HPE ProLiant BL460c Gen10 Server Blade User Guide

Abstract

This document is for the person who installs, administers, and troubleshoots server blades.

Hewlett Packard Enterprise assumes you are qualified in the servicing of computer equipment

and trained in recognizing hazards in products with hazardous energy levels.

Part Number: 876833-006

Published: May 2019

Edition: 6

©

Copyright 2017-2019 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

microSD is a trademark or a registered trademark of SD-3C in the United States, other countries or both.

Red Hat® is a registered trademark of Red Hat, Inc. in the United States and other countries.

VMware® is a registered trademark or a trademark of VMware, Inc. in the United States and/or other

jurisdictions.

Contents

Component identification.......................................................................6

Front panel components............................................................................................................... 6

Front panel LEDs and buttons...................................................................................................... 7

Front panel LED power fault codes....................................................................................8

Serial label pull tab information.......................................................................................... 8

Drive numbering............................................................................................................................9

Hot-plug drive LED definitions...................................................................................................... 9

NVMe SSD components............................................................................................................. 10

SFF flash adapter components and LED definitions...................................................................11

SUV cable connectors................................................................................................................ 12

System board components......................................................................................................... 13

System maintenance switch.............................................................................................14

DIMM slot locations..........................................................................................................15

DIMM label identification.................................................................................................. 15

NVDIMM identification......................................................................................................17

NVDIMM LED identification..............................................................................................18

Mezzanine connector definitions......................................................................................19

Mezzanine connector guide pin locations........................................................................ 19

Operations............................................................................................. 21

Power up the server blade.......................................................................................................... 21

Power down the server blade..................................................................................................... 21

Remove the server blade............................................................................................................22

Remove the access panel...........................................................................................................22

Install the access panel...............................................................................................................23

Remove the DIMM baffles...........................................................................................................23

Install the DIMM baffles...............................................................................................................25

Remove an M.2 SSD from the M.2 riser board...........................................................................26

Remove the M.2 interposer board and the M.2 riser board........................................................ 27

Relocate the PEM nut and rubber stopper..................................................................................28

Remove the direct connect SATA cable......................................................................................31

Install the direct connect SATA cable..........................................................................................31

Remove the mezzanine assembly.............................................................................................. 32

Install the mezzanine assembly.................................................................................................. 33

Remove the FlexibleLOM........................................................................................................... 33

Remove the storage controller or NVMe pass-through board.................................................... 34

Remove an NVMe SSD.............................................................................................................. 35

Remove a SAS or SATA drive.....................................................................................................35

Remove the front panel/drive cage assembly.............................................................................36

Install the front panel/drive cage assembly.................................................................................37

Setup...................................................................................................... 39

Overview..................................................................................................................................... 39

Server blade warnings and cautions...........................................................................................39

Installing an HPE BladeSystem c-Class enclosure.....................................................................39

Preparing the enclosure................................................................................................... 40

Installing server blade options.................................................................................................... 40

Installing interconnect modules...................................................................................................40

3

Interconnect bay numbering and device mapping........................................................... 40

Connecting to the network.......................................................................................................... 42

Install the server blade................................................................................................................42

Completing the configuration...................................................................................................... 44

Hardware options installation..............................................................45

Introduction................................................................................................................................. 45

Drive bay options........................................................................................................................ 45

Installing the SAS and SATA drive options.......................................................................45

Installing the NVMe SSD options..................................................................................... 46

Installing the SFF Flash Adapter option........................................................................... 47

HPE Smart Array P204i SR Gen10 Controller option................................................................. 48

HPE Smart Storage Battery........................................................................................................ 50

Installing the HPE Smart Storage Battery........................................................................ 51

Mezzanine card option................................................................................................................53

Installing the mezzanine card option................................................................................53

FlexibleLOM option..................................................................................................................... 55

Installing the FlexibleLOM................................................................................................55

M.2 enablement option............................................................................................................... 56

Installing the M.2 riser board and M.2 interposer board...................................................57

Installing the M.2 SSDs....................................................................................................59

Memory options...........................................................................................................................60

DIMM and NVDIMM population information.....................................................................60

DIMM-processor compatibility..........................................................................................60

HPE SmartMemory speed information.............................................................................60

Installing a DIMM..............................................................................................................60

HPE 16GB NVDIMM option............................................................................................. 62

Installing the processor-heatsink assembly................................................................................ 66

HPE Trusted Platform Module 2.0 Gen10 option........................................................................68

Overview.......................................................................................................................... 68

TPM 2.0 location.............................................................................................................. 69

HPE Trusted Platform Module 2.0 Guidelines..................................................................69

Installing and enabling the HPE TPM 2.0 Gen10 Kit....................................................... 70

Cabling................................................................................................... 75

Cabling resources....................................................................................................................... 75

HPE Smart Storage Battery cabling............................................................................................75

Direct connect SATA cabling.......................................................................................................75

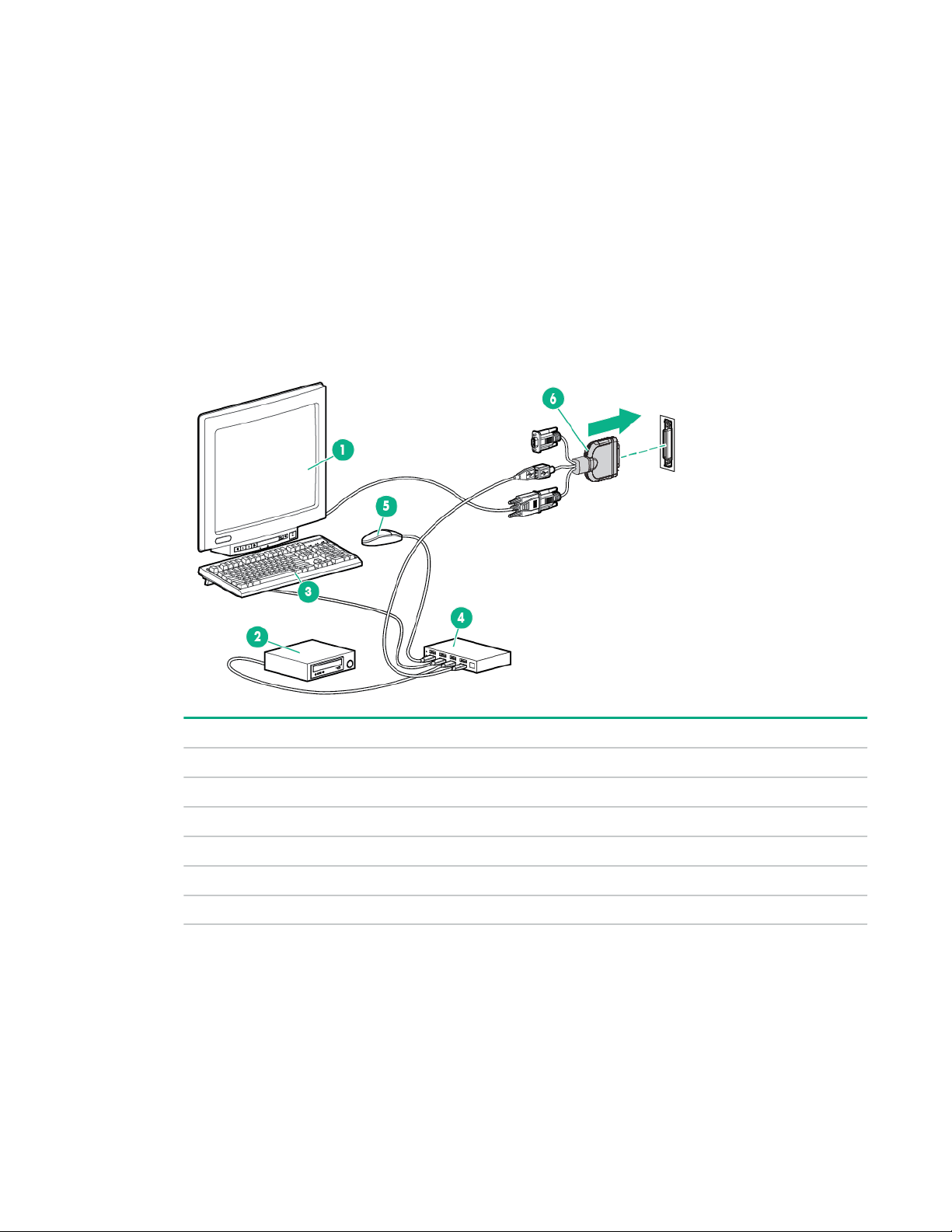

Using the HPE c-Class Blade SUV Cable.................................................................................. 76

Disconnecting and replacing the SUV cable...............................................................................76

Connecting locally to a server blade with video and USB devices............................................. 76

Accessing a server blade with local KVM........................................................................ 77

Accessing local media devices........................................................................................ 77

Troubleshooting.................................................................................... 79

Troubleshooting resources..........................................................................................................79

Software and configuration utilities.................................................... 80

Server mode................................................................................................................................80

Product QuickSpecs................................................................................................................... 80

Active Health System Viewer......................................................................................................80

Active Health System....................................................................................................... 81

4

HPE iLO 5................................................................................................................................... 81

iLO Federation..................................................................................................................82

iLO Service Port............................................................................................................... 82

iLO RESTful API...............................................................................................................83

RESTful Interface Tool..................................................................................................... 83

iLO Amplifier Pack............................................................................................................83

Integrated Management Log.......................................................................................................83

Intelligent Provisioning................................................................................................................ 84

Intelligent Provisioning operation..................................................................................... 84

Management Security................................................................................................................. 85

Scripting Toolkit for Windows and Linux..................................................................................... 85

UEFI System Utilities.................................................................................................................. 86

Selecting the boot mode ................................................................................................. 86

Secure Boot......................................................................................................................87

Launching the Embedded UEFI Shell ............................................................................. 87

HPE Smart Storage Administrator.............................................................................................. 88

HPE InfoSight for servers .......................................................................................................... 88

USB support................................................................................................................................89

External USB functionality................................................................................................89

Redundant ROM support............................................................................................................ 89

Safety and security benefits............................................................................................. 89

Keeping the system current........................................................................................................ 89

Updating firmware or system ROM.................................................................................. 89

Drivers..............................................................................................................................92

Software and firmware..................................................................................................... 92

Operating system version support................................................................................... 92

HPE Pointnext Portfolio....................................................................................................93

Proactive notifications...................................................................................................... 93

Removing and replacing the system battery......................................94

Electrostatic discharge.........................................................................96

Preventing electrostatic discharge.............................................................................................. 96

Grounding methods to prevent electrostatic discharge...............................................................96

Specifications........................................................................................97

Environmental specifications ..................................................................................................... 97

Server blade specifications......................................................................................................... 97

Websites................................................................................................ 98

Support and other resources...............................................................99

Accessing Hewlett Packard Enterprise Support......................................................................... 99

Accessing updates......................................................................................................................99

Customer self repair..................................................................................................................100

Remote support........................................................................................................................ 100

Warranty information.................................................................................................................100

Regulatory information..............................................................................................................101

Documentation feedback.......................................................................................................... 101

5

Component identification

1

2

3

4

5

7

6

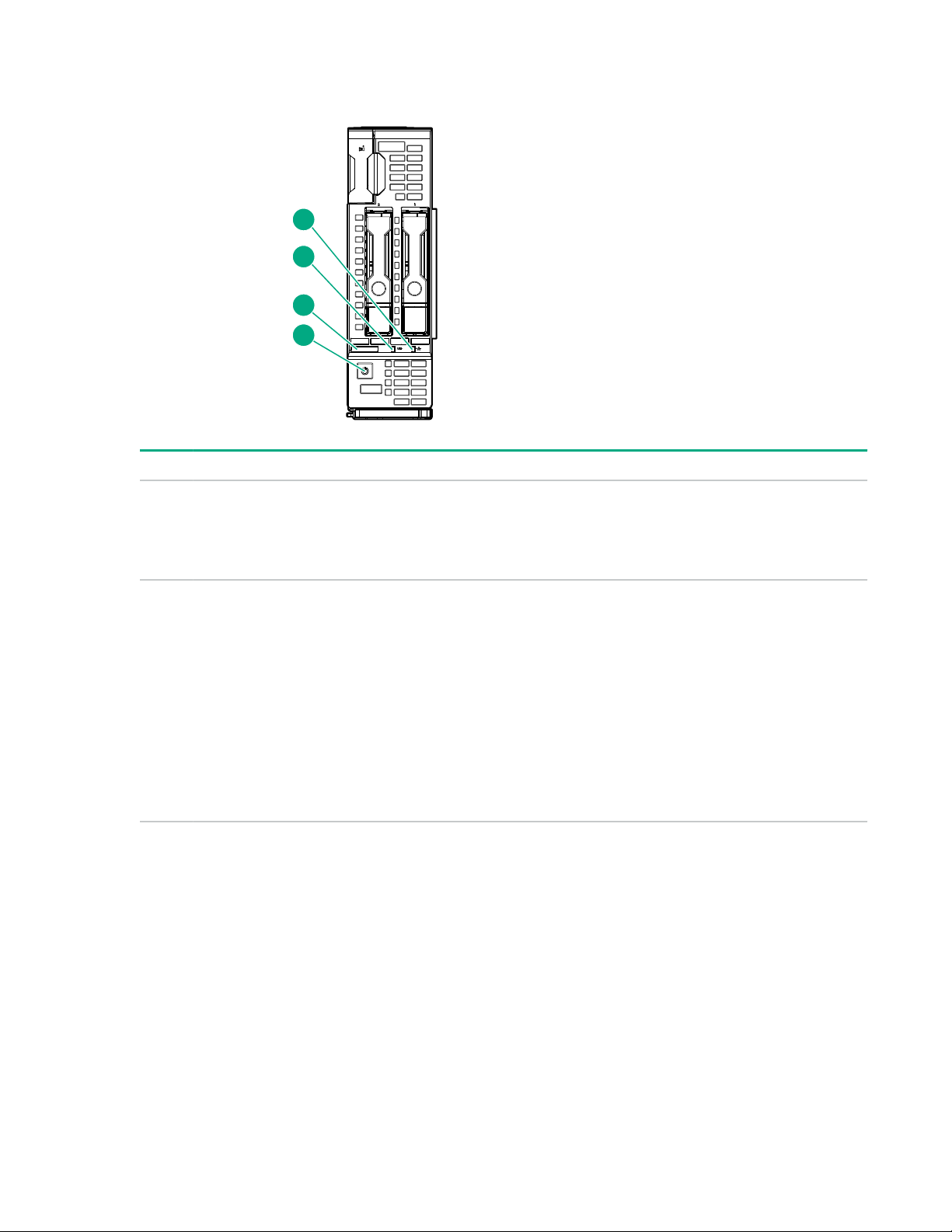

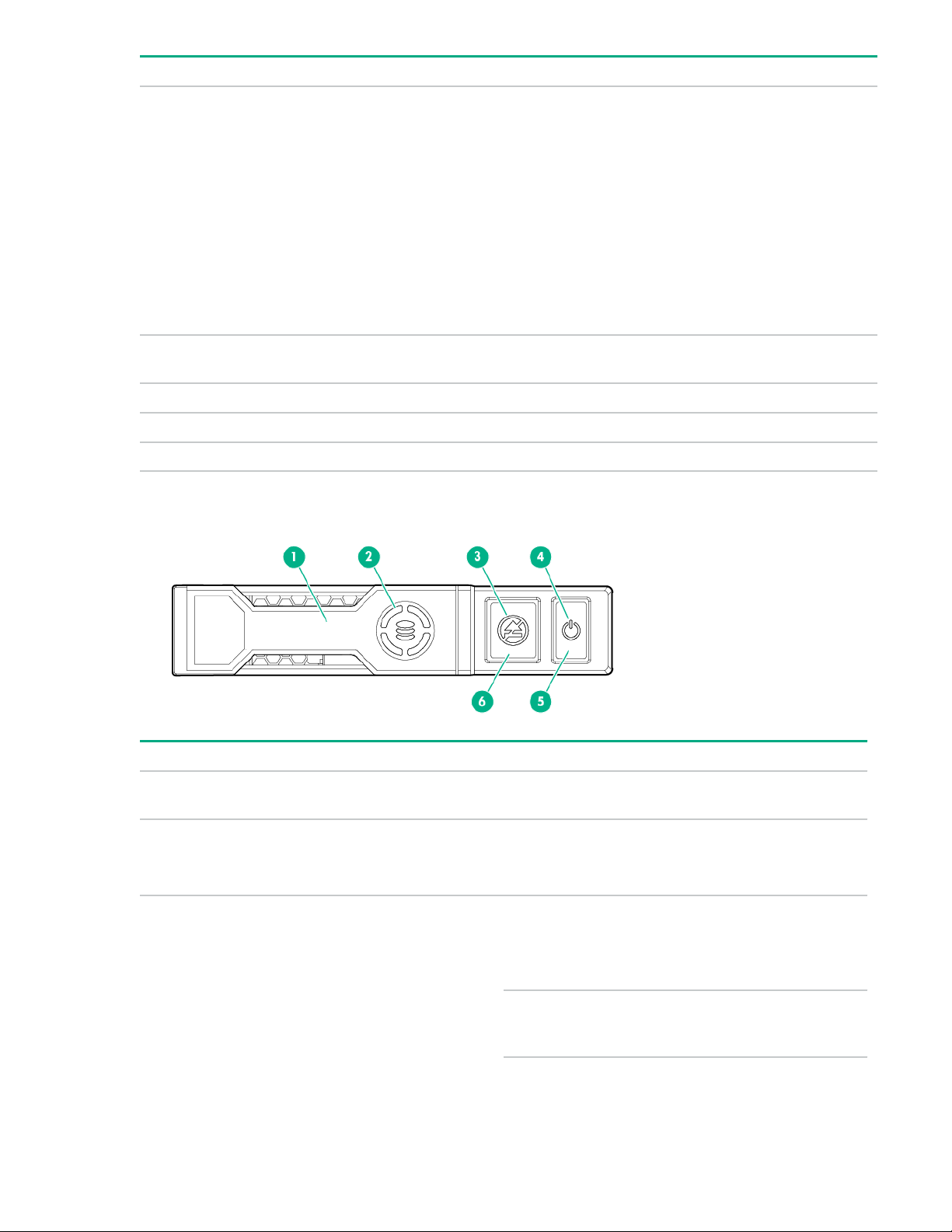

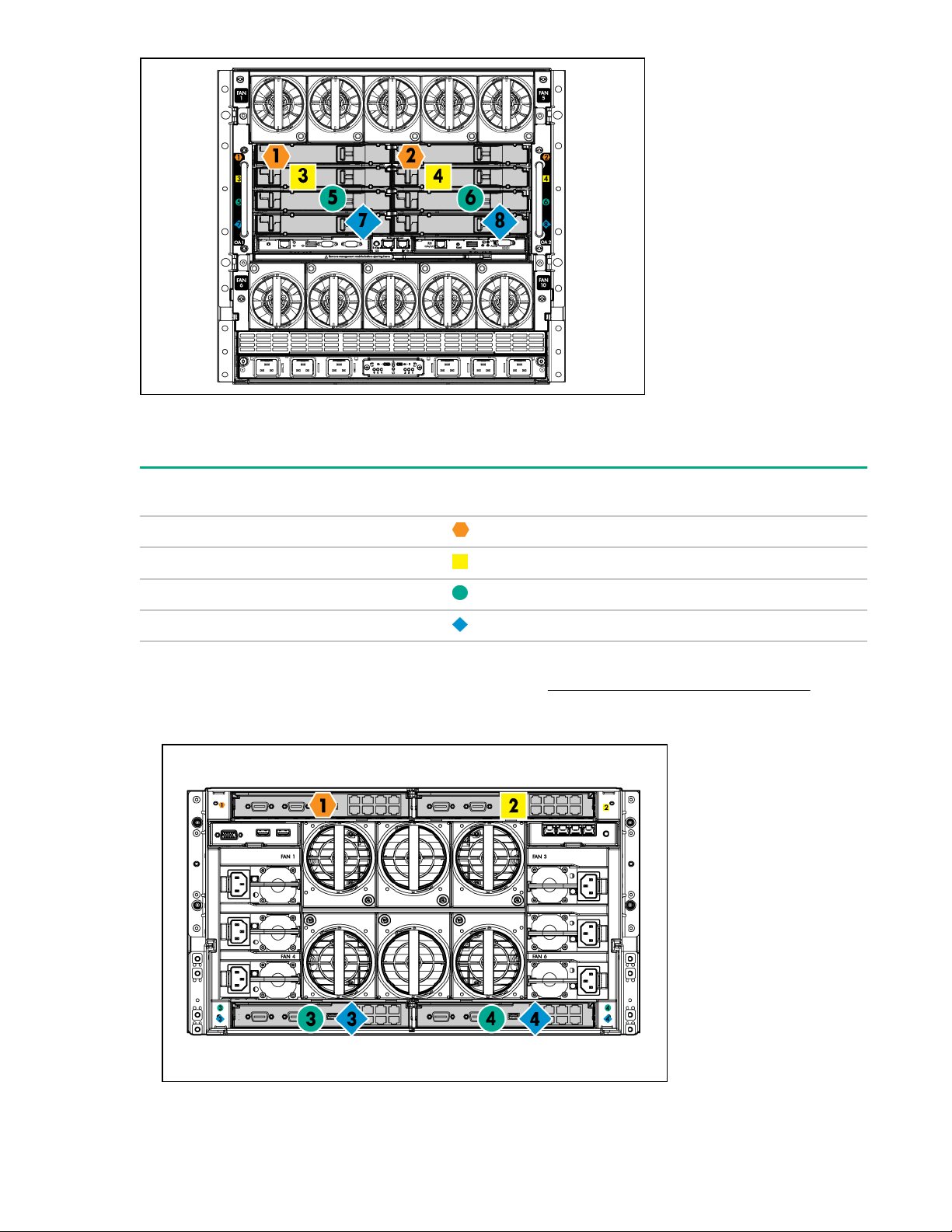

Front panel components

Item Description

1 Serial label pull tab

2 HPE c-Class Blade SUV connector1 (behind the serial label pull tab)

3 Drive bay 2

4 Drive bay 1

5 iLO Service port

6 Server blade release lever

7 Server blade release latch

1

The SUV connector and the c-Class Blade SUV Cable are used for some server blade configuration and diagnostic

procedures.

6 Component identification

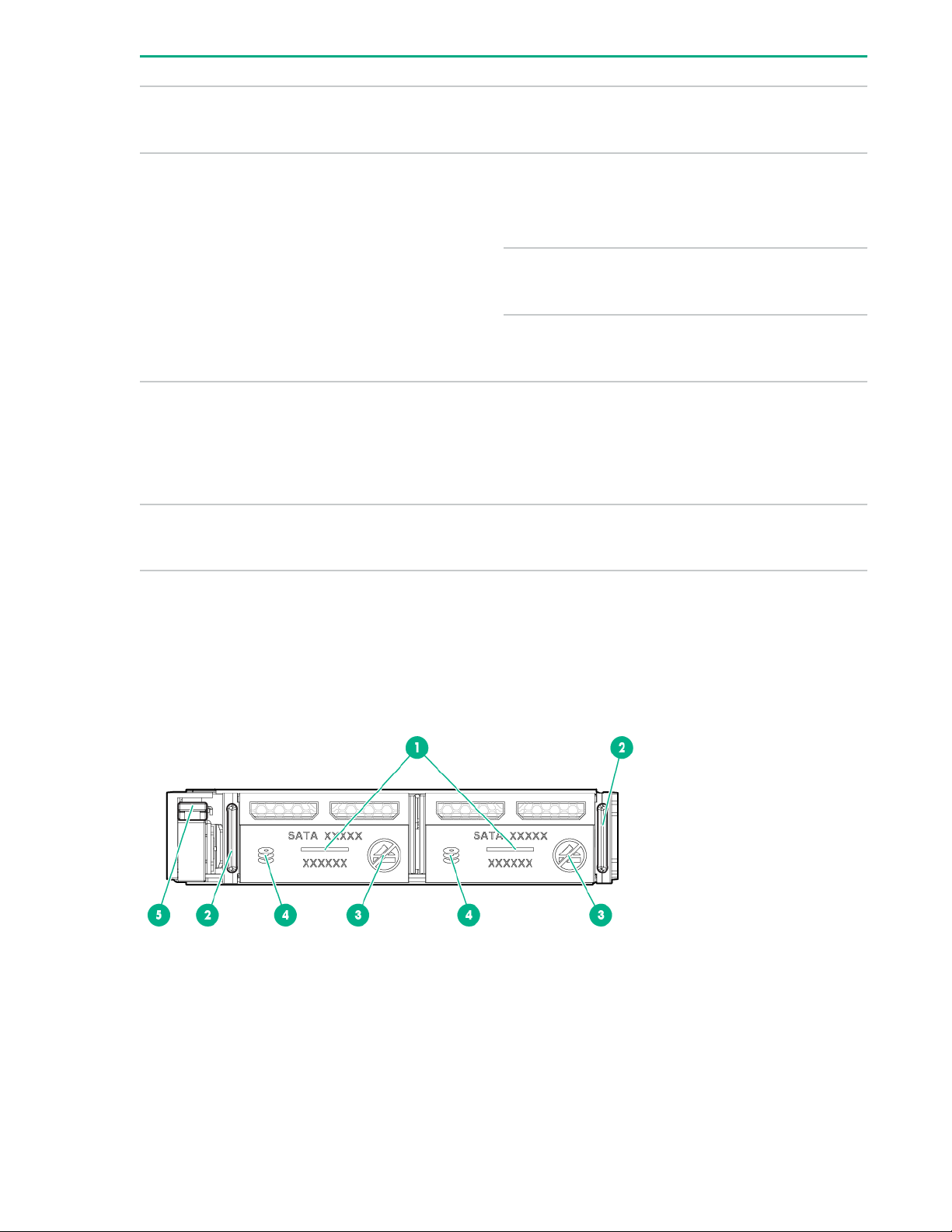

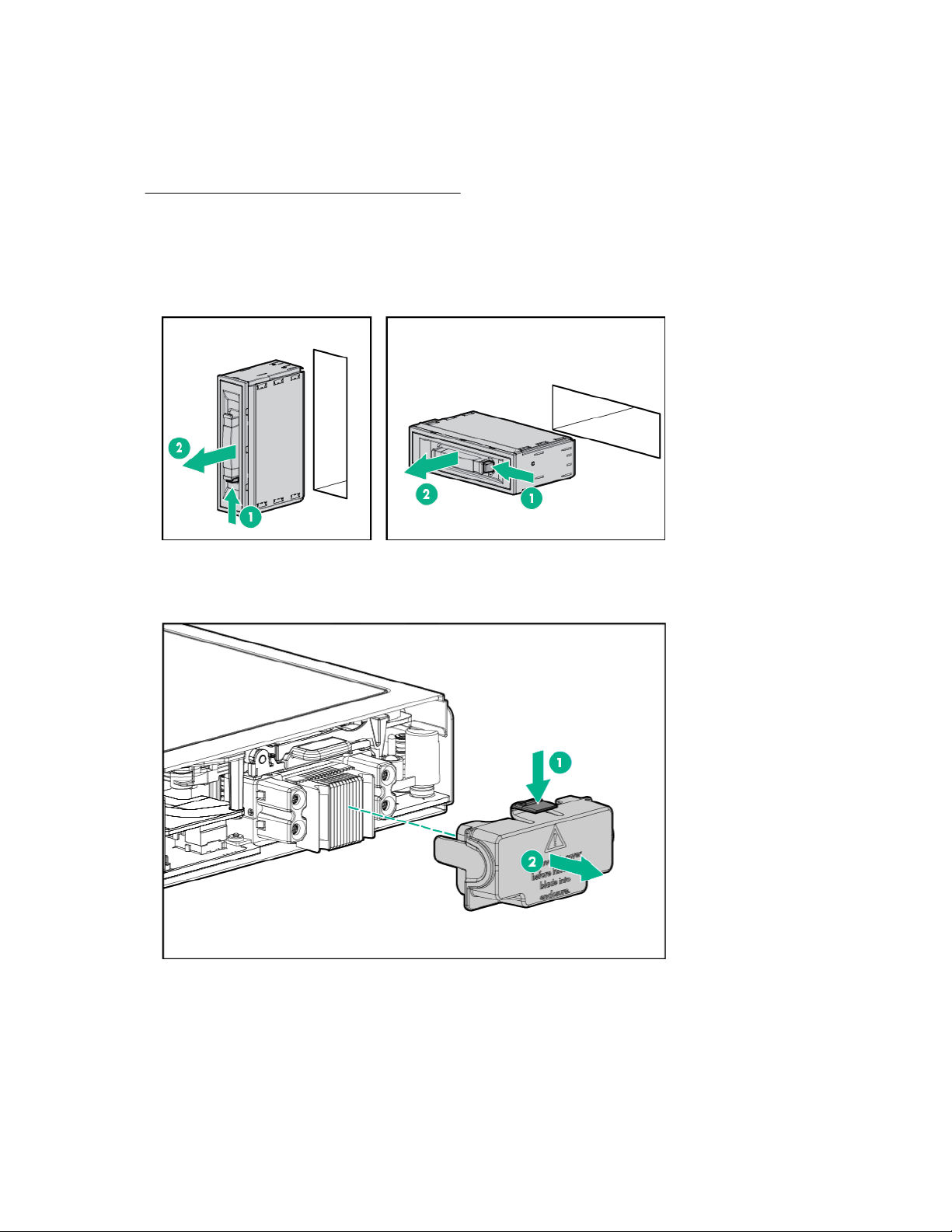

Front panel LEDs and buttons

1

2

3

4

Item Description Status

1 NIC status LED Solid green = Link to network

Flashing green (1 flash per second) = Network active

Off = No network activity

2 UID LED Solid blue = Activated

Flashing blue:

• 1 flash per second = Remote management or firmware

upgrade in progress

• 4 flashes per second = iLO manual reboot sequence initiated

• 8 flashes per second = iLO manual reboot sequence in

progress

Off = Deactivated

Table Continued

Component identification 7

Item Description Status

3 Health LED Solid green = Normal

Flashing green (1 flash per second) = iLO is rebooting

Flashing amber = System degraded

Flashing red (1 flash per second) = System critical

If the health LED indicates a degraded or critical state, review the

system IML or use iLO to review the system health status.

4 Power On/Standby button

and system power LED

Solid green = System on

Flashing green (1 flash per second) = Performing power on

sequence

Solid amber = System in standby

Off = No power present

Facility power is not present, power cord is not attached, no

power supplies are installed, power supply failure has occurred,

or the server blade is not plugged in.

Front panel LED power fault codes

The number of flashes in each sequence corresponds to the subsystem impacted by the power fault. The

following table provides a list of power fault codes, and the subsystems that are affected. Not all power

faults are used by all Server Blades.

Subsystem Front panel LED behavior

System board 1 flash

Processor 2 flashes

Memory 3 flashes

Mezzanine slots 4 flashes

FlexibleLOM 5 flashes

Removable HPE Flexible Smart Array controller/

NVMe Pass-Through

Power backplane or storage backplane 8 flashes

Serial label pull tab information

The serial label pull tab is on the front panel of the server blade. To locate the serial label pull tab, see

Front panel components on page 6. The serial label pull tab provides the following information:

• Product serial number

• iLO information

• QR code that points to mobile-friendly documentation

8 Component identification

6 flashes

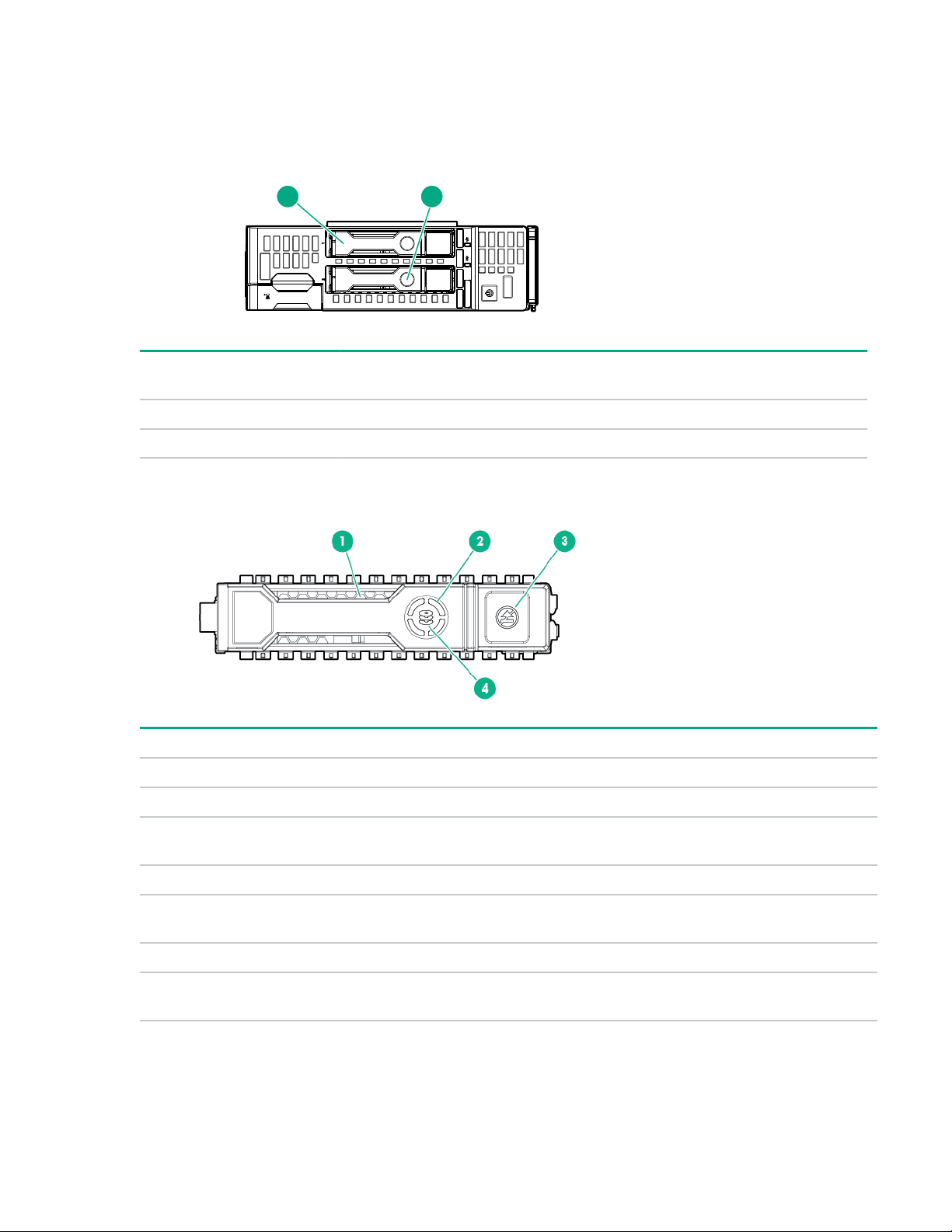

Drive numbering

1 2

Depending on the configuration, this server blade can support hard drives, SSDs, NVMe SSDs, and uFF

drives (supported in a SFF Flash Adapter) in the drive bays. Depending on the device installed, the bay

number might be different.

Item Hard drive/SSD bay

numbering

1 1 1 and 101 1

2 2 2 and 102 2

uFF drive bay

numbering

NVMe drive bay numbering

Hot-plug drive LED definitions

Item LED Status Definition

1 Locate Solid blue The drive is being identified by a host application.

Flashing blue The drive carrier firmware is being updated or requires an update.

2 Activity

ring

Off No drive activity

3 Do not

remove

Off Removing the drive does not cause a logical drive to fail.

4 Drive

status

Rotating green Drive activity

Solid white Do not remove the drive. Removing the drive causes one or more of

the logical drives to fail.

Solid green The drive is a member of one or more logical drives.

Component identification 9

Table Continued

Item LED Status Definition

Flashing green

The drive is doing one of the following:

• Rebuilding

• Performing a RAID migration

• Performing a strip size migration

• Performing a capacity expansion

• Performing a logical drive extension

• Erasing

• Spare part activation

Flashing amber/

green

Flashing amber The drive is not configured and predicts the drive will fail.

Solid amber The drive has failed.

Off The drive is not configured by a RAID controller or a spare drive.

The drive is a member of one or more logical drives and predicts the

drive will fail.

NVMe SSD components

Item Component Status Definition

1 Release lever — Ejects the NVMe drive

carrier from the cage.

2 Activity ring LED

3 Do Not Remove LED

10 Component identification

Rotating green

Off

Solid white Drive is powered on and

Flashing white Ejection request

Drive activity

No drive activity

configured in system.

Do not remove the drive.

pending. Do not remove

the drive.

Table Continued

Item Component Status Definition

Off Drive removed from the

PCIe bus and can be

ejected.

4 Power LED

5 Power button — Momentary press to

6 Do Not Remove button — Releases the release

Upon NVMe SSD insertion, an LED initiation sequence will be visible - lighting each LED in the carrier in

sequence from left to right. The sequence will cycle until the drive is recognized by the system. When the

SSD is recognized by the system - the Do Not Remove LED will be solid white and the Power LED will be

solid green.

Solid green Drive is powered on and

configured in system.

Do not remove the drive.

Flashing green Ejection request

pending. Do not remove

the drive.

Off Drive removed from the

PCIe bus and can be

ejected.

request drive removal

from PCIe bus and

ejection. Drive removal

request can be denied

by operating system.

lever for removal and

insertion.

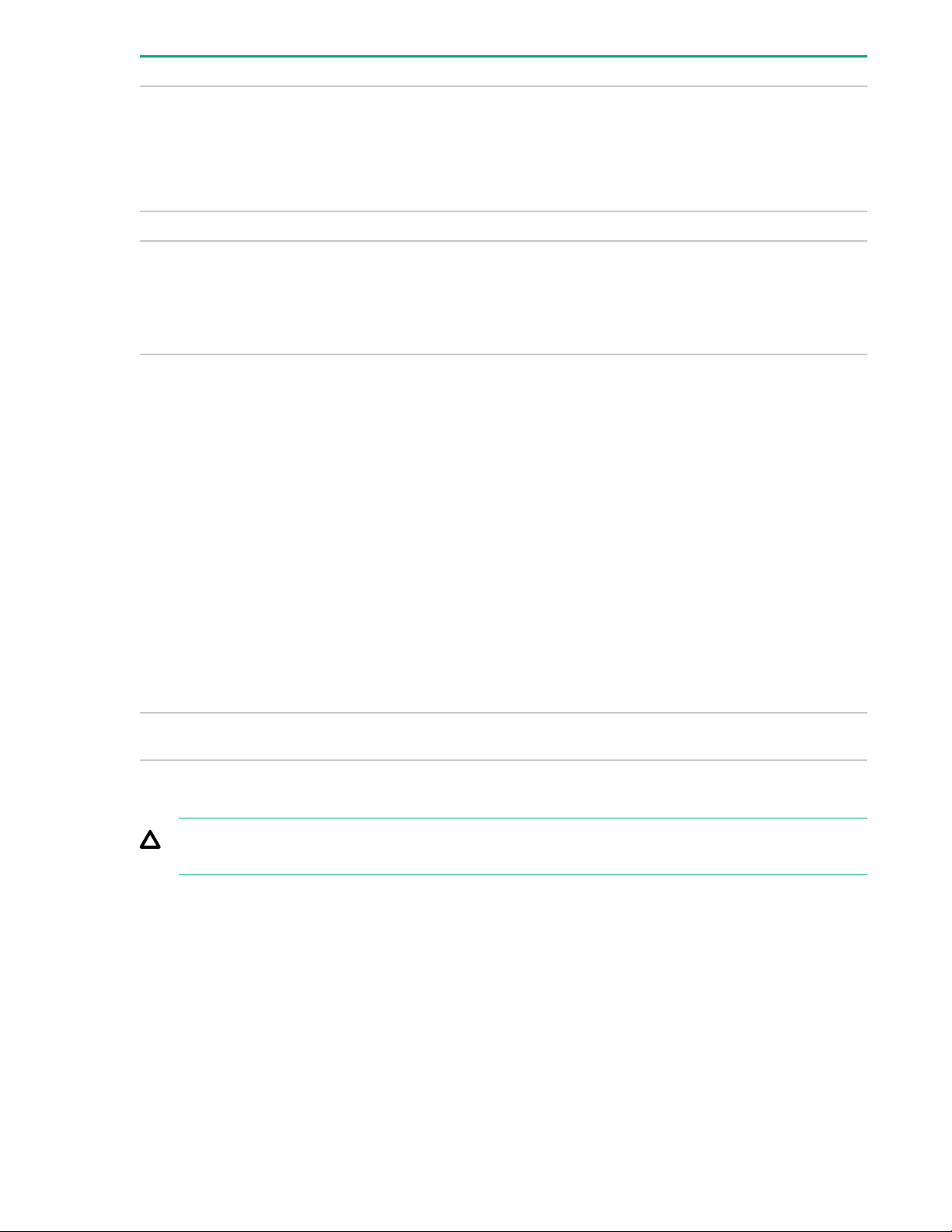

SFF flash adapter components and LED definitions

Component identification 11

Item Component Description

1 Locate • Off—Normal

• Solid blue—The drive is being identified by a host application.

• Flashing blue—The drive firmware is being updated or

requires an update.

2 uFF drive ejection latch Removes the uFF drive when released.

3 Do not remove LED • Off—OK to remove the drive. Removing the drive does not

cause a logical drive to fail.

• Solid white—Do not remove the drive. Removing the drive

causes one or more of the logical drives to fail.

4 Drive status LED • Off—The drive is not configured by a RAID controller or a

spare drive.

• Solid green—The drive is a member of one or more logical

drives.

• Flashing green (4 Hz)—The drive is operating normally and

has activity.

• Flashing green (1 Hz)—The drive is rebuilding, erasing, or

performing a RAID migration, stripe size migration, capacity

expansion, logical drive extension, or spare activation.

5 Adapter ejection release latch

and handle

SUV cable connectors

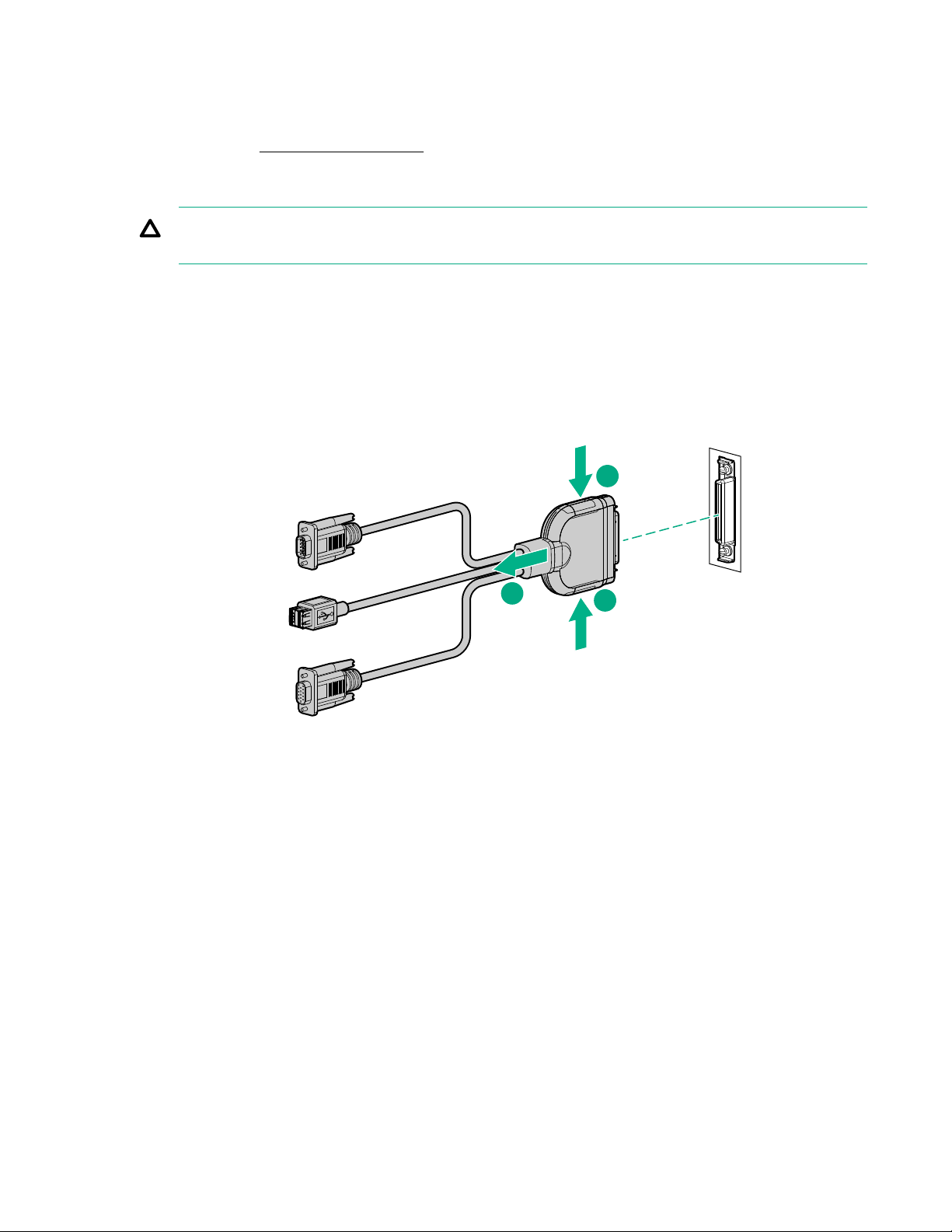

CAUTION: Before disconnecting the SUV cable from the connector, always squeeze the release

buttons on the sides of the connector. Failure to do so can result in damage to the equipment.

• Flashing amber/green (1 Hz)—The drive is a member of one

or more logical drives that predicts the drive will fail.

• Solid amber—The drive has failed.

• Flashing amber (1 Hz)—The drive is not configured and

predicts the drive will fail.

Removes the SFF flash adapter when released.

12 Component identification

Item Connector Description

1 2 3

P2 P1

54

8

911

10

1314

15

16

43

6

12

7

1 Serial For trained personnel to connect a null modem serial cable

2 USB

1

3 Video For connecting a video monitor

1

The USB connectors on the SUV cable do not support devices that require greater than a 500mA power source.

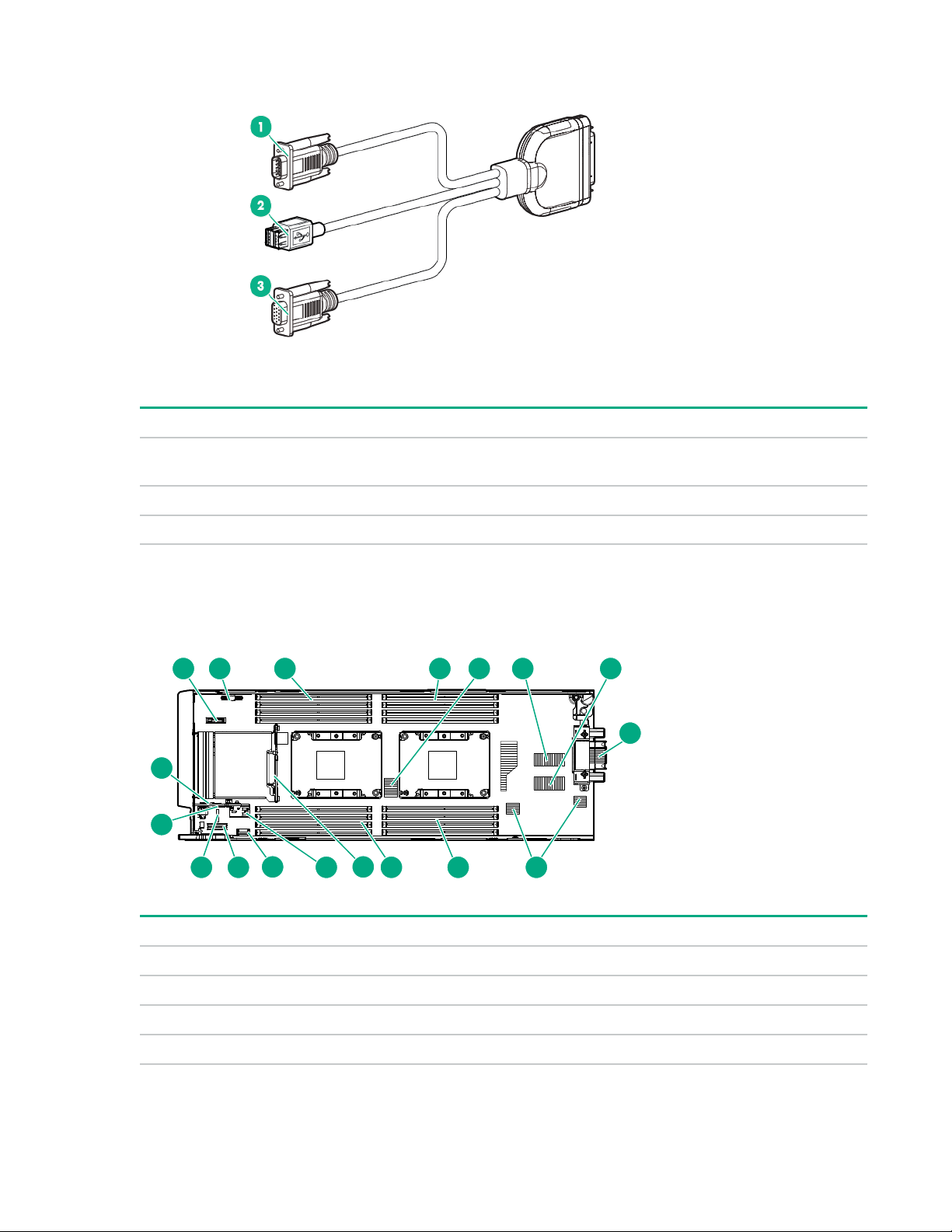

System board components

and perform advanced diagnostic procedures

For connecting up to two USB 2.0 devices

Item Description

1 System battery

2 M.2 enablement option connector

3 Processor 2 DIMM slots (8)

4 Processor 1 DIMM slots (8)

Table Continued

Component identification 13

Item Description

5 Storage controller or NVMe pass-through board connector

6 Mezzanine connector 1 (Type A mezzanine only)

7 Mezzanine connector 2 (Type A or Type B mezzanine)

8 Enclosure connector

9 FlexibleLOM connectors (2)

10 SAS/SATA or NVMe backplane

11 Internal USB 3.0 connector

12 Energy pack connector

13 Direct-connect SATA connector

14 System maintenance switch

15 microSD card slot

16 TPM connector

System maintenance switch

Position Default Function

S1 Off

S2 Off

S3 Off Reserved

S4 Off Reserved

S5 Off

S6 Off

S7 Off Reserved

S8 — Reserved

S9 Off Reserved

Off = iLO security is enabled.

On = iLO security is disabled.

Off = System configuration can be changed.

On = System configuration is locked.

Off = Power-on password is enabled.

On = Power-on password is disabled.

Off = No function.

On = ROM reads system configuration as invalid.

S10 — Reserved

S11 — Reserved

S12 — Reserved

14 Component identification

CAUTION: Clearing CMOS, NVRAM, or both deletes configuration information. Be sure to configure

Ch 6

P2 P1

Ch 5 Ch 4

Ch 3 Ch 2 Ch 1

Ch 1 Ch 2 Ch 3

Ch 4 Ch 5 Ch 6

1

2

3

4

5

6

7

8

8

7

6

5

3

2

1

4

8GB 1Rx4 DDR4-2666P -R

8GB 1 Rx4 DDR 4-2666P -R

1 2 3 4 5 6 7

the server blade properly to prevent data loss.

DIMM slot locations

DIMM slots are numbered sequentially (1 through 8) for each processor and designate the DIMM slot ID

for population rules and spare replacement.

For specific DIMM population information, see the DIMM population guidelines on the Hewlett Packard

Enterprise website (

http://www.hpe.com/docs/memory-population-rules).

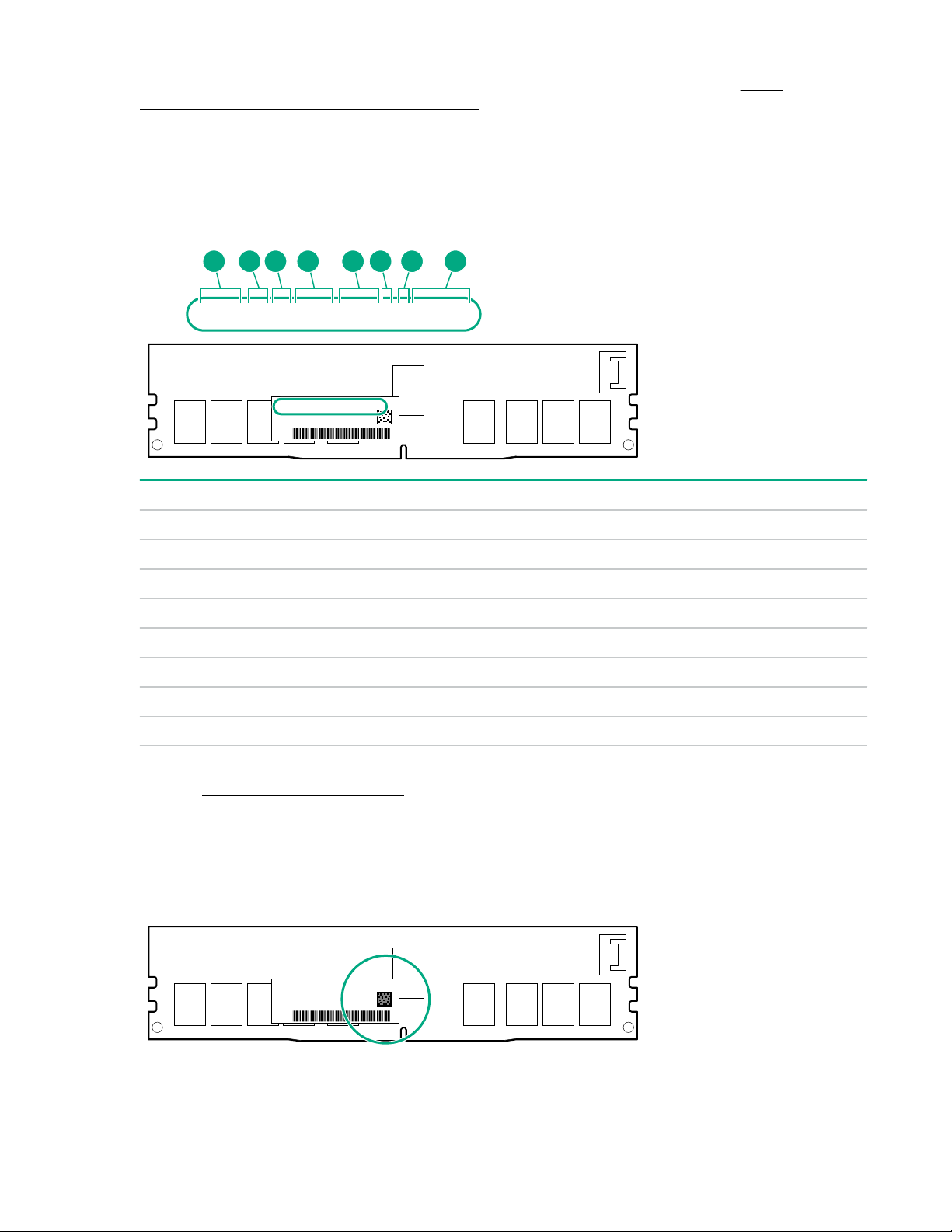

DIMM label identification

To determine DIMM characteristics, see the label attached to the DIMM. The information in this section

helps you to use the label to locate specific information about the DIMM.

Component identification 15

Item Description Example

1 Capacity

2 Rank

3 Data width on DRAM

4 Memory generation

8 GB

16 GB

32 GB

64 GB

128 GB

1R = Single rank

2R = Dual rank

4R = Quad rank

8R = Octal rank

x4 = 4-bit

x8 = 8-bit

x16 = 16-bit

PC4 = DDR4

5 Maximum memory speed

6 CAS latency

7 DIMM type

2133 MT/s

2400 MT/s

2666 MT/s

2933 MT/s

P = CAS 15-15-15

T = CAS 17-17-17

U = CAS 20-18-18

V = CAS 19-19-19 (for RDIMM, LRDIMM)

V = CAS 22-19-19 (for 3DS TSV LRDIMM)

Y = CAS 21-21-21 (for RDIMM, LRDIMM)

Y = CAS 24-21-21 (for 3DS TSV LRDIMM)

R = RDIMM (registered)

L = LRDIMM (load reduced)

16 Component identification

E = Unbuffered ECC (UDIMM)

For more information about product features, specifications, options, configurations, and compatibility, see

16GB 1Rx4 NN4-2666V-RZZZ-10

16GB 1Rx4 N N4-2666 V-RZZZ-1 0

1 2 3 74 5 6 8

the HPE DDR4 SmartMemory QuickSpecs on the Hewlett Packard Enterprise website (http://

www.hpe.com/support/DDR4SmartMemoryQS).

NVDIMM identification

NVDIMM boards are blue instead of green. This change to the color makes it easier to distinguish

NVDIMMs from DIMMs.

To determine NVDIMM characteristics, see the full product description as shown in the following example:

Item Description Definition

1 Capacity 16 GiB

2 Rank 1R (Single rank)

3 Data width per DRAM chip x4 (4 bit)

4 Memory type NN4=DDR4 NVDIMM-N

5 Maximum memory speed 2667 MT/s

6 Speed grade V (latency 19-19-19)

7 DIMM type RDIMM (registered)

8 Other —

For more information about NVDIMMs, see the product QuickSpecs on the Hewlett Packard Enterprise

website (http://www.hpe.com/info/qs).

NVDIMM 2D Data Matrix barcode

The 2D Data Matrix barcode is on the right side of the NVDIMM label and can be scanned by a cell phone

or other device.

When scanned, the following information from the label can be copied to your cell phone or device:

Component identification 17

• (P) is the module part number.

1 2

• (L) is the technical details shown on the label.

• (S) is the module serial number.

Example: (P)HMN82GR7AFR4N-VK (L)16GB 1Rx4 NN4-2666V-RZZZ-10(S)80AD-01-1742-11AED5C2

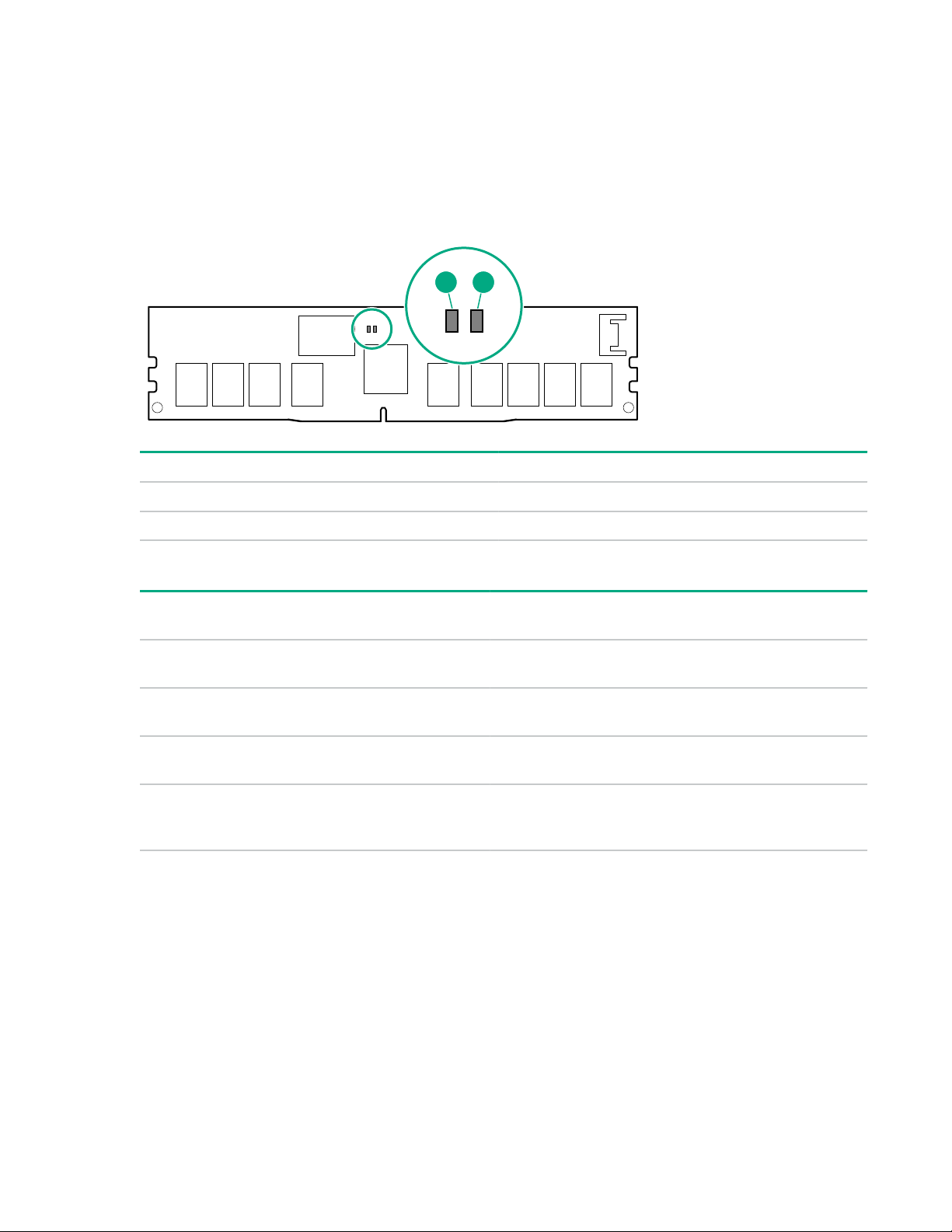

NVDIMM LED identification

Item LED description LED color

1 Power LED Green

2 Function LED Blue

NVDIMM-N LED combinations

State Definition NVDIMM-N Power LED

0 AC power is on (12V rail) but the NVM

controller is not working or not ready.

1 AC power is on (12V rail) and the NVM

controller is ready.

2 AC power is off or the battery is off (12V

rail off).

3 AC power is on (12V rail) or the battery is

on (12V rail) and the NVDIMM-N is active

(backup and restore).

NVDIMM Function LED patterns

For the purpose of this table, the NVDIMM-N LED operates as follows:

• Solid indicates that the LED remains in the on state.

• Flashing indicates that the LED is on for 2 seconds and off for 1 second.

• Fast-flashing indicates that the LED is on for 300 ms and off for 300 ms.

NVDIMM-N Function

(green)

On Off

On On

Off Off

On Flashing

LED (blue)

18 Component identification

State Definition NVDIMM-N Function LED

2

3

4

1

0 The restore operation is in progress. Flashing

1 The restore operation is successful. Solid or On

2 Erase is in progress. Flashing

3 The erase operation is successful. Solid or On

4 The NVDIMM-N is armed, and the NVDIMM-N is in

normal operation.

5 The save operation is in progress. Flashing

6 The NVDIMM-N finished saving and battery is still

turned on (12 V still powered).

7 The NVDIMM-N has an internal error or a firmware

update is in progress. For more information about an

NVDIMM-N internal error, see the IML.

Mezzanine connector definitions

Item PCIe

Mezzanine connector 1 x16, Type A mezzanine card only

Mezzanine connector 2 x16, Type A or B mezzanine card

NOTE: When installing a mezzanine card option on mezzanine connector 2, processor 2 must be

installed.

Mezzanine connector guide pin locations

Solid or On

Solid or On

Fast-flashing

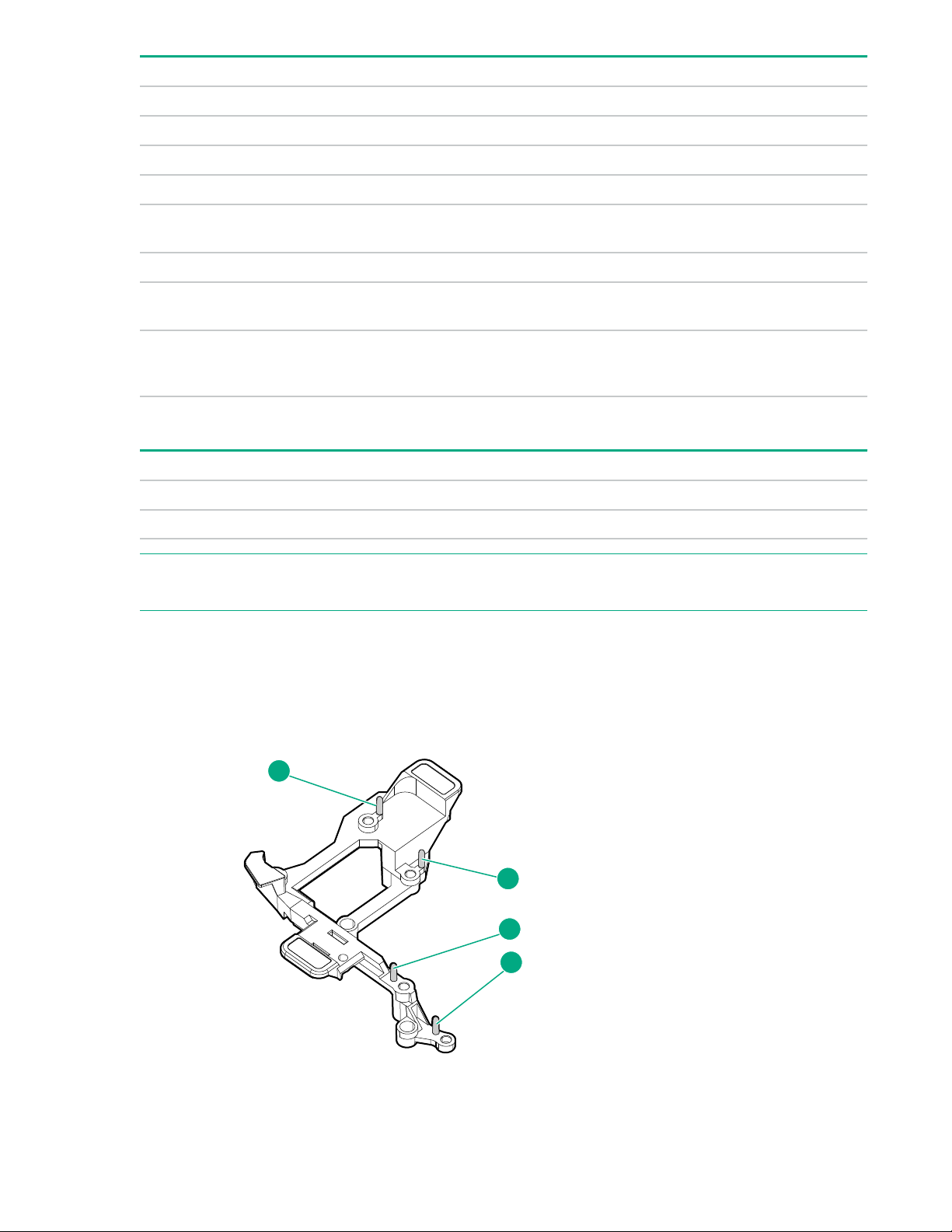

The mezzanine assembly supports two mezzanine cards in this server blade. When installing a

mezzanine card into the assembly, be sure to use the guide pins associated with the mezzanine

connector.

Component identification 19

Item Description

1 and 3 Mezzanine connector 2

2 and 4 Mezzanine connector 1

20 Component identification

Operations

Power up the server blade

The OA initiates an automatic power-up sequence when the server blade is installed. If the default setting

is changed, use one of the following methods to power up the server blade:

• Use a virtual power button selection through iLO.

• Press and release the Power On/Standby button.

When the server blade goes from the standby mode to the full power mode, the system power LED

changes from amber to solid green. The health LED flashes green when the Power On/Standby Button

service is being initialized. For more information about the system power LED status, see

LEDs and buttons on page 7.

For more information about the OA, see the OA setup and installation guide on the Hewlett Packard

Enterprise website.

Power down the server blade

Procedure

• Press and release the Power On/Standby button.

Front panel

This method initiates a controlled shutdown of applications and the OS before the server blade enters

standby mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server blade to

enter standby mode.

This method forces the server blade to enter standby mode without properly exiting applications and

the OS. If an application stops responding, you can use this method to force a shutdown.

• Use a virtual power button selection through iLO.

This method initiates a controlled remote shutdown of applications and the OS before the server blade

enters standby mode.

• Use the OA CLI to execute one of the following commands:

◦ poweroff server [bay number]

This command initiates a controlled shutdown of applications and the OS before the server blade

enters standby mode.

◦ poweroff server [bay number] force

This form of the command forces the server blade to enter standby mode without properly exiting

applications and the OS. If an application stops responding, this method forces a shutdown.

• Use the OA GUI to initiate a shutdown:

1. Select the Enclosure Information tab.

2. In the Device Bays item, select the server.

3. From the Virtual Power menu, initiate a shutdown of applications and the OS:

Operations 21

◦ For a controlled shutdown, select Momentary Press.

◦ For an emergency shutdown, select Press and Hold.

Before proceeding, verify that the server blade is in standby mode by observing that the system power

LED is amber.

Remove the server blade

Procedure

1. Identify the proper server blade.

2. Power down the server blade on page 21.

3. Remove the server blade.

4. Place the server blade on a flat, level work surface.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server blade

before beginning any installation procedure. Improper grounding can cause electrostatic

discharge.

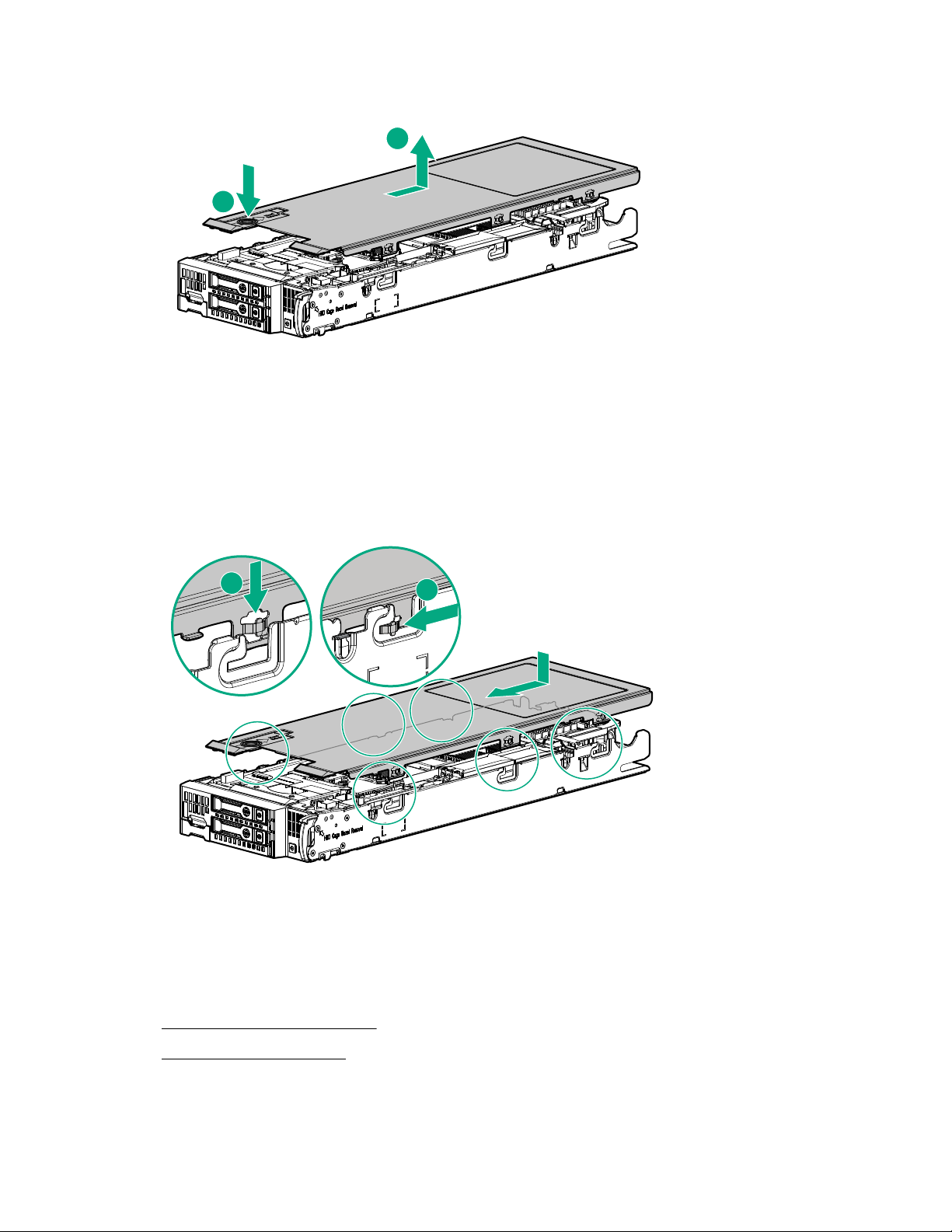

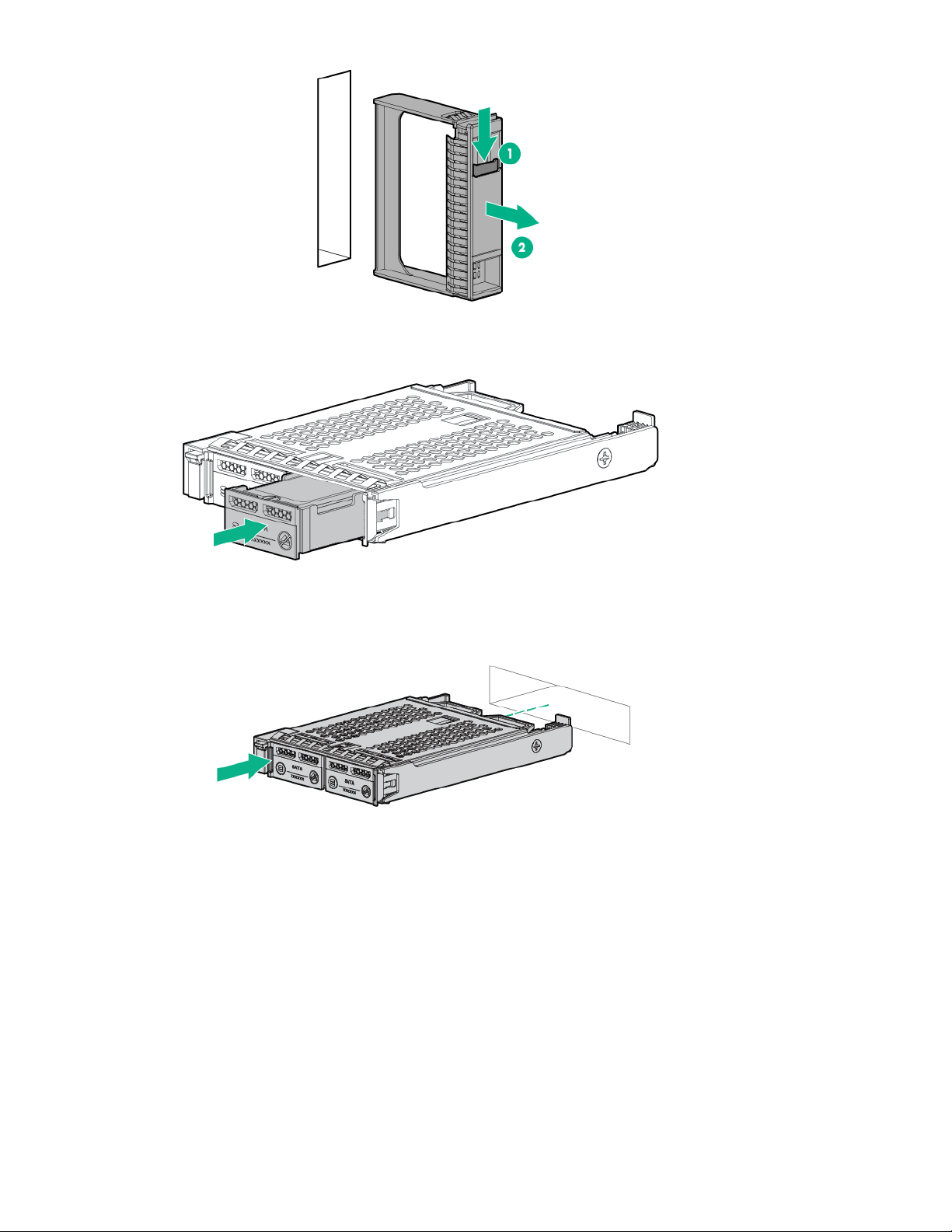

Remove the access panel

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

22 Operations

4. Press the access panel release button.

1

2

1

2

5. Slide the access panel towards the rear of the server blade, and then lift to remove the panel.

Install the access panel

Procedure

1. Align the access panel with the guides on the server blade in all six places and place the access panel

on top of the server blade.

2. Slide the access panel forward until it clicks into place.

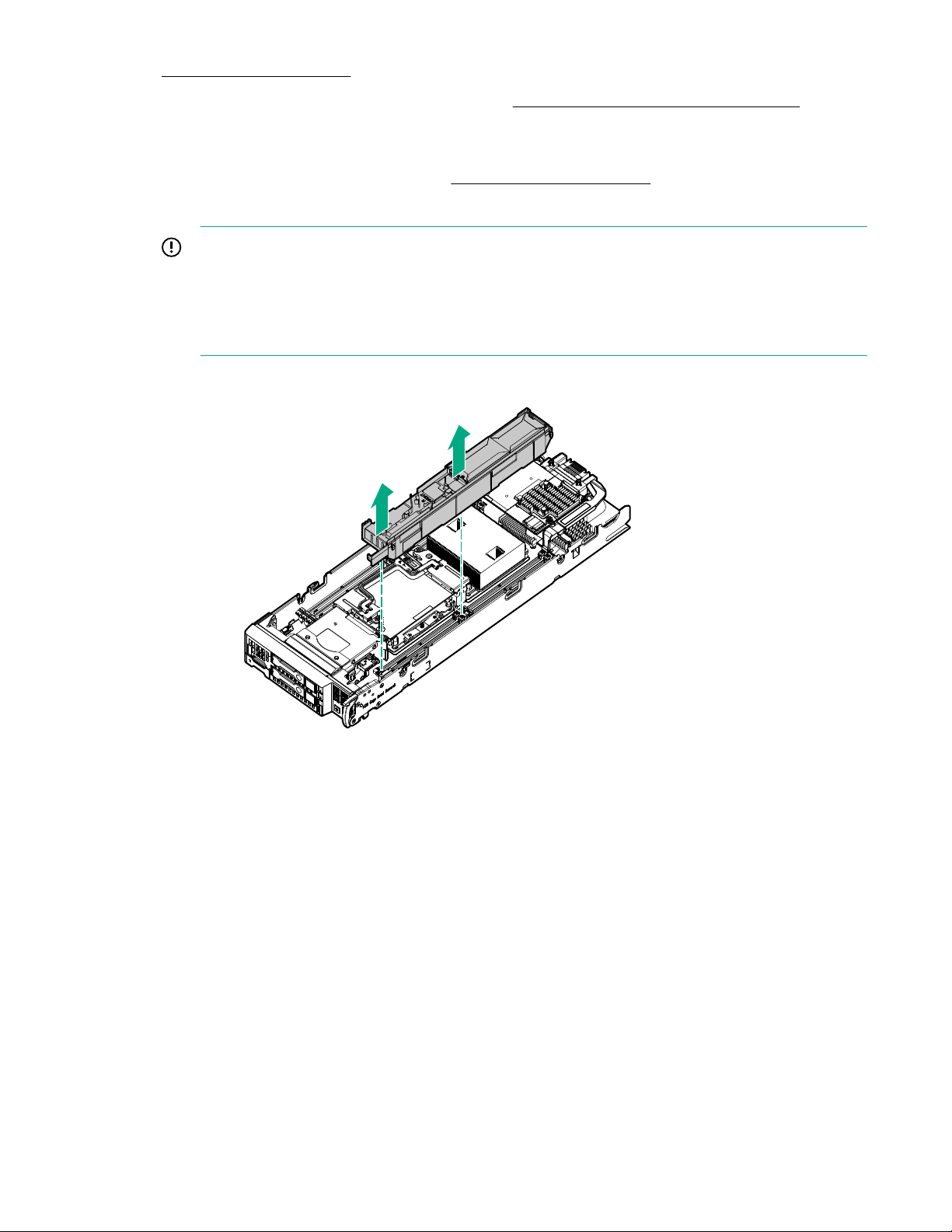

Remove the DIMM baffles

The server contains two DIMM baffles.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

Operations 23

4. Remove the access panel on page 22.

5. If installed, remove the direct connect SATA cable (Remove the direct connect SATA cable on page

31).

6. If installed, remove the internal USB drive.

To locate the internal USB connector, see System board components on page 13.

7. Remove one or more DIMM baffles:

IMPORTANT: When removing a DIMM baffle, do not remove the following options when installed

on the DIMM baffle:

• M.2 enablement option (left DIMM baffle)

• HPE Smart Storage Battery (right DIMM baffle)

• DIMM baffle (right side)

• DIMM baffle (left side)

24 Operations

Install the DIMM baffles

The server has two DIMM baffles.

Procedure

1. Align and install the DIMM baffle:

IMPORTANT: When installing each DIMM baffle, be sure that the alignment tabs engage with

the side of the server blade.

• DIMM baffle (right side)

• DIMM baffle (left side)

Operations 25

2. If removed, install the internal USB drive.

To locate the internal USB connector, see System board components on page 13.

3. If removed, install the direct connect SATA cable (Install the direct connect SATA cable on page

31.

4. Install the access panel on page 23.

5. Install the server blade on page 42.

6. Power up the server blade on page 21.

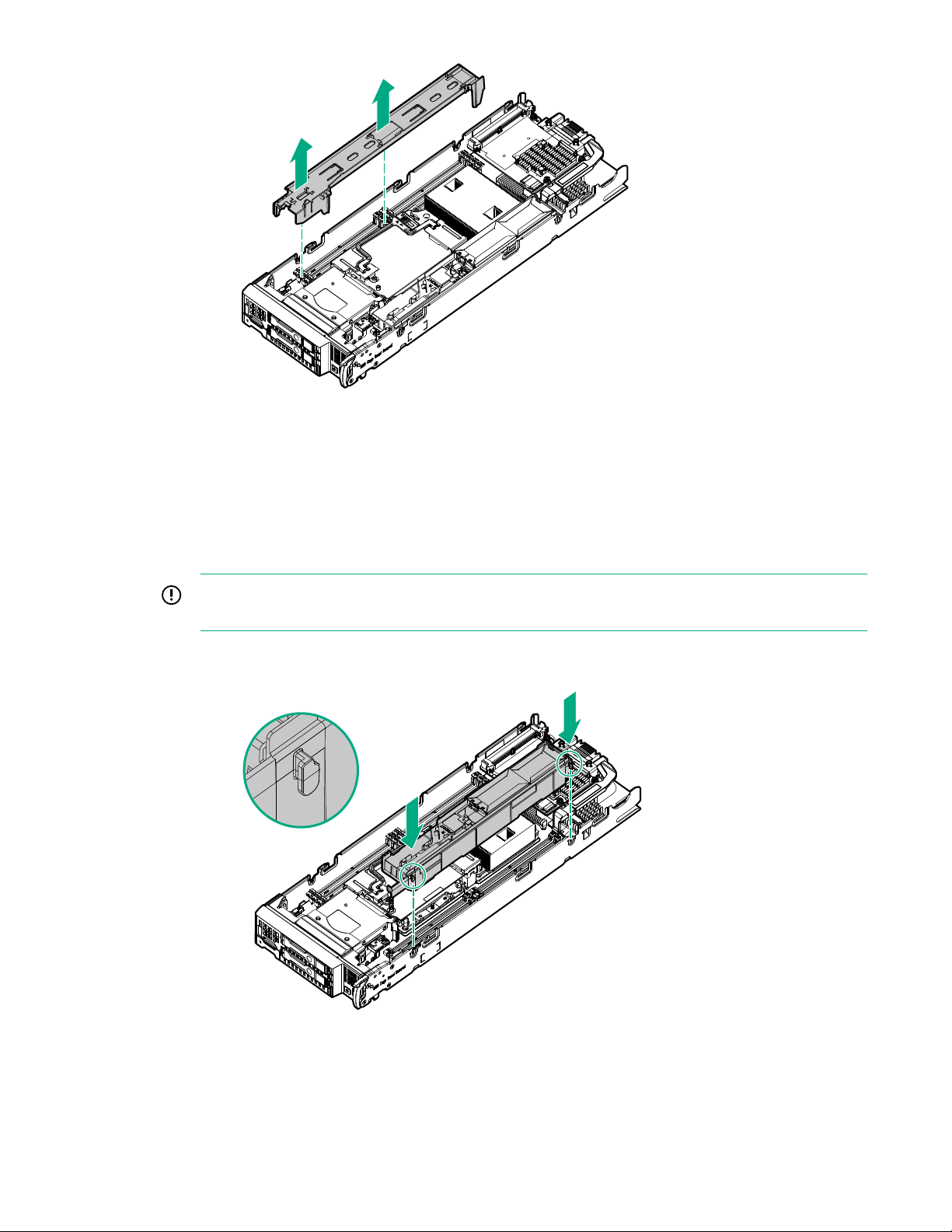

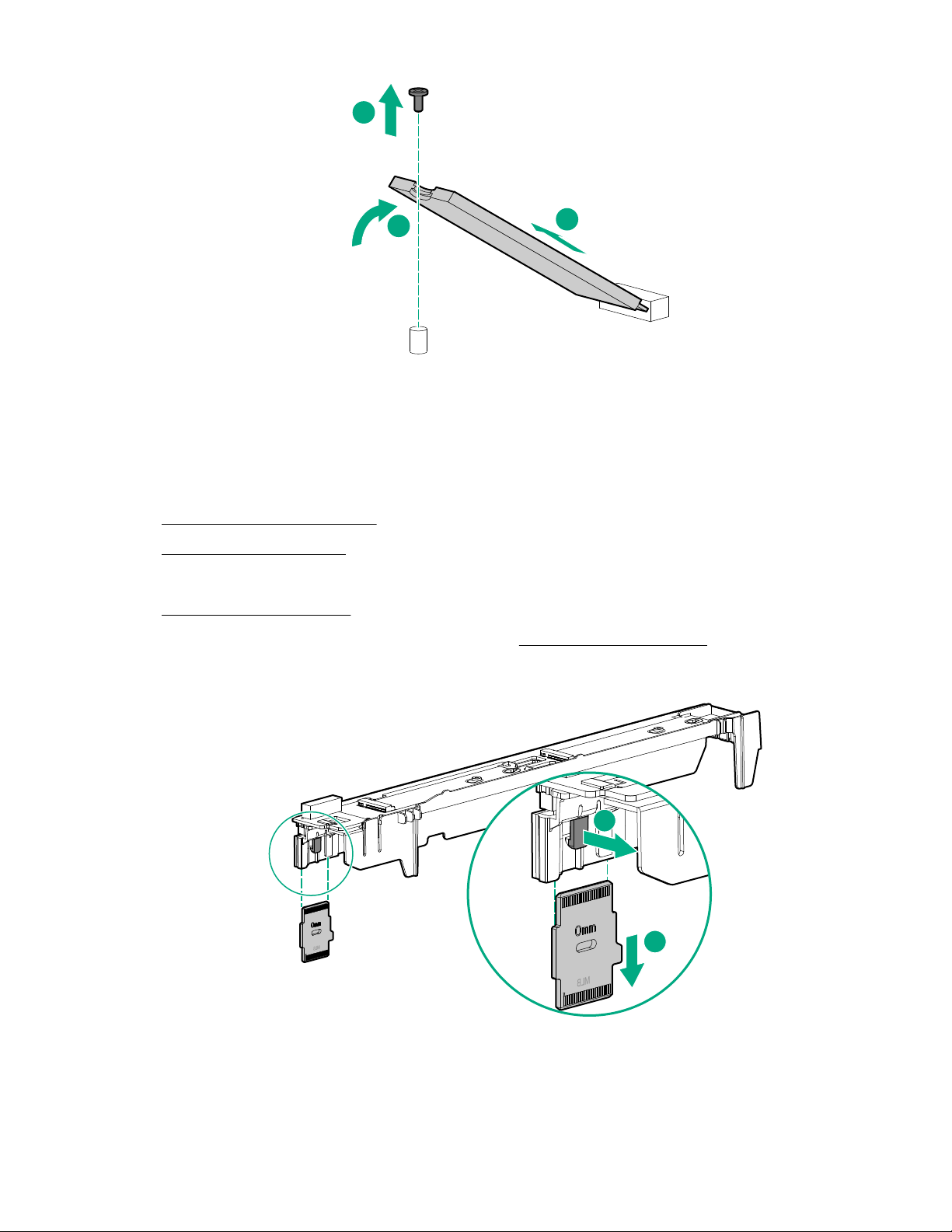

Remove an M.2 SSD from the M.2 riser board

Prerequisites

To remove an M.2 SSD from the M.2 riser, you need a No. 1 Phillips screwdriver.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the left DIMM baffle from the server blade (Remove the DIMM baffles on page 23).

6. Remove the M.2 SSD from the M.2 riser board. Use a No. 1 Phillips screwdriver to disengage the

screw.

26 Operations

1

2

3

7. If necessary, repeat the M.2 SSD removal procedure for a second drive.

2

1

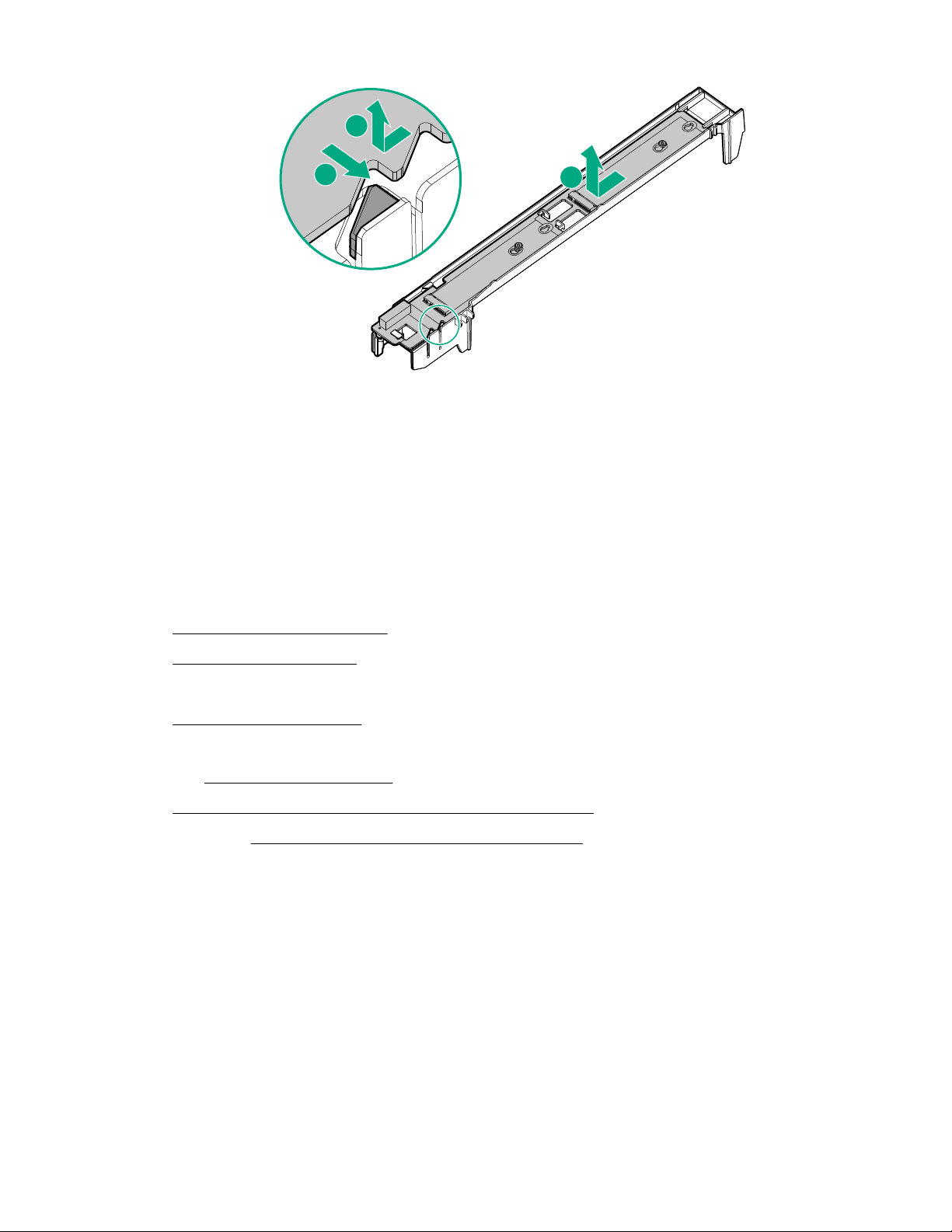

Remove the M.2 interposer board and the M.2 riser board

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the left DIMM baffle from the server blade (Remove the DIMM baffles on page 23).

6. Remove the M.2 interposer board.

7. Remove the M.2 riser board from the left DIMM baffle.

Operations 27

1

2

2

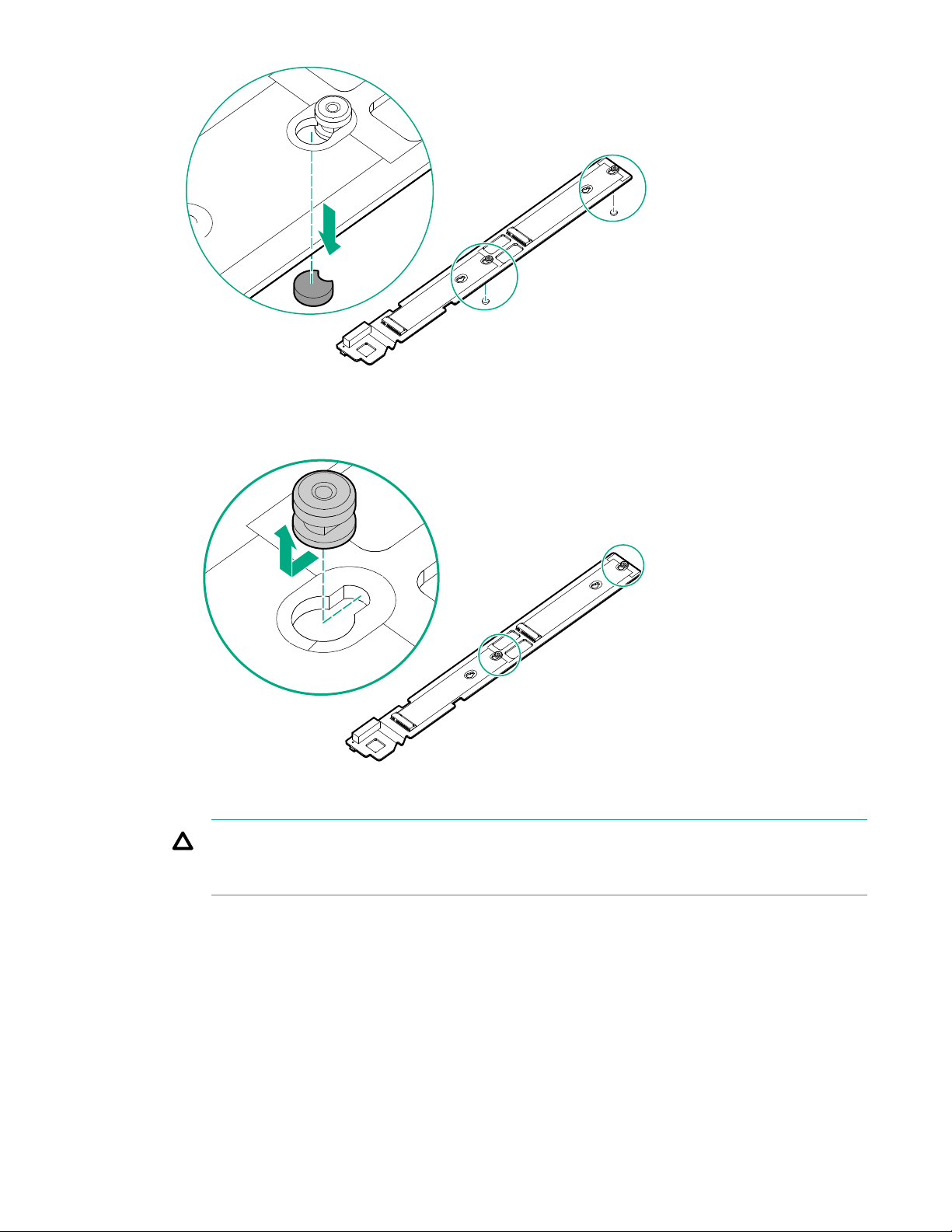

Relocate the PEM nut and rubber stopper

This procedure is required if the PEM nut and rubber stoppers must be relocated to support the length of

the M.2 SSDs being installed.

Prerequisites

To remove the M.2 SSDs from the M.2 riser, you need a No. 1 Phillips screwdriver.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the left DIMM baffle.

See Remove the DIMM baffles on page 23.

6. Remove the M.2 interposer board and the M.2 riser board on page 27.

7. If installed, Remove an M.2 SSD from the M.2 riser board on page 26.

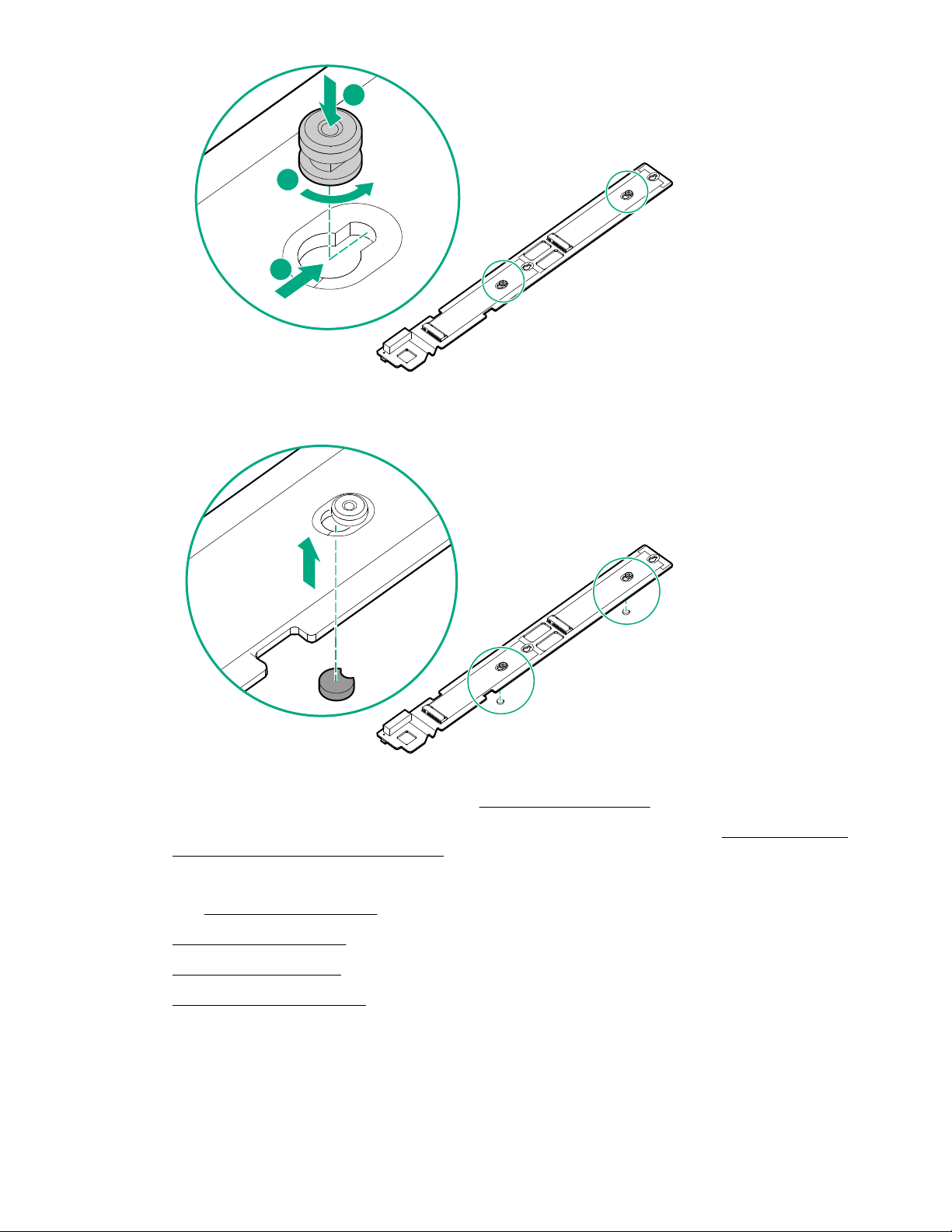

8. Remove the rubber stoppers from the M.2 riser.

28 Operations

9. Remove the PEM nuts from the M.2 riser.

10. Install the PEM nuts in the new location on the M.2 riser.

CAUTION: Always install the PEM nut with the thicker edge on top of the M.2 riser and the

thinner edge on the bottom of the M.2 riser. Failure to install the PEM nut in the proper

orientation can cause damage to the components.

Operations 29

1

2

3

11. Install the rubber stoppers in the new locations to secure the PEM nuts in the M.2 riser.

12. Install the M.2 SSDs on the M.2 riser board (Installing the M.2 SSDs on page 59).

13. Install the M.2 riser board and the M.2 interposer board on the left DIMM baffle (Installing the M.2

riser board and M.2 interposer board on page 57).

14. Install the left DIMM baffle.

See Install the DIMM baffles on page 25.

15. Install the access panel on page 23.

16. Install the server blade on page 42.

17. Power up the server blade on page 21.

30 Operations

Remove the direct connect SATA cable

1

2

3

4

5

Prerequisites

To remove the direct connect SATA cable, you need a T-15 Torx screwdriver.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the direct connect SATA cable.

Install the direct connect SATA cable

Prerequisites

To install the direct connect SATA cable, you need a T-15 Torx screwdriver.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Install the direct connect SATA cable.

Operations 31

3

2

1

4

Remove the mezzanine assembly

1

2

3

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the mezzanine assembly.

32 Operations

Install the mezzanine assembly

2

1

1

Procedure

1. Install the mezzanine assembly

2. Install the access panel on page 23.

3. Install the server blade on page 42.

4. Power up the server blade on page 21.

Remove the FlexibleLOM

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the mezzanine assembly on page 32.

6. Use the FlexibleLOM handle to remove the FlexibleLOM from the system board.

Operations 33

Remove the storage controller or NVMe pass-through

1

2

board

1. Back up all server blade data.

2. Power down the server blade on page 21.

3. Remove the server blade on page 22.

4. Place the server blade on a flat, level work surface.

5. Remove the access panel on page 22.

6. Prepare the storage controller/NVMe pass-through board for removal.

7. Remove the storage controller/NVMe pass-through board.

34 Operations

Remove an NVMe SSD

Procedure

1. Observe the LED status of the drive and determine if it can be removed.

2. Remove the drive:

a. Press the power button.

The Do Not Remove button illuminates and flashes. Wait until the flashing stops and the Do Not

Remove button is no longer illuminated.

b. When the Do Not Remove button is no longer illuminated, press the Do Not Remove button and

then remove the drive.

Remove a SAS or SATA drive

1. Determine status of drives from LED Definitions.

For more information, see Hot-plug drive LED definitions on page 9.

2. Back up all server blade data on the drive.

3. Remove the drive.

Operations 35

Remove the front panel/drive cage assembly

Prerequisites

To remove the front panel/drive cage assembly, you need a T-15 Torx screwdriver.

Procedure

1. Power down the server blade on page 21.

2.

Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Do one of the following:

• Remove the storage controller or the NVMe passthrough board, if installed (Remove the storage

controller or NVMe pass-through board on page 34).

• Remove the direct connect SATA cable on page 31.

6. If installed, remove the internal USB drive. To locate the internal USB connector, see System board

components on page 13.

7. Remove the DIMM baffles on page 23.

8. Remove the front panel/drive cage assembly:

a. Extend the serial label pull tab from the front of the server blade.

b. Remove the two T-15 screws from the front panel/drive cage assembly.

c. Remove the component.

36 Operations

IMPORTANT: When removing a DIMM baffle, do not remove the following options when installed

on the DIMM baffle:

• M.2 enablement option (left DIMM baffle)

• HPE Smart Storage Battery (right DIMM baffle)

2

2

1

3

Install the front panel/drive cage assembly

Prerequisites

To install the front panel/drive cage assembly, you need a T-15 Torx screwdriver.

Procedure

1. Install the front panel/drive cage assembly:

a. Extend the serial label pull tab from the front of the server blade.

b. Align the pins on the chassis and slide the front panel/drive cage assembly into the server blade.

c. Secure the assembly with two T-15 screws.

d. Close the serial label pull tab.

Operations 37

2

3

3

1

4

2. Install the DIMM baffles on page 25.

3. Do one of the following:

• Install the storage controller (HPE Smart Array P204i SR Gen10 Controller option on page 48)

or the NVMe pass-through board.

• Install the direct connect SATA cable on page 31.

4. Install the access panel on page 23.

5. Install the server blade on page 42.

6. Power up the server blade on page 21.

38 Operations

Setup

Overview

Installation of a server blade requires the following steps.

Procedure

1. Install and configure a BladeSystem c-Class enclosure.

2. Install any server blade options.

3. Install interconnect modules in the enclosure.

4. Connect the interconnect modules to the network.

5. Install a server blade.

6. Complete the server blade configuration.

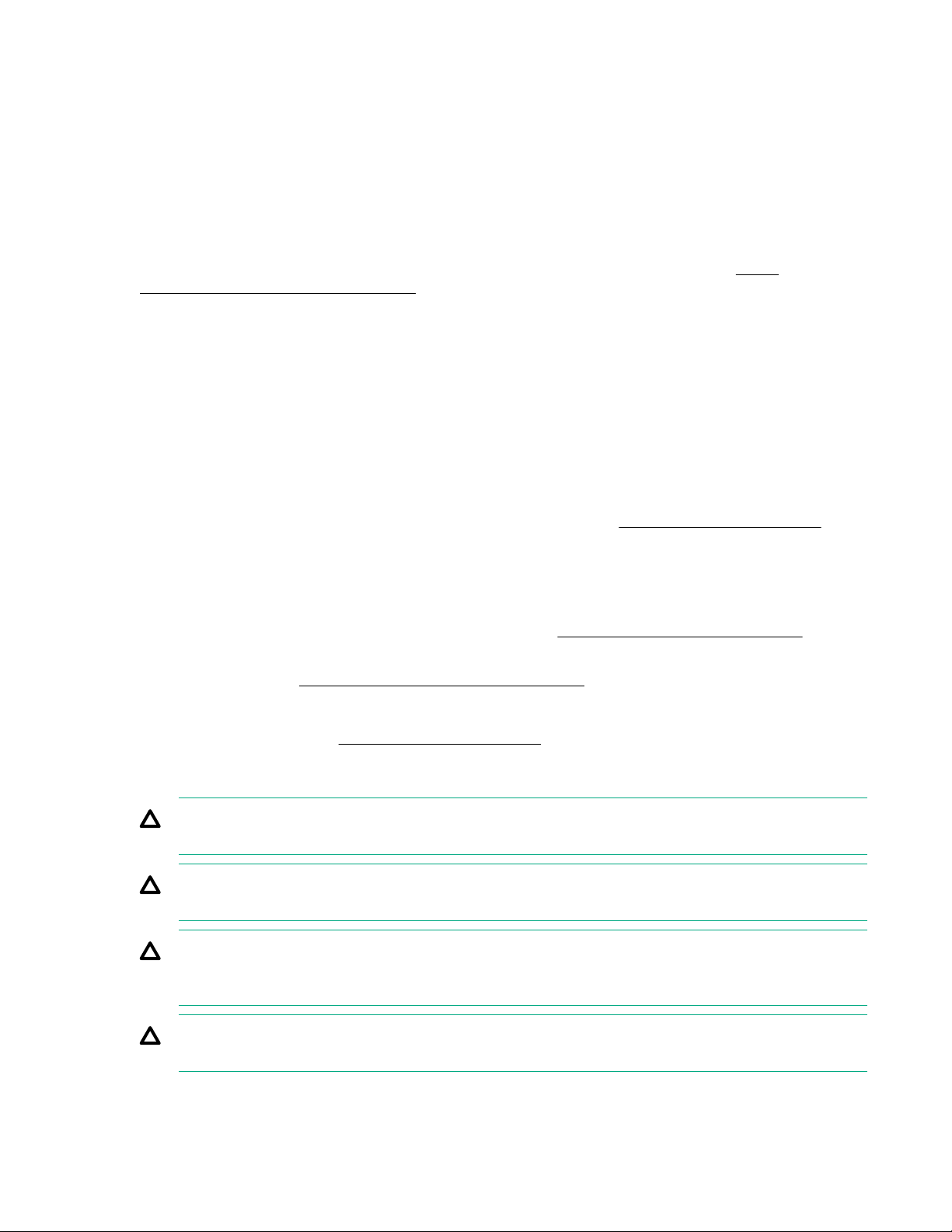

Server blade warnings and cautions

WARNING: To reduce the risk of shock or injury from high-current electrical energy, do not remove

the server blade access panel and then install the server blade into the enclosure.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal

system components to cool before touching them.

CAUTION: Do not operate the server blade with the access panel removed. Operating the server

blade in this manner results in improper airflow and improper cooling that can lead to thermal

damage.

CAUTION: When performing non-hot-plug operations, you must power down the server blade

and/or the system. However, it might be necessary to leave the server blade powered up when

performing other operations, such as hot-plug installations or troubleshooting.

WARNING: To reduce the risk of fire or burns after removing the energy pack:

• Do not disassemble, crush, or puncture the energy pack.

• Do not short external contacts.

• Do not dispose of the energy pack in fire or water.

After power is disconnected, battery voltage might still be present for 1s to 160s.

Installing an HPE BladeSystem c-Class enclosure

Before performing any server blade-specific procedures, install an HPE BladeSystem c-Class enclosure.

The most current documentation for the server blade and other BladeSystem components is available on

the Hewlett Packard Enterprise website.

Setup 39

Preparing the enclosure

Each HPE BladeSystem enclosure ships with device bay dividers to support half-height devices. If the

dividers have been removed, always reinstall the dividers before installing half-height devices and device

bay blanks. For more information on installing the device bay dividers, see the enclosure setup and

installation guide.

Prerequisites

Review the following alerts before installing the enclosure.

CAUTION: When installing half-height blades in a quadrant, always install a divider in that quadrant.

Failure to install the divider can result in damage to the connectors on the server blades.

CAUTION: To prevent improper cooling and thermal damage, do not operate the server blade or the

enclosure unless all recommended drive and device bays are populated with either a component or

a blank.

IMPORTANT: For optimal cooling and system performance, configure the HPE BladeSystem c7000

enclosure with 10 fans.

Installing server blade options

Before installing and initializing the server blade, install any server blade options, such as an additional

processor, hard drive, or mezzanine card. For server blade options installation information, see

"Hardware options installation."

Installing interconnect modules

For specific steps to install interconnect modules, see the documentation that ships with the interconnect

module.

Interconnect bay numbering and device mapping

HPE BladeSystem c7000 Enclosure

40 Setup

To support network connections for specific signals, install an interconnect module in the bay

corresponding to the FlexibleLOM or mezzanine signals.

Server blade

signal

FlexibleLOM 1 and 2

Mezzanine 1 3 and 4

Mezzanine 2 5 and 6

Mezzanine 2 7 and 8

For detailed port mapping information, see the BladeSystem enclosure installation poster or the

BladeSystem enclosure setup and installation guide on the Hewlett Packard Enterprise website.

• HPE BladeSystem c3000 Enclosure

Interconnect bay Interconnect bay labels

Setup 41

Server blade

signal

FlexibleLOM 1 —

Mezzanine 1 2 Four-port cards connect to bay 2.

Interconnect bay

number

Interconnect bay

label

Notes

Mezzanine 2 3 and 4

Connecting to the network

To connect the BladeSystem to a network, each enclosure must be configured with network interconnect

devices to manage signals between the server blades and the external network.

Two types of interconnect modules are available for BladeSystem c-Class enclosures:

• Pass-Thru modules

• Switch modules

For more information about interconnect module options, see the Hewlett Packard Enterprise website.

IMPORTANT: To connect to a network with a Pass-Thru module, always connect the Pass-Thru

module to a network device that supports Gigabit or 10 Gb speed, depending on the corresponding

Pass-Thru model.

Install the server blade

◦ Four-port cards

◦ Ports 1 and 3 connect to bay 3.

◦ Ports 2 and 4 connect to bay 4.

42 Setup

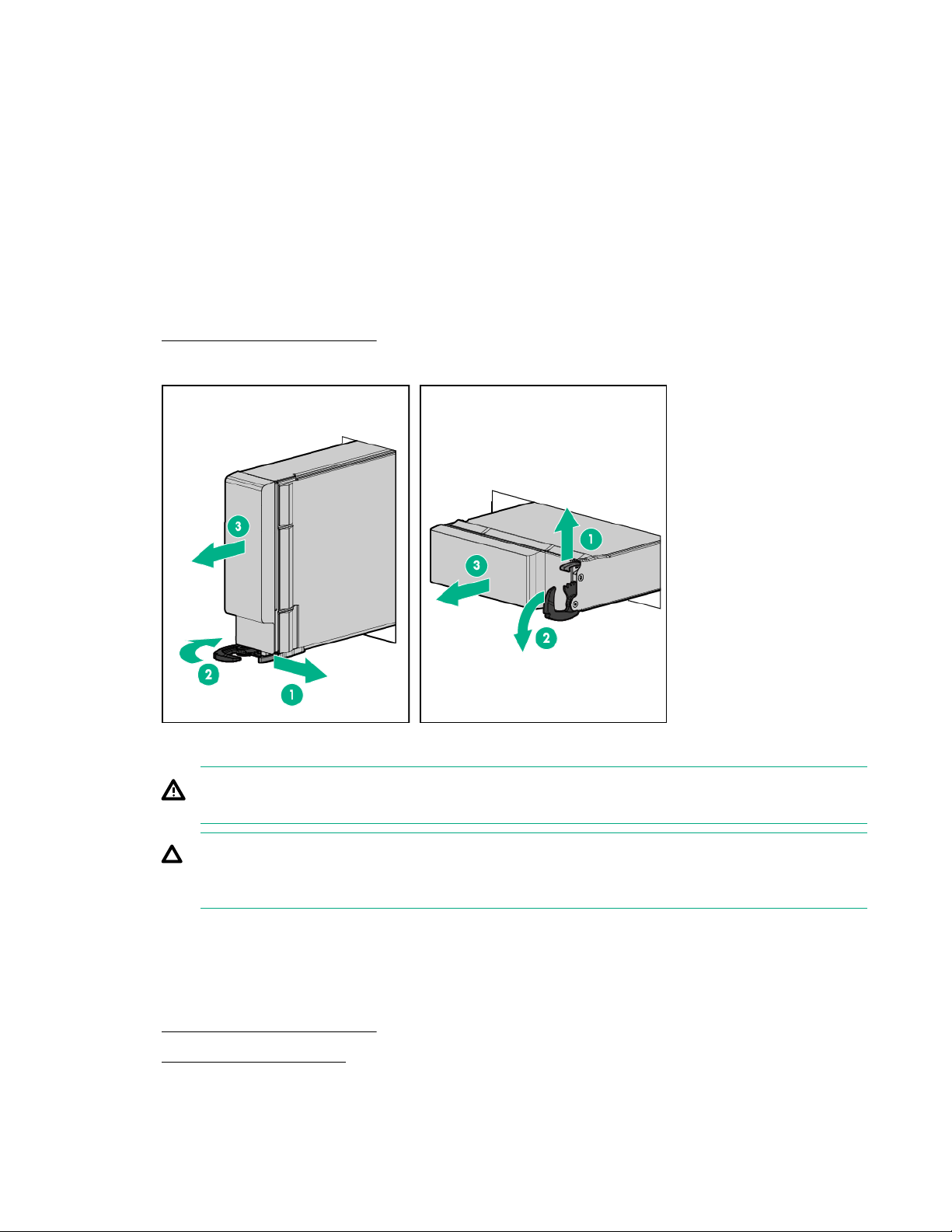

CAUTION: To prevent improper cooling and thermal damage, do not operate the server blade or the

enclosure unless all device bays are populated with either a component or a blank.

CAUTION: Failure to install the divider in a quadrant when installing half-height blades can result in

damage to the connectors on the server blade.

For the best possible BladeSystem and Virtual Connect experience, and to prevent a future reboot,

Hewlett Packard Enterprise requires updating the Onboard Administrator and Virtual Connect to the

correct version before installing an HPE ProLiant Gen10 server blade. The version information is on the

tag on the front of the server blade.

For more information on this and other specific firmware and driver requirements, as well as the latest

firmware and driver versions, download the latest SPP from the Hewlett Packard Enterprise website

(http://www.hpe.com/servers/spp/download).

Procedure

1. Remove the device bay blank.

Retain the blank for future use.

2. Remove the enclosure connector cover.

Retain the cover for future use.

3. Install the server blade.

Setup 43

Completing the configuration

To complete the server blade and BladeSystem configuration, see the overview card that ships with the

enclosure.

44 Setup

Hardware options installation

Introduction

Install any hardware options before initializing the server. For options installation information, see the

option documentation. For server-specific information, use the procedures in this section.

If multiple options are being installed, read the installation instructions for all the hardware options to

identify similar steps and streamline the installation process.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal

system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server before

beginning any installation procedure. Improper grounding can cause electrostatic discharge.

Drive bay options

Two SFF drive bays are on the front panel of the server blade. The following options are supported in the

drive bays:

• SFF SAS hard drives

• SFF SATA hard drives

• SFF SAS SSDs

• SFF SATA SSDs

• NVMs SSDs

• uFF SATA SSDs with the SFF Flash Adapter

Ensure that the server blade is configured properly when installing the drive options. For example, be

sure that the drive option is configured with the proper backplane and other required components.

Installing the SAS and SATA drive options

The server blade supports hot plug SAS and SATA hard drives and hot plug SAS and SATA SSDs.

Prerequisites

To support SAS and SATA hard drives or SSDs, install the SAS/SATA HDD backplane with one of the

following:

• Direct connect SATA cable (supports SATA drives only)

• HPE Smart Array P204i SR Gen10 Controller (supports both SAS and SATA drives)

Procedure

1. Remove the drive blank.

Hardware options installation 45

2. Prepare the drive.

3. Install the drive.

4. Determine the status of the drive from the drive LED definitions.

For more information, see Hot-plug drive LED definitions on page 9.

Installing the NVMe SSD options

The server blade supports hot-plug NVMe SSDs when configured for NVMe drive support.

Prerequisites

Before installing an NVMe SSD into a server blade, the server blade must be configured with the

following components:

• NVMe pass-through board

• NVMe backplane

Procedure

1. Remove the drive blank.

46 Hardware options installation

2. Press the Do Not Remove button to release the Release lever.

3. Install the drive.

4. Determine the status of the drive.

For more information, see the NVMe SSD components on page 10.

Installing the SFF Flash Adapter option

CAUTION: To prevent improper cooling and thermal damage, do not operate the server blade or the

enclosure unless all device bays are populated with either a component or a blank.

Prerequisites

To support uFF drives and the SFF Flash Adapter option, install the SAS/SATA HDD backplane with one

of the following:

• Direct connect SATA cable

• HPE Smart Array P204i SR Gen10 Controller

Procedure

1. Remove the drive blank.

Hardware options installation 47

2. Install the uFF drives in the SFF Flash Adapter.

3. Install the SFF Flash Adapter by pushing firmly near the left-side adapter ejection handle until the

latching spring engages in the drive bay.

HPE Smart Array P204i SR Gen10 Controller option

When the HPE Smart Array P204i SR Gen10 Controller is installed, this server blade supports the

following options:

• Up to two SAS or SATA SSDs

• Up to two SAS or SATA hard drives

• Up to two SFF Flash Adapters (up to 4 uFF drives)

48 Hardware options installation

Prerequisites

1

2

To support this storage controller, the SAS/SATA backplane is installed on the server blade. For server

blades that support NVMe drives, an NVMe backplane is installed and an NVMe passthrough board will

be installed in this location.

Procedure

1. Back up all server blade data.

2. Power down the server blade on page 21.

3. Remove the server blade on page 22.

4. Place the server blade on a flat, level work surface.

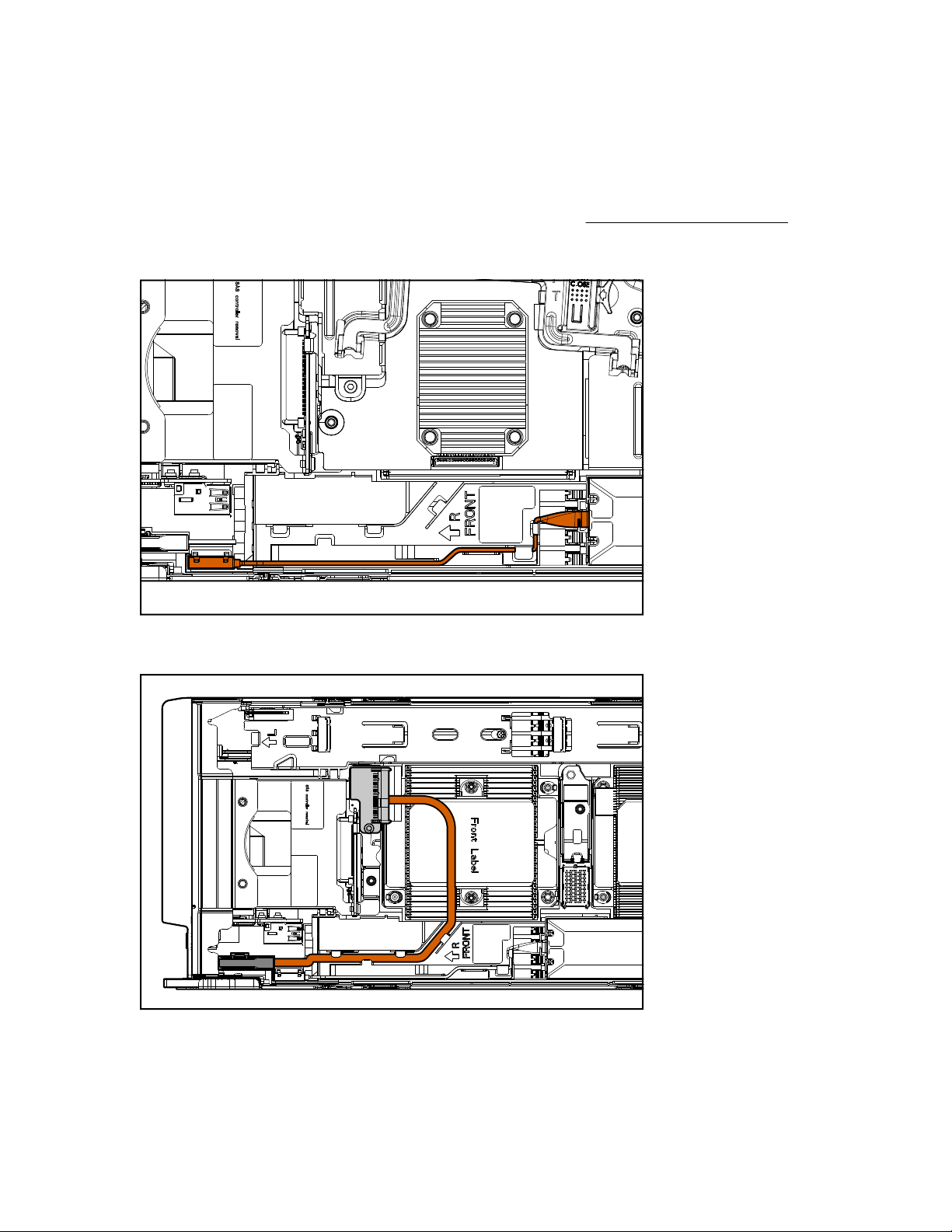

5. Remove the access panel on page 22.

6. Remove the direct connect SATA cable, if installed (Remove the direct connect SATA cable on

page 31).

7. Prepare the storage controller for installation.

8. Align the storage controller with the alignment pins and lower it onto the connector.

Hardware options installation 49

9. Close the storage controller handle to seat the storage controller on the connector.

1

2

10. Install the access panel on page 23.

11. Install the server blade on page 42.

12. Power up the server blade on page 21.

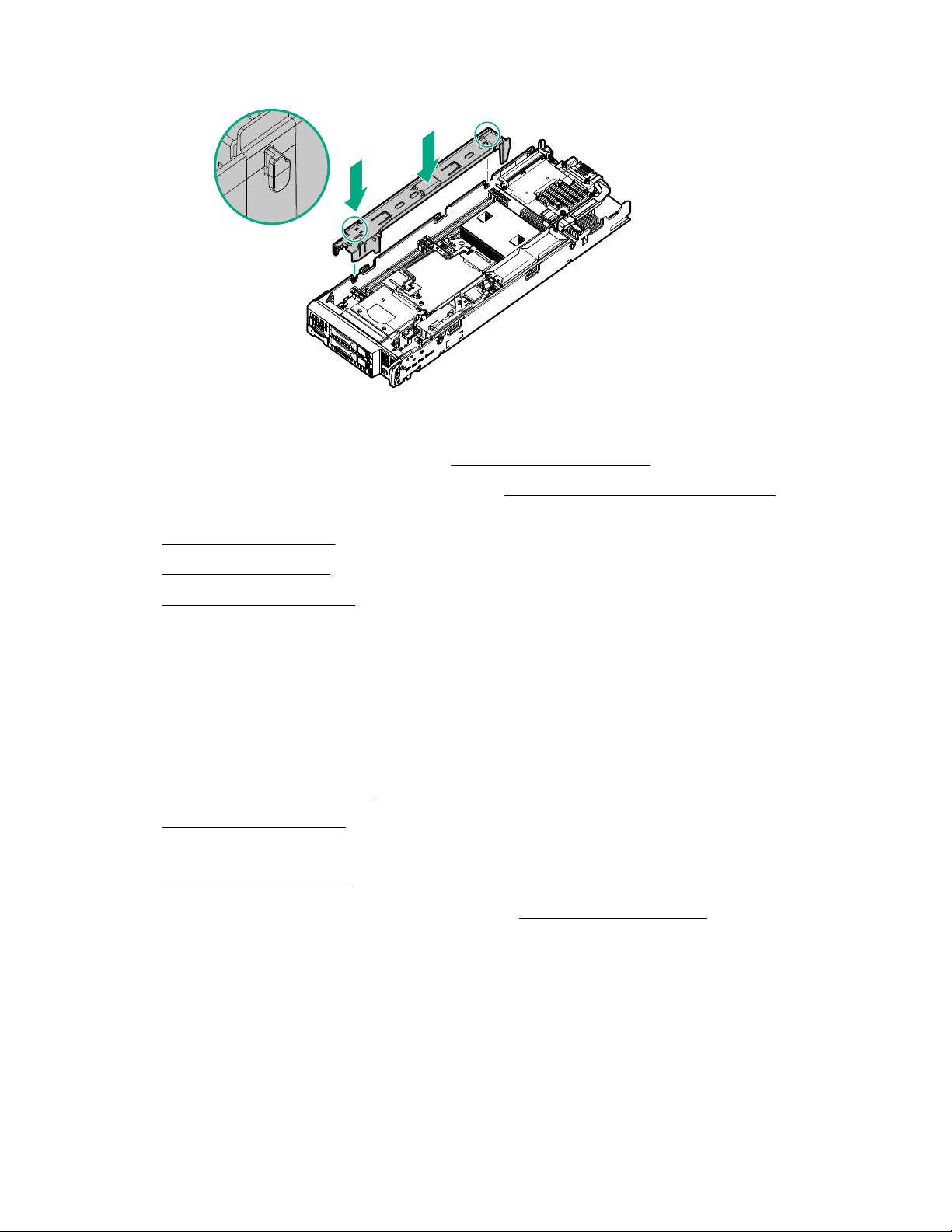

HPE Smart Storage Battery

The HPE Smart Storage Battery supports the following devices:

HPE Smart Array SR controllers

A single 96W battery can support up to 24 devices.

After the battery is installed, it might take up to two hours to charge. Controller features requiring backup

power are not re-enabled until the battery is capable of supporting the backup power.

50 Hardware options installation

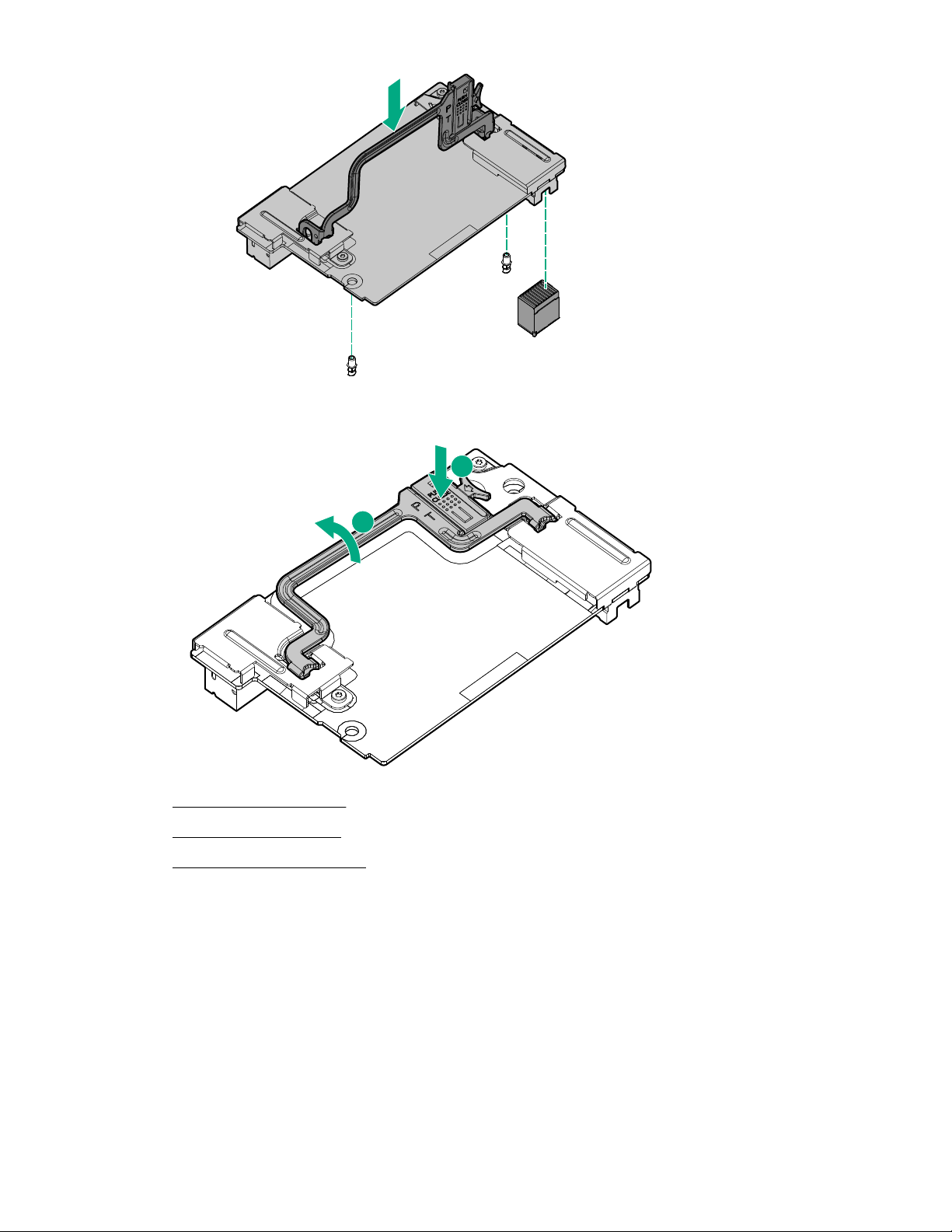

Installing the HPE Smart Storage Battery

WARNING: The server blade may contain internal replaceable battery cells or battery packs. A risk

of fire, burns, or explosions exists if the battery pack is not properly handled. To reduce the risk of

personal injury:

• Do not attempt to recharge the battery outside of the installed application.

• Do not expose the battery to temperatures higher than 60°C (140°F).

• Do not disassemble, crush, puncture, short external contacts, or dispose of the battery in fire or

water.

• Replace only with the Hewlett Packard Enterprise spare battery designated for this product.

Dispose of used batteries according to the manufacturer's instructions and local disposal

requirements.

• For battery holders (for example, coin cells), observe the correct polarity when changing the

battery/cell. A danger of explosion exists if the battery is installed incorrectly.

System ROM and firmware messages may display "energy pack" in place of "Smart Storage Battery."

Energy pack refers to both HPE Smart Storage Batteries and HPE Smart Storage Hybrid Capacitors.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. If installed, remove the direct connect SATA cable (Remove the direct connect SATA cable on

page 31).

6. If installed, remove the internal USB drive.

To locate the internal USB connector, see System board components on page 13.

7. Remove the right DIMM baffle (Remove the DIMM baffles on page 23).

8. Install the HPE Smart Storage Battery on the right DIMM baffle.

Hardware options installation 51

1

2

3

9. Route the cable on the right DIMM baffle.

IMPORTANT: When installing each DIMM baffle, be sure that the alignment tabs engage with

the side of the server blade.

10. Align and install the DIMM baffle.

Press down on the cable connector to fully seat the HPE Smart Storage Battery cable connector to

the system board.

52 Hardware options installation

11. If removed, install the direct connect SATA cable (Install the direct connect SATA cable on page

31).

12. If removed, install the internal USB drive.

To locate the internal USB connector, see System board components on page 13.

13. Install the access panel on page 23.

14. Install the server blade on page 42.

15. Power up the server blade on page 21.

Mezzanine card option

Optional mezzanine cards are classified as Type A mezzanine cards and Type B mezzanine cards. The

type of the mezzanine card determines where it can be installed in the server blade.

• Install Type A mezzanine cards on Mezzanine 1 connector or Mezzanine 2 connector.

• Install Type B mezzanine cards on Mezzanine 2 connector.

Before installing the mezzanine card, be sure to review the following:

• System board components on page 13 for mezzanine connector location

• Mezzanine connector definitions on page 19

• Mezzanine connector guide pin locations on page 19

• Interconnect bay numbering and device mapping on page 40

When installing a mezzanine option on mezzanine connector 2, processor 2 must be installed.

Optional mezzanine cards enable external storage, network connectivity, or provide Fiber Channel

support.

Installing the mezzanine card option

Prerequisites

To install the mezzanine card option, you need a T-15 Torx screwdriver.

Hardware options installation 53

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the mezzanine assembly on page 32.

6. Align the mezzanine card using the appropriate guide pins on the mezzanine assembly.

7. Install the mezzanine card in the mezzanine assembly.

8. Align the mezzanine assembly with the guide pins on the system board, and then install the

mezzanine assembly on the system board.

Press firmly on the mezzanine assembly handles, and then close the mezzanine assembly latch.

54 Hardware options installation

9. Install the access panel on page 23.

10. Install the server blade on page 42.

11. Power up the server blade on page 21.

FlexibleLOM option

Installing the FlexibleLOM

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the mezzanine assembly on page 32.

6. Install the FlexibleLOM.

Hardware options installation 55

7. Install the mezzanine assembly on page 33.

1

2

8. Install the access panel on page 23.

9. Install the server blade on page 42.

10. Power up the server blade on page 21.

M.2 enablement option

The M.2 enablement option consists of an M.2 riser and an M.2 interposer board that installs on the left

DIMM baffle. When the option is installed, the server blade supports up to two M.2 SSDs.

The M.2 riser board can support both 2280 and 22110 M.2 SSD options. If the M.2 riser is not configured

for the correct length of the M.2 SSDs being installed, relocate the PEM nut and rubber stoppers to the

location that support the drives being installed (Relocate the PEM nut and rubber stopper on page 28).

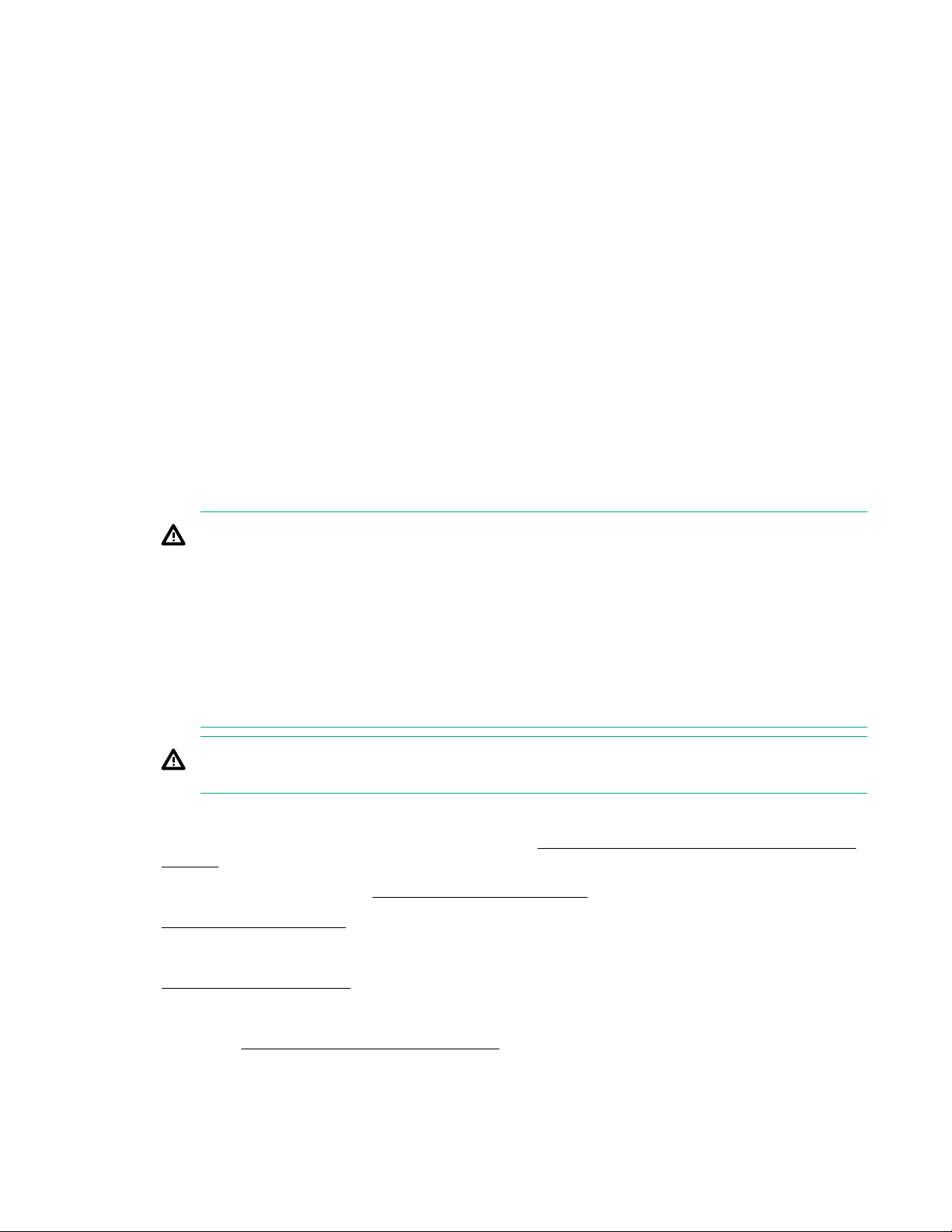

Figure 1: M.2 SSD PEM nut locations

56 Hardware options installation

1. Supports M.2 2280 SSD installation

2. Supports M.2 22110 SSD installation

Installing the M.2 riser board and M.2 interposer board

The M.2 riser board supports two M.2 SSDs. This server blade does not support mixing M.2 SSD sizes or

bus protocols.

Prerequisites

To install the M.2 SSDs on the M.2 riser board, you need a No. 1 Phillips screwdriver.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the left DIMM baffle.

6. Verify that the PEM nuts and rubber stoppers are in the correct location to support the length of the

M.2 SSDs being installed. Relocate the PEM nuts and rubber stoppers, if necessary.

See Relocate the PEM nut and rubber stopper on page 28.

7. Install the M.2 SSDs on the M.2 riser board.

See Installing the M.2 SSDs on page 59.

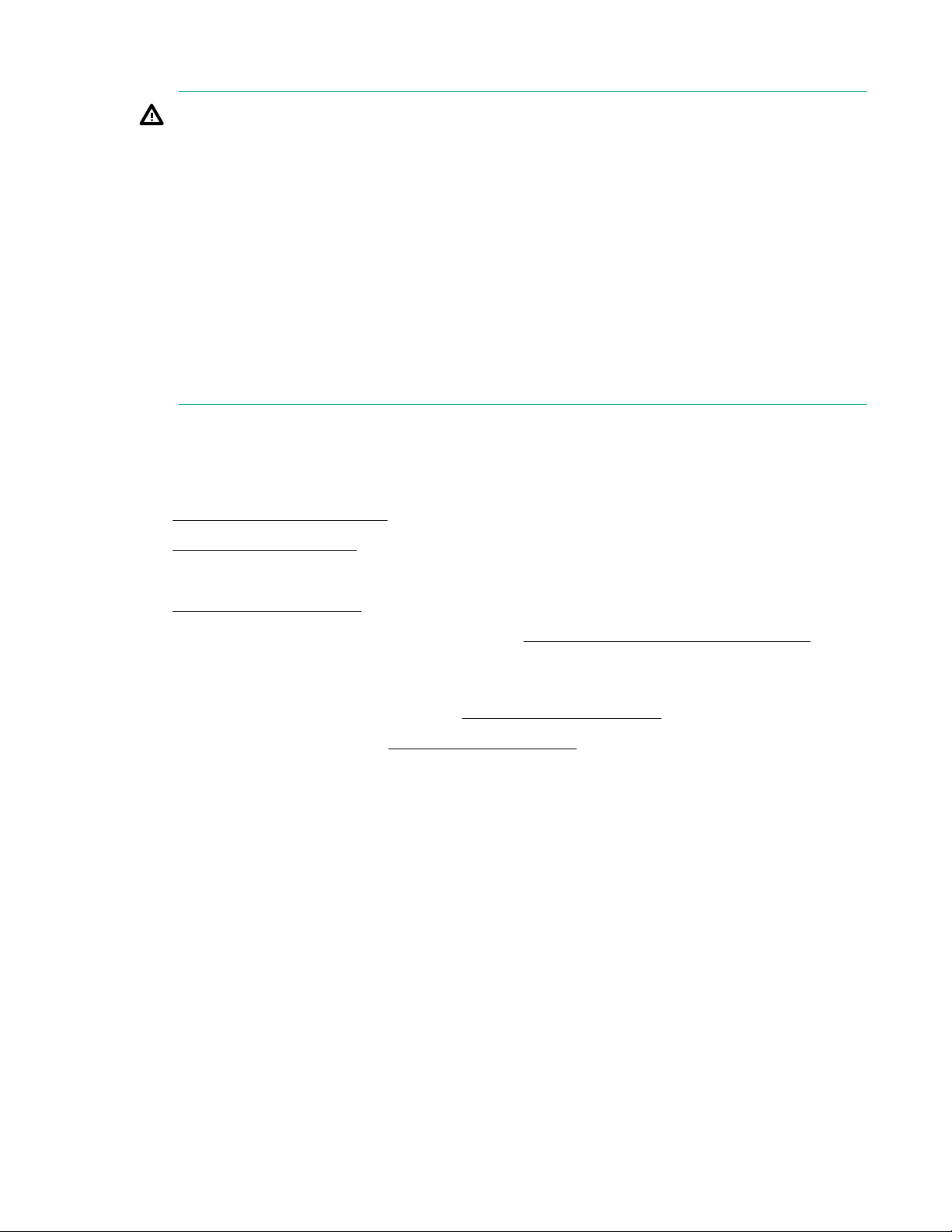

8. Align and install the M.2 riser board on the left DIMM baffle.

IMPORTANT: Be sure that the M.2 riser board aligns with the 7 guides and the triangular notch

on the left DIMM baffle.

Hardware options installation 57

9. Install the M.2 interposer board on the left DIMM baffle.

1

2

3

IMPORTANT: MLB is printed on the M.2 interposer board to indicate edge of the board that

connects to the system board. When the M.2 interposer board is installed, MLB must face out

towards the edge of the server blade.

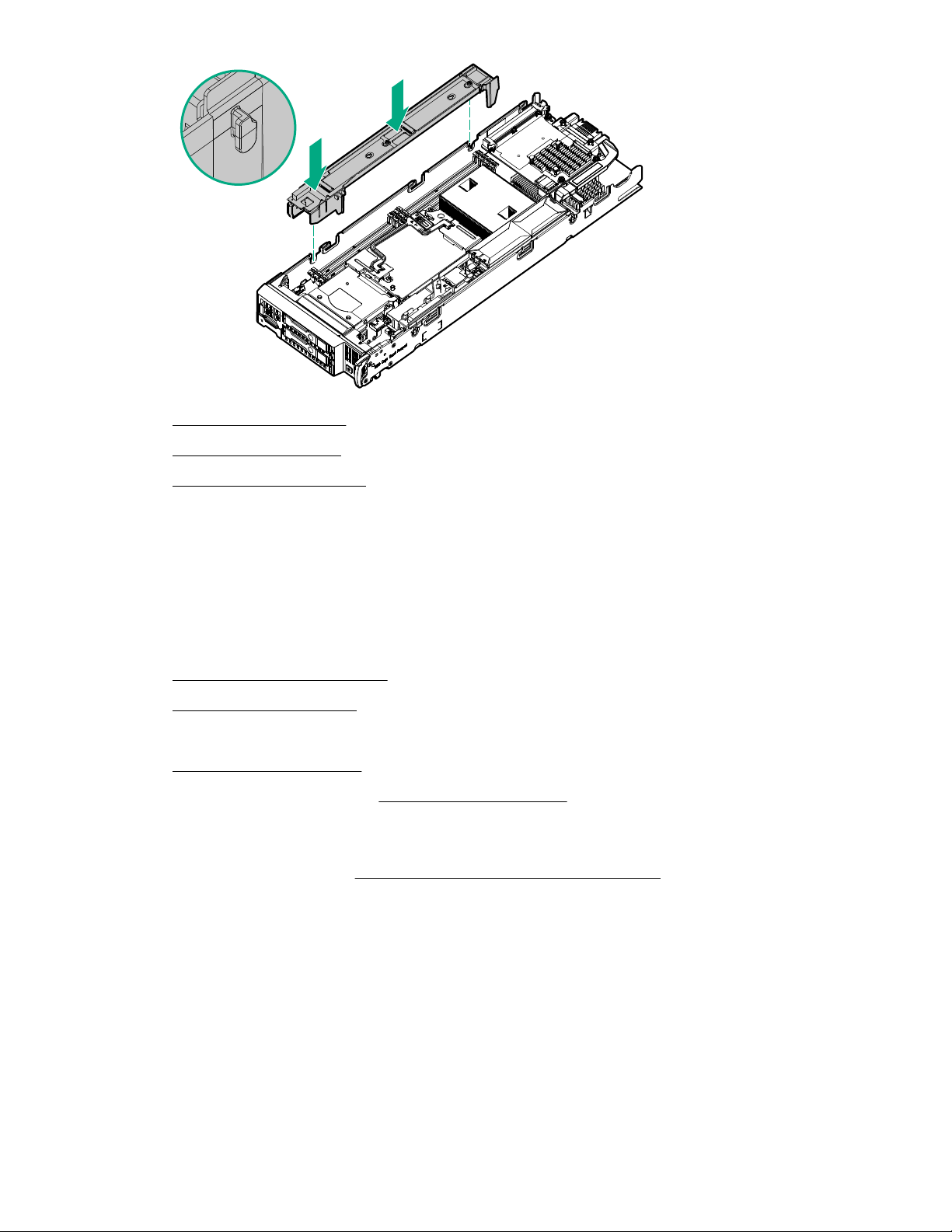

10. Align and install the left DIMM baffle in the server blade.

IMPORTANT: When installing each DIMM baffle, be sure that the alignment tabs engage with

the side of the server blade.

58 Hardware options installation

11. Install the access panel on page 23.

12. Install the server blade on page 42.

13. Power up the server blade on page 21.

Installing the M.2 SSDs

Prerequisites

A No. 1 Phillips screwdriver is required to perform this procedure.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

5. Remove the left DIMM baffle (Remove the DIMM baffles on page 23).

6. Verify that the PEM nuts and rubber stoppers are in the correct location to support the length of the

M.2 SSDs being installed. Relocate the PEM nuts and rubber stoppers, if necessary.

For more information, see Relocate the PEM nut and rubber stopper on page 28.

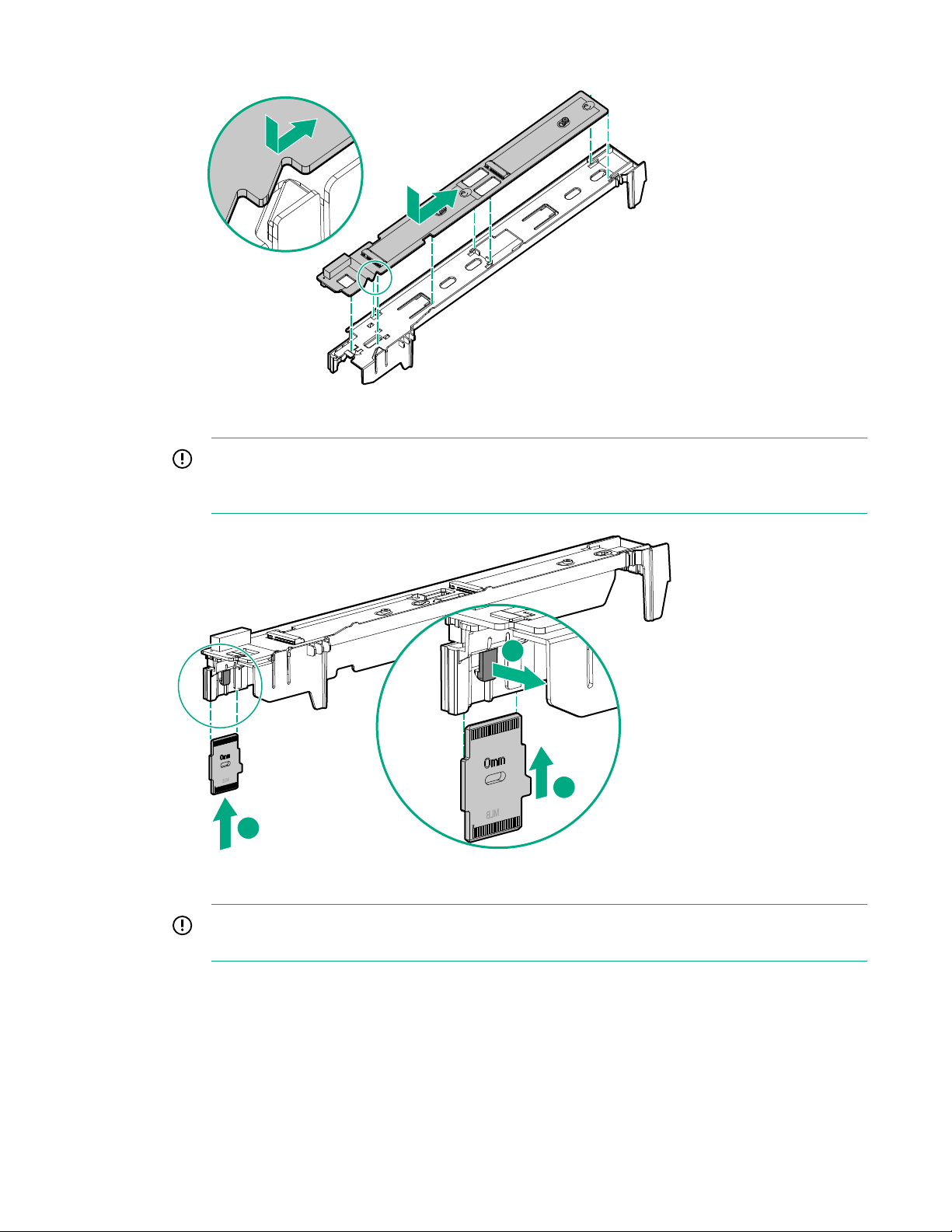

7. Remove the screw with a No. 1 Phillips screwdriver, and then install the M.2 SSD.

Hardware options installation 59

1

2

3

8. If necessary, repeat the M.2 SSD installation procedure for a second drive.

9. Install the left DIMM baffle (Install the DIMM baffles on page 25).

10. Install the access panel on page 23.

11. Install the server blade on page 42.

12. Power up the server blade on page 21.

Memory options

IMPORTANT: This server blade does not support mixing LRDIMMs and RDIMMs. Attempting to mix

any combination of these DIMMs can cause the server to halt during BIOS initialization. All memory

installed in the server blade must be of the same type.

DIMM and NVDIMM population information

For specific DIMM and NVDIMM population information, see the DIMM population guidelines on the

Hewlett Packard Enterprise website (http://www.hpe.com/docs/memory-population-rules).

DIMM-processor compatibility

The installed processor determines the type of DIMM that is supported in the server blade:

• First-generation Intel Xeon Scalable processors support DDR4-2666 DIMMs.

• Second-generation Intel Xeon Scalable processors support DDR4-2933 DIMMs.

Mixing DIMM types is not supported. Install only the supported DDR4-2666 or DDR4-2933 DIMMs in the

server blade.

HPE SmartMemory speed information

For more information about memory speed information, see the Hewlett Packard Enterprise website

(https://www.hpe.com/docs/memory-speed-table).

Installing a DIMM

The server supports up to 16 DIMMs.

60 Hardware options installation

Prerequisites

Before installing this option, be sure that you have the following the components included with the

hardware option kit.

For more information on specific options, see the server blade QuickSpecs on the Hewlett Packard

Enterprise website (http://www.hpe.com/info/qs).

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

IMPORTANT: When removing a DIMM baffle, do not remove the following options when

installed on the DIMM baffle:

• M.2 enablement option (left DIMM baffle)

• HPE Smart Storage Battery (right DIMM baffle)

5. Remove the DIMM baffles on page 23.

6. Open the appropriate DIMM slot latches.

7. Install the DIMM.

8. Install the DIMM baffles on page 25.

9. Install the access panel on page 23.

10. Install the server blade on page 42.

11. Power up the server blade on page 21.

To configure the memory mode, use the BIOS/Platform Configuration (RBSU) in the UEFI System

Utilities.

Hardware options installation 61

HPE 16GB NVDIMM option

HPE NVDIMMs are flash-backed NVDIMMs used as fast storage and are designed to eliminate smaller

storage bottlenecks. The HPE 16GB NVDIMM for HPE ProLiant Gen10 servers is ideal for smaller

database storage bottlenecks, write caching tiers, and any workload constrained by storage bottlenecks.

The HPE 16GB NVDIMM is supported on select HPE ProLiant Gen10 servers with first generation Intel

Xeon Scalable processors. The server blade can support up to 12 NVDIMMs in 2 socket servers (up to

192GB) and up to 24 NVDIMMs in 4 socket servers (up to 384GB). The HPE Smart Storage Battery

provides backup power to the memory slots allowing data to be moved from the DRAM portion of the

NVDIMM to the Flash portion for persistence during a power down event.

For more information on HPE NVDIMMs, see the Hewlett Packard Enterprise website (http://

www.hpe.com/info/persistentmemory).

NVDIMM-processor compatibility

HPE 16GB NVDIMMs are only supported in servers with first generation Intel Xeon Scalable processors

installed.

Server requirements for NVDIMM support

Before installing an HPE 16GB NVDIMM in a server blade, make sure that the following components and

software are available:

• A supported HPE server using Intel Xeon Scalable Processors: For more information, see the

NVDIMM QuickSpecs on the Hewlett Packard Enterprise website (

http://www.hpe.com/info/qs).

• An HPE Smart Storage Battery

• A minimum of one regular DIMM: The system cannot have only NVDIMM-Ns installed.

• A supported operating system with persistent memory/NVDIMM drivers. For the latest software

information, see the Hewlett Packard Enterprise website (http://persistentmemory.hpe.com).

• For minimum firmware versions, see the HPE 16GB NVDIMM User Guide on the Hewlett Packard

Enterprise website (http://www.hpe.com/info/nvdimm-docs).

To determine NVDIMM support for your server blade, see the server blade QuickSpecs on the Hewlett

Packard Enterprise website (http://www.hpe.com/info/qs).

Installing an NVDIMM

CAUTION: To avoid damage to the hard drives, memory, and other system components, the air

baffle, drive blanks, and access panel must be installed when the server is powered up.

CAUTION: To avoid damage to the hard drives, memory, and other system components, be sure to

install the correct DIMM baffles for your server model.

CAUTION: DIMMs are keyed for proper alignment. Align notches in the DIMM with the

corresponding notches in the DIMM slot before inserting the DIMM. Do not force the DIMM into the

slot. When installed properly, not all DIMMs will face in the same direction.

CAUTION: Electrostatic discharge can damage electronic components. Be sure you are properly

grounded before beginning this procedure.

62 Hardware options installation

CAUTION: Failure to properly handle DIMMs can cause damage to DIMM components and the

1

2

2

system board connector.

CAUTION: Unlike traditional storage devices, NVDIMMs are fully integrated in with the ProLiant

server blade. Data loss can occur when system components, such as the processor or HPE Smart

Storage Battery, fails. HPE Smart Storage battery is a critical component required to perform the

backup functionality of NVDIMMs. It is important to act when HPE Smart Storage Battery related

failures occur. Always follow best practices for ensuring data protection.

Prerequisites

Before installing an NVDIMM, be sure the server blade meets the Server requirements for NVDIMM

support on page 62.

Procedure

1. Power down the server blade on page 21.

2. Remove the server blade on page 22.

3. Place the server blade on a flat, level work surface.

4. Remove the access panel on page 22.

IMPORTANT: When removing a DIMM baffle, do not remove the following options when

installed on the DIMM baffle:

• M.2 enablement option (left DIMM baffle)

• HPE Smart Storage Battery (right DIMM baffle)

5. Remove the DIMM baffles on page 23.

6. Locate any NVDIMMs already installed in the server blade.

7. Verify that all LEDs on any installed NVDIMMs are off.

8. Install the NVDIMM.

9. Install and connect the HPE Smart Storage Battery, if it is not already installed (HPE Smart Storage

Battery option).

Hardware options installation 63

10. Install any components removed to access the DIMM slots and the HPE Smart Storage Battery.

11. Install the access panel on page 23.

12. Install the server blade on page 42.

13. Power up the server blade on page 21.

14. If required, sanitize the NVDIMM-Ns. For more information, see NVDIMM sanitization on page 64.

Configuring the server blade for NVDIMMs

After installing NVDIMMs, configure the server blade for NVDIMMs. For information on configuring

settings for NVDIMMs, see the HPE 16GB NVDIMM User Guide on the Hewlett Packard Enterprise

website (

The server blade can be configured for NVDIMMs using either of the following:

• UEFI System Utilities—Use System Utilities through the Remote Console to configure the server blade

• iLO RESTful API for HPE iLO 5—For more information about configuring the system for NVDIMMs,

http://www.hpe.com/info/nvdimm-docs).

for NVDIMM memory options by pressing the F9 key during POST. For more information about UEFI

System Utilities, see the Hewlett Packard Enterprise website (http://www.hpe.com/info/uefi/docs).

see https://hewlettpackard.github.io/ilo-rest-api-docs/ilo5/.

Saving system default settings as user default settings