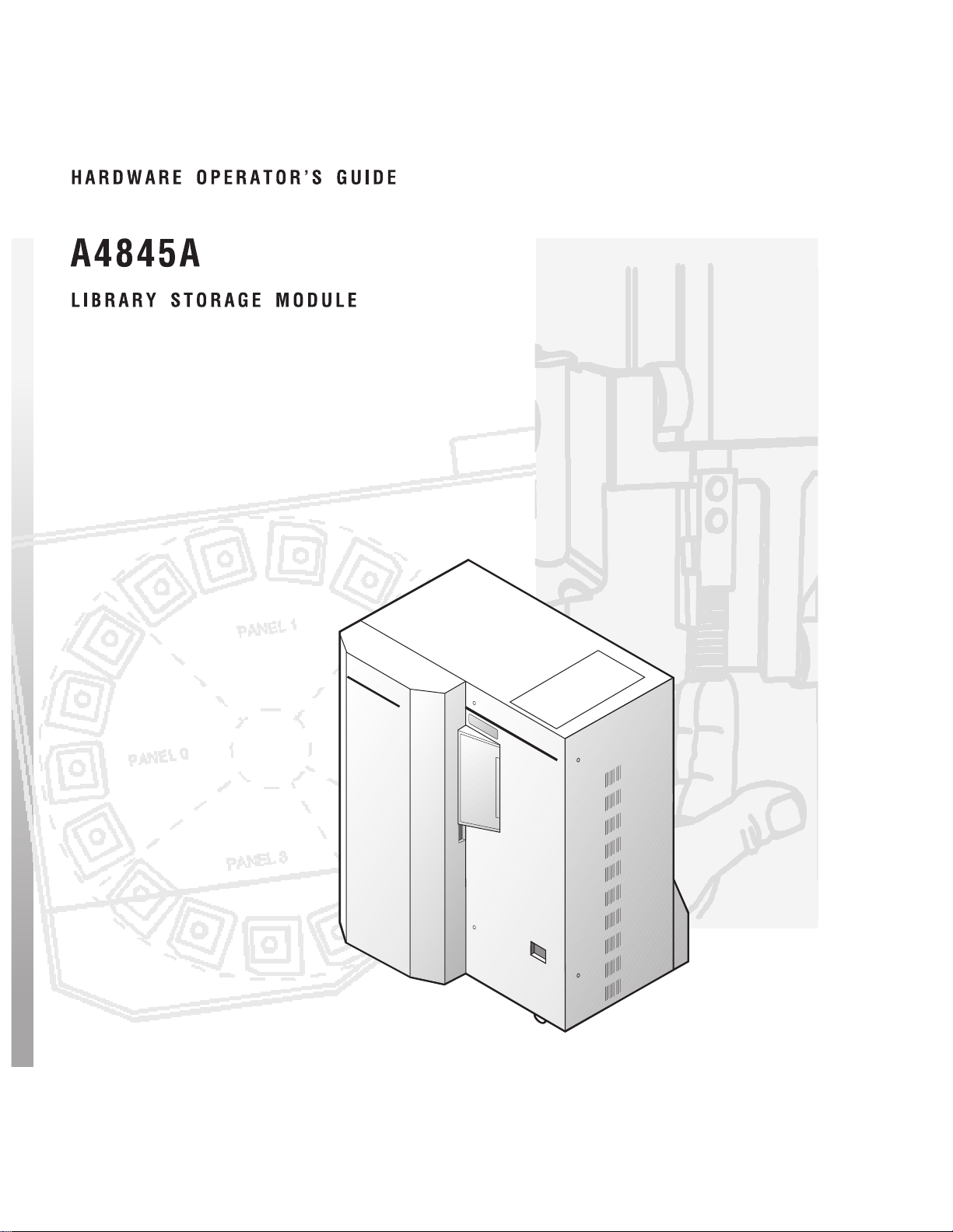

Page 1

StorageTek

Page 2

Page 3

Page 4

Printing History

New editions of this guide incorporate all material updated since the previous edition.

The manual printing date and part number indicate the current edition. The printing

date changes when a new edition is printed. (Minor corrections and updates

incorporated at reprint do not cause the date to change.)

1 November 1997 Edition 1

23 February 1998 Edition 2

15 May 1999 Edition 3

© 1997 through 1999 by Storage Technology Corporation and Hewlett-Packard Company. All rights reserved.

ii

Page 5

List of Pages

Document Title: A4845A LSM Hardware Operator’s Guide

Manufacturing Doc PN: A4845-96014

Customer Doc PN: A4845-90000

Vendor PN: 95762

Edition 1: 1 November 1997, EC 83907

Edition 2: 23 February 1998, EC 83963, KIT PN 80967

Edition 3: 15 May 1999, EC 53855, KIT PN 14691

This document contains 92 pages:

Section Disposition

Cover Replace

Blank Page entire

Title Page guide

Copyright

iii through xxii

1-1 through 1-10

2-1 through 2-10

3-1 through 3-22

4-1 through 4-8

A-1 through A-10

Glossary-1 through Glossary-2

Index-1 through Index-4

Reader’s Comment Form

Business Reply Mailer

Blank Page

Back Cover

iii

Page 6

List of Pages

This page intentionally left blank.

iv

Page 7

Regulatory Statements

Regulatory Statements

■ FCC Radio Frequency Interference Statement

(USA)

Note: This equipment generates, uses and can radiate radio frequency energy.

If it is not installed and used in accordance with the instruction manual,

it may cause interference to radio communications. It has been tested

and found to comply with the limits for a Class A computing device

pursuant to Part 15 of FCC rules, which are designed to provide

reasonable protection against interference when operated in a

commercial environment. Operation of this equipment in a residential

area is likely to cause interference, in which case the user, at his own

expense, will be required to take whatever measures necessary to

correct the interference.

Hewlett-Packard’s device certification tests were conducted with HP

computer systems and HP shielded cables, such as those received with

your product. Changes or modifications not expressly approved by

Hewlett-Packard could void the user’s authority to operate the

equipment. Cables used with this device must be properly shielded to

comply with the requirements of the FCC.

■ IEC Statement (Worldwide)

Note: This is a Class A product. In a domestic environment, this product may cause

radio interference, in which case the user may be required to take adequate

measures.

■ EMC Statement (Canada)

Note: This Class A digital apparatus meets all requirement of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du

Réglement sur le matériel brouelleur du Canada.

■ General Approval (U.K.)

Note: The Hewlett-Packard A4845A DLT Library is approved under approval

number NS/G/1234/J/100003 for indirect connection to Public

Telecommunication Systems in the U.K.

v

Page 8

Regulatory Statements

■ Herstellerbescheinigung (Germany)

Note: Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärm information sverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp # 70 dB(A)

• Am Arbeitsplatz

• Normaler Betrieb

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung)

■ VCCI Class A (Japan)

Note: This equipment is in the Class A category information technology

equipment based on the rules of Voluntary Control Council For

Interference by Information Technology Equipment (VCCI). When used

in a residential area, radio interference may be caused. In this case, user

may be required to take appropriate corrective actions.

Consequently, when used in residential area or in an adjacent area thereto,

radio interference may be caused to radios and TV receivers, etc. Read the

instructions for correct handling.

vi

Page 9

■ Harmonics Conformance (Japan)

This product conforms Power Line Harmonics guidelines for the User’s manual

display. No product labeling required for JAPAN.

■ Taiwan Warning Label Statement

The following is the warning label statement from Taiwan, R.O.C.:

Regulatory Statements

vii

Page 10

Regulatory Statements

■ European Compliance Statement

The following is the compliance statement from Europe:

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:Hewlett-P ackard Company

Enterprise Storage Solutions Division

Manufacturer’s Address:8000 Foothill s Blvd.

Roseville, CA 95747

USA

declares, that the product

Product Name: Automated Tape Library Model 10/588 or

HP SureStore E Tape Library 10/588

Order Number:A4845A

Product Options:all

conforms to the following Product Specifications:

Safety: IEC 950:1991 + A1, A2, A3, A4 / EN 60950:1992 + A1, A2, A3, A4

GB 4943-1 995

IEC 825-1:1993 / EN 60825-1:1993, Class 1

EMC: CISPR 22:1993 +A1, A2 / EN 55022:1994+A1, A2 - Class A

GB 9254-1 988

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992,4 kV CD, 8 kV AD

IEC 801-3:1984 / prEN 55024-3:1991,3 V/m

IEC 801-4:1988 / prEN 55024-4:1993,0.5 kV Signal Lines

1 kV Power Lines

IEC 1000-3-2:1995 / EN 61000-3-2:1995, Class D, Harmonics

IEC 1000-3-3:1994 / EN 61000-3-3:1995, Flicker

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage

Directive 73/23/EEC and the EMC Directive 89/336/EEC and carries the CE

marking accordingly.

The Product was tested in a typical configuration with multiple PC based SCSI

emulators.

1

Roseville, April 8, 1999

European Contact: Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department HQ-TRE, Herrenberger Straße 130, D-71034 Böblingen (FAX: + 49-7031-14-3143)

viii

Page 11

Contents

List of Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Regulatory Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

FCC Radio Frequency Interference Statement (USA) . . . . . . . . . . . . . . . . . . . . . . . . . v

IEC Statement (Worldwide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

EMC Statement (Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

General Approval (U.K.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Herstellerbescheinigung (Germany) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

VCCI Class A (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Harmonics Conformance (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Taiwan Warning Label Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

European Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Important Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Internal Code License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Library Storage Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Storage Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Cartridge Access Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

ix

Page 12

Contents

Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

LSM Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Controlling Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Library Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Automated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

AUTO CLEAN Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Controls, Indicators, and Configuration . . . . . . . . . . . . . . . . . . 2-1

LSM Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setting the SCSI Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Setting Cleaning Cartridge Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Operating the LSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering On or IPLing the LSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering Off the LSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Operating in Automated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Entering Cartridges through the CAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Ejecting Cartridges through the CAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Replacing the Cleaning Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Operating in Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Opening the LSM Front Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Moving the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Locating a Cartridge in the Storage Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Removing a Cartridge from the Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Mounting a DLT Cartridge into a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Mounting a Cartridge into a 9840 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Dismounting a Cartridge from a DLT Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Dismounting a Cartridge from a 9840 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Returning the LSM to Online Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preparing Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Handling a Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Inspecting a Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Applying DLT Cartridge Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Applying 9840 Cartridge Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Setting the DLT Write-Protect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Setting the 9840 Write-Protect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

x

Page 13

Contents

Maintaining Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Storing Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Cleaning the Cartridge Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Ordering DLT Cartridge Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Basic Requirements for Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

DLT Cartridge Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

9840 Cartridge Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

LSM Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Agency Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

xi

Page 14

Contents

This page intentionally left blank.

xii

Page 15

Figures

Figures

Figure 1-1. LSM Major External Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Figure 1-2. Robot Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Figure 1-3. Locating Cartridges—Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Figure 1-4. Locating Cartridge-Panels, Columns, Cells, Rows . . . . . . . . . . . . . . . . . . . . .1-6

Figure 2-1. LSM Operator Panel Softkeys, Indicators, and Display . . . . . . . . . . . . . . . . .2-2

Figure 2-2. Symbol Definitions for Menu Block Diagram . . . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-3. Setting the SCSI Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Figure 2-4. Setting the Cleaning Cartridge Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Figure 2-5. Power Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 3-1. DLT Handle Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Figure 3-2. Entering DLT or 9840 Cartridges through the Cartridge Access Port . . . . . . .3-4

Figure 3-3. Opening Access Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Figure 3-4. Raising and Lowering the Z Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Figure 3-5. Rotating the Z Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Figure 3-6. Locating Cartridges—Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-7. Locating Cartridges—Panels, Cells, Rows, Cells . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-8. Diagnostic and Cleaning Cartridge Cell Locations . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-9. Extending the Gripper Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Figure 3-10. Removing a Cartridge from the Hand . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Figure 3-11. DLT Handle Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Figure 3-12. Inserting a DLT Cartridge into a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Figure 3-13. Mounting a Cartridge into the 9840 Drive . . . . . . . . . . . . . . . . . . . . . . . .3-21

Figure 4-1. Inspecting a DLT Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Figure 4-2. Inspecting a 9840 Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Figure 4-3. Applying DLT Cartridge Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Figure 4-4. Applying 9840 Cartridge labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Figure 4-5. Setting the DLT Write-Protect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Figure 4-6. Setting the 9840 Write-Protect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

xiii

Page 16

Figures

This page intentionally left blank.

xiv

Page 17

Tables

Table 1-1. LSM Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Table A-1. Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table A-2. EDP DLT Cartridge Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-3. Basic Requirements for DLT Cartridges. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-4. 9840 Cartridge Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-5. DLT Cartridge Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . A-6

Table A-6. 9840 Cartridge Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . A-7

Table A-7. LSM Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Table A-8. LSM Main Power Distriution Unit Specifications . . . . . . . . . . . . . . . . . . . . . A-8

Table A-9. LSM Second Power Distribuition Unit Requirements . . . . . . . . . . . . . . . . . . A-9

Table A-10. LSM Environmental Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Table A-11. Agency Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

xv

Page 18

Tables

This page intentionally left blank.

xvi

Page 19

About This Guide

This guide describes how to operate the A4845A Library Storage Module (LSM).

Most of the information pertains to hardware. For LSM management software

information and drive information, refer to the publications that pertain to these

specific topics.

This guide is intended primarily for data center operators who operate the LSM.

System programmers and computer system administrators might also find the

information in this guide useful.

■ Organization

This guide has four chapters and one appendix:

Chapter 1 “General Information” describes the LSM hardware.

Chapter 2 “Controls, Indicators, and Configuration” shows the locations of

the power switch and operator panel, and describes the

functions of the softkeys, indicators, and display. This chapter

also shows how to set the SCSI robotic address and maximum

usage count for the cleaning cartridge.

Chapter 3 “Operating the LSM” contains the procedures to operate the

LSM. The procedures include how to power on and power off

the units, perform automated operations (enter and eject a

cartridge through the cartridge access port), and perform manual

operations (mount and dismount cartridges).

Chapter 4 “Cartridges” describes how to prepare, inspect, store, and clean

cartridges.

Appendix A “Specifications” lists basic supplies and accessories,

specifications, and agency certifications.

A glossary of relevant terms and acronyms and an index are located after the

appendix. A Reader Comment Form at the back of the guide is for

communicating suggestions or requests for change. We encourage and

appreciate reader feedback.

xvii

Page 20

About This Guide

■ Important Messages

This guide contains important messages that must be read carefully and

followed:

Note A note calls attention to information that can be helpful in

understanding the operation of the product. A note usually, but

not always, follows the information to which it relates.

CAUTION A caution calls attention to an operating procedure or practice

that could result in damage to the product if not correctly

performed. Do not proceed beyond this caution until you fully

understand and meet the indicated conditions. A caution

usually precedes the information to which it relates.

WARNING A warning calls attention to a procedure or practice that could

result in personal injury if not correctly performed. Do not

proceed beyond this warning until you fully understand and

meet the indicated conditions. A warning always precedes the

information to which it relates.

■ Related Publications

The following list contains the names and order numbers of publications that

provide additional information about the LSM, the cartridge subsystems, and

cartridge tapes.

Name Product Number

Quantum DLT 7000 Tape Drive Product Manual KT-TH6XB-EW

Quantum DLT 4000 Tape Drive Product Manual KT-TH5XA-TE

9840 Tape Drive User’s Reference Manual 95739

■ Servicing

Any servicing, adjustment, maintenance or repair must be performed only by

authorized service-trained personnel.

■ Warranty

If you have any questions about the warranty for this product, contact your

dealer or your local Hewlett-Packard sales representative.

xviii

Page 21

■ Grounding

The computer in which this product is installed is a safety class I product and

has a protective earthing terminal. There must be an uninterruptible safety earth

ground from the main power source to the product’s input wiring terminals,

power cord or supplied power cord set. Whenever it is likely that the protection

has been impaired, disconnect the power cord until the ground has been

restored.

About This Guide

xix

Page 22

About This Guide

■ Internal Code License

The following is the internal code license from StorageTek:

xx

Page 23

About This Guide

xxi

Page 24

About This Guide

This page intentionally left blank.

xxii

Page 25

General Information

This chapter describes the hardware components of the A4845A Library Storage

Module (LSM). For LSM management software information and drive

information, refer to the publications that pertain to these specific topics.

The LSM is the hardware component in an automated cartridge system. An

automated cartridge system is a removable media, robotic system that mounts

cartridges into a storage cell or into a drive for read/write operations. Figure 1-1

and Figure 1-2 show the major components of an LSM, described in the

following pages.

■ Library Storage Module Components

The LSM has four major, internal components:

• A robot

• Storage cells for 224 to 588 cartridges

• A cartridge access port (CAP) that holds up to 14 cartridges

• Drives

1

Robot

The robot moves cartridges between storage cells and drives when the LSM

management software makes a request to move cartridges. The robot consists

mainly of the Z column assembly and the hand. Figure 1-2 shows the robot

components.

The Z column assembly contains a Z column and Z carriage. The Z column

attaches to the floor and ceiling of the LSM. The Z column rotates almost 360

degrees to allow access to all the cells in the LSM.

The hand mounts to the Z carriage. The Z carriage moves the hand vertically up

and down the Z column to storage cells, drives, or the CAP.

A camera located on the hand reads the cartridge volume serial numbers

(VOLSERs) during audits, but is not used to locate cartridges during robotic

moves. The camera does not read the VOLSERs of cartridges in the drives. If

you manually replace a cartridge in a drive, the host memory will retain the

previous VOLSER. You must request a host update using the LSM management

software to add the information to the host memory.

1-1

Page 26

Library Storage Module Components

Figure 1-1. LSM Major External Components

OPERATOR

PANEL

CARTRIDGE

ACCESS

PORT

(CAP)

DOOR

LATCHES

EXPANSION

DOOR

(OPTIONAL)

RIGHT

FRONT

DOOR

POWER

SWITCH

LOCATION

An audit occurs when:

• You power on the LSM.

• You open and close an LSM door.

• You perform an initial program load (IPL) on the LSM.

• You make a request using the LSM management software.

DRIVES

(INSIDE

LSM)

H_C60022

1-2

Page 27

Figure 1-2. Robot Components

CAMERA

HAND

Library Storage Module Components

Z MOTOR

THETA

MOTOR

Z CARRIAGE

Z COLUMN

H_C60183

1-3

Page 28

Library Storage Module Components

Storage Cells

The LSM is configured by panel, column, row, and cell, so that the LSM

management software can locate a cartridge. The LSM contains storage cells for

224 to 588 cartridges, excluding the CAP cells. The number of cells is

determined by the number of drives installed and whether the LSM has the

standard left front door or the expansion door. The expansion door provides

additional storage space for 168 cartridges. Arrays can be installed above the

drives if fewer than 10 drives are installed.

Cartridges are stored in cell arrays that hold 14 cartridges. The cell arrays are

stacked in columns and the columns are arranged in a circle around the robot

assembly. Each column can hold 42 cartridges.

Table 1-1 lists LSM storage cell capacities. Figure 1-3 and Figure 1-4 show cell

locations for an LSM with the base unit, expansion door, and maximum number

of drives installed.

Note: The two cells located next to drive 4 are designated cleaning cartridge

cells if you have the AUTO CLEAN feature enabled. as described in

“AUTO CLEAN Feature” at the end of this chapter. If you do not, you

must leave those cells empty. You can use the View Config section of

Figure 2-4 in Chapter 2 to determine whether the feature is enabled.

The array targets are used for robotic calibration during IPL.

The drive and CAP locations are not used to store cartridges.

If the LSM loses power while the hand contains a cartridge, the hand

will place the cartridge into the empty/dropoff cell.

Table 1-1. LSM Capacity

Expansion

Door, Panel 3

Yes 0,1,2,3 1 to 3 2 588

No 0,1,2 1 to 3 2 420

Panels

Available

1,2 1 to 3 2 252

Drives

Installed

4 to 6 1 574

7 to 10 0 560

4 to 6 1 406

7 to 10 0 392

4 to 6 1 238

7 to 10 0 224

14-Pack Arrays

above drives

Total

Cartridges

1-4

Page 29

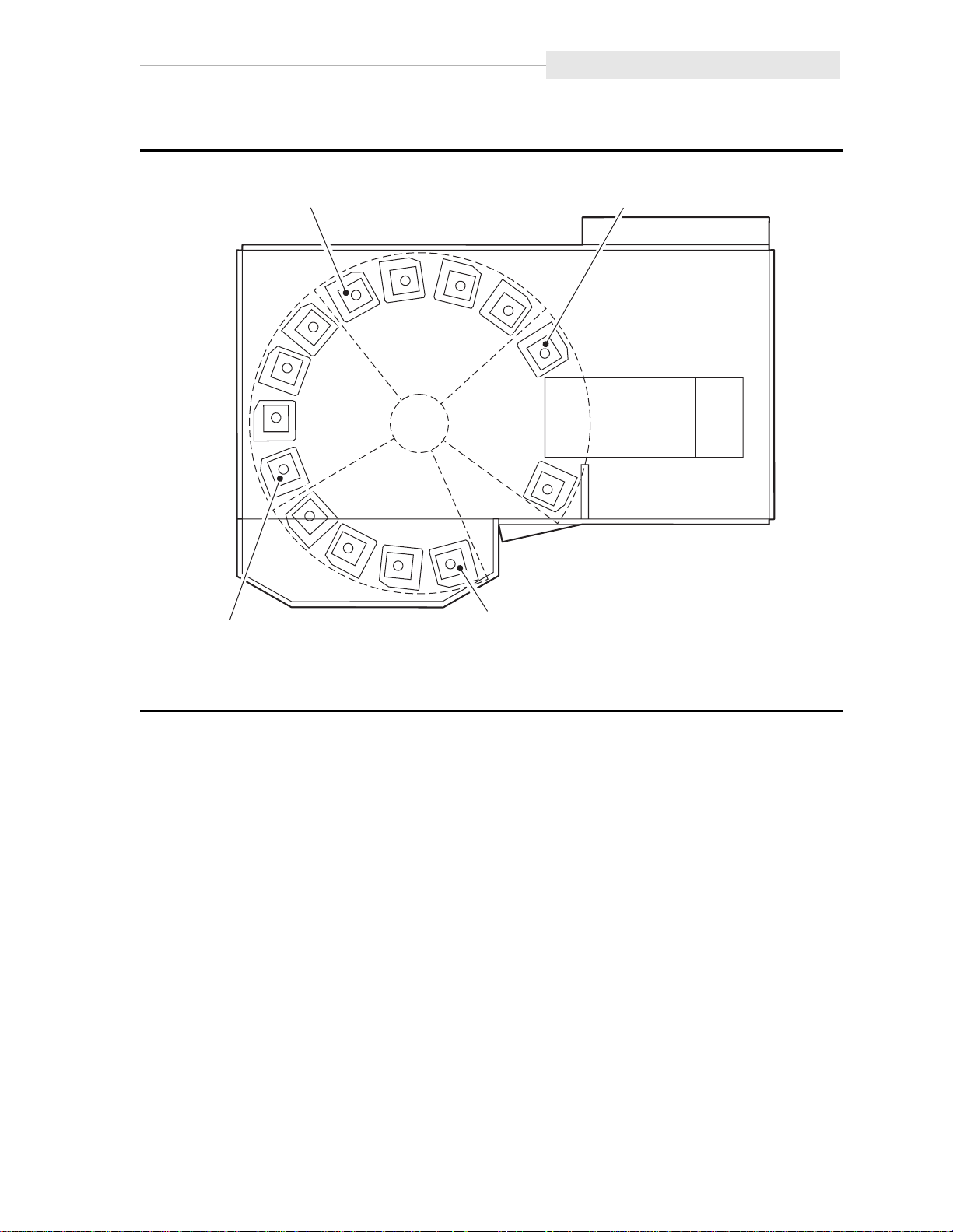

Figure 1-3. Locating Cartridges—Top View

Library Storage Module Components

COLUMN 0

COLUMN 0

PANEL 0

COLUMN 0

PANEL 1

PANEL 2

PANEL 3

COLUMN 0

LSM WITH EXPANSION DOOR

H_C60035

1-5

Page 30

Library Storage Module Components

Figure 1-4. Locating Cartridge-Panels, Columns, Cells, Rows

PANEL 2

COLUMNS

PANEL 1

COLUMNS

0

2

1

DRIVE 9

0

00

3

2

00

1

0

0

0

3

T

DRIVE 8

13

DRIVE 7

CAP

FOR

AREA

RESERVED

DRIVE 6

LATCH

ASSEMBLY

DRIVE 5

23

DRIVE 4

T

DRIVE 3

DRIVE 2

T

DRIVE 1

41

DRIVE 0

41 41

41 41

41

41

14

ARRAY TARGET

(USED FOR

T =

56 CELLS

42 42

42

168 CELLS

42

NOT A STORAGE CELL

CLEANING CARTRIDGE CELL

42

42

H_C60148

ROBOTIC

CALIBRATION)

EMPTY/DROPOFF CELL

DIAGNOSTIC CARTRIDGE CELL

CAP CELLS

2

PANEL 0

COLUMNS

1

0

3

2

PANEL 3

COLUMNS

1

(EXPANSION)

0

000

0

000

TTTT TTTTTTT T

T

TTTTTTTTTTTT T

TTTTTTTTTTTT T

42

168 CELLS

42

41 41 41

42

14 560

41

CAP TOTAL

42

41

42

EXPANSION

4141

42

42

168 CELLS

392 168

BASEDRIVES

CUSTOMER CARTRIDGE CAPACITY CHART

10

1-6

Page 31

Cartridge Access Port

A CAP is the location where you add cartridges to or remove cartridges from an

LSM without interrupting normal cartridge mounts and dismounts by the robot

assembly. The CAP is located on the right front door.

The CAP array can remain in place so that you can insert cartridges into or

remove cartridges from the individual cells. Or, you can remove the top screw

from the array, lift the array out, load all the cells, and slide the array back into

the CAP.

For detailed procedures, refer to “Entering Cartridges through the CAP” and

“Operating the LSM” in Chapter 3, “Operating the LSM.”

Drives

The cartridge is placed into the drive for data read or write operations. The

A4845A can contain three types of drives: DLT4000, DLT7000 and 9840.

Multiple drive types are not allowed in a single library.

The maximum number of drives is ten. The drives are numbered 0 to 9, with 0

at the bottom.

LSM Safety Features

Note: Some software might number the drives from 1 to 10.

For specific drive information, refer to your drive publications.

■ LSM Safety Features

Safety features are incorporated into the LSM. If the front doors to the LSM are

opened, electrical interlocks remove power from the robot assembly.

Behind the right front door, covers are placed over the card and the power

distribution units (PDUs) to prevent you from coming into contact with the

hazardous voltages and sensitive electronics.

■ Controlling Software

Controlling software, within the customer server, requests tape read/write

operations to the drives and robotic move operations for the LSM robotic

components. The software determines where the cartridge is located by

tracking the VOLSER and cell location during audits, then allocates which drive

receives the cartridge. For specific information, refer to your software

publications.

1-7

Page 32

Library Operating Modes

■ Library Operating Modes

An operating mode is the way in which an LSM and the controlling software

(also referred to as the LSM management software) interact. An LSM can operate

in either automated mode or manual mode, as described in the subsections

below.

Automated Mode

Automated mode is the normal operating mode of the LSM. The controlling

software instructs the robot to move the cartridge among the storage cells,

drives, and CAP. The operator tasks include:

• Monitoring the LSM operator display for messages

• Entering a cartridge through the CAP

• Ejecting a cartridge through the CAP

• Replacing a cleaning cartridge

Refer to Chapter 3 for the procedures.

Manual Mode

Manual mode occurs when the LSM right front door is opened to allow operator

intervention. The operator tasks include:

• Moving the robot

• Locating a cartridge

• Removing a cartridge from the hand

• Mounting a cartridge into a drive

• Dismounting a cartridge from a drive

• Returning the LSM to automated mode

Refer to Chapter 3 for the procedures.

■ AUTO CLEAN Feature

Drives might occasionally need to be cleaned to prevent read/write errors.

When your LSM is configured during installation, the AUTO CLEAN feature can

be enabled. You can use the View Config section of Figure 2-4 in Chapter 2 to

determine whether the feature is enabled. If it is, then when a drive needs

cleaning, the robot will receive a software message telling it to retrieve the

cleaning cartridge from the cleaning cartridge cell in the LSM and place it into

the drive.

If AUTO CLEAN is not enabled, you must periodically look at the lights on the

drive. When the Use Cleaning Cartridge light is on, you must place a cleaning

cartridge into the drive.

1-8

Page 33

AUTO CLEAN Feature

Refer to “Setting Cleaning Cartridge Count” in Chapter 2 and “Replacing the

Cleaning Cartridge” in Chapter 3 for more information and procedures.

1-9

Page 34

AUTO CLEAN Feature

This page intentionally left blank.

1-10

Page 35

Controls, Indicators, and Configuration

This chapter shows the locations and describes the functions of the library

storage module (LSM) operator panel and the power switch. It also shows how

to set the Small Computer Systems Interface (SCSI) address and the maximum

usage count of the cleaning cartridges. Refer to the drive publications for

information about operating the drives.

■ LSM Operator Panel

The LSM operator panel is on the right front door of the LSM. The panel

contains softkeys and indicators, plus a two-line display. The LSM operator

panel shows LSM status, configuration, test sequences, and error information.

Figure 2-1 shows the panel and describes each item.

You use this panel to:

• Resolve machine problems.

If an error occurs, the display shows a fault symptom code (FSC) that you

can give to the customer engineer to help resolve problems. Write down the

FSC as soon as it is displayed.

2

• Receive instructions to close the door or cartridge access port (CAP).

• Set the SCSI robotic address.

• Set the maximum usage count of the cleaning cartridge.

2-1

Page 36

LSM Operator Panel

Figure 2-1. LSM Operator Panel Softkeys, Indicators, and Display

2-2

Page 37

■ Setting the SCSI Address

You set the SCSI robotic address from the LSM operator panel. You might need

to get the address from your systems administrator.

Refer to Figure 2-2 and Figure 2-3 to set the SCSI address.

Note: You cannot set the SCSI drive addresses from the LSM operator panel.

For DLT drives, your customer representative uses the switches on the

drive to set the SCSI drive addresses, as described in the installation

manual. For 9840 drives, SCSI drive addresses are set through the drive’s

front panel. This can only be done by a certified Customer Service

Engineer.

CAUTION:

During this procedure, the panel displays “Press Execute to Enter Lib

Size.” This is not normally an operator function. Altering the library size

can cause initialization errors or damage the hand if the size is set

incorrectly to full size when the library has a standar d door i nstead of an

expansion door. Instead of pressing Execute, press Menu.

Setting the SCSI Address

2-3

Page 38

Setting the SCSI Address

Figure 2-2. Symbol Definitions for Menu Block Diagram

Symbol Definitions for Menu Block Diagrams

= display screen with actual display screen text from a top level menu

= display screen with actual display screen text

Test Screens

a bullet ( ) plus

a number and a

multiplication symbol

(Example: 3X)

PATH

INDICATORS

= display screen and type of information screen is displaying

= operator panel softkey operations used in menu sequences

= repeat previous menu actionbullet ( )

= the number of times a previous menu action is repeated

between the first and last option in a sequential menu set

How Used

This configuration

indicates a display

screen and its

softkey options.

H_C60169

2-4

Page 39

Setting the SCSI Address

Refer to Figure 2-2 to make sure that you understand how to read the block

diagrams. Usually, pressing Execute means “yes,” that you want to perform the

activity in the block, and pressing Menu means “no,” that you want to continue

through the choices until your activity appears in the block. Usually, when you

are at the end of the activity, you press Execute. Press Menu if you make a

mistake and need to go through the choices again.

2-5

Page 40

Setting the SCSI Address

Figure 2-3. Setting the SCSI Address

2-6

Page 41

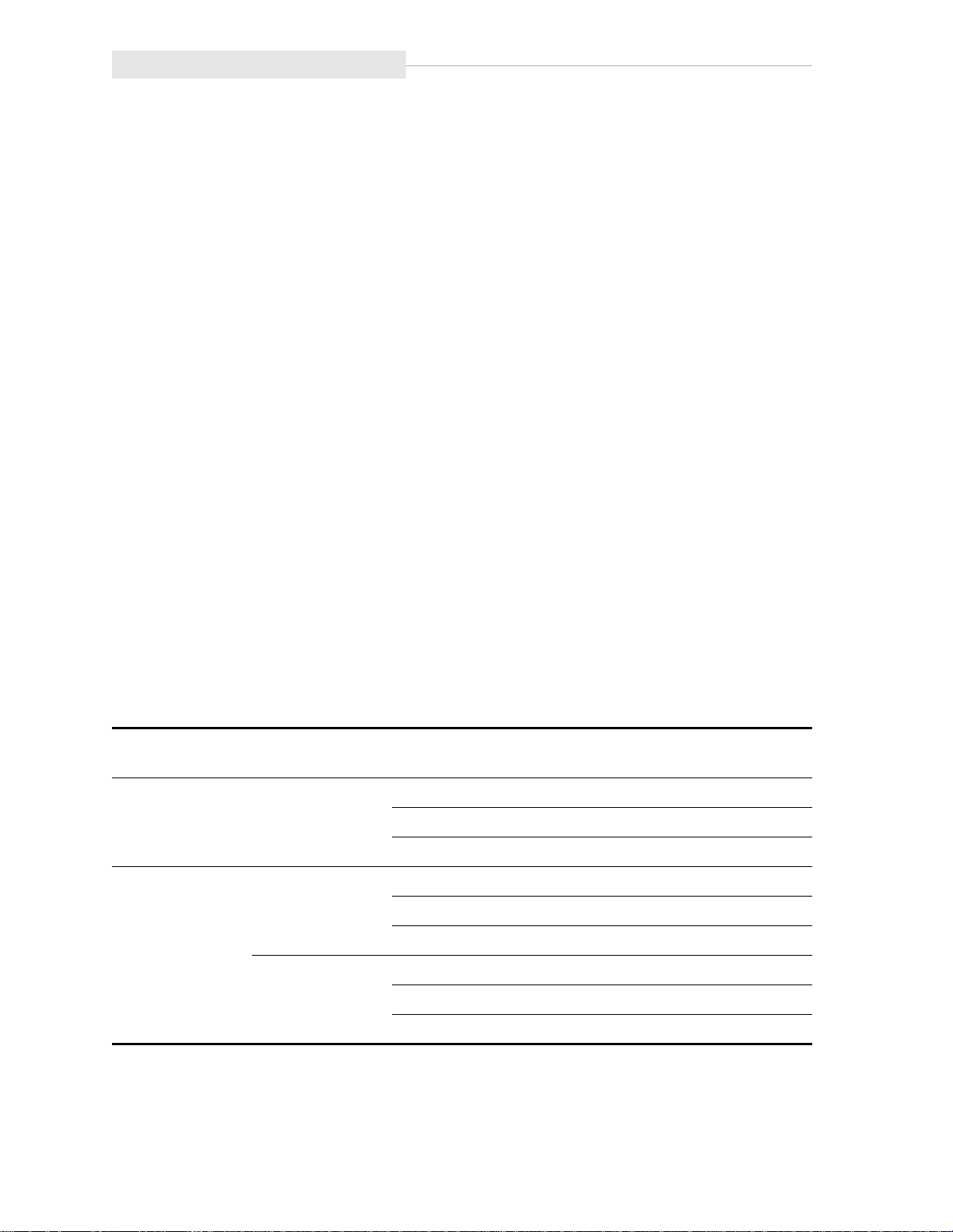

■ Setting Cleaning Cartridge Count

Drives might occasionally need to be cleaned to prevent read/write errors. The

drives are cleaned with a special cleaning cartridge. After a specified number of

uses, the cartridge must be replaced.

If your LSM was configured during installation to have the AUTO CLEAN feature

enabled, you can use the LSM operator panel to set the maximum number of

times a cartridge can be used. You can use the View Config section of

Figure 2-4 in Chapter 2 to determine whether the feature is enabled. The DLT

Tape Drive Product Manual suggest that you use a DLT cleaning cartridge about

20 times. For 9840 linear serpentine cartridges, refer to the 9840 Tape Drive

User’s Reference Manual PN 95739.

Refer to Figure 2-2 and Figure 2-4 to set the count.

Setting Cleaning Cartridge Count

2-7

Page 42

Setting Cleaning Cartridge Count

Figure 2-4. Setting the Cleaning Cartridge Count

Online Cap

Unlk Disabld

MENU

PRESSED

Press Execute to

Run Diagnostics

MENU

PRESSED

Press Execute to

Examine FSC's

MENU

PRESSED

Press Execute to

View Config

MENU

PRESSED

Press Execute to

Replace Cln Cart

MENU

PRESSED

Press Execute to

See/Chg Cln Data

EXECUTE

PRESSED

Press Execute to

*

Show 9840 Data

EXECUTE

PRESSED

MENU

PRESSED

Press Execute to

Exit Menu

EXECUTE

PRESSED

MENU

PRESSED

9840 Limit = XXX

*

Count = XXX

Press Execute to

Change Limit

EXECUTE

PRESSED

Press Execute to

*

EXECUTE

PRESSED

PRESSED

Set to 100

PRESSED

Press Execute to

Set to 1

EXECUTE

PRESSED

PRESSED

Online - Press

Exe to Unlk CAP

MENU

MENU

19X

MENU

If the LSM is configured for DLTs, the DLT screen option will appear instead of

*

9840.

9840 limits decrease from 100 to 1 in decrements of 5; DLT from 20 to 1 in

*

decrements of 1.

H_C60287

2-8

Page 43

■ Power Switch

The power switch is a circuit breaker located in the lower right corner of the

right front door of the LSM.

Lift the switch to supply power to the robot and the drives.

Make sure that all jobs being performed by the drives and robot are complete,

then push down on the switch to remove power to the drives and the robot.

Figure 2-5 shows the power switch location.

Figure 2-5. Power Switch Location

Power Switch

A

POWER

SWITCH

DETAIL A

H_C60155

2-9

Page 44

Power Switch

This page intentionally left blank.

2-10

Page 45

Operating the LSM

This chapter contains the procedures for:

• Powering on the LSM

• Powering off the LSM

• IPLing the LSM

• Operating in automated mode

• Operating in manual mode

Note: When the LSM is controlled by the host, refer to your software

publications and enter the command using the LSM management

software to perform the desired activity. For some activities, you might

have to ask your systems administrator for the required information

■ Powering On or IPLing the LSM

CAUTION:

To prevent damage to the drive, make sure that each drive is empty and

each DLT handle is up. On DLT4000 model drives, you can see whether

the handle is down. On DLT7000 model drives, look for the white hub. If

the hub is up, the handle is down. Figure 3-1 shows the handle

positions.

3

If the handle is down and the Operate Handle indicator is on, push the

shuttle all the way back, pause, then release. The handle will rise. If the

indicator is not on, contact your customer engineer for assistance.

The above caution does not apply to the 9840 tape drives. The 9840

drives do not have a handle.

To power on the LSM, lift the power switch on the bottom right corner of the

right front door of the LSM.

To IPL the LSM, press the IPL softkey on the LSM operator panel.

3-1

Page 46

Powering On or IPLing the LSM

Figure 3-1. DLT Handle Position

A,B

DRIVE

SHUTTLE

CARTRIDGE

HOOK (UP)

DRIVE

HUB

(UP)

HANDLE HANDLE

VIEW A

HANDLE DOWN POSITION

OPERATE

HANDLE

INDICATOR

CARTRIDGE

HOOK (DOWN)

HANDLE UP POSITION

VIEW B

HUB

(DOWN)

UNLOAD

BUTTON

H_E60438

3-2

Page 47

■ Powering Off the LSM

To power off the LSM:

1. Make sure that no jobs are being run by the drives or robot and that no

tapes are in the drives.

2. Push down the power switch on the bottom right corner of the right front

door of the LSM.

■ Operating in Automated Mode

Automated mode is the normal operating mode of the LSM. When the LSM is

online and the robot is mounting and dismounting cartridges, monitor the LSM

operator panel for messages and respond appropriately. The normal message is

“ONLINE CAP UNLK DISABLD” or “ONLINE - PRESS EXE TO UNLK CAP.”

When an LSM is online, you might need to:

• Enter cartridges into the LSM through the cartridge access port (CAP)

• Eject cartridges from the LSM through the CAP

• Replace the cleaning cartridge

The following text describes how to perform these activities.

Powering Off the LSM

Entering Cartridges through the CAP

If the LSM operator panel displays “ONLINE CAP UNLK DISABLD,” the CAP is

locked by the host. Issue the command using the LSM management software

that puts the LSM in the “ONLINE - PRESS EXE TO UNLK CAP” mode. Then

perform the steps below.

To unlock the CAP so that you can open the CAP and enter cartridges into it:

1. Press EXECUTE on the LSM operator panel.

a. The LSM operator panel displays “ONLINE CAP UNLK PENDING.”

b. The hand unlocks the CAP.

c. The LSM operator panel displays “ONLINE CAP UNLOCKED.”

CAUTION:

You must enter the cartridges properly or you might damage the robot or

the drive, or cause the LSM to stop operating. Use only DLT cartridges

for the DLT drives. Use only 9840 cartridges for 9840 drives.

2. Open the CAP to gain access to the cells.

3. Enter the cartridges so that they lie flat, with the customer label on top and

the tape leader block cutout on the right side of the cartridge.

3-3

Page 48

Operating in Automated Mode

CAUTION:

Do not slam the CAP. Cartridges could become unseated and be

extended out into the path of the r obotics , causing se vere dama ge to the

robot hand.

4. Close the CAP. The lock automatically engages.

Note: The LSM management software determines what happens when you

enter a cartridge upside down or with an unreadable label. Under

normal conditions, the camera on the hand audits the CAP and

recognizes that a cartridge is present, but the hand does not move it.

You must remove the cartridge from the CAP. With some host software,

the LSM might stop operating. With other host software, you are

prompted to type a label number when no VOLSER is read. If you do

type a label number, you might cause a problem later during an audit,

because the camera still will not be able to read an unreadable VOLSER

on the cartridge.

Figure 3-2. Entering DLT or 9840 Cartridges through the Cartridge Access Port

3-4

Page 49

Ejecting Cartridges through the CAP

When you want the robot to eject cartridges from the LSM through the CAP, use

the LSM management software to enter the

of the cartridges you require. The robot will retrieve them and place them into

the CAP.

If the LSM operator panel displays “ONLINE CAP UNLK DISABLD,” the CAP is

locked by the LSM management software. Issue the command using the LSM

management software that puts the LSM in the “ONLINE - PRESS EXE TO UNLK

CAP” mode. Then perform the steps below.

To unlock the CAP so that you can open the CAP and remove cartridges from it:

1. Press EXECUTE on the LSM operator panel.

a. The LSM operator panel displays “ONLINE CAP UNLK PENDING.”

b. The hand unlocks the CAP.

c. The LSM operator panel displays “ONLINE CAP UNLOCKED.”

Operating in Automated Mode

2. Open the CAP to gain access to the cells.

3. Remove the cartridges or the array from the CAP.

4. Properly store the cartridges outside the LSM (refer to “Storing Cartridges” in

Chapter 4).

CAUTION:

Do not slam the CAP. Cartridges could become unseated and extend out

into the path of the robotics, causing severe damage to the robot hand.

5. Close the CAP. The lock automatically engages.

6. Repeat these steps until all the desired cartridges have been removed.

Replacing the Cleaning Cartridge

The following paragraphs pertain to an LSM that has the AUTO CLEAN feature

enabled. You can use the View Config section of Figure 2-4 to determine

whether the feature is enabled.

If the feature is not enabled, you will need to record the number of times a

cleaning cartridge has been used, and replace it when necessary.

When a cleaning cartridge has been used a number of times, as defined in

“Setting Cleaning Cartridge Count” in Chapter 2, the LSM operator panel

displays “CLEANING CARTRIDGE USED UP.” If your machine has AUTO

CLEAN enabled, use the procedures in the following sections to replace the

cartridge.

3-5

Page 50

Operating in Automated Mode

Note: The DLT Tape Drive Product Manual recommends using a cleaning

cartridge about 20 times. The 9840 Tape Drive User’s Reference Manual

recommends using the cleaning cartridge 100 times.

Cleaning cartridges have a unique 3-character alphanumeric prefix in their

VOLSER (default is “CLN”). Cleaning cartridges cannot be used as scratch

cartridges or initialized by software utilities.

Note: Make sure that the CAP has an empty cell so that the hand can place the

cartridge into it.

Replacing the Expired Cleaning Cartridge

To replace the expired cleaning cartridge:

1. Press MENU until the LSM operator panel displays “PRESS EXECUTE TO

REPLACE CLN CART.”

2. To replace the DLT cleaning cartridge, press MENU.

The LSM operator panel displays “PRESS EXECUTE TO REPLACE DLT

CART.”

Press EXECUTE and wait until the CAP unlocks.

a. The hand takes the expired cleaning cartridge from its cell inside the

LSM and inserts it into the CAP.

b. The hand unlocks the CAP.

c. Go to Step 4.

3. To replace the 9840 cleaning cartridge, press MENU.

The LSM operator panel displays “PRESS EXECUTE TO REPLACE 9840

CART.”

Press EXECUTE and wait until the CAP unlocks.

a. The hand takes the expired cleaning cartridge from its cell inside the

LSM and inserts it into the CAP.

b. The hand unlocks the CAP.

c. Go to Step 4.

4. Open the CAP and remove the expired cartridge.

5. Throw away the expired cartridge.

CAUTION:

Do not re-enter a cleaning cartridge that has been ejected from an LSM.

When you enter a cleaning cartridge, the software consider s it to be ne w

and sets the usage counter to zero.

3-6

Page 51

6. Insert one new cleaning cartridge into a CAP cell.

CAUTION:

Do not slam the CAP. Cartridges could become unseated and be

extended out into the path of the r obotics , causing se vere dama ge to the

robot hand.

7. Close the CAP. The lock automatically engages.

a. The robot performs a brief audit.

b. The operator panel displays “MOVING CLEANING CART TO CELL.”

c. The hand inserts the cartridge into its cell.

d. The operator panel displays “ONLINE CAP UNLK DISABLD” or

“ONLINE – PRESS EXE TO UNLK CAP.”

■ Operating in Manual Mode

The following text describes operations you can perform when the LSM is in

manual mode. Manual mode occurs when the LSM right front door is opened or

the LSM loses power.

Operating in Manual Mode

Opening the LSM Front Doors

You must open the right front door, then the left front door to perform manual

operations. Refer to Figure 3-3.

1. Make sure that all jobs have ended.

2. Open the LSM right front door by using a latch key to unlock the top and

bottom latches. Turn the key counterclockwise.

3. Open the LSM left front door. For the standard door, pull gently from the

top right corner. For the expansion door, pull from the recessed area on the

right side.

3-7

Page 52

Operating in Manual Mode

Figure 3-3. Opening Access Doors

TOP

LATCH

LATCH

KEY

TOP

LATCH

BOTTOM

LATCH

LSM WITH STANDARD DOOR

LSM WITH EXPANSION DOOR

H_C60032

3-8

Page 53

Moving the Robot

After you open the LSM doors, you might need to move the robot to make it

easier to access the stored cartridges or the drives.

Read and observe the following caution before you attempt to move any

portion of the robot.

CAUTION:

To prevent damaging the hand or Z carriage, make sure that the reach

mechanism on the hand is fully retracted before moving any part of the

robot. Turn the hand pulley to retract the reach mec hanism (refer to

Figure 3-9). If the LSM goes offline due to a power failure, the reach

mechanism might be extended in to a storage cell or drive. If the r obot is

rotated when this condition exists, the hand will be damaged.

Move the Z column and Z carriage only as shown in Figure 3-4 and

Figure 3-5.

Do not touch exposed electrical parts when moving any part of the robot.

Operating in Manual Mode

3-9

Page 54

Operating in Manual Mode

Raising and Lowering the Z Carriage

If you need to raise or lower the hand, slowly and carefully move it by placing

your fingers on the Z carriage as shown in Figure 3-4.

Figure 3-4. Raising and Lowering the Z Carriage

RAISING THE Z CARRIAGE

LOWERING THE Z CARRIAGE

H_E60033

3-10

Page 55

Rotating the Z Column

If you need to rotate the Z column, grasp it and carefully rotate it, as shown in

Figure 3-5.

The Z column does not rotate the full 360 degrees. If the Z column meets

resistance and stops before the desired position is reached, it has contacted a

stopping mechanism. Do not force it. Rotate the column in the opposite

direction.

Figure 3-5. Rotating the Z Column

Operating in Manual Mode

H_E60034

3-11

Page 56

Operating in Manual Mode

Locating a Cartridge in the Storage Cells

Figure 3-6 and Figure 3-7 show the locations of the panels, rows, and columns

of the cartridge storage cells when the expansion door and 10 drives are

installed. The decal at the top of each column also provides location

information.

Figure 3-8 shows the locations of reserved storage cells. These cells are used to

store diagnostic and cleaning cartridges, and to provide an empty/dropoff cell

where the robot inserts a cartridge when the LSM loses power while a cartridge

is in the hand.

CAUTION:

Do not insert data cartridges into reserved cells or the LSM will not be

able to complete its initialization routines. If it does not initialize, it

cannot be placed online.

Figure 3-6. Locating Cartridges—Top View

COLUMN 0

COLUMN 0

PANEL 0

COLUMN 0

PANEL 1

PANEL 2

PANEL 3

COLUMN 0

LSM WITH EXPANSION DOOR

H_C60035

3-12

Page 57

Figure 3-7. Locating Cartridges—Panels, Cells, Rows, Cells

Operating in Manual Mode

PANEL 2

COLUMNS

PANEL 1

COLUMNS

0

2

1

DRIVE 9

0

00

3

2

00

1

0

0

0

3

T

DRIVE 8

13

DRIVE 7

FOR

AREA

RESERVED

DRIVE 6

CAP

LATCH

ASSEMBLY

DRIVE 5

23

DRIVE 4

T

DRIVE 3

T

DRIVE 2

DRIVE 1

41

DRIVE 0

41 41

41 41

41

41

14

ARRAY TARGET

(USED FOR

T =

56 CELLS

42 42

42

168 CELLS

42

NOT A STORAGE CELL

CLEANING CARTRIDGE CELL

42

42

H_C60148

ROBOTIC

CALIBRATION)

EMPTY/DROPOFF CELL

DIAGNOSTIC CARTRIDGE CELL

CAP CELLS

2

PANEL 0

COLUMNS

1

0

3

2

PANEL 3

COLUMNS

1

(EXPANSION)

0

000

0

000

TTTT TTTTTTT T

T

TTTTTTTTTTTT T

TTTTTTTTTTTT T

42

168 CELLS

42

41 41 41

42

14 560

41

CAP TOTAL

42

41

42

EXPANSION

4141

42

42

168 CELLS

392 168

BASEDRIVES

CUSTOMER CARTRIDGE CAPACITY CHART

10

3-13

Page 58

Operating in Manual Mode

Figure 3-8. Diagnostic and Cleaning Cartridge Cell Locations

Removing a Cartridge from the Hand

If the LSM experiences a power failure and the empty/dropoff cell is full, a

cartridge might be left in the hand. You can remove it from the hand and

manually mount it into a drive for a read/write operation.

CAUTION:

Follow the proc edures described in “Movi ng the Robot” above. Faili ng to

do so could damage the hand.

Make sure that you do not touch the TWH card on the hand assembly. It

contains ESD-sensitive components and could be damaged.

To remove a cartridge from the hand:

1. Rotate the Z column:

• If the LSM has an expansion door, move the hand until it is facing the

expansion door location.

• If the LSM has a standard door, move the hand until it is on the left, top

side of the LSM (Panel 0 Column 0).

3-14

Page 59

2. Rotate the hand pulley (refer to Figure 3-9) until the gripper mechanism is

extended to its full position (refer to Figure 3-10).

Figure 3-9. Extending the Gripper Mechanism

TAPE

CARTRIDGE

(SHOWN

RETRACTED)

TWH

CARD

Operating in Manual Mode

HAND

PULLEY

H_C60037

3. Hold the hand pulley with one hand and grasp the cartridge with the other.

Pull gently on the cartridge until it is released from the gripper mechanism,

as shown in Figure 3-10.

4. Turn the hand pulley until the gripper mechanism is fully retracted.

CAUTION:

Make sure that the gripper mechanism is full y retracted. If it is left

extended and you turn the robot, the gripper mechanism will strike a

storage cell. If it is left extended and the hand is f acing the LSM door

when it is closed, the door will strike the gripper mec hanism.

3-15

Page 60

Operating in Manual Mode

Figure 3-10. Removing a Cartridge from the Hand

REACH

MECHANISM

(SHOWN

EXTENDED)

GRIPPER

MECHANISM

TAPE

CARTRIDGE

TWH

CARD

HAND

PULLEY

H_C60036

3-16

Page 61

Mounting a DLT Cartridge into a Drive

CAUTION:

Before you mount a cartridge into the drive, you must make sure that

power is on, and that the Operate Handle indicator is on. Use the drive

shuttle to operate, not the drive handle.

A safety mechanism protects the drive if y ou try to operate it in an

incorrect state. The shuttle will not operate if this mechani sm is

activated. To reset the safety mechanism, wait for the Operate Handle

indicator to turn on. Pull firmly on the shuttle, then push the shuttle in

completely. If the cartridge did not eject, or if the handle di d not ri se, pull

and push again.

To mount a cartridge into a drive:

1. Obtain the cartridge VOLSER, location, and drive number using the LSM

management software.

2. Open the LSM right front door by using a latch key to unlock the top and

bottom latches. Refer to Figure 3-3.

Operating in Manual Mode

3. Open the LSM left front door. For the standard door, pull gently from the

top right corner. For the expansion door, pull from the recessed area on the

right side.

4. Locate the cartridge.

5. Make sure that the DLT handle is up and the cartridge handle hook and hub

are down. Figure 3-11 shows the handle positions.

CAUTION:

You must insert the cartridge properly or you will damage the drive.

Make sure that the cartridge has a readable V O LSER.

6. Hold the cartridge so that the VOLSER is facing you and the write-protect

switch is on the right side of the cartridge. Refer to Figure 3-13.

7. Insert the cartridge into the shuttle and push the cartridge into the back of

the drive until it is firmly seated.

8. Push the shuttle all the way back, pause for about two seconds, then release

the shuttle.

CAUTION:

If the cartridge has been ejected from the dri ve, y ou must remove it from

the shuttle before you can reload it into the drive. Otherwise, the shuttle

will become jammed by simultaneously holding onto the cartridge and

lowering the handle. If this happens, release the cartridge from the

shuttle latch under the right side of the cartridge. Then push the

cartridge into the drive and lower the handle.

3-17

Page 62

Operating in Manual Mode

Figure 3-11. DLT Handle Position

A,B

DRIVE

SHUTTLE

CARTRIDGE

HOOK (UP)

DRIVE

HUB

(UP)

HANDLE HANDLE

VIEW A

HANDLE DOWN POSITION

OPERATE

HANDLE

INDICATOR

CARTRIDGE

HOOK (DOWN)

HANDLE UP POSITION

VIEW B

HUB

(DOWN)

UNLOAD

BUTTON

H_E60438

3-18

Page 63

Figure 3-12. Inserting a DLT Cartridge into a Drive

DRIVE

Operating in Manual Mode

CARTRIDGE

H_E60374

3-19

Page 64

Operating in Manual Mode

Mounting a Cartridge into a 9840 Drive

To mount the cartridge in a 9840 drive:

1. Insert the cartridge into the 9840 drive using the direction shown in

Figure 3-13.

2. Wait for one of the following messages to display and take the appropriate

action, if necessary:

• The “Ready F” (File Protected) message displays when a write-protected

cartridge loads successfully.

• The “Ready U” (File Unprotected) message displays when a cartridge

that is not write-protected loads successfully.

• The “NTReady” message displays when the tape in the cartridge has lost

tension. If this occurs call your Customer Support Engineer

• The LOADxxxx” message displays when the cartridge unsuccessfully

loads, where the xxxx is a fault symptom code. If this occurs call your

Customer Support Engineer.

3-20

Page 65

Figure 3-13. Mounting a Cartridge into the 9840 Drive

Operating in Manual Mode

Dismounting a Cartridge from a DLT Drive

To dismount a cartridge from a drive:

1. Obtain the drive number using the LSM management software and place the

drive offline.

2. Open the LSM right front door by using a latch key to unlock the top and

bottom latches. Refer to Figure 3-3.

3. Open the LSM left front door. For the standard door, pull gently from the

top right corner. For the expansion door, pull from the recessed area on the

right side.

4. Locate the desired drive.

5. Make sure that the job is done.

6. Make sure that the Operate Handle indicator is on. If it is not, press the

Unload button on the drive to unload the drive. The indicator will turn on.

7. Push the shuttle all the way back, pause for about two seconds, then release

the shuttle.

3-21

Page 66

Operating in Manual Mode

Note: If the cartridge does not come out of the drive, remount the cartridge

by releasing it from the shuttle latch under the right side of the

cartridge. Then push the cartridge into the drive and lower the

handle. If this fails, the tape leader might be dislodged and require

rethreading.

8. Remove the cartridge from the drive.

9. Properly store the cartridge outside the LSM (refer to “Storing Cartridges” in

Chapter 4).

Dismounting a Cartridge from a 9840 Drive

To dismount a cartridge from a 9840 drive:

1. Ensure that the 9840 drive is not selected form the host.

2. Press the Unload switch.

3. After the tape rewinds, the cartridge ejects from the 9840 drive. Remove the

cartridge form the 9840 drive.

Returning the LSM to Online Status

To place the LSM online for automated operations:

1. Make sure that the drive shuttle Operate Handle indicator is on and the

handle is up.

2. Close and lock the LSM doors. The robot will perform an audit of the cells.

3-22

Page 67

Cartridges

The chapter describes how to prepare and maintain cartridges.

■ Preparing Cartridges

The following pages describe how to prepare a cartridge for use in the LSM.

Handling a Cartridge

Generally observe the following protocols when handling cartridges:

• Keep cartridges clean.

• Inspect a cartridge before each use.

• Do not put a damaged cartridge into a drive or LSM.

• Do not open a cartridge.

• Do not release a leader block and pull tape from a cartridge.

• Do not handle tape that is outside the cartridge.

• Do not expose the tape or cartridge to direct sunlight or moisture.

• Do not expose a recorded cartridge to magnetic fields.

4

Inspecting a Cartridge

A defective or dirty cartridge can damage a drive. If you suspect a problem with

a cartridge, inspect it for these defects:

• Cracked or broken cartridge

• Broken leader block

• Broken leader block latch

• Damaged write protect switch

• Moisture

• Labels not firmly attached or extending over the cartridge edge

• Any other obvious damage

4-1

Page 68

Preparing Cartridges

Figure 4-1. Inspecting a DLT Cartridge

Figure 4-2. Inspecting a 9840 Cartridge

4-2

Page 69

Applying DLT Cartridge Labels

The LSM uses DLTtape IV or IIIXT cartridges for data, plus diagnostic and

cleaning cartridges. Different types of data cartridges are distinguished by a

small “E” or “D” next to the last number in the VOLSER. Cleaning and

diagnostic cartridges are distinguished by “CLN” or “DG” in the prefix in the

VOLSER. The correct labeling follows:

• DLTtape IV data cartridges should be labeled with a “D” label.

• DLTtape IIIXT data cartridges should be labeled with an “E” label.

• Cleaning cartridges should be labeled with a “CLN” label.

• Diagnostic cartridges should be labeled with a “DG” label.

Note: Diagnostic cartridges are physically the same as data cartridges. The LSM

software requires the “DG” label before it will use a cartridge for

diagnostic routines. One diagnostic cartridge is supplied with the LSM.

The operator is responsible for applying labels correctly as indicated above and

in Figure 4-3. Cartridge surfaces should be clean and at room temperature when

applying labels. Labels can be inserted into the recessed area, or the backing

can be peeled away to expose the adhesive, if a more permanent application is

desired. Do not place labels anywhere but in the recessed VOLSER slot, and

make sure that the edges do not curl up, which might cause misreading or

sticking.

Preparing Cartridges

Figure 4-3. Applying DLT Cartridge Labels

4-3

Page 70

Preparing Cartridges

Applying 9840 Cartridge Labels

Figure 4-4. Applying 9840 Cartridge labels

Cartridge labels reflect the cartridge media and usage. Cleaning cartridges have

DG CLN in the VOLSER and a “U” beneath the VOLSER. Diagnostic cartridges

have DG 000 in the VOLSER and an “R” beneath the VOLSER.

Refer to Figure 4-4 and insert the label into the recessed area provided on each

cartridge.

1. Make sure that the cartridge has been at room temperature for at least 24

hours.

2. Clean the surface where the labels will be placed using a cleaning solution

made for this purpose. Refer to “Cleaning the Cartridge Exterior” for

additional information.

3. Locate the label that you require and refer to Figure 4-4.

Refer to Figure 4-4 and slide the label under the slots in the recessed area. If

you want, peel the backing from the label and then slide it under the slots,

pressing it into place.

Notes:

1. Make sure that the labels are not placed elsewhere on the cartridge surface.

2. Make sure that the edges of the labels do not curl up; curling causes the

cartridge to stick in the drive loader.

4-4

Page 71

3. Use labels that do not leave a residue when removed.

4. Make sure that the label contains a VOLSER.

Preparing Cartridges

4-5

Page 72

Preparing Cartridges

Setting the DLT Write-Protect Switch

Refer to Figure 4-5 to see the location of the write protect switch. To set the

cartridge to write-protected, slide the switch to the left so the orange indicator is

visible. In this position, the drive can only read data from the tape and cannot

write data to the tape.

To set the cartridge to write-enabled, slide the switch to the right so the orange

indicator is not visible. In this position, the drive can write as well as read data.

Figure 4-5. Setting the DLT Write-Protect Switch

4-6

Page 73

Setting the 9840 Write-Protect Switch

To write-protect a cartridge, follow these steps:

1. Hold the cartridge with the customer label side up and the rear VOLSER

label toward you. (Refer to Figure 4-6 on page 4-7.)

2. Locate the write-protect switch on the right side of the cartridge.

3. Move the write-protect switch to the front of the cartridge (away from you)

to the write-protect position.

Figure 4-6. Setting the 9840 Write-Protect Switch

Preparing Cartridges

4-7

Page 74

Maintaining Cartridges

■ Maintaining Cartridges

The following sections describe how to store and clean cartridges.

Storing Cartridges

When you store a cartridge:

• Do not take a cartridge out of its protective wrapping until you are ready to

use it.

• Store cartridges in a clean environment that duplicates the conditions of the

room in which they are used.

• Before using a cartridge, make sure that it has been in its operating

environment for at least 24 hours.

Cleaning the Cartridge Exterior

CAUTION:

Do not use certain solvents to remove labels or to clean cartridges

because they can damage the cartridges. Do not use acetone,

trichloroethane, toluene, xylene, benzene, ketone, methylethyl ketone,

methylene chloride, ethyldichloride, esters, ethyl acetate, or similar

chemicals.

Wipe all dust, dirt, and moisture from the cartridge with a lint-free cloth.

4-8

Page 75

Specifications

This appendix lists the supplies and accessories, specifications, and agency

certifications.

■ Supplies and Accessories

Table A-1 lists supplies and accessories:

Table A-1. Supplies and Accessories

A

Item

DLT Tape Cartridges

HP DLTtape IV Data Cartridge

20 GByte/35 Gbyte native

capacity

HP DLTtape III XT Data

Cartridge

15 Gbyte native capacity

Cleaning Tape Cartridge

DLT Bar Code Labels

DLT Bar code labels are not available through Hewlett-Packard, but may be ordered from

Engineered Data Products (EDP). Refer to the following page.

9840 Tape Cartridges and

Bar Code Labels

9840 tape cartridges and labels are not available through Hewlett-Packard, but may be

ordered from the StorageTek Media Department. Refer to Ordering 9840 Tape Cartridge

and Labels.

SCSI Cables (68-pin to 68-pin)

HP Product Number HP Part Number

C5141F Not applicable

C5141A Not appli cabl e

C5142A Not appli cable

0.5m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

A-1

C6509A 8120-6147

Page 76

Supplies and Accessories

Table A-1. Supplies and Accessories

2.5m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

5.0 SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

10m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

20m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

SCSI Cables for V-Class (68-pin to 68-pin)

5.0m SCSI cable; high-density

with thumb screws to highdensity with thumb screws, mm; with inline terminator for

V-Class

C2924A A1658-62020

C6510A A1658-62021

C2925A A1658-62022

C2926A A1658-62023

Not applicable A4801-63004

10m SCSI cable; high-density

with thumb screws to highdensity with thumb screws, mm; with inline terminator for

V-Class

SCSI Cables (50-pin to 68-pin)

1.0m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

1.5m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

2m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

Not applicable A4801-63002

C2961A 5181-7705

C2962A 5181-7706

C2906A 5181-7707

A-2

Page 77

Table A-1. Supplies and Accessories

Ordering DLT Cartridge Labels

5m SCSI cable; high-density

with thumb screws to highdensity with thumb screws,

m-m

SCSI Terminators (68-pin)

Single-ended SCSI Terminator

Wide Differential Terminator

C2907A 5181-7708

C6511A 5063-5324

C2905A A1658-62024

■ Ordering DLT Cartridge Labels

Each LSM is supplied with a sufficient quantity of data cartridge labels (with the

“D” designation) to match a fully populated library (588 cartridges). To order

additional labels, contact Engineered Data Products (EDP) for a reference to a

dealer who services your area.

Engineered Data Products, Inc. (EDP)

2550 West Midway Blvd.

Broomfield, CO 80020

U.S. Sales Line: 1-800-432-1337

Fax: 303-465-4936

Engineered Data Products Europe, Ltd.

43 Redhills Road

South Woodham Ferrers

Chelmsford; Essex CM3 5UL

Phone: (44) 1245-322380

Fax: (44) 1245-323484

Table A-2 lists EDP DLT cartridge label specifications:

Table A-2. EDP DLT Cartridge Label Specifications

Data Cartridge Label Diagnostic Cartridge Label Cleaning Cartridge Label

EDP PN 1703-OD

Bar code 3 of 9

Dimensions: 0.82” x 2.20”

Sold in sets of 200

Customer to specify numeric

sequence

EDP PN 1703-DG

Bar code 3 of 9

Dimensions: 0.82” x 2.20”

Sold in sets of 20

Customer to specify numeric

sequence

EDP PN 1703-CN

Bar code 3 of 9

Dimensions: 0.82” x 2.20”

Sold in sets of 20

Customer to specify numeric

sequence

A-3

Page 78

Ordering 9840 Tape Cartridge and Bar

■ Ordering 9840 Tape Cartridge and Bar Code

Labels

To order 9840 tape cartrdiges and bar code labels, contact StorageTek Media

Department.

Austria: 0800-20-1631

Belgium: 0800-75-327

Denmark 8088-0744

Finland 08001-13361

France 0800-82-83-57

Germany 0800-181-6238

Holland 0800-022-8496

Ireland 1800-55-33-54

Italy 167-790-852

Norway 800-11-220

South America 0800-99-5820

Spain 900-99-33-66

UK 0800-731-8852

US 800-905-8502

Canada 905-602-5586

Asia/Pacific 61-2-9433-1700

Japan 81-3-3746-9711

Latin America 303-661-5398

A-4

Page 79

Basic Requirements for Cartridges

■ Basic Requirements for Cartridges

LSM cartridges must meet specifications defined in, American National

Standard Magnetic Tape & Cartridge for Information Interchange, ACS X3B5.

Cartridges must meet the following requirements:

Table A-3. Basic Requirements for DLT Cartridges

Cartridges 10.16 cm x 12.7 cm x 2.54 cm (4 in. x 5 in. x 1 in.)

Integrated thumbwheel

Media Chromium dioxide

1.27 cm (0.5 in.) wide

165 m (541 ft) long minimum

No beginning of tape/end of tape reflective markers

Volume serial number

(VOLSER) label

Table A-4 shows the specifications for the tape cartridges to be inserted into the

9840 Tape Drive System.

Table A-4. 9840 Cartridge Specifications

Characteristics Values

Cartridge type STK1R

Cartridge type STK1U

Dimensions 125 x 109 x 24.5 mm

Weight 260 g (9.17 oz.)

Data compression LZ-1 Enhanced

Media life 10 year minimum

Data error rates, including those caused by

media defects

Valid characters are A-Z, 0-9, # (crosshatch), or trailing blanks.

Leading blanks are not allowed.

270 m (886 ft) 8 microns tape

Cleaning cartridge

(4.92 x 4.29 x 0.958 in.)

Uncorrected bit error rate (BER) is 1 in 10

bytes

18

A-5

Page 80

Basic Requirements for Cartridges

DLT Cartridge Environmental Specifications

The following specifications refer to the operating and storage environments for

DLT cartridges, according to international standard ECMA-209.

Table A-5. DLT Cartridge Environmental Specifications

Operating environment

Temperature

Relative humidity

Wet bulb temperature

CAUTION:

Tape temperatures above 49ºC (120ºF) might damage the tapes. If during storage or

transportation a cartridge has been exposed to conditions outside th e abo ve val ues,

before using the cartridge, keep the cartridge within those operating environment