HPE Apollo 4520 Gen9 Chassis Setup and Installation Guide

Abstract

This document contains setup, installation, and configuration information for the HPE Apollo

4520 Gen9 Chassis. This document is for the person who installs, administers, and

troubleshoots servers and storage systems. Hewlett Packard Enterprise assumes you are

qualified in the servicing of computer equipment and trained in recognizing hazards in

products with hazardous energy levels.

Part Number: 819251-006

Published: September 2018

Edition: 6

©

Copyright 2015-2018 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Contents

Planning the installation.........................................................................5

Identifying components and LEDs........................................................ 9

Verifying the pallet contents..........................................................................................................5

Warnings and cautions..................................................................................................................6

Space and airflow requirements................................................................................................... 7

Temperature requirements............................................................................................................7

Power requirements......................................................................................................................7

Grounding requirements............................................................................................................... 8

Front panel components............................................................................................................... 9

Storage display LEDs.........................................................................................................9

Server front panel components........................................................................................ 10

Server front panel LEDs and buttons............................................................................... 11

Rear panel components..............................................................................................................12

Power supply LEDs .........................................................................................................12

Management module components...................................................................................13

Management module LEDs..............................................................................................14

I/O module components................................................................................................... 14

I/O module LEDs..............................................................................................................15

PCIe slot definitions (standard I/O module)..................................................................... 15

PCIe slot definitions (I/O module with x16 riser option)................................................... 16

HPE H240 Smart Host Bus Adapter port identification.................................................... 18

I/O module power connector identification..................................................................................18

LFF drive bay identification......................................................................................................... 19

Expander module LEDs.............................................................................................................. 19

Expander link mapping............................................................................................................... 19

Installing the chassis............................................................................20

Setting up and installing the chassis...........................................................................................20

Disassembling the chassis..........................................................................................................20

Installing the chassis into the rack.............................................................................................. 24

Installing the system components into the chassis..................................................................... 27

Installing a server............................................................................................................. 27

Installing a hot-plug drive................................................................................................. 28

Installing a flex slot power supply.....................................................................................29

Installing the system fan...................................................................................................30

Installing a management module..................................................................................... 31

Installing the expansion board......................................................................................... 31

Installing an I/O module................................................................................................... 33

Cabling and powering up the chassis.................................................35

Cabling the chassis.....................................................................................................................35

Installing the cable management arm.............................................................................. 35

Converting the cable management arm for opposite side mounting................................37

I/O module option cabling........................................................................................................... 38

HPE H240 Smart Host Bus Adapter cabling.................................................................... 38

3

Powering up the system..............................................................................................................40

Hot-plug power supply calculations..................................................................................40

Power capping............................................................................................................................ 41

Power capping modes......................................................................................................41

Configuring a power cap.................................................................................................. 41

Setting the chassis power cap mode with the PPIC utility.....................................42

Setting the chassis power cap mode with HPE APM............................................ 42

Troubleshooting.................................................................................... 44

Important safety information ...................................................................................................... 44

Symbols on equipment.....................................................................................................44

Troubleshooting resources..........................................................................................................45

Specifications........................................................................................46

Environmental specifications ..................................................................................................... 46

Chassis specifications ................................................................................................................46

Power supply specifications........................................................................................................46

HPE 800W Flex Slot Platinum Hot-plug Low Halogen Power Supply..............................47

HPE 800W Flex Slot -48VDC Hot-plug Low Halogen Power Supply...............................47

HPE 800W Flex Slot Titanium Hot-plug Low Halogen Power Supply..............................49

HPE 800W Flex Slot Universal Hot-plug Low Halogen Power Supply.............................49

HPE 1400W Flex Slot Platinum Plus Hot-plug Power Supply..........................................50

Hot-plug power supply calculations............................................................................................ 51

Environmental considerations.............................................................52

Communications interference..................................................................................................... 52

Preventing electrostatic discharge.............................................................................................. 52

Grounding methods to prevent electrostatic discharge...............................................................52

Websites................................................................................................ 54

Support and other resources...............................................................55

Accessing Hewlett Packard Enterprise Support......................................................................... 55

Accessing updates......................................................................................................................55

Customer self repair....................................................................................................................56

Remote support.......................................................................................................................... 56

Warranty information...................................................................................................................56

Regulatory information................................................................................................................57

Documentation feedback............................................................................................................ 57

Acronyms and abbreviations...............................................................58

4

Planning the installation

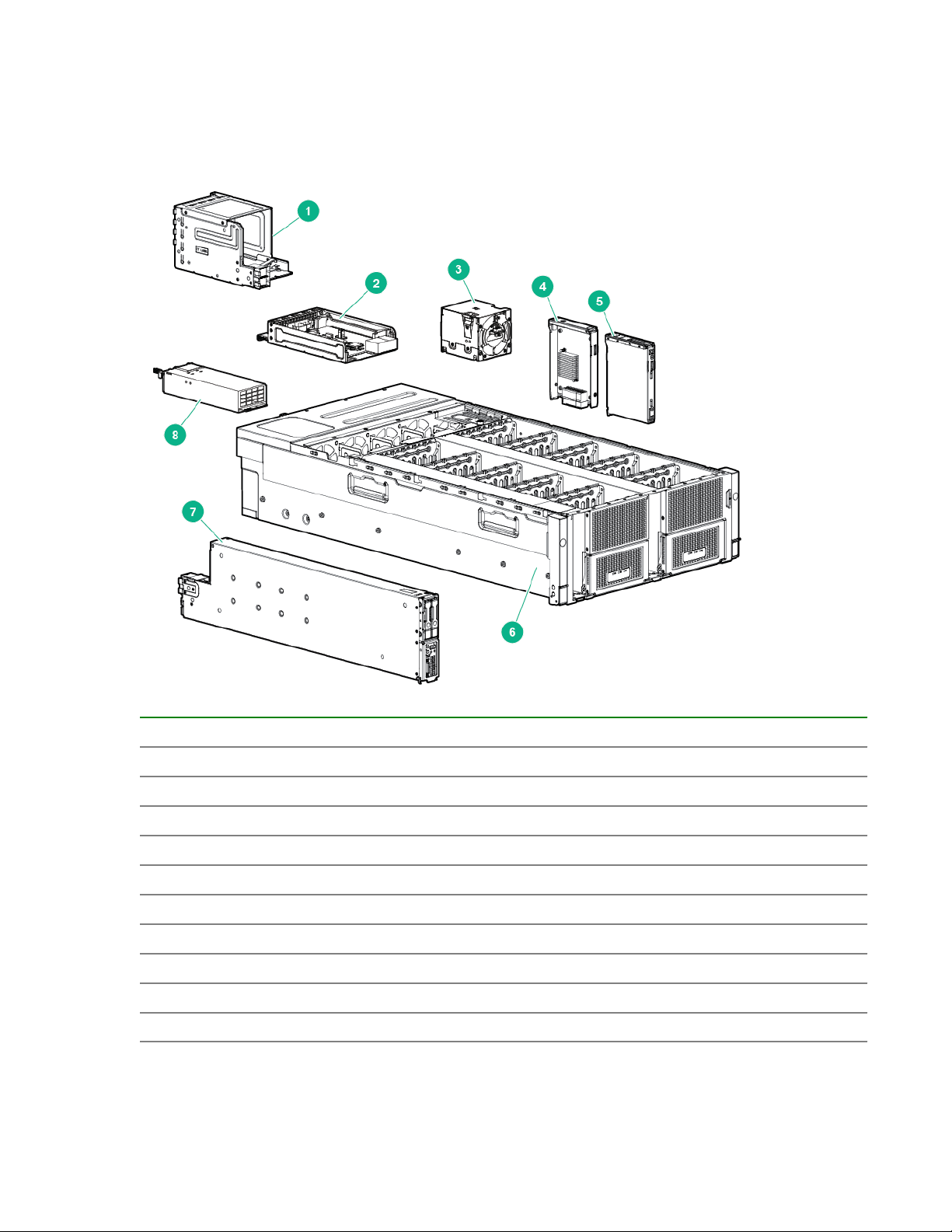

Verifying the pallet contents

Item Description

1 I/O module

2 Management module

3 System fans (5)

4 SAS expander module

5 Drive

6 HPE Apollo 4520 Gen9 Chassis

7 Server

8 Power supply

9 Power supply blank

10 Rack rails and cable management arm

1

The quantity depends on the configuration ordered.

2

Not shown

1

1

2

2

Planning the installation 5

Warnings and cautions

WARNING: To reduce the risk of personal injury or damage to equipment, heed all warnings and

cautions throughout the installation instructions.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The rack is bolted to the floor using the concrete anchor kit.

• The leveling feet extend to the floor.

• The full weight of the rack rests on the leveling feet.

• The racks are coupled together in multiple rack installations.

• Only one component is extended at a time. If more than one component is extended, a rack

might become unstable.

WARNING: The chassis is very heavy. To reduce the risk of personal injury or damage to the

equipment:

• Observe local occupational health and safety requirements and guidelines for manual material

handling.

• Remove all installed components from the chassis before installing or moving the chassis.

• Use caution and get help to lift and stabilize the chassis during installation or removal, especially

when the chassis is not fastened to the rack.

WARNING: To reduce the risk of personal injury or damage to the equipment, you must adequately

support the chassis during installation and removal.

WARNING: Always have at least two people to lift the chassis into the rack. If the chassis is being

loaded into the rack above chest level, an additional person must assist with aligning the chassis

with the rails while the other people support the weight of the chassis.

WARNING: Be sure to install enclosures starting from the bottom of the rack and work your way up

the rack.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal

system components to cool before touching them.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Never reach inside the chassis while the system is powered up.

• Perform service on system components only as instructed in the user documentation.

CAUTION: Always be sure that equipment is properly grounded and that you follow proper

grounding procedures before beginning any installation procedure. Improper grounding can result in

ESD damage to electronic components. For more information, see Preventing electrostatic

discharge.

6 Planning the installation

CAUTION: When performing non-hot-plug operations, you must power down the chassis and/or the

system. However, it may be necessary to leave the chassis powered up when performing other

operations, such as hot-plug installations or troubleshooting.

Space and airflow requirements

To enable servicing and ensure adequate airflow, observe the following spatial requirements when

deciding where to install a rack:

• Leave a minimum clearance of 121.9 cm (48.0 in) in front of the rack and between rows of racks.

• Leave a minimum clearance of 76.2 cm (30.0 in) in back of the rack for a single row of racks or after

the final row of racks.

Hewlett Packard Enterprise Rack products draw cool air in through the front and expel warm air through

the rear of the enclosure. Therefore, the front of the rack enclosure must be adequately ventilated to

enable ambient room air to enter the enclosure, and the rear of the enclosure must be adequately

ventilated to enable the warm air to escape from the enclosure.

IMPORTANT: Do not block the ventilation openings.

If the front of the rack is not completely filled with components, the remaining gaps between the

components can cause changes in the airflow, which can adversely affect cooling within the rack. Cover

these gaps with blanking panels.

CAUTION: Always use blanking panels to fill empty vertical spaces in the rack. This arrangement

ensures proper airflow. Using a rack without blanking panels results in improper cooling that can

lead to thermal damage.

Racks provide proper server cooling from flow-through perforations in the front and rear doors that

provide a 65% open area for ventilation.

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the rack in a well-ventilated,

climate-controlled environment.

The operating temperature inside the rack is always higher than the room temperature and is dependent

on the configuration of equipment in the rack. Check the TMRA for each piece of equipment before

installation.

CAUTION: To reduce the risk of damage to the equipment when installing third-party options:

• Do not permit optional equipment to impede airflow around the chassis or to increase the internal

rack temperature beyond the maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of IT equipment by licensed electricians. This equipment is designed to operate in installations

covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for Protection of

Electronic Computer/Data Processing Equipment). For electrical power ratings on options, refer to the

product rating label or the user documentation supplied with that option.

Planning the installation 7

WARNING: To reduce the risk of personal injury, fire, or damage to the equipment, do not overload

the AC supply branch circuit that provides power to the rack. Consult the electrical authority having

jurisdiction over wiring and installation requirements of your facility.

CAUTION: Protect the chassis from power fluctuations and temporary interruptions with a regulating

UPS. This device protects the hardware from damage caused by power surges and voltage spikes

and keeps the chassis in operation during a power failure.

Grounding requirements

This equipment must be grounded properly for proper operation and safety. In the United States, you

must install the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article

250, as well as any local and regional building codes.

In Canada, you must install the equipment in accordance with Canadian Standards Association, CSA

C22.1, Canadian Electrical Code.

In all other countries, you must install the equipment in accordance with any regional or national electrical

wiring codes, such as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7.

Furthermore, you must be sure that all power distribution devices used in the installation, such as branch

wiring and receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with this equipment, Hewlett Packard Enterprise

recommends the use of a PDU that is either permanently wired to the building’s branch circuit or includes

a nondetachable cord that is wired to an industrial-style plug. NEMA locking-style plugs or those

complying with IEC 60309 are considered suitable for this purpose. Using common power outlet strips to

supply power to this equipment is not recommended.

8 Planning the installation

Identifying components and LEDs

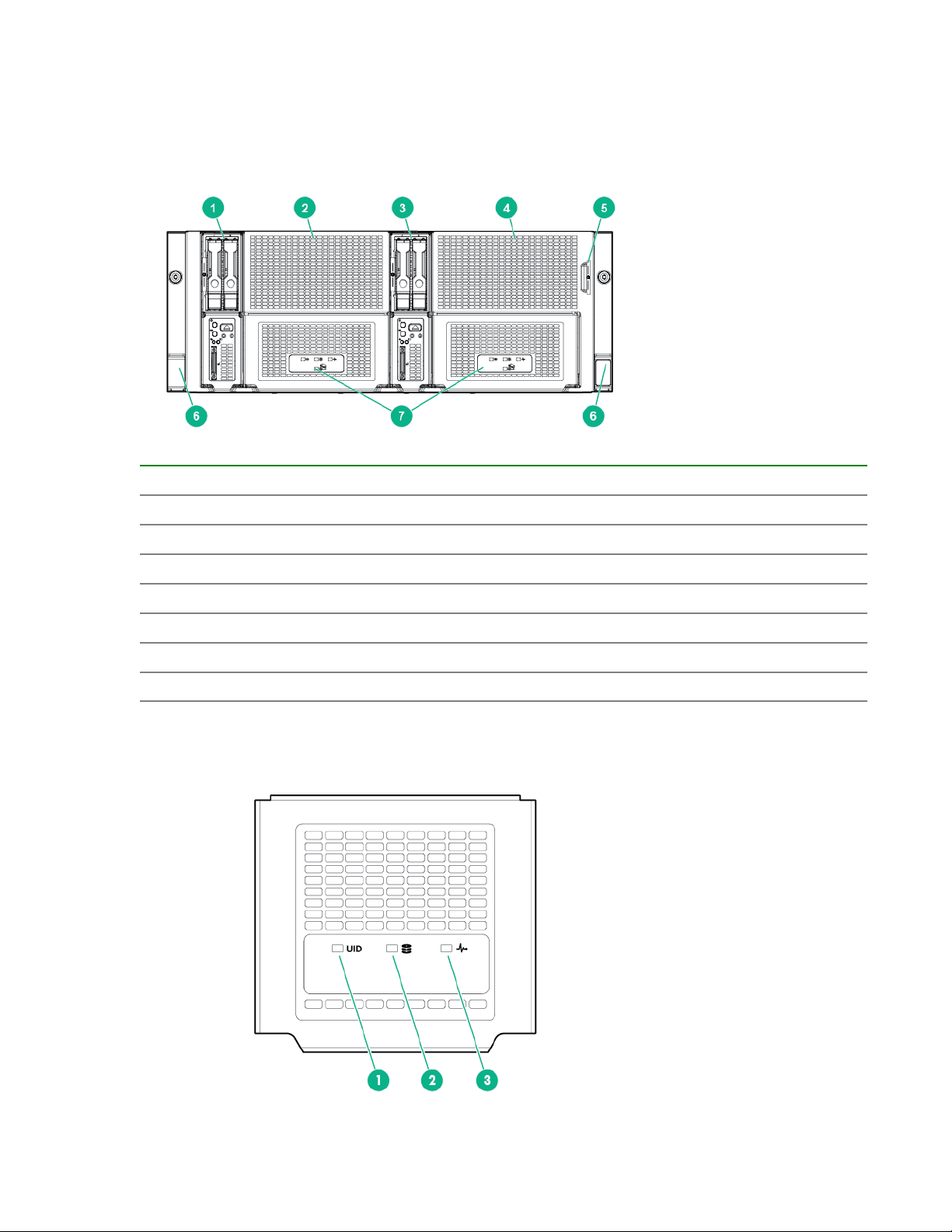

Front panel components

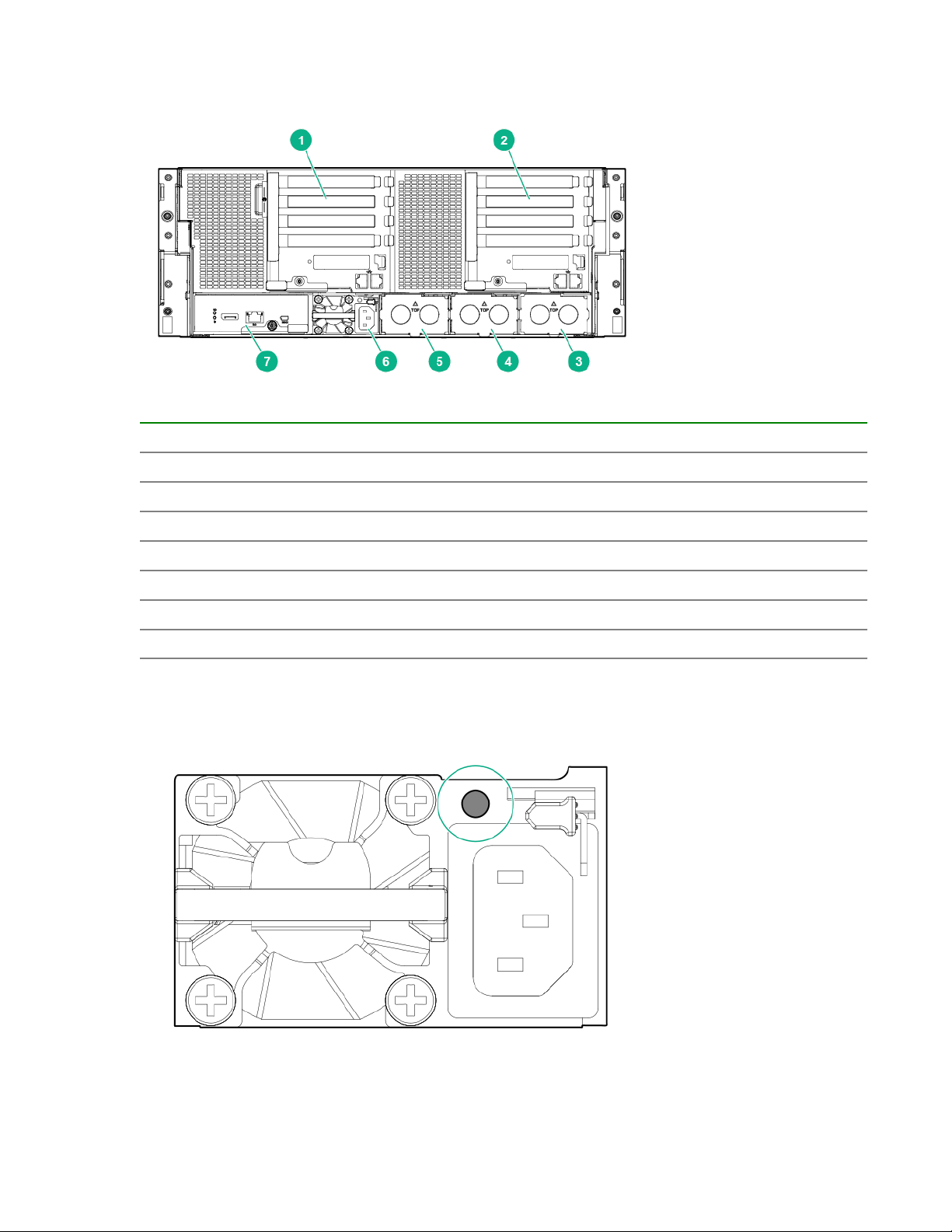

Item Description

1 Server bay 1

2 Server bay 1 LFF drives

3 Server bay 2

4 Server bay 2 LFF drives

5 Chassis serial label pull tab

6 Quick-release levers (2)

7 Storage LED display

Storage display LEDs

Identifying components and LEDs 9

Item LED description LED state

1 UID LED

2 Drive health LED

3 Backplane health

LED

Off = Normal operating mode

Solid blue = One or more drives is in locate mode.

Flashing blue = Firmware update is in progress.

Off = No drives are configured.

Solid green = One or more drives are members of a logical drive.

Flashing green = One or more drives are rebuilding or performing a RAID

migration, stripe size migration, capacity expansion, logical drive extension,

or erasing.

Flashing amber = One or more drives are predicted to fail.

Solid amber = One or more drives have failed.

Green = Backplane health is normal.

Amber = Backplane error detected

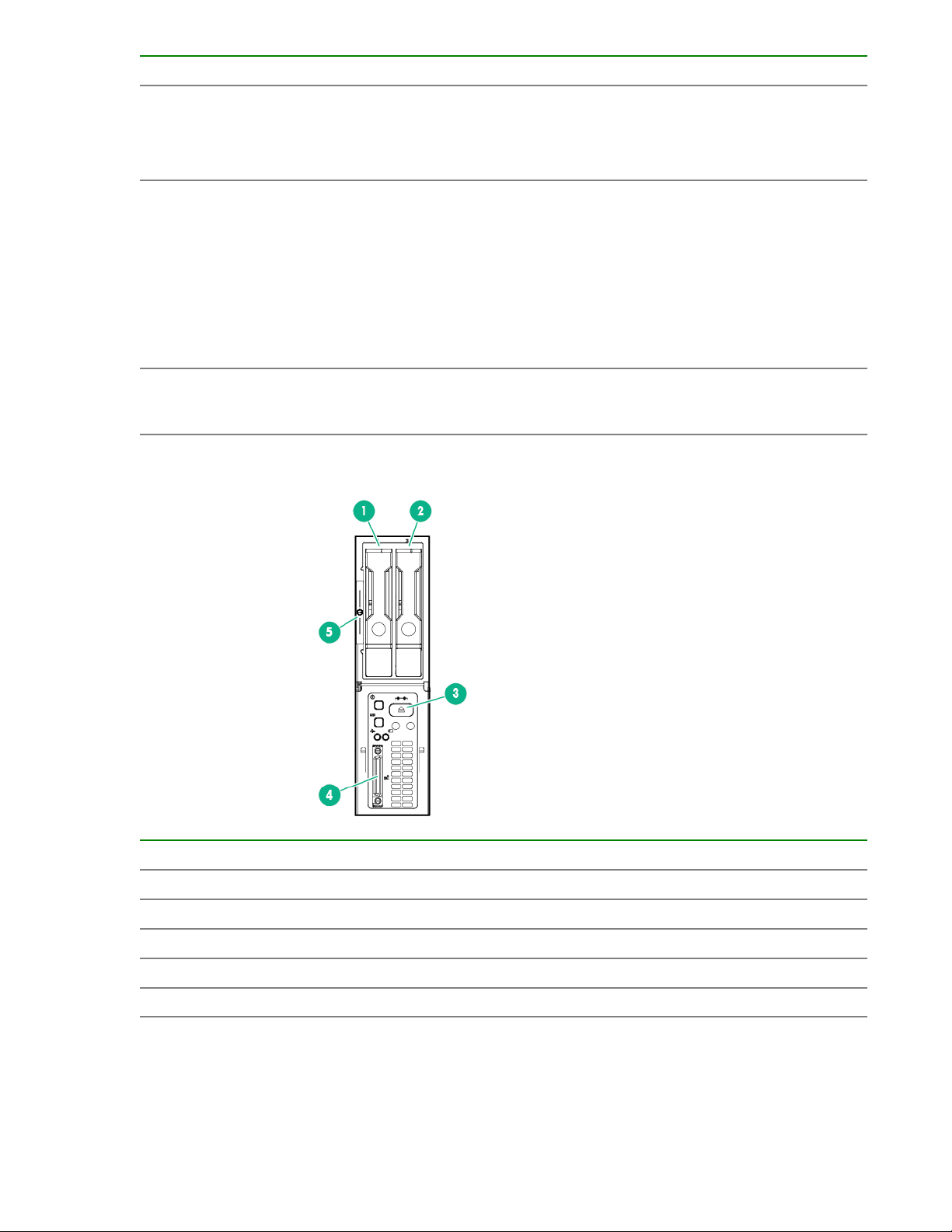

Server front panel components

Item Description

1 Drive bay 1

2 Drive bay 2

3 Server ejector button

4 SUV cable connector

5 Server serial label pull tab

10 Identifying components and LEDs

Server front panel LEDs and buttons

Item Description Status

1 Power On/Standby

button and system power

LED

Solid green = System on

Flashing green (1 Hz/cycle per sec) = Performing power on

sequence

2 UID button/LED

3 Server health LED

4 Server backup LED

Solid amber = System in standby

Off = No power present

Solid blue = Activated

Flashing blue:

• 1 Hz/cycle per sec = Remote management or firmware upgrade

in progress

• 4 Hz/cycle per sec = iLO manual reboot sequence initiated

• 8 Hz/cycle per sec = iLO manual reboot sequence in progress

Off = Deactivated

Solid green = Normal

Flashing green (1 Hz/cycle per sec) = iLO is rebooting

Flashing amber = System degraded

Flashing red (1 Hz/cycle per sec) = System critical

Off = Normal operations. No backup in progress.

Flashing white = Backup in progress. Do not remove drives or

associated system components, and do not power down the server.

Identifying components and LEDs 11

Rear panel components

Item Description

1 Server bay 2 I/O module

2 Server bay 1 I/O module

3 Power supply bay 4

4 Power supply bay 3

5 Power supply bay 2

6 Power supply bay 1

7 Management module

Power supply LEDs

The power supply LED is located on each power supply.

12 Identifying components and LEDs

LED Status Description

Off System is off or power supply has failed.

Solid Green Normal

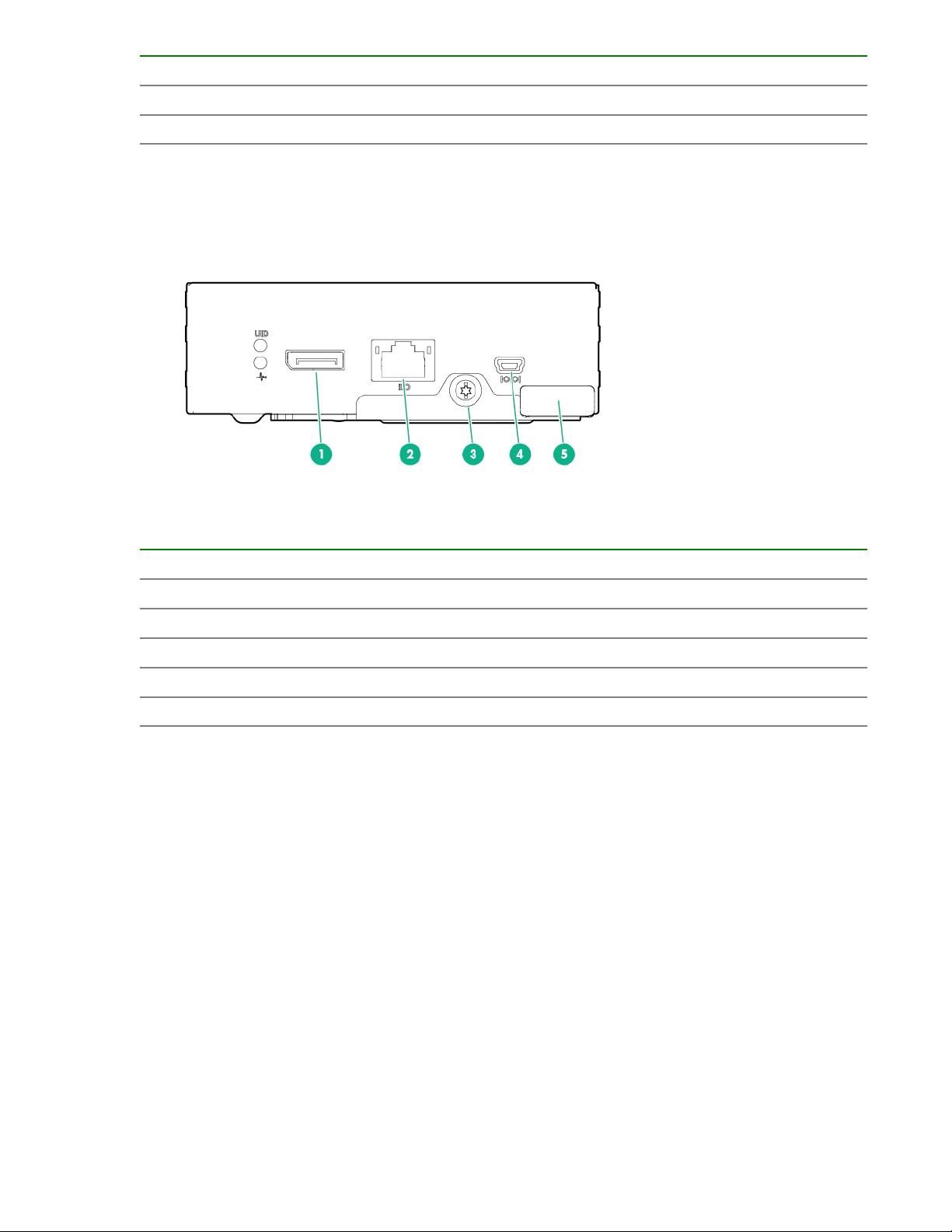

Management module components

Item Description

1 HPE APM connector

2 HPE iLO connector

3 Management module thumbscrew

4 Reserved

5 Management module release lever

Identifying components and LEDs 13

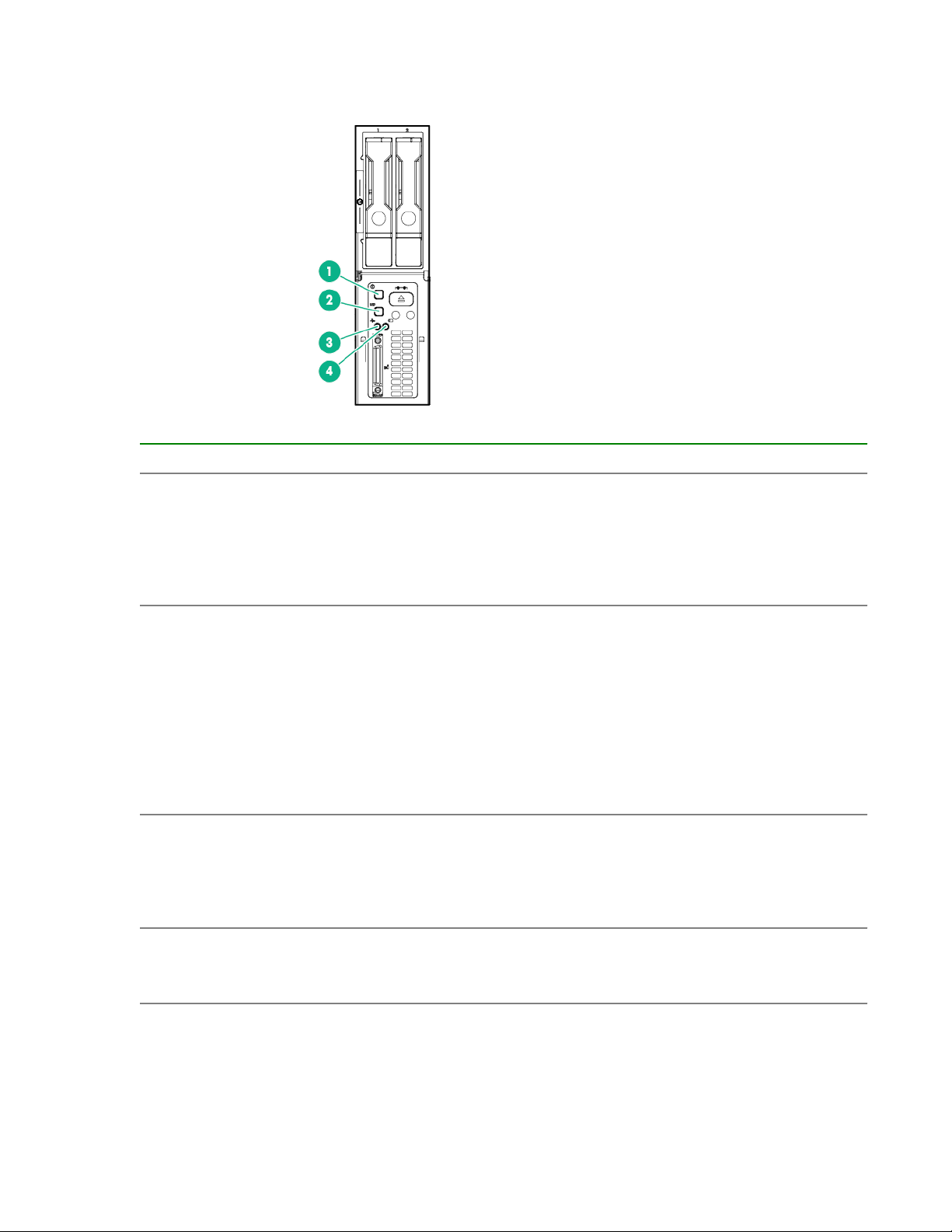

Management module LEDs

Item Description

1 Management module UID LED

2 Management module health LED

3 iLO link LED

4 iLO activity LED

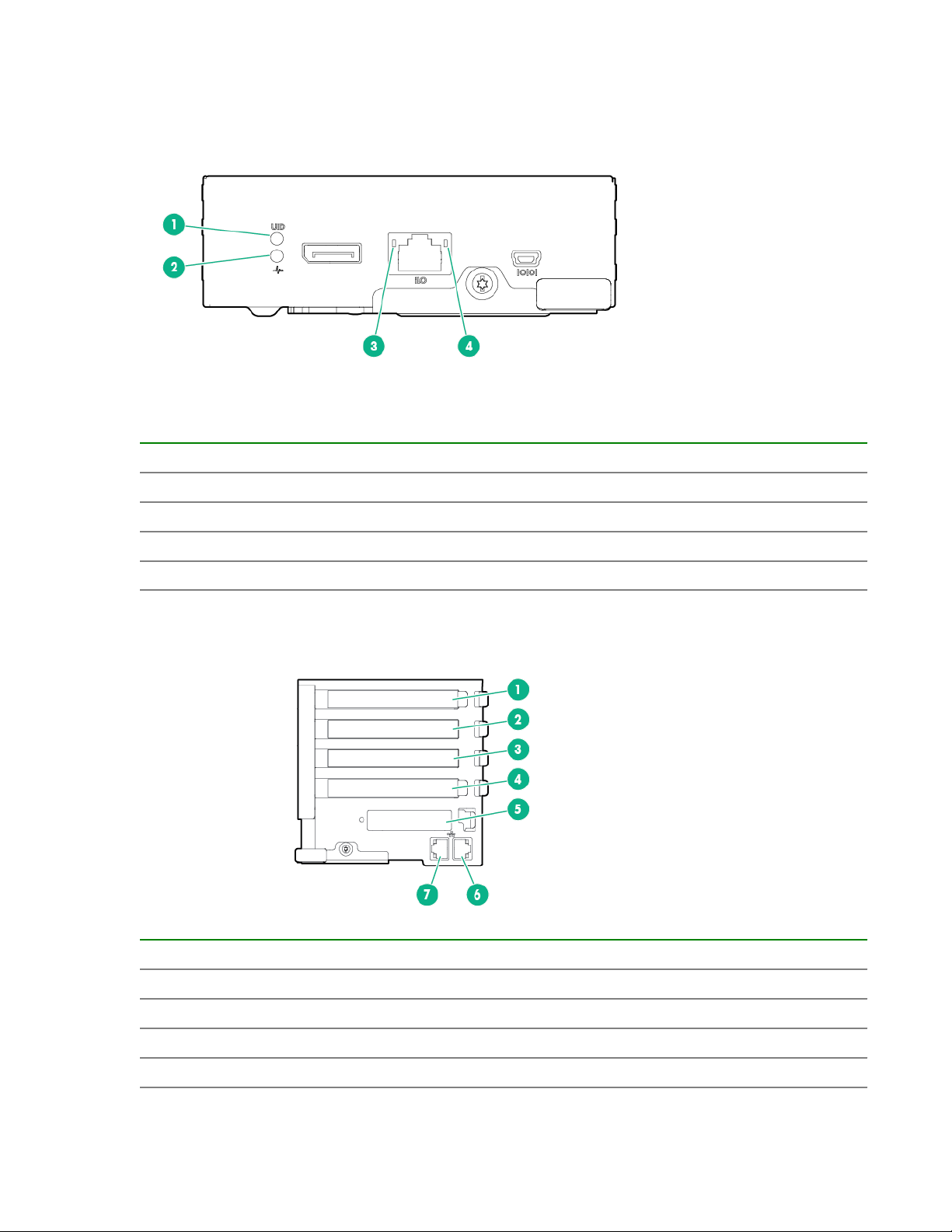

I/O module components

Item Description

1 PCIe expansion slot 4

2 PCIe expansion slot 3

3 PCIe expansion slot 2

4 PCIe expansion slot 1

14 Identifying components and LEDs

Table Continued

Item Description

5 FlexibleLOM slot

6 NIC 2

7 NIC 1

The FlexibleLOM slot is not available on the I/O module with the x16 PCIe riser option.

I/O module LEDs

Item Description

1 NIC 1 activity LED

2 NIC 1 link LED

3 NIC 2 activity LED

4 NIC 2 link LED

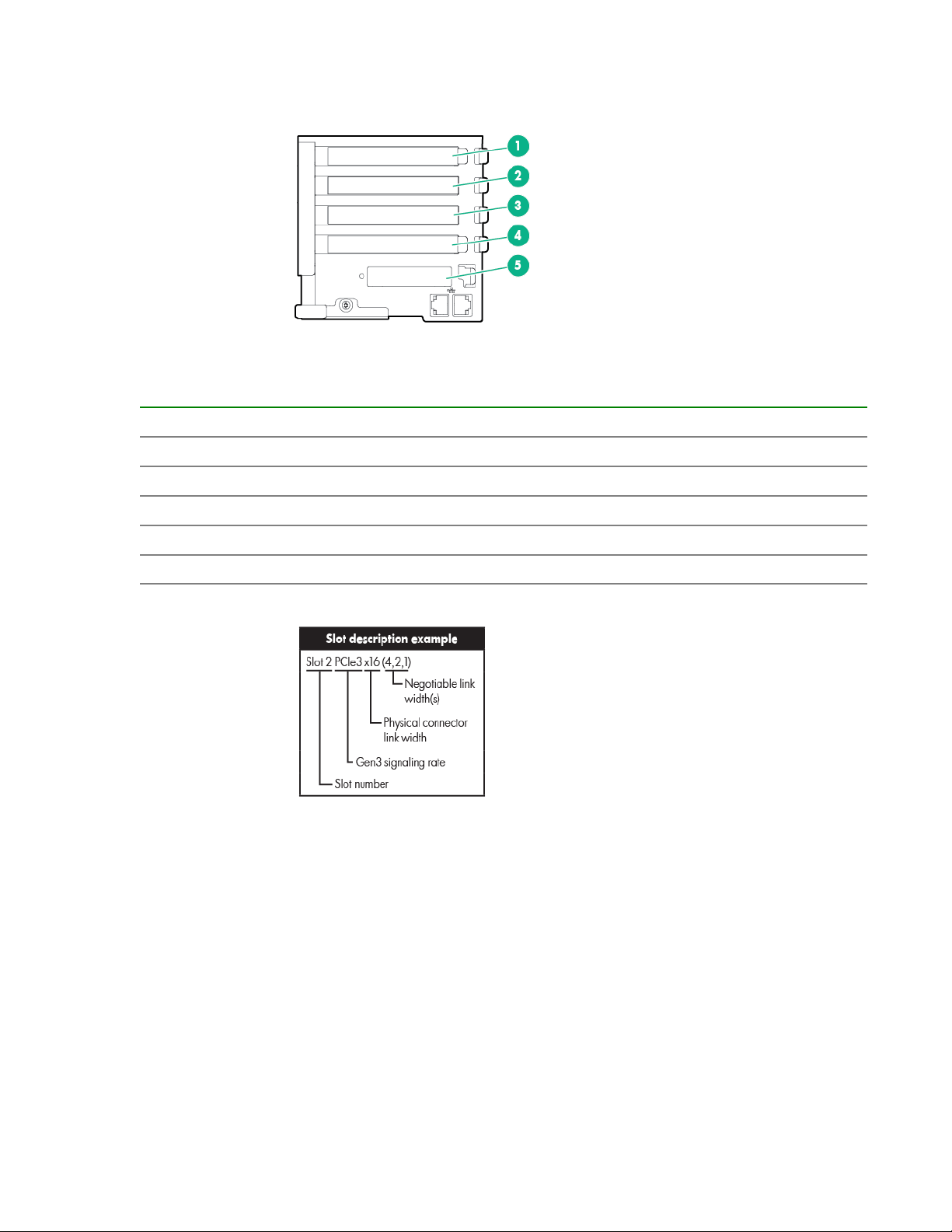

PCIe slot definitions (standard I/O module)

Processor 2 must be installed to support options installed in PCIe expansion slots 3 and 4.

Identifying components and LEDs 15

Item Description

1 PCIe expansion slot 4 — PCIe3 x8 (8, 4, 2, 1)

2 PCIe expansion slot 3 — PCIe3 x8 (8, 4, 2, 1)

3 PCIe expansion slot 2 — PCIe3 x8 (8, 4, 2, 1)

4 PCIe expansion slot 1 — PCIe3 x8 (8, 4, 2, 1)

5 FlexibleLOM slot — PCIe3 x8

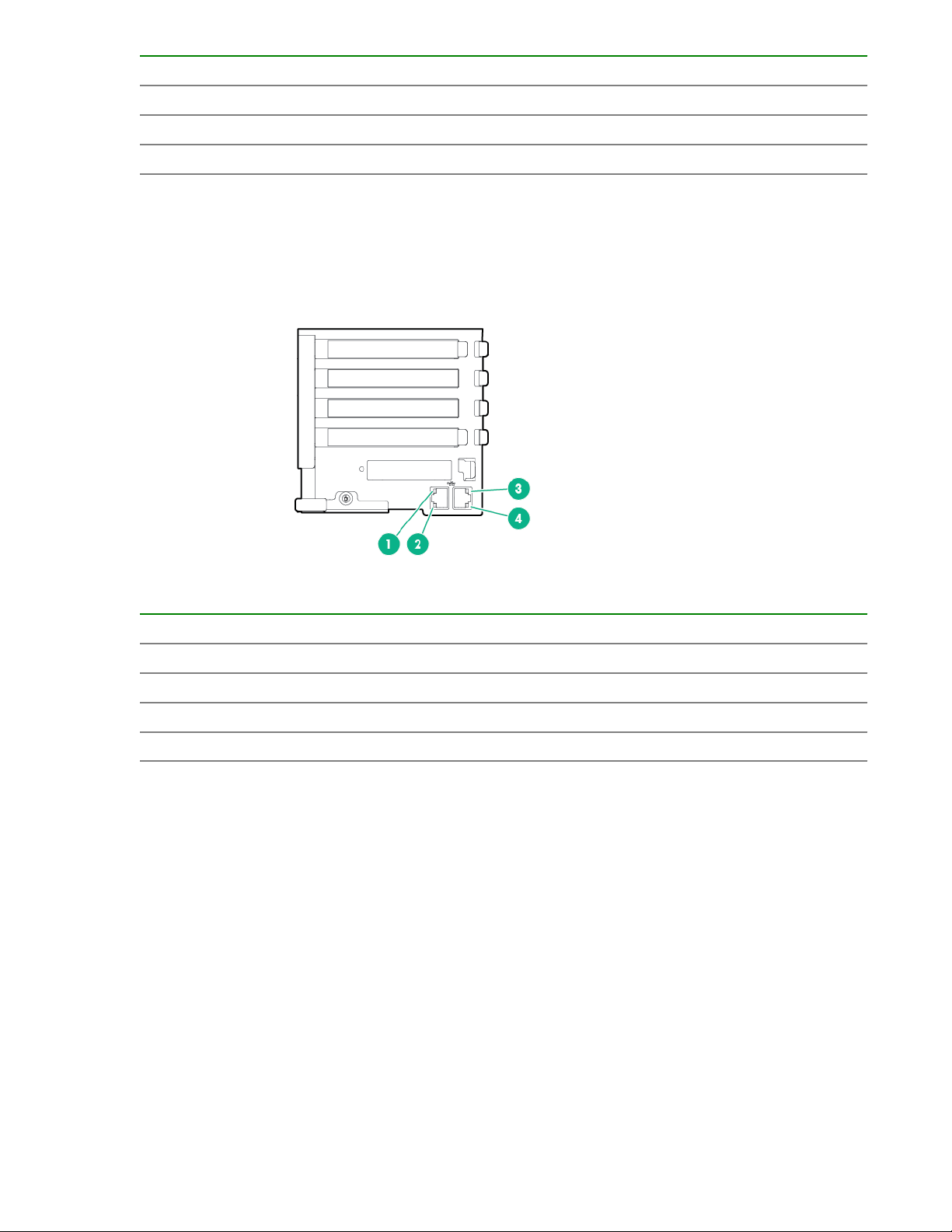

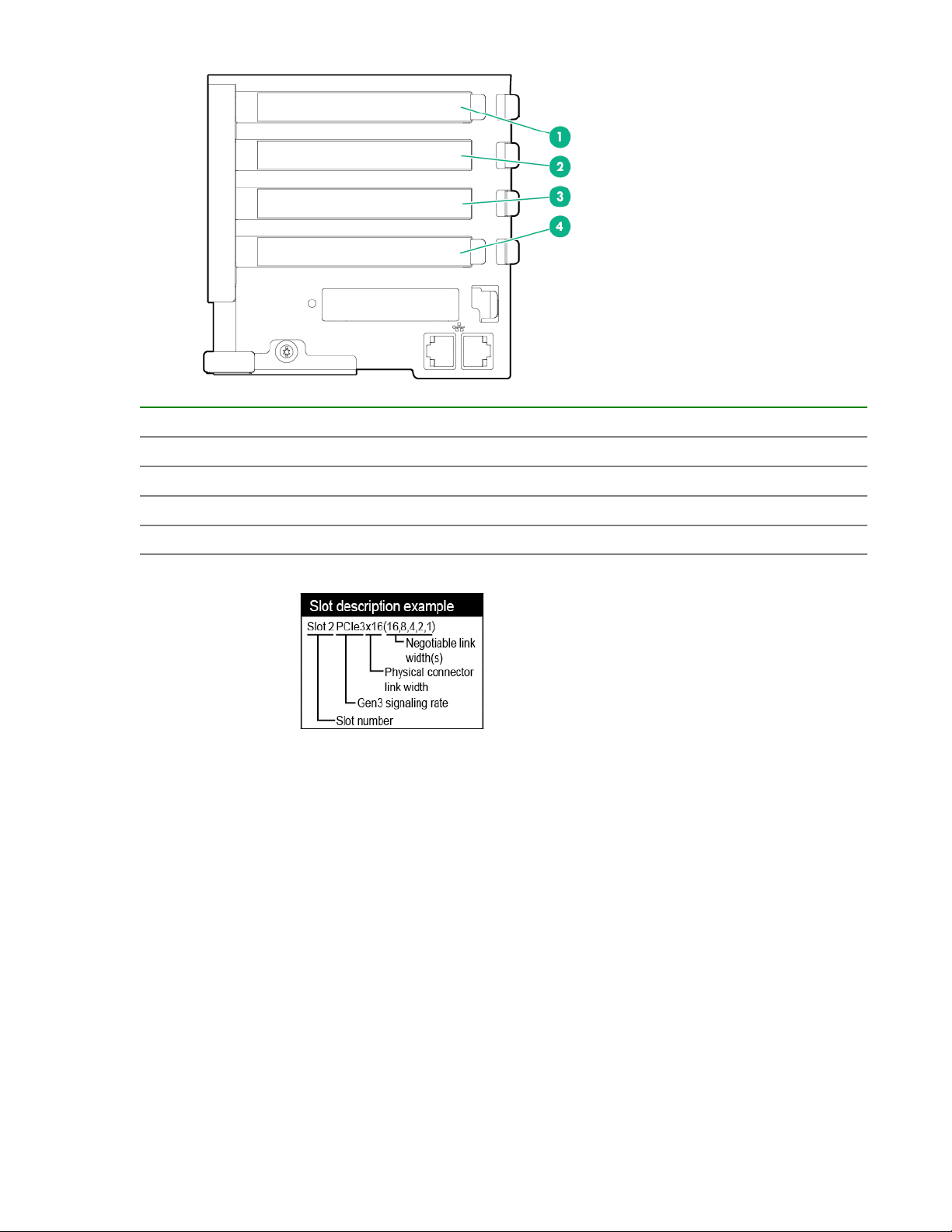

PCIe slot definitions (I/O module with x16 riser option)

Processor 2 must be installed to support options installed in PCIe expansion slots 3 and 4.

16 Identifying components and LEDs

Item Description

1 PCIe expansion slot 4 — PCIe3 x8 (8, 4, 2, 1)

2 PCIe expansion slot 3 — PCIe3 x8 (8, 4, 2, 1)

3 PCIe expansion slot 2 — PCIe3 x16 (16, 8, 4, 2, 1)

4 PCIe expansion slot 1 — PCIe3 x8 (8, 4, 2, 1)

Identifying components and LEDs 17

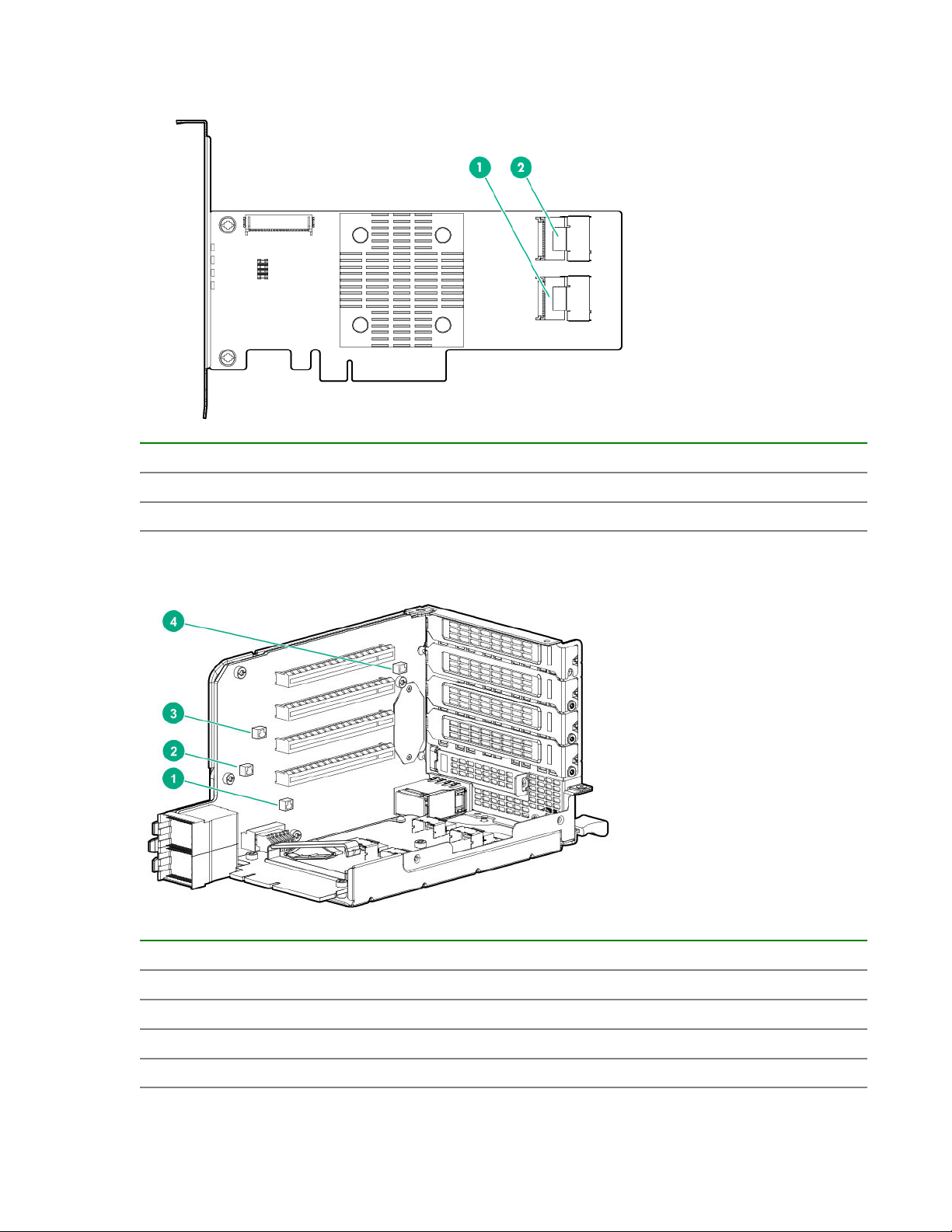

HPE H240 Smart Host Bus Adapter port identification

Item Description

1 Port 2i

2 Port 1i

I/O module power connector identification

Item Description

1 PCIe expansion slot 1 power connector

2 PCIe expansion slot 2 power connector

3 PCIe expansion slot 3 power connector

4 PCIe expansion slot 4 power connector

18 Identifying components and LEDs

Loading...

Loading...