative characteristic of polyline

P/A(setting) P/A(setting)

F05.04

F05.08

F05.16

F05.14

F05.12

F05.10

F05.19

F05.18

F05.17

F05.01

F05.05

Setting frequ ency after c alculated

F05.03

F05.07

Inflection point 1

Inflection point 2

Settingfrequency

Skip range

―34― HD31 Series User Manual V1.1

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Function Introduction

6.2.5 F08: Asynchronous Motor Parameters

R1 R2LI

I1 I2

U1

Io

L

m

LI

1-S

R2

S

R1=F08.07 (Stator resistance)

R2=F08.08 (Rotor resistance)

Io=F08.11 (Excitation current)

LI=F08.09 (Leakage inductance)

Lm=F08.10 (Mutual inductance)

S=Slipratio

The idling excitation current (F08.11) can be calculated by the rated current (F08.02) and power factor

(F08.05) or detected by parameter auto-tuning (F08.06 = 2).

The relationship between rated torque current, F08.11 and F08.02 is below:

Ratedtorquecurrent F08.05F08.02

IdlingexcitationcurrentF08.11 1 F08.052F08.02

MutualinductanceF08.10

Note: Except F08.03, F08.04 and F08.06, the other factory settings are depended on motor.

Ref. Code Func tion Des cription Setting Range [Default]

F08.00 Rated power of motor 0.2 - 500.0kW

F08.01 Rated voltage of motor 0 - 999V

F08.02 Rated current of motor 7.5kW above motor 0.1 - 999.9A

7.5kW and below motor 0.01 - 99.99A

F08.03 Rated frequency of motor 1.0 - 400.0 [50.0Hz]

F08.04 Rated RPM of motor 1 - 24000 [1500rpm]

F08.03 and F08.04 should be set in accordance with the parameters of motor nameplate.

F08.05 Power factor of motor 0.001 - 1.000

F08.06 Parameter auto-tuning of motor 0 - 2 [0]

0: Auto-tuning is disabled.

1: Stationary auto-tuning.

• In the process of stationary auto-tuning, the motor is at rest. The stator resistance, rotor resistance and

leakage inductance will be measured and written into F08.07, F08.08 and F08.09 automatically.

2: Rotary auto-tuning.

• In process of rotary auto-tuning, the motor is at rest at the beginning, and the stator resistance, rotor

resistance and leakage inductance will be measured. Hinterher the motor will start rotating,

accordingly mutual inductance and idling excitation inductance will be measured automatically. All the

measured values above will be saved respectively in F08.07, F08.08, F08.09, F08.10 and F08.11

• When the motor is in rotating status, oscillation, even overcurrent, might occur. In this case, press the

key to stop auto-tuning and then adjust the F09.15 (oscillation-suppression mode) and F09.16

(oscillation-suppression coefficient) suitably to mitigate the possible oscillation.

Note: The auto-tuning is enabled only in keypad control mode (F00.11 = 0).

F08.01

2√3πF08.03F08.11

F08.09

6

HD31 Series User Manual V1.1 ―35―

Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

V

y

V

Ref. Code Func tion De scripti on Setting Range [Default]

F08.07 Stator resistance of motor 7.5kW above motor 0.000 - 9.999Ω

7.5kW and below motor 0.00 - 99.99Ω

F08.08 Rotor resistance of motor 7.5kW above motor 0.000 - 9.999Ω

7.5kW and below motor 0.00 - 99.99Ω

F08.09 Leakage inductance of motor 7.5kW above motor 0.00 - 500.00mH

7.5kW and below motor 0.0 - 5000.0mH

F08.10 Mutual inductance of motor 7.5kW above motor 0.00 - 500.00mH

7.5kW and below motor 0.0 - 5000.0mH

F08.11 Idling excitation current of motor 7.5kW above 0.0 - 999.9A

7.5kW and below 0.00 - 99.99A

Auto-tuning steps:

• 1. Input correct motor parameters as per its nameplate (F08.00 - F08.04).

• 2. When F08.06 is set as 2, set proper Acc time (F03.01) and Dec time (F03.02) and make sure the motor is

disconnected with the load for security.

• 3. Set F08.06 as 1 or 2 firstly, then press the key, and therewith press key to star t auto-tuning.

The LED will display “tunE”.

• 4. When the RUN indicator is flashing, it indicates that auto-tuning has been completed.Now the keypad

displays the parameters of stop status and F08.06 resets to 0.

6.2.6 F09: V/f Control Parameters

Ref. Code Name Description Setting Range [Default]

F09.00 V/f curve of motor 0 - 4 [0]

Defines flexible V/f setting modes so as to meet requirements of different load characteristics.

F09.01 V/f frequency of motor (F3) F09.03 - F08.03 [0.00Hz]

F09.02 V/f voltage of motor (V3) F09.04 - F08.01 [0V]

F09.03 V/f frequency of motor (F2) F09.05 - F09.01 [0.00Hz]

F09.04 V/f voltage of motor (V2) F09.06 - F09.02 [0V]

F09.05 V/f frequency of motor (F1) 0.00 - F09.03 [0.00Hz]

F09.06 V/f voltage of motor (V1) 0 - F09.04 [0V]

F09.01 - F09.06 is user- definable V/f curve.

• Four curves and one user-defined curve can be selected

according to the setting of F09.00.

0: Line. Shown as curve 0 in figure.

1: Square curve. Shown as curve 1 in the figu re.

2: 1.2 exponential curve. Shown as curve 2 in the Figure.

3: 1.7 exponential curve. Shown as curve 3 in the Figure.

4: User-defined curve.

• If F09.00 = 4 (user-definable curve), F09.06 is

enabled.

• The V/f curve can be defined by connecting 3

points of (V1, F1), (V2, F2) and (V3, F3), to

adapt to special load.

• According to the actual condition, set proper

curve to meet the requirements of load

characteristics.

F09.02×F08.01

F09.04×F08.01

F09.06×F08.01

F08.01

0

1/3

×F08. 01

F08.01

oltage