Page 1

quick start guide

hp surestore

fc switch 6164

www.hp.com

Page 2

Notice

© Hewlett-Pack a rd C om pa n y, 2001. All rights rese r v ed .

Part number: A7326-90901

Edition: E0801

Hewlett-Packard Company makes no warranty of any

kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and

fitness for a particular purpose. Hewlett-Packard shall not

be liable for errors contained herein or for incidental or

consequential damages in c o nn ectio n with the furnish in g,

performance, or use of this material.

This document conta in s p rop rie ta ry info rm at ion , whic h is

protected by copyr ight. No part of this document may be

photocopie d, reproduced, or translated into another

language without the prior written consent of

Hewlett-Packard. The i nformation contained in this

document is subject to change without notice.

All other brands, product or service names are or may be

trademarks or service ma rks of, and are used to identify

products of services of their respective owners.

Brocade Extende d Fabrics, Brocade Fabr ic Manager,

Brocade Fabric OS, Brocade Fabric Watch, Brocade

QuickLoop, Brocade Remote Switch, Brocade Web T ools,

and Brocade Zoning are hereafter referred to as Extended

Fabrics, Fabric Manager, Fabric OS, Fabric Watch,

QuickLoop, Remote Switch, Web Tools, and Zoning

respectively.

Safety notices

Any servicing , adjustme nt, mainte nance, or re pair must be

performed only by authorized service-trained personnel.

Format convention s

variable Indicates that you must supply a value.

Use, duplication, or disclosure by government is subject

to restrictions as set forth in subdivision (c) (1) (ii) of the

Rights in Technical Data and Computer Software Clause

at DFARS 252.227.7013.

Warranty

If you have any ques tions about the warranty for this

product, contact your d eal er or local Hewlett-Packard

sales representative.

Trademarks

Brocade, SilkWorm, Brocade Extended Fabrics, Brocade

Fabric Manage r, Brocade Fabric OS, Brocade Fabric

Watch, Brocade QuickLoop, Brocade Remote Switch,

Brocade Web Tools, and Brocade Zoning are tradema rks

or registered trademarks of Brocade Communications

Systems, Inc. in the United States and/or in other

countries.

output Denotes text displayed on the screen.

[ ] Indicates that the enclo sed element is

optional and may be left out.

{ } Indicates that you must specify one of the

listed options.

| Separates alternatives.

. . . Indicates a repetition of the precedi ng

parameter.

Denotes ideas for enhanced product usage.

Tip

Note Denotes significant concepts or ope rat ing

instructions.

CAUTION Denotes a hazard that can cause hardware or

software damage.

WARNING Denotes a hazard that can cause personal

injury or death.

2

Page 3

CONTENTS

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rack-Mount Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fibre Channel Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Initialize the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fabric Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

GBIC Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3

Page 4

Serial Port and Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Serial Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4 Installing Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Launching Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Adding the Browser Pathnam e to the Properties File . . . . . . . . . . . . 54

Uninstalling Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installing Remote Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installing Through Telnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installing Through Web Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Installing Extended Fabrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing Through Telnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing Through Web Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Product Regulatory Information . . . . . . . . . . . . . . . . . . . 69

4

Quick Start Guide

Page 5

Revision History

August 2001 First release.

Updates

For the most current technical support information for the fc-Switch 6164,

visit the HP web site lo cated at:

http://www.hp.com

Firmware and software updates are found on the HP web site at:

http://www.hp.com

For information ab out produ ct avai labil ity, configurat ion, and co nnecti vity,

consult your HP account representative.

Related Publications

Related product information can be found in the following publications.

Those publications with part numbers are provided as printed copies with

your product. The HP Surestore FC Switch 6164 Documentation CD

contains all publications listed in the table below and is also provided with

your product.

Title Part Number

HP Surestore FC Switch 6164 Documentation

CD

HP Surestore FC Switch 6164 Installation and

Reference Guide

Distributed Fabrics User’s Guide, version 2.2 Available only on CD

Fabric OS Reference Manual, version 2.4 Available only on CD

Fabric Wa tch User’s Guide, versi on 2.2 Available only on CD

MIB Reference Manual, version 2.3 Available only on CD

A7326-11011

A7326-90902

5

Page 6

Title Part Number

QuickLoop User’s Guide, version 2.3 Available only on CD

Web Tools User’s Guide, version 2.3 Available only on CD

Zoning User’s G uide, version 2.2 Available only on CD

For information about Fibre Channel standards, visit the Fibre Channel

Association web site, locat ed at

http://www.fibrechannel.com.

6

Quick Start Guide

Page 7

1

OVERVIEW

The HP Surestore FC Switch 6164 provides a 64-port ent erpri se-cl ass fi bre

channel switching solution for any-to-any connectivity requirements in a

Storage Area Network (SAN). The FC 6164 provides a cost- effective

means of meeting the large-port-count requirements of workgroups and

enterprises.

The FC 6164 is a rack-mountable solution, comprised of a chassis and six

fully integrated Silkworm 2250 switch modules, with preconfigured

inter-switch link (ISL) fibre optic cables and enhanced management

software. The FC 6164 includes Fabr ic Manager , a management application

that provides a centralized view of the integrated switch modules to

simplify administration and maintenance.

Using this preconfigured, stand-alone fabric as a building block of larger

fabrics, you can sca le your st orage envi ronment as n eeded while leveragi ng

your existing server and storage infrastructure.

7

Page 8

8

Quick Start Guide

Page 9

INSTALLING THE SWITCH

This chapter provides the step-by-step instructions for installing the FC

Switch 61 64 in either a HP rack or a Compaq/Rit tal 19-inch rack.

2

Note

was installed at an HP inte grati on cente r prior to sh ipme nt. However, Steps

16 and 17 (assembling and installing the plenum) and Step 19 (installing

the switch door) must be performed for factory-integrated switches (see

pages 29 and 32).

Most of the steps in this procedure are unnecessary if the FC 6164

9

Page 10

Rack-Mount Safety Guidelines

In a rack-mount installation, follow these safety guidelines:

• When installing a switch in a closed or multi-rack assembly, make

certain the air te mper ature, measured a t th e front panel, doe s not exce ed

40° C during operation.

• Ensure that the airflo w available to the switch is at least 300 cfpm .

• Verify the supply circuit, line fusing, and wire size are adequate. Refer

to the switch’s nameplate for its p ower requirements.

• Verify that all equipment installed in the rack has a reliable ground

connection. Do not rely on conn ection to a branc h circuit , such as powe r

strips.

• Route and support the power cord to ensure that it does not become

crimped or damaged a nd to preve nt it from interfering with other

equipment and cabling installed in the rack.

• The FC 6164 weighs approximately 200 pounds. A lift is required to

move and position the switc h safely, and at lea st two people ar e require d

to lift and position the switch onto the lift. Two or more people are also

required to move the switch from the lift into the rack and when

positioning the switch in the rack. Move the switch chassis slowly and

carefully at all times, and continue supporting it until it is correctly

positioned on the rail tray and fastened t o t he r ac k. Use extreme caution

when handling or transporting the switch to prevent injury to personnel,

damage to the switch, and/or damage to the rack and other equipment

mounted in it.

10

Quick Start Guide

Page 11

Package Contents

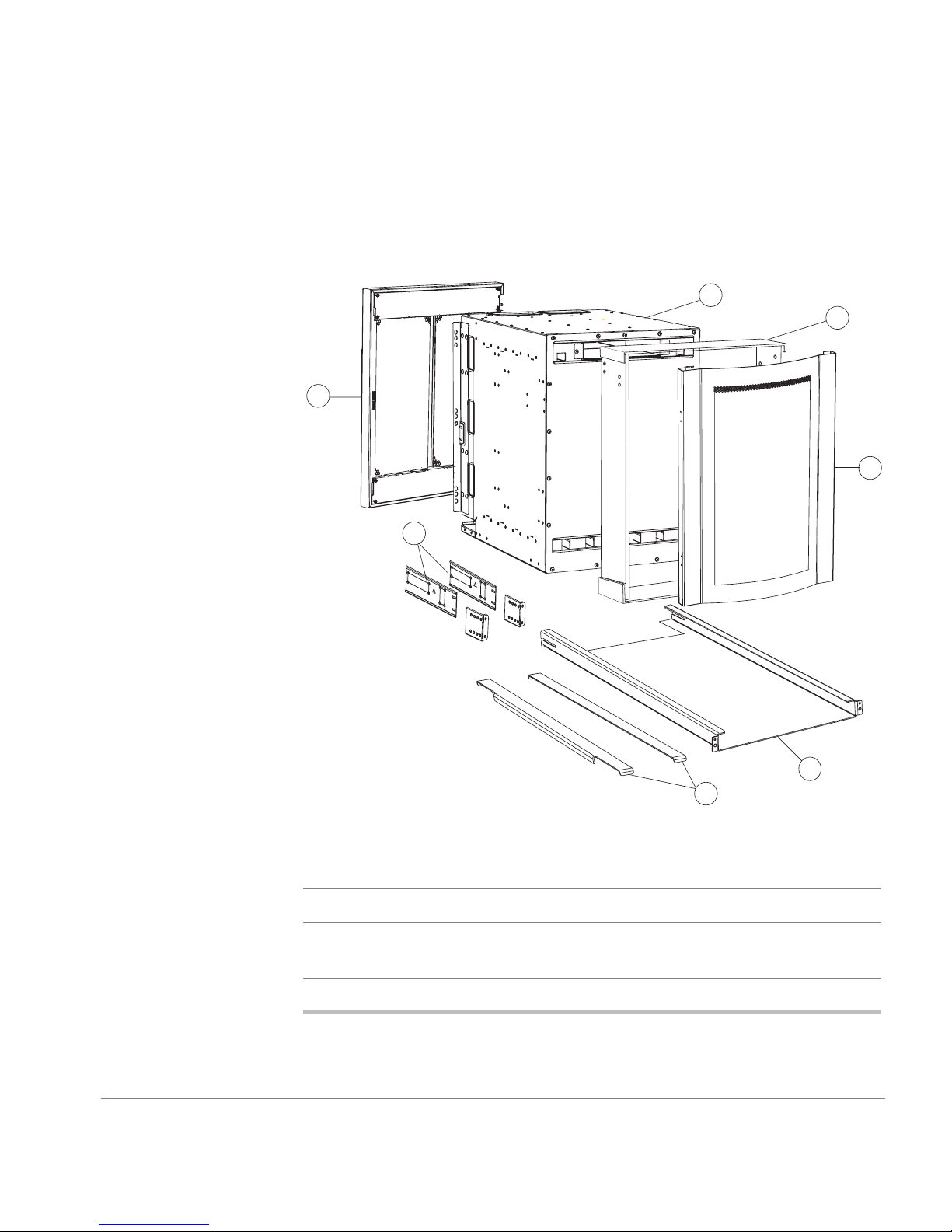

Figure 1 shows the major items contained in the FC 6164 shipping

carton(s). Table 1 lists the contents of the shipping carton.

G

A

B

C

F

F

Figure 1. Major Items Contained in the Shipping Carton(s)

Table 1. Contents of the Shipping Carton(s)

ASwitch

B Plenum kit (4 rectangular sheets of Lexan with 6 adhesive strips

C Front bezel (HP P/N A7326-40001)

Installing the Switch

D

E

pre-attached) (HP P/N A7326-87903)

11

Page 12

Table 1. Contents of the Shipping Carton(s) (continued)

D Rail Tray kit (Rail tray, 2 brackets, 2 M5 Tinnerman nuts, 4 M5 torx

screws) (HP P/N A6534-60016)

E Shim plates (2 ea. HP P/N A7326-87904)

F Rack-Mount Bracket set (2 Rack-Mount brackets)

(HP P/N A7326-87901)

G Switch door (part of Accessory kit [HP P/N A7326-70001], which

also includes: software CD, docu mentation C D, and seri al cable)

H Miscellaneous hardware: (not shown) (HP P/N A7326-87905)

Note: The hardware in the standard hardware package (unmarked plastic bag)

is required to install the switch in an HP rack. Some of the hardware in the

standard hardware package and the hardware in the Compaq/Rittal hardware

package is required to install the switch in a Compaq/Rittal rack.

Standard hardware package

8 #8-32 x .375-inch (.3125) flat-head screws w/patchlock

8 M5 torx screws with lock washers

6 M5 Tinnerman nuts

4 1/4-20 x 1/2-inch Phillips pan-head screws with lock washers

Compaq/Rittal hardware package

6 #10-32 Tinnerman nuts

6 #10-32 x 5/8-inch Phillips pan-head screws with captive lock washers

6 spacers

4 1/4-inch flat wash e r s

4 M5 flat washers

Note

A package containing two mounting rails may be included with the

switch. These rails are not used and can be discarded.

12

Quick Start Guide

Page 13

Tools Required

The following tools are required to install the switch:

• #2 Phillips screw driver

• T20 torx screwdriver

• Genie lift (to transport switch); for information on the li ft, see:

http://www.genielift.com/ml-series/ml-1-2.html

or

http://slick2.atl.hp.com/ceworld/siteservices/tools/genie/genielift_ordering.htm

Installing the Switch

13

Page 14

Hardware Identification

Figure 2 contains drawings and descriptions of the hardware used when

installing the FC 6164 in an HP rack or a Compaq /Ri tt al rack. Use this key

to help identify the hardware specified in the installation procedure in this

chapter.

#8-32 x .375-inch flat-head Phillips screw

M5 Torx screw with captive lock washer

M5 Tinnerman nut

1/4-20 x 1/2 inch Phillips screw and washer

14

#10-32 Tinnerman nut

#10-32 X 5/8-inch pan-head Phillips screw

Spacers for Compaq/Rittal racks

1/4-inch flat washer

M5 flat washer

Figure 2. Hardware Key

Quick Start Guide

Page 15

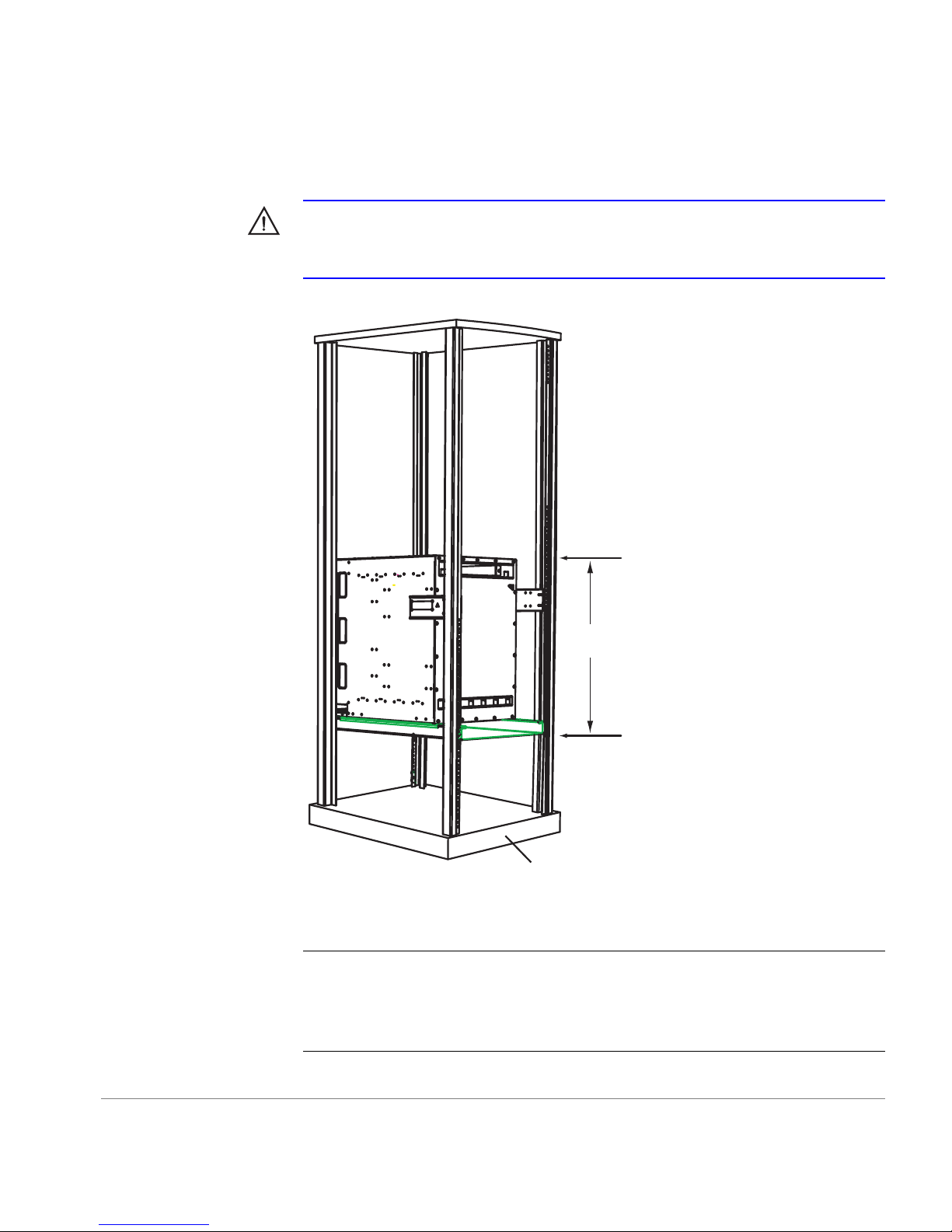

Installing the Switch

WARNING

Mount the switch as low as possible in the rack to ensure that

the weight of the switch does not make the rack unstable. 15 Rack Units

(RUs) are required (see Figure 3).

Back

of

switch

15 RU

Figure 3. Switch Mounted Back-to-Front and Low in the Rack

CAUTION

of the rack. When the switch is mounted this way, the air flows throu gh t he

switch in the same direction as it does through the other equipment in the

rack (see Figure 3).

Installing the Switch

Front of rack

The switch must be installed with the front end facing the back

15

Page 16

Note

In these inst ruc ti ons , the 15 RUs used to mount the switch ar e called

RU-1 through RU-15 (see Figure 3); RU-1 is the lowest of the 15 RUs.

1. Check the contents of the shipping carton and the kits within the carton

to verify that all of the required parts and hardware are available (see

Figure 2, Table 1, and Figure 3).

2. Choose a mounting l ocation in the rack f or the switch (see the W ARNING

at the beginning of this section and Figure 3).

3. Install the rail tray in the rack:

a. Locate the lowest RU of the 15 you chose for mounting the switch

(this is RU-1).

b. Attach the rear rail-tray brackets to the r ear rack uprights at RU-1:

For an HP rack, use one M5 torx screw for each bracket (see Figure 4).

For a Compaq/Rittal rac k, insert spacers in th e upper and lower hol es

where the brackets are to be mounted, position the brackets on the

spacers, and use one M5 torx screw with captive lock washer and two

M5 flat washers to attach each bracket (see Figure 4).

16

Quick Start Guide

Page 17

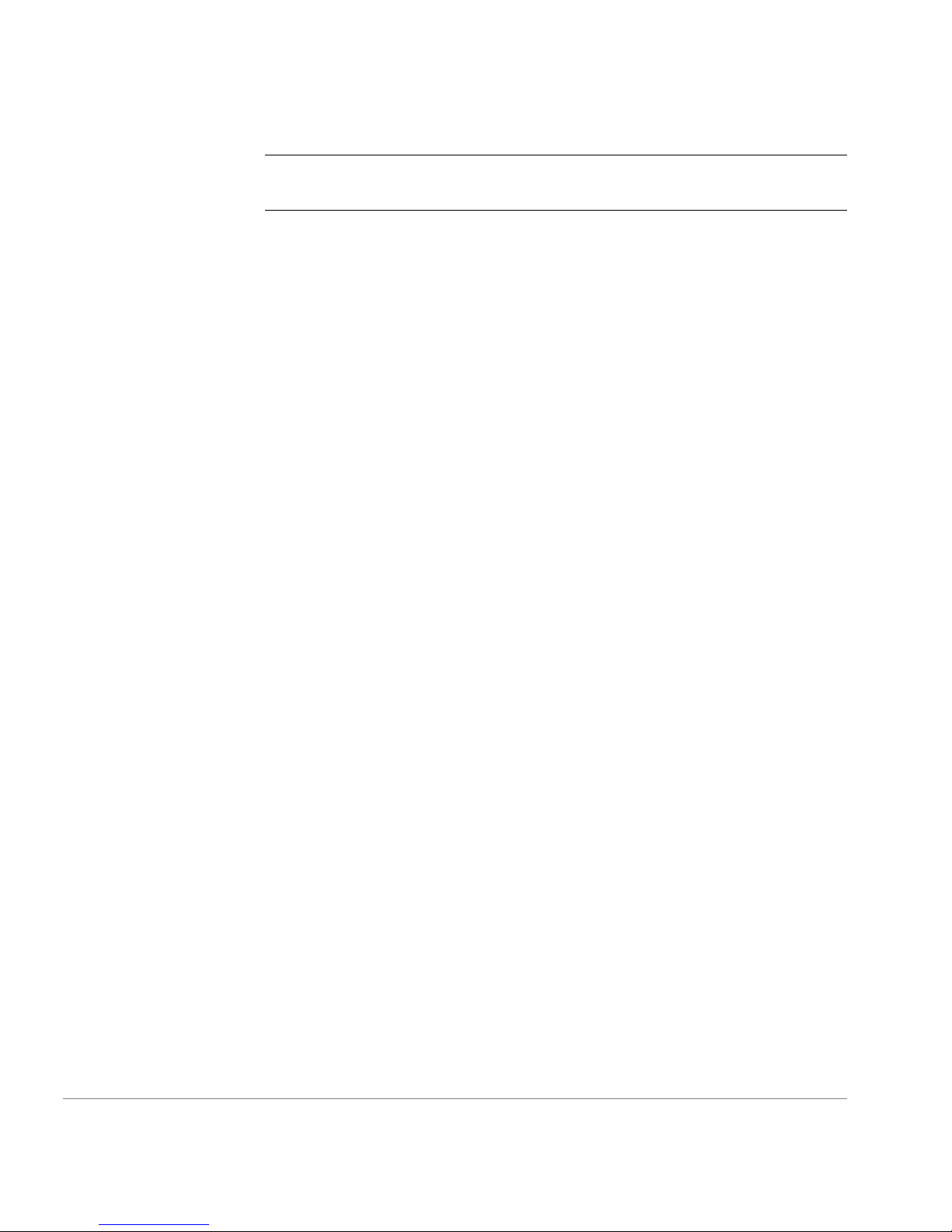

HP rack

M5 Screw

with attached

lock washer

Compaq/Rittal

rack

M5 Screw

with attached

lock washer

Figure 4. Installing the Rear Rail-Tray Brackets

M5

flat

washer

Spacer

M5

flat

washer

Rear Tray

bracket

Rear Tray

bracket

Installing the Switch

17

Page 18

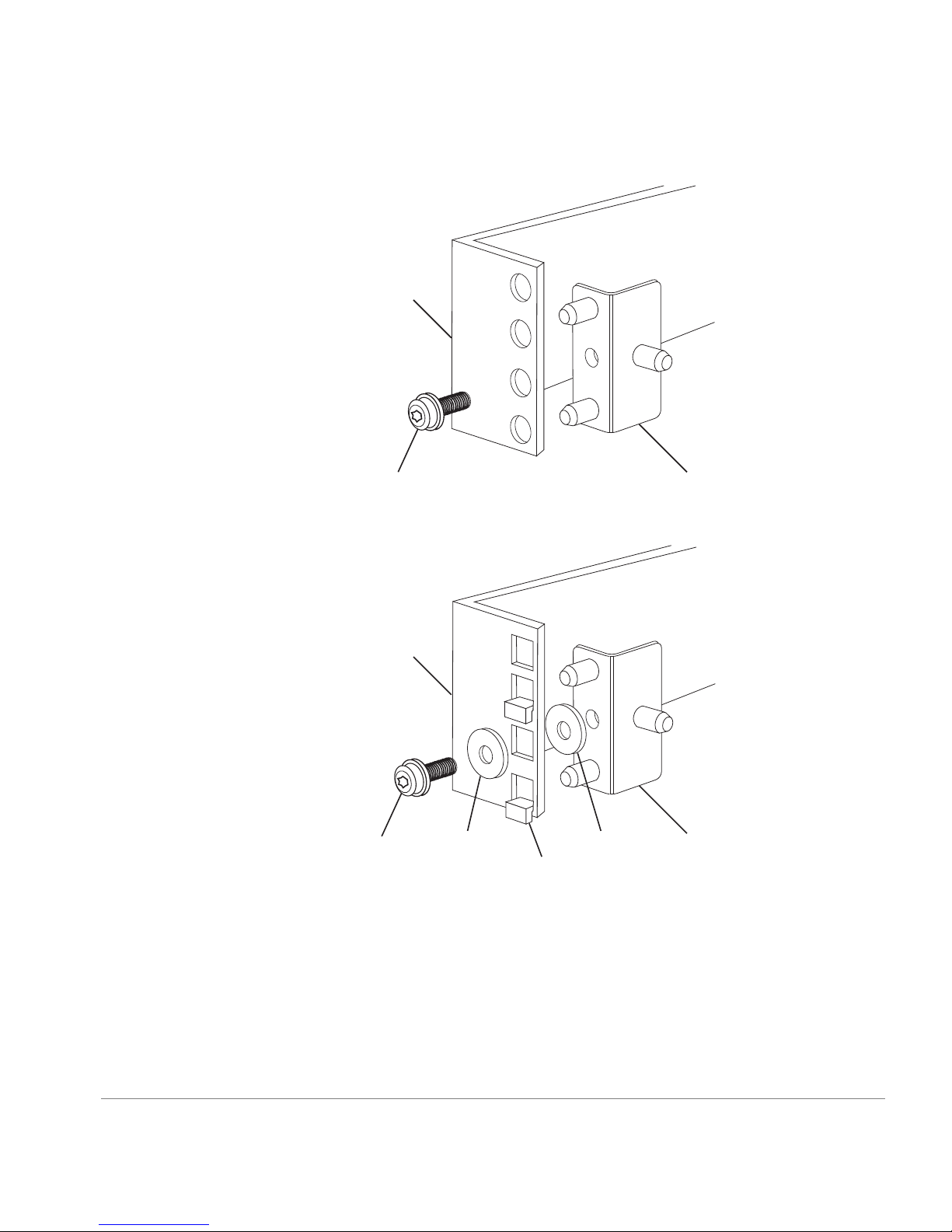

Note

When installing the rail tray in a Compaq/Rittal rack, ignore the

mounting instructions on the label attached to the rail tray (some rail

trays do not have this label).

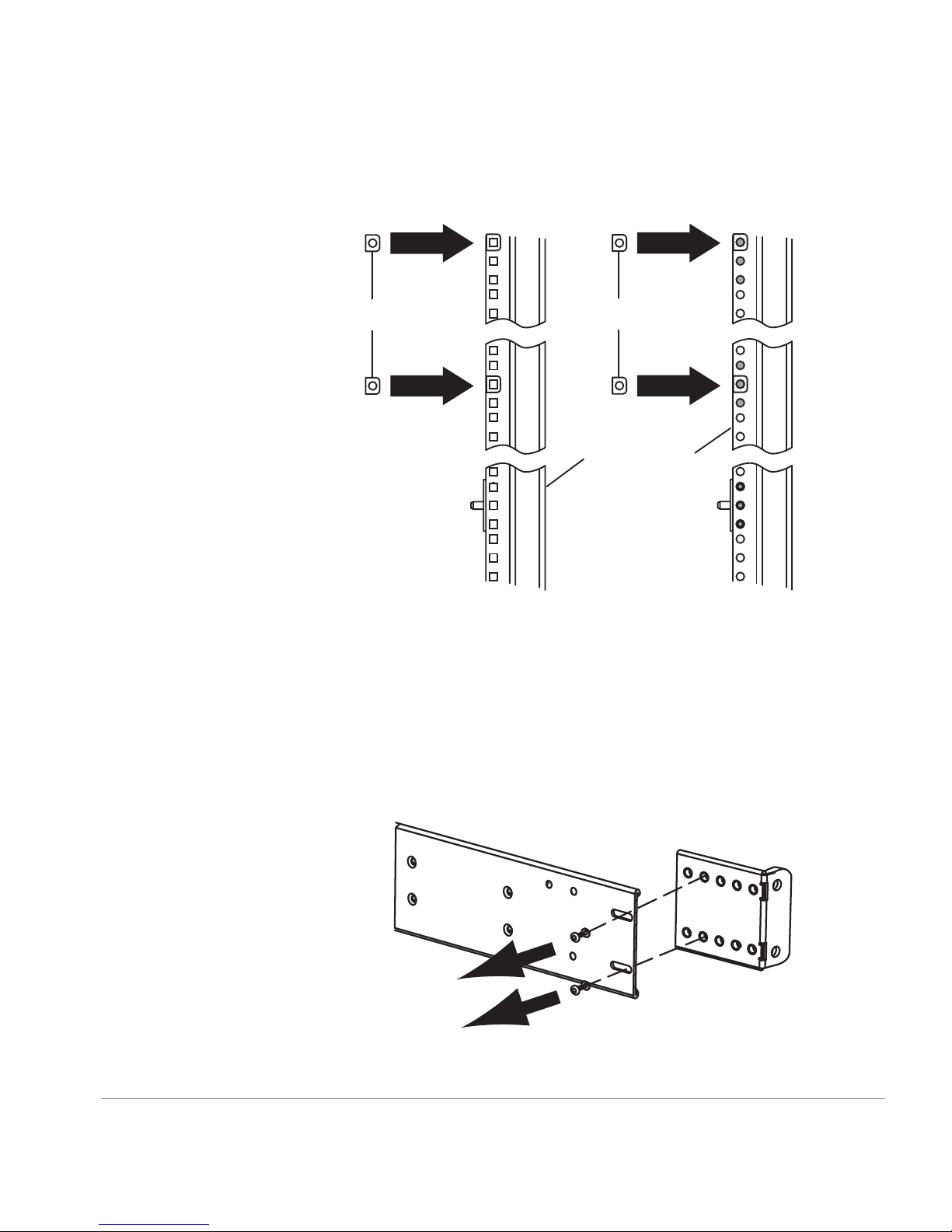

c. Install Tinnerman nuts for the top hol es of RU-1 in both of the r ack’s

front uprights (see Figure 5).

Note

The Tinnerman nuts used for the two types of racks (HP and

Compaq/ Rittal) are o f different styles and diffe rent sizes. Refer to

Figure 3 and Figure 5 to identify the correct Tinnerman nut to use with

the rack you are installing the switch in.

Tinnerman

nut

Spacer

Inner surface of

Outer surface of

HP rack

Compaq/Rittal

rack

Figure 5. Installing Tinnerman Nuts and Spacers on the Front Uprights

18

Quick Start Guide

Page 19

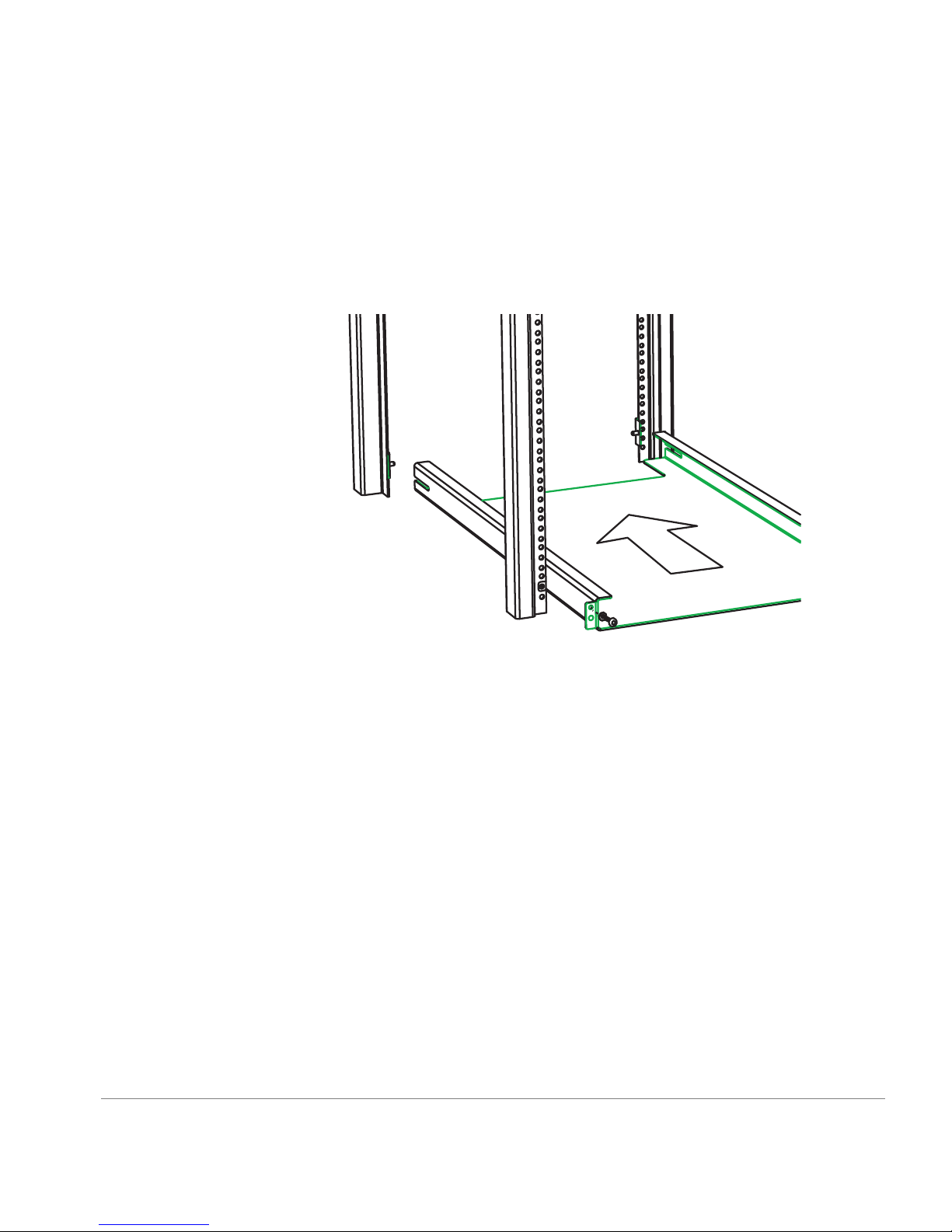

d. For a Compaq/Ritt al rack, insert spacers in the holes immediately

below the Tinnerman nuts you inserted in Step 3c (see Figure 5).

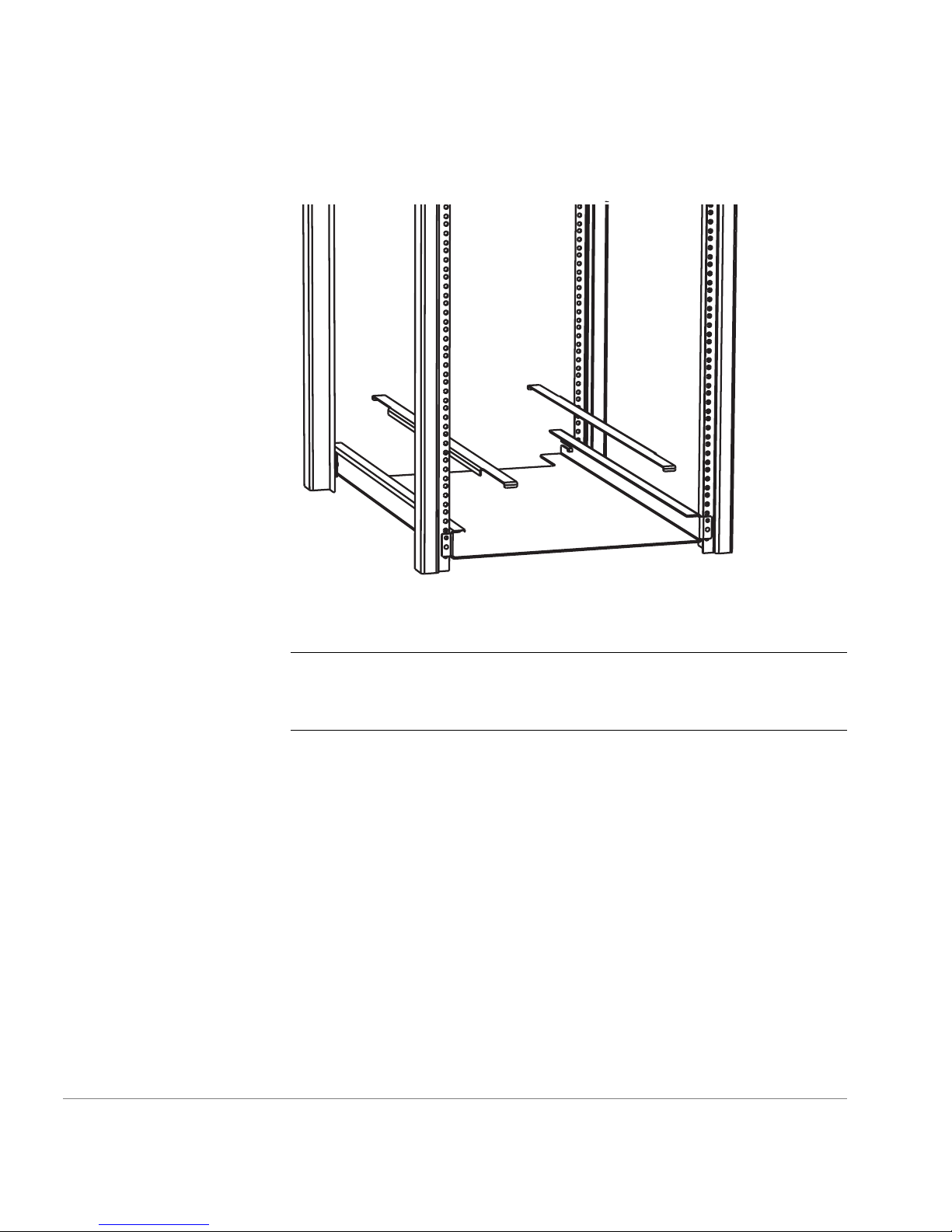

e. Orient the rail tray as shown in Figure 6, and insert it into the rack

from the front. The slots in the sides of the rail tray must slide over

the posts on the re ar ra il-t ray br acket s, and t he pos ts on the rail tra y’s

front mounting flanges must be inserted in the center holes of RU-1.

Installing the Switch

Figure 6. Inserting the Rail Tray in the Rack

f. Insert M5 torx screws through the top holes in both of the rail tray

mounting flanges. The screws pass through the holes in the rack

uprights and thread into the Tinnerman nuts you installed on the

uprights in Step 3c. Tighten the screws.

19

Page 20

4. Place a shim plate on each side of the rail tray (see Figure 7).

Figure 7. Placing the Shim Plates on the Rail Tray

CAUTION

The shim plates must be placed on top of both sides of the

rail tray to prevent mis alignment b etween the mounting holes in the

switch flanges and the holes in the rack uprights.

20

Quick Start Guide

Page 21

5. Insert T inner man nuts ont o the cent er holes of RU-5 a nd the top h oles of

RU-12 in both of the rack’s rear uprights (see Figure 8).

12

11

M5 Tinnerman nuts

5

4

#10-32Tinnerman nuts

Rack uprights

1

HP Rack Rittal Rack

Figure 8. Installing Tinnerman Nuts in RU-5 and RU-12

12

11

5

4

1

Installing the Switch

6. Install the rack-mount brackets on the switch:

a. The rack-mount b rackets consist of a stati onary plate and an adjusta ble

plate that are attache d to each other with two s crews. Remove the

screws that attach th e adjustable plates t o the stationary plate s. Set the

screws and the adjustable plates aside for later use (see Figure 9).

Figure 9. Separating the Rack-Mount Bracket Plates

21

Page 22

b. Use four #8-32 x 5/1 6-inch Phil lips flat -head screws to moun t one of

the stationary p lat es ont o ea ch side of the switch. The plates must b e

oriented so that the end of the plat e that has the slot ted holes protrude s

past the back of the switch, and if the plate has arrows stamped into

it, the arrows must point up (see Figure 10). Do not tighten the screws

fully at this time.

Note

Some stationary plates have arro ws sta mped into th em, and som e

do not. The arrow determines which side of the switch the plate must be

mounted on. If the stationary plates provided with the switch do not

have arrows, they can be mounted on either side.

Figure 10. Mounting the Rack-Mount Bracket Stationary Plates to the Switch

22

Quick Start Guide

Page 23

7. If you have adequate access to the back of the rack to insert the switch

from the back, sk ip Steps 8, 9, and 10. If yo u do not have a dequate access

to the back of the rack, proceed with Step 8.

Note

If you cannot insert the swi tch int o t he r ack fr om the back , you must

remove several pieces of hardware from the sides of the switch at the front

end as described in Steps 8, 9, and 10. If you have adequate access to insert

the switch into the rack from the back, you can skip these steps.

8. Remove the four #6-32 x 1/4-inch flat-he ad screws that attach each of the

two hinge plates to the left side of the switch at the front end (see

Figure 11). Set the scr ews and the hinge plates aside for later use.

x 8

Installing the Switch

Figure 11. Removing the Hinge Plates from the Switch

23

Page 24

9. Remove the two screws that attach the latch plate to the right side of the

switch at the front, an d remove the latch plate (see Figure 12). Set the

latch plat e and the screws aside for later use.

Note

The latch plate fits through a cutout in the rack-mounting flange on

the right side of the switch.

Rack-mounting

flange

Latch plate

Figure 12. Removing the Latch Plate and the Mounting Flanges

10.Remove the eight #10-32 Phillips screws that attach each of the

rack-mounting fla nges to t he sides o f the swit ch at th e front, a nd remove

the rack-mountin g flanges (see Figure 12). Set the rack-mounti ng flanges

and the screws aside for later use.

24

Quick Start Guide

Page 25

WARNING

If the rack you are mounting the switch in is on wheels,

make sure the l eveli ng feet are down or the wheels are lock ed to pr event

the rack from moving while you are installing the switch. Failure to

prevent the rack from moving could result in injury to personnel and/or

damage to the switch, the rack, or other equipment.

11.Insert the switch in the rack:

WARNING

The FC 6164 weighs approximately 200 pounds. A lift is

required to move and position the switch safely, and at least two people

are requi red to lift and position the switch ont o the lift. Two or more

people are also require d to move the switch from the lift into the rack

and when positioning the switch in the rack. Move the switch chassis

slowly and carefully at all times, and continue supporting it until it is

correctly positioned on the rail tray and fasten ed to the rack. Use

extreme caution when handling or transporting the switch to prevent

injury to personnel, damage to the switch, and/or damage to the rack and

other equipment mounted in it.

a. Place the switch on a lift. If you are instal ling the switch from the f ront

of the rack, orient the switch so t hat its front end faces the front of the

rack. If you are i nstal ling t he s witch f rom the bac k of th e rack, ori ent

the switch so that its back end is at the edge of the lift. (The switch

must be installed so the front of the switch faces the back of the rack.)

b. Position the lift close to the rack, and raise it until the bottom of the

switch is even with or very slightly above the t op surfaces of the shim

plates that you positioned on top of the rail tray in Step 4.

Installing the Switch

c. Carefully slide the switch from the lift onto the shim plates on the rail

tray.

d. Position the switch so that its front end protrudes out the back of the

rack approximately six inches.

25

Page 26

12.If you in serted the switch into th e rack from th e back, skip this step.

Reinstall the removed hardware:

a. Use the 16 #10-32 Philli ps screws you removed in Step 10 to re-attach

the rack-m ounting flan ges to the switch (see Figure 12).

b. Use the two screws you remove d in Step 9 to re-attach the latch plate

(see Figure 12). Make sure that there is a gap of approximately

3/16-inch between the edges of the latch plate and the edges of the

cutout in the rack-mounting flange.

c. Orient the hinge plates so th at th e sides tha t have the loo ps face eac h

other (see Figure 13). Use the eight #6-32 x 1/4-inch f lat-head screws

you removed in Step 8 to re- att ac h the hinge plates to the left side of

the switch at the front end (see Figure 11).

Loops

Figure 13. Orienting the Hinge Plates Prior to Reinstallation

13.Re-attach the rack-mount bracket adjustable plates:

a. From t he front of the rack, slide the switch forward a short distance.

b. Insert one of the a djustable plates i nto one of the stati onary plates (see

Figure 14).

26

Quick Start Guide

Page 27

Figure 14. Re-attaching the Rack-Mount Bracket Adjustable Plates

c. Insert the scr ews yo u remove d in Ste p 6a thro ugh the slott ed holes in

the stationary plate and into the second set of threaded ho les in the

adjustable plate from the rack-mounting flange (see Figure 14). Do

not tighten the screws at this time.

d. Repeat Steps b and c for the rack-m ount bra cket on th e opposit e side

of the switch.

e. Move t he switch forward in the rack as far as it can go. T he amount

of movement is limited by the rack-mount bracket adjustable plates

contacting the rack uprights.

Installing the Switch

WARNING

The FC 6164 weighs approximately 200 pounds.Two or

more people are requi red when positioni ng the switch i n the r ack. Mo ve

the switch chassis slowly and carefully at all times, and continue

supporting it until it is correctly positioned on the rail tray and fastened

to the rack. Use extreme caution when handling or transporting the

switch to prevent inju ry to personnel, damage to the switch, and/or

damage to the rack and other equipment mounted in it.

f. Put flat washers on four 1/4-20 scre ws with captive l ock washers, an d

insert the screws through the holes in the rack uprights and into the

threaded holes in the flanges of the rack-mount bracket adjustable

plates (see Figure 14). Do not tighten the screws at this time.

27

Page 28

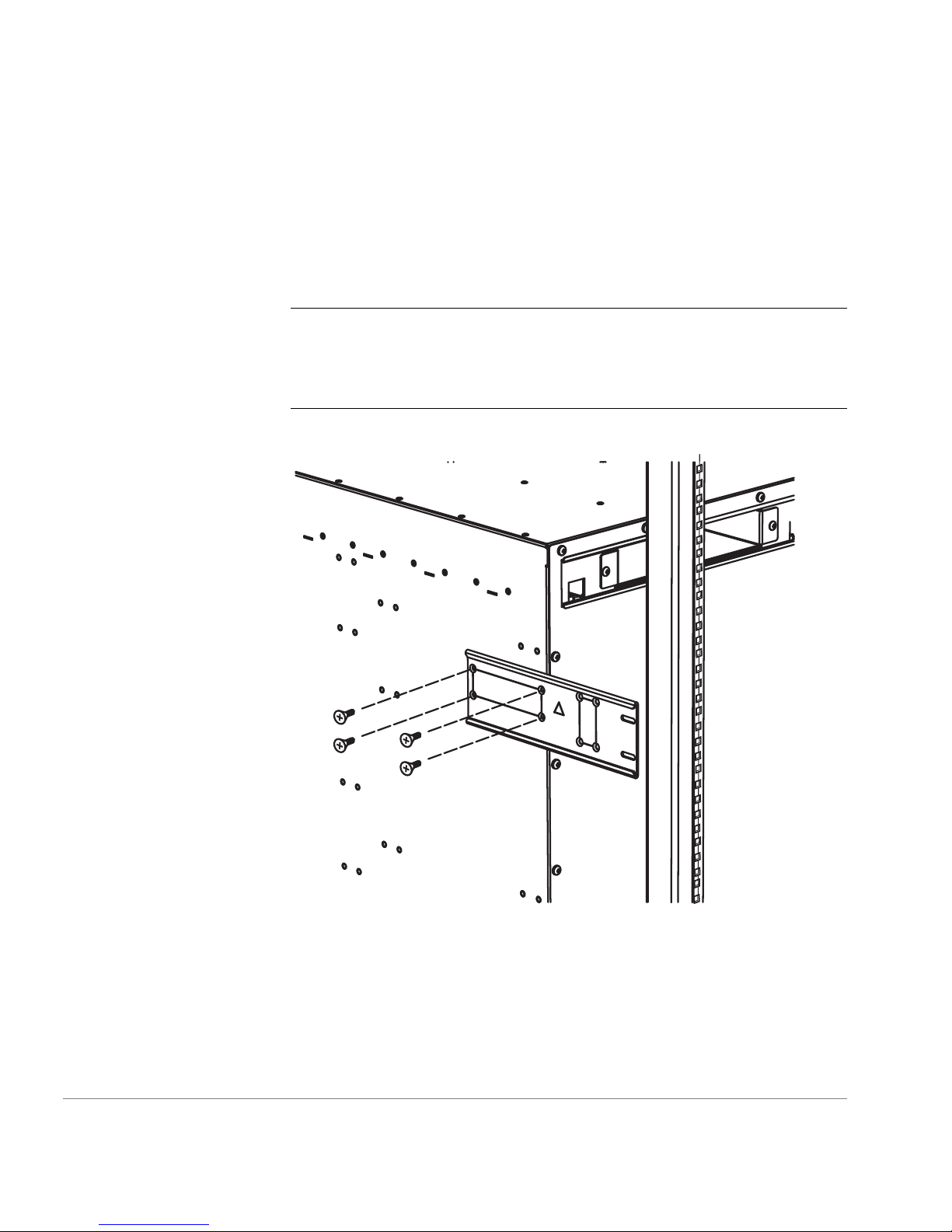

14.From the back of the rack, insert fou r #10-32 x 5/8-inch Phil lips pan-head

screws with captive lock washers through the holes in the rack-mount

flanges attached to the front end of the switch and i nto the Tinnerman nut s

you placed in the ra ck in Step 5 (see Figure 8 and Figure 15). Tighten the

screws fully.

Note

For an HP rack, you may have to adjust the positions of the

Tinnerman nuts to get them to align properly with the holes in the rack

uprights. If neces sary, use a screwdriver bl ade inserted through the hole s

in the rack uprights to reposition the Tinnerman nuts.

Figure 15. Attaching the Rack-Mount Flanges to the Rack

28

Quick Start Guide

Page 29

15.Fully tighten the screws that attach the rack-mount bracket adjustable

plates to rack uprights, then fully tighten the screws that attach the

adjustable plates to the stationary plates an d the screws that attach the

stationary plates to the switch chassis (see Figure 14).

16.Assemble the plenum:

a. Position the bottom pane l of the plenum on a flat surfa ce with the two

folded ends facing up (see Figure 16).

Adhesive

strips

Adhesive

strips

Bottom of

plenum

Adhesive

strips

Figure 16. Assembling the Plenum

b. Remove the paper backing from one of th e adhe sive strips on one of

the plenum side panels, and carefully position the side panel against

the inner surface of one of the folded ends of the bottom panel (see

Figure 16). Press the side panel firmly against the upright end of the

bottom panel to ensure that the adhesi ve strip on the side pan el makes

full contact wit h the end of the bottom panel. Y ou can use a s crewdriver

handle to increase the pressure you apply when joining the parts.

c. Repeat Step 16b for the other side panel.

d. Remove the paper b acking from the adhesiv e strips on the upper ends

of both plenum side panels.

Installing the Switch

29

Page 30

e. Carefully position the plenum top panel over the side panels so that

the folded ends of the top panel fa ce down and ar e outside of the side

panels.

f. Wit h the top panel aligned with the side panels, press one of the side

panels firmly against the inner surface of the folded end of the top

panel to ensure that the adhesive strip on the side panel makes full

contact with the folded end of the top panel. Re peat this step for the

other side panel.

17.Install the plenum in the rack:

a. Remove the paper backing from the two a dhesive strips on th e bottom

surface of the plenum.

b. Position the plenum against the back of the switch and slide it down

until the adhesive strips on the underside of the plenum contact the

shim plates that are on top of the rail tray (see Figure 17).

Back

of

switch

Figure 17. Inserting the Plenum

c. Press down firmly on the bottom panel of the plenum above the

adhesive strips t o ensure that the adhesive strips make full contact with

the shim plates on top of the rail tray.

30

Quick Start Guide

Page 31

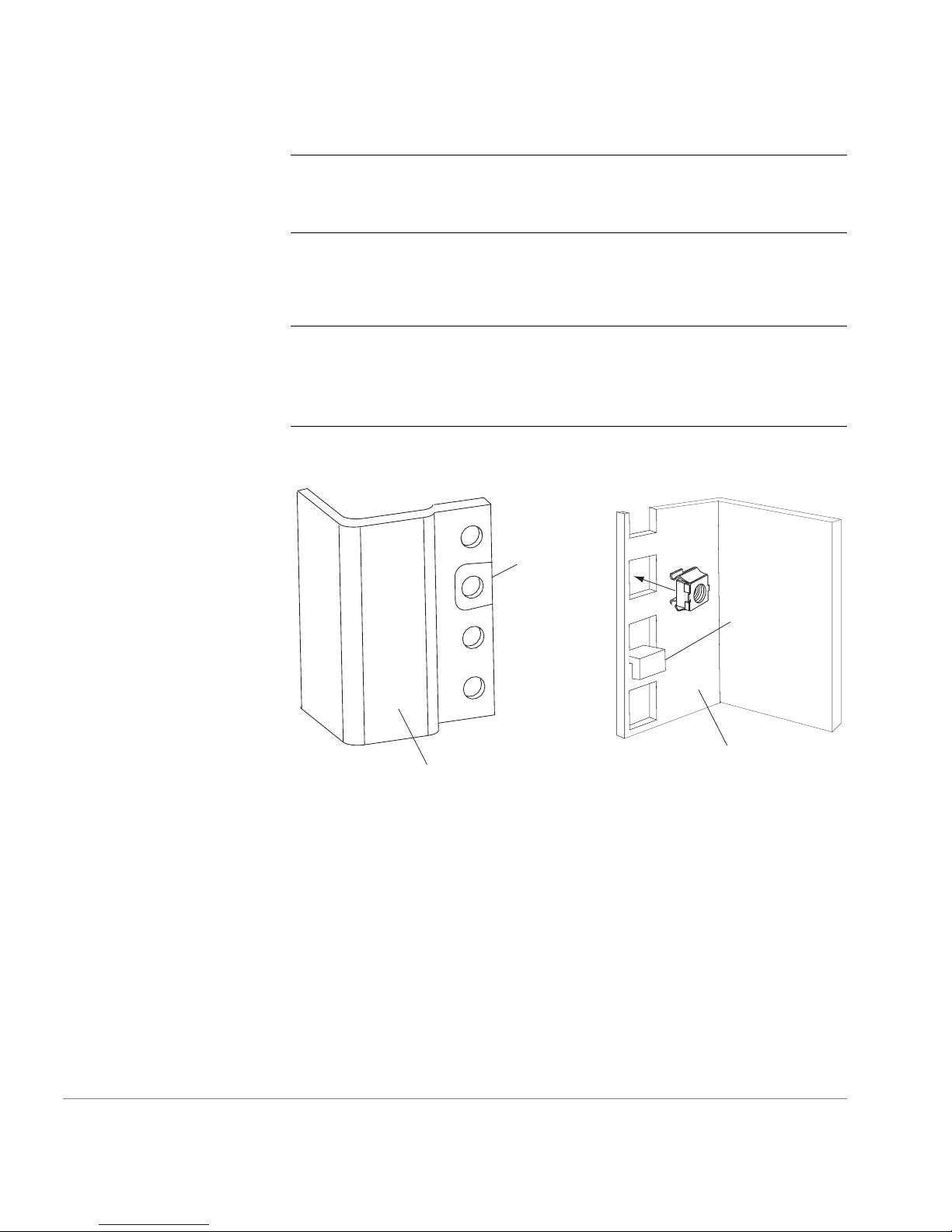

18.Install the front bezel:

a. Orient the front bezel so that its outer surface is facing you.

b. Align the bottom end of the front bezel with the bottom edge of the

rail tray (see Figure 18). There are two alignment posts and two spring

clips on each s ide of th e bezel t hat grip the rack u prights and hold the

bezel in position. Each of the lower alignment posts fits into the second

unused hole above the front mounting flange on each side of the rail

tray.

Installing the Switch

Figure 18. Installing the Front Bezel

c. Press the sides of the bezel against the rack uprights until the bezel

snaps into place. Snap the bottom end in first and then the top end.

d. Inspec t the bezel to ensure that i t is installed so that its top edge is

aligned with the top su rface of the switch.

31

Page 32

19.Install the switch door:

a. Rotate the knobs on the switch door so that they are in the down

position and the springs are compressed.

b. Position the door so that the hinge pins are between the loops on the

hinge plates mounted on the switch (see Figure 13 and Figure 19).

Note

When you rotate the door to the closed position, the

spring-loaded hinge pins will snap into the loops on the hinge plates.

Figure 19. Installing the Switch Door

Note

be installed, and it must be kept closed during normal operation.

32

T o ensur e that the swit ch does not emi t RFI, the switch doo r must

Quick Start Guide

Page 33

System Components

Power Supply

The SilkWorm 2250 switch is ready to use once the unit is plugged in.

When the power cord is connected to the switch, the switch is powered on.

The 2250 switch meets IEC 61000-4-5 surge voltage requirements. See

Chapter 6 for specific in formation o n power requ irements for the switch.

3

SETUP

33

Page 34

AC Module

Figure 20. 2250 Switch

DB-9 port

GBIC port

10/100BaseT port

Note

The 2250 switch does not have a power switch. When the power

cord is connected to the switch, the switch is powered on.

Fabric Operating System

Included with the switch is the Fabric OS. The system provides a large

number of commands and libraries to manage real-time tasks. See the

Fabric OS Reference Manual, Version 2.4 for details.

GBIC Modules

The switch accommodates up to sixteen GBIC modules. All interfaces have

status lights visible from the front panel giving a quick, visual check of the

switch port’s status and activity.

GBIC modules supported are the short wavelength (SWL) and long

wavelength (LWL) fibre-optics.

34

Quick Start Guide

Page 35

If your installation requires installing less than sixteen GBIC modules, the

unused port positions are protected by a metal, spring-loaded door that

covers the opening.

SWL Fibre-Optic GBIC Module

The SWL fibre-optic GBIC module, with a bl ack SC connector, is based on

short-wavelength 850 nm lasers supporting 1.0625 Gbps link speeds. This

GBIC module supports both 50-micron and 62.5-micron, multi-mode fibre

optic cables up to 500 meters in length. Figure 21 shows a SWL GBIC

module.

Figure 21. Short-Wavelength Las er (SWL) Fib r e-O pti c GBIC Mod ule

Note

The SWL GBIC module uses a Class 1 laser, which complies with

the 21 CFR, subpart (J) as of the date of manufacture.

LWL Fibre-Optic GBIC Module

The LWL fibre-optic GBIC module, with a blue SC connector, is based on

long-wavelength 1300 nm lasers supporting 1.0625 Gbps link speeds. This

Setup

35

Page 36

GBIC module supports 9-micron single-mode fibre optic cables up to 10

kilometers. Figure 22 shows a LWL GBIC module.

Figure 22. Long-Wavelength Laser (LWL) Fibre-Optic GBIC Module

Fibre Channel Cable Connections

All network cable connections are to the switch’s front panel. All

recommended cabling supports the switch’s 1.0625-Gbps transfer rate, as

shown in Table 2.

Table 2. Cabling Connections

Cable type Cable Specification

SWL Fibre Optic Duplex SC plug connectors

Multi-mode fibre

50 µm core diameter

62.5 µm core diameter

125 µm cladding diameter duplex cable

LWL Fibre Optic Duplex SC plug connectors

Single-mode fibre

9 µm core diameter

125 µm cladding diameter duplex cable

Note

The switch is not designed to interoperate with devices using an

Open Fibre Control optical interface.

Maximum run

length

500 meters

1641 feet

10 Kilometers

32,808 feet

GBIC module

Optical Wavelength

780-860 nm

without open fibre

control (non-O FC)

1270-1350 nm

without open fibre

control (non-O FC)

36

Quick Start Guide

Page 37

Fibre cable connect ions are made to GBICs loc ated on the fron t panel of the

switch using standard dual SC plug connectors as shown in Figure 23.

Figure 23. Dual SC Fibre Optic Plug Connector

The connectors are keyed and must be inserted into the GBIC module

connector in proper alignment. In most cases, one of the two connector

plugs is a different color to aid in proper connector alignment.

Note

optic plug into the GBIC module as you may damage the connector, the

GBIC module, or both. Make certain the fibre surface is clean and free of

dust or debris before inserting the connector into the GBIC module.

Initialize the Switch

To initialize the switch:

1. Insert the GBICs into th e GBIC ports and connect the Fibre Channel cable

to the GBIC. This may be done before o r after the switch is initialized.

2. Connect the power cord to the AC module of the switch. The switch

automatically performs a Power On Self Test (POST). The POST will

take approximately 2.5 minutes.

Remove the protective plug from the GBIC. Do not force the fibre

Setup

37

Page 38

Note

If a switch boot failure occurs, the switch must be taken offline

for repair or replacement. Contact your switch supplier for assistance.

3. If the factory- set IP address is compatible with your network, connect th e

Ethernet connection.

Note

The factory-set IP address is: 10.77.77.77. The Subnet Mask is:

255.255.255.0.

4. If the factory-se t IP address is not compatible wit h your network, connect

the serial por t connect ion, then f ollow the pr ocedure to s et the IP a ddress

on page 39.

5. Monitor the status indicators for port status, see “Status Indicators” on

page 40.

If a malfunction occurs during POST, specific error messages are written to

the system error log and can be analyzed via a Te lnet session when the

POST session completes. If the malfunction prohibits the switch from

completing the boot process (fatal error), the swit ch stops the boot process.

If the switch does not fully boot, the switch prompt will not be displayed

when the serial port is connected.

Serial Port and Ethernet Connections

The 2250 switch contains a serial port for initial configuration and an

Ethernet connection for remote monitoring and testin g.

Ethernet Connection

An Ethernet connection must be es tablished to obtain access to the inte rnal

SNMP agent in the switch and local area network (LAN). Once the

connection is made, remote Telnet and Web access is made available. To

establish an Ethernet connection, connect to an existing Ethernet

10/100BaseT LAN via the front panel RJ45 connector.

Note

Ethernet cable.

38

Remove shipping plug from the Ethernet port before inserting

Quick Start Guide

Page 39

Serial Port Connection

The 2250 switch has a serial port for initial configuration of the IP address.

This port can also be used for service purposes. The serial port should not

be used during normal operation.

Note

Remove the dust cover fr om the s erial port bef ore inse rting the se rial

cable.

Note

Do not use the serial port during normal operation or for regular

maintenance. Remove the serial port cable and, using the dust cover

supplied with the switch, cover the port during normal operation of the

switch.

To set the IP address on the switch for normal Ethernet access, perform the

following initial procedure:

1. Attach the provi ded serial cab le between the serial port o n the switch an d

an RS-232 serial port on your l aptop or host computer . The cable is wir ed

with only pins 2, 3, and 5 wired straight through.

Note

If needed, the adapter can be removed to allow for RJ45 serial

connection to your host computer.

2. Turn on the switch and wait for the power on self test (POST) to complete.

POST is complete whe n all LED activity has stopped; this takes

approximately 2 minutes.

3. Disable all serial communication programs running on your computer,

4. Run a terminal emulation program such as Hyperterm on Windows

5. Configure the te rminal for 9600 Baud, 8 Data Bi ts, No Parity, 1 Stop Bit,

6. Press

7. If prompted, provide a log in and password. The default is logi n =

Setup

such as sy nc programs for a PDA .

95/NT, or TERM in a Unix environment.

and no flow control. Click OK.

Enter

to get a prompt.

and the password =

password

admin

39

Page 40

8. At the prompt, type the command

ipAddrSet

, then press

Enter

9. When prompted, provide the IP Address, Subnet mask, and Gateway

Address in the standa rd IP form of xxx.xxx.xxx.xxx.

Note

address.

10.When prompted type

11.Power down the switch and disconnect the serial cable (and adapter, if

12.Power up the switch. IP-based management (T elnet, SNMP , or W ebTool s)

13.Record the IP address on the label provided on the switch.

Status Indicators

Each port contains an LED that indicates the status for that port. Table 3

describes the status indicators and possible corrective actions.

Table 3. Status Indicators and Corrective Actions

LED Description Action

For now, only edit the Ethernet addresses, not the Fibre Channel

y

and press

Enter

to apply the new values.

used). Connect the switch to a 10/100BaseT Ethernet connection.

can now be accessed by using the newly defined IP address.

40

No light showing No light or signal carrier (no

module, no cable) for media

interface LEDs.

Steady yellow Receiving light or signal

carrier, but not yet online.

Slow yellow Disabled (result of diagnostics

or port Disable command).

Flashes every 2 seconds.

Fast yellow Error, fault with port. Flashes

every 1/2 second.

Steady green Online (connected with device

over cable).

Check media

connection.

No action required.

Reset at management

station.

Reset switc h.

No action required.

Quick Start Guide

Page 41

Table 3. Status Indicators and Corrective Actions (continued)

LED Description Action

Slow green Online, but segmented

(loopback cable or

incompatible switch ). Flashes

every 2 seconds.

Fast green Internal loopback (diagnostic).

Flashes every 1/2 second.

Flickering green Online and frames flowing

through port.

Interleaving green

Port is bypassed. Reset at management

and yellow

AC Module LE D Description

No light showing No power is being supplied to

the switch. Check power cord

connection to the switch.

Steady Green Receiving power. Switch is

online.

Check media

connection at both

ends.

No action required.

station.

Setup

41

Page 42

42

Quick Start Guide

Page 43

INSTALLING SOFTWARE

This chapter provides instructions for installing the following software:

• Fabric Manager

• Remote Switch

• Extended Fabrics

Installing Fabric Manager

Fabric Manager p rov ides a graphi cal inter face tha t allo ws the admini stra tor

to monitor and manage a fabric from a standard workstation. Fabric

Manager runs on the workstation and can be used to manage any switches

that have Fabric OS version 2.0 or later and We b Tools version 2.2 or later

installed (this documentation describes Web Tools version 2.3

functionality).

4

Requirements

The switch and computer workstation must meet specific requirements for

the correct installation and operation of Fabric Manager.

43

Page 44

Switch Requirements

Fabric Manager can be used to manage switches that meet the following

requirements:

• SilkWorm 2400, 2800.

• Fabric OS a2.4.1 or later versions of HP supported Fabric OS.

Fabric Manager can be used to manage switches with earlier versions,

but status and event information is not available.

• HP Surestore FC Switch 6164

Workstation Requirements

The follow ing items are required for the correct installation and operation

of Fabric Manager on the computer workstation:

• one of the following operating systems:

– Windows 2000

– Windows NT 4.0

• adequate RAM:

– 128 MB for fabrics of 21 switches or less

– 256 MB for fabrics containing more than 21 switches

• 10 MB of free disk space

• one of the following web browsers:

– Netscape Communicator 4.51 or later

– Internet Explorer 4.01 or later

Note

The browser must be specifically configured to work with Fabric

Manager. For information about how to do this, see “Configuring the

Web Browser” on page 45.

• Java™ plug-in version 1.2.2-007 or later

44

Quick Start Guide

Page 45

Installing Fabric Manager

Preparing to use Fabric Manager to manage your fabric requires the

following steps:

• installation of one of the supported web browsers on the workstation, if

not already installed

• configuration of the web browser for use with Fabric Manager

• installation of the required Java plug-in on the workstation, if not

already installed

• installation of Fabric Manager on the computer to be used as a

workstation

Installing a Web Browser

Install one of the foll owing browsers, if not already inst alled:

• Netscape Communicator 4.51 or later (available at

http://www.netscape.com

)

• Internet Explorer 4.01 or later (available at

http://www.microsoft.com

)

Configuring the Web Browser

Specific browser settings are required for the correct operation of Fabric

Manager with either Netscape Communicator or Internet Explorer.

Configuring Netscape Communicator

The web browser cache must be cleared after the installation of Fabric OS.

The browser can use local cache copies of jar files and image files to

improve performance (depending on options selected in the browser),

which can cause incorrect display.

To remove cached files from Netscape Communicator:

1. Select Edit > Preferences.

2. Click Advanced in the left text box to expand it, then click Cache.

3. On the Cache panel, click Clear Memory Cache.

4. Click Clear Disk Cache.

Installing Software

45

Page 46

5. Click OK.

6. Exit and relaunch the browse r.

Configuring Internet Explorer

Correct op eration of Fabric Manager with Internet Explorer requires

clearing the web browser cache after installation, and specifying the

appropriate settings for the browser refresh frequency and process model.

The browser cache must be cleared after the installation of Fabric OS. The

browser can use local cache copies of jar files and image files to improve

performance (depending on options selected in the browser), which can

cause incorrect display.

To remove cached files from Internet Explorer:

1. Select Internet Options from the View menu if using Internet Explorer

4.x, or from the Tools menu if using 5.x.

2. Select the General tab.

3. Click Delete Files... (under “Temporary Internet Files”).

4. Click OK.

5. Exit and relaunch the browse r.

Browser pages must be refreshed at every visit to ensure the correct

operation of the Switch Admin feature.

To set the refresh frequency:

1. Select Internet Options from the View menu if using Internet Explorer

4.x, or from the Tools menu if using 5.x.

2. Select the General tab and click Settings (under “Temporary I nternet

Files”).

3. Under “Check for newer versions of stored pages,” s elect “Every visit to

the page.”

The correct Browser Process Model must be selected.

46

Quick Start Guide

Page 47

To select the Browser Process Model (only required for Windows NT):

1. Select View > Internet Option s if using In tern et Expl orer 4.x, or Tools >

Internet Options if using Internet Explorer 5.x.

2. Select the Advanced tab and click to expand the Browsing category.

3. Under “Browsing,” select “Browse in a new process” if using Internet

Explorer 4.x, or “Launch browser windows in a separat e process” if using

Internet Explorer 5. x.

Installing the Java plug-in on the Workstation

A Java plug-in must be instal led on the works tation for the Fabri c Manag er

installer to function, and for Fabric Manager and Web Tools to operate

properly Windows 2000 and NT workstations require Java plug-in version

1.2.2-007.

To determine the version of the Java plug-in installed on Windows 2000 or

NT, and install the plug-in if necessary:

1. Launch the Java plug-in control panel by selecting Start > Programs >

Java plug-in Control Panel and turning on the Java console.

2. Launch the web br owser, enter the name or IP address of a switch running

Fabric OS a2.4.1 or later, and press

Enter

.

The switch launches the Java plug-in console, which displays the Java

plug-in version currently installed.

3. Determine whether the c orrect Java plug-in version is inst alled, and install

if necessary:

– If the correct version is installed, Fabric Manag er is ready for use.

– If no Java plug-in is installed, point the browser towards a switch

running Fabric OS a2.4.1 or later, follow the link to the Sun

Microsystems W eb site, and download the correct Java plug-in, then

double-click the downloaded file to install the plug-in.

– If an outdated version is cur re ntl y in stalled, uninstall it, relaunch the

browser, enter the address of a switch running Fabric OS a2.4.1 or

later , follow th e link to the Sun Web site, and download the new Java

plug-in.

Installing Software

47

Page 48

Installing Fabric Manager on the Workstation

The Fabric Manager 1.0 installation package includes the following items:

• ReadMe.txt file, providing product name, version, and late-breaking

news

• Java plug-in version 1.2.2-007

• FabricManager.Jar file, containing the required Java classes

• FabricManager.Properties file, containing configuration information

To install Fabric Manager 1.0:

1. Insert the Fabri c Manager 1. 0 CD-ROM in the CD dri ve of the compu ter

workstation.

The installer automatically launches.

If Fabric Manager is already installed on the computer, a window

displays to indicat e t his . If t his window displays, you can either exit the

installer and uninstall the existing version, or click Next to continue

with the installatio n.

Note

If you decide to cont inue wit h the i nst alla tion an d selec t the s ame

location, all existing files are overwritten, e xcept for the

FabricManager.Properties file, which contains the selections from the

previous installation, and is saved as FabricManager.Properties.old.

48

Quick Start Guide

Page 49

The Welcome window displays, providing product information and

version.

2. Click Next.

After the Welcome window is dismissed, the installer searches the local

system for the correct version of the Java plug-in. If this version is not

installed, a window displays warning that the correct version of the

plug-in is missing. If the installer warns that the plug-in is missing,

perform Step 3 before continuing. Otherwise, continue with Step 4.

3. If the installer warns that the Java plug- in is missing:

a. Click Exit to close th e Fabric Manager insta ller, then click Exit Instal l

in the warning dialog box that displays.

b. View the local drives, right-click on the icon for th e F abr ic Mana ger

CD-ROM, and select Explore.

c. Click to open the JRE folder, then click the file

jre-1_2_2_007-win.exe.

The plug-in installer launches.

d. Read the license agreement, and click Next if you accept the

agreement.

A window displays to allow selection of the installation location.

Installing Software

49

Page 50

e. Click Next to accept the defaul t inst allat ion loca tion, or br owse for a

custom location and then click Next.

The installation completes and the plug-in installer window closes.

f. Relaunch the Fa bric Manager instal ler by double-cli cking the icon f or

your CD-ROM drive.

The Welcome window displays again.

g. Click Next to dismiss the Welcome window.

When the Java plug-in is successfully located, a window listing Fabric

Manager’s web browser requirements displays.

4. Determine whether a compatible browser is installed. If a compatible

browser is not installed, exit the Fabric Manager installation, install the

browser, and then relaunch the Fabric Manager installation.

Note

installed so that the pathname for the browser can be written to the

Fabric Manager properties file.

5. Click Next to continue.

50

The browser should be installed before Fabric Manager is

Quick Start Guide

Page 51

6. Select the preferred location for the installation.

– To select the default location, click Next.

– To select another location:

a. Click Choose.

b. Select a location fr om the browser window that display s, and click

OK.

c. Click Next in the Select Destination Folder window.

Installing Software

7. Click Install to accept the defaul t installat ion location, or browse for a

custom location.

The installer searches the registry for the web browser and adds the

complete pathname to the FabricManager.Properties file. If the installer

is unable to locate a web browser, a window displays warning that no

browser was found. If this window displays, exit the Fabric Manager

installation, install the browser, and then relaunch the Fabric Manager

installation.

51

Page 52

Note

If the browser is installed or moved after Fabric Manager is

installed, see “Adding the Browser Pathname to the Properties File” on

page 54.

When the ins tallation of Fabric Manag er is complete, the follow ing

window displays:

52

8. Check the checkbox if yo u want to view the ReadMe file, then click Done

to close the installer.

Note

Clicking Exit a t thi s point does not undo th e inst alla tion, but doe s

prevent the ReadMe file from displaying.

Quick Start Guide

Page 53

Launching Fabric Manager

To launch Fabric Manager:

1. Select Start > Programs > Fabric Manager > Fabric Manager.

2. Enter th e switch name or IP addre ss in the Switch URL field.

Note

This switch is assumed to be the local domain. If you want

information specific to QuickLoop to be available, the QuickLoop

switch must be the local domain.

3. If you want to add the addre ss e ntered in the field to the drop-down list,

click Add. To remove an address from the drop- down list, select that

address a nd click De l.

4. Press Enter to submit the address.

Note

If an incorrect address or format is used, an error message

displays, listing the formats that can be used. If this message displays,

determine and enter the correct address.

Installing Software

53

Page 54

When a correct address is ent ered, Fab ric Manage r launch es, display ing

the default view, Fabric View. For more information about using Fabric

Manager, see the HP Surestore FC Switch 6164 Installation and

Reference Guide.

Adding the Browser Pathname to the Properties File

If the browser is installed after Fabric Manage r is installe d, the proper ties

file must be edited to sh ow the correct path for the browser.

Note

Editing any information other than the browser pathname in the

properties file is not recommended.

To add the browser pathname to the properties file:

1. Open the directory where Fabric Manager is installed. T he default

directory is

2. Double-click the FabricManager.Properties

(such as Notepad) as the application for this file.

3. Enter a new line starting with “BrowserPath=”, followed by the correct

pathname for the browser, in quotes. For example:

BrowserPath=“C\:\\Program Files\\Internet Explorer\\iexplore.exe”

This line can be added anywhere in the file, provided it does not

interrupt another line.

Uninstalling Fabric Manager

Note

uninstall an additional installation, open the corresponding installation

folder, open the subdirectory UninstallerData, and double-click Uninstall

FabricManager.exe to launch the uninstaller.

The uninstaller can only access the most recent installation. To

c:\Program Files\Fabric Manager\

file, and select a text editor

, where “c” is the local drive.

To uninstall Fabric Manager:

1. Select Start > Settings > Control Panel.

2. Double-click the Add/Remove control panel.

54

Quick Start Guide

Page 55

3. On the I nstall/Uninstall tab of the control panel, select Fabric Mana ger

and click Add/Remove.

4. Click Uninstall to continue.

A window showing the progress of the uninstallation displays.

5. Click Exit to close the Uni nstall Comp lete window.

Installing Remote Switch

You can use the Remote Switch feature to configure a pair of switches to

operate over an extended WAN interface. This enables the switches to

communicate across an ATM network by using a comp atible Fibre Channel

to an ATM gateway. For detailed information on th e Remote Switch

feature, see the Distributed Fabrics User’s Guide.

Note

Remote Switch can only be implemented in a fabric that contains

exactly two switches.

A Remote Switch fabric requires two switches with Fabric OS version

a2.4.1 or later ins talled; both t he switches must ha ve the same conf iguration

and a separate license for each switch. The switch licenses are applied by

your HP Customer Engineer (CE). You can also install a license through

Telnet or Web Tools. Should any license keys be needed to access features

not already lic ensed on your FC S witch 6 164, t hey ca n be obt ained throug h

the following web site:

http://www.hp.com/support/fc6164

Installing Through Telnet

1. Log onto the switch by Telnet (see the user’s guide provided with the

hardware for detai ls), using an account that has administ rative privil eges.

2. If you want to determine whether a Remote Switch license is already

installed on the s witch, type licenseShow on the T elnet com mand line.

Installing Software

A list displays all licenses currently installed on the switch.

55

Page 56

Example:

admin> licenseShow

1A1AaAaaaAAAA1a:

Release v2.2

Web license

Zoning license

SES license

QuickLoop license

If the Remote Switch license is not includ ed in the li st or is incorr ec t,

continue with Step 3.

3. Enter the following on the command line:

licenseAdd “key”

where “key” is the license key provided to you, surrounded by double

quotes. The license key is case sensitive and must be entered exactly as

given.

4. Verify the license was added by ent er ing the following on the command

line:

licenseShow

If the Remote Switch license is listed, the feature is installed and

immediat ely available. If the license is not l isted, repeat Step 3.

Installing Through Web Tools

1. Launch the web browser, enter the switch name or IP address in the

Location/Address field, and press Enter.

Web Tools launches, displaying the Fabric View.

2. Click the Admin button on the relevant switch panel.

56

Quick Start Guide

Page 57

3. Enter a logon na me and password with administra tive privileges and press

Enter.

The Administration View displays.

4. Select the License Admin tab, enter the license key in the License Key

field, and click Add License.

The Remote Switch feature is available as soon as the license key is

added.

Installing Extended Fabrics

The Extended Fabric feature enables you to configure ports for a

long-distance l ink of up t o 100 km. For d etailed informati on on this feature ,

see the Distributed Fabri cs User’s Guide.

Extended Fabrics requires a switch with Fabric OS version a2.4.1 installed

and a license for each switch in the fabric. An Extended Fa brics licen se is

installed on each switch by your HP Customer Engineer (CE). This license

is installed through either Telnet or Web Tools as described in this chapter.

Should any license keys be needed to access features not already licensed

on your FC Switch 6164, they can be obtained through the follow ing web

site:

http://www.hp.com/support/fc6164

Installing Through Telnet

1. Log on to the switch by Telnet (see the user’s guide provided with the

hardware for detai ls), using an account that has administ rative privil eges.

2. If you want to determine wheth er an Exten ded Fabrics license is alre ady

installed on the switch, type

A list dis plays of all the licenses currentl y installed on the switch.

Installing Software

licenseShow

on the Telnet command line.

57

Page 58

Example:

admin> licenseShow

1A1AaAaaaAAAA1a:

Web license

Zoning license

QuickLoop license

Fabric license

Fabric Watch license

If the Extended Fabrics license is not included in the list, or i s incorrect,

continue with Step 3. If the licence is correctly listed, it is already

installed.

3. Enter the following on the command line:

licenseAdd “key”

where “

key

quotes. The license key is case sensitive and must be entered exactly as

given.

4. Verify the license was added by ent er ing the following on the command

line:

licenseShow

If the Extended Fabric s license is listed, the feature is installed and

immediat ely available. If the license is not l isted, repeat Step 3.

Installing Through Web Tools

1. Launch the web browser, enter the switch name or IP address in the

Location/Address field, and press Enter.

Web Tools launches, displaying the Fabric View.

2. Click the Admin button on the relevant switch panel.

” is the license key provided to you, surrounded by double

58

Quick Start Guide

Page 59

3. Enter a logon na me and password with administra tive privileges and press

Enter.

The Administration View displays.

4. Select the License Admin tab, enter the license key in the License Key

field, and click Add License.

The Extended Fabrics feature is available as soon as the license key is

added.

Installing Software

59

Page 60

60

Quick Start Guide

Page 61

5

DIAGNOSTICS

The 2250 switch is designed for maintenance-free operation. It contains

self-diagnostic capabilities that provide switch status and operating

statistics. In the case of a failure, the self-diagnostics aid in isolating the

problem.

The 2250 switch has loopback pat hs incorpor ated into th e switch hardwa re.

Internal Fibre Channel port logic functions and the paths between the

interfaces and central memory are verified by an internal loopback path test

within the switch. An external loopback path test that includes the main

board, fixed medi a, and the GBIC modul e, checks i nstalle d fibre ca bles and

port fault isolation in cross-port configurations. This test requires external

cables to be looped from one port to another.

61

Page 62

Diagnostic Tests

Available tests which are run from the local Te lnet port are listed below,

along with the command to initiate each. See the Fabric OS Reference

Manual, for detailed information on commands.

Table 4. Diagnostic Tests for the 2250 Switches

Test Command Description

Error Log errDump Displays the error log without

Switch Offline switchDisable Sets the switch to offline state

Memory Test ramTest Checks CPU RAM m emory. Run

page breaks.

necessary to run certain switch

diagnostics.

offline or online.

Port Register

Test

portRegTest Checks that the registers and stat ic

memory in each ASIC can be

successfully accessed. Run

offline.

Central Memory

Test

centralMemoryTest Checks that t he centra l memory in

each ASIC can be successfully

accessed. Run offline.

Control Message

Interface (CMI)

Conn Test

Content

Addressable

cmiTest Verifies that control messages can

be sent from ASIC to ASIC.

Run offline.

camTest Verifies CAM functionality.

Run offline.

Memory (C AM)

Test

Error Log errDump Displays error log without page

breaks.

Port Loopback

Test

portLoopbackTest Checks all switch main board

hardware. Frames transmitted are

looped back and received.

Run offline.

62

Quick Start Guide

Page 63

Table 4. Diagnostic Tests for the 2250 Switches (continued)

Test Command Description

Cross Port Test crossPortTest Checks all switch paths. Frames

transmitted by port M are looped

back via external cable and

received at port N. Run offline or

online.

Spin Silk Test spinSilk Checks all switch paths at the

maximum speed of 1 Gbps.

Frames transmitted by port M are

looped back via external cables

and when received by p ort N are

sent again by port M in an

external loop. Run offline.

Error Messages

SRAM Data

Retention Test

sramRetentionTest Verifies that data written into

ASIC memories is retained. Runs

offline.

CMem Data

Retention Test

CmemRetentionTest Verifies that data written into

ASIC SRAMs is retained. Runs

offline.

Switch Online switchEnable Returns switch to online state.

To analyze error messages, access the error message log via a Telnet

session using the

errDump

command. Note any messages befor e removi ng

power from the switch; error messages are stored in RAM and are lost

when power is removed. See the Fabric OS Reference Manual for a

detailed description of each message.

Diagnostics

63

Page 64

64

Quick Start Guide

Page 65

General

6

SPECIFICATIONS

Table 5 lists the 2250 switch specifications:

Table 5. Switch Specifications

Specification Description

Fabric initialization Complies with FC-SW 3.2

IP over Fibre Channel

(FC-IP)

System architecture Nonblocking shared-memory switch

System processor Superscalar 33 MHz Intel i960RP

Number of Fibre Channel

ports

Fibre Channel port speed 1.0625 Gbps full duplex

Modes of operation Fibre Channel Class-2 service and Fibre

Aggregate switch I/O

bandwidth

Complies with FC-IP 2.3 of the FCA profile

16 GBIC ports

Channel Class-3 connectionless service

16 Gbps, full duplex

65

Page 66

Environmental

Table 5. Switch Specifications (continued)

Specification Description

Frame buffers 16 buffers per port at 2112 bytes per frame

Port to port latency Less than 2 microseconds with no contention

Data transmission range Up to 500 meters (1,625 ft.) for

short-wavelength

optical link

Up to 10 kilometers (32,820 ft.) for

long-wavelength optical link

Chassis type Back-to-front airflo w (AC power connection

out front)

The acceptable environmental ranges for the FC Switch 6164 are shown in

Table 6.

Table 6. FC Switch 6164 Environmental Specifications

Parameter Specification

Temperature (operating) 10°C to 40°C

T emperature

–35°C to 65°C

(non-operating)

Operating humidity 5% to 85% non-condensing @ 40°C

Non-operating humidity 95% RH non-conducting @ 40°C

Operating altitude 0 to 3 kilometers above sea level

Non-operating altitude 0 to 12 kilometers above sea level

Operating shock 4G, 11MS duration, half sine

Non-op erating s hock 20G, 11MS duration, sq.wave

Operating vibratio n 5G, 0–3 kHz

Non-operating vibration 10G, 0–5 kHz

66

Quick Start Guide

Page 67

Dimensions

Table 7. The 2250 Switch Physical Specifications

Power Supply

Rack-Mount Dimensions

1.5U, 19-in. rack-mount (EIA compliant)

(including rail tray)

Weight 7.7 kg (16.9 lbs.)

Table 8. Power Supply Requirements

Total power 660 watts maximum

Input voltage

100 - 230 VAC

(nominal)

Input line frequency 47 Hz minimum to 63 Hz maximum

Harmonic distortion Power factor correction per IEC1000-3-2

BTU rating 2250 BTU/hr

Specifications

67

Page 68

68

Quick Start Guide

Page 69

PRODUCT REGULATORY INFORMATION

FCC EMC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency ener gy and, if n ot installed an d used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense. The end u ser of this product should be aware that any changes or

modifications made to this equipment without the approval of Hewlett-Packard

could result in the product not meeting the Class A limits, in which case the FC C

could void the user’s authority to operate the equipment.

EMC Statement (Canada)

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du Règlement

sur le matér iel b rouilleur du Canada.

EMC Statement (European Union)

This is a Class A product. In a domestic environment this product may cause r a dio

interference, in which case the user may be required to take adequate measures.

Spécification ATI Classe A (France)

DECLARATION D’INSTALLATION ET DE MISE EN EXPLOITATION d’un

matériel de traitement de l'information (ATI), classé A en fonction des niveaux de

perturbations radioélectriques émis, définis dans la norme européenne EN 55022

concernant la Compatibilité Electromagnétique.

69

Page 70

Germany Noise Declaration

Schalldruckpegel Lp = 55 dB(A)

Am Arbeitsplatz (op erator position)

Normaler Betrieb (normal operation)

Nach ISO 7779:1999 (Typprüfung)

VCCI EMC Statement (Japan)

Harmonics Conformance (Japan)

BSMI EMC Statement (Taiwan)

RRL EMC Statement (Korea)

70

Quick Start Guide

Page 71

Laser Safety

A. Certification and Classification Information

This product contains a laser internal to the GigaBit Interface Converter (GBIC)

transceiver module for connection to the Fibre communications port.

In the USA, the GBIC module is certified as a Class 1 laser product conforming to

the requirements contained in the Department Of Health and Human Services

(DHHS) regulation 21 CFR, Subchapter J. The certification is indicated by a label

on the metal GBIC housing.

Outside the USA, the GBIC is certified as a Class 1 laser product conforming to the

requirements contained in IEC 825-1:1993 and EN 60825-1:1994, including

Amendment 11:1 996 .

The GBIC includes the following certifications:

• UL Recognized Component (USA)

• CSA Certified Component (Canada)

• TUV Certified Component (European Union)

• CB Certificate (Worldwide)

The following figure shows the Class 1 information label that appears on the metal

housing of the GBIC.

CLASS 1 LASER PRODUCT DHHS 21 CFR(J)

B. Product Information

Each communications port consists of a transmitter and receiver optical

subassembly. The transmitter subassembly contains internally a semiconductor

laser diode in the wavelength range of 780 nanometers (shortwave laser) or 1310

nanometers (longwave laser). In the event of a break anywhere in the fibre path,

the GBIC control system prevents laser emissions from exceeding Class 1 levels.

Class 1 laser products are not considered hazardous.

WARNING

performed on any GBIC module.

There are no user maintenance operations, or adjustments to be

C. Usage Restrictions

Failure to comply with these usage restrictions may result in incorrect operation of

the system and points of access may emit laser radiation above the Class 1 limits

established by the IEC and U.S. DHHS.

Product Regulatory Information

71

Page 72

Declaration of Conformity

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name: Hewlett-Packard Company

Netwo rk Storage Solu t ions Organization

Manufacturer's Address: 8000 Foothills Blvd.

Roseville, CA 95747

USA

declares, that the product

Product Name:

Model Number(s):

HP SureStore FC Switch 6164

A7326A, A7326AZ

Product Op ti ons: All

conforms to t he f ollowing Product Specifications :

Safety: IEC 60950:1991 + A1, A2, A3, A4 / EN 60950:1992 + A1, A2, A3, A4, A11

GB 4943-1995

IEC 60825-1:1993 / EN 60825-1:1994 + A11, Class 1 (Laser/LED)

EMC: CISPR 22: 1997 +A1 / EN 55022:1998 +A1 Class A

CISPR 24:1997 / EN 5502 4:1 998

IEC 61000-3-2:1995 / EN 61000-3-2:1995 +A14

IEC 61000-3-3:1994 / EN 61000-3-3:1995

GB 9254-1988

1

72

Suppleme nt ary Information

The product h erewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE marking accordingly.

1) The Product was tested in a worst-case test configuration which maximizes RFI

emissions.

:

Roseville, July 16, 2001

European Contact: Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department HQ-TRE, Herrenberger Straße 130, D-71034 Böblingen (FAX: + 49-7031-14-3143)

Quick Start Guide

Loading...

Loading...