Page 1

HP DLT Tape Library

15-Slot

User’s Guide

Model A4851A

November 1997

Printed in United Stat es

© Copyright 1997 Hewlett-Packard Company

DLTt ap e is a trad emark of Quantu m Cor poration

Page 2

Notice

This document contains information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or

translated into another language without the prior written consent of

Hewlett-Packard Company. The information contained in this document is

subject to change without notice.

Hewlett-Packard makes no warran ty of any kind with regard to this printed

material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard shall

not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this

materia l.

See Appendix B for important safety and regulatory information.

Printing Histor y

New editions of this manual incorporate all material updated since the

previous edition. The manual printing date and part number indicate the

current editi on. The p ri n tin g d ate changes when a new edition is printed.

(Minor corrections and updates incorporated at reprint do not cause this date

to change.)

November 1997 Edition 1

ii

Page 3

Typographical Conventions

This manual uses the following typographical conventions:

Font Used for

Italics

Typewriter Font

COMMAND TEXT

KEYCAP TEXT

NOTE Notes provide information that can be helpful in understanding the operation

of the product.

CAUTION Cautions call attention to an operating procedure or practice that could

result in damage to the product if not correctly performed. Do not proceed

beyond this box until you fully understand and meet the indicated

conditions.

WARNING

War nings call attention to a procedure or practice that could result in

personal injury if not correctly performed.

this box until you fu lly understand and m eet the indicated

conditions.

Document titles and statements that need to be

emphasized.

Commands you type on your keyboard or screen

menu items you can select.

Information displayed in the display window of

the library.

Keys on the library control panel.

Do not proceed beyond

This warning symbol on a product label indicates that personal injury could

result if the product is used improperly, and that more detailed information is

given in the installation and/or user manuals.

iii

Page 4

iv

Page 5

Contents

1 Product De s cription

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

HP DLT Tape Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Product Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Supported Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Library Rear Panel Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Quantum DLT4000 and DLT7000 Drive Mechanism Specifications . . . . . 1-7

DLT Tape Library Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

DLTtape Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

DLT Tape Library Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

2 Library Installa tio n

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Step 1: Choose a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Step 2: Prepare Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Step 3: Install the Host SCSI Card(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Step 4: Mount the Library in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Step 5: Set the SCSI Interface Mode Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Step 6: Connect Library to Host. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Routing SCSI and Power Cables on Rack Mounted Libraries . . . . . . . . . 2-10

Step 7: Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Step 8: Configure the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Moving or Shipping the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

3 Tape Cartridges

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Choosing Tape Cartridges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Labeling Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Write-Protecting Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Maintaining Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

v

Page 6

Contents

Labeling Bulk Load Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

4 Library Operat i on

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operating the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Understanding the Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Drive Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Activity Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Control Panel Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

First Level Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Second Level Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Control Panel Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Entering the Administration Menu Password . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Setting a New Administration Menu Password. . . . . . . . . . . . . . . . . . . . . . . . 4-8

Specifying SCSI Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Viewing Current SCSI Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Setting SCSI Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Interpreting SCSI Bus Status Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . 4-12

Loading Cartridges Into the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Inserting/Removing Cartridges with Software. . . . . . . . . . . . . . . . . . . . . . 4-13

Keeping Cartridges in the Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Loading Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Removing Tape Cartridges from the Library . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Viewing Cartridge Bar Code Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Cleaning the Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Drive Cleaning Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Setting Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Retrieving Performance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Running an Internal Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

vi

Page 7

Contents

Using Online Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Clearing a Drive Cleaning Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Operating System-based Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Running Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

DLT Drive Expert Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Robotics Controller Expert Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Resolving Other Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

A Supplies and Accessories

Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

B Safety and Regulatory In formation

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

CDRH Regulations (USA Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Regulatory Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

FCC Radio Frequency Interferen ce Statement (USA Only). . . . . . . . . . . .B-4

EC Radio Frequency Interference Statement (Europe Only) . . . . . . . . . .B-4

United Kingdom Telecommunications Act 1984 . . . . . . . . . . . . . . . . . . . . .B-4

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Herstellerbescheinigung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

English Translation of German Sound Emission Directive. . . . . . . . . . .B-6

Turvallisuusyhteenveto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

English Translation of Finnish Regulatory Information . . . . . . . . . . . . .B-8

Japanese VCCI Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-9

English Translation of Japanese VCCI Statement . . . . . . . . . . . . . . . . . . B-9

vii

Page 8

Contents

viii

Page 9

Figures

Figure 1-1 HP DLT Tape Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2 Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 2-1 SCSI Interface Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-2 SCSI/Power Cables and Strain Relief Bracket. . . . . . . . . . . . . . . 2-10

Figure 2-3 Front Access Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-4 Secured SCSI and Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-5 Front Access Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 3-1 Proper Label Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-2 Write-Protect Button Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3 Magazin e La be l Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 4-1 Tape Library Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-2 Control Panel Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-3 Opening the Fron t Access Door . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-4 Loading Tape Cartridges into the Magazine. . . . . . . . . . . . . . . . . 4-15

Figure 4-5 Inserting Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Figure 4-6 Opening the Fron t Access Door . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 4-7 Removing Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

ix

Page 10

Figures

x

Page 11

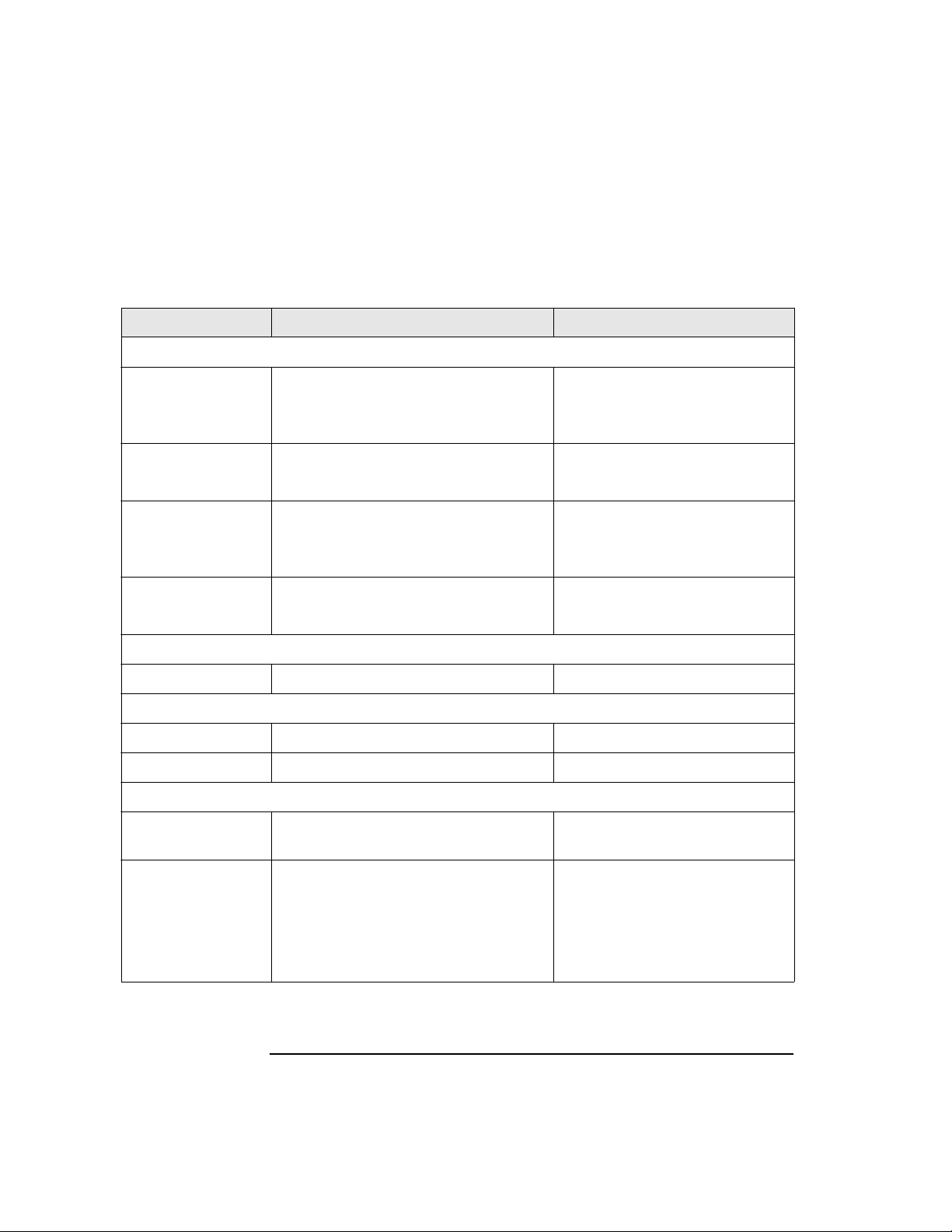

Tables

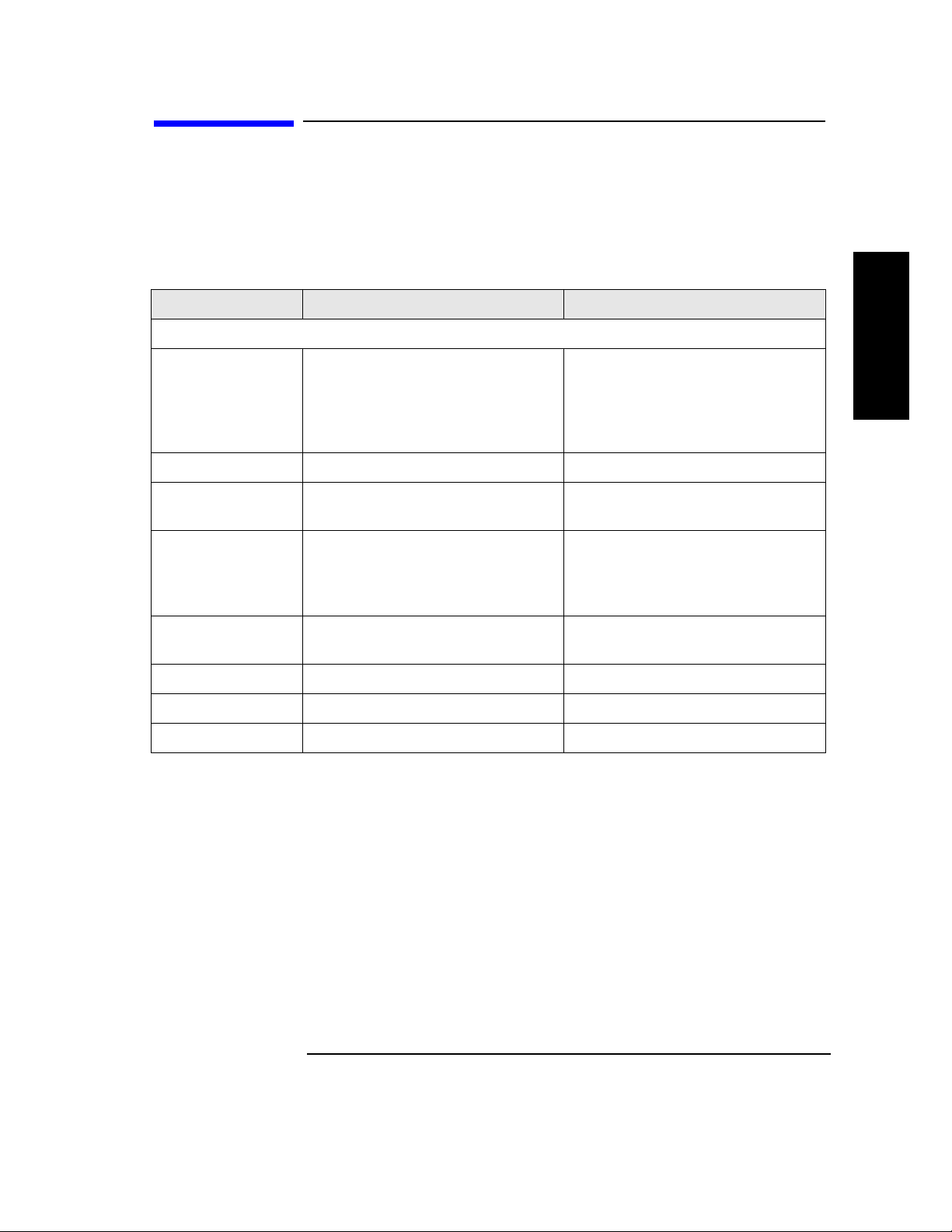

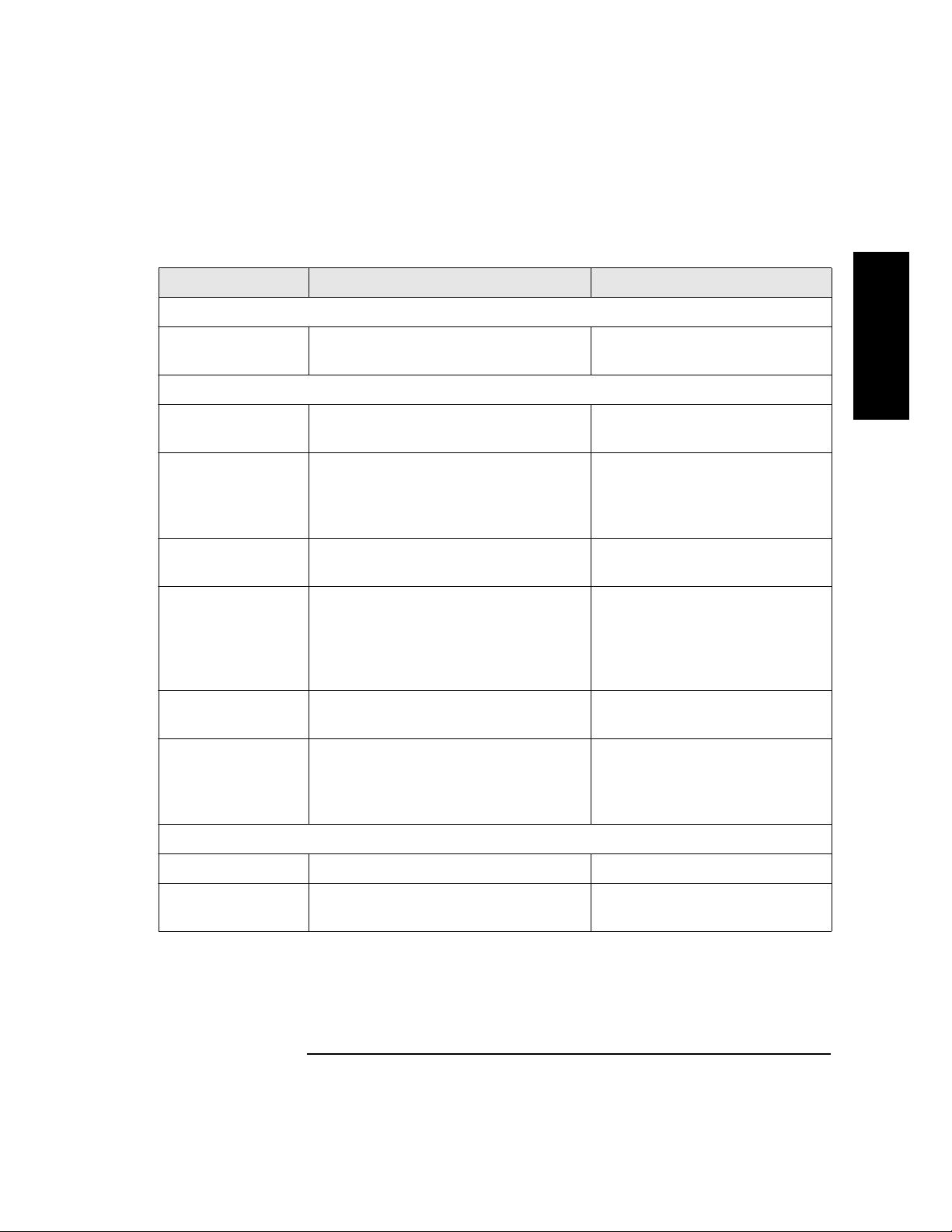

Table 1-1 DLT Tape Library Offerings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-2 Upgrade/Conversion Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-3 DLT Tape Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

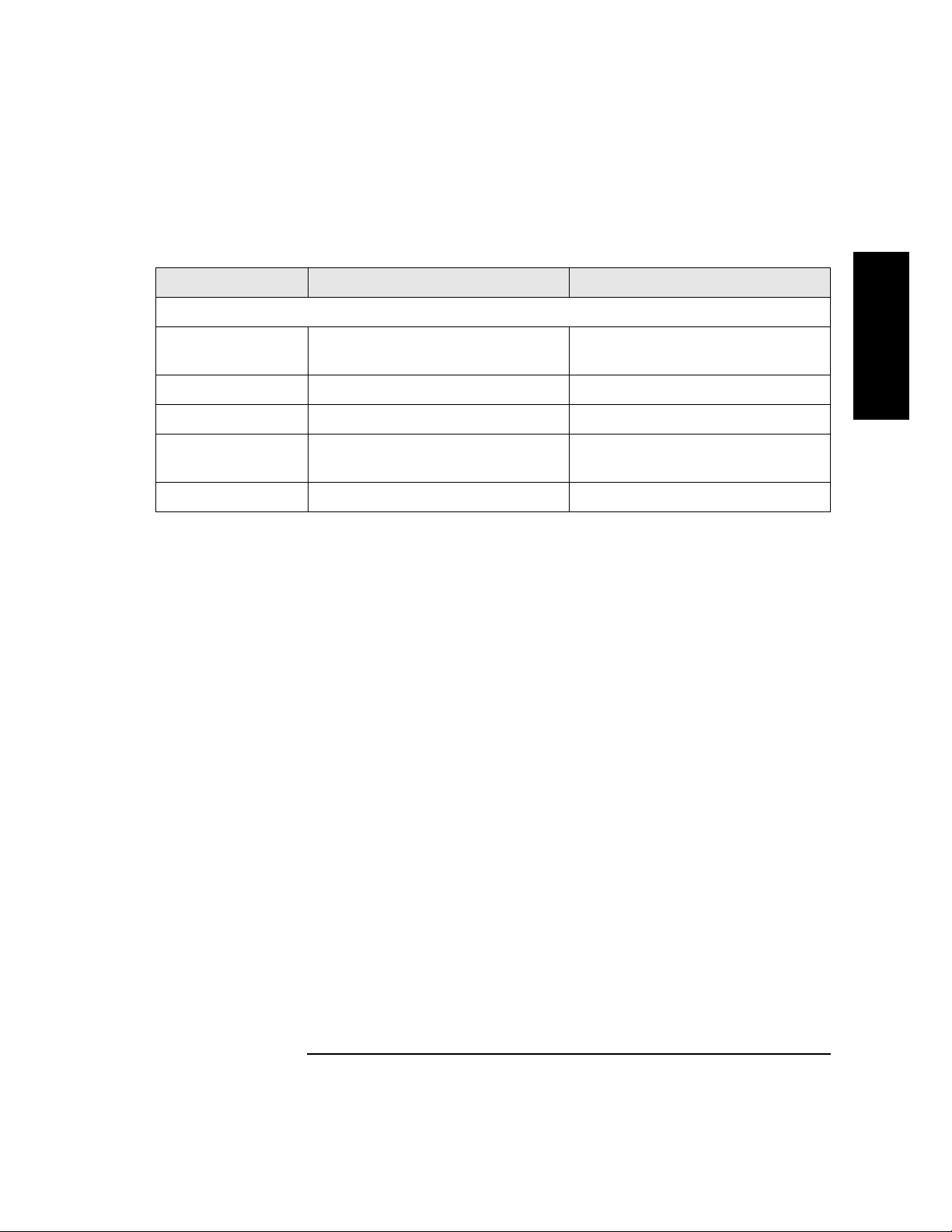

Table 1-4 DLT Tape Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-5 DLT Drive Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-6 Library Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-7 Tape Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Table 1-8 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Table 1-9 Product Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Table 2-1 Location Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-2 Components Required for Installation and Use . . . . . . . . . . . . . . . 2-4

Table 2-3 SCSI Interface Mode Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-4 Library Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 3-1 Supported Tape Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-2 Tape Cartridge Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Table 4-1 SCSI ID Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-2 Default SCSI Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-3 SCSI Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Table 4-4 Drive Cleaning Issues Relating to Tape Cartri dges. . . . . . . . . . . 4-23

Table 4-5 Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Table 4-6 Information Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Table 4-7 Internal Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Table 4-8 Support Tool Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Table 4-9 Drive Expert Tool Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Table 4-10 Roboti c s Controller Expert To ol Commands. . . . . . . . . . . . . . . 4-42

Table A-1 Basic Supplies and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

xi

Page 12

Tables

xii

Page 13

1Product Description

1-1

Page 14

Product Description

Overview

Overview

• HP DLT T ape Library

• Product Matrix

• Supported Platforms

• Library Rear Panel Features

• Specifications

1-2

Page 15

HP DLT Tape Library

• Fully automated

• State-of-the-art patented HP robotics

• Industry-leading data ava ilability

• Industrial-strength durability

• User-maintenance-free library system

A vailable configurat io n s ar e d escribed in Tab le 1-1 on page 1-4.

Figure 1-1 HP DLT Tape Library

Product Description

HP DLT Tape Library

Product Description

1-3

Page 16

Product Description

Product Matrix

Product Matrix

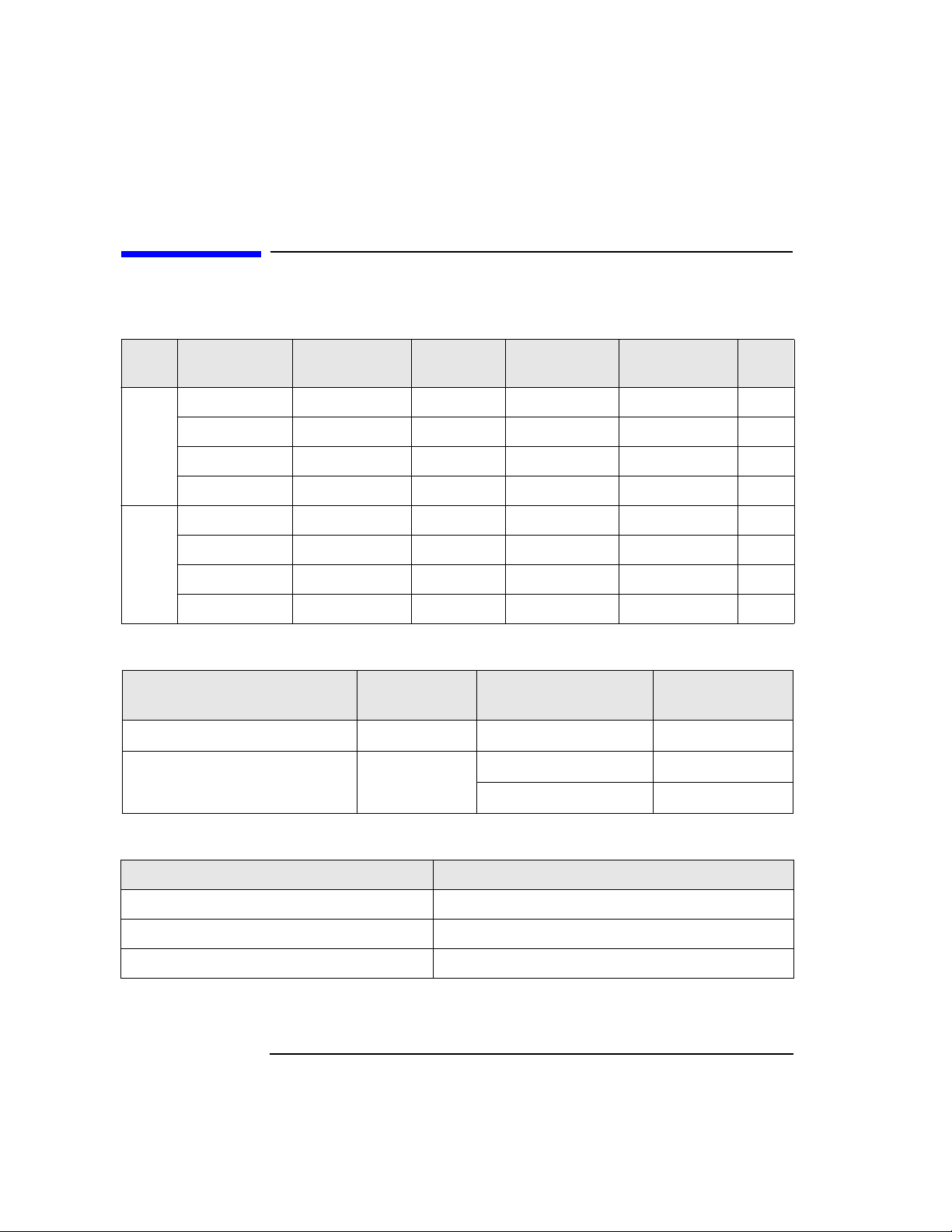

Table 1-1 DLT Tape Library Offerings

Library

Model

DLT4000 1/15 A4851A #A6K #401 One DLT4000 15

DLT4000 2/15 A4851A #A6K #402 Two DLT4000 15

Deskside

Field Rack

Table 1-2 Upgrade/C onver sion Kits

DLT4000 Upgrade Kit A4842A DLT4000 1/15 DLT4000 2/15

DLT 7000 Up grade/Conversion

Kit

DLT7000 1/15 A4851A #A6K #701 One DLT7000 15

Libraries

DLT7000 2/15 A4851A #A6K #702 Two DLT7000 15

DLT4000 1/15 A4851A #A6L #401 One DLT4000 15

DLT4000 2/15 A4851A #A6L #402 Two DLT4000 15

DLT7000 1/15 A4851A #A6L #701 One DLT7000 15

Libraries

DLT7000 2/15 A4851A #A6L #702 Two DLT7000 15

Kit

HP Product

Number

HP Product

Number

Mounting

Option

A4843A DLT4000 1/15 DLT7000 1/15

Config.

Option

Upgrades/Converts To

DLT7000 1/15 DLT7000 2/15

Drives Slots

Table 1 -3 DLT Tape Media

Media HP Product Number

HP DLTtape Type III XT C5141A

HP DLTtape Type IV C5141F

Cleaning Cartridge C5142A

1-4

Page 17

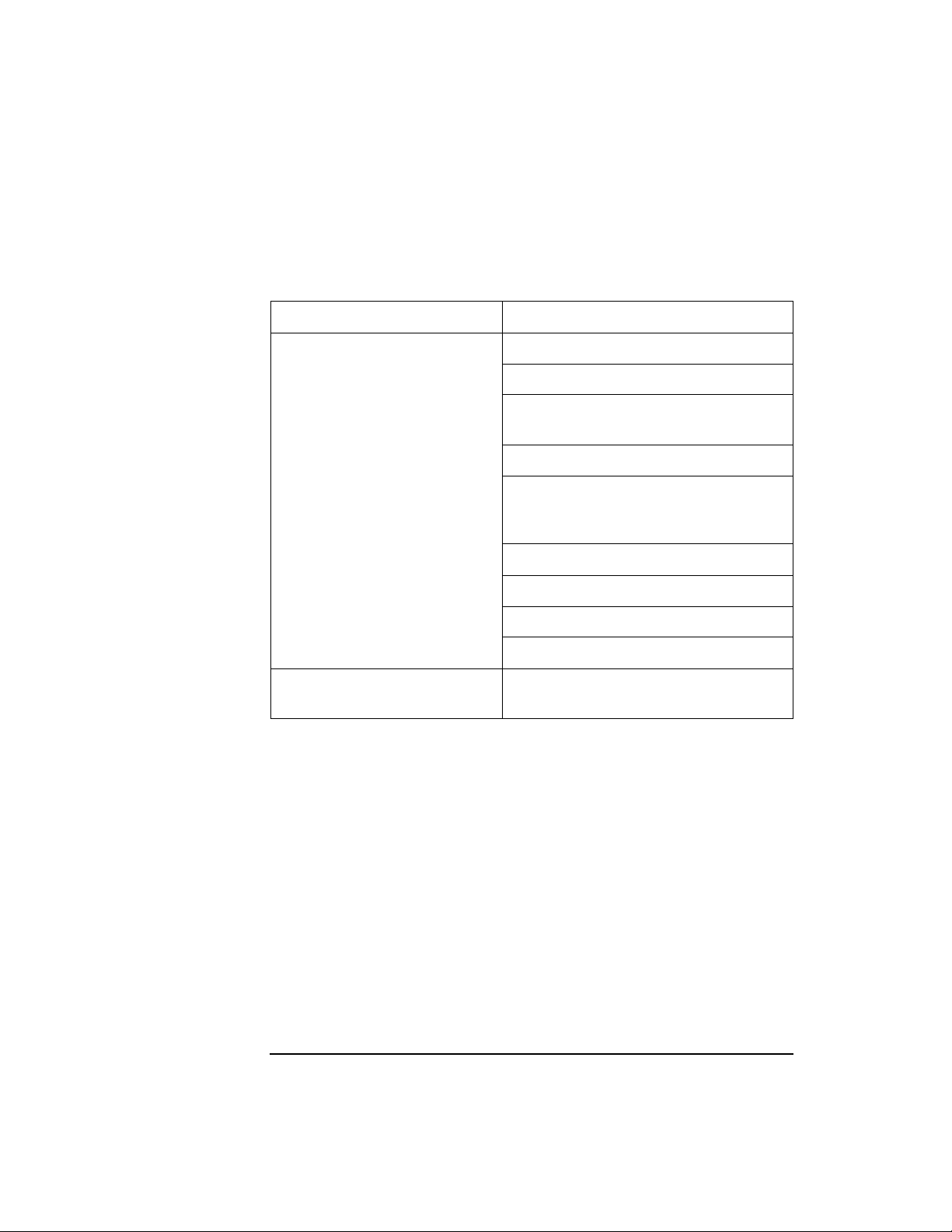

Supported Pl atforms

Table 1-4 DLT Tape Media

Product Description

Supported Platforms

Product Description

Servers

Workstation

On supporting platforms, the library can be connected to an HP Fibre

Channel SCSI multiplexer (HP A3308A and HP A3511A/Z) and thereby benefi t

from Fibre Channel speed and dis t an ce. The FC-SCSI multiplexer is

supported on K, T, and V platforms running HP-UX 10.20 TFC or higher.

(Consult an HP sales representative for the latest information.)

D-Class

E-Class

K-Class

Nova

T-Class

V-Class

J-Class

1-5

Page 18

Product Description

Library Rear Panel Features

Library Rear Panel Features

Figure 1-2 Rear Panel Features

6

1

5

5

1.

Bus 1 SCSI ports

robotics controller are internally connected to Bus 1.

2.

SCSI interface mode switches

differential settings for each SCSI bus.

3.

Bus 2 SCSI ports

connected to Bus 2 (two-drive library only)

4.

SCSI bus status indicator label

indicators.

5.

Power connector

6.

SCSI bus indicators

indicator.

4

(single-ended and differential). Drive 1 and the

specify term power, terminatio n and

(single-ended and di ffer ential). Drive 2 is inter nally

explains the SCSI bus status

connects the power cord to the library.

indicate SCSI bus status. Each SCSI bus has an

2

3

1-6

Page 19

Specificatio ns

Quantum DLT4000 and DLT7000 Drive

Mechanism Specifications

Product Description

Specificati ons

Table 1-5 DLT Drive Specifications

Characteristic DLT4000 DLT7000

Performance

Read/write transfer

rate:

maximum

sustained (DLTtape

Type I V)

Ave ra ge access time 68 seconds 60 seconds

Rewind 45 seconds (average)

Loading time to

BOT (for

previously written

tape)

Unloading time to

BOT

External Interface 8-bit SCSI-2, differential 16-bit fast/wide SCSI-2, differential

Internal Interface 8-bit SCSI-2, single-ended 16-bit fast/wide SCSI-2, single-ended

non-compressed mode:

1.5 MB/second

compressed (2:1 typical):

3.0 MB/second

90 seconds (maximum)

48 seconds (average) 48 seconds (average)

17 seconds (average) 17 seconds (average)

non-compressed mode:

5.2 MB/second

compressed (2:1 typical):

10.0 MB/second

60 seconds (average)

120 seconds (maximum)

Product Description

Read-write head 2-channel, ferrite w/MIG 4-channel, ferrite w/MIG

1-7

Page 20

Product Description

Specifications

Table 1-5 DLT Drive Specifications (Continued)

Characteristic DLT4000 DLT7000

Recording format 128 track serial serpentine variable

block (64 pairs)

208 track serpentine (52 quads)

416-tpi track density

256-tpi track density

Data compress

DLZ DLZ

algorithm

Reliability

Soft read error rate

Soft write error rate

Hard read error rate

Hard write

7

1 in 10

bytes minimum

(read as one error maximum

allowable in 10

7

of data read

minimum)

6

1 x 10

bytes minimum 1 x 106 bytes minimum

17

1 x 10

bytes minimum 1 x 1017 bytes minimum

Not allowed Not allowed

7

1 in 10

bytes minimum

(read as one error maximum

allowable in 10

minimum)

error rate

Undetected

1 x 10

30

bits read 1 x 1027 bits read

error rate

MTBF 80,000 hours 200,000 hours

Head life 10,000 hours 30,000 hours

7

of data read

Power Specifications

Total Power

consumption

22 W (average)

33 W (m a x i m u m)

5 volt supply 5.0 V +/- 5% (maximum)

@2.5 A (average) ,

3.0 A (maximum)

12 volt supply 12.0 V +/- 5%

@ 0.8 A (average),

1.5 A (maximum)

1-8

37 W (average)

47 W (maximum)

5.0 V +/- 5% (maximum)

@3.6 A (average),

3.8 A (maximum)

12.0 V +/- 5%

@ 1.6 A (average),

2.6 A (maximum)

Page 21

Table 1-5 DLT Drive Specifications (Continued)

Characteristic DLT4000 DLT7000

Physical Specifications

Product Description

Specificati ons

Product Description

Form factor 5 1/4 in. (height with modified

depth)

5 1/4 in. (height with modified

depth)

Height 3.25 in. (w/o bezel) 3.25 in. (w/o bezel)

Width 5.7 in. (behind bezel) 5.7 in. (behind bezel)

Depth 9 .0 in. (measured from back of front

bezel)

9.0 in. (measured from back of front

bezel)

We ight (net) 6 lb 7 oz 6 lb 7 oz

1-9

Page 22

Product Description

Specifications

DLT Tape Library Specifications

Table 1-6 Library Specifications

Characteristic A4851A Library

Performance

A verage tape

access

A verage tape

exchange

Interface SCSI-2 (single ended or differential)

MTBF 100,000 hours

MSBF (robotics) 1 million swaps

Preventive

maintenance

Total power

consumption

Line voltage 100 - 127/

Line frequency 50 to 60 Hz

Height 348 mm (13.7 in.) w/o bezel

<12 seconds

24 seconds (mean time to eject tape from drive, robotically exchange tape

from magazine and reload drive)

Reliability

None required

Power Requirements

140 W (typical) NOTE: After 30 minutes of non-operation,

150 W (maximum) the library operates in reduced power mode.

200 - 240 Vac

Physical Specifications

353.4 mm (13.9 in.) with bezel

Width 442 mm (17. 4 in .) w/o bezel

482.6 mm (19.0 in.) with bezel

Depth 717.3 mm (28.2 in.) w/o bezel

752.6 mm (29.6 in.) with bezel (t o tip of hand le)

Weight (net) 43.5 kg (96 lbs)

W e igh t (packaged) 49 kg (108 lbs)

1-10

Page 23

DLTtape Specificati ons

Table 1-7 Ta pe Specifications

Characteristic DLTtape Type III XT DLTtape Type IV

Product Description

Specificati ons

Product Description

Formatted capacity 15 GB

(non-compresse d)

30 GB

(2:1 typical compression)

20/35 GB

(non-compressed)

40/70 GB

(2:1 typical compression)

Basic description 0.5 in. (met al particle) 0.5 in. (metal pa rticle)

Tape length 1167 ft 1778 ft

Cartridge

4.1 in. x 4.1 in. x 1.0 in. 4.1 in. x 4.1 in. x 1.0 in.

dimensions

Shelf life

30 years (min) @ 20

40% RH

(non-condensing)

Usage 1,000,000 passes (min)

10,0 00 lo a d s/un lo a d s (mi n )

o

C

30 years (min) @ 20o C

40% RH

(non-condensing)

1,000,000 passes (min)

10,000 loads/unloads (min)

1-11

Page 24

Product Description

Specifications

Envir onmenta l Specific a t ions

Table 1-8 Environmental Specifications

Characteristic Tape/Drive DLT Tape Library

Temperature and Humidity

Operating 10° to 40° C

20% to 80% RH (drive, non-condensing)

40% to 60% RH (tape, non-condensing)

Non-operating

w/o disk

Storage/shi pmen t -40° to 66° C (drive)

Archive 18° to 28° C

Operating 0 to 30,000 ft N/A

Non-operating 0 to 50,000 ft N/A

Operating 60 half sine shock impulses of 5 g’s for

0° to 55° C

10% to 95% RH

16° to 32° C (tape)

10% to 95% RH

40% to 60% RH

Gradient

10° C/hour 15° C/hour

Altitude

Shock

11 sec in 3 axes

10° to 40° C

10% to 90% RH

-40° to 70° C

10% to 90% RH

-30° to 60° C

(<14 consecutive days)

-30° to 60° C

(<14 consecutive days)

4-in. half sine edge drop, 4faces

Non-operating half sine, 55 g, 11 ms

half sine, 140 g, 2 ms

half sine, 15 g, 20 ms

half sine, 150 g, 3 ms

half sine, 40 g, 11.8 ms

(all measured in 6 axes)

1-12

30 g

(trapezoidal wave, edge drop)

Page 25

Table 1-8 Environmental Specifications (Cont i nued)

Characteristic Tape/Drive DLT Tape Libra ry

Package shock

Product Description

Specificati ons

Product Description

Drop tests 42 in. (packaged drive dropped on six

sides, three edges, one corner)

Vibration

Operating random 5 - 500 Hz @ 1 grms

10 minutes, 3 axes

Operating sine 0.25 g peak 10 - 300 Hz

0.1 g peak 300 - 500 Hz

10 - 500 - 10 Hz @ 1/4 octav e/m inute in 3

axes

Non-operating

random

Non-operating

swept- sine

5 - 500 Hz @ 2 grms

60 minutes, 6 axes

5 - 10 Hz @ 0.5 g peak

10 - 50 Hz @ 1 g peak

50 - 500 Hz @ 3 g peak

5 - 500 - 5 Hz @ 1/2

octave/minute in 6 axes

Non-operating

random packaged

Non-operating

swept si ne

packaged

2 - 200 Hz @ 1.5 grms

6 axes, dwell = 30 m

5 - 150 Hz @ 0.5 g peak

5 - 150 - 5 Hz @ 1/2 oct/min, 6 axes with

dwell at lowest natural resonance in

each axes

12-in. drop, 5 faces

0.21 grms

N/A

2.1 grms

0.5 grms (0 to peak)

1.49 grms, top-to-bottom

0.5 G (0-pk), 3 - 200 - 3 Hz 1

oct/min, 1 axis (top-to-bottom)

Acoustic Emission

Media exchange N/A 6.5 Bels

Read/write

4.3 Bels (max) A-weighted 6.5 Bels

operation

1-13

Page 26

Product Description

Specifications

DLT Tape Library P r oduct Certifications

Table 1-9 Product Certification

Safety EN60950/IEC 950

Electromagnetic emissions EN55022/CISPR - 22, Class B

EN50082 - 1

EN55024 - 2/IEC 1000 - 4 - 2, 4kV CD,

8kV AD

EN55024 - 3/IEC 1000 - 4 - 3, 3 V/m

EN55024 - 4/IEC 801 - 4,

1kV Peak Power lines

0.5 k V S ignal lines

FCC 47 CFR Part 15 - Cla ss B

VCCI Class B

EN61000 - 3 - 2/IEC 1000 - 3 - 2

EN61000 - 3 - 3/IEC 1000 - 3 - 3

Laser EN60825 (1994)/IEC 825 (1993)

+A1, Laser Class 1

1-14

Page 27

2 Library Installation

2-1

Page 28

Library Installation

Overview

Overview

To install the library:

1. Choose a location.

2. Prepare library components.

3. Install the host SCSI card(s).

4. Mount the library in a rack (rack mount configuration only).

5. Set the SCSI interface mode switch.

6. Con n ect th e libr ary to the host.

7. Con n ect power.

8. Con f igu r e th e hos t .

This chapter also explains how to move or ship the library.

NOTE Installation must be performed by HP qualified personnel.

2-2

Page 29

Step 1: Choose a Location

Choose a location that meets the following criteria. Take the library there

before unpacking it.

Table 2-1 Location Criteria

Library Installation

Step 1: Choose a Location

Room

temperature

Power source AC power voltage: 100-127 V or 200-240 V

Air quality Minimal sources of particulate contamination. Avoid

Adequate

clearance

50-104° F (10-40° C)

areas near frequently-used doors and walkways,

stacks of supplies that collect dust, and smoke-filled

rooms.

CAUTION: Excessive dust and debris can damage

tapes and tape drives.

Standalone configuration — free stand in g o r against a

wall/desk:

Back 56 cm (22 in.) for cooling and service.

Front 86 cm (34 in.) for operator access.

Sides56 cm (22 in.) for removal of the external cover.

Rack mount configuration:

Back Allow adequate room to open the rear

door of the rack for service access,

usually 46-61 cm (18-24 in.), depending

on the rack.

Library Installatio n

Front 86 cm (34 in.) for operator access.

Height For ease of use, the bottom of the lib rary

should be 60-120 cm (24-4 8 in.) above th e

floor .

2-3

Page 30

Library Installation

Step 2: Prepare Components

Step 2: Prepare Components

Make sure all required components are available.

Table 2-2 Components Required for Installation and Use

Component Installation Notes

Library Do not unpack the library until it is in the

proper location.

SCSI card(s) Required number of cards installed in host depends on

library configuration. Connect drives and robotics

controller t o differential fast/wid e SCSI cards.

SCSI cables Required number of cables (68-pin) is one per drive and

one for the robotics controller. Maximum cable length

(total) is 25 meters.

Power cord P ower c ord is included wit h library.

Rack mount kit Rack mount kit is included with rack mount libraries.

Data cartridge One HP DLTtape IV data cartridge is incl u de d with

library.

Cleaning

cartridge

If any components are missing, contact a sales representative.

2-4

Cleaning cartridge is included with library.

Page 31

Library Installation

Step 3: Install the Host SCSI Card(s)

Step 3: Install the Host SCSI Card(s)

Refer to the host user manual and the SCSI card installation instructions for

information on installing SCSI cards.

Library Installatio n

2-5

Page 32

Library Installation

Step 4: Mount the Library in a Rack

Step 4: Mount the Library in a Rack

For rack mount configurations, refer to the ins t allation instructions included

in the rack mount kit.

2-6

Page 33

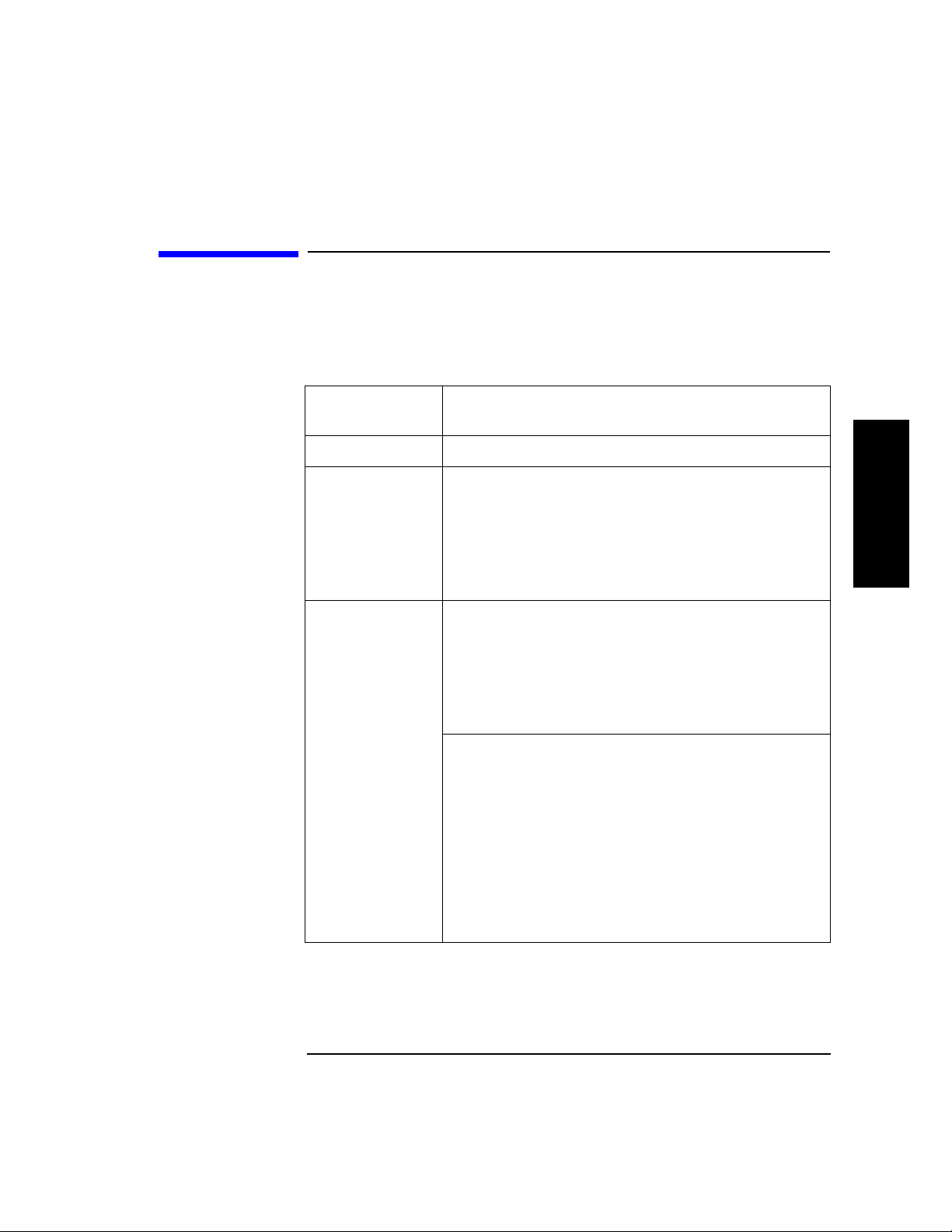

Step 5: Set the SCSI Interface Mode Switch

Do not connect any cables yet.

The SCSI interface mode switch, shown below, is on the rear panel between

the bus 1 and bus 2 SCSI ports.

Figure 2-1 SCSI Interfac e Mode Switch

To set the SCSI interface mo de switch:

1. Determine h ow to connect the library according to:

Library Installation

Step 5: Set the SCSI Interface Mode Switch

Library Installatio n

• Number of drives in the library and drive type (only DLT4000 drives

are supported as daisy-chained)

• Number of SCSI cards

2. Set the SCSI interf ace mode switch.

Table 2-3 SCSI Interface Mode Sw it ch Settings

Setting Purpose Set to

Term Pwr Sends power to the terminator ON in most installations

Termination Terminates the SCSI bus; functions

the same as a physical terminator

DIFF/SE Specifies interface mode DIFF for differential

ON if one port on the bus is open

OFF if both ports on the bus are

connected to a cable

2-7

Page 34

Library Installation

•bus 2 not

used

Step 5: Set the SCSI Interface Mode Switch

Table 2-4 shows three ways to connect the library and the corresponding

SCSI interface mode switch settings .

Table 2-4 Library Con nection Options

Configuration Cabling

One-Drive Library

Two-Drive Library

Daisy chained

(DL T4000 drives only)

Minimu m host

I/O slots used

SCSI Interface Mode Switch

Settings

Two-Drive Library

Bus 1 and bus 2

connect to separate

SCSI cards

Maximum performance

Additional card and

cable required

2-8

Page 35

Library Installation

Step 6: Connect Library to Host

Step 6: Connect Library to Host

1. Ensure the host system has been properly shut down and powered off.

2. Con n ect th e SCSI cables.

The SCSI bus configuration was de termined when the SCSI interface

mode switch was set (see the connect ion diagr am on page 2-8). Us ing this

configuration, connect the library to the host. Make sure:

• The differential port is used.

• The last device in the SCSI bus is terminated.

3. Make sure the power switch o n the li brar y fr o n t panel is switched off (0

position).

4. Plu g the power cord int o the power port on the back of the li b rary.

Stand-alone in stallations: Go to “Step 7: Connect Power” on page 2-13.

Library Installatio n

Rack mount installations: Go to the next section, ”Routing SCSI and Power

Cables on Rack Mounted Libraries.”

2-9

Page 36

Library Installation

Step 6: Connect Library to Host

Routing SCSI and Power Cables on Rack Mounted

Libraries

CAUTIO N SCSI and power cables must be routed and secured properly on rack

mounted libraries. Failure to properly route library cables could result in

damage to the cables.

To properly route and secure rack mounted library power and SCSI

cables:

1. Rou te the SCSI/power cables through the strain relief bracket:

a. Squeeze the two plas tic ends of the cable stra in relief bracket toget her.

b. Pull off the plastic strai n rel ief clamp.

c. R oute the SCSI cable(s) and the power cord through the cable strain

relief bracket.

d. Slide the strain r elief clamp back onto the bracket.

e. Attach a cable tie (included in the rack mount kit) to the SCSI and

power cables about eight inches back from the strain relief bracket.

f. Attach another cable tie abo ut eight inches back from the first cable

tie.

Figure 2-2 SCSI/Power Cables and Strain Relief Bracket

2-10

Page 37

Library Installation

Step 6: Connect Library to Host

2. Extend the rack’s antitip rail and verify that the leveller feet are down.

WARNING

Failure to extend the antitip rail could result in personal injury

and/or damage to the library if the rack tips over.

3. Use the key to open the front access door. Remove the tw o scre ws that

secure the library to the rack.

Figure 2-3 Front Ac cess Door

Library Installatio n

4. Slide the library out of the rack so that it is in the fully extendedposition.

5. Gently pull the SCSI and power cables back toward t he rear o f the rack .

Use a cable tie to secure them to the ra il at the back of the rack. T he cable

tie should be at about the same height as the top of the library.

2-11

Page 38

Library Installation

Step 6: Connect Library to Host

6. Carefully route the cables down along the back rail. Use a cable tie to

secure them to the rail just above the sli d e mounting bracket. Clip off the

ends of all four cable ties.

Figure 2-4 Secured SCSI and Power Cables

7. Close the back door on the rack.

8. Push the library back into the rack.

9. Open the front access door. Replace the two screws that secure the

library to the rack, then reloc k the door.

Figure 2-5 Front Ac cess Door

2-12

Page 39

Library Installation

Step 7: Connect Power

Step 7: Connect Power

1. Plug the power cord into a proper outlet.

2. Turn on the power switch.

SELF TEST and NOT READY, and then NOT READY and INVENTORY

CHECK display alternately. After the power-on test completes (in about 3

minutes), the drive status information displays. (See “Understanding the

Display Window” on page 4-4.)

NOTE If the drive status information does not display, the power-on test was not

successful and DEVICE FAILED displays. See “resolving Other Problems”

on page 4-43.

3. Turn on the host system.

Library Installatio n

2-13

Page 40

Library Installation

Step 8: Configure the Host

Step 8: Configure the Host

An HP qualified service representative must configure the library on the host.

This procedure includes installing drives, creating device files and verifying

the configuration.

2-14

Page 41

Library Installation

Moving or Shipping the Library

Moving or Shipping the Library

This section explains how to move the library a short distance, such as to

another office or to another floor in the building, and how to ship the library

to another location.

WARNING

CAUTION Do not switch off power to the library until the SCSI bus is inactive.

The library weighs nearly 100 pounds (45 kilograms). To avoid

personal injury and possible damage to the library, at least two

people must move the library.

To move or ship the library:

1. Properly shut down and power off the host.

2. Unmount (unreserve) any tape cartridges in the library if necessary. See

your computer operating system documentation, or software application

documentation for instructions on how to unmount tape cartridges.

3. Verify that all drives in the library are empty:

displays after the drive number if the drive is empty.

displays after the drive number if the drive is full.

If the drives are full, empty them before shipp ing th e library. (For

instructions, refer to the software documentation your host system uses

to manage the library.)

4. Switch off the power switch on the library front panel.

Removing power from a SCSI peripheral when the bus is active can result in

data loss and/or indeterminate bus states. (Check your host system manuals

for information about checking the SCSI bus status.) If your computer is

connected to a LAN, be sure to check with your system administrator before

shutting off power to the library.

Library Installatio n

5. Remove the power cord and the SCSI cable connections from the library

rear panel.

2-15

Page 42

Library Installation

Moving or Shipping the Library

6. If the library is rack mounted:

a. Extend the antitip rail on the rack.

WARNI NG

Failure to extend the antitip rail could result in personal injury

and/or damage to the library if the rack tips over.

b. Slide the library out of the rack so that it is in the full y ex ten d ed

position.

c. Reattach the handles to the side of library using two screws. Make

sure the handle flanges are on top of the slides. (The handles and

hardware for reattaching them should have been saved with the

original shi p pi n g materials. If they are missing, call your service

representativ e for assistance in getting replacemen t handles.)

d. Remove the three 8-32 screws on each side of the library that secure

the library to the rack slides.

7. IMPORTANT — two people needed: With a person on each side of the

library, lift the library onto a cart.

8. Transpo rt th e lib rar y:

• To move the library a short distance, roll the cart to the new location.

• To ship the library, repackage the library in the same materials and

ship it in the same manner in which it was received, then unpack it at

its new destination.

CAUTION The library can be seriou sly damaged if it is not shipped usin g appro p riate

shipping mater ials. A service representative can p rovide assistan ce o r advice

on how to best repackage and ship the library.

9. Re-install the librar y. Refer to install ation st eps 3 through 8 in th is chapte r.

2-16

Page 43

3 Tape Cartridges

3-1

Page 44

Tape Cartridges

Overview

Overview

• Choosing Tape Cartridges

• Labeling Tape Cartridges

• Write-Protecting Tape Cartridges

• Maintaining Tape Cartridges

• Labeling Bulk Load Magazines

3-2

Page 45

Tape Cartridges

Choosing Tape Cartridges

Choosing Tape Cartridges

Two tape cartridges are supported.

Table 3-1 Supported Tape Types

Cartridge Type Available Densities

DLTt ap e IV Data Cartridge 20 GBytes (DLT 4000 drive)

35 GBytes (DLT7000 drive)

DLTtape III XT Data Cartridge 15 GBytes

NOTE Hewlett-Packard rec ommends using the HP DLTtape IV Data Cartridge. (See

Appendix A for ordering information.)

Tape Cartridges

3-3

Page 46

Tape Cartridges

Labeling Tape Cartridges

Labeling Tape Cartridges

Make it a practice to use bar code labels on your tape cartridges. Your host

software may need to keep track of the following information and the

associated bar code:

• date of format or initialization

• cartridge owner (such as group or department)

• storage purpose (such as backup, old version of operating system)

If the host software does not keep track of this information, create a method

of doing so.

Slide the label into th e slot o n the fac e of the car tridge as illustrated in

Figure 3-1.

NOTE If bar code labels are not used and the Barcode On/Off configuration is set to

On, the Inventory Check test perfor mance can b e significantly affected. Thi s

test runs when the library is powered on an d w he ne ver the front access door

is used.

Figure 3-1 Proper Label Positio n

3-4

Page 47

Tape Cartridges

Write-Protecting Tape Cartridges

Write-Protecting Tape Cartridges

The use of the write protect switch ensur es data safety for files that have

been previously wri tten t o the tape and prevents any additional files from

being written to the tape.

To change the write-protect setting,

• Left to

prevent

data from being written to the cartridge. The orange

indicator on the cartridge can be seen when the write-protect switch is in

the “ON” position (see “A” in Figure 3-2).

•Right to

data to be written to the cartr idge. The or ange i ndicator on

allow

the cartridge cannot be seen when the write-protect switch is in the

“OFF” position (see “B” in Figure 3-2).

With the write-protect switch in either position, data can be read from the

cartridge.

Figure 3-2 Write-Protect Button Set tings

Write-Protected

move the write-protect switch:

Tape Cartridges

Not Write-Protected

3-5

Page 48

Tape Cartridges

Maintaining Tape Cartridges

Maintaining Tape Cartridges

Table 3-2 Ta pe Cartridge Maintenance

DO NOT: DO:

• Expose cartridges to magnetic fields.

• Leave cartridges in the tape drive when library

power is off.

• Expose cartridges to extreme temperatures or

extreme humidity. Acceptable operating

temperatures range from 10- 40° C (50-104° F).

Acceptable storage temperatures range from

16-32° C (60-90° F). Accep table operatin g h u midity

ranges from 20-80%; acceptable storage humidity

ranges from 10-95%.

• Expose cartridges to moisture or direct sunlight.

• Dro p the cartridges or carry them in a loose

container that could submit the cartr id ges to any

unnecessary physical shock.

• Open cartridges lid, exposing the tape to possible

contamination or physical damage.

• Touch the tape surface.

• Take cartridges apart.

• Use graphite pencils, water soluble felt pens, or

other debris-producing writing instruments to

label cartridges.

• Store cartridges in a clean, safe

place in their protective plastic

containers when not in use.

• Remove dust on the outside of

cartridges using a damp cloth.

(Older, frequently used tapes may

build up dust.)

• Store cartridges vertically, not flat.

• Store cartridges intended for

archiving data in th eir plastic

containers and in environmental

conditions of 18-28° C (64-82° F)

and 40-60% relati ve h umidity.

• Use labels like th ose include d in the

accessories kit or that meet the

specifications listed in Appendix A,

“Supplies and Accessories”

• Erase a label; replace it instead.

3-6

Page 49

Labeling Bulk Load Magazines

Bulk load magazines can b e labeled in a manner similar to tape cartr id ges.

To label bulk load magazines:

1. Clean the magazine surface with isopropyl alcohol (optional, but

recommended).

2. Remove the adhesive backing from the label pouch.

3. Apply the pouch to the magazine.

4. Slide the label into the pouch.

Figure 3-3 M agaz ine Label Position

Tape Cartridges

Labeling Bulk Load Magazines

Tape Cartridges

3-7

Page 50

Tape Cartridges

Labeling Bulk Load Magazines

3-8

Page 51

4 Library Oper ation

4-1

Page 52

Library Operation

Overview

Overview

• Operating the Control Panel

• Understanding the Display Window

• Entering the Administration Menu Password

• Setting a New Administration Menu Password

• Specifying SCSI Addresses

• Setting Configuration Options

• Retrieving Performan ce In fo rmatio n

• Running an Internal Test

• Using Online Repair

• Loading Cartridges Into the Library

• R emoving Tape Cartridges from the Library

• C leaning the Tape Drives

• C learing a Drive Cleaning Error

• Viewing Cartridge Bar Code Labels

• Troubleshooting

4-2

Page 53

Operating the Control Panel

Figure 4-1 Tape Library Control Panel

1.

Selection buttons

•

•

CANCEL

PREV

cancels the current operation or option.

scrolls the display options backward by one. When held

continuously, the options scroll quickly.

NEXT

•

scrolls the display options forward by one. When held

continuously, the options scroll quickly.

ENTER

•

2.

Activity light

selects the displayed option.

• Steady Green – power is on.

• Flashing Green – a tape cartridge is be in g accessed.

• Amber – fault indicator.

3.

16-Character Display

or drive status.

An asterisk (*) indicates there is a menu beneath the option. Press

to access the menu. Press

4.

Power switch

5.

Door latch

locks/unloc ks door for access to bulk load magazines.

perform the following operations:

indicates the following:

displays information about the current operation

switches power to the unit on and off.

NEXT

or

Operating the Control Panel

PREV

to display the menu options.

Library Operation

ENTER

Library Operation

4-3

Page 54

Library Operation

Understanding the Display Window

Understanding the Display Window

The display window displays drive status indicators and menu options.

Drive Status

Drive status displays when the library is in the “read y” state. For example:

Drive number

Status indicator

Activity indicat or

1 2

In this example:

• Drive 1 has a cartridge inserted and data is being written to the tape.

• Drive 2 has a write-protected cartridge inserted.

P

The library has one or two drives,

depending on the model number.

Status Indic ators

The drive is full.

The drive is empty.

The drive needs to be cleaned .

C

The tape cartridge in th e drive is write-protect ed .

P

Blank – The drive is offline.

Activity Indicat or s

The activity light flashes during the following operations:

Information is being written to the tape in the drive.

Information is bein g read from the tape in the drive.

The tape in the drive is being searched backward or is rewinding.

The tape in the drive is being searched forward.

C

The drive is being cleaned.

4-4

Page 55

Contro l Panel Opt ions

Library Operation

Understanding the Display Window

Press

PREV

or

NEXT

while the library is in the “ready” state to display first

level options. Access second level options from ADMIN* (second level

options require a password; see “Entering the Administration Menu

Password” on page 4-7).

An asterisk (*) indicates that the option has multiple selections.

or

ENTER

to select the option or display

NEXT

to display other available options.

When a menu selection is flashing, press

the option’s selections. Press

PREV

First Level Options

RELEASE DOOR Allows the rear access door to be unlocked.

VIEW BAR

CODES*

Displays the bar code labels on each tape cartridge

by slot number.

ADMIN* Accesses second-level options.

Second Level Options

INFO* Displays performance information stored in the

library.

TEST* Runs internal library tests.

Library Operation

CONFIG* Customizes the way the library functions.

CLEAN DRIVES* Displays the drive numbers to clean.

OVERRIDE DOOR* Opens door when media is in drives.

SCSI IDs* Sets the SCSI addresses for the robotics and the

library drives.

ONLINE REPAIR* De-ac t ivates a drive for replacement.

4-5

Page 56

Library Operation

Understanding the Display Window

Control Panel Menu Tree

Figur e 4-2 Control Panel Menu Options

PREV/NEXT

1 2 ADMIN *

Drive Status Indicators

C

drive needs to be cleaned

tape is write-protected

P

drive is empty

drive is full

(blank) drive is offline

drive is being cleaned

C

↓

drive is writing to tape

drive is reading from tape

searching tape forward

<<

searching tape backward

TEST *

RELEASE DOOR

If the drive(s) are not empty:

ENTER

EMPTY DRIVES NO

PREV/NEXT

EMPTY DRIVES YES

PREV/NEXT

VIEW BAR CODES

###### S LOT 1

###### SLOT 15

PREV/NEXT

CLEAN DRIVES *

ENTER

PREV/NEXT

PREV/NEXT

PSWD 00 0 000 000

(See “Changing the

Administration Password.”)

SCSI IDs *

ENTER

ENTER

INFO * CONFIG *

ENTERENTER ENTER

REVISION

LIB ODOMETERS *

HOURS

MOVES

XLATES

DRIVE LOADS *

DRIVE 1

DRIVE 2

DRIVE FW *

D1 REVISION #

D2 REVISION #

INTERFACE FW *

BUS NUM = #

FAST/WIDE SCSI

8052 REV #

8052 CKSUM #

COBRA REV #

HARD ERRORS *

HARDWARE ERR #

FRU 1-3 #

MOTION <name>

SOURCE #

DESTINATION 1 #

DESTINATION 2 #

ODOMETER #

MICROMOVE 1-6 #

MICROMOVE ER #

SOFT ERRORS *

(same logs available

as under "HARD

ERRORS")

RECOVERY ERRORS *

(same logs available

as under "HARD

ERRORS")

EXERCISE MECH

EXCHANGE DEMO

IO DRI VE

IO MAGAZINE

INVENTORY CHECK

TEST TRANSLATE

TEST VERTICAL

WELLNESS TEST

FIND PLUNGE HOME

FIND VERT HOME

FIND XLATE HOME

INIT MECHANICS

EMPTY DRIVES

EMPTY PICKER

FILL PICKER

REWIND MEDIA

CLEAR SOFT LOG

CLEAR HARD LOG

PLUNGE FULL SPD

PLUNGE 1/2 SPD

SENSOR TRANSLATE

SENSORS MAGAZINE

SENSORS ST ARWARS

VERTICAL ENCODER

ONLINE REPAIR*

ENTER ENTER

DRIVE POWER *

DRV1 PO WER ON/OFF

DRV2 POWER ON/OFF

DRIVE STATUS *

DRV1 ON/ GOOD

OFF/FAILED

DRV2 ON/GOOD

OFF/FAILED

RECOVERY ON/OFF

RESTORE DEFA ULTS

CLEAR ODOMETERS

STARWARS ON/OFF

NEW PASSWORD

SCSI LOG ON/OFF

SECURE ON/ OFF

POWER SECURE

ON/OFF

REP RECO V ERED

ON/OFF

CONF40 ON/OFF

BARCODE ON/OFF

OVERRIDE DOOR *

ENTER

SEL CLEAN CART *

###### SLOT #

or

CLN CART LOC #

CLEAN DRIVE 1

CLEAN DRIVE 2

CLEAN DRIVE ALL

SET IDs *

LIB ID #

DRIVE 1 ID #

DRIVE 2 ID #

UPDATE IDs NOW

VIEW IDs *

LIB ID #

DRIVE 1 ID #

DRIVE 2 ID #

• An asteris k (*) ind icates there are menu choices

below the displayed option.

•Press

•Press

•Press

PREV

ENTER

CANCEL

NEXT

or

to scroll through the menus or options.

to select a menu or option.

to go “up” a level on the menu tree.

4-6

Page 57

Library Operation

Entering the Administration Menu Password

Enterin g the Ad ministration Menu

Password

1 2 ➔ ADMIN* ➔ PSWD 000-000-000 ➔ CONFIG*

A numeric password is required to access options beneath ADMIN* menu of

the library (see Figure 4-2 on page 4- 6). A three-part password of 000-000-000

is set at the factory. To allow only authorized persons to access the library

and change operation settings, the password must be changed.

NOTE To change the password, s ee “Setting a New Administration Menu Password ”

on page 4-8.

Do not forget the password. Only an HP qualified service representative can

reset the security code to the factory setting.

To enter the password:

1. Verify that the drive status displays (if not, press

2. Press

NEXT

until ADMIN* displays, then pres s

ENTER

CANCEL

until it does).

.

3. PSWD 000-000-000 displays, and the first set of zeros flashes.

ENTER

Press

NEXT

or

to accept this number (if no password has been set), or pres s

PREV

until the set number displays. Press

ENTER

.

4. The middle set of zeros flashes.

ENTER

Press

NEXT

or

to accept this number (if no password has been set), or pres s

PREV

until the set number displays. Press

ENTER

.

5. The last set of zeros flashes.

ENTER

Press

NEXT

or

To access options under the ADMIN* menu, press

desired option displays, then press

to accept this number (if no password has been set), or pres s

PREV

until the set number displays. Press

ENTER

.

PREV

ENTER

. INFO* displays.

NEXT

or

until the

Library Operation

4-7

Page 58

Library Operation

Setting a New Administration Menu Password

Setting a New Administration Menu

Password

1 2 ➞ ADMIN* ➞ PSWD 000 000 000 ➞ CONFIG* ➞ NEW PASSWORD

NOTE Do not forget the password. Only an HP qualified service representative can

reset the security code to the factory setting.

To set a new password:

1. Follow the steps on the previous page to enter the existing or factory -set

password.

NEXT

NEXT

NEXT

ENTER

until

or

or

2. Press

3. Press

NEW 000-000-000

4.

Press

press

PREV

PREV

.

CONFIG*

until

displays, then press

NEW PASSWORD

displays, and the first set of zeros flashes.

to display the desired first part of the password, then

ENTER

.

displays, then press

ENTER

.

5. The second set of zeros flashes.

NEXT

Press

then press

PREV

or

ENTER

to display the desired second part of the password,

.

6. The last set of zeros flashes.

NEXT

Press

ENTER

press

PASSWORD CHANGED

7.

or

.

PREV

to display the desired third part of the password, then

displays. Press

CANCEL

three times to return to the

drive status (“ready” state).

NOTE Save the new password to flash ROM by power cycling the library (turning

the library off and then on). This allows the password to be recovered if the

library is powered off for more than ten days.

4-8

Page 59

Library Operation

Specifying SCSI Addre sses

Specifying SCSI Addresses

1 2 ➞ ADMIN* ➞ PSWD 00 000 000 ➞ SCSI IDs

NOTE The tape library has a Fast/Wide SCSI interface. SCSI addresses can be set

from:

• 0 to 7 on a DLT4000-based library

• 0 to 15 on a DLT7000-based library

If connecting to a narrow host, use only addr esses 0 to 7.

Table 4-1 SCSI ID Options

Option Purpose Explained in

SET IDs* Assigns individual SCSI IDs to each

drive and the robotics contr o ller .

VIEW IDs* Displays the current drive and robotics

controller settin gs.

Table 4-2 Default SCSI Address Settings

DEVICE SCSI ID BUS #

LIB 6 Bus 1

DRV 1 5 Bus 1

DRV 2 (two-drive models only) 4 Bus 2

“Setting SCSI Addresses” on

page 4-10

Library Operation

Viewing Current SCSI Addresses”

on page 4-10

4-9

Page 60

Library Operation

Specifying SCSI Addresses

Viewing Current SCSI Address Settings

1 2 ➞ ADMIN* ➞ PSWD 000 000 000 ➞ SCSI IDs ➞ VIEW IDs

To view the current SCSI address settings:

a. Verify that the drive stat us displ ays (if not, press

NEXT

b. Press

until ADMIN* displays, then press

CANCEL

ENTER

until it does).

.

c. Enter the three-part numerical passwor d (see “E ntering the

Administration Menu Password” on page 4-7).

NEXT

d. Press

until SCSI IDs* displays, then press

8. SET IDs* displays. Press

ENTER

.

NEXT

until VIEW IDs* displays, then press

ENTER

.

9. BUS1 LIB ID# or BUS# DRV * ID * displays. (BUS1 LIB ID # stands

for the current SCSI ID of the robotics controller.

BUS# DRV # ID # is the current SCSI ID setting for the displayed dri ve

number and its associated BUS#.)

Press

a. Press

NEXT

CANCEL

PREV

or

to scroll through the current address settings.

until the next operation to perform displays, or until the

drive status (library “ready” state) displays.

Sett i ng SCSI Addr esses

1 2 ➞ ADMIN* ➞ PSWD 000 000 000 ➞ SCSI IDs ➞ SET IDs

A SCSI address is required for the robotics controller and each drive. For

more information, see Table 4-2, “Default SCSI Address Setting” on page 4-9,

and the section “Vi ewi ng Current SCSI Addresses” on page 4-10.

When setting SCSI addresses, note that:

• On bus 1, drive 1 uses one address and the robotics controller uses one

address.

• On bus 2, drive 2 uses one address (two-drive libraries only). If the drives

are daisy-chained, the robotics and each drive use one addres s on the bus.

To change the current SCSI address setting s:

1. Verify that the drive status displays (if not, press

2. Press

NEXT

until ADMIN* displays, then pres s

ENTER

CANCEL

until it does).

.

4-10

Page 61

Specifying SCSI Addre sses

3. Enter the three-part numerical password (see “Entering the

Administration Menu Password” on page 4-7).

Library Operation

NEXT

4. Press

until SCSI IDs* displays, then press

5. SET IDs* displays. Press

ENTER

.

ENTER

.

LIB BUS1 ID # or DRV# BUS# ID # displays. (LIB BUS1 ID # stands

for the current SCSI ID of the robotics controller .

DRV# BUS# ID # is the current SCSI ID setting for the drive number and

its associated bus #.)

6. Press

NEXT

until the setting to change displays, then press

7. The current SCSI address setting flashes. Press

desired address displays, th en pres s

NEXT

8. Press

until UPDATE IDs NOW displays, then press

ENTER

.

NEXT

or

ENTER

PREV

ENTER

.

until the

.

9. WAIT FOR UPDATE displays briefly, then IDs SAVED displays.

• If the new settings do not conflict with other SCSI IDs on the bus,

SCSI IDs* displays.

• If the new settings conflict with other IDs on the SCSI bus, CONFLICT

ABORTED displays briefly, then SET IDs* displays. Any changes

entered are lost, and previous steps must be repeated to set a new

address.

• If any buses are daisy chained together, make sure the SCSI IDs are

different for each devic e on the bus.

• If a serial communications error is detected while trying to set the

SCSI IDs, DRV CONNECT ERR displays, followed by IDs NOT

CHANGED. Any changes entered ar e lo st. The SCSI IDs* menu

displays.

Library Operation

10. Press

CANCEL

three times to return to the drive status (“ready” state) .

11. To save new settings can be saved to flash ROM, turn the library off, then

turn it back on. This allows the settin gs to be recovered if the library is

powered off for more than ten days.

NOTE After changing an address, it may be necessary to reboot the host for the new

SCSI IDs to be recognized.

4-11

Page 62

Library Operation

Specifying SCSI Addresses

Interpreting SCSI Bus Status Indicator LEDs

Each SCSI bus has an LED to indicate the bus status.

Table 4-3 SCSI Status Indicators

Indication Status

Steady green Port active and OK. Internal (on-board) termination

enabled.

Flashing green Port active and OK. Internal (on-b o ard) termination

disabled.

No light Port not active or not configured.

Flashing red Bus mismatch or loss of external termination power.

Flashing yellow Bus offline for online drive replacement.

4-12

Page 63

Library Operation

Loading Cartridges Into the Library

Loading Cartridges Into the Library

Inserting/Removing Cartridges with Software

If the software package requires that cartridges be inserted and removed

using the software, check the softw are documentation before proceeding .

Label all cartridges before inserting them into the magazines. (See “Labeling

Tap e Cartridges” on page 3-4.)

The bar codes and storage slo t lo cations are stored in library me morywhen

the door is closed and the Inventory Check test is automatically run.

Keeping Cartridges in the Magazine

To prevent cartridges from slid in g o ut of the bulk load magazines when

inserting them into the library:

• DO NOT use excessive force when insertin g th e magaz in es. This can

cause the magazine “latching” mechanisms to fail.

Library Operation

• DO NOT insert magazines when the library power is turned off. During

normal library operation, the cartridge release button on top of the

magazine is pushed down by a special mechanism inside the library. This

“unlocks” the cartridges, allowing them to be inserted and removed from

the storage slots as needed. When the control panel RELEASE DOOR

option is enabled, the button on top of the magazine is released, which

“relocks” the cartridges into the magazine slots. During a power failure,

however, this button is not released, and cartridges can slide out of their

storage slots if a magazine is inserted or removed from the library. (If no

magazines are in a library, the special mechanism defaults to the position

that keeps cartridges locked into the magazine storage slot.)

4-13

Page 64

Library Operation

Loading Cartridges Into the Library

Loadin g Tapes

Tapes are bulk loaded into magazines, which are then inserted into the

library through the front access door. The library holds from one to three

5-slot magazines.

To load tapes:

1. Verify that the drive status displays (if not, press

CANCEL

until it does).

2. Verify that all drives in the library are empty (see the n ote below).

displays after the drive number if the drive is empty.

displays after the drive number if the drive is full.

3. Press

4. Press

NEXT

ENTER

PREV

or

until RELEASE DOOR displays .

. DOOR RELEASED displays. (See the note below. If an error

message displays, see “Resolving Other Problems” on page 4-43.)

NOTE The drive(s) must be empty before the access door can be released. If the

drive(s) are not empty, EMPTY DRIVES NO displays. Pre s s

until EMPTY DRIVES YES displays, then press

ENTER

.

NEXT

or

PREV

NOTE Some security configurations may prevent the access door from being

released. If a security option is enabled, SECURITY ENABLED displays after

the RELEASE DOOR option is chosen.

In some situations it may be necessary to override a security option and open

the access door . To open the acces s door when a secur ity option p revents the

door from being released, use the OVERRIDE DOOR option under the

ADMIN* menu (see Figure 4-2 on page 4-6) .

5. Unlock the access door using the key.

4-14

Page 65

Loading Cartridges Into the Library

6. Open the access door by pulling the top of the door outward.

NOTE Do not let the door fall open. The door straps may be damaged.

Figure 4-3 Opening the Front Acc ess D oor

7. Insert up to five tape cartridges into a magazine so that the tape brand

name printed on the top of the cartridge is facing up and the tape label is

facing out. The tapes should “click” into place.

Library Operation

Library Operation

Figure 4-4 Loading Tape Cartridges into the Magazine

4-15

Page 66

Library Operation

Loading Cartridges Into the Library

8. Insert the magazine so it lines up with the arrow on the label inside the

library, the handle is facin g the front of the library , and the tapes are

facing the inside of the tape library. The magazine should “click” into

place.

Figure 4-5 Inserting Magazines

9. Shut and lock the access door using the key lock. Make sure the door is

shut completely.

NOTE The library Inventory Check test runs when the access door is closed so that

an inventory of tape bar code labels and storage slot locations can be stored

into library memory. This process takes about one minute. The test fails if the

door is not completely shut.

WARNING

Do not attempt to disable the interlocks. If the library is operating

with fewer than thr ee magazin es inserted a nd the door open , the user

can be exposed to Class II laser light emitted from the bar code

reader.

4-16

Page 67

Library Operation

Removing Tape Cartridges from the Library

Removing Tape Cartridges from the Library

Some software package s re qu ire that tape cartridges be inserted and

removed using the software. If a softwar e pac ka ge manages files in the

library, check the software documentation before proceeding.

All drives must be empty before the access door can be rele ased. In additi on,

some security configurations may prevent the access door from being

released. If a security option is enabled, SECURITY ENABLED displays after

the RELEASE DOOR option is chosen.

To remove magazines from the library:

1. Verify that the drive status displays (if not, press

CANCEL

until it does).

2. Verify that all drives in the library are empty;

displays after the drive number if the drive is empty

displays after the drive number if the drive is full

3. Press

4. Press

NEXT

ENTER

PREV

or

until RELEASE DOOR displays .

. DOOR RELEASED displays. (See the following note. If an

error message displa ys, see “ Resolving Other Problems” on page 4-43.)

NOTE The drive(s) must be empty before the access door can be released. If the

drive(s) are not empty, EMPTY DRIVE NO displays. Press

EMPTY DRIVE YES display, then press

ENTER

.

NEXT

or

PREV

until

Some security configurations may prevent the access door from being

released. If a security option is enabled, SECURITY ENABLED displays after

the RELEASE DOOR option is chosen.

In some situations it may be necessary to override a security option and open

the access door . To open the acces s door when a secur ity option p revents the

door from being released, use the OVERRIDE DOOR option under the ADMIN*

menu (see Figure 4-2 on page 4-6).

Library Operation

4-17

Page 68

Library Operation

Removing Tape Cartridges from the Library

5. Unlock the access door using the key, then open the door.

NOTE Do not let the door fall open. Damage to the door straps may occur.

Figure 4-6 Opening the Front Acc ess D oor

6. Remove the desired magazine by pushing the button at the top of the

magazine handle (see Figure 4-7) and pulling out the magazine.

Figure 4-7 Removing Ma gazines

7. If necessary, remove tapes from the magazine. Press the button on top of

the magazine, then pull out the tape.

4-18

Page 69

Library Operation

Removing Tape Cartridges from the Library

WARNING

Do not attempt to disable the interlocks. If the library is operating

with fewer than thr ee magazin es inserted a nd the door open , the user

can be exposed to Class II laser light emitted from the bar code

reader.

8. Shut and lock the access door using the key lock. Make sure the door is

shut completely.

NOTE The library Inventory Check test runs when the access door is completely

closed so that an inventory of tape bar code labels and storage slot locations

can be stored into library memory. This process takes about one minute.

Library Operation

4-19

Page 70

Library Operation

Viewing Cartridge Bar Code Labels

Viewing Cartridge Bar Code Labels

Bar code label information can be viewed for each tape cartridge in the

library us in g the control panel. Bar co d e information displays sequentially by

storage slot number.

To view bar code information:

1. Verify that the drive status displays (if not, press

NEXT

2. Press

until VIEW BAR CODES* displays, then press

CANCEL

until it does).

ENTER

.

###### SLOT # displays. (“######” represents the bar code

information, and “#” represents the first storage slot that contain s a bar

coded tape cartridge.)

NOTE If there are no bar coded tape cartridges in the lib r ary , LIBRARY EMPTY

displays briefly, then VIEW BAR CODES* displays. Press

CANCEL

to return to

the drive status indic ato r s (“read y” state).

3. Press

NEXT

or

PREV

to scroll through the storage slot locations that

contain bar coded tape cartridges.

4. Press

CANCEL

twice to re tu rn to the drive st atu s indicators ( “read y” state).

4-20

Page 71

Cleaning the Tape Drives

1 2 ➞ ADMIN* ➞ PSWD 000 000 000 ➞ CLEAN DRIVES*

Cleaning the drives , which tak es about 5 minutes per drive, requ ires a special

digital linear tape cleaning cartridge. (T yp ically, cleaning cartridges are light

yellow and data cartridges are black, brown, or white . See Ap pe ndix A for a

list of supplies.)

The drive mechanisms do not require scheduled cleanings and should be

cleaned only if a “clean drive” status indicator ( ) displays after the drive

number.

If the cleaning car tridge needs to be r eplaced, REPLACE CLEANING di spl ays,

and the cleaning cartrid ge ejects through the mailslot.

NOTE The software package may manage drive cleaning.

C

Library Operation

Cleaning the Tape Drives

To clean one or more of the dr ives:

1. Verify that the drive status displays (if not, press

CANCEL

until it does).

2. Make sure all drives are empty ( displays after the drive number). To

empty the drives, refer to the documentation for the software package.

3. Press

NEXT

until ADMIN* displays, then pres s

ENTER

.

4. Enter the three-part numerical password (see “Entering the

Administration Menu Password” on page 4-7).

NEXT

5. INFO* displays. Press

ENTER

.

until CLEAN DRIVES* displays, then press

• If the library power has been turned off or the access door has been

opened since a cleaning car tridge location was las t selected, SET

CLEAN CART* displays. Pre ss

ENTER

.

• If the library power h as not been turned off or the access door has no t

been opened since a cl eaning c artridge loca tion was last s elected, CLN

CART LOC # displays (the number of the cleaning cartridge storage

slot last selected is flashing.) If the storage slot location is correct,

ENTER

press

. To select a different storage slot lo cation, press

until the correct st orage slot location displays, the press

ENTER

NEXT

.

Library Operation

4-21

Page 72

Library Operation

Cleaning the Tape Drives

###### SLOT # displays (“##### #” is a barcode number or is blank if

barcodes are not being used, and the storage slot location number is

or

ENTER

to select the displayed storage slot location or

PREV

to select a different storage slot lo cation, then press

NEXT

until the drive number to clean

ENTER

.

flashing). Press

NEXT

press

ENTER

.

6. CLEAN DRIVE 1 displays. Press

displays, then press

To clean both drives, press

displays, then press

ENTER

NEXT

.

or

PREV

until CLEAN DRIVE ALL

NOTE If the drives are not empty, a DRIVE FULL message displays, and the drives

must be emptied before they can be cleaned.

If the slot location chosen in Step 4 did not contain a cleani ng cartridg e, NOT

CLEAN CART displays briefly , then CLEAN FAIL # displays. Press

CANCEL

to twice to return to the “ready” state. Ch eck th e bulk load magazines in the

library to locate the cleaning cartridge. If no cleaning cartridge is present,

insert one into an avai lab le slot.

In the event of a driv e error, such as a seri al communicati ons fai lur e, FAILED

displays and the CLEAN DRIVES* menu displays.

CLEANING DRV # displays (# is the number of the drive being cleaned).

When the drive has been clean ed, CLEANED DRV # displays briefly, then

CLEAN DRIVES* is again displayed.

NOTE If the software package controls drive cleaning, the drive status indicator

C

displays after the dri ve numbe r(s) being cleaned and the activity indi cato r

flashes until the drive( s) are clean.

NOTE Cleaning takes about five minutes per drive.

7. Press

CANCEL

until the next operation to perform displays, or until the

drive status indicators (library “ready” state) are displayed.

4-22

Page 73

Drive Cleaning Issues

Library Operation

Cleaning the Tape Drives