Page 1

V1.1 2017.07

HD09 Series

Smart Inverter

User Manual

Single-phase 220 - 240V, 0.25 - 2.2kW

Three-phase 380 - 460V, 0.4 - 5.5kW

Page 2

FOREWORD

Thank you for purchasing HD09 series smart inverter manufactured by Shenzhen

Hpmont Technology Co., Ltd.

This User Manual describes how to use HD09 series inverters and their installation

wiring, parameter setting, troubleshooting and daily maintenance etc.

Before using the product, please read through this User Manual carefully. In addition,

please do not use this product until you have fully understood safety precautions.

Note:

Preserve this Manual for future use.

If you need the User Manual due to damage, loss or other reasons, please contact

the regional distributor of our company or directly contact our company Technical

Service Center.

If you still have some problems during use, please contact our company Technical

Service Center.

Due to product upgrade or specification change, and for the purpose of

improving convenience and accuracy of this manual, this manual’s contents may

be modified.

Telephone: 4008-858-959 or 189 4871 3800

Page 3

Version and Revision Records

Version information: At the bottom right corner of the front cover.

Time: 2017/07

Version: V1.1

Revised chapter Revised contents

Chapter 4

Chapter 5

• AI termials can be selected as DI input, see clause 4.2

• Modify input and output routh, see clause 5.1.1

• Add selection of power terminals wiring lugs, see clasue 5.1.2

Chapter 8 • Add F00.17 (Running direction), F00.19 (Dead time from positive rotation to oppositve

rotation), F00.20 (External keypad), F00.21 – F00.25 (Sleep function)

• Add parameter copy function: F01.02 add function 2/3, add parameter F00.13

• Add F03.03 – F03.16 (Ace. and Dec. parameter)

• Modify F04.16 (Integral regulation selection) default value: [0]

• Modify F06.01 - F06.06 (Multi-frequency) default value: [5.0Hz]

• Add F08.04 (Rated Rpm of motor)

• Add F09.09 – F09.12 (Motor compensation function), F09.14 (Auto-voltage adjustment

function). Modify defination of F09.15: Oscillation-suppression mode

• Add F15.44 (AI as function of DI). DI function (F15.00 – F15.03, F15.44) add: 26/27 (Ace. and

Dec. time selection)

• Modify F17.03 (Host PC response time) default: [1ms], add F17.10 (Detecting time when

network communication over time)

• Add group F18 (Display control parameter)

• Add F19.12 – F19.15 (Instant power failure without stop), F17.37 (Frequency adjust range),

F17.39 (Input voltage)

• Add F20.00 (Over-load protection function)

Page 4

CONTENTS

Chapter 1 Safety Information .................................................................................................................................. 1

Chapter 2 Product Information ............................................................................................................................... 3

2.1 Nameplate ................................................................................................................................................................. 3

2.2 Rated Value ............................................................................................................................................................... 4

Chapter 3 Machenical Installation .......................................................................................................................... 5

3.1 Dimension and Weight ......................................................................................................................................... 5

3.2 Requirement for the Installation Site .............................................................................................................. 6

3.3 Installation of Exterior Keypad ........................................................................................................................... 7

Chapter 4 Electrical Installation .............................................................................................................................. 9

4.1 Power Terminals and Connection ................................................................................................................... 10

4.2 Control Terminals and Connection ................................................................................................................. 11

4.3 External Keypad or Upper Computer ............................................................................................................ 14

Chapter 5 Technical Data ....................................................................................................................................... 15

5.1 Peripheral Accessories Selection ..................................................................................................................... 15

5.2 Braking Resistor ..................................................................................................................................................... 16

5.3 Technical Data ........................................................................................................................................................ 17

Chapter 6 Keypad .................................................................................................................................................... 19

Chapter 7 Troubleshooting .................................................................................................................................... 21

Chapter 8 Parameter ............................................................................................................................................... 25

Page 5

Page 6

Shenzhen Hpmont Technology Co., Ltd. Chapter 1 Safety Information

HD09 Series User Manual V1.1 -1-

Chapter 1 Safety Information

Safety Definition

Pay attention to contents with following marks in the user manual or on the product.

Danger: A Danger contains information which is critical for avoiding safety hazard.

War ning: A Warning contains information which is essential for avoiding a risk of damage to products or other

equipements..

Note: A Note contains information which helps to ensure correct operation of the product.

Professional Staff

Only qualified electrical engineer can perform electrical installation.

Only professional staff that received special training and authorized can carry out maintenances.

Danger

W

arning

Note

Page 7

Page 8

Shenzhen Hpmont Technology Co., Ltd. Chapter 2 Product Information

HD09 Series User Manual V1.1 -3-

Chapter 2 Product Information

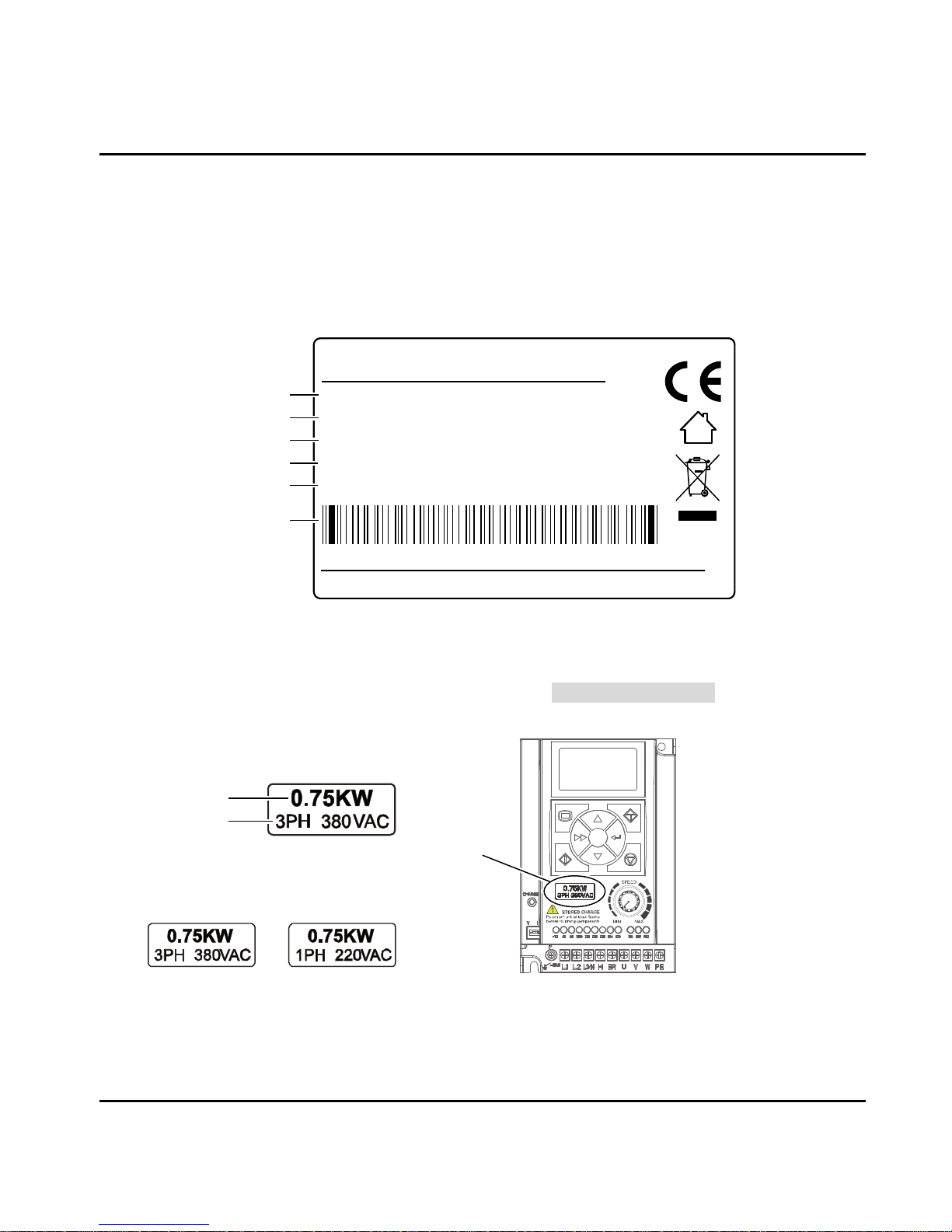

2.1 Nameplate

Nameplate Label

Name plate label is pasted on right side of the product. Its contents are shown in the following figure.

Power Label

Power label is below the keypad for recognizing the products easily and quickly.

Power label includes motor power and supply voltage. See 2.2 Rated Value, page 4.

Its contents are shown in the following figure.

MODEL:

HD09-4T0P7G

0.75kW

POWER:

3PH 380-460V 3.4A 50/60Hz

INPUT:

1.5kVA 0-460V 2.3A 0-1000Hz

OUTPUT:

1.00Version:

Product model

Motor power

Input specification

Output specification

Software version

Serial number

HD09-4T0P7G

Power Label

HD09-2S0P7G

Power Label

Power Label

Motor power

Power voltage

Page 9

Chapter 2 Product Information Shenzhen Hpmont Technology Co., Ltd.

-4- HD09 Series User Manual V1.1

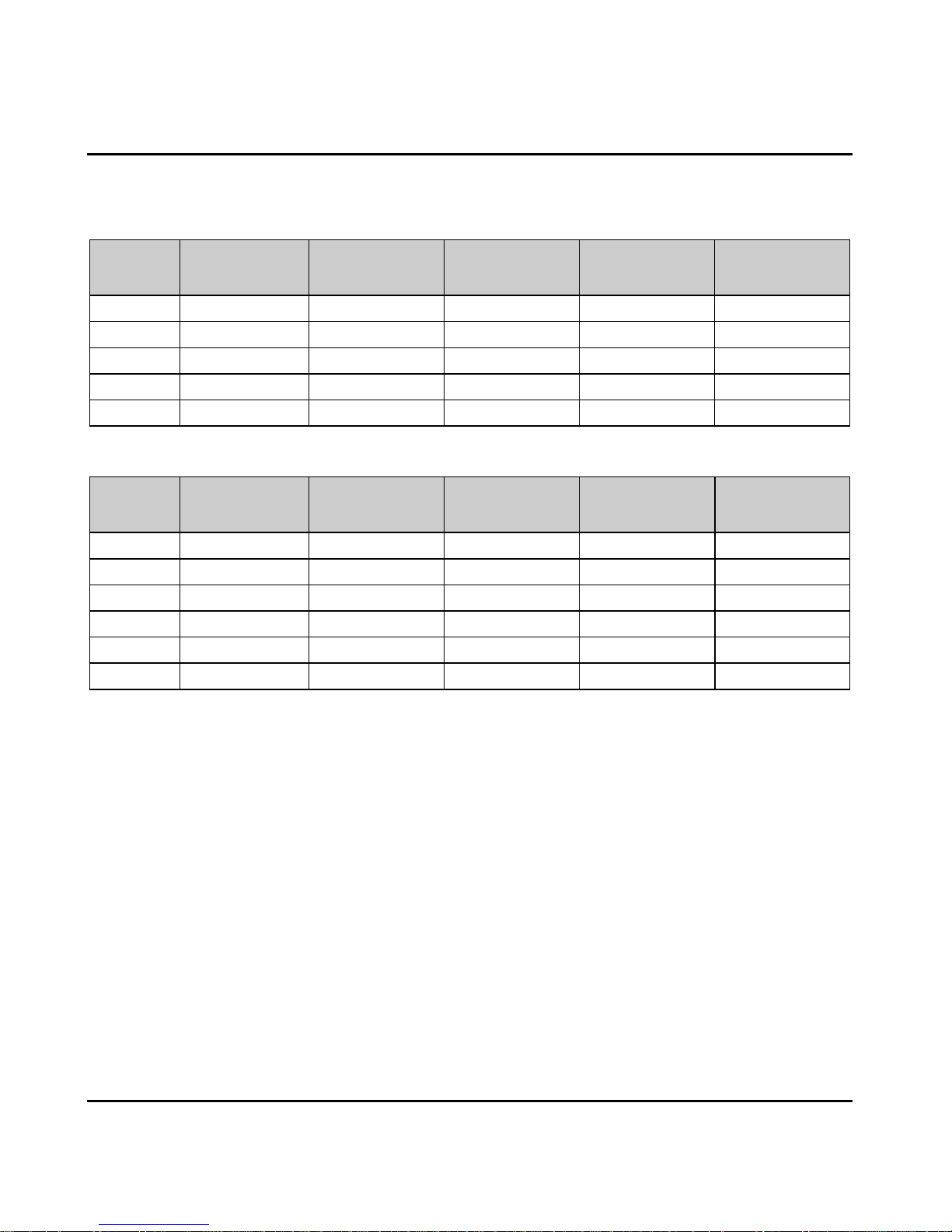

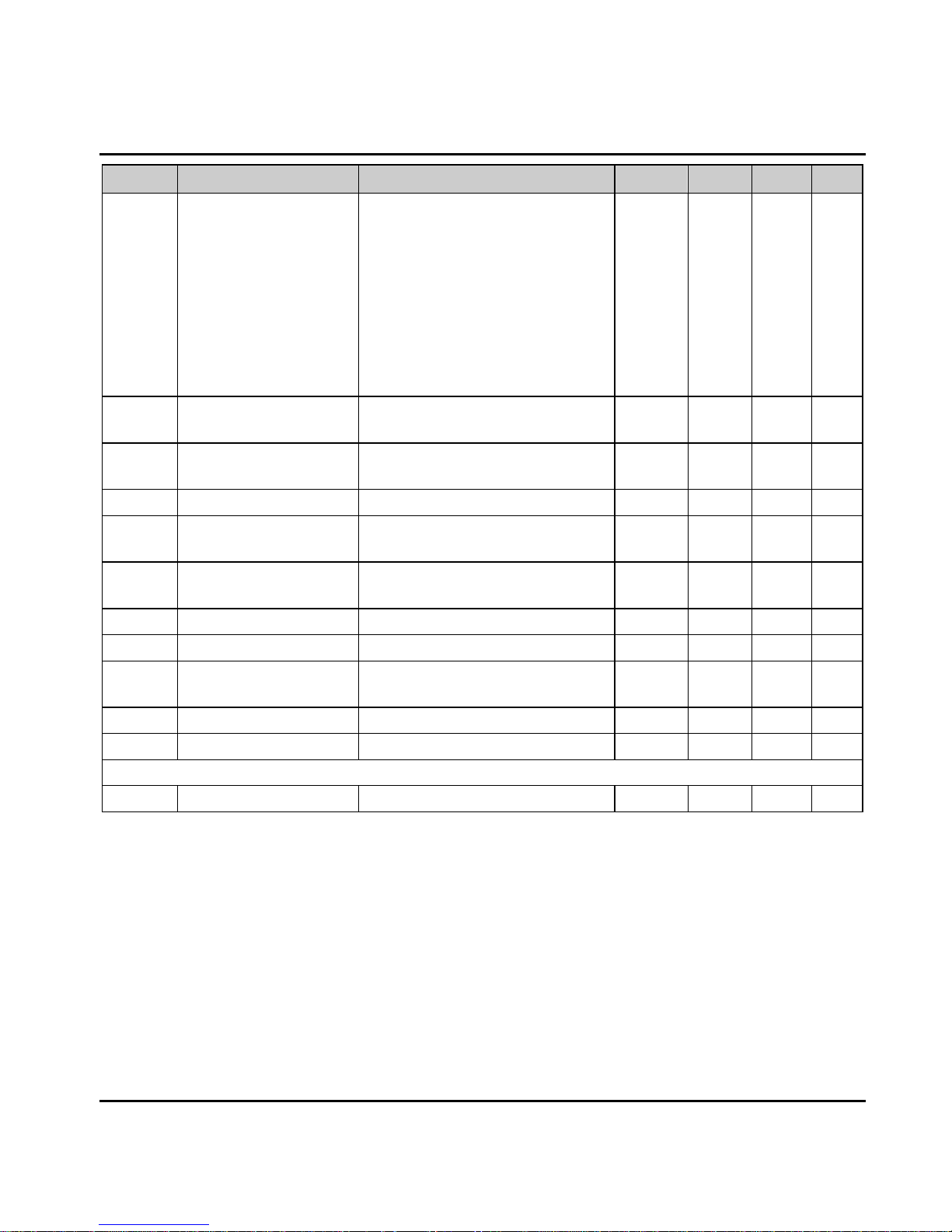

2.2 Rated Value

Single-phase: 200 - 240V, 50/60Hz

Size Model

Motor power

(kW)

Rated input

current (A)

Rated volume

(kVA)

Rated output

current (A)

Size A HD09-2S0P2G 0.25 4.3 0.6 1.7

Size A HD09-2S0P4G 0.4 5.8 1.0 2.5

Size A HD09-2S0P7G 0.75 10.5 1.5 4.0

Size A HD09-2S1P5G 1.5 18.5 2.8 7.5

Size A HD09-2S2P2G 2.2 24.1 3.8 10.0

Three-phase: 380 - 460V, 50/60Hz

Size Model

Motor power

(kW)

Rated input

current (A)

Rated volume

(kVA)

Rated output

current (A)

Size A HD09-4T0P4G 0.4 1.8 1.0 1.4

Size A HD09-4T0P7G 0.75 3.4 1.5 2.3

Size A HD09-4T1P5G 1.5 5.2 2.5 3.8

Size A HD09-4T2P2G 2.2 7.3 3.4 5.1

Size B HD09-4T4P0G 4.0 11.9 5.9 9.0

Size B HD09-4T5P5G 5.5 15.0 8.5 13.0

Page 10

Shenzhen Hpmont Technology Co., Ltd. Chapter 3 Machenical Installation

HD09 Series User Manual V1.1 -5-

Chapter 3 Machenical Installation

• After opening the package, if damage or incompleteness is found, please do not install it and

contact our distributor or us for solutions.

• When conveying the inverter, please employ suitable tools according to its weight. Please avoid

scratch to the product. Be careful: rollover and drop may cause hurt.

• Avoid scaps of the drill slip into the inverter during installation.

• For inverter with more than 2 year’s storage, please use regulator to power it slowly.

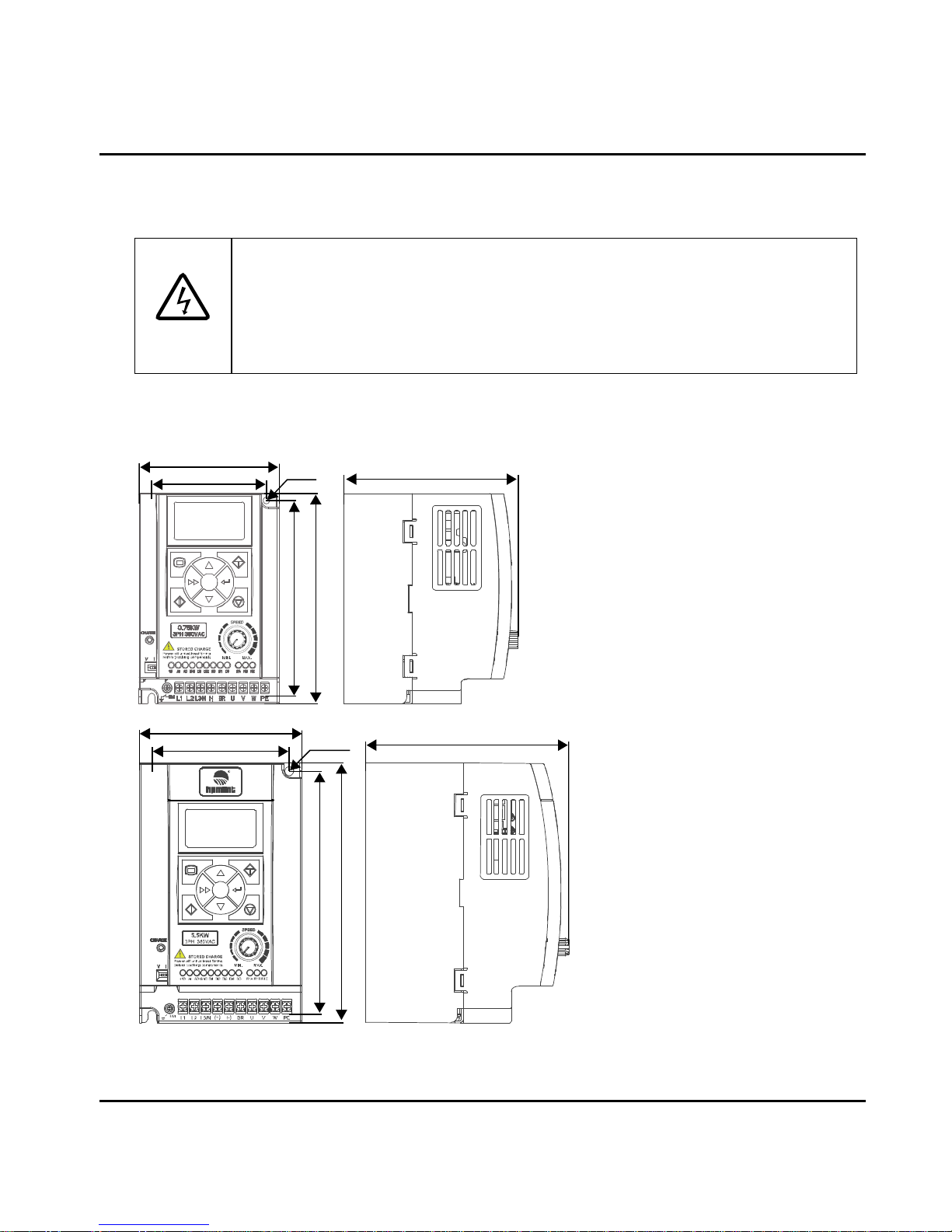

3.1 Dimension and Weight

Size A:

Dimension: 100×150×125 mm

Mounting dimension: 82×140 mm

Mounting aperture: 5 mm

G.W.: 1.5 kg

Size B:

Dimension: 116×185×145 mm

Mounting dimension: 98×174 mm

Mounting aperture: 6.5 mm

G.W.: 2.7 kg

Danger

82

1

0

0

2-Ø5

140

150

125

98

11

6

2-Ø6.5

174

185

145

Page 11

Chapter 3 Machenical Installation Shenzhen Hpmont Technology Co., Ltd.

-6- HD09 Series User Manual V1.1

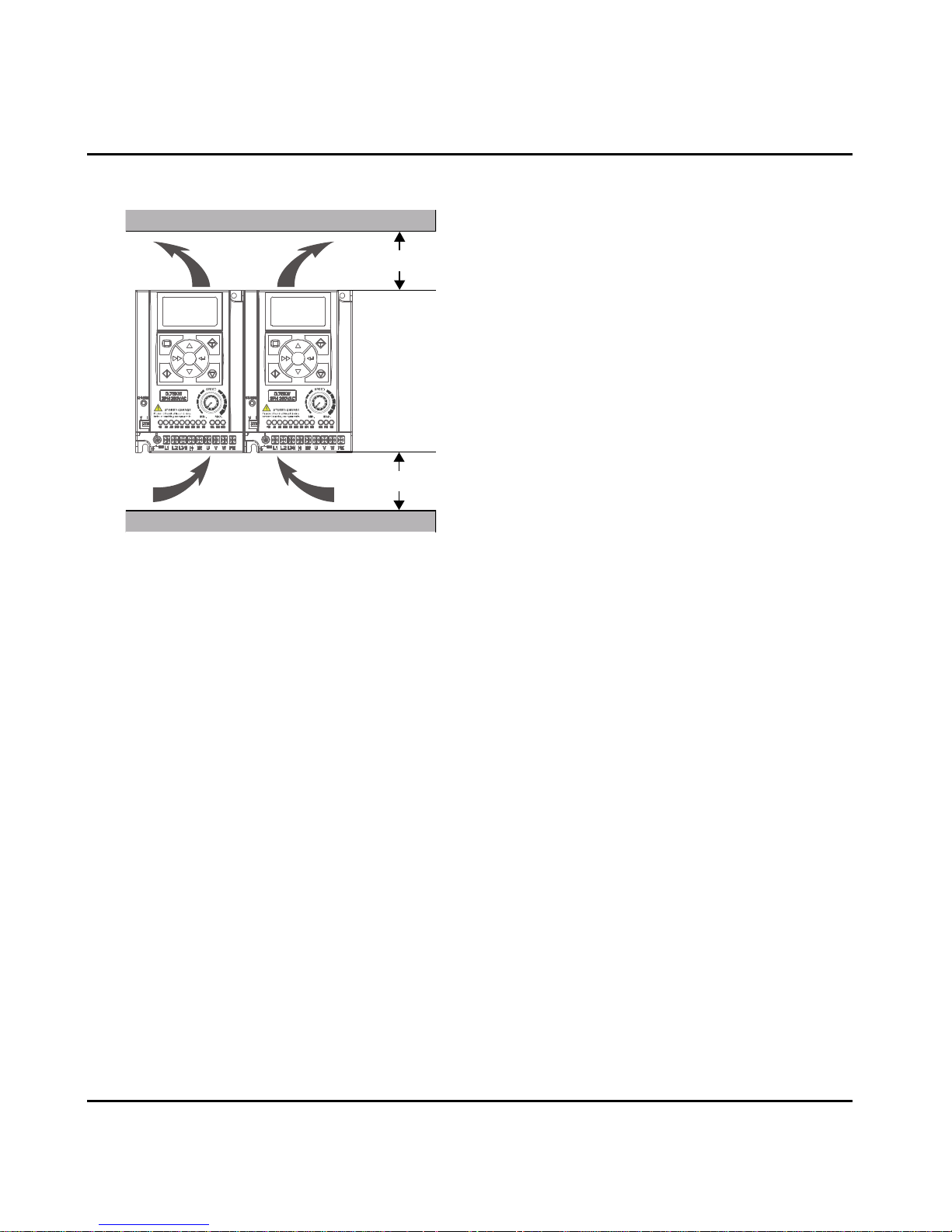

3.2 Requirement for the Installation Site

Ensure the installation site meets the following

requirements:

• Do not install at the direct sunlight, moisture,

water droplet location;

• Do not install at the flammability, explosive,

corrosive gas and liquid locations;

• Do not install at the oily dust, fiber and metal

powder location;

• Be vertical installation on fire-retardant material

with a strong support;

• Install at where the humidity is less than 95%RH

and non-condensing location;

• Install at where the vibration is 3.5m/s

2

in 2 - 9Hz, 10m/s2 in 9 - 200Hz (IEC60721-3-3);

• This inverter meets IP20, and Pollution Degree level 2 (Dry, Non conducting dust pollution);

• Make sure adequate cooling space for the inverter so as to keep the ambient temperature between

-10 - 40℃, as shown in the figure at the left;

It needs derating use if the inverter operation temperature exceeds 40℃. The derating value of the

output current of the inverter shall be 2% for each degree centigrade, Max. allowed temperature is

50℃.

≥100 mm

≥100 mm

Page 12

Shenzhen Hpmont Technology Co., Ltd. Chapter 3 Machenical Installation

HD09 Series User Manual V1.1 -7-

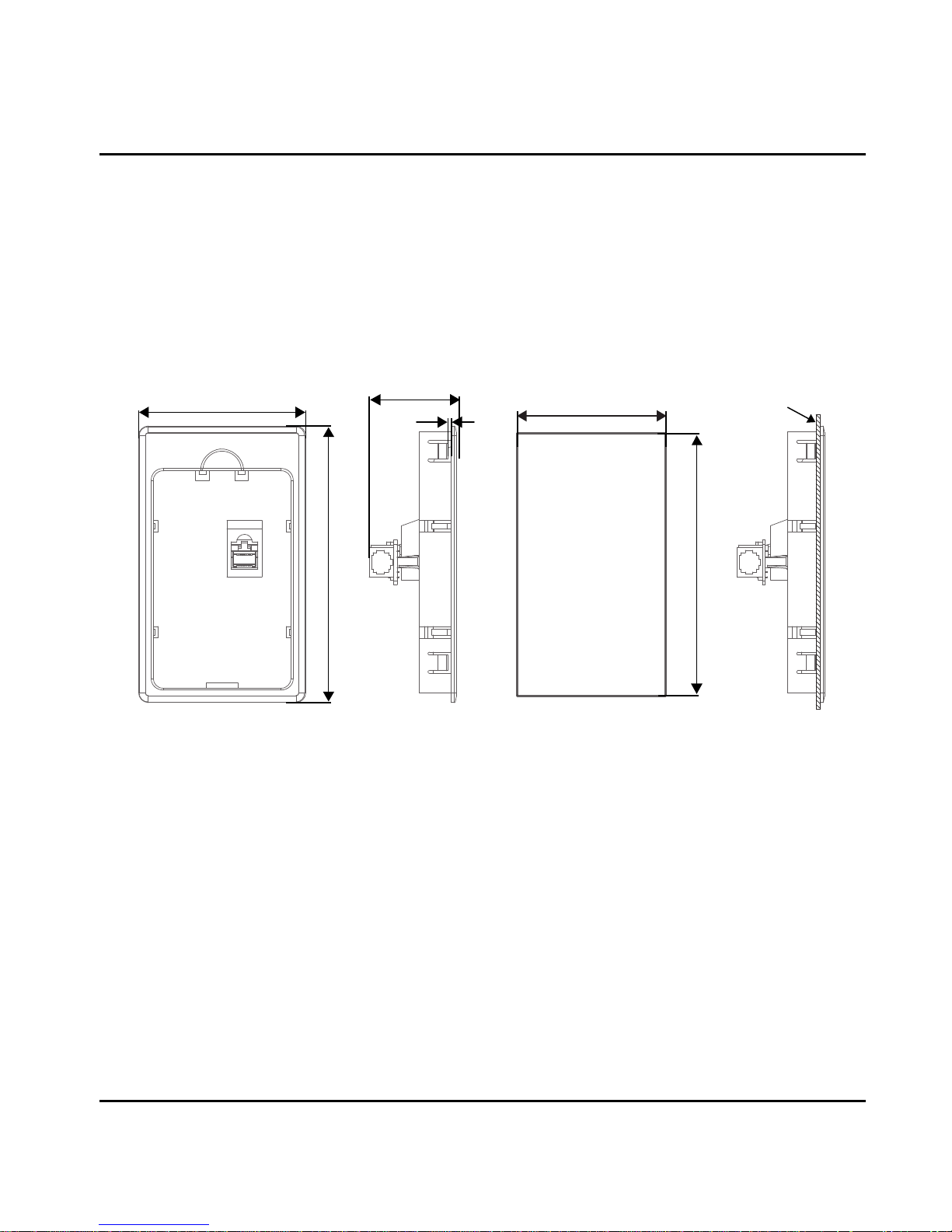

3.3 Installation of Exterior Keypad

HD09 allows installing the optional keypad on the keypad of control door cabinet. The optional

keypads are HD-LED-P and HD-LED-S.

3.3.1 Installation of HD-LED-P

HD-LED-P needs a mounting base HD-KMB for installation. Firstly install the base on the keypad of

control door cabinet, and then install HD-LED-P inside the base.

The HD-KMB base and mounting aperture sizes are shown in the following figure (unit: mm).

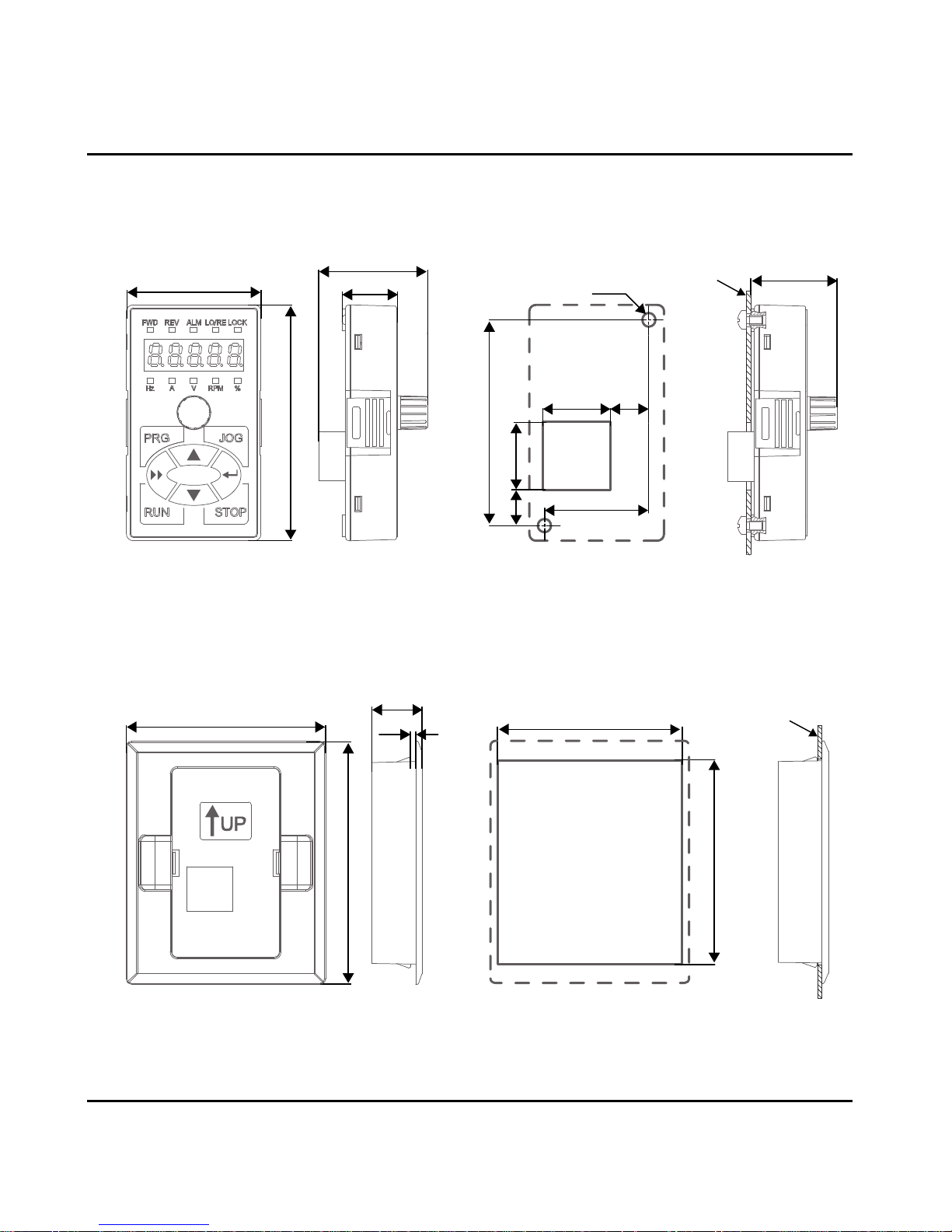

3.3.2 Installation of HD-LED-P-S

There are 2 installation methods selectable for HD-LED-P-S: install with screws or a mounting base.

Packing contents: mounting base, keypad, 2 pieces of M3x5 screws, 1 meter extension cable.

Installatio

n

Door cabinet

76.5±0.2

134.5±0.2

142

86

44.8

1.8

Mounting aperture sizeHD-KMB size

Page 13

Chapter 3 Machenical Installation Shenzhen Hpmont Technology Co., Ltd.

-8- HD09 Series User Manual V1.1

To Install with Screws

Install the HD-LED-P-S on the keypad of control door cabinet with screws.

Dimension and mounting aperture sizes are shown in the following figure (unit: mm).

To Install with a Mounting Base

Firstly install the mounting base HD-KMB-S on the keypad of control door cabinet, and then install

HD-LED-S inside the base.

The HD-KMB-S base and mounting aperture sizes are shown in the following figure (unit: mm).

HD-LED-P-S dimension Mounting aperture size

10.7 20

61

2-Ø4

31

20 11.5

25.4

70

40

16.5

32.3

Installatio

n

Door cabinet

Door cabinet

90

74

Mounting aperture size

75.5±0.2

68.5±0.2

19

1.8

Installatio

n

HD-KMB-S size

Page 14

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

HD09 Series User Manual V1.1 -9-

Chapter 4 Electrical Installation

• Only qualified electrical engineer can perform wiring job.

• Only when the power supply switch is completely off can you do the wiring job.

• Check that the operation is effective and reliable after conneting to the emergency stop

terminal of external power supply.

• You must wrap the bare metal part of the power terminal with insulating tape.

• Do not touch the wire terminals of the inverter when it is live.

Ensure the power supply is completely off

Only when the power supply switch is completely off can you do the wiring job.

Steps:

First, disconnect the power supply of the inverter.

Second, wait till the internal power supply indicator goes out (its position shown in the following

figure) or wait until 5 minutes later.

Danger

Power supply indicator

Page 15

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

-10- HD09 Series User Manual V1.1

4.1 Power Terminals and Connection

Power Terminal Description

Te rm in al Description

L1, L2, L3/N

Three-phase AC power input

terminals

L1, L3/N

One-phase AC power input

terminals

U, V, W

Output terminals, connect to

AC motor

(+), BR

Braking resistor connection

terminals

PE

Ground terminal, connect to

the ground

123

Te rm in al Description

L1, L2, L3/N

Three-phase AC power

input terminals

L1, L3/N

One-phase AC power

input terminals

U, V, W

Output terminals,

connect to AC motor

(+), BR

Braking resistor

connection terminals

(+), (-)

DC supply input

terminals

PE

Ground terminal,

connect to the ground

L1

Size A:

L2

L3/N

(+)BR

UVW

PE

L1 L2

L3/N

PE

WVU

BR(+) (-)

Size B:

Page 16

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

HD09 Series User Manual V1.1 -11-

Power Terminal Connection

Power Terminal Wiring is as shown in following figure.

For selection of contactor, MCBB, power supply cable, motor cable, ground cable and braking resistor,

please refer to section 5.1.1 Wiring Specifications of Input and Output, page 15.

4.2 Control Terminals and Connection

Control Terminals Description

Te rm in al Description

+10 External power Max. output current100mA

AI

Analogue input

The DIP switch decides the voltage input or current input

• Voltage 0 - 10V, impedance 32kΩ (Factory setting)

• Current 0 - 20mA, impedance 500Ω

Digital input (DI

function)

When AI is used as DI, switch signals above 6V can be received

• Function F15.44 is the same with DI1 - DI3 (F15.00 - F15.02)

AO Analogue output Voltage 0 - 10V

GND Power ground Analogue and digital site, 0V

DI1, DI2, DI3 Digital input Effective with GND short circuit

L1 L2 L3/N

(+) BR

UVW

Braking resistor*

HD09

MCCB

Contactor

Supply

ground

3~

(-)

PE

M

3~

*Braking resisto is

optional three-phase

model type exclusively

+10 AI AOGND

DI1 DI2 DI3 DI4 DO

R1A R1B R1C

VI

1

ON

DIP Switch

V

I

1

ON

Page 17

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

-12- HD09 Series User Manual V1.1

Te rm in al Description

DI4 Digital input

Effective with GND short circuit

or

High frequency input (F15.03 set as No. 53 function)

• Max. frequency 50.0kHz (F16.17 setting)

DO Digital output

Open collector output

• External voltage 10 - 30VDC, max. current 50mA

or

High frequency input (F15.19 set as No. 38 function)

• Max. frequency 50.0kHz (F16.26 setting)

R1A, R1B, R1C Relay output

• Contact rating: 250VAC / 3A or 30VDC / 1A

• R1B, R1C: normally closed; R1A, R1C: normally open

Note:

Limit the current within 3A if the relay terminal is to connect to AC 220V voltage signal.

Control Terminals Connection

The following figure shows wire connection of control terminal (factory setting).

+10

AI

Reference frquency: refer to F16.19

Frequency setting sources : refer to F16.01

REV function: refer to F15.00

REV function: refer to F15.01

External power: +10V, Max. output current100mA

Power ground: 0V, analogue and digital site

Unused

Inverter is running: refer to F15.19

Relay output

Inverter fault: refer to F15.20

AO

GND

DI1

DI2

DI3

DI4

DO

R1A

R1B

R1C

V

Unused

Page 18

Shenzhen Hpmont Technology Co., Ltd. Chapter 4 Electrical Installation

HD09 Series User Manual V1.1 -13-

Analogue Input Connection

Digital Input Connection

Digital Output Connection

+10

HD09

AI GND

V

I

1

ON

AI

HD09

GND

V

I

1

ON

DI1 DI2 DI3 DI4 GND

HD09 HD09

DI1 DI2 DI3 DI4 GND

External controller

Dry contact

connection

NPNconnection

10-30VDC

10kΩ

DO GND

+

-

HD09

+10 GND

DO

HD09

f

Relay coil Digital frequency

meter

Page 19

Chapter 4 Electrical Installation Shenzhen Hpmont Technology Co., Ltd.

-14- HD09 Series User Manual V1.1

4.3 External Keypad or Upper Computer

The RJ45 terminal can connect the optional keypad or upper computer, as shown in the following

figure.

RJ45

Pin Definition

1, 3 +5V

2 485+

4, 5, 6 GND

7 485-

8 Unused

Keypad

Can connect the optional keypad to realize keypad control

• Refer to Chapter 6 Keypad, page 19

Upper Computer

Can connect the upper computer to realize communication control

• The upper computer includes PLC, touch screen, PC, etc.

Connection Cable

• 1m conncection cable [HD-CAB-1M]

• 2m conncection cable [HD-CAB-2M]

• 3m conncection cable [HD-CAB-3M]

• 6m conncection cable [HD-CAB-6M]

RJ45

Connection

cable

Keypad or

upper computer

RJ45

18

Page 20

Shenzhen Hpmont Technology Co., Ltd. Chapter 5 Technical Data

HD09 Series User Manual V1.1 -15-

Chapter 5 Technical Data

5.1 Peripheral Accessories Selection

5.1.1 Wiring Specifications of Input and Output

The AC supply to the drive must be installed with suitable protection against overload and

short-circuits, i.e. MCCB (molded case circuit breaker) or equivalent device.

The recommended specification of MCCB, contactor & cables were shown as following tables.

The size of earth wire should not be smaller than the requirement in 4.3.5.4 of IEC61800-5-1.

Size Model

MCCB

(A)

Contactor

(A)

Power Cable

(mm2)

Motor Cable

(mm2)

Ground Cable

(mm2)

Size A HD09-2S0P2G 16 10 0.5 0.2 2.5

Size A HD09-2S0P4G 16 10 0.75 0.5 2.5

Size A HD09-2S0P7G 16 10 2.5 0.5 2.5

Size A HD09-2S1P5G 20 16 6.0 1.5 6.0

Size A HD09-2S2P2G 32 20 6.0 2.5 6.0

Size A HD09-4T0P4G 10 10 0.5 0.2 2.5

Size A HD09-4T0P7G 10 10 0.5 0.5 2.5

Size A HD09-4T1P5G 16 10 1.0 0.5 2.5

Size A HD09-4T2P2G 16 10 1.5 0.75 2.5

Size B HD09-4T4P0G 25 16 2.5 2.5 2.5

Size B HD09-4T5P5G 32 25 4.0 4.0 4.0

Note:

1. Please select braking resistor based on the above table.

Bigger resistor can protect the braking system in fault condition, but oversized resistor may bring a

capacity decrease, lead to over voltage protection.

2. The braking resistor should be mounted in a ventilated metal housing to prevent inadevertent contact

during it works, for the temperature is high.

Page 21

Chapter 5 Technical Data Shenzhen Hpmont Technology Co., Ltd.

-16- HD09 Series User Manual V1.1

5.1.2 Power Terminal Lug

The wiring lugs of the power terminals (round bare terminals) can be selected according to the

terminal wiring specifications, screw size, and the maximum outside diameter of the wiring lugs.

Size

Size A Size B

Screw size

M3 M3.5

Tightening torque (N. M)

0.6 - 0.8 0.8 - 1.2

Max. outer diameter of lug

d (mm)

6.1 7

5.2 Braking Resistor

Model Resistance Value (Ω) Resistance Power (W)

HD09-4T0P4G 300 - 400 80

HD09-4T0P7G 250 - 350 100

HD09-4T1P5G 200 - 300 200

HD09-4T2P2G 150 - 250 250

HD09-4T4P0G 100 - 150 300

HD09-4T5P5G 80 - 100 500

Note:

Braking unit is built in three-phase model type exclusively.

d

Page 22

Shenzhen Hpmont Technology Co., Ltd. Chapter 5 Technical Data

HD09 Series User Manual V1.1 -17-

5.3 Technical Data

Electrical

Inout voltage

HD09-2S■P■G: single-phase 200 - 240V

HD09-4T■P■G: three-phase 380 - 460V

Fluctuating within±10%, imbalance rate<3%

Input frequency 50/60Hz±5%

Output voltage 0 - input voltage

Output frequency 0 - 1000Hz

Specification

Control mode V/f

Maximum current 150% rated output current 2 minutes; 180% rated output current 10 seconds

Speed resolution

Digital setting: 0.1Hz;

Analogue setting: 0.1%×maximum frequency

Wave frequency

Default setting: 4kHz; setting range: 1 - 16kHz;

4 - 16kHz: The derating value of wave frequency shall be 2% for each more than 1kHz

Environment

Operation

temperature

-10 - +40℃, no ferating;

40 - 50℃, the derating value of the output current shall be 2% for each more than 1℃

Storage temperature -40 - +70℃

Location for use

Indoor, preveting from direct sunlight, no dust, corrosive, flammable gases, oil mist, water

vaper, dripping or salt etc.

Altitude Less than 1000m, no ferating; otherwise shouldbe serating use

Humidity Less than 95%RH, non-condensing

Vibration Resistance It is 3.5m/s2 in 2 - 9Hz, it is 10m/s2 (IEC60721-3-3) in 9 - 200Hz

Protection level IP20

Pollution degree Level 2 (Dry, Non conducting dust pollution)

Accessories

Keypad

HD-LED-P: LED keypad with potentiometer, matched with HD-KMB mounting base

HD-LED-P-S: small size keypad, matched with HD-KMB-S mounting base

Connection cable 1m / 2m / 3m / 6m connection cable [HD-CAB-1M / 2M / 3M / 6M]

Page 23

Page 24

Shenzhen Hpmont Technology Co., Ltd. Chapter 6 Keypad

HD09 Series User Manual V1.1 -19-

Chapter 6 Keypad

HD09 can either installed with LCD display keypad (standard), or LED display keypad (optional).

2 3

4 5

6

7

8 9

10

1a

1b

1c

2 3

4 5

6

6

7

7

8 9

10

10

1a

1b

1c

LCD display keypad

Standard

LED display keypad

Optional

HD-LED-P-S HD-LED-P

ENTSHF

JOGPRG

STOPRUN

Hz

AVRPM%

REVFWD ALM LO/RE LOCK

1a

1b

1c

2

3

4 5

8 9

Page 25

Chapter 6 Keypad Shenzhen Hpmont Technology Co., Ltd.

-20- HD09 Series User Manual V1.1

No. Description

1 The standard keypad contains LCD display, while the optional keypad contains LED nixie tube display.

• Three status: lighting, flashing and lightless.

• Do not remove the standard LCD keypad.

a. Status indicator: indicating current status.

• FWD (Forward status): Motor is forward running (standard LCD) / lighting (optional LED)

• REV (Reverse status): Motor is reverse running (standard LCD) / lighting (optional LED)

• ALM (Alarm status): Motor is faulty (standard LCD) / lighting (optional LED)

• LO/RE(Local/Remote status): Inverter is in terminal or communication control mode (standard LCD) /

lighting (optional LED)

• LOCK (Password locked status): User password lock of the inverter is avail (standard LCD) / lighting

(optional LED)

b. Display area: Normal: displays parameter. Faulty: displays error code when the inverter is faulty.

• If a value is flashing, it mean that the value is revisable.

c. Unit indicator: Display unit of the current value.

• Include: Hz (frequency), A (current), V (voltage), RPM (rotate speed), % (percentage)

2

Program/Exit button: Entry or programming button

3

Jog button: In the keypad control, jog start the inverter

4

Run button: In the keypad control, press this button to run the inverter

5

Stop/Reset button: In the keypad control, to stop the inverter and reset the fault

6

Increment button: In selecting parameter status, press it to increass the value of

parameter; In setting parameter status, press it to incress the setting value.

7

Decrement button: In selecting parameter status, press it to decreass the value of

parameter; In setting parameter status, press it to decress the setting value.

8

SHE shift button: In selecting pr setting parameter status, shift 1 bit.

9

ENT enter/confirm button: Enter lower menu; In setting parameter status, confirm and

save the data.

10

Potentiometer: In setting parameter status, anti-clockwise means decrease, while clockwise means

increase.

Page 26

Shenzhen Hpmont Technology Co., Ltd. Chapter 7 Troubleshooting

HD09 Series User Manual V1.1 -21-

Chapter 7 Troubleshooting

HD09 series inverter has inbuilt protective and warning self-diagnostic functions. If a fault occurs, the

fault code will be displayed on the display keypad. At the same time, fault relay acts, accordingly the

inverter stops output and the motor coasts to stop.

When fault or alarm occurs, please record the fault details and take proper actions according to the

below table. If you need some technical help, please contact to the suppliers or directly call Shenzhen

Hpmont Technology Co., Ltd..

After the fault is eliminated, please reset the inverter by any of the following methods:

1. Display keypad. Press (standard) / (optional).

2. External reset terminal (multi-function terminal set as No. 46 function).

3. Communication.

4. Switching on the inverter after switching off.

Fault Fault reasons Counter-measures

-Lu- DC bus undervoltage

• At the begining of powering on

and at the end of powering off

• Input voltage is too low

• Improper wiring leads to

undervoltage of hardware

• It is normal status of powering on

and powering off

• Please check input power voltage

• Please check wiring and wire the

inverter properly

E0001

Inverter acceleration

overcurrent

• Improper connection between

inverter and motor

• Improper motor parameters

• The rating of the used inverter is

too small

• Acceleration/deceleration time is

too short

• Connect the inverter and motor

properly

• Please set correct motor parameters

(F08.00 - F08.03)

• Select inverter with higher rating

Please set proper acceleration time

and deceleration time (F03.01,

F03.02)

E0002

Inverter deceleration

overcurrent

E0003

Inverter constant

speed overcurrent

E0004

DC bus acceleration

over voltage

• Input voltage is too high

• Deceleartion time is too short

• Improper wiring leads to

overvoltage of hardware

• Improper selection of the

braking devices

• Please check power input

• Please set a proper value for

deceleration time (F03.02)

• Please check wiring and wire the

inverter properly

• Select according to the

recommended braking devices of

section 5.2 Braking Resistor, page 16

E0005

DC bus deceleration

over voltage

E0006

DC bus constant

speed over voltage

Page 27

Chapter 7 Troubleshooting Shenzhen Hpmont Technology Co., Ltd.

-22- HD09 Series User Manual V1.1

Fault Fault reasons Counter-measures

E0007 Stall overvoltage

• Bus voltage is too high

• The setting of stall overvoltage is

too low

• Please check power input or the

function of brake

• Set the value of stall overvoltage

properly (F19.19)

E0008

Fault of power

module

• Short circuit between phases

output

• Short circuit to the ground

• Output current is too high

• Power module is damaged

• Please check the connection and

connect the wire properly

• Please check the connection and

connect the wire properly

• Please check the connection and

mechanism

• Please contact the supplier for

repairing

E0009 Heatsink overheat

• Ambient temperature is too high

• Inverter external ventilation is

not good

• Fan fault

• Fault occurs to temperature

detection circuit

• Please use inverter with higher

power capacity

• Improve the ventilation around the

inverter

• Replace the cooling fan

• Please seek technical support

E0011 CPU fault • CPU abnormal

• Please detect at power on after

completely power outage

• Please seek technical support

E0012

Parameters

auto-tuning fault

• Parameter auto-tuning is time

out

• Please check the motor’s connection

• Input the correct motor parameters

(F08.01 - F08.03)

• Please seek technical support

E0013

Contactor is not

actuated

• Contactor fault

• Fault of control circuit

• Replace the contactor

• Please seek technical support

E0014

Fault of current

detection circuit

• Current detection circuit is

damaged

• Please contact the supplier for

repairing

E0016 Fault of output phase

• Output phase disconnection or

loss

• Heavy imbalance of inverter’s

three-phase load

• Please check the connection

between inverter and motor

• Please check the quality of motor

E0017 Inverter overload

• Acceleration time is too short

• Improper setting of V/f curve or

torque boost leads to over

current

• Mains supply voltage is too low

• Motor load is too high

• Adjust acceleration time (F03.01)

• Adjust V/f curve (F09.01 - F09.06) or

torque boost (F09.07, F09.08)

• Please check mains supply voltage

• Please use inverter with proper

power rating

Page 28

Shenzhen Hpmont Technology Co., Ltd. Chapter 7 Troubleshooting

HD09 Series User Manual V1.1 -23-

Fault Fault reasons Counter-measures

E0019 Motor overload

• Improper setting of V/f curve

• Mains supply voltage is too low

• Normal motor runs for a long

time with heavy load at low

speed

• Motor runs with blocked torque

or load is too heavy

• Adjust the setting of V/f curve

(F09.01 - F09.06)

• Check the power input

• Please use special motor

• Please check the load and

mechanical transmission devices

E0021

Access fault of

Control board

EEPROM

• Memory circuit fault of control

board EEPROM

• Please contact the supplier for

repairing

E0024

Fault of external

equipment

• Fault terminal of external

equipment operates

• Please check external equipment

E0028

SCI communication

time-out

• Connection fault of

Communication cable

• Disconnected or not well

connected

• Please check the connection

E0029

SCI communication

error

• Connection fault of

Communication cable

• Disconnected or not well

connected

• Communication setting error

• Communication data error

• Please check the connection

• Please check the connection

• Please correctly set the

communication format (F17.00), and

the baud rate (F17.01)

Note:

If E0028 or E0029 are displayed on the keypad, there is no need to stop the inverter.

Page 29

Page 30

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -25-

Chapter 8 Parameter

Attributes are changed:

“X”: It denotes that the setting of this parameter cannot be modified when the inverter is in run

status.

“O”: It denotes that the setting of this parameter can be modified when the inverter is in run status.

“*”: It denotes that the value of this parameter is the actual value which cannot be modified.

Ref. Code Function Setting Range Default Unit Attribute Setting

F00: Basic Parameter

F00.06

Inverter max. output

frequency

50.0 - 1000.0Hz 50.0Hz 0.1Hz ×

F00.08

Upper limit of operation

frequency

0.0 - F00.06 50.0Hz 0.1Hz ×

F00.09

Lower limit of operation

frequency

0.0 - F00.08 0.0Hz 0.1Hz ×

F00.10

Frequency setting

sources selection

0: Keypad digital setting

1: Terminal digital setting

2: SCI communication setting

3: AI analogue setting

4: Terminal pulse setting

0 1 ×

F00.11

Command setting

source selection

0: Keypad running source

1: Terminal running source

2: SCI communication running source

0 1 ×

F00.13

Starting frequency digital

setting

0.0 - F00.08 50.0Hz 0.1Hz ○

F00.14

UP/DOWN digital setting

control

Units: Frequency setting save selection

at power outage

0: Not save in power off

1: Save in power off

Tens: Frequency setting control

selection at stop

0: Set frequency keeping in stop

1: Rcovery frequency to F00.13 in stop

Hundreds: Communication setting

frequency storage selection

1001 1 ×

Page 31

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-26- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

0: Not save in power off

1: Save in power off

Thousands: Switch the frequency

channel to the analogue selection

0: Not save

1: Save

F00.15

Jog operation frequency

digital setting

0.0 – up limitation (F00.08) 5.0Hz 0.1Hz ○

F00.17

Running direction

selection

0: Same direction

1: Reserved direction

0 1 ×

F00.19

Dead time of direction

switch

0.0 - 3600.0s 0.0s 0.1s ×

F00.20 Keypad enbale

Unit: Button enbale

0: Enable

1: Disable

Ten: Potentiometer enbale

0: Potentiometer priority for keypad

1: Potentiometer with keypad

2: Potentiometer with external keypad

00 1 ○

F00.21 Sleep function enbale

0: Disable

1: Enable 1

2: Enable 2

0 1 ×

F00.22 Dormant wake time 0.0 - 360.0s 0.0s 0.1s ×

F00.24 Sleep delay 0.0 - 3600.0s 0.0s 0.1s ×

F00.25 Sleep frequency 0.0Hz - F00.08 0.5Hz 0.1Hz ○

F01: Protection of Parameters

F01.00 User’s password 00000 - 65535 00000 1 ○

F01.01 Menu mode selection

0: Full menu mode

1: Checking menu mode

0 1 ○

F01.02

Function code parameter

initialization (parameter

download)

0: No operation

1: Restore to factory settings

2/3: keypad stored parameter 1/2

iscopied to control board and update

current function value

4: Clear fault information

0 1 ×

F01.03

Copy parameter to keypad

0: No operation 0 1 ○

Page 32

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -27-

Ref. Code Function Setting Range Default Unit Attribute Setting

(parameter uploading)

1/2: Current function values are copied

to keypad stored parameter 1/2

F02: Run / Stop Control Parameters

F02.02

Start DWELL frequency

setting

0.0 - F00.08 0.0Hz 0.1Hz ×

F02.03

Retention time of starting

DWELL frequency

0.00 - 10.00s 0.00s 0.01s ×

F02.04 DC braking current setting 0 - 100% 50% 1% ×

F02.05 DC braking time at start 0.00 - 60.00s 0.00s 0.01s ×

F02.13 Stop mode selection

1: Coast to stop

2: Decelerate to stop

2 1 ×

F02.14

DWELL frequency setting

at stop

0.0 - F00.08 0.0Hz 0.1Hz ×

F02.15

Retention time of DWELL

frequency at stop

0.00 - 10.00s 0.00s 0.01s ×

F02.16

DC braking initial

frequency at stop

0.0 - 50.0Hz 0.5Hz 0.1Hz ×

F02.18 DC braking time at stop 0.00 - 60.00s 0.00s 0.01s ×

F03: Acceleration/Deceleration Parameters

F03.01 Acceleration time 1 0.01 - 600.00s 10.00s 0.01s ○

F03.02 Deceleration time 1 0.01 - 600.00s 10.00s 0.01s ○

F03.03 Acceleration time 2 0.01 - 600.00s 10.00s 0.01s ○

F03.04 Deceleration time 2 0.01 - 600.00s 10.00s 0.01s ○

F03.05 Acceleration time 3 0.01 - 600.00s 10.00s 0.01s ○

F03.06 Deceleration time 3 0.01 - 600.00s 10.00s 0.01s ○

F03.07 Acceleration time 4 0.01 - 600.00s 10.00s 0.01s ○

F03.08 Deceleration time 4 0.01 - 600.00s 10.00s 0.01s ○

F03.09

Ace. time 2 and 1 switch

frequency

0.0 - up limitation 0.0Hz 0.0Hz ×

F03.10

Dec. time 2 and 1 switch

frequency

0.0 - up limitation 0.0Hz 0.0Hz ×

F03.15 Spot Ace. time 0.01 - 600.00s 6.00s 0.01s ○

F03.16 Spot Dec. time 0.01 - 600.00s 6.00s 0.01s ○

F04: Process PID Control

F04.00

Process PID control

selection

0: PID control is disabled

1: PID control is enabled

0 1 ×

Page 33

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-28- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

F04.02 Feedback source selection

0: AI analogue feedback

1: Terminal pulse feedback

0 1 ×

F04.03 Setting digital reference 0.0 - 100.0% 0.0% 0.1% ○

F04.04 Proportional gain (P) 0.00 - 10.00 2.00 0.01 ○

F04.05 Integral time (I) 0.01 - 10.00s 1.00s 0.01s ○

F04.07 Differential time (D) 0.00 - 10.00s 0.00s 0.01s ○

F04.08

Differential amplitude limit

value

0.0 - F00.08 20.0Hz 0.1Hz ○

F04.09 Sampling cycle (T) 0.01 - 50.00s 0.10s 0.01s ○

F04.10 Bias limit 0.0 - 20.0% 2.0% 0.1% ○

F04.16

Integral regulation

selection

0: Stop integral regulation when the

frequency reaches the upper or lower

limit

1: Continue the integral regulation

when the frequency reaches the upper

or lower limit

0 1 ×

F04.17 PID output filter time 0.01 - 10.00s 0.05s 0.01s ○

F04.18

PID output reverse

selection

0: PID regulation disable reverse

(When PID output is negative, 0 is the

limit)

1: PID regulation enable reverse

0 1 ×

F04.19

PID output reverse

frequency’s upper limit

0.0 - F00.08 50.0Hz 0.1Hz ×

F05: External Reference Curve Parameters

F05.01 Minimum reference of line 0.0% - F05.03 0.0% 0.1% ○

F05.02

Minimum reference

corresponding value of

line

0.0 - 100.0% 0.0% 0.1% ○

F05.03 Maximum reference of line F05.01 - 100.0% 100.0% 0.1% ○

F05.04

Maximum reference

corresponding value of

line

0.0 - 100.0% 100.0% 0.1% ○

F05.17 Skip frequency F00.09 - F00.08 0.0Hz 0.1Hz ×

F05.20 Range of skip frequency 0.0 - 30.0Hz 0.0Hz 0.1Hz ×

F06: Multi-step Speed Parameters

F06.00

Multi-step frequency

Command 1

F00.09 - F00.08 5.0Hz 0.1Hz ○

Page 34

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -29-

Ref. Code Function Setting Range Default Unit Attribute Setting

F06.01

Multi-step frequency

Command 2

F00.09 - F00.08 5.0Hz 0.1Hz ○

F06.02

Multi-step frequency

Command 3

F00.09 - F00.08 5.0Hz 0.1Hz ○

F06.03

Multi-step frequency

Command 4

F00.09 - F00.08 5.0Hz 0.1Hz ○

F06.04

Multi-step frequency

Command 5

F00.09 - F00.08 5.0Hz 0.1Hz ○

F06.05

Multi-step frequency

Command 6

F00.09 - F00.08 5.0Hz 0.1Hz ○

F06.06

Multi-step frequency

Command 7

F00.09 - F00.08 5.0Hz 0.1Hz ○

F08: Motor Parameters

F08.00 Rated power of motor 0.2 - 5.5kW

Depende

nt on

HD09

0.1kW ×

F08.01 Rated voltage of motor 0V - inverter’s rated voltage 1V ×

F08.02 Rated current of motor 0.01 - 99.99A 0.01A ×

F08.03 Rated frequency of motor 1 - 1000Hz 50Hz 1Hz ×

F08.04 Rated Rpm of motor 1 - 24000rpm

Depende

nt on

HD09

1rpm ×

F08.06

Parameter auto-tuning of

motor

0: Auto-tuning is disabled

1: Stationary auto-tuning

0 1 ×

F08.07 Stator resistance of motor 0.00 - 99.99Ω

Depende

nt on

HD09

0.01Ω ×

F09: V/f Control Parameters

F09.01 V/f frequency value F3 F09.03 - 100.0% (F08.03) 100.0% 0.1% ×

F09.02 V/f voltage value V3 F09.04 - 100.0% (F08.01) 100.0% 0.1% ×

F09.03 V/f frequency value F2 F09.05 - F09.01 (F08.03) 0.0% 0.1% ×

F09.04 V/f voltage value V2 F09.06 - F09.02 (F08.01) 0.0% 0.1% ×

F09.05 V/f frequency value F1 0.0% - F09.03 (F08.03) 0.0% 0.1% ×

F09.06 V/f voltage value V1 0.0% - F09.04 (F08.01) 0.0% 0.1% ×

F09.07 Torque boost 0.0 - 30.0% 2.0% 0.1% ×

F09.08

Cut-off point used for

manual torque boost

0.0 - 50.0% (F08.03) 30.0% 0.1% ○

F09.09

Motor transfer

compensation gain

0.0 - 300.0% 0.0% 0.1% ○

Page 35

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-30- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

F09.10

Compensation filtering

time for motor transfer

0.01 - 10.00s 0.10s 0.01s ○

F09.11

Differential compensation

for motor differential

0.0 - 250.0% 200.0% 0.1% ×

F09.12

The time constant of the

motor compensation

0.1 - 25.0s 2.0s 0.1s ○

F09.14

AVR (automatic voltage

regulation) function

0: No action

1: Keep acting

2: No action only in Dec.

1 1 ○

F09.15

Oscillation-suppression

mode

0: Oscillation-suppression mode 1

1: Oscillation-suppression mode 2

0 1 ○

F09.16

Oscillation-suppression

coefficient

0 - 200 50 1 ○

F15: Digital Input/Output Terminal Parameters

F15.00 DI1 function

0: Unused

1: Inverter enabled

2,3: FWD / REV function

4: Three-wire operation mode

8: AI to be the frequency source

11: Terminal control mode to be the

run command source

13 - 15: Multi-step frequency terminal

1 - 3

17: Frequency ramp (UP)

18: Frequency ramp (DN)

19: Clearing auxiliary frequency setting

20,21: Forward and reverse jog

command control input (JOGF / JOGR)

26,27: Selection terminals in Ace. and

Dec. time 1,2

41: Coast to stop (normally-open

input)

42: Coast to stop (normally-closed

input)

44: External fault signal (normally-open

input)

45: External fault signal (normallyclosed input)

46: External reset input (RST)

2 1 ×

F15.01 DI2 function 3 1 ×

F15.02 DI3 function 0 1 ×

F15.03 DI4 function 0 1 ×

Page 36

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -31-

Ref. Code Function Setting Range Default Unit Attribute Setting

F15.44

AI terminal (ADI function)

selection

50: Clearing the counter to zero

51: Counter’s triggering signal input

53: Pulse frequency input (only DI4

terminal is enabled)

ADI is valid when F15.44 is not as . as 0,

only AI is valid.

0 1 ×

F15.12

Acc / Dec rate of UP/DN

terminal

0.0 - 99.9Hz/s 1.0Hz/s 0.1Hz/s ×

F15.14

Terminal detecting filter

number

0 - 10000 2 1 ○

F15.15

Terminal input positive

and negative logic setting

Bit0 - Bit3 is corresponding to DI1 - DI4

Bit12 is corresponding to AI

Bitx: DIy terminal input positive and

negative logic

0: Positive logic

1: Negative logic

0 1 ○

F15.16

FWD / REV operation

mode

0: Two-wire operation mode 1

1: Two-wire operation mode 2

2: Three-wire operation mode 1

3: Three-wire operation mode 2

0 1 ×

F15.19 DO function

0: Unused

2: Inverter is running (RUN)

3: Inverter is forward running

4: Inverter is reverse running

5: Inverter is DC braking

9: Frequency detection threshold (FDT)

11: Frequency arriving signal (FAR)

20: Output data from SCI

communication

21: Preset operating time out

23: Preset counting value reach

24: Indicating counting value reach

31: Inverter fault

38: High-frequency output (only DO)

2 1 ×

F15.20 Relay function 31 1 ×

F15.27 FAR range 0.0 - 100.0Hz 2.5Hz 0.1Hz ○

F15.31 FDT level 0.0 - F00.06 50.0Hz 0.1Hz ○

F15.32 FDT lag - F00.06 - F00.06 1.0Hz 0.1Hz ○

F15.36 Preset operating time 0 - 65535h 0h 1h ○

Page 37

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-32- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

0: Preset operating time is disabled

F15.37

Preset counting value

arriving

F15.38 - 9999 0 1 ○

F15.38

Specified counting value

arriving

0 - F15.37 0 1 ○

F15.43 Terminal output delay 0.0 - 100.0s 0.0s 0.1s ×

F16: Analogue I/O Terminal Parameters

F16.00

Keypad with

potentiometer function

0: Unused

2: Frequency setting source

3: Auxiliary frequency reference

5: Process PID feedback

0 1 ×

F16.01 AI function 2 1 ×

F16.05 AI bias -100.0 - 100.0% 0.0% 0.1% ○

F16.06 AI gain 0.00 - 10.00 1.00 0.01 ○

F16.07 AI input filtering time 0.01 - 10.00s 0.05s 0.01s ○

F16.17

DI4 max. input pulse

frequency

0.0 - 50.0kHz 10.0kHz 0.1kHz ○

F16.18

DI4 input pulse filtering

time

0 - 500ms 10ms 1ms ○

F16.19 AO function

0: Unused

2: Reference frquency (0 - max. output

frequency)

3: Motor speed (0 - max. output

frequency corresponding to speed)

5: Output current (0 - twice motor’s

rated current)

11: Output voltage (0 - 1.2 times

inverter’s rated voltage)

12: Bus voltage (0 - 2.2 times inverter’s

rated voltage)

2 1 ○

F16.21 DO function 0 1 ○

F16.22 AO bias -100.0 - 100.0% 0.0% 0.1% ○

F16.23 AO gain 0.0 - 200.0% 100.0% 0.1% ○

F16.26

DO max. output pulse

frequency

0.1 - 50.0kHz 10.0kHz 0.1kHz ○

F17: SCI Communication Parameters

F17.00 Data format

0: 1-8-2 format, no parity, RTU

1: 1-8-1 format, even parity, RTU

2: 1-8-1 format, odd parity, RTU

0 1 ×

F17.01 Baud rate selection 0: 1200bps 3 1 ×

Page 38

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -33-

Ref. Code Function Setting Range Default Unit Attribute Setting

1: 2400bps

2: 4800bps

3: 9600bps

4: 19200bps

5: 38400bps

F17.02 Local address 0 - 247 2 1 ×

F17.03 Host PC response time 0 - 1000ms 1ms 1ms ×

F17.04

Time threshold for

detecting communication

status

0.0 - 1000.0ms

0.0: Not detecting communicaiton over

time

0.0s 0.1s ×

F17.05

Detecting time at

communication error

0.0 - 1000.0ms

0.0: Not detecting communicaiton error

0.0s 0.1s ×

F17.09

Communication write

function parameter of

storage EEPROM method

selection

Units: Communication write function

parameter of storage EEPROM method

selection (Except for F00.13 and

F19.03)

Tens: Communication write function

parameter of storage EEPROM method

selection for F00.13 and F19.03

0: Without storage EEPROM

1: Storage EEPROM

01 1 ×

F17.10

Detecting time when

network communication

over time

0.0 - 600.0s

0.0: Not detecting communicaiton error

0.0s 0.1s ×

F18: Display Control Parameter

F18.02

Running display

parameter 1 setting

0: Reserved

1: Inverter rated current

3: Inverter status

4: Main setting frequency channel

5: Main setting frequency

7: Setting frequency

8: Given frequency (after Dec. and Ace.)

9: Output frequency

10: Setting RPM

11: Running rpm

13: Output voltage

14: Output current

8 1 ○

Page 39

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-34- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

F18.08

Stop display parameter 1

setting

15: Torque given

16: Output torque

17: Output power

18: DC bus voltage

19: Keypad potentiometer input

voltage

20: AI input voltage

21: AI input voltage (after handling)

28: DI4 terminal pulse input frequency

29: AOoutput

32: Heat sink temperature

33: Given line speed

34: Given line speed

42: External value

43: Input terminals statues

44: Output terminals status

48: Total power time accumulates

(hours)

49: Total running time accumulates

(hours)

7 1 ○

F18.14 Frequency display gain 0.1 - 160.0 1.0 0.1 ○

F18.15 Max. line speed 0 - 65535 1000 1 ○

F18.16

Line speed display

accuracy

0: Integer

1: A decimal

2: Two decimals

3: Three decimals

0 1 ×

F18.17

LCD Backlighting screen

saver mode

0: Current mode

1: External signal input changed,

cancenl backlighting screen

0 1 ○

F19: Function-boost Parameters

F19.07

Control selection of

cooling fan

0: Auto stop mode

1: Immediate stop mode

2: The fan runs continuously when

power on

0 1 ×

F19.08

Cooling fan controls

delaying time

0.0 - 600.0s 30.0s 0.1s ×

F19.12

Instantaneous loss of

power and no stop

function selection

0: Disable instantaneous loss and no

stop

1: Enbale instantaneous loss and no

0 1 ×

Page 40

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -35-

Ref. Code Function Setting Range Default Unit Attribute Setting

stop

F19.13

Instant stop function

deceleration time

0.01 - 600.00s 5.00s 0.01s ○

F19.14

Voltage rerise judgement

time for Instantaneous loss

of power and no

downtime

0.00 - 10.00s 0.10s 0.01s ○

F19.15

Voltage judgement for

Instantaneous loss of

power and no downtime

0 - 999V

220V

inverter:

248V

380V

inverter:

430V

1V ×

F19.18

Protection of stall

overvoltage

0: Disabled (with braking resistance)

1: Enabled

1 1 ×

F19.19 Stall overvoltage point 0 - 999V

Depende

nt on

HD09

1V ×

F19.20

Auto current limiting

selection

0: Disabled

1: Enabled in Acc / Dec running

process, but disabled in constant

speed runnng process

2: Enabled both in Acc / Dec and in

constant speed running proces

1 1 ×

F19.21

Auto current limiting

threshold

20.0 - 200.0% 150.0% 0.1% ×

F19.22

Deceleration time at auto

current limiting

0.00 - 600.00s 0.00s 0.01s ×

F19.23

Enabled mode of terminal

run command

0: Rise edge enabled mode

1: Level enabled mode

0 1 ○

F19.24

Action voltage of braking

unit

630 - 750V

Depende

nt on

HD09

1V ×

F19.37

Frequency adjust range

selection

Unit: Main frequency range

0: 0 - max. frequency

1: Negative maximum frequency to

maximum frequency

100 1 ○

Page 41

Chapter 8 Parameter Shenzhen Hpmont Technology Co., Ltd.

-36- HD09 Series User Manual V1.1

Ref. Code Function Setting Range Default Unit Attribute Setting

Ten : U n u s e d

Hundreds: The range of synthetic

frequencies

0: 0 - up limitation frequency

1: Negative upper limit frequency to

upper limit frequency

F19.39 Input voltage selection

Unit : 380V input voltage

0: 380 - 460V

1: 260 - 460V

2: 200 - 460V

Ten: 220V input voltage selection

0: 200 - 240V

1: 140 - 240V

00 1 ×

F19.44 LCD Backlight display time 0.0 - 999.9min 5.0min 0.1min ○

F20: Protection of Fault Parameters

F20.00

Selection for overload

prediction police check

out

00000: Enbale overload protection

10000: Disbale overload protection

00000 1 ○

F20.10

Output phase loss

detection reference

0 - 50% 20% 1% ×

F20.11

Output phase loss

detection time

0.00 - 20.00s 3.00s 0.01s ×

F20.18 Auto reset times 0 - 100 0 1 ×

F20.19 Auto reset interval 2.0 - 20.0s/times

5.0

s/times

0.1

s/times

×

F20.21

Type of third latest (the

last) fault

-Lu-: DC bus undervoltage

E0001: Acc overcurrent

E0002: Dec overcurrent

E0003: Costant overcurrent

E0004: Acc overvoltage

E0005: Dec overvoltage

E0006: Constant overvoltage

E0007: Stall overvoltage

E0008: Fault of power module

E0009: Heatsink overheat

E0011: CPUfault

E0012: Parameters auto-tuning fault

E0013: Contactor is not actuated

0 1 *

Page 42

Shenzhen Hpmont Technology Co., Ltd. Chapter 8 Parameter

HD09 Series User Manual V1.1 -37-

Ref. Code Function Setting Range Default Unit Attribute Setting

E0014: Fault of current detection circuit

E0016: Fault of output phase

E0017: Inverter overload

E0019: Motor overload

E0021: Access fault of control board

EEPROM

E0024: Fault of external equipment

E0028: SCI communication time-out

E0029: SCI communication error

F20.22

Setting frequency at the

last fault

0.0 - 1000.0Hz 0.0Hz 0.1Hz *

F20.23

Running frequency at the

last fault

0.0 - 1000.0Hz 0.0Hz 0.1Hz *

F20.24 Bus voltage at the last fault 0 - 999V 0V 1V *

F20.25

Output voltage at the last

fault

0 - 999V 0V 1V *

F20.26

Output current at the last

fault

0.00 - 99.99A 0.00A 0.01A *

F20.29 Interval of third latest fault 0.0 - 6553.5h 0.0h 0.1h *

F20.30 Type of second latest fault 0 - 99 0 1 *

F20.31

Interval of second latest

fault

0.0 - 6553.5h 0.0h 0.1h *

F20.32 Type of first latest fault 0 - 99 0 1 *

F20.33 Interval of first latest fault 0.0 - 6553.5h 0.0h 0.1h *

F23: PWM Control Parameters

F23.00 Set the carrier frequency 1 - 16kHz 4kHz 1kHz ×

Loading...

Loading...