®

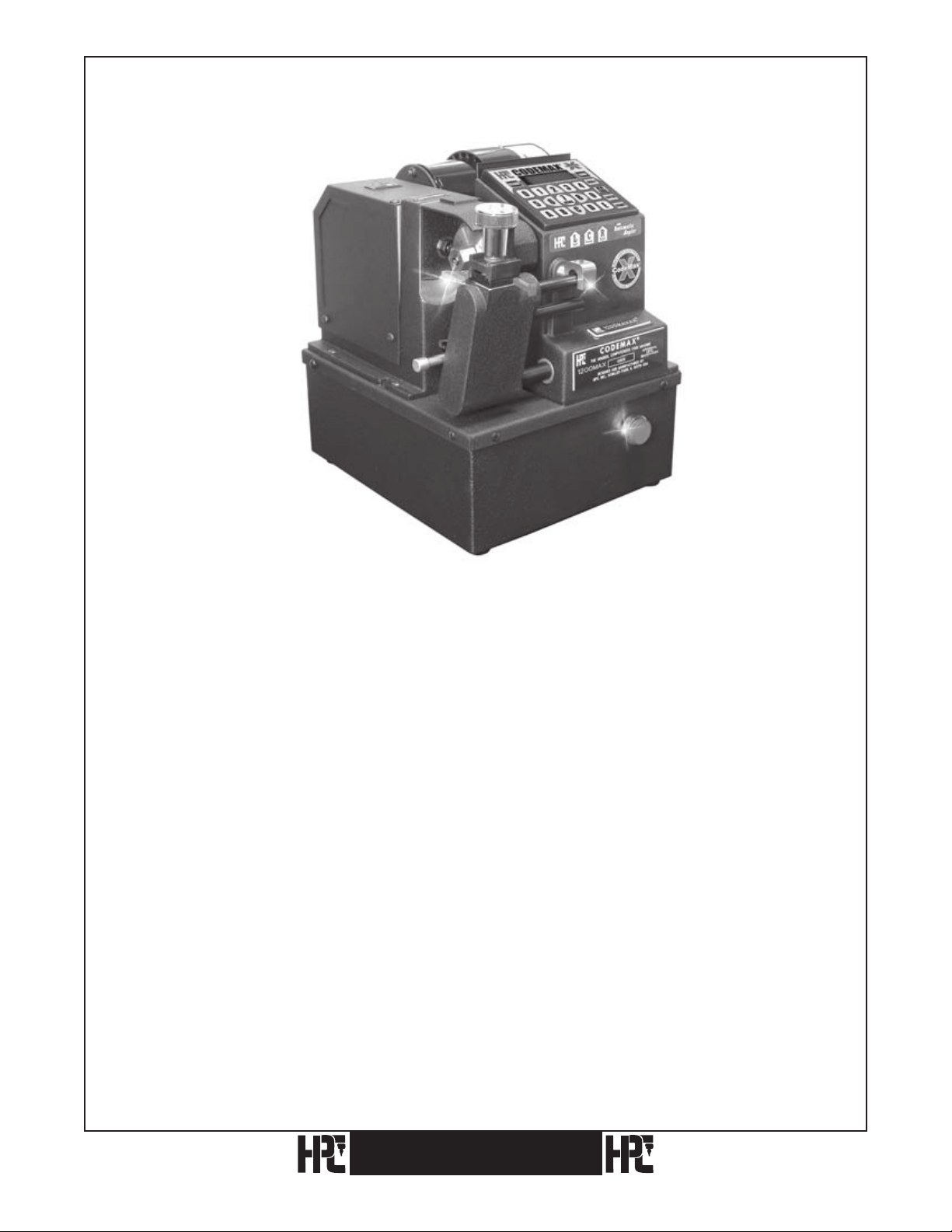

CodeMax

Machine

Computerized

No. 1200MAXAA

Cutting

Code

No. 1200MAX

Exploded View

Parts List Inside

&

© 2013 HPC, Inc. • Schiller Park, IL • 60176 • USA • www.hpcworld.com

041013 36012_000_00

The CodeMax

Computerized Code Key Machine

®

This manual and the internal software and data of the CodeMax® described in this manual

are copyrighted by:

HPC, Inc., Schiller Park, Illinois, U. S. A.

The internal software and data is a work fully protected by the United States

Copyright Laws.

Federal Law: This manual or the internal software of the CodeMax®may not be copied,

translated, photocopied, microfilmed, or reproduced in any manner to be machine readable

in any form (in whole or in part), without the express written consent of the

copyright holder.

HPC, Inc.

Schiller Park, Illinois

Copyright 2008

CodeMax

®

1

X

Visit the CodeMax® web page at

www.hpcworld.com/km/codemax

to learn about your machine.

Look For...

Look For...

Look For...

1 2 3 4 5

Look For...

Look For...

Watch Our

Other Videos

Features of the

CodeMax®

Depth & Space

Data

Manuals

and

Exploded Views

Exploded

Views

To watch the videos showing the

important features of the CodeMax®.

To learn the features of CodeMax®

Version 10 (Upgrades are available).

To view or download the current list

of DSD numbers and the key cutting

details for each one.

To view or download a PDF of the

CodeMax® Operation Manual.

To access the Exploded View and Parts

List to identify a spare part needed.

Look For...

Key Machine

Accessories

2

CodeMax

To see the accessories that are

available for your CodeMax®.

®

Index

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Product Packaging Checklist

1.2 Parts Designation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Preparation of the CodeMax

1.4 Basic Codemax Setup

1.5 Emergency Button

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

®

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Cutter Wheels

2.1 Cutter Wheel Descriptions

2.2 Changing Cutters

2.3 Resharpening Cutters

3. Holding And Gauging Keys

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1 Vise Jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Key Gauges

3.3 Gauging Methods

3.3.1 Standard Cylinder Key With Shoulder Gauge Using Jaw A

3.3.2 Standard Cylinder Key With Shoulder Gauge Using Jaw B

3.3.3 Red Full Short Tip Stop Gauging Using Jaw A

3.3.4 Red Middle Short Tip Stop Gauging Using Jaw A

3.3.5 Black Horseshoe Tip Stop Gauging Using Jaw B

3.3.6 Medeco

Using Jaw C (optional equipment)

3.3.7 Black Horseshoe Full End Tip Stop Gauging Using Jaw A or B

4. Key Cutting Methods

4.1. Stand Alone Key Cutting

4.1.1

4.1.2 Medeco® Keys

4.1.3 After The Key Has Been Cut

4.1.4 Additional Notes

4.2 Computer Assisted Key Cutting

4.3 Micrometer Key Cutting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . 25

®

– Standard Commercial Jaw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Standard Keys

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

30

5. Recalibration Of The CodeMax

5.1 Electronic Calibration

5.1.1 Depth Instructions

5.1.2 Space Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1.3 DSD Specific Instructions

5.2 Manual Calibration

Space Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

®

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.1 Cutting Too Close To The Tip On Keys Gauged From The Tip

5.2.2 Cutting Too Far From The Tip On Keys Gauged From The Tip

5.2.3 Cutting Too Far From The Shoulder

5.2.4 Cutting Too Close To The Shoulder

5.3 Depth Adjustment

6. Updates

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7. Troubleshooting

8. Glossary

9. Exploded Views

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10. Preventive Maintenance, Lubrication, Repairs, and Guarantee

CodeMax

®

. . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . .

68

3

1. Introduction

Thank you for purchasing this CodeMax® Machine; we appreciate your business.

The CodeMax® represents the latest development in the industry’s first computerized code

machine. Utilizing cutting edge technology, this version allows for electronic calibration,

DSD modification, and updates installed by your computer.

Please read this manual to become familiar with the features and operation of your

CodeMax®. This machine is updated every year with new information and features. Please

complete and return the enclosed warranty registration card to ensure you receive notice of

future updates.

We are confident your CodeMax® will provide years of service for you. If you have any

questions or comments about this machine (or any HPC products), please contact us.

Thank you,

HPC, Inc.

3999 N. 25th Avenue

Schiller Park, Illinois 60176

U.S.A.

Tel: 847.671.6280

Toll-free in U.S.A. and Canada: 800.323.3295

Fax: 847.671.6343

Email: hpc@hpcworld.com

www.hpcworld.com

4

CodeMax

®

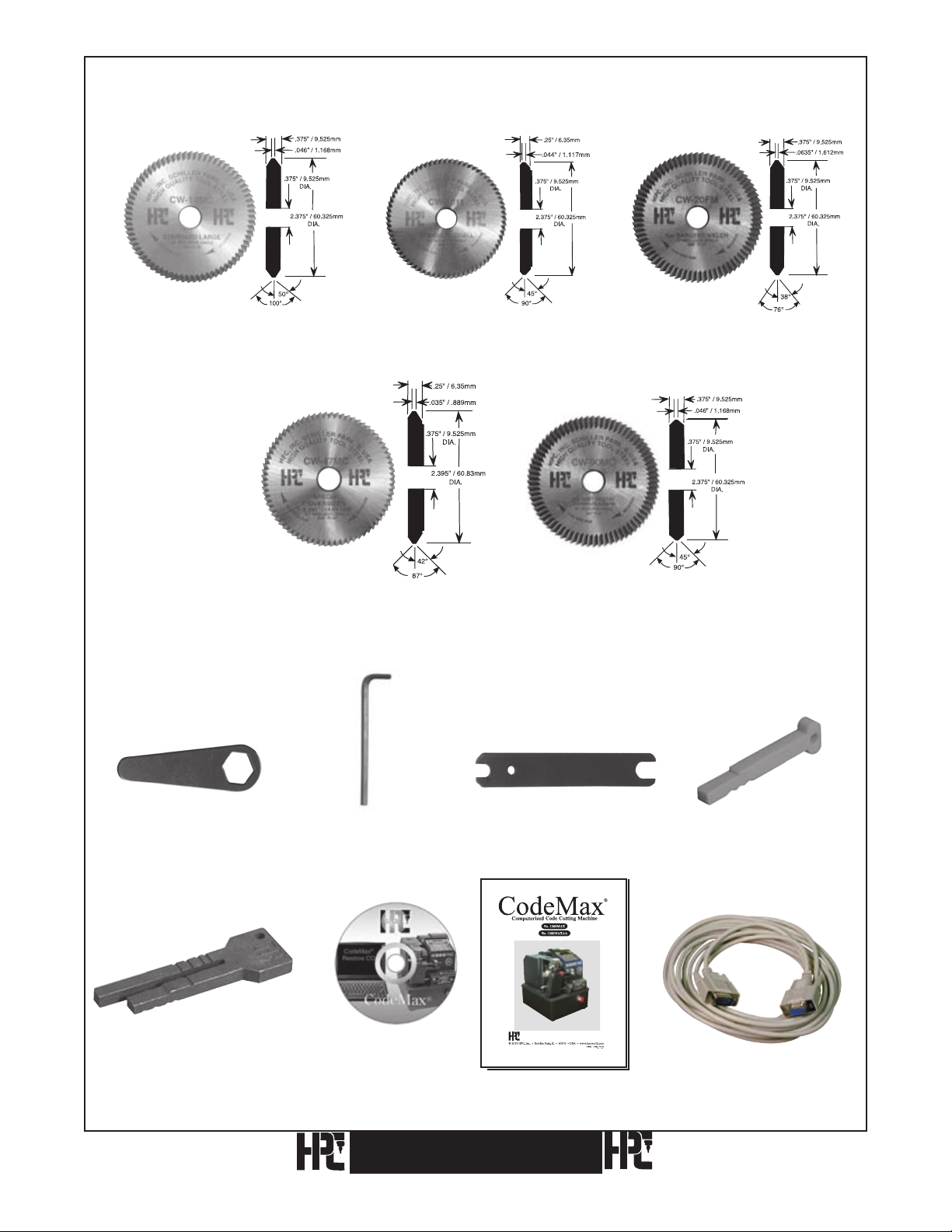

1.1 Product Packaging Checklist

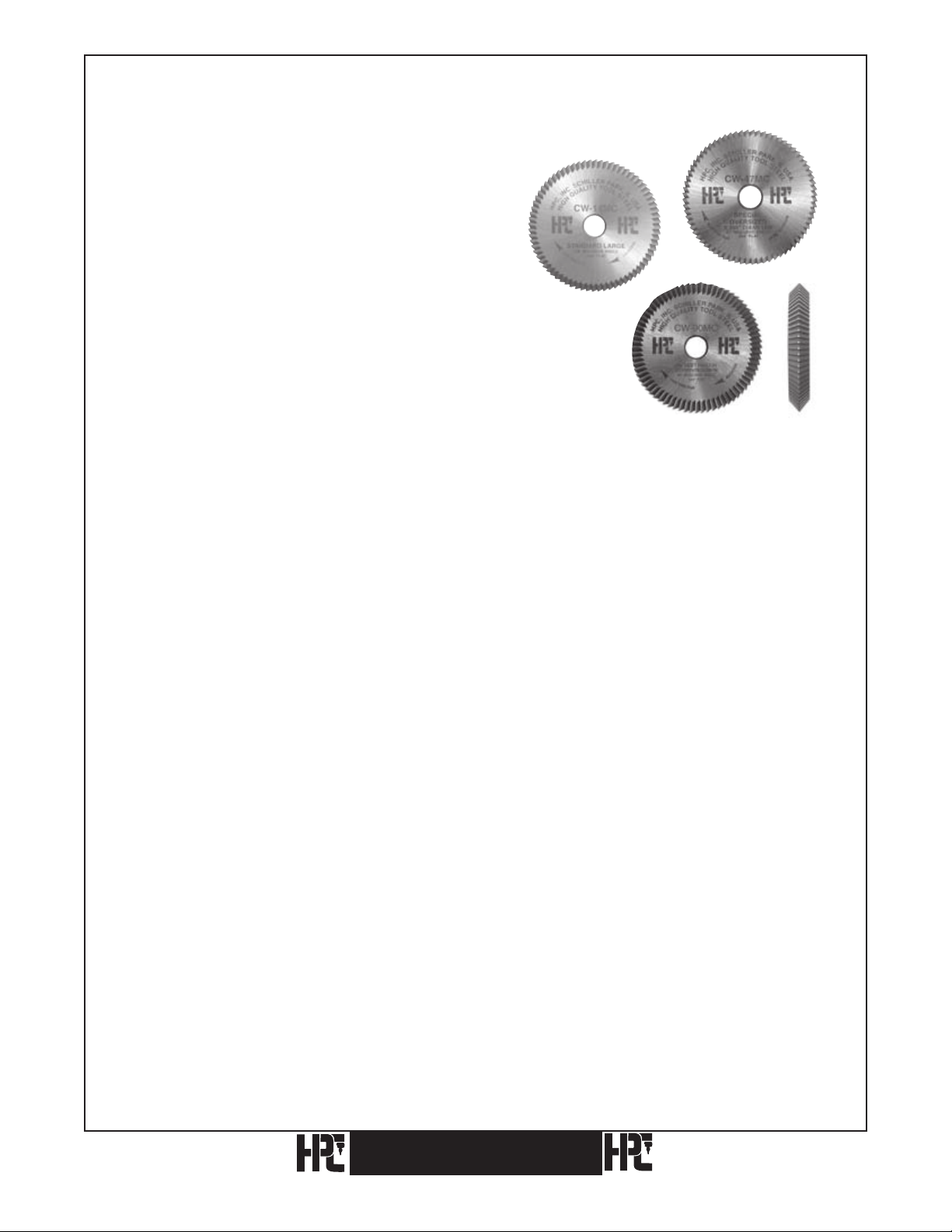

HPC Cutter Wheel (installed) HPC Cutter Wheel HPC Cutter Wheel

(CW-14MC) (CW-1011) (CW-20FM)

HPC Cutter Wheel HPC Cutter Wheel

(CW-47MC) (CW-90MC)

Cutter Wrench Allen Wrench, 5/64" Cutter/Adjustment Wrench Red Tip Gauge

(WRENCH-3) (WRENCH-2) (WRENCH-1) (CM-1054MA)

Horseshoe Tip Gauge DSD List

(CM-1054R) CodeMax® Update &

Restore CD

(MAX-CD)

CodeMax

CodeMax® Manual

(1200MAX-MAN)

®

Serial Cable

(CABLE-25S)

5

Your CodeMax® computerized code machine comes with the following additional items

(see the photos on the previous page):

Qty. Stock No. Description

1 CW-14MC HPC Cutter Wheel (Installed on Machine)

1 CW-1011 HPC Cutter Wheel

1 CW-20FM HPC Cutter Wheel

1 CW-47MC HPC Cutter Wheel

1 CW-90MC HPC Cutter Wheel

1 WRENCH-1 Cutter Shaft/Adjustment Wrench

1 WRENCH-3 Cutter Nut Wrench

1 WRENCH-2 Allen Wrench, 5/64-inch

1 CM-1054R Black Horseshoe Tip Gauge

1 CM-1054MA Red Tip Gauge

®

1 MAX-CD DSD List, CodeMax

®

1 1200MAX-MAN CodeMax

Manual

Update and Restore CD

1 — Warranty Registration Card

1 CABLE-25S Serial Cable

6

®

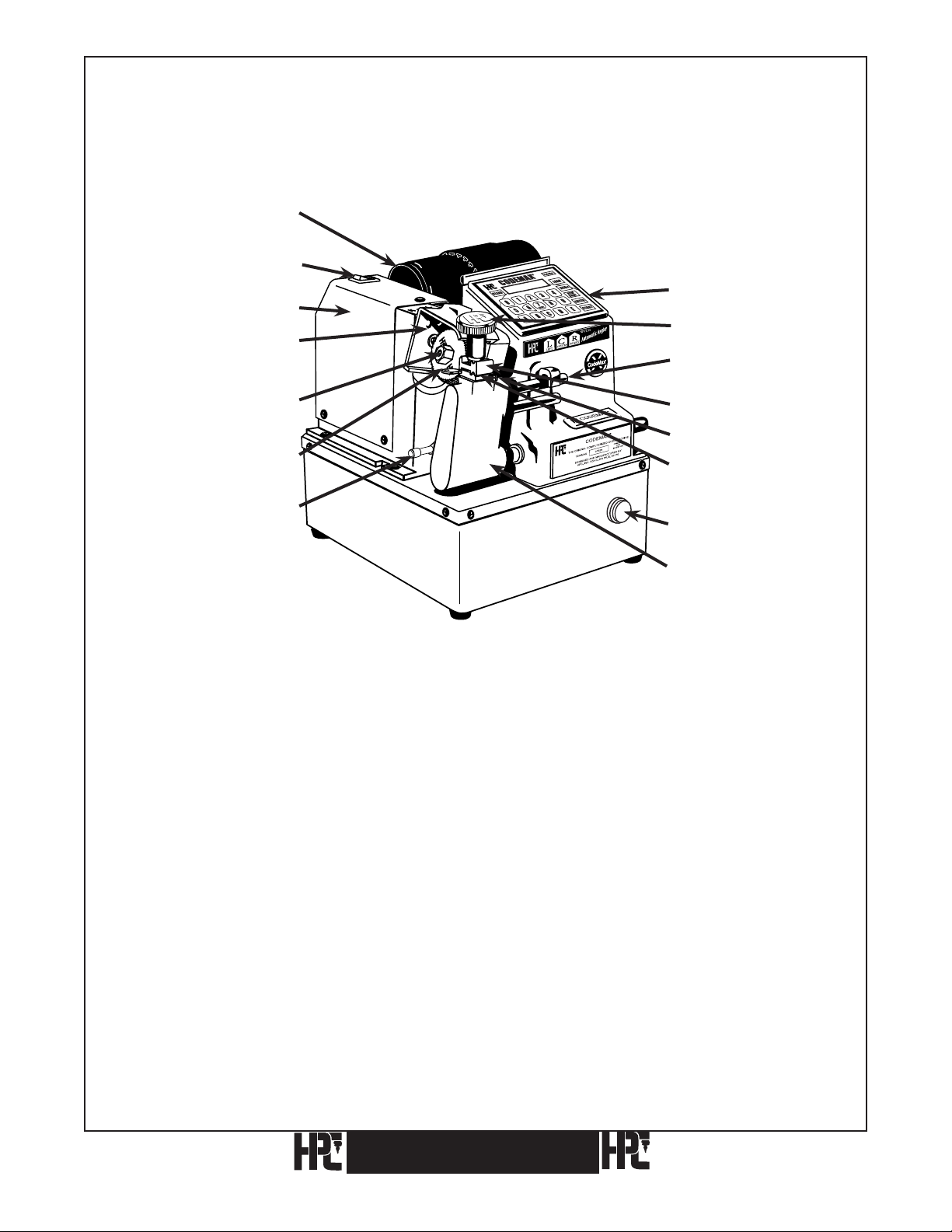

1.2 Parts Designation

X

120VAC Motor (CM-1080MA)

240VAC Motor (CM-1070)

Power Switch

120VAC (KM-1017)

240VAC (9160-SW)

Automatic Angler

Cutter Head (KM-1016)

Keypad (MAX-4)

Wing Nut (EGN-1)

Eccentric Shaft

(CM-1041)

Cutter Nut (CM-1039MA)

Cutter (Wide Selection

Available)

Shoulder Gauge (CMB-FG)

Top Jaw (CM-1056MA)

Tip Gauge (CM-1054MA)

Bottom Jaw

(CM-1055MA)

Emergency Stop Button

(MAX-50)

Pivot Arm (CM-1024X)

CodeMax® CodeMax

7

1.3 Preparing To Use The CodeMax® Computerized Key Machine

Before using the CodeMax® key machine, read this manual in order to gain a thorough

understanding of all of its capabilities. You will receive peak performance and efficiency

from your machine by fully comprehending all of its functions.

Make sure that the power outlet that the CodeMax® will attach to is properly wired, i.e.,

grounded with correct hot and neutral leads. If the outlet is not wired properly or power

from the available outlet is not regular (i.e., you experience frequent power brownouts), the

CodeMax® may malfunction. While the CodeMax® contains an internal surge protector, it

is recommended that you also use an external surge/brownout protector when operating the

CodeMax®.

8

CodeMax

®

1.4 Basic CodeMax® Setup

Find a suitable location for the

CodeMax® machine. This should be

an area with good ventilation for the

cutter motor and easy access to the

front and top of the machine for use

and cleaning.

Plug the cord into the back of

the CodeMax® and then into the

appropriate electrical outlet. Turn

on the CodeMax® using the switch

located at the left rear of the

machine.

The display will read “Emergency

Stop Depressed”. Make sure there

is nothing interfering with the

pivot arm, cutter wheel, and motor.

Push the large, red emergency stop

button located at the front of the

CodeMax® until it pops out.

The CodeMax® will go through a brief test

routine to prepare itself for use. The CodeMax®

display will read “CodeMax Ready”, indicating

that the machine is in its main screen and ready

for use.

CodeMax

CodeMax Ready

HPCSoft Version 10.0

®

9

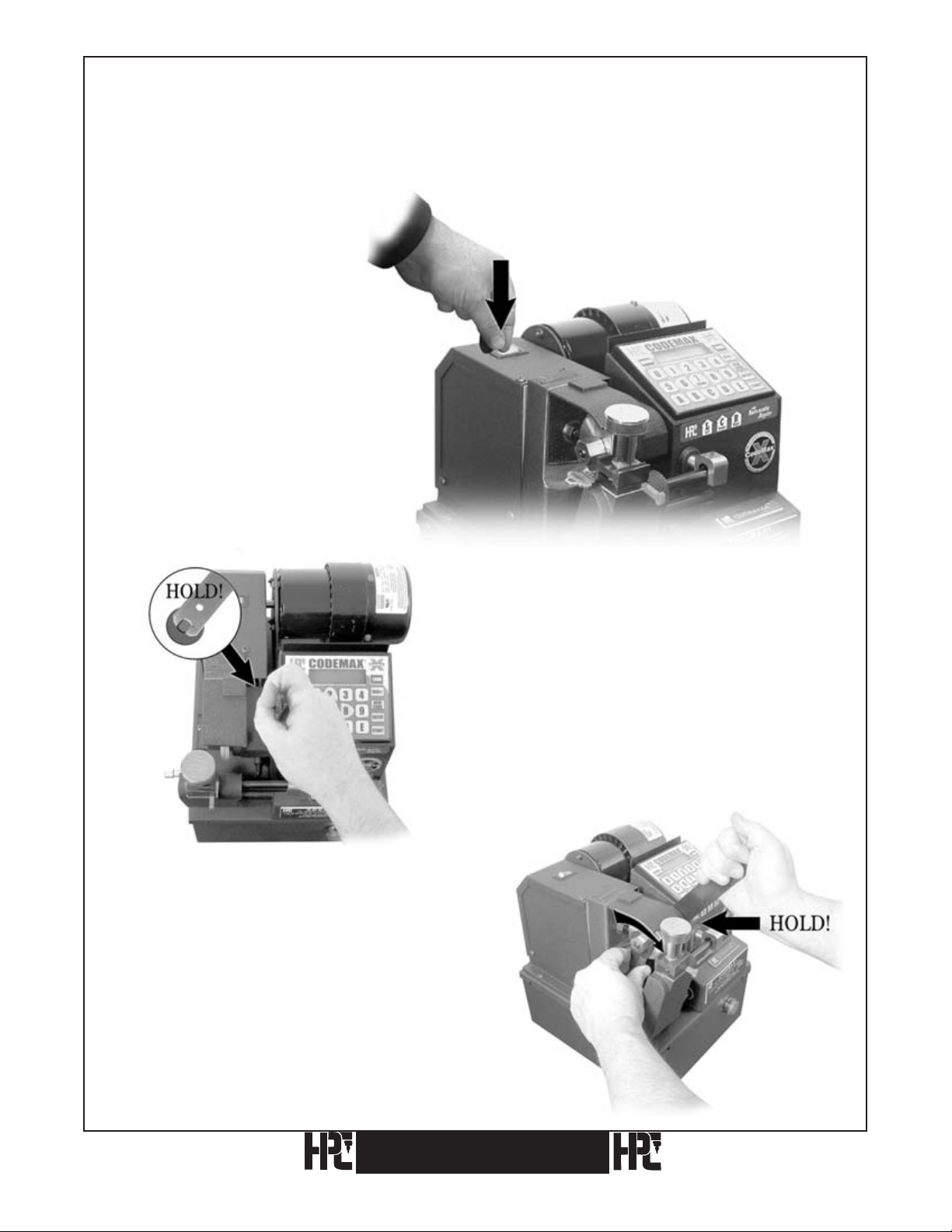

1.5 The Emergency Stop Button

The CodeMax® has an emergency stop button installed.

Pushing the emergency stop button at any time will immediately freeze the operation in

which the machine is engaged. For example, if you started the cutting process and realized

you had the wrong cutter or key blank, pushing the emergency stop button would instantly

turn off the cutter motor and stop the pivot arm from traveling.

To reset the CodeMax®, after the

machine freezes, push the emergency

stop button until it pops out, and

the machine will return to its Home

Position. Make the necessary

adjustments (e.g. put the shoulder

gauge down, or install the correct

cutter or key blank), and start the key

cutting process again.

*Note: When the emergency stop button is pushed, the CodeMax® will clear the bittings entered,

if the bittings were entered directly on the CodeMax

®

keypad.

If you have any questions, please call the HPC Service Dept. 1-800-323-3295.

10

CodeMax

®

2. Cutter Wheels

2.1 Cutter Wheel Descriptions

The model CodeMax®is supplied with five

standard cutter wheels. The CW-1011 cutter

is used for cabinet, padlock, and most vehicle

applications. The CW-14MC cutter is used for

cutting most standard cylinder keys. The CW90MC is similar to the CW-14MC but makes cuts with

a steeper slope for special applications. The CW-20FM cutter

is a 76 degree cutter used for Sargent applications.

The CW-47MC is an 87 degree cutter used for certain

automotive applications.

Flat steel cutters, the Medeco® cutter (CW-1012), the Emhart cutter (CW-1013), and the

Assa Cutter (CW-32MC) are all optional cutter wheels that are available for use with the

CodeMax®. Additionally, the Medeco® Commercial Jaw (MJ-1) is an optional jaw for

cutting the Medeco® Standard Commercial Keyway (Air). The KeyMark® Jaw is available

from Medeco®.

CodeMax

®

11

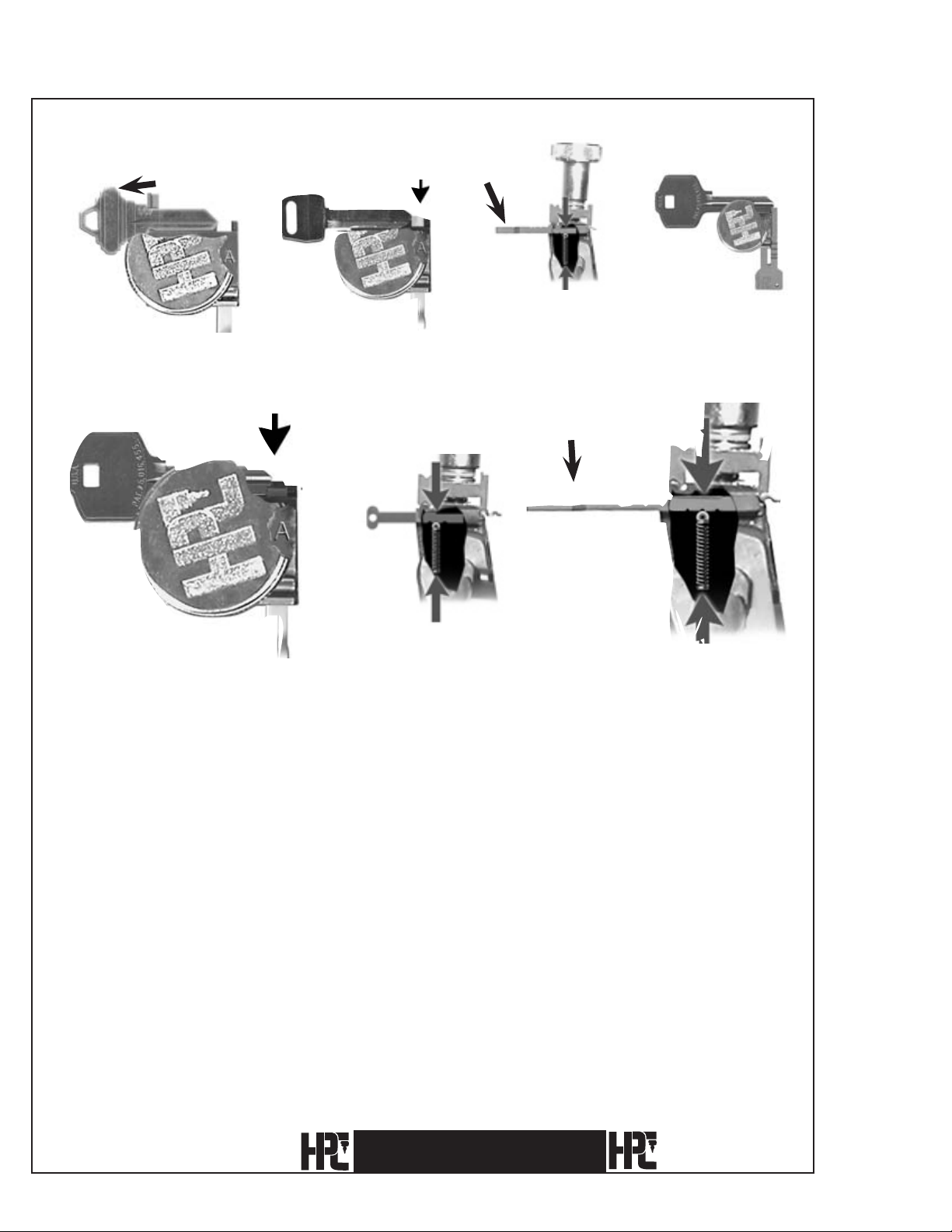

2.2 Replacing Cutter Wheels

The following procedure is recommended when changing cutters:

IMPORTANT NOTE: Be sure the cutter is installed for a clockwise rotation, with the arrow

facing the outside, so it can be seen.

1) Turn the CodeMax® off.

3) Loosen the cutter shaft nut with

the 3/4 inch WRENCH-3 by turning

it clockwise (left hand thread). The

cutter shaft is threaded with reverse,

left-hand thread.

2) Hold the cutter shaft with the

1/2 inch end of WRENCH-1.

12

CodeMax

®

4) Remove the cutter. Slide the

replacement cutter onto the shaft.

IMPORTANT NOTE: Be sure the cutter is installed

for a clockwise rotation, with the arrow facing the outside, so it can be seen.

6) Install the nut, turning

counterclockwise

onto the cutter shaft with the

3/4 inch wrench.

Do not overtighten the nut!

5) Hold the shaft with the 1/2 inch WRENCH-1.

CodeMax

®

13

2.3 Resharpening Cutter Wheels

One of the most important features of the CodeMax® is its capability to maintain correct

depth and spacing with virtually no setup time involved, including the changing of the

cutter wheels. This capability is dependent upon the use of cutters whose outside diameters

are carefully calibrated. We recommend using only HPC cutter wheels.

Eventually, cutters become worn and should be replaced. We do not recommend sharpening

cutters.The diameter of a resharpened

if no depth adjustment is made.

cutter is smaller and will therefore make cuts shallower

See Depth Adjustment Section (5.2) for further information.

In order to maintain matched cutter diameters, all cutters for the CodeMax® must be

resharpened at the same time to account for material lost during this process.

14

CodeMax

®

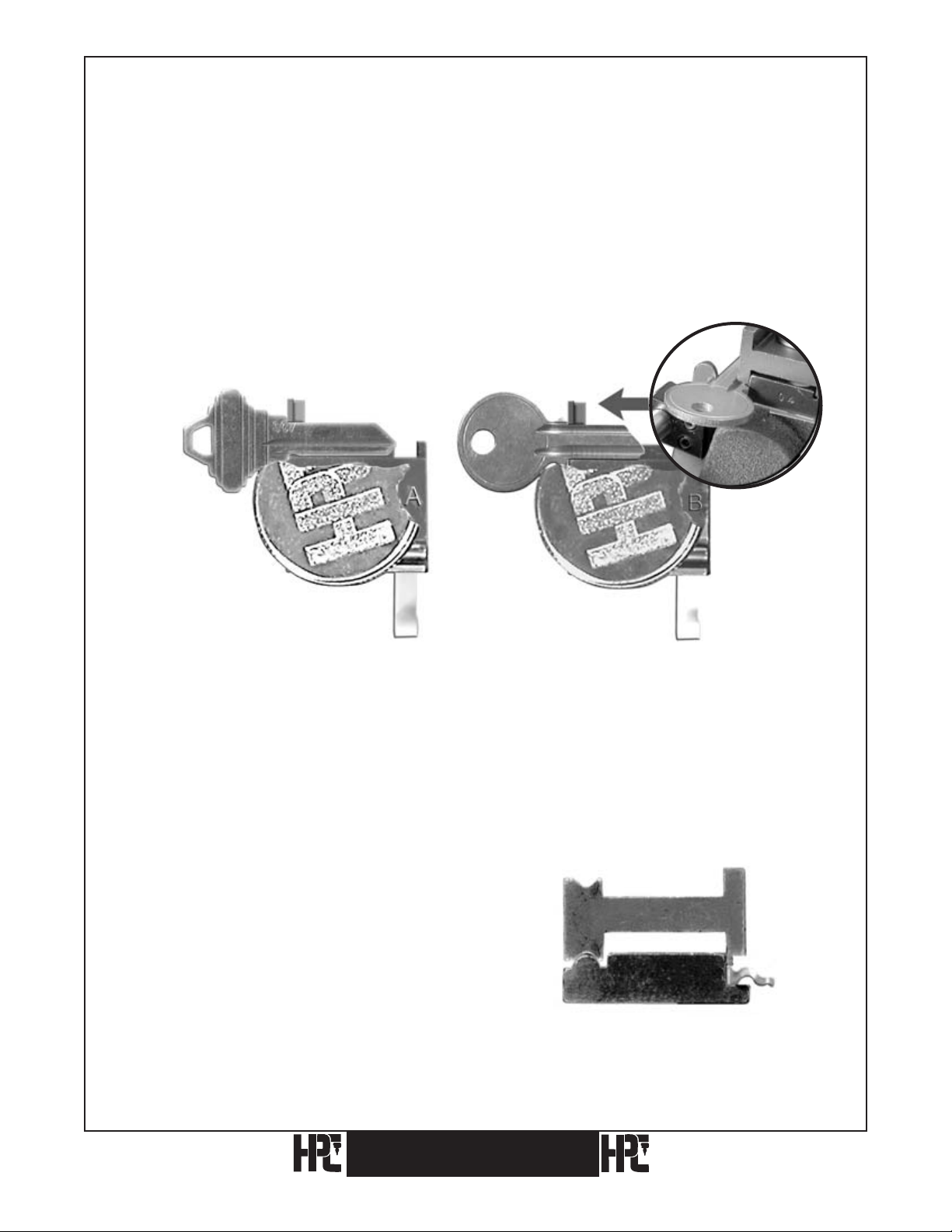

3. Holding And Gauging Keys

The CodeMax® comes from the factory calibrated and ready to cut keys to manufacturers’

specifications. The necessity for special gauges and adapters has been held to a minimum.

Basically, one upper Vise Jaw, which is removable and reversible, covers the greatest range

of key cutting. This upper Vise Jaw (CM-1056MA) is marked “A” on one side and “B” on

the other. When the A side is in use, the letter “A” faces up, in sight of the operator. The

B side is in position when the “B” is seen. Manufacturers’ data and information about the

corresponding jaws can be found on the DSD-CD.

3.1 Vise Jaws

Jaws A & B – Standard Jaws (CM-1056MA) Installed

Fig. 1A. Properly seated key in jaw A. Fig. 1B. Properly seated key in jaw B.

Vise jaw A is used for all standard keys with the deepest cut no less than .142 inches (see

Fig. 1A). Jaw B is used for small keys that use cuts of such great depth that a lip on the jaw

is provided to hold the key closer to the cutter. See Fig. 1B.

Some keys (Best™ for example) will tip

when using Jaw A. If there is a problem

holding the key in Jaw A, use Jaw B

by placing the lip of Jaw B on the edge

of the blank. The blank must still be

positioned at the back of the bottom jaw.

See Fig. 2.

Fig. 2.

CodeMax®

15

Jaw C – Medeco® Jaw (MJ-1) Optional Equipment Required For Cutting Medeco®

Keys (Not Required For Biaxial Keys)

Shoulder Gauge

Fig. 3A. Fig. 3B. Properly seated key in jaw C.

An optional cutter (CW-1012) and Jaw C (MJ-1) are required to cut commercial level

Medeco® keys. Both parts are readily available from your HPC distributor. Biaxial keys

only require the CW-1012 cutter, not MJ-1.

The optional Jaw C is a specially milled CodeMax® jaw. It is required for holding the

standard Medeco® keys (see Fig. 3A). Vise Jaw C is milled to fit and firmly nest into

the Medeco® commercial key grooves. The proper and firm grip provided by Jaw C is

necessary due to the extremely deep cuts used on Medeco® keys. Instructions for using

Medeco’s KeyMark® Jaw are available from Medeco®.

Gauge the key from the shoulder, making sure the key grooving and special jaw milling are

nested together (see Fig. 3B).

16

CodeMax

®

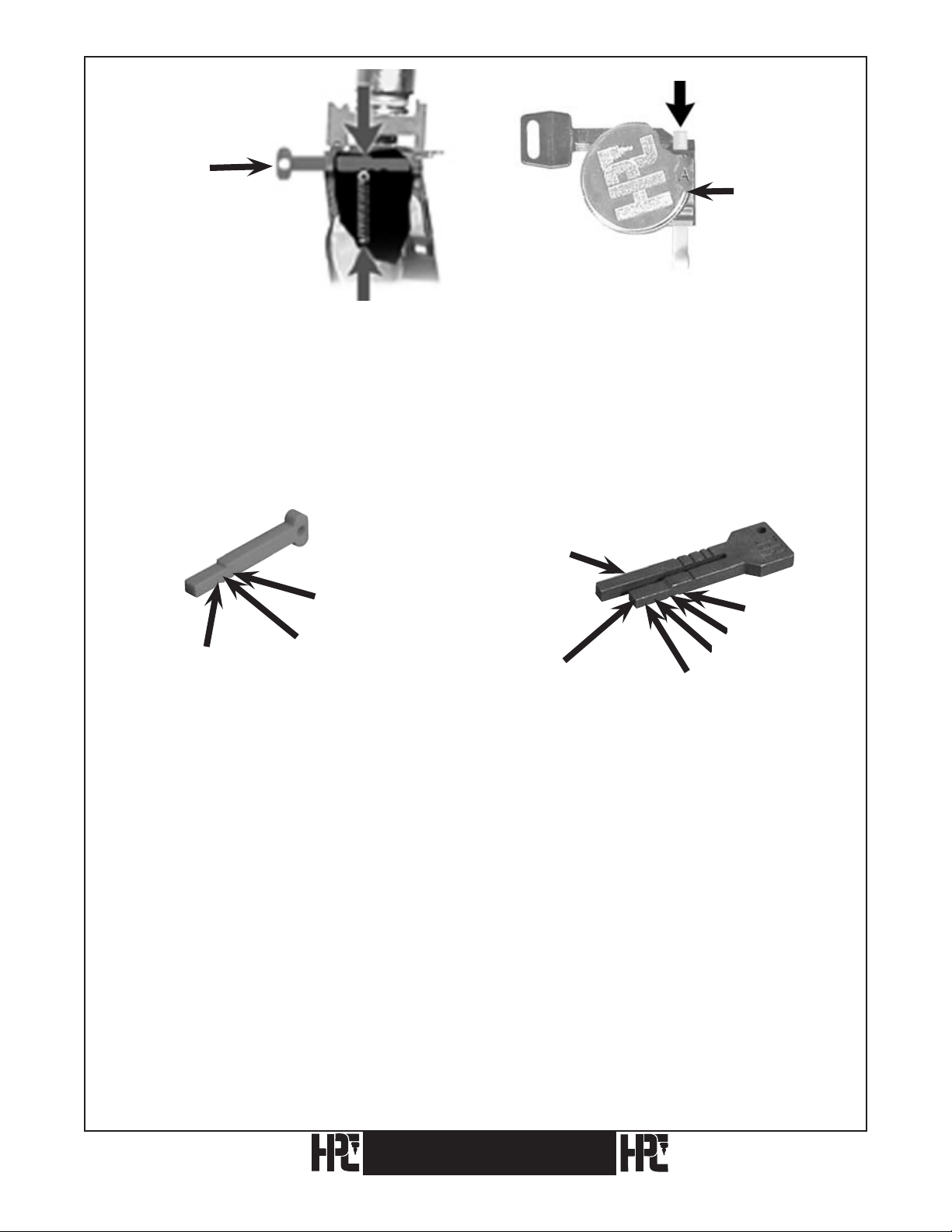

3.2 Key Gauges

Shoulder

Gauge

Fig. 4 Fig. 5 Fig. 6 Fig. 7

Red Tip

Gauge

Horseshoe Tip

Gauge

Position 1

Top View of

Horseshoe

Tip Gauge in

Position 1

Red Tip

Gauge

Top View of

Red Tip Gauge

in Position 2

Position 2

Fig. 8 Fig. 9 Fig. 10

Horseshoe Tip

Gauge

Position 2

Keys with shoulders are gauged by placing them squarely into the vise assembly and

swinging the key Shoulder Gauge (CMB-FG) upward. The key is moved laterally, as

required, until the key’s shoulder just touches the left hand surface of the gauge (see Fig. 4).

Note: Be sure to tighten the wing nut and swing the Shoulder Gauge back down before starting

the cutting process.

Keys without shoulders are properly gauged by using the Red Tip Gauge (CM-1054MA) or

the black Horseshoe Tip Gauge (CM-1054R). The bottoms of these tip gauges have several

grooves, allowing them to be held in different positions by a spring loaded ball bearing.

These tip gauges are pulled back to the first position where they are held within the base of

the lower jaw (Figs. 5 & 6) safely out of the path of the cutting wheel.

See Figs. 7, 8, 9, & 10 for tip gauge references.

CodeMax

®

17

Red Tip Gauge

Red Tip

Gauge

Wing Nut

Fig. 11. Fig. 12. 5 Pin Ford.

Position 3

In the third position, the Red Tip Gauge is sent forward into the third groove and this is

the proper setting for old, 5-pin Ford keys (see Figs. 11 & 12). To clamp and gauge double

sided Ford type keys, the offset of the key is set against the face of the jaw. Slide the key to

the right until the tip butts against the tip gauge and tighten the wing nut. The blank is held

off the key rest by this method, thereby eliminating the need for any special blocks (see

Figs. 11 & 12).

Right Leg

Position 3

Position 1

Position 2

Left Leg

Position 1

Position 4

Position 3

Position 2

Red (Plastic) Tip Gauge (CM-1054MA) (Black) Horseshoe Tip Gauge (CM-1054R)

Position 1: Out of the way Position 1: Best – Right Leg

Position 2: Best Position 2: Ford – Right Leg

Position 3: Ford Position 3: Best – Left Leg (same as 2 red)

Position 4: Ford – Left Leg (same as 3 red)

Note: Red Tip Gauge should be pulled back to position 1 or removed when

cutting shoulder gauged keys.

Remove Black Horseshoe Tip Gauge completely when gauging or cutting shoulder gauged

keys or when gauging from positions 3 and 4 prior to cutting.

Positions 1 and 2 of Horseshoe Tip Gauge are designed to bring the tips of key blanks even

with the right side of the jaw. If the right leg is bent inward (so the tip gauge doesn’t enter

the jaw) or bent outward (so key blanks gauge beyond the right side of the jaw) the right leg

should be gently tapped back into alignment.

18

CodeMax

®

3.3 Gauging Methods

3.3.1 Standard Cylinder Key With Shoulder Gauging Using Jaw A (Example:

Schlage, DSD #60)

Shoulder Gauge

1) Place the key blank in Jaw A. Raise the Shoulder

Gauge to its upright position. Position the key blank

with the shoulder of the key lightly touching the left

hand edge of Shoulder Gauge (avoid undue pressure

– see Note below).

Note: The spacing of the key cuts can be significantly affected

by any damage incurred to the Shoulder Gauge. Handle the

Shoulder Gauge with care! Damage to the Shoulder Gauge

most often occurs when the gauge comes in contact with the

cutter, or when undue pressure is used when gauging against

the key’s shoulder. Make sure to gently position the key blank

against the Shoulder Gauge to avoid damage.

Red Tip

Gauge

Position 1

CodeMax

2) Make sure the Tip Gauge

(if installed) is out of

the way. The Red Tip

Gauge is pulled to the rear

and safely in the detent

position (Position 1)

before continuing, and the

Horseshoe Tip Gauge is

removed.

®

19

3) Tighten the Wing Nut and flip the

Shoulder Gauge down before continuing.

Fig. 4. Wing Nut and Top Jaw of vise removed to show top view of the Bottom Jaw only, for key

positioning.

4) Make sure the key is lying flat

against the back of the Bottom Jaw

before tightening the Wing Nut.

20

CodeMax

®

3.3.2 Standard Cylinder Key With Shoulder Gauging Using Jaw B (Example: Master,

DSD #49)

Shoulder Gauge

Jaw B

Wing Nut

1) Place the key blank in Jaw B. Make sure that the key lies in front of the lip, and flat

against the lip. Raise the Shoulder Gauge to its upright position. Position the key

blank with the shoulder of the key lightly touching the left hand edge of Shoulder

Gauge (avoid undue pressure – see Note below).

Note: The spacing of the key cuts can be significantly affected by any damage incurred to the

Shoulder Gauge. Handle the Shoulder Gauge with care! Damage to the Shoulder Gauge most

often occurs when the gauge comes in contact with the cutter, or when undue pressure is used

when gauging against the key’s shoulder. Make sure to gently position the key blank against the

Shoulder Gauge to avoid damage.

Red Tip

Gauge

Position 1

3) Make sure that the key lies in front

of the lip, and flat against the lip.

2) Make sure the Tip Gauge is completely out

of the way, and that the Horseshoe Tip Gauge

is removed.

CodeMax

®

21

4) Tighten the

Wing Nut

and flip the

Shoulder Gauge

down before

continuing.

Wing Nut

Shoulder Gauge

in the Down Position

22

CodeMax

®

3.3.3 Red Tip Gauge In Position 3 (Full Short Tip Stop) Using Jaw A

(Example: Ford, DSD #34)

1) The Red Tip Gauge is pushed inward to

position 3.

Note: Make certain to pull the Tip Gauge to the rear

(position 1) before cutting.

Red Tip Gauge

Position 3

2) The key is gauged from the tip. Make sure

the Shoulder Gauge is lowered before continuing.

Fig. 3. The Wing Nut and Top Jaw of the vise removed

to show a top view of the Bottom Jaw only, for key

positioning and Tip Stop settings.

3) Make sure the blank is lying flat on the ledge

against the back of the Bottom Jaw before

tightening the Wing Nut.

CodeMax

Note: For Ford blanks (DSD#34), the key blank grooving

edge lies directly on the face of the jaw for ignition and

trunk keyways. No riser blocks are used.

®

23

3.3.4 Red Tip Gauge In Position 2 (Middle Short Tip Stop) Using Jaw A (Example:

KABA-PEAKS 6-Pin, DSD #608)

1) The Red Tip Gauge is pushed inward to Position 2.

The Tip Gauge is pulled to the rear (position 1)

while cutting.

Position 2

Note: Make certain to pull the Tip Gauge to the

rear (position 1) before cutting.

Red Tip Gauge

3) Be sure the key lies flat against the back

edge of the Bottom Jaw before

tightening the Wing Nut.

2) The key is gauged from the

bottom stop, not the tip.

Wing Nut

Jaw A

Red Tip Stop

24

Fig. 3. The Wing Nut and Top Jaw of the vise partially

removed to show a top view of the Bottom Jaw only

for key positioning and Tip Stop settings.

CodeMax

®

3.3.5 Black Horseshoe Tip Gauge In Position 1 (Short Tip Stop) Using Jaw B

(Example: DSD #3)

1) The Tip Gauge is pushed

inward to position 1.

2) The key is gauged from the bottom

stop of the key, not the tip.

Horseshoe Tip Gauge

Position 1

Wing Nut

Jaw B

Horseshoe Tip Stop

3) Slide the key to the right until the bottom

stop of the key touches the right leg of the

Horseshoe Tip Stop. Be sure the key lies

flat against the back edge of the bottom

jaw before tightening the wing nut.

Note: Undue pressure against the right leg will cause

the legs to spread, resulting in inaccurately cut keys.

4) Note the special holding on the key milling

using Jaw B. (The key must be lying flat against the

back ledge of the Bottom Jaw as shown.)

CodeMax

®

25

3.3.6 Medeco® Standard Commercial Key Using Jaw C (Optional

Equipment) With Shoulder Gauging (Example: DSD #51)

Shoulder gauge

1) The key shoulder touches the left

hand edge of the Shoulder Gauge.

Jaw C

Avoid undue pressure – see note

below.

Note: The spacing of the key cuts can be significantly affected by any damage incurred to the

Shoulder Gauge. Handle the Shoulder Gauge with care. Damage to the Shoulder Gauge most

often occurs when the gauge comes in contact with the cutter, or when undue pressure is used

in gauging against the key’s shoulder. Make sure to gently position the key blank against the

Shoulder Gauge to avoid damage.

Red Tip Gauge

2) The jaw and key grooves “nest” into each other.

The Tip Gauge (if installed) is pulled back to

the rear to position 1 (Horseshoe Tip Gauge is

removed). Open Jaw C only enough to slide the

key into position. Be sure the key groove and jaw

milling mate before tightening the Wing Nut.

Position 1

3) Flip the Shoulder Gauge down and tighten

the Wing Nut before proceeding.

Medeco® is a registered trademark of Medeco Security Locks, Inc.

26

CodeMax

®

3.3.7 Black Horseshoe Tip Gauge In Position 2 Using Jaw A or B

(Example: GM Modular 94+, DSD #259)

1) The Horseshoe Tip Gauge is

pushed inward to position 2.

Horseshoe Tip

Gauge

Position 2

2) The key is gauged from the tip as shown. Be sure

the key lies flat against the back of the Bottom

Jaw before tightening the Wing Nut. Lower the

Shoulder Gauge.

Note: Undue pressure against the right leg will cause the legs to

spread, resulting in inaccurately cut keys.

Note: On Ford blanks (DSD’s 35 and 261) the key blank grooving

edge lies directly on the face of the key vise. No riser blocks are

used.

CodeMax

®

27

Look For...

Look For...

Look For...

1 2 3 4 5

X

Visit the CodeMax® web page at

www.hpcworld.com/km/codemax

to learn about your machine.

See it in use!

Features of the

CodeMax®

Depth & Space

Data

To watch the videos showing the

important features of the CodeMax®.

To learn the features of CodeMax®

Version 10 (Upgrades are available).

To view or download the current list

of DSD numbers and the key cutting

details for each one.

Look For...

Look For...

Look For...

Manuals

and

Instructions

Exploded

Views

Key Machine

Accessories

To view or download a PDF of the

CodeMax® Operation Manual.

To access the Exploded View and Parts

List to identify a spare part needed.

To see the accessories that are

available for your CodeMax®.

28

CodeMax

®

4. Key Cutting Methods

1) Stand Alone Key Cutting utilizing the internal capabilities of the CodeMax®.

2) Computer

to the CodeMax® via a serial cable (No. CABLE-25S) attached to the back of the

CodeMax®.

3) Micrometer

CodeMax®.

Assisted Key Cutting using a computer loaded with HPC software connected

Key Cutting using space and depth information manually inputted into the

CodeMax

®

29

4.1 Stand Alone Key Cutting

4.1.1 Standard Keys

The computer chip in the CodeMax® contains a database of nearly 1000 DSD Numbers. DSD

stands for Depth and Space Data, these are charts of key-cutting information.

For Direct Digit keys (such as Schlage or Kwikset) or if you know the bitting needed for an

indirect-coded key (such as an automotive or furniture key), you can utilize the internal DSD

to cut a new key. Refer to the DSD List or to CodeSource® for the applicable DSD number,

gauge point and cutter to use.

For example, if you were cutting a key for a standard

Schlage large pin cylinder you would: Press DSD#.

Enter “60” (press “6”, then press “0”, then press ENTER

to accept this selection)

Note: At anytime during this process you can clear a wrong

entry or return to the previous screen by pressing CLEAR.

The CodeMax® displays the name of the selected

manufacturer and displays the correct gauging point.

For example, the Schlage

display will read “Use

Shoulder Stop as Gauge”.

*Note: Certain manufacturers,

such as Best, list bittings tip to

bow. Tip to bow bittings need to be

reversed to bow to tip order when

inputting.

Insert and gauge the key accordingly (refer to Section 3, Key Gauging for details).

The display then indicates “Enter Bitting”.

Enter the bitting desired starting with the cut

closest to the bow.* For this example we will

make thebitting “43264”. Enter “43264”

by pressing “4”, “3”, “2”, “6”, “4”, and

then ENTER.

The display now shows the

CodeMax® is READY to

CODEMAX

READY 43264

®

cut the key.

From the Ready screen, you have several options:

1. Press START to begin cutting the key bitting shown on the screen.

2. Press NEW CODE or CLEAR and enter in a new bitting. (Remember to

press Enter to accept the new bitting.)

3. Press CLEAR twice to return to the “Enter DSD Number” prompt, or twice

more to reset the CodeMax®.

30

CodeMax

®

4. P ress “A” to change to the Contour Cutting Mode. Contour Cutting will

remove peaks between cuts on a key, for smoother operating automotive keys (only

recommended for automotive keys). Press “A” again to return to the Standard

Cutting Mode.

CONTOUR

Switch Contour cutting on and off.

5. P ress “6” to decrease the rate of speed at which the pivot arm approaches

the cutter or press “8” to increase the rate of speed at which the pivot arm

approaches the cutter. This is particularly useful when dealing with hardened

keys and wanting to cut them at a slower rate.

CUT SPEED

Fewer bars = slower

More bars = faster

6. In the case of “Double-Sided Different” keys, after cutting the first side, press ENTER

to autoload the next DSD Number associated with the manufacturer chosen.

If cutting a single-sided key or if the second side is the same as the first, pressing

ENTER will return to the Main Screen.

CodeMax

®

31

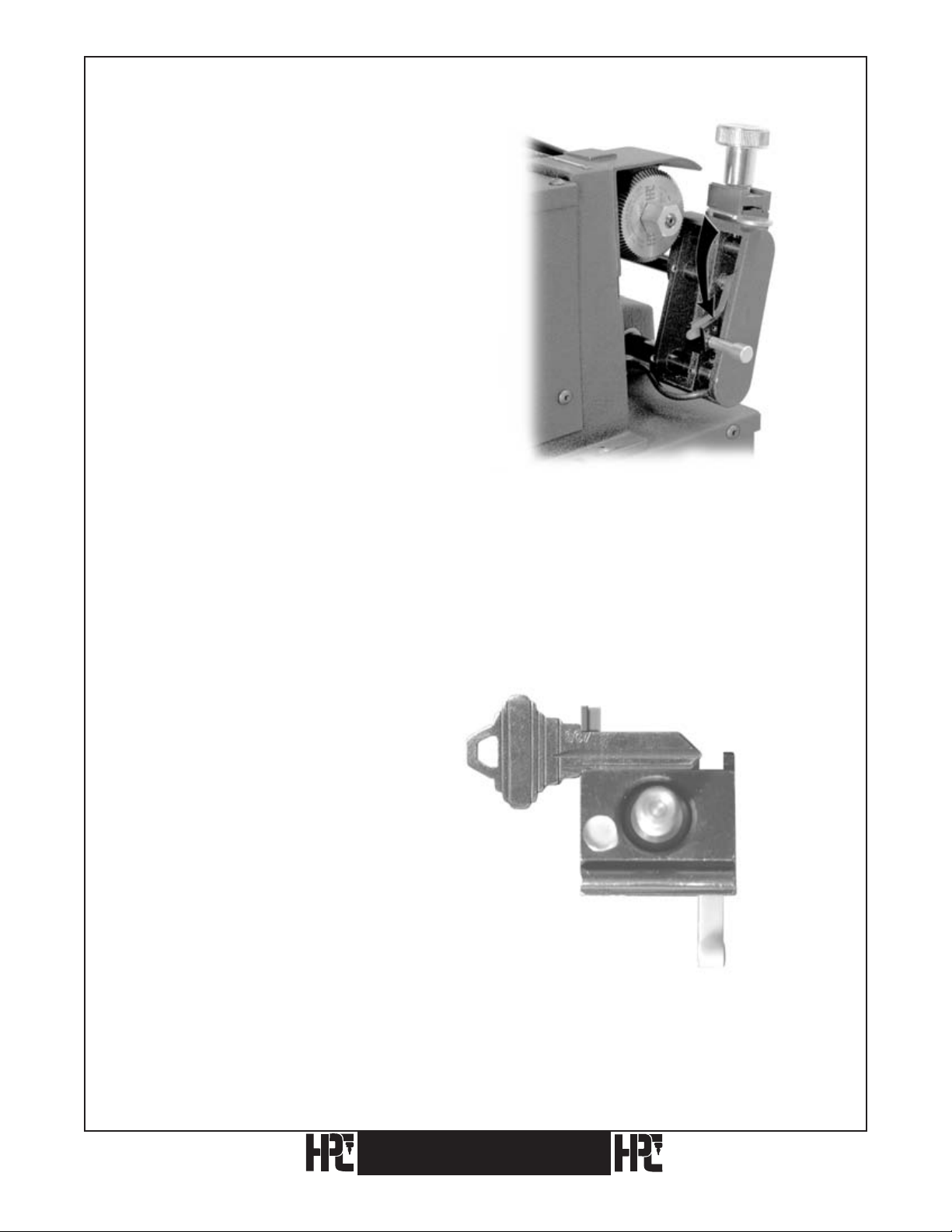

4.1.2 Medeco® Keys

Some high security keys, such as Medeco and Emhart, incorporate angles in their cuts.

Both the depths and angles must be determined prior to cutting the key.

Use the HPC Pocket Size Decoder (No. HKD-75) to decode the depths and angles of these

high security keys, as well as standard keys.

When cutting angle-cut keys on the CodeMax® Automatic Angler model, the cutter head

rotates automatically to make the angle cuts.

If you are using the Standard Model

CodeMax®, then the machine pauses at each

position and prompts you to manually rotate

the cutter head.

1. Pull the spring loaded Angle Index Pin

back.

2. Rotate the cutter head using the Pivot Pin,

to the “L” on the machine to make a left

Pull

Angle

Index

Pin

Pivot Pin

ROTATE CUTTER

HEAD NOW

angled cut, or to the “R” to make a right

angled cut.

3. Release the Angle Index Pin making sure it

is properly seated before proceeding to the

next cut.

4. Once the Cutter Head is properly

positioned, press “Enter” to begin the

next cut.

Cutting Medeco Standard Keys

Medeco Standard keys have an angle (Left, Right or Center) associated with each cut.

On the standard model CodeMax®, use DSD Number 51.

The machine will pause after each cut and prompt you to rotate the cutter head as needed.

For the Automatic Angler model, use DSD

Number 3051. The bittings screen has room

for 12 characters. Think of the 12 characters

as 6 sets of 2 characters each, one number for

the bitting and one letter for the direction of

the angle, to represent each cut on the key.

For example, the bitting of 324323 with the

first cut being a “Left” angle, the second a

“Right”angle, the third a “Center”, fourth a

“Left”, fifth a “Right” and sixth a “Left.”

Using the “B” key for Left, the “C” key for

Center and the “D” key for Right, the bitting

would be entered as:3L2R4C3L2R3L

32

CodeMax

®

Cutting Medeco Biaxial Keys

Medeco Biaxial keys utilize the Left, Right and Center angles and add the position of the angle:

“Fore” (the depth comes before the angle) or “Aft” (the depth comes after the angle). Medeco

designates the angles and positions as follows:

Medeco® Code Position & Angle

K Fore, Left

B Fore,Center

Q Fore, Right

M Aft, Left

D Aft, Center

S Aft, Right

On the standard model CodeMax®, use DSD Number 76.

The bitting screen will display 12 spaces to accommodate the position of the angle relative to the

depth on a 6-space key. This is accomplished by inserting a zero (0) (representing the position of

the angle) before the depth for an AFT cut or after the depth for a FORE cut. For example, a key

that reads:

D4 3B M5 D2 3K S2

aft fore aft aft fore aft

On the standard model CodeMax® it is entered as:

043005023002

The machine will pause at each position and prompt you to rotate the cutter head as needed.

4.1.3. Use of the CodeMax® AA Automatic Angler

On the Automatic Angler model, use DSD Number 3076.

The bitting screen will display 12 spaces to accommodate both the angle and the position.

The position is designated by the sequence it is input relative to the depth.

Medeco® Code Position & Angle DSD 3076 Buttons

K

B

Q

M

D

S

Use the “B” key for Left, the “C” key for Center

and the “D” key for Right.

To specify a 3-depth in the FORE position, with a

LEFT angle, enter the depth then the angle: 3L.

To specify a 5-depth, in the AFT position with a

RIGHT angle, enter the angle then the depth: R5.

Fore, Left

Fore, Center

Fore, Right

Aft, Left

Aft, Center

Aft, Right

Depth, then Left

Depth, then Center

Depth, then Right

Left, then Depth

Center, then Depth

Right, then Depth

CodeMax

®

33

Example: 3LR2C43LR23L

3L number 3 depth in the “Fore” position with a Left angle.

R2 number 2 depth in the “Aft” position, with a Right angle.

C4 number 4 depth in the “Aft” position with a Center or no angle.

3L number 3 depth in the “Fore” position with a Left angle.

R2 number 2 depth in the “Aft” position with a Right angle.

3L number 3 depth in the “Fore” position with a Left angle.

34

CodeMax

®

4.1.3 After The Key Has Been Cut

After the key has been cut you will have four options:

1) Press START to cut an additional key to the same bitting.

2) Press NEW CODE or CLEAR to enter a new bitting, using the same DSD.

Press CLEAR twice to enter a different DSD number.

3)

4) Press ENTER to autoload the next DSD number associated with a “Double-Sided

Different” key. If no autoload specifications are present, the CodeMax® will return to

the main screen.

5) Press CLEAR until you reach the main screen.

NOTE: At all screens you may press CLEAR to return to the previous screen.

CodeMax

®

35

4.1.4 Additional Notes

®

1) The CodeMax

from tip to bow. However, all bittings must be

always cuts shoulder-gauged keys from bow to tip, and tip-gauge keys

entered into the CodeMax

®

in bow to

tip order.

2)

If the original manufacturer (such as Kwikset) widens some or all of the cuts, the

CodeMax

®

will automatically do the same.

3) When cutting double-sided keys where there is a shoulder on only one side of the key,

or where the shoulders are not symmetrical (such as some VW keys), always cut the

shoulder gauged side of the key first, then press ENTER to cut the plain side.

Because most double-sided keys are

4)

back of the jaw, the recommended cutting

CodeMax

®

and then cut both sides of another

gauged by placing an uncut blade against the

procedure is to cut the first side on the

blank in a duplicator, using the code-cut

key as the original.

5) At all screens you may press CLEAR to return to the previous screen.

36

CodeMax

®

4.2 Computer Assisted Key Cutting

A personal computer that uses a Current Version of Windows® as its operating system, and

has authorized HPCSoft™ software products properly installed, can be connected to the

CodeMax® using a serial cable for computer assisted key cutting.

The CodeMax® cable (CABLE-25S) is a 25-foot serial cable designed for this purpose.

It is attached to the serial port on the computer and to the RS422 port on the back of the

CodeMax® . Refer to your computer manual to locate the serial port on the computer. For

computers without serial ports there are USB to serial adapters available at most computer

stores.

A single bitting may be downloaded from CodeSource® or KeyTrail

®

to the CodeMax®,

or as many as 250 different bittings from MasterKing® may be downloaded for master key

systems.

To download data from the computer, make sure the CodeMax® is in a clear condition. The

display will read:

Codemax Ready

HPCSoft Ver 10.0

Follow the instructions for each software program to send data to the CodeMax® . The

computer will then perform its handshake with the CodeMax® and download the data. The

display will read:

Making

Connection

Once the download transmission is complete, the CodeMax® may display an information

message about the incoming keys. This message will appear for approximately 2 seconds,

then the key bitting will appear at the Ready screen.

CodeMax

®

37

When downloading from MasterKing®, the first bitting appears at the Ready screen and

you may:

1) Press START to cut the key to the bitting displayed. Press START again to cut

additional keys to that bitting.

2) Press “C” (DOWN ARROW) to move forward through the key bittings.

3) Press “2” (UP ARROW) to move backward through the key bittings.

4) Press HOME (7) to change functions. For example, this feature may be used to

temporarily stop cutting keys for a master key system, so that one or more keys not

in the master key system may be cut. To return to the original function press ENTER,

then press HOME (7). The CodeMax® will resume from the point of interruption.

38

CodeMax

®

4.3 Micrometer Key Cutting

From the main screen press DSD#. The display shows:

Enter DSD Number

[ ]

Press “0” to signify that you wish to use the micrometer function of the CodeMax®. Press

ENTER and the display changes to:

Micrometer Key

Cutting Function

The display then changes to:

Enter Jaw Type

[ ]

Press A, B, or C to signify which jaw will be used. For our example, press A. The display

changes to:

Choose: A for In

B for mm

Press A or B to indicate the use of inches or millimeters for space and depth measurements.

For this example, press A for inches. The CodeMax® advances to the main micrometer

screen and the display shows:

Space 0.000 In

Depth 0.000 In

CodeMax

®

39

SPECIAL NOTE: To cut keys on the CodeMax® using the micrometer method you must use standard CodeMax® cutters

that have a center line of .188" and 2

require special calculations. The zero point for the Horseshoe Tip Stop is 1.215 and all spacing must be calculated from

this point. So, even if you are using a Tip Stop you must calculate spacings as though they were from a shoulder The zero

point for the Red Tip Stop is .940" and all spacing must be calculated from this point.

3⁄

8" diameter. Keys may be gauged from either the shoulder or the tip. Tip gauged keys

You must indicate that the first cut is to be measured from the shoulder of the key to the

right. Press “8” (>). The following display appears:

Space 0.000 In>

Depth 0.000 In

The arrow to the right of the spacing display line (>) confirms that the first cut is to be to

the right of the shoulder of the key. After setting the direction, set the spacing value from

the shoulder to the first cut. For our example, the value is .231, so press “2”, “3”, “1”, then

press ENTER. The display changes to:

Space 0.231 In>

Depth 0.000 In

Press START and the CodeMax® aligns the Pivot Arm for the first cut. When the

CodeMax® stops, press “2” (UP ARROW) to signify that the Pivot Arm will be moving up

into the cutter. The display shows:

Space 0.231 In

Depth 0.000 In^

40

CodeMax

®

Next, indicate the depth of the first cut. Our example requires a depth of .290. Press “2”,

“9”, “0”, then press ENTER. You will see the following display:

Space 0.231 In

Depth 0.290^ In

Press start to make the cut. Notice that the CodeMax® stays in the cut position and the

cutter continues to spin. This allows you to widen the cut, if necessary, by using the space

commands. Press HOME (7) to ready the machine for the next cut.

Review Of Micrometer Key Cutting Procedures

Let’s quickly review the basic steps required:

1) Press “8” (>).

2) Set spacing numbers from shoulder to first cut, then press

ENTER.

3) Press start to activate spacing stepper motor.

4) Press “2” (up arrow).

5) Enter depth numbers.

®

6) Press start for the CodeMax

to make the cut.

7) Repeat steps 1, 2, and 3 if the cut has to be widened. If the cut does not have to be

widened, press Home (7) to return to the home position.

CodeMax

®

41

Final Micrometer Key Cutting Procedures

We will now continue with cutting an example key using the Micrometer Key Cutting

Procedure.

Press “8” (>) to set the direction from the shoulder of the key.

Next, enter the cut-to-cut spacing. For our Schlage example, this is .156. Press “1”, “5”,

“6”, then press ENTER and START. Notice that the carriage does not move to “.156”, but

to “.387”. The CodeMax® totals the distances of our first and second cuts (.231 + .156 =

.387) and the display shows the real location, 0.387.

Remember, the cutter wheel does not move laterally. Only the carriage holding the key

blank moves. To position the cutter to the right of the shoulder at a designated spacing,

the carriage moves to the left. Do not let this confuse you as you watch movements for

spacings.

Next, indicate the direction and depth of the cut. For our example, press “2 (up arrow) to set

the direction (the carriage moves up to the cutter), then press “2”, “4”, and “5” (the depth of

the cut is .245). Press ENTER and START to make the cut. When the cut is complete, press

HOME in preparation for the next cut.

Now that you have the hang of things, repeat steps 1 through 7 until all of the cuts are

made. Once the key is complete, press CLEAR to return to the main screen.

42

CodeMax

®

5. Recalibration Of The CodeMax

5.1 Electronic Calibration

The CodeMax® is capable of Electronic Calibration. Minor depth and space adjustments,

as well as DSD Specific Depth adjustments, can be performed using the CodeMax® keypad

and stored in the CodeMax® CPU board. These adjustments can be used to offset normal

wear and tear on the machine, or after replacing or sharpening cutters.

DSD Specific adjustments allow you to make minor depth adjustments to accommodate

worn locks or keys or special applications.

®

CodeMax

®

43

5.1.1 Depth Instructions

Total Machine adjustments affect all DSD’s including keys downloaded from software. To

make Total Machine electronic Depth Adjustments on the CodeMax® start with the “LOAD”

button.

Press “LOAD”

Enter “CC” and press the “ENTER” button

Choose between Inches and Metric.

“A” for Inches and “B” for Metric

Choose: A for in

B for mm

Choose Depth or Space adjustment.

“A” for Depths and “B” for Space

Use: A for Depth

B for Space

If Depths were chosen the screen will read:

Depth Adjustment

0.000 In

44

CodeMax

®

Use the Up Arrow (2) keypad button or the Down Arrow (C) button to change the Depths.

The Display will show how much of an adjustment you are making.

Use the “ENTER” button when you are done.

Depth Adjustment

0.025 In

Press “A” to proceed out of the Adjustment screens or “B” to return to the Depth

Adjustment screen.

Confirm 0.000 In

A=Yes B=No

Depth Adjustment Confirmation Screen will flash twice indicating the adjustment has been

saved. The CodeMax® now returns to the Main menu and is ready to use.

(Although the adjustment will not be shown next time you access machine adjustments,

CodeMax® saves the adjustment in memory even after power has been turned off.)

CodeMax

®

45

5.1.2 Space Instructions:

Total Machine adjustments affect all DSD’s including keys downloaded from software. To

make Total Machine electronic Space Adjustments on the CodeMax® start with the “LOAD”

button.

Press “LOAD”

Enter “CC” and press the “ENTER” button

Choose between Inches and Metric.

“A” for Inches and “B” for Metric

Choose: A for in

B for mm

Choose Depth or Space adjustment.

“A” for Depths and “B” for Space

Use: A for Depth

B for Space

If Space was chosen “Space Adjustment” will flash twice and bring you to the next screen.

You can choose “A” for Shoulder adjustment and “B” for Black Tip Stop adjustment.

Use: A=Shoulder

B=Black tip

46

CodeMax

®

Increase .000 ^ (no previous adjustments should be displayed)

Decrease .000 v

Use the Up Arrow (2) keypad button or the Down Arrow (C) button to change the Space.

The Display will show how much of an adjustment you are making. Use the "ENTER"

button when you are done.

Confirm +.000

A=Yes B=NO

(auto enter)

("No" returns to adjust screen)

Space Adjustment ***FLASH for 1 second***Saved +.000

Press ”A” to proceed out of the Adjustment screens or “B” to return to the Space adjustment

screen.

Space Adjustment Confirmation Screen will flash the adjustment and that it has been saved.

The CodeMax® now clears and reinitializes completing the Space adjustment.

CodeMax

®

47

5.1.3 DSD Specific Instructions:

Use the “DSD” button and enter the DSD you want to adjust.

After displaying the DSD name and gauge point the “Bitting Window” appears.

Enter a bitting and hit the “ENTER” button.

Once at the “Ready Screen” press the “LOAD” button to access the DSD Specific Depth

adjustment.

Note: A previously adjusted DSD will add “**ADJ**” on the top line of the display.

Ready...**ADJ**

[52354]

This DSD can be used as is or adjusted again

After hitting “LOAD” the following message will be on the screen.

“Depth Adjustment”

0.000 In

Any previous adjustments will be displayed here.

Use the Up Arrow (2) keypad button or the Down Arrow (C) button to change the Depths.

The display will show how much of an adjustment you are making. Use the “ENTER”

button when you are done. To clear any previous adjustments just follow the above

instructions until the display reads “0.000 In”

48

®

Press “A” to proceed out of the Adjustment screens or “B” to return to the Depth

adjustment screen.

Confirm 0.000 In

A=Yes B=No

Depth Adjustment Confirmation Screen will flash twice indicating the adjustment has

been saved.

You will now return to the “Ready...**ADJ**” screen and cut your key with the new

adjustment. As long as the adjustment is stored all keys cut with this DSD will be

offset by the selected amount.

CodeMax® CodeMax

49

5.2 Manual Calibration

The Electronic Adjustment Function is suitable for making minor adjustments.

Manual Calibration will be required if the carriage is replaced or is accidentally moved

significantly out of position.

I. Space Calibration

No readjustment of space is required when changing from one depth and spacing

specification to another. The information sent by the DSD number or computer positions

the correct lateral alignment when using factory cutters. The need to readjust the space is

rare and should be attempted only after the more common causes for miscut keys have been

eliminated.

Remember, when originating a key by code, quite often, code numbers are misread. Locks

can sometimes be coded incorrectly when they are new, and code books occasionally have

typographical errors. All this distracts from successful cutting of keys by code.

You may proceed after eliminating the above mentioned causes for miscut keys and

checking for correct depth calibration.

50

CodeMax

®

5.2.1 Cutting Too Close To The Tip (On Keys Gauged From The Tip Stop)

Fig. 1

Tools required: 5/64" Allen wrench, factory cut key, rubber or rawhide mallet.

1) Select a tip-gauged, factory cut large cylinder type key, such as Best, Falcon, or Ford.

Make sure that all cuts are deeper than a #1 depth.

2) Install the correct cutter wheel.

3) Turn on the CodeMax

®

.

4) Select and enter the proper Depth and Spacing Data number.

5) Enter in all #1 cuts for the depths. Then press ENTER

to accept, and then press START

to begin the cutting process.

6) The CodeMax® will start to travel laterally towards the key. When the machine travels

to the first cut (closest to the tip) and the key begins traveling towards the cutter

(making depth cut), push the emergency stop button.

7) Check to see if the cutter is in the center of the cut (see Fig. 1).

8) If the cutter is too close to the tip of the original key, use a 5/64 inch allen wrench to

loosen the four set screws on the lower inside and bottom of the pivot arm

(CM-1024X).

CodeMax

®

51

Fig. 2

Fig. 3

9) With a small rawhide or plastic mallet, lightly tap the lower, left side of the Pivot Arm

until the pin seat of the cut is directly opposite the flat of the cutter (see Fig. 2). With

the cutter aligned opposite the cut, retighten the set screws (see Fig. 3).

10) Release the Emergency Stop Button. The Pivot Arm will return to the

Note: You may have to recalibrate the Shoulder Gauge after recalibrating the Tip Gauge.

52

CodeMax

®

HOME position.

5.2.2 Cutting Too Far From The Tip (On Keys Gauged From The Tip Stop)

Fig. 1

1) Select a tip-gauged, factory cut large cylinder type key, such as Best, Falcon, or Ford.

Make sure that all cuts are deeper than a #1 depth.

2) Install the correct cutter wheel.

®

3) Turn on the CodeMax

.

4) Select and enter the proper DSD number.

5) Enter all #1 cuts for the depths. Then press ENTER

to accept, and then START to

begin the cutting process.

6) The CodeMax

®

will start to travel laterally towards the key. When the machine travels

to the first cut (closest to the tip) and the key begins traveling towards the cutter

(making the depth cut), push the Emergency Stop Button.

7) Check to see if the cutter is in the center of the cut (see Fig. 1).

CodeMax

®

53

Fig. 2. Loosen four (4) set screws

Fig. 3. Lightly tap inside of carriage arm.

8) If the cutter is too far from the the tip of the original key, use a 5/64 inch allen wrench

to loosen the four set screws on the lower inside and bottom of the Pivot Arm

(CM-1024X) (see Fig. 2).

9) With a small rawhide or plastic mallet, lightly tap the inside of the Pivot Arm to move

the cutter closer to the top of the key while centering the cutter flat with the pin seat

(see Fig. 3).

10) Release the Emergency Stop Button. The Pivot Arm will return to the Home position.

Note: You may have to recalibrate the Shoulder Gauge after recalibrating the Tip Gauge.

54

CodeMax

®

5.2.3 Cutting Too Far From The Shoulder

Note: Only recalibrate the shoulder gauge after being sure that the tip gauge is properly

calibrated.

1) Select a shoulder gauged, factory cut type key, such as a Schlage or Arrow. Check to

see that the #1 space (closest to the shoulder) is greater in depth than a #1 cut.

2) Install the correct cutter wheel.

®

3) Turn the CodeMax

on.

4) Select and enter the proper DSD number.

5) Enter in a #1 cut for the depth. Then press ENTER

to accept, and press START to

begin the cutting process.

6) The Pivot Arm will start to travel laterally towards the key. When the Pivot Arm travels

to the first cut (closest to the shoulder) and the key begins traveling towards the cutter

(making the depth cut), push the Emergency Stop Button.

7) Loosen the key in the jaw. Slide the key to your right until the pin seat of the cut is

directly opposite the flat of the cutter. Tighten the key in the jaw.

8) Release the Emergency Stop Button to allow the machine to return to the Home

position.

CodeMax

®

55

Fig. 1

Fig. 2

9) Loosen the set screw that holds the Turn Bar in place in the Pivot Arm. See Fig. 2.

Swinging the Shoulder Gauge should also rotate the Turn Bar.

Note: If the Turn Bar does not rotate, squirt some WD-40, or equivalent, on the threaded end.

Then work it loose by simultaneously swinging the Shoulder Gauge and rotating the Turn Bar

(see Fig. 1).

10) Swing the key Shoulder Gauge down to release the Turn Bar. Then, firmly gripping

the right end of the Turn Bar so that it remains stationary, swing the key Shoulder

Gauge up against the key. The Shoulder Gauge should be just touching the shoulder of

the key. Now, without rotating the Turn Bar anymore, tighten the set screw that holds

the Turn Bar (see Fig. 2).

56

CodeMax

®

5.2.4 Cutting Too Close To The Shoulder

Note: Only recalibrate the Shoulder Gauge after being sure that the Tip Gauge is properly

calibrated.

Swing

Shoulder

Gauge

Turn Bar

Turn Bar Set Screw

Fig. 1

1) Select a shoulder gauged, factory cut original large cylinder type key, such as a Schlage

or Arrow. Check to see that the #1 space (closest to the shoulder) is greater in depth

than a #1 cut.

2) Install the correct cutter wheel.

®

3) Turn the CodeMax

on.

4) Select and enter the proper DSD number.

5) Enter in a #1 cut for the depth. Then press ENTER

to accept, and then press START to

begin the cutting process.

6) The Pivot Arm will start to travel laterally towards the key. When the Pivot Arm travels

to the first cut (closest to the shoulder) and the key begins traveling towards the cutter

(making the depth cut), push the Emergency Stop Button.

7) Loosen the key in the vise. Slide the key to the left to line up the cutter flat opposite

the pin seat. Tighten the key in the jaw.

8) Release the Emergency Stop Button to allow the machine to return to the Home

position.

9) Loosen the set screw that holds the Turn Bar in place in the Pivot Arm. Swinging the

Shoulder Gauge should also rotate the Turn Bar.

Note: If the Turn Bar does not rotate, squirt some WD-40, or equivalent, on the threaded end.

Then work it loose by simultaneously swinging the Shoulder Gauge and and rotating the Turn

Bar. (See Fig. 2)

CodeMax

®

57

Swing Shoulder

Gauge

Rotate Turn

Bar

Fig. 2

10) Swing the key Shoulder Gauge down to release the Turn Bar. Then, firmly gripping the

right end of the Turn Bar so that it remains stationary, swing the key Shoulder Gauge up

against the key. Rotate the Turn Bar to the desired position and hold it there. The Shoulder

Gauge should just touch the shoulder of the key (see Fig. 2). Now, without rotating

the Turn Bar any more, tighten the set screw that holds the Turn Bar.

58

CodeMax

®

5.3 Depth Adjustment

Fig. 1

The need to readjust depth is caused by cutter wear or cutter replacement It is easily

accomplished by rotating the eccentric shaft (CM-1041) with the 3/8 inch end of

WRENCH-1, turning towards you to cut deeper, and away from you to cut shallower. The

180 degree rotation allows depth adjustments of plus or minus .015 inch. Since the eccentric

shaft is made of drill rod, there is no need to loosen the two binding screws prior to rotating

it (see Fig. 1).

Tools Required: Key Micrometer or Caliper, Key Blanks, Correct Depth and Spacing Data,

WRENCH-1 (use 3/8 inch end for depth adjustment).

®

1) Install a key blank in the CodeMax

®

2) Turn the CodeMax

on.

jaw.

3) Select and enter the proper DSD number (e.g. 60 for Schlage Large Pin).

4) Enter the depths, press ENTER

to accept, and press START to begin the key cutting

operation.

5) After the key has been cut, use a micrometer or caliper to measure the depth cut and

compare it against the Depth and Spacing specifications chosen in step 3 above. If

the reading of the micrometer is the same as the Depth and Spacing specifications, the

machine is cutting correctly. If the cuts are higher or lower, adjust the Eccentric Shaft

as explained in the beginning of this section (see Fig. 1). When checking the calibration

on a key machine, it is very important to use the proper tools in order to maintain the

accuracy of the machine. A key micrometer or caliper is a small investment and is

highly recommended to acquire the greatest accuracy.

CodeMax

®

59

6. Updates

Updates to the CodeMax® are now performed using your PC and a

CD supplied by HPC, Inc. Connect the Serial Cable (included with

CodeMax®) to the correct Com Port on your PC and the RS422

port on the back of the CodeMax®. Follow the directions that come

with the CD to update your CodeMax®. It is no longer necessary to

open any part of the CodeMax® to perform updates.

Program name: Update.exe

To start, double click the desktop shortcut

Update or, in My Computer, open your C: drive, open the Program Files folder, open the HPCSoft™ folder, open the

CodeMax® Update folder, double click Update.exe (application).

Make sure your serial cable is connected to the back of the CodeMax

®

To update your CodeMax

Status will display progress: Waiting for Load Command, Waiting for STX, Sending Data (514 bytes, 1, 2, etc.), Waiting

for ACK, Send Complete. During the update process, CodeMax® screen will display “Starting Upgrade **Please Wait**”.

CodeMax® will beep when the update is completed.

If the new update information does not appear in CodeMax

files.

®

If CodeMax

screen remains dark after Send Complete, use the following correction procedure:

1. Turn off your CodeMax® , leave off until

instructed below.

2. On your computer, open

3. Open the

4. Open the Program Files folder.

5. Open the HPCSoft folder.

6. Open the CodeMax

7. LEAVE THE CodeMax

8. In HPC CodeMax

Program.

9. Click

10. When Status reads “Waiting for STX”, turn

ON CodeMax

11. CodeMax

download.

If your CodeMax

Key Machine Services.

does not beep on completion of the update process, or if the update process is interrupted, or if the CodeMax®

C: drive.

Start Update

®

®

operating instructions will

®

, click on the Com Port to which CodeMax® is connected and click Start Update.

My Computer

®

Update folder

®

TURNED OFF!

®

Update Program, click

.

fails to start after this procedure, contact HPC

CodeMax® Update, or click Start, Program files, HPCSoft™ and CodeMax®

®

.

®

, repeat the update process. Be sure you are using the latest

60

CodeMax

®

7. Troubleshooting

Problem: The CodeMax® is turned on but nothing appears on the display screen and the

internal stepper motors do not start.

Solution: Check the cord, fuse, and the available power supply.

®

Problem: The CodeMax

is turned on but all that appears on the display

screen are square blocks.

Solution: Remove the Key Pad from the casting. This problem is most often associated

with a shorted keyboard wire against the casting. Once the keyboard has

been removed from the casting, attempt to turn on the machine again. If the

screen starts normally, inspect the keyboard wire or call HPC to obtain a new

keyboard wire.

®

Problem: The stepper motors jam while using the CodeMax

.

Solution: Try turning off the CodeMax® for a few seconds to clear the memory, then

turn it back on to reset the machine. If this does not clear the jam, consult

factory assistance.

Problem: Keys are not being cut accurately.

Solution: Check three possibilities: Either your cutter wheel is dull (or not the proper

diameter), the machine is out of adjustment, or the cutter belt is loose.

Attempt to cut the key utilizing the micrometer function. If the keys cut

utilizing the micrometer function are also not accurate, the machine probably

requires adjusting. Make sure the belt is snug (not overtight) and see Section

5: Recalibration of CodeMax®.

®

Problem: The CodeMax

is turned on but the stepper motors produce a grinding sound,

like they have crashed into the casting.

Solution: Turn off the machine (several electronic switches may have gone bad). Under

these conditions you should consult factory assistance.

In the event that this troubleshooting section does not solve your problems, or

you have any additional questions, call the HPC Service Center:

800.323.3295

847.671.6280

Monday-Friday

8:00am-3:30pm Central Time

CodeMax

®

61

8. Glossary

Autoload:

The downloading of information from compatible software packages.

CodeMax®:

HPC’s computerized code machine.

Contour Cutting

The carriage moves laterally across the cutter, producing a key with no peaks between cuts.

Depth:

Measured in thousandths of an inch or hundredths of a millimeter. Refers to y-axis cutting

on the CodeMax®. Also, a measurement from the bottom of the key to the root of the cut.

Emergency Stop Button:

A red button in the front of the CodeMax® used for stopping all machine movements.

Jaw:

The vise that holds the key in position for cutting on the CodeMax® or any other machine.

Jaw Type:

Denoted by the letters A, B, or C. Indicates the proper jaw used for cutting a specific key.

Plain Side

The flat side of the key which faces towards the cutter when properly positioned for cutting

(the gauging point for this type of key is referred to as a Left Side Jaw Gauge).

Series:

A set of numbers within a given range, which refers to a key code number.

:

:

Shoulder Gauge:

Used to gauge standard cylinder and automotive keys. (Refer to section 3.3).

Shoulder Side

The non-flat side of the key which faces towards the cutter when properly positioned for

cutting (the gauging point for this type of key is referred to as a Shoulder Gauge).

Speed Adjustment

Increase or decrease rate of feed in the y-axis or depths.

62

:

:

CodeMax

®

Tip:

The end of the key that enters the lock first. Also, certain keys may be gauged utilizing

the tip of the key (the gauging point for this type of key is referred to as Red Tip Stop or

Horseshoe Tip Stop gauging).

Tip Gauge

:

Used to gauge keys with no shoulders. (Refer to section 3.3)

Widen Cut

:

On keys such as Kwikset, Weiser, Volkswagen, etc. the x-axis (or spacing) often needs to be

widened more than the standard cutter wheel allows. In this manual, this is usually referred

to as general widening or specific widening. This is a function that is specified by the

manufacturer and performed automatically by the CodeMax®.

CodeMax

®

63

9. Exploded Views

Pivot Arm With Safety Switch Assembly

# Description Stock #

1. Easy Grip Wing Nut EGN-1

2. Ball Bearing Washer BBW-2

3. Top Jaw CM-1056MA

4. Spring CM-1293MA

5. Stud CM-1019MA

6. Ball Bearing CM-50108

7. Set Screw CM-50110

8. Bottom Jaw (factory installation recommended) CM-1055MA

9. Tip Stop CM-1054MA

10. Spring CM-1090MA

11. Set Screw CM-50139

12. Eccentric Shaft CM-1041

13. Set Screw CM-50109

14. Set Screw CM-50112

15. & 16 Turn Bar & Shoulder Gauge CMB-FG

17. Retaining Ring CM-50105

18. 2-56 Screw MAX-92

19. Shoulder Gauge Wire Assembly MAX-90

20. Shoulder Gauge Micro Switch Bracket MAX-91

21. 6-32 Set Screw MAX-89

64

CodeMax

®

CodeMax® Pivot Arm with Safety Switch Assembly

CodeMax

®

65

CodeMax® Parts List

# Description Stock #

1. Keypad MAX-4

2. Pad Locator MAX-5

3. Keypad Display Circuit Board MAX-6

4. Pivot Arm Assembly CM-1024X

5. Cutter Head Assembly CM-1053X

6. Grip Spring CM-1079

7. Belt Guard CM-1014B

8. Angle Index Pin CM-1042

9. Belt CM-1083MA

10. Motor Pulley CM-1060MA

11. Set Screw 9100-11

12. Nut CM-50148

13. Screw CM-50158

14. Motor Mounting Bracket CM-1040MA

15. Hex Nut CM-50157

16. Screw CM-50167

17. Motor CM-1080MA

18. Pivot Pin CM-1043

19. Washer CM-50100

20. Power Cord MAX-34

21. Screw MAX-35

22. Plunger U-Bracket MAX-43

23. Display Board Wire Assembly MAX-44

24. Screw #8-32 x 1/4 MAX-46

25. Gasket MAX-47

26. Rubber Bumper CM-50133MA

27. Screw CM-50134

28. Amp Fuse MAX-78

29. Washer CM-50167-1

30. Motor Support CM-50186

31. Motor Support Screws (2) CM-50188

66

Circuit Connections

A1 connects to: A

B1 connects to: B

C1 connects to: C

D1 connects to: D

E1 connects to: E

F1 connects to: F

G1 connects to: G

H1 connects to: H

J1 connects to: J

CodeMax

®

2

CodeMax® Primary Assembly and Circuit Connections

CodeMax

®

67

10. Preventive Maintenance, Lubrication,

Repairs, and Warranty

1) WARRANTY — The CodeMax® Code Machine is fully warranted for one year from the

date of purchase, against factory defects in material and workmanship. Mail the Warranty Card

and a copy of your invoice immediately, to validate your warranty. Should your machine require

factory repairs, please contact the Key Machine Service Department before returning your machine.

During the one year warranty period, you will be billed for handling and shipping only.

2) MOTOR — The motor is equipped with sealed bearings that require no lubrication.

3) CUTTER HEAD — The cutter head is equipped with precision ball bearings for years of

trouble free service and requires no lubrication. The cutter head swivel surface and plunger

angle holes should be given a light coat of LPS#3 or equivalent, once every four to six months.

4) BEARINGS AND SLIDING SURFACES — These are to be given a light coat of a light grease

at least every six months.

5) EXPOSED STEEL SURFACES — All remaining exposed steel shafts, cutters, etc., should be

sprayed with WD-40 or equivalent light oil at least every six months. Wipe off any excess.

6) CLEANING — Remove all brass chips, dirt, and grit from the surface of your machine daily,

with a soft bristle brush. Take particular care in keeping the jaw area clean and free of all

residue build-up.

7) CALIBRATING DEPTH FOR RESHARPENED CUTTERS — Sharpening cutters changes

the diameter; HPC, Inc. recommends replacing cutters instead of sharpening. The diameter of

a resharpened cutter is smaller and therefore will make cuts shallower (if no depth adjustment

is made). In order to maintain matched cutter diameters, all cutters for this machine must be

resharpened at the same time, and all diameters must be sharpened proportionately.

8) DRIVE BELT — The drive belt (CM-1083MA) was selected especially for this machine and

should give years of good service. If it becomes worn or broken and requires replacement, be

sure to install the new belt with the teeth outward.

Note: The drive belt is somewhat more noisy when it is made to “cross-over” as the cutter head

is swiveled to either the left or right angle when cutting Medeco®keys.

HPC Key Machine Service Dept.

Tel: 800.323.3295 (USA & Canada)

Tel: 847.671.6280

Monday-Friday

8:00 - 3:30 Central Time

68

CodeMax

®

HPC SERVICE CENTER

If your HPC Key Machine should require service, please note the following information:

HOURS: The HPC Service Center answers questions involving key machine repair and replacement parts Monday

through Friday from 8:00 am to 3:30 pm Central time.

Please call 800-323-3295 (from the U.S. and Canada) or 847-671-6280 (from other countries).

REPAIRS: We recommend the replacement of cutters, brushes and external parts, the preventive maintenance and

recalibration (as outlined in this manual) be the only repairs or adjustments that are done by the user. Internal parts and

mechanisms should be factory-repaired only. Additional repair charges may be incurred by attempting to make these

types of repairs by yourself.

FACTORY SERVICE: If you need to send your HPC key machine in for repair, first call the HPC Service Center

to obtain a Repair Order number, then follow these instructions:

Include a letter explaining the problem you are having, as well as any other work you want done on the machine. Make sure

your business name, address and phone number, as well as the name of the contact person are on the letter.

Your machine should be equipped with an HPC cutter when it is sent in for repairs. If you are sending in a Blitz™ or

CodeMax™ machine also include the Black Horseshoe Tip Stop to insure proper tip gauge calibration. Please do not send in

any other accessories (such as other cutters and code cards).

Pack the machine securely in a box strong enough to prevent damage during shipping (preferably the original box).

The Repair Order Number should be marked on the outside of the box.

All machines must be shipped prepaid. Collect shipments will not be accepted.

Our shipping address is:

HPC, Inc.

Attn. Service Center

3999 N. 25th Avenue

Schiller Park, IL 60176 USA

REPAIR CHARGES & ESTIMATES: Upon receipt and evaluation of your machine our technicians will

provide a written estimate (by fax) of the repair charges. Some problems may be detected only while the repair work is being

done. If after informing you of the repair estimate it becomes apparent that the cost will be higher, you will be notified of the

additional charges before any additional work is done.

REPLACEMENT PARTS: Key machine parts can be purchased through an Authorized HPC Distributor or

directly from the HPC Service Center. When ordering parts over the phone, please have the part numbers and descriptions

ready to expedite the ordering process. A parts listing and an exploded view drawing is included in this manual. If the parts

are needed urgently, express processing is available at an additional charge.

PAYMENT: Payment for parts and repair is required at the time of repair and before the parts are shipped. We accept

payment by credit card (Visa, Mastercard or Discover) or by check. Repaired machines and parts can also be sent C.O.D.

with an extra charge. If you wish to have your Authorized HPC Distributor billed for the parts or repairs, the distributor must

call us with approval of the billing and provide a purchase order number for the parts or work being done, before the machine

is repaired or parts are shipped.