Page 1

HP StorageWorks

D2600/D2700 Disk Enclosure User Guide

Smart Array P212/P411 Controller Environments

This guide describes the D2600/D2700 6Gb SAS disk enclosure. Installation, cabling, and configuration

procedures are also included.

Part number: 504227–001

First edition: September 2009

Page 2

Legal and notice information

© Copyright 2009 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set

forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as

constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Microsoft, Windows, Windows XP, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Page 3

Contents

1 Hardware ......................................................................................... 7

Overview ................................................................................................................................... 7

Small Form Factor disk enclosure chassis ........................................................................................ 8

Front view ........................................................................................................................... 8

Rear view ............................................................................................................................ 8

Drive bay numbering ............................................................................................................ 8

Large Form Factor disk enclosure chassis ........................................................................................ 9

Front view ........................................................................................................................... 9

Rear view ............................................................................................................................ 9

Drive bay numbering ............................................................................................................ 9

Disk drives ............................................................................................................................... 11

Disk drive LEDs .................................................................................................................. 11

Disk drive blanks ................................................................................................................ 11

Front status and UID module ....................................................................................................... 12

Front UID module LEDs ........................................................................................................ 12

Unit identification (UID) button ............................................................................................. 13

Power supply module ................................................................................................................ 14

Power supply LED ............................................................................................................... 14

Fan module .............................................................................................................................. 15

Fan module LED ................................................................................................................. 15

I/O module ............................................................................................................................. 16

I/O module LEDs ............................................................................................................... 16

Rear power and UID module ...................................................................................................... 18

Rear power and UID module LEDs ........................................................................................ 18

Unit identification (UID) button ............................................................................................. 19

Power on/standby button .................................................................................................... 19

SAS cables .............................................................................................................................. 20

2 Technical specifications ..................................................................... 21

General specifications ............................................................................................................... 21

Power and environmental specifications ....................................................................................... 21

3 Installation ...................................................................................... 23

Installation overview .................................................................................................................. 23

Required items .......................................................................................................................... 23

Preliminary tasks ....................................................................................................................... 24

Determining who will install and configure the disk enclosure ................................................... 24

Saving the disk enclosure website as a favorite in your browser ................................................ 24

Confirming support for your hardware and software components .............................................. 24

Signing up to automatically receive advisories, notices, and other messages .............................. 25

Confirming warranty support and finding out about related services .......................................... 25

Gathering and recording information .................................................................................... 26

Planning the storage configuration ........................................................................................ 26

System and performance expectations ............................................................................ 26

D2600/D2700 Disk Enclosure User Guide 3

Page 4

Striping methods .......................................................................................................... 27

RAID levels ................................................................................................................. 27

Disk drive sizes and types ............................................................................................. 28

Spare disks ................................................................................................................. 28

Array sizing ................................................................................................................ 28

Preparing the site ...................................................................................................................... 29

Providing adequate structural support for the floor .................................................................. 29

Providing adequate clearance space and ventilation ............................................................... 29

Providing adequate and redundant sources of power .............................................................. 29

Racking the disk enclosure ......................................................................................................... 30

Rack installation best practices ............................................................................................. 30

Racking procedures ............................................................................................................ 31

Installing disk drives .................................................................................................................. 33

Installing 6Gb SAS controllers and preparing the servers ............................................................... 35

Connecting cables and power cords ........................................................................................... 36

Overview .......................................................................................................................... 36

Cabling best practices ........................................................................................................ 36

Cabling the disk enclosure to the controller ............................................................................ 37

Cabling cascaded disk enclosures ........................................................................................ 38

Labeling cables using labeling kit ......................................................................................... 38

Connecting power cords ..................................................................................................... 39

Powering on the disk enclosure ................................................................................................... 40

Power on best practices ....................................................................................................... 40

Power on procedures .......................................................................................................... 40

Verifying the operating status of the devices ................................................................................. 41

Verify the operating status of the disk enclosures ..................................................................... 41

Verify the operating status of the servers and SAS controllers .................................................... 42

4 Configuration .................................................................................. 43

Configuration overview .............................................................................................................. 43

Configuration best practices ....................................................................................................... 43

Supported software tools ........................................................................................................... 43

HP Systems Insight Manager ................................................................................................ 44

HP Array Configuration Utility .............................................................................................. 45

Option ROM Configuration for Arrays (ORCA) ....................................................................... 46

Smart Components for firmware updates ............................................................................... 46

5 Operation and management ............................................................. 47

Powering on disk enclosures ....................................................................................................... 47

Powering off disk enclosures ....................................................................................................... 48

Updating disk enclosure firmware ............................................................................................... 48

6 Cabling examples ............................................................................ 49

Large Form Factor D2600 disk enclosures + Smart Array P411 controller; Single I/O path ................. 49

Large Form Factor D2600 disk enclosures + Smart Array P411 controller; Single I/O path—Maximum

configuration ............................................................................................................................ 50

Large Form Factor D2600 disk enclosures + Smart Array P212 controller; Single I/O path—Maximum

configuration ............................................................................................................................ 51

Small Form Factor D2700 disk enclosures + Smart Array P411 controller; Single I/O path ................. 52

Small Form Factor D2700 disk enclosures + Smart Array P411 controller; Single I/O path—Maximum

configuration ............................................................................................................................ 53

Small Form Factor D2700 disk enclosures + Smart Array P212 controller; Single I/O path—Maximum

configuration ............................................................................................................................ 54

4

Page 5

7 Troubleshooting ............................................................................... 55

If the enclosure does not initialize ............................................................................................... 55

Diagnostic steps ....................................................................................................................... 55

Is the enclosure front fault LED amber? .................................................................................. 55

Is the enclosure rear fault LED amber? ................................................................................... 56

Is the power on/standby button LED amber? .......................................................................... 56

Is the power supply LED amber? ........................................................................................... 56

Is the I/O module fault LED amber? ...................................................................................... 57

Is the fan LED amber? ......................................................................................................... 57

Recognizing disk drive failure ..................................................................................................... 58

Effects of a disk drive failure ................................................................................................ 58

Compromised fault tolerance ............................................................................................... 58

Factors to consider before replacing disk drives ...................................................................... 58

Automatic data recovery (rebuild) ......................................................................................... 59

Time required for a rebuild ............................................................................................ 59

Failure of another drive during rebuild ............................................................................ 59

Handling disk drive failures ........................................................................................... 60

8 Replacement procedures ................................................................... 61

Customer self repair (CSR) ......................................................................................................... 61

Parts-only warranty service ................................................................................................... 61

Best practices for replacing hardware components ........................................................................ 61

Verifying component failure ................................................................................................. 61

Identifying the spare part .................................................................................................... 62

Replaceable parts ..................................................................................................................... 62

Replacing the failed component .................................................................................................. 62

Replacement instructions ............................................................................................................ 63

Exploded view ......................................................................................................................... 63

9 Support and other resources .............................................................. 65

Contacting HP .......................................................................................................................... 65

Before you contact HP ......................................................................................................... 65

HP contact information ........................................................................................................ 65

Subscription service ............................................................................................................ 65

Documentation feedback ..................................................................................................... 66

Related information ................................................................................................................... 66

Websites ........................................................................................................................... 66

Document conventions and symbols ............................................................................................. 66

Customer self repair .................................................................................................................. 67

Rack stability ............................................................................................................................ 67

10 Regulatory compliance notices ......................................................... 69

Regulatory compliance identification numbers .............................................................................. 69

Federal Communications Commission notice ................................................................................ 69

FCC rating label ................................................................................................................ 69

Class A equipment ....................................................................................................... 69

Modifications .................................................................................................................... 70

Cables .............................................................................................................................. 70

Canadian notice (Avis Canadien) ............................................................................................... 70

Class A equipment ............................................................................................................. 70

European Union notice .............................................................................................................. 70

Japanese notices ...................................................................................................................... 70

VCCI-A notice .................................................................................................................... 70

D2600/D2700 Disk Enclosure User Guide 5

Page 6

Japanese power cord statement ............................................................................................ 71

Korean notices ......................................................................................................................... 71

Class A equipment ............................................................................................................. 71

Taiwanese notices ..................................................................................................................... 71

BSMI Class A notice ........................................................................................................... 71

Chinese notice ................................................................................................................... 71

Recycling notices ...................................................................................................................... 71

English notice .................................................................................................................... 71

Bulgarian notice ................................................................................................................. 72

Czech notice ..................................................................................................................... 72

Danish notice .................................................................................................................... 72

Dutch notice ...................................................................................................................... 72

Estonian notice .................................................................................................................. 73

Finnish notice ..................................................................................................................... 73

French notice ..................................................................................................................... 73

German notice ................................................................................................................... 73

Greek notice ...................................................................................................................... 74

Hungarian notice ............................................................................................................... 74

Italian notice ...................................................................................................................... 74

Latvian notice .................................................................................................................... 74

Lithuanian notice ................................................................................................................ 75

Polish notice ...................................................................................................................... 75

Portuguese notice ............................................................................................................... 75

Romanian notice ................................................................................................................ 75

Slovak notice ..................................................................................................................... 76

Spanish notice ................................................................................................................... 76

Swedish notice ................................................................................................................... 76

Turkish notice ..................................................................................................................... 76

Index ................................................................................................. 77

6

Page 7

1 Hardware

Overview

6Gb SAS disk enclosures are available in two models:

• Small Form Factor (SFF): Supports 25 SFF (2.5 inch) disk drives

• Large Form Factor (LFF): Supports 12 LFF (3.5 inch) disk drives

Large Form Factor disk enclosureSmall Form Factor disk enclosure

NOTE:

Depending on your disk enclosure model and controller installation environment, one or more disk

enclosures can be cascaded from the disk enclosure that is connected to the controller. For more

information, see the QuickSpecs for your enclosure model, available at

http://www.hp.com/go/D2000.

The enclosure and its components are detailed in the following sections:

• Small Form Factor disk enclosure chassis, page 8

• Large Form Factor disk enclosure chassis, page 9

• Disk drives, page 11

• Front status and UID module, page 12

• Power supply module, page 14

• Fan module, page 15

• I/O module, page 16

• Rear power and UID module, page 18

• SAS cables, page 20

D2600/D2700 Disk Enclosure User Guide 7

Page 8

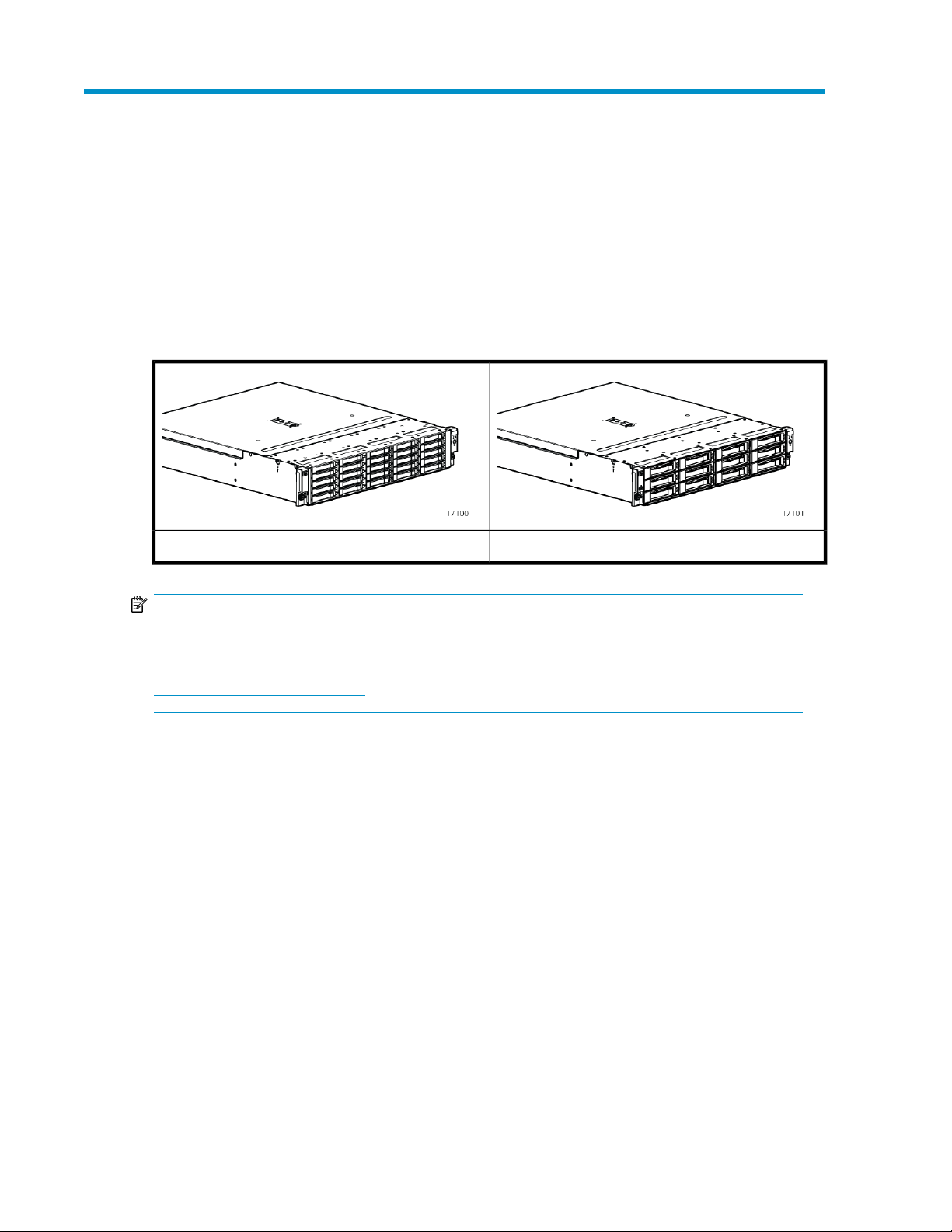

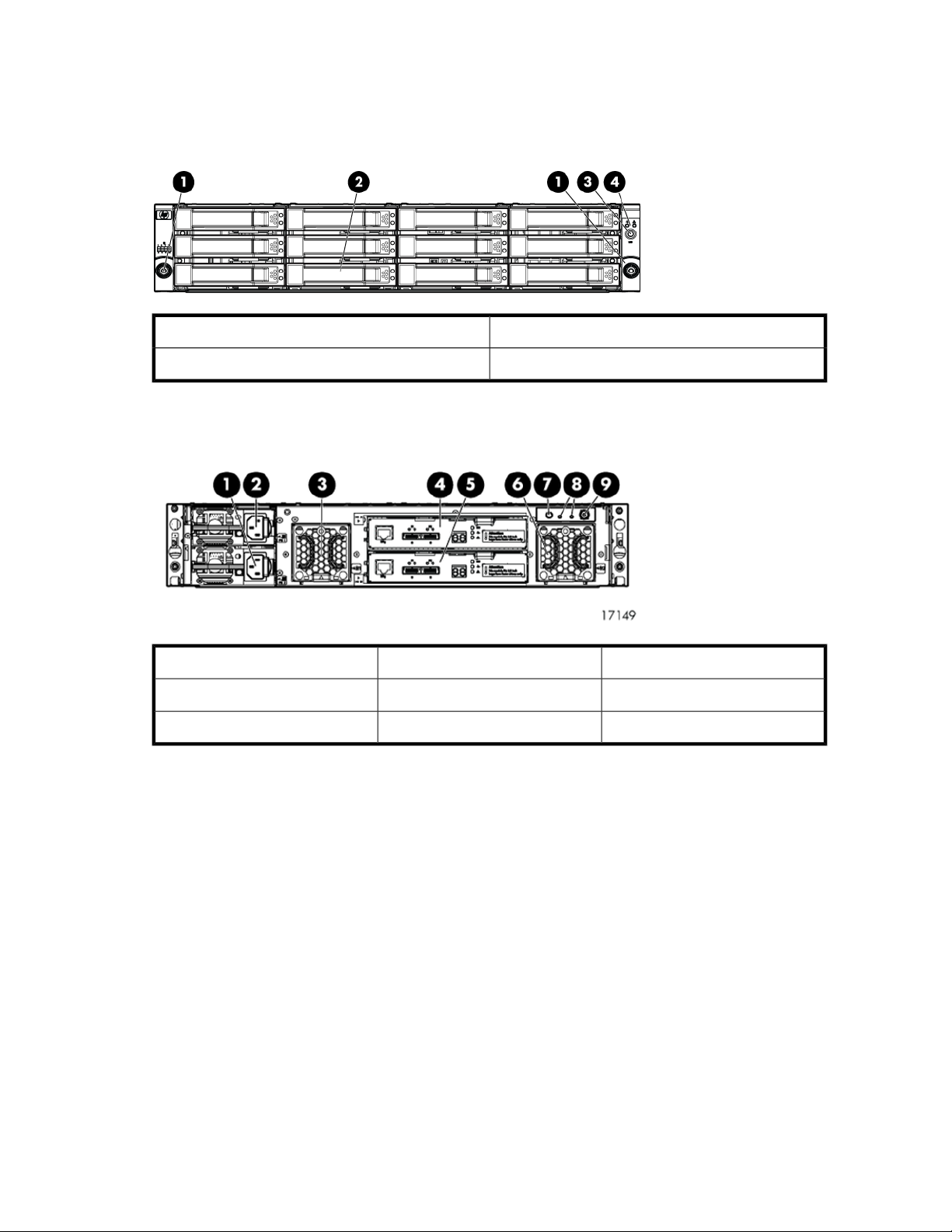

Small Form Factor disk enclosure chassis

Front view

3. UID push button and LED1. Rack-mounting thumbscrews

4. Enclosure status LEDs2. Disk drive in bay 9

Rear view

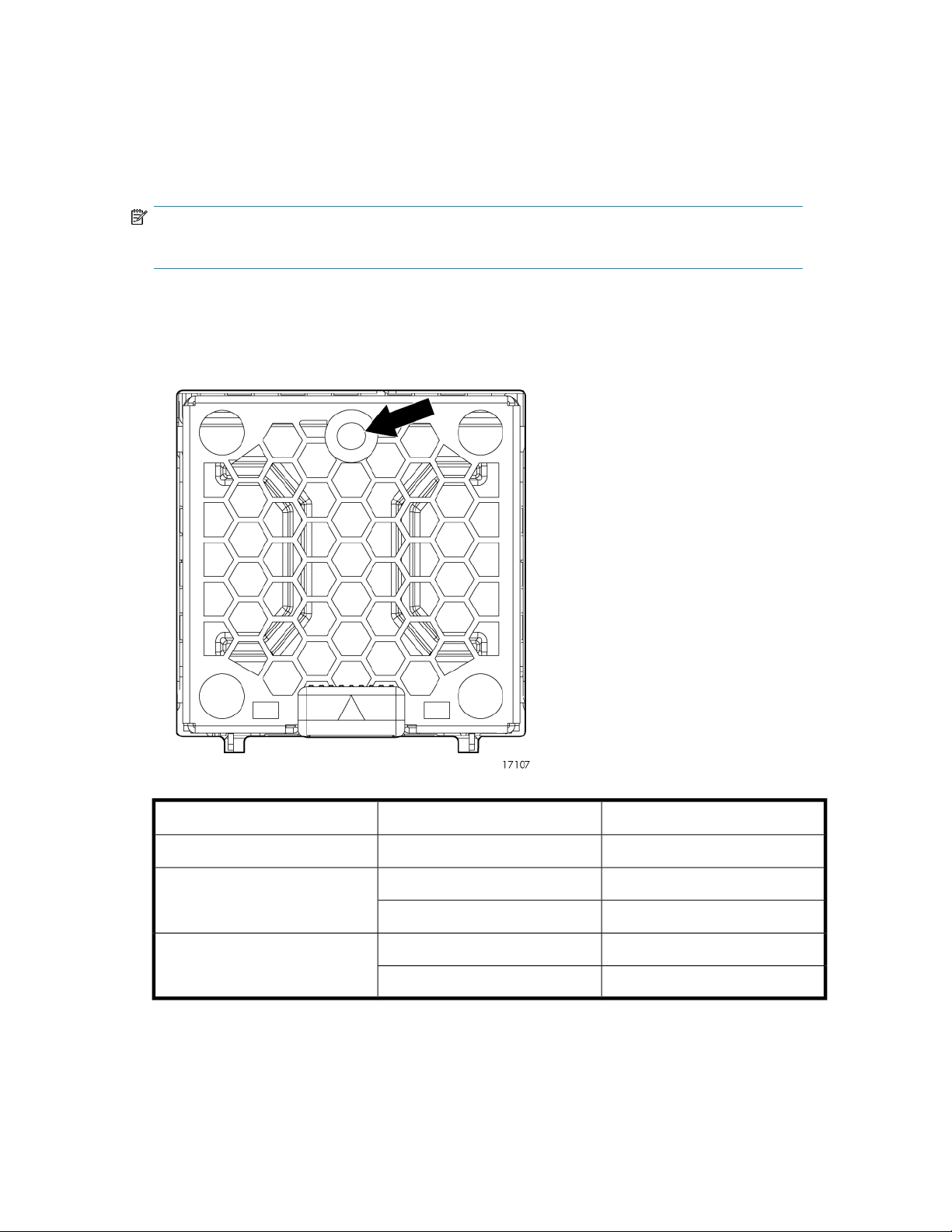

Drive bay numbering

Disk drives mount in bays on the front of the enclosure. Bays are numbered sequentially from top to

bottom and left to right. Bay numbers are indicated on the left side of each drive bay.

7. UID push button and LED4. I/O module A1. Power supply 1

8. Enclosure status LEDs5. I/O module B2. Power supply 2

9. Power push button and LED6. Fan 23. Fan 1

Hardware8

Page 9

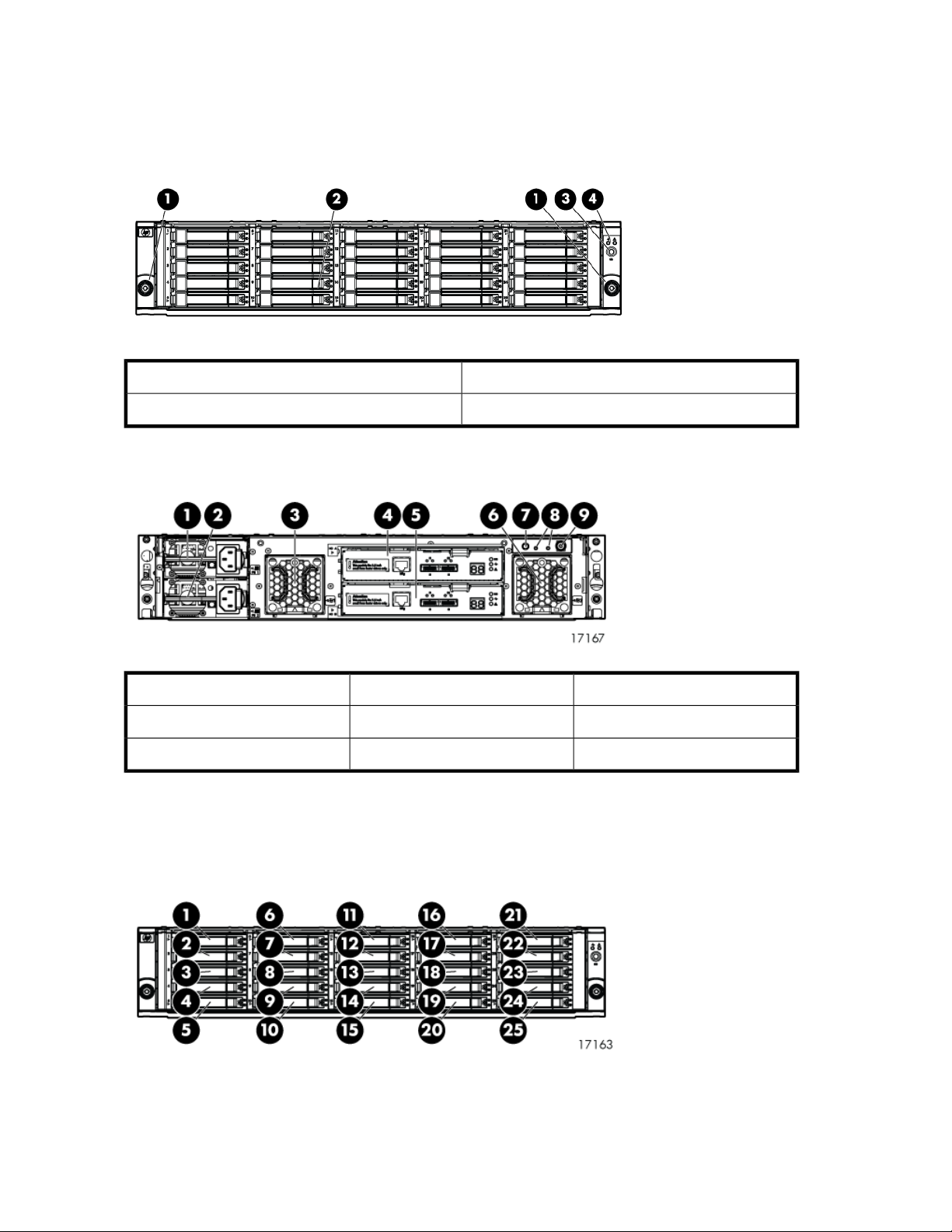

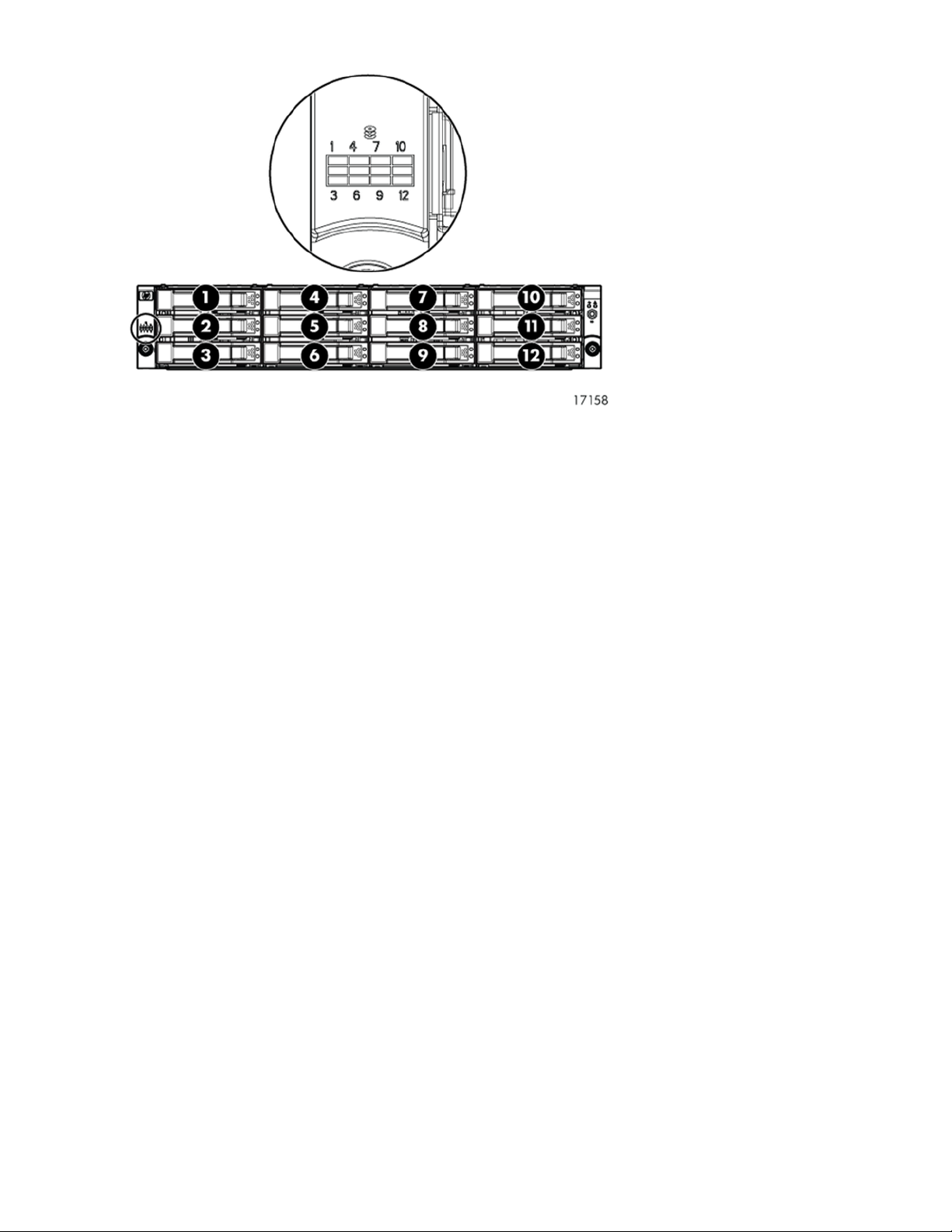

Large Form Factor disk enclosure chassis

Front view

3. UID push button and LED1. Rack-mounting thumbscrews

4. Enclosure status LEDs2. Disk drive in bay 6

Rear view

Drive bay numbering

Disk drives mount in bays on the front of the enclosure. Bays are numbered sequentially from top to

bottom and left to right. A drive-bay legend is included on the left bezel.

7. UID push button and LED4. I/O module A1. Power supply 1

8. Enclosure status LEDs5. I/O module B2. Power supply 2

9. Power push button and LED6. Fan 23. Fan 1

D2600/D2700 Disk Enclosure User Guide 9

Page 10

Hardware10

Page 11

Disk drives

A variety of disk drive models are supported for use, including dual-ported SAS disk drives and

single-ported SATA disk drives. For more information, see the QuickSpecs for your enclosure model,

available on the D2000 website: http://www.hp.com/go/D2000.

Disk drives are hot-pluggable.

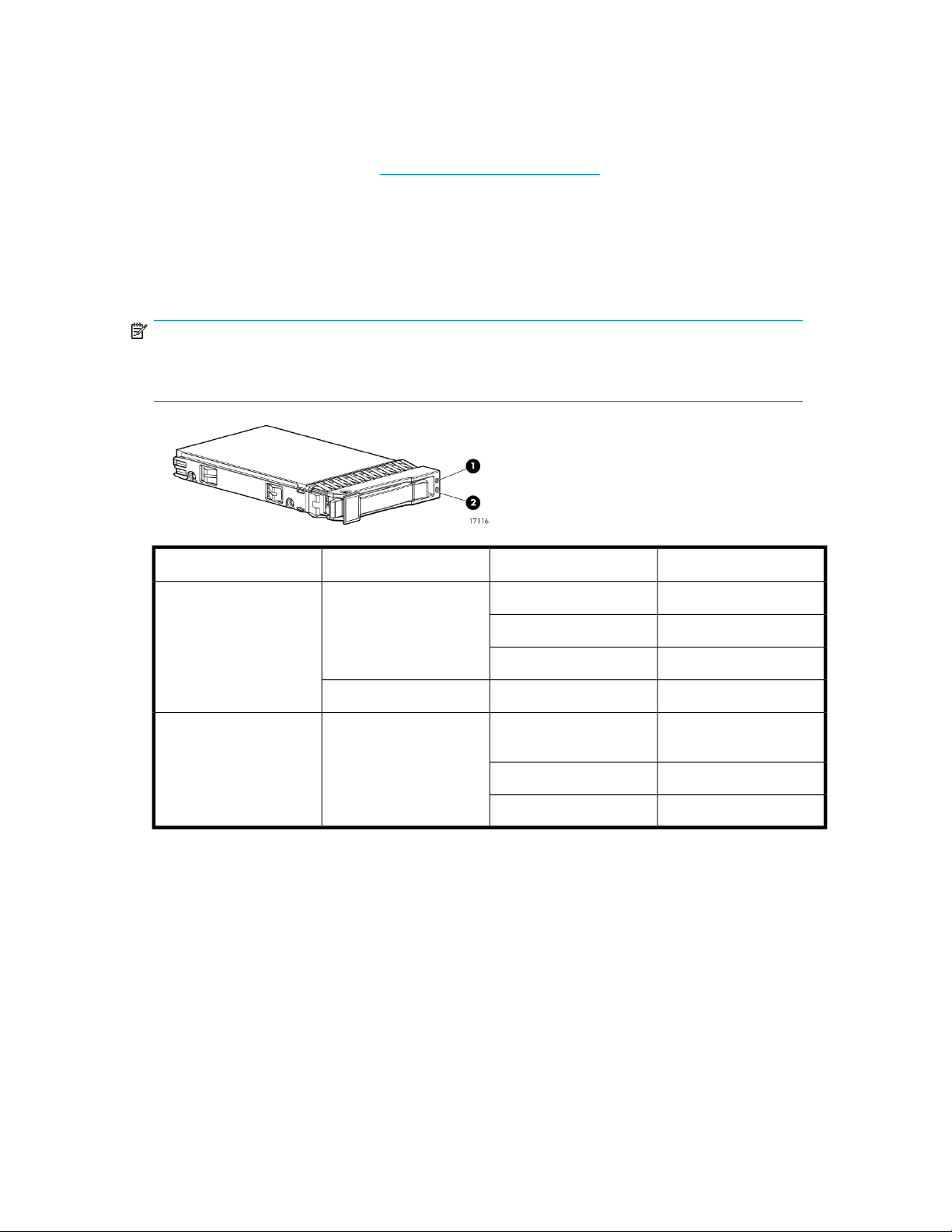

Disk drive LEDs

Two LEDs indicate drive status.

NOTE:

The following image shows a Small Form Factor (SFF) disk drive. LED patterns are the same for SFF

and LFF disk drives.

1. Locate/Fault

Disk drive blanks

To maintain the proper enclosure air flow, a disk drive or a disk drive blank must be installed in each

drive bay. The disk drive blank maintains proper airflow within the disk enclosure.

Blue

Green2. Status

Blinking

DescriptionLED statusLED colorLED

Used to locate driveSlow blinking

Used for critical locateMedium blinking

Used for reserved locateFast blinking

Drive faultSolidAmber

Drive is spinning up or

down and is not ready

Drive activityFast blinking

Ready for activitySolid

D2600/D2700 Disk Enclosure User Guide 11

Page 12

Front status and UID module

The front status and UID module includes status LEDs and a unit identification (UID) button.

Front UID module LEDs

DescriptionLED statusLED colorLED iconLED

No powerOff

Green1. Health

Amber2. Fault

Blue3. UID

Blinking

Blinking

Solid

Off

Blinking

Solid

Enclosure is starting up and

not ready, performing POST

Normal, power is onSolid

Normal, no fault conditionsOff

A fault of lesser importance

was detected in the enclosure

chassis or modules

A fault of greater importance

was detected in the enclosure

chassis or modules

Not being identified or power

is off

Unit is being identified from

the management utility

Unit is being identified from

the UID button being pushed

Hardware12

Page 13

Unit identification (UID) button

The unit identification (UID) button helps locate an enclosure and its components. When the UID button

is activated, the UID on the front and rear of the enclosure are illuminated.

NOTE:

A remote session from the management utility can also illuminate the UID.

• To turn on the UID light, press the UID button. The UID light on the front and the rear of the enclosure

will illuminate solid blue. (The UID on cascaded storage enclosures are not illuminated.)

• To turn off an illuminated UID light, press the UID button. The UID light on the front and the rear

of the enclosure will turn off.

D2600/D2700 Disk Enclosure User Guide 13

Page 14

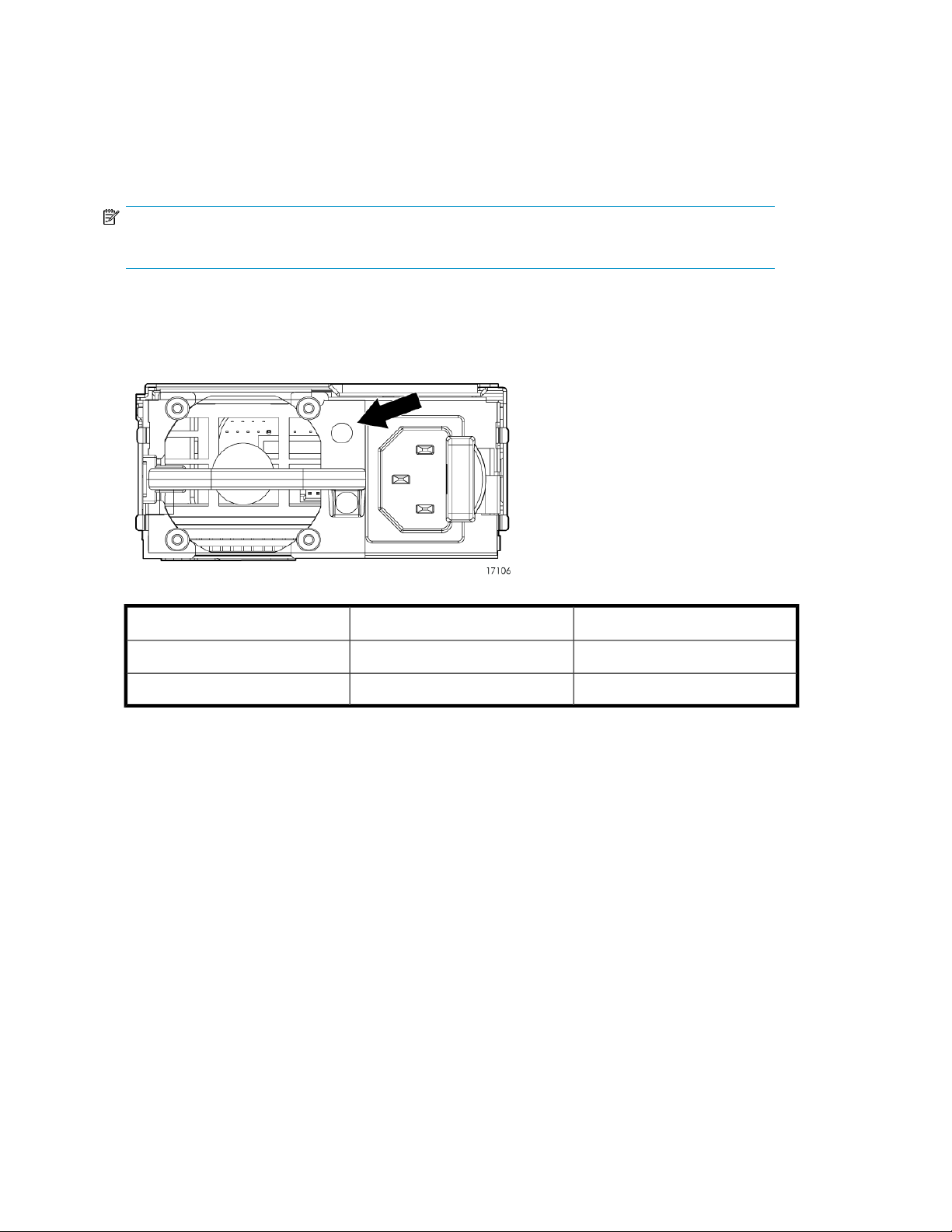

Power supply module

Two power supplies provide the necessary operating voltages to all controller enclosure components.

If one power supply fails, the remaining power supply is capable of operating the enclosure. (Replace

any failed component as soon as possible.)

NOTE:

If one of the two power supply modules fails, it can be hot-replaced.

Power supply LED

One LED provides module status information.

DescriptionLED statusLED color

No powerOffOff

Normal, no fault conditionsSolidGreen

Hardware14

Page 15

Fan module

Fan modules provide cooling necessary to maintain proper operating temperature within the controller

enclosure. If one fan fails, the remaining fan is capable of cooling the enclosure. (Replace any failed

component as soon as possible.)

NOTE:

If one of the two fan modules fail, it can be hot-replaced.

Fan module LED

One bi-color LED provides module status information.

Green

Amber

DescriptionLED statusLED color

No powerOffOff

The module is being identifiedBlinking

Normal, no fault conditionsSolid

Fault conditions detectedBlinking

Problems detecting the moduleSolid

D2600/D2700 Disk Enclosure User Guide 15

Page 16

I/O module

The I/O module provides the interface between the disk enclosure and the host.

Each I/O module has two ports that can transmit and receive data for bidirectional operation.

3. SAS Port 2

I/O module LEDs

LEDs on the I/O module provide status information about each I/O port and the entire module.

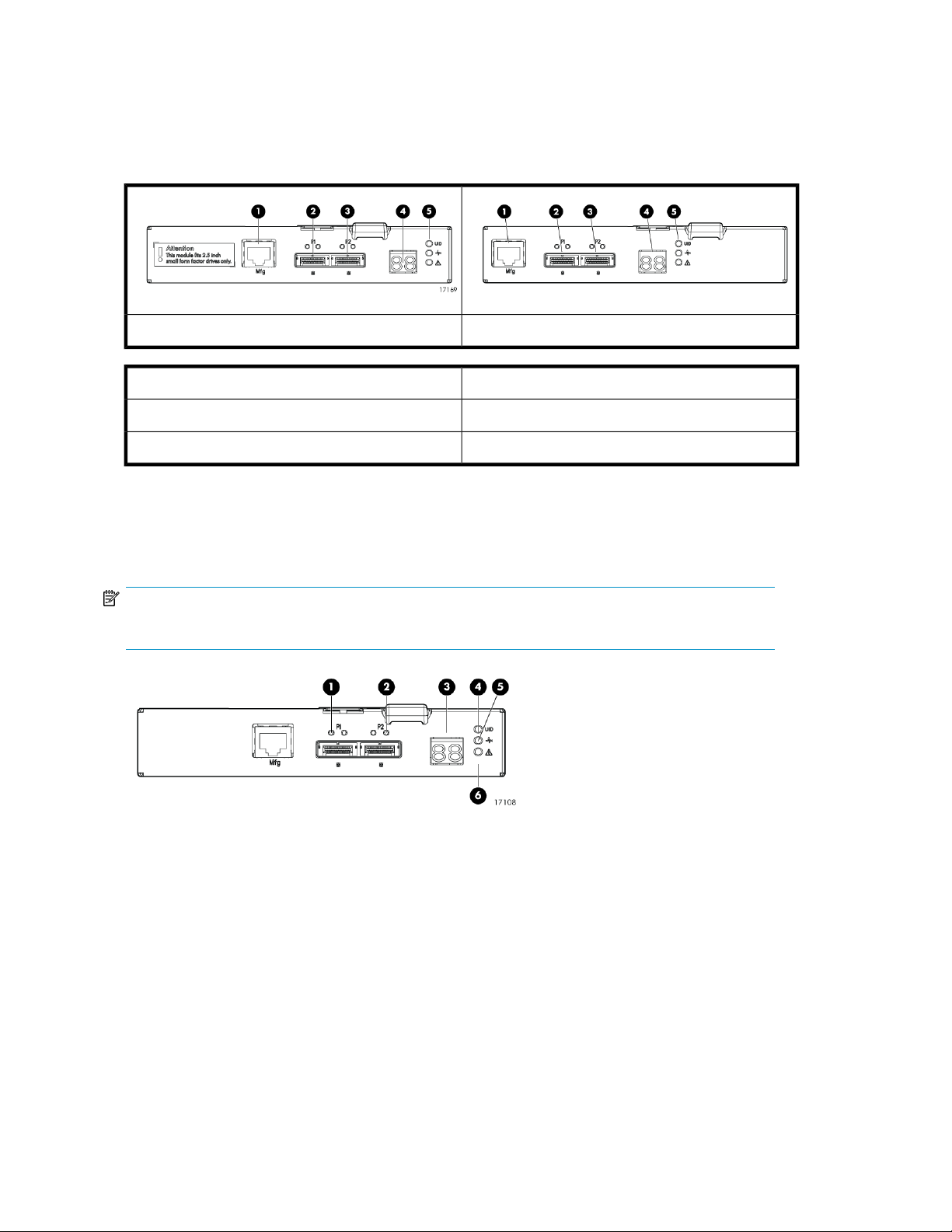

Large Form Factor I/O moduleSmall Form Factor I/O module

4. Double 7–segment display1. Manufacturing diagnostic port

5. I/O module LEDs2. SAS Port 1

NOTE:

The following image illustrates LEDs on the Small Form Factor I/O module.

Hardware16

Page 17

DescriptionLED statusLED colorLED iconLED

3. 7–segment display

Off

Greenn/a1. SAS Port Link The port is being identified by

Ambern/a2. SAS Port Error

n/an/a

Blue4. UID

Blinking

Blinking

Solid

Off

Off

Solid

Off

No cable, no power, or port

not connected

an application client

Healthy, active linkSolid

Normal, no errors detectedOff

Error detected by application

client

Error, fault conditions detected

on the port by the I/O module

No cable, no power, enclosure

not detected

The enclosure box numberNumber

Not being identified or no

power

Module is being identified,

from the management utility

No power or firmware malfunction

Green5. Health Enclosure is starting up and not

Amber6. Fault

Blinking

Solid

ready, performing POST

Normal, power is onSolid

Normal, no fault conditionsOff

A fault of lesser importanceBlinking

A fault of greater importance,

I/O failed to start

D2600/D2700 Disk Enclosure User Guide 17

Page 18

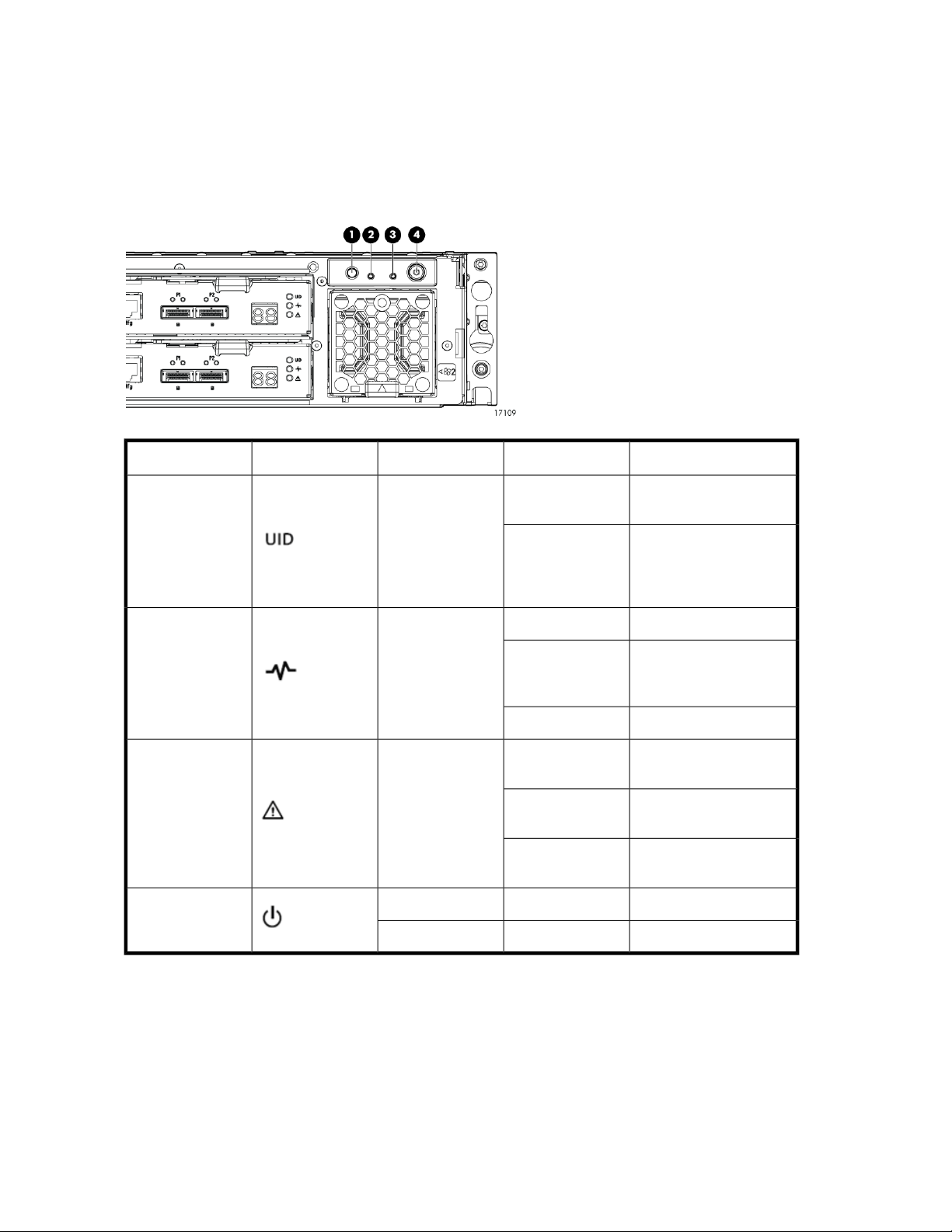

Rear power and UID module

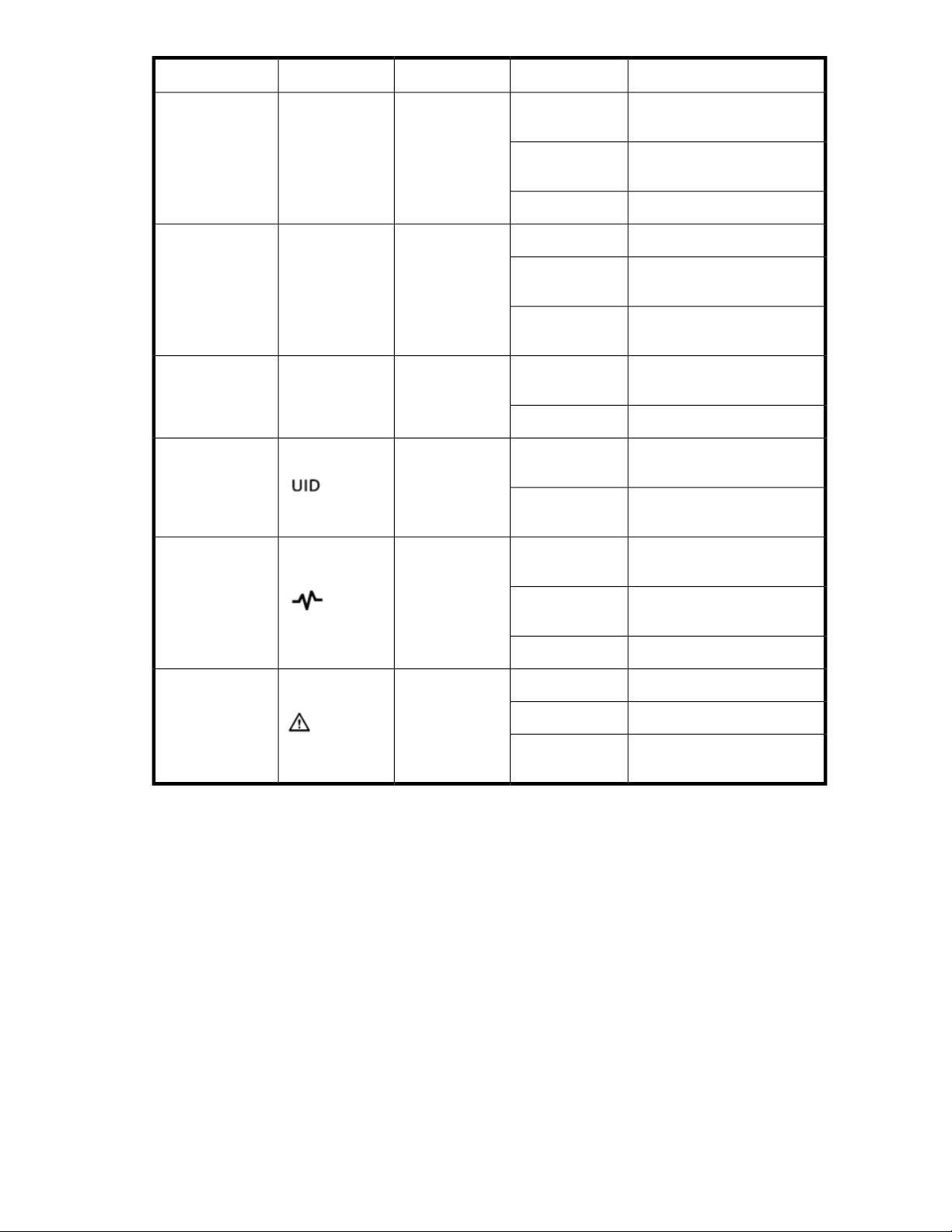

The rear power and UID module includes status LEDs, a unit identification (UID) button, and the power

on/standby button.

Rear power and UID module LEDs

DescriptionStatusLED colorLED iconLED

4. On/Standby

Off

Blue1. UID

On

Green2. Health

Amber3. Fault

Blinking

Off

Blinking

Solid

Not being identified or no

power

Unit is being identified,

either from the UID button

being pushed or from the

management utility

No powerOff

Enclosure is starting up

and not ready, performing POST

Normal, power is onSolid

Normal, no fault conditions

A fault of lesser importance

A fault of greater importance

Power is onSolidGreen

Standby powerSolidAmber

Hardware18

Page 19

Unit identification (UID) button

The unit identification (UID) button helps locate an enclosure and its components. When the UID button

is activated, the UID on the front and rear of the enclosure are illuminated.

NOTE:

A remote session from the management utility can also illuminate the UID.

• To turn on the UID light, press the UID button. The UID light on the front and the rear of the enclosure

will illuminate solid blue. (The UID on cascaded storage enclosures are not illuminated.)

• To turn off an illuminated UID light, press the UID button. The UID light on the front and the rear

of the enclosure will turn off.

Power on/standby button

The power on/standby button applies either full or partial power to the enclosure chassis.

• To initially power on the enclosure, press and hold the on/standby button for a few seconds, until

the LEDs begin to illuminate.

• To place an enclosure in standby, press and hold the on standby button for a few seconds, until

the on/standby LED changes to amber.

NOTE:

System power to the disk enclosure does not completely shut off with the power on/standby button.

The standby position removes power from most of the electronics and components, but portions of

the power supply and some internal circuitry remain active. To completely remove power from the

system, disconnect all power cords from the device.

D2600/D2700 Disk Enclosure User Guide 19

Page 20

SAS cables

These disk enclosures use cables with mini-SAS connectors for connections to the controller and

cascaded disk enclosures.

Hardware20

Page 21

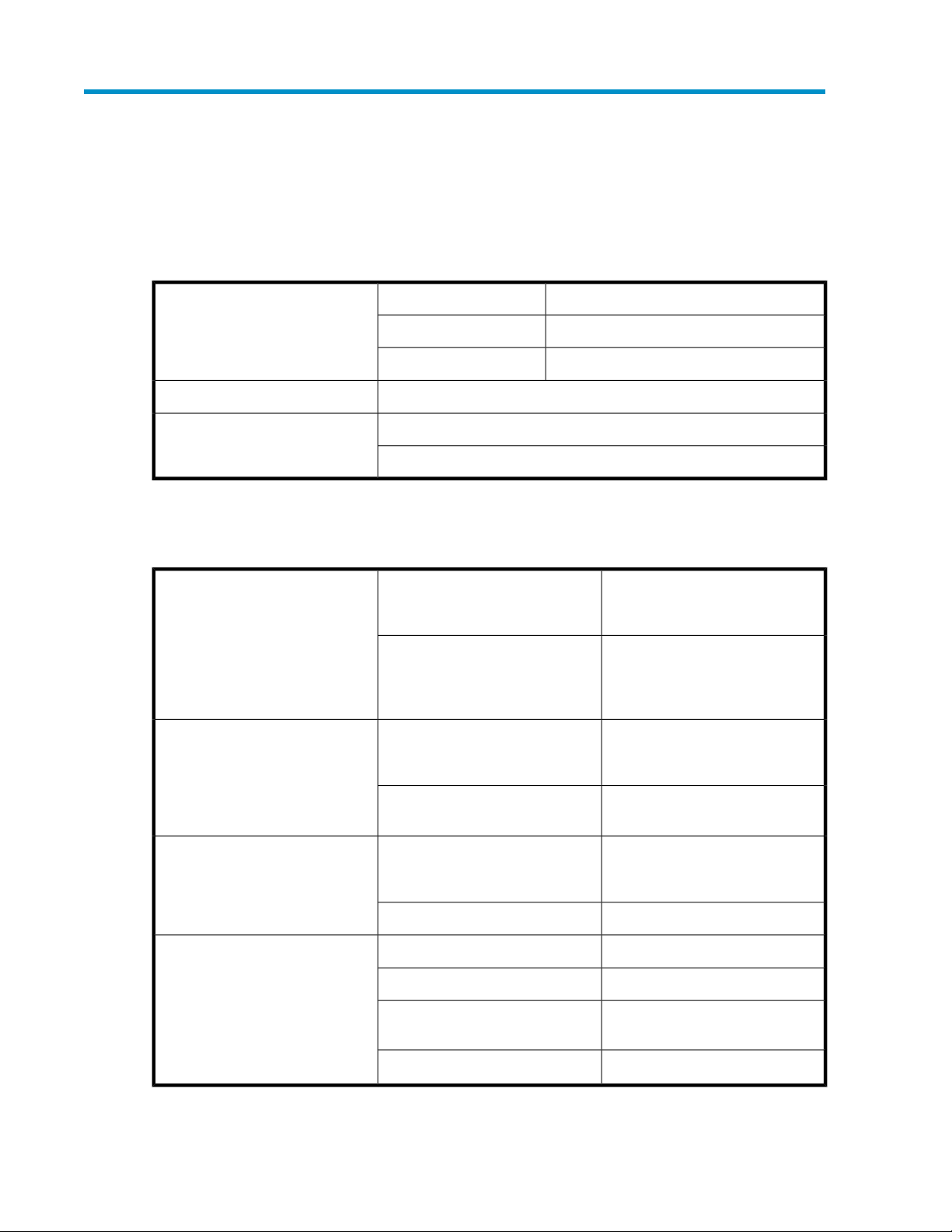

2 Technical specifications

General specifications

Dimensions 45.0 cm (17.99 in)Width

17.2 kg (38 lb)Weight (base unit; no disk drives)

SFF disk drives: 24.9 kg (54.90 lb)

Weight (fully populated)

LFF disk drives: 27.2 kg (59.97 lb)

Power and environmental specifications

8.8 cm (3.47 in)Height (2U)

56.7 cm (22.3 in)Depth

Temperature range (Temperature

ratings shown are for sea level. An

altitude rating of 1°C per 300 m

(1.8°F per 1,000 ft) to 3048 m

(10,000 ft) is applicable. No direct

sunlight allowed. The upper limit

might be limited by the type and

number of options installed.)

Relative humidity (Non-operating

maximum humidity of 95% is based

on a temperature of 45°C (113°F).

Altitude maximum for storage corresponds to a pressure minimum of

70 KPa.)

Altitude (Maximum allowable altitude change rate is 457 m/min

(1500 ft/min))

Dissipation specifications are maximum values and apply to worstcase conditions at full rated power

supply load. The power/heat dissipation for your installation will vary

depending on the equipment configuration.)

Operating

Shipping

Operating

Operating

Rated input current

10°C to 35°C (50°F to 95°F)

Maximum rate of change is

10ºC/Hr (18ºF/Hr)

–40°C to 66°C (–40°F to 150°F)

Maximum rate of change is

20ºC/Hr (36ºF/Hr)

10% to 90% relative humidity (Rh)

28ºC (82.4ºF) Maximum wet bulb

temperature non-condensing

5% to 95% relative humidity (Rh)Non-operating

3048 m (10,000 ft) This value

might be limited by the type and

number of options installed.

9144 m (30,000 ft)Non-operating

100 to 240 VACRated input voltageInput power (Input Power and Heat

50 to 60 HzRated input frequency

2.68 A at 115 VAC typical, 4 A

maximum

300 WInput power (max)

D2600/D2700 Disk Enclosure User Guide 21

Page 22

Technical specifications22

Page 23

3 Installation

Installation overview

Installation steps include:

1. Locating Required items, page 23

2. Completing Preliminary tasks, page 24

3. Preparing the site, page 29

4. Racking the disk enclosure, page 30

5. Installing disk drives, page 33

6. Installing 6Gb SAS controllers and preparing the servers, page 35

7. Connecting cables and power cords, page 36

8. Powering on the disk enclosure, page 40

9. Verifying the operating status of the devices, page 41

Required items

Items required for installation include the following, some of which ship with the disk enclosure:

• Rack mounting kit

• Disk enclosure

• Disk drives and drive blanks

• 6Gb SAS controller

• SAS cables

• Power cables

• Access to a workstation on the server

• Access to the Internet

NOTE:

A variety of disk drives, 6Gb SAS controllers, and SAS cables are supported for use with this disk

enclosure. For more information, see the QuickSpecs for your disk enclosure model, available on the

D2000 disk enclosures website: http://www.hp.com/go/D2000.

D2600/D2700 Disk Enclosure User Guide 23

Page 24

Preliminary tasks

Planning tasks include:

• Determining who will install and configure the disk enclosure, page 24

• Saving the disk enclosure website as a favorite in your browser, page 24

• Confirming support for your hardware and software components, page 24

• Signing up to automatically receive advisories, notices, and other messages, page 25

• Confirming warranty support and finding out about related services, page 25

• Gathering and recording information, page 26

• Planning the storage configuration, page 26

Determining who will install and configure the disk enclosure

Storage management experience is required to successfully install and configure this product. If you

are not familiar with installing and configuring storage array systems, HP can install this product for

you. For more information, see the Business & IT Services website: http://www.hp.com/go/services.

Different levels of assistance are available. For example, the following services might be included:

• Site inspection

• Verification of operating system patch levels

• Customized virtual disk design

• Array hardware installation and activation of optional software

• Array initialization

• Verification that the implemented solution meets your specifications

• Availability of an HP Services Storage Specialist to answer questions during the deployment process

• Verification testing to confirm product functionality and adherence to HP installation quality

standards

• On-site orientation, including highlights of basic operation and a review of documentation

Saving the disk enclosure website as a favorite in your browser

This site includes the latest information, including:

• QuickSpecs (product specifications and compatibility information)

• User documents

• Software and firmware downloads

• Support advisories and notifications

For more information, see the D2000 website: http://www.hp.com/go/D2000.

Confirming support for your hardware and software components

Specific versions of hardware, firmware, software, drivers, and other components are designed to

work together.

The QuickSpecs for your disk enclosure model provide an up-to-date list of supported servers, operating

systems, controllers, switches, and software tools. Download and review the QuickSpecs for your

enclosure model to confirm that the components you plan to use are supported for use with the disk

enclosure.

Installation24

Page 25

Check the QuickSpecs before initially installing the disk enclosure and before making any changes

to an existing installation. QuickSpecs are available on the D2000 disk enclosures website:

nl

http://www.hp.com/go/D2000.

Signing up to automatically receive advisories, notices, and other messages

The Subscriber's Choice website includes options to register for and automatically receive, by e-mail,

personalized product tips, update information, driver- and support-related advisories, and other notices

for this and other HP devices. Although optional, HP recommends registering all of your HP products

with Subscriber's Choice. For more information, see the Subscriber's Choice website:

nl

http://www.hp.com/go/e-updates.

• E-mail options:

• Driver and support alerts—Stay up-to-date using e-mail notices customized to your product and

frequency needs.

• HP Technology at Work—Receive monthly customized driver/support updates and news about

technology, new products, and promotions.

• Monthly promotions—Get up to the minute specials, promotions, and newly launched product

offers for small and medium business, government agencies, and schools.

• HP Business Outlet offers—Refurbished, closeout, and overstock product offers.

• Catalogs:

• Small and Medium Business catalog—Your comprehensive guide to HP business products and

promotions, featuring HP computers, servers, printers, accessories, supplies, and services.

• Public Sector catalog—Your guide to the full range of HP products, services and promotions

for public sector, with customized additions just for higher education, K-12 and federal government.

• State and Local Solutions magazine—Learn how state and local governments are harnessing

technology to better serve citizens with fewer resources. Includes case studies, products, promotions, and services.

• Online classes:

• Learning center—Register for online classes taught by some of the foremost industry experts.

Classes are free and available 24 x 7.

To register for and automatically receive product tips, update information, driver- and support-related

advisories, see the Subscriber's Choice website: http://www.hp.com/go/e-updates. Click Subscribe

and follow the onscreen instructions to select all of the HP products for which you want to receive

notices. While subscribing, indicate your delivery preference (HTML, text, or RSS) and frequency of

delivery (as they become available, weekly, or monthly).

Confirming warranty support and finding out about related services

The standard warranty protects against product defects and some causes of downtime. You can extend

your warranty with HP Care Pack Services. This portfolio of predefined packages is flexible, allowing

you to extend coverage to the exact level of support required. You choose the support level that meets

your business requirement, from basic to mission-critical.

Recommended service levels and appropriate related services for your particular disk enclosure model

are listed on the QuickSpecs. For more information, see the Storage Services website:

nl

http://www.hp.com/hps/storage.

D2600/D2700 Disk Enclosure User Guide 25

Page 26

Gathering and recording information

A brief worksheet is included on the getting started instructions that is shipped with the disk enclosure.

As you gather and identify the hardware and software components for your environment, use the

worksheet to record information about your components and your configuration. Some information

is easily obtained before installing the disk enclosure, while some of the information is created during

the configuration process.

A basic worksheet is included on the poster, but HP recommends creating and keeping more detailed

records.

Information recorded on the worksheet is used during the initial system setup and configuration, and

is helpful for future configuration changes and troubleshooting purposes.

NOTE:

If a supplier is installing or configuring your disk enclosure, provide them with the poster, and verify

that they complete the worksheet and record other important configuration and set up information.

Planning the storage configuration

Proper planning of the system storage and its subsequent performance is critical to a successful

deployment of the disk enclosure. Improper planning or implementation can result in wasted storage

space, degraded performance, or inability to expand the system to meet growing storage needs.

Considerations include:

• System and performance expectations

• Striping methods

• RAID levels

• Disk drive sizes and types

• Spare drives

• Array sizing (capacity)

NOTE:

For the minimum supported configuration, and other configuration information, see the QuickSpecs

for the disk enclosure.

System and performance expectations

To help determine the best way to configure your storage, rank the following three storage

characteristics in order of importance:

• Fault tolerance (high availability)

• I/O performance

• Storage efficiency

With priorities established, you can determine which striping method and RAID level to use.

As highlighted in the following section, some configuration methods offer greater fault tolerance, while

other configuration methods offer better I/O performance or storage efficiency.

Installation26

Page 27

Striping methods

There are two methods for configuring the physical layout of the disk arrays:

• Vertical striping

• Horizontal striping

In a vertical configuration, a single RAID array uses one physical drive from each disk enclosure.

In a horizontal configuration, the RAID array uses multiple drives contained within one or more disk

enclosures.

RAID levels

Smart Array controllers use hardware-based RAID technology to group multiple disk drives together

in larger logical units (LUNs).

Key RAID methods include the use of data striping, data mirroring, and parity error checking. Data

striping improves speed by performing virtual disk I/O with an entire group of physical disks at the

same time. Mirroring provides data redundancy by storing data and a copy of the data. Parity error

checking provides automatic detection and correction if corruption of a physical disk occurs.

Depending on the host environment, the following RAID levels are supported with this disk enclosure:

RAID0, RAID1, RAID5 and RAID6 with ADG. Each level uses a different combination of RAID methods

that impact data redundancy, the amount of physical disk space used, and I/O speed. After you

create a LUN, you cannot change the RAID level.

The following table compares the different RAID levels.

Best practicesSummary

IMPORTANT: Do not use RAID0

for LUNs if fault tolerance is required. Consider RAID0 only for

noncritical storage. RAID0 LUNs

provide the best performance for

applications that use random I/O.

In general, RAID1 virtual disks

provide better performance characteristics over a wider range of

application workloads than

RAID5.

RAID5 virtual disks can provide

performance advantages over

RAID1 for some applications that

use sequential I/O. Consider

RAID5 disks for applications with

high sequential I/O of records in

multiples of 8K bytes. The larger

the record size, the greater the

advantage.

RAID0

RAID1

RAID5

RAID0 is optimized for I/O

speed and efficient use of

physical disk capacity, but

provides no data redundancy.

RAID1 is optimized for data

redundancy and I/O speed,

but uses the most physical

disk space. IMPORTANT:

RAID1 uses about 100%

more physical disk space

than RAID0 and 70% more

than RAID5.

RAID5 provides a balance

of data redundancy, I/O

speed and efficient use of

physical disk space.

Data redundancy

Medium

RAID method

StripingNone

MirroringHigh

Striping and

parity

D2600/D2700 Disk Enclosure User Guide 27

Page 28

Like RAID5, RAID6 generates and stores parity information to protect against data

loss caused by drive failure.

RAID6

With RAID6, however, two

different sets of parity data

are used, allowing data to

be preserved if two drives

fail.

Disk drive sizes and types

RAID arrays should be composed of disk drives of the same size and performance capability. When

drives are mixed within a disk enclosure, the usable capacity and the processing ability of the entire

storage sub-system is affected. For example, when a RAID array is composed of different sized drives,

the RAID array defaults to the smallest individual drive size, and capacity in the larger drives goes

unused.

Spare disks

Best practicesSummary

RAID6 is most useful when data

loss is unacceptable but cost is

also an important factor. The

probability that data loss will occur when an array is configured

with RAID6 is less than it would

be if it was configured with

RAID5. However, write performance is lower than RAID5 because of the two sets of parity

data.

Data redundancy

High

RAID method

Striping and

parity

Spares are disks that are not active members of any particular array, but have been configured to

be used when a disk in one of the arrays fails. If a spare is present, it will immediately be used to

begin rebuilding the information that was on the failed disk, using parity information from the other

member disks. During the rebuilding process, the array is operating in a reduced state and, unless it

is a RAID6 or RAID1+0 array, it cannot tolerate another disk failure in the same array. If another disk

fails at this time, the array becomes inaccessible and information stored there must be restored from

backup.

After the rebuild of the data onto the spare is completed, when a replacement drive is inserted to

replace the failed drive, the system will automatically transfer the data from the spare onto the

replacement drive and return the spare to an available-spare state. It is important to note that the

process of rebuilding the spare or the replacement drive must not be interrupted or the process will

be aborted.

Some administrators have multiple spare disks, so that multiple arrays can experience failure and

successfully recover, before administrative intervention would be required to replace the spare or

failed disk. When assigning a spare to an array, the administrator chooses which arrays and how

many arrays are protected by that spare.

Array sizing

As a general rule, the greater the number of drives that are included in an array, the greater the

performance level that can be achieved. However, performance considerations are offset by fault

tolerance considerations. The greater the number of drives in an array, the higher the probability of

one or more disk failures in that array. The administrator must strike a balance between performance

and fault tolerance.

Installation28

Page 29

Preparing the site

Preparing your site includes:

• Providing adequate structural support for the floor, page 29

• Providing adequate clearance space and ventilation, page 29

• Providing adequate and redundant sources of power, page 29

To ensure continuous, safe, and reliable operation of your equipment, place your system in an approved

environment.

Consider using the HP Enterprise Configurator (eCO) to help plan and configure racks and

rack-mountable devices. The eCO is available on the HP website:

nl

http://h30099.www3.hp.com/configurator.

Providing adequate structural support for the floor

Calculate the total weight of your equipment and verify that your site can support the weight.

For HP ProLiant server environments, consider using Rack Builder, a software tool that provides a

simplified method to planning and configuring racks and rack-mountable products. Rack Builder is

available on the Options tab of the ProLiant Home page of the HP servers website:

nl

http://www.hp.com/country/us/eng/prodserv/servers.html.

Providing adequate clearance space and ventilation

Be sure to provide adequate clearance around the front and back of the racks. Provide at least 63.5

cm (25 in) in the front of the rack to allow the doors to open fully and provide at least 76.2 cm (30

in) in the rear of the rack to allow for servicing and airflow.

If there are unused spaces in your rack, attach blanking panels across those empty spaces to force

the airflow through the components instead of through the open spaces.

Providing adequate and redundant sources of power

Make sure that you have two high-line power feeds installed near your computer. These two power

sources usually come from the same external power grid, but occasionally might originate from different

grids or even entirely different sources.

For protection against a power-source failure, obtain and include two uninterruptible power supplies

in your installation.

For power consumption specifications, see the QuickSpecs for your disk enclosure model.

D2600/D2700 Disk Enclosure User Guide 29

Page 30

Racking the disk enclosure

The disk enclosure can be installed into most standard server racks. To verify that your rack is supported

for use with the disk enclosure, see the QuickSpecs for your disk enclosure model, available on the

D2000 website: http://www.hp.com/go/D2000.

CAUTION:

Install disk drives in the enclosures only after mounting the enclosures in the rack.

• An enclosure populated with disk drives is too heavy to lift safely.

• Movement of an enclosure during installation might damage the internal storage media of installed

disk drives.

Rack installation best practices

In addition to industry-standard recommendations, consider the following:

• Locate the heaviest items, such as uninterruptable power supplies (UPS) and additional disk enclos-

ures near the bottom of the rack.

• To make cabling easy, install the disk enclosures below the server.

• Install similar components next to each other in the rack. Because enclosures, switches, and servers

are of differing depths, if you have more than one of a device, mount those devices adjacent to

one another to accommodate working behind the rack.

WARNING!

To reduce the risk of personal injury or damage to the equipment, be sure that:

• At least two people lift the storage system during removal or installation if the weight exceeds

22.7 kg (50 lb). If the system is being loaded into the rack above chest level, a third person MUST

assist with aligning the system with the rails while the other two people support the weight of the

system.

• The leveling jacks on the rack are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component in a rack is extended at a time. A rack might become unstable if more than

one component is extended.

• To prevent damage and to ease insertion of the device into the rack, support the weight of the

device and keep it level when sliding it into the rack.

Installation30

Page 31

Racking procedures

1. Position left and right rack rails at the desired 'U' position in the rack, adjusting the rails to fit the

rack, as needed (1).

2. Secure rack rails to the front and back rack columns using screws. Make sure that the shoulders

of the screws fit inside the square or round holes of the rack (2).

NOTE:

If installing rails in a square hole rack, use larger-sized shoulder screws and pins for mounting.

If installing rails in a round hole rack, use smaller-sized shoulder screws and pins for mounting.

3. Slide the device into position on the rails (1) and then tighten the thumbscrews on the front of the

device to secure the device to the rack.

NOTE:

The rear ends of the rails have a bracket that must engage the device chassis to secure the rear

of the chassis to the rails.

D2600/D2700 Disk Enclosure User Guide 31

Page 32

Installation32

Page 33

Installing disk drives

CAUTION:

Install disk drives in the enclosures only after mounting the enclosures in the rack.

• An enclosure populated with disk drives is too heavy to lift safely.

• Movement of an enclosure during installation might damage the internal storage media of installed

disk drives.

CAUTION:

• Follow industry-standard practices when handling disk drives. Internal storage media can be

damaged when drives are shaken, dropped, or roughly placed on a work surface.

• When installing a disk drive, make sure the drive is fully seated in the drive bay.

• When removing a disk drive, press the release button and pull the drive only slightly out of the

enclosure. Then, to allow time for the internal disk to stop rotating, wait approximately 10 seconds

before completely removing the drive from the enclosure.

Disk drives are hot-pluggable. A variety of disk drive models are supported for use, including

dual-ported SAS disk drives and single-ported SATA disk drives.

For more information about supported disk drives, see the QuickSpecs for your disk enclosure model,

available on the D2000 website: http://www.hp.com/go/D2000.

NOTE:

SAS and SATA disk drives can be installed in the same disk enclosure.

1. Unlatch and swing out the drive handle, and slide the drive into the enclosure.

2. Rotate the handle to the closed position when the drive is fully seated in the enclosure.

D2600/D2700 Disk Enclosure User Guide 33

Page 34

3. Continue until all drives are installed.

IMPORTANT:

For proper airflow and cooling, a drive blank must remain installed in all unused drive bays.

Installation34

Page 35

Installing 6Gb SAS controllers and preparing the servers

When preparing servers for the disk enclosure, be sure to do the following.

• Record information about the server and controller that will connect to the disk enclosure.

• Verify that the servers, Smart Array controllers, operating system version, and service packs are

supported for use with the disk enclosure. For more information, see the QuickSpecs for the your

disk enclosure model, available on the D2000 website: http://www.hp.com/go/D2000.

• Install all operating-system-specific service packs, patch kits, or other required tools.

• Install HP system management and monitoring tools, such as HP Systems Insight Manager (HP-SIM)

and the Array Configuration Utility (ACU).

• Install one or more Smart Array controller in the server that will access the disk enclosure. For in-

structions, see the documentation provided with the controller and the server.

NOTE:

For detailed installation and configuration information about the server, the controller, or software

tools, see the documentation provided with the server, controller, or software.

D2600/D2700 Disk Enclosure User Guide 35

Page 36

Connecting cables and power cords

Overview

Connecting cables includes the following steps:

1. Reading the Cabling best practices, page 36.

2. Cabling the disk enclosure to the controller, page 37.

3. Cabling cascaded disk enclosures, page 38.

4. Labeling cables using labeling kit, page 38.

5. Connecting power cords, page 39.

NOTE:

For examples of cabling scenarios, see Chapter 6 on page 49.

Cabling best practices

• Use the shortest possible cable between devices. Shorter cables are easier to manage and route

along the back of the rack. In addition, shorter cables reduce the possibility of signal degradation

that might occur over longer distances.

• Gather the cables in the rear of the disk enclosure to ensure that the cabling in the back of the

rack system does not interfere with system operation or maintenance. Bind the cables loosely with

cable ties and route the excess cables out of the way, along the side of the rack. When the cables

are tied together and routed down the side of the rack, system components and indicators are

easily visible and accessible.

• Attach a label near both ends of each cable to identify the device connected to that cable. Include

the device, device name, port, or other useful information.

• Use colored markers to color code both ends of each cable, to help visually identify a particular

cable without having to read or locate the label.

• In multipath configurations, you might want to loosely bind the matching pair of cables connecting

devices.

Installation36

Page 37

Cabling the disk enclosure to the controller

To connect the first disk enclosure to the controller, use a standard mini-SAS cable.

IMPORTANT:

When connecting this disk enclosure to single-path HP Smart Array P212 or P411 6Gb SAS controllers,

the second I/O module (I/O module B) in the disk enclosure is not supported for use.

The following illustration shows an HP ProLiant DL380 G6 server with a two-port HP Smart Array

P411 controller connecting to Small Form Factor (SFF) disk enclosures. Your environment might include

a different model server, controller, or disk enclosure, but the cabling principles are the same. For

additional examples of cabling scenarios, see Chapter 6 on page 49

D2600/D2700 Disk Enclosure User Guide 37

Page 38

Cabling cascaded disk enclosures

Use standard mini-SAS cables to cascade additional disk enclosures from the disk enclosure that is

connected to the controller.

As additional disk enclosures are connected to the first disk enclosure, they are assigned a box number.

The assigned box number is displayed on the 7-segment display on the rear of the disk enclosure.

IMPORTANT:

• The number of supported cascaded disk enclosures varies per disk enclosure model and installation

environment. For more information, see the QuickSpecs for your disk enclosure model, available

on the D2000 website: http://www.hp.com/go/D2000.

• When connecting this disk enclosure to single-path HP Smart Array P212 or P411 controllers, the

second I/O module (I/O module B) is not supported for use.

• Use provided color clues on the disk enclosure when cabling cascaded disk enclosures; for example,

connect “green” ports to “green” ports (connect I/O module A on one disk enclosure to I/O

module A on the additional disk enclosure).

The following illustration shows an HP ProLiant DL380 G6 server with an HP Smart Array P411

controller connecting to Small Form Factor (SFF) disk enclosures. Your environment might include a

different model server, controller, or disk enclosure, but the cabling principles are the same. For

additional examples of cabling scenarios, see Chapter 6 on page 49

Labeling cables using labeling kit

A labeling kit is provided with the disk enclosure. Label both end of each cable using the materials

in the supplied labeling kit.

Installation38

Page 39

Connecting power cords

To protect the system from power-failure-related downtime, each disk enclosure ships standard with

a redundant power supply. Depending how you connect the power supplies to the power source,

you can eliminate downtime caused by power-related failures.

When connecting the power cables, use the power cables shipped with the disk enclosure. After

power is supplied to the disk enclosure, the power supply automatically senses the input voltage and

the power supply LED illuminates as solid amber.

Disk enclosure power supplies connected to:

one power source

Disk enclosure power supplies connected to:

two separate power sources

Level of ProtectionConnection Method

Protects you from downtime when one of the disk

enclosure power supplies fails.

The remaining power supply/fan module can operate

the disk enclosure until you install a replacement

module.

Protects you from downtime when one of the disk

enclosure power supplies fails.

Protects you from data loss when one of your power

sources fails, due to a pulled cable or tripped breaker.

The remaining power source can power the disk

enclosure until the failed power source is restored or

relocated. Depending on the cause and duration of

the power outage, you can use this time to properly

shut down your storage sub-system.

Protects you from downtime when one of the disk

enclosure power supplies fails.

Protects you from data loss when one or both of your

Disk enclosure power supplies connected to:

two UPS

two separate power sources

power sources fails, due to a pulled cable, tripped

breaker, or local power outage.

The remaining power source or the UPS will power

the disk enclosure until power is restored to the source.

Depending on the cause and duration of the power

outage, you can use this time to properly shut down

your storage sub-system.

WARNING!

To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

• Route the power cord so that it is not likely to be walked on or pinched by items placed against

it. Pay particular attention to the plug, electrical outlet, and the point where the cord is attached

to the disk enclosure.

D2600/D2700 Disk Enclosure User Guide 39

Page 40

Powering on the disk enclosure

After disk enclosures are physically installed and cabled, power on all devices and verify that they

are operating properly.

Power on best practices

Observe the following best practices before powering up the enclosure for the first time:

• Complete the controller installation in the server. See the controller documentation.

• Install the disk enclosures.

• Install disk drives in the disk enclosures so that the connected host controller can identify and

configure them at power-up.

• Connect the SAS cables and power cords to the enclosure.

Power on procedures

1. Apply power to each UPS.

2. Apply power to all disk enclosures by pressing and holding the power on/standby button on the

rear of the disk enclosures until the system power LED illuminates solid green.

The LED on the power on/standby button changes from amber to solid green, indicating that the

disk enclosure has transitioned from a standby state to fully powered.

3. Wait a few minutes for the disk enclosures to complete their startup routines.

CAUTION:

If power is applied to the server before the disk enclosures complete their startup routine, the

server might not properly discover the storage.

4. Power on (or restart) the server with access to the disk enclosures, start the operating system, and

log on as administrator.

CAUTION:

When you power on the server, the monitor might display a “New Hardware Found” message.

Cancel out of this window to prevent the installation of unsupported software.

5. Verify that each component is operating properly.

Installation40

Page 41

Verifying the operating status of the devices

To verify that the devices are operating properly, view their LEDs.

Included sections:

• Verify the operating status of the disk enclosures, page 41

• Verify the operating status of the servers and SAS controllers, page 42

Verify the operating status of the disk enclosures

To verify that the disk enclosures and disk drives are operating properly, view the enclosure and disk

drive LEDs and compare them with the patterns described below.

For more information about disk enclosure LEDs, see Chapter 1 on page 7.

Front UID module

LEDs

Power supply module

Fan module

nl

LEDDisk enclosure component

1. Port Link

Startup condition

condition

OffBlinking amber2. Fault

Solid greenSolid greenStatus

Blinking or solid

green

Fault conditionOperating

OffSolid greenBlinking green1. Health

Blinking or Solid

Amber

OffOffBlinking blue3. UID

OffSolid greenGreenStatus

Blinking or solid

amber

Off

I/O module

3. 7–segment

display

Solid amberOff2. Port Error

A number, representing the

box number

Off4. Fault

Off

Blinking or solid

amber

OffSolid greenBlinking green5. Health

OffOff6. UID

D2600/D2700 Disk Enclosure User Guide 41

Page 42

If LED patterns are not as expected:

• Check cable connections between the devices.

• Check the availability of your power source.

• Review the installation procedures.

• Remove and reinsert the module.

Verify the operating status of the servers and SAS controllers

Verify that the server is operating properly. A simple test is to verify that the operating system loaded

and then open a software application or browser.

If the server is not operating properly, see the documentation that came with the server for help.

Installation42

Page 43

4 Configuration

Included topics:

• Configuration overview, page 43

• Configuration best practices, page 43

• Supported software tools, page 43

Configuration overview

Regardless of the operating system environment or software tool used to configure the disk enclosure,

the following tasks must be completed:

• Updating controller firmware or drivers. Instructions are included with the controller.

• Updating disk enclosure firmware. Instructions are included with the firmware. For more information,

see “Updating disk enclosure firmware” on page 48.

• Configuring the disk enclosure and its storage.

• Creating the logical storage units (LUNs).

• Entering global controller settings, such as setting the read/write cache ratio, setting the re-

build/expand priority, and setting the redundancy level.

• Identifying the operating system type (also called Host Mode or Profile) of the host that will

access the disk enclosure. This ensures that the disk enclosure will communicate properly with

that host.

• Verifying that the configured storage is visible to the host.

Configuration best practices

• Maintain detailed records of your storage network, including information about the hosts and disk

enclosures. A brief worksheet is provided on the getting started instructions poster, shipped with

the disk enclosure. However, HP recommends creating your own spreadsheets and maintaining

detailed records.

Supported software tools

The following is a partial list of the tools that are supported for use with the disk enclosure:

• HP Systems Insight Manager, page 44

• HP Array Configuration Utility, page 45

• Option ROM Configuration for Arrays (ORCA), page 46

• Smart Components for firmware updates, page 46

D2600/D2700 Disk Enclosure User Guide 43

Page 44

HP Systems Insight Manager

HP Systems Insight Manager (SIM) is the foundation for the HP unified server-storage management

strategy. SIM is a hardware-level management product that provides basic management features

through a single management view. SIM provides device management capabilities that consolidate

and integrate management data from HP and third-party devices. SIM reports hardware fault conditions

(both failure and pre-failure) and collects data for reporting and graphing. SIM also provides base-level

management of HP clients, printers, and selected storage.

HP recommends using HP SIM to monitor the performance of your systems.

NOTE:

You must install and use SIM to benefit from the Pre-Failure Warranty for processors, SAS, SCSI, and

SATA disk drives, and memory modules.

Key SIM benefits include:

• System discovery and identification

• Fault management and event handling

• Inventory data collection

• Data collection and inventory reports on system devices

For more information, see the SIM website http://www.hp.com/go/hpsim.

Configuration44

Page 45

HP Array Configuration Utility

The Array Configuration Utility (ACU) is a server-based, browser-accessed tool used to configure an

array controller and its storage. The ACU is supported for use in Windows, Linux, and NetWare

environments and can run locally from the server or remotely through HP Systems Insight Manager

(HP SIM).

The ACU:

• Is available in both a graphical user interface and a command line interface.

• Allows the setting of access rights to disk enclosures by hosts.

• Supports local or remote access.

NOTE:

When creating arrays using the graphical user interface, the ACU provides easy-to-use configuration

wizards and suggested settings. Consider these defaults (especially the RAID level and rebuild priority)

and make sure that they are acceptable according to your plans.

For information about using the ACU, see the ACU section of the Configuring Arrays Reference Guide.

This guide is available on the Support page of the ACU website: http://h18000.www1.hp.com/

products/servers/proliantstorage/software-management/acumatrix/.

D2600/D2700 Disk Enclosure User Guide 45

Page 46

Option ROM Configuration for Arrays (ORCA)

Before installing an operating system, you can use the ORCA utility to create the first logical drive,

assign RAID levels, and establish online spare configurations.

The utility also provides support for the following functions:

• Reconfiguring one or more logical drives

• Viewing the current logical drive configuration

• Deleting a logical drive configuration

• Setting the controller to be the boot controller

If you do not use the utility, ORCA defaults to the standard configuration.

For more information about array controller configuration, see the controller user guide. For more

information regarding the default configurations that ORCA uses, see the HP ROM-Based Setup Utility

user guide.

Smart Components for firmware updates

Firmware updates on the controller, disk enclosure, and disk drives are performed using HP Smart

Components. Smart Components are available from the following locations:

• Firmware Maintenance CD

• HP support website for the controller, disk enclosure, or disk drive

A Firmware Maintenance CD is shipped with each server, with the latest version of the Firmware

Maintenance CD available on the HP SmartStart website:

nl

http://h18006.www1.hp.com/products/servers/management/smartstart.

NOTE:

Not all available Smart Components are included on the Firmware Maintenance CD. Newly-released

Smart Components might be scheduled for inclusion on a future release of the CD, and some Smart

Components might not be scheduled for inclusion on the CD and be available exclusively via the HP

support website for the product.

To update device firmware using a Smart Component:

1. Find the most recent version of the component that you require, knowing that it might be on the

Firmware Maintenance CD or the HP support website.

2. Follow the instructions for installing the component. Instructions are provided with the CD and

on the same website as the component.

Configuration46

Page 47

5 Operation and management

Included topics:

• Powering on disk enclosures, page 47

• Powering off disk enclosures, page 48

• Updating disk enclosure firmware, page 48

Powering on disk enclosures

IMPORTANT:

Always power up disk enclosures before controllers and servers. This ensures that the servers, during

their discovery, see the enclosure as an operational device. If you do not power up the disk enclosures

before powering up the controllers and servers, you will need to power down the servers, ensure that

the disk enclosures are powered up, and then power back up the servers.

1. Apply power to each UPS.

2. Apply power to the disk enclosures by pressing and holding the power on/standby button on

the rear of the disk enclosures until the system power LED illuminates solid green.

The LED on the power on/standby button changes from amber to solid green, indicating that the

disk enclosure has transitioned from a standby state to fully powered.