Page 1

Deutsch

Français

9

Engine Manual エンジン取扱説明書

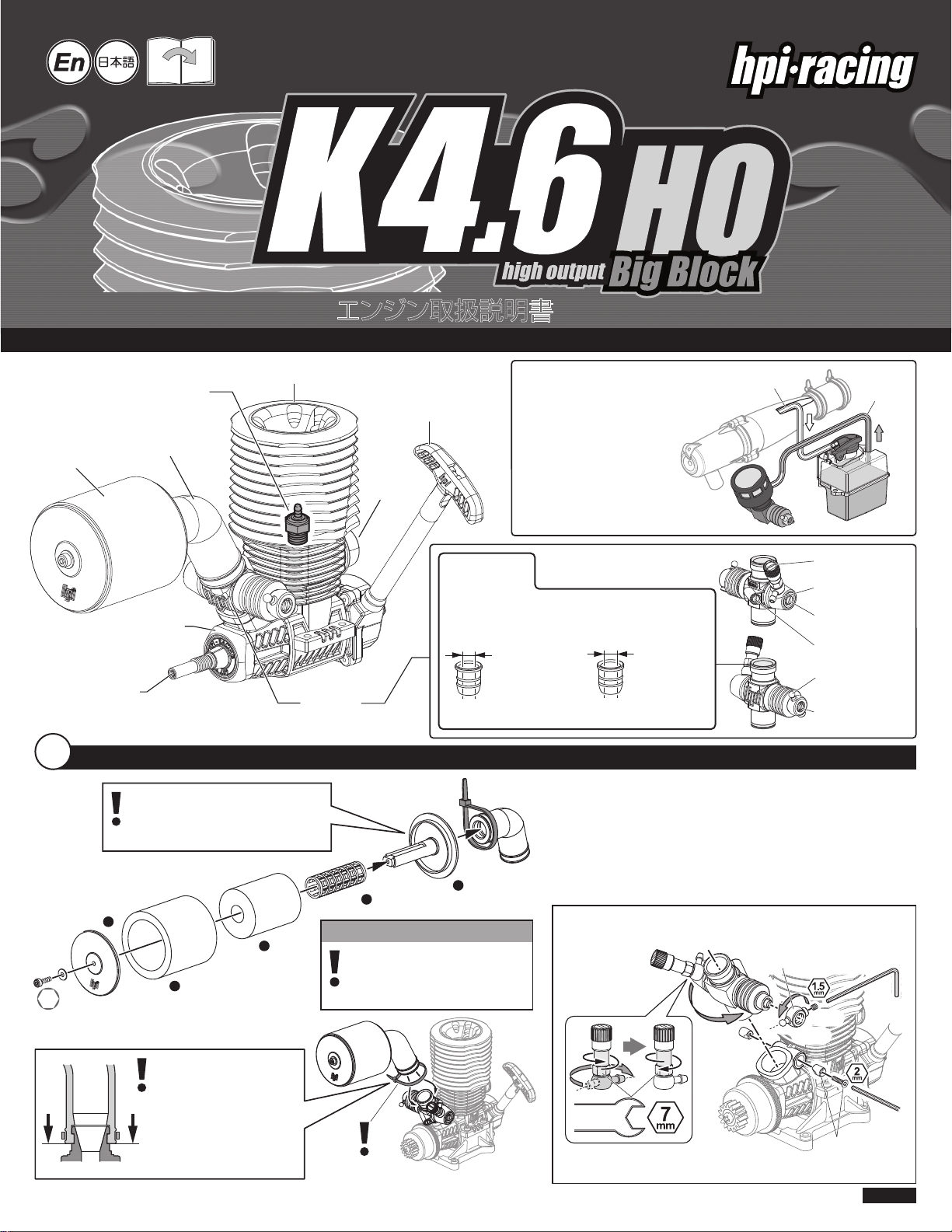

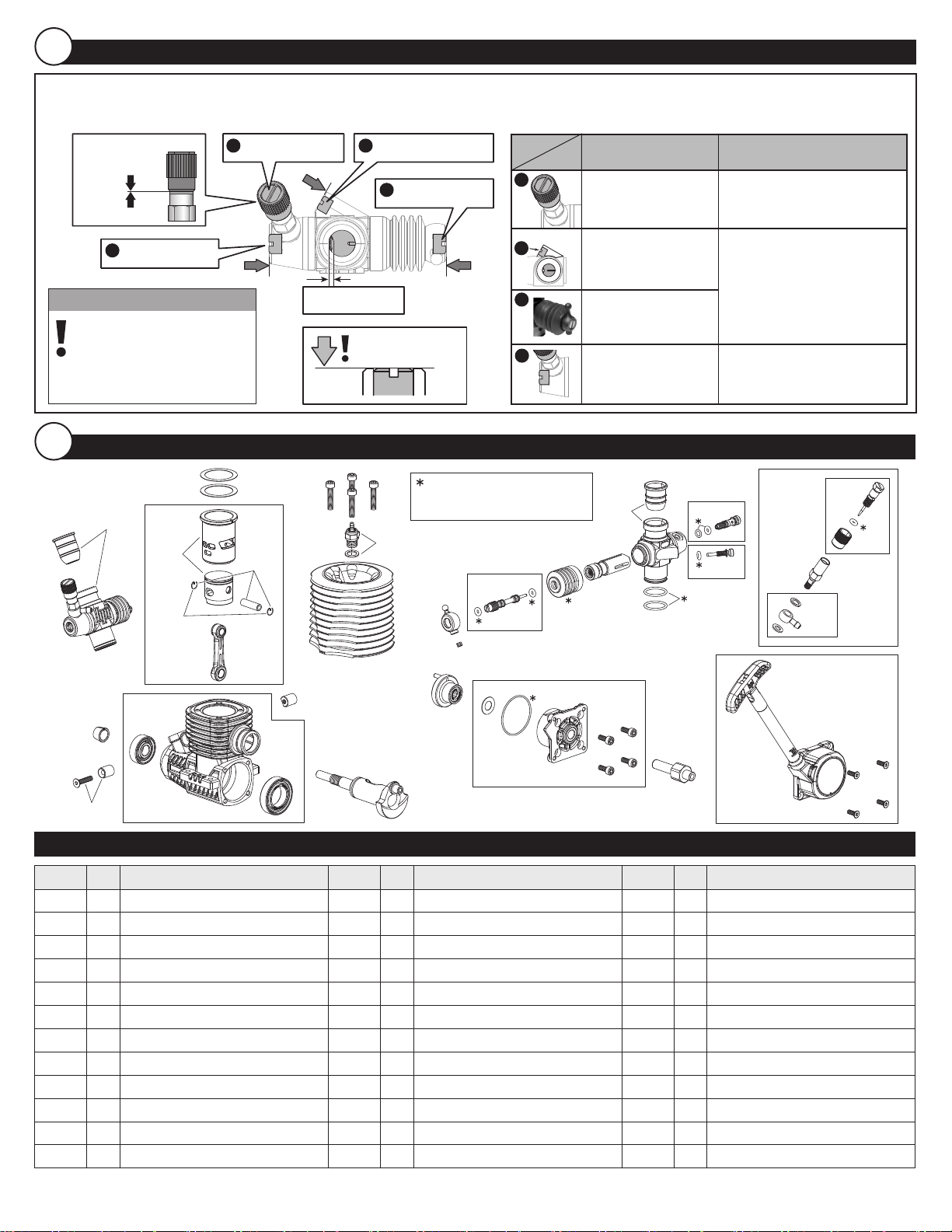

Engine Features

Glow Pulug

グロープラグ

Air Filter Boot

Air Filter

エアフィルター

エアフィルターブーツ

エンジン解説

Heat Sink

ヒートシンクヘッド

Pull Starter

リコイルスターター本体

Exhaust Outlet

排気口

Fuel Line System

The Fuel Line supplies fuel to

the engine. The Pressure line

pressurizes the fuel tank to

keep the fuel flow even.

燃料系統

燃料チューブは、燃料をエンジンに供給

します。エアプレッシャーチューブは、

燃料タンクに圧力をかけ燃料の供給が

安定して行われるようにします。

Pressure Line

エアプレッシャーチューブ

Fuel Line

燃料チューブ

Crankcase

クランクケース

Crankshaft

クランクシャフト

1

Reinstalling the Filter Element エアフィルターの取り付け

Carburetor

キャブレター

Make sure the air filter is fully seated

on the carburetor and secure it with

a nylon tie strap (6154).

ナイロンストラップ(6154)で確実に固定してください。

87199

b

87199

a

Z224

M3x8mm

2.5

mm

Z543

M3x10mm

87199

87204

b

87204

a

Attention注意

If the air filter falls off, you must

stop the engine immediately.

走行中にエアフィルターが外れた場合はすぐ

に走行をやめエンジンを停止してください。

Make sure the air filter is

fully seated on the carburetor and secure it with a

nylon tie strap (6154).

エルボーをしっかり溝にはめ込みナ

イロンストラップ(6154 )で確実に

固定してください。固定されていな

いと走行中に外れ、エンジン内にゴ

ミが入りエンジンが破損します。

6154

Option

オプション

You can change the engine characteristics by installing

a restrictor.

レデューサーを交換することでエンジンの特性を変更できます。

8.0mm

Restrictor 8.0mm

レデューサー

For less fuel consumption

燃費が良くなります。

6154

8.5mm

More top end power

パワーが出やすくなります。

Use thread lock on mounting screws when installing the engine in to the chassis.

エンジンをシャーシに取り付ける時は、取り付けネジにネジ止め剤を使用してください。

Carburetor

キャブレター

Restrictor 8.5mm

レデューサー

Make sure the throttle and brake linkage are in the correct position.

スロットルリンケージの位置を確認してください。

Do not adjust carburetor needles until break in is complete. The needle are set

87509

c

flush with the carburetor body from the factory, this is the proper break in setting.

キャブレターのニードルは変更しないでください。

出荷時にブレークイン用のセッティングになっています。

For use with savage rotate the carburetor 180 degrees.

SAVAGEに使用する時は、キャブレターの向きを逆にします。

Push down on carburetor while tightening the carburetor lock pin screw.

キャブレターを固定するときは押し込みながらロックピンを固定します。

Page 1/16

15231

High Speed Needle

メインニードル

Fuel Inlet

燃料取入れ口

Mid Range Needle

ミッドレンジニードル

Idle Adjustment Screw

アイドリング調整ネジ

Throttle Linkage

スロットルリンケージ

ボールジョイント

Low Speed Needle

スローニードル

Horizontal position.

水平にします。

Z700

15266

15231

Z901

Z904

I-15204-1

Page 2

2

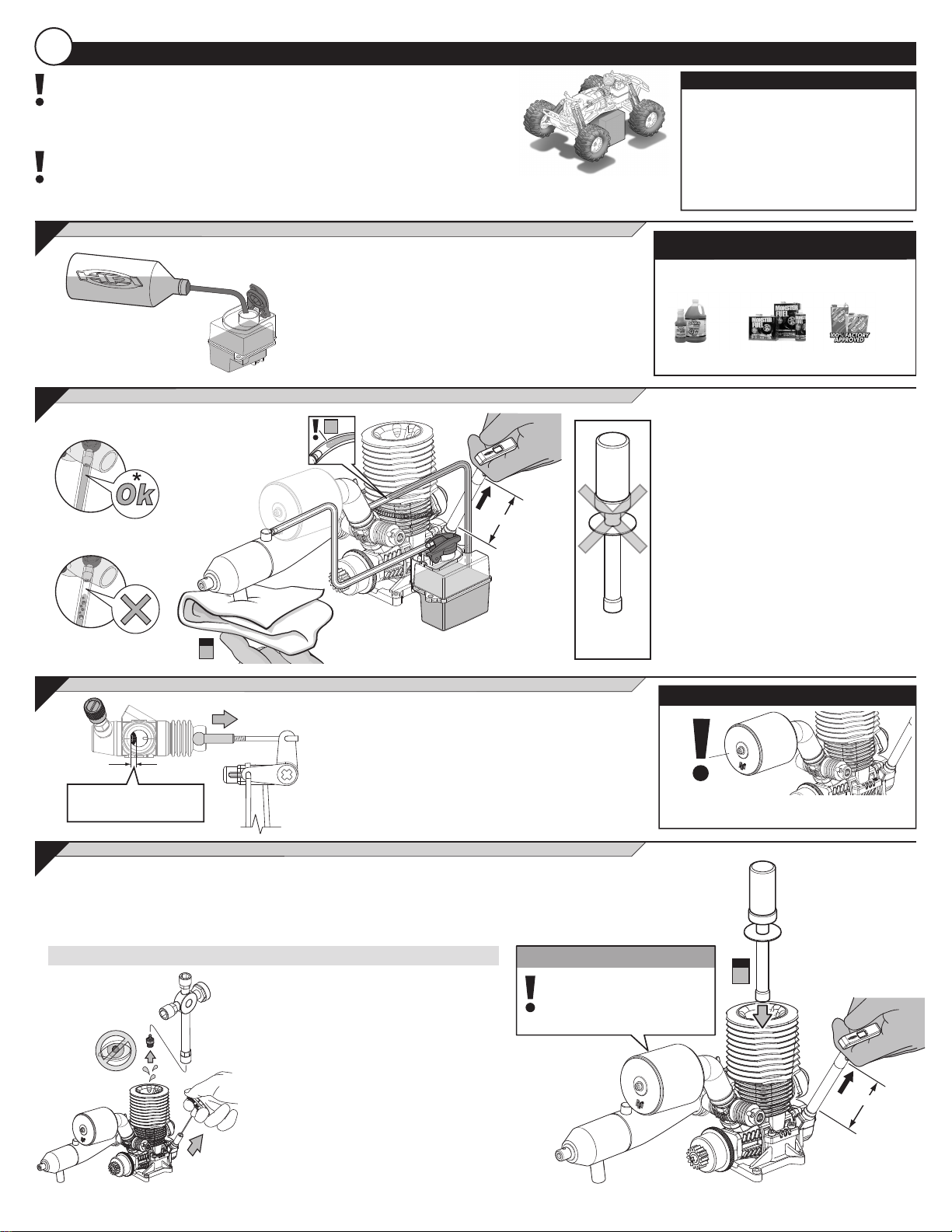

Engine Break In エンジンブレークイン

Important:

HPI engines will feel tight at the top of their stroke when they are new or when they have not

reached their normal operating temperatures. The piston and cylinder sleeves are designed

to achieve proper running tolerances when they are properly broken in and are operating at

the correct temperature. New engines need a break in period of about 3 to 4 tanks of fuel

before they can be run at Full throttle, if not the engine could be damaged.

重要

HPI製のエンジンは新品時及びエンジンが十分に温まっていないときには動きが硬く感じることがあります。これは適切なブレ

ークインがされ、エンジンが十分に温まったときにピストンとシリンダーがスムーズに作動するように設計されているためです。

新品のエンジンは全開走行するまでに3-4タンク分のブレークインが必要です。ブレークインが不十分な場合はエンジンを破損

する恐れがあります。

Fill Fuel Tank 燃料タンクに燃料をいれます。

1

Fill the tank completely with fuel. Use only 20 to 25% Nitro content

fuel. Use high quality branded model car fuel only. Using the non-car

fuels could void your warranty.d be damaged.

燃料タンクに燃料をいっぱいまで入れてください。燃料はHPI製RCカー専用燃料もしくは、ニト

ロ含有量20-25%の高品質RCカー専用燃料をご使用ください。カー専用燃料以外の燃料をご

使用された場合の保障は致しかねます。

Priming Engine 燃料をキャブレターに送る

2

3

12"30cmMAX!

Keep the wheels off the ground.

ダイなどを使ってタイヤが地面から離れて

いる状態にします。

Attention 注意

For non-pull start engines, please refer to

the engine start up section of your car kit

manual for proper starting procedures.

プルスターター装着者 でない場合 は、お手持ちのキットの

説明書を参考にしてエンジンを始動させてください。

Recommended Nitro Content

下記ニトロ含有量の燃料をお使いください。

20% - 25%

74318/ 74348

20% Glow Fuel

(US only)

To prime the engine, use your finger to cover the

exhaust tip. Pull the starter chord several times

until fuel reaches the carburetor and no bubbles

are seen. Never pull the starter chord more than

30cm max as it will damage the starter.

エンジン始動準備のため、マフラー出口を指で塞いでプルスター

ターを数回引き、燃料がキャブレターまで行き渡るようにします。こ

のとき燃料に気泡が混ざっていないように気をつけてください。気

泡がみられるときにはもう一度プルスターターを引いてください。(

プルスターターを何度も引くと、燃料がエンジン内にあふれエンジ

ンが始動できなくなりますので注意してください)。

また、プルスターターの破損を防ぐために30cm以上引かないでく

ださい!

38704/ 38705

38706 グロー燃料

(JP only)

25% Nitro Content

25% Kraftstoff

25% Carburant

Step

1

Open the Carburetor スロットルを開きます

3

Make sure the receiver switch is off. Manually turn the throttle

servo by hand until the carburetor is 1/4 of the way open.

受信機スイッチが切れていることを確認します。手動でスロットルサーボを動かしてキャブレ

ターを1/4開けます。

1/4 of the way open.

キャブレターを1/4開けます。

Glow Plug and Starter エンジン始動

4

Attach the glow igniter to the glow plug. Start the engine by pulling the starter chord in short pulls (no longer than 30cm max). Adjust

the throttle servo so the engine runs fast enough to idle smoothly without engaging the clutch or turning the wheels. Remove the glow

igniter as soon as the engine is running. Run the engine for one tank of gas. If the motor shuts off, repeat steps 1-4.

グロープラグにプラグブースターを取り付け、プルスターターを短く引きます。(30cm以上は絶対に引っ張らないでください。) アイドリングが安定し、クラッチがつながっていない状

態になるようスロットルを調節します。エンジンが始動したらプラグブースターを取り外してください。

そのままの状態でエンジンを1タンクまわしてください。もしエンジンが燃料を使い切る前にストップした場合はステップ1-4を繰り返してください。

Flooded Engine オーバーチョーク

70332

If there is too much fuel in the cylinder, the

engine will not start.

Follow the step below to remove excess fuel

from the cylinder.

NO!

Attention 注意

The engine must never be run without the air filter in place!

エアフィルターなしでは絶対にエンジンを始動しないでください。

Attention注意

The engine must never be run

without the air filter in place!

エアフィルターなしでは絶対にエンジン

を始動しないでください。

Remove the glow plug and pull the starter

cord several times to remove excess fuel.

Reinstall the glow plug .

燃料を多く送りすぎるとエンジン内に燃料があふれ、エンジ

ンの始動ができなくなります。

次の手順でエンジン内の燃料を取り除いてください。

グロープラグを取り外し、プルスターターを数回引き、エンジン

内にあふれた燃料を抜き取ります。この時プラグ穴から燃料が

吹き出すので燃料が目にはいらないように注意してください。

燃料が抜けた後、再びグロープラグを取り付けます。

Step

1

12"30cmMAX!

Page 2/16

Page 3

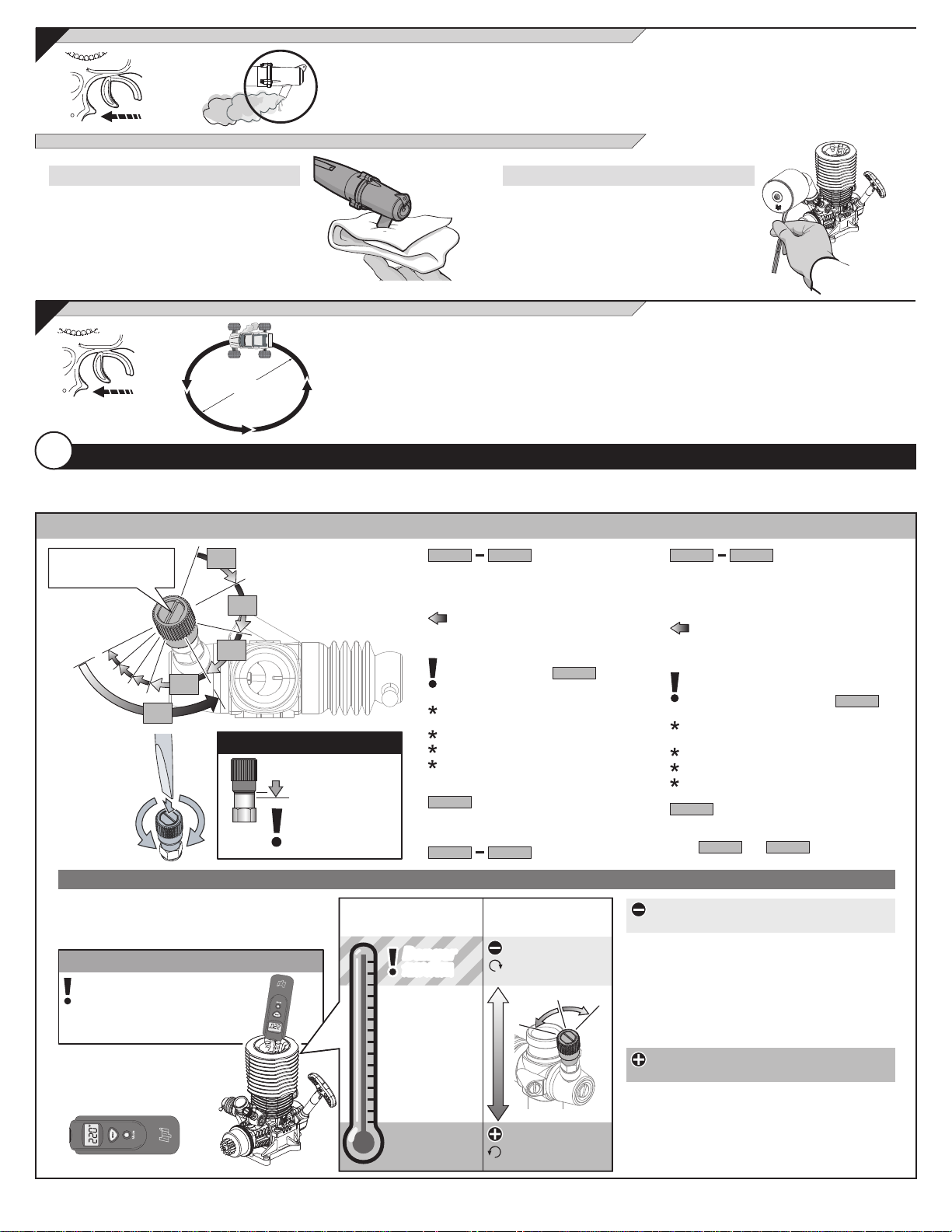

Keeping it Running 走行ブレークインの準備

5

Slowly.

ゆっくりとスロ

ット ル を開 け

ていきます。

Tip エンジンの停止方法

Turn on the transmitter and receiver, re-fill the fuel tank and follow the starting procedures in steps 1-4. With the tires

off the ground, use the radio to slowly increase the throttle until it reaches full speed, then release. This will help

clean the excess oil out of the engine. Because of the rich break-in settings, the motor needs to periodcally be

"cleaned out" to prevent it from stalling.

送信機、受信機の順に電源を入れます。燃料タンクに燃料を入れ、1-4の順にスタートをしてください。タイヤが地面から離れている状態のまま、送信機を操作

してゆっくりスロットルを開けます。最高速になったら、スロットルを緩めてください。こうすることでエンジン内にたまったオイルを排出することが出来ます。ブ

レークイン時は燃料が濃い状態になっています。そのためエンストを防ぐために時々エンジン内のオイルを排出する必要があります。

Use a Rag 布を使う

Use a rag to cover the exhaust tip. This will

stop the engine. Be careful! The exhaust is

extremely hot so be sure to use a thick rag.

排気口を布で覆うことでエンジンを停止することができます。

排気口は大変熱いので必ず厚手の布を使い火傷をしないよう

にに十分注意してください。

1/2 Throttle Driving ハーフスロットルによるブレークイン走行

6

20' (6mm)

1/2 Throttle

ハーフスロットル

3

Tuning After Break In ブレークイン後の調整

Rag

ウエス

Place the vehicle on the ground. The vehicle should not move when idling. If it does, adjust the trim setting on the

transmitter so the vehicle does not move. Drive the vehicle in a 20 foot (6m) oval applying throttle (below 1/2

throttle), coast for a short period of time to allow the engine to cool, then accelerate again. Continue this process for

a total of two tanks of fuel.

エンジンを始動して、車を地面に置いてください。アイドリング状態では車は動きません。もし車が進み始める場合は、スロットルトリムで車が走らないように調

節してください。スロットルを半分ほど開けた状態で、車が直径6mほどの円を描くように走らせます。エンジンの温度を上げないためにアクセルを戻したり、

1/2ほど開けたりを繰り返します。2タンク分、この動作を繰り返してください。

Pinch the Fuel Line 燃料チューブをつまむ

In extreme cases or emergencies you can pinch

the fuel line to stop the flow of fuel to the carb.

燃料チューブをつまむことで燃料の供給を止めエンジンを停

止することができます。

Important! Read this section carefully: Failure to follow these tuning steps could result in damage your engine, and void your warranty !

重要この項目にはエンジンの破損につながる大切なことが書かれています。必ずよくお読みください。この項目に従わなかった場合の破損には保障をいたしかねますのでご承知ください。

Tuning for Optimum Performance エンジンの性能を引き出す為の調節

High Speed Needle

メインニードル

Step X

ステップ

Use screwdriver to

adjust high speed

needle.

ニードルはマイナスドラ

イバーで回します。

Step 4

ステップ4

X

1/8

1/4

Step 1

ステップ1

Step 2

ステップ2

Step 3

ステップ3

Caution 警告

2 1/2 turn

MAX

2 1/2 turn MAX

clockwise from Groove.

溝切り部から2 1/2回転以上は

締め込まないでください。

STEP 1 STEP 4

Turn the high speed needle clockwise in 1/8 turn

increments to lean out the fuel mixture for increased

top speed and throttle performance. Drive the car to

notice changes in speed and throttle response.

Continue Tuning:

Continue leaning the carb in Clockwise 1/8

turn increments.

(Maximum of 2 1/2 turns from flush.)

STOP Tuning:

Stop tuning and go to if your

engine shows any of the follow signs.

(Engine is running too lean.)

At full throttle, these is no smoke from the

exaust.

STEP X

The engine hesitates or bogs.

Reduced top speed and loss of power.

Overheating

Temperatures above 250°C (120°F)

at the glow plug.

STEP X

If your engine is running lean, turn the needle

counter clockwise 1/4 turn to richen the fuel

mixture and repeat

STEP X

STEP 1

ステップ1 ステップ4

メインニードルを時計回りにの方向に1/8回転ずつ締めこん

でいきます。こうすることで燃料の混合比を薄くすることがで

き、最高速、スロットル操作に対する反応が向 上します。車を

運転しながら、スピードとスロットル操作に対する反応の違い

に注意してください。

調節を続けます

メインニードルを1/8回転 ずつ締め込み、混合 比を薄くして

いきま す。(最大 締め 込み量 はキャブレター 同 一面 から2

1/2回転までです。)

調整の中止

もし、エンジンが以下に記した症状のうちのどれか一つで

も示したときは、チューニングを中止してに

戻ってください。

スロットルを全開にした状態で、マフラーから煙が排出さ

れていない。

スロットル操作に対して反応が鈍い。息継ぎをする。

最高速が落ちる、またはパワーが出ていない。

オーバーヒート

エンジン(グロープラグの位置で計測)の温度が120度以上

ステップX

もし燃料の混 合比が薄すぎる場合は、メインニードルを1/4

回転反時計回りにまわし、混合比を濃くします。

そして から を繰り返します。

ステップ1

ステップX

ステップ4

Fuel Mixture Tuning Tip 適切な燃料混合比のヒント

Engine temperature can tell you if the engine is

running lean or rich.

燃料混合比とエンジン温度の関係は比例しています。

Attention 注意

Adjust carburetor to keep the

operating temperature below

250°F.

エンジン温度が120℃以下になるように

燃料混合比を調整します。

74151

HPI Racing Temp Gun

HPI温度計

Engine Temperature

エンジン温度

Danger

Danger

危険範囲

危険範囲

250°F

(

)

120°C

230°F

(

)

110°C

Safe Range

安全範囲

210°F

(

)

99°C

190°F

(

)

90°C

Break in

ブレークイン

Page 3/16

Fuel Mixture Tuning

燃料混合比の調節

Less Fuel = Lean

ニードルを時計回り=

混合比が薄くなる

More Fuel = Rich

ニードルを反時計回り=

混合比が濃くなる

Less Fuel = Lean

ニードルを時計回り=混合比が薄くなる

Lean Fuel Mixture

Provides strong and efficient combustion and power,

but if you lean out too much the result is less lubrication, more engine heat and shorter engine life.

混合比が薄い状態

燃料の燃焼 が効率よく行われパワーがでます。しかし、薄くしすぎると

燃料の潤滑が行われずオーバーヒートを招きエンジンの寿命が短くな

り破損します。

More Fuel = Rich

ニードルを反時計回り=混合比が濃くなる

Rich Fuel Mixture

A slightly rich fuel mixture delivers a cooler running

temperature and more lubrication but with slightly

less power and longer engine life.

混合比が濃い状態

混合比が濃い状態ではエンジン内の潤滑が良くエンジン温度も低めに

安定します。エンジンに対して優しいですが、パワーはやや落ちます。

Page 4

4

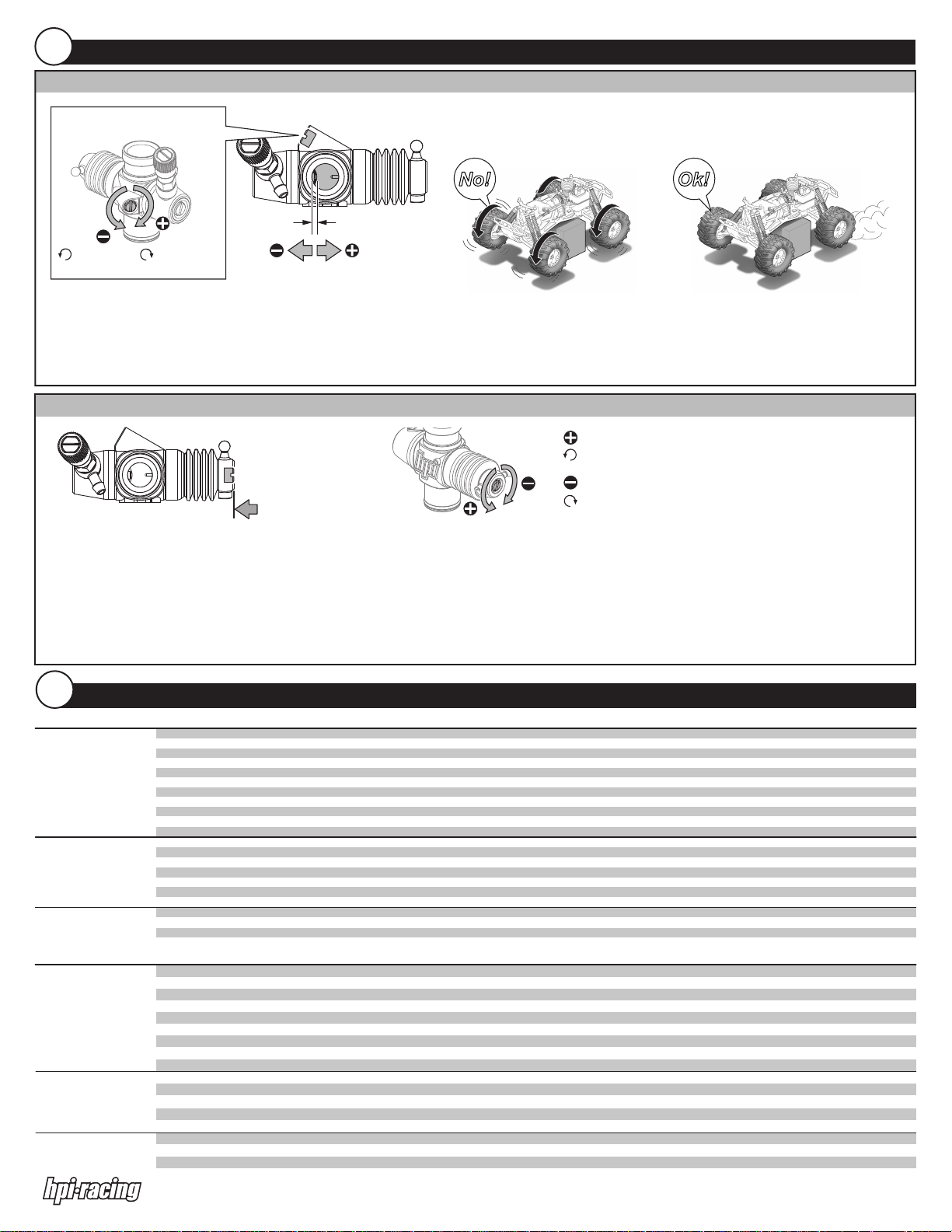

Optional Tuning その他のエンジン調整

Idle Adjustment Screw アイドリング調整ネジ

Idle Adjustment Screw

アイドリング調整ネジ

Improper Idle Speed Setting

Clutch engaged and wheels turning.

アイドリングの調整ができていない場合

クラッチがつながった状態で、タイヤが回転します。

Proper Idle Speed Setting

Engine runs smoothly without wheels turning.

アイドリングの調整が正しくできている状態

アイドリングが安定した状態で、タイヤが回転していません。

No! Ok!

About 1mm (0.04")

約1mm

RPM Low

回転数低くなる

The idle speed is set after the high-speed needle is adjusted and the engine is up to operating temperature. To properly set the Idle Adjustment Screw, turn on your radio system and

set the throttle trim on the transmitter so that the throttle is in its neutral position. This will ensure that the throttle slide is fully closed and resting against the idle adjustment screw. Turn

the idle adjustment screw counter clockwise to reduce the idle speed, or clockwise to increase it. The idle speed should be set high enough to keep the engine running smoothly but not

engage the clutch and turn the wheels. Too high of an idle speed will prematurely wear out the clutch shoes and brake disk.

アイドリングの調整はスロットルがニュートラルの時にタイヤが回転してしまう場合に調整が必要となります。アイドリングの調整はメインニードルの調整が済んだ後、エンジンが充分に温まった状態で行います。アイドリングスピードを

上げたいときにはアイドリング調整ネジを時計回りに、下げたいときには反時計回りに回してください。アイドリングはエンジン回転が安定しながらクラッチはつながらずタイヤが回転していない状態が最適の状態です。アイドリングの

回転が高すぎるとクラッチシューやブレーキディスクの消耗が早くなります。

Low Speed Needle Adjustment スローニードルの調節

RPM High

回転数高くなる

Flush (Factory Setting)

キャブレター本体と同一面

(工場出荷時設定)

Low Speed Needle

スローニードル

More Fuel = Rich

ニードルを反時計回り=

混合比が濃くなる

Less Fuel = Lean

ニードルを時計回り=

混合比が薄くなる

If idle is unstable, adjust the low

speed needle to get a stable idle.

Afterwards, you need to readjust

the idle adjustment screw.

スローニードルを調整するとアイドリング状態

の燃料混合比が 変化します。再度アイドリング

の調整を行ってください。

We recomend that you do not touch the Low Speed Needle. If adjustment is needed, the low-speed mixture is set after the high-speed needle is adjusted and the engine is up to

operating temperature. Set the needle flush (Factory Setting) with the carburetor body, this setting is ideal for and breaking in and starting your motor. For increased performance turn the

needle in 1/8 turn increments; this will improve bottom end throttle response. To test your setting, place the car on the ground and let the engine idle for 30 seconds then accelerate to 3/4

throttle. If there is a lot of white smoke and the car accelerates slowly, the mixture is too rich. If the engine accelerates quickly and then sputters, the mixture is too lean.

When the low-speed needle is set correctly the engine's throttle response should be smooth and quick. CAUTION: Never turn in more than 2 turns from flush this will cause the

engine to run too lean and may damage your engine! If the Low Speed Needle is set too lean you will experience the following: Flame out at part or 3/4 throttle, Overheating

(Temperatures above 250°C (120°F) at the glow plug). If your engine is running too lean, reset the Low Speed Needle to its factory setting (Flush) and start the tuning process again.

スローニードルの調節は工場出荷時設定(初期設定)のままにしておくことをお勧めします。調整が必要な場合はメインニードルの調整が済んだ後、エンジンが十分に温まった状態で行います。

スローニードルはエンジンの反応を調節することができます。適切な調整か確認するためには、車を地面に置いて30秒ほどアイドリング状態にした後、スロットルを3/4ほど開けてください。このとき白い煙がたくさん排出されエンジ

ン反応が悪い場合には混合比が濃すぎます。エンジンが素早く反応した後エンジン回転がばらつく場合は混合比が薄すぎる状態です。スローニードルの調節が適切にできているときには、スロットル操作に対する反応が素早くスムーズ

になります。注意;スローニードルはキャブレター本体と同一面(工場出荷時設定)の状態から2回転以上締めないでください。混合比が薄すぎる状態になりエンジンが破損します。

5

Troubleshooting トラブルシューティング

Description Possible Problem Solution

Engine does not start

Engine starts, then stalls

Ralenti trop haut

Fuel mixture needle settings are out of range

Engine could be worn out

Out of fuel

Contaminated fuel

Glow plug igniter is not charged

Glow plug is bad

No fuel flow

Engine flooded

Engine has overheated

Throttle valve isn’t adjusted properly

Air cleaner is blocked

Idle speed is set too low

Air bubbles in the fuel line

Glow plug is bad

Engine is overheated

Airflow through system is bad

Throttle servo is improperly set up

Throttle servo glitch

Idle adjustment screw is set too high

Low speed needle set too lean

Improperly set neutral on transmitter throttle trigger See your radio and car kit instructions for setting neutral on transmitter throttle trigger

Set the needles to the factory setting, see page 5 sec 6

Replace piston and sleeve

Refill fuel tank

Replace fuel

Charge glow igniter

Replace glow plug

Check fuel lines for cracks, leaks, and holes. Replace fuel line if necessary.

Remove glow plug and discharge fuel

Allow engine to cool, richen the fuel mixture and then restart

Set idle and adjust neddle valve to the maunfacturers recommended settings

Check air filter. Clean or replace if necessary

Adjust the idle speed

Check for leaks or cracks in the fuel line

Replace glow plug

Allow engine to cool and then restart

Check connections between tank, engine and exhaust

Set servo to neutral and reset linkages according to radio and model manufacturer’s specifications.

Replace the radio batteries

Set idle screw to factory setting, see page 5 for proper idle speed adjustment

Set low speed needle to factory setting, see page 5 for proper low speed needle adjustment

症状 原因 調べる箇所と直し方

エンジンがかからない

エンジンはか かるが

すぐに止まる

アイドリングが高すぎる

ニードルの調節が適切に出来ていない

エンジンが傷んでいる

燃料が入っていない。燃料がエンジンまで来ていない。

プラグが切れている。プラグヒート用電池が減っている。

燃料チューブ・燃料タンクのつまり

エアクリーナー・マフラー内の汚れ

オーバーチョーク(チョークのしすぎ)

キャブレターの調整不良

サーボリンケージの調整不良

燃料タンクに燃料が入っていない

燃料チューブ・エアクリーナー・マフラー内の汚れ

スロットルバルブの調整不備

エンジンのオーバーヒート

スロットルサーボの動作不良

アイドリングの設定が高すぎる

低速の燃料混合比が薄すぎる

送信機のスロットルのニュートラルが出ていない

説明書5ページの6を参照に工場出荷時の設定に戻す

ピストンとシリンダーを交換する

燃料タンクに燃料をいれ、エンジンまで燃料を送る。(チョーク)

プラグを交換する。電池を新品に交換する。

燃料チューブ・燃料タンクの掃除、又は交換

エアクリーナー・マフラー内の掃除、又は交換

プラグを外しエンジン内の燃料を空にする。

ニードルバルブ・アイドリング調整ネジを元の位置に戻す

サーボをニュートラルにしてから、再度リンケージを調整

燃料タンクに燃料を入れる

汚れている部分の掃除、又は交換

スロットルバルブ及びアイドル・ニードルの調整

エンジンが冷えるのを待ってからニードルを1/4開ける。

プロポのバッテリーを交換する

アイドリング調整ネジを説明書5ページを参照に工場出荷時の設定に戻す

スローニードルを説明書5ページを参照に工場出荷時の設定に戻す

お手持ちのプロポ、キットの説明書を参照にスロットルのニュートラルの設定をする

Page 4/16

Page 5

6

Carburetor Factory Setting (Break In Setting) キャブレター工場出荷時設定(初期設定)

High Speed Needle is set flush with groove, Idle Adjustment Screw, Low speed needle and Mid Range Needle are designed to be set flush with the carburetor body. This makes

it easy to reset the carburetor to the Factory Break In Setting if needed.

工場出荷時設定(初期設定)に戻しやすいよう、各ニードルの工場出荷時設定(初期設定)はメインニードルは本体溝切り部と同一線上、アイドリング調整ネジ、スローニードル及び、ミッドレンジニードルはキャブレター本体と同一面上にな

るように設計されています。

Flush with Groove.

溝切り部と同一線上

High Speed Needle

a

メインニードル

Idle Adjustment Screw

b

アイドリング調節ネジ

Low Speed Needle

c

スローニードル

Break-in Setting

ブレークイン時の設定

a

Flush with groove

溝切り部と同一線上

After Break-in Setting

ブレークイン終了後の設定

Please refer to the Tuning After Break-in

section on pg. 3 for tuning tips.

3ページのブレークイン後の調整を参照してください。

Mid Range Needle

d

ミッドレンジニードル

Attention 注意

When needle is over tightened

the needle is damaged.

ニードルが止まる所ま閉めてしまうとニード

ルの先端に傷がつき(破損)、燃料混合比が

調節できなくなります。ニードルが止まるま

で閉めないでください。

7

Exploded View 分解図

15261

15218

15217

15215

,

15228

15214

15213

About 1mm (0.04")

約1mm

Flush

キャブレター本体と同一面

15237

15243

15241

Dust Protection And O-ring Complete Set

スロットルカバー/Oリングセット

1504

15268

15266

Z700

b

c

Flush with groove

キャブレター本体と同一面上

Flush with groove

キャブレター本体と同一面上

Please refer to the Optional Tuning

section on pg. 4 for tuning tips.

4ページのその他のエンジン調整を参照してく

ださい。

d

Flush with groove

キャブレター本体と同一面上

15283

15269

Do not need to adjust

設定変更はしないでください。

15282

15271

15285

15275

15274

15272

15226

86077

15231

15244

Spare Parts スペアパーツ

Number

品番

15204 x1 Nitro Star K4.6 HO Engine With Pullstart

1504 x1 Glow Plug Cold R5

15213 x1 Connecting Rod

15214 x1 Piston Pin/retainer Set

15215 x3 Retainer For Piston Pin

15217 x1 Cylinder/Piston Set

15218 x1 Cylinder/piston/connecting Rod Set

15226 x1 Pullstart Assy. (W/o One-way Bearing)

15228 x1 Gasket Set For Cylinder (0.15mm/0.3mm)

15231 x1 Lock Pin Set For Carburetor

15233 x1 Pullstart Shaft Holder

15234 x1 Starting Shaft

Qty.

Description

入数

品名

ナイトロスターK4.6HOエンジン(リコイル付)

グロープラグコールドR5

コンロッド

ピストンピン/リテーナーセット

リテーナー

シリンダー/ピストンセット

シリンダー/ピストン/コンロッドセット

リコイルスターターセット(ワンウェイ無)

ガスケットセット(0.15mm/0.3mm)

キャブレターロックピンセット

ワンウェイホルダー

スターターシャフト

15231

15233

15236

15245

Number

品番

15236 x1 Cover Plate Set

15237 x4 Screw M3.5x16mm For Heatsink Head

15241 x1 Dust Protection And O-ring Complete Set

15243 x1 Heatsink Head (Gray/K4.6 HO)

15244 x1 Crank Case (K4.6 HO)

15245 x1 Crankshaft (K4.6 HO)

15261 x1

15266 x1 Uniball

15268 x1 Low Speed Needle Valve With O-ring

15269 x1 Slide Valve

15271 x1 Idle Adjustment Screw With O-ring

15272 x1 Fuel Line Fitting/Washer Set

Qty.

Description

入数

品名

カバープレートセット

シリンダーヘッドスクリュー

スロットルカバー/Oリングセット

ヒートシンクヘッド(グレー/K4.6HO)

クランクケース

クランクシャフト

Slide Carburetor Complete W/ Restrictors (Type KB)

スライドキャブレターセットレデューサー付(タイプKB)

スロットルバルブボール

スローニードルバルブ

スライドバルブ

アイドルアジャストスクリュー

ニップル

Z542

15234

Number

品番

15274 x1 High Speed Needle Valve Holder

15275 x1 High Speed Needle Valve With O-ring

15282 x1 Mid Range Needle Valve With O-ring

15283 x1

15285 x1 High Speed Needle Valve Set

86077 x2 Collet 7x6.5mm (Brass/21 Size)

87198 x1 Air Cleaner (21+ Size)

87199 x1 Air Cleaner Sleeve Set (For #87198)

87204 x1 Air Cleaner Foam Element Set (For #87198)

94154 x12 Flat Head Screw M2.6x8mm (Hex Socket)

Z542 x12 Cap Head Screw M3x8mm

Z700 x6 Set Screw M3x3mm

Qty.

Description

入数

品名

メインニードルバルブホルダー

メインニードル

ミッドレンジニードルバルブ(Oリング付)

Slide Carburetor Main Body W/restrictors(Type KB)

スライドキャブレターメインボディー(コンポジット)

メインニードルバルブセット

コレット(21サイズ)

エアフィルター(21サイズエンジン以上)

スリーブセット(#87198エアクリーナー用)

エレメントセット(#87198エアクリーナー用)

サラネジ(六角ソケット)

キャップネジ

セットスクリュー

94154

Page 5/16

Page 6

8

Optional Tuning メンテナンス

Glow Plug グロープラグ

How Glow Plugs Work:

Unlike full sized car engines that use spark plugs and a distributor to fire the cylinders in the combustion cycle, glow engines rely on glow plugs. In a Nitro engine,

ignition is initiated by the application of a glow igniter. When the igniter is disconnected, the heat inside the combustion chamber keeps the glow plug filament

glowing, firing the next cycle thereby keeping the engine running. Ignition timing in a glow engine is automatic. At higher RPM’s the plug becomes hotter, firing the

fuel/air mixture earlier, effectively advancing the timing. At lower RPM’s the plug becomes cooler, firing the fuel/air mixture later, effectively retarding the timing. Since

the glow plug performs so many important functions, proper plug selection and maintenance are crucial to a properly running engine.

グロープラグの仕組み

スパークプラグと点火装置によって点火する実車のエンジンと異なり、グローエンジンの点火はグロープラグによってのみ行われます。最初はグロープラグブースターを使用しエンジンに点火します。グロープ

ラグブースターが外された後は、エンジン燃焼室内の温度によりグロープラグのフィラメントが発熱し、次の燃焼を起こします。この繰り返しによりエンジンが回り続けるのです。また、グローエンジンの点火時

期は回転数、エンジン温度に合わせて変化します。高回転時にはグロープラグが高温になり、点火時期が早くなります。反対に、低回転時にはグロープラグが低温になり、点火時期が遅くなります。以上のように

グロープラグはエンジンにとって非常に重要な働きをしています。そのためグロープラグの選択、メンテナンスを適切に行うことがたいへん重要になります。

Outdoor Temp

外気温

Hot

暑い

Cold

寒い

When to replace the glow plug:

Fuel and temperature will have an effect on the performance, reliability, and life span of the

glow plug and therefore should be considered expendable engine components. Aside from

burnout or plug failure, there are several signs that can indicate the plug should be replaced.

Plug filament/plug body is discolored or the surface is rough.

Engine cuts out when idling.

グロープラグの交換時期

グロープラグの性能、寿命は使用燃料や条件により異なります。そのため、グロープラグは消耗品と考えてください。プ

ラグの焼き切れや損傷以外にも以下のような症状が出た場合にはプラグの交換が必要な可能性があります。

プラグフィラメントや本体が変色しているか、表面が荒れている

アイドリング時にエンジンが止まる

Glow Plug

グロープラグの種類

Glow Plug Cold R5

グロープラグコールドR5

Glow Plug Medium Cold R4

グロープラグミディアムコールドR4

Glow Plug Medium R3

グロープラグミディアムR3

Glow Plug Characteristics

グロープラグの特性

Cold plug will have better mid, high

RPM power and will last longer at

high temperature.

エンジン中高速の性能が安定する。

エンジンが高温になった時の耐久性が高い。

Hot plug will be easy to start and

stable for tuning. But will fail

sooner at high engine temperature.

エンジンの始動性、低速安定性が良い。

エンジンが高温になった時の耐久性が低い。

Plug filament is distorted or bent.

Engine becomes difficult to start.

プラグフィラメントが変形している

エンジンのかかりが悪くなる

Proper Glow Plug Selection:

Proper glow plug selection depends on several factors. Fuel type, nitro methane content, weather, and

altitude can drastically effect performance. Finding the best combination of fuel and plug temperature

for your driving condition is the key to getting the maximum performance out of your Nitro Star Engine.

Extending the life of your Glow Plug:

To maximize and extend the life of your glow plug follow these simple tips:

Remove the glow igniter when using more than 1/2 throttle or if the engine does not start after a few seconds.

Do not run the engine lean. Lean conditions will overheat the plug causing the element to be damaged or fail.

Use the best Fuel/Plug combination for your driving conditions.

Use a fuel that has a lower nitro content.

適切なグロープラグの選択

グロープラグの選択は、使用燃料、燃料のニトロ含有量、天候、走行場所の標高など、環境により大きく左右されます。

燃料と使用プラグを正しく選択することで、エンジンの持つ性能を最大限に引き出すことができます。

グロープラグを長持ちさせるコツ

グロープラグを長持ちさせるためには、以下の点を守ってください。

エンジン始動時にスロットルを1/2以上開けるとストップしてしまう、またはエンジンが始動しなかったときには

すぐにプラグヒーターを外してください。

燃料の混合比が薄すぎる状態では使用しないでください。エンジンがオーバーヒートを起こしプラグを損傷します。

エンジンを使用する環境に最適な燃料とプラグを使用してください。

ニトロ成分の含有率が低い燃料を使用することでプラグへの負担が減ります。

Filament

フィラメント

Bad Plug

Element may be damaged or

broken if it doesn’t light up

completely.

不合格

よく光らない場合はエレメントが破

損している恐れがあります。

Bad Plug

Element is broken or doesn’t

light up at all.

不合格

全く光らない場合はエレメントが破

損しています。

HOT!

高温!

Glow Plug Igniter

プラグブースター

Glow Plug

グロープラグ

Pliers

ペンチ

Good Plug

Element glows when tested.

合格

エレメントが光ります。

Air Filter エアフィルター

Proper Air Filter Maintenance:

Dirt is the biggest enemy of a nitro engine and proper air filter maintenance is one of the most important factors

that will effect your engines longevity. If you are using the air filter supplied with your kit, we recommend cleaning the

element after every run. If you are using an after market air filter, please follow the manufacturers recommendations.

Regardless, it is always a good habit to check the element after every run to make sure it is properly seated in the

filter body and that the body is fully seated on the carburetor. Never run the engine without the airfilter!

エアフィルターのメンテナンス

エンジンにとって大敵である泥やホコリからエンジンを守るために、エアフィルターのメンテナンスを正しく行ってください。キットに付属のエアフィ

ルターをご使用の場合は、一回の走行が終了するごとにエアフィルターの洗浄を行うことをお勧めします。他社製のエアフィルターをご使用の場合は

、他社製品の説明書にしたがってください。走行ごとにエアフィルターの状態(フィルターの汚れ具合、エアクリーナーの取り付け状態)を確認される

ことをお勧めします。エアフィルターを付けない状態では、決してエンジンをかけないでください!

Z190

Air Filter Oil

エアフィルターオイル

1 2 3

Reinstalling The Air Filter:

After properly cleaning the filter element make sure it is reinstalled

correctly. If you are using the filter that came with your kit, follow the

illustration to reinstall the filter element in the filter body. Make sure

there are no gaps between the element and body. Make sure the

filter is fully seated on the carburetor and secure it with a tie strap

(HPI part #6154). Never run the engine without the air filter!

エアフィルターの取り付け

エアフィルターの洗浄後、エアフィルターを正しく付け直します。キット付属のエアフィル

ターをご使用の場合は、付属の説明書を参考にエアフィルターの再装着を行ってくださ

い。フィルターを取り付ける際には、エアフィルターエレメントとエアクリーナー本体の間

に隙間がないように十分注意してください。そして、エアフィルターがキャブレター本体

にしっかりと取り付けられているか確認し、ストラップ(HPI製品番号#6154)で固定して

ください。エアフィルターを付けない状態では、決してエンジンをかけないでください!

Cleaning The Filter Element:

Remove and clean the air filter with nitro fuel when soiled. Spray fuel through the clean side to ensure proper dirt

removal.Squeeze the filter to remove excess fuel. To re-coat the air filter with oil, place the element in a plastic bag

with several drops of air filter oil. Using your fingers, work the oil into the element making sure it is evenly distributed.

エアフィルターの洗浄

エアフィルターが汚れた場合には、フィルターエレメントをエアフィルター本体から外して走行用燃料で洗います。フィルターエレメントのきれいな側か

ら走行用燃料をかけ、汚れを流し落としてください。そして、フィルターエレメントを絞り余分な燃料を取り除きます。洗い終わったフィルターエレメント

に市販のエアフィルターオイルを数滴注ぎ、ビニール袋等にいれ指先で揉むようにしてオイルをフィルターエレメント全体にいきわたらせてください。

87204

b

87199

6154

Z224

M3x8mm

Z543

M3x10mm

87199

87204

a

a

Never run the engine without the air filter!

エアフィルターを付けない状態では、決してエンジンをかけないでください!

6154

c

87199

87509

b

Note: Hinweis: 重要

OK!

Page 6/16

Page 7

Engine Storage Tips エンジンの保管上の注意

Storing The Engine:

Using proper storage techniques are not only a good habit but are critical to the life of your engine. Nitro fuel contains castor for lubrication. If the castor is not burned out of the engine, over

time it can gum up and damage the crank bearings. Using your fuel bottle, drain all remaining fuel from the tank. Use a fully charged igniter and try to restart the engine to burn any

remaining fuel out of the lines. Repeat this step until the engine will not start. After burning off the fuel, remove the glow plug and add several drops of after run oil then crank the engine over

to spread it throughout the engine. If you plan on storing your engine for long periods of time (more than 3 months), the after run oil may gum up as well but will not damage the bearings. To

prepare the engine for re use, use 70% Isopropyl Alcohol or Denatured Alcohol and cycle it through the engine using the pull starter or roto start. DO NOT TRY TO START THE ENGINE

WITH THE ALCOHOL! The few minutes you take to properly prepare your engine for storage can add valuable time to its operating life and maintain its optimum performance.

エンジンの保管方法

エンジンを長期間使用しないときには以下に示す方法により保管することでエンジンの寿命を延ばすことができます。走行用燃料内に含まれてる潤滑油が十分に燃焼されないと、残った潤滑油がエンジン内で固まり、ベアリングを破損すること

があります。そうならないために、まず燃料ボトルを使用し、燃料タンクに残った燃料を全て取り除いてください。次に、タンクを空にした状態でエンジンを始動させ、燃料パイプ内に残った燃料も全て燃焼させます。この作業を、エンジンがかから

なくなるまで繰り返します。燃料を完全に燃焼させた後、グロープラグを取り外し、プラグ口から市販のエンジンメンテナンスオイルを数滴、エンジン内部に注入します。数回エンジンをクランキングし、メンテナンスオイルをエンジン内部にいきわ

たらせます。3ヶ月以上エンジンを使用しない場合には、エンジンメンテナンスオイルがエンジン内で固まることがありますが、ベアリングを損傷させることはありません。エンジンを使用する際には、工業用アルコールをエンジン内に注入し、シャ

フトをクランクしてエンジン内部にいきわたらせてください。アルコールを使用してエンジンを始動させることは絶対にしないでください。適切なエンジンの保管方法を心がけることで、エンジンの寿命、性能を長時間維持することができます。

Engine Rebuilding エンジンのリビルト

There comes a time when your engine just won’t provide the performance it did when it was new. When that time comes a rebuild is in

order. Follow the steps below to disassemble, repair and then

reassemble the engine.

エンジンが新品時と同等の性能を発揮しないと感じたときは、エンジンのリビルドを行います。

下記の手順を参考に分解、修理及び組み立てをしてください。

Check engine compression.

If there is no compression, the

engine will not start.

エンジン圧縮の確認

エンジンの圧縮がなくなるとエンジンは始

動しません。

OK! NO!

Z903

2.5

mm

Allen Wrench 2.5mm

六角レンチ

Z904

2

mm

Allen Wrench 2.0mm

六角レンチ

70332

Glow Plug Wrench

グロープラグレンチ

Z164

Grease

グリス

39014

Oil Spray (Japan only)

オイルスプレー(日本のみ)

Z159

Thread Lock

ネジロック剤

1 2 3

2.5

mm

8

mm

1504

15237

Thread Lock

ネジロック剤

15243

2

94154

mm

15228

15217

5 4

15217

15215

15214

15215

Note Direction.

向きに注意

15213

0.1mm

NO!

Note: 重要

1

a

15236

15236

Before removing the back plate,

rotate crankshaft so the piston is at

the top of its stroke. If piston is in the

lower position, It will be damaged.

バックプレートを取り外す際、ピストンの位置に注

意してください。クランクシャフトをまわしてピス

トンの位置を上側にします。ピストンが下側にあ

るとエンジンが破損するので注意してください。

2

2.5

mm

Z542

15236

b

Grease

グリス

Z164

c

15234

6

15245

Engine Assembly エンジンの組立

After completely disassembling the engine, examine the components to determine which parts need to be

replaced. Scratches on the crankshaft, or piston and sleeve are signs that dirt has entered the engine.

Before reassembly, thoroughly clean all parts to make sure they are free of foreign debris. Reassemble the

engine in the reverse order of disassembly (Step 6 - Step 1). Make sure to note the direction of the oil hole

on the rod and the direction of the sleeve as they are critical to proper engine function. As you assemble the

engine, use a small amount of oil on each part to make sure they are well lubricated and move freely. When

you are finished, the new components will need to be broken in. Please turn to Page 2 and follow the

instructions to break in the new components.

エンジンを完全に分解した後、交換が必要な部品をチェックをします。クランクシャフトやピストン、シリンダー等に傷が入っている場合はエンジン内に異物

が入り込んだ可能性があります。再組み立てをする前に、異物の付着がないようにしっかりと洗浄してください。エンジンの組み立ては、分解の逆の順番で

行います。(ステップ6- ステップ1)組み立てる際には、コンロッドの油溝の向きとシリンダーの向きに充分注意してください。各部がスムーズに動くように、

少量のオイルを付けながら組み立てを行います。リビルド終了後は、新しく組み込んだパーツのブレークインが必要です。説明書2ページを参考にブレーク

インを行ってください。

Page 7/16

Page 8

9

Optional Tuning 保障

North American and European Customers

Your HPI product is warranted to be free from defects in materials and workmanship for a period of two (2) years from the purchase date. For verification,

please keep your original receipt in a safe place. If there are any defects with the materials, workmanship, or assembly of your engine, HPI will gladly

repair or replace it for you at our discretion. Products which have been worn out, abused, or improperly operated will not be covered under warranty.

Due to the complex nature of HPI Products and the legal requirements of different regions, warranties issued by HPI USA are only valid for products

sold to and used in the USA, Canda and South America. HPI USA warranties are not transferable to other parts of the world.

Not Covered By Warranty:

This warranty does not cover problems from normal wear, abuse, neglect, or any damage arising as a result of improper use, use of improper fuel, overheating, continuous

neglect, or damage from glow plugs. Please see the warranty cautions contained in this instruction manual to identify damage that may have been caused by improper use

or care of your engine.

HPI Racing shall not be liable for any loss or damages, whether direct, indirect, special, incidental, or consequential, arising from the use, misuse, or abuse of this product

and any accessory or chemical required to operate this product.

DO NOT return engines without prior approval. Please note any returned engine, which is inspected by our staff and is found to have an invalid warranty claim may be

subject to an inspection & handling fee before it can be returned. Any repairs made to engines resulting from neglect or misuse will be charged (parts & labor) before the

work is started.

Please contact Customer Service at Hobby Products International, Inc. for any warranty claims at 949 . 753 . 1099. Our Customer Service hours are Monday

7:30am-4:30pm, Tuesday to Friday 7:30am-5:00pm, Pacific Standard Time.

If directed to send your engine in for evaluation, customer service will issue an RMA#. When sending an engine to HPI for warranty service, the RMA# must be

clearly written on the packaging and must include a copy of the original receipt (please keep your original), a written description of the problem, and a daytime

phone number where you can be reached for questions. The engine must be returned complete with crankcase, crankshaft, piston, sleeve, connecting rod,

cylinder head, carburetor, and pull starter. You should not return the clutch, flywheel, flywheel collet, nut, air cleaner, manifold or muffler.

USA EUROPE

Send it prepaid UPS to:

Hobby Products International, Inc.

Attn: Customer Service

70 Icon Street

Foothill Ranch, CA 92610

For warranty claims please return the engine to the shop where you bought it, along with a copy of the original receipt (please keep the original), if directed by

HPI's distributor the shop will then return the engine for professional inspection. The engine must be returned with a written description of the problem, showing

a daytime phone number where you can be reached for questions. The engine must be returned complete with crankcase, crankshaft, piston, sleeve, connecting

rod, cylinder head, complete carburetor & pull starter. You should not return the clutch, flywheel, flywheel collet, nut, air cleaner, manifold or muffler.

In case of any further problems, please contact your local distributor, please check www.hpi-europe.com for details or call HPI Europe in the UK on 44 1283

229400 in normal office hours.

Asian and Oceania Customers:

アジア、オセアニア地区のお客様へ

If you have any questions or problems with your HPI product, please see a local HPI retailer in your country.

HPI製品に関して疑問や問題がございましたら、お住まいの国のHPI販売店へご相談ください。

Please return to your each instruction manual for proper after-run maintenance tips.

走行後のメンテナンスは各取り扱い説明書を参照してください。

Page 8/16

Page 9

De Fr

1

Motoranleitung Manuel du moteur

English

Motor Teile

Glühkerze

Luftfilter

Filtre à air

Bougie

Kühlkopf

Radiateur de refroidissement

Caractéristiques du moteur

Auslass

Sortie d'échappement

Seilzugstarter

Lanceur

Kraftstoffleitungs-System

Die Kraftstoffleitung versorgt den

Motor mit Kraftstoff. Die Druckleitung

setzt den Tank unter Druck, um für

einen gleichmäßigen Kraftstofffluss

zu sorgen.keep the fuel flow even.

Système d'alimentation en carburant

L'alimentation amène le carburant

au moteur. La conduite de surpression pressurise le réservoir afin de

réguler le débit de carburant.

Vergaser

Carburateur

Sie können die Charakteristik des Motors verändern, indem Sie

Luftfiltergehäuse

Gaine du filtre à air

Vergaser

87204

Carburateur

b

87199

Falls sich der Luftfilter lösen sollte,

müssen Sie den Motor sofort stoppen.

Si le filtre à air tombe, vous devez arrêter

le moteur immédiatement.

Kurbelwelle

Vilebrequin

1

Montage des Luftfilters Remise en place du filtre à air

Achten Sie darauf, dass der Luftfilter immer korrekt auf dem Vergaser

sitzt und verwenden Sie einen Kabelbinder (6154) um ihn zu befestigen.

Vérifiez que le filtre à air est bien installé sur le carburateur et

fixez-le avec un collier souple en nylon (6154).

a

87199

Z224

M3x8mm

2.5

mm

Z543

M3x10mm

Kurbelwellengehäuse

Carter

a

87204

Luftmengenbegrenzer einbauen.

Vous pouvez modifier les caractéristiques du moteur en installant

un restricteur.

8.0mm

Begrenzer 8.0mm

Restricteurs

Für weniger Kraftstoffverbrauch.

Moins de consommation de carburant

6154

c

87199

b

AchtungAttention

Druckleitung

Conduite de surpression

Vergaser

Carburateur

8.5mm

Begrenzer 8.5mm

Restricteurs

Mehr Leistung im hohen Drehzahlbereich.

Plus de puissance à haut régime

Verwenden Sie Schraubensicherung an den Schrauben, mit denen Sie den Motor ins Chassis einbauen.

Utilisez du frein à filet sur les vis de montage lorsque vous installez le moteur sur le châssis.

Achten Sie darauf, dass das Gas- und Bremsgestänge korrekt montiert sind.

Vérifiez que la tringlerie d'accélération et de freinage sont dans la bonne position.

Verstellen Sie den Vergaser nicht, bis der Einlaufvorgang abgeschlossen ist. Die Werkseinstellung (für die Einlaufphase) sieht vor, dass alle Nadeln bündig mit dem Gehäuse sind.

Ne réglez pas les pointeaux du carburateur avant que le rodage soit terminé. Les pointeaux sont

87509

d'origine en affleurement avec le corps du carburateur, c'est le réglage correct pour le rodage.

Bei Verwendung im Savage, muss der Vergaser um 180 Grad gedreht werden.

Pour une utilisation avec le Savage, faites tourner le carburateur de 180 degrés.

15231

Nadel für hohe Drehzahlen

Pointeau de haut régime

Kraftstoffanschluss

Admission du carburant

Nadel für mittleren Drehzahlbereich

Pointeau de régime moyen

Leerlaufdrehzahlschraube

Vis de réglage du ralenti

Gasanlenkung

Commande d'accélération

Nadel für niedrige Drehzahlen

Pointeau de bas régime

Horizontale Ausrichtung.

Position horizontale

Z700

15266

Kraftstoffleitung

Conduite de

carburant

Z901

Achten Sie darauf, dass der

Luftfilter immer korrekt auf dem

Vergaser sitzt und verwenden

Sie einen Kabelbinder (6154)

um ihn zu befestigen.

Vérifiez que le filtre à air est

bien installé sur le carburateur et fixez-le avec un collier

souple en nylon (6154).

6154

Page 9/16

Z904

Drücken Sie den Vergaser nach unten, wenn Sie die Schraube zum Festklemmen des Vergasers anziehen.

Poussez le carburateur vers le bas pendant que vous serrez la vis.

15231

I-15204-1

Page 10

2

Einlaufphase Rodage du moteur

Achtung!

HPI Motoren klemmen ein wenig am oberen Totpunkt, wenn sie neu sind, oder noch nicht ihre

Betriebstemperatur erreicht haben. Der Kolben und die Laufbuchse sind so entwickelt worden,

dass sie genau passen, wenn sie ordentlich eingelaufen sind und die richtige Temperatur

haben. Neue Motoren brauchen eine Einlaufphase von ungefähr 3 bis 4 Tankfüllungen, bevor

sie bei Vollgas betrieben werden können. Andernfalls kann der Motor beschädigt werden.

Rodage du moteur

Les moteurs HPI n'ont pas le jeu suffisant à régime maximal lorsqu'ils sont neufs ou qu'ils n'ont pas

atteint leur température de fonctionnement normale. Le piston et la chemise sont conçus pour avoir des

tolérances adéquates lorsqu'ils sont correctement rodés et atteignent la température correcte de

fonctionnement. Les moteurs neufs nécessitent une période de rodage d'environ 3 à 4 réservoirs de

carburant avant de pouvoir fonctionner à plein régime, faute de quoi le moteur pourrait être endommagé.

Befüllen des Tanks Remplir le réservoir

1

Füllen Sie den Tank komplett mit Kraftstoff. Verwenden Sie nur

Kraftstoff mit 20 bis 25% Nitromethan Anteil. Verwenden Sie nur

hochwertigen Kraftstoff für Modellautos. Kraftstoff der nicht speziell

für Modellautos ist, kann einen Verlust der Garantie bewirken.

Remplissez le réservoir complètement de carburant. N'utilisez que

du carburant avec 20 à 25 % de nitro. N'utilisez que du carburant de

marque de haute qualité. L'utilisation de carburants non spécifiques

aux voitures pourrait annuler votre garantie.

Füllen des Vergasers Amorçer le moteur

2

3

12"30cmMAX!

Achten Sie darauf, dass die Räder den

Boden nicht berühren.

Positionnez les roues au-dessus du sol.

Achtung Attention

Bei Motoren ohne Seilzugstarter, beachten

Sie bitte den Abschnitt über das Starten

des Motors in ihrer Baukasten Anleitung.

Pour les moteurs sans lanceurs, veuillez

vous reporter au chapitre sur le démarrage

du moteur du manuel de votre voiture pour

y voir les procédures adéquates.

Empfohlener Nitromethan Gehalt

Concentration conseillée en nitro

20% - 25%

74318/ 74348

20% Glow Fuel

(US only)

Um den Vergaser mit Kraftstoff zu füllen, decken

Sie den Auslass des Reso-Rohres ab und

ziehen mehrmals an der Startschnur bis der

Kraftstoff den Vergaser erreicht und keine

Luftblasen mehr zu sehen sind. Ziehen Sie die

Schnur niemals weiter als 30cm, da dies den

Starter beschädigt!

Pour amorçer le moteur, bouchez l'échappement avec votre doigt. Tirez le lanceur plusieurs

fois jusqu'à ce que le carburant arrive dans le

carburateur et qu'il n'y ait plus de bulles. Ne

tirez jamais le lanceur de plus de 30 cm car cela

pourrait endommager son mécanisme !

38704/ 38705

38706 グロー燃料

(JP only)

25% Nitro Content

25% Kraftstoff

25% Carburant

Step

1

Öffnen Sie den Vergaser Ouvrir le carburateur

3

Drehen Sie das Gasservo (bei ausgeschaltetem Empfänger)=

soweit, dass der Vergaser zu ca. 1/4 geöffnet ist.

Veillez à ce que la commande du récepteur soit en position

d'arrêt. Tournez à la main le servo du carburateur jusqu'à ce que

1/4 geöffnet.

le carburateur soit ouvert à un quart du maximum.

un quart de l'ouverture maximum.

Glühkerze und Seilzugstarter Bougie et lanceur

4

Stecken Sie den Glühkerzenstecker auf die Glühkerze. Ziehen Sie den Seilzugstarter in kurzen, schnellen Zügen. Ziehen Sie nie weiter

als 30cm (12 inches). Stellen Sie das Gasservo so ein, dass der Motor ruhig im Leerlauf läuft, ohne dass die Kupplung schleift und die

Räder sich drehen. Entfernen Sie den Glühkerzenstecker sobald der Motor läuft. Lassen Sie den Motor eine Tankfüllung laufen.

Stoppt der Motor, wiederholen Sie die Schritte 1 bis 4.

Fixez le chauffe-bougie sur la bougie. Tirez sur le lanceur par à-coups brefs, ne tirez jamais plus de 30 cm (12 pouces). Réglez la

tringlerie du servo d'accélérateur afin que le moteur tourne suffisamment vite au ralenti pour ne pas débrayer ou tourner les roues.

Retirez le chauffe-bougie dès que le moteur tourne. Faites tourner le moteur pendant un réservoir de carburant. Si le moteur s'arrête,

recommencez les étapes 1 à 4

Abgesoffener Motor Moteur noyé

70332

Falls zuviel Kraftstoff im Zylinder ist, kann der Motor

nicht starten. Folgen Sie den aufgeführten Schritten,

um den überflüssigen Kraftstoff zu entfernen.

Retirez la bougie et tirez le lanceur plusieurs fois pour

NO!

Achtung Attention

Der Motor darf niemals ohne Luftfilter betrieben werden.

Le moteur ne doit jamais tourner sans que le filtre à air soit en place.

AchtungAttention

Der Motor darf niemals ohne

Luftfilter betrieben werden.

Le moteur ne doit jamais tourner

sans que le filte à air soit en place.

retirer l’excédent de carburant. Remettez la bougie.

Entfernen Sie die Glühkerze und ziehen Sie ein

paar Mal am Seilzugstarter um den überflüssigen

Kraftstoff zu entfernen. Montieren Sie anschließend

wieder die Glühkerze.

S’il y a trop de carburant dans le cylindre, le moteur

ne démarrera pas. Suivez l’étape ci-dessous pour

retirer le carburant en excès du cylindre.

Step

1

12"30cmMAX!

Page 10/16

Page 11

Am Laufen halten Continuer à le faire tourner

5

LANGSAM

LENTEMENT

Tipp Astuce

Schalten Sie den Sender und Empfänger ein. Befüllen Sie den Kraftstofftank neu und folgen Sie den Start-Schritten 1-4.

Während die Reifen weiter i n der Luft sind, geben Sie an der Fernsteuerung langsam Gas. Nachdem Sie Vollgas erreicht

haben, gehen Sie wieder vom Gas. Damit entfernen Sie überschüssiges Öl aus dem Motor, welches sich dort durch die

fetten Einlauf Einstellungen angesammelt hat. Der Motor muß regelmäßig "freigeblasen" werden, damit er nicht verfettet.

Allumez l'émetteur et le récepteur, remplissez de nouveau le réservoir et suivre les étapes 1 à 4 de la procédure de départ. Les roues

étant au-dessus du sol, accélérez légèrement à l'aide de l'émetteur jusqu'à la vitesse maximale, puis relâchez. Cela fera partir l'excès

d'huile du moteur. Du fait des réglages de rodage riches, le moteur doit être périodiquement "décrassé" pour l'empêcher de caler.

Verwenden Sie ein dickes Tuch Utilisez un chiffon

Bei Ausnahmen oder Notfällen kann man auch die Kraftstoffleitungzudrücken und somit verhindern, dass weiterer Kraftstoff in

denVergaser fliesst. Durch diese Methode läuft der Motor aber

kurzzeitig zu mager, was zu Defekten am Motor führen kann.

Verwenden Siedeswegen grundsätzlich die Methode mit dem Tuch.

Dans des situations extrêmes ou en cas d'urgence, vous pouvez

pincer la conduite de carburant pour bloquer l'arrivée du carburant

dans le carburateur. Attention, le moteur risque d'être endommagé

s'il continue à tourner sur un mélange pauvre. Il vaut mieux arrêter

le moteur à l'aided'un chiffon.

Einfahren mit Halbgas Demi-accélération

6

Halbgas

Moins de la moitié

du plein régime

3

Einstellung nach dem Einlaufen Réglage après le rodage

Putzlappen

Chiffon

Stellen Sie das Auto auf den Boden. Es sollte sich nicht im Leerlauf bewegen. Wenn doch, stellen Sie die Trimmung

am Sender so ein, dass sich das Auto nicht bewegt. Fahren Sie das Auto in einem Kreis mit ca. 6m (20 feet)

Durchmesser. Geben Sie dabei nur kurze Halbgasstöße um dem Motor immer wieder Zeit zum Abkühlen zu geben.

Machen Sie dies für zwei komplette Tankfüllungen.

Placez le véhicule sur le sol. Il doit être immobile au ralenti. S'il bouge, ajustez le réglage de la manette de l'émetteur

pour qu'il ne bouge plus. Faites le tourner sur un ovale de 6 m (20 pieds) de diamètre, laissez-le continuer sur son

élan pendant de courts moments pour faire refroidir le moteur, puis accélérez de nouveau. Continuez à faire cela

pendant deux réservoirs de carburant.

Zudrücken der Kraftstoffleitung Pincez l'alimentation en carburant

Wenn das Fahrzeug außer Kontrolle ist, oder bei Notfällen,

können Sie die Kraftstoffleitung zudrücken, so dass der

Vergaser keinen Kraftstoff mehr bekommt.

Dans les cas extrêmes ou les urgences, vous pouvez pincer

l'alimentation en carburant pour empêcher le carburant

d'arriver au carburateur.

Wichtig! Lesen Sie diesen Teil besonders aufmerksam: Fehler bei der Vergasereinstellung können zu Schäden an Ihrem Motor sowie zum Verlust der Garantie führen!

Important Lisez soigneusement ce chapitre : ne pas suivre ces étapes pourrait conduire à endommager votre moteur, et faire annuler votre garantie !

Einstellung für optimale Leistung Réglage pour des performances optimales

Nadel für hohe Drehzahlen

Pointeau de haut régime

Schritt X

ÉTAPE

Verwenden Sie einen

Schraubenzieher, um

die Nadel zu verstellen

Utilisez un tournevis

pour régler le pointeau

de haut régime.

Schritt 4

ÉTAPE

X

Schritt 1

ÉTAPE

1

1/8

Schritt 2

ÉTAPE

Schritt 3

ÉTAPE

3

4

1/4

Achtung Attention

2

2 1/2 Umdrehungen maximal

2 tours 1/2 MAXI

Maximal 2 1/2 Umdrehungen

can not be split this way.

2 tours 1/2 MAXI dans le sens

horaire à partir de la rainure

Schritt 1

Drehen Sie die Nadel für hohe Drehzahlen in 1/8

Schritten im Uhrzeigersinn um das Gemisch magerer

zu stellen. Damit erreichen Sie höhere Geschwindigkeiten und eine bessereGasannahme. Fahren Sie das

Auto um die Veränderungen zu spüren.

Weitere Einstellung:

Stellen Sie den Motor weiter in 1/8 Schritten magerer.

(Maximal 1 1/2 Umdrehungen von bündig)

STOPP :

Drehen Sie den Motor nicht magerer, wenn

Ihr Motor eines der folgenden Zeichen zeigt.

(Der Motor läuft zu mager)

Bei Vollgas ist keine Rauchentwicklung zu sehen.

Schritt 4

Der Motor stottert oder stockt

Abnehmende Höchstgeschwindigkeit oder

Leistung.

Überhitzung Temperatur über 120°C (250F)

an der Glühkerze.

Schritt X

Falls Ihr Motor zu mager läuft, drehen Sie die Nadel

in 1/4 Schritten gegen den Uhrzeigersinn um das

Gemisch fetter zu stellen und wiederholen Sie

Schritt 1

Schritt 4

ÉTAPE 1 ÉTAPE 4

Tournez le pointeau de haut régime dans le sens

horaire par incréments de 1/8ème de tour pour

appauvrir le mélange et augmenter la vitesse de

pointe et les performances en accélération. Essayez

de piloter la voiture pour voir les modifications.

Continuez la mise au point :

Continuez à appauvrir la carburation par incréments

de 1/8ème de tour dans le sens horaire.

(Maximum 1 tour 1/2 de l'affleurement.)

ARRÊTEZ :

ARRÊTEZ le réglage et allez à l'

ÉTAPE X si votre moteur montre l'un des

signes suivants.

À l'accélération, il n'y a pas de fumée blanche

à l'échappement.

ÉTAPE X

(Moteur réglé trop pauvre.)

Le moteur tousse ou cale.

Vitesse maximale réduite, perte de puissance.

Surchauffe

Températures supérieures à 120°C (250°F) à la bougie.

ÉTAPE X

Si votre moteur est réglé trop pauvre, tournez le

pointeau dans le sens antihoraire par quarts de tours

pour enrichir le mélange et recommencez les étapes :

ÉTAPE 1 ÉTAPE 4

Tipps zum Einstellen des Vergasers Astuce de réglage de la richesse

Die Motortemperatur kann zeigen, ob der Motor mager

oder fett läuft.

La température du moteur peut vous dire si le moteur

tourne pauvre ou riche.

Achtung Attention

Stellen Sie den Vergaser so ein, dass

die Temperatur unter 120°C leigt.

Réglez le carburateur de façon à

ce que la température reste endessous de 120°C (250° F).

74151

Hpi Racing Temperaturmesspistole

Sonde de température Hpi Racing

Motortemperatur

Température du moteur

GEFAHR

GEFAHR

DANGER

DANGER

250°F

(

)

120°C

230°F

(

)

110°C

Sicherer Bereich

Plage de sécurité

210°F

(

)

99°C

190°F

(

)

90°C

Einlaufphase

Rodage

Gemischeinstellung

Réglage du mélange

Page 11/16

Weniger Sprit = Mager

Moins de carburant =

pauvre

Mehr Sprit = Fett

Plus de carburant =

Riche

Weniger Sprit = Mager

Moins de carburant = Pauver

Magere Gemischeinstellung

Führt zu einer besseren Verbrennung und zu mehr Leistung.

Bei zu magerer Einstellung, mangelt es jedoch an Schmierung.

Dies führt zu erhöhter Motortemperatur und einer kürzeren

Lebensdauer.

Mélange de carburant pauvre

Donne une combustion plus efficace et plus de puissance, mais si

vous appauvrissez trop le résultat est une moindre lubrification,

plus de chaleur et une durée de vie du moteur plus courte.

Mehr Sprit = Fett

Plus de carburant = Riche

Fette Gemischeinstellung

Ein fetteres Gemisch führt zu mehr Kühlung und Schmierung, somit zu einer höheren Lebensdauer, jedoch auch zu

etwas weniger Leistung.

Mélange de carburant riche.

Un mélange légèrement riche donne une température de

fonctionnement plus basse et une meilleure lubrification mais un

peu moins de puissance et une durée de vie du moteur plus longue.

Page 12

4

Weitere Einstellungen Réglage optionnel

Leerlaufdrehzahlschraube Vis de réglage du ralenti

Falsche Leerlaufdrehzahl

Leerlaufdrehzahlschraube

Vis de réglage du ralenti

ca. 1mm (0.04")

About 1mm (0.04")

Kupplung packt und die Räder drehen sich.

Mauvais réglage de la vitesse du ralenti

L'embrayage est engagé et les roues tournent

No! Ok!

Korrekte Leerlaufdrehzahl

Motor läuft ruhig ohne Drehen der Räder.

Réglage correct de la vitesse du ralenti

Le moteur tourne régulièrement sans que les roues ne tournent.

weniger U/min

Bas régime

Die Leerlaufdrehzahlschraube wird eingestellt nachdem die Nadel für hohe Drehzahlen eingestellt wurde und der Motor auf Betriebstemperatur ist. Um die Leerlaufdrehzahlschraube korrekt

einzustellen, schalten Sie die RC Anlage ein und stellen Sie die Gastrimmung am Sender auf neutral. Dies stellt sicher, dass der Vergaser vollständig geschlossen ist und gegen die Leelaufdrehzahlschraube drückt. Drehen Sie die Leelaufdrehzahlschraube gegen den Uhrzeigersinn um die Leerlaufdrehzahl zu verringern, oder im Uhrzeigersinn um sie zu erhöhen. Die leerlaufdrehzahl sollte

so hoch sein, dass der Motor ruhig läuft, aber die Kupplung nicht schleift und die Räder dreht. Eine zu hohe Leelaufdrehzahl führt zu erhöhtem Kupplungs- und Bremsverschleiß.

La vitesse du ralenti est ajustée après le réglage du pointeau de haut régime et de la température du moteur. Pour ajuster correctement la vis de réglage du ralenti, allumez votre système

radio et mettez la manette d'accélérateur de l'émetteur en position neutre. Cela garantit que la commande d'accélération est fermée et se trouve contre la vis de réglage du ralenti. Tournez la vis

de réglage du ralenti dans le sens antihoraire pour réduire la vitesse ou dans le sens horaire pour l'augmenter. La vitesse du ralenti doit être suffisamment élevée pour que le moteur tourne

régulièrement mais que l'embrayage ne soit pas engagé et que les roues ne tournent pas. Une vitesse de ralenti trop élevée usera prématurément les sabots d'embrayage et le disque de frein.

mehr U/min

Haut régime

Einstellung der Nadel für niedrige Drehzahlen Réglage du pointeau de bas régime

Bündig (Werkseinstellung)

En affleurement (réglage d'usine)

Nadel für niedrige Drehzahlen

Pointeau de bas régime

Mehr Sprit = Fett

Plus de carburant = Riche

Weniger Sprit = Mager

Moins de carburant = Pauvre

Die Nadel für niedrige Drehzahlen wird eingestellt, nachdem die Nadel für hohe Drehzahlen eingestellt wurde und der Motor auf Betriebstemperatur ist. Stellen Sie die Nadel so ein, dass sie bündig mit dem

Vergasergehäuse ist. Diese Einstellung ist ideal um den Motor einlaufen zu lassen und um ihn zu starten. Für mehr Leistung drehen Sie die Nadel in 1/8 Schritten im Uhrzeigersinn. Dies verbessert die Beschleunigung und die

Gasannahme. Um die Einstllung zu überprüfen, stellen Sie Ihr Auto auf den Boden und lassen Sie den Motor für ca. 30 Sekunden im Leerlauf laufen. Geben Sie dann 3/4 Gas. Wenn dann viel Rauch zu sehen ist, und dass

Auto langsam beschleunigt, ist die Einstellung zu fett. Wenn das Auto schnell beschleunigt und dann stottert, ist die Einstellung zu mager. Wenn die Nadel für niedrige Drehzahlen korrekt eingestellt ist, sollte die Gasannahme

des Motors gleichmäßig und schnell sein. ACHTUNG: Drehen Sie die Nadel niemals mehr als 2 Umdrehungen von bündig in das Gehäuse, da dies eine zu magere Einstellung für den Motor ist und er beschädigt werden

kann! Wenn die Nadel für untere Drehzahlen zu mager eingestellt ist, werden Sie folgendes merken: Ausgehen bei Halb- oder 3/4 -Gas, Überhitzung (Temperatur über 120°C an der Glühkerze). Wenn Ihr Motor zu mager läuft,

stellen Sie die Nadel für niedrige Drehzahlen wieder in die Werkseinstellung (bündig) und beginnen Sie erneut mit dem Einstellvorgang. Wir empfehlen die Nadel für untere Drehzahlen nicht zu verstellen.

Le réglage du bas régime est effectué après le réglage du pointeau de haut régime et de la température de fonctionnement du moteur. Positionnez le pointeau en affleurement (réglage d'usine)

avec le corps du carburateur, ce réglage est idéal pour le rodage et pour les débuts de votre moteur. Pour de meilleures performances tournez le pointeau par incréments de 1/8ème de tour, cela améliorera

l'accélération à bas régime. Pour tester votre réglage, posez le véhicule sur le sol et laissez-le au ralenti pendant 30 secondes puis accélérez aux ¾. S'il y a beaucoup de fumée blanche et que la voiture

accélère lentement, le mélange est trop riche. Si la voiture accélère rapidement puis se met à tousser, le mélange est trop pauvre. Lorsque le pointeau de bas régime est correctement réglé, la réponse du

moteur à l'accélération doit être régulière et rapide. ATTENTION : Ne jamais tourner plus de ¾ de tours à partir de la position en affleurement car cela appauvrirait trop le moteur qui pourrait s'abîmer ! Si le

pointeau de bas régime est réglé trop pauvre vous verrez les signes suivants : extinction à accélération partielle ou ¾, surchauffe (températures supérieures à 120°C, 250°F). Si votre moteur est trop

pauvre, remettez le pointeau de bas régime à son réglage d'origine (affleurement) et recommencez le processus de réglage. Nous vous conseillons de ne pas toucher au pointeau de bas régime.

Falls das Standgas unruhig läuft, verstellen

Sie die Nadel für den unteren Drehzahlbereich. Stellen Sie danach wieder die Standgasschraube ein.

Si le ralenti est instable, ajustez le pointeau de bas

régime de manière à obtenir un ralenti stable. Vous

devrez ensuite régler de nouveau la vis de ralenti.

5

Problembehebung

Problem Ursache Lösung

Motor startet nicht

Motor startet und geht

dann aus

Motor läuft im Leerlauf

zu hoch

Problème Cause Solution

Le moteur ne démarre pas

Le moteur démarre, puis cale

Ralenti trop haut

Gemischeinstellung stimmt nicht.

Motor ist verschlissen.

Kein Kraftstoff.

Verunreinigter Kraftstoff.

Glühkerzenstecker ist nicht geladen.

Glühkerze ist kaputt.

Kein Kraftstofffluss.

Motor geflutet.

Motor ist überhitzt.

Vergaserküken nicht korrekt eingestellt.

Luftfilter ist verdreckt.

Leelaufdrehzahl ist zu niedrig.

Luftblasen in der Kraftstoffleitung.

Glühkerze ist kaputt.

Motor ist überhitzt.

Luftstrom im System ist nicht OK.

Gasservo ist nicht korrekt eingestellt.

Aussetzer des Gasservos.

Leerlaufdrehzahlschraube ist falsch eingestellt.

Nadel für niedrige Drehzahlen ist auf zu mager gestellt.

Neutralstellung am Sender stimmt nicht. Schauen Sie in die Anleitung Ihrer RC Anlage sowie in die Anlage Ihres Autos um die Neutralstellung korrekt einzustellen.

Réglages de pointeau hors plage.

Moteur usé.

Manque de carburant.

Carburant contaminé.

Chauffe-bougie non chargé.

Bougie défectueuse.

Pas d'alimentation en carburant.

Moteur noyé.

Moteur ayant surchauffé.

Mauvaise installation du papillon d'accélérateur.

Filtre à air bouché.

Ralenti trop bas.

Bulle d'air dans l'alimentation de carburant.

Bougie défectueuse.

Moteur qui surchauffe.

Flux de l'air défectueux.

Servo d'accélérateur mal monté.

Problème du servo d'accélérateur (mouvements erratiques).

Vis de ralenti réglée trop haut.

Pointeau de bas régime réglé trop pauvre.

Position neutre mal ajustée sur la manette de l'émetteur.

Pannes et remèdes

Stellen Sie die Nadeln auf Werkseinstelung, siehe Seite 13 Abschnitt 6.

Ersetzen Sie Kolben und Laufbuchse.

Füllen Sie den Kraftstofftank.

Ersetzen Sie den Kraftstoff.

Laden Sie den Glühkerzenstecker.

Ersetzen Sie die Glühkerze.

Überprüfen Sie die Kraftstoffleiungen auf Risse, Lecks oder Löcher.

Entfernen Sie die Glühkerze und entfernen Sie den Kraftstoff.

Lassen Sie den Motor abkühlen. Drehen Sie den Motor fetter und starten Sie ihn wieder.

Stellen Sie das Vergaserküken wieder in Werkseinstellung.

Überprüfen Sie den Luftfilter. Reinigen oder Ersetzen Sie ihn, falls nötig.

Stellen Sie die Leelaufdrehzahl korrekt ein.

Überprüfen Sie die Kraftstoffleitungen auf Risse, Lecks oder Löcher.

Ersetzen Sie die Glühkerze.

Lassen Sie den Motor abkühlen und starten Sie dann erneut.

Überprüfen Sie die Verbindungen zwischen Tank, Motor und Auspuff.

Stellen Sie das Servo auf neutral und stellen Sie das Gasgestänge anhand der Anleitung Ihrer RC Anlage und Ihres Autos neu ein.

Ersetzen Sie die Empfängerbatterien.

Stellen Sie die Leerlaufdrehzahlschraube zurück auf die Werkseinstellung, siehe Seite 13.

Stellen Sie die Nadel für niedrige Drehzahlen zurück auf die Werkseinstellung, siehe Seite 13.

Remettre les pointeaux aux réglages d'usine.

Remplacer le piston et la chemise.

Remplir le réservoir.

Changer le carburant.

Charger le chauffe-bougie.

Remplacer la bougie.

Vérifier qu'il n'y ait pas de fissures, fuites ou trous sur l'alimentation. Remplacer celle-ci si nécessaire.

Retirer la bougie et évacuer le carburant.

Laisser refroidir le moteur, puis enrichir le mélange et redémarrer.

Régler le ralenti et positionner le papillon d'accélérateur suivant les indications du fabricant.

Vérifier le filtre à air. Le nettoyer ou le remplacer si nécessaire.

Ajuster la vitesse du ralenti.

Vérifier qu'il n'y ait pas de fissures ou de fuites dans l'alimentation de carburant.

Remplacer la bougie.

Laisser le moteur refroidir puis redémarrer.

Vérifier les connexions entre le réservoir, le moteur et l'échappement.

Mettre le servo en position neutre et re-monter la tringlerie en fonction des spécifications des fabricants de la radio et du modèle.

Remplacer les batteries du système radio.

Régler la vis de ralenti aux réglages d'usine, voir page 13 le réglage correct de la vitesse de ralenti.

Remettre le pointeau de bas régime aux réglages d'usine, voir page 13 les réglages de bas régime corrects.

Voir les instructions de votre radio et de votre kit de voiture pour le réglage de la position neutre de la manette de l'émetteur.

Page 12/16

Page 13

6

Werkseinstellungen des Vergasers (Einlaufphase) Réglage usine du carburateur (réglage de rodage)

Alle Nadeln des Vergasers sind so gebaut, dass die Werkseinstellung genau bündig mit dem Vergasergehäuse ist. Dies macht es einfach den Vergaser wieder auf die Grundeinstellung zu bekommen.

Le pointeau de haut régime, la vis de ralenti, le pointeau de bas régime et le pointeau de moyen régime sont conçus pour être mis en affleurement avec le corps du carburateur.

De ce fait il est facile de remettre le carburateur aux réglages d'usine si nécessaire.

Nadel für hohe Drehzahlen

Mit der Nut bündig

En affleurement

avec la rainure

Nadel für mittleren Drehzahlbereich

d

Pointeau de régime moyen

AchtungAttention

a

Pointeau de haut régime

Ungefähr 1mm (0.04")

Environ 1mm (0.04")

Wenn die Nadel zu weit gedreht

wird, wird sie beschädigt.

Si le pointeau était trop serré il

pourrait être endommagé.

7

Explosionszeichnung Vue éclatée

15228

15237

15261

15218

15217

15215

15214

Leerlaufdrehzahlschraube

b

Vis de réglage du ralenti

Nadel für niedrige Drehzahlen

c

Pointeau de bas régime

Bündig

En affleurement

15241

Staubschutz und O-Ring Set

Prot. anti-poussière et jeu comp. joints toriques

1504

15266

15268

Einstellung für Einlaufphase

Réglage de rodage

a

b

c

Mit der Nut bündig

En affleurement avec

la rainure

Bündig

Affleurement

Bündig

Affleurement

d

Bündig

Affleurement

Nach der Einlaufphase

Réglage après le rodage

Bitte schauen Sie bei den Einstellung

nach dem Einlaufen auf Seite 11 für Tipps.

Veuillez vous reporter à la section

Réglage après le rodage à la page 11

pour les astuces de réglage

Bitte schauen Sie bei den weiteren

Einstellungen auf Seite 12 für Tipps.

Veuillez vous reporter à la section

réglages optionnels à la page 12

pour les astuces de réglage

Verstellen Sie die Nadel nicht.

N'ajustez pas

15285

15275

15282

15283

15269

15271

15274

15272

15213

86077

15231

Ersatzteile

Nummer

Numéro

15204 x1

1504 x1

15213 x1

15214 x1

15215 x3

15217 x1

15218 x1

15226 x1

15228 x1

15231 x1

15233 x1

15234 x1 Welle Fuer Seilzugstarter K-serie

15244

Pièces détachées

Anzahl

Beschreibung

Qté.

Description

Nitro Star K4.6 HO Motor Mit Seilzugstarter

Moteur Nitro Star K4.6 HO Avec Lanceur

Gluehkerze Kalt R5

Bougie Froide R5

Pleuel Ns K4.6

Bielle

Kolbenbolzen Mit Clip Ns K4.6

Jeu Axe De Piston/clips

Kolbenbolzen Clips Ns K4.6

Clips Pour Axe De Piston

Zylinder/kolben Set K4.6

Jeu Cylindre/piston

Zylinder/kolben/pleuel Set K4.6 (Montiert)

Jeu Piston/cylindre/bielle (Monte)

Seilzugstarter Ohne Freilauflager Ns K4.6

Ensemble Lanceur (Sans Roulement Roue Libre)

Zylinderkopfdichtungs-set (0.15mm/0.3mm) Ns K4.6

Jeu De Joints Pour Cylindre (0.15mm/0.3mm)

Vergaser Sicherungspin Set K-serie

Jeu Butee Pour Carburateur

Seilzugstarter-welle Halter (Gebaut) Ns K4.6

Support De Lanceur (Monte)

Arbre De Demarreur

15231

15243

15245

Nummer

Numéro

15236 x1

15237 x4

15241 x1

15243 x1

15244 x1

15245 x1

15261 x1

15266 x1

15268 x1

15269 x1

15271 x1

15272 x1

Anzahl

Qté.

Z700

15233

Z542

15236

Beschreibung

Description

Abdeckplatte (Set) K-serie

Jeu Plaque De Fermeture

Schraube M3.5x16mm Fuer Zylinderkopf Ns K4.6

Vis M3.5x16mm Pour Tete De Refroidissement

Staubschutz Und O-ring Set Ns K4.6

Prot. Anti-pouss. Et Jeu Comp. Joints Toriques

Kuehlkopf (Grau-schwarz/k4.6hO)

Tete De Refroidissement (Gris Noir/k4.6 HO)

Krubelwellengehaeuse (K4.6hO)

Carter (K4.6 HO)

Kurbelwelle (K4.6HO)

Vilebrequin (K4.6 HO)

Schiebevergaser Komplett Mit Begrenzern (Typ Kb)

Carb. A Tiroir Complet Av.restricteur (Type Kb)

Vergaser Kugelkopf Ka-serie

Uniball

Duesennadel Unterer Bereich Mit O-ring Ka-serie

Pointeau De Ralenti Avec Joint Torique

Schiebevergaser Einsatz Ka-serie

Tiroir

Leerlaufschraube Mit O-ring Ka-serie

Vis De Reglage De Ralenti Avec Joint Torique

Einlasstutzen Mit Unterlagscheiben Ka-serie

Jeu Adaptateur Alim. En Carburant/rondelles

15234

Nummer

Numéro

15274 x1

15275 x1

15282 x1

15283 x1

15285 x1

86077 x2

87198 x1

87199 x1

87204 x1

94154 x12

Z542 x12

Z700 x6

Anzahl

Qté.

15226

94154

Beschreibung

Description

Hauptdusennadelhalter Ka-serie

Siege Du Pointeau De Haut Regime

Hauptdusennadel Mit O-ring Ka-serie

Pointeau De Haut Regime Avec Joint Torique

Duesennadel Mittlerer Bereich Mit O-ring Ka-serie

Pointeau Moyen Avec Joint Torique

Schiebevergasergehause Mit Begrenzern (Typ Kb)

Corps De Carb. A Tiroir Av.restricteur (Type Kb)

Hauptduesennadel Set Ka-serie

Jeu Pointeau De Haut Regime

Lagerhuelse 7x6.5mm (Messing)

Cone Volant (Laiton/21 Dim)

Luftfilter (21+ Motoren)

Filtre A Air (Taille 21+)

Luftfilter Schlauch Set (Fuer #87198)

Jeu Manchon De Filtre A Air (Pour Ref.87198)

Luftfilter Schaumstoff Set (Fuer #87198)

Jeu Element Mousse Filtre A Air (Pour Ref.87198)

Senkkopfschraube M2.6x8mm (Inbus)

Vis Tete Plate (Six Pans Creux)

Inbusschraube M3x8mm

Vis Tete Cylindrique

Madenschraube M3x3mm

Vis Hallen Sans Tete

Page 13/16

Page 14

8

Wartung Entretien

Glühkerze Bougie

Wie Glühkerzen funktionieren:

Anders als beim echten Auto, das Zündkerzen und einen Verteiler besitzt, um im richtigen Moment zu zünden, haben Modellmotoren eine Glühkerze. Die erste Zündung wird durch das Aufsetzen

des Glühkerzensteckers verursacht. Wenn dieser entfernt wurde, ist es die Hitze des Motors, die die Glühkerze am Glühen hält und somit die nächsten Zündungen verursacht um den Motor am

Laufen zu halten. Der Zündzeitpunkt ist bei Modellmotoren automatisch. Bei höheren Drehzahlen wird die Glühkerze heisser und zündet das Gemisch früher. Bei niedrigeren Drehzahlen bleibt

die Glühkerze kälter und zündet später. Da die Glühkerze so wichtig für den Motor ist, muss sie sehr sorgfältig ausgewählt und überprüft werden um einen guten Lauf des Motors zu garantieren.

Comment fonctionne la bougie :

Contrairement aux moteurs des voitures de taille réelle qui utilisent des bougies à étincelles et un distributeur pour allumer les cylindres lors du cycle de combustion, les moteurs à bougie luisante n'utilisent que la bougie.

Dans un moteur thermique nitro, l'allumage est déclenché par l'application du chauffe-bougie. Lorsque celui-ci est débranché, la chaleur à l'intérieur de la chambre de combustion suffit à continuer à faire luire le filament,

provoquant l'allumage du cycle suivant et par là le moteur continue à tourner. La vitesse d'allumage dans un moteur à bougie luisante se règle automatiquement. À plus haut régime la bougie est plus chaude, déclenchant

l'allumage du mélange carburant/air plus rapidement, et accélérant donc la vitesse d'allumage. À plus bas régime la bougie est plus froide, déclenchant l'allumage du mélange carburant/air plus tard, et retardant donc la

vitesse d'allumage. Dans la mesure où les fonctions de la bougie luisante sont aussi nombreuses et importantes, l'adéquation de son choix et son entretien sont cruciaux pour un fonctionnement correct du moteur.

Umgebungstemperatur

Température extérieure

Heiss

Heiss

Kalt

Froide

Wann muss die Glühkerze ausgetauscht werden:

Der Kraftstoff sowie die Temparatur haben Einfluss auf die Leistung, Zuverlässigkeit und Lebensdauer der Glühkerze.

Sie sollten also als wichtige Komponenten für den Motor betrachtet werden. Mögliche Gründe für den Austausch sind,

dass die Kerze gar nicht mehr glüht oder beschädigt ist. Weitere Zeichen für einen Wechsel sind:

Die Wendel oder das Gehäuse der Glühkerze sind verfärbt

oder haben eine rauhe Oberfläche.

Der Motor stirbt im Leerlauf ab.

Quand remplacer la bougie :

Le carburant et la température ont un effet sur la performance, la fiabilité et la durée de vie de la bougie

et celle-ci doit par conséquent être considérée comme une pièce d'usure du moteur. En dehors du fait

qu'elle soit grillée ou défaillante, il y a plusieurs signes qui peuvent indiquer que la bougie doit être

remplacée.

Le filament/le corps de la bougie est décoloré et la surface

est rugueuse.

Le moteur s'arrête au ralenti. Le moteur devient difficile à démarrer.

Glühkerze

Glühkerze

Glühkerze Kalt R5

Bougie Froide R5

Glühkerze Mittel Kalt R4

Bougie Médium Froide R4

Glühkerze Mittel R3

Bougie Médium R3

Charakteristik der Glühkerze

Caractéristiques de la bougie