Page 1

technical reference guide

hp workstation zx2000

Document Part Number: 5969-3154

April 2003

This manual contains an overview of system specifications, instructions

for removing and replacing system components, information on

configuring your system using the included tools and interfaces, and

detailed troubleshooting information.

Page 2

© 2003 Hewlett-Packard Development Company, L.P.

®

Microsoft

Corporation in the U.S. and other countries.

Intel

under license.

LINUX® is a registered trademark of Linus Torvalds in the U.S. and other countries.

NVIDIA and NVIDIA Quadro are registered trademarks or trademarks of NVIDIA Corporation in the United

States and/or other countries.

All other product names mentioned herein may be trademarks of their respective companies.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material. The

information in this document is provided “as is” without warranty of any kind, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose, and is subject to change without notice.

The warranties for HP products are set forth in the express limited warranty statements accompanying such

products. Nothing herein should be construed as constituting an additional warranty.

This document contains proprietary information that is protected by copyright. No part of this document may be

photocopied, reproduced, or translated to another language without the prior written consent of Hewlett-Packard

Company.

WARNING: Text set off in this manner indicates that failure to follow directions could result in bodily

Å

harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result in

Ä

damage to equipment or loss of information.

, Windows®, Windows 2000®, and Windows XP® are registered trademarks of Microsoft

®

and Itanium® are registered trademarks of Intel Corporation in the U.S. and other countries and are used

technical reference guide

hp workstation zx2000

First Edition (April 2003)

Document Part Number: 5969-3154

Page 3

important safety warnings

WARNING: Avoid Electrical Shocks. To avoid electrical shock, do not open the power supplies. There

Å

are no user-serviceable parts inside.

To avoid electrical shock and harm to your eyes by laser light, do not open the DVD laser module. The

laser module should be serviced by service personnel only. Do not attempt to make any adjustment to the

laser unit. Refer to the label on the DVD for power requirements and wavelength. This product is a class I

laser product.

WARNING: Removing and Replacing the Cover. For your safety, never remove the system side cover

Å

without first disconnecting the power cord from the power outlet and removing any connection to a

telecommunications network. If a Power Protection Device is fitted to your system, you must shut down

your computer using its on/off switch, then remove the power cord before removing the system’s side

cover. Remove the Power Protection Device cables before any servicing operation. Always replace the

side cover before switching the system on again.

WARNING: Battery Safety Information. There is a danger of explosion if the battery is incorrectly

Å

installed. For your safety, never attempt to recharge, disassemble, or burn an old battery. Replace the

battery with the same or equivalent type, as recommended by the manufacturer.

The battery in this system is a lithium battery that does not contain any heavy metals. However, to protect

the environment, do not dispose of batteries in household waste. Return used batteries either to the shop

from which you bought them, to the dealer from whom you purchased your system, or to HP so that they

can either be recycled or disposed of in the correct way. Returned batteries will be accepted free of

charge.

WARNING: Avoid Burn Injuries. Some parts inside the computer will be hot. Wait approximately three

Å

to five minutes for them to cool down before touching them.

CAUTION: Avoid Static Electricity. Static electricity can damage electronic components. Turn OFF all

Ä

equipment before installing an accessory card. Don’t let your clothes touch any accessory card. To

equalize the static electricity when replacing an accessory card, rest the accessory card bag on top of the

system unit while you are removing the card from the bag. Handle the card as little as possible and with

care.

CAUTION: Information on Ergonomic Issues. It is strongly recommended that you read the ergonomics

Ä

information, available in the “Working In Comfort” section of this manual, before using your system. You

can access more extensive ergonomics information at: www.hp.com/ergo

NOTE: Recycling Your System. HP has a strong commitment toward the environment. Your HP

system has been designed to respect the environment as much as possible. HP can also take back

your old system for recycling when it reaches the end of its useful life. HP has a product

take-back program in several countries. The collected equipment is sent to an HP recycling

facilities in Europe or the U.S.A. As many parts as possible are reused. The remainder is

recycled. Special care is taken for batteries and other potential toxic substances, these are

reduced into non-harmful components through special chemical processes. If you require more

details about the HP product take-back program, contact your local dealer or your nearest HP

Sales Office.

Page 4

Page 5

Contents

1 Product Information

System features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Power specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Power consumption and cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Environmental specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Rear panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

2 Installing or Replacing Parts and Accessories

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Internal components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Removal and replacement prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Read the power and EMI warning and note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Gather your tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Follow electrostatic discharge (ESD) precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Removing and replacing covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Removing the plastic and metal covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Replacing the covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Removing and replacing the front bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Removing and replacing internal components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Memory modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Accessory and graphics cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

Optical drives (CD or DVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–17

Hard drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

System fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

Airflow guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

LED status panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Processor assembly and power module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–28

System board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–33

System battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–36

3 System Configuration

Extensible Firmware Interface (EFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Accessing and navigating the EFI shell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Using the Boot Option Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

Using the Security/Password menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–21

Baseboard Management Controller (BMC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

Using the BMC command line interface (CLI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

technical reference guide v

Page 6

Contents

3 System Configuration

Extensible Firmware Interface (EFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Accessing and navigating the EFI shell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Using the Boot Option Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

Using the Security/Password menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–21

Baseboard Management Controller (BMC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

Using the BMC command line interface (CLI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

BMC commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–24

IPMI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–26

Firmware upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–31

4 Troubleshooting

Troubleshooting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Identifying and diagnosing hardware problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

System e-buzzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

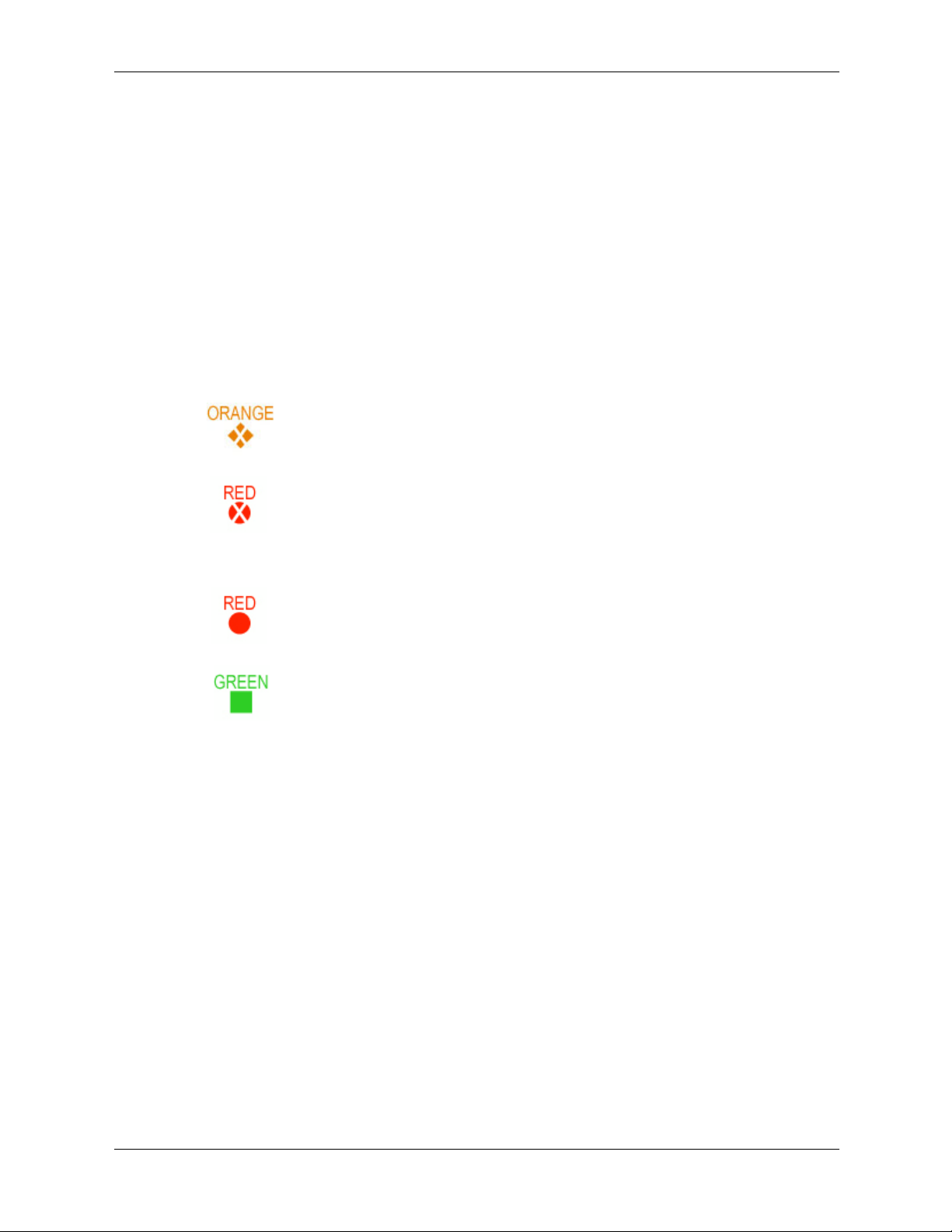

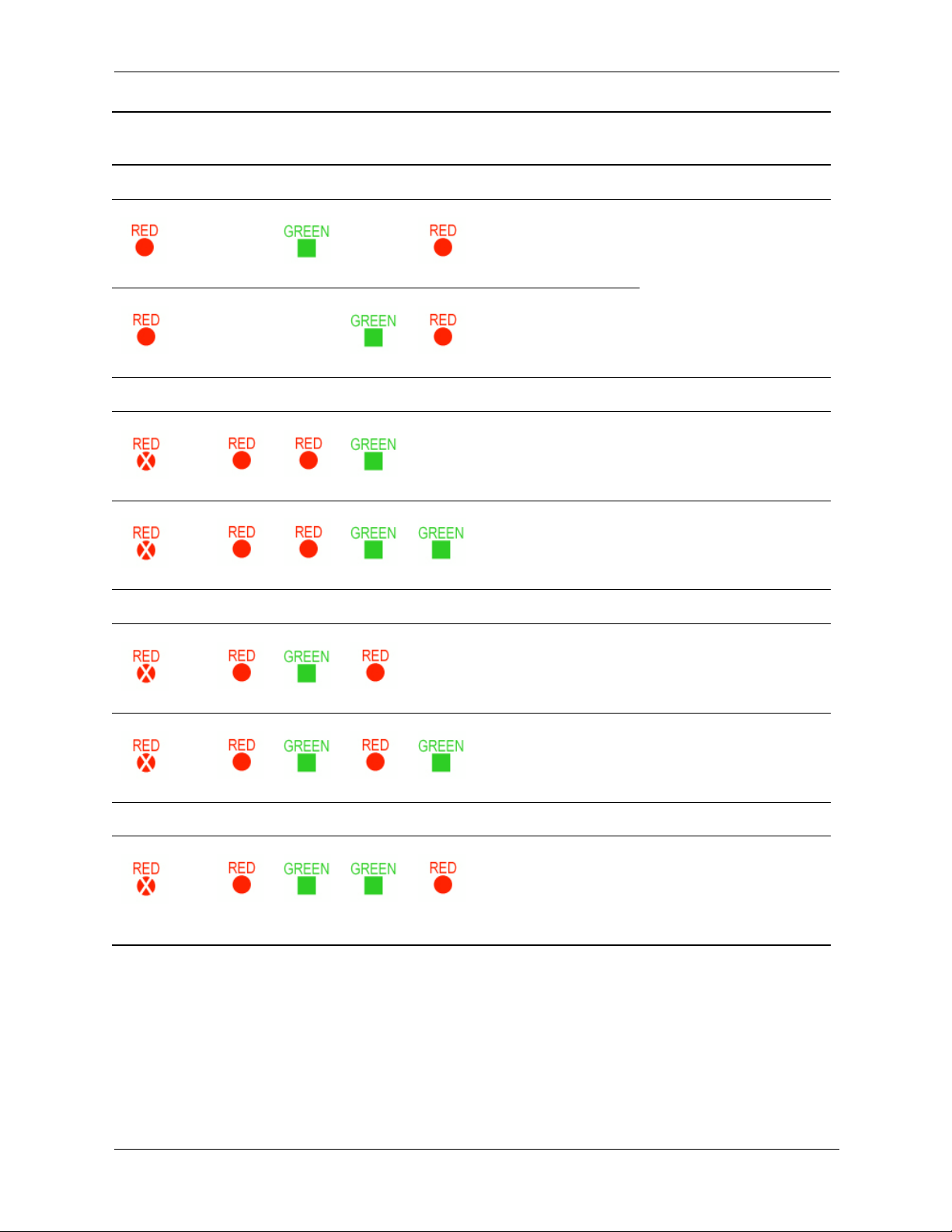

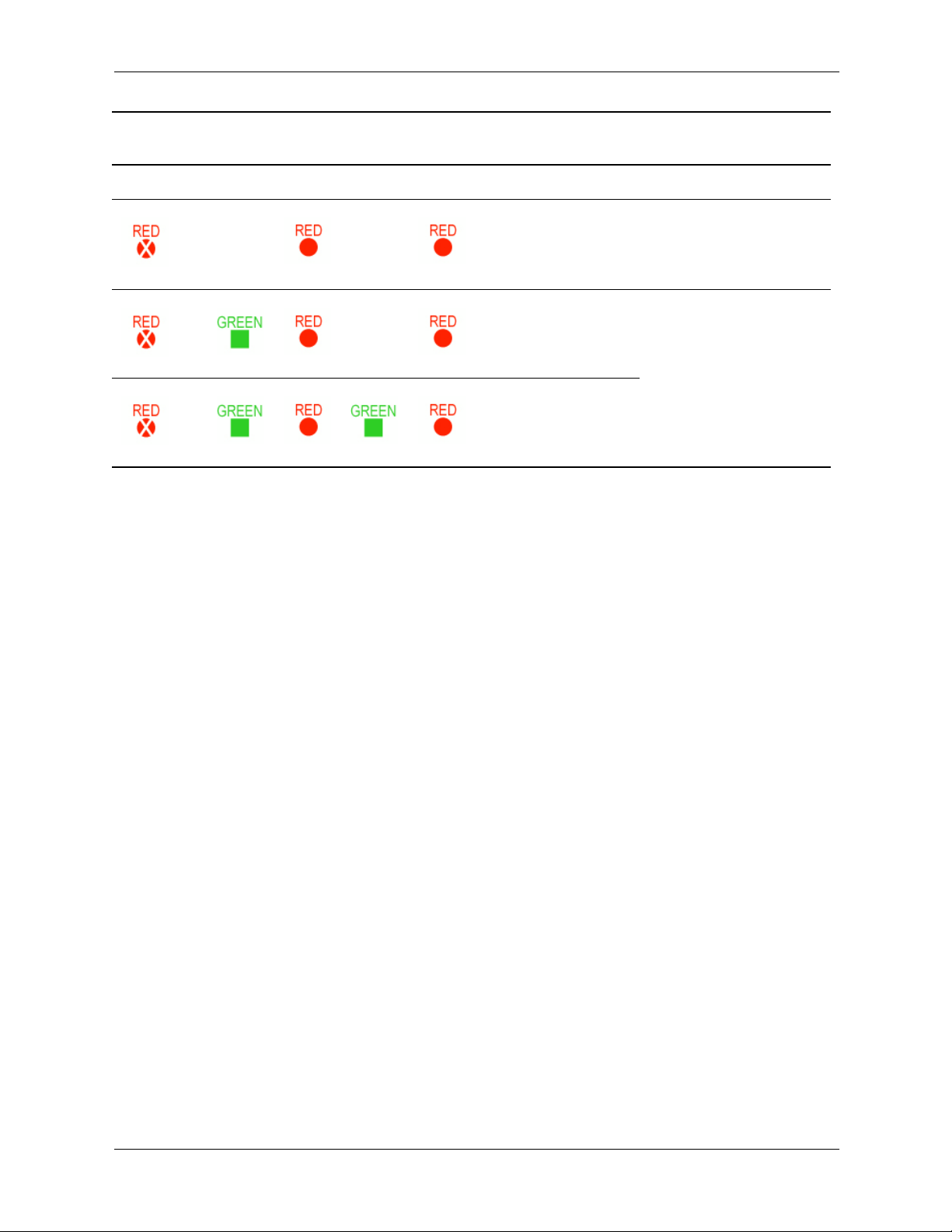

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Monitor troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

Running Diagnostic Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

HP e-DiagTools hardware diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

Additional diagnostics tools for HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–18

A System Accessories

Graphics cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Supported graphics cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Selecting a monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Mass storage devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Hard disk drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

CD-RW drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

DVD-ROM drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–8

B System Board

System board overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

System board components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

Intel® Itanium® 2 processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

Processor bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–3

ZX1 I/O and memory controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–4

I/O bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–4

Processor dependent hardware controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–5

Dual serial controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–5

Field programmable gate array controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–6

Baseboard management controller (BMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–6

IDE interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–6

10/100/1000 BT LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–7

vi technical reference guide

Page 7

C Part Numbers

Exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

D Event, Error and Warning Messages

EFI error and warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

SEL and FPL log entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–4

Accessing the logs with BMC CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–4

System specific events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–5

Events without sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–8

Index

Contents

technical reference guide vii

Page 8

Contents

viii technical reference guide

Page 9

This chapter provides an overview of the hp workstation zx2000, including:

■

System features

■

Physical characteristics

■

Power specifications

■

Environmental specifications

■

Front panel features

■

Rear panel connectors

system features

Feature Description

Processor Intel® Itanium® 2

1

product information

•900 MHz

• 1.5 MB cache on chip

Firmware 8 MB flash EEPROM

• Configured using Extensible Firmware Interface (EFI)

Operating system Models include one of the following:

•HP-UX

•Linux®

• Microsoft® Windows® XP 64-Bit Edition Version 2003

Main memory Capacity:

• 512 MB min. (2 x 256 MB)

• 8 GB max. (4 x 2 GB)

Type: PC2100 ECC registered DDR266 SDRAM

Sockets: Four DIMM sockets

Bus Bandwidth: 4.25 GB/sec

For memory loading order and detailed memory installation

instructions, see “Loading Order” on page 2-12.

Hard drive(s) Models include one or two of the following:

• Ultra ATA-100 IDE: 40 GB, 80 GB or 120 GB

• Ultra 160 SCSI: 36 GB, 73 GB or 146 GB

technical reference guide 1–1

Page 10

Product Information

Feature Description

Optical drive(s) Models include one of the following IDE drives:

• 48X CD-RW

•16X DVD-ROM

SCSI controller

(optional)

IDE controller Ultra ATA-100 capable controller supporting a total of two IDE buses

Graphics controllers Models available with a range of AGP graphics cards (Appendix A).

Accessory card sockets Six sockets total:

I/O connectors • 10/100/1000 LAN connector

Models may include one Ultra 160 SCSI adapter

and four IDE devices:

•Two internal hard drives

• Two front-access optical drives

• One AGP Pro 50 1.5V-only 4

• Three full-length and one half-length 3.3V 64-bit 66 MHz PCI-X

sockets

• One full-length 3.3V 64-bit 133 MHz PCI-X socket.

• Four USB 2.0 480 Mb/s connectors:

•Two front-access

•Two rear-access

•Two 9-pin serial ports:

•UART 16550 buffered

• RS-232-C

32-bit socket

×

Input devices USB keyboard and mouse:

• HP 104/105 key keyboard, available in 13 localized layouts

• HP three-button mouse, standard or scroll-wheel

IEEE-1394 FireWire

(optional)

Audio Integrated audio features:

1–2 technical reference guide

Models may include IEEE-1394 interface cards:

• IEEE-1394A, OHCI

• Three ports (two rear, one internal)

• 16-bit stereo

• Internal CD audio connector

• Full duplex

• Three rear-connect audio jacks:

•Microphone

•Line in

•Line out

Page 11

physical characteristics

Characteristic hp workstation zx2000

Product Information

Weight

1

Tower system Minimum: 21.98 kg (48.45 lb.)

Maximum: 24.80 kg (54.68 lb.)

Rack system Minimum: 17.77 kg (39.18 lb.)

Maximum: 20.60 kg (45.41 lb.)

Dimensions

Tower system Height: 502.6 mm (19.79 in.)

Depth: 512.4 mm (20.17 in.)

Width: 268.0 mm (10.55 in.)

Rack system Height: 175.3 mm (6.90 in.)

Depth: 510.9 mm (20.11 in.)

Width: 482.5 mm (18.99 in.)

Footprint, tower system

Space requirement, rack system

1. Excludes keyboard, mouse and display.

0.09 m2 (0.98 sq. ft.)

4 units

technical reference guide 1–3

Page 12

Product Information

power specifications

Available power (output) is the maximum DC power that the power supply can supply to the

system.

Maximum input power is what the power supply requires from the AC line to deliver that

maximum DC output (given worst case efficiency and max loading).

Maximum input current is the worst case/highest current given the lowest input voltage and the

maximum input power.

Parameter Total Rating PCI Sockets AGP Sockets

Input voltage (wide-range) 100-127VAC

200-240VAC

Max input current 6.4A at 100VAC

3.2A at 200VAC

Input frequency 50 – 60 Hz

Max input power required 643W

Max available output power 450W

Max current at +12V 14A

Max current at +12V-CPU 16A

Max current at +3.3V 34A

Max current at +5V 20A

Max current at –12V 0.55A

Max current at +5Vsb 2A

5 sockets

available at

15W/socket

Total of 75W

1 socket

available at

50W/socket

The power supply has Active Power Factor Correction (APFC) that meets EN61000-3-2 over the

range of 88-255 VAC rms.

1–4 technical reference guide

Page 13

power consumption and cooling

The power consumptions listed in the following table are valid for a standard configuration as

shipped (4 GB of memory, 450W power supply, two hard disk drives, and one graphics card).

All information in this section is based on primary power consumptions.

Additional Component

Processor 130W 443.6 Btu/h

IDE hard disk drive with I/O access 23W 78.4 Btu/h

IDE hard disk without I/O access (idle) 16W 54.5 Btu/h

PCI card 10W to 25W 34.12 Btu/h to 85.30 Btu/h

AGP card 50W (maximum) 170.6 Btu/h

environmental specifications

Environmental Specifications (System Processing Unit with Hard Disk)

Product Information

Operating temperature +5° C to +35° C (+41° F to +95° F)

Storage temperature -40° C to +70 C (-40° F to +158° F)

Over-temperature shutdown +40° C (+104° F)

Operating humidity 15% to 85% relative (non-condensing)

Storage humidity 8% to 85% relative (non-condensing)

Operating altitude 0-3000 m (0-10,000 ft.)

Storage altitude (long-term) 0-4600 m (0-15,000 ft.)

Operating temperature and humidity ranges may vary depending on the installed mass storage

devices. High humidity levels can cause improper disk operation. Low humidity levels can

aggravate static electricity problems and cause excessive wear of the disk surface.

technical reference guide 1–5

Page 14

Product Information

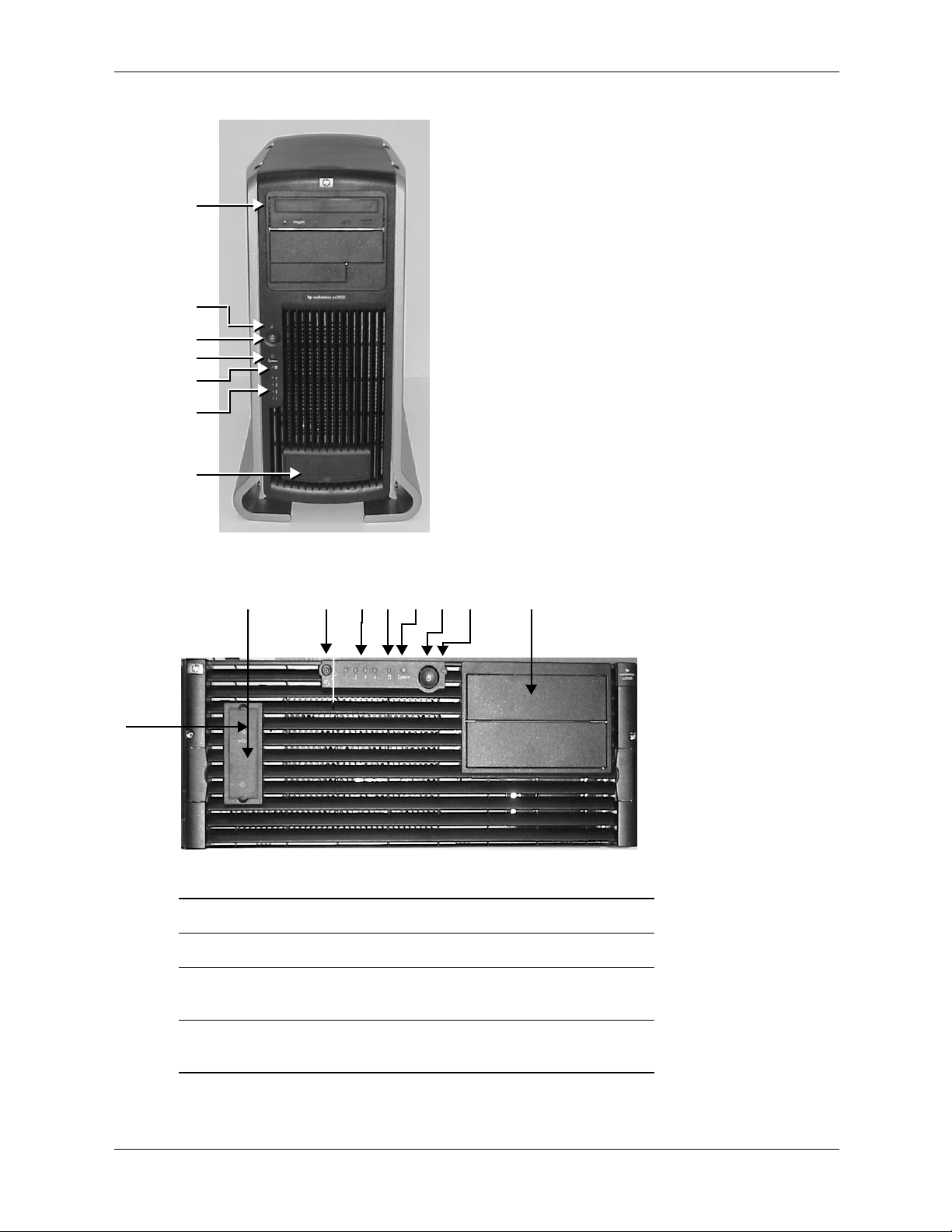

front panel

The hp workstation zx2000 front panel has the following features:

■

Two front-access USB connectors.

■

Two front-access optical drive bays.

Power Button turns the system power on or off.

■

Power LED is green when the power is on or the power button is pushed in. If the power is

■

on and the button is pushed in, the light will stay on even after the system is powered down.

When the button is released, the green light turns off.

Activity LED indicates whether the system is accessing any of the hard drives or optical

■

drives (IDE or SCSI). If the LED is:

off, the system is off, or the system is not accessing internal drives

❏

blinking green, the system is accessing an internal drive

❏

NOTE: The Activity LED automatically communicates with IDE hard drives or optical drives.

To communicate with SCSI drives, a SCSI LED activity cable must connect the SCSI card and

the system board. The Activity LED is active only on systems purchased after March 2003.

System and Diagnostic LEDs provide information about system errors.

■

Locator Button and LED (rack-mount configuration only) identifies the rack position of

■

the workstation.

1–6 technical reference guide

Page 15

Product Information

1

2

3

4

5

6

7

Front Panel, Tower Configuration

12345687

Front Panel, Rack Configuration

1 Optical drive bays 5 Activity LED

2 Power LED 6 Diagnostic LEDs 1-4

3 Power button 7 Front-access USB connectors

(behind door)

4 System LED 8 Locator LED and button

(rack-mounted system only)

technical reference guide 1–7

Page 16

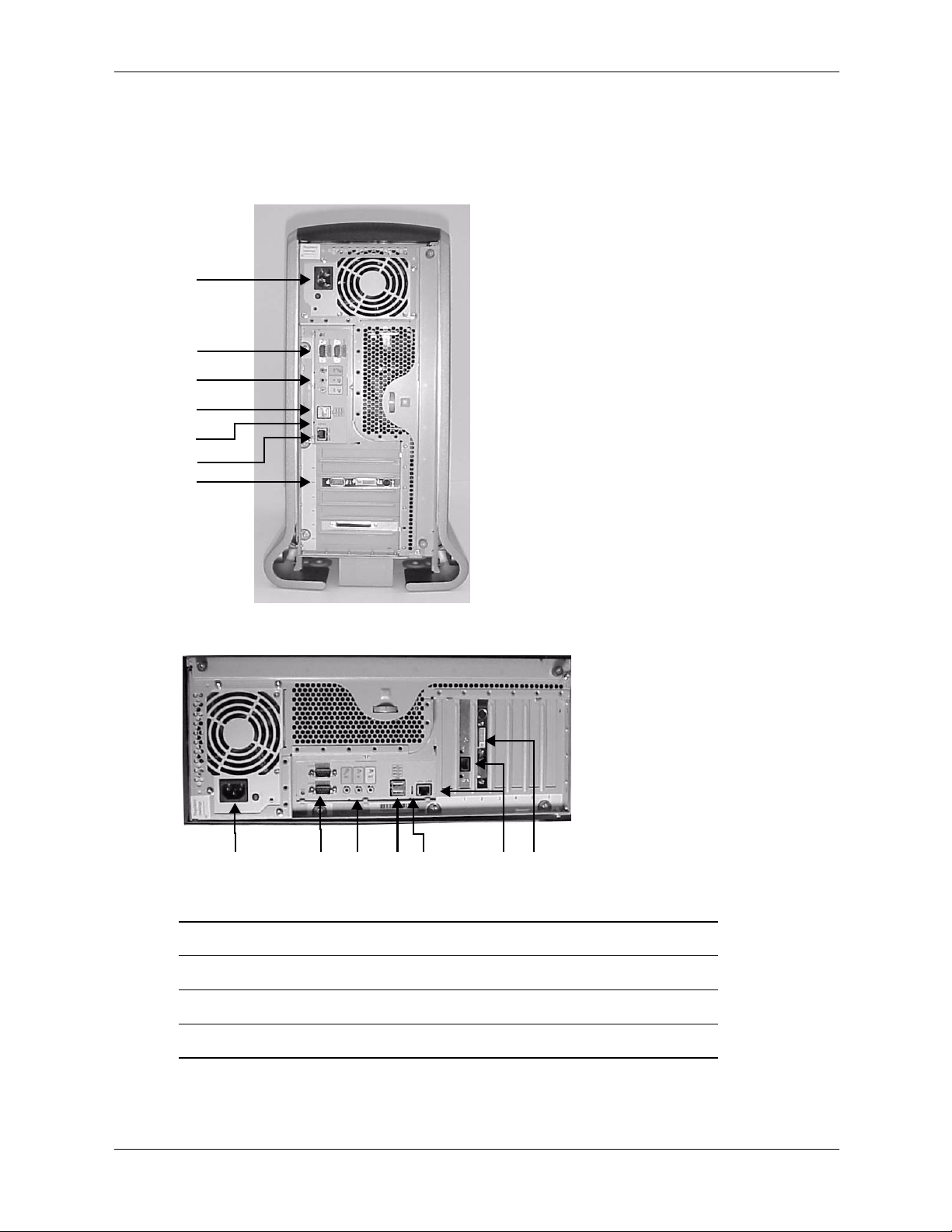

Product Information

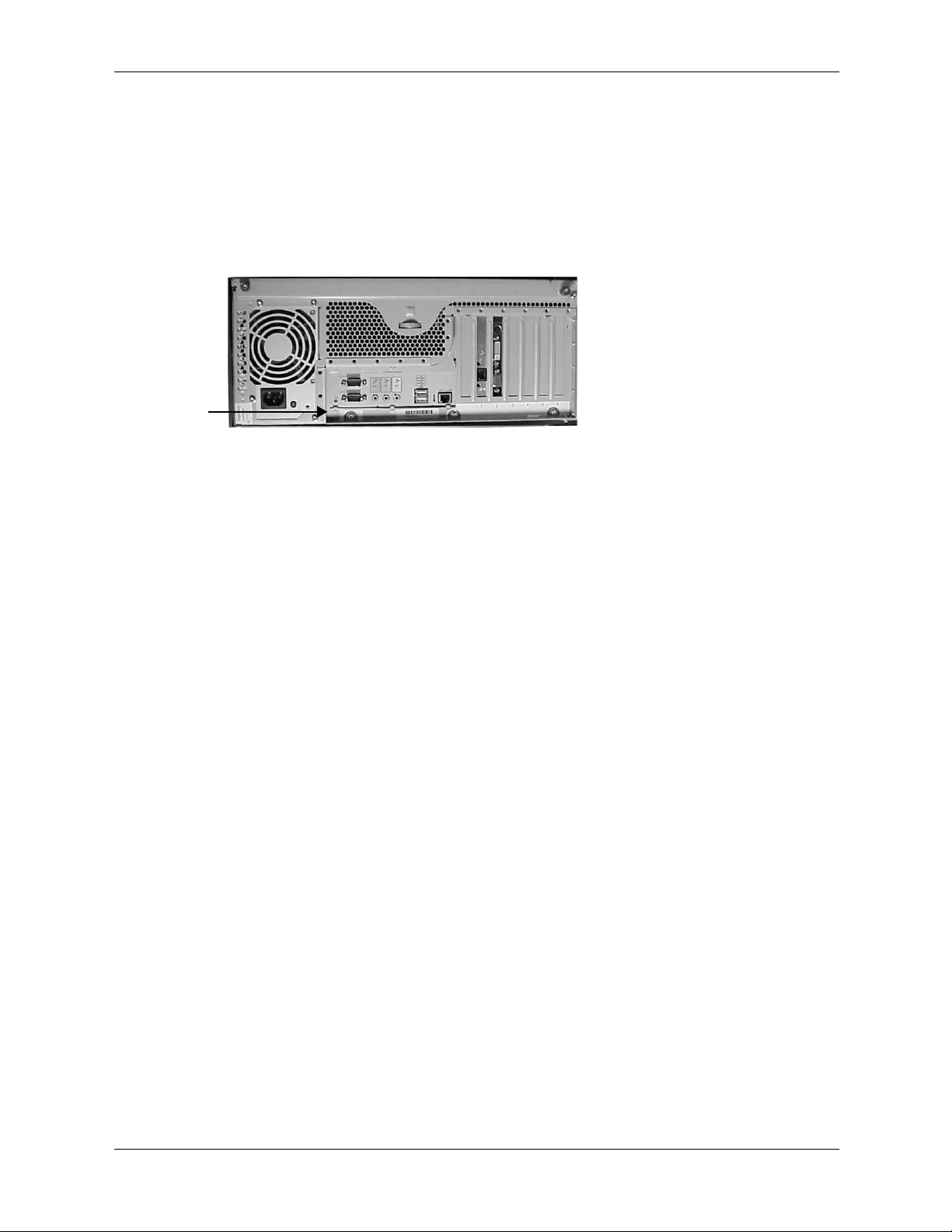

rear panel

The connectors are shaped to go in one way only. Refer to the label on the back of the

workstation.

1

2

3

4

5

6

7

Rear Panel Connectors, Tower Configuration

124

Rear Panel Connectors, Rack-mounted Configuration

1 Power 5 LAN LEDs

2 Serial ports 6 Built-in LAN and optional 2nd LAN ports

3 Audio

4 USB

(headphone, microphone)

37

5

7 Monitor port(s) on graphics card

6

1–8 technical reference guide

Page 17

installing or replacing parts and accessories

overview

This chapter contains the following sections:

■

“Internal components” on page 2-2 shows photos of the internal components and system

board. These will help you locate components.

■

“Removal and replacement prerequisites” on page 2-4 provides information you must know

before you remove components.

■

“Removing and replacing covers” on page 2-5 and “Removing and replacing the front bezel”

on page 2-10 explain two tasks you perform for many remove/replace procedures.

■

The remaining sections explain how to remove and replace components:

❏

Memory modules, page 2-11

❏

Accessory and graphics cards, page 2-13

❏

Optical drives (CD or DVD), page 2-17

2

❏

Hard drives, page 2-20

❏

Power supply, page 2-23

❏

System fans, page 2-24

❏

Airflow guide, page 2-26

❏

LED status panel, page 2-27

❏

Processor assembly and power module, page 2-28

❏

System board, page 2-33

❏

System battery, page 2-36

technical reference guide 2–1

Page 18

Installing or Replacing Parts and Accessories

6

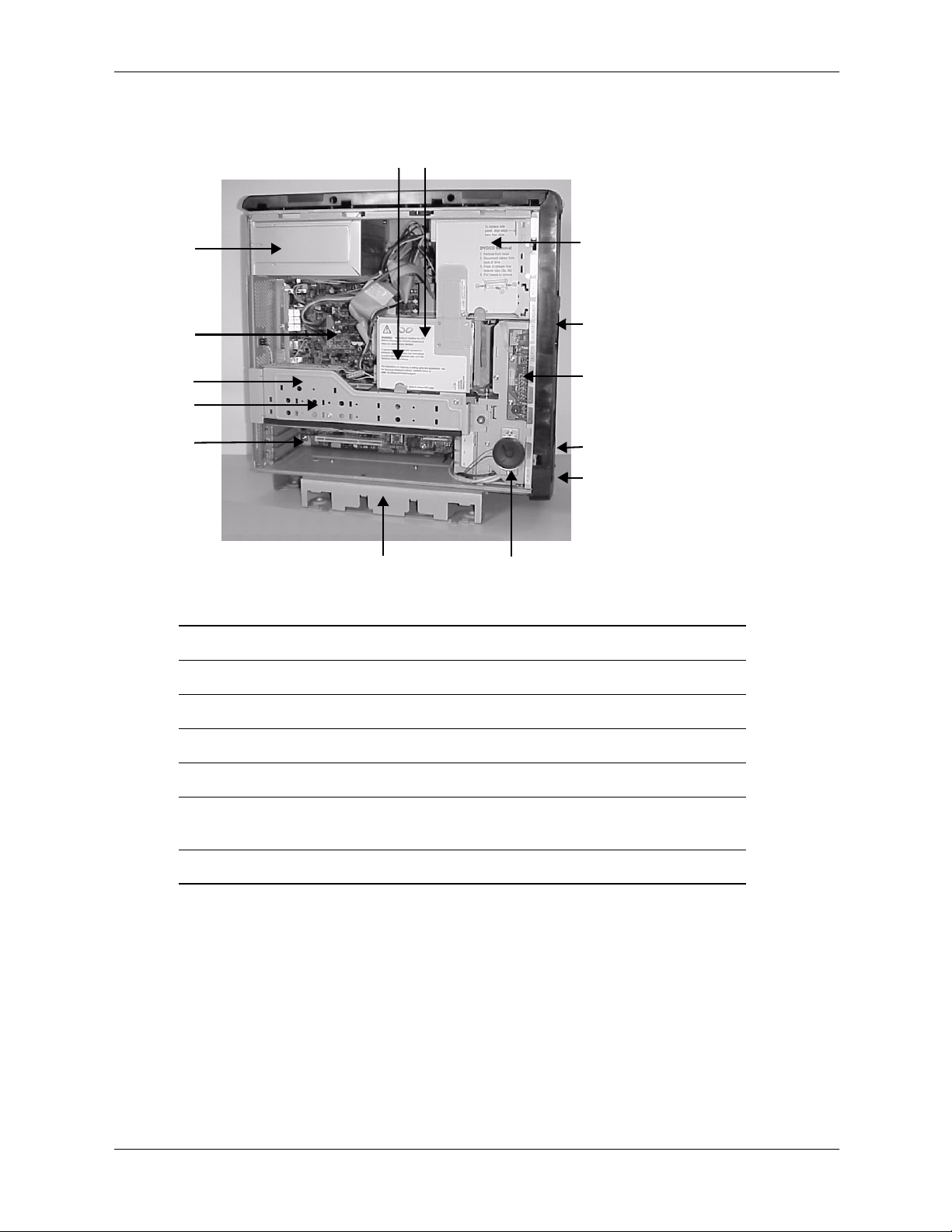

internal components

7

5

4

3

2

1

14

zx2000 Main Components

1 PCI sockets 8 Optical drive(s)

2 AGP video card (behind arm) 9 System fans (behind front bezel)

13

8

9

10

11

12

3 AGP retainer arm 10 LED status panel

4 Memory DIMMs 11 Serial number label (behind door)

5 Power supply 12 Front-access USB ports (behind door)

6 Processor/fan assembly

(behind hard-drive cage)

7 Hard-drive cage 14 Pedestal (tower system)

2–2 technical reference guide

13 Internal speaker

Page 19

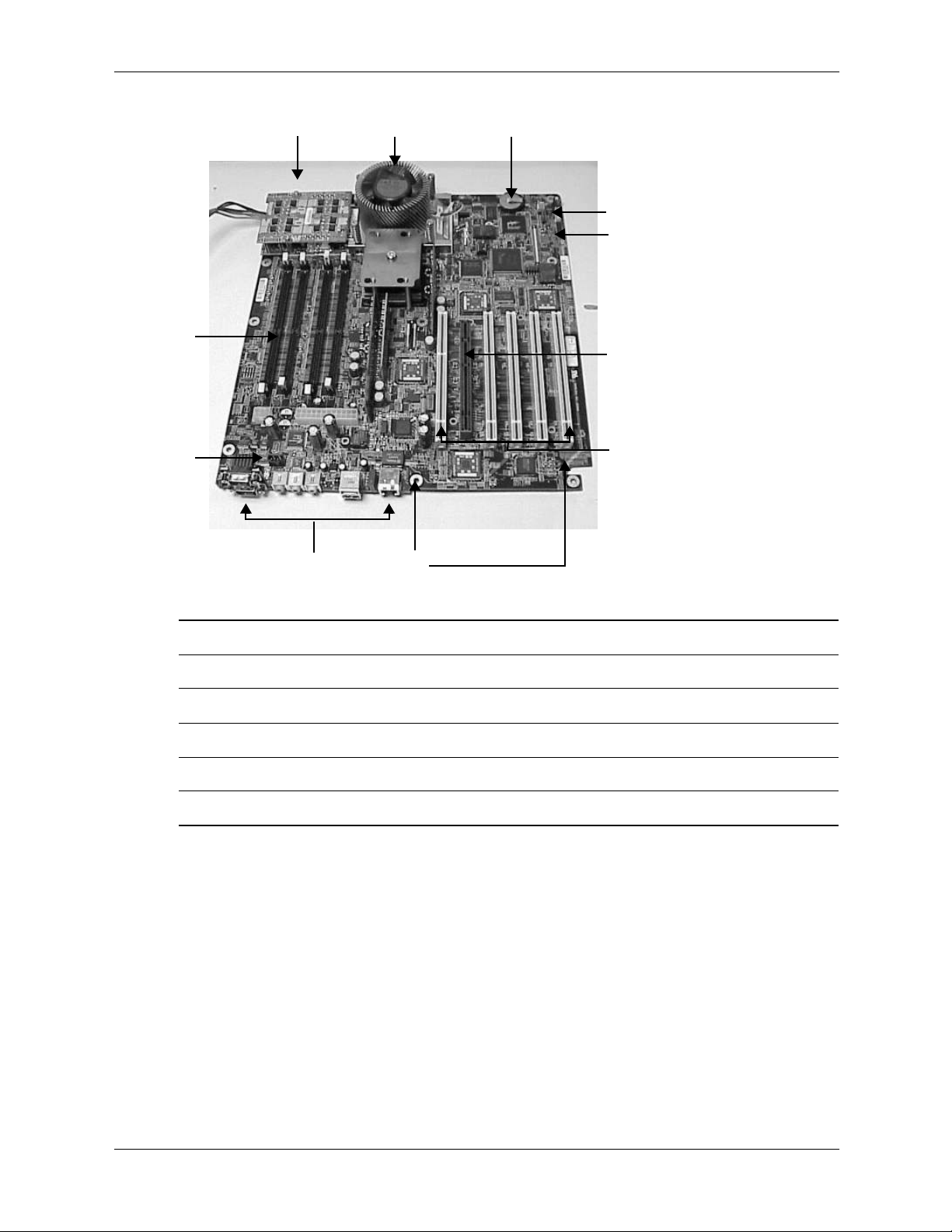

Installing or Replacing Parts and Accessories

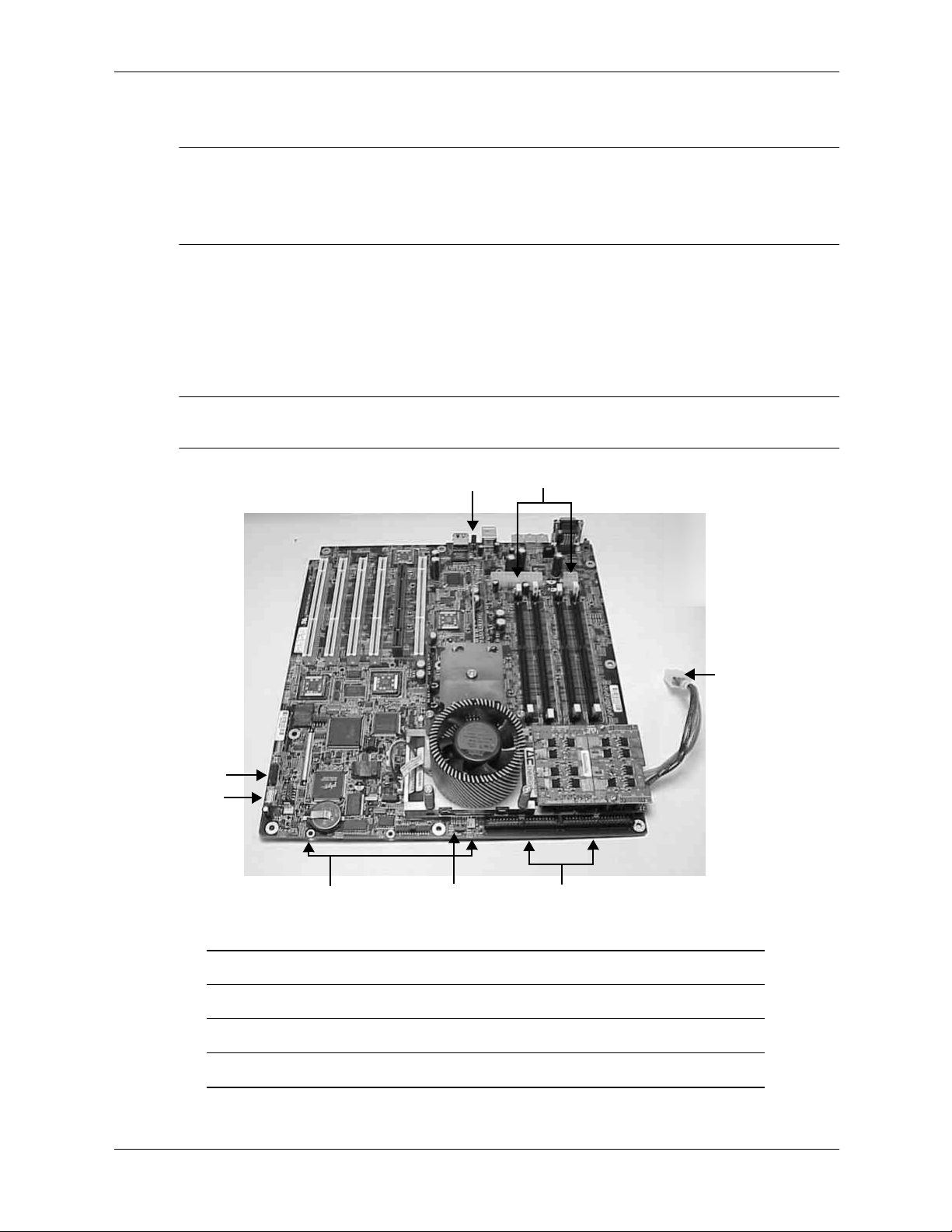

543

6

7

2

8

1

11

10

9

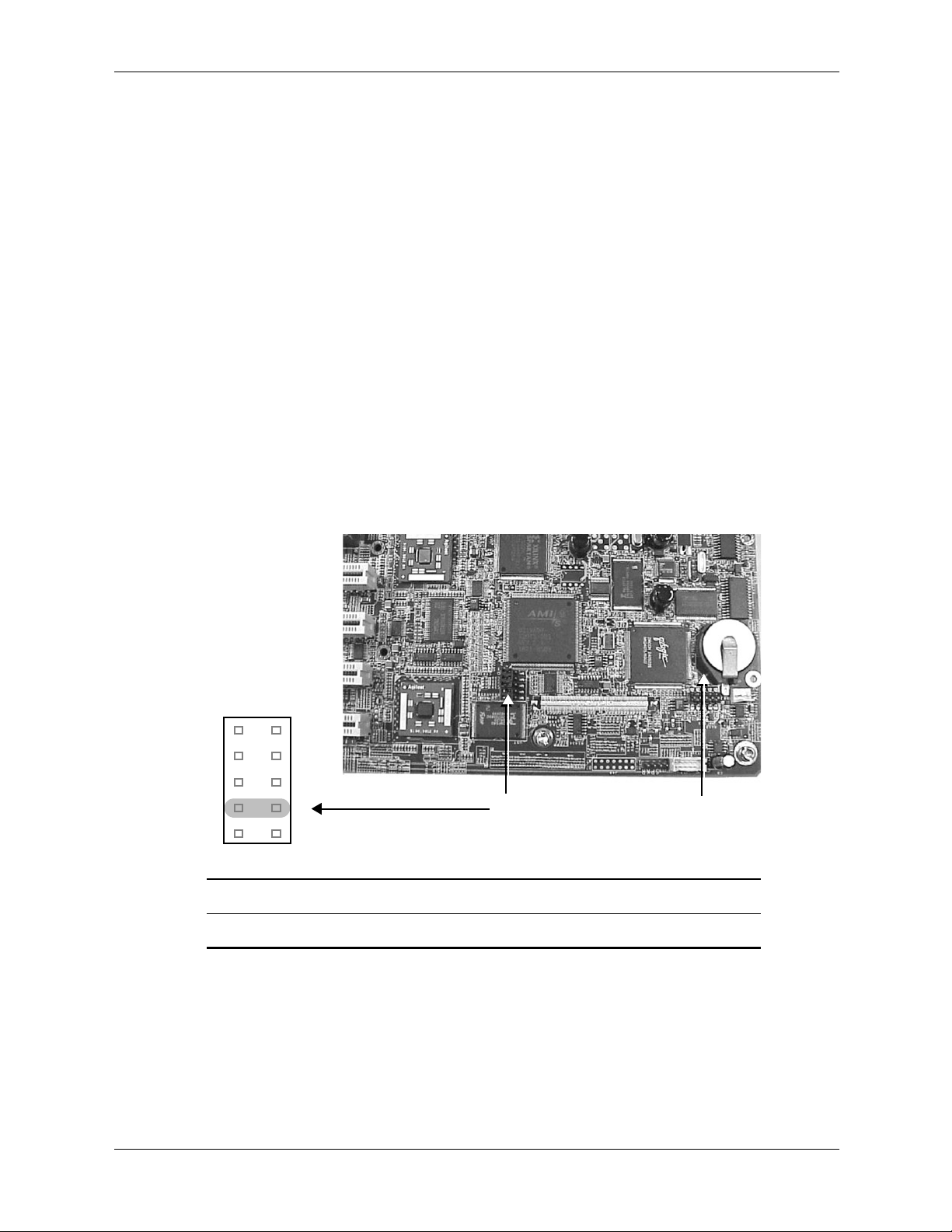

zx2000 System Board

1 CD Audio connector 7 Internal speaker connector

2 Memory DIMM sockets (4) 8 AGP-Pro 50 socket

3 CPU Power Module 9 PCI sockets (5)

4 CPU Assembly 10 SCSI LED activity connectors

5 Battery 11 Rear panel connectors

6 USB front cable connector

For additional information on the system board, see Appendix B.

technical reference guide 2–3

Page 20

Installing or Replacing Parts and Accessories

removal and replacement prerequisites

Before you remove or replace parts, you must:

■

Read the power and EMI warning and note below. (Your safety is important!)

■

Gather your tools.

■

Follow electrostatic discharge (ESD) precautions.

read the power and EMI warning and note

WARNING: For the installation and removal procedures in this chapter, you must:

Å

gather your tools

power off the workstation, and

■

unplug the workstation power cord from the AC power outlet.

■

NOTE: To maintain FCC Electromagnetic Interference (EMI) compliance, verify that all covers

are replaced and that all screws are properly seated.

You ne e d:

■

Flat blade screwdriver

■

T-15 Torx driver

■

Special processor tool (provided with replacement CPU)

■

Static-free mat

■

Static strap

follow electrostatic discharge (ESD) precautions

To prevent damage to this system, observe all of the following ESD precautions while

performing the system parts removal/replacement procedures:

■

Work on a static-free mat.

■

Wear a static strap to ensure that any accumulated electrostatic charge is discharged from

your body to ground.

■

Create a common ground for the equipment you are working on by connecting the static-free

mat, static strap and peripheral units to that piece of equipment.

■

Keep uninstalled printed circuit boards in their protective antistatic bags.

■

Handle printed circuit boards by their edges, once you have removed them from their

protective antistatic bags.

2–4 technical reference guide

Page 21

removing and replacing covers

To upgrade, remove or replace system components, you must first remove the covers from the

system chassis. This section explains how to remove and replace the covers for both tower and

rackmount configurations.

WARNING: Never remove the system cover(s) without first turning the system off and unplugging the

Å

power cord from the outlet or Power Protection Device. Always replace the cover(s) before turning the

workstation on.

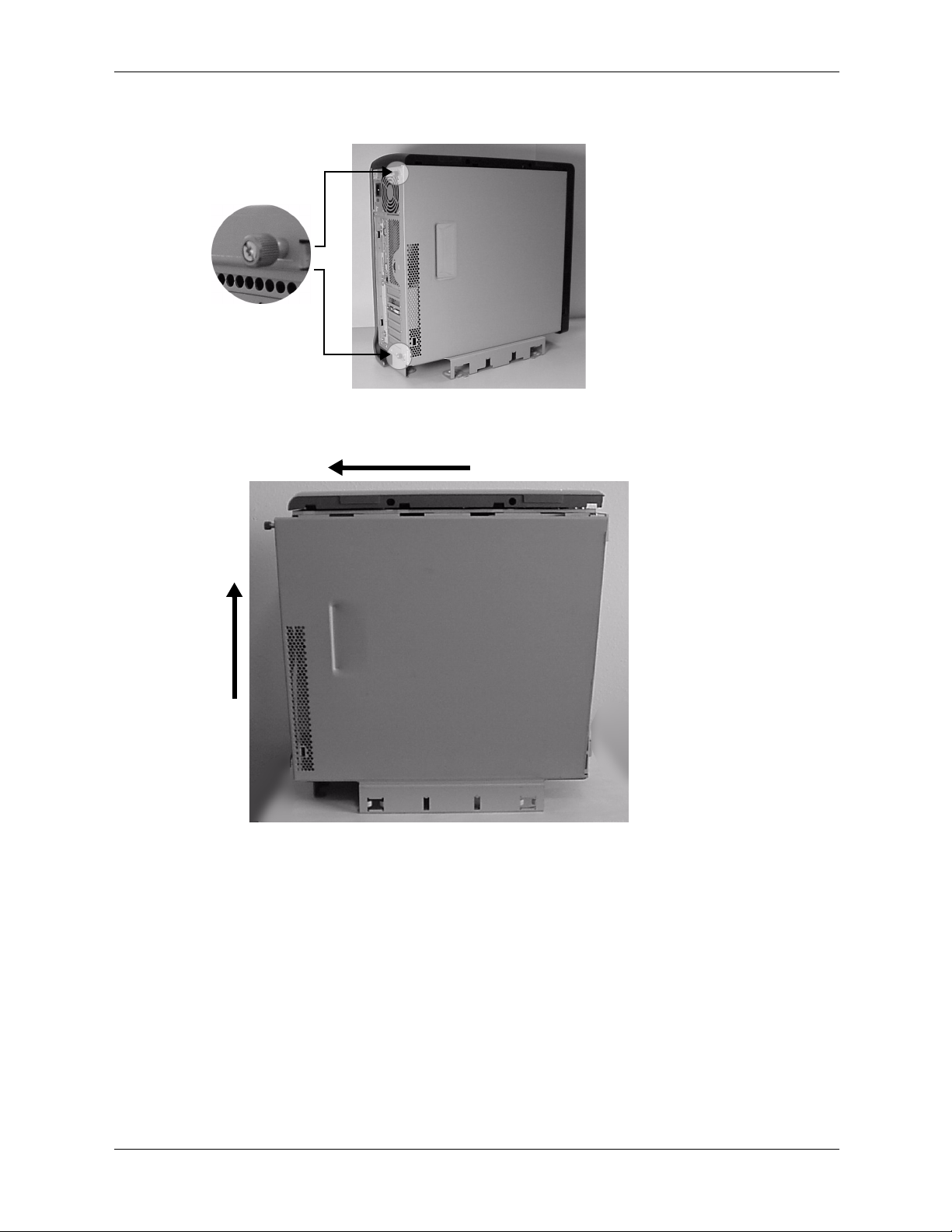

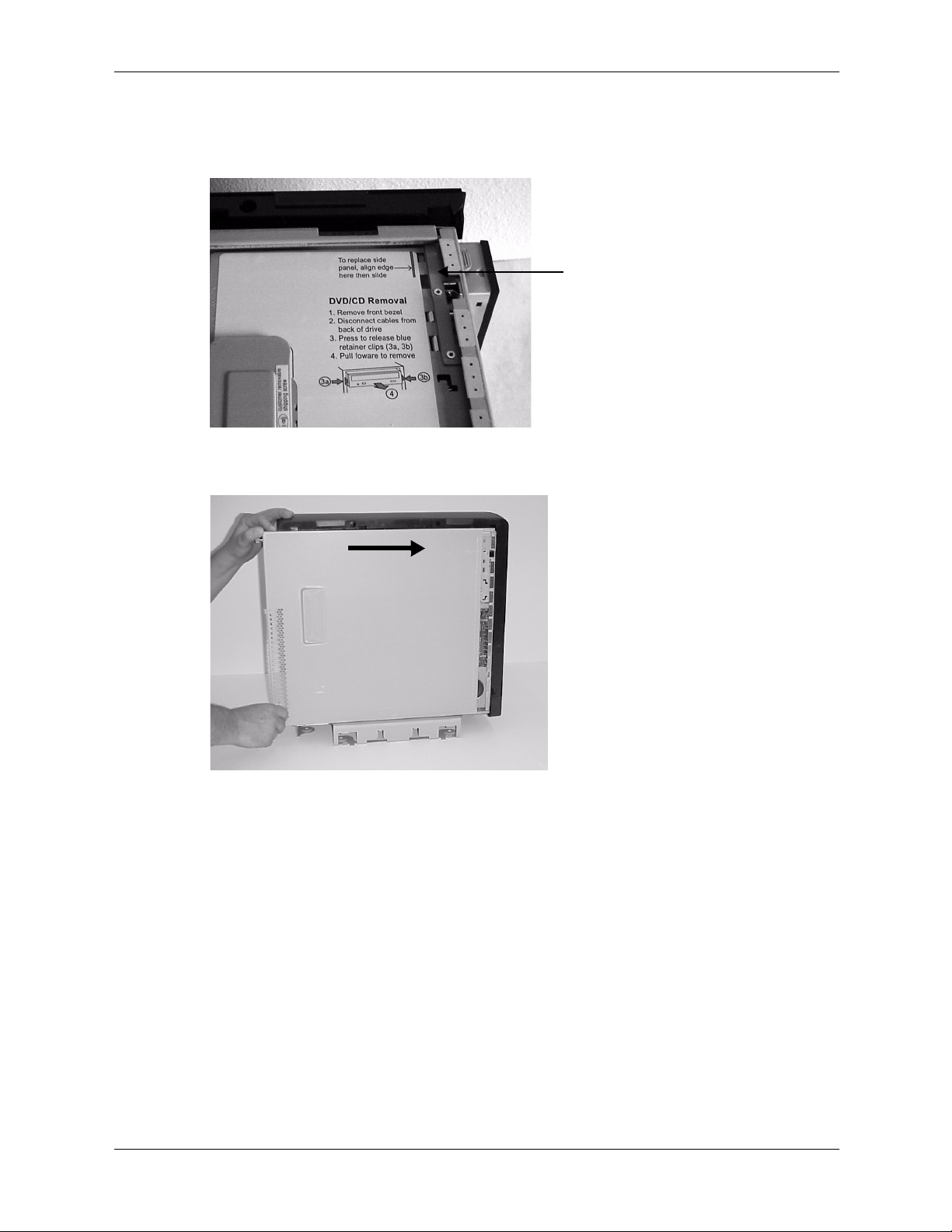

removing the plastic and metal covers

1. Turn off the system and disconnect the power cable and all other cables from the back of the

system.

2. Access the metal cover.

Rackmount system: Release the glide-rail retainers and slide the system outward as far as you

can so that you have access to the system cover.

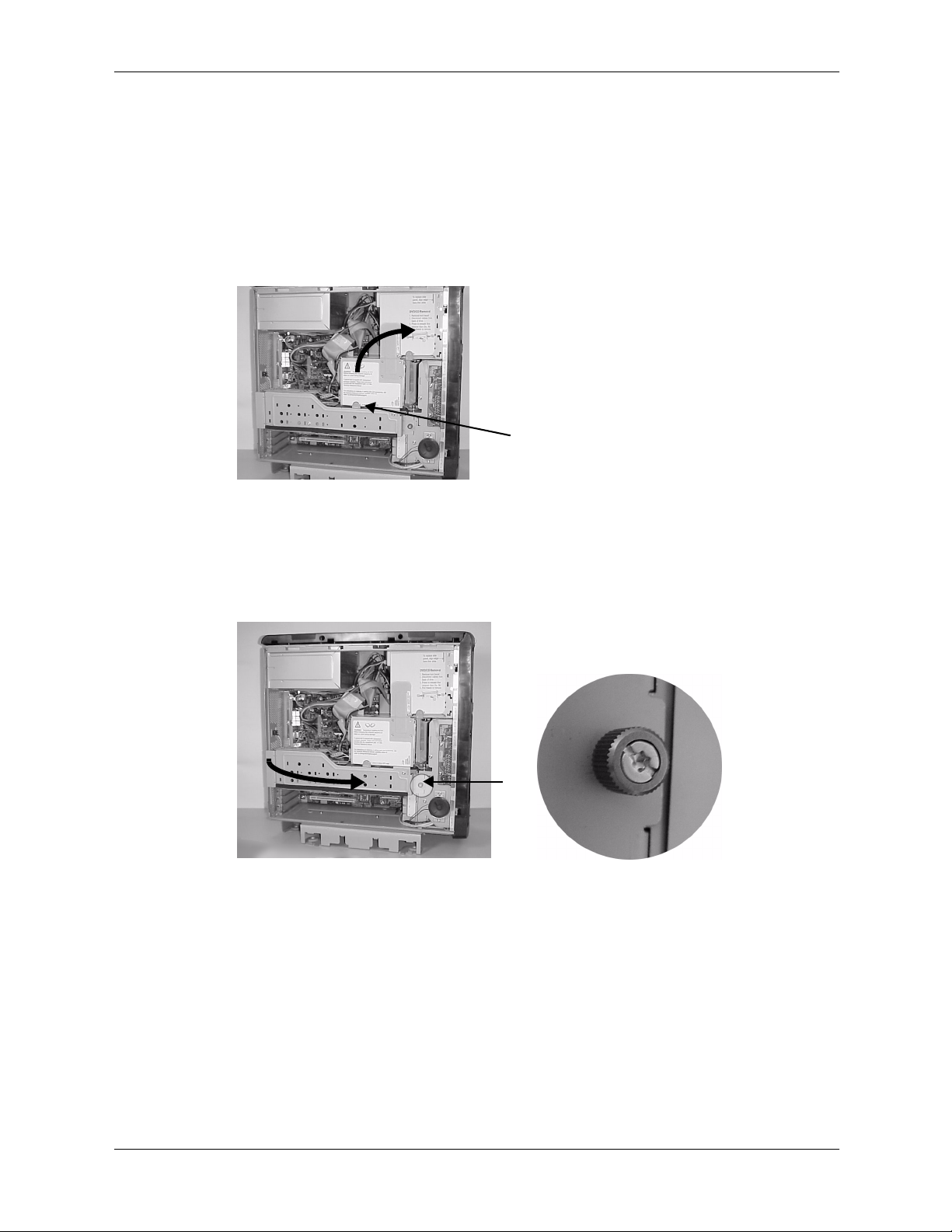

Tower system: remove the plastic cover. With the front panel of the tower case facing right:

a. Grasp both indentations at the top of the side panel and pull outward.

Installing or Replacing Parts and Accessories

b. Lift the plastic cover off of the system chassis.

Removing the Plastic Cover (Tower System Only)

technical reference guide 2–5

Page 22

Installing or Replacing Parts and Accessories

3. Loosen the two blue screws on the cover near the back panel of the chassis.

Unscrewing the Metal Side Cover

4. Slide the cover about 60 mm (1.5 in.) toward the back of the chassis, then lift it off.

A

B

Removing the Metal Side Cover

2–6 technical reference guide

Page 23

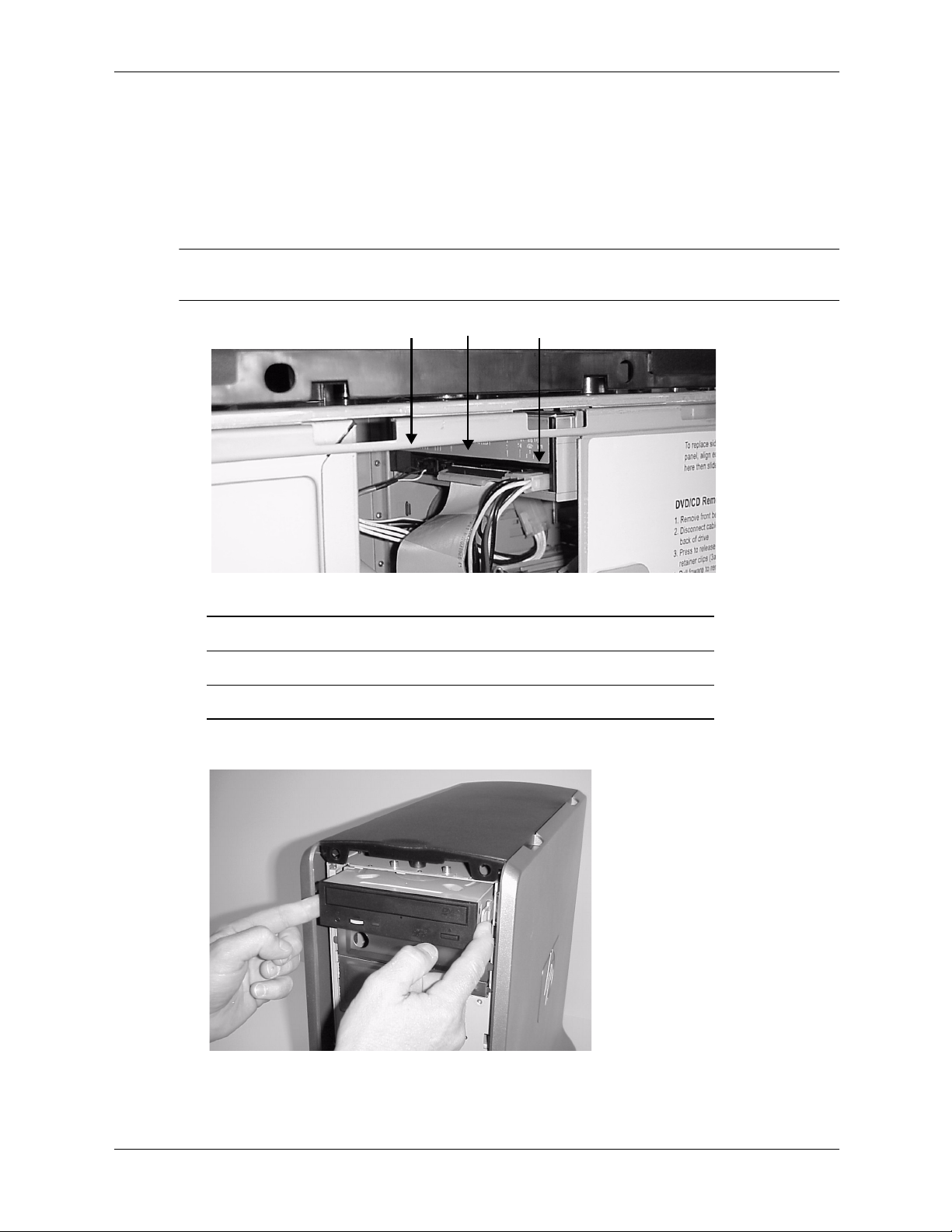

removing the shipping screws

The first time you open the case to work on the system, remove the screws that hold the hard

drive cage and AGP retainer arm in place for shipping. Replacing these screws is not necessary.

Installing or Replacing Parts and Accessories

Shipping Screws

technical reference guide 2–7

Page 24

Installing or Replacing Parts and Accessories

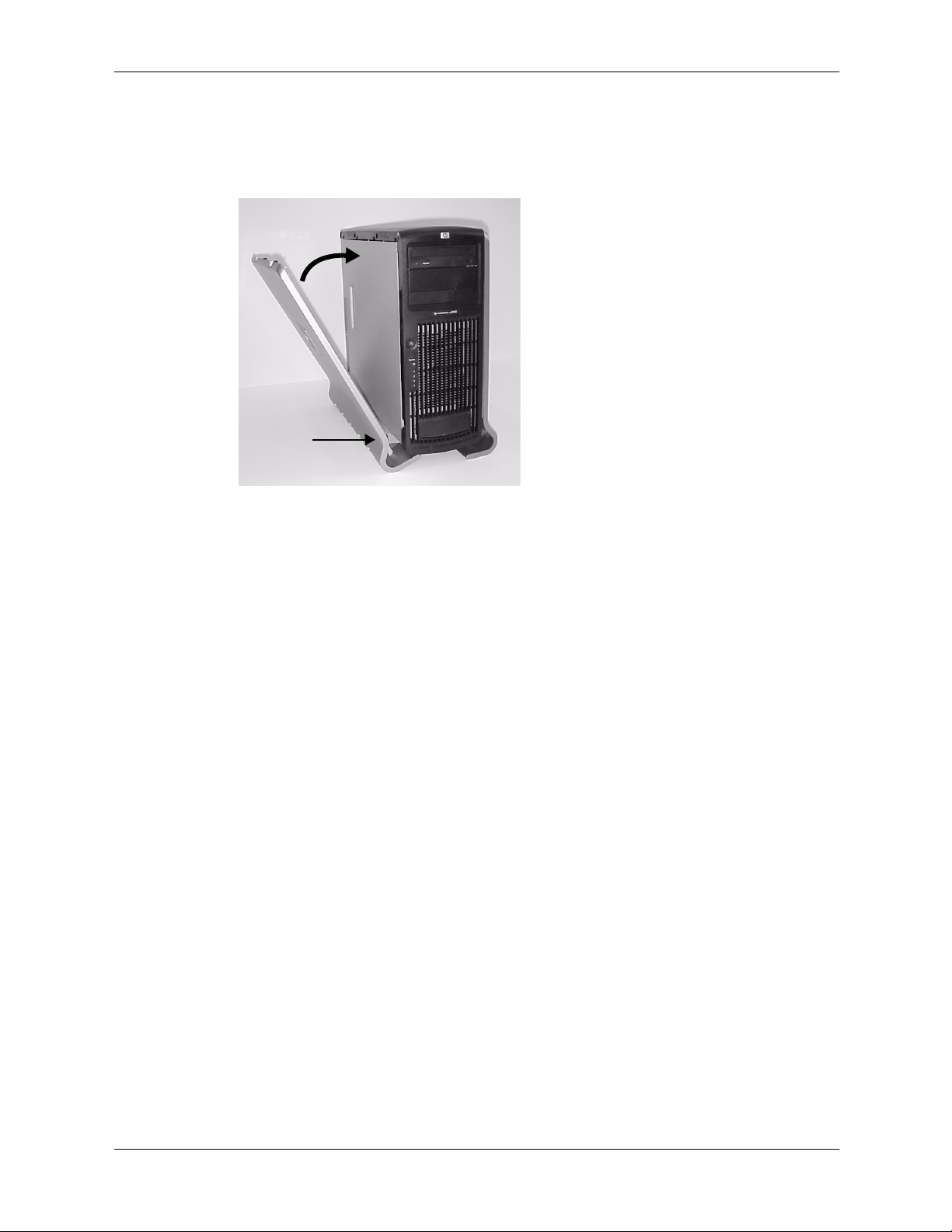

replacing the covers

1. Align the right edge of the metal cover with the blue line on the system chassis.

Align the Metal Cover

2. Place the metal cover on the chassis and slide it toward the system front panel.

Replace the Metal Cover

3. Tighten the two blue screws on the cover near the rear panel of the chassis.

4. Rackmount system: Slide the system inward until the glide-rail retainers latch.

2–8 technical reference guide

Page 25

Installing or Replacing Parts and Accessories

5. Tower system: Replace the plastic cover.

a. Align the cover mounting holes with the matching tabs on the system chassis.

b. Close the cover until it snaps onto the system chassis.

B

A

Replacing the Plastic Cover (tower system only)

technical reference guide 2–9

Page 26

Installing or Replacing Parts and Accessories

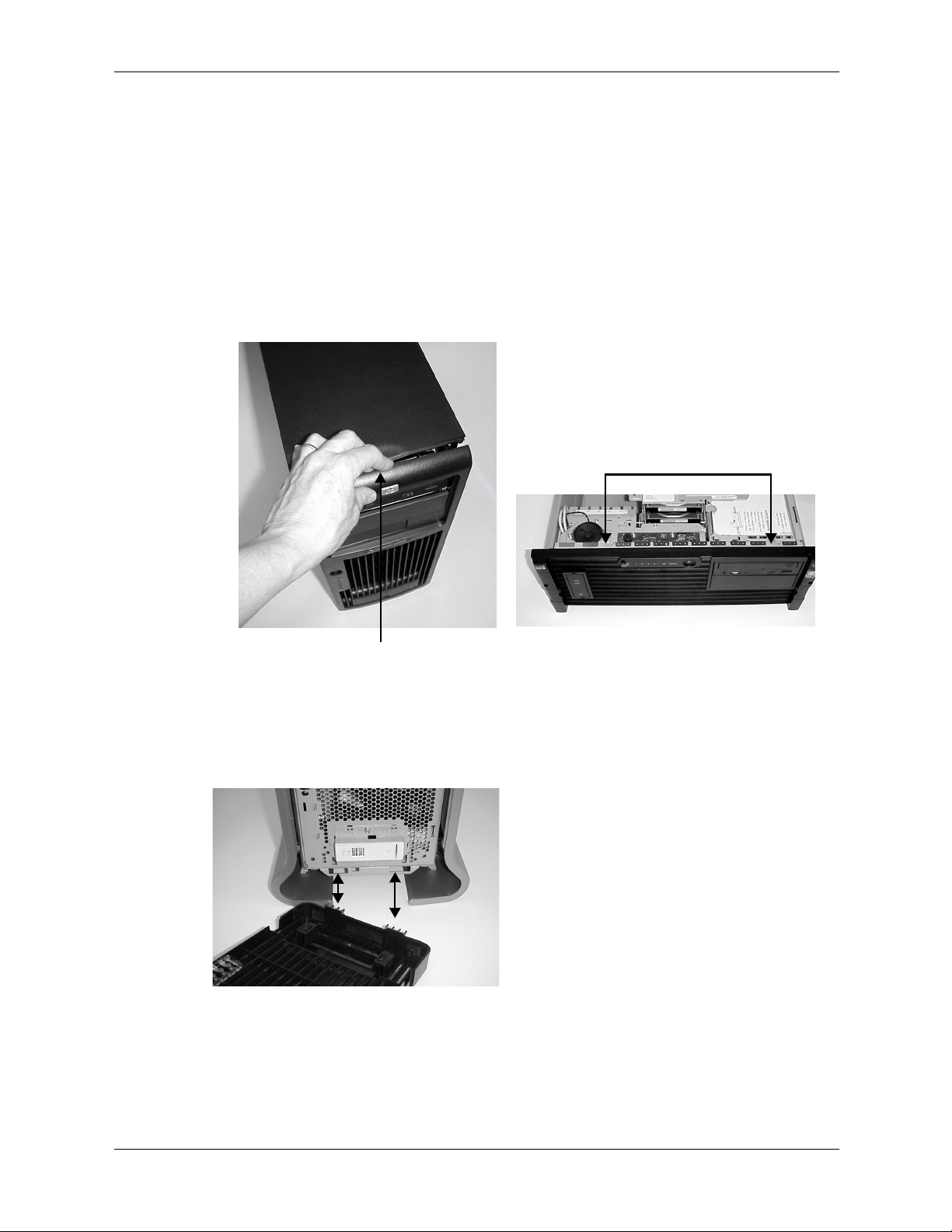

removing and replacing the front bezel

You must remove the front bezel from the chassis to upgrade, remove or replace an optical drive.

removing the front bezel

1. To remove the front bezel:

❏

Tower system: Firmly grasp the finger grip at the top of the bezel and pull forward until

the bezel snaps open.

❏

Rack-mounted system: Remove the metal cover, then depress the blue release tabs inside

the chassis and rotate the bezel away from the chassis.

Removing the Front Bezel

2. Lift the bezel off of the chassis.

replacing the front bezel

1. Insert the bezel latches into the matching slots on the system chassis.

Replacing the Front Bezel

2. Close the bezel and push toward the front of the system until it snaps into place.

3. Rack-mounted system only: Replace the metal cover.

2–10 technical reference guide

Page 27

Installing or Replacing Parts and Accessories

removing and replacing internal components

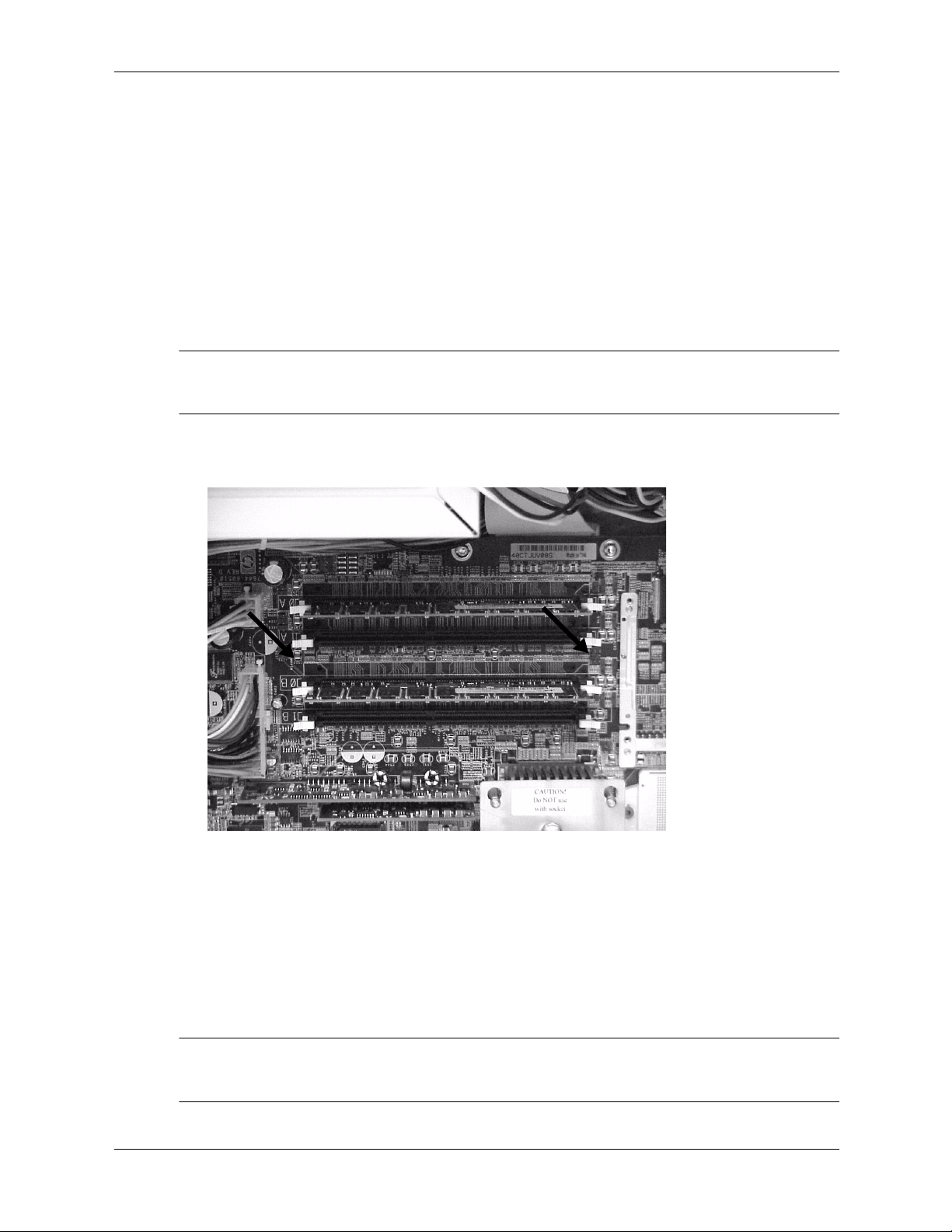

memory modules

The hp workstation zx2000 has four memory sockets for memory modules. These modules can

be 256 MB, 512 MB, 1 GB or 2 GB. DIMMs must be installed in ordered pairs of equal size. You

can install between 512 MB and 8 GB of memory in the system. For a list of approved memory

modules, see Appendix C.

removing memory modules

1. Turn off the system, disconnect all cables, and remove the system covers.

WARNING: To ensure that memory modules are not damaged during removal or installation, power off

Å

the workstation and unplug the power cord from the AC power outlet. Wait until the LED on the back of

the power supply turns off before removing memory.

2. Press down on the memory module retainer clips and lift the module by its edges out of its

memory socket.

Memory Module Retainer Clips

3. If the removed memory is functional, store it in a static-free container for future use.

4. Replace the system covers, reconnect all cables, and turn on the system.

5. Execute the EFI shell info mem command to verify the new memory configuration.

For more information on EFI, see Chapter 3

installing memory modules

1. Turn off the system, disconnect all cables, and remove the system covers.

WARNING: To ensure that memory modules are not damaged during removal or installation, power off

Å

the workstation and unplug the power cord from the AC power outlet. Wait until the LED on the back of

the power supply turns off before removing or installing memory.

technical reference guide 2–11

Page 28

Installing or Replacing Parts and Accessories

2. Holding the memory module by its left and right edges, insert the module into the socket.

❏

DDR SDRAM must be loaded as matched pairs. For example, if you place a memory

module of 1 GB in DIMM 0A, you must insert a 1 GB module in DIMM 0B. Matched

pairs should be loaded in sockets 0A and 0B first, and then in sockets 1A and 1B.

❏

To verify that DIMMs are matched pairs, make sure the HP part numbers are identical.

❏

It is not necessary for DIMMs in the two pairs to match. For example, you may install a

pair of 256 MB DIMMs in sockets 0A and 0B and a pair of 1 GB DIMMs in sockets 1A

and 1B.

Location of power supply (reference point)

Loading Order Memory DIMM Sockets

1st DIMM 0A

2nd DIMM 1A

1st DIMM 0B

2nd DIMM 1B

NOTE: The memory modules are keyed and can only be inserted in one direction. When the

module is correctly seated, the retainer clips will return to their fully upright position. Snap the

clips firmly into place to ensure that the DIMMs are seated properly.

3. Replace the system covers, reconnect all cables, and turn on the system.

4. Execute the EFI shell info mem command to verify the new memory configuration.

For more information on EFI, see Chapter 3.

2–12 technical reference guide

Page 29

accessory and graphics cards

The zx2000 has the following accessory card sockets:

■

One half-length 64-bit 66 MHz PCI-X socket

■

One AGP-Pro 50 4X video card socket

■

Three full-length 64-bit 66 MHz PCI-X sockets

■

One full-length 64-bit 133 MHz PCI-X socket

1

2

3

4

Installing or Replacing Parts and Accessories

PCI and AGP Sockets

1 Half-length PCI socket

2 AGP-Pro 50 socket

3 66 MHz full-length PCI sockets (3)

4 133 MHz full-length PCI sockets

This section explains how to:

■

access the sockets, and

■

remove and replace AGP video and PCI accessory cards.

technical reference guide 2–13

Page 30

Installing or Replacing Parts and Accessories

removing an accessory or video card

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Disconnect the hard drive power connection and IDE or SCSI cable.

3. Raise the hard drive cage:

a. Depress the blue latch on the hard drive cage.

b. Lift up the hard drive cage until it snaps into the upright position.

B

Lifting the Hard Drive Cage

A

4. Remove the AGP retainer arm:

a. Unscrew the blue AGP retainer arm screw.

b. Lift the arm, sliding it slightly toward the front of the system to release the latches from

the slots in the chassis.

B

A

Removing the AGP Retainer Arm

2–14 technical reference guide

Page 31

Installing or Replacing Parts and Accessories

5. Pull the blue lever on the end of the retainer clip at the rear of the system and lift it out.

Removing the PCI Retainer Clip

6. Grasp the bulkhead end of the card and its opposite edge and lift the card out of its connector.

7. Insert a bulkhead blank, then replace the PCI retainer clip.

8. Replace the AGP retainer arm, making sure that the latches on the arm are inserted securely

into the slots on the rear edge of the system chassis and the retainer clip is securely holding

the AGP card in place. Lower the arm into place and tighten the blue screw.

9. Close the hard drive cage:

a. Depress the blue latch holding the hard drive cage in the upright position.

b. Lower the cage until it snaps into place.

A

B

Releasing and Lowering the Hard Drive Cage

10. Reattach the hard drive power connection and IDE or SCSI cable.

11. Replace the system covers and cables, and restart the workstation.

technical reference guide 2–15

Page 32

Installing or Replacing Parts and Accessories

installing or replacing an accessory or video card

NOTE: For specifications on your video card, visit the manufacturer’s web site or refer to the

graphics documentation included in the acccessory kit.

To install or replace an accessory or video card:

1. Remove the existing card or bulkhead blank that is in the socket you want to use.

2. Grasp the bulkhead end of the card and its opposite edge and insert the card into its

connector.

Insert the New Card

3. Replace the PCI retainer clip. First insert the tab at the lower end, then press down until the

blank snaps into place.

4. Replace the AGP retainer arm and lower the hard drive cage.

5. Replace the covers and reconnect all cables.

6. Turn the system on, then execute the EFI firmware shell info io command to verify that

the accessory card has been properly installed. For more information on EFI, see Chapter 3.

2–16 technical reference guide

Page 33

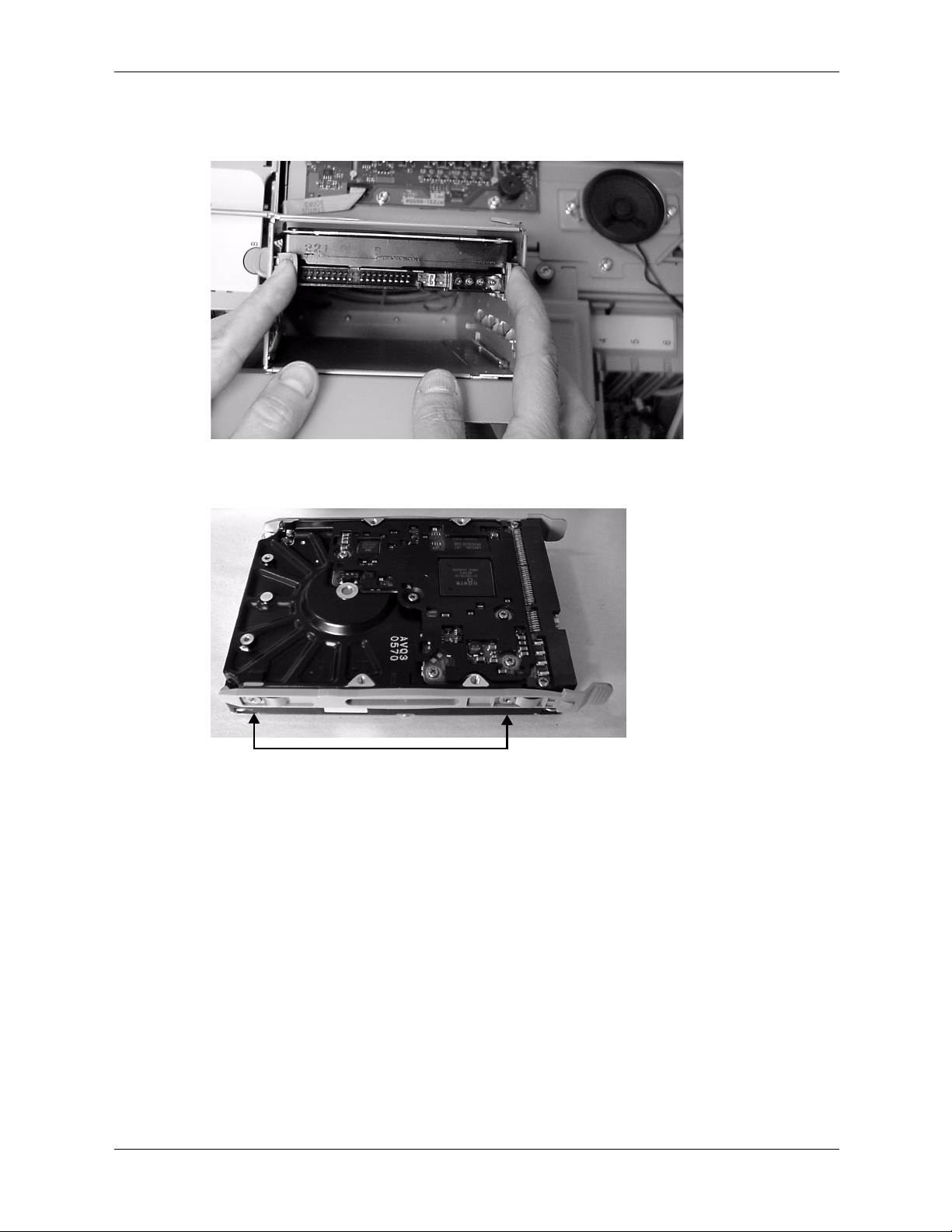

optical drives (CD or DVD)

removing an optical drive

1. Turn off the system, disconnect all cables, and remove the system covers and front bezel.

2. Disconnect the power, IDE and audio cables from the back of the optical drive.

NOTE: The audio cable has a small release clip on the side of the connector. Squeeze in on the

connector and pull gently to remove it from the drive.

Installing or Replacing Parts and Accessories

3

Disconnecting the Cables

1 Audio

2 IDE

3 Power

1

2

3. Release the small blue retainer clips on both sides of the optical drive by pressing in on them.

Releasing the Optical Drive Retainer Clips

4. Slide the optical drive forward and pull it out of the drive bay.

technical reference guide 2–17

Page 34

Installing or Replacing Parts and Accessories

5. Remove the rails from the drive by unscrewing the two screws on each rail.

Removing the Optical-drive Rail Screws

6. To save these rails for future use, attach them to the inside of the AGP retainer arm.

Rail Storage on AGP Retainer Arm

7. If you are not replacing the optical drive with a new drive, install a blank in the drive bay

opening.

replacing an optical drive

1. Turn off the system, disconnect all cables, and remove the system covers and front bezel.

2. Attach the rail labeled “L” to the left side of the optical drive and the rail labeled “R” to the

right side. Make sure the EMI gasket is installed on the top of the drive as shown:

EMI Gasket

3. Slide the optical drive into the drive bay until it stops.

4. Ensure that the retainer clips on both sides of the optical drive have snapped in place. To do

this, grasp both sides of the drive without pressing in on the retainer clips and pull. If you can

pull gently on the optical drive without it sliding out of its bay, the optical drive is securely in

place.

2–18 technical reference guide

Page 35

Installing or Replacing Parts and Accessories

5. Connect the IDE, power, and audio cables on the back of the optical drive.

NOTE: The system has two IDE cables — one is marked “Hard Drives,” the other is marked

“Optical Devices.” Make sure you connect them properly. The black connector on each cable is

for the master device; the gray connector is for the slave device. Make sure the jumper on the

optical drive is set to cable select (CSEL), not to master (M) or slave (S). See the documentation

provided with your drive for help locating the jumper.

6. Replace the covers and reconnect all cables.

7. Turn the system on, then execute the EFI shell info io command to verify that the optical

drive has been properly installed. For more information on EFI, see Chapter 3.

technical reference guide 2–19

Page 36

Installing or Replacing Parts and Accessories

hard drives

removing a hard drive

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Disconnect the hard drive power connection and IDE or SCSI cable.

21

Disconnect the Drive Cables

1 Power cable

2 IDE or SCSI cable

3. Raise the hard drive cage:

a. Depress the blue latch.

b. Lift up the hard drive cage until it snaps into the upright position.

B

A

Lifting the Hard Drive Cage

2–20 technical reference guide

Page 37

Installing or Replacing Parts and Accessories

4. Place your fingers on the colored release clips, located on the sides of the drive, and squeeze

inward. Then, pull outward to remove the drive from the system.

Removing the Hard Drive

5. Remove the rails from the hard drive by unscrewing the two screws on each rail.

Removing the Hard Drive Rail Screws

6. To save these rails for future use, attach them to the inside of the AGP retainer arm.

technical reference guide 2–21

Page 38

Installing or Replacing Parts and Accessories

replacing a hard drive

1. Attach rails to the hard drive (page 2-21).

NOTE: Extra hard drive rails are attached to the inside of the AGP retainer arm (page 2-18).

2. Push inward on the drive until it no longer slides inward.

3. If you removed the AGP retainer arm to access stored rails, replace it, making sure that the

latches on the arm are inserted securely into the sockets on the rear edge of the system

chassis and the retainer clip is securely holding the AGP card in place. Lower the arm into

place and tighten the blue screw using your fingers.

4. Depress the blue latch holding the hard drive cage in the upright position, and lower the cage

until it snaps into place.

5. Reattach the hard drive power connection and IDE or SCSI cable.

NOTE: The system has two IDE cables — one is marked “Hard Drives,” the other is marked

“Optical Devices.” Make sure you connect them properly. The black connector on each cable is

for the master device; the gray connector is for the slave device. Make sure the jumper on the

hard drive is set to cable select (CSEL), not to master (M) or slave (S). See the documentation

provided with your drive for help locating the jumper.

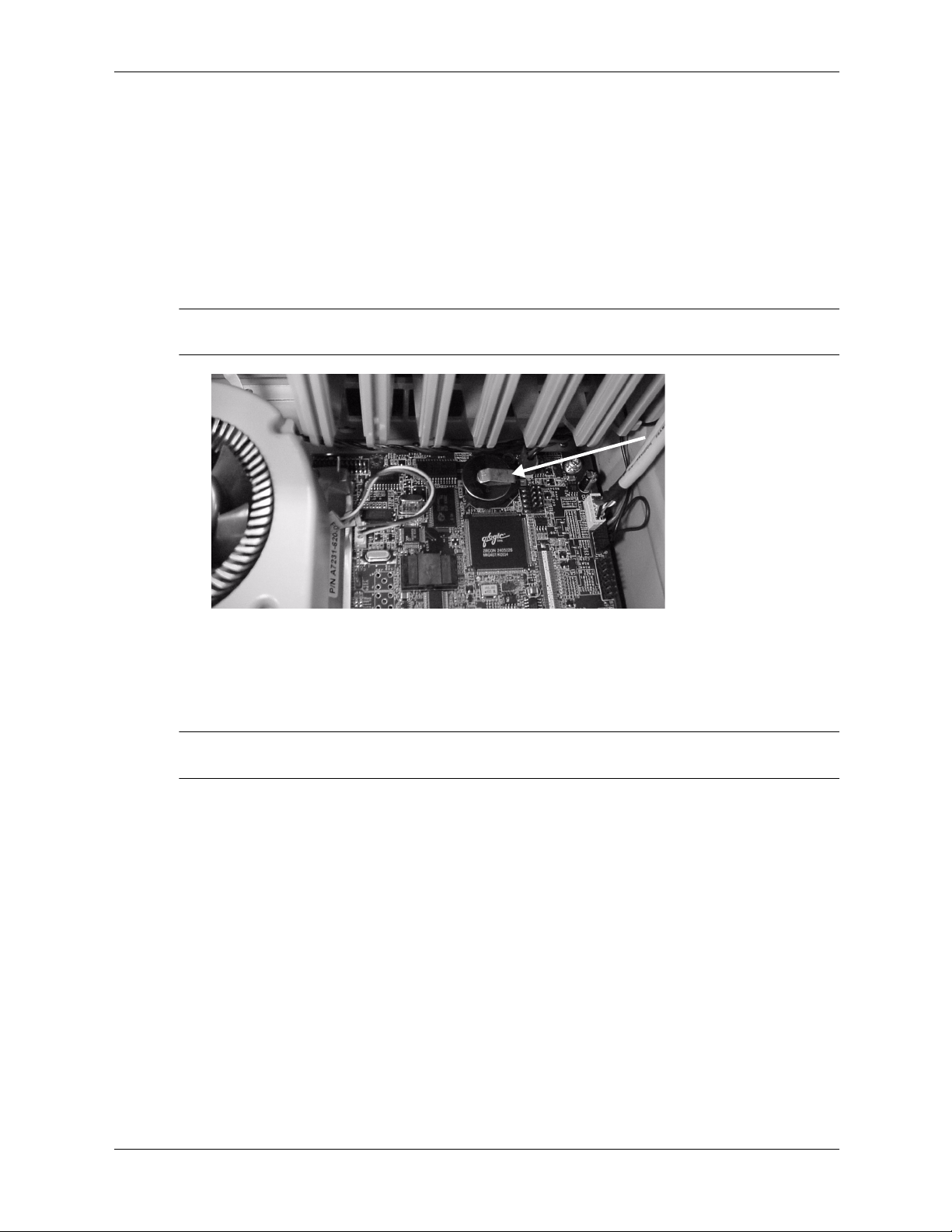

6. SCSI Drives only: Connect the SCSI Activity LED cable provided with the SCSI card to the

system board (A) and SCSI card (B).

B

A

Connect the SCSI LED Cable

NOTE: The SCSI Activity LED is only active on systems purchased after March 2003.

7. Replace the system covers and cables.

8. Turn the system on, then execute the EFI shell info io command to verify that the optical

drive has been properly installed. For more information on EFI, see Chapter 3.

2–22 technical reference guide

Page 39

power supply

removing the power supply

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Unplug the power supply power connectors from all components in the system including the

hard drive, optical drive, CPU and motherboard (large and small connectors).

3. Unscrew the four screws attaching the power supply to the back of the system chassis.

Installing or Replacing Parts and Accessories

Unscrew the Power Supply

4. Pull the power supply forward and lift it out of the chassis.

Removing the Power Supply

replacing the power supply

1. Insert the new power supply into the system chassis.

2. Attach the four screws to the rear panel of the system.

3. Plug the power supply power connectors into all components in the system including the

hard drive, optical drive, CPU and motherboard (large and small connectors).

technical reference guide 2–23

Page 40

Installing or Replacing Parts and Accessories

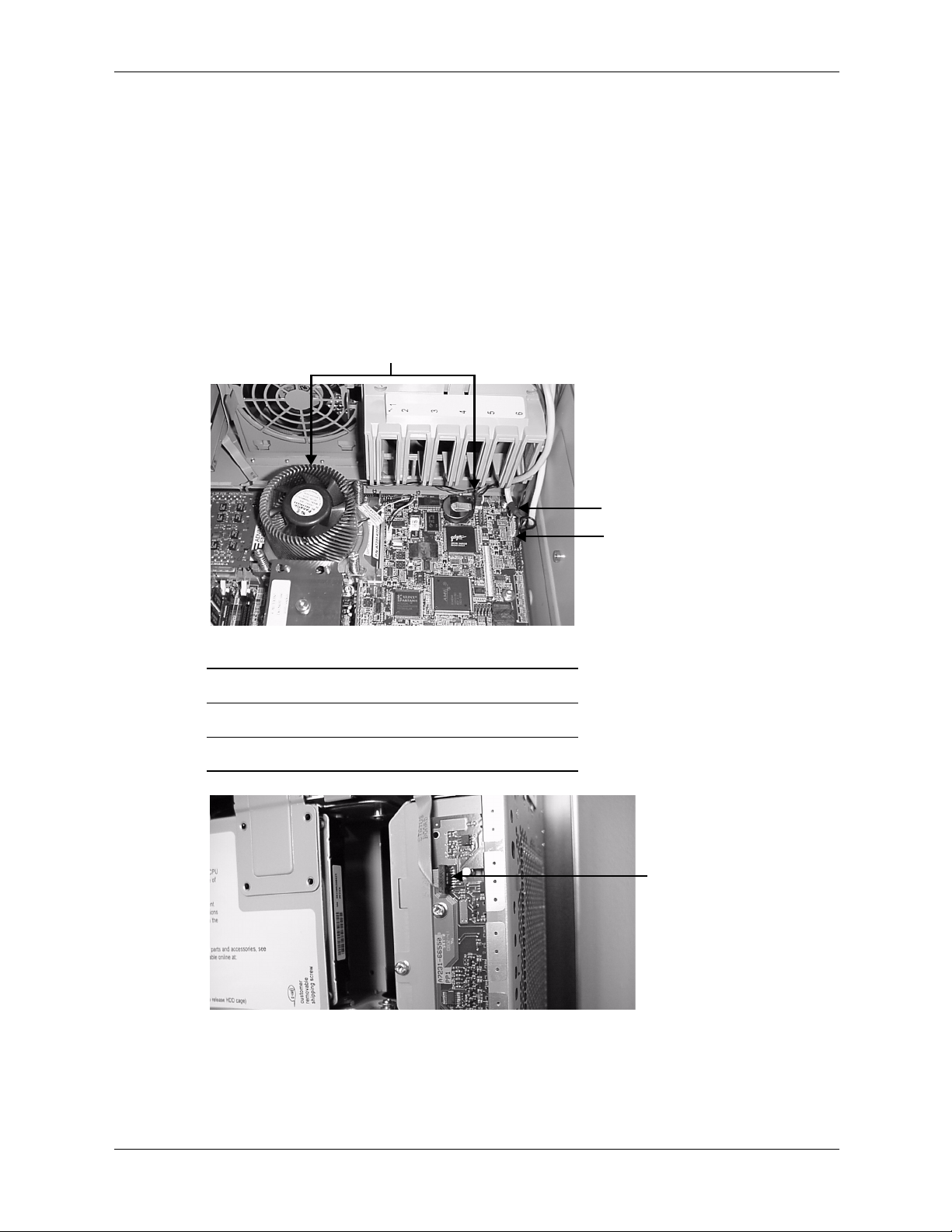

system fans

Two cooling fans are mounted in a single removable module behind the system front bezel.

removing the system fans

1. Turn off the system, disconnect the power cable, and remove the system covers.

2. Remove the covers from the system, lift the hard drive cage, and remove the AGP retainer

arm.

3. Disconnect the two system fan power cables, as well as the speaker, front-access USB

connectors and the LED status panel.

1

2

Disconnecting the Fans and Cables

1 Two fan connectors (one behind CPU assembly)

2 Speaker connector

3 USB connector

3

Disconnecting the LED Status Panel Cable

2–24 technical reference guide

Page 41

Installing or Replacing Parts and Accessories

B

4. Unscrew the fan cover (A), lift it off of the fan enclosure (B), and move it to the side.

A

Removing the System Fan Cover

5. Grasp the fan enclosure firmly and pull it out of the system chassis.

Removing the System Fans

replacing the system fans

1. Grasp the replacement fan module firmly and insert it into its fan slot.

2. Re-attach the LED status panel and all cables, replace the system covers, and turn on the

system.

3. Verify that the fans have been properly installed by verifying that none of the Diagnostic

LEDs on the front of the system are lit.

technical reference guide 2–25

Page 42

Installing or Replacing Parts and Accessories

airflow guide

The airflow guide on your system ensures that the proper volume of air for cooling the voltage

regulator modules (VRMs), processor, and processor power module flows over these

components.

You may need to replace the airflow guide if it becomes damaged to the point that airflow across

the processor is restricted. You may need to remove the airflow guide to gain access to

components under it.

removing the airflow guide

1. Turn off the system and disconnect all power.

2. Disconnect all cables, and remove the system covers.

3. Raise the hard drive cage and remove the AGP retainer arm.

4. Lift the airflow guide out of the system chassis.

Airflow Guide

replacing the airflow guide

1. Insert the airflow guide so the CPU assembly fits into the opening in the guide.

2. Lower the hard drive cage, making sure it lowers fully and fits firmly against the airflow

guide and replace the AGP retainer arm.

3. Replace the system covers and reconnect all cables.

2–26 technical reference guide

Page 43

LED status panel

The LED status panel contains a set of LEDs and buzzer that provide status and troubleshooting

information.

CAUTION: Some system settings are saved to the LED status panel. If you are replacing both the LED

Ä

status panel and the system board, they must be replaced one at a time to avoid loss of system settings.

First replace one component, then turn on the system and boot to the EFI prompt. After confirming that the

first component has been replaced successfully, shut down the system and replace the second

component.

removing the LED status panel

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Disconnect the LED status panel controller cable.

3. Unscrew the two LED status panel mounting screws and remove the panel.

Installing or Replacing Parts and Accessories

2

1

Disconnecting the LED Status Panel

1 Mounting screws

2 LED controller cable

3 LED status panel

replacing the LED status panel

1. Replace the LED status panel in the system and screw in the two LED status panel mounting

screws.

2. Connect the LED status panel controller cable.

3. Replace the system covers and reconnect all power cables. Turn on the system and verify that

the system and power LEDs light up.

3

technical reference guide 2–27

Page 44

Installing or Replacing Parts and Accessories

processor assembly and power module

CAUTION: You must follow these steps exactly and in the correct sequence to avoid serious

Ä

damage to the system.

removing a processor

1. Turn off the system, disconnect all power cables, and remove the system covers.

2. Raise the hard drive cage and remove the AGP retainer arm and airflow guide.

3. Disconnect the power module power cable.

1

Disc onnect the Power Module Power Cable

1 Power module

2 Power module cable

4. Unscrew the power module mounting screws, then disconnect the module from its processor

by sliding it toward the back of the system chassis.

2

Unscrewing and Removing the Power Module

5. Remove the power module from the system.

2–28 technical reference guide

Page 45

Installing or Replacing Parts and Accessories

6. Disconnect the small power cable for the processor turbo fan.

1

2

Disconnect the Power Cable for the Processor Turbo Fan

1 Turbo fan heatsink

2 Power connector for processor turbo fan

7. Use the special processor tool provided with the replacement processor to unscrew the four

captive heatsink screws.

Unscrew the Four Turbo Fan Captive Heatsink Screws

8. Slide the sequencing plate to the open position: towards the top (tower) or right side

(rackmount) of the system. This opens up the hole in the edge of the turbo fan’s heatsink for

insertion of the special processor tool into the processor locking mechanism.

Slide the Sequencing Plate This Way to Remove

technical reference guide 2–29

Page 46

Installing or Replacing Parts and Accessories

9. Unlock the processor locking mechanism using the special processor tool shipped with your

replacement processor assembly. To do this, you need to rotate the mechanism 180 degrees

counter-clockwise.

NOTE: There is a hole that runs down through the edge of the turbo fan’s heatsink, which allows

you access to the processor’s locking mechanism using the hex-key end of the special processor

tool.

2

3

4

1

Unlock the Processor Locking mechanism

1 Insert special processor tool here

2 The special processor tool rotates this lock underneath the heat sink

3 Unlocked

4 Locked

10. Lift the turbo fan heatsink and processor out of the system.

Remove the Turbo Fan Heatsink and Processor Assembly

2–30 technical reference guide

Page 47

replacing a processor

1. Remove the existing processor (page 2-28).

2. Make sure the processor locking mechanism is rotated into the unlock position.

Installing or Replacing Parts and Accessories

1

2

Processor Locking Mechanism

1 Unlocked

2 Locked

2

1

3. Use the four locator posts on the heatsink and the turbo fan power cable to properly align the

fan and processor assembly on the system board:

❏

The four locator posts fit in locator holes on the system board’s processor mount.

❏

The turbo fan’s power cable must be positioned so that it is located on the side of the

heatsink that faces the bottom (tower) or left side (rackmount) of the system.

1

2

Aligning the Turbo Fan and Processor Assembly

1 Locator posts

2 Locator holes

technical reference guide 2–31

Page 48

Installing or Replacing Parts and Accessories

4. Use the special processor wrench shipped with your replacement processor assembly to lock

the processor in place on the system board:

a. Insert the special processor tool into the hole that runs down the side of the heatsink and

rotate it clockwise 180 degrees. Remove the tool.

b. Slide the sequencing plate to the closed position.

Slide The Sequencing Plate This way to Install

c. Screw in the four captive heatsink screws.

5. Connect the small power cable for the processor turbo fan to its connector on the system

board.

6. Place the power module in the system.

7. Slide the power module on the system board’s metal mounting bracket so that the power

module’s connector connects with the processor’s connector. The two mounting screw holes

on the power module must align themselves with their screw holes on the system board’s

metal mounting bracket. Screw in the power module’s mounting screws.

8. Connect the power module power cable.

9. Replace the airflow guide. Replace the AGP retainer arm and lower the hard drive cage.

10. Replace the system covers and reattach all cables.

11. Verify that the processor works by turning the system.

2–32 technical reference guide

Page 49

system board

CAUTION: Some system settings are saved to the LED status panel. If you are replacing both the LED

Ä

status panel and the system board, they must be replaced one at a time to avoid loss of system settings.

First replace one component, then turn on the system and boot to the EFI prompt. After confirming that the

first component has been replaced successfully, shut down the system and replace the second

component.

removing the system board

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Raise the hard drive cage and remove the AGP retainer arm.

3. Disconnect the system board connectors.

NOTE: Disconnect the IDE cables from the hard disks and optical drives. Leave them attached

to the system board.

Installing or Replacing Parts and Accessories

B

A

H

System Board Connectors

G

C

D

E

F

A Front-access USB connectors E CPU power

B Speaker F IDE connectors

C Chassis intrusion switch G LED status panel connector

D System board power connectors H System fan connectors (2)

technical reference guide 2–33

Page 50

Installing or Replacing Parts and Accessories

4. Remove the following cables and components. Do not remove the CPU.

NOTE: To help with re-assembly, make note of which cables were connected to which

connector.

❏

DIMMs

❏

Accessory and video cards

❏

Fan, LED status panel and front-access USB connections

❏

Airflow guide

❏

Power connections and power supply

5. Unscrew the three backplane system board mounting screws that connect the system board

to the rear of the system chassis.

Unscrewing the System Board Mounting Screws

6. Grasp the chipset heatsink and the processor heatsink and slide the system board toward the

front of the system.

7. Lift up the rear edge of the system board and lift it out of the chassis.

2–34 technical reference guide

Page 51

replacing the system board

1. Complete all of the steps in the section “Removing the System Board” on page 2-33.

2. Grasp the new system board by its edges and carefully place it in the system. Remember that

the system board keyholes must be aligned with their corresponding standoffs on the

system’s chassis. Once the system board is in the system aligned with the keyhole standoffs,

slide it back toward the rear of the system. This locks the system board in place.

Aligning the System Board

3. Screw in the three rear backplane system board mounting screws.

4. Connect the system board cables.

Installing or Replacing Parts and Accessories

5. Replace all cables and components on the system board:

❏

Memory DIMMs

❏

IDE devices — hard drives and optical drives

❏

Accessory and graphics cards

❏

Fan, LED and front-access USB connections

❏

Airflow guide

❏

Power connections and power supply

6. Replace the AGP retainer arm, lower the hard drive cage. Replace the system covers and

reconnect the cables.

7. Verify that the processor works by turning the system.

technical reference guide 2–35

Page 52

Installing or Replacing Parts and Accessories

system battery

removing the system board battery

1. Turn off the system, disconnect all cables, and remove the system covers.

2. Raise the hard drive cage. Remove the AGP retainer arm and any PCI or AGP cards that are

blocking access to the battery.

3. Lift up on the battery and push on the back of it with a small flat-head screwdriver. This will

remove the battery from its holder.

CAUTION: Lift the battery just high enough to clear its holder. Too much stress on the retainer clip can

Ä

break it.

The System Board Battery Retainer Clip

replacing the system board battery

1. Lift up on the battery holder’s retainer clip with a small flat-head screwdriver and slide the

battery into its holder with your finger. The positive side of the battery should face up.

CAUTION: Lift the battery holder retainer clip just high enough to slide the battery into the battery

Ä

holder. Too much stress on the retainer clip can break it.

2. Replace any accessory cards you removed. Replace the AGP retainer arm and lower the hard

drive cage.

3. Replace the system covers and reconnect all cables.

4. Verify that the battery has been installed correctly by turning on the system and executing the

time command at the EFI prompt.

+

+

You may need to reset the system time and date using the EFI time and date commands.

Once you have set the time, turn the system off, unplug the power cord, and wait for a minute

before turning it back on. Execute the time and date commands again. If the time and date

are now correct, you have installed the battery correctly.

For details on using EFI commands, see Chapter 3.

2–36 technical reference guide

Page 53

system configuration

This chapter covers the tools available for configuring the hp workstation zx2000 system:

■

Extensible Firmware Interface (EFI), page 3-1

■

Baseboard Management Controller (BMC), page 3-23

■

Firmware upgrades, page 3-31

extensible firmware interface (EFI)

The Extensible Firmware Interface (EFI) is an interface between the operating systems and the

workstation firmware.

The following topics introduce you to the EFI and explain how to use it to configure your

system:

■

Accessing and navigating the EFI shell, page 3-2

■

Using the Boot Option Maintenance menu, page 3-11

3

■

Using the Security/Password menu, page 3-21

technical reference guide 3–1

Page 54

System Configuration

accessing and navigating the EFI shell

When you turn on your system and it begins to start up, your system pauses at the

boot option

screen:

EFI Boot Manager ver x.xx [xx.xx]

Please select a boot option

your OS will be listed here

[

EFI Shell [Built-in]

Boot option maintenance menu

Security/Password Menu

Use up and down arrows to change option(s).

Use Enter to select an option

]

NOTE: You have 7 seconds to change the boot option before the system boots to the default OS.

Use the up or down arrow keys to highlight an option, then press

■

EFI Shell [Built-in]

The

is a command line interface that allows you to operate the EFI

Enter

.

commands or create and run automated scripts.

Boot Option Maintenance Menu

■

allows you to select the order of the devices from

which you want the firmware to attempt to boot the OS. You can also configure the system to

boot from a configuration file.

Security/Password Menu

■

passwords.

remote access

You can also access the EFI remotely.

1. With the workstation turned off, connect a 9-pin to 9-pin serial cable to Serial Port A on the

rear panel of the workstation, and to your remote device.

2. Configure the terminal emulation software with these settings:

❏

Baud rate: 9600

❏

Bits: 8

❏

Parity: None

❏

Stop Bits: 1 (one)

❏

Flow Control: XON/XOFF

NOTE: The default terminal emulation type is VT100+. The default baud rate is 9600. These

settings can be changed from the EFI

3. Using the terminal emulation software, connect to the workstation with a direct connection.

4. Turn on the workstation and follow the steps below to access the EFI.

lets you add, change and delete system administrator and user

Boot Options Maintenance Menu

.

3–2 technical reference guide

Page 55

using the EFI shell

To access the EFI shell:

System Configuration

1. When the EFI boot option screen displays, use the arrow keys to highlight

Enter

press

.

EFI Shell

, then

NOTE: You have 7 seconds to change the boot option before the system boots to the default OS.

2. A list of file systems (drives and partitions), and block devices on hard drives is displayed.

For example:

Device mapping table

fs0: Acpi(HWP0002,100)/Pci(1|0)/Scsi(Pun0,Lun0)/HD(Part1,Sig00112233)

blk0: Acpi(HWP0002,0)/Pci(2|0)/Ata(Primary,Master)

blk1: Acpi(HWP0002,100)/Pci(1|0)/Scsi(Pun0,Lun0)

3. The EFI shell first searches for an optional script file named startup.nsh.

❏

If this file is found, it is executed automatically.

❏

If the script does not automatically start an OS or other application, the shell then waits

for commands to be entered at the command prompt.

4. You can now enter commands.

To run an individual command:

a. Type the command at the shell prompt. For example, to clear the display on the monitor

enter the

b. Press

cls

command:

Shell:> cls

Enter

to execute the command.

◆

Some commands require additional arguments to further define their action. For

example, to display information about the system memory, you must type the

info

command name (

fs0:\> info mem

◆

When you enter individual commands at the command prompt, the shell performs

), plus the desired category of information to display (

variable substitution, then expands wild cards before the command is executed.

◆

To switch to a different file system, execute the following, where

fsx

is the selected

file system, as listed on the screen (see step 2). For example:

Shell> fs0:

You see this prompt:

fs0:\> _

◆

You can also run EFI applications (files ending with

ls

current file system, run the

fs0:> ls

command. For example:

.efi

). To list applications in the

You see a list of applications on the fs0 file system.

mem

):

technical reference guide 3–3

Page 56

System Configuration

command syntax

The EFI shell uses a programming language to control the execution of individual commands.

Some characters have special meanings in the EFI shell. This section includes instructions for

running EFI shell commands and a list of the available commands.

To run an individual command:

1. Type the command at the shell prompt.

For example, to clear the display on the monitor:

fs0:\> cls

2. Press

Enter

to execute the command.

Arguments

Some commands require additional arguments to further define their action. For example, to

display information about the system memory, you must type the command name, plus the

desired category of information to display:

fs0:\> info mem

Rules

Follow these rules or the commands will not run correctly.

#

>

Denotes a comment. All text after this symbol is ignored.

Denotes an output redirect. Output of EFI shell commands can be saved to

files instead of being displayed on the monitor or in the terminal emulation

program. The shell redirects standard output to a single file and standard error

to a single file. Redirecting both standard output and standard error to the

same file is allowed. Redirecting to more than one file on the same command

is not supported.

The output redirect options, include:

>

redirect output to a unicode file

>a

redirect output to an ASCII file

>>

>>a

append output to a unicode file

append output to an ASCII file

The syntax for redirecting script output is:

Command > output_file_pathname

%

Denotes an environment variable. Environment variables can be set and

set

viewed through the use of the set command (see

command in this chapter).

To access the value of an environment variable as an argument to a shell

command, delimit the name of the variable with the

after the variable name; for example,

*

?

3–4 technical reference guide

Denotes a wildcard character. Matches zero or more characters in a file name.

Denotes a wildcard character. Matches exactly one character of a file name.

%myvariable%

%

character before and

.

Page 57

System Configuration

[

^

“ ”

space

newline

Denotes a wildcard character. Defines a set of characters; the pattern matches

any single character in the set. Characters in the set are not separated. Ranges

of characters can be specified by specifying the first character in a range, then

-

the

character, then the last character in the range. For example:

[a-zA-Z]

Denotes a literal argument. When a command contains a defined alias the

alias

shell replaces the alias with its definition (see

^

If the argument is prefixed with the

character, however, the argument is

command in this chapter).

treated as a literal argument and alias processing is not performed.

Quotation marks in the EFI shell are used for argument grouping. A quoted

string is treated as a single argument to a command, and any whitespace

characters included in the quoted string are just part of that single argument.

Quoting an environment variable does not have any effect on the

de-referencing of that variable. Double quotation marks (“ ”) denote strings.

Single quotation marks are not treated specially by the shell in any way.

Empty strings are treated as valid command line arguments.

Used to format batch scripts to separate command names, parameters and so

forth.

Used to format batch scripts. Each line represents a new command.

technical reference guide 3–5

Page 58

System Configuration

command descriptions

The following sections provide brief descriptions of the EFI commands. For more information,

use the EFI shell’s help system. To access a:

■

List of EFI command classes, execute help at the EFI shell prompt.

■

Detailed description of a command, execute help and the command name or other options

at the EFI shell prompt. For example:

❏

fs0:\> help date displays help for the date command

❏

fs0:\> help -a displays all commands in alphabetical order

❏

fs0:\> help -a-b displays all commands in alphabetical order with page breaks

❏

fs0:\> help class displays all commands in the specified command class (see

below)

Command Classes

EFI commands are organized into different classes based on their functions. The classes include:

boot

configuration

device

memory

shell

scripts

Get device, driver and handle information

Boot options and disk-related commands

Change and retrieve system information

Memory related commands

Basic shell navigation and customization

EFI shell script commands

Boot Commands

The boot class commands let you set boot and disk options.

autoboot

bcfg

dblk

boottest

mount

reset

vol

View or set autoboot timeout variable

Display/modify the driver/boot configuration

Display the contents of blocks from a block device

Set/view BootTest bits

Mount a file system on a block device

Reset the system

Display volume information of the file system

Configuration Commands

The configuration class commands let you change and retrieve system information.

cpuconfig

date

err

errdump

info

3–6 technical reference guide

Deconfigure or reconfigure CPUs

Display the current date or sets the date in the system;

format is

mm/dd/yyyy

Display or change the error level

View/clear logs

Display hardware information

Page 59

System Configuration

monarch

palproc

salproc

time

ver

View or set the monarch processor

Make a PAL procedure call

Make a SAL procedure call

Display the current time or set the time of the system; format is

Display the version information

Device Commands

The device class commands provide device, driver and handle information.

baud

connect

devices

devtree

disconnect

dh

driver

drivers

drvcfg

Set serial port settings

Bind an EFI driver to a device and start the driver

Display the list of devices being managed by EFI drivers

Display the tree of devices that follow the EFI Driver Model

Disconnect one or more drivers from a device

Display the handles in the EFI environment

List and install ROM-based drivers

Display the list of drivers that follow the EFI Driver Model

Invoke the Driver Configuration Protocol

hh:mm:ss

drvdiag

guid

lanaddress

load

loadpcirom

map

openinfo

pci

reconnect

unload

Invoke the Driver Diagnostics Protocol

Display all the GUIDs in the EFI environment

Display core I/O MAC address

Load and optionally connect EFI drivers

Load a PCI Option ROM

Display or define mappings

Display the protocols on a handle and the agents

Display PCI devices or PCI function configuration space

Reconnect one or more drivers from a device

Unload a protocol image

Memory Commands

The memory class commands let you manage your memory.

default

dmpstore

dmem

memmap

Reset all NVM values to system defaults

Display all NVRAM variables

Display the contents of memory

Display the memory map

mm

pdt

technical reference guide 3–7

Display or modify memory, memory-mapped IO and PCI settings

View or clear the Page Deallocation Table (PDT)

Page 60

System Configuration

Shell Commands

The shell class commands let you navigate and customize your shell.

alias

attrib

cd

cls

comp

cp

edit

eficompress

efidecompress

exit

help

hexedit

ls

mkdir

mode

mv

Display, create, or deletes aliases in the EFI shell

Display or change the attributes of files or directories

Display or change the current directory

Clear the standard output with an optional background color

Compare the contents of two files

Copy one or more files/directories to another location

Edit an ASCII or UNICODE file in full screen

Compress a file

Uncompress a file

Exit the EFI shell

Display help menus, command list, or verbose help of a command

Edit with hex mode in full screen

Display a list of files and subdirectories in a directory

Create one or more directories

Display or change the mode of the console output device

Move one or more files/directories to destination

rm

set

setsize

touch

type

xchar

Delete one or more files or directories

Display, create, change or delete EFI environment variables

Set the size of the file

Update the specified file with the current time

Display the contents of a file

Turn on/off extended character features

Scripts Commands

The scripts class commands let you use shell scripts.

echo

for/endfor

Make batch file execution jump to another location

goto

if/endif

pause

stall

Display messages or turn command echoing on or off

Execute commands for each item in a set of items

Execute commands in specified conditions

Print a message and suspends for keyboard input

Stalls, or pauses, the processor for the specified time in microseconds

3–8 technical reference guide

Page 61

EFI scripts

The EFI scripting language allows you to create executable shell scripts. You can place a set of

EFI commands in the shell script, then execute the script as often as needed. You also can modify

the script to make it perform different tasks. Script files can be either unicode or ASCII format.

Note that commands executed from a batch script are not saved by the shell for DOSkey history

(up-arrow command recall).

The optional script startup.nsh is automatically executed when you enter the EFI shell

environment. All EFI shell scripts have the “.nsh” suffix.

This section provides a brief explanation of how to create, edit and run an EFI shell script.

To create or edit a shell script:

1. At the EFI shell prompt, run the shell’s editor. Execute:

System Configuration

fs0:\> edit

file.nsh

where file.nsh represents the name of the new shell script you are creating or the existing

script you want to edit.

2. Type or edit the commands to be executed when the script is run. For example:

echo This is a test file.

3. When you are finished writing the script: press F2 to save the file, then press F3 to exit the

editor.

The EFI editor is controlled by function key commands. A menu of available commands is