h/p/cosmos 150/50 locomotion de med, mercury, quasar, pulsar, stellar Operating Instructions And Service Manual

...

Operating instruction and service manual

h/p/cosmos running-machine-series 5.0

Running machines

h/p/cosmos mercury

h/p/cosmos mercury med

h/p/cosmos quasar

h/p/cosmos quasar med

h/p/cosmos pulsar

h/p/cosmos pulsar 3p

h/p/cosmos stellar

h/p/cosmos stellar med

h/p/cosmos stratos

h/p/cosmos stratos med

incl. lt-models

running machine

manual

Running machines

h/p/cosmos 150/50 locomotion E med

h/p/cosmos 150/50 locomotion DE med

h/p/cosmos venus - all sizes

h/p/cosmos saturn - all sizes

Manual-version

MCU5 -V1.04

Revision 20080901

manual order-no.:

[cos14310m5-v1.04hpc-en]

Development, production, sales & service

h/p/cosmos sports & medical gmbh

Am Sportplatz 8

DE 83365 Nussdorf-Traunstein

Germany

phone +49 / 86 69 / 86 42 0

fax +49 / 86 69 / 86 42 49

service@h-p-cosmos.com

www.h-p-cosmos.com

h/p/cosmos sports & medical gmbh Am Sportplatz 8 DE 83365 Nussdorf-Traunstein / Germany

phone +49 / 86 69 / 86 42 0 fax +49 / 86 69 / 86 42 49 email@h-p-cosmos.com www.h-p-cosmos.com

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh created 01.09.2008 printed 08.10.2008 page: 1 of 176

h/p/cosmos saturn 300/125

h/p/cosmos saturn 450/300rs

This manual is only valid for the firmware-/software version noted on the first page of this manual and only for the original

configuration of the first delivery of the machine.

Firmwareupdates, softwareupdates, changes of the system configuration or retrofittings of additional equipment or

accessories can result in invalidity of this manual. In case of alterations of the device or the additional equipment always the

actual version of the manual or the according additional information has to be considered.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 2 of 176

introduction

[1.]Introduction

Dear customer,

We would like to express our gratitude for putting your trust in us, in deciding for this top of the range running machine. Since

1988 we have been developing and manufacturing running machines for sports and medical application. When it comes

down to technology, design and safety, we have set extremely high standards for ourselves.

Because the running machine is a motor-driven device, you must pay special attention to the mentioned safety regulations. If

proper notice is taken of the safety regulations, the operation of our running machines is almost without any risk. The neglect

of the safety regulations could result in dangerous situations and serious accidents. Therefore please read the installation

and operation manual and the danger precautions before taking the device into operation.

Simple maintenance, as described, can easily be done by yourself. We recommend to call our competent service team or

entering into a maintenance contract for a routine service in an interval of 6 or 12 months. A form for registration of your

institution and device is included in the delivery. In order to be able to supply you with the latest technical information and

service, it is important for you to fill out the form. Therefore please fill out the form for registration immediately and send it

back via fax.

The instruction manual as a firm part of the delivery has to be accessible for the user at any time. This instruction manual

has been written with great care. Should you, however, still find any details, which do not correspond with your device,

please give us notice, so that we can correct any mistakes as soon as possible. Subject to alterations without prior notice,

errors and omissions excepted. E & OE.

We wish you a lot of fun and success while exercising and working with your h/p/cosmos running machine.

h

Franz Harrer

President

h/p/cosmos sports & medical gmbh

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 3 of 176

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

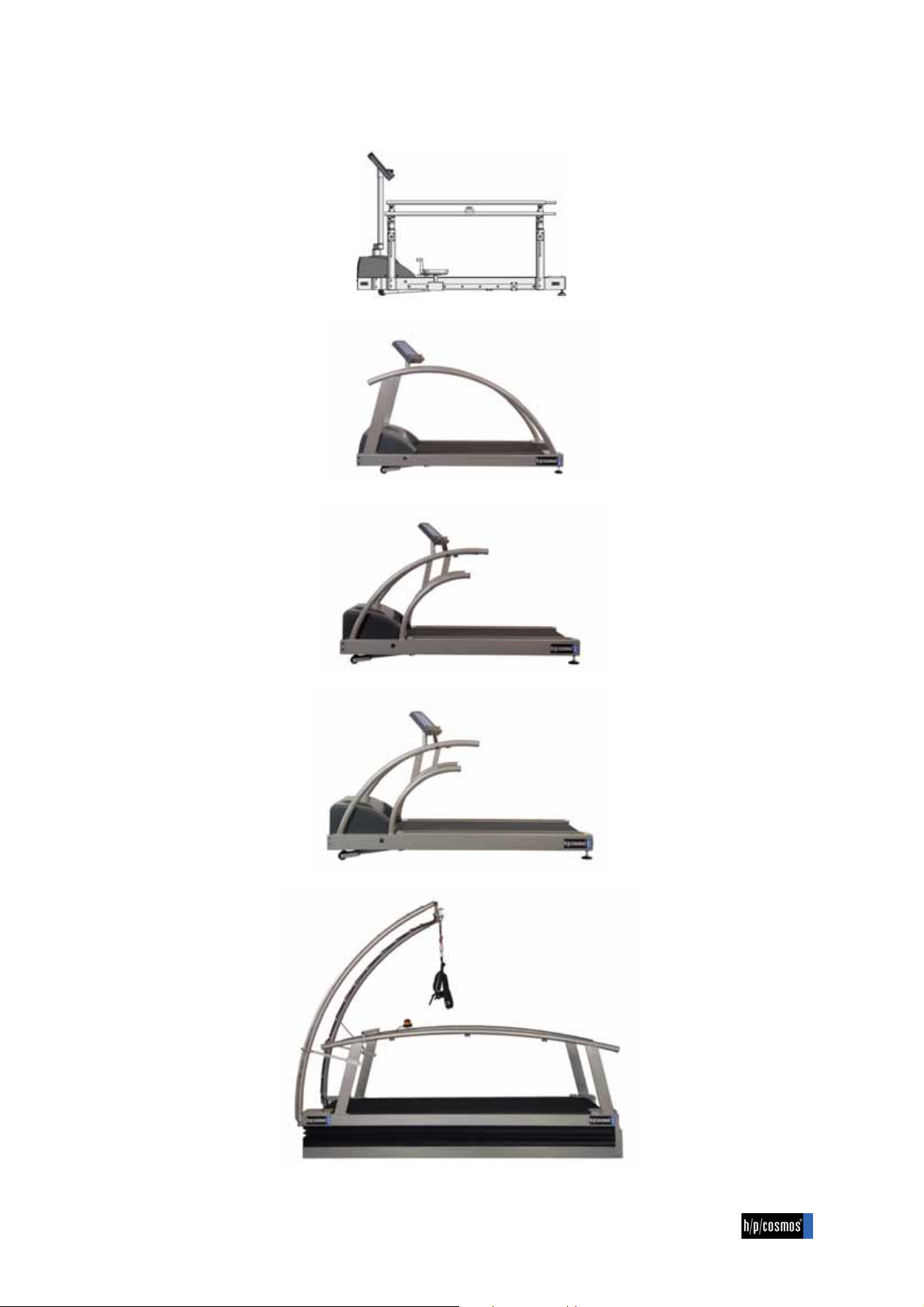

h/p/cosmos running machine series

introduction

h/p/cosmos 150/50 locomotion DE med

h/p/cosmos mercury

h/p/cosmos quasar

h/p/cosmos pulsar

h/p/cosmos venus & h/p/cosmos saturn

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 4 of 176

content

[2.]Content

[1.] Introduction ........................................................................................................................................................................ 3

[2.] Content ............................................................................................................................................................................... 5

[3.] Safety, warnings, precautions, prohibitions ................................................................................................................. 10

[3.A] Safety precautions, safety regulations, prohibitions and warnings ................................................................................. 10

[3.B] Exit the device in emergency case ................................................................................................................................. 11

[3.C] General Instructions / Safety .......................................................................................................................................... 11

[3.D] Instructions for safety and operation .............................................................................................................................. 12

[3.D1] Electric safety / Safety classes .......................................................................................................................... 12

[3.D2] Patient security according to VDE 0750 (IEC 601-1) type B .............................................................................. 12

[3.D3] Potential equalization ......................................................................................................................................... 12

[3.D4] Connection of units installed outside medically utilized locations ...................................................................... 13

[3.D5] Medical electrical systems ................................................................................................................................. 13

[3.D6] Subject's surroundings ....................................................................................................................................... 13

[3.D7] Protection against the danger of electrical shocks ............................................................................................. 14

[3.D8] Environmental requirements .............................................................................................................................. 14

[3.E] Economic life-time .......................................................................................................................................................... 15

[3.F] Symbols used ................................................................................................................................................................. 15

[3.G] Safety standards, norms ................................................................................................................................................ 15

[3.G1] VDE norm .......................................................................................................................................................... 16

[3.G2] The c mark ..................................................................................................................................................... 16

[3.G3] The n mark ........................................................................................................................................... 16

[3.G4] EMC Electromagnetic Compatibility ................................................................................................................... 17

[3.G5] General advice ................................................................................................................................................... 17

[3.H] Fields of application / intended use ................................................................................................................................ 17

[3.H1] Professional application in sports and fitness .................................................................................................... 17

[3.H2] Professional application in the medical field ...................................................................................................... 17

[3.H3] h/p/cosmos medical running machines - MDD medical device directive. Safety standards .............................. 18

[3.I] Forbidden use ................................................................................................................................................................ 21

[4.] Installation & commissioning ......................................................................................................................................... 22

[4.A] Transport, unpacking and packaging ............................................................................................................................. 22

[4.A1] Transport to upper or lower floors and through narrow doors ............................................................................ 22

[4.A2] Transport with trolleys ........................................................................................................................................ 24

[4.A3] Transport of oversize running machines ............................................................................................................ 24

[4.B] Mechanical installation ................................................................................................................................................... 24

[4.C] Electrical installation ....................................................................................................................................................... 26

[4.C1] Name plate ......................................................................................................................................................... 27

[4.C2] Electric safety measurements and „First Measured Values“ ............................................................................. 28

[4.C3] Potential equalization ......................................................................................................................................... 28

[4.C4] Plug assignment at the UserTerminal ................................................................................................................ 29

[4.D] Starting the running machines ........................................................................................................................................ 33

[4.D1] Unlocking of the emergency-stop switch ........................................................................................................... 33

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 5 of 176

content

[4.D2] Switching the device on ..................................................................................................................................... 33

[4.D3] Switching the device off ..................................................................................................................................... 34

[4.E] Emergency-Stop / Emergency-Off ................................................................................................................................. 35

[4.F] Installation, Overview, Checklist ..................................................................................................................................... 36

[5.] Operation .......................................................................................................................................................................... 38

[5.A] UserTerminal, keyboard and display .............................................................................................................................. 38

[5.A1] The keyboard ..................................................................................................................................................... 39

[5.A2] The display ......................................................................................................................................................... 39

[5.A3] The display (standard configuration) .................................................................................................................. 40

[5.B] Mode of operation .......................................................................................................................................................... 41

[5.B1] General notes .................................................................................................................................................... 41

[5.B2] Acceleration levels ............................................................................................................................................. 41

[5.B3] Manual mode ..................................................................................................................................................... 42

[5.B4] Automatic mode ................................................................................................................................................. 43

[5.B5] Profile Mode / Pre-programmed training profiles ............................................................................................... 43

[5.B6] Possibilities of interfering into the profile mode manually .................................................................................. 45

[5.B7] Profile outline ..................................................................................................................................................... 46

[5.B8] Cardio mode – general notes ............................................................................................................................. 49

[5.B9] Cardio mode - Field of application / control ....................................................................................................... 49

[5.B10]Cardio mode – Operation ................................................................................................................................... 51

[5.B11]Possibilities of interfering with the Cardio Mode manually ................................................................................. 53

[5.B12]Test mode and free program profiles – General notes ...................................................................................... 54

[5.B13]Test profiles / Field of application ...................................................................................................................... 54

[5.B14]Test mode - Operation ....................................................................................................................................... 67

[5.B15]The UKK 2 km walk test ..................................................................................................................................... 67

[5.B16]Programing example: UKK walk test ................................................................................................................. 69

[5.B17]Programming-example: free definable profile .................................................................................................... 70

[5.B18]Possibilities of interfering in test mode manually ............................................................................................... 74

[6.] Optional settings .............................................................................................................................................................. 75

[6.A] Settings of control and display options ........................................................................................................................... 75

[6.A1] Select user options ............................................................................................................................................ 75

[6.A2] List of user options / optional functions .............................................................................................................. 76

[6.A3] Standard settings for the user options ............................................................................................................... 82

[6.B] Administrator options ...................................................................................................................................................... 83

[6.B1] List of the administrator options ......................................................................................................................... 83

[6.B2] Standard settings of administrator options ......................................................................................................... 96

[6.B3] List of running machines types .......................................................................................................................... 98

[7.] Maintenance and safety inspections ............................................................................................................................. 99

[7.A] Preventive maintenance ................................................................................................................................................. 99

[7.B] Immediate maintenance ............................................................................................................................................... 100

[7.C] Regular inspections/examinations ................................................................................................................................ 100

[7.C1] Visual inspections ............................................................................................................................................ 100

[7.C2] Protective Earth Resistance RPE measurement ............................................................................................... 101

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 6 of 176

content

[7.C3] Isolation Resistance R

[7.C4] Equivalent (alternative) leakage current I

measurement .......................................................................................................... 101

ISO

measurement ............................................................................. 102

EDL

[7.C5] Leakage current measurement ........................................................................................................................ 102

[7.C6] Electric Safety Tester and measurements ....................................................................................................... 103

[7.C7] Building installation: Electric Checks, Protective Earth Function, RCD, Leakage Current .............................. 103

[7.D] Lubrication of the running belt/running surface ............................................................................................................ 104

[7.D1] Devices with UserTerminal and without automatic oil-pump ........................................................................... 104

[7.D2] Lubricant test ................................................................................................................................................... 106

[7.D3] Devices without UserTerminal and without automatic oil-pump ...................................................................... 107

[7.D4] Devices with UserTerminal & automatic oil-pump (models "r" for cycle & wheelchair) .................................... 108

[7.D5] Set back of oil message MCU 4 without UserTerminal .................................................................................... 110

[7.D6] Set back of oil message MCU with UserTerminal ............................................................................................ 110

[7.E] Control and tightening of the running belt .................................................................................................................... 111

[7.F] Adjustment (centering) of the running belt ................................................................................................................... 112

[7.G] Control and tightening of the driving belt ...................................................................................................................... 113

[7.G1] Driving belt with poly-V-belt system ................................................................................................................. 113

[7.G2] Driving belt with timing-belt system .................................................................................................................. 115

[7.H] Side step platforms: Check for non-slipping ................................................................................................................. 115

[7.I] Hygiene, cleansing, cleansing of the interior ................................................................................................................ 115

[7.J] Cleansing and adjustment of the speed-sensor/Light-barrier ....................................................................................... 116

[7.K] Cleansing and adjustment of the light-barrier at belt-re-entry-zones ........................................................................... 117

[8.] Trouble shooting ............................................................................................................................................................ 118

[8.A] Mechanical / Noise problems ....................................................................................................................................... 118

[8.B] Running belt adjustment problems ............................................................................................................................... 118

[8.C] Fuses ............................................................................................................................................................................ 118

[8.D] Interference factor ........................................................................................................................................................ 119

[8.D1] Electrostatic Discharge .................................................................................................................................... 119

[8.D2] Source of Interference ..................................................................................................................................... 119

[8.E] Voltage at the device housing / electric shock ............................................................................................................. 120

[8.E1] Open (interrupted) earth wire / ground ............................................................................................................. 120

[8.F] Malfunctions of the heart rate measurement system POLAR ...................................................................................... 120

[8.F1] Troubleshooting heart rate measurement system POLAR .............................................................................. 121

[8.G] Malfunctions of the RS232 interface ............................................................................................................................ 121

[8.G1] Troubleshooting and testing of the RS232 interface ........................................................................................ 121

[8.H] Malfunctions of the control unit ..................................................................................................................................... 121

[8.I] Error messages / Error codes ...................................................................................................................................... 122

[8.I1] Devices with UserTerminal .............................................................................................................................. 122

[8.I2] Devices without UserTerminal ......................................................................................................................... 127

[8.J] Set back of error message ........................................................................................................................................... 127

[8.J1] Devices with UserTerminal .............................................................................................................................. 127

[8.J2] Devices without UserTerminal ......................................................................................................................... 127

[9.] Technical data ................................................................................................................................................................ 128

[9.A] Running machines ........................................................................................................................................................ 128

[9.B] EMC electromagnetic compatibility. Guidance and manufacturer's declaration ........................................................... 132

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 7 of 176

content

[9.C] Compatibility RS232 interface / USB converter ............................................................................................................ 134

[10.] Accessories and options ............................................................................................................................................ 135

[10.A]Arm support for body weight support and safety .......................................................................................................... 135

[10.A1]Danger precaution and operation of the adjustable arm supports ................................................................... 135

[10.A2]Reproducibility of adjustments ......................................................................................................................... 136

[10.B]Additional keyboard and add. stop-button for arm support and remote control............................................................ 136

[10.C]Handrails adjustable with gear tooth locking elements ................................................................................................ 137

[10.C1]Danger precaution and operation .................................................................................................................... 138

[10.C2]Reproducibility of adjustments ......................................................................................................................... 138

[10.D]Handrails adjustable. Parallel bars with gas struts and locking lever ........................................................................... 139

[10.D1]Safety precautions and operation .................................................................................................................... 139

[10.D2]Adjustment of the bar handrails ....................................................................................................................... 140

[10.D3]Reproducibility of adjustments ......................................................................................................................... 141

[10.E]Therapist’s seat and foot support adjustable ................................................................................................................ 141

[10.E1]Safety precautions and operation .................................................................................................................... 141

[10.E2]Operation and adjustment ................................................................................................................................ 142

[10.F]Special handrails .......................................................................................................................................................... 143

[10.G]h/p/cosmos airwalk se 135 (available as of 10/2008) ................................................................................................... 144

[10.H]Unweighting system h/p/cosmos airwalk ...................................................................................................................... 145

[10.H1]Vests for subjects for h/p/cosmos airwalk ........................................................................................................ 145

[10.I] Wheelchair ramp .......................................................................................................................................................... 146

[10.J]h/p/cosmos wheel chair stabilizer for oversize running machines ................................................................................ 146

[10.K]Safety arch with chest belt and harness ....................................................................................................................... 147

[10.L]Running belt rotation reversible for downhill walk ........................................................................................................ 148

[10.L1]Ripcord with magnet switch ............................................................................................................................. 148

[10.L2]Change from forward to reverse rotation ......................................................................................................... 148

[10.L3]Change from reverse to forward rotation ......................................................................................................... 149

[10.M]Bottle holder ................................................................................................................................................................. 149

[10.N]Retrofitting UserTerminal ............................................................................................................................................. 149

[10.O]Monitor / laptop arm ..................................................................................................................................................... 149

[10.P]Safety multiple socket .................................................................................................................................................. 150

[10.Q]Digital (serial) RS232 interface / USB converter .......................................................................................................... 150

[10.Q1]Interface cable RS232 for connection to PC .................................................................................................... 151

[10.Q2]Interface cable RS232 for connection to ECG Schiller .................................................................................... 151

[10.Q3]Interface cable RS232 for connection to Ergospirometrie JAEGER / VIASYS / Cardinal Health OXYCON .... 151

[10.R]Printer protocol ............................................................................................................................................................. 152

[10.S]POLAR Heart rate measurement system ..................................................................................................................... 153

[10.S1]Note from POLAR for patients with pacemaker ............................................................................................... 153

[10.S2]Chest belt and transmitter ................................................................................................................................ 153

[10.S3]Radius of transmission ..................................................................................................................................... 153

[10.S4]Battery of the transmitter .................................................................................................................................. 154

[10.S5]Correct placement of transmitter belt ............................................................................................................... 154

[10.S6]Transmission problems .................................................................................................................................... 154

[10.T]PC Software h/p/cosmos para control 4.0® .................................................................................................................. 154

[10.U]PC Software h/p/cosmos para graphics® ..................................................................................................................... 156

[10.V]PC Software h/p/cosmos para analysis® ...................................................................................................................... 157

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 8 of 176

content

[10.W]PC Software h/p/cosmos para motion ......................................................................................................................... 158

[11.] Certificates ................................................................................................................................................................... 159

[11.A]Certificate of the TSA (TÜV) according to ISO 9001-2000 ........................................................................................... 159

[11.B]Certificate of the TSA (TÜV) according to EN ISO 13485-2003 ................................................................................... 160

[11.C]EC Certificate of the TSA (TÜV) ................................................................................................................................... 161

[11.D]Certificate of compliance for sports and fitness devices .............................................................................................. 162

[11.E]Certificate of compliance medical devices ................................................................................................................... 163

[12.] Disposal ........................................................................................................................................................................ 164

[12.A]Disassemble and cut up ............................................................................................................................................... 164

[12.B]h/p/cosmos running machine ....................................................................................................................................... 164

[12.C]h/p/cosmos service oil / grease .................................................................................................................................... 164

[12.D]h/p/cosmos running belt ............................................................................................................................................... 164

[13.] Contact .......................................................................................................................................................................... 165

[13.A]Service department ...................................................................................................................................................... 165

[13.B]Sales department ......................................................................................................................................................... 165

[13.C]Headquaters ................................................................................................................................................................. 165

[14.] Appendix – Instruction and commissioning ............................................................................................................. 166

[14.A]Instruction into general operation ................................................................................................................................. 166

[14.B]Instruction into functions ............................................................................................................................................... 167

[14.C]Instruction into maintenance works .............................................................................................................................. 169

[14.D]Advice and support documents .................................................................................................................................... 170

[14.E]Confirmation of commissioning and introduction / instruction ...................................................................................... 171

[14.F]Service report – cos15531 ........................................................................................................................................... 172

[14.G]Control protocol – cos15533 ........................................................................................................................................ 173

[14.H]Wiring diagram load circuit quasar med 5.0 / pulsar 5.0 .............................................................................................. 174

[14.I] Wiring diagram control circuit quasar med 5.0 / pulsar 5.0 – page 1 ........................................................................... 175

[14.J]Wiring diagram control circuit quasar med 5.0 / pulsar 5.0 – page 2 ........................................................................... 176

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 9 of 176

safety, warnings, precautions, prohibitions

[3.]Safety, warnings, precautions, prohibitions

[3.A] Safety precautions, safety regulations, prohibitions and warnings

N Use the running machine and accessories only under supervision of your doctor or/and trainer. Using the running

machine and the accessories without supervisory staff and introduction is forbidden.

N Before using the running machine, read the operation manual, safety precautions and safety regulations carefully.

N Start with slow walking. After some minutes increase the speed slowly according to your fitness level.

N It is strongly recommended to visit a doctor before using a sports device.

N Do not jump onto the rotating running belt. Do not jump off the rotating running belt (not even towards the front).

Do not stop moving or turn around on the rotating running belt. Never run sideways or backwards. Do not do

anything which could interfere with your balance. Do not set too high loads (speed, elevation).

N Always train with sports or running shoes (no spikes) - never run barefoot - and sports clothing.

N At the time of use the emergency-stop has to be in reach for the subject and the supervisory staff at any time.

N Use emergency-stop only if in danger or in danger of falling.

N At set elevation (e.g. by pressing the stop-button or the emergency-off-button, power failure, etc.), the bodyweight

of the subject and the force of gravity may cause an acceleration of the running belt. Do not step on the slant of

roller when getting on or off the running surface; the gravity force might cause a movement of the running belt.

N Dangerous capture areas/gaps at the elevation system as well as at the rear end and the sides of the running belt.

(At reverse belt rotation: danger as well at the motor hood and the front area).

N Please make sure that, in case of a fall, subjects with long hair, wide clothes, jewellery, etc. do not get caught in

the capture area at the rear end of the running belt. Possibly use a hairnet and make the subject aware of the

danger or secure the person with a safety harness against fall. Do not deposit any clothes, towels, jewellery, etc.

on the running machine – because of danger of tripping over and danger of capturing.

N Children and animals are not allowed to use the running machine and must not get too near (4 m distance) to it.

N Using the running machine under the influence of alcohol, drugs and/or anesthetic is prohibited.

N Interrupt the training immediately if you start feeling sick, dizzy or pain and see your doctor.

N Improper or excessive training or strain by tests may cause serious health injury or even death.

N Subjects with a cardiac pacemaker or those who suffers from any kind of physical restriction must see their doctor

and get a permission before using the running machine.

N The subject has to be secured by a safety arch with fall stop an chest belt while performing sprints, max.

endurance test and while training on wide running surfaces and/or other higher dangers.

N Please keep a safety area of at least 2 m in length and 1 m width directly behind the running machine. For running

machines equipped with reverse-belt-rotation keep a safety area of 2 m in length and 1 m width in the front and the

back of the running machine and always use the pull-rope emergency-stop or better the chest belt with fall-stop.

N Explicit warning of improper and forbidden use.

N Ensure that all cables (power connection, interface, potential equalization, etc.) and accessories are installed

properly and safely and that nobody can stumble or fall over the cables and/or accessories.

N Pay attention to further safety regulations and operation instructions in the appendix of this instruction manual. Pay

special attention to all maintenance and service instructions (also in manuals of accessories).

N

In case of any detected and/or assumed malfunctions and/or defects or unreadable safety warning labels the

device has to be taken out of operation, the device has to be marked and secured against operation and the

supplier and authorized service personnel has to be informed in writing.

N Disregard of warnings, disregard of intended and forbidden use, safety precautions and also unauthorized or lack

of maintenance and/or regular safety checks may lead to injuries or death and/or can damage the device and will

result in loss of any liability and warranty.

N Do not drink and eat any lubrication material and no other material or parts of this device, and keep all lubrication

material and all other parts away from children and animals.

N These safety precautions and regulations are to be displayed within sight of the running machine. The warnings,

safety regulations and dangers have to be pointed out to every user and operator. The manufacturer does not

undertake any liability for any injury to persons or damage to property.

N Valuable articles (like watches, emblazonments, etc.) must be abated before using the device and must also not

be in near environment of the device.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 10 of 176

safety, warnings, precautions, prohibitions

[3.B] Exit the device in emergency case

In any emergency case (e.g. danger of stumbling and/or falling, etc.) the emergency button has to be pressed instantly!

Hold the side rails and/or the front rail with both hands and step on the footrest (step-platforms) with both feet.

[3.C] General Instructions / Safety

This instruction manual is part of the device and must always be accessible for every user.

Exact observance of the instruction manual is a requirement for the appropriate operation of an h/p/cosmos device.

Holding the handrails during exercise may effect the exercise results (e.g. heart rate, ECG, oxygen uptake, etc.). Under

normal conditions and for healthy subjects we recommend to hold the handrails only for emergency or when needed for

safety or unweighting.

Important notes, warnings and safety precautions are marked with the opposite sign. It also

reminds you of concerns which have to be considered for measurements and connection with

other devices.

The safety of your subjects and the compliance to the mentioned accuracy of measurement can only be achieved, if the

consumption goods, sensors and detectors, described in the instruction manual, are being used and the recommended

preventive maintenance and safety checks are performed by personnel authorised by h/p/cosmos.

Absorption-, cleansing- and disinfecting chemicals are only to be kept in the appropriate reservoirs. At the connection of

gas pressure container it has to be examined about its MOT-admissibility (TÜV) first. Pull the plug before cleansing or

disinfecting electric devices.

Safety, reliability and function can only be achieved if ...

N installation, extension, alteration and repair is performed by authorized people.

N the room for installation corresponds to the DIN and VDE installation directives.

N the device is plugged in at a socket with a protection system.

N the room for installation corresponds to the requirements of the surroundings for the device.

N the device after the instruction is being used in accordance with the instruction manual.

The entry of fluid into the device has to be removed immediately by the authorized customer service and a safety

examination has to be performed. Damaged socket connections, wires and pressure control switches have to be

replaced instantly by trained personnel or by authorised persons.

In case of any detected and/or assumed malfunctions and/or defects or unreadable safety warning

labels the device has to be taken out of operation, the device has to be marked and secured

against operation (for example pull power plug and affix warning/defect label on the power plug)

and the supplier and authorised service personnel has to be informed in writing.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 11 of 176

safety, warnings, precautions, prohibitions

[3.D] Instructions for safety and operation

The regulations mentioned in this chapter refer to the Federal Republic of Germany. For all other states take into

account the national legislation. If the running machine is a sports device (only c mark without 4-digit number), it must

not be connected with a medical product and must not be used for medical purposes. Due to higher safety requirements

medical instruments and devices are not allowed to be connected via extension cable and/or multiple plug socket with

the power supply, and a medical product must not be connected with a sports device either.

Disregard of warnings, disregard of intended and forbidden use, safety precautions and also

unauthorized or lack of maintenance and/or regular safety checks may lead to injuries or even

death and/or can damage the device and will result in loss of any liability and warranty

[3.D1] Electric safety / Safety classes

In order to protect the subject (athlete and/or patient) and the personnel, the association of German electrotechnicians Inc, (VDE) has published special directives for medical used rooms and electro-medical devices.

Devices with a power supply therefore have to, in order to prevent the passing on of the mains voltage over to

touchable metal pieces, be equipped with not only a reliable isolation of the parts being under voltage but also

additional safety precautions. The VDE-association divides it into so called safety classes.

Of the, for electro-medical devices, licensed safety classes are mainly used the safety class I (i.e. safety

precautions with protective wiring), and the safety class II, (i.e. safety measures without protective wiring but with

double isolation): Devices of the safety class I are devices, where the metallic casing-parts are connected with the

protective wire of the line net via the safety contact. In the case of an isolation error the inserted fuse element

switches off.

[3.D2] Patient security according to VDE 0750 (IEC 601-1) type B

If your h/p/cosmos device has a c mark with a 4-digit number (e.g. n) at the identification plate, it is a

medical product. At your h/p/cosmos medical product the patient is protected/isolated from the mains in

accordance with the safety standard referring to the requirements for leakage current values according to IEC 6011 type B. The connection of further mains-operated units to your h/p/cosmos-unit may cause that all the leakage

currents add and the safety of the patient is reduced. Due to this the connection of further units may only be

carried out on consultation with h/p/cosmos.

[3.D3] Potential equalization

The connection of e.g. EDP units to the V24 / RS 232 / USB / LAN / FireWire interface of the computer or of other

independent measuring stations can only be carried out in medically utilized locations according to VDE 0107 / EN

ISO 60601-1-1. Parallel connection of the potential equalization ensures, that in case of insulation failure none of

the connected units exceeds a voltage of 10mV and thus endangers the patient.

For this purpose all of the h/p/cosmos units are equipped with a connection fixture with which the equipotent

conductor, being part of the standard equipment, is connected to the equipotent bus bar of the room.

Standard potential equalization cable (length 5m) with 4mm

2

cross-section [cos10223]

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 12 of 176

safety, warnings, precautions, prohibitions

[3.D4] Connection of units installed outside medically utilized locations

If units installed outside medically utilized locations (e. g. external printer, host computer etc.) are connected to an

h/p/cosmos unit installed in a medically utilized location the VDE 0750 regulations must be observed. Connection

only via …

1. Optical fibre or optocoupler (4 kV checked and approved) or …

2. Protective isolation via insulation transformer according to IEC 601-1, appendix k. These units are to be

connected to the equipotent conductor.

Due to the increased safety requirements medical instruments may not be connected via extension leads or multiway connectors.

[3.D5] Medical electrical systems

The medical electrical system (later in this text referred as “system”) is a combination of several devices, of which

at least one is a medical electrical equipment. A combination occurs when devices are connected via so called

“functional connections” or via a mobile multiple socket. Not only electrical connections are defined as “functional

connections” but also those for the transmission of signals, electrical energy and/or substances. Thus already the

operation of two or more devices on the same multiple outlet is defined as a system. Even a mechanical

connection or a wireless connection produces a medical electrical system.

Basically it is imperative that a system is as safe as a single medical electrical equipment. The requirements in the

medical devices act and the applicable regulations (for example MPBetreibV) must be met. The system as a whole

must ensure that within the patients environment or at contact with patients the same level of safety prevails, as

determined by DIN EN 60601-1 (VDE 0750 Part 1).

[3.D6] Subject's surroundings

The surroundings of the subject must

have a gap of 1.5 m as it has been

proofed by experience. This has been

laid down here as the surrounding.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 13 of 176

[3.D7] Protection against the danger of electrical shocks

Casing and cover: Parts of non-medical

electric devices within the surrounding of

the subject, which, after having taken off

the coverings etc. without the use of tools

for a routine maintenance etc., are in

touchable reach, have to operate with a

voltage that does not exceed 25 volt

alternate voltage and 60 volt direct

voltage, which is produced by a separate

source as described in IEC 601-1.

According to this example the leakage

current would flow from the electric device

to the earthened subject via the trainer/doctor.

Electrical equipment [3] and a subject [1] must never be touched by the doctor or trainer [2]

at the same time.

[3.D8] Environmental requirements

safety, warnings, precautions, prohibitions

Running machines are not to be used in medically utilized rooms with a danger of explosions or in easily

inflammable atmospheres. The devices must not be installed near to e.g. an x-ray device, motors or transformer

with high connection power, as the electric and magnetic interference can falsify measurements or even make

them impossible. High voltage lines must be avoided nearby the device. h/p/cosmos electrical devices with mains

connections must neither be used in wet and humid areas (e.g. swimming pool, sauna, etc.) nor in environmental

chambers.

If not stated otherwise in the delivery information h/p/cosmos devices are designed for operation in normal climatic

surroundings (DIN IEC 601-1):

N Temperature: + 10° ... + 40° C

N Relative humidity: 30 ... 70 % (non condensing!)

N Air pressure: 700 ... 1060 mbar

N Maximum operating altitude: approx. 10,000 feet (3000m), without pressurization

The running machine has to be protected from high humidity. Venting slots are not to be covered; otherwise it

would hinder the air circulation. Store the devices at a temperature of – 20° ... + 50° C.

All devices can be stored without power-connection and without operation for a period of 6 – 9 months. After this

period batteries in the device may be discharged and maintenance and/or a new setup/programming of the device

could required by authorized h/p/cosmos technician.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 14 of 176

safety, warnings, precautions, prohibitions

T

[3.E] Economic life-time

The economic life time of the product is determined at common usage and application to 20 years, provided that after 10

years all electrical parts and component are renewed (at damage or unusual heavy duty possibly earlier) and the

recommended maintenance intervals are kept. Every maintenance and repair work needs to be carried out by

authorized h/p/cosmos technicians. For expendable parts a shorter life-time is due.

[3.F] Symbols used

All symbols used comply with the according norms IEC417, IEC878, EN957-1:2005 and Council Directive 2002/96/EC.

Read manufacturer’s guide, advises,

instructions and manual

Warning / safety precautions

Pay attention to accompanying instructions

R

J

[3.G] Safety standards, norms

All h/p/cosmos running-machines are produced according to strict safety- and quality controls. The running machine

must not be used, if the certificates/permissions and the (according to the list of technical specifications) defined safety

standards do not correspond with the local and country-specific requirements. The country-specific requirements must

be compared before initial operation. Operate running machine only, if the requirements correspond. Full list of

applicable norms see also in the CE-certificate of compliance.

The standards with date in this manual with reference to design and construction characteristics, refer to the up to date

valid versions at the time of manufacture.

The standards with date in this manual applying to routine measurements and continual safety relevant measures (e.g.

electrical measurements to determine leakage current, insulation resistances etc.) can and will change with time.

Therefore the up to date valid versions of the respective standards at the time of measurement and their limit values,

which can deviate then from the procedures and limit values in this manual, apply.

Devices of the type B

Dangerous electric voltage

Alternating current (AC)

M

N

P

Protection ground

Earth

Potential compensation

Symbol for collection, treatment, recycling

and disposal of waste electrical and

electronic equipment (WEEE) as set out in

Directive 2002/96/EC of 27 January 2003

of the European Parliament and of the

Council on waste electrical and electronic

equipment are necessary to reduce the

waste management problems linked to the

heavy metals concerned and the flame

retardants concerned.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 15 of 176

safety, warnings, precautions, prohibitions

[3.G1] VDE norm

The running-machines for the professional application in sports and fitness have been built corresponding to the

DIN EN 60335-1 (VDE 0700) guidelines. The running-machines for the professional application in the medical area

have been built corresponding to the DIN EN 60601-1 (VDE 0750) guidelines.

[3.G2] The c mark

The c mark on the nameplate of the sports and fitness running machines confirms the compliance to the council

directive 89/336/EEC appendix I (EMC electromagnetic compatibility). The audit has been conducted after the

criterion of jamming and interference immunity.

[3.G3] The n mark

The n mark on the nameplate of the running machine for medical application confirms the compliance to

the council directive 93/42/EEC (MDD Medical-Device-Directive).

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 16 of 176

safety, warnings, precautions, prohibitions

[3.G4] EMC Electromagnetic Compatibility

The running-machines for the professional application in sports and fitness (with c mark) have been built

corresponding to the European Union Council Directive 89/336/EEC (EMC) and the low voltage directive

73/23/EEC. Norms: EMC: EN55011; EN61000-6-1; EN61000-3-2; EN61000-3-3, Safety: EN60950

The running-machines for medical applications (with n mark) have been built corresponding to the

European Union Council Directive 93/42/EEC

Norms: EMC: EN60601-1-2; EN61000-3-2; EN61000-3-3, Safety: EN60601-1

Certification bodies: Mitsubishi Electric Europe / EMC-Laboratroy, Mündelheimer Weg 35, DE 40472 Düsseldorf

EMV Testhaus GmbH, Gustav - Hertz - Strasse 35, DE 94315 Straubing / Germany, J. Schmitz GmbH, 83022

Rosenheim

Strong electromagnetic fields, transmitters and interferences, which are above the normal tolerance, can interfere

with measuring fuctions and displays of the running machines and can lead to other malfunctions.

Follow details to EMC values, guidance and manufacturers declaration in this manual in chapter „technical data“

[3.G5] General advice

The device is assigned to overvoltage-category II and pollution level I.

[3.H] Fields of application / intended use

All running-machines are built corresponding to the classes S and A based on EN 957-1:2005 / EN 957-6:2001.

[3.H1] Professional application in sports and fitness

The running machine models designed for sports and fitness have not been tested for application in medical areas

and therefore are not qualified for that field of application. They must not be connected to other medical devices.

You can apply these models in endurance training walking and running.

[3.H2] Professional application in the medical field

The running machine models designed for professional application in the medical field are also qualified for sports

and fitness use as well as for application in the medical field.

N Endurance training walking and running

N Endurance tests and EMG-measuring with the subject in the laboratory (only with safety arch / fall stop)

N Ergometry on the Running-Machine, Exercise- ECG and Ergospirometrie (only with safety arch / fall stop)

N Gait training

N Recreational fitness training

Children are only allowed to use the running machine under constant supervision of a

medical doctor and only when safeguarded by safety harness with fall-stop. Additionally

h/p/cosmos suggests the use of adjustable handrails.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 17 of 176

safety, warnings, precautions, prohibitions

[3.H3] h/p/cosmos medical running machines - MDD medical device directive. Safety standards

Over 20 years of experience in the production of treadmill-ergometers and complex systems with accessories and

special options have made h/p/cosmos the absolute treadmill specialist. We consider ourselves as the “market

precursor in technology and safety” amongst all treadmill manufacturers. Safety has a very high priority for us –

above all because we know from experience what kind of accidents can occur and which consequences might

result from these accidents.

On the one hand a treadmill is a very effective instrument in rehabilitation, therapy and diagnostics. However, like

in many areas of daily life (i.e. all kinds of traffic, may it be by car, train or bus or the handling of electrical machine

tools etc.) the use of a treadmill involves dangers which can be minimized by abiding strictly to safety procedures,

but can never be fully ruled out. As a manufacturer it is h/p/cosmos’ duty, and as the distributor or enduser/operator of the running machine it is your duty, to minimize those dangers as far as possible.

In medical applications many additional risks (patients with pacemakers, ECG lead and electrode connections to

the skin, health and physical limitations, high workloads during stress tests, medication, etc.) have to be

considered. Therefore medical treadmills with interface and interactive heart rate based load controls are classified

as risk class IIb medical devices. They have specific additional design characteristics compared to fitness

treadmills, and can only be sold and serviced by authorized and certified distributors. h/p/cosmos has the

responsibility to ensure that the systems are correctly installed (with usage instruction) and maintained. Therefore

we have implemented a medical device observation and reporting system based on the statutory obligations

contained in, Guideline 93/42 EEC, MDD (medical device directive), ISO9001 and EN13485 standard and our

internal safety policy and risk management system. This is of utmost importance and all our distributors must sign

a contract that they will comply with these important international rules for medical devices, particularly for class IIb

devices and their respective statutory requirements.

h/p/cosmos fulfils its duty in different ways:

N All medical treadmill-ergometer device-families have to undergo an internal product-type examination as well

as external tests performed by the respective examination institutes such as the TUV Product Service in

Munich / Germany or the EMC laboratory. Our medical treadmill-ergometers meet the norms and guidelines

stipulated for medical applications such as the, MDD, EU guideline 93/42 EEC for medical products, IEC EN

60601-1 (VDE 0750), VDE 0751, IEC EN 60601-1-2 (EMC), IEC EN 60601-1-4, EN 957-1, EN 957-6.

N All h/p/cosmos medical treadmill-ergometers must undergo a 24-hour non-stop test after production with strict

safety tests, high-voltage-tests and electrical as well as mechanical safetychecks. All tests are recorded,

checked by a second independent employee and filed. h/p/cosmos treadmills have to pass the checks 100%

without exception.

N All medical h/p/cosmos treadmill-ergometers have an Emergency Off Switch (current off with mains

disconnection, not only the “standard software controlled emergency stop button”), power supply with

increased voltage resistance, electrical installation and wiring according to IEC 60601-1, a potential

equalization pin and a potential equalization transformer.

N h/p/cosmos has a quality management and risk management system according to ISO 9001:2000 & ISO

13485:2003 as well as medical device observation and incident reporting system.

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 18 of 176

safety, warnings, precautions, prohibitions

N In the course of maintenance work h/p/cosmos technicians or authorised service personnel check the

electrical safety of the treadmill together with all safety relevant details and measure the accuracy of speed

and elevation of the treadmills at the customer’s premises.

N h/p/cosmos trains all relevant service technicians and sales personnel as medical device consultants with

respective certification.

N The user manuals of h/p/cosmos treadmills contain all important information and safety advice as well as

maintenance instructions and user regulations. The treadmills have a label with the date of the next safety

check /maintenance.

N h/p/cosmos offers numerous options and accessories such a safety arch with harness for fall prevention,

chest belt with automatic stop, arm supports or the unweighting system h/p/cosmos airwalk, which increase

safety for the patient during the use of a treadmill-ergometer. http://www.h-p-cosmos.com/en/safety/index.htm

All running machines and other machines with moving belts and parts, hold a great potential of danger at the belt

re-entry zones on the sides and at the end of the running surface, as the gap between running belt and frame is

frequently too wide. To reduce the risk for users, h/p/cosmos running machines have a gap of less than 4 mm and

it is marked clearly with additional danger precaution stickers.

Therefore we take it as our responsibility to inform our partners and customers about the background and

necessity only to use medical products in the medical application field. Statutory requirements only permit us to

supply medically classified equipment for medical applications.

Medical Device Directive Article 1 Definitions, scope 2 a.)

“medical device” means any instrument, apparatus, appliance, material or other article, whether used alone or in

combination, including the software necessary for its proper application intended by the manufacturer to be used

for human beings for the purpose of: Diagnosis, prevention, monitoring, treatment or alleviation of disease,

diagnosis, monitoring, treatment, alleviation of or compensation for any injury or handicap, investigation,

replacement or modification of the anatomy or of a physiological process, control of conception, and which does

not achieve its principal intended action in or on the human body by pharmacological, immunological or metabolic

means, but which may be assisted in its function by such means;

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 19 of 176

safety, warnings, precautions, prohibitions

The use of a product not released for medical use by the manufacturer in a medical application can result in

increased risks for the patients and for the operator – especially in the case of an accident on the treadmill

ergometer. In this case all parties involved (your insurance company, your professional association, possibly

patients lawyers and courts) will question negligence and liability. Therefore the use of a sports device for medical

purposes bears increased risks for the distributor, customer, operator, end user and last but not least the patient.

Despite that some of the above mentioned laws and guidelines are only binding within the European Union, the

patient’s needs, the risks and the required safety procedures are the same all over the world. We ask all parties

involved to help in improving safety.

Some examples for safety features at h/p/cosmos devices:

Potential isolation

Opto coupler board Potential equalization

transformer

Medical devices are equipped with an Emergency-OffButton instead of a conventional Safety-Stop-Button,

which disconnects the device from the power supply when

pushing the button in emergency cases. Sport devices

mostly are only equipped with an emercency-stop-button,

which only stops the machine but does not disconnet it

completely from the mains.

Shielded motor

connector

cable

Frequency inverter metal housing (for shielding)

Danger zone sticker

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 20 of 176

safety, warnings, precautions, prohibitions

[3.I] Forbidden use

N All prohibitions in the chapter "safety precautions, safety regulations, prohibition and warnings"

N The running machine must not be used without being carefully instructed by specialist staff and without having

received notes on the safety regulations.

N Interrupt the training immediately if you start feeling sick or dizzy and see your doctor.

N Subject with a cardiac pacemaker or who suffers from any kind of physical restriction must see a doctor before

using the running machine and ask for allowance.

N Children and animals are not allowed to use the running machine and must not get near (4m safety area) to it.

N Other use, then explicitly listed directed use at the point field of application.

N In case of any detected and/or assumed malfunctions and/or defects or unreadable safety warning labels the

device has to be taken out of operation, the device has to be marked and secured against operation and the

supplier and authorized service personnel has to be informed in writing.

N Every kind of overload of test person / subject / patient is forbidden.

N Every kind of use with increased risk, e.g. sprint or medical application with patients and increased risk of falling, is

forbidden without using additional safety precautions and safety equipment, such as e.g. safety-arch with fall-stop.

N In case of existence of one or more of the following contraindications we strongly suggests to see a medical doctor

or a specialist before using the running machine: pregnancy, acute thrombosis, heart- and/or arteries disease,

fresh wounds e.g. after surgery, artificial joints and limbs, acute fracture, damaged disc or traumatic caused

disease of the spine, diabetes, epilepsy, inflammations, acute migraine and any kind of tumors. Please contact the

manufacturer h/p/cosmos, if your doctor or specialist needs further information about the running machine.

N The automatic operation (modes profile, cardio, test, remote control via PC and peripheral devices) is forbidden, if

the health and condition of the test person / subject / patient does not allow it and if a doctor has not authorized it.

Disregard may cause injuries and dangerous health problems and even death.

N All use with wheels (cycling, wheelchair, inline-skating or roller-ski) is forbidden at standard running surfaces and -

belts. Such applications are only allowed at special running machines marked with „r“(e.g. h/p/cosmos saturn

300/100r). Additionally a safety harness with fall-stop is prescribed. The brakes at the bike respectively wheelchair

must be deactivated (e.g. demount brake suspension) and the stop at the inline-skates must be demounted during

the exercise on the running machine. Do not forget to reactivate brakes before using this equipment outdoor again.

N Never use running shoes or other shoes with spikes or studs at the standard running surface resp. running belt.

These applications are only allowed on special running machines with suffix „rs“ which have as an option

additionally an extra thick running belt. A safety arch with chest belt and fall-stop is also obligatory in this case.

N In environmental conditions, others than specified in the chapter „technical specifications“ and “environmental

conditions“, h/p/cosmos devices must not be used (e.g. in wet and humid areas, swimming pools, sauna,

environmental chambers, high-pressure-, low-pressure, altitude- and oxygen-chambers, etc.).

At the suspicion of unauthorized access or other reasons to lock the running machine, it has to be

locked for starting: See „option 40“ in chapter „option settings“. With option 41 ... 44 you can lock

also separate modes (manual, profile, cardio, test).

file: n:\article\cos14310m5-v1.04hpc-en\20080901_cos14310m5-v1.04hpc-en_manual_h-p-cosmos_running_machine.doc

© 2008 h/p/cosmos sports & medical gmbh email@h-p-cosmos.com created 01.09.2008 printed 08.10.2008 page: 21 of 176

installation & commissioning

[4.]Installation & commissioning

[4.A] Transport, unpacking and packaging

When receiving the machine in a crate or unpacked, make sure the machine, the accessories and/or the packaging is

not damaged. If you discover any damage and/or missing parts make a note on the packing-list / delivery note of the

carrier. Inform h/p/cosmos and your dealer immediately in writing about any damages and/or missing parts.

The manufacturer does not undertake any liability for any damage, complaints and missing parts

which is not reported immediately by delivery on the packing-list / delivery note.

Before you unpack the machine and accessories read instructions on the crate. Make sure that the machine, power

connection cable or any optional equipment will not be damaged during unpacking. Pay special attention on small parts,

so that you do not dispose them or any instructions with the packaging. Within Germany mostly all devices are delivered

and assembled by h/p/cosmos directly or by an authorised forwarder. If delivered by h/p/cosmos the packaging will be

taken back and recycled.

If the running machine is being delivered by a carrier, you can recycle the packaging yourself or send it back to the