HPE ProLiant ML110 Gen9 Server

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage systems. Hewlett Packard Enterprise

User Guide

assumes you are qualified in the servicing of computer equipment and trained in recognizing hazards in products with hazardous energy

levels.

Part Number: 781889-004

Octorber 2017

Edition: 4

©

Copyright 2017 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard

Enterprise products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional warranty. Hewlett

Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use,

or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer Software

Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government under

vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard Enterprise

website.

Acknowledgments

Intel®, Itanium®, Pentium®, Intel Inside®, and the Intel Inside logo are trademarks of Intel Corporation in the

United States and other countries.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Adobe® and Acrobat® are trademarks of Adobe Systems Incorporated.

Java® and Oracle® are registered trademarks of Oracle and/or its affiliates.

UNIX® is a registered trademark of The Open Group.

Contents

Component identification .......................................................................................................................... 6

Front panel components ........................................................................................................................................... 6

Front panel LEDs and buttons .................................................................................................................................. 7

Front panel LED power fault codes ............................................................................................................... 7

Rear panel components ........................................................................................................................................... 8

Rear panel LEDs ...................................................................................................................................................... 9

System board components ..................................................................................................................................... 10

DIMM slot locations ..................................................................................................................................... 11

System maintenance switch ........................................................................................................................ 11

NMI functionality .......................................................................................................................................... 12

Fan locations .......................................................................................................................................................... 13

Drive numbering ..................................................................................................................................................... 13

Hot-plug drive LED definitions ................................................................................................................................ 15

Operations .............................................................................................................................................. 17

Power down the server ........................................................................................................................................... 17

Remove the access panel ...................................................................................................................................... 17

Install the access panel .......................................................................................................................................... 18

Remove the front bezel .......................................................................................................................................... 19

Install the front bezel .............................................................................................................................................. 19

Remove the PCI air baffle ...................................................................................................................................... 20

Install the PCI air baffle .......................................................................................................................................... 20

Remove the system air baffle ................................................................................................................................. 21

Install the system air baffle ..................................................................................................................................... 22

Setup ...................................................................................................................................................... 23

Optional services .................................................................................................................................................... 23

Optimum environment ............................................................................................................................................ 23

Space and airflow requirements .................................................................................................................. 23

Temperature requirements .......................................................................................................................... 24

Power requirements .................................................................................................................................... 24

Electrical grounding requirements ............................................................................................................... 25

Server warnings and cautions ................................................................................................................................ 25

Identifying tower server shipping carton contents .................................................................................................. 26

Installing hardware options ..................................................................................................................................... 26

Setting up a tower server ....................................................................................................................................... 26

Installing the server into a rack ............................................................................................................................... 27

Rack warnings ........................................................................................................................................................ 28

Installing the operating system ............................................................................................................................... 28

Powering on and selecting boot options in UEFI Boot Mode ................................................................................. 29

Registering the server ............................................................................................................................................ 29

Hardware options installation .................................................................................................................. 30

Introduction ............................................................................................................................................................. 30

Drive cage options .................................................................................................................................................. 30

4-bay LFF hot-plug drive cage option .......................................................................................................... 30

8-bay SFF hot-plug drive cage option ......................................................................................................... 33

Drive options .......................................................................................................................................................... 36

Drive installation guidelines ......................................................................................................................... 36

Installing a non-hot-plug drive ..................................................................................................................... 37

Installing a hot-plug drive............................................................................................................................. 39

Drive cable options ................................................................................................................................................. 40

Host Bus Adapter Mini-SAS cable option .................................................................................................... 40

Smart Array Controller Mini-SAS cable option ............................................................................................ 42

Storage controller options ...................................................................................................................................... 44

Contents 3

Storage controller installation guidelines ..................................................................................................... 45

Installing the storage controller and FBWC module options........................................................................ 46

Installing a Smart Storage Battery ............................................................................................................... 48

M.2 SSD enablement option .................................................................................................................................. 49

Smart Storage Battery holder option ...................................................................................................................... 52

GPU options ........................................................................................................................................................... 53

Optical drive option ................................................................................................................................................. 56

PCI fan and baffle option ........................................................................................................................................ 58

System fan upgrade option .................................................................................................................................... 60

Dual 8Gb microSD Enterprise Midline USB device ................................................................................................ 61

Memory options ...................................................................................................................................................... 62

Memory-processor compatibility information ............................................................................................... 62

DIMM type ................................................................................................................................................... 62

SmartMemory .............................................................................................................................................. 64

Memory subsystem architecture.................................................................................................................. 64

Single-, dual-, and quad-rank DIMMs .......................................................................................................... 65

DIMM identification ...................................................................................................................................... 65

Memory configurations ................................................................................................................................ 66

General DIMM slot population guidelines .................................................................................................... 67

Identifying the processor type...................................................................................................................... 67

Installing a DIMM ......................................................................................................................................... 68

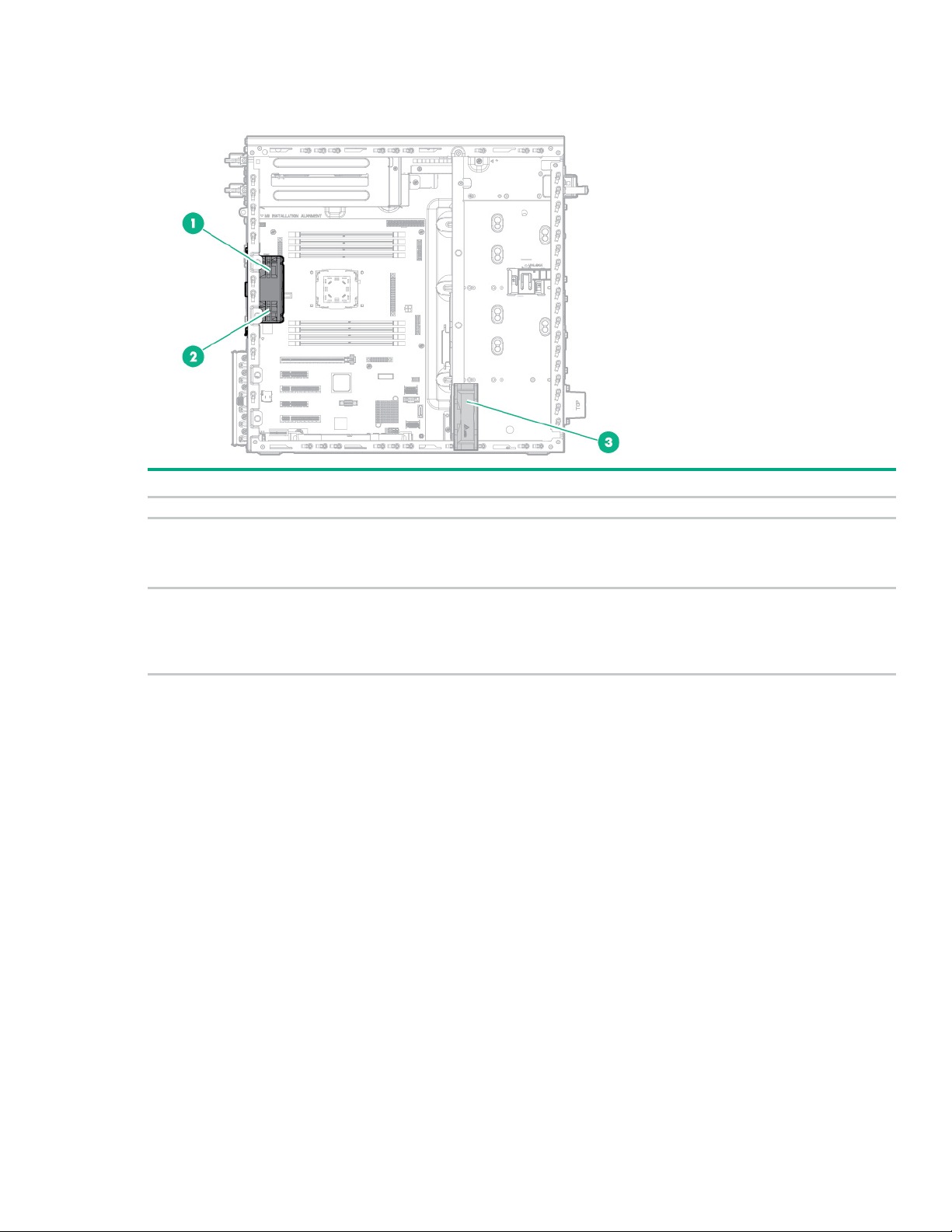

Dedicated iLO management module option ........................................................................................................... 69

Enabling the dedicated iLO management module....................................................................................... 70

HPE ATX 550 W power supply option .................................................................................................................... 70

Redundant power supply option ............................................................................................................................. 73

HP Trusted Platform Module option ....................................................................................................................... 79

Installing the Trusted Platform Module board .............................................................................................. 80

Retaining the recovery key/password.......................................................................................................... 81

Enabling the Trusted Platform Module ........................................................................................................ 82

Cabling .................................................................................................................................................... 83

Cabling overview .................................................................................................................................................... 83

Storage cabling ...................................................................................................................................................... 83

4-bay LFF non-hot-plug drive cabling .......................................................................................................... 83

4-bay LFF hot-plug drive cabling ................................................................................................................. 84

8-bay SFF hot-plug drive cabling................................................................................................................. 86

M.2 SSD cabling .......................................................................................................................................... 90

FBWC module cabling ............................................................................................................................................ 90

Smart Storage Battery cabling ............................................................................................................................... 91

Optical drive cabling ............................................................................................................................................... 92

GPU cabling ........................................................................................................................................................... 92

Fan cabling ............................................................................................................................................................. 93

Power supply cabling ............................................................................................................................................. 94

HPE ATX 350 W power supply (non-hot-plug) ............................................................................................ 94

HPE ATX 550 W power supply (non-hot-plug) ............................................................................................ 95

HPE 750 W redundant power supply .......................................................................................................... 95

Front I/O cabling ..................................................................................................................................................... 96

Front USB 3.0 cabling ............................................................................................................................................ 96

Software and configuration utilities ......................................................................................................... 97

Server mode ........................................................................................................................................................... 97

Product QuickSpecs ............................................................................................................................................... 97

HPE iLO ................................................................................................................................................................. 97

Active Health System .................................................................................................................................. 97

iLO RESTful API support ............................................................................................................................. 98

Integrated Management Log ....................................................................................................................... 99

Intelligent Provisioning ........................................................................................................................................... 99

HPE Insight Diagnostics .............................................................................................................................. 99

HPE Insight Diagnostics survey functionality ............................................................................................ 100

Erase Utility ............................................................................................................................................... 100

Scripting Toolkit for Windows and Linux .............................................................................................................. 100

Service Pack for ProLiant ..................................................................................................................................... 100

Contents 4

HP Smart Update Manager ....................................................................................................................... 101

HPE UEFI System Utilities ................................................................................................................................... 101

Using UEFI System Utilities ....................................................................................................................... 101

Flexible boot control .................................................................................................................................. 102

Restoring and customizing configuration settings ..................................................................................... 102

Secure Boot configuration ......................................................................................................................... 102

Embedded UEFI shell................................................................................................................................ 103

Embedded Diagnostics option ................................................................................................................... 103

iLO RESTful API support for UEFI ............................................................................................................ 103

Re-entering the server serial number and product ID ............................................................................... 104

Utilities and features ............................................................................................................................................. 104

HPE Smart Storage Administrator ............................................................................................................. 104

Automatic Server Recovery ....................................................................................................................... 104

USB support .............................................................................................................................................. 105

Redundant ROM support........................................................................................................................... 105

Keeping the system current .................................................................................................................................. 105

Access to Hewlett Packard Enterprise Support Materials ......................................................................... 105

Updating firmware or System ROM ........................................................................................................... 105

Drivers ....................................................................................................................................................... 107

Software and firmware............................................................................................................................... 108

Operating System Version Support ........................................................................................................... 108

Version control........................................................................................................................................... 108

Operating systems and virtualization software support for ProLiant servers ............................................. 108

HPE Technology Service Portfolio ............................................................................................................ 108

Change control and proactive notification ................................................................................................. 109

Troubleshooting .................................................................................................................................... 110

Troubleshooting resources ................................................................................................................................... 110

System battery replacement ................................................................................................................. 111

Warranty and regulatory information ..................................................................................................... 113

Warranty information ............................................................................................................................................ 113

Regulatory information ......................................................................................................................................... 113

Safety and regulatory compliance ............................................................................................................. 113

Belarus Kazakhstan Russia marking ......................................................................................................... 113

Turkey RoHS material content declaration ................................................................................................ 114

Ukraine RoHS material content declaration .............................................................................................. 114

Electrostatic discharge .......................................................................................................................... 115

Preventing electrostatic discharge ....................................................................................................................... 115

Grounding methods to prevent electrostatic discharge ........................................................................................ 115

Specifications ........................................................................................................................................ 116

Environmental specifications ................................................................................................................................ 116

Server specifications ............................................................................................................................................ 116

Power supply specifications ................................................................................................................................. 117

Hot-plug power supply calculations ...................................................................................................................... 117

Support and other resources ................................................................................................................ 118

Accessing Hewlett Packard Enterprise Support ................................................................................................... 118

Information to collect ................................................................................................................................. 118

Accessing updates ............................................................................................................................................... 118

Websites ............................................................................................................................................................... 118

Customer Self Repair ........................................................................................................................................... 119

Remote support .................................................................................................................................................... 126

Acronyms and abbreviations................................................................................................................. 127

Documentation feedback ...................................................................................................................... 131

Index ..................................................................................................................................................... 132

Contents 5

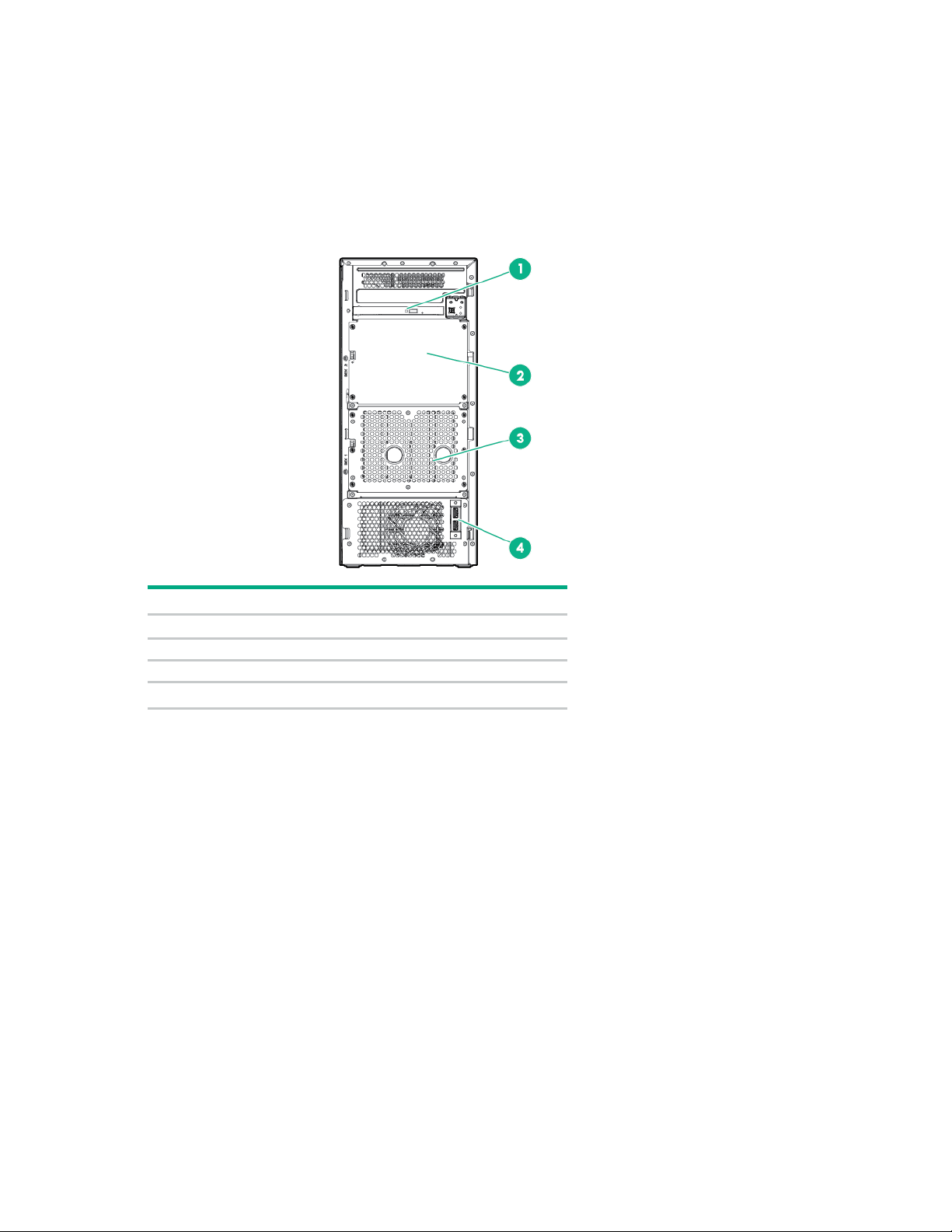

Component identification

Item

Description

Optical drive (optional)

2

Box 2

3

Box 1

USB 3.0 connectors

Front panel components

1

4

Component identification 6

Front panel LEDs and buttons

Item

Description

Status

Power On/Standby button

Solid green = System on

•

•

•

•

Health LED

Solid green = Normal

NIC status LED

Solid green = Link to network

1

and system power LED

Flashing green (1 flash per second) = Performing power on sequence

Solid amber = System in standby

Off = No power present

If the system power LED is off, verify the following conditions:

Facility power is present.

The power supply is installed and is working correctly.

The power cord is attached and is connected to a power source.

The front I/O cable is connected.

2

3

Flashing green (1 flash per second) = iLO is rebooting

Flashing amber = System degraded

Flashing red (1 flash per second) = System critical

If the health LED indicates a degraded or critical state, review the

system IML ("Integrated Management Log" on page 99) or use iLO

("HPE iLO" on page 97) to review the system health status.

Flashing green (1 flash per second) = Network active

Off = No network activity

When all three LEDs described in this table and the UID button/LED on the rear panel flash

simultaneously, a power fault has occurred. For more information, see "Front panel LED power fault

codes (on page 7)." For the location of the UID button/LED on the rear panel, see "Rear panel LEDs (on

page 9)".

Front panel LED power fault codes

The following table provides a list of power fault codes, and the subsystems that are affected. Not all

power faults are used by all servers.

Component identification 7

behavior

System board

1 flash

Processor

2 flashes

Memory

3 flashes

Riser board PCIe slots

4 flashes

FlexibleLOM

5 flashes

controller/Smart SAS HBA controller

6 flashes

System board PCIe slots

7 flashes

Power backplane or storage backplane

8 flashes

Power supply

9 flashes

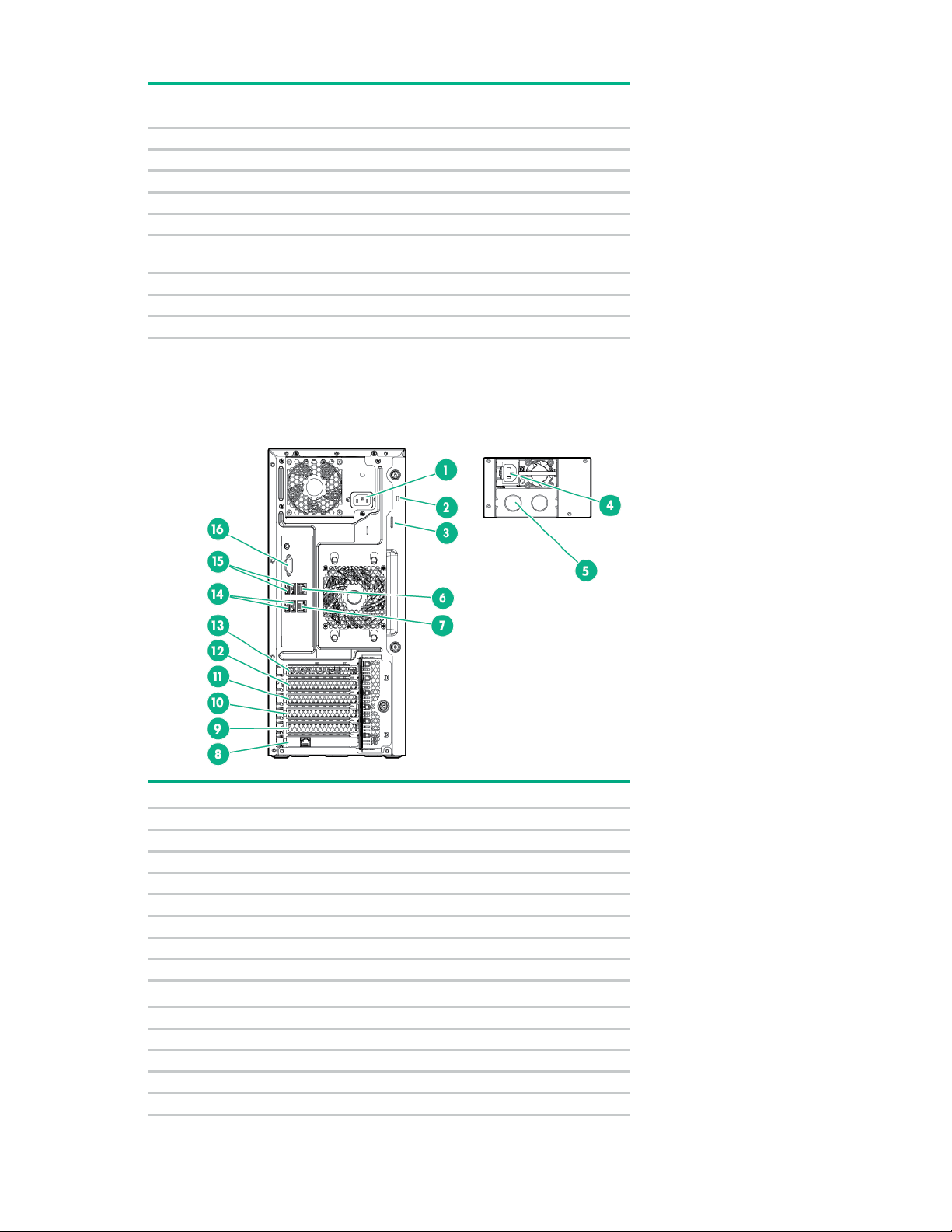

1

Non-hot-plug power supply

2

Kensington security slot

3

Padlock slot

4

Power supply bay 1 of the hot-plug power supply (optional)

5

Power supply bay 2 of the hot-plug power supply (optional)

6

NIC connector 1

7

NIC connector 2

8

Dedicated iLO port (optional)

Slot 5 PCIe3x8 (8, 4, 1)

10

Slot 4 PCIe3x4 (4, 1)

11

Slot 3 PCIe3x8 (8, 4, 1)

12

Slot 2 PCIe3x4 (4, 1)

13

Slot 1 PCIe3x16 (16, 8, 4, 1)

14

USB 2.0 connectors

Subsystem

Removable HPE Flexible Smart Array

Front panel LED

For more information, see "Front panel LEDs and buttons (on page 7)."

Rear panel components

Item Description

9

Component identification 8

Item

Description

15

USB 3.0 connectors

16

Video connector

Power supply LED

Solid green = Normal

•

•

•

•

iLO link LED

Green = Linked to network

iLO activity LED

Green or flashing green = Network activity

NIC activity LED

Green or flashing green = Network activity

NIC link LED

Green = Linked to network

UID button/LED

Solid blue = Activated

•

•

•

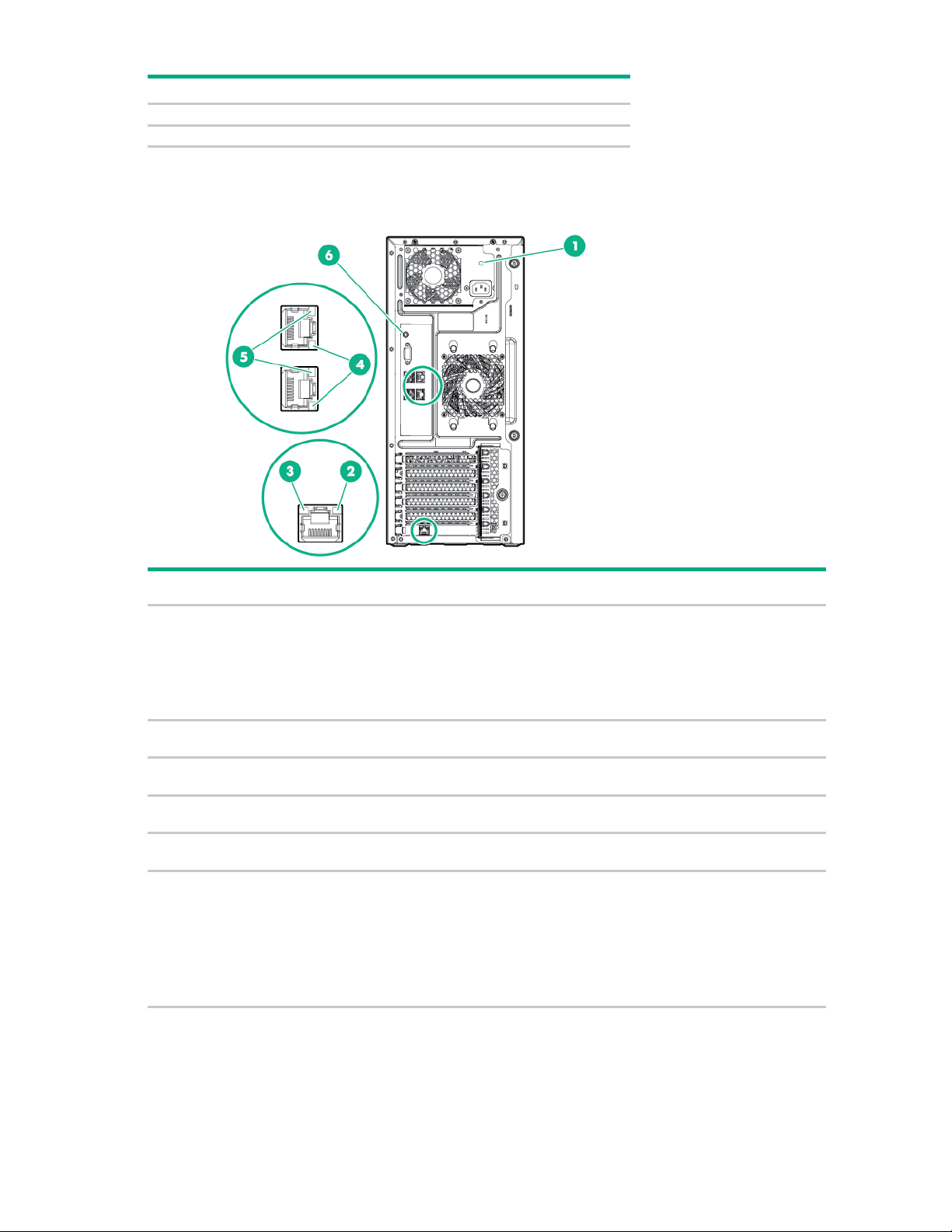

Rear panel LEDs

Item Description Status

1

Off = One or more of the following conditions exists:

Power is unavailable

Power supply failed

Power supply is in standby mode

Power supply error

2

Off = No network connection

3

Off = No network activity

4

Off = No network activity

5

Off = No network connection

6

Flashing blue:

1 flash per second = Remote management or firmware upgrade in

progress

4 flashes per second = iLO manual reboot sequence initiated

8 flashes per second = iLO manual reboot sequence in progress

Off = Deactivated

Component identification 9

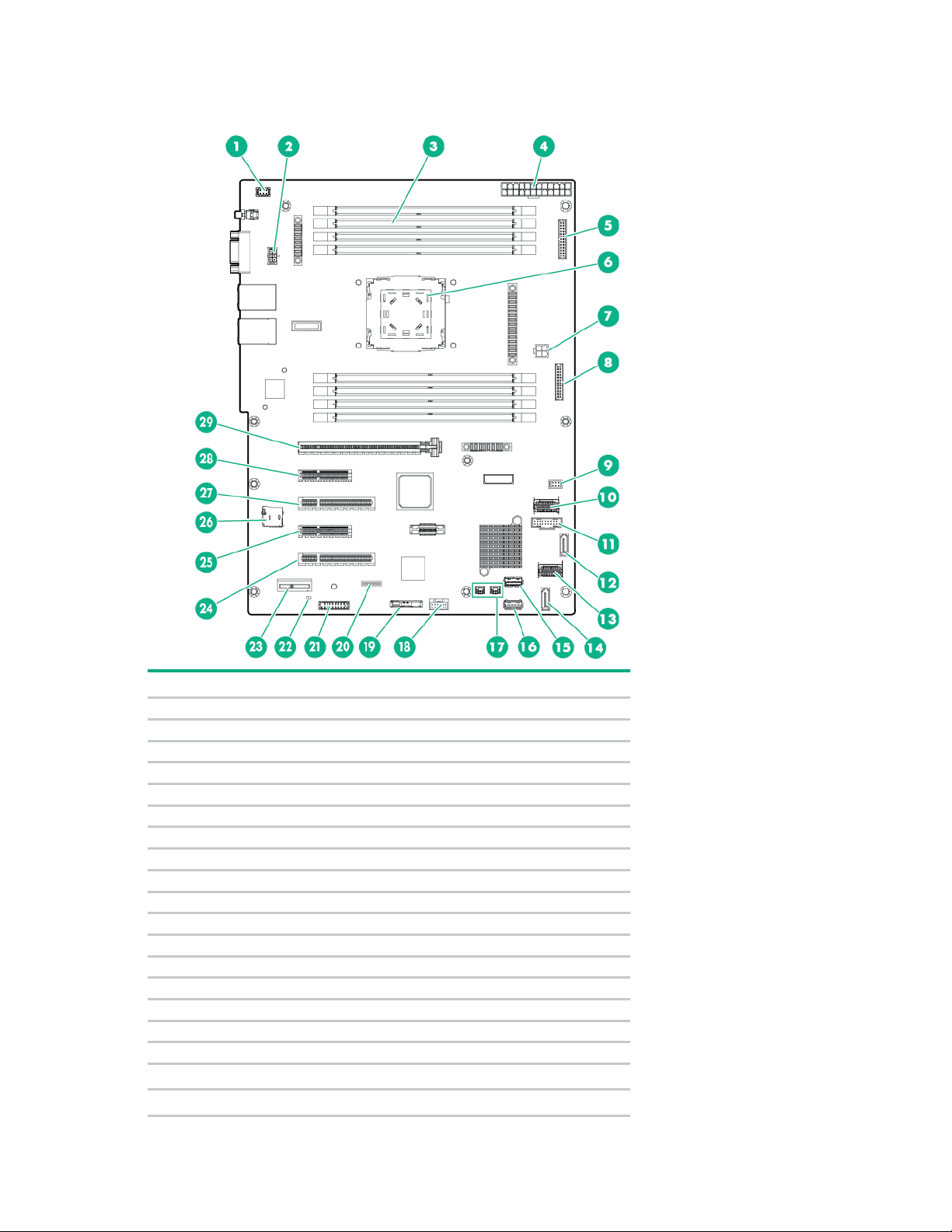

System board components

1

Fan connector 3

2

Fan connector 2

3

DIMM slots

4

24-pin power supply connector

5

RPSU connector

6

Processor

7

4-pin power supply connector

8

Front I/O connector

9

Fan connector 1

10

Mini-SAS connector 1

11

Front USB 3.0 connector

12

SATA connector 2 (for M.2 SSD 2)

13

Mini-SAS connector 2

14

SATA connector 1 (for M.2 SSD 1 or optical drive)

15

Internal USB 3.0 connector

16

Internal USB 2.0 connector

17

Storage backup power connector

Smart Storage Battery connector

System battery

Item Description

18

19

Component identification 10

Item

Description

20

System maintenance switch

21

TPM connector

22

NMI header

23

Dedicated iLO port connector

24

Slot 5 PCIe3 x8 (8, 4, 1)

25

Slot 4 PCIe3 x4 (4, 1)

26

microSD card slot

27

Slot 3 PCIe3 x8 (8, 4, 1)

28

Slot 2 PCIe3 x4 (4, 1)

29

Slot 1 PCIe3 x16 (16, 8, 4, 1)

Off

Off = iLO 4 security is enabled.

Off

Off = System configuration can be

S3

Off

Reserved

S4

Off

Reserved

Off

Off = Power-on password is enabled.

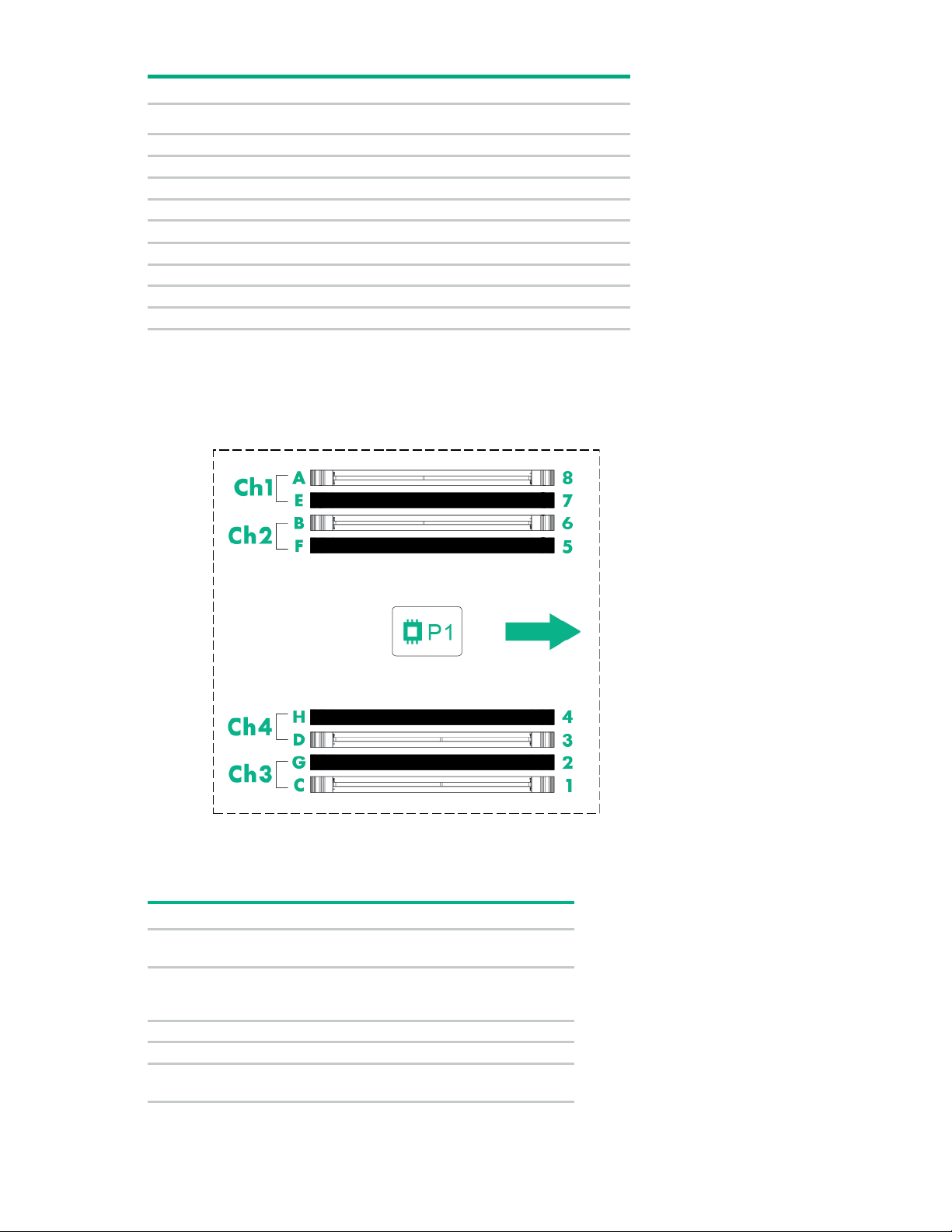

DIMM slot locations

DIMM slots are numbered sequentially (1 through 8) for the processor. The supported AMP modes use

the letter assignments for population guidelines.

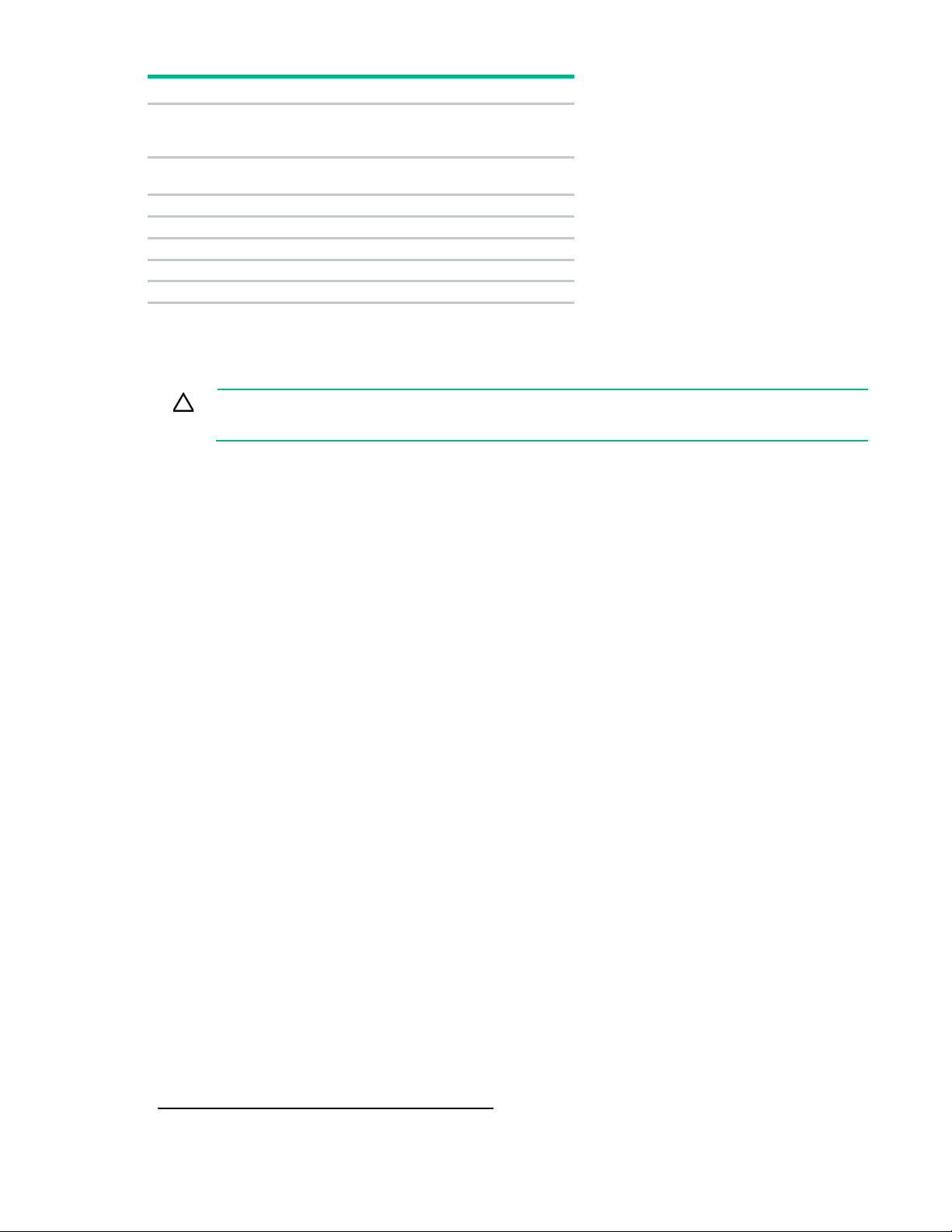

System maintenance switch

The arrow points to the front of the server.

Position Default Function

S1

S2

S5

On = iLO 4 security is disabled.

changed.

On = System configuration is locked.

On = Power-on password is disabled.

Component identification 11

Position

Default

Function

Off

Off = No function

Off

Off = Set default boot mode to UEFI.

S8

—

Reserved

S9

—

Reserved

S10

—

Reserved

S11

—

Reserved

S12

—

Reserved

S6

S7

On = ROM reads system

configuration as invalid.

On = Set default boot mode to legacy.

To access the redundant ROM, set S1, S5, and S6 to On.

When the system maintenance S6 switch is set to the On position, the system will erase all system

configuration settings from both CMOS and NVRAM on the next reboot.

CAUTION: Clearing CMOS and/or NVRAM deletes configuration information. Be sure to

properly configure the server or data loss could occur.

Before using the S7 switch to change the boot mode to Legacy BIOS Mode, you must first disable the

Dynamic Smart Array B140i Controller.

To disable the Dynamic Smart Array B140i Controller:

1. Reboot the server.

The server restarts and the POST screen appears.

2. Press F9.

The System Utilities screen appears.

3. Select System Configuration → BIOS/Platform Configuration (RBSU) → System Options →

SATA Controller Options → Embedded SATA Configuration, and then press Enter.

4. Select Enable SATA AHCI Support, and then press Enter.

5. Press F10 to save the selection.

6. Press Y to save the changes.

The Change saved confirmation prompt appears.

7. Select Exit and resume system boot, and press Enter.

The server continues the normal boot process.

NMI functionality

An NMI crash dump creates a crash dump log before resetting a system which is not responding.

Crash dump log analysis is an essential part of diagnosing reliability problems, such as failures of

operating systems, device drivers, and applications. Many crashes freeze a system, and the only

available action for administrators is to restart the system. Resetting the system erases any information

which could support problem analysis, but the NMI feature preserves that information by performing a

memory dump before a system reset.

To force the system to invoke the NMI handler and generate a crash dump log, do one of the following:

• Use the iLO Virtual NMI feature.

• Short the NMI header ("System board components" on page 10).

For more information, see the Hewlett Packard Enterprise website

(http://www.hpe.com/support/NMI-CrashDump).

Component identification 12

Fan locations

Item

Description

1

Default system fan (92 x 32 mm)

Upgrade system fan (92 x 38 mm)

PCI fan

2

3

The option is required to replace the default system fan when a 140 W workstation processor or

SAS SSD drives are installed.

The PCI fan is part of the PCI fan and baffle option. The option is required when a storage

controller, GPU card or any expansion board is installed in the PCIe slot area except the

dedicated iLO module.

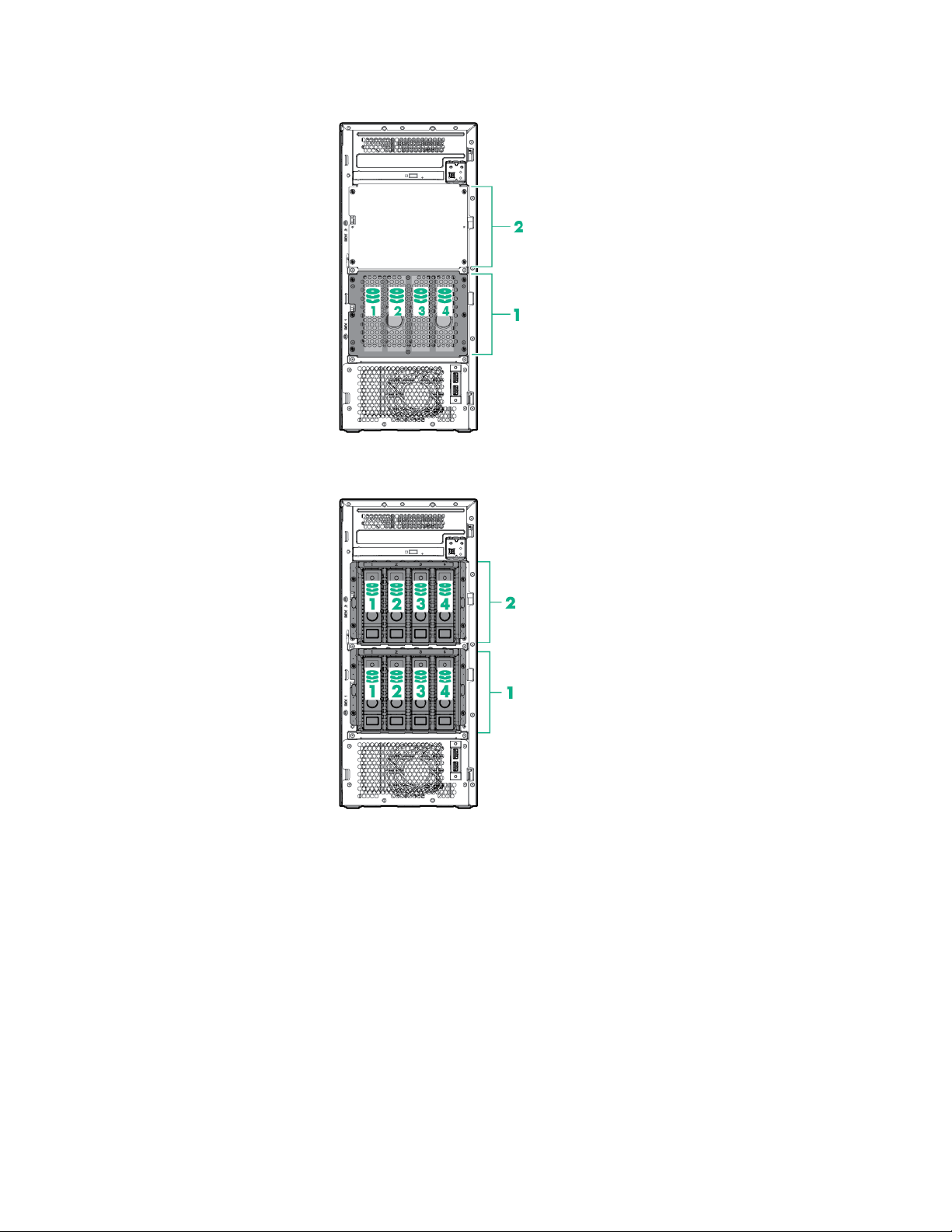

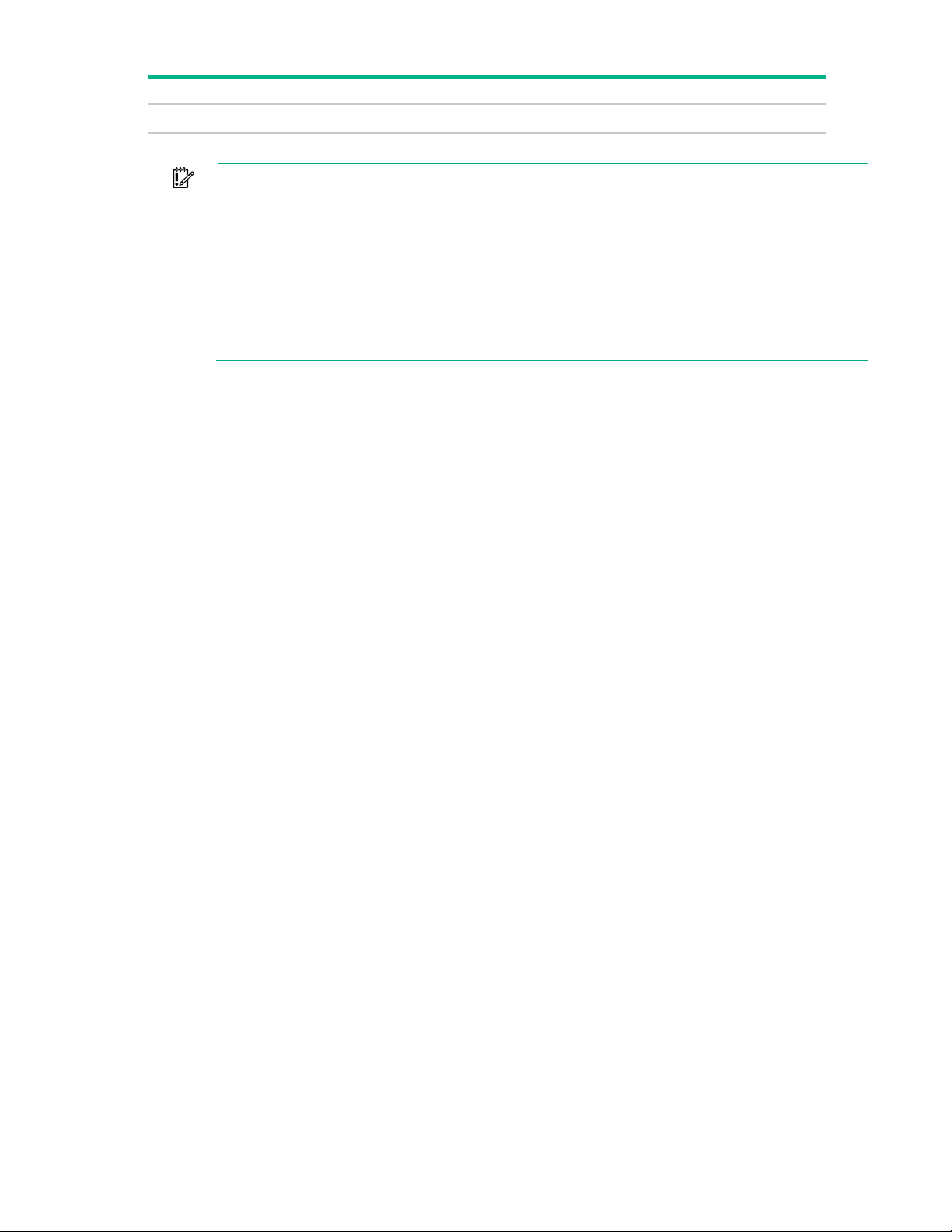

Drive numbering

The following images show the drive numbering for each of the supported drive configurations. For drive

box numbering information, see "Front panel components (on page 6)."

With optional drive cages installed, the server supports up to 4 LFF non-hot-plug drives, 8 LFF hot-plug

drives or 16 SFF hot-plug drives. If only one drive cage is installed, it must be installed in box 1. The server

does not support mixing SFF and LFF drives.

Hewlett Packard Enterprise recommends that you populate drive bays starting with the lowest drive

number. Drives are numbered from left to right in each component box.

Component identification 13

• Four-bay LFF non-hot-plug drive model

• Four-bay LFF hot-plug drive model

Component identification 14

• Eight-bay SFF hot-plug drive model

Item

LED

Status

Definition

1

Locate

Solid blue

The drive is being identified by a host application.

Flashing blue

The drive carrier firmware is being updated or requires an

2

Activity ring

Rotating green

Drive activity

Off

No drive activity

Do not remove

Solid white

Do not remove the drive. Removing the drive causes one or

Off

Removing the drive does not cause a logical drive to fail.

4

Drive status

Solid green

The drive is a member of one or more logical drives.

Flashing green

The drive is rebuilding or performing a RAID migration, strip size

Flashing

The drive is a member of one or more logical drives and predicts

Flashing amber

The drive is not configured and predicts the drive will fail.

Solid amber

The drive has failed.

Hot-plug drive LED definitions

3

update.

more of the logical drives to fail.

amber/green

migration, capacity expansion, or logical drive extension, or is

erasing.

the drive will fail.

Component identification 15

Item

LED

Status

Definition

Off

The drive is not configured by a RAID controller.

SAS connectors operate in AHCI or Legacy mode.

The blue Locate LED is behind the release lever and is visible when illuminated.

IMPORTANT: The Dynamic Smart Array B140i Controller is only available in UEFI Boot

Mode. It cannot be enabled in Legacy BIOS Boot Mode. If the B140i controller is disabled,

drives connected to the system board MiniUnder this condition:

• The drives cannot be a part of a hardware RAID or a logical drive.

• The Locate, Drive status, and Do not remove LEDs of the affected drives are disabled.

Use BIOS/Platform Configuration (RBSU) in the UEFI System Utilities ("HPE UEFI System

Utilities" on page 101) to enable or disable the B140i controller (System Configuration →

BIOS/Platform Configuration (RBSU) → System Options → SATA Controller Options →

Embedded SATA Configuration).

Component identification 16

Operations

Power down the server

Before powering down the server for any upgrade or maintenance procedures, perform a backup of

critical server data and programs.

IMPORTANT: When the server is in standby mode, auxiliary power is still being provided to

the system.

To power down the server, use one of the following methods:

• Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server enters

standby mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server to enter

standby mode.

This method forces the server to enter standby mode without properly exiting applications and the

OS. If an application stops responding, you can use this method to force a shutdown.

• Use a virtual power button selection through iLO 4.

This method initiates a controlled remote shutdown of applications and the OS before the server

enters standby mode.

Before proceeding, verify the server is in standby mode by observing that the system power LED is

amber.

Remove the access panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: For proper cooling do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed.

CAUTION: To prevent damage to electrical components, take the appropriate anti-static

precautions before beginning any installation, removal, or replacement procedure. Improper

1. Power down the server (on page 17).

2. Remove all power:

3. If a Kensington security cable is installed, disconnect it from the rear panel. See the security cable

4. Place the server on its side.

5. Remove the access panel:

grounding can cause electrostatic discharge.

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

documentation for instructions.

a. Loosen the access panel thumbscrews.

Operations 17

b.

Slide and remove the access panel from the server.

Install the access panel

1. Install the access panel:

a. Place the access panel on the chassis, and slide it towards the front of the server.

b. Tighten the thumbscrews.

2. Return the server to an upright position.

3. If a Kensington security cable was removed, connect it to the rear panel. See the security cable

documentation for instructions.

4. Connect each power cord to the server.

5. Connect each power cord to the power source.

6. Power up the server.

Operations 18

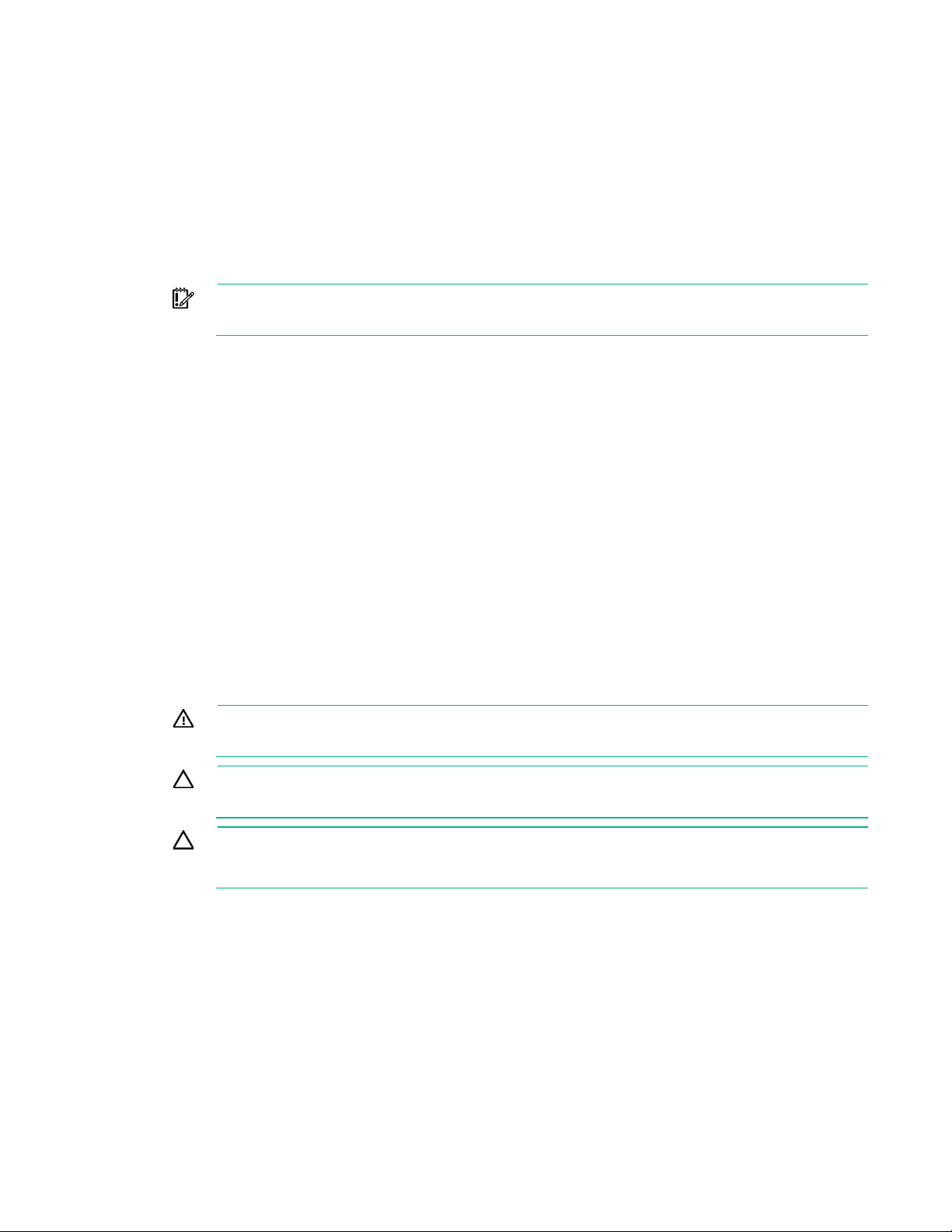

Remove the front bezel

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. Unlock the internal locker. Then open and remove the front bezel.

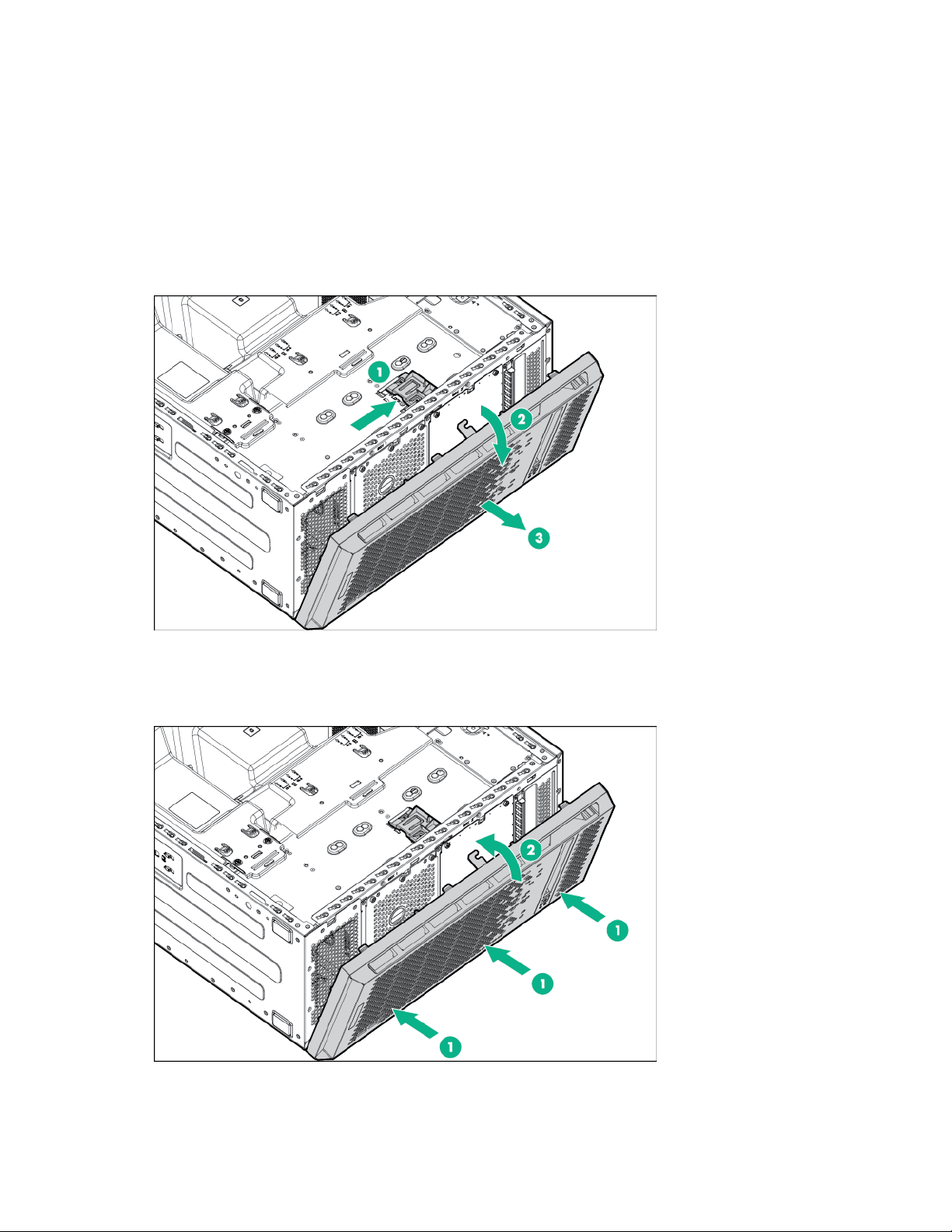

Install the front bezel

1. Install and close the front bezel.

2. Do one of the following:

Operations 19

o

Lock the internal locker.

o Leave the internal locker in unlock position if you want to access the front panel any time without

removing the access panel.

3. Install the access panel (on page 18).

4. Return the server to an upright position.

5. Connect each power cord to the server.

6. Connect each power cord to the power source.

7. Power up the server.

Remove the PCI air baffle

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. Remove the PCI air baffle.

Install the PCI air baffle

CAUTION: For proper cooling do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed.

Operations 20

1.

Install the PCI air baffle.

2. Install the access panel (on page 18).

3. Return the server to an upright position.

4. Connect each power cord to the server.

5. Connect each power cord to the power source.

6. Power up the server.

Remove the system air baffle

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. If installed, remove the PCI air baffle (on page 20).

Operations 21

6.

Remove the system air baffle.

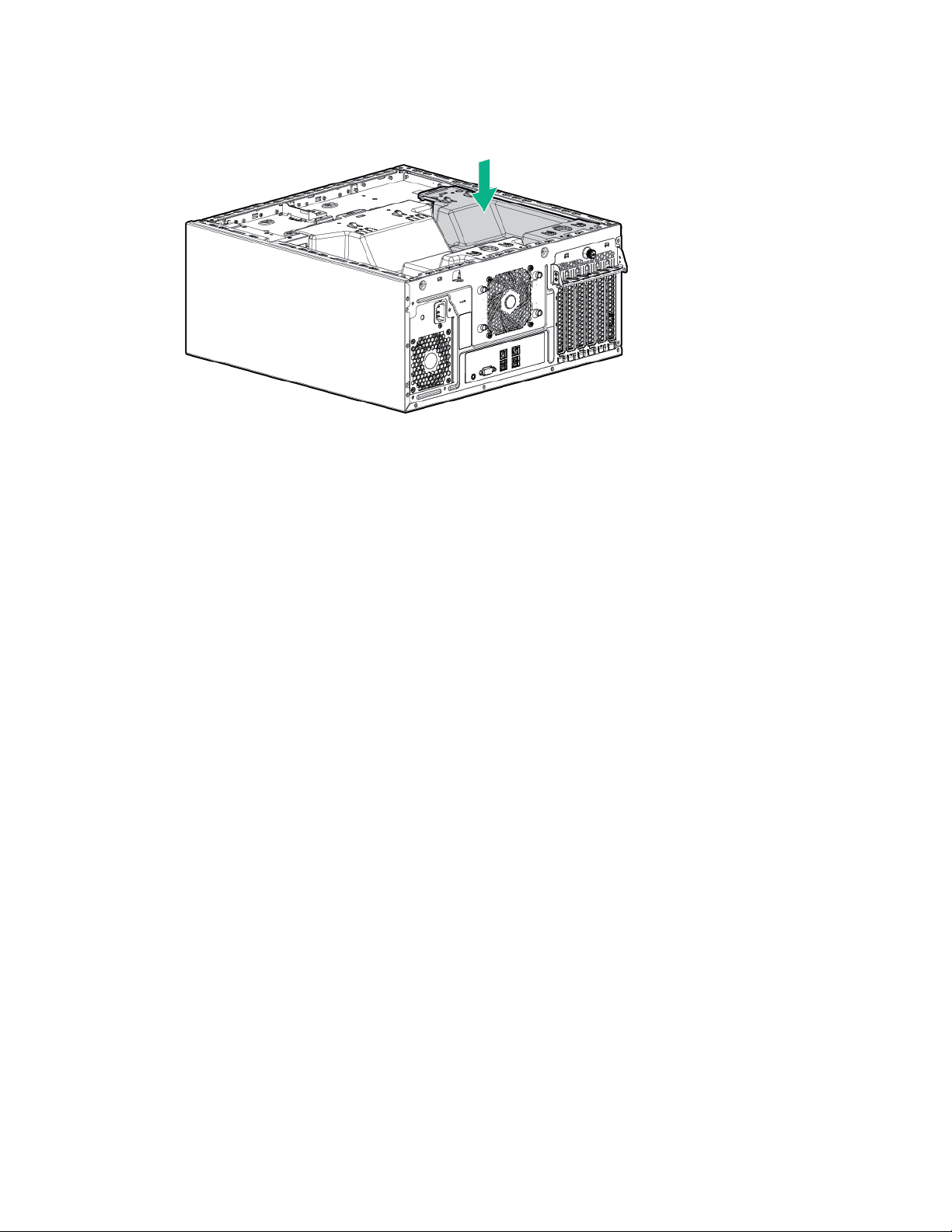

Install the system air baffle

CAUTION: For proper cooling do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed.

1. Install the system air baffle.

2. Install the access panel (on page 18).

3. Return the server to an upright position.

4. Connect each power cord to the server.

5. Connect each power cord to the power source.

6. Power up the server.

Operations 22

Setup

Optional services

Delivered by experienced, certified engineers, HPE support services help you keep your servers up and

running with support packages tailored specifically for HPE ProLiant systems. HPE support services let

you integrate both hardware and software support into a single package. A number of service level

options are available to meet your business and IT needs.

HPE support services offer upgraded service levels to expand the standard product warranty with

easy-to-buy, easy-to-use support packages that will help you make the most of your server investments.

Some of the HPE support services for hardware, software or both are:

• Foundation Care – Keep systems running.

o 6-Hour Call-to-Repair

o 4-Hour 24x7

o Next Business Day

• Proactive Care – Help prevent service incidents and get you to technical experts when there is one.

o 6-Hour Call-to-Repair

o 4-Hour 24x7

o Next Business Day

• Startup and implementation services for both hardware and software

• HPE Education Services – Help train your IT staff.

For more information on HPE support services, see the Hewlett Packard Enterprise website

(http://www.hpe.com/services).

Optimum environment

When installing the server, select a location that meets the environmental standards described in this

Space and airflow requirements

section.

Tower server

In a tower configuration, leave at least a 7.6-cm (3-in) clearance space at the front and back of the server

for proper ventilation.

Rack server

To allow for servicing and adequate airflow, observe the following space and airflow requirements when

deciding where to install a rack:

• Leave a minimum clearance of 85.09 cm (33.5 in) in front of the rack.

• Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

• Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to the back of another rack

or row of racks.

Setup 23

Hewlett Packard Enterprise servers draw in cool air through the front door and expel warm air through the

arrangement ensures proper airflow. Using a rack without blanking panels results in improper

the server beyond the maximum

rear door. Therefore, the front and rear rack doors must be adequately ventilated to allow ambient room

air to enter the cabinet, and the rear door must be adequately ventilated to allow the warm air to escape

from the cabinet.

CAUTION: To prevent improper cooling and damage to the equipment, do not block the

ventilation openings.

When vertical space in the rack is not filled by a server or rack component, the gaps between the

components cause changes in airflow through the rack and across the servers. Cover all gaps with

blanking panels to maintain proper airflow.

CAUTION: Always use blanking panels to fill empty vertical spaces in the rack. This

cooling that can lead to thermal damage.

The 9000 and 10000 Series Racks provide proper server cooling from flow-through perforations in the

front and rear doors that provide 64 percent open area for ventilation.

CAUTION: When using a Compaq branded 7000 series rack, install the high airflow rack

door insert (PN 327281-B21 for 42U rack, PN 157847-B21 for 22U rack) to provide proper

front-to-back airflow and cooling.

CAUTION: If a third-party rack is used, observe the following additional requirements to

ensure adequate airflow and to prevent damage to the equipment:

• Front and rear doors—If the 42U rack includes closing front and rear doors, you must allow

5,350 sq cm (830 sq in) of holes evenly distributed from top to bottom to permit adequate

airflow (equivalent to the required 64 percent open area for ventilation).

• Side—The clearance between the installed rack component and the side panels of the rack

must be a minimum of 7 cm (2.75 in).

Temperature requirements

To ensure continued, safe, and reliable equipment operation, install or position the system in a

well-ventilated, climate-controlled environment.

The maximum recommended TMRA for most server products is 35°C (95°F). The temperature in the

room where the server is located must not exceed 35°C (95°F).

CAUTION: To reduce the risk of damage to the equipment when installing third-party options:

• Do not permit optional equipment to impede airflow around

allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of information technology equipment by licensed electricians. This equipment is designed to

operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992

(code for Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on

options, refer to the product rating label or the user documentation supplied with that option.

WARNING: To reduce the risk of personal injury, fire, or damage to the equipment, do not

overload the AC supply branch circuit that provides power to the rack. Consult the electrical

authority having jurisdiction over wiring and installation requirements of your facility.

Setup 24

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

caused by power surges and voltage spikes and keeps the system in operation during a power

This server is very heavy. To reduce the risk of personal injury or damage to the

Use caution when installing the server in or removing the server from the rack; it is unstable

To reduce the risk of personal injury, electric shock, or damage to the equipment,

regulating uninterruptible power supply. This device protects the hardware from damage

failure.

When installing more than one server, you might need to use additional power distribution devices to

safely provide power to all devices. Observe the following guidelines:

• Balance the server power load between available AC supply branch circuits.

• Do not allow the overall system AC current load to exceed 80% of the branch circuit AC current

rating.

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for the server.

For more information on the hot-plug power supply and calculators to determine server power

consumption in various system configurations, see the Hewlett Packard Enterprise Power Advisor

website (http://www.hpe.com/info/poweradvisor/online).

Electrical grounding requirements

The server must be grounded properly for proper operation and safety. In the United States, you must

install the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article 250, as

well as any local and regional building codes. In Canada, you must install the equipment in accordance

with Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries, you

must install the equipment in accordance with any regional or national electrical wiring codes, such as the

International Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be

sure that all power distribution devices used in the installation, such as branch wiring and receptacles, are

listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same

power source, Hewlett Packard Enterprise recommends the use of a PDU that is either permanently wired

to the building’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug.

NEMA locking-style plugs or those complying with IEC 60309 are considered suitable for this purpose.

Using common power outlet strips for the server is not recommended.

Server warnings and cautions

WARNING:

equipment:

• Observe local occupational health and safety requirements and guidelines for manual

material handling.

• Get help to lift and stabilize the product during installation or removal, especially when the

product is not fastened to the rails. Hewlett Packard Enterprise recommends that a

minimum of two people are required for all rack server installations. A third person may be

required to help align the server if the server is installed higher than chest level.

•

when not fastened to the rails.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

WARNING:

remove the power cord to remove power from the server. The front panel Power On/Standby

button does not completely shut off system power. Portions of the power supply and some

internal circuitry remain active until AC power is removed.

Setup 25

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

power surges and voltage spikes and keeps the system in operation during a power

d improper cooling

To reduce the risk of electric shock, fire, or damage to the equipment, do not plug

regulating uninterruptible power supply. This device protects the hardware from damage

caused by

failure.

CAUTION: Do not operate the server for long periods with the access panel open or

removed. Operating the server in this manner results in improper airflow an

that can lead to thermal damage.

Identifying tower server shipping carton contents

Unpack the server shipping carton and locate the materials and documentation necessary for installing

the server.

The contents of the server shipping carton include:

• Server

• Power cord

• Hardware documentation

In addition to the supplied items, you might need:

• Hardware options

• Operating system or application software

• PDU

• Torx T-15 screwdriver

Installing hardware options

Install any hardware options before initializing the server. For options installation information, refer to the

option documentation. For server-specific information, refer to "Hardware options installation (on page

30)."

Setting up a tower server

Follow the steps in this section to set up a tower server.

1. Place the server on a flat, stable surface.

2. Connect peripheral devices to the server. ("Rear panel components" on page 8)

WARNING:

telephone or telecommunications connectors into RJ-45 connectors.

3. Connect the power cord to the rear of the server.

4. Connect the power cord to the AC power source.

Setup 26

WARNING: To reduce the risk of electric shock or damage to the equipment:

Do not route the power cord where it can be walked on or pinched by items placed against

This server is very heavy. To reduce the risk of personal injury or damage to the

Use caution when installing the server in or removing the server from the rack; it is unstable

Always plan the rack installation so that the heaviest item is on the bottom of the

to the equipment, do not plug

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

•

it. Pay particular attention to the plug, electrical outlet, and the point where the cord extends

from the server.

Installing the server into a rack

To install the server into a rack with square, round, or threaded holes, refer to the instructions that ship

with the rack hardware kit.

If you are installing the server into a telco rack, order the appropriate option kit at the RackSolutions

website (http://www.racksolutions.com/hp). Follow the server-specific instructions on the website to

install the rack brackets.

Use the following information when connecting peripheral cables and power cords to the server.

WARNING:

equipment:

• Observe local occupational health and safety requirements and guidelines for manual

material handling.

• Get help to lift and stabilize the product during installation or removal, especially when the

product is not fastened to the rails. Hewlett Packard Enterprise recommends that a

minimum of two people are required for all rack server installations. A third person may be

required to help align the server if the server is installed higher than chest level.

•

To install the server in a Hewlett Packard Enterprise, Compaq-branded, Telco, or a third-party rack:

1. Prepare the server for rack installation by installing the HPE 100kg Sliding Shelf option kit (PN

234672-B21). For instructions, see the option kit documentation.

2. Connect peripheral devices to the server. For information on identifying connectors, see "Rear panel

components (on page 8)."

3. Connect each power cord to the server.

4. Connect each power cord to the power source.

when not fastened to the rails.

CAUTION:

rack. Install the heaviest item first, and continue to populate the rack from the bottom to the top.

WARNING: To reduce the risk of electric shock, fire, or damage

telephone or telecommunications connectors into RJ-45 connectors.

Setup 27

all

Do not route the power cord where it can be walked on or pinched by items placed against

from the pallet. An empty 42U rack

When installing a server in a telco rack, be sure that the rack frame is adequately

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

•

it. Pay particular attention to the plug, electrical outlet, and the point where the cord extends

from the server.

Rack warnings

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARNING: To reduce the risk of personal injury or equipment damage when unloading a

rack:

• At least two people are needed to safely unload the rack

can weigh as much as 115 kg (253 lb), can stand more than 2.1 m (7 ft) tall, and might

become unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp from the pallet. Always

handle the rack from both sides.

WARNING:

secured to the top and bottom of the building structure.

Installing the operating system

This ProLiant server does not ship with provisioning media. Everything needed to manage and install the

system software and firmware is preloaded on the server.

To operate properly, the server must have a supported operating system. Attempting to run an

unsupported operating system can cause serious and unpredictable results. For the latest information on

operating system support, see the Hewlett Packard Enterprise website

(http://www.hpe.com/info/supportos).

Failure to observe UEFI requirements for ProLiant Gen9 servers can result in errors installing the

operating system, failure to recognize boot media, and other boot failures. For more information on these

requirements, see the HPE UEFI Requirements on the Hewlett Packard Enterprise website

(http://www.hpe.com/info/ProLiantUEFI/docs).

To install an operating system on the server, use one of the following methods:

• Intelligent Provisioning—For single-server deployment, updating, and provisioning capabilities.

To install an operating system on the server with Intelligent Provisioning (local or remote):

a. Connect the Ethernet cable between the network connector on the server and a network jack.

b. Press the Power On/Standby button.

c. During server POST, press F10.

Setup 28

d.

Complete the initial Preferences and Registration portion of Intelligent Provisioning (on page 99).

e. At the 1 Start screen, click Configure and Install.

f. To finish the installation, follow the onscreen prompts. An Internet connection is required to

update the firmware and systems software.

• Insight Control server provisioning—For multi-server remote OS deployment, use Insight Control

server provisioning for an automated solution. For more information, see the Insight Control

documentation on the Hewlett Packard Enterprise website

(http://www.hpe.com/info/insightcontrol/docs).

For additional system software and firmware updates, download the Service Pack for ProLiant from the

Hewlett Packard Enterprise website (http://www.hpe.com/servers/spp/download). Software and

firmware must be updated before using the server for the first time, unless any installed software or

components require an older version.

For more information, see "Keeping the system current (on page 105)."

For more information on using these installation methods, see the Hewlett Packard Enterprise website

(http://www.hpe.com/info/ilo).

Powering on and selecting boot options in UEFI Boot Mode

On servers operating in UEFI Boot Mode, the boot controller and boot order are set automatically.

1. Press the Power On/Standby button.

2. During the initial boot:

o To modify the server configuration ROM default settings, press the F9 key in the ProLiant POST

screen to enter the UEFI System Utilities screen. By default, the System Utilities menus are in the

English language.

o If you do not need to modify the server configuration and are ready to install the system software,

press the F10 key to access Intelligent Provisioning.

For more information on automatic configuration, see the UEFI documentation on the Hewlett Packard

Enterprise website (http://www.hpe.com/info/ProLiantUEFI/docs).

Registering the server

To experience quicker service and more efficient support, register the product at the Hewlett Packard

Enterprise Product Registration website (http://www.hpe.com/info/register).

Setup 29

Hardware options installation

Introduction

If more than one option is being installed, read the installation instructions for all the hardware options and

identify similar steps to streamline the installation process.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server before

beginning any installation procedure. Improper grounding can cause electrostatic discharge.

Drive cage options

4-bay LFF hot-plug drive cage option

To install the component:

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. Remove the front bezel (on page 19).

6. If installed, remove the PCI air baffle (on page 20).

7. Remove the system air baffle (on page 21).

8. Disconnect all existing drive cage cables.

Hardware options installation 30

9.

Remove the installed drive cage assembly.

10. Install the 4 LFF hot-plug drive cage assembly in box 1.

11. Connect the drive cage cables:

a. Connect one end of the Mini-SAS cable to the drive backplane and the other end to the system

board.

b. Connect the 8-pin power cable to the drive backplane.

Hardware options installation 31

c.

Route the cables underneath the metal tabs.

If the kit contents include the drive power good cable, disregard it.

12. Install the drives, based on the drive numbering (on page 13) sequence. Start from the drive bay with

the lowest number in box 1.

13. If installing a 4-bay LFF hot-plug drive cage in box 2, remove the drive cage blank.

Hardware options installation 32

14.

Install the 4-bay LFF hot-plug drive cage assembly in box 2.

15. Connect the drive cage cables. See "4-bay LFF hot-plug drive cabling (on page 84)." Then, install

the drives.

16. Install the system air baffle (on page 22).

17. If removed, install the PCI air baffle ("Install the PCI air baffle" on page 20).

18. Install the front bezel (on page 19).

19. Install the access panel (on page 18).

20. Return the server to an upright position.

21. Connect each power cord to the server.

22. Connect each power cord to the power source.

23. Power up the server.

8-bay SFF hot-plug drive cage option

To install the component:

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. Remove the front bezel (on page 19).

6. If installed, remove the PCI air baffle (on page 20).

7. Remove the system air baffle (on page 21).

8. Disconnect all existing drive cage cables.

Hardware options installation 33

9.

Remove the installed drive cage assembly.

10. Install the 8 SFF hot-plug drive cage in box 1.

11. Connect the drive cage cables:

a. Connect one end of the Mini-SAS cable to the drive backplane and the other end to the system

board.

b. Connect the 8-pin power cable to the drive backplane.

Hardware options installation 34

c.

Route the cables underneath the metal tabs.

If the kit contents include the drive power good cable, disregard it.

12. Install the drives, based on the drive numbering (on page 13) sequence. Start from the drive bay with

the lowest number in box 1.

13. If installing a 8-bay SFF hot-plug drive cage in box 2, remove the drive cage blank.

Hardware options installation 35

14.

Install the 8-bay SFF hot-plug drive cage assembly in box 2.

15. If two 8-bay SFF hot-plug drive cages are installed, install the storage controller ("Installing the

storage controller and FBWC module options" on page 46).

16. Connect the drive cage cables. See "8-bay SFF hot-plug drive cabling (on page 86)." Then, install

the drives.

17. Install the system air baffle (on page 22).

18. If removed, install the PCI air baffle ("Install the PCI air baffle" on page 20).

19. Install the front bezel (on page 19).

20. Install the access panel (on page 18).

21. Return the server to an upright position.

22. Connect each power cord to the server.

23. Connect each power cord to the power source.

24. Power up the server.

Drive options

For a list of drive configurations supported in this server, see "Drive numbering (on page 13)."

The embedded storage controller supports SATA drive installation. For SAS drive installation, install a

Host Bus Adapter or a Smart Array Controller board option.

For more information about product features, specifications, options, configurations, and compatibility,

see the product QuickSpecs on the Hewlett Packard Enterprise website (http://www.hpe.com/info/qs).

Drive installation guidelines

When adding drives to the server, observe the following general guidelines:

If installing a drive in a server that previously has no drive installed, reboot the server after the new drive

•

installation. This action enables the drive thermal protection feature. This feature applies to all drives

supported in this server.

The system automatically sets all device numbers.

•

Populate drive bays, based on the drive numbering sequence. Start from the drive bay with the

•

lowest device number ("Drive numbering" on page 13).

• All drives grouped into the same drive array must meet the following criteria:

o

They must be either all SAS or all SATA.

Hardware options installation 36

o

They must be either all hard drives or all solid state drives.

o Drives should be the same capacity to provide the greatest storage space efficiency when drives

are grouped together into the same drive array.

Installing a non-hot-plug drive

AUTION: To prevent improper cooling and thermal damage, do not operate the server

C

unless all bays are populated with either a component or a blank.

To install the component:

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. Remove the front bezel (on page 19).

6. If installed, remove the PCI air baffle (on page 20).

7. Remove the system air baffle (on page 21).

8. Disconnect all existing drive cage cables.

9. Remove the installed drive cage assembly.

10. Use the screws on the drive cage to install the drives.

Hardware options installation 37

11.

Install the drive into the non-hot-plug drive cage.

12. Install the drive cage into the chassis.

Hardware options installation 38

13.

Connect all the drive cables.

14. Install the system air baffle (on page 22).

15. If removed, install the PCI air baffle ("Install the PCI air baffle" on page 20).

16. Install the front bezel (on page 19).

17. Install the access panel (on page 18).

18. Return the server to an upright position.

19. Connect each power cord to the server.

20. Connect each power cord to the power source.

21. Power up the server.

Installing a hot-plug drive

CAUTION: To prevent improper cooling and thermal damage, do not operate the server

unless all bays are populated with either a component or a blank.

To install the component:

1. Remove the drive blank.

Hardware options installation 39

2.

Prepare the drive.

3. Install the drive.

4. If a hot-plug drive is installed into an empty backplane after the initial boot, reboot the system to get

optimal ventilation.

5. Determine the status of the drive from the drive LED definitions ("Hot-plug drive LED definitions" on

page 15).

To configure arrays, see the HPE Smart Storage Administrator User Guide on the Hewlett Packard

Enterprise website (http://www.hpe.com/info/smartstorage/docs).

Drive cable options

Use these drive cable options to install a Host Bus Adapter or a Smart Array Controller board option.

For more information about product features, specifications, options, configurations, and compatibility,

Host Bus Adapter Mini-SAS cable option

see the product QuickSpecs on the Hewlett Packard Enterprise website (http://www.hpe.com/info/qs).

To install the component:

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. If installed, remove the PCI air baffle (on page 20).

6. Remove the system air baffle (on page 21).

7. Disconnect the existing Mini-SAS cables from the drive backplane and the Mini-SAS connectors on

the system board.

Hardware options installation 40

8.

Port 1 controller connection

2

Box 1 drive backplane connection

3

Port 2 controller connection

4

Box 2 drive backplane connection

Port 1 controller connection

2

Mini-SAS port 1 connection

3

Port 2 controller connection

4

Mini-SAS port 2 connection

Connect one end of the cable to the Host Bus Adapter, route the cable underneath the metal tabs,

and then connect the other end to the drive backplane.

o Two 4 LFF hot-plug drive cages connected to a H240 adapter

Item Description

1

o 8 SFF hot-plug drive cage connected to a H240 adapter

Item Description

1

Hardware options installation 41

9.

Install the Host Bus Adapter ("Installing the storage controller and FBWC module options" on page

46).

Hewlett Packard Enterprise recommends installing the H240 Host Bus Adapter in slot 3 or slot 5.

10. If not installed, install the fan included in the PCI fan and baffle option ("PCI fan and baffle option" on

page 58).

11. Install the system air baffle (on page 22).

12. If removed, install the PCI air baffle ("Install the PCI air baffle" on page 20).

13. Install the access panel (on page 18).

14. Return the server to an upright position.

15. Connect each power cord to the server.

16. Connect each power cord to the power source.

17. Power up the server.

Smart Array Controller Mini-SAS cable option

To install the component:

1. Power down the server (on page 17).

2. Remove all power:

a. Disconnect each power cord from the power source.

b. Disconnect each power cord from the server.

3. Place the server on its side.

4. Remove the access panel (on page 17).

5. If installed, remove the PCI air baffle (on page 20).

6. Remove the system air baffle (on page 21).

7. Disconnect the existing Mini-SAS cables from the drive backplane and the Mini-SAS connectors on

the system board.

8. Connect one end of the cable to the Smart Array Controller, route the cable underneath the metal

tabs, and then connect the other end to the drive backplane.

o Two 4 LFF hot-plug drive cages connected to a P440 controller

Hardware options installation 42

Controller connection

2

Port 1 of the Mini-SAS Y-cable to box 1 drive backplane

3

Port 2 of the Mini-SAS Y-cable to box 2 drive backplane

Port 1 controller connection

2

Port 1 of the Mini-SAS Y-cable to box 1 drive backplane

3

Port 2 of the Mini-SAS Y-cable to box 2 drive backplane

Controller connection

Item Description

1

o Two 4 LFF hot-plug drive cages connected to a P840 controller

Item Description

1

o 8 SFF hot-plug drive cage connected to a P440 controller

Item Description

1

Hardware options installation 43

Item Description

Port 1 of the Mini-SAS Y-cable to Mini-SAS port 1 on the drive

Port 2 of the Mini-SAS Y-cable to Mini-SAS port 2 on the drive

Port 1 controller connection

Port 1 of the Mini-SAS Y-cable to Mini-SAS port 1 on the drive

Port 2 of the Mini-SAS Y-cable to Mini-SAS port 2 on the drive

2

3

backplane

backplane

o 8 SFF hot-plug drive cage connected to a P840 controller

Item Description

1

2

3

backplane

backplane

For the second 8 SFF hot-plug drive cage in box 2, connect the second Mini-SAS Y cable to port

2 on the P840 controller.