Burson Automotive

handles growth with

Case Study

Objective

Replace existing infrastructure with

scalable and stable systems to cope

with business growth

Approach

Compared upgrade to replacement and

consulted with application provider on

available options

IT Matters

• Quadrupled performance, cutting time

required for overnight batch process

from eight or nine hours to only two

• Improved response times so users

no longer experience any lag

between screens

• Reduced number of racks required

for the system from eight to two,

saving costs

• Simplified installation, as the new

system could be set up and tested in

parallel to existing infrastructure

• Provided suicient performance

and storage capacity to handle new

ERP features

Business Matters

• Enabled the system to scale with

unpredictable business growth, from

originally 112 stores to 175 or more

• Reduced total cost of ownership, with

15 month payback period

• Cut operating expenditure, as support

costs included in the system price

scalable infrastructure

Fast, flexible system scales with

retailer’s expansion

Burson Automotive needed

to replace its main

IT infrastructure to handle

growth. It chose a HPE

blade system with HP-UX

and HPE 3PAR StoreServ

7450 flash storage, which

has improved performance,

cut operating costs and

provided the required

scalability. The new

system has enabled

Burson to consolidate

multiple systems and

improve its disaster

recovery capabilities.

Challenge

Unpredictable growth

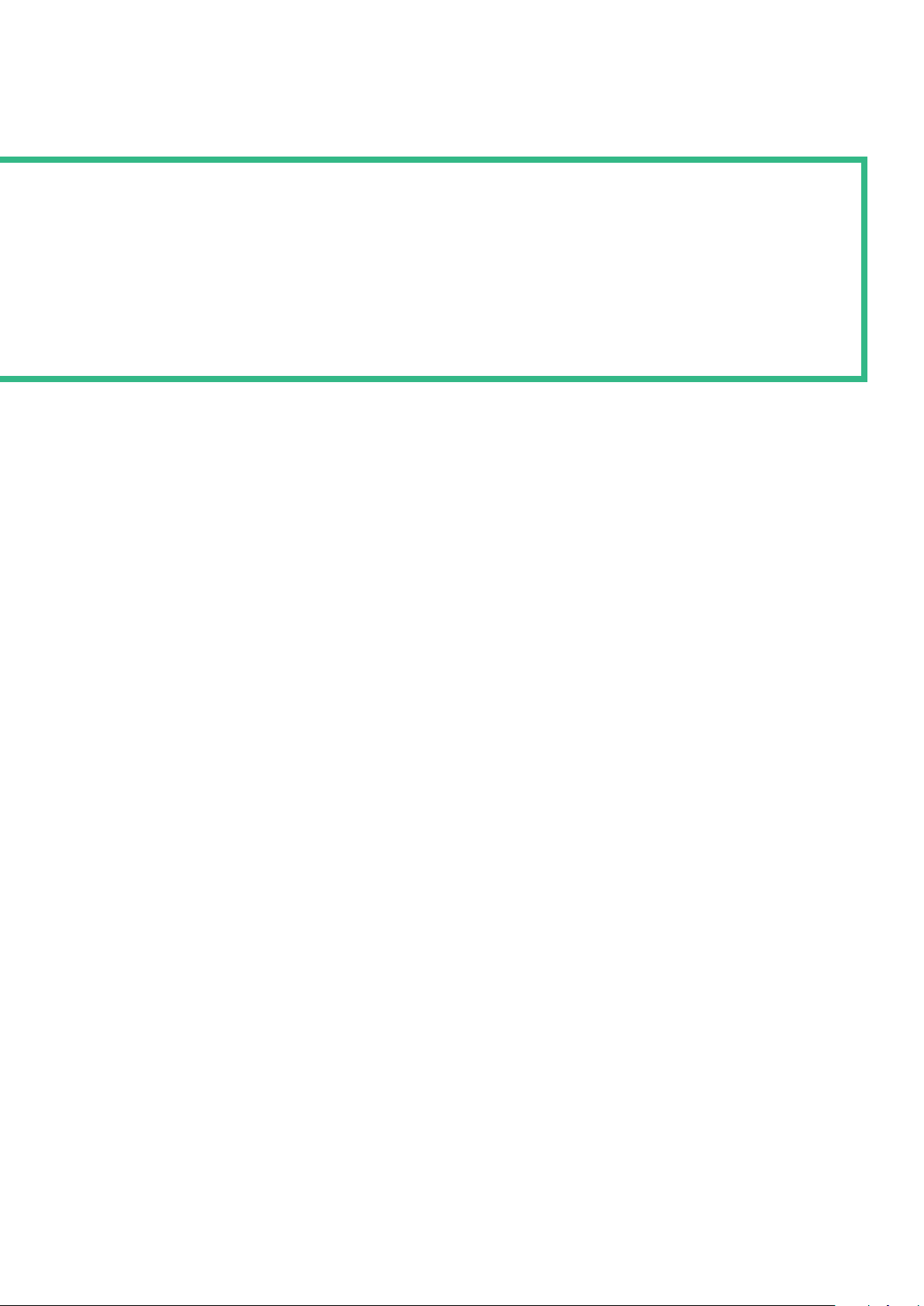

Burson Automotive keeps Australia’s cars

and light trucks on the road, supplying

aftermarket parts, accessories and workshop

equipment from more than 120 stores and

500 delivery vehicles.

Since it was founded in 1971, Burson has

continually expanded. Recently, this growth

has accelerated, requiring the company’s

IT systems to scale in response.

“We were running servers and storage

area network (SAN) from Hewlett Packard

Enterprise but with the business’s growth

we were coming to a point where we’d

either need to upgrade or replace our

infrastructure,” says Leon Rawlins, business

systems manager at Burson Automotive.

Case study

Burson Automotive

“The project has gone very well and exceeded my expectations. I was

surprised at the ease of deployment – all the dierent components

integrated well together.”

— Leon Rawlins, business systems manager, Burson Automotive

Industry

Trade

Page 2

At this point, Burson had 112 stores but

was planning to expand to 175 within five

years, both via acquisition and organic

growth. Rawlins comments, “We looked at

what had to change to reach that point.

We either needed to upgrade the CPU

and buy additional disks for the SAN,

or replace everything – we considered

both possibilities.”

Solution

Proven HP-UX stability

Rawlins spoke to HPE and discussed the

options, and talked to the provider of the

main application used at Burson, which is

the MomentumPro Enterprise Resource

Planning (ERP) system running on a

Progress database.

“The application provider did have a version

running on Windows®, but we wanted the

proven stability of UNIX®, and in particular

of HP-UX. MomentumPro is businesscritical, and runs all our inventory and

financial systems.

“We considered systems based on other

UNIX platforms, but that would have

involved bringing in a completely new

operating system, which would add

additional risk.”

“If we had a year for the project we might

have looked at other UNIX versions, but our

business’s rapid expansion meant we had

tight timescales – so we stayed on HP-UX

to simplify the migration.

“Once we had decided on HP-UX, we looked

at the blades, storage and chassis available

from HPE,” says Rawlins. “The blade system

had the benefit that, as well as handling the

expansion of the ERP, we could consolidate

Windows environments and other servers

onto the new infrastructure.”

Rawlins chose an infrastructure housed in an

HPE BladeSystem c7000 enclosure, and it

selected an HPE Integrity BL870c i4 Server

Blade featuring HP-UX 11i v3. For storage,

they selected HPE 3PAR StoreServ 7450

Storage System with thirty-two 480GB solid

state disks (SSDs). The system includes HPE

FlexFabric interconnects.

Fast payback

“Had we upgraded, we would have had

perhaps just a year before we had to

upgrade again,” says Rawlins. “Also, with an

upgrade, maintenance costs are increasing

each year – but the replacement system

included support, so we are ahead on

operating expenditure. When we did a

comparison, the replacement was lower in

cost than the upgrade, with a fifteen month

payback period on the hardware.”

Case study

Burson Automotive

Industry

Trade

Page 3

“By replacing the system, we could build

everything and get it up and running

without interfering with the current

operation. If we had done an upgrade, there

would have been significant downtime,

even if there were no problems – but with a

replacement we could build it all in parallel,

do comprehensive testing and make sure

everything was working.”

HPE Technology Services designed the

new system with Burson’s Infrastructure

& Operations manager Nick Dawson to

check all aspects were considered. Rawlins

comments, “The implementation went

extremely well, and the engineering support

people at HPE were excellent – everything

was here on time or early, and it all

went smoothly.

“We built the new system and got the

operating system loaded, the disks up and

database restored, and were able to run

tests until we were satisfied to give us a

comfort factor,” says Rawlins. “Then we

took the users o the system and started

the migration of data at 6pm, and had

everything up and running by 11pm

that night.”

Benefits

Performance quadrupled

With the new infrastructure, Rawlins says

the biggest single benefit is improved

performance, not least due to the system’s

solid state storage. He comments, “Although

going all flash with the 3PAR storage was

more expensive, it was worth it for the

performance advantage.”

Burson runs an overnight batch job to

process all the orders from its stores, and to

calculate the orders and picking lists needed

for its warehouse management system

(WMS). Previously, this took up to four to

five hours, but the new system and disk I/O

has cut this – a saving of at least 75 per cent.

“We knew we had to speed up the

processing, if we expand into Western

Australia we would lose three hours from

the overnight window, due to the time

dierence,” says Rawlins. “We had to do the

same tasks in a smaller timeframe.”

As of today, Burson has grown to 121 stores,

and Rawlins says, “The old system would

already have been unable to cope – we

would have been on about 99 per cent

CPU, but at the moment we’re sitting at

15 per cent CPU. It’s a massive change – we

would have been happy with a 50 per cent

improvement, but we’ve got almost an

80 per cent increase.”

Based on its current application layer,

this speed increase means that Burson

has plenty of headroom for growth to its

planned 175 stores and beyond. The HPE

server can also be upgraded to double the

performance if required. Rawlins comments,

“While the store rollout is the priority,

we’re also going to look at adding extra

functionality in the ERP application. In the

past we were constrained by hardware

performance, but the new system is giving

us the opportunity to add more modules.”

Case study

Burson Automotive

Industry

Trade

Customer at a glance

Applications

• MomentumPro ERP system

• Progress database

Hardware

• HPE BladeSystem c7000 enclosure

• HPE FlexFabric interconnects (four

1GB copper, four 8Gb SAN SFP)

• HPE Integrity BL870c i4 Server Blade

(four 9540 CPU, 512GB RAM)

• HPE 3PAR StoreServ 7450

Storage Systems

Software

• HP-UX 311i v3

HPE services

• Data centre consulting

• Care Pack installation services

“When we did a comparison, the replacement was

lower in cost than the upgrade, with a fifteen month

payback period.”

— Leon Rawlins, business systems manager, Burson Automotive

Consolidation reduces costs

As well as the main ERP system, Burson is

also starting to use the new infrastructure

to consolidate its other systems, including

file, print and Exchange servers. By moving

from a rack-based server system to

blades, the company will be able to shrink

its infrastructure from eight cabinets to

only two.

“HPE’s deduplication features will also save

us money, as we will need to buy fewer disks

to migrate our existing external servers onto

Hyper-V virtual machines on the blades,”

says Rawlins.

“We were at full storage capacity on the old

system, but now with the 3PAR we will be at

around 70 per cent after we have migrated

Exchange onto the infrastructure – and

that’s even before we add in the benefits of

deduplication,” says Rawlins.

The current system has two controller nodes

for the storage, but for the future, Burson

is expecting to scale this to four nodes if

required. Rawlins comments, “This was a

deliberate choice – we wanted a system with

the flexibility to grow, without having to buy

hardware now that we wouldn’t use for six or

twelve months.”

Another reason Burson replaced its

infrastructure was to improve disaster

recovery (DR). Previously, when it failed

over to its DR site Burson had to reduce

the number of users to 50 per cent. Now, it

uses its old production system for DR, which

enables Burson to run at around 90 per cent

capacity if it has to fail over to the DR site.

Exceeded expectations

“The project has gone very well and

exceeded my expectations, and I was

surprised at the ease of deployment – all

the dierent components integrated well

together,” says Rawlins. “Overall, the biggest

benefits for us were performance, simplicity

of implementation and cost.

“Due to this positive experience with HPE,

we’re now looking at working with them

in other areas of our business, and we’re

already rolling out HP Thin Clients at some

of our stores,” concludes Rawlins.

Learn more at

hpe.com/go/3par

Sign up for updates

Rate this document

© Copyright 2014-2016 Hewlett Packard Enterprise Development LP. The information contained herein is subject to change without

notice. The only warranties for Hewlett Packard Enterprise products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Windows is a U.S. registered trademark of the Microsoft group of companies.

UNIX is a registered trademark of The Open Group.

4AA5-5925EEW, March 2016, Rev. 2

Loading...

Loading...