HPE ENTMS-002 User Manual

HPE ProLiant MicroServer Gen10 User Guide

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage

systems. Hewlett Packard Enterprise assumes you are qualified in the servicing of computer

equipment and trained in recognizing hazards in products with hazardous energy levels.

Part Number: 872677-001

Published: June 2017

Edition: 1

©

Copyright 2017

Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard

Enterprise products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional warranty. Hewlett

Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use,

or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer Software

Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government under

vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard Enterprise

website.

Acknowledgments

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

Contents

Component identification........................................................................... 6

Setup...........................................................................................................14

Front panel components

Front panel LEDs and buttons.............................................................................................................7

Rear panel components...................................................................................................................... 8

Rear panel LEDs................................................................................................................................. 9

System board components................................................................................................................10

PCIe slot description............................................................................................................... 11

DIMM slot locations.................................................................................................................11

Drive numbering................................................................................................................................ 12

Drive screws......................................................................................................................................12

Optional services...............................................................................................................................14

Initial server setup overview.............................................................................................................. 14

Unpacking the server shipping carton............................................................................................... 14

Prerequisites for the initial server setup............................................................................................ 15

Optimum environment....................................................................................................................... 15

Site requirements....................................................................................................................15

Space and airflow requirements............................................................................................. 15

Temperature requirements......................................................................................................15

Power requirements................................................................................................................16

Electrical grounding requirements.......................................................................................... 16

Connecting the I/O devices............................................................................................................... 16

Connecting the network cable........................................................................................................... 17

Connecting the power cord................................................................................................................18

Powering on the server for the first time............................................................................................18

Installing an operating system...........................................................................................................18

Install the preloaded ClearOS image......................................................................................19

Install an OS from a bootable installation media.................................................................... 19

Installing the latest system software and firmware............................................................................ 19

Registering the server....................................................................................................................... 20

......................................................................................................................6

Operations..................................................................................................21

Server warnings and cautions........................................................................................................... 21

Electrostatic discharge...................................................................................................................... 21

Preventing electrostatic discharge..........................................................................................21

Grounding methods to prevent electrostatic discharge.......................................................... 22

Power up the server.......................................................................................................................... 22

Power down the server......................................................................................................................22

Prepare the server for hardware installation or removal....................................................................23

Prepare the server for operation........................................................................................................23

Remove the front bezel..................................................................................................................... 23

Removing a locked front bezel............................................................................................... 23

Removing an unlocked front bezel......................................................................................... 24

Install the front bezel......................................................................................................................... 25

Remove the chassis cover................................................................................................................ 26

Install the chassis cover.................................................................................................................... 27

Install the chassis cover..........................................................................................................27

Contents 3

Install the system board assembly.................................................................................................... 27

Install the system board assembly..........................................................................................27

Remove the system board assembly

Remove the system board assembly......................................................................................29

................................................................................................ 28

Hardware options installation.................................................................. 31

Introduction........................................................................................................................................31

Drive support information.................................................................................................................. 31

Drive installation guidelines...............................................................................................................31

Installing an LFF drive....................................................................................................................... 31

Install the LFF drive................................................................................................................ 32

Installing an SFF drive.......................................................................................................................33

Install the SFF drive................................................................................................................34

Installing an SSD...............................................................................................................................36

Install the SSD........................................................................................................................37

Installing an optical drive................................................................................................................... 40

Install an optical drive............................................................................................................. 40

Memory support.................................................................................................................................44

DIMM identification................................................................................................................. 44

DIMM ranks ........................................................................................................................... 46

DIMM handling guidelines...................................................................................................... 46

DIMM installation guidelines................................................................................................... 46

Installing a DIMM....................................................................................................................46

Install the DIMM........................................................................................................... 47

Expansion board options...................................................................................................................47

Installing an expansion board.................................................................................................47

Remove the air baffle from the expansion board......................................................... 48

Install a low-profile bracket on the expansion board....................................................48

Install the expansion board..........................................................................................49

Internal USB device options.............................................................................................................. 50

Install an internal USB device.................................................................................................50

External HPE RDX Backup System option........................................................................................51

HP Trusted Platform Module............................................................................................................. 51

Trusted Platform Module (TPM) — China Import Restrictions................................................52

HP Trusted Platform Module installation guidelines............................................................... 52

Installing the Trusted Platform Module overview.................................................................... 52

Installing the Trusted Platform Module board......................................................................... 52

Install the Trusted Platform Module board................................................................... 53

Retaining the recovery key/password.....................................................................................54

Enabling the Trusted Platform Module....................................................................................54

4 Contents

Cabling........................................................................................................55

Cabling overview .............................................................................................................................. 55

Four-bay non-hot-plug drive cabling..................................................................................................55

Solid state drive cabling.....................................................................................................................56

Optical drive cabling.......................................................................................................................... 57

Fan cabling........................................................................................................................................57

Power supply cabling.........................................................................................................................58

Software and configuration utilities.........................................................59

Server mode......................................................................................................................................59

Product QuickSpecs..........................................................................................................................59

Aptio Setup Utility.............................................................................................................................. 59

Using the Aptio Setup Utility .................................................................................................. 59

Boot option control..................................................................................................................60

Boot option

Selecting the boot mode ............................................................................................. 60

Restoring and customizing configuration settings.................................................................. 60

Clearing the BIOS configuration settings................................................................................60

Clearing the BIOS settings by using the Aptio Setup Utility.........................................61

Clearing the BIOS settings by using the CMOS header.............................................. 61

Embedded UEFI Shell ........................................................................................................... 62

Secure Boot configuration ..................................................................................................... 63

Utilities and features..........................................................................................................................63

HPE Smart Storage Administrator ......................................................................................... 63

Marvell Storage Utility ............................................................................................................63

Marvell BIOS Utility.................................................................................................................64

Accessing the Marvell BIOS Utility under legacy boot mode....................................... 64

Accessing the Marvell BIOS Utility under UEFI boot mode......................................... 64

USB support .......................................................................................................................... 64

Keeping the system current...............................................................................................................64

Firmware ................................................................................................................................64

Firmware update.....................................................................................................................65

Updating the system ROM using the EFI tool from within the Embedded UEFI

Shell ............................................................................................................................65

Online Flash components ........................................................................................... 66

Drivers, firmware, and software updates ............................................................................... 66

Operating System Version Support........................................................................................ 66

HPE Pointnext Portfolio.......................................................................................................... 66

Change control and proactive notification...............................................................................67

...................................................................................................................60

Troubleshooting.........................................................................................68

Troubleshooting resources................................................................................................................68

Specifications............................................................................................ 69

Environmental specifications.............................................................................................................69

Server specifications......................................................................................................................... 69

Power supply specifications.............................................................................................................. 69

200 W power supply specifications.........................................................................................70

Warranty and regulatory information.......................................................71

Warranty information......................................................................................................................... 71

Regulatory information...................................................................................................................... 71

Belarus Kazakhstan Russia marking...................................................................................... 71

Turkey RoHS material content declaration............................................................................. 72

Ukraine RoHS material content declaration............................................................................72

Support and other resources................................................................... 73

Accessing Hewlett Packard Enterprise Support................................................................................ 73

Accessing updates............................................................................................................................ 73

Customer self repair.......................................................................................................................... 73

Documentation feedback...................................................................................................................74

Acronyms and abbreviations................................................................... 75

Contents 5

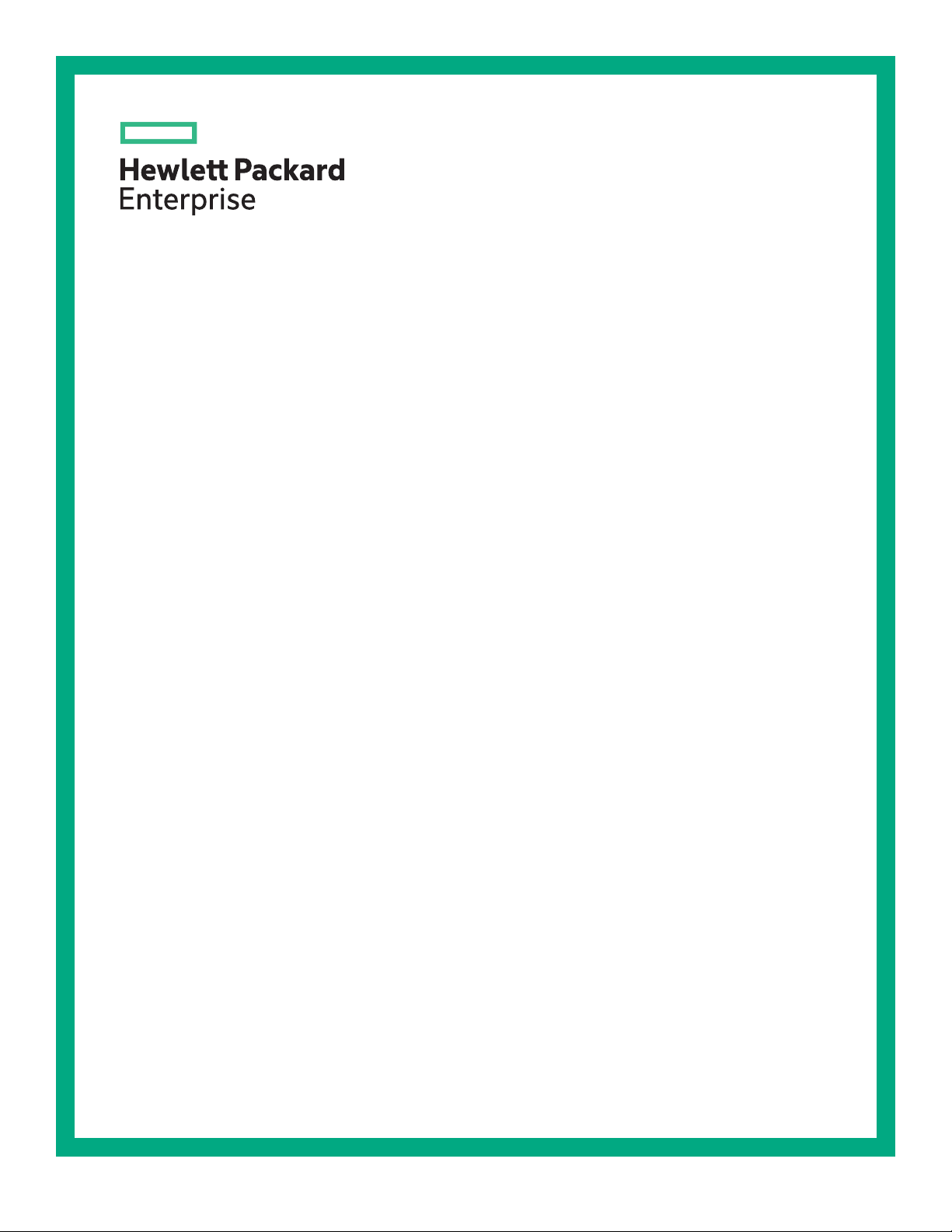

Component identification

5

6 1

2

3

4

This chapter describes the external and internal server features and components.

Front panel components

Item Component Description

1 Drive bays (4, behind the front

bezel)

2 Front bezel unlock indicator To remove the front bezel from the chassis, this groove must

3 Front bezel lock indicator To lock the front bezel in the chassis, this groove must show

4 Front bezel To access the front drive bays, remove this bezel.

5 USB 3.0 ports (2) Connect USB 3.0 devices to these ports. USB 3.0 support

6 Media bay When the relevant enablement options kits are installed, this

By default, the drive bays support 3.5-inch LFF SATA drives.

To support 2.5-inch SFF drives, install the SFF drive converter

option.

show the blue indicator.

the blue indicator.

after POST varies by operating system.

bay supports either a slim-type optical disc drive or solid state

drive option.

6 Component identification

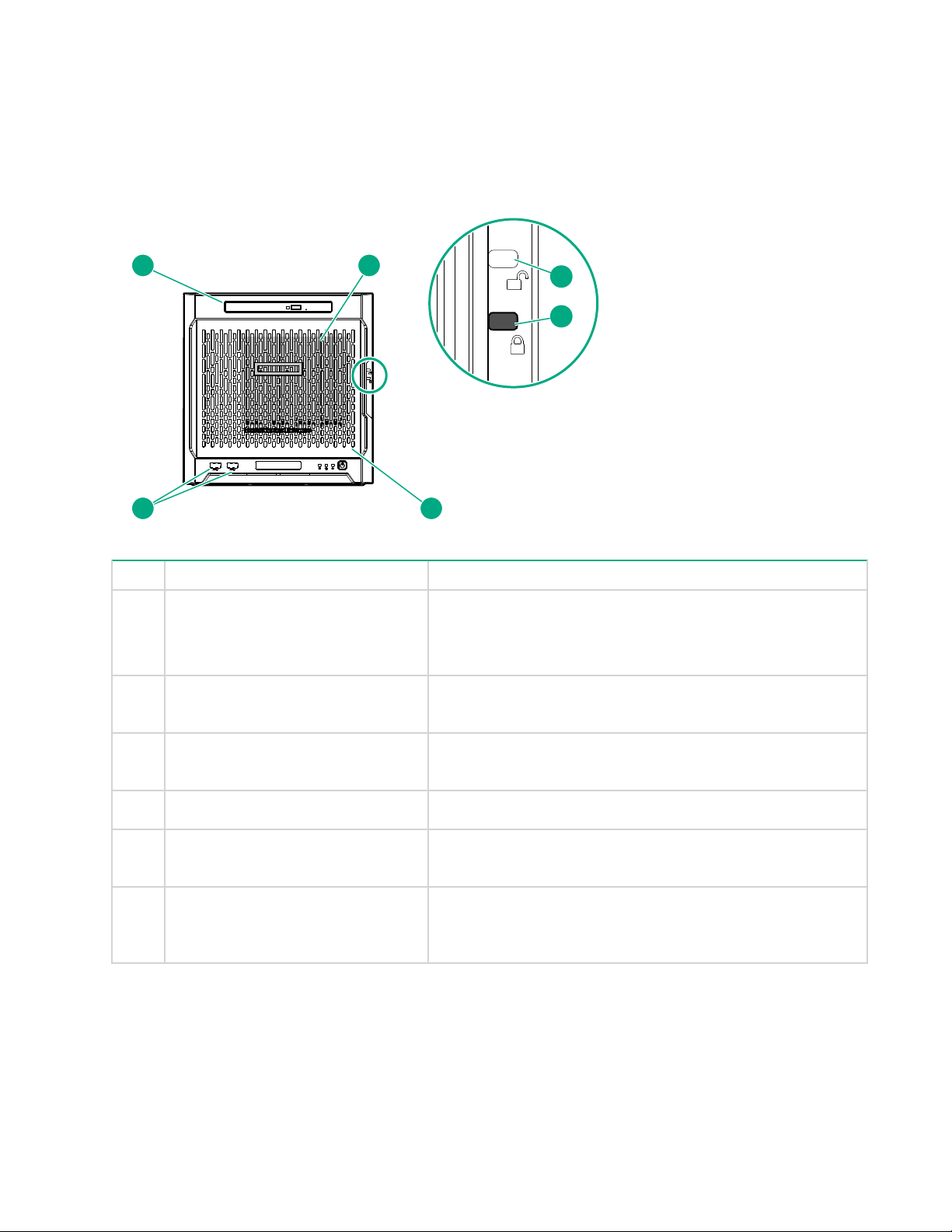

Front panel LEDs and buttons

1 2

3

4

Item Description Status

1 Drive activity LED Flashing green = Ongoing drive activity

Off = No drive activity

This LED only reflects the status of LFF/SFF drives and SSD that

are connected to the onboard SATA ports.

2 NIC status LED Solid green = Linked to network

Flashing green = Network active

Off = No network activity

This LED only reflects the status of Ethernet connections

managed by the embedded Broadcom BCM5720 Gigabit Ethernet

controller.

3 Health LED Solid green = Normal

Flashing amber = One or more component is in degraded

condition.

1

Flashing red = One or more component is in critical condition.

4 Power on/Standby button and

system power LED

Flashing green = Ongoing power-on sequence

Solid green = System on and normal operation

Amber = System in standby

Off = No power present

1

To identify which component is in the degraded or critical state, reboot the server. A POST error message

2

screen showing the affected component will appear for about 30 seconds. Depending on how critical the

component health status is, the system boot may or may not be completed. For troubleshooting information,

see the HPE ProLiant MicroServer Gen10 Troubleshooting Guide.

2

If the server does not power on, verify the following items:

1

Front panel LEDs and buttons 7

Item Description Status

1

3

4

567

9

10

11

2

12

8

• The site power is available.

• The power cord is properly connected to the server power jack and to a working power source.

• The internal power supply cable is properly connected to the system board.

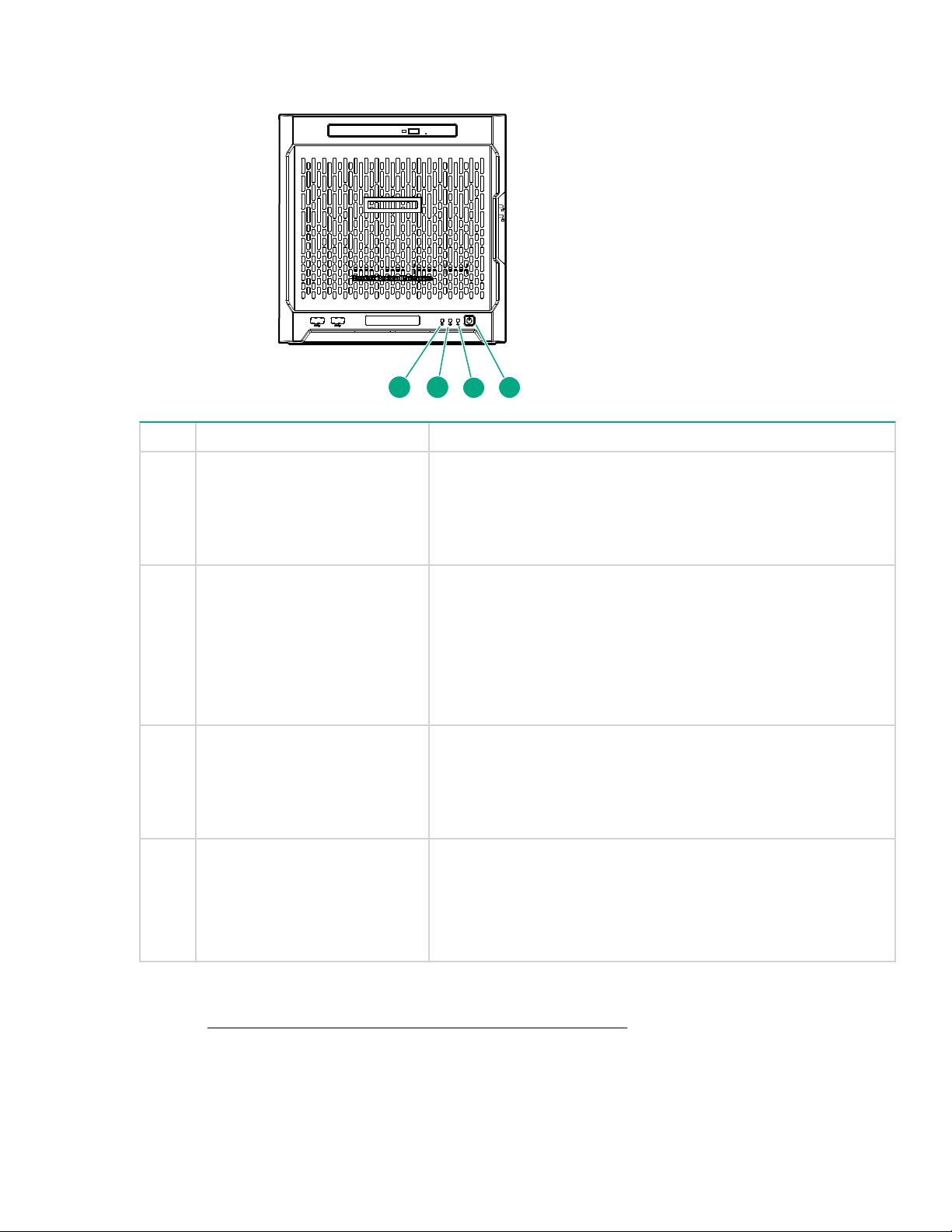

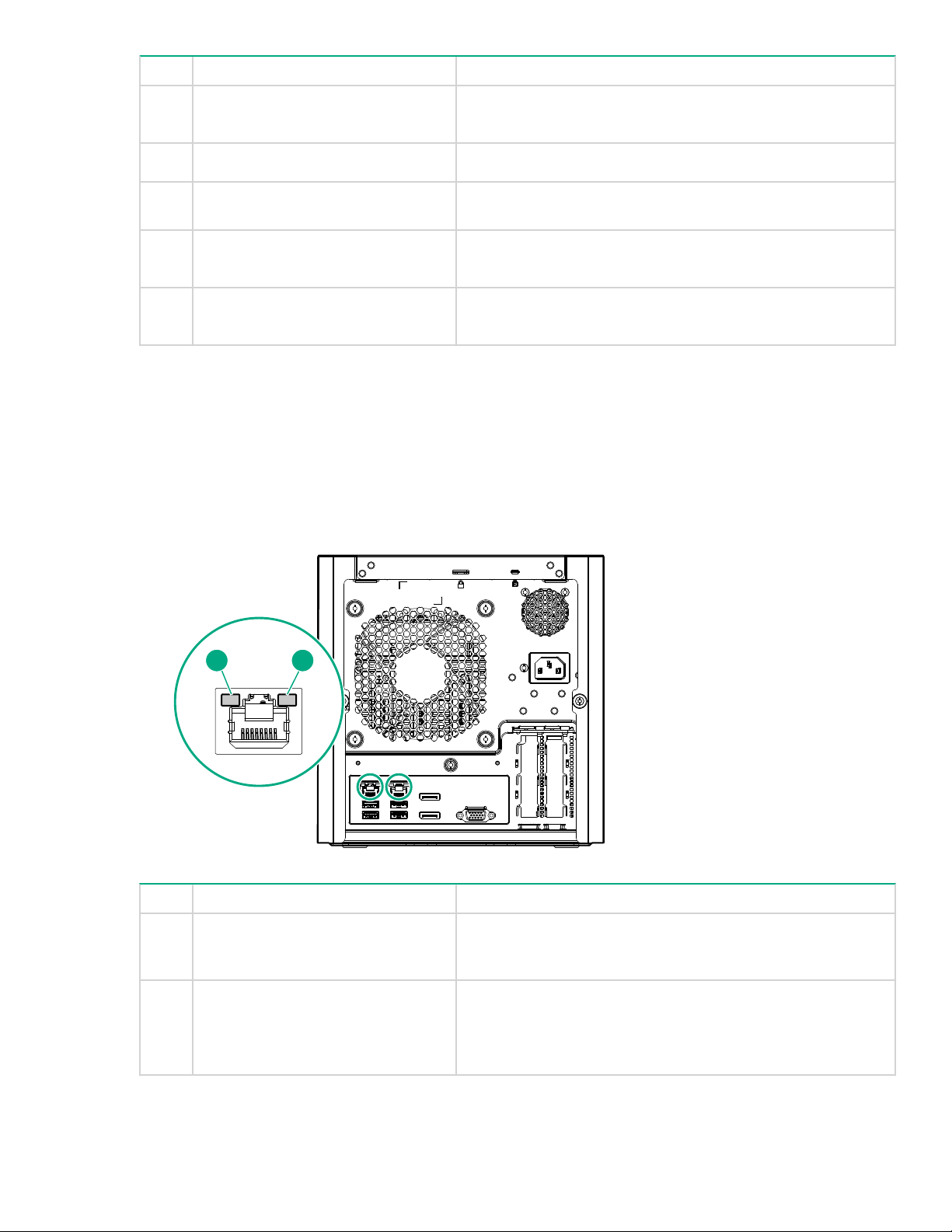

Rear panel components

Item Component Description

1 Padlock eye To lock the chassis cover and prevent access to the internal

components, attach a padlock here.

2 Kensington security slot To secure the server to a heavy or immovable object, connect

an anti-theft security cable here.

3 Power jack Connects the power cord.

4 Expansion slot 2, PCIe3 ×4 (1) For additional hardware capabilities, install a compatible

low‑profile PCIe expansion board here. This expansion slot

supports expansion boards with a physical connector link

widths of up to ×16.

1

5 Expansion slot 1, PCIe3 ×8 (8, 4, 1) For additional hardware capabilities, install a compatible

low‑profile PCIe expansion board here. This expansion slot

supports expansion boards with a physical connector link

widths of up to ×16.

6 Video port

7 Display port 1 Connects to a digital display device, such as a high-resolution

Connects to an analog VGA monitor or projector.

set top boxes or TV displays.

1

2

8 Rear panel components

Table Continued

Item Component Description

21

8 Display port 2 Connects to a digital display device, such as a high-resolution

9 USB 2.0 ports (2)

10 USB 3.0 ports (2)

11 NIC port 1 (1 Gb) Connect an Ethernet cable here to connect the server to a

12 NIC port 2 (1 Gb) Connect an Ethernet cable here to connect the server to a

1

This expansion slot is open-ended, which enables down-plugging. Down-plugging means a larger

expansion board can be installed in a smaller

low-profile expansion boards with a physical connector link width of up to ×16. The board operates at the

highest common negotiable link width specified for the slot.

2

To support 4K resolution at a full 60 Hz frame rate, this Display port requires dual-channel memory

configuration. Single-channel memory configuration will only support up to 30 Hz frame rate.

3

This NIC port supports 10/100/1000 Mbps data transfer rate per port.

Rear panel LEDs

set top boxes or TV displays.

2

Connect USB 2.0 devices to these ports.

Connect USB 3.0 devices to these ports. USB 3.0 support

after POST varies by operating system.

wired network.

wired network.

3

3

-width

-width connector. For this server, the expansion slot supports

Item Description Status

1 NIC link LED Solid green = Link exists

Off = No link exists

2 NIC status LED Solid green = Linked to network

Flashing green = Network active

Off = No network activity

Rear panel LEDs 9

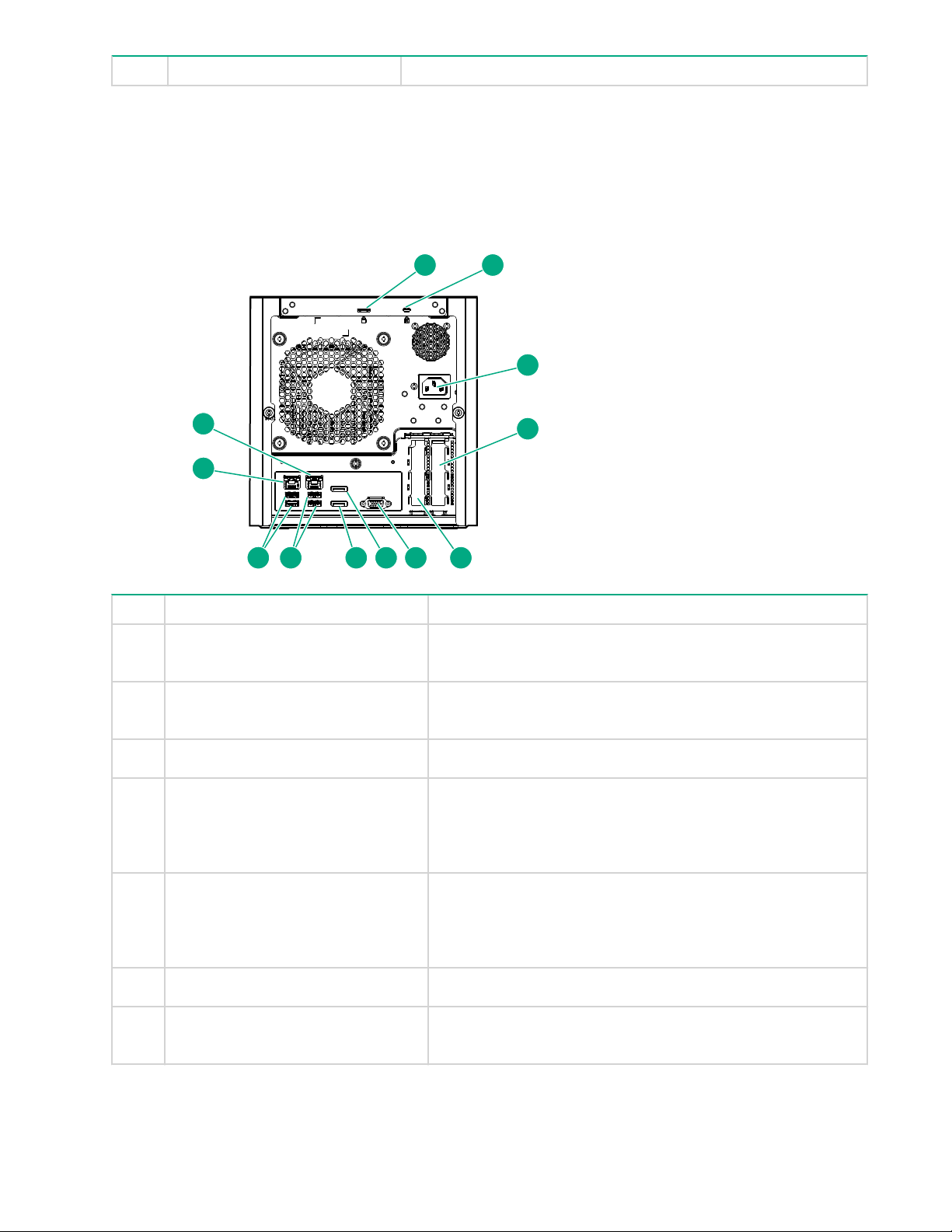

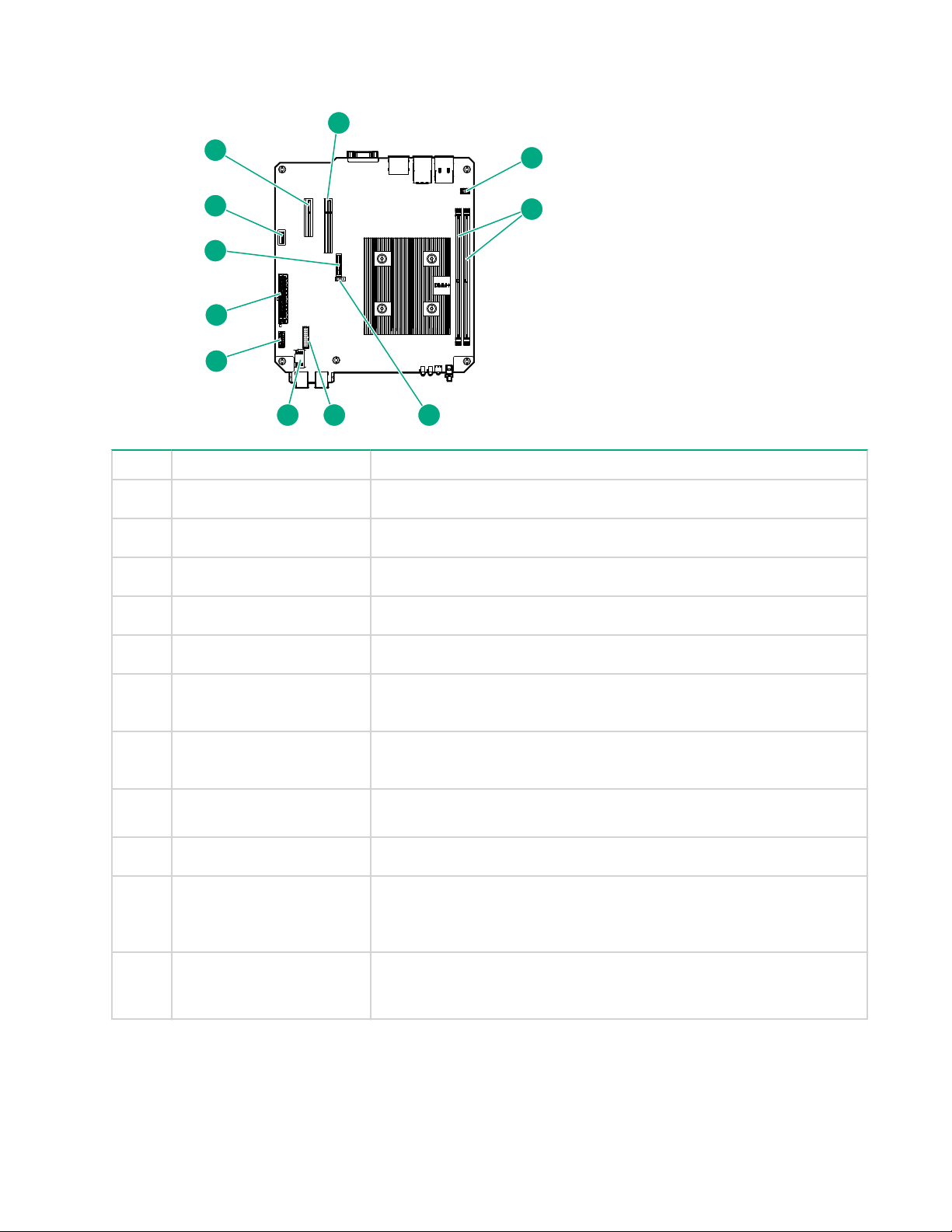

System board components

4

5

6

11

1

2

3

7

8

9

10

Item Component Description

1 Fan connector

2 DIMM slots

3 CMOS header

4 TPM connector

5 LFF/SFF drive SATA port

6 Optical drive or SSD SATA

Connects the fan cable.

These slots support standard UDIMMs with ECC only.

Use the jumper on this header to clear the CMOS.

This connector supports the TPM 2.0 option for data security solution.

Connects the LFF/SFF drive SATA cable.

Connects the optical drive or SSD SATA cable.

port

7 System board power

Connects the power supply cable.

connector

8 System battery

This battery provides power to the server real-time clock and BIOS

settings.

9 Internal USB 2.0 port

10 Expansion slot 2, PCIe3

×4 (1)

11 Expansion slot 1, PCIe3

1

This expansion slot is open-ended, which enables down-plugging. Down-plugging means a larger-width

expansion board can be installed in a smaller

×8 (8, 4, 1)

Connect internal USB devices to this port.

For additional hardware capabilities, install a compatible low-profile

PCIe expansion board here. This expansion slot supports expansion

boards with a physical connector link widths of up to ×16.

1

For additional hardware capabilities, install a compatible low-profile

PCIe expansion board here. This expansion slot supports expansion

boards with a physical connector link widths of up to ×16.

1

-width connector. For this server, the expansion slot supports

low-profile expansion boards with a physical connector link widths of up to ×16. The board operates at the

highest common negotiable link width specified for the slot.

10 System board components

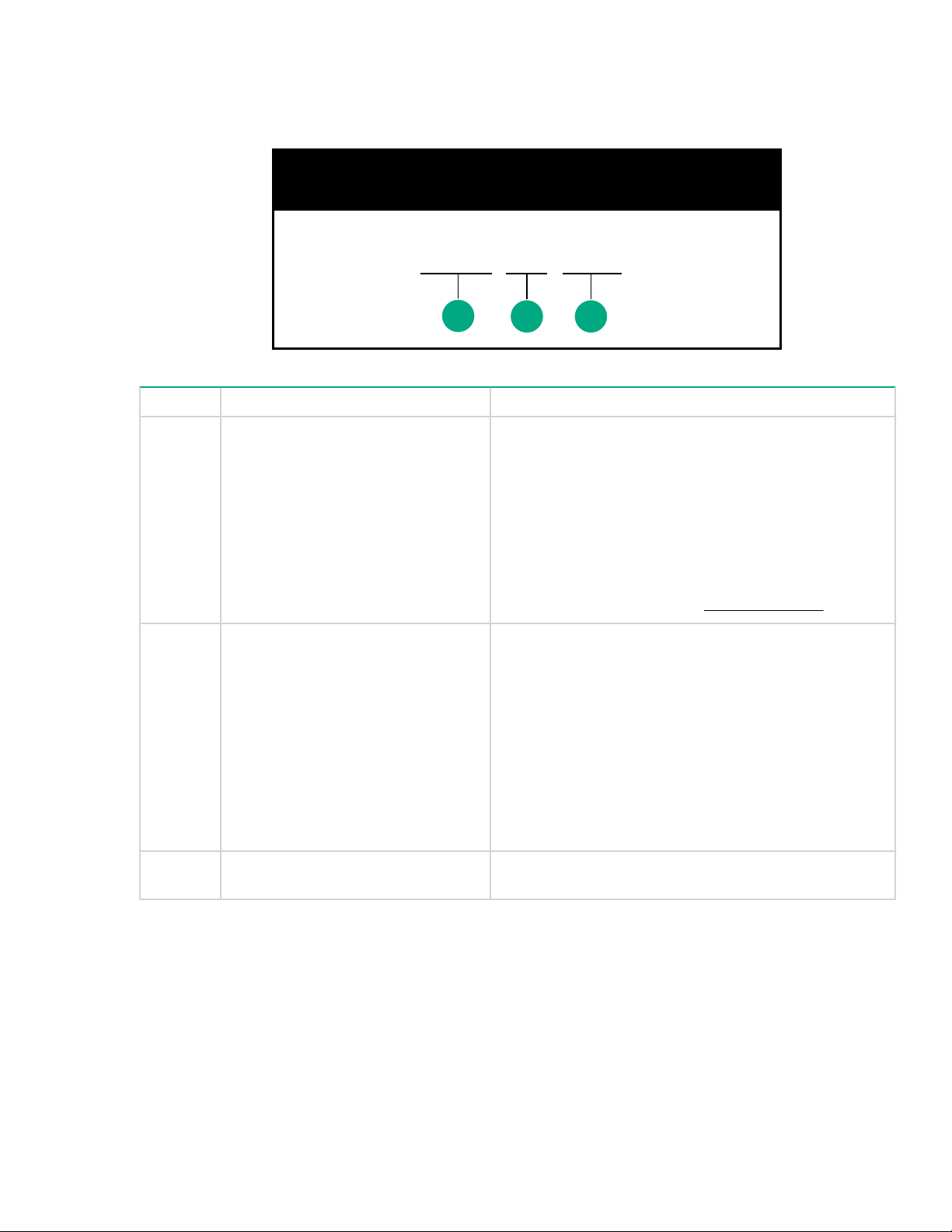

PCIe slot description

PCIe3 x8 (8,4,1)

PCIe slot description

1

2 3

Item Description Definition

1 PCI Express version

2 Physical connector link width PCIe devices communicate via a logical connection

3 Negotiable link width These numbers correspond to the maximum link

Each PCIe version corresponds to a specific data

transfer rate between the processor and peripheral

devices. Generally, a version update corresponds to an

increase in transfer rate.

• PCIe 1.x

• PCIe 2.x

• PCIe 3.x

The PCIe technology is under constant development. For

the latest information, see the PCI-SIG website.

called an interconnect or link. At the physical level, a link

is composed of one or more lanes. The number of lanes

is written with an "×" prefix with ×16 being the largest

size in common use.

• ×1

• ×2

• ×4

• ×8

• ×16

bandwidth supported by the slot.

DIMM slot locations

The DIMM slots are numbered 1 and 2. The arrow in the following illustration points to the front of the server.

PCIe slot description 11

1A 2B

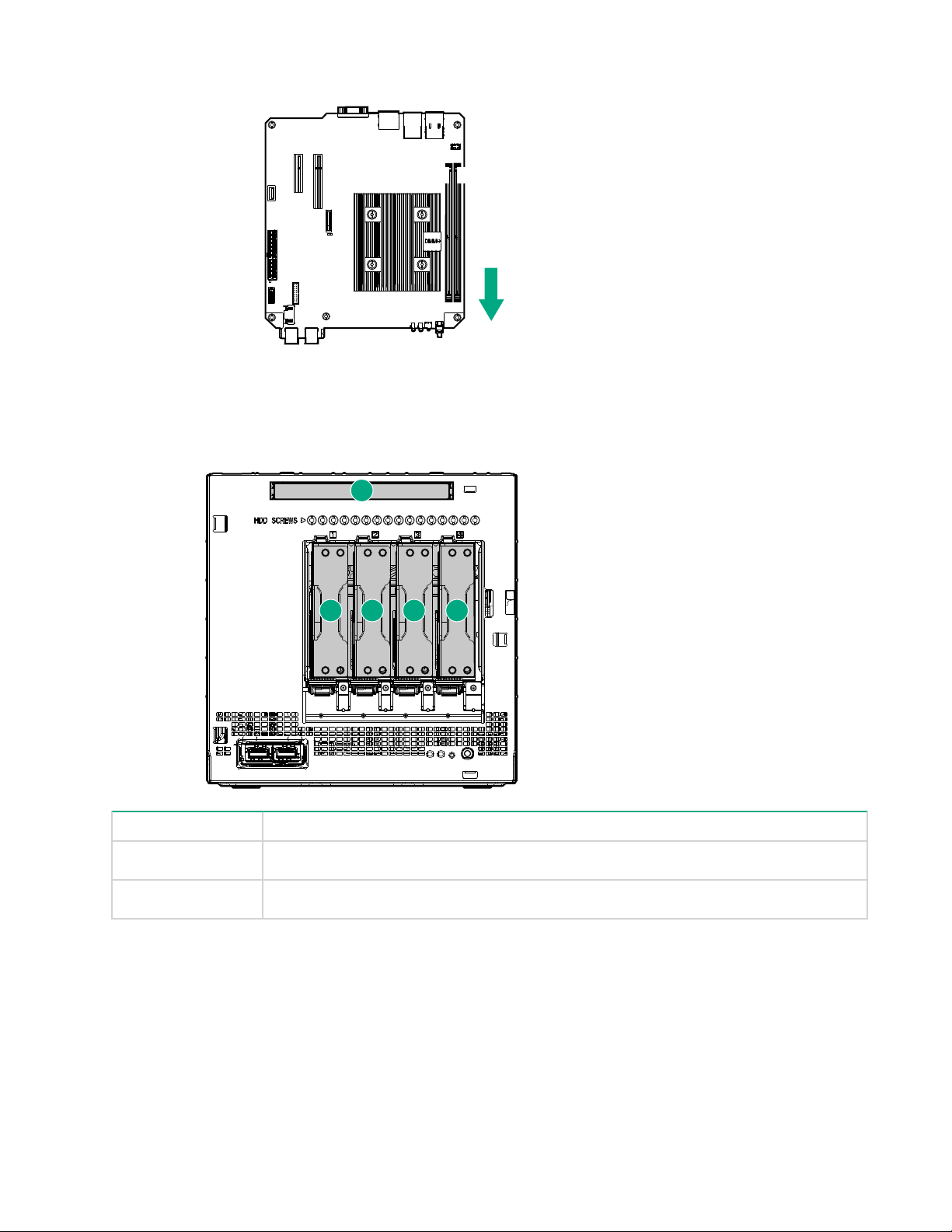

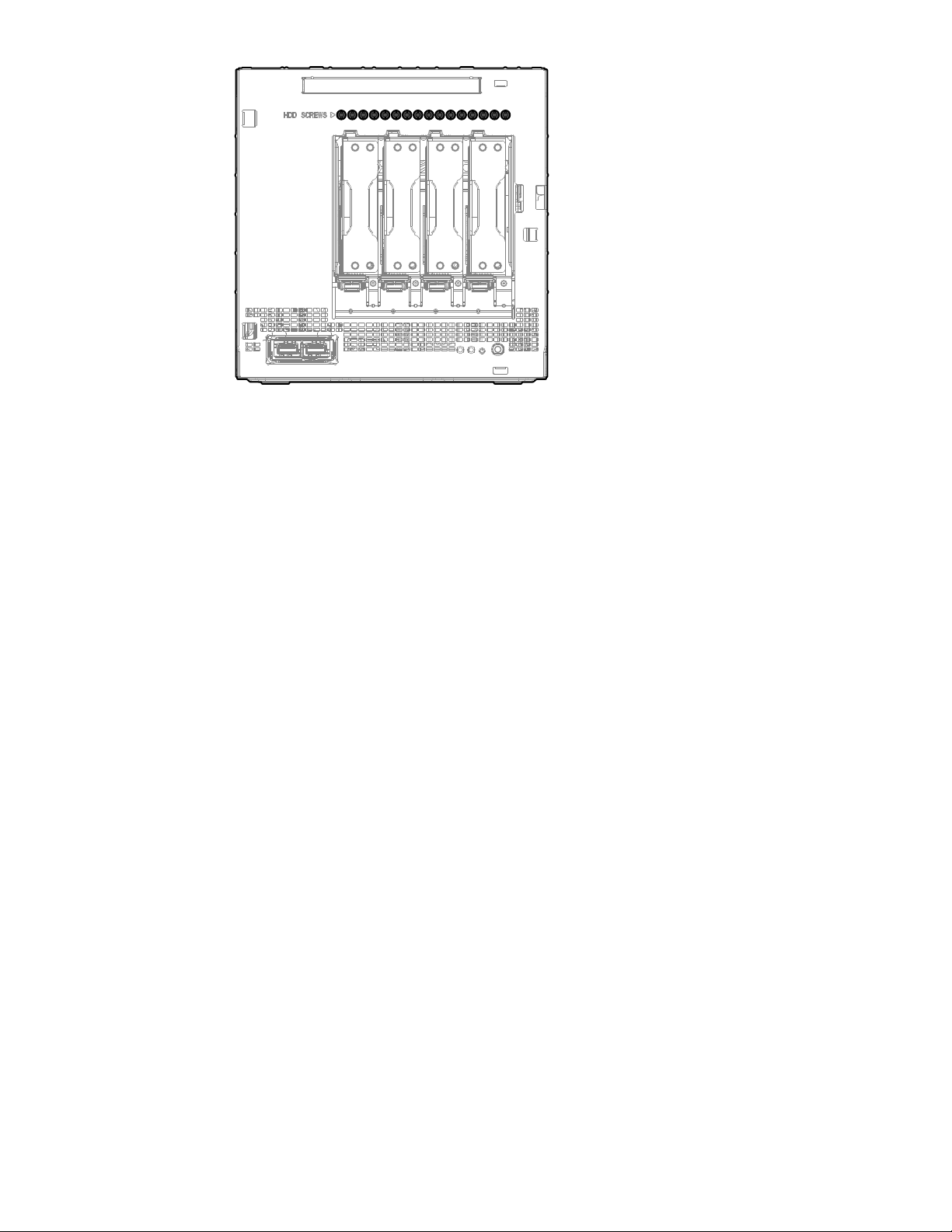

Drive numbering

1 2

5

3 4

Item Description

1-4 LFF/SFF drives

5 Solid state drive or optical disc drive

Drive screws

There are 16 T-15 T

the server.

12 Drive numbering

orx screws located above the drive bays. Use these screws to install LFF or SFF drives in

Component identification 13

Setup

This chapter describes the initial setup procedures to prepare the server for operation.

Optional services

Delivered by experienced, certified engineers, HPE support services help you keep your servers up and

running with support packages tailored specifically for HPE ProLiant systems. HPE support services let you

integrate both hardware and software support into a single package. A number of service level options are

available to meet your business and IT needs.

HPE support services offer upgraded service levels to expand the standard product warranty with

‑to‑buy, easy‑to‑use support packages that will help you make the most of your server investments.

easy

Some of the HPE support services for hardware, software, or both are:

• Foundation Care – Keep systems running.

The time commitment for this service might vary depending on the site's geographical region. For more

service information available at your site, contact your local

• Deployment service for both hardware and software.

HPE Education Services – Help train your IT staff.

•

For more information on HPE support services, see the HPE Pointnext website:

http://www.hpe.com/services

HPE support center.

Initial server setup overview

Procedure

1. Unpack the server shipping carton.

2. If applicable, install any hardware options that are shipped separately from the server.

For detailed option installation instructions, see the relevant section in Hardware options installation on

page 31.

3. Review the initial server setup prerequisites.

4. Connect the I/O devices.

5. Connect the network cable.

6. Connect the power cord.

7. Power on the server for the first time.

8. Install an operating system (OS).

9. As a best practice, Hewlett Packard Enterprise recommends that you install the latest firmware,

drivers, and system software before using the server for the first time.

10. Register the server.

Unpacking the server shipping carton

Unpack the server shipping carton. The contents of the server shipping carton include:

Server

•

•

Power cord

• Printed setup documentation

14 Setup

Prerequisites for the initial server setup

Procedure

Verify that the optimum environmental requirements are satisfied.

Review and observe the server warnings and cautions.

Prepare the following items:

◦ Keyboard, mouse, and monitor

Ethernet cables of an appropriate length for each of the LAN and/or WAN connections.

◦

◦ Verify the network settings needed to integrate the server into the site network, in particular from an IP

addressing perspective and from a domain perspective.

◦ Verify that there are sufficient ports available on the devices to which the server will be connected (for

example, router, LAN switch).

Optimum environment

When installing the server, select a location that meets the environmental requirements described in this

section.

Site requirements

The server may be located in an office space or a purpose-made equipment room. The location must:

• Comply with local health and safety regulations.

• Be clean, tidy, and free of excessive dust and vibration.

• Be in an area in which the server cannot easily be disconnected from its power source.

• Not be adjacent to or underneath any area or piece of equipment where liquid is stored.

• Not be in a place where the server might be bumped, scratched, or disturbed.

• Be within an area that is ideally locked or at minimum not accessible to unauthorized personnel.

• Be within patching distance, directly or via cable management cross-patches, of the location of the WAN

connection and the switch that supplies the office/room floor network ports.

Space and airflow requirements

Leave at least a 10 cm (4 in) clearance space at the front and back of the server for proper ventilation.

CAUTION:

The server draws in cool air through the ventilation openings on the front side, and expels warm air

through the ventilation openings on the rear side. Do not block these openings. Failure to observe this

caution will result in improper airflow and insufficient cooling that can lead to thermal damage.

Temperature requirements

To ensure continued, safe, and reliable equipment operation, install or position the system in a well-ventilated,

climate-controlled environment.

The maximum recommended TMRA for most server products is 35°C (95°F). The temperature in the room

where the server is located must not exceed 35°C (95°F).

Prerequisites for the initial server setup 15

CAUTION:

To reduce the risk of damage to the equipment when installing third-party options:

Do not permit optional equipment to impede airflow around the server beyond the maximum

•

allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of information technology equipment by licensed electricians. This equipment is designed to

operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFP

for Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on options,

see the product rating label or the user documentation supplied with that option.

CAUTION:

Protect the server from power fluctuations and temporary interruptions with a regulating uninterruptible

power supply. This device protects the hardware from damage caused by power surges and voltage

spikes and keeps the system in operation during a power failure.

When installing more than one server, you might have to use additional power distribution devices to safely

provide power to all devices. Observe the following guidelines:

• Balance the server power load between available AC supply branch circuits.

Do not allow the overall system AC current load to exceed 80% of the branch circuit AC current rating.

•

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for the server.

A-75, 1992 (code

Electrical grounding requirements

The server must be grounded properly for proper operation and safety. In the United States, you must install

the equipment in accordance with NFP

local and regional building codes. In Canada, you must install the equipment in accordance with Canadian

Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries, you must install the

equipment in accordance with any regional or national electrical wiring codes, such as the International

Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be sure that all

power distribution devices used in the installation, such as branch wiring and receptacles, are listed or

certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same power

source, Hewlett Packard Enterprise recommends the use of a PDU that is either permanently wired to the

building’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug. NEMA

locking-style plugs or those complying with IEC 60309 are considered suitable for this purpose. Using

common power outlet strips for the server is not recommended.

A 70, 1999 Edition (National Electric Code), Article 250, as well as any

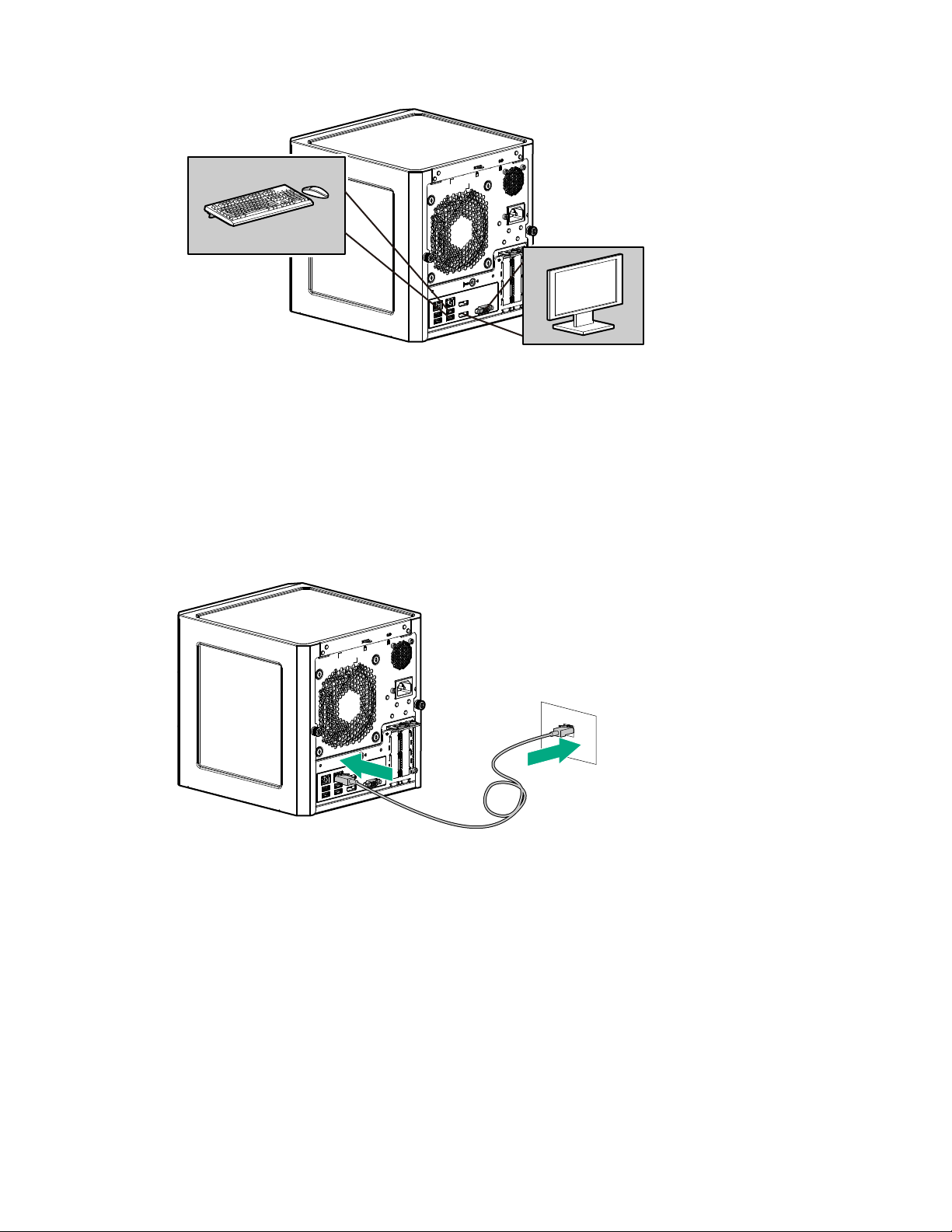

Connecting the I/O devices

About this task

To view and navigate the initial server setup screens, connect I/O devices to the server.

Procedure

1. Connect a keyboard and mouse to the USB ports.

2. Connect a monitor to the VGA or Display port.

16 Power requirements

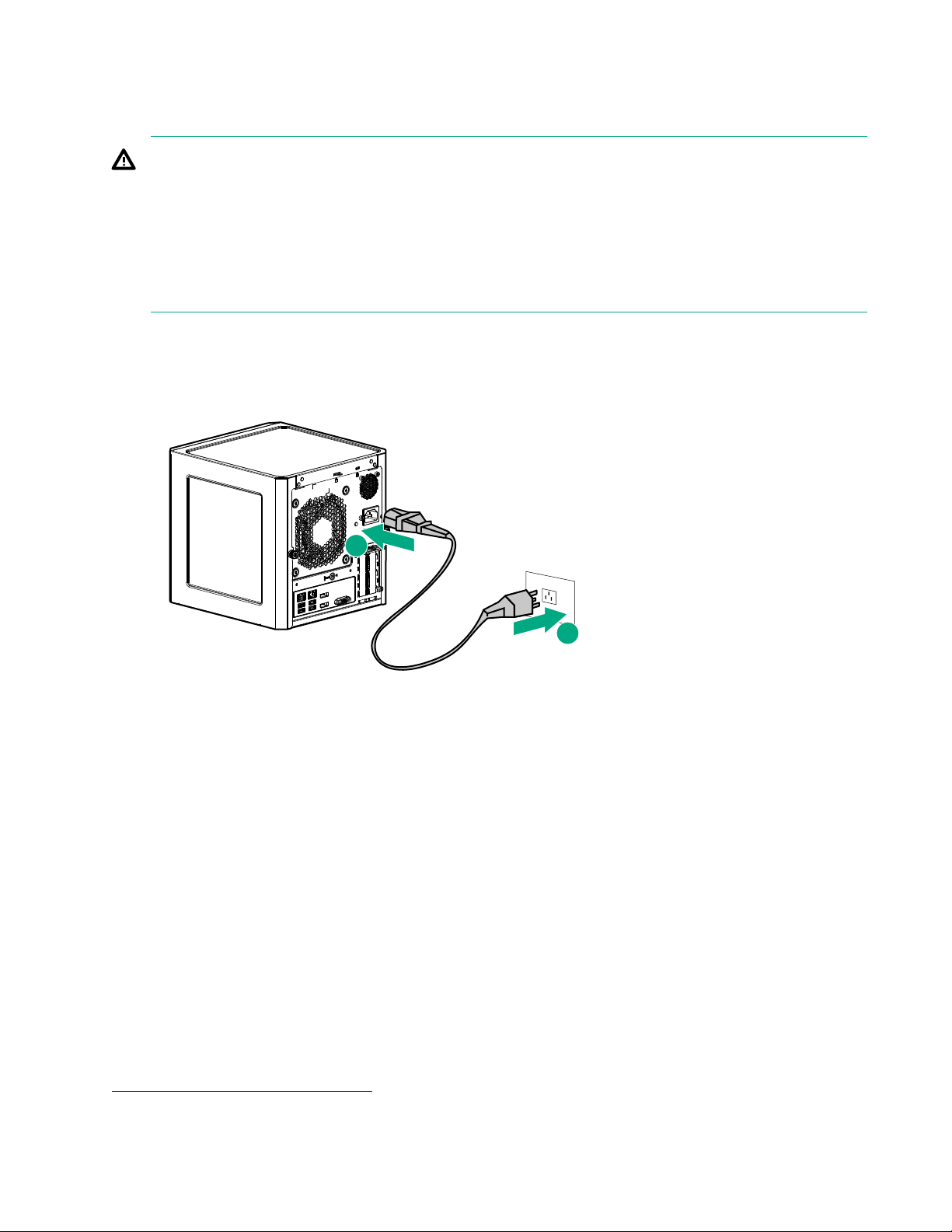

Connecting the network cable

Procedure

1. Connect one end of the network cable to the NIC port.

2. Connect the other end of the network cable to a network jack or a network device such as router or LAN

switch.

Connecting the network cable 17

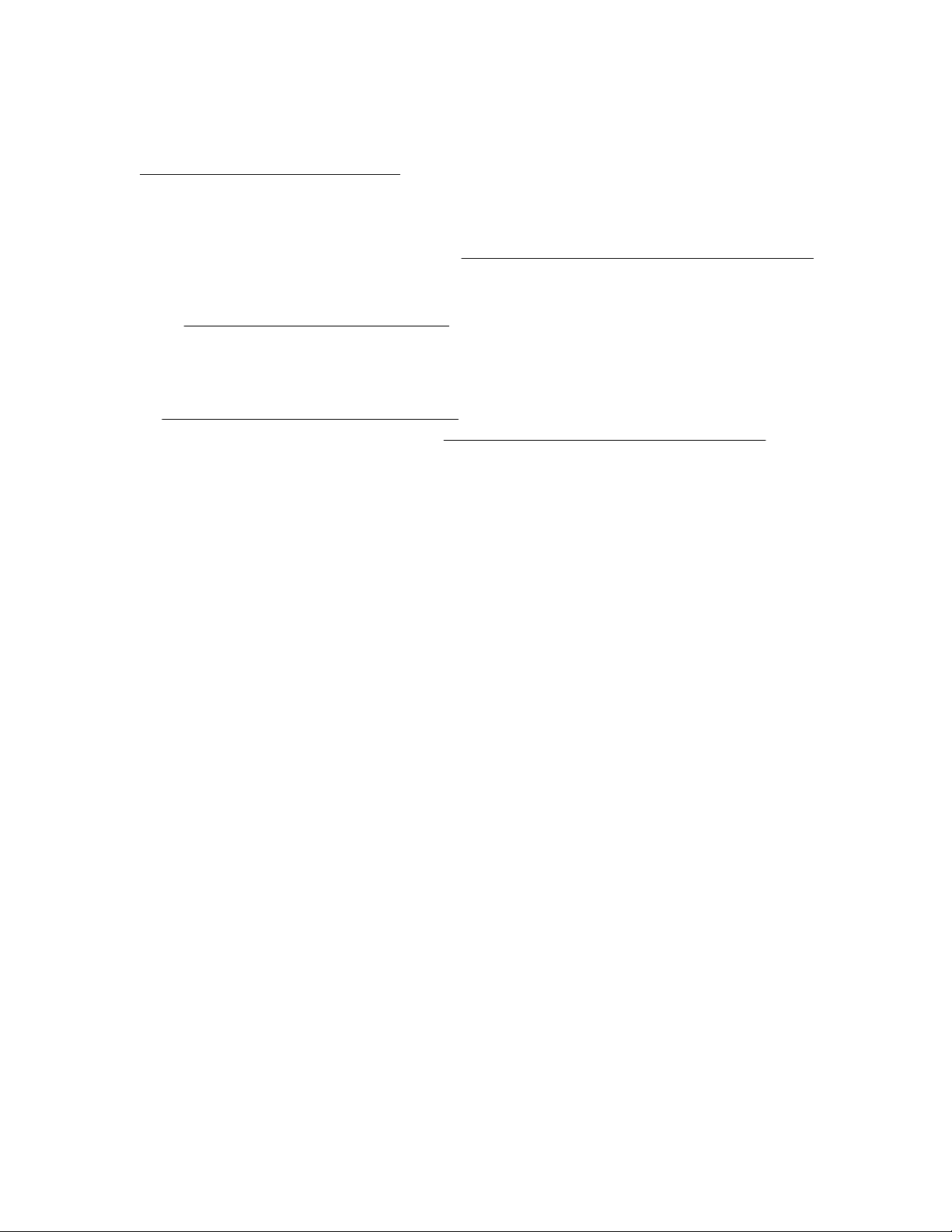

Connecting the power cord

1

2

About this task

WARNING:

To reduce the risk of electric shock or damage to the equipment:

Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

•

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it. Pay

particular attention to the plug, electrical outlet, and the point where the cord extends from the server.

Procedure

1. Connect the power cord to the server power jack.

2. Connect the power cord to the AC power source.

Powering on the server for the first time

Procedure

1. If you are installing an operating system from a bootable media, insert the media into the server.

2. Press the Power On/Standby button.

3. Verify that the system power LED changes to green.

4. During the initial boot, on the enter setup prompt, press the F2 or Del key to access the Aptio Setup Utility

and do one of the following:

• Modify the default BIOS configuration settings.

• Access the preloaded ClearOS image.

• Adjust the boot order to select the OS bootable media.

Installing an operating system

To operate properly

operating systems, see the Hewlett Packard Enterprise website:

http://www.hpe.com/info/supportos

18 Connecting the power cord

, the server must have a supported operating system. For information on supported

This server supports Class 2 UEFI implementation. UEFI Class 2 implementation supports both UEFI boot

mode and legacy BIOS boot mode. The boot mode is configured in the Aptio Setup Utility. When the server is

configured for UEFI boot mode, observe the appropriate operating system, boot mode, network device, and

controller requirements. For more information on these requirements, see the Important UEFI Requirements

(for the HPE ProLiant MicroServer Gen10) on the Hewlett Packard Enterprise Information Library:

http://www.hpe.com/info/UEFI/docs

To install an operating system on the server

• If you are planning to install ClearOS, there are two install scenarios:

◦ For a server that shipped with ClearOS,

◦ For a server that does not have ClearOS preloaded, download the software from the Hewlett Packard

Enterprise website:

http://www.hpe.com/servers/clearos

ClearOS is a Linux-based OS with a web-based interface with its own application marketplace for small to

medium businesses. For detailed ClearOS installation instructions, see the ClearOS 7 on HPE ProLiant

Servers Installation Guide at:

http://www.hpe.com/support/ClearOS-IG

• If you are planning to install another OS, boot directly from the OS installation media.

This installation media can either be an optical disc or a USB drive. If you are using an OS installation disc

and the server does not have an internal optical drive installed, an external USB optical drive is required.

, use one of the following methods:

Install the preloaded ClearOS image

Procedure

1. On the Aptio Setup Utility screen, select the Boot menu.

2. Under Boot Option Priorities, verify that Boot Option #1 is set as [ClearOS Utilities].

If it is not set, select Boot Option #1, press the Enter key, and then change the setting to [ClearOS

Utilities].

o confirm the change and exit the utility, press the F4 key.

3. T

boot the server to the preloaded ClearOS image.

The server automatically reboots to the selected device.

4. Follow the OS installation wizard instructions.

Install an OS from a bootable installation media

Procedure

1. On the Aptio Setup Utility screen, select the Boot menu.

2. Under Boot Option Priorities, verify that Boot Option #1 is set to the OS installation media device.

If it is not set, select Boot Option #1, press the Enter key, and then change the setting.

o confirm the change and exit the utility, press the F4 key.

3. T

The server automatically reboots to the selected device.

4. Follow the OS installation wizard instructions.

Installing the latest system software and firmware

As a best practice, Hewlett Packard Enterprise recommends that you install the latest firmware, drivers, and

system software before using the

see the server download page:

server for the first time. T

o get the latest firmware and software updates,

Install the preloaded ClearOS image 19

http://www.hpe.com/downloads/microservergen10

Registering the server

To experience quicker service and more ef

https://myenterpriselicense.hpe.com/

ficient support, register the server at the My License Portal website:

20 Registering the server

Operations

This chapter describes the hardware operations carried out prior to and after installing or removing a

hardware option, or performing a server maintenance or troubleshooting procedure.

Before performing these hardware operations, review and observe the server warnings and cautions.

Server warnings and cautions

WARNING:

To reduce the risk of personal injury

cord to remove power from the server. Pressing the Power On/Standby button does not shut off system

power completely. Portions of the power supply and some internal circuitry remain active until AC power

is removed.

WARNING:

To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system

components to cool before touching them.

CAUTION:

Protect the server from power fluctuations and temporary interruptions with a regulating UPS. This

device protects the hardware from damage caused by power surges and voltage spikes and keeps the

server in operation during a power failure.

CAUTION:

To prevent improper cooling and thermal damage, do not operate the server with the media bay blank,

chassis cover

CAUTION:

To prevent damage to electrical components, properly ground the

installation procedure. Improper grounding can cause electrostatic discharge.

, or the front bezel removed.

, electric shock, or damage to the equipment, disconnect the power

server before beginning any

CAUTION:

To avoid data loss, Hewlett Packard Enterprise recommends that you back up all server data before

installing or removing a hardware option, or performing a server maintenance or troubleshooting

procedure.

Electrostatic discharge

Preventing electrostatic discharge

About this task

To prevent damaging the system, be aware of the precautions you must follow when setting up the system or

handling parts. A discharge of static electricity from a finger or other conductor may damage system boards or

other static-sensitive devices. This type of damage may reduce the life expectancy of the device.

Operations 21

Procedure

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

Place parts on a grounded surface before removing them from their containers.

•

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Grounding methods to prevent electrostatic discharge

Several methods are used for grounding. Use one or more of the following methods when handling or

installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or computer chassis. Wrist straps

are flexible straps with a minimum of 1 megohm ±10 percent resistance in the ground cords. To provide

proper ground, wear the strap snug against the skin.

•

Use heel straps, toe straps, or boot straps at standing workstations. Wear the straps on both feet when

standing on conductive floors or dissipating floor mats.

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an authorized reseller install

the part.

For more information on static electricity or assistance with product installation, contact an authorized reseller.

Power up the server

Press the Power On/Standby button.

The server exits standby mode and applies full power to the system. The system power LED changes to

green.

Power down the server

Prerequisites

Before powering down the server for any upgrade or maintenance procedures, perform a backup of critical

server data and programs.

Procedure

• Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server enters standby

mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server to enter standby

mode.

This method forces the server to enter standby mode without properly exiting applications and the OS. If

an application stops responding, you can use this method to force a shutdown.

The system power LED changes to red indicating that the server is in standby mode. Auxiliary power is still

present in the system in this mode.

22 Grounding methods to prevent electrostatic discharge

Prepare the server for hardware installation or removal

Procedure

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server.

3. Disconnect all peripheral cables from the server

4. If installed, unlock and remove the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

.

Prepare the server for operation

Procedure

1. If removed, attach the security padlock and/or the Kensington security lock.

For more information, see the lock documentation.

2. Connect all peripheral cables to the server.

3. Connect the power cord to the server power jack, and then to the AC source.

4. Secure the power cord and rear panel cables based on the standard cable management practices.

5. Power up the server on page 22.

Remove the front bezel

o access the drive bays, remove the front bezel.

T

Removing a locked front bezel

Prerequisites

1. Power down the server on page 22.

2. Disconnect the power cord from the AC source, and then from the server

3. Disconnect all peripheral cables from the server.

4.

Remove the chassis cover on page 26.

Procedure

1. To unlock the front bezel from the chassis, slide the release tab upward.

.

Prepare the server for hardware installation or removal 23

Loading...

Loading...